Catalytic rectification method for removing MAPD by selective hydrogenation

A catalytic rectification and selective technology, applied in the field of ethylene, can solve the problems that the concentration of propylene has not been effectively reduced, the conversion selectivity of MAPD has not been greatly improved, and the selectivity of the hydrogenation process is low, so as to achieve the effect of catalyst deactivation Low, the influence of process conditions is reduced, and the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

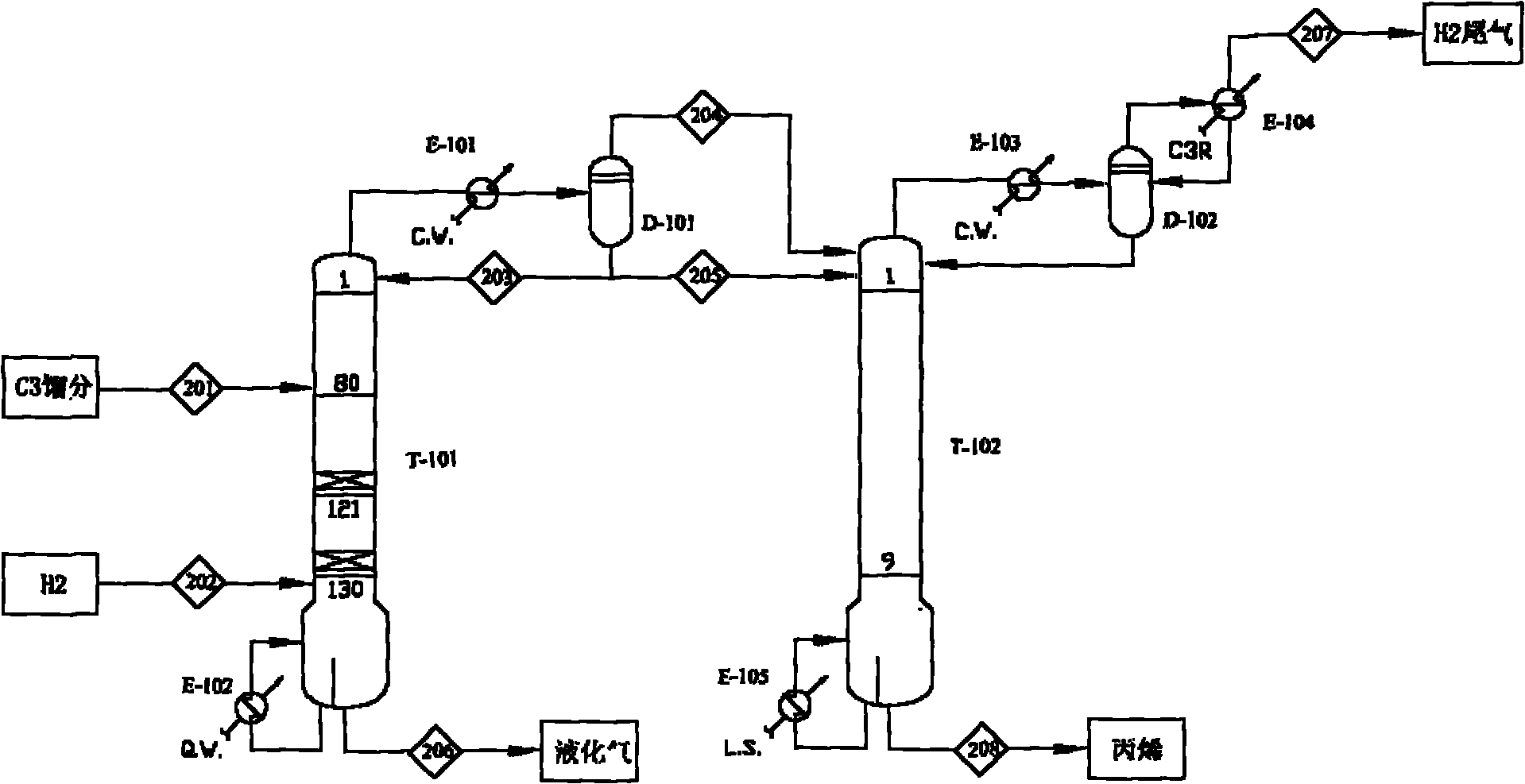

[0051] Such as figure 1 As shown, the propylene rectification tower T-101 has a total of 130 trays, and a catalytic rectification component with a height of 2m is placed under the 130th tray in the stripping section, and its structure is corrugated plate structured packing BCD-1 (purchased from Sinopec Beijing Research Institute of Chemical Industry), using BC-L-83 catalyst (purchased from Sinopec Beijing Research Institute of Chemical Industry) to fill it, the volume filling fraction is about 25%, and the liquid on the 130th tray flows down through the liquid redistributor. The C3 fraction feed 201 has a flow rate of about 22t / h, a MAPD content of about 3.5%, and a propylene content of about 92.8%. It enters the propylene rectifying tower T-101 from the 80th tray. The hydrogen feed 202 contains 5% methane, which is passed into the propylene rectification tower T-101 tower from the bottom of the catalytic rectification component, and the flow rate is 68kg / h. The reaction on t...

Embodiment 2

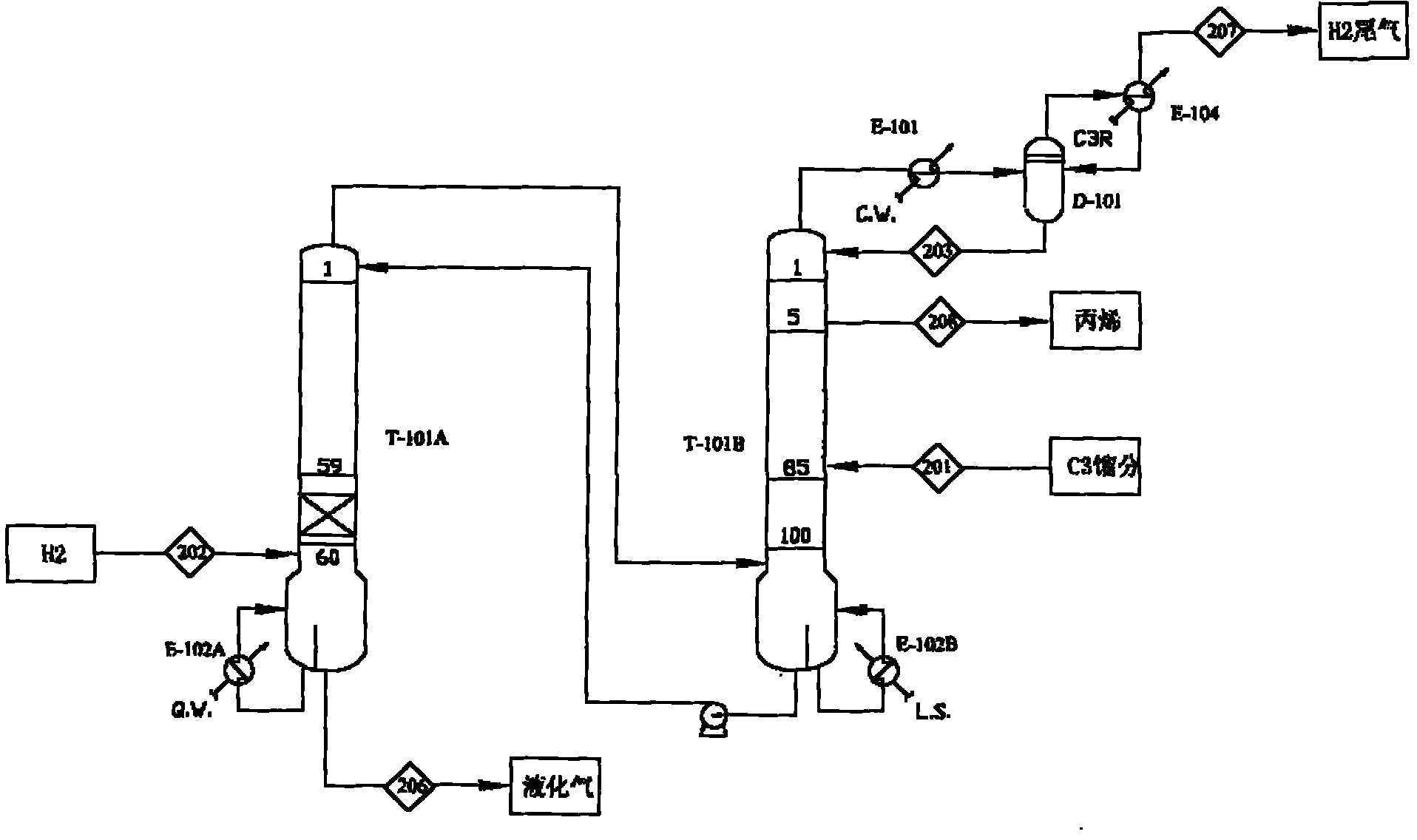

[0056] Such as figure 2 As shown, the operating conditions are the same as in Example 1, and the two-stage catalytic rectification member (same as in Example 1) is placed on the 121st and 130th tray plates of the propylene rectification tower T-101, and its conversion rate to MAPD is about 25%.

[0057] The output of liquefied gas 206 in the bottom of propylene rectification tower T-101 is 1.14t / h, and the concentration of MAPD and propylene are 0.24% and 9.7% respectively. The selectivity of MAPD to propylene is about 70%.

[0058] The contents of propylene, hydrogen, methane, ethane, and propane at the top of the propylene rectification tower T-101 are 99.3%, 0.07%, 0.25%, 0.055%, and 0.3%, respectively, and the light components are removed by the methane stripping tower T-102 After the propylene extraction 208, the polymer grade propylene product can be obtained, the output is about 20.8t / h, the temperature of the top of the methane stripping tower T-102 is reduced to 5°...

Embodiment 3

[0060] Such as figure 1 Shown, operating condition is the same as embodiment 1, but reflux ratio improves to 20. The hydrogen flow rate is 54kg / h.

[0061] The contents of propylene, hydrogen, methane, ethane, and propane at the top of the propylene rectification tower T-101 are 99.36%, 0.09%, 0.2%, 0.05%, and 0.29%, respectively, and the light components are removed by the methane stripping tower T-102 After the propylene extraction 208, the polymer grade propylene product can be obtained, the output is about 21.08t / h, the gas is cooled to 5°C, the non-condensable gas is extracted 207, the output is about 70kg / h, and the propylene molar concentration is 47%. The weight is about 54kg / h.

[0062] Propylene rectification tower T-101 bottom liquefied gas production 206, production volume is 0.86t / h, in which propylene and MAPD concentrations are 4.4% and 0.20% respectively. The MAPD conversion is about 50%, and the selectivity of MAPD to propylene is about 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com