Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Methyl acetylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Colorless gas with a sweet odor, used as fuel and shipped as compressed gas

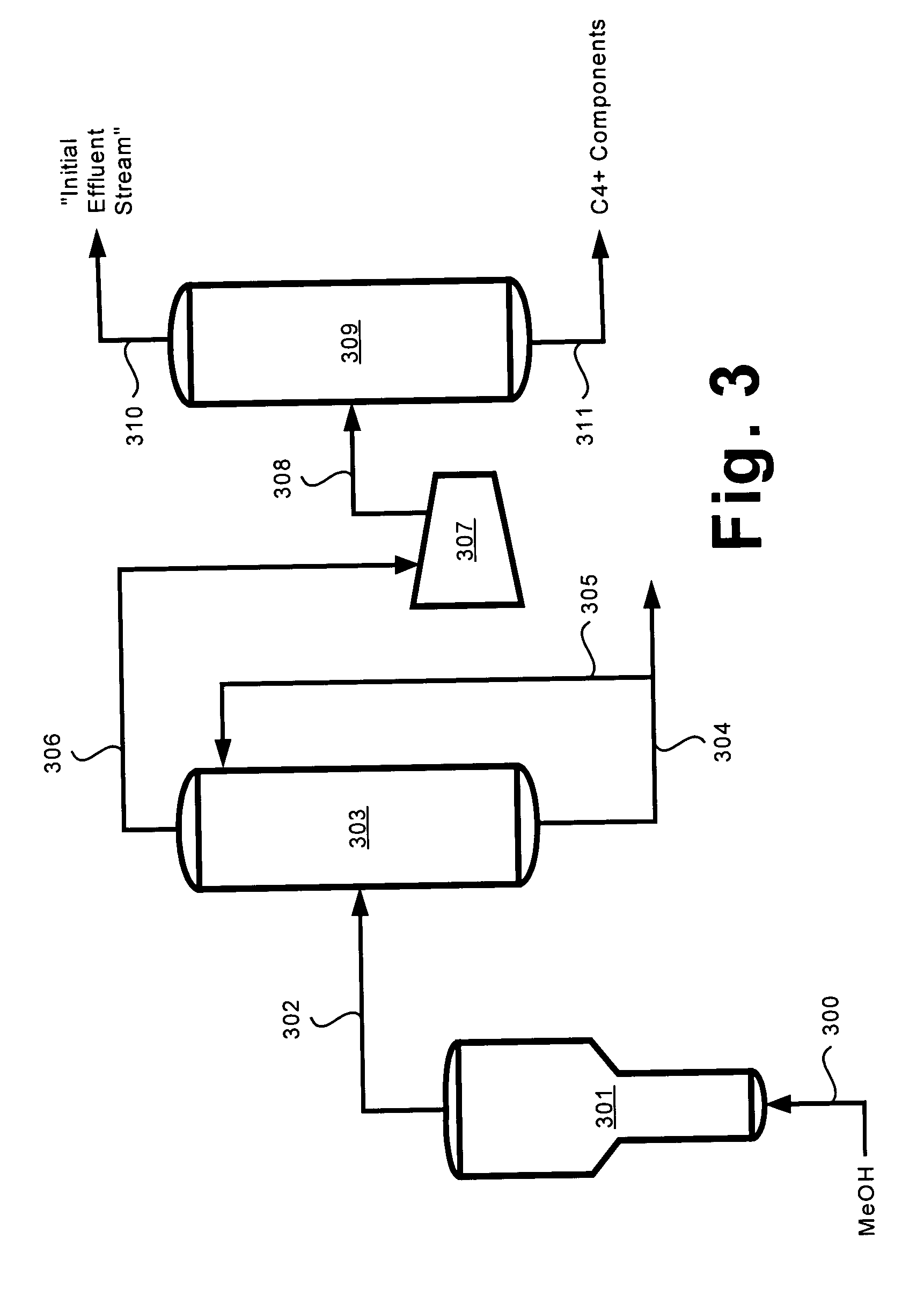

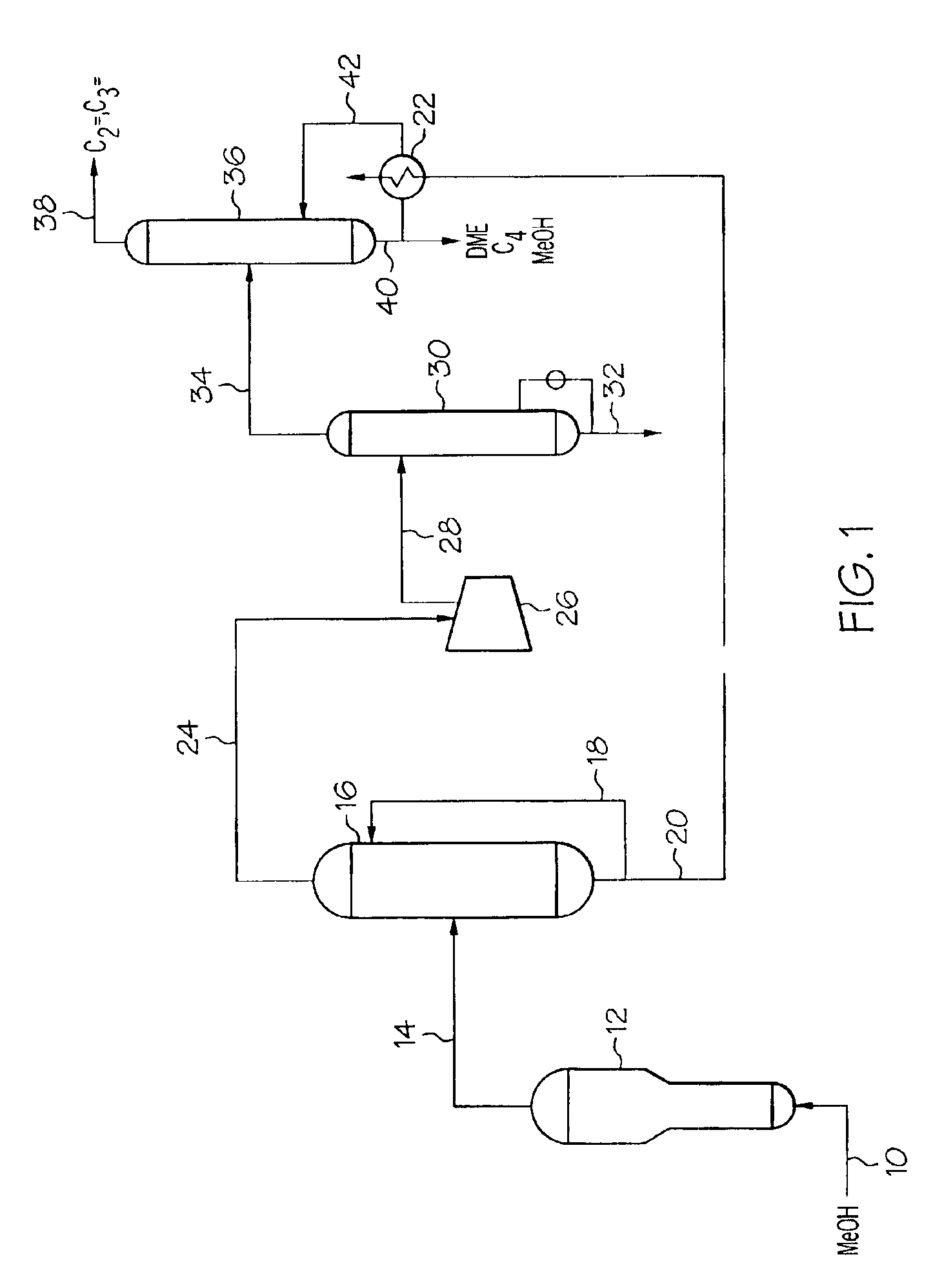

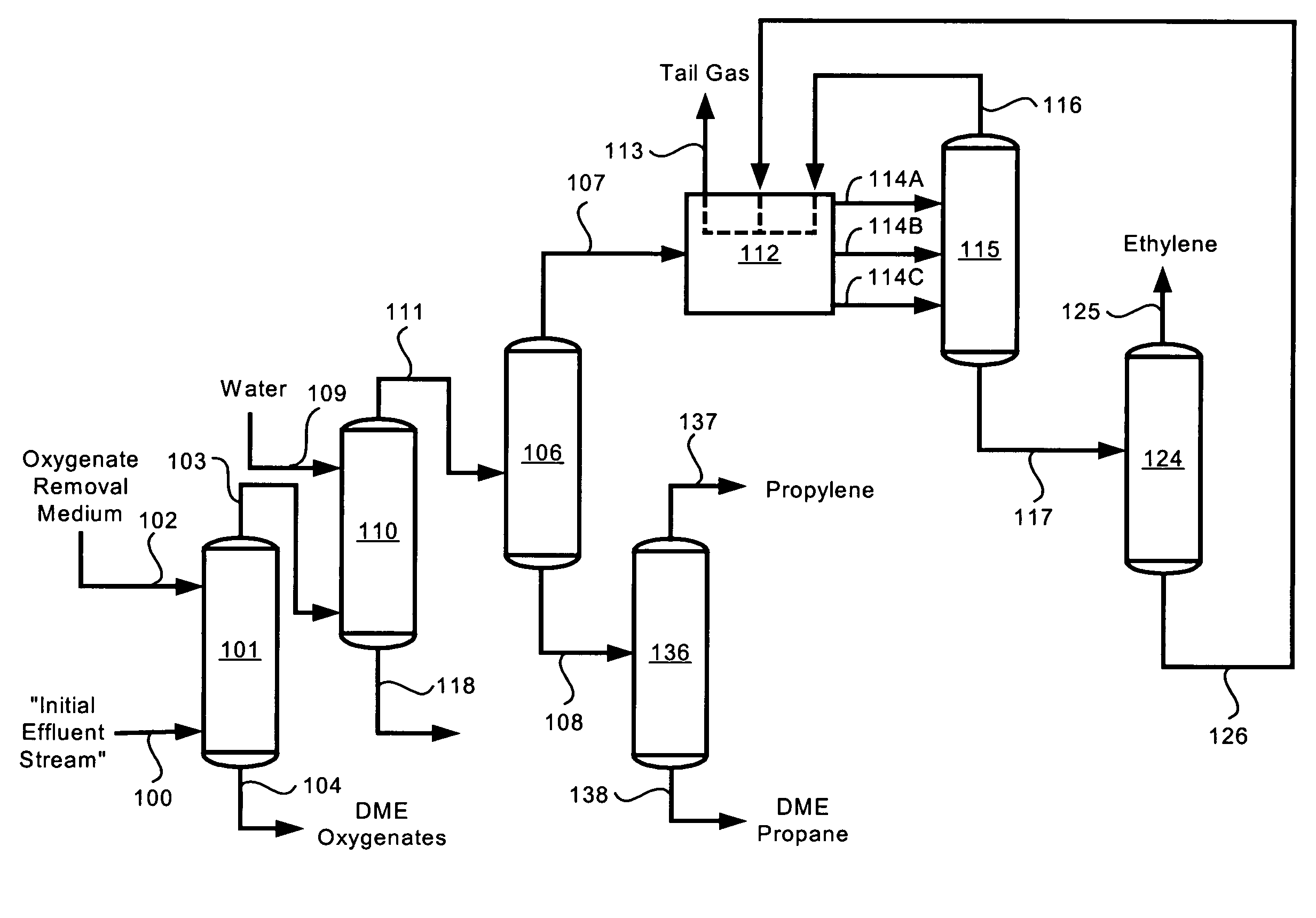

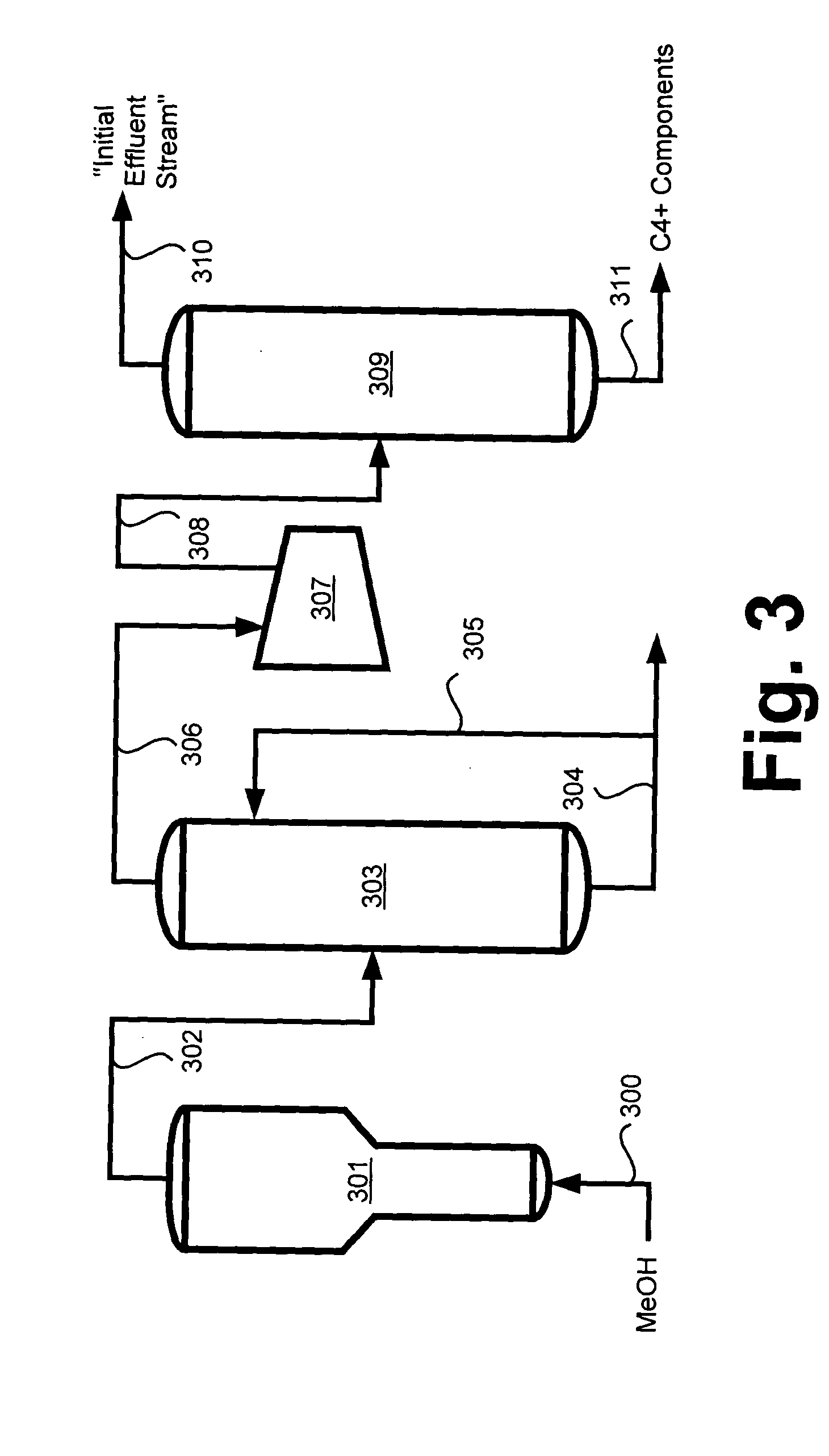

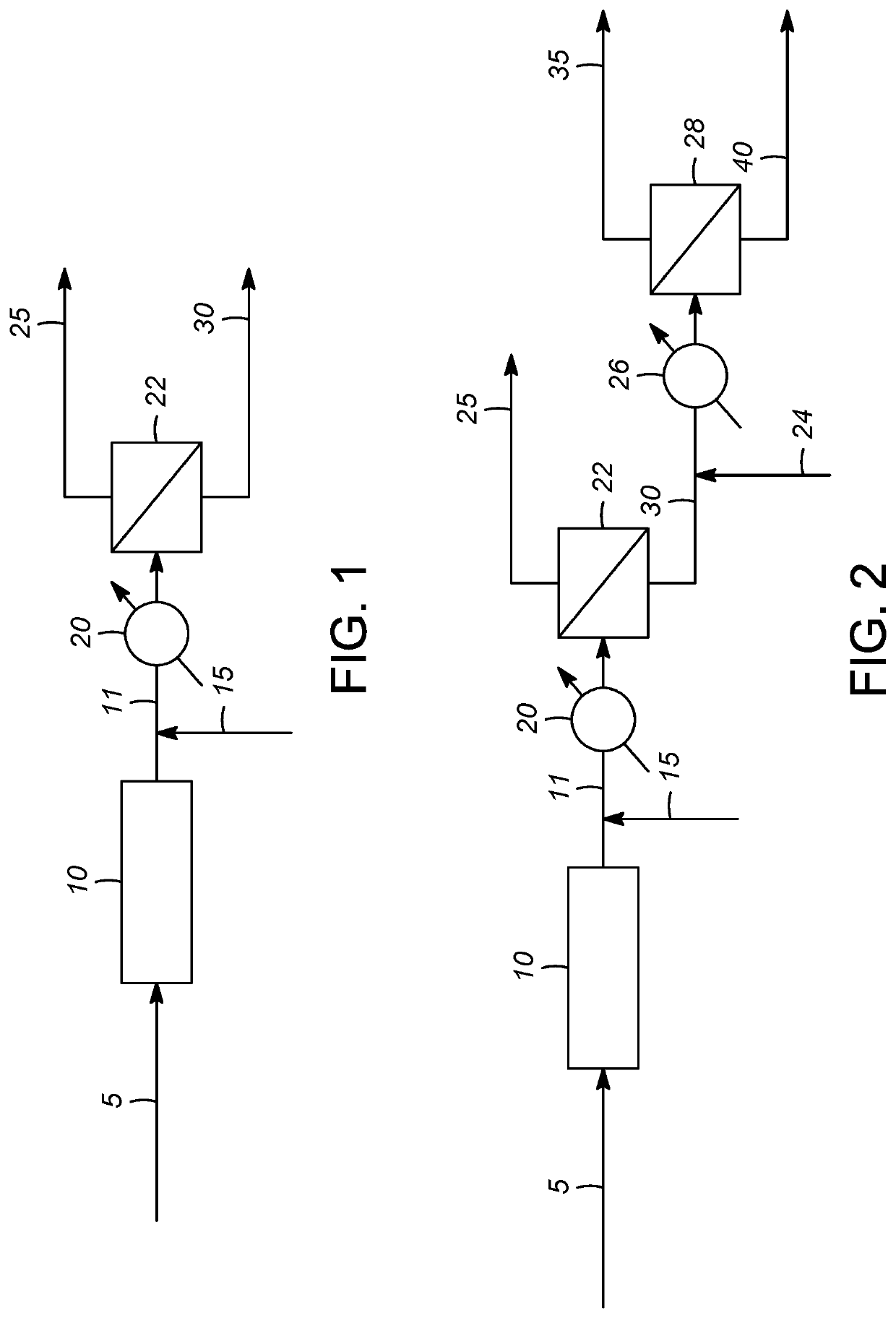

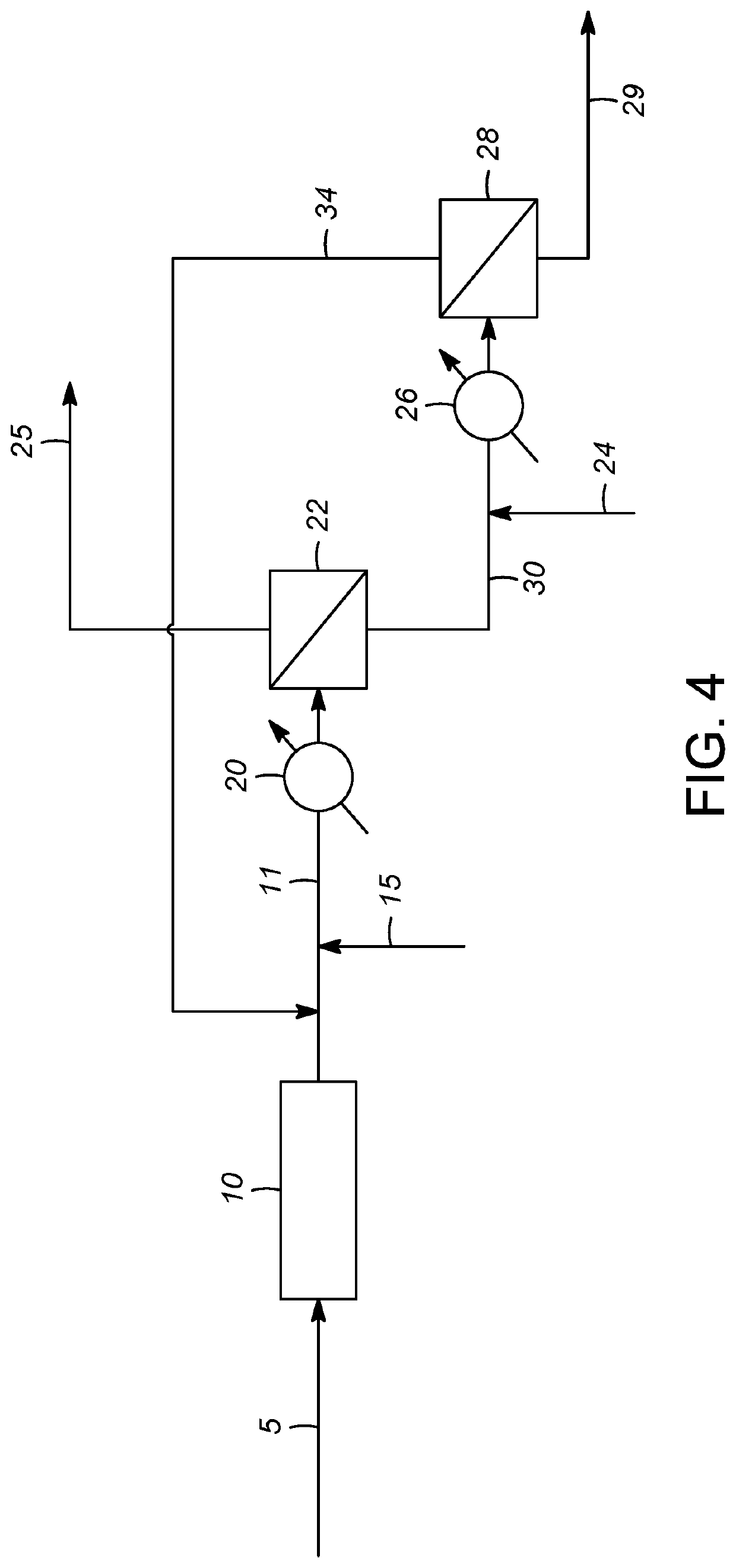

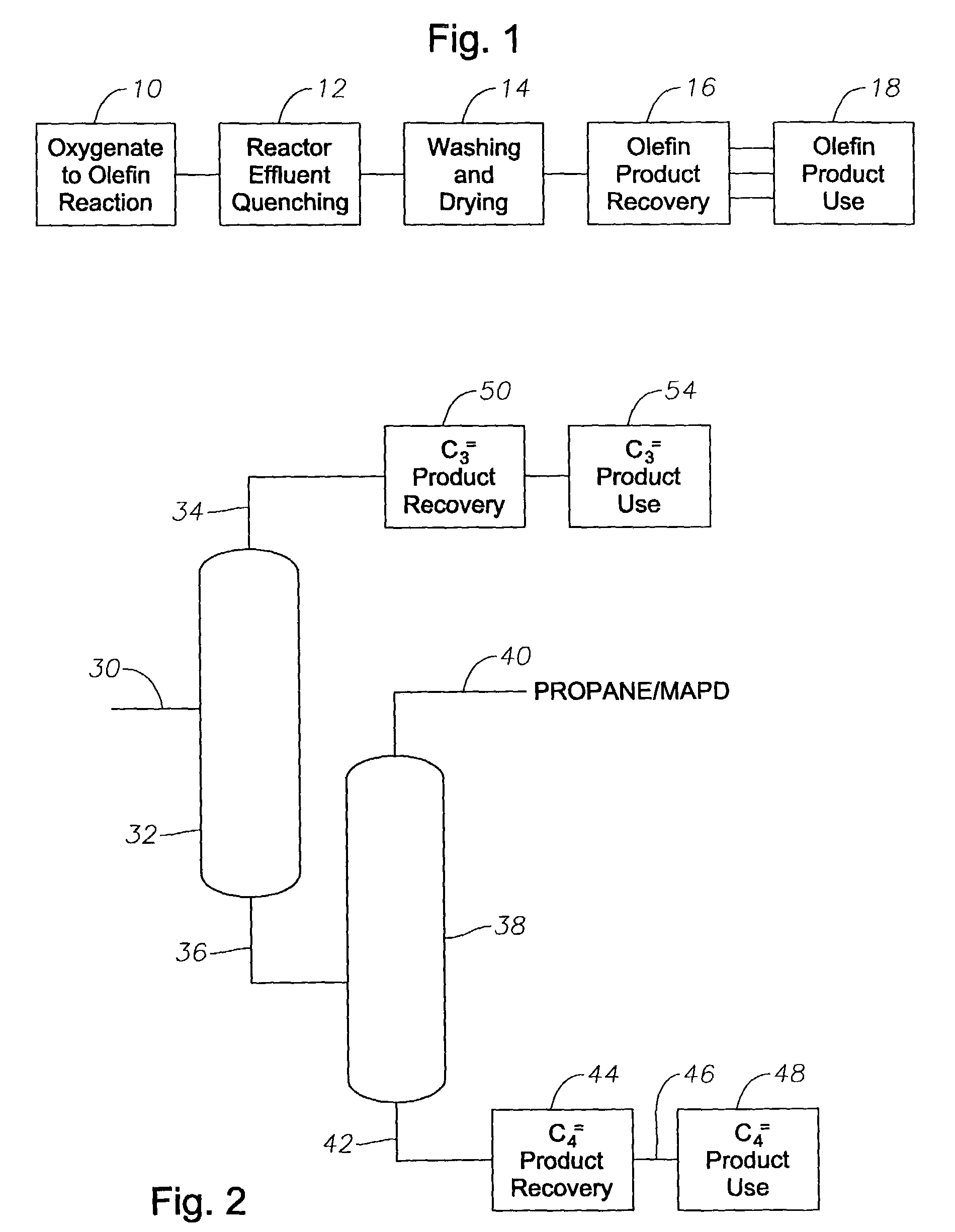

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS20050033104A1Efficient removalMinimizing equipment countHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionPropadieneDimethyl ether

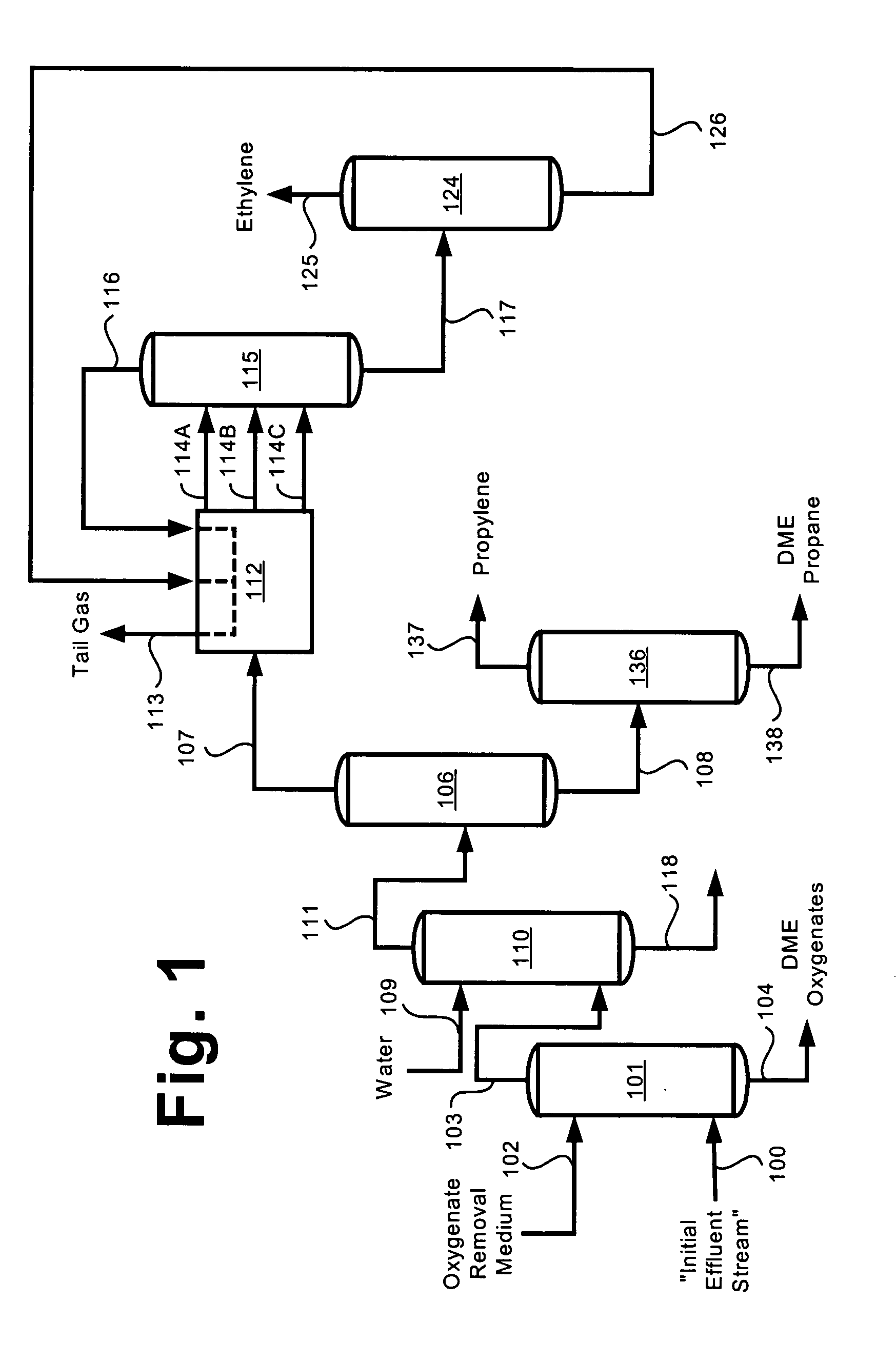

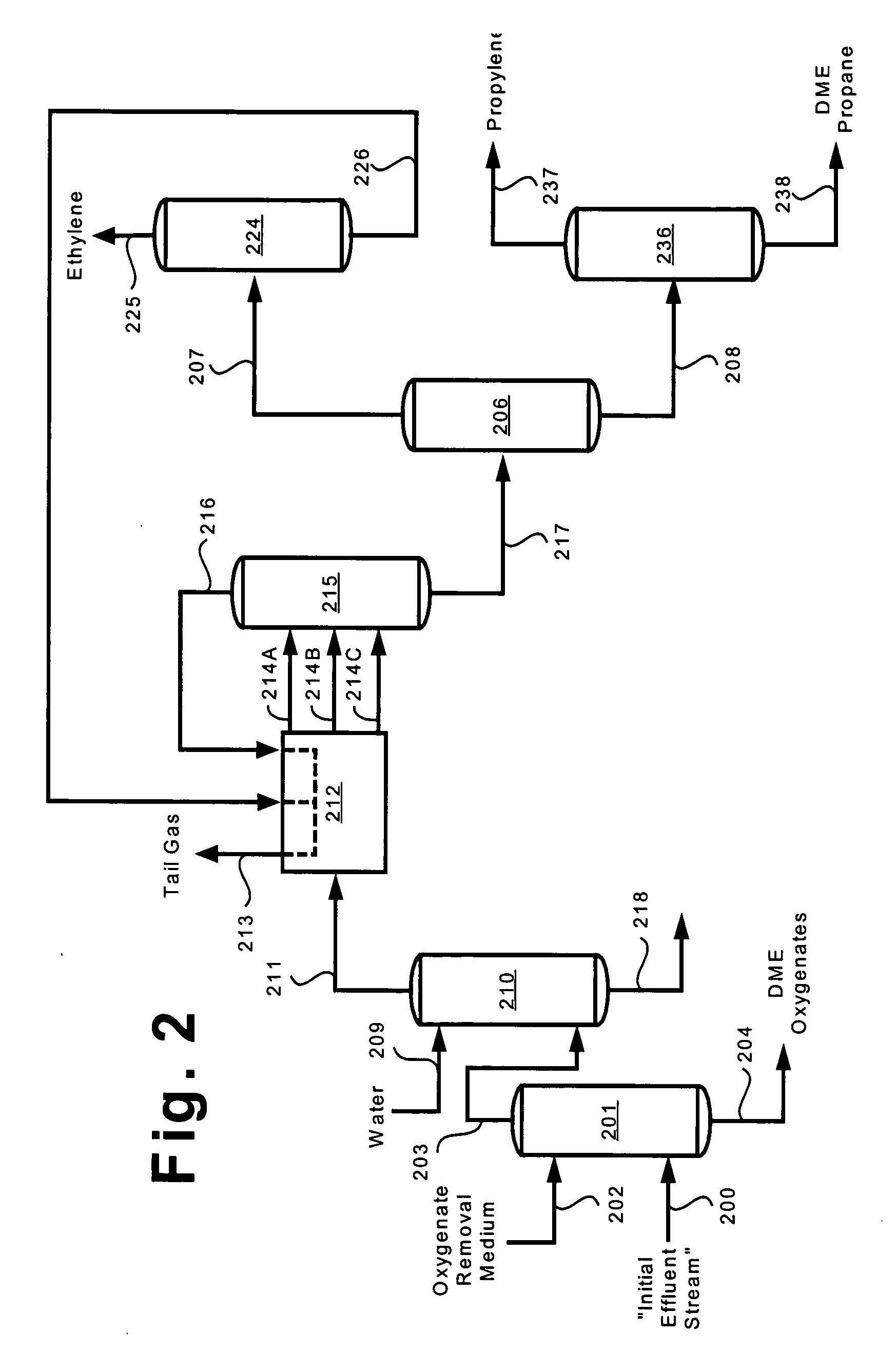

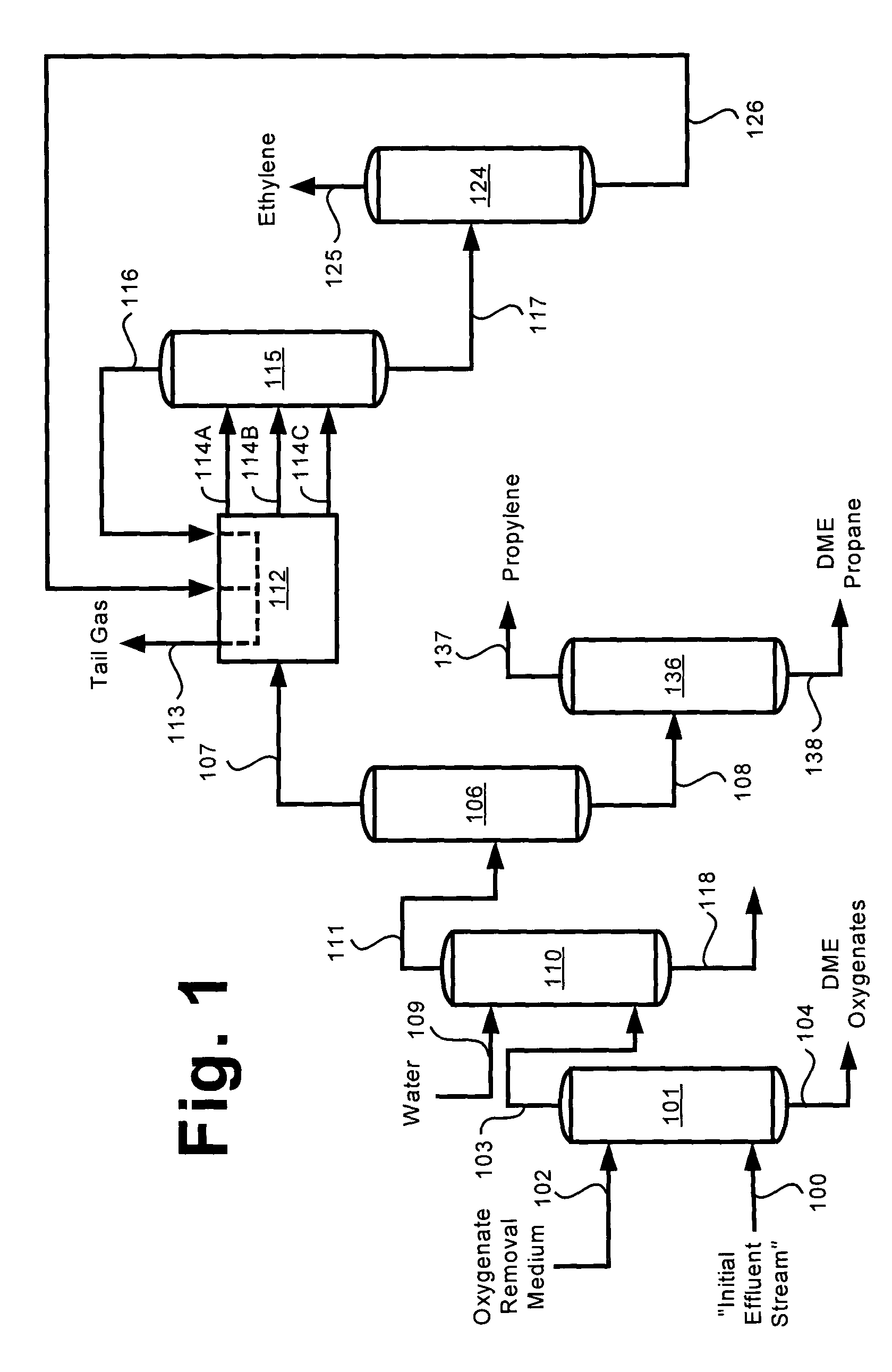

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

Recovery of ethylene and propylene from a methanol to olefin reaction system

ActiveUS20050033103A1Efficient removalMinimizing equipment countLiquid hydrocarbon mixture productionHydrocarbonsPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

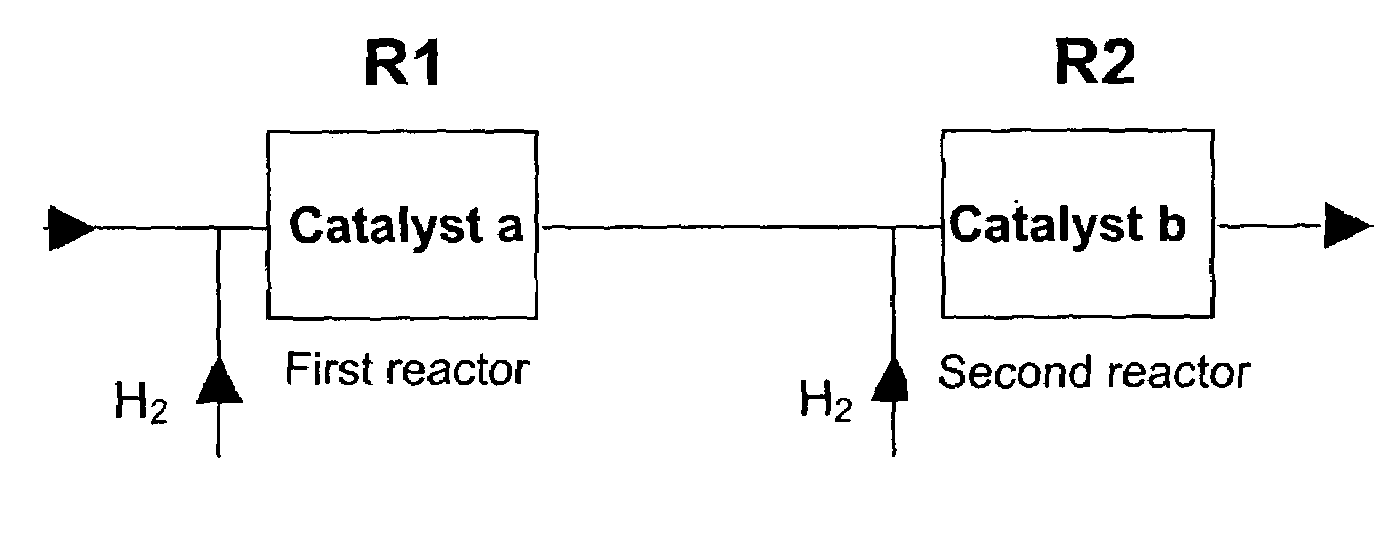

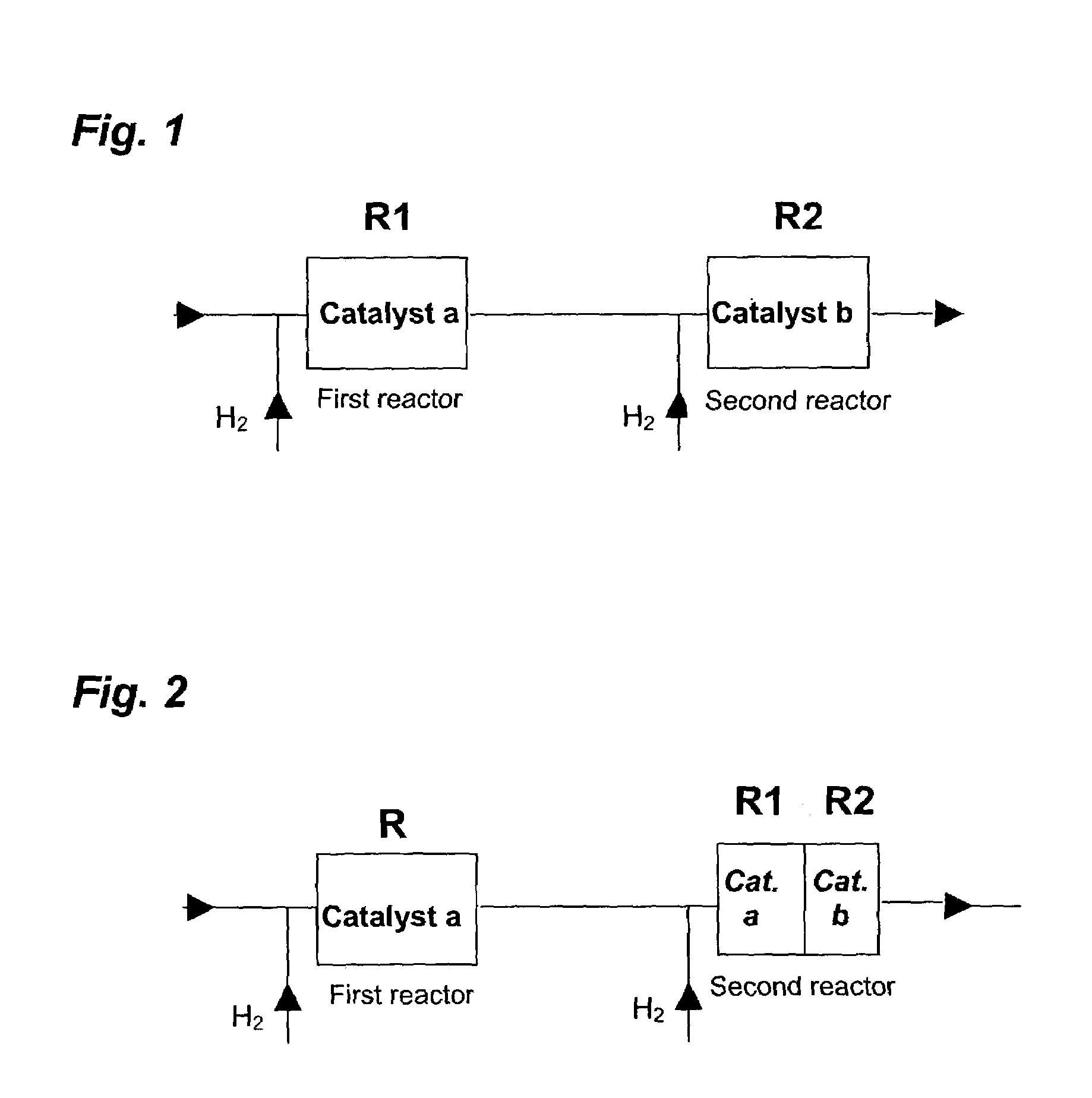

Dual bed process using two different catalysts for selective hydrogenation of acetylene and dienes

InactiveUS7038097B2Many solutionsMaintains and improves conversionHydrocarbon by hydrogenationHydrocarbon purification/separationOligomerHydrogen

It has been discovered that a dual bed process using two different catalysts for the selective hydrogenation of acetylene and / or methyl acetylene (MA) and / or propadiene (PD) in a light olefin-rich feedstream can be accomplished with less selectivity to making oligomers (green oil) as compared with existing commercial technologies, if a low oligomers selectivity catalyst is used first in the process. A palladium catalyst may be used as a second, sequential catalyst to further hydrogenate acetylene and / or MAPD while consuming at least a portion of the balance of the hydrogen present. The first catalyst should be different from the second catalyst.

Owner:EXXONMOBIL CHEM PAT INC

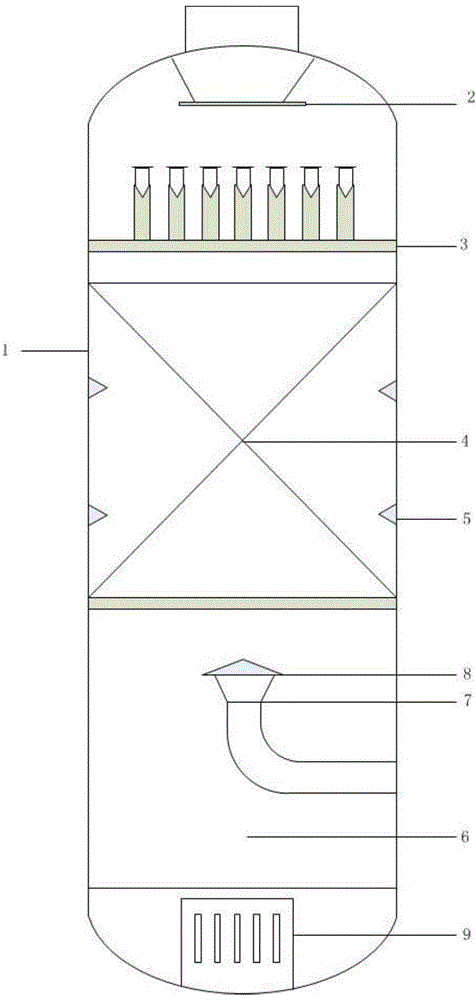

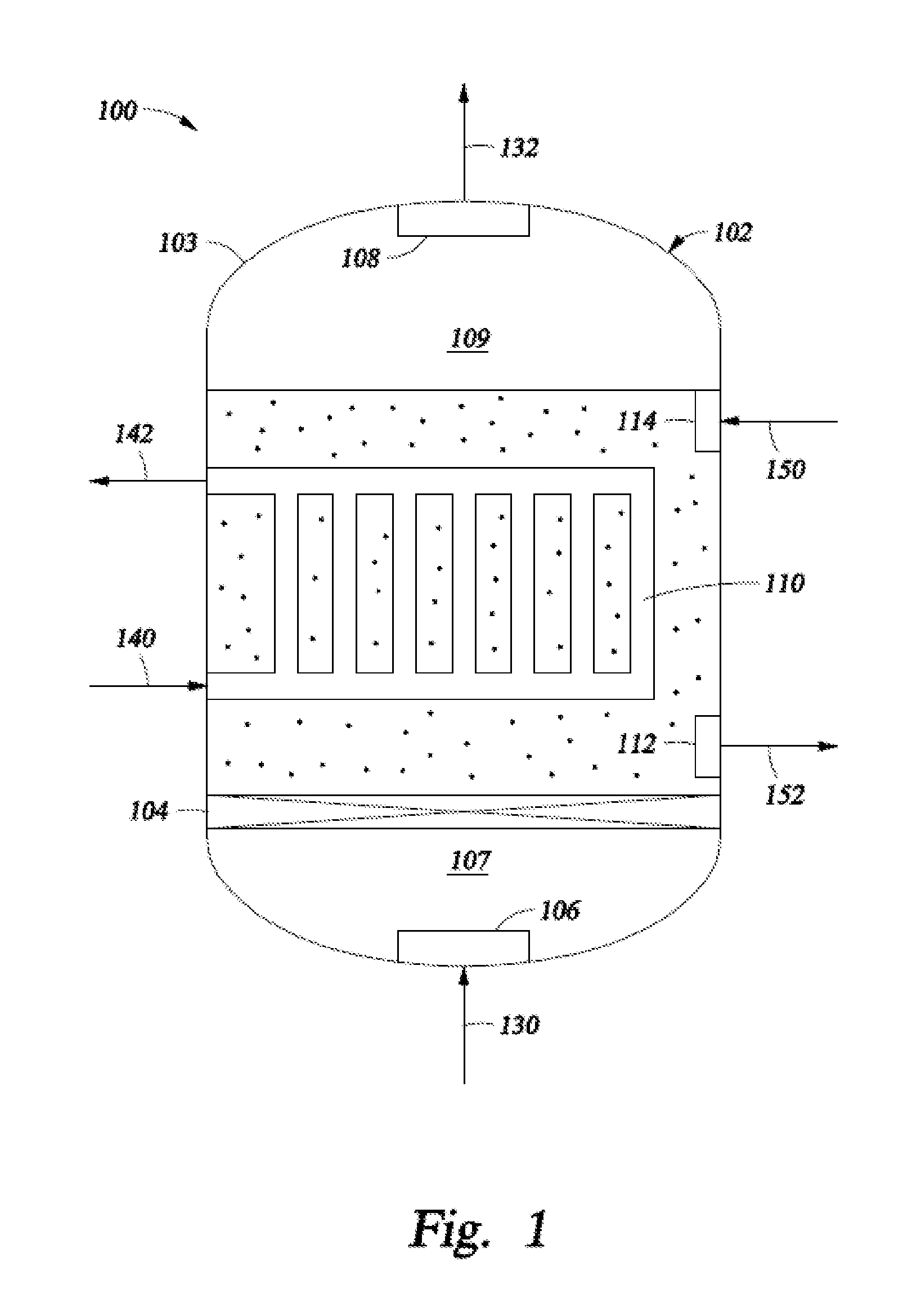

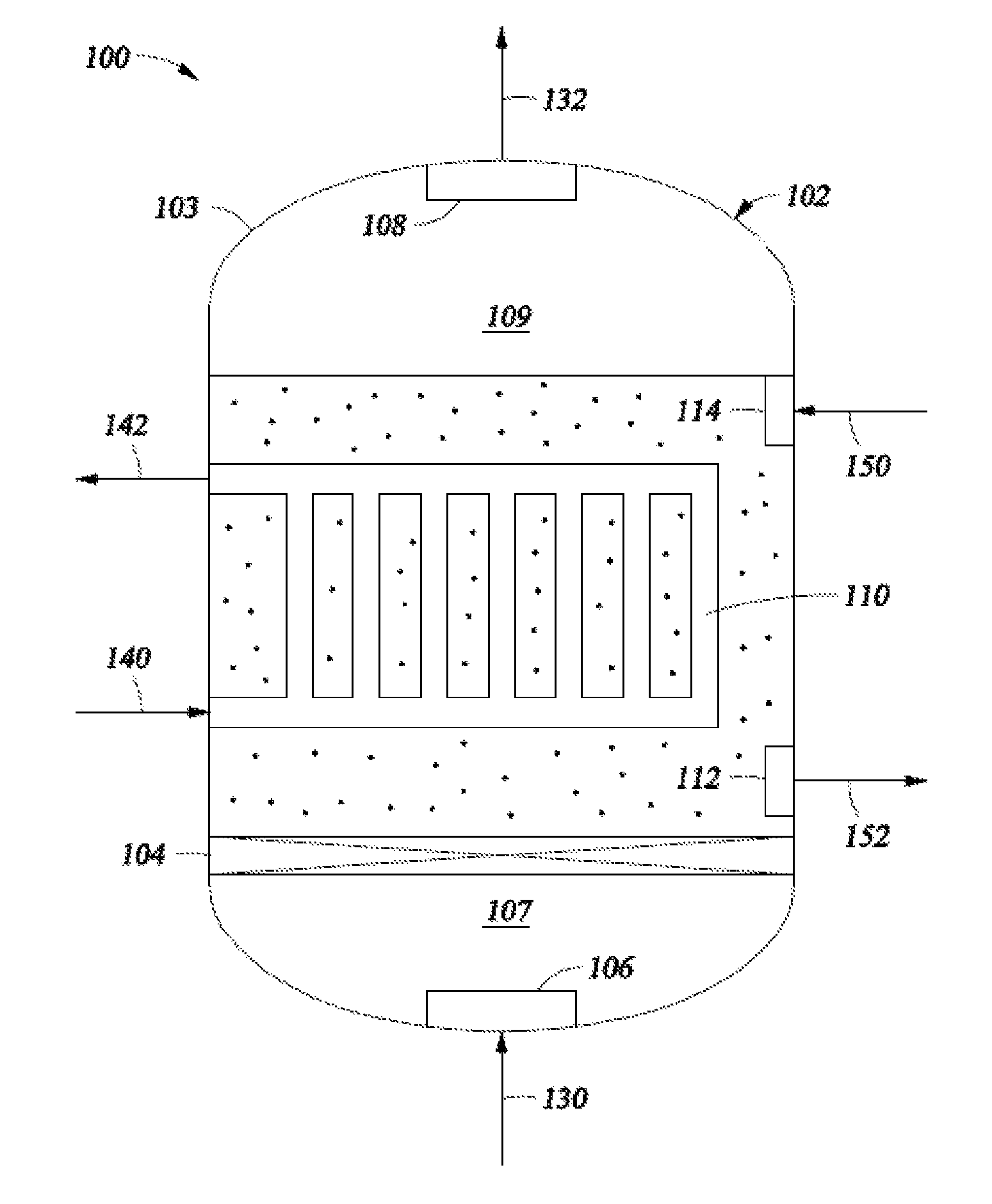

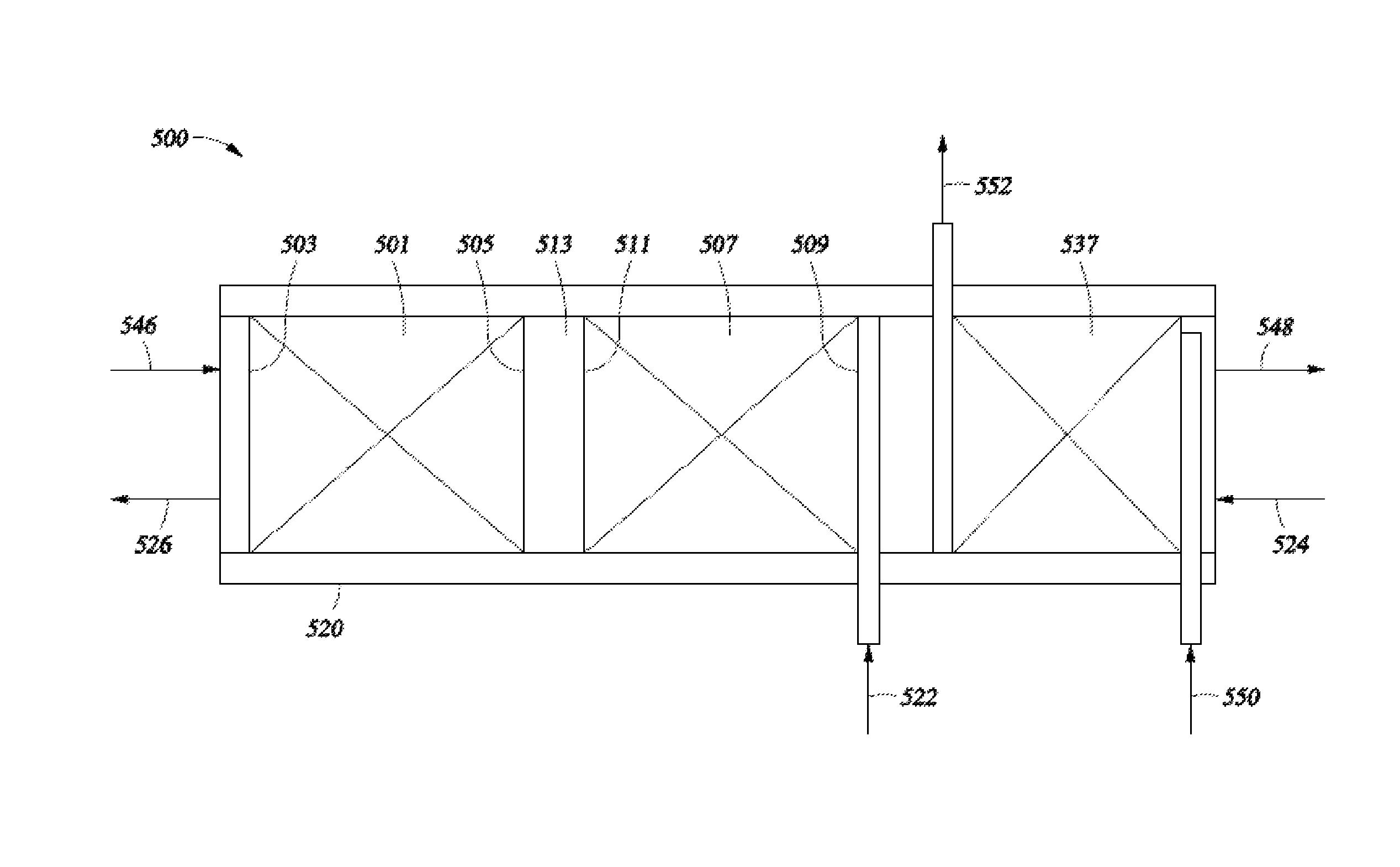

Fixed bed hydrogenation reactor and application method thereof

ActiveCN105582854AEasy to operateImprove the efficiency of refining reactionHydrocarbon by hydrogenationRefining by selective hydrogenationSeparation technologyHydrogenation reaction

The invention discloses a fixed bed hydrogenation reactor and an application method thereof. In the fixed bed hydrogenation reactor, a gas-liquid phase product pre-separation technology with gas phase withdrawal in an axial center position is employed, wherein a plurality layers of baffle plates are arranged on the inner wall of the reactor, thereby improving operation stability of the hydrogenation system, improving gas-liquid distribution status in the reactor and eliminating wall flow, deflected flow and the like defects. The reactor, when being used in a reaction process of C3 fraction liquid-phase selective hydrogenation to remove methyl acetylene (MA) and propadiene (PD), can not only increase the MAPD hydrogenation purification reaction efficiency of a propadiene material but also is low in residual hydrogen, so that separation load in a down-stream propylene rectification column is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

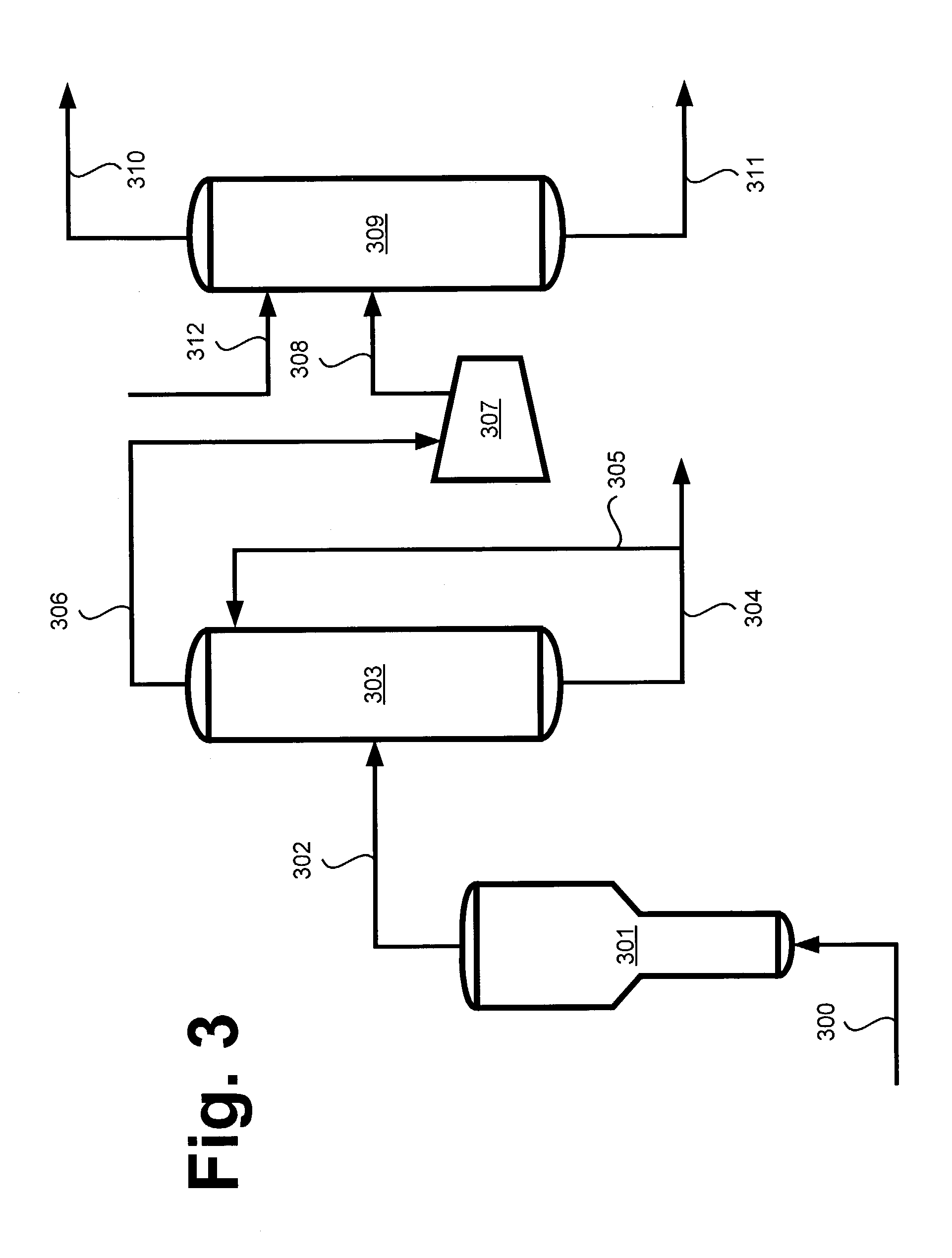

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS7074971B2Efficient removalCount is minimizedEther separation/purificationOrganic compound preparationPropadieneDimethyl ether

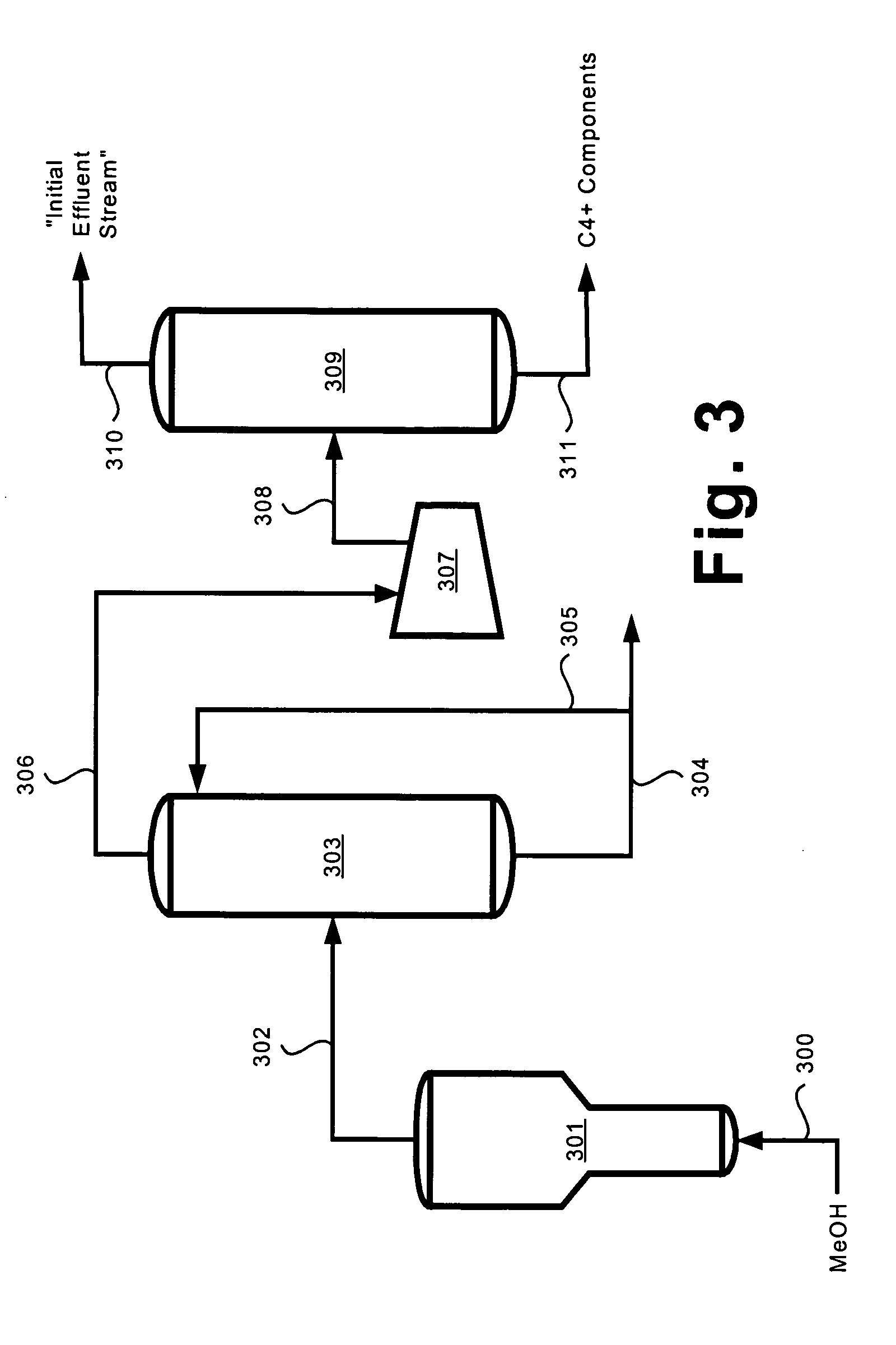

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that the best separation of these components is realized when DME is selectively removed in a first separation step, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

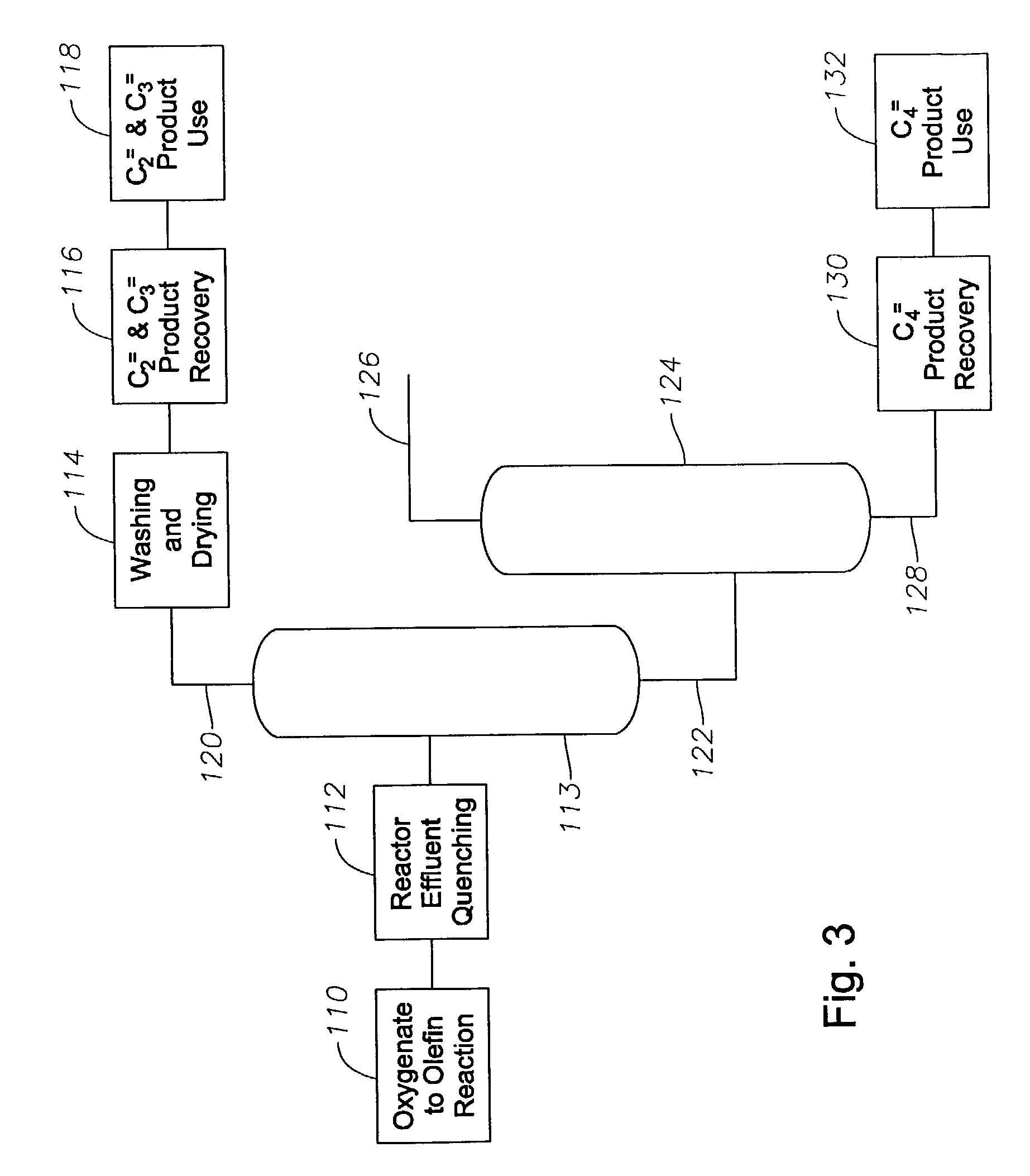

Heat-integrated high pressure system for separation of byproducts from an olefin stream

InactiveUS6864401B2Large temperature differenceIncrease temperature differenceChemical industryDistillation purification/separationButeneFractionating column

The present invention is a heat-integrated process for obtaining an ethylene and propylene enriched stream from an oxygenate to olefin reactor. The process comprises providing an effluent stream from an oxygenate to olefins reactor. The effluent stream comprises ethylene, propylene and one or more byproducts selected from the group consisting of propane, methyl acetylene, propadiene, dimethyl ether, acetaldyhyde and butylene. The process further includes quenching the effluent stream with the quench medium to provide an olefin stream. The olefin stream is separated into a heavy fraction and a remaining fraction. The remaining fraction is directed to a distillation column which separates the remaining fraction into a first fraction comprising a majority of both ethylene and a propylene and a second fraction comprising at least a majority of one or more heavier fraction. The bottoms of the distillation column is reboiled by the quench medium. The separation step allows the bottoms of the distillation column to be reboiled at a lower temperature.

Owner:EXXONMOBIL CHEM PAT INC

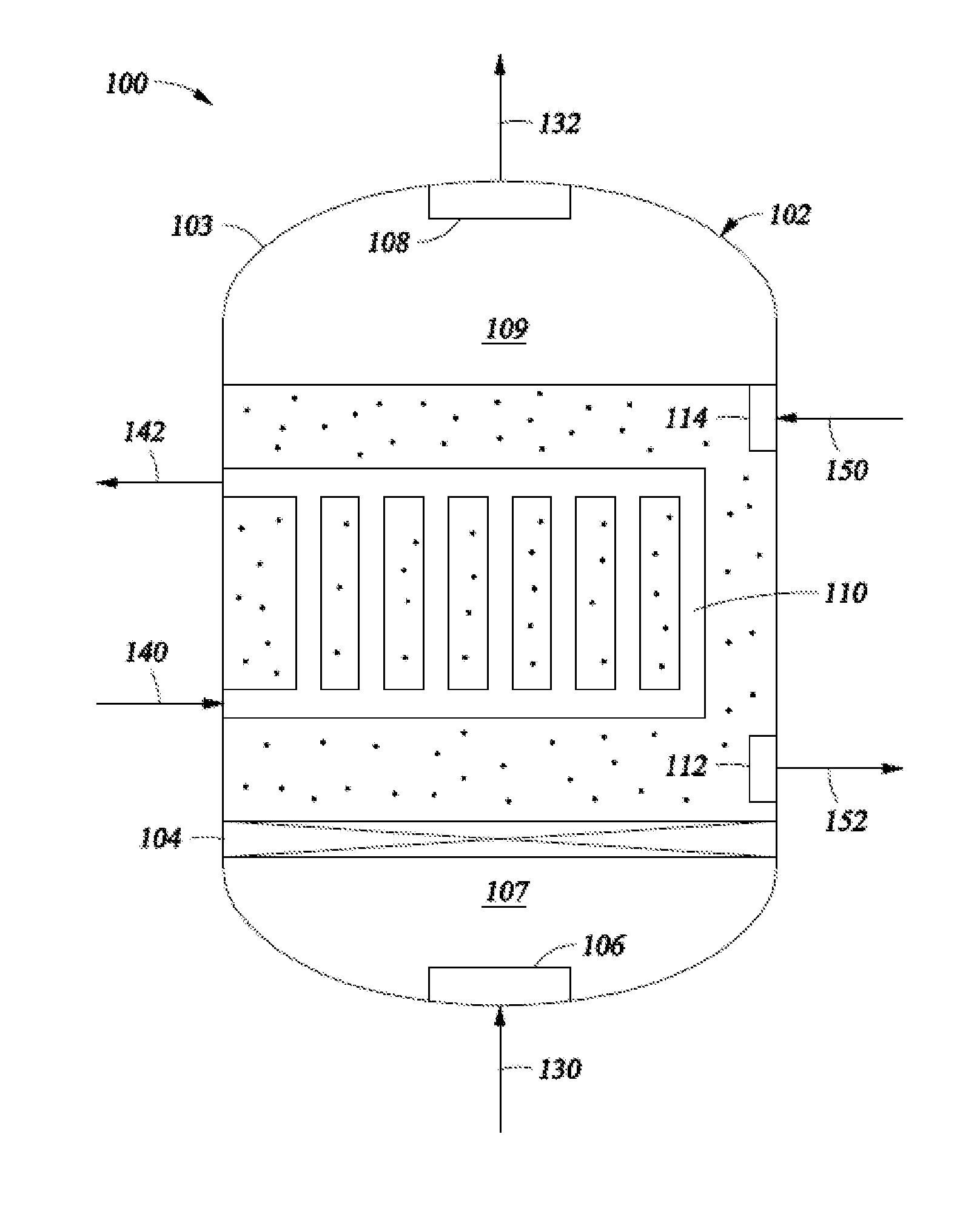

Selective Hydrogenation of Alkynyl-Containing Compounds and Polyunsaturated Compounds

ActiveUS20130204055A1Efficient heat recoveryImprove system efficiencyHydrocarbon by hydrogenationHydrocarbonsCompound aHydrogenation process

A selective hydrogenation process that is particularly effective in selectively hydrogenating alkynl compounds, such as acetylene or methyl acetylene, over alkenyl compounds, such as ethylene, is described. The process utilizes a slurry conversion unit for heat efficiency purposes during the conversion of acetylene into ethylene.

Owner:EXXONMOBIL CHEM PAT INC

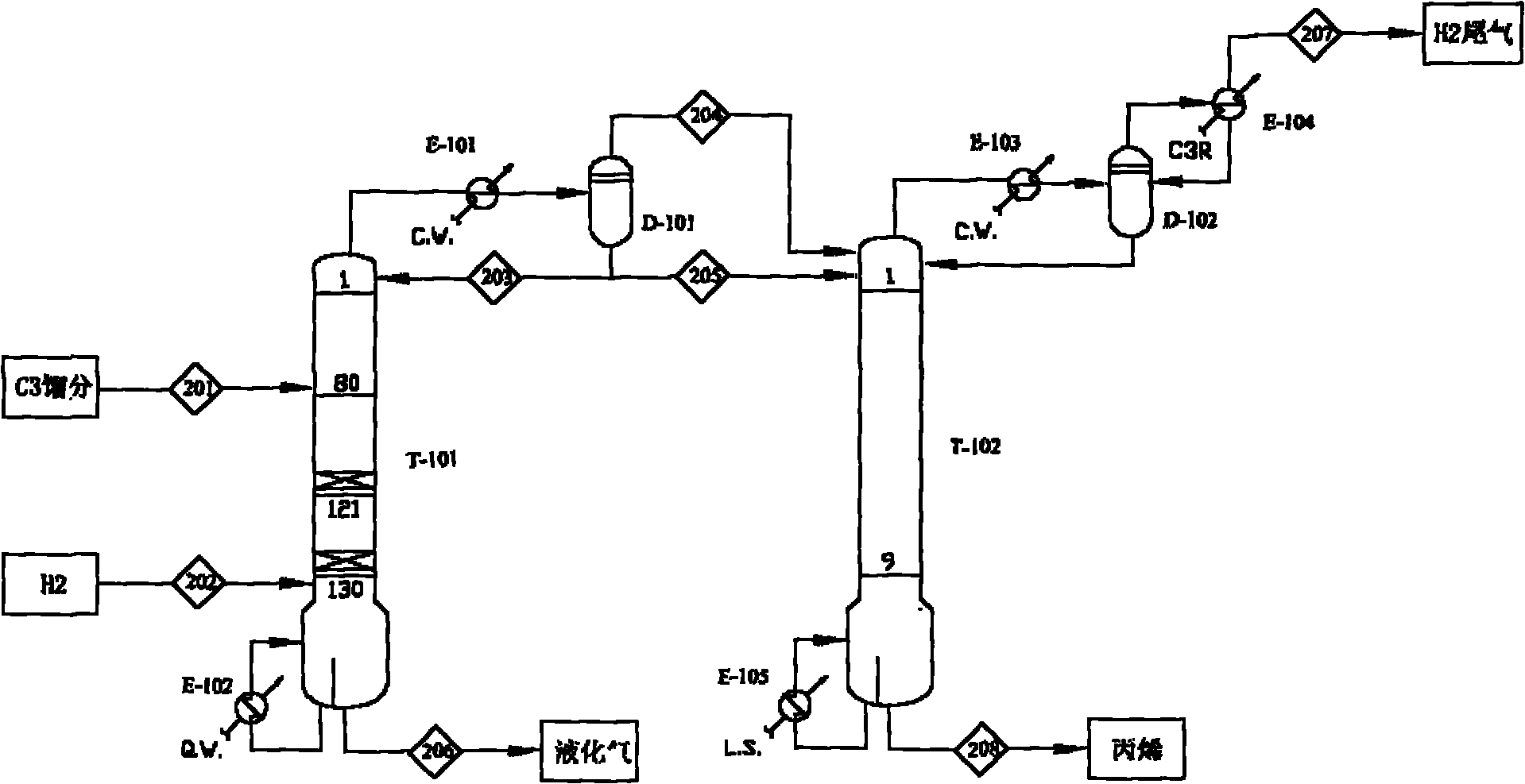

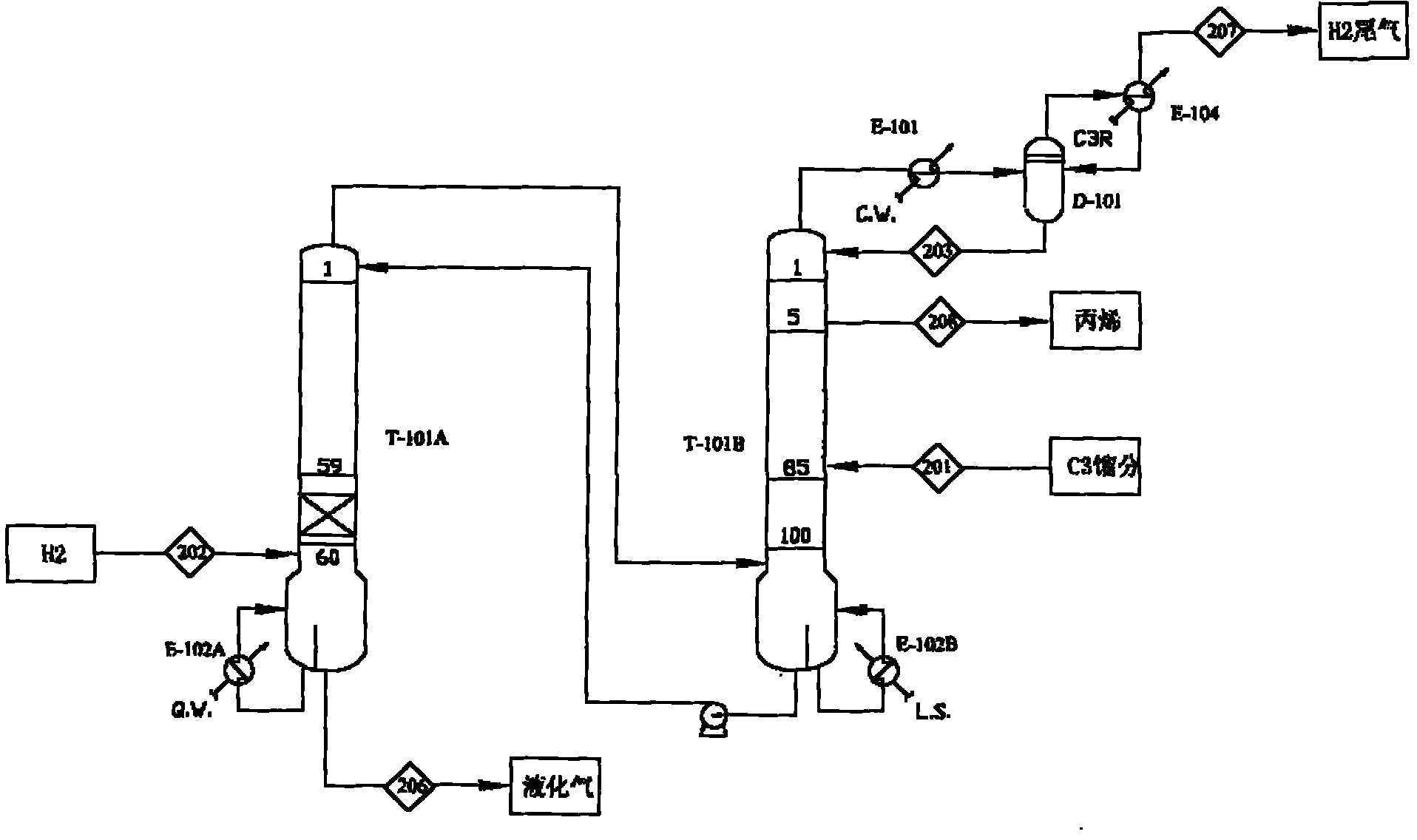

Catalytic rectification method for removing MAPD by selective hydrogenation

ActiveCN102040446AHigh conversion selectivityLow inactivation effectHydrocarbon by hydrogenationGaseous fuelsHydrogenTower

The invention provides a catalytic rectification method for removing methyl acetylene and propadiene (MAPD) by selective hydrogenation. The method comprises the following steps of: placing a catalytic rectification member below a C3 fraction feeding position of a propylene rectification tower, introducing hydrogen into the tower from the lower part of the catalytic rectification member, and making the hydrogen upwards flow through the catalytic rectification member; and directly feeding the C3 fraction containing the MAPD into the propylene rectification tower or feeding the C3 fraction whichis pre-transformed through a first MAPD reactor into the propylene rectification tower to perform catalytic rectification and remove MAPD, directly recovering propylene meeting the polymerization level requirement from a lateral line, or recovering the material from the top of the tower, and removing light components to obtain polymerization level propylene, wherein the molar fraction of the MAPDin the tower can be directly reduced to below 0.1 to 2 percent. The method is characterized in that: by using the characteristic of low concentration of the propylene in the propylene rectification tower, the probability of side reaction of transforming the propylene into propane can be reduced, the selectivity of MAPD transformation is improved, and the purpose of high propylene yield is fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS7208650B2Efficient removalEfficient separationHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

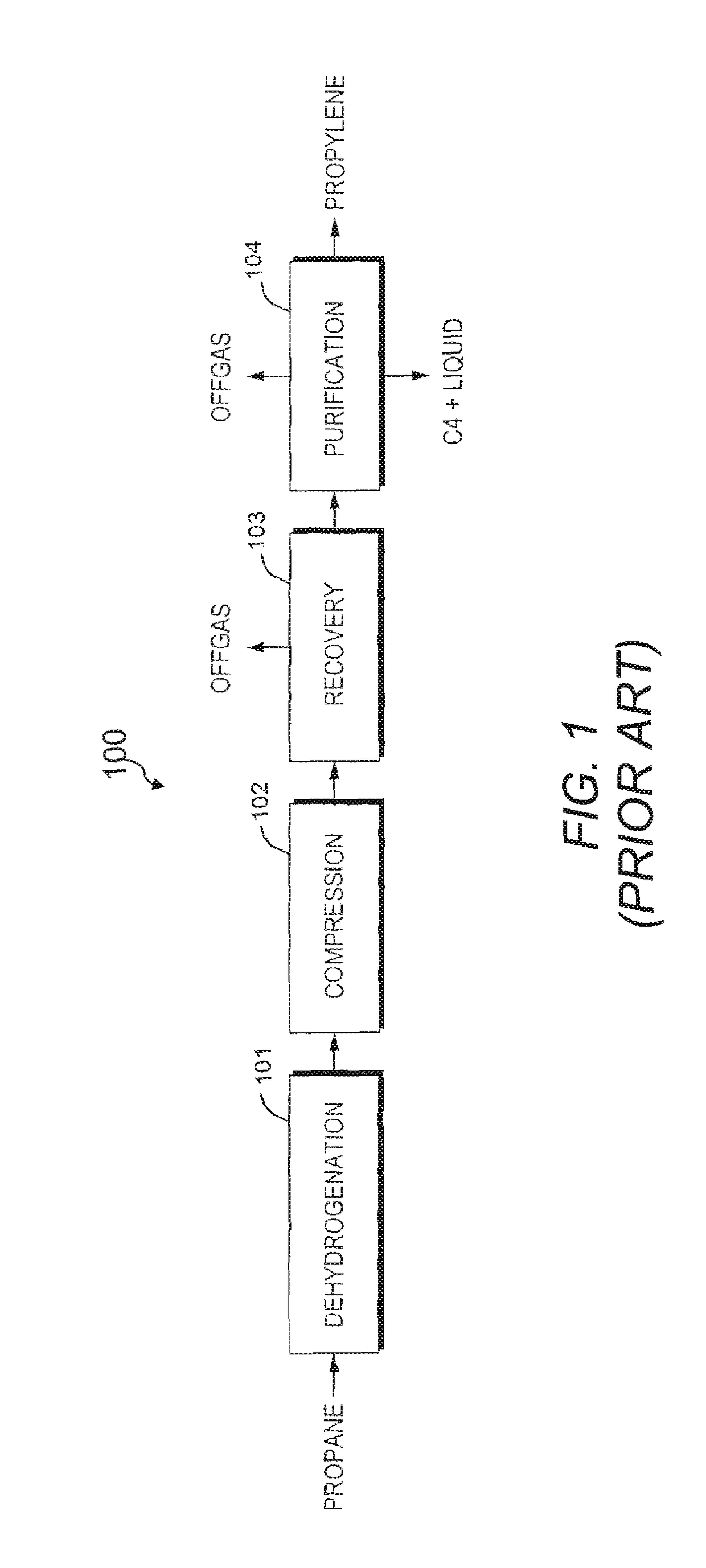

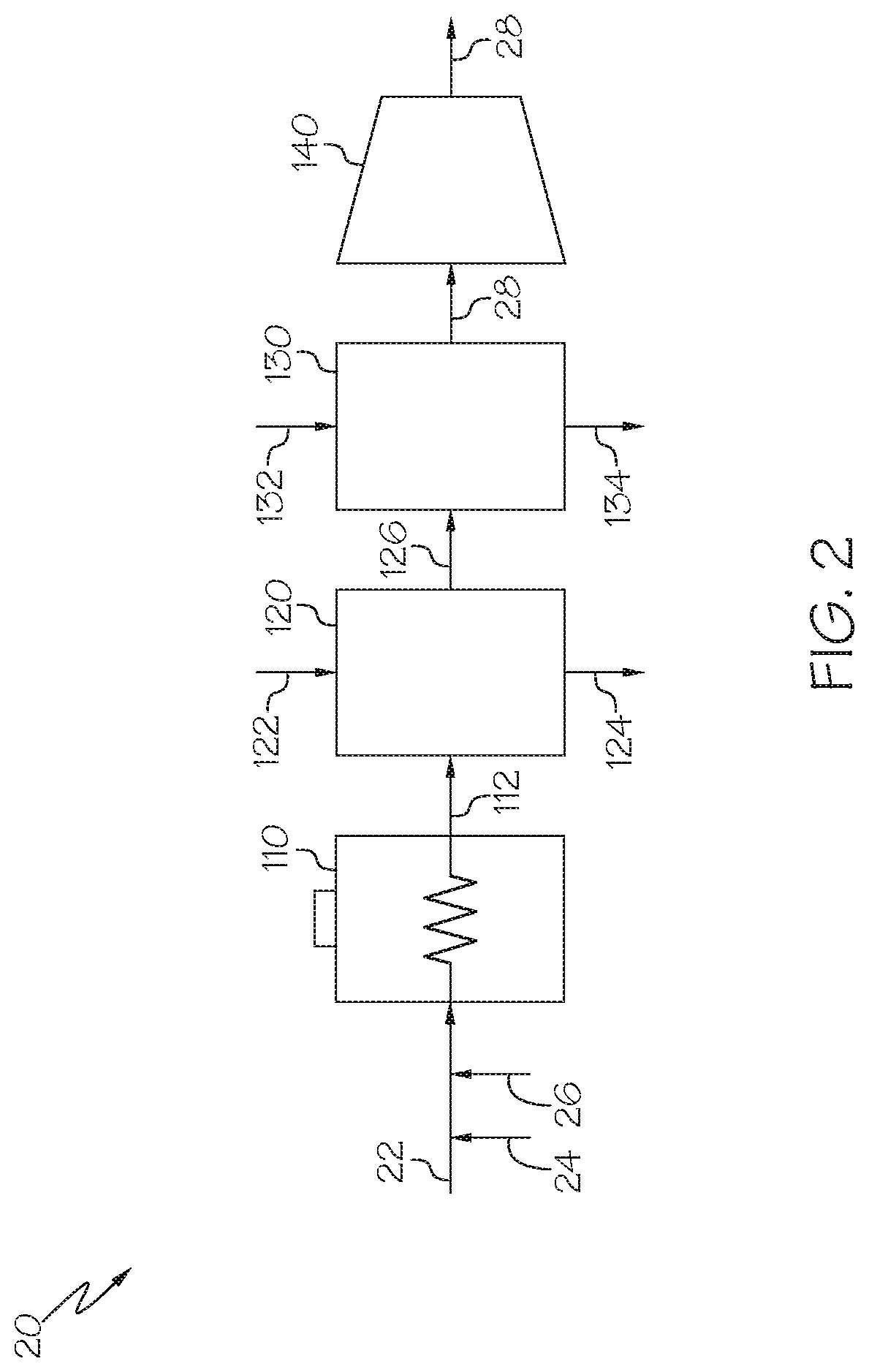

Method for improving propane dehydrogenation process

ActiveUS20170305814A1Operational securityExcessive pressureHydrocarbon by hydrogenationDistillation purification/separationReactor systemHydrogen

A propane dehydrogenation and propylene purification process in which a stream comprising propylene, propane, and methyl acetylene and propadiene (MAPD) is mixed with a hydrogen stream then reacted in at least three distinct reaction zones in a hydrogenation reactor system where MAPD is hydrogenated by a high-selectivity hydrogenation catalyst in a first reaction zone, and a second and a third reaction zones each have a low-selectivity hydrogenation catalyst to remove unreacted hydrogen. The outlet stream leaving the hydrogenation reactor system is MAPD-free and can be fed to a splitter column, which now mainly serves to separate propylene from propane. Various embodiments of reaction zone arrangements in a single or multiple reactors are also provided.

Owner:NAT INDZATION CO

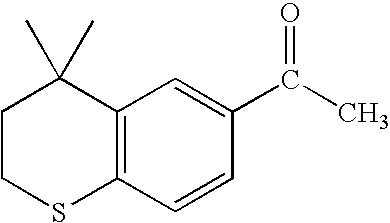

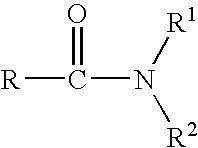

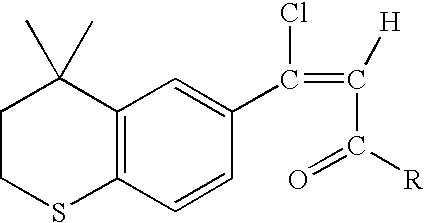

Process for the preparation of 4,4-dimethyl-6-ethynylthiochroman

An improved process for the preparation of key intermediates for tazarotene, 4,4-dimethyl-6-ethynylthiochroman, is provided comprising (a) reacting 4,4-dimethyl-6-acetylthiochroman of the formula with an acid chloride and an amido-group containing compound of the general formula wherein R is hydrogen or a hydrocarbyl of from 1 to 15 carbon atoms and R1 and R2 can be the same or different and are hydrocarbyls of from 1 to 15 carbon atoms or R1 and R2 together with the nitrogen atom to which they are bonded are joined together to form a heterocyclic group, optionally containing one or more additional heterocyclic atoms, or one of R1 and R2 together with the nitrogen atom to which it bonded are joined together with the carbonyl radical to form a heterocyclic group, optionally containing one or more additional heterocyclic atoms to form a β-chloro vinyl carbonyl compound intermediate of the general formula wherein R has the aforestated meanings; and (b) reacting the β-chloro vinyl carbonyl compound intermediate with an alkali metal to provide the 4,4-dimethyl-6-ethynylthiochroman.

Owner:GLENMARK GENERRICS LTD

Method to purify olefin-containing hydrocarbon feedstocks

A process for purifying an olefin-containing hydrocarbon feedstock comprising the steps of:(a) passing the said hydrocarbon feedstock in the presence of hydrogen over a first catalyst bed material comprising nickel deposited on a support material wherein said nickel is present as both nickel oxide and metallic nickel(b) recovering the feedstock having a substantially reduced acetylenics (in particular methylacetylene) and allenes (in particular propadiene) content.

Owner:TOTAL RES & TECH FELUY

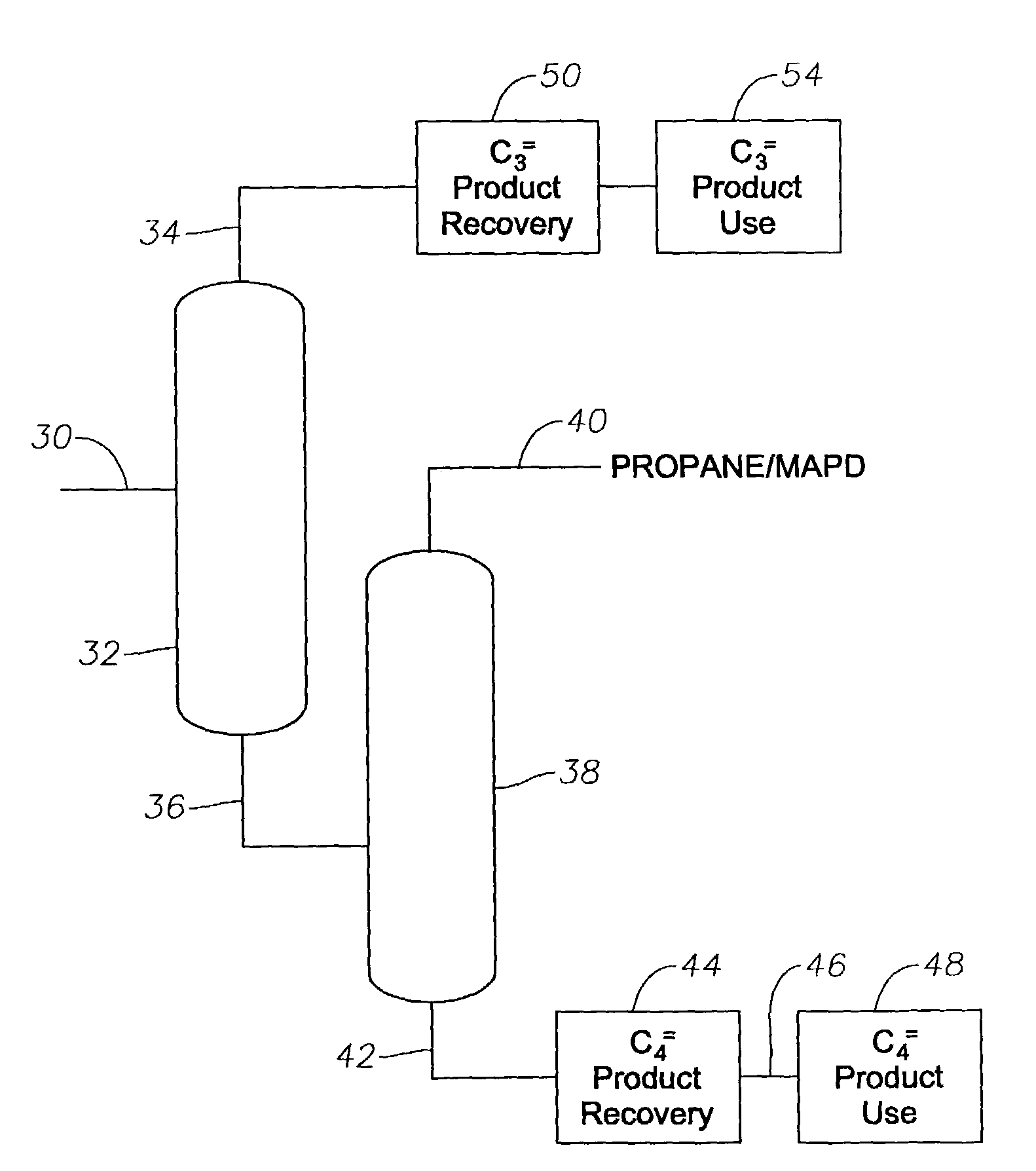

Propylene-containing composition

InactiveUS20050033013A1Shorten the counting processLow production costOrganic chemistryOxygenateOxygen compound

The present invention provides a new propylene-containing compositions, which preferably are suitable for polymerization disposition. The propylene-containing compositions include propylene, propane, dimethyl ether and one or more of ethylene, ethane, methanol, acetylene, methyl acetylene, propadiene, C4+ hydrocarbons and water. The propylene-containing composition can be derived from an oxygenate to olefin reaction system without expending resources on propane / propylene separation.

Owner:EXXONMOBIL CHEM PAT INC

Membrane process for olefin separation

A process is provided to separate a hydrocarbon stream comprising a mixture of light olefins and light paraffins, the process comprising sending the hydrocarbon stream through a pretreatment unit to remove impurities selected from the group consisting of sulfur compounds, arsine, phosphine, methyl acetylene, propadiene, and acetylene to produce a treated hydrocarbon stream; vaporizing the treated hydrocarbon stream to produce a gaseous treated hydrocarbon stream; adding liquid or vapor water to the gaseous treated hydrocarbon stream; then contacting the gaseous treated hydrocarbon stream to a membrane in a membrane system comprising one or more membrane units to produce a permeate stream comprising about 96 to 99.9 wt % light olefins and a retentate stream comprising light paraffins.

Owner:UOP LLC

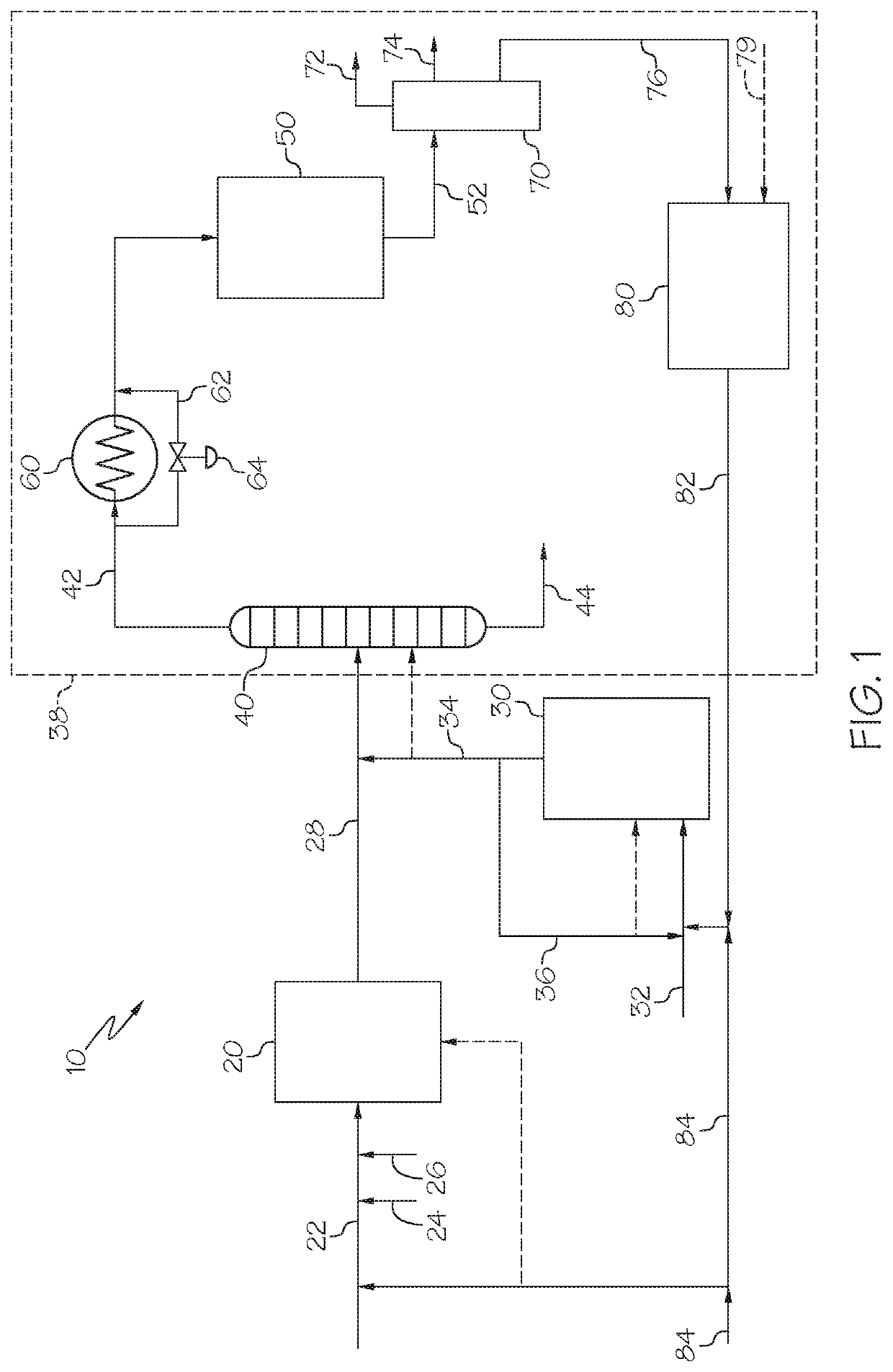

Methods for operating integrated chemical processing systems for producing olefins

ActiveUS20220251006A1Reduced activityHigh activityHydrocarbon by hydrogenationDistillation purification/separationChemical treatmentPtru catalyst

A method for operating an integrated system for producing olefins may include contacting a hydrogenation feed with a first hydrogenation catalyst to produce a hydrogenated effluent, the hydrogenation feed including at least a portion of a first process effluent from a first olefin production process and at least a portion of a second process effluent from a second olefin production process. The hydrogenation feed may include at least hydrogen, ethylene, carbon monoxide, acetylene, methyl acetylene, and propadiene, and the first hydrogenation catalyst may be a hydrogenation catalyst having a temperature operating range of at least 40° C. The hydrogenated effluent may include methyl acetylene, propadiene, or both. The method may further include contacting at least a portion of the hydrogenated effluent with a second hydrogenation catalyst, which may cause hydrogenation of at least a portion of the methyl acetylene and propadiene to produce an MAPD hydrogenated effluent.

Owner:DOW GLOBAL TECH LLC

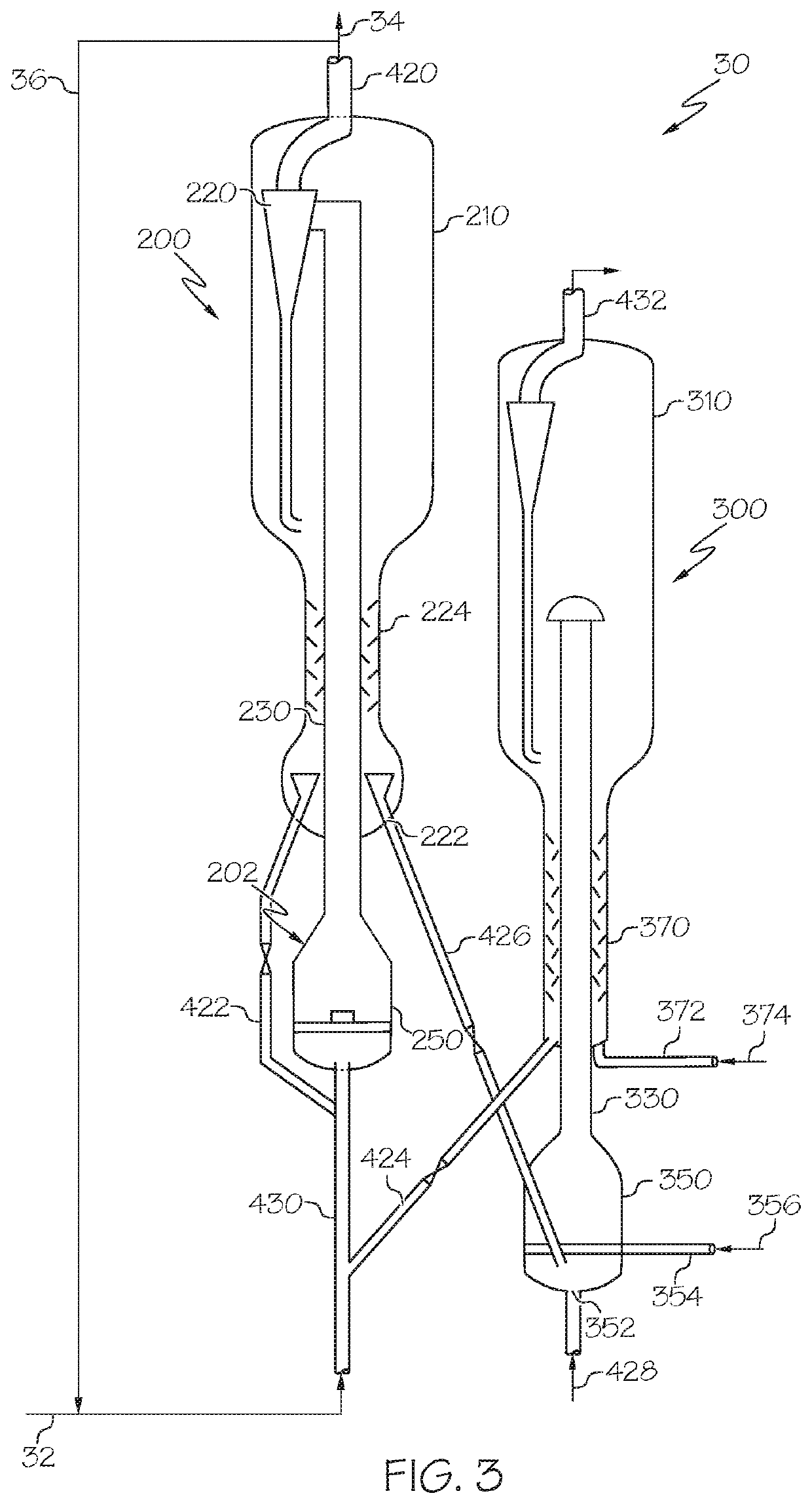

Distillation process for removal of methyl acetylene and/or propadiene from an olefin stream

InactiveUS7402720B2Eliminate needSolvent extractionDistillation regulation/controlDistillationFractionation

The present invention provides a process for removing methyl acetylene and / or propadiene from a propylene stream and / or a butylene stream by two step fractionation. Methyl acetylene and / or propadiene avoids the use of a hydrogenation reactor and makes the methyl acetylene and / or propadiene recoverable from the process.

Owner:EXXONMOBIL CHEM PAT INC

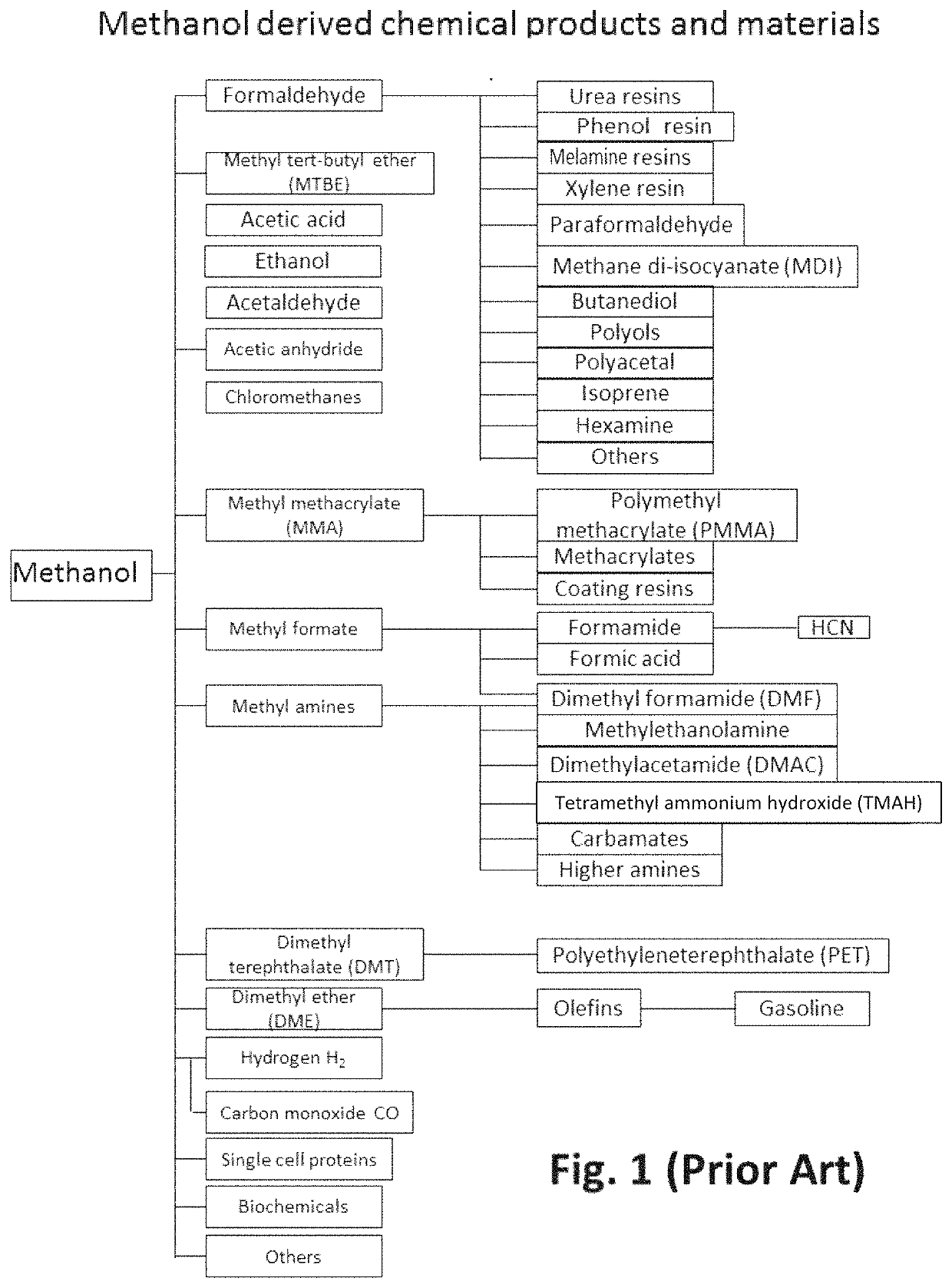

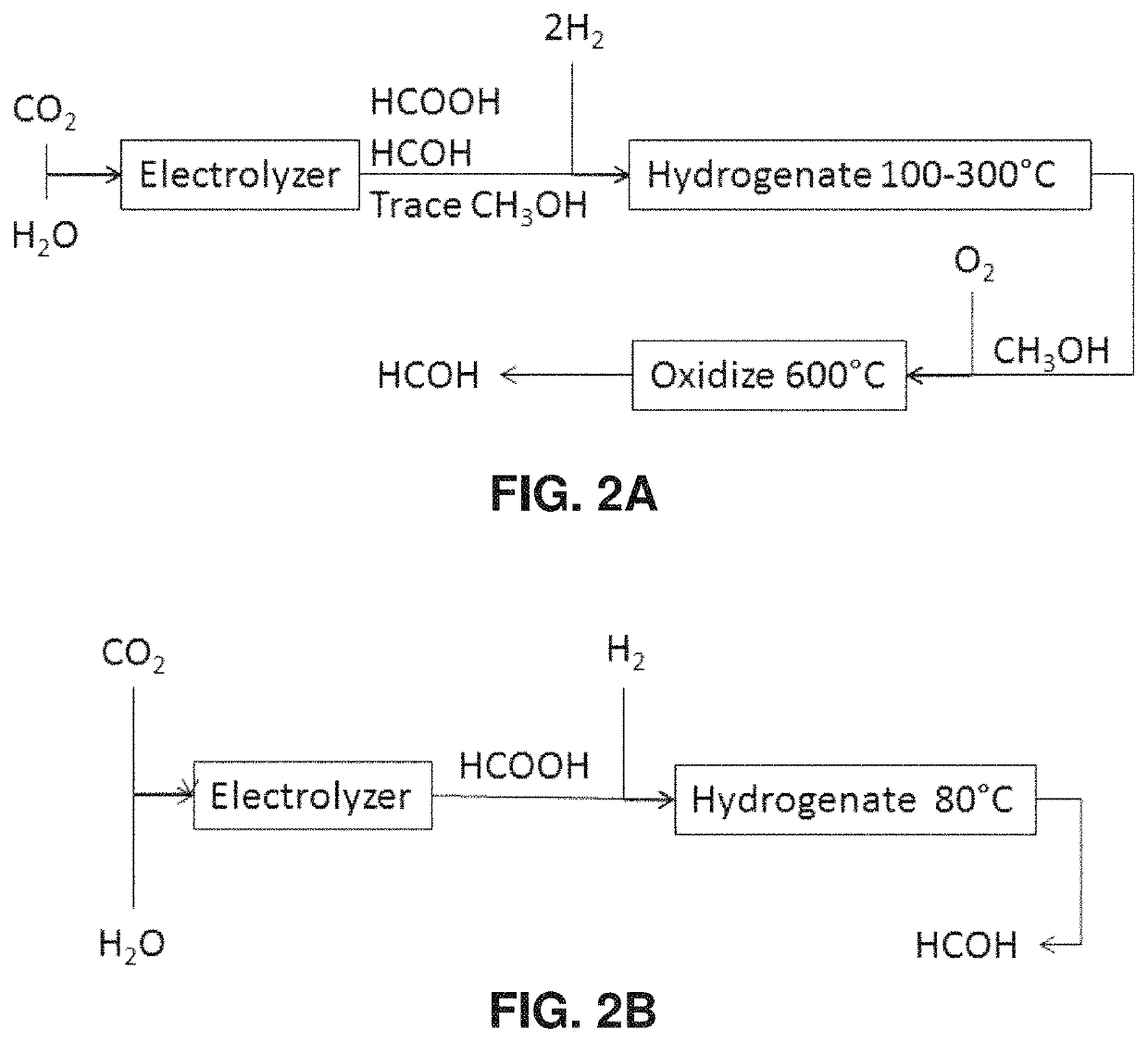

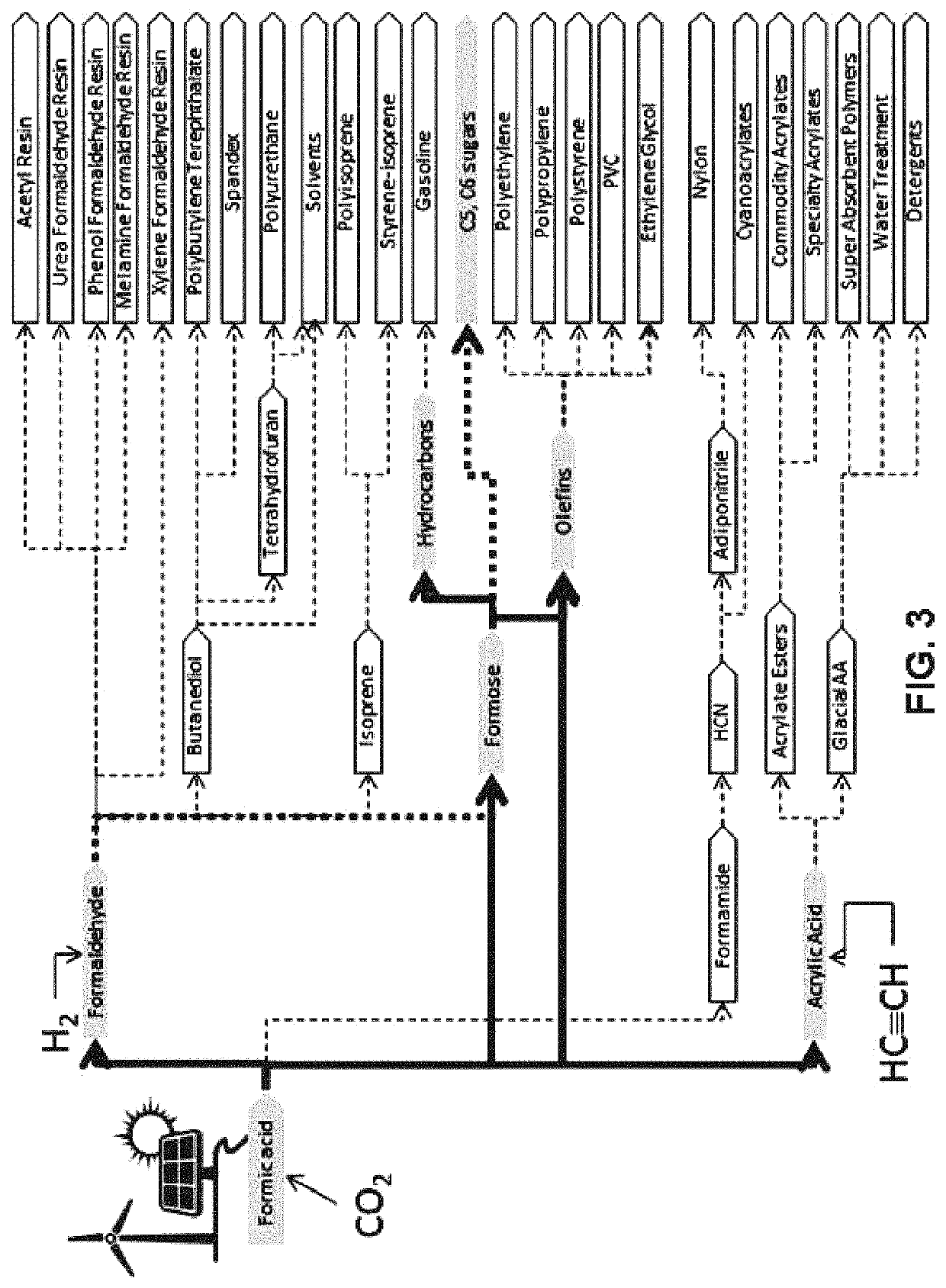

Process for the sustainable production of acrylic acid

A process for the production of organic acids having at least three carbon atoms comprises the steps of forming an amount of carbon monoxide and reacting the amount of carbon monoxide with an amount of an unsaturated hydrocarbon. The reaction is preferably carried out in the presence of a supported palladium catalyst, a strong acid, and a phosphine. In some embodiments, the unsaturated hydrocarbon is one of acetylene and methylacetylene, and the organic acid is one of acrylic acid and methyl acrylic acid. The reacting step is preferably performed with carbon monoxide produced from carbon dioxide.

Owner:GREENLYZER US INC

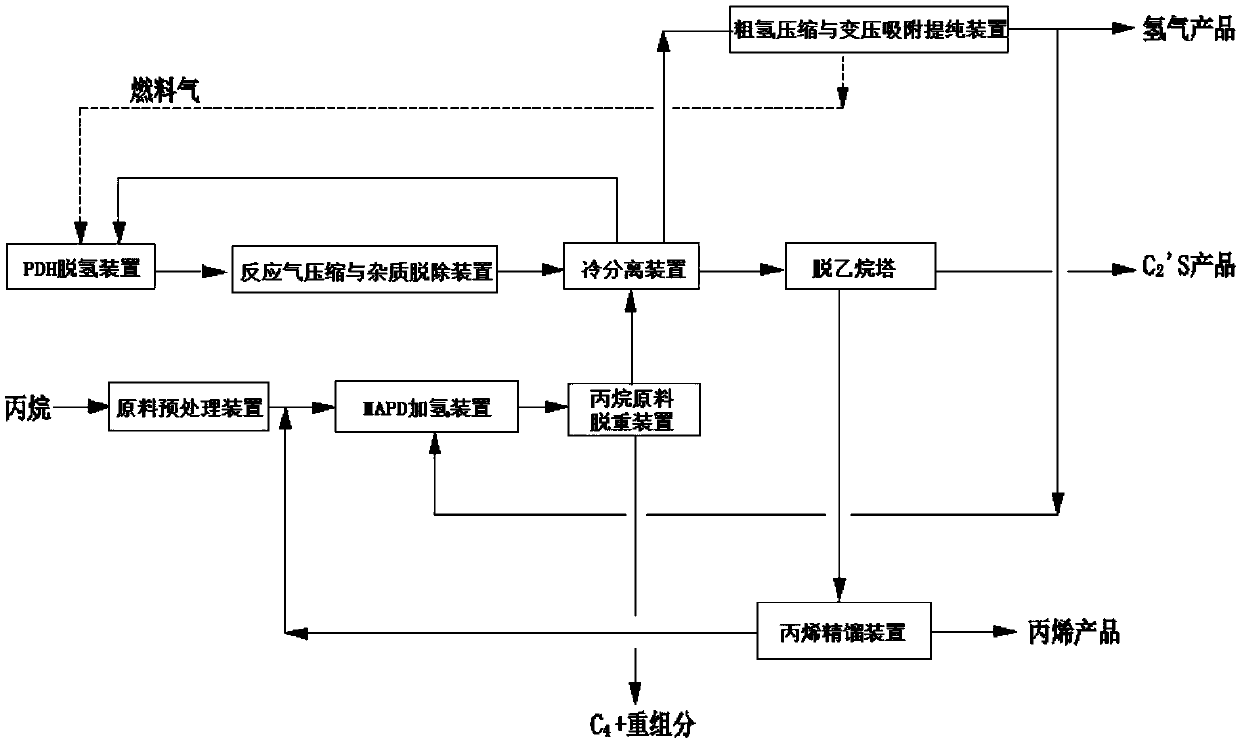

Method and system for preparing propylene

InactiveCN110937975AAvoid lostLoss will not causeHydrocarbon purification/separationHydrocarbonsDistillationDehydrogenation

The invention relates to a method and a system for preparing propylene. The method comprises the following steps: carrying out MAPD hydrotreatment on a propane raw material to obtain a hydrotreated material; carrying out heavy component removal treatment on the hydrotreated material to remove heavy components containing more than 4 carbon atoms so as to obtain a heavy component-removed material; carrying out PDH dehydrogenation treatment on the material having undergone heavy component removal treatment so as to obtain a material having undergone PDH dehydrogenation treatment; removing hydrogen and ethane from the material having undergone PDH dehydrogenation treatment, and carrying out rectification treatment to obtain distilled propylene and a second distillation residual material; and carrying out MAPD hydrotreatment on the second distillation residual material and the propane raw material. According to the invention, the problems of unstable device operation, high energy consumption and large investment in conventional methods can be solved, the limitation on the content of methylacetylene and propadiene during raw material purchasing is eliminated, and separation difficulty isreduced.

Owner:SINOPEC ENG +1

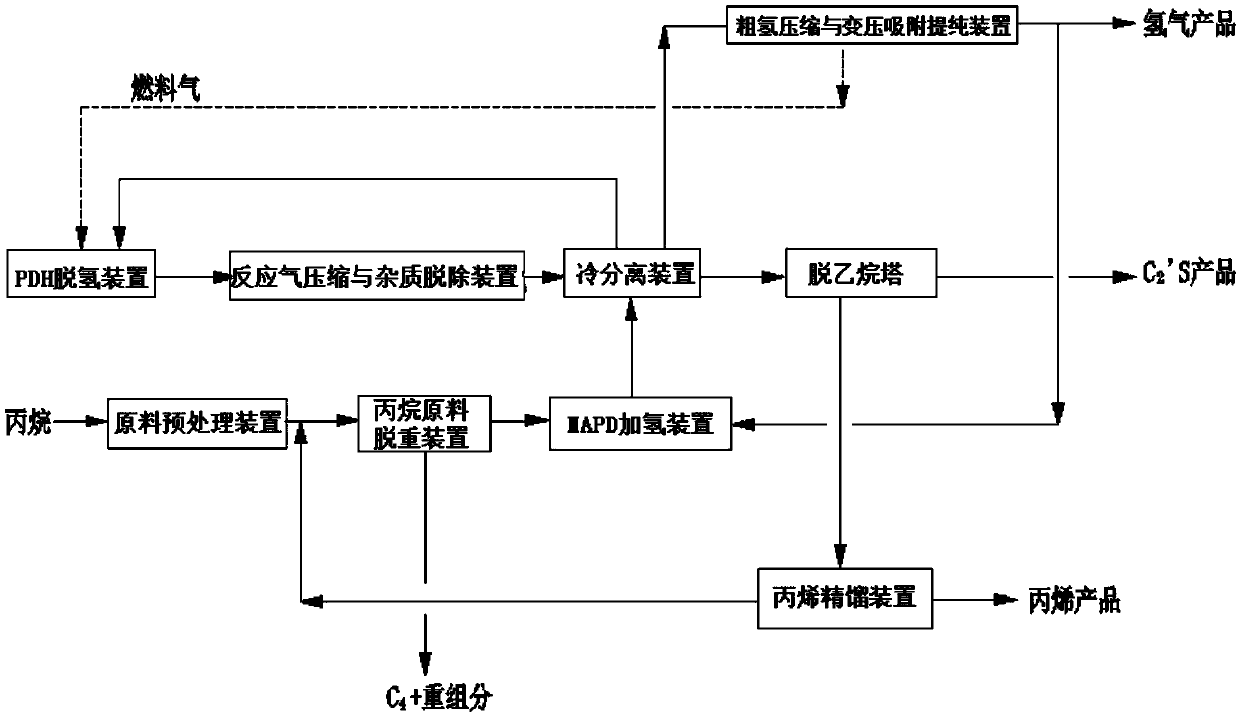

Method and system for preparing propylene

ActiveCN110937970AAvoids the problem of prone dehydrogenation catalyst cokingRelaxation of MAPD contentDistillation purification/separationHydrocarbonsMeth-Distillation

The invention relates to a method and a system for preparing propylene. The method comprises the following steps: carrying out heavy component removal treatment on a propane raw material to remove heavy components containing more than 4 carbon atoms so as to obtain a heavy-component-removed material; carrying out MAPD hydrogenation treatment on the heavy-component-removed material to obtain a hydrogenated material; carrying out PDH dehydrogenation treatment on the hydrotreated material to obtain a PDH-dehydrogenated material; removing hydrogen and ethane from the PDH-dehydrogenated material, and rectifying to obtain distilled propylene and a second distillation residue material; and carrying out heavy component removal treatment on the second distillation residue material and the propane raw material. According to the invention, the problems of unstable device operation, high energy consumption and large investment in the prior art can be overcome, and the limitation on the content ofmethylacetylene and propadiene in fed materials is relaxed.

Owner:SINOPEC ENG +1

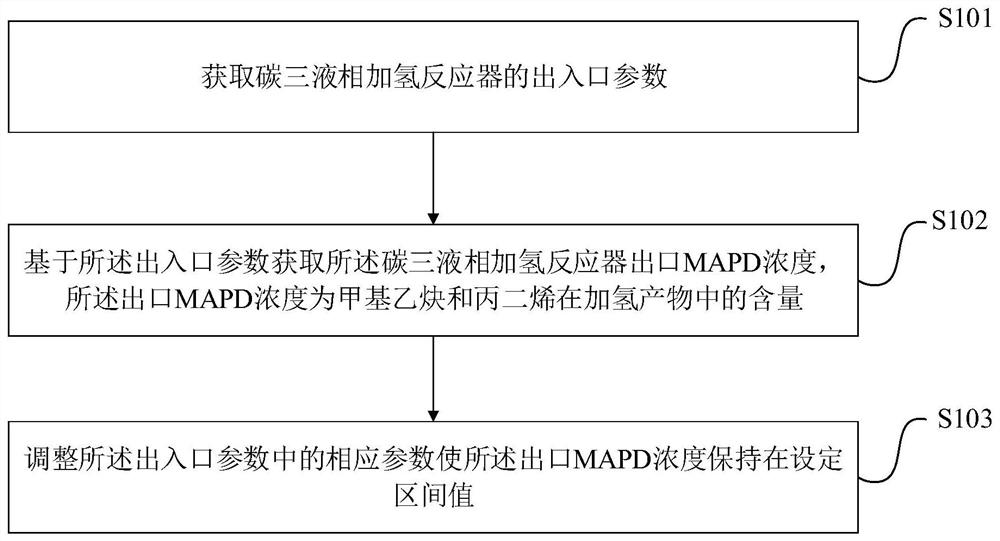

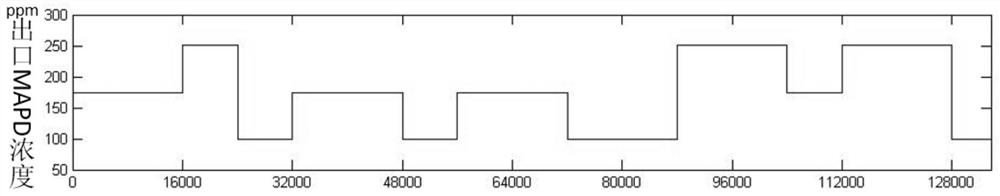

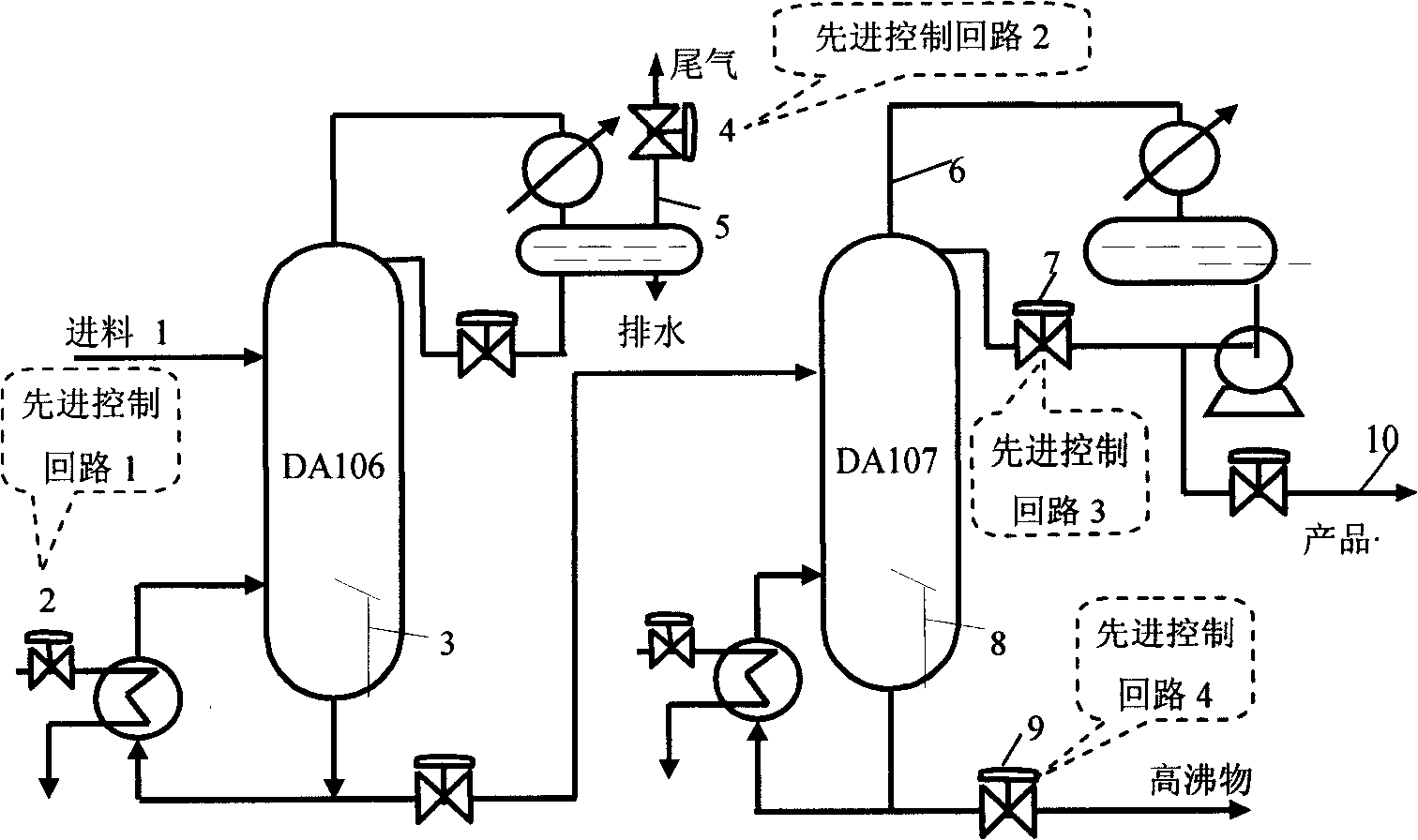

Automatic control method and equipment for C3 liquid phase hydrogenation reactor

ActiveCN113721683AHigh selectivityHydrocarbon by hydrogenationTotal factory controlAutomatic controlFluid phase

The invention discloses an automatic control method and equipment for a C3 liquid phase hydrogenation reactor. The automatic control method for the C3 liquid phase hydrogenation reactor comprises the following steps: acquiring inlet and outlet parameters of the C3 liquid phase hydrogenation reactor; obtaining the outlet MAPD concentration of the C3 liquid phase hydrogenation reactor based on the inlet and outlet parameters, wherein the outlet MAPD concentration is the volume content of methylacetylene and propadiene in a hydrogenation product; and adjusting corresponding parameters in the inlet and outlet parameters so that the outlet MAPD concentration is kept in a set interval value. The method and the equipment can achieve the purpose of improving the propylene selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

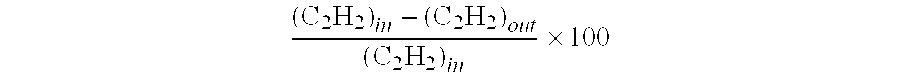

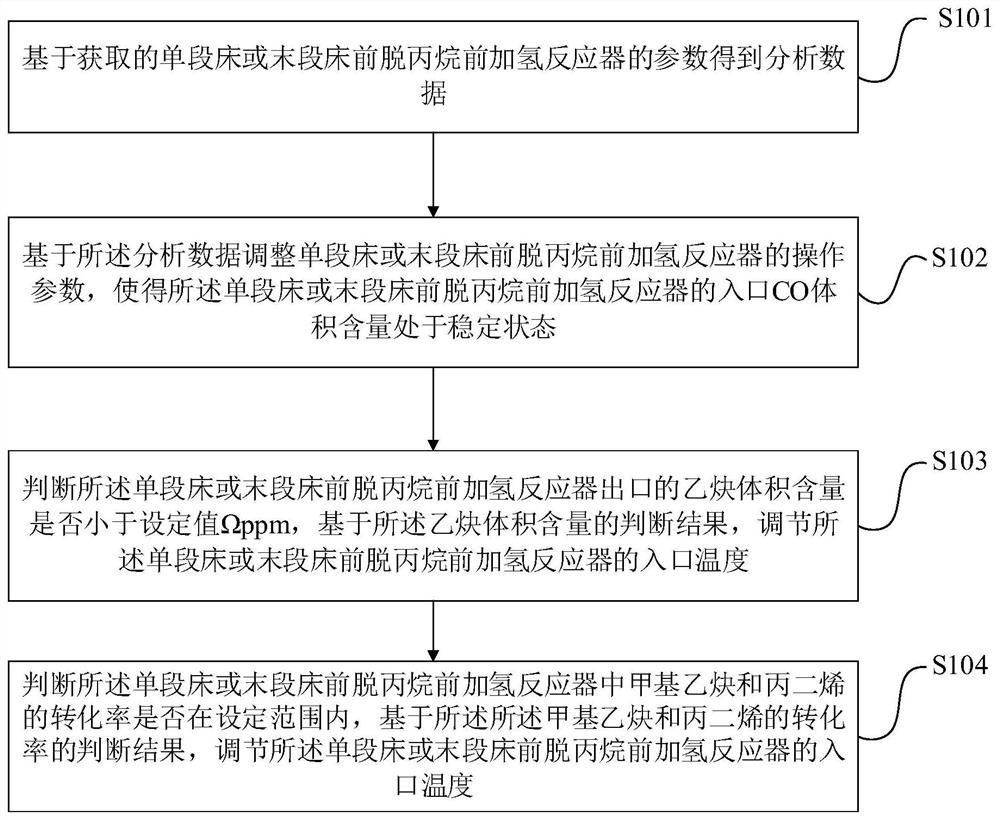

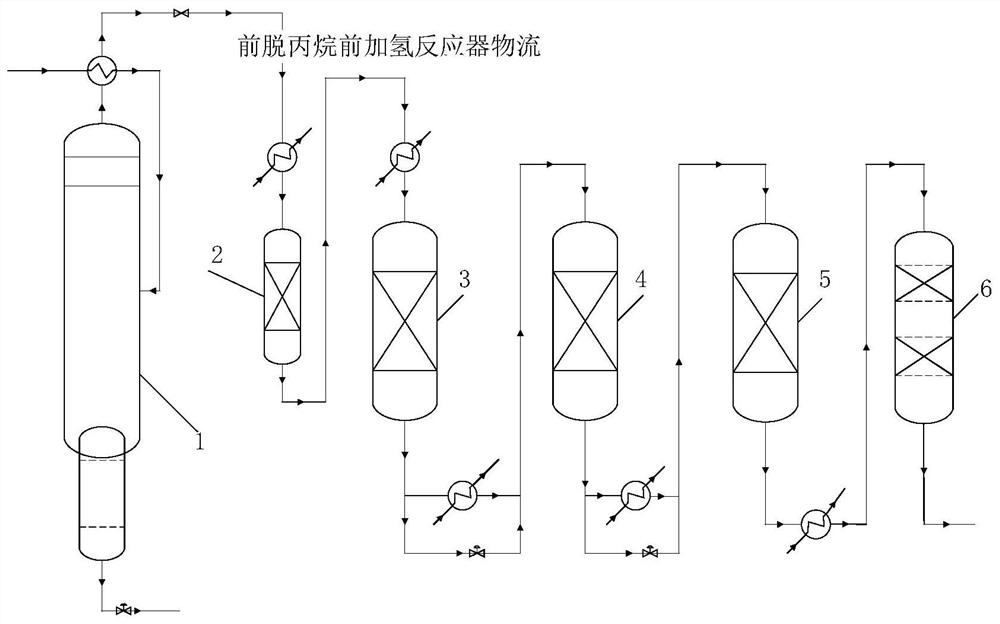

Automatic control method and application of front-end depropanization front-end hydrogenation reactor

PendingCN114426454AHigh yieldHydrocarbon purification/separationHydrocarbonsAutomatic controlHydrogenation reaction

The invention discloses an automatic control method and application of a front-end depropanization front-end hydrogenation reactor. The automatic control method of the front-end depropanization front-end hydrogenation reactor comprises the following steps: obtaining analysis data based on obtained parameters of the front-end depropanization front-end hydrogenation reactor; operating parameters are adjusted, so that the inlet CO volume content is in a stable state; judging whether the volume content of acetylene at the outlet is smaller than a set value omegappm or not, and adjusting the inlet temperature based on the judgment result of the volume content of acetylene; and judging whether the conversion rates of the methylacetylene and the propadiene in the front hydrogenation reactor are within a set range or not, and adjusting the inlet temperature of the front hydrogenation reactor based on the judgment result of the conversion rates of the methylacetylene and the propadiene. According to the method, the inlet temperature is adjusted based on the volume content of acetylene and the conversion rate of methylacetylene and propadiene at the same time, so that the aim of obtaining the optimal ethylene yield is achieved while the volume content of acetylene at an outlet is ensured to be qualified.

Owner:CHINA PETROLEUM & CHEM CORP +1

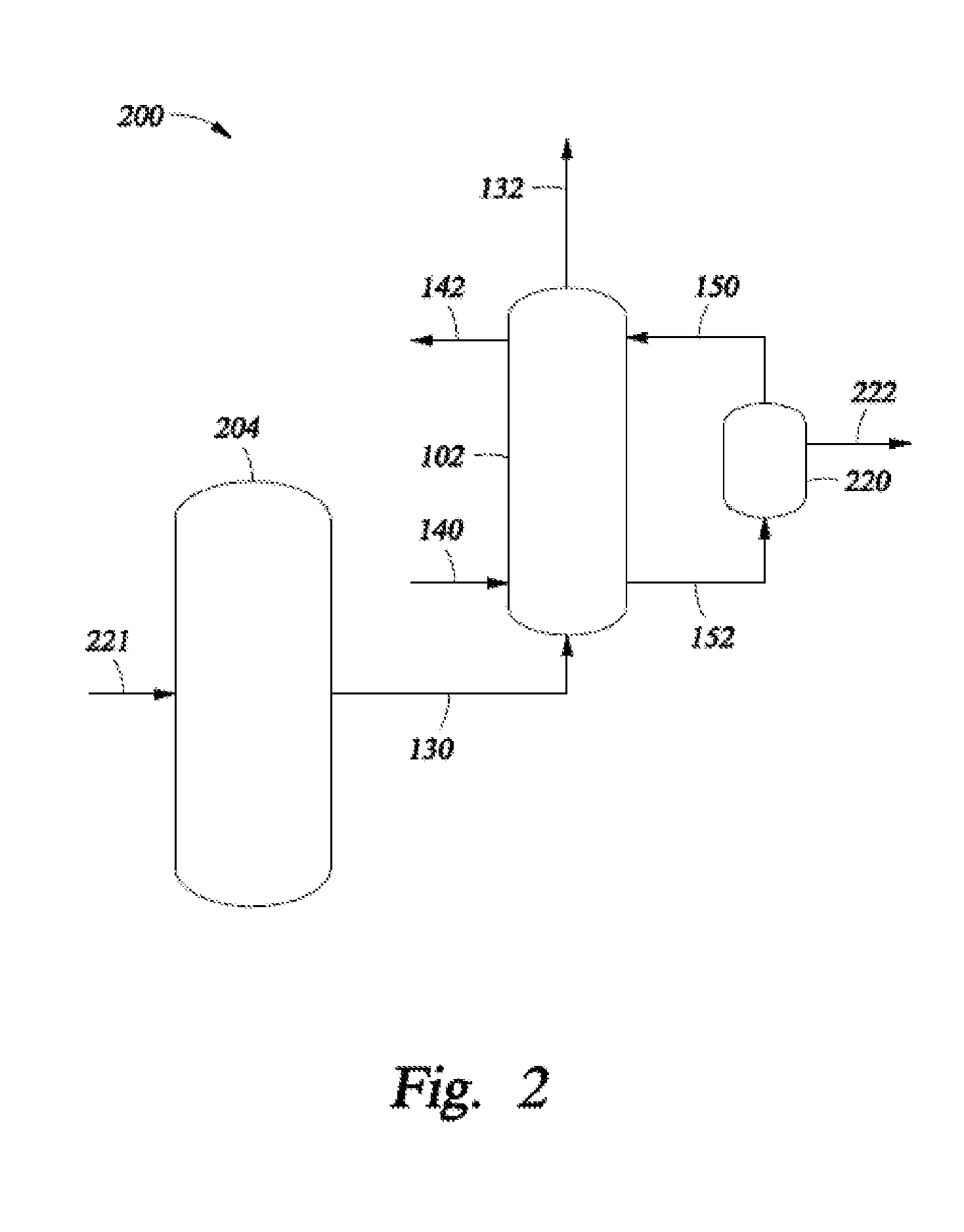

Selective hydrogenation of alkynyl-containing compounds and polyunsaturated compounds

ActiveUS9233893B2Improve system efficiencyEfficient heat recoveryHydrocarbon by hydrogenationHydrocarbonsHydrogenation processMethyl group

A selective hydrogenation process that is particularly effective in selectively hydrogenating alkynl compounds, such as acetylene or methyl acetylene, over alkenyl compounds, such as ethylene, is described. The process utilizes a slurry conversion unit for heat efficiency purposes during the conversion of acetylene into ethylene.

Owner:EXXONMOBIL CHEM PAT INC

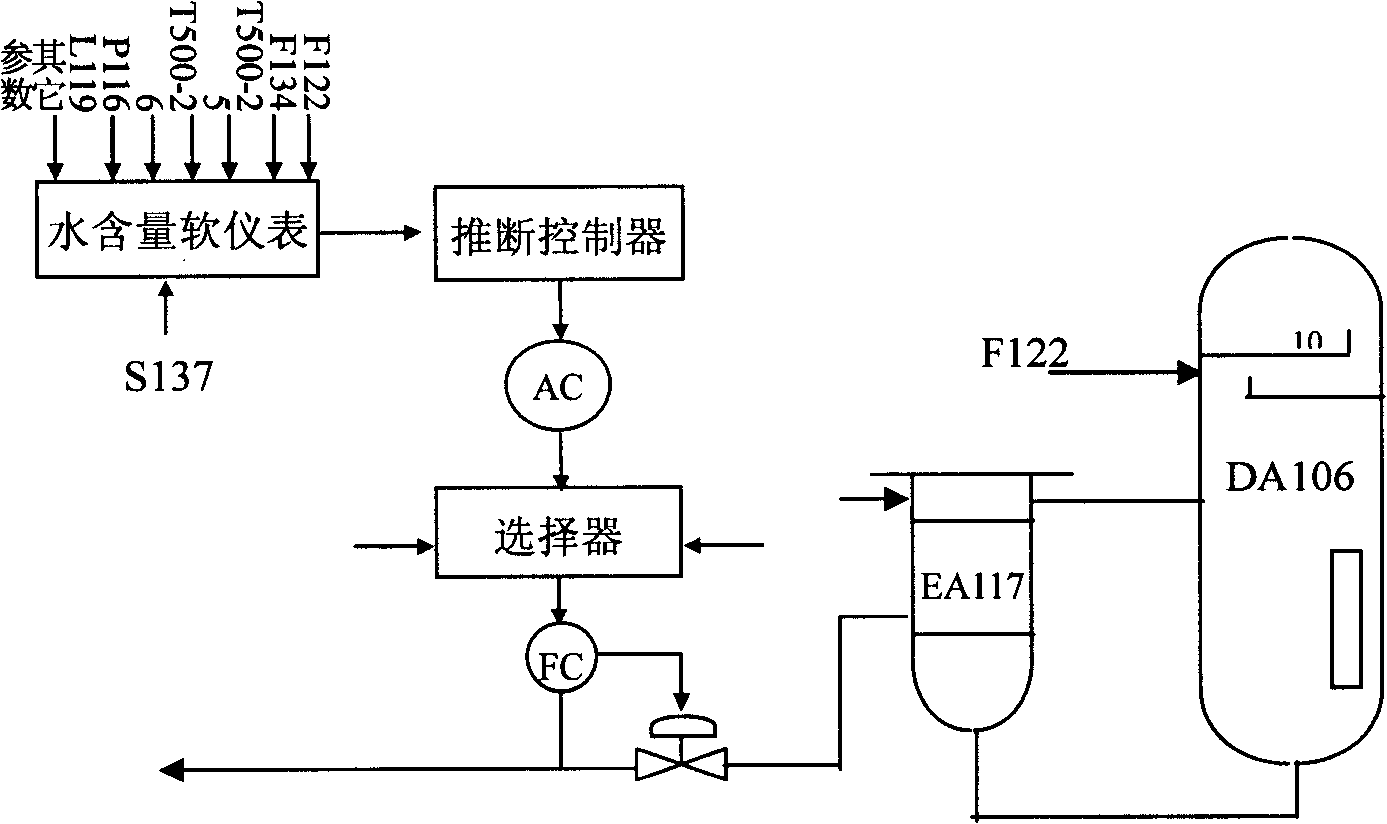

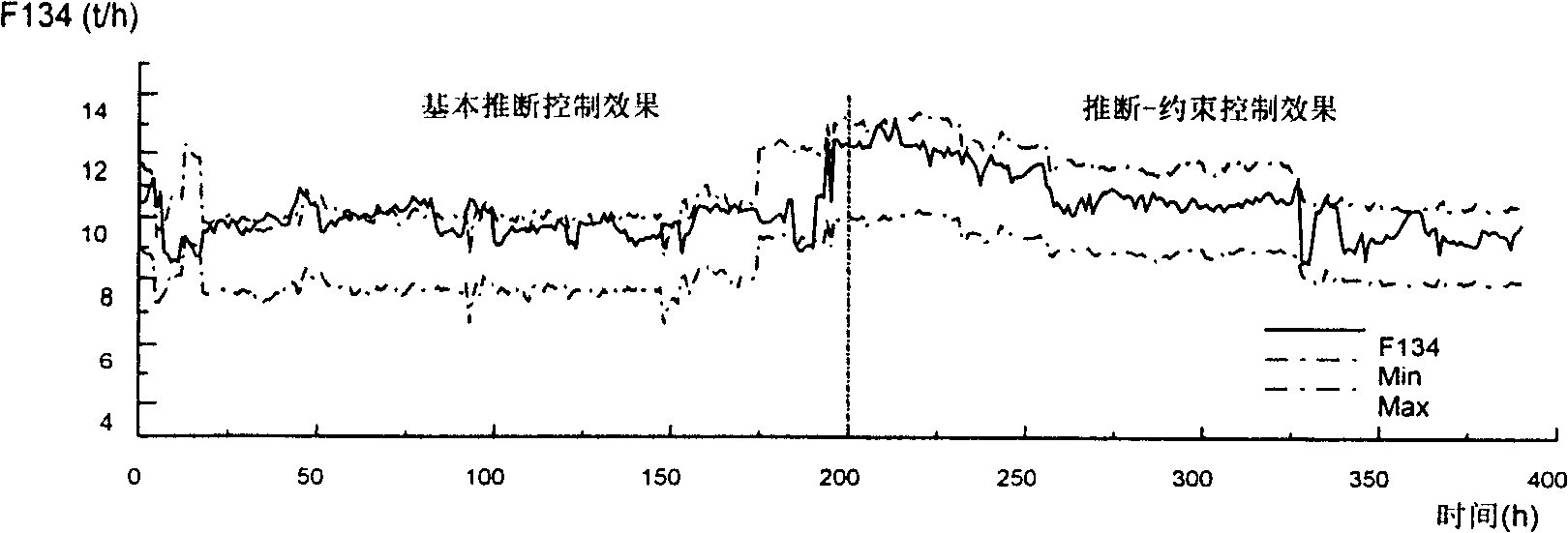

Process for advanced controlling rectifying apparatus of butadiene

ActiveCN100441552CPure excessProduct quality is easy to controlDistillation regulation/controlDistillation purification/separationReal-time dataDistillation

The invention relates to a control method in the fields of chemical engineering and system engineering, in particular to an advanced control system for a rectification device in butadiene production. The technical solution of the present invention is: an advanced control method for a butadiene rectification device, the rectification device includes a first rectification tower and a second rectification tower, and the method includes the following steps: using a measuring instrument to obtain The real-time data of the measurement point of the first rectification tower; start the soft-sensing model, filter the real-time data and input it into the soft-sensing model, and measure the water content in the bottom of the first rectification tower; start the soft-sensing model, and filter the real-time data Input the soft sensor model to measure the methyl acetylene content at the top of the first rectification tower; according to the soft sensor model, the water content in the bottom of the first rectification tower and the methyl acetylene content at the top of the tower are calculated on the basis of DCS Real-time online closed-loop optimization control of product quality in the first distillation column.

Owner:SINOPEC YANGZI PETROCHEM

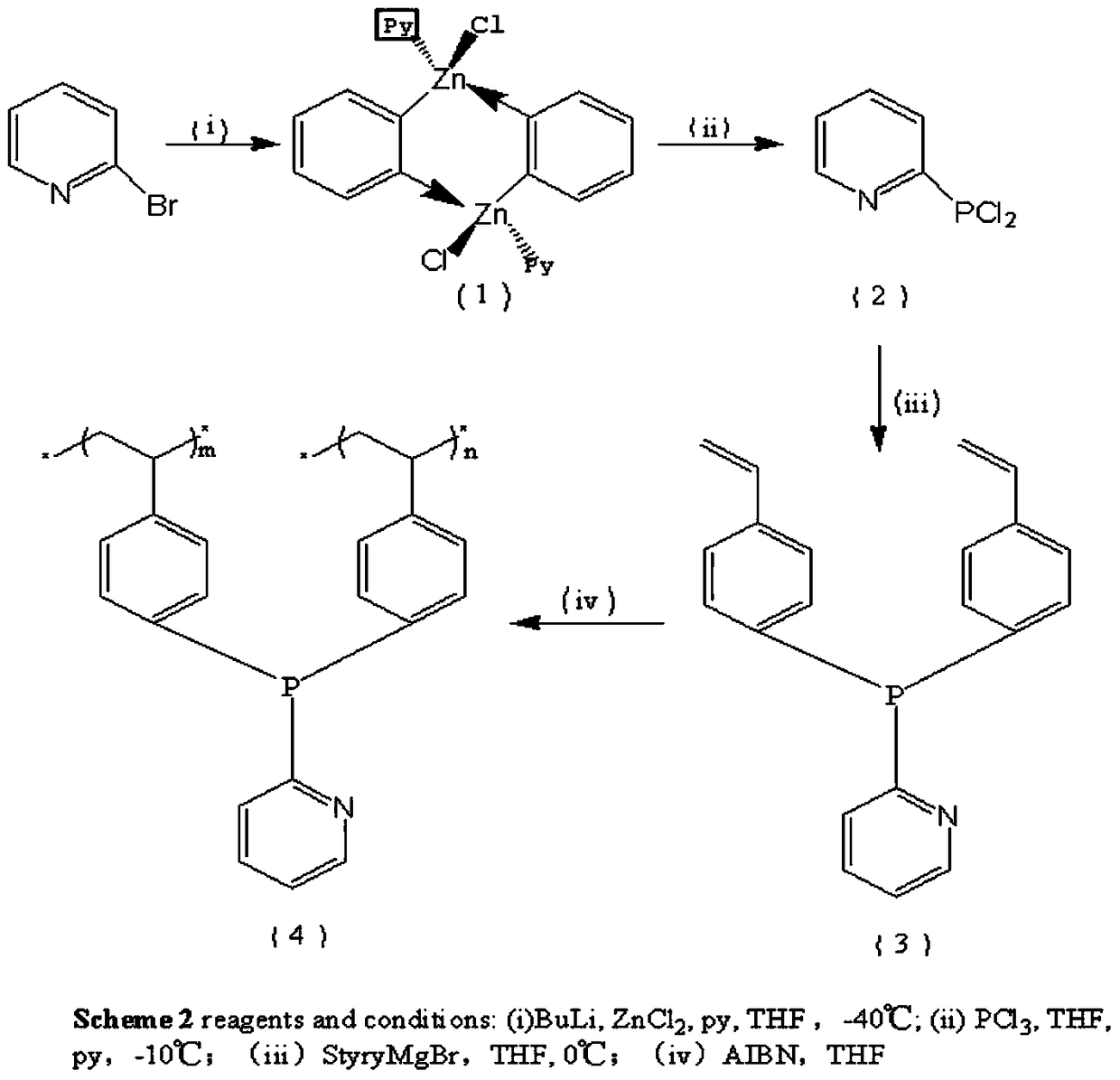

A kind of method for acetylene carbonylation to synthesize methyl acrylate

ActiveCN105753700BOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryReaction temperatureHigh activity

A method for synthesizing methyl acrylate by carbonylation of acetylene. The invention provides a method for synthesizing methyl acrylate by carbonylation of acetylene, using acetylene, methanol and carbon monoxide as reaction raw materials, under the condition of reaction temperature of 30-80°C and initial pressure of 1.2-6.5MPa, using organic ligands A polymer-supported palladium-based catalyst catalyzes the carbonylation of acetylene to synthesize methyl acrylate. The present invention adopts 2-pyridyl diphenylphosphine (2-PyPPh2) as an organic ligand, connects a vinyl group to prepare vinyl 2-pyridyl diphenylphosphine, and performs hinge polymerization under certain conditions to form a solid organic ligand. The organic ligand polymer (N-PPOL) is prepared by complexing the organic ligand polymer and immobilizing palladium acetate to prepare the organic ligand polymer-immobilized palladium-based catalyst. The one-step carbonylation of acetylene into methyl acrylate has the advantages of high activity, high selectivity, and excellent performance of easy separation and recycling.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

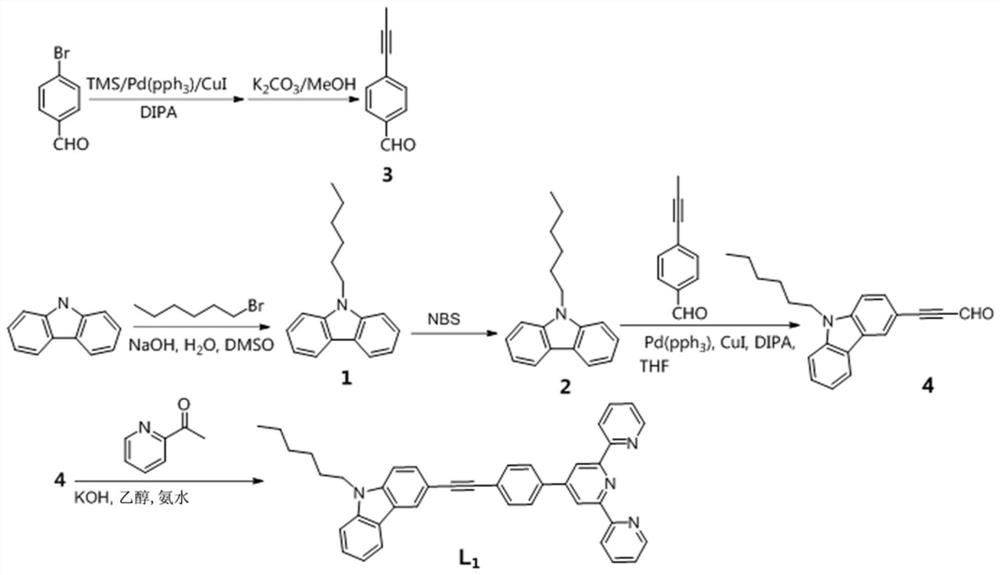

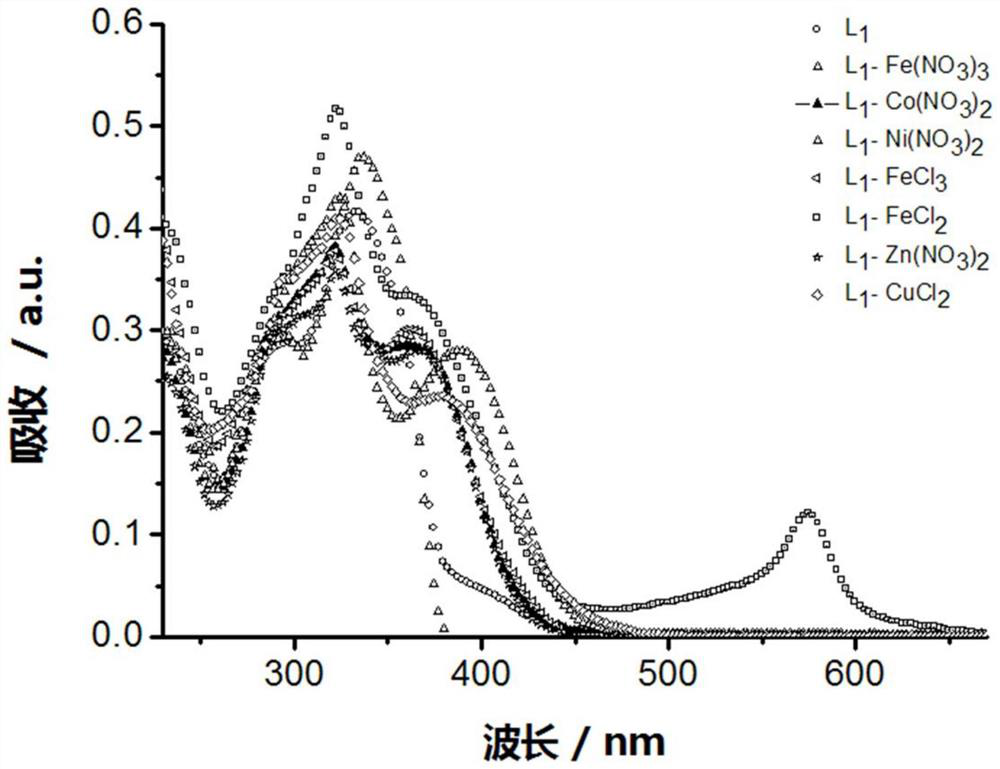

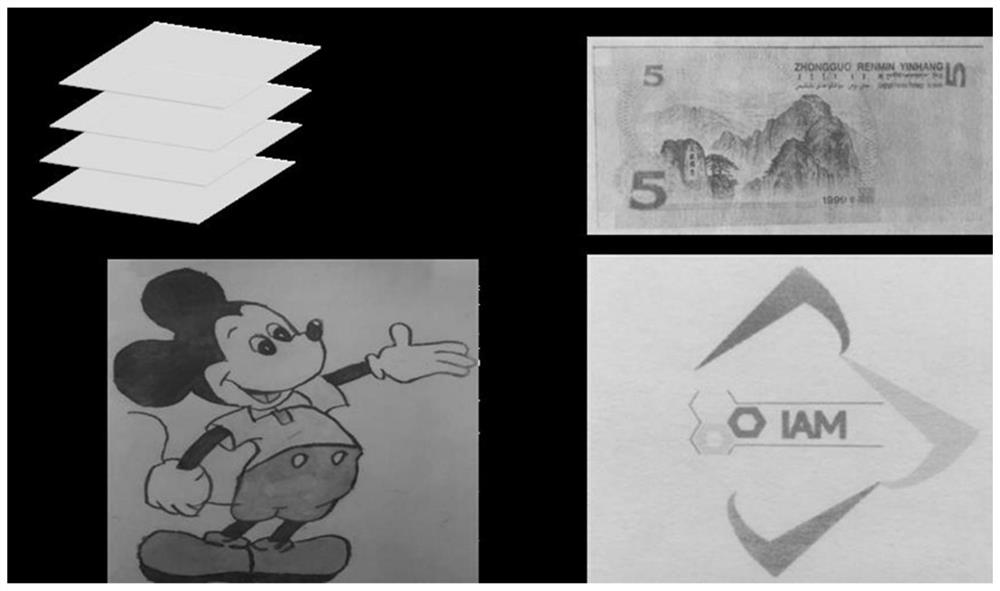

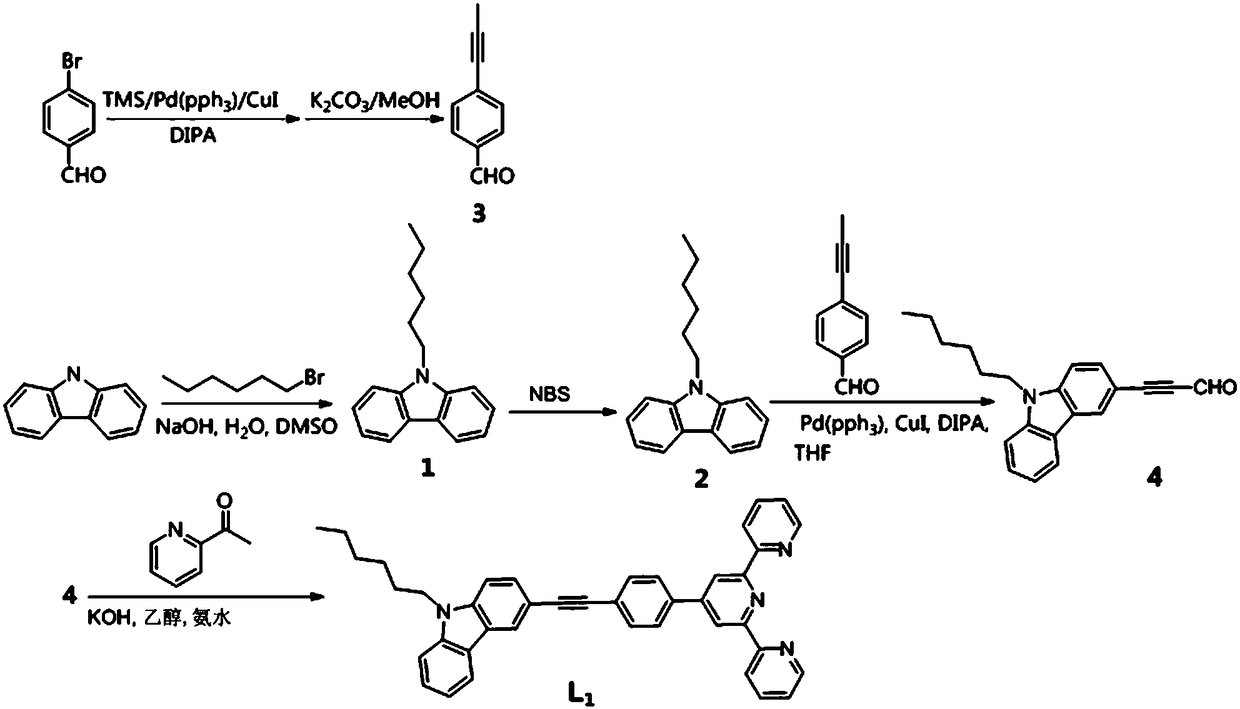

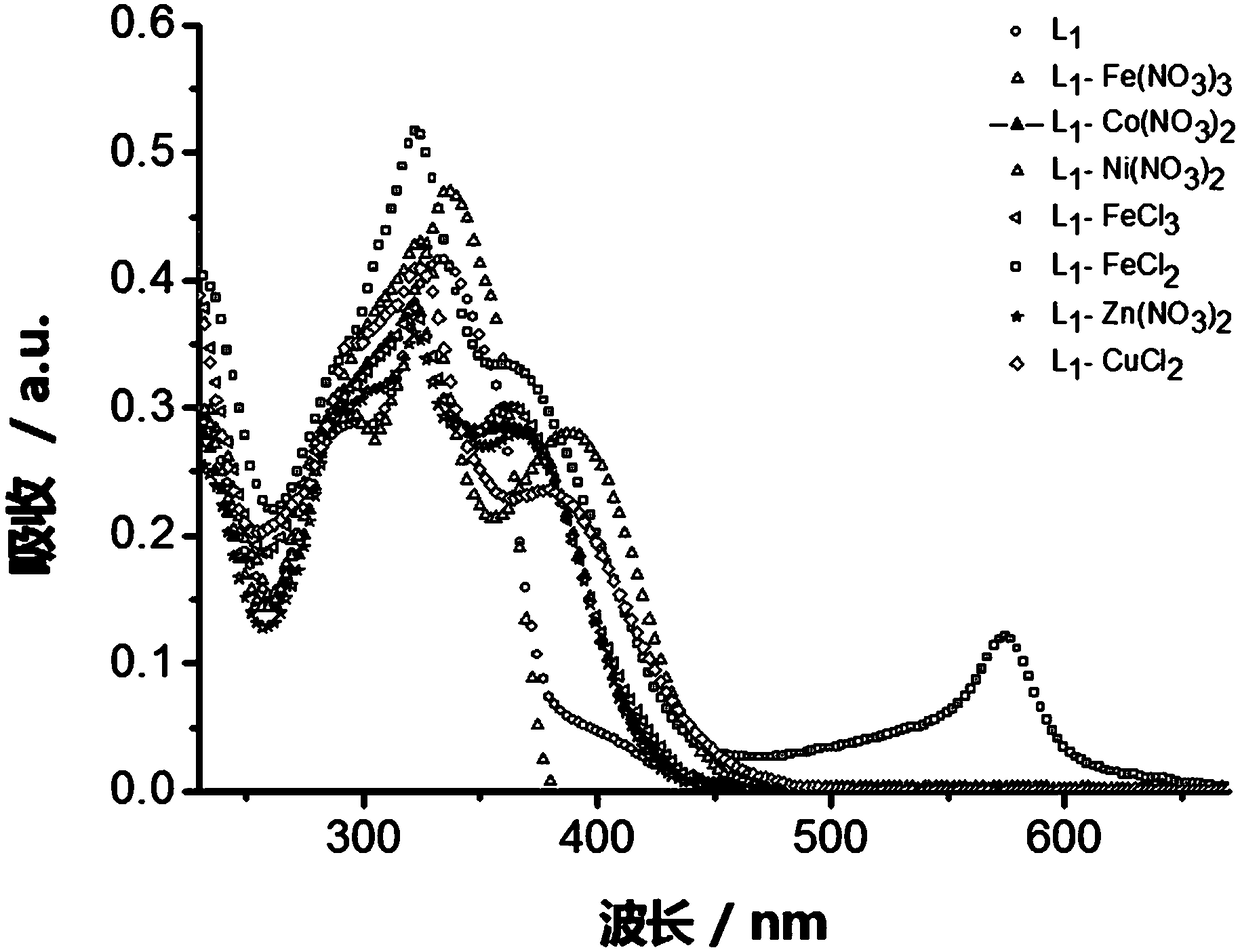

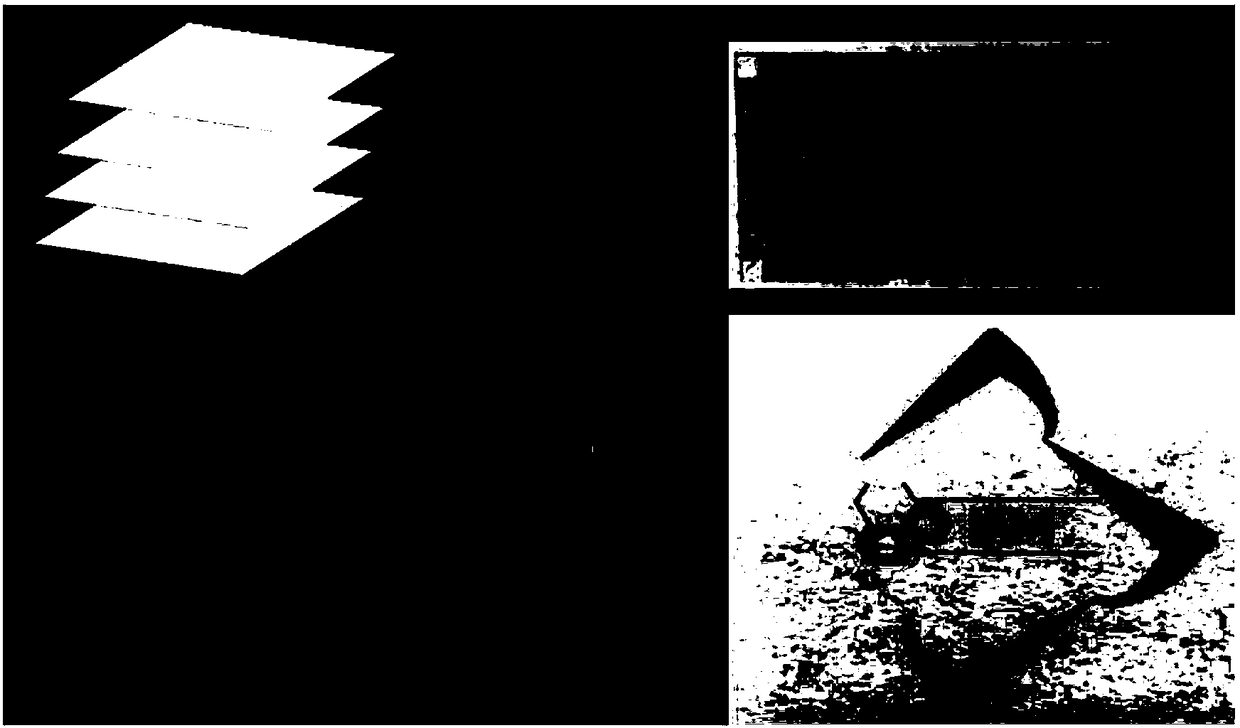

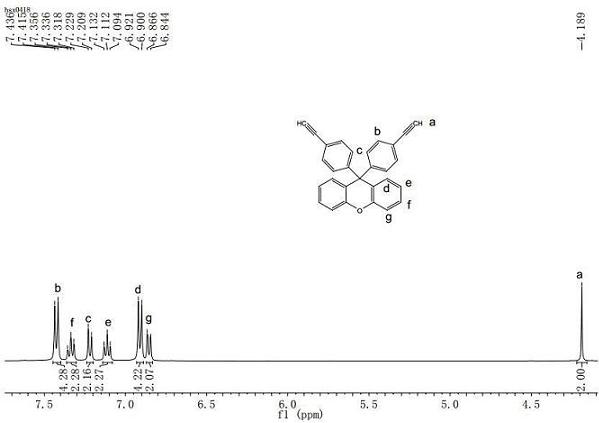

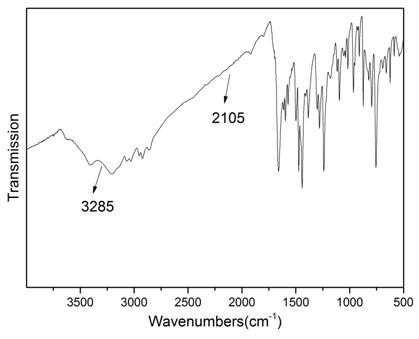

Preparation method and application of a kind of terpyridine compound and metal complex thereof

The invention discloses preparation methods and applications for a terpyridine compound and a terpyridine metal complex. The preparation method for the terpyridine compound comprises the following steps: subjecting carbazole, bromohexane and a sodium hydroxide aqueous solution with the concentration of 50% to a substitution reaction in a DMSO solvent system at 50 DEG C; subjecting a compound 1 andNBS to a regioselective bromination reaction in a dichloromethane solvent system at 25 DEG C; subjecting bromobenzaldehyde, trimethylsilylacetylene, cuprous iodide and (beta-4)-platinum to a Sonogashira coupling reaction in a nitrogen gas environment and a dry diisopropylamine solution system at 80 DEG C; subjecting a compound 2, a compound 3, cuprous iodide and (beta-4)-platinum to a Sonogashiracoupling reaction in a nitrogen gas environment and a dry diisopropylamine and tetrahydrofuran solution system; and subjecting an alkyne-containing compound 4, diacylpyridine and potassium hydroxideto a Krohnke intermediate cyclization process reaction in an ethanol solvent system at 25 DEG C. The preparation method for the terpyridine compound provided by the invention has simple synthetic steps and mild conditions, and realizes multi-color printing and encrypted printing under visible sunlight.

Owner:NANJING UNIV OF POSTS & TELECOMM

Preparation methods and applications for terpyridine compound and terpyridine metal complex

The invention discloses preparation methods and applications for a terpyridine compound and a terpyridine metal complex. The preparation method for the terpyridine compound comprises the following steps: subjecting carbazole, bromohexane and a sodium hydroxide aqueous solution with the concentration of 50% to a substitution reaction in a DMSO solvent system at 50 DEG C; subjecting a compound 1 andNBS to a regioselective bromination reaction in a dichloromethane solvent system at 25 DEG C; subjecting bromobenzaldehyde, trimethylsilylacetylene, cuprous iodide and (beta-4)-platinum to a Sonogashira coupling reaction in a nitrogen gas environment and a dry diisopropylamine solution system at 80 DEG C; subjecting a compound 2, a compound 3, cuprous iodide and (beta-4)-platinum to a Sonogashiracoupling reaction in a nitrogen gas environment and a dry diisopropylamine and tetrahydrofuran solution system; and subjecting an alkyne-containing compound 4, diacylpyridine and potassium hydroxideto a Krohnke intermediate cyclization process reaction in an ethanol solvent system at 25 DEG C. The preparation method for the terpyridine compound provided by the invention has simple synthetic steps and mild conditions, and realizes multi-color printing and encrypted printing under visible sunlight.

Owner:NANJING UNIV OF POSTS & TELECOMM

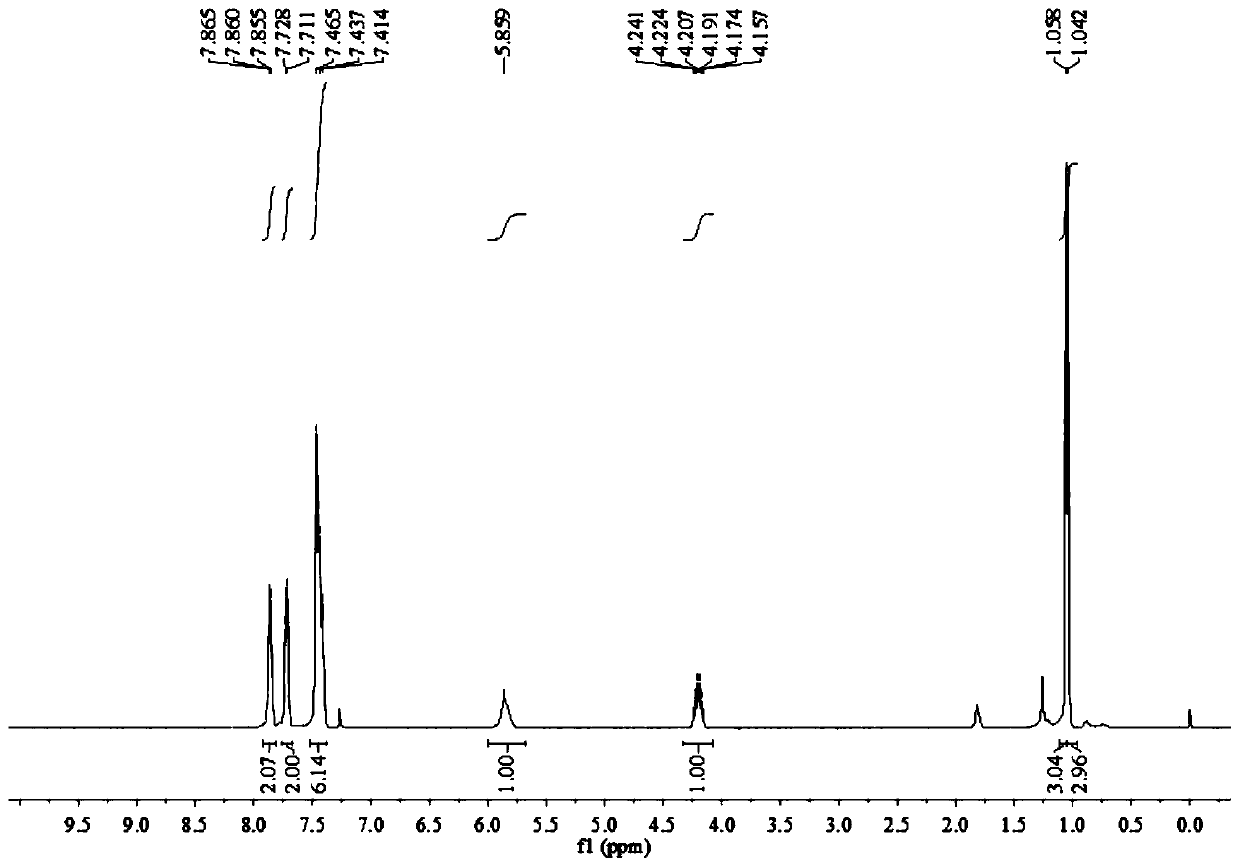

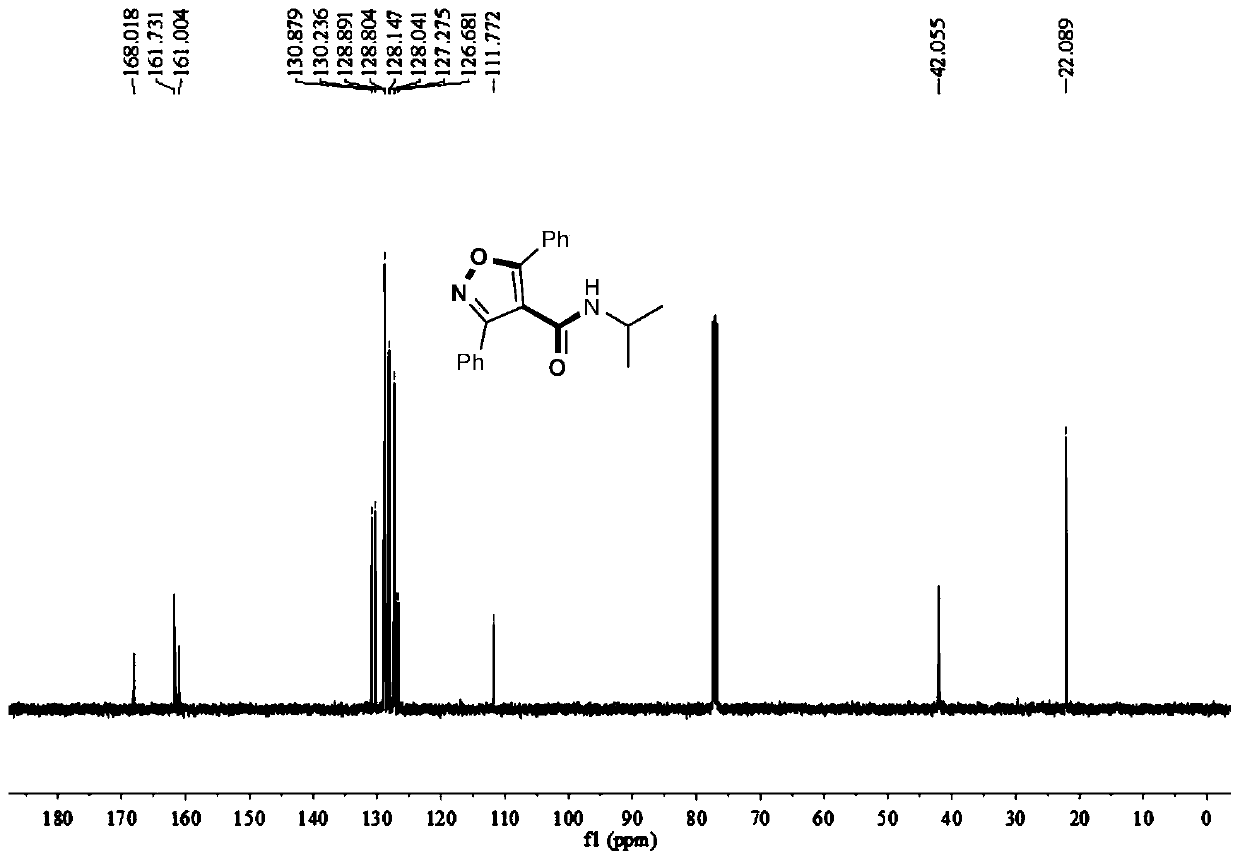

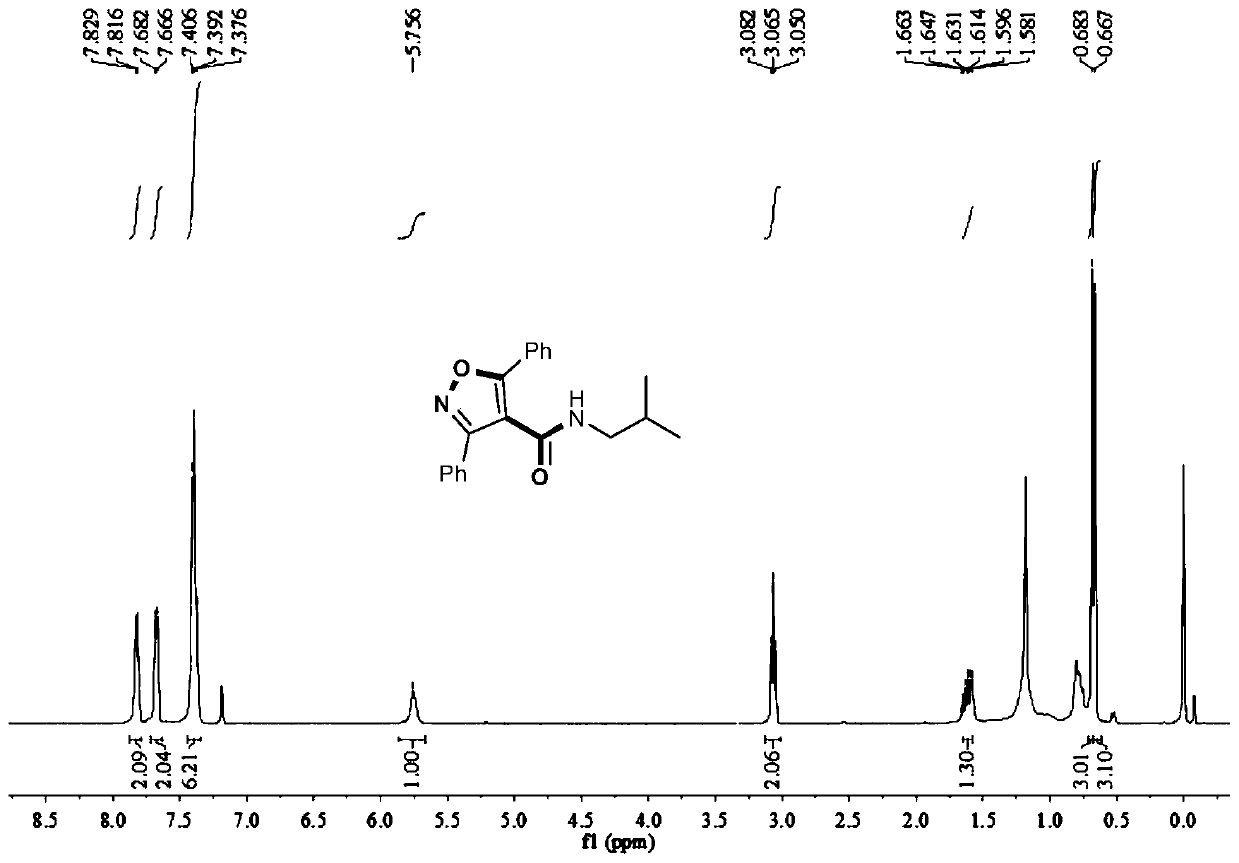

Method for synthesizing 4-amide isooxazole

The invention belongs to the technical field of organic synthesis and discloses a method for synthesizing 4-amide isooxazole. The method comprises the following steps: adding a palladium salt catalyst, additives, O-methyl acetylene ketoxime ether of a structure of a formula (1) shown in the description, amine of a structure of a formula (2) shown in the description and an organic solvent into a reactor, injecting carbon monoxide, performing a stirring reaction at 40-80 DEG C, and performing separation and purification on the reaction product, so as to obtain 4-amide isooxazole of a structure of a formula (3) shown in the description. According to the method, palladium salt is adopted as the catalyst, O-methyl acetylene ketoxime ether and amine are adopted as raw materials, and the carbon monoxide is injected to implement a serial reaction of three components to synthesize the 4-amide isooxazole by using a "one step" method. The type diversity of the 4-amide isooxazole is expanded. In addition, all raw materials are cheap and easy to obtain, and the method is simple and feasible, good in functional group tolerance, wide in substrate universal range, mild in reaction condition, simple and safe in operation and good in industrial application prospect.

Owner:SOUTH CHINA UNIV OF TECH

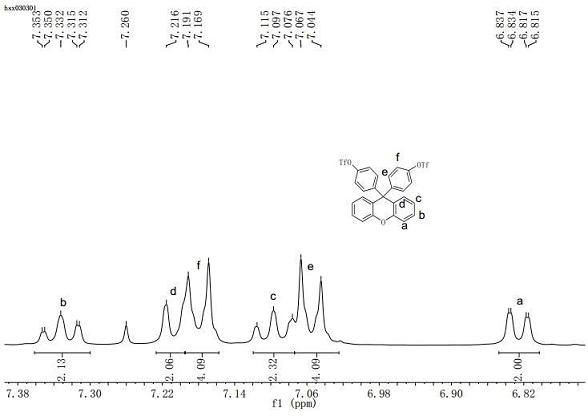

A kind of polypyrazole containing xanthene structure and preparation method thereof

Owner:江西德璟材料科技有限公司

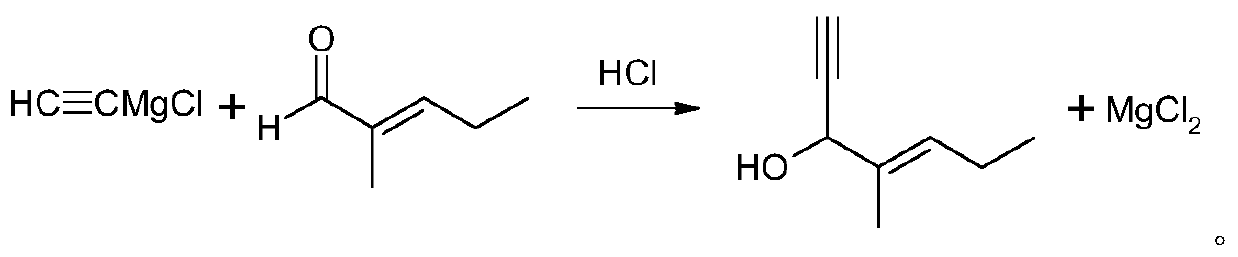

The preparation method of 2-methyl-1-ethynyl-2-penten-1-ol

ActiveCN108059585BEasy dischargeAvoid safety hazardsOrganic compound preparationHydroxy compound preparationPtru catalystMethylmagnesium chloride

The invention discloses a preparation method of 2-methyl-1-ethynyl-2-penten-1-ol, wherein the preparation method comprises the steps: firstly, introducing chloromethane into tetrahydrofuran and magnesium chips, carrying out a Grignard reaction, and generating methyl magnesium chloride; cooling, adding a catalyst, and introducing acetylene to generate acetylene magnesium chloride; and after completion of the reaction, dropwise adding 2-methyl-2-pentenal, hydrolyzing with dilute hydrochloric acid, washing an organic layer by water, carrying out reduced pressure distillation, and rectifying a residual material to obtain 2-methyl-1-ethynyl-2-penten-1-ol. The method is easy to operate, cheap and easily obtained chloromethane is used as a raw material, dangerous sodium amide or liquid ammonia isnot used, and tetrahydrofuran, toluene and other solvents can be reused, the product yield is high, the purity is high, and the cost is low.

Owner:JIANGSU YANGNONG CHEM +1

Selective hydrogenation of alkynyl-containing compounds

InactiveUS9067851B2Improve system efficiencyReduced footprintHydrocarbon by hydrogenationChemical industryCompound aHydrogenation reaction

Owner:EXXONMOBIL CHEM PAT INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com