Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Efficient heat recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

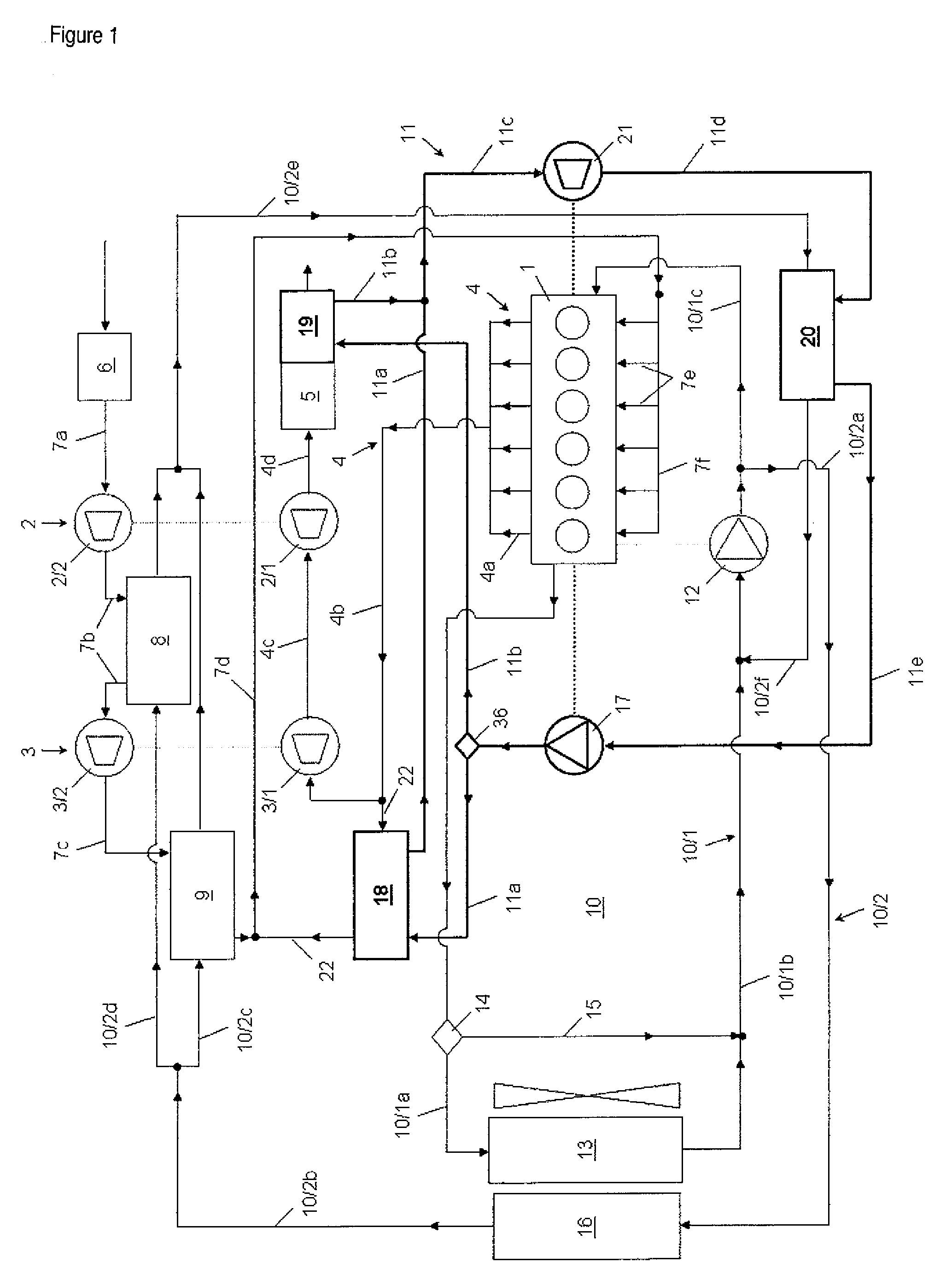

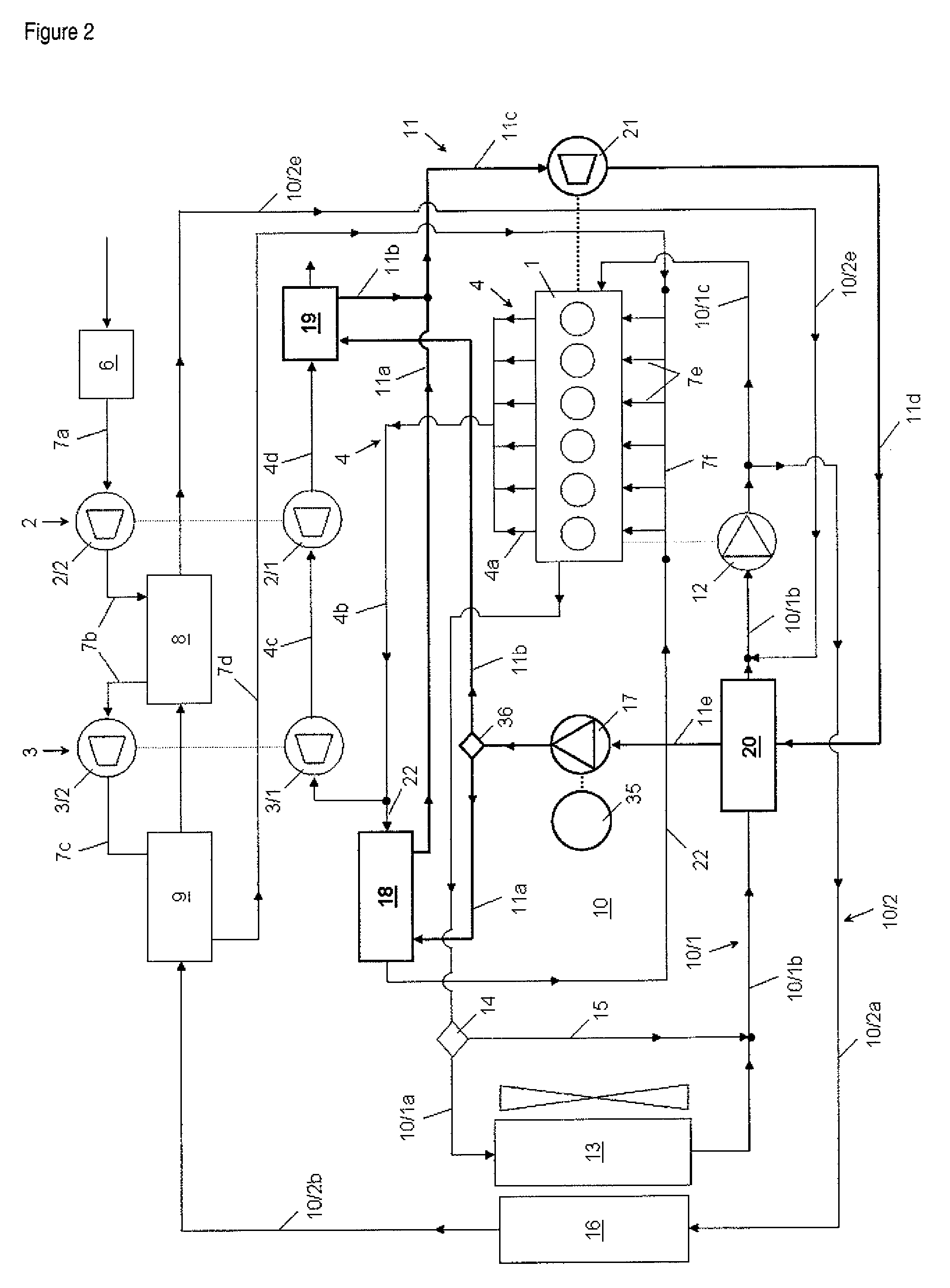

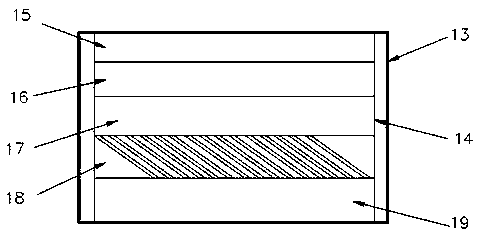

Drive Unit with Cooling Circuit and Separate Heat Recovery Circuit

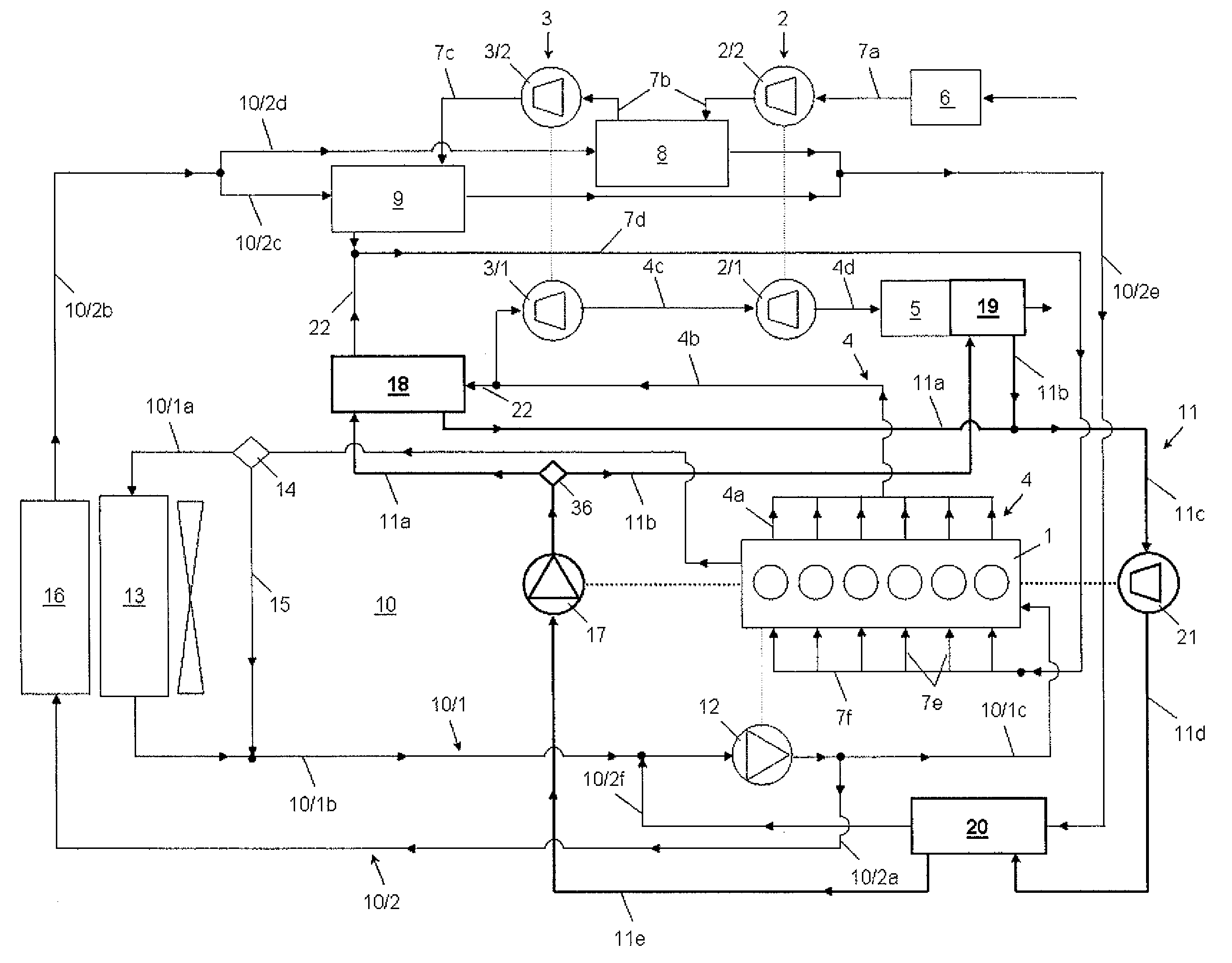

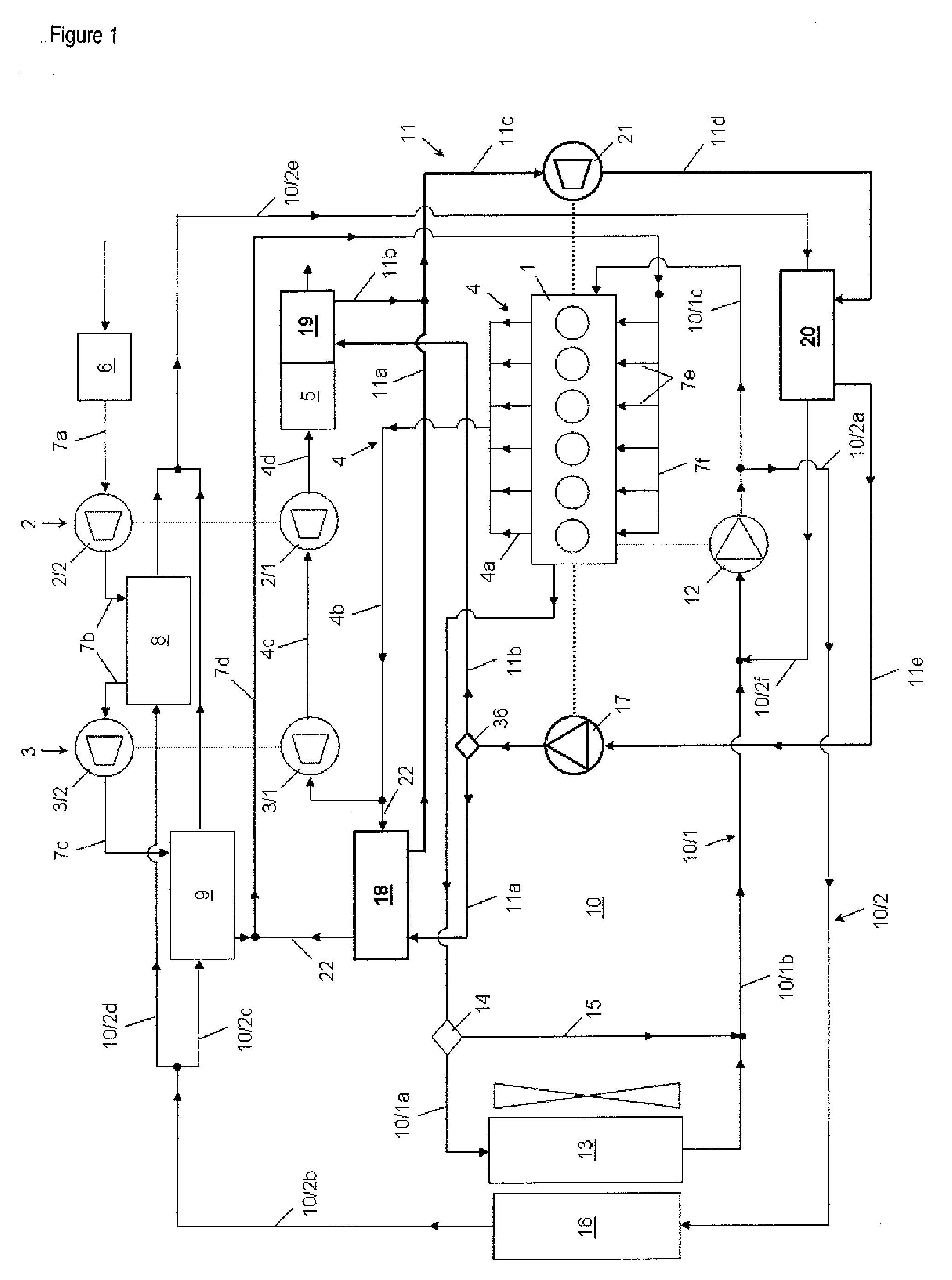

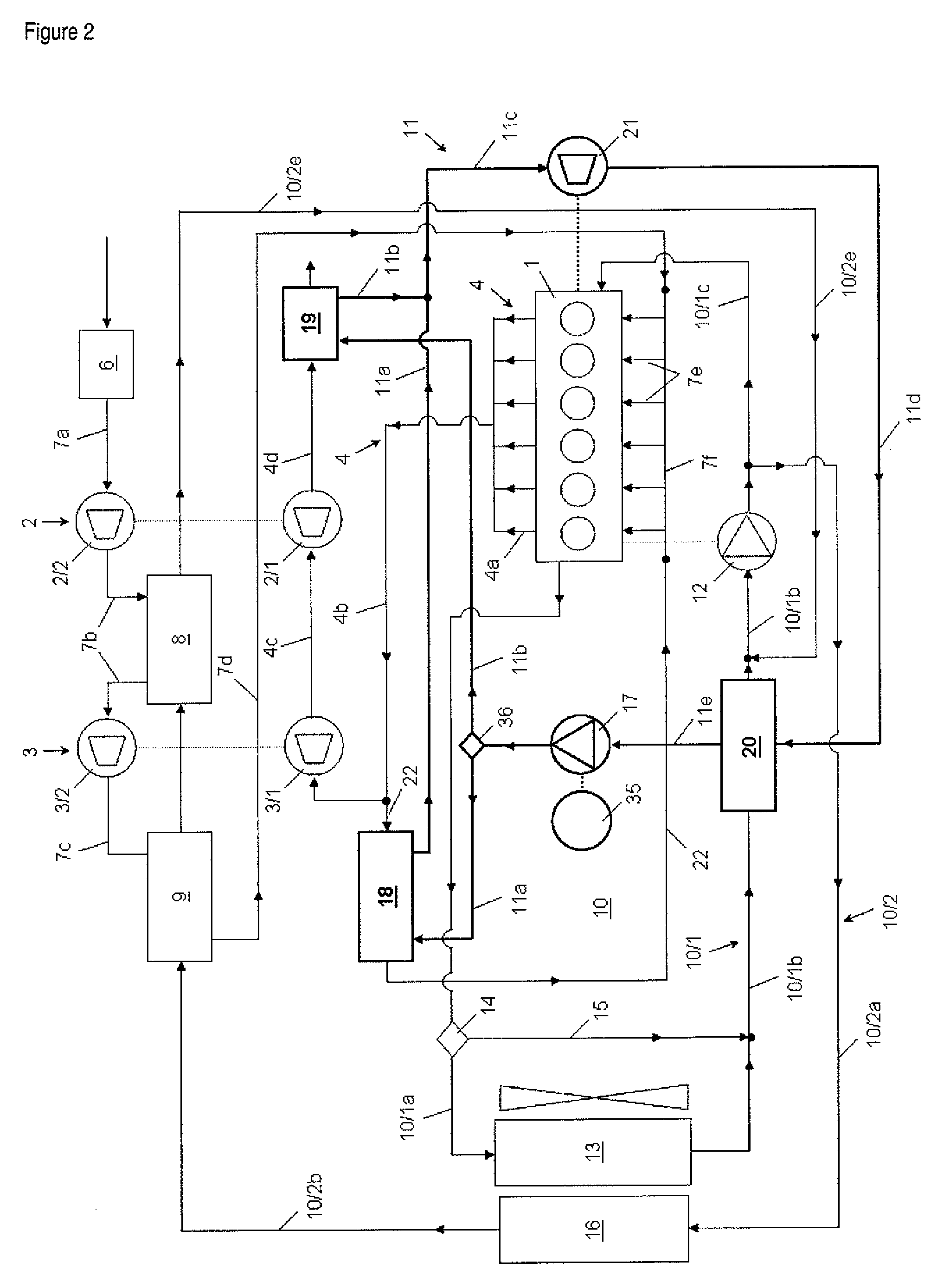

ActiveUS20100139626A1Improve cooling effectEfficient heat recoveryCoolant flow controlNon-fuel substance addition to fuelEngineeringInternal combustion engine

A cooling circuit and an independent heat recovery circuit are associated with an internal combustion engine. A coolant is circulated a pump in a first and a second cooling sub-circuit. An increase in pressure in a work medium is achieved within the heat recovery circuit by a pump. This work medium is changed from liquid aggregate state to vaporous aggregate state and back to the liquid aggregate state in heat exchangers. This work medium is divided after the pump into two parallel partial flows and is changed into vaporous state in a first parallel branch in an EGR heat exchanger through which recycle exhaust gas flows and in a second parallel branch in an exhaust gas heat exchanger through flow exhaust gas downstream of the low-pressure turbine flows. This vaporous work medium is then fed to an expander and is then conducted through a cooled condenser and, liquefied again.

Owner:MAN TRUCK & BUS AG

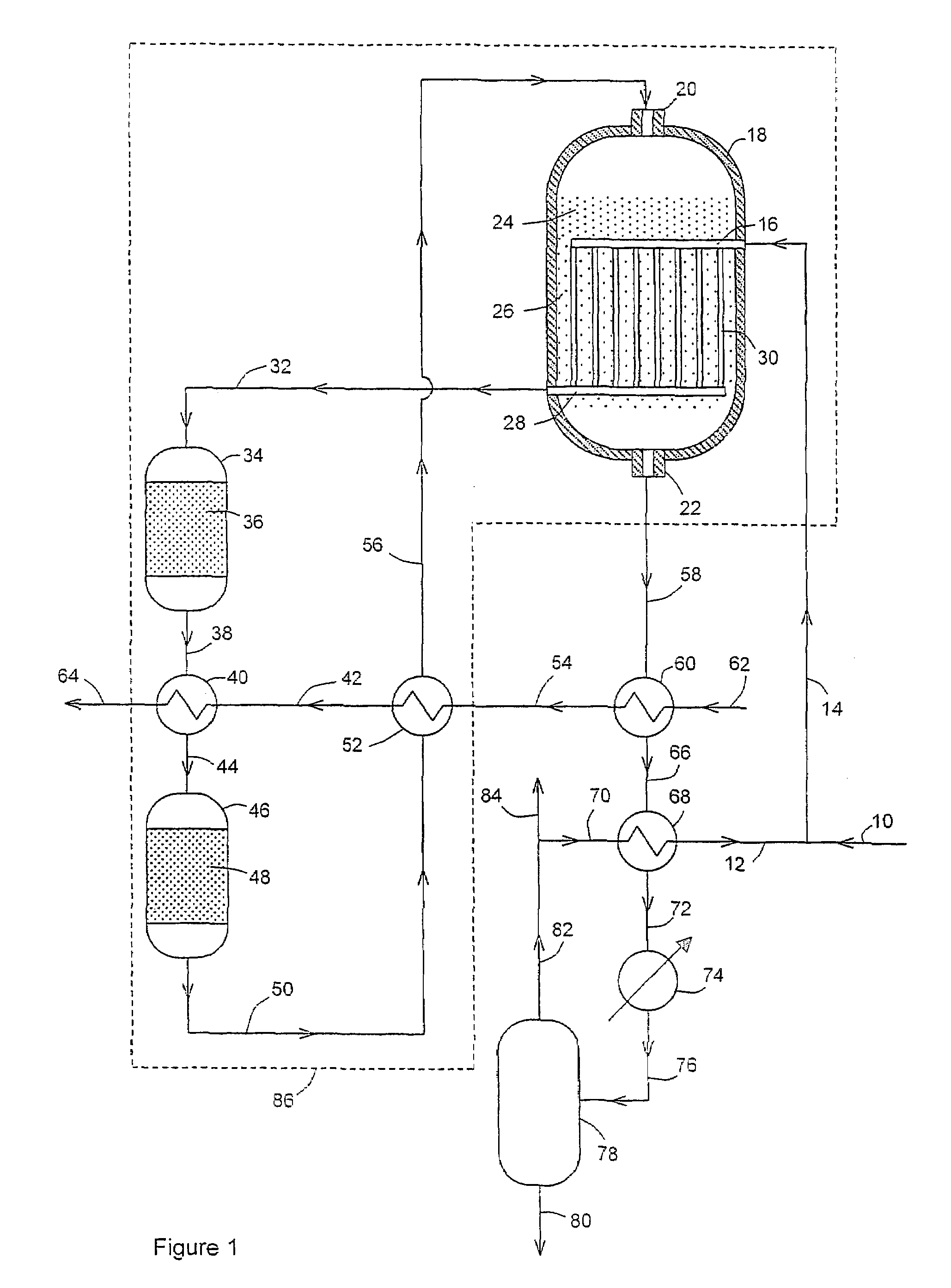

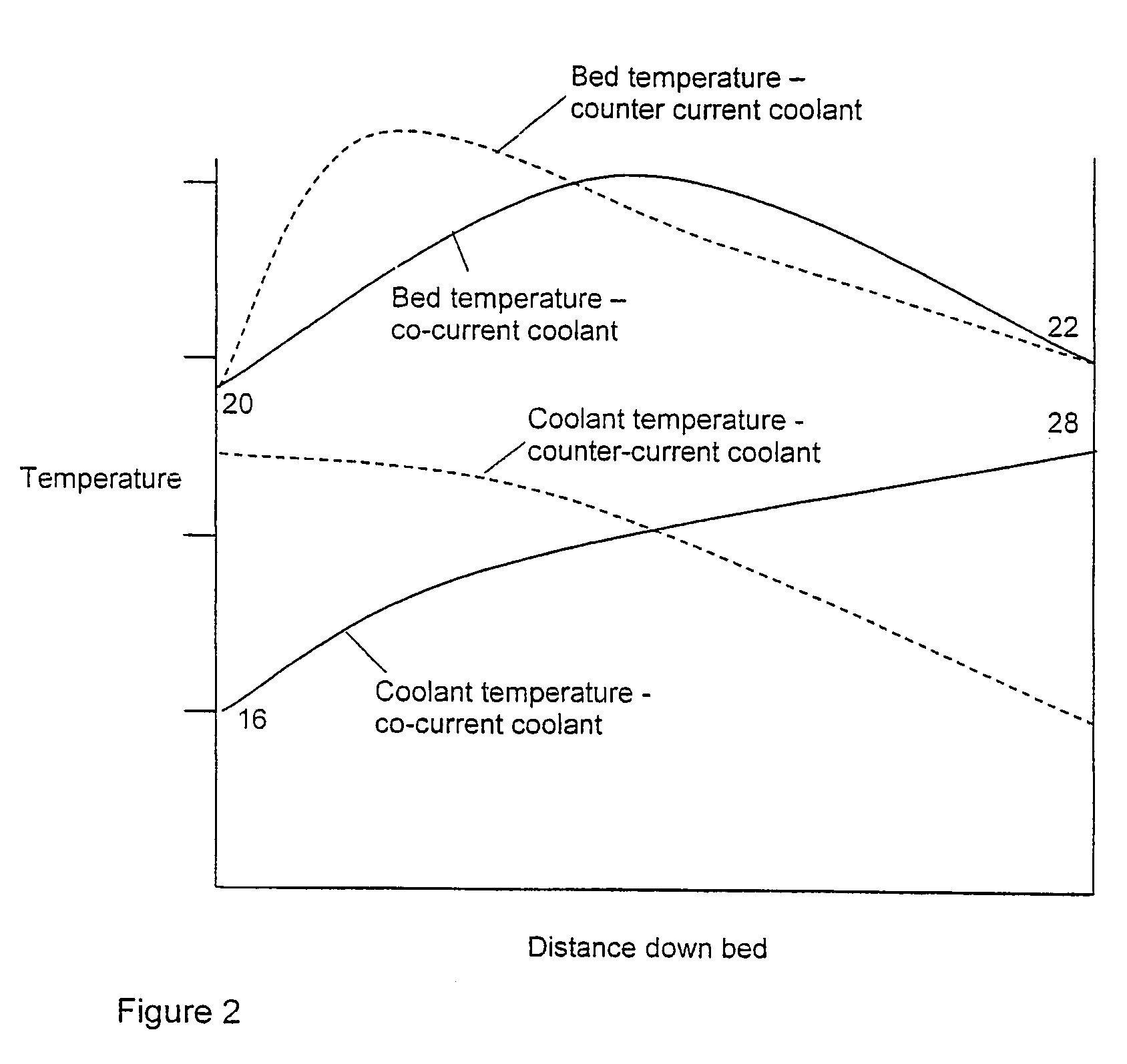

Methanol synthesis

InactiveUS7144923B2Easy temperature controlEfficient heat recoveryOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasCoolant flow

Methanol is synthesized from pre-heated methanol synthesis gas in one or more adiabatic synthesis stages with cooling of the resultant gas after each stage. Further methanol synthesis is then effected on the resultant partially reacted synthesis gas in a bed of synthesis catalyst cooled by means of a coolant flowing co-currently through tubes disposed in the catalyst bed. After cooling methanol is separated from the unreacted gas. Part of the unreacted gas is combined with make-up gas and used as the coolant fed to the aforesaid tubes, thus producing the pre-heated synthesis gas to be fed to the adiabatic synthesis stages.

Owner:JOHNSON MATTHEY PLC

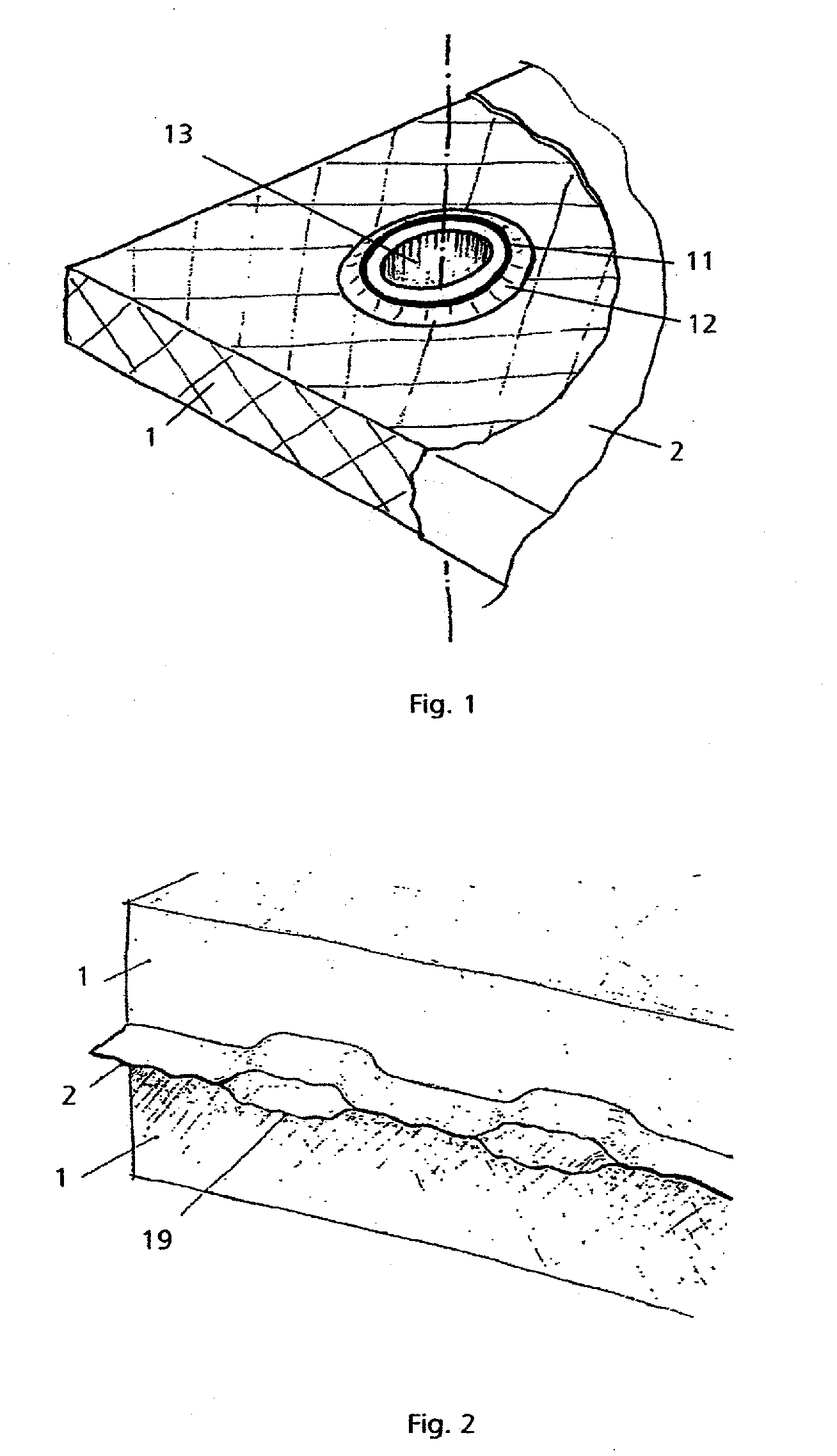

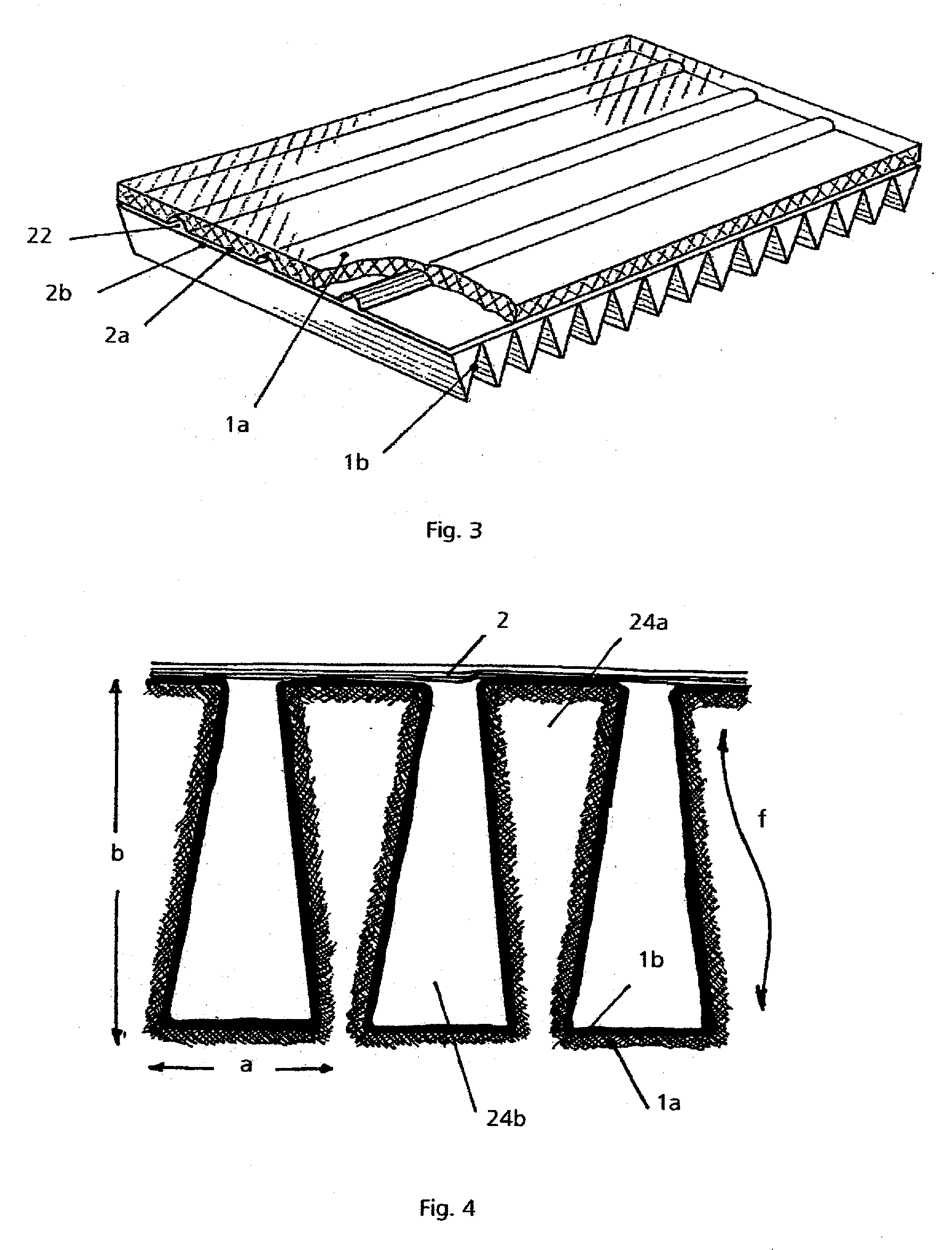

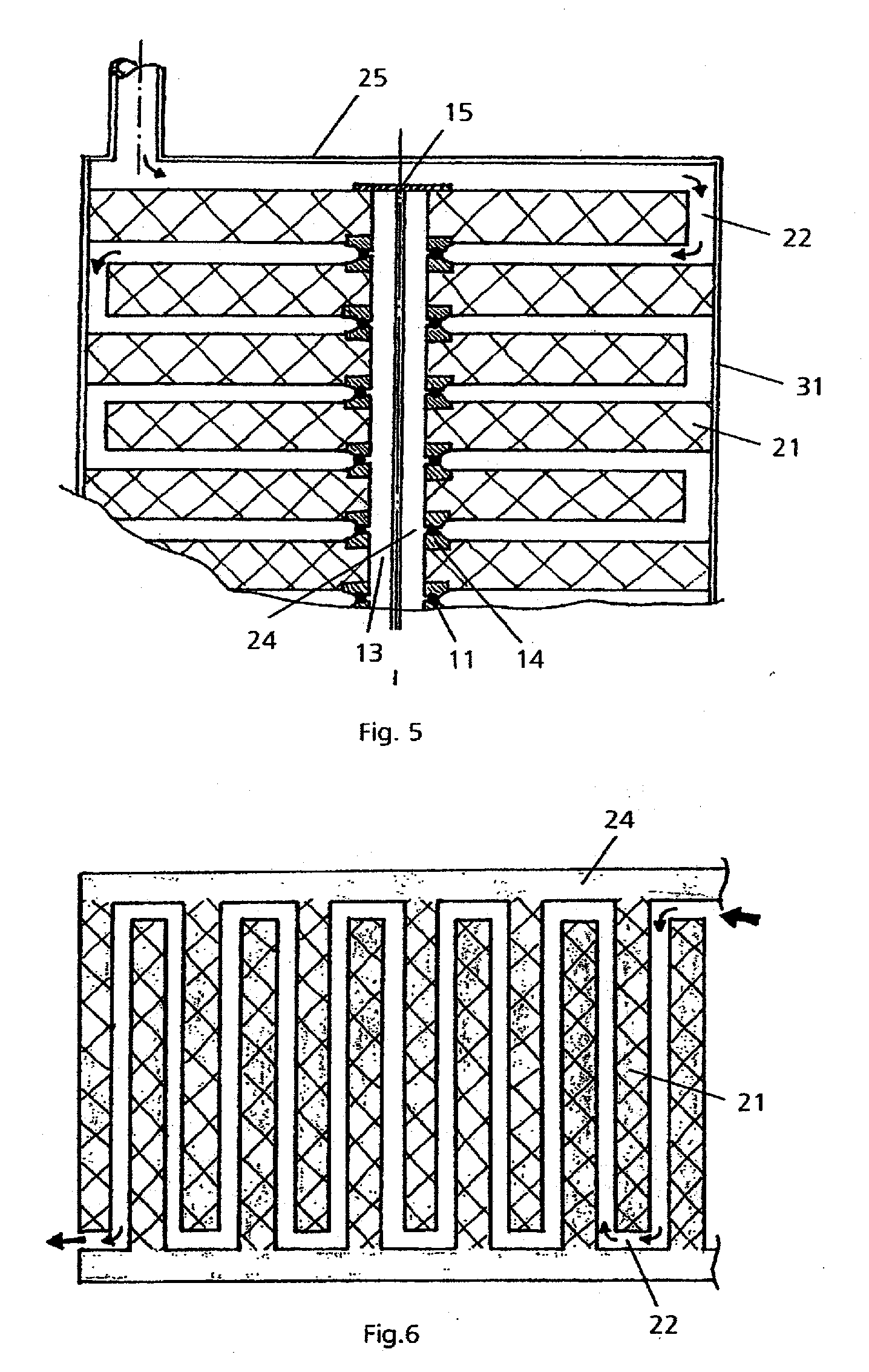

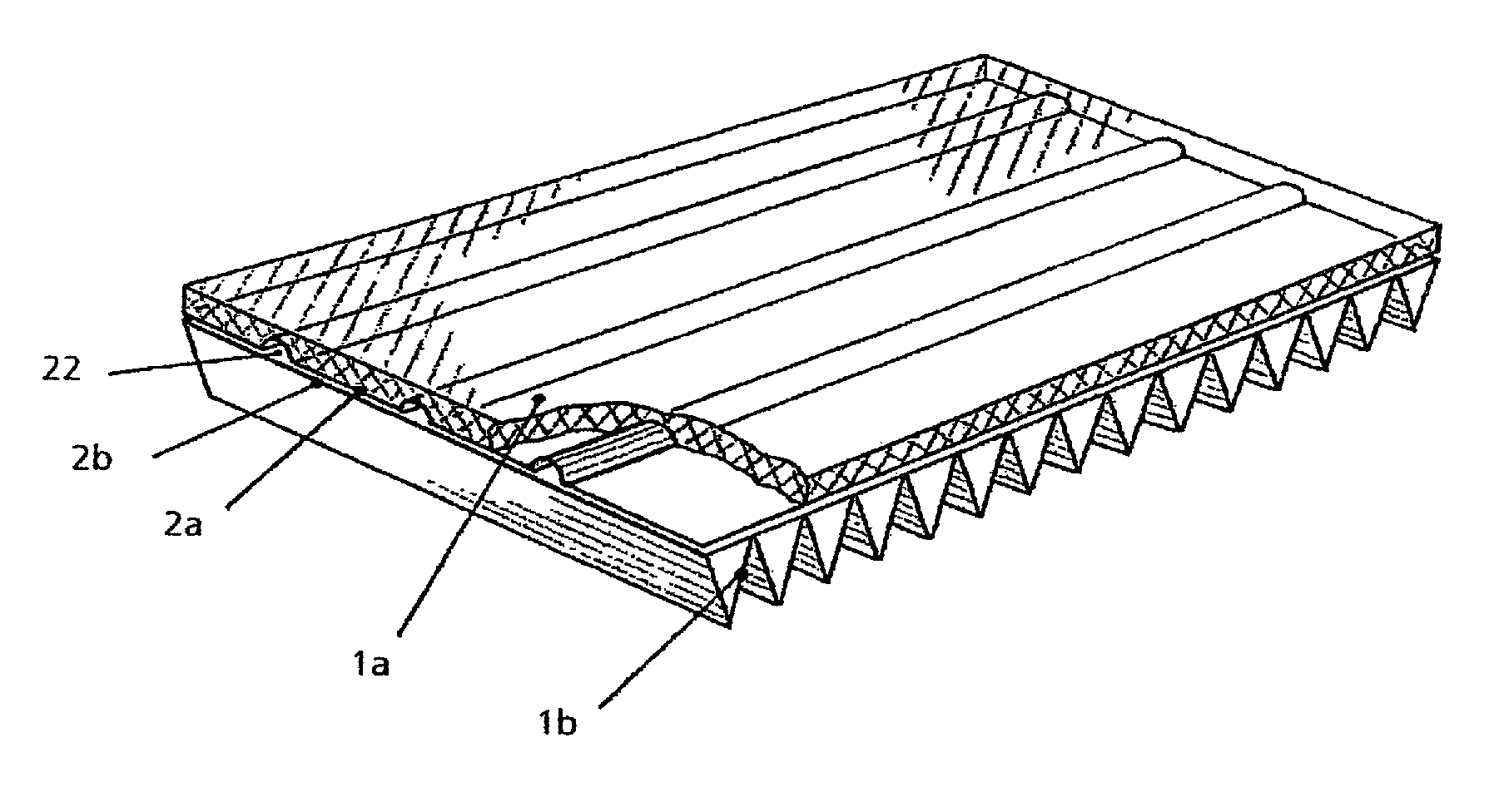

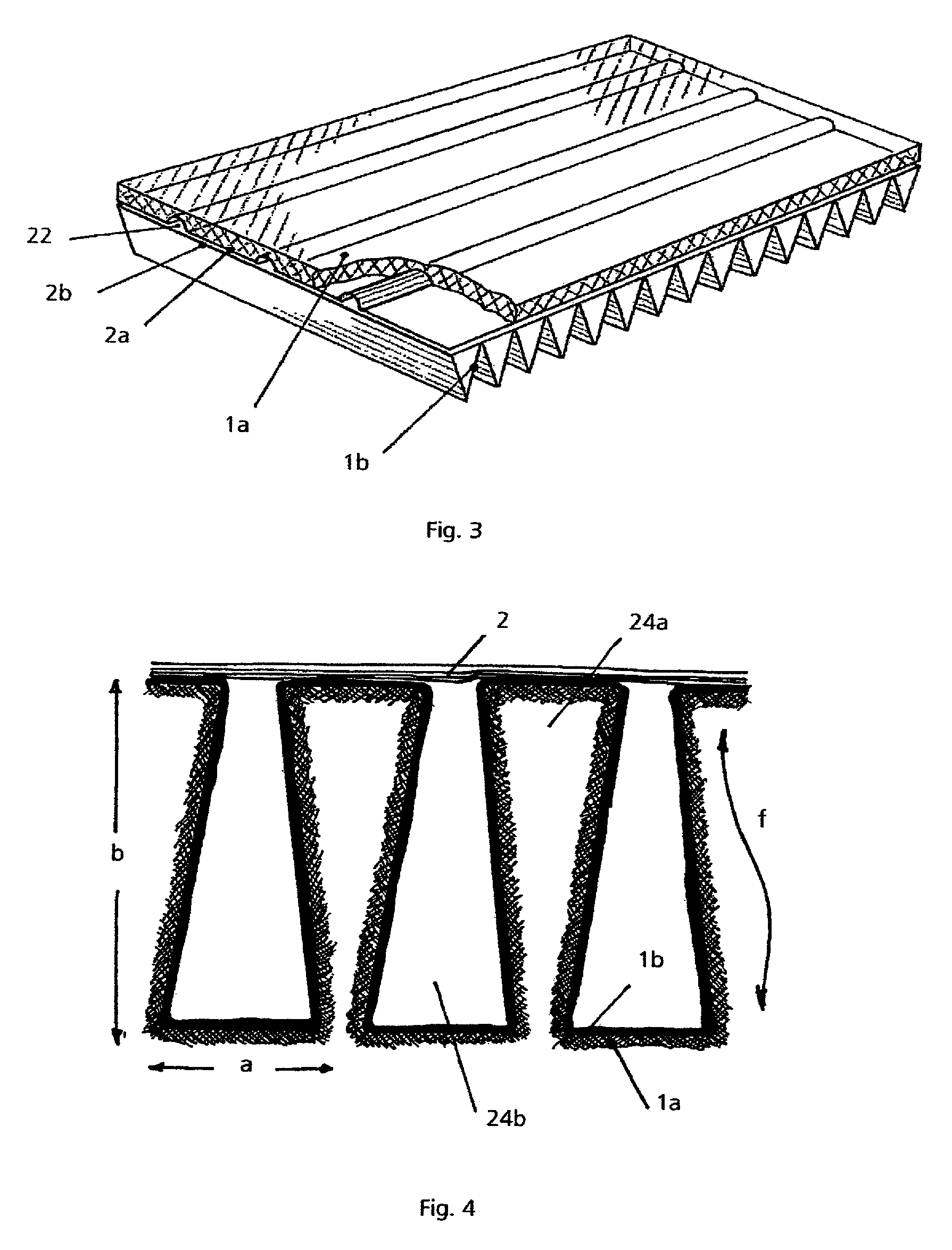

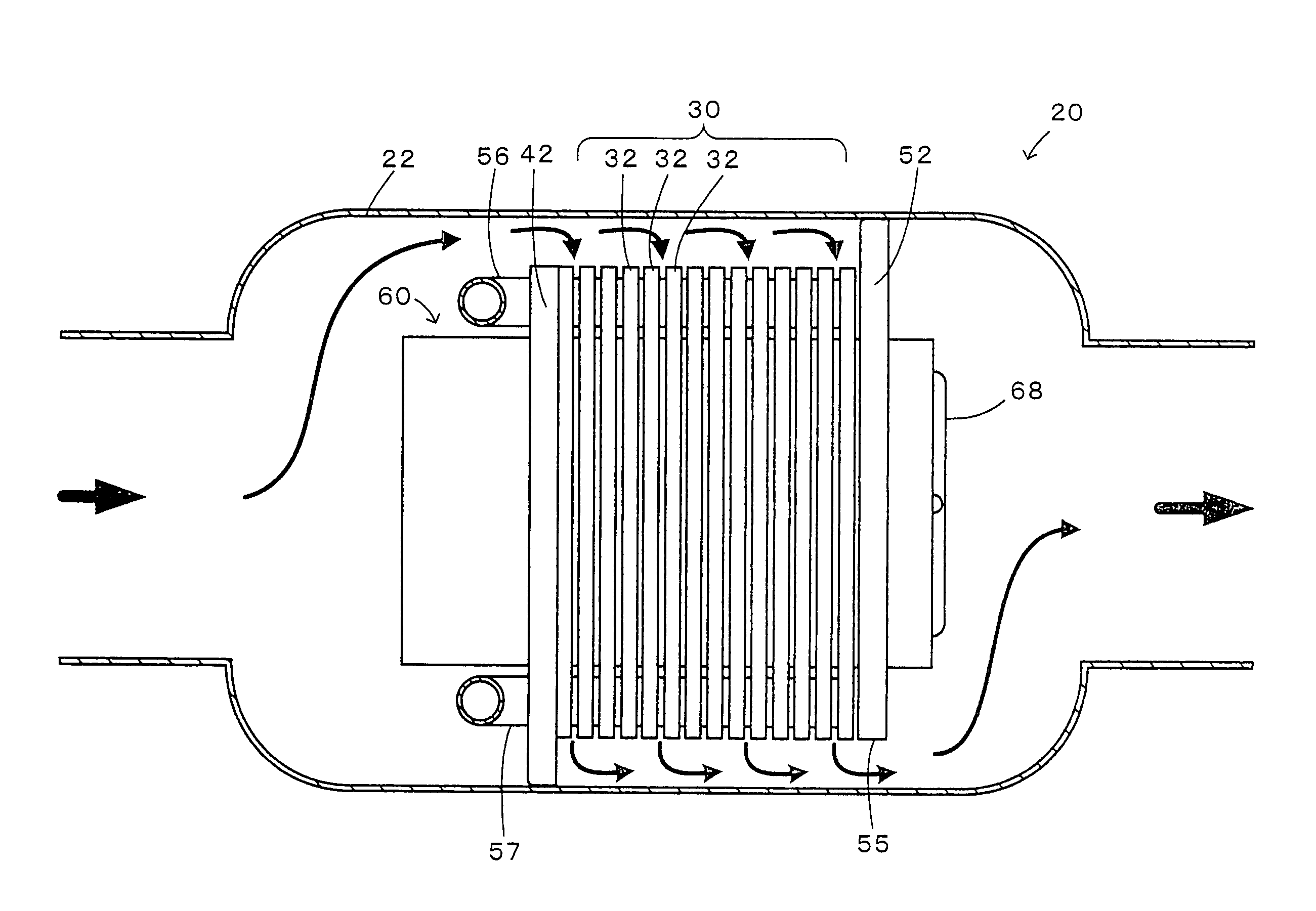

Adsorption Heat Pump, Adsorption Refrigerator and Adsorber Elements Therefor

InactiveUS20090217691A1Efficiently dissipatedProne to feverDomestic cooling apparatusBoiler absorbersHeat conductingEngineering

The invention relates to an adsorber element for a heat exchanger and an adsorption heat pump or adsorption refrigerator that contains at least one such adsorber element. The adsorber element includes a heat-conducting solid body and a sorption material for a vaporous adsorbate arranged on the surface of this solid body. A fluid-tight foil composite is arranged on the outer surface of the open-pore solid body, at least in the areas in which a contact with a heat transfer fluid is provided, wherein this adsorber element is embodied such that the heat exchange between the open-pore solid body and the heat transfer fluid can take place via the fluid-tight foil composite.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

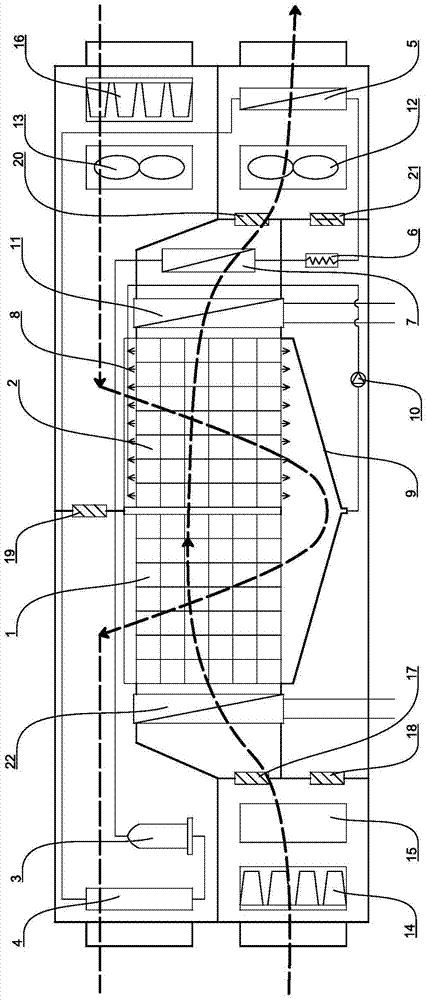

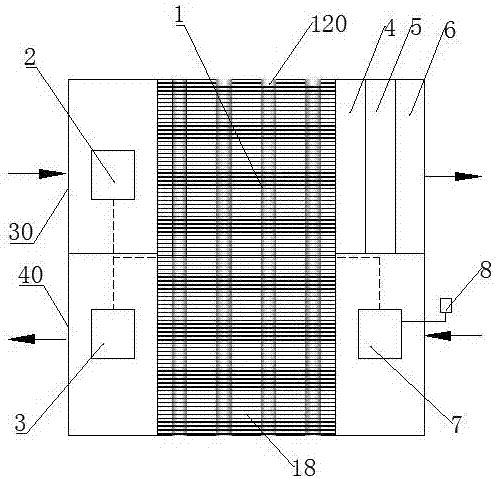

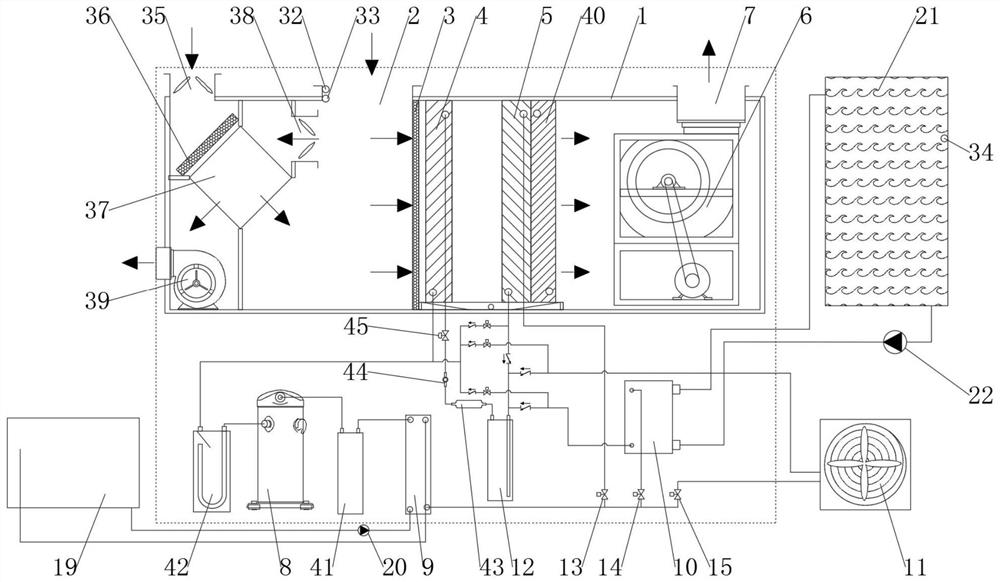

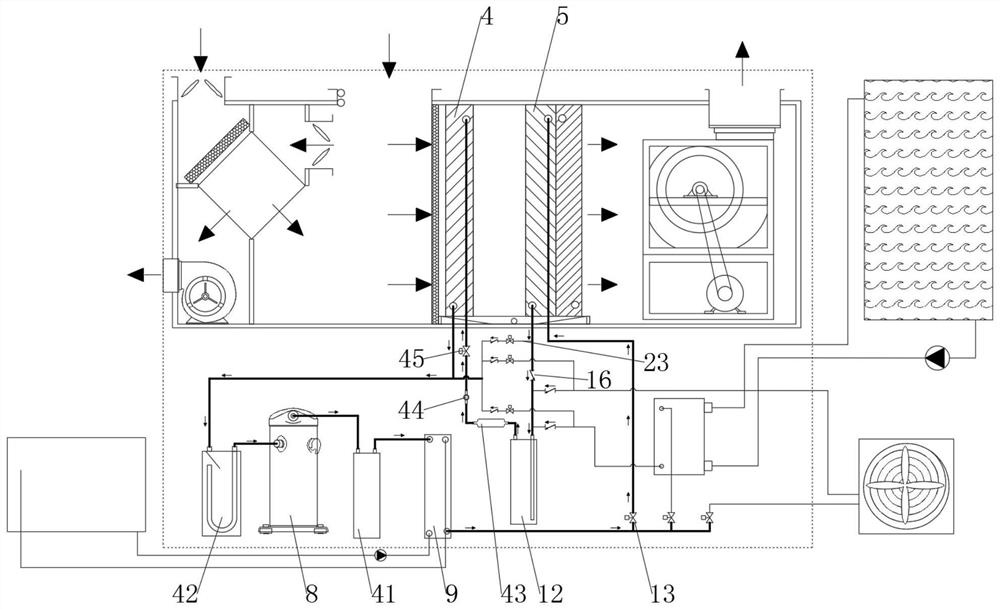

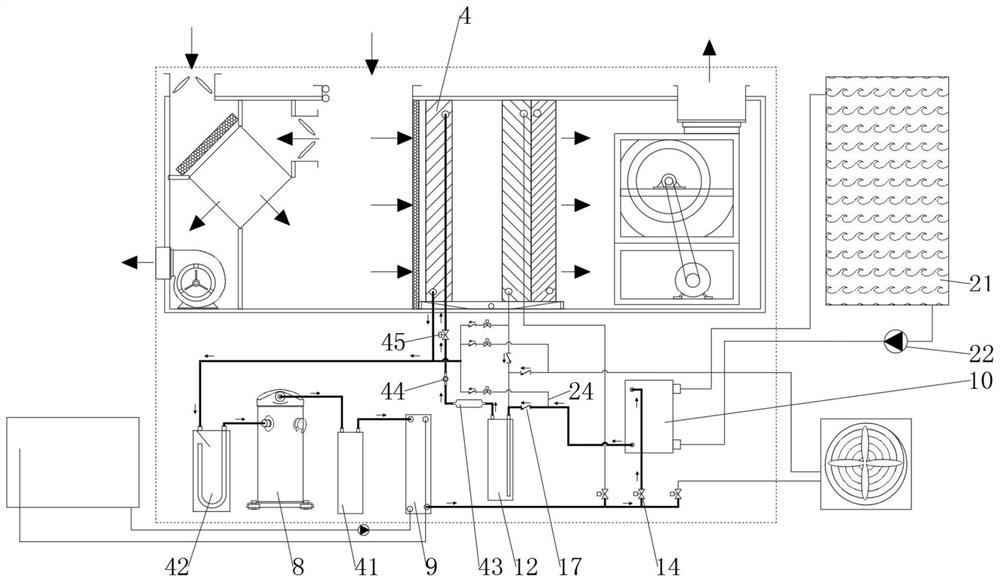

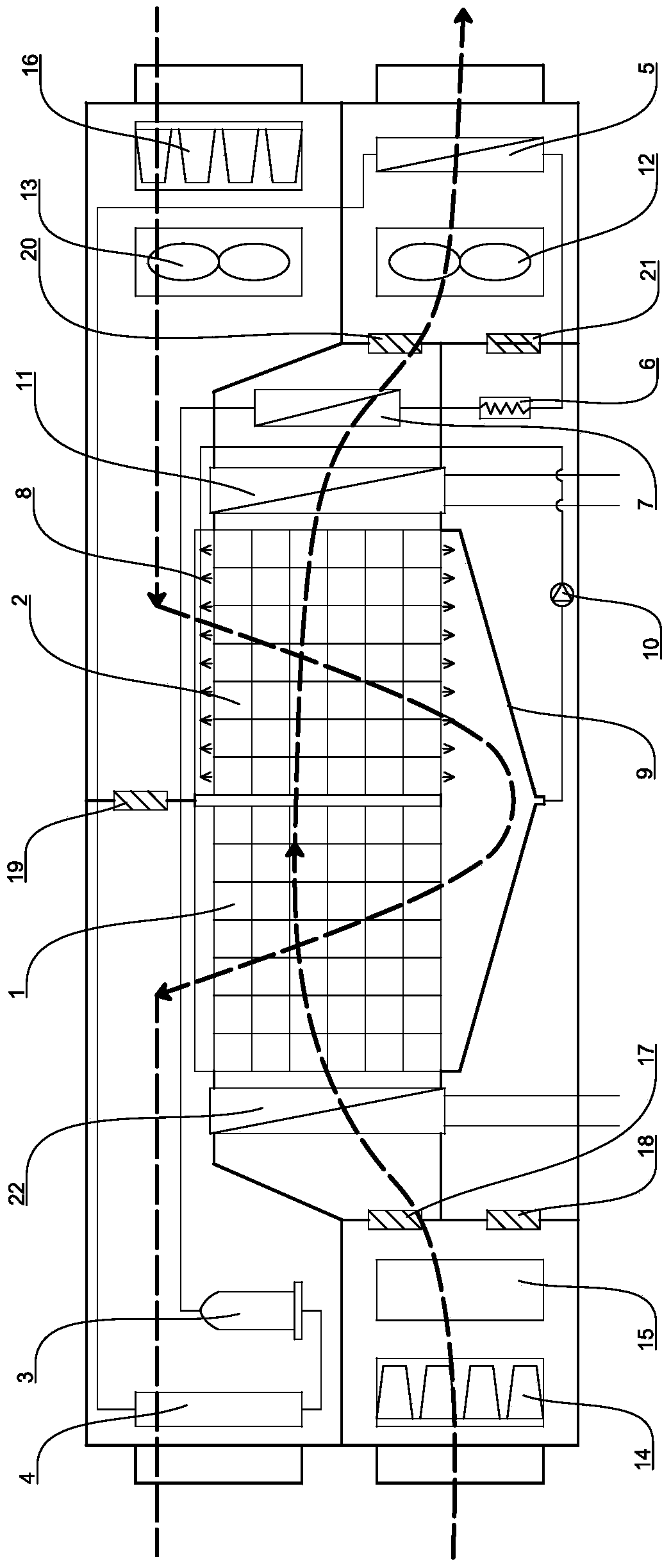

Double-plate and double-cold-source intelligent air refresher unit

ActiveCN105444310AImprove performanceImprove heat exchange efficiencyLighting and heating apparatusSpace heating and ventilation detailsHigh energyEvaporator

The invention relates to a double-plate and double-cold-source intelligent air refresher unit. The double-plate and double-cold-source intelligent air refresher unit comprises a plate type heat exchange unit, a heat pump circulating unit and a spraying unit; the plate type heat exchange unit includes a first plate heat exchanger and a second plate heat exchanger arranged side by side from left to right; the heat pump circulating unit includes a compressor, a cooling condenser, a reheat condenser, an expansion valve and an evaporator; and the spraying unit includes a spraying device, a water collecting tank and a circulating pump. The double-plate and double-cold-source intelligent air refresher unit further comprises a surface cooler; outdoor fresh air reaches an indoor passage, provided with a fresh air-air supply way, after passing through an air supply channel of the first plate heat exchanger, an air supply channel of the second plate heat exchanger, the surface cooler, the evaporator and the reheat condenser in sequence; and indoor returned air is exhausted out of an outdoor passage, provided with a returned air-exhaust air way, after passing through a returned air channel of the second plate heat exchanger, a returned air channel of the first plate heat exchanger and the cooling condenser in sequence. The double-plate and double-cold-source intelligent air refresher unit has the advantages of simple structure, complete functions, stable operation, low cost and high energy-efficiency ratio, and can realize year-round high-efficiency and low-energy-consumption operation.

Owner:HUNDRED TECH CO LTD +1

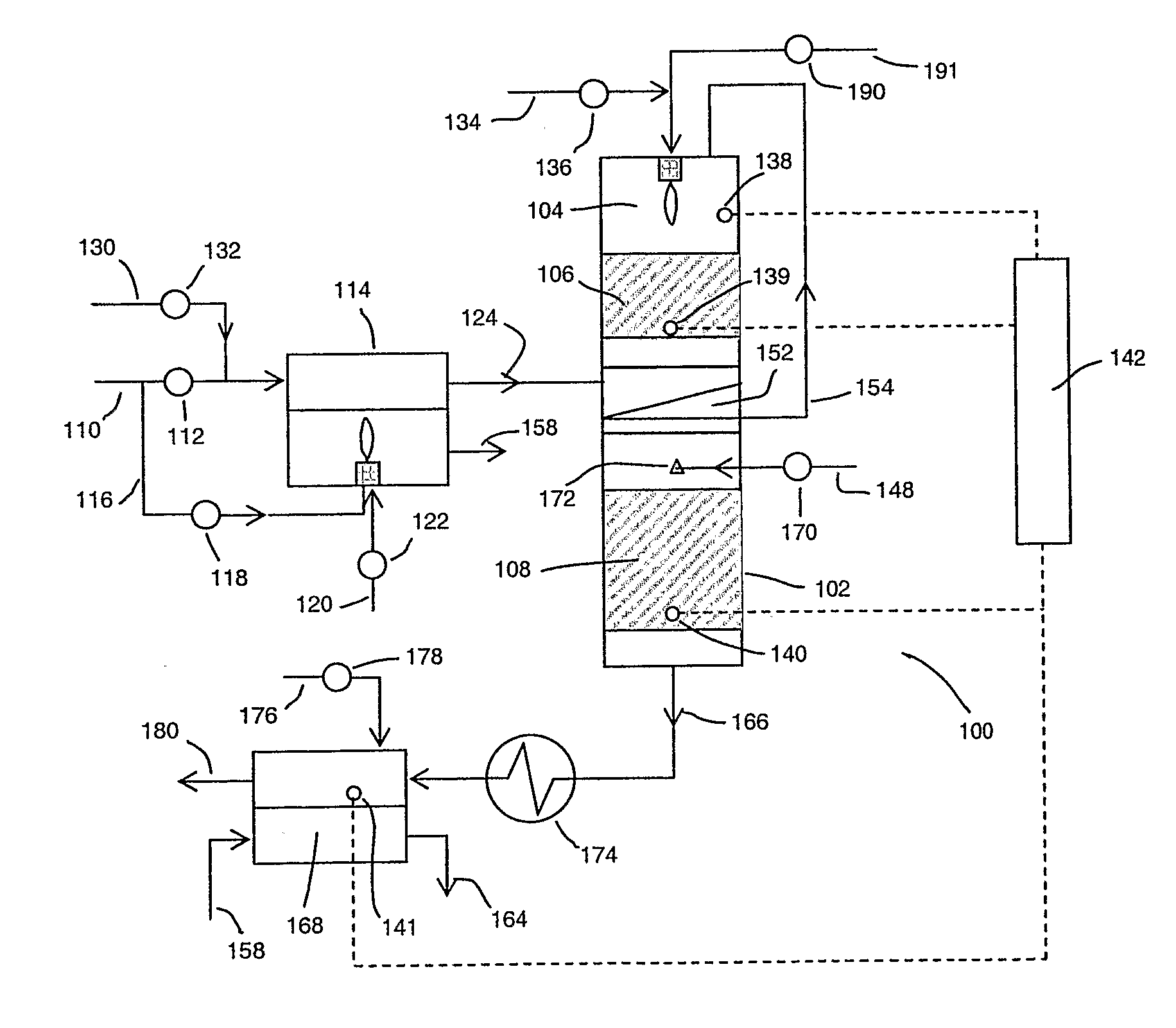

Hydrogen Generator Apparatus And Start-Up Processes

InactiveUS20070196267A1Lower cost of capitalReduce operating costsHydrogen separation using solid contactHydrogen productionHydrogenPartial oxidation

Apparatus and process are provided to enable rapid start up of hydrogen generator (1) that use partial oxidation reforming. In the start up processes, a heated oxygen containing gas (110) is passed through the reformer (106) and at least one downstream unit operation (108) to achieve a first temperature regime. Then a heated steam containing gas is used to raise the temperatures of the reformer (106) and at least one downstream unit operation (108) to a second temperature regime at which partial oxidation reforming can be initiated.

Owner:HYRADIX INC

Drive unit with cooling circuit and separate heat recovery circuit

ActiveUS8365527B2Improve cooling effectEfficient heat recoveryCoolant flow controlInternal combustion piston enginesExhaust fumesEngineering

A cooling circuit and an independent heat recovery circuit are associated with an internal combustion engine. A coolant is circulated a pump in a first and a second cooling sub-circuit. An increase in pressure in a work medium is achieved within the heat recovery circuit by a pump. This work medium is changed from liquid aggregate state to vaporous aggregate state and back to the liquid aggregate state in heat exchangers. This work medium is divided after the pump into two parallel partial flows and is changed into vaporous state in a first parallel branch in an EGR heat exchanger through which recycle exhaust gas flows and in a second parallel branch in an exhaust gas heat exchanger through flow exhaust gas downstream of the low-pressure turbine flows. This vaporous work medium is then fed to an expander and is then conducted through a cooled condenser and, liquefied again.

Owner:MAN TRUCK & BUS AG

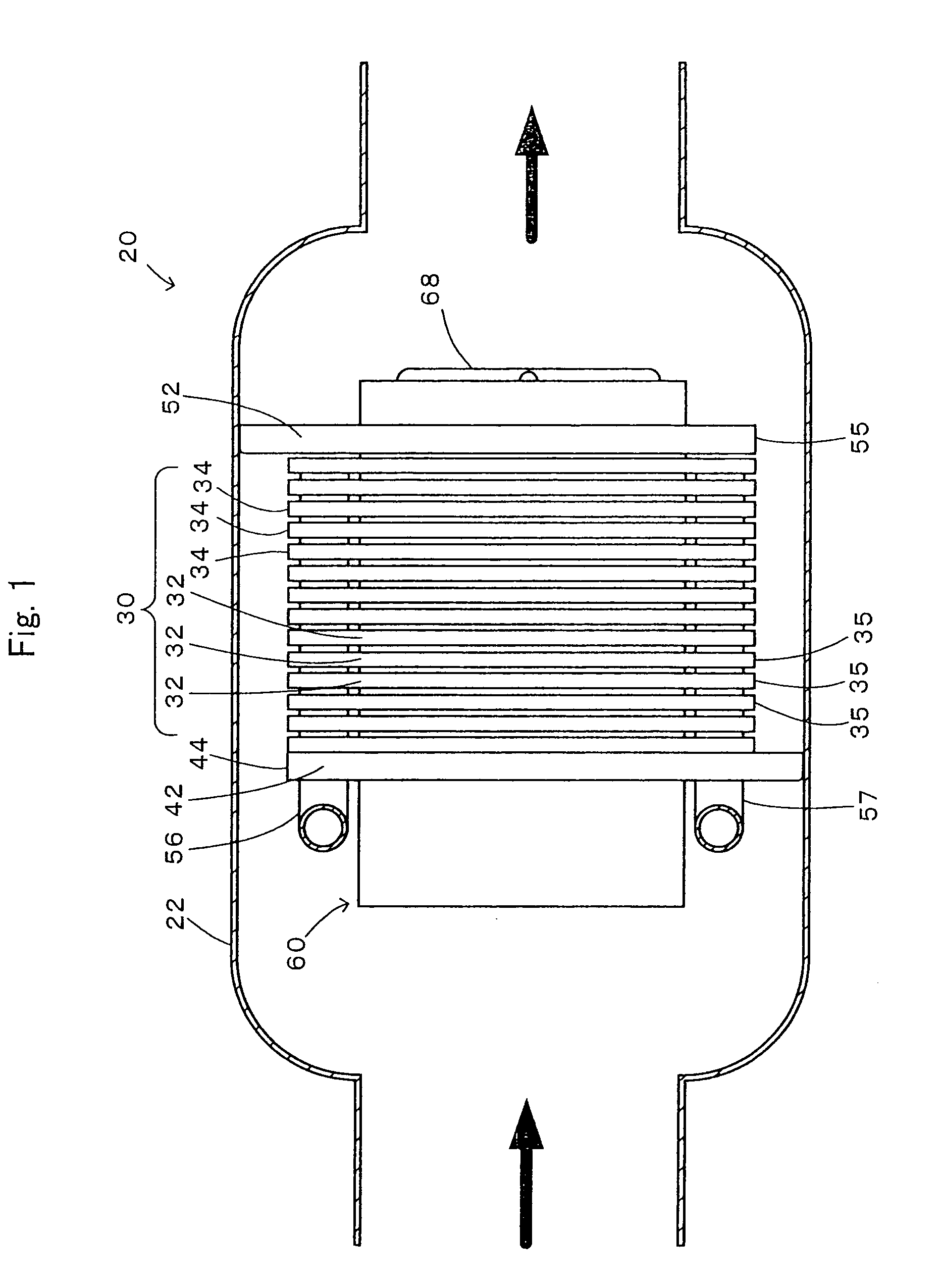

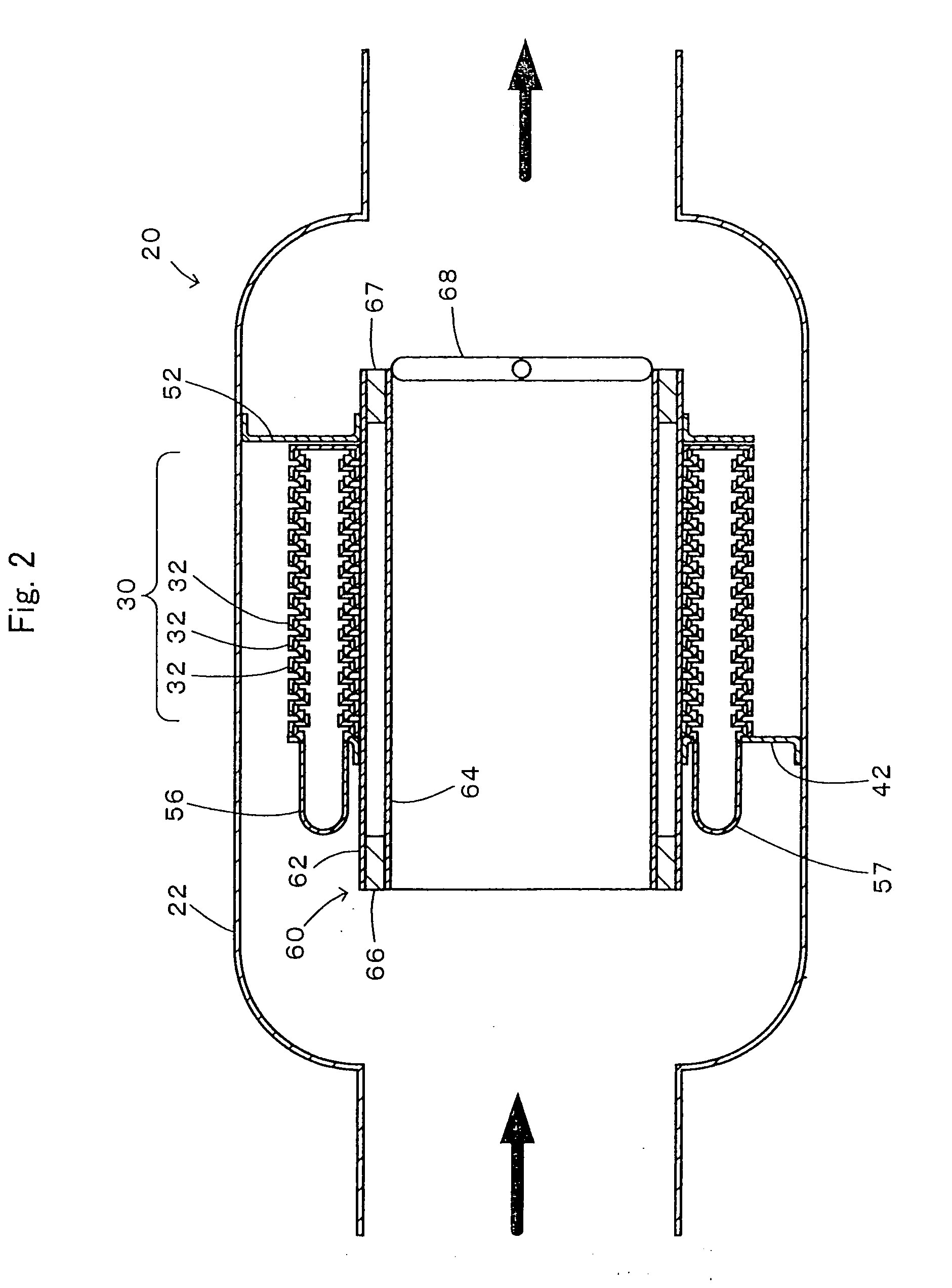

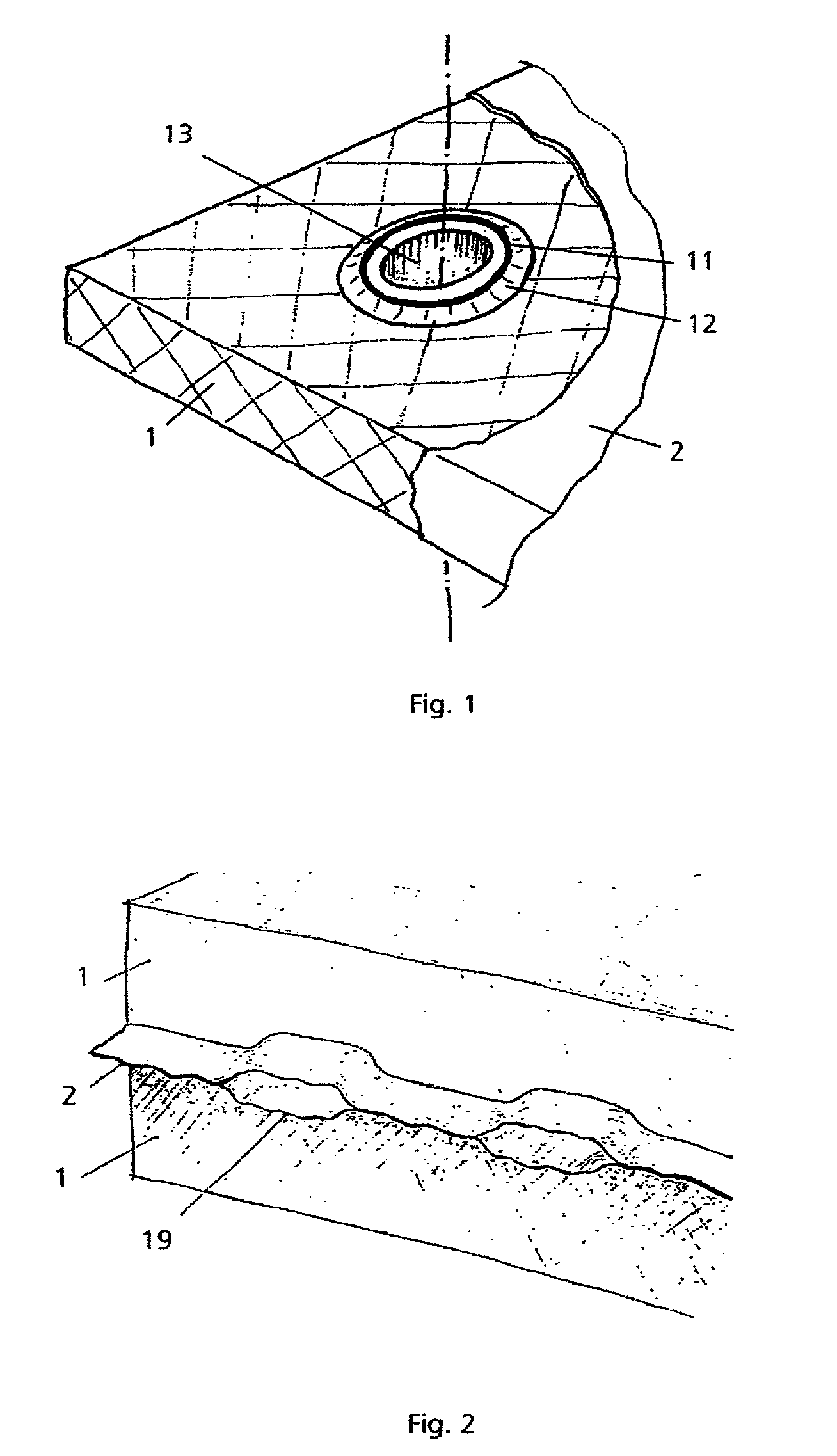

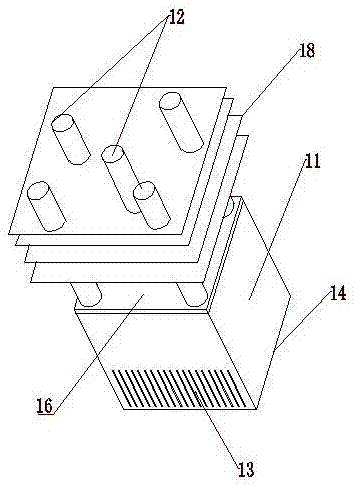

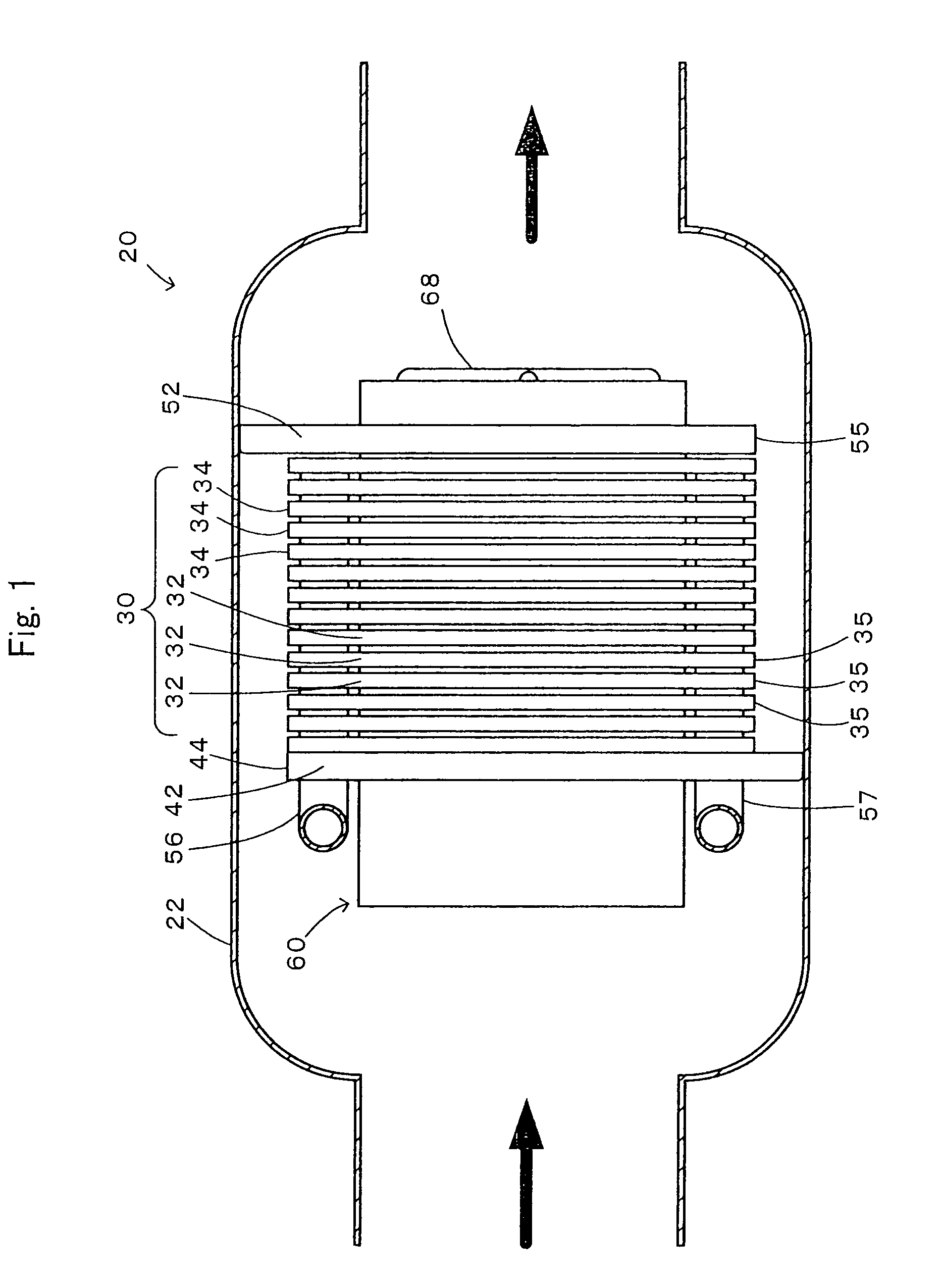

Heat Recovery System

InactiveUS20100251702A1Improve warm-upEfficient heat recoveryInternal combustion piston enginesRecuperative heat exchangersEngineeringInternal combustion engine

A plurality of flat tubes formed as a tube having notches by linearly cutting upper and lower parts from a hollow flat circular doughnut shape are stacked to structure a tube laminate. It is attached to a case so that a notch aligns with the notch and faces upward by an exhaust inflow end plate and that a notch aligns with the notch and faces downward by an exhaust outflow end plate. A cutoff valve is provided at an exhaust outflow end of an exhaust communication tube passing through the center of the tube laminate by heat insulation. While an internal combustion engine is warming up, the cutoff valve is closed to cause the exhaust to flow in gaps of the respective flat tubes from upward to downward as a whole and also a heat exchange medium is caused to flow in the respective flat tubes from downward to upward as a whole to have heat exchanged between the exhaust and the heat exchange medium to recover the exhaust heat.

Owner:THE UNIV OF TOKYO +3

Adsorption heat pump, adsorption refrigerator and adsorber elements therefor

InactiveUS8707729B2Efficiently dissipatedProne to feverDomestic cooling apparatusBoiler absorbersAdsorption refrigerationHeat conducting

The invention relates to an adsorber element for a heat exchanger and an adsorption heat pump or adsorption refrigerator that contains at least one such adsorber element. The adsorber element includes a heat-conducting solid body and a sorption material for a vaporous adsorbate arranged on the surface of this solid body. A fluid-tight foil composite is arranged on the outer surface of the open-pore solid body, at least in the areas in which a contact with a heat transfer fluid is provided, wherein this adsorber element is embodied such that the heat exchange between the open-pore solid body and the heat transfer fluid can take place via the fluid-tight foil composite.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

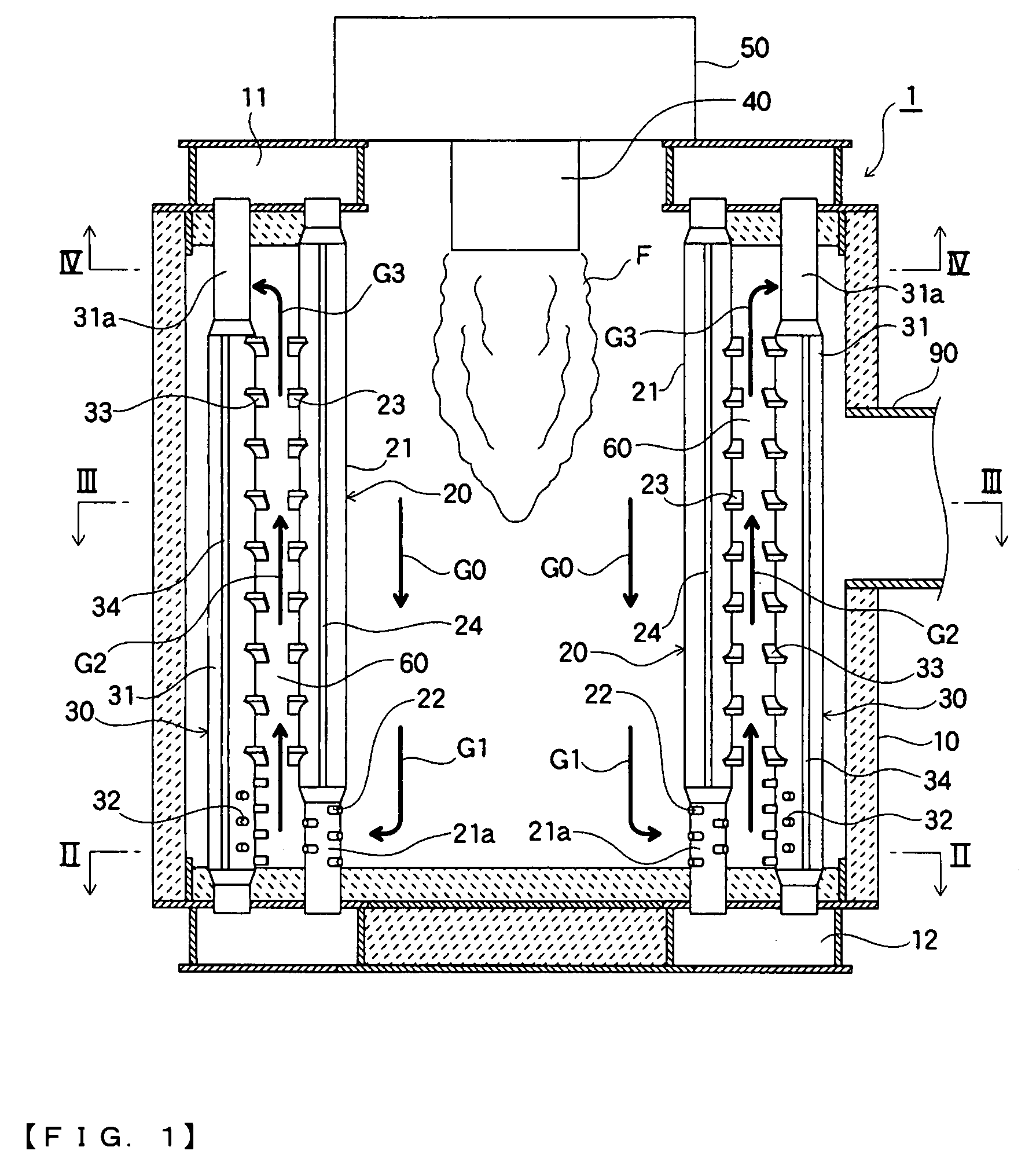

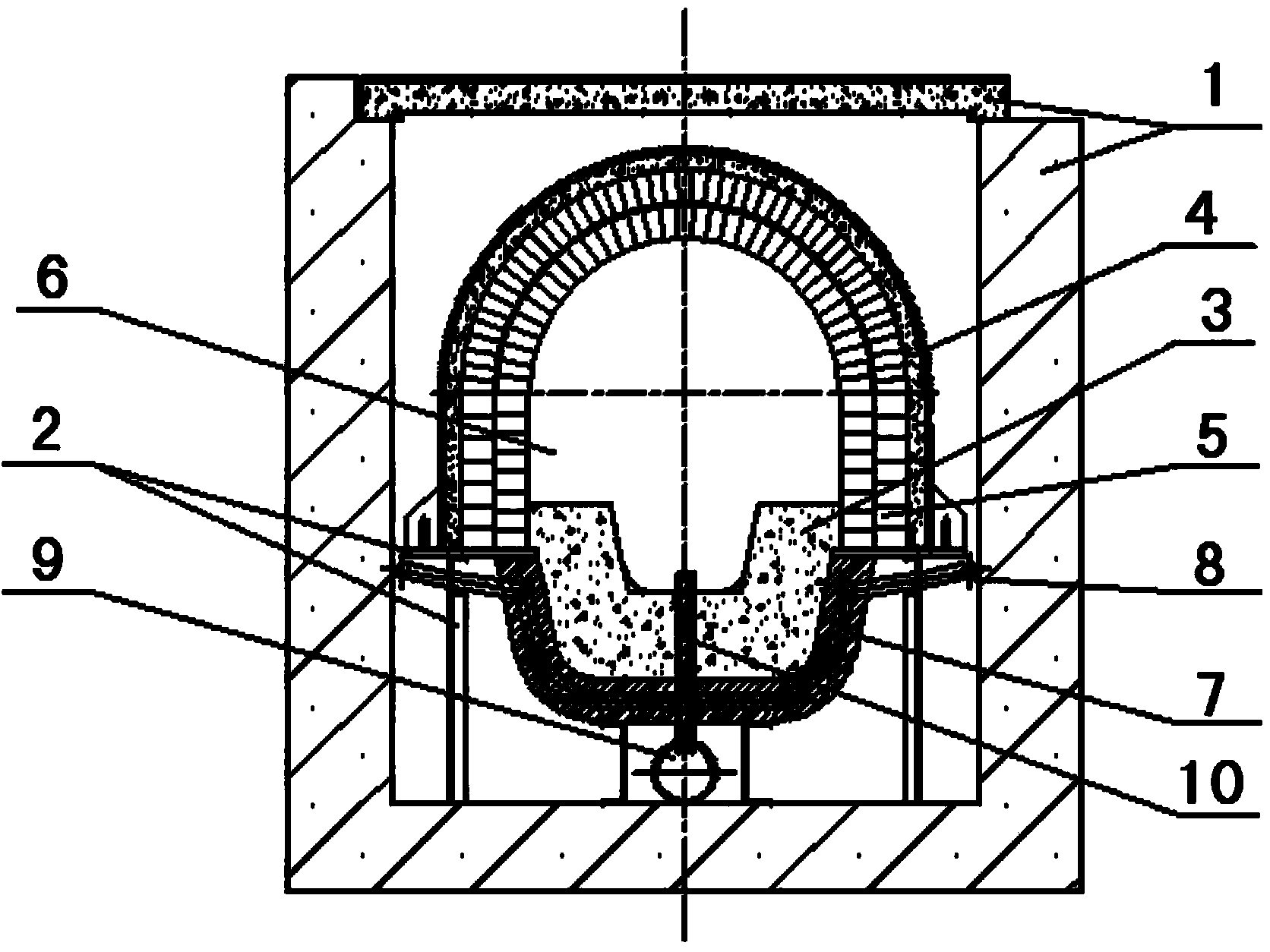

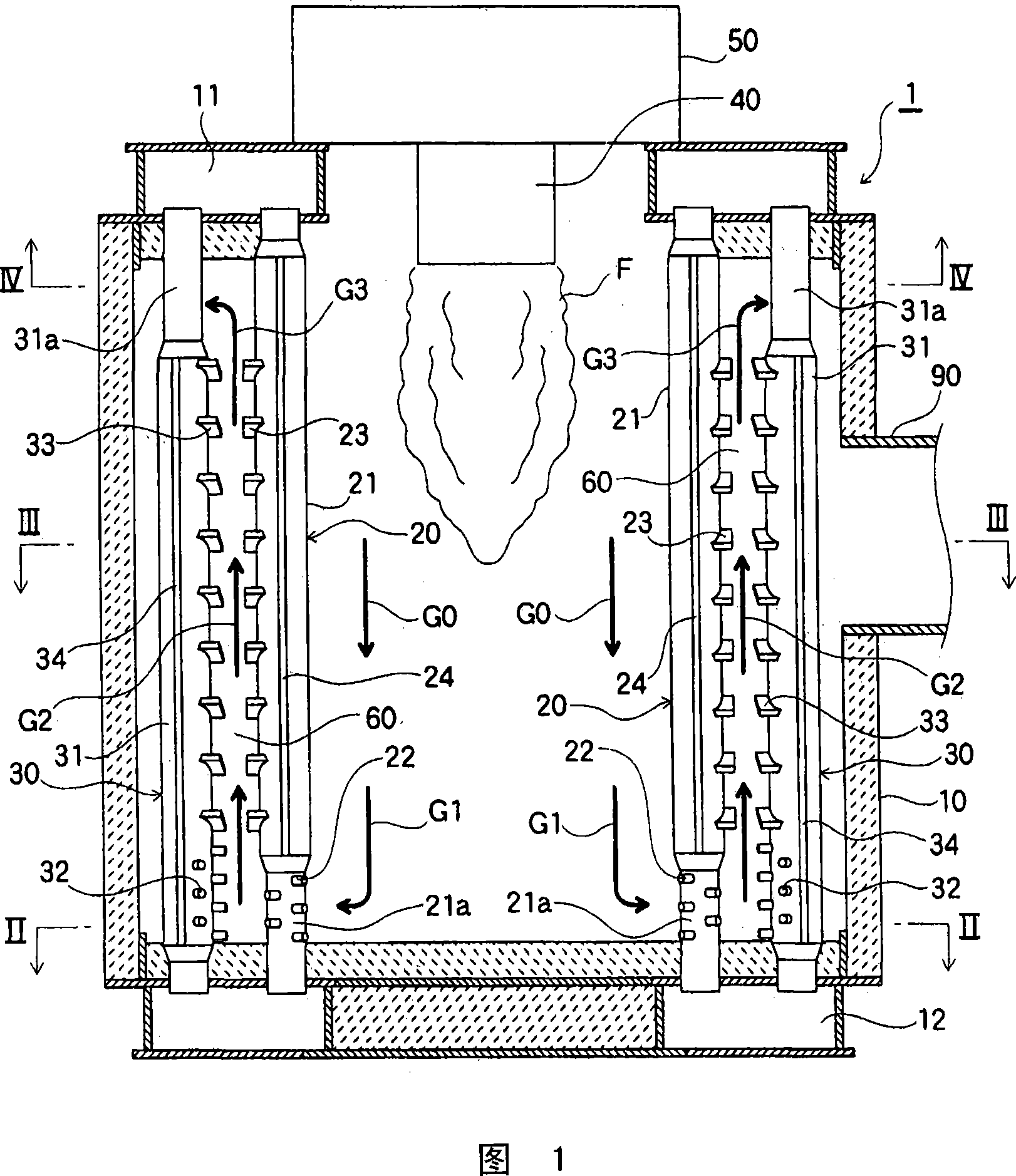

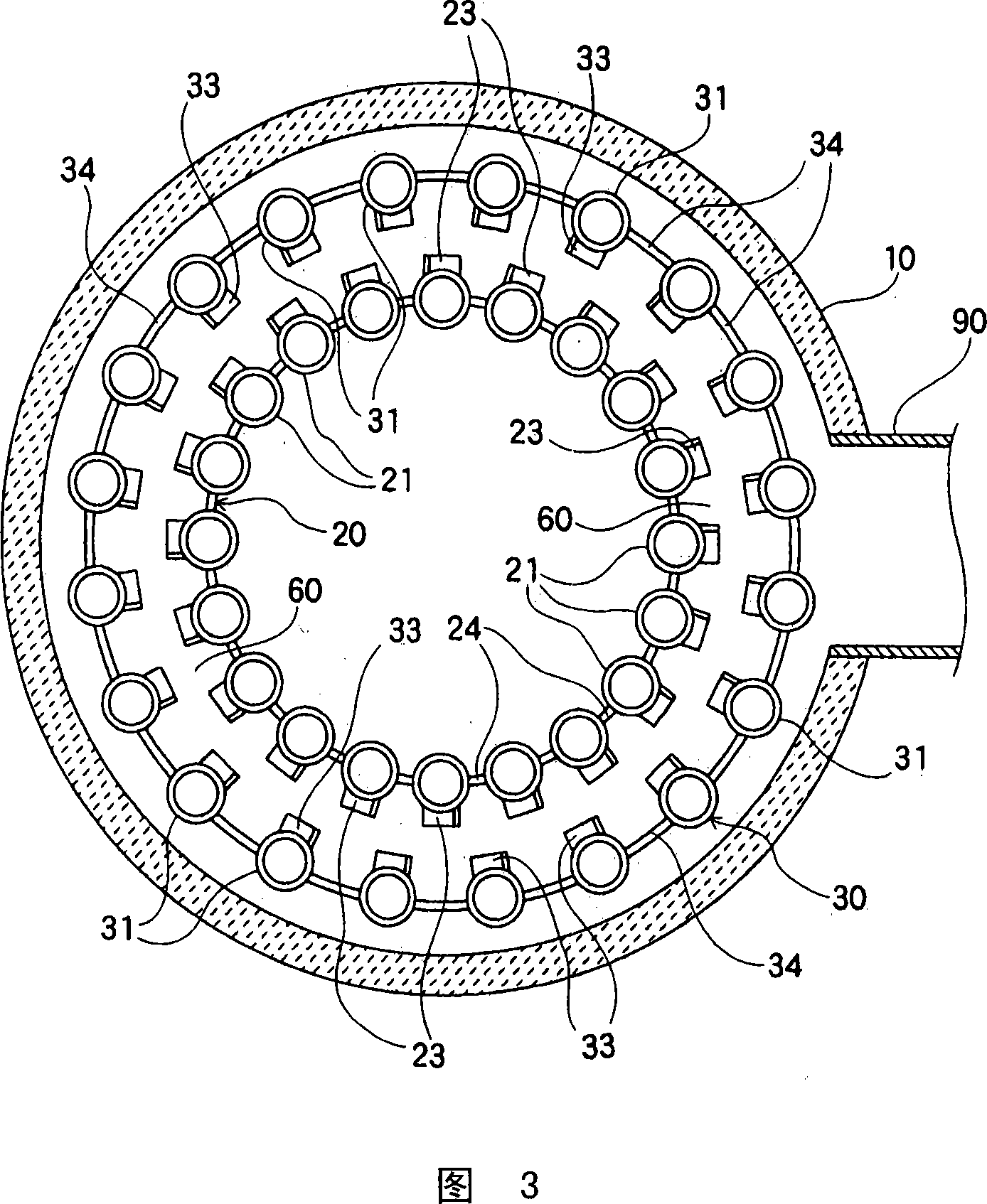

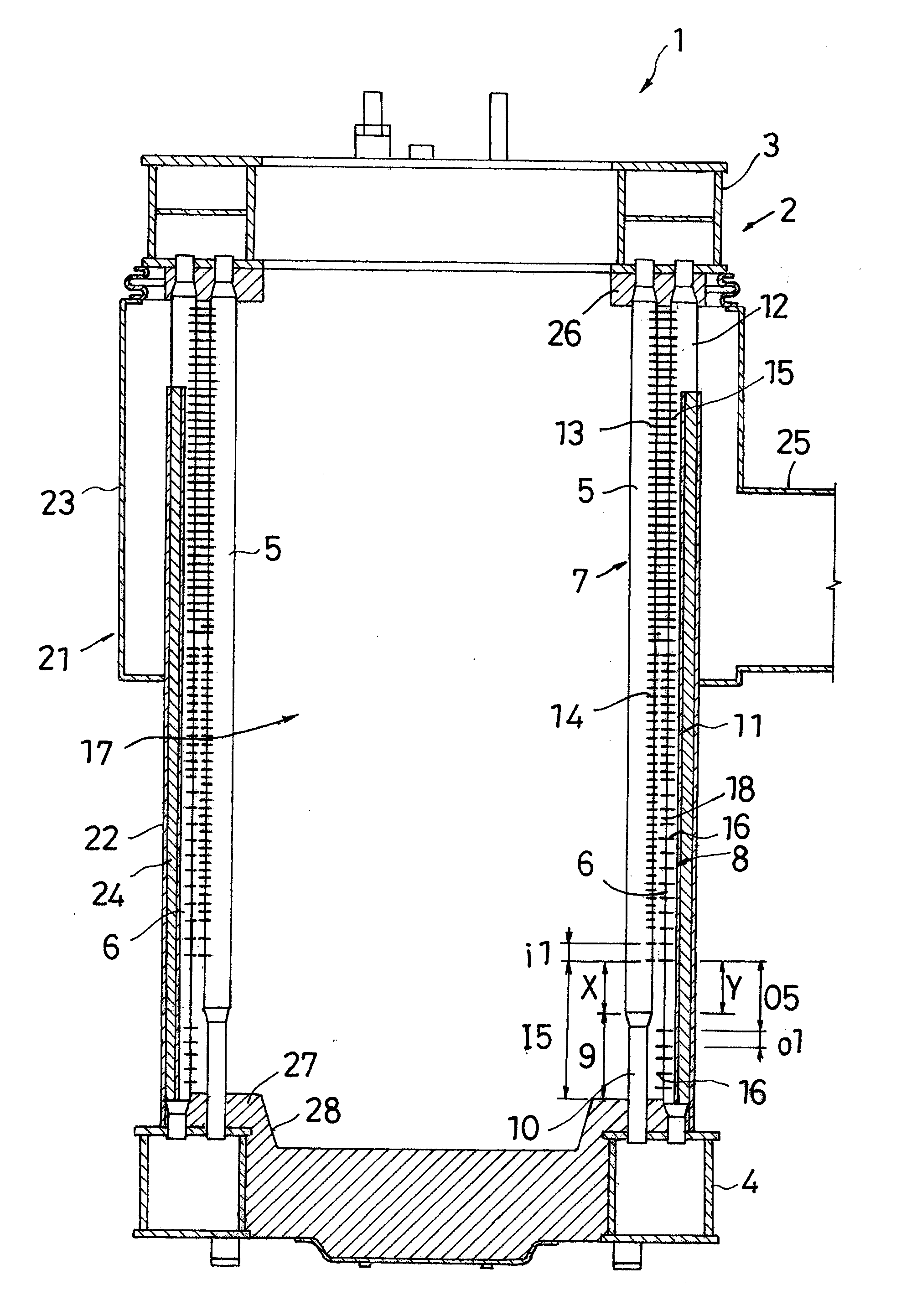

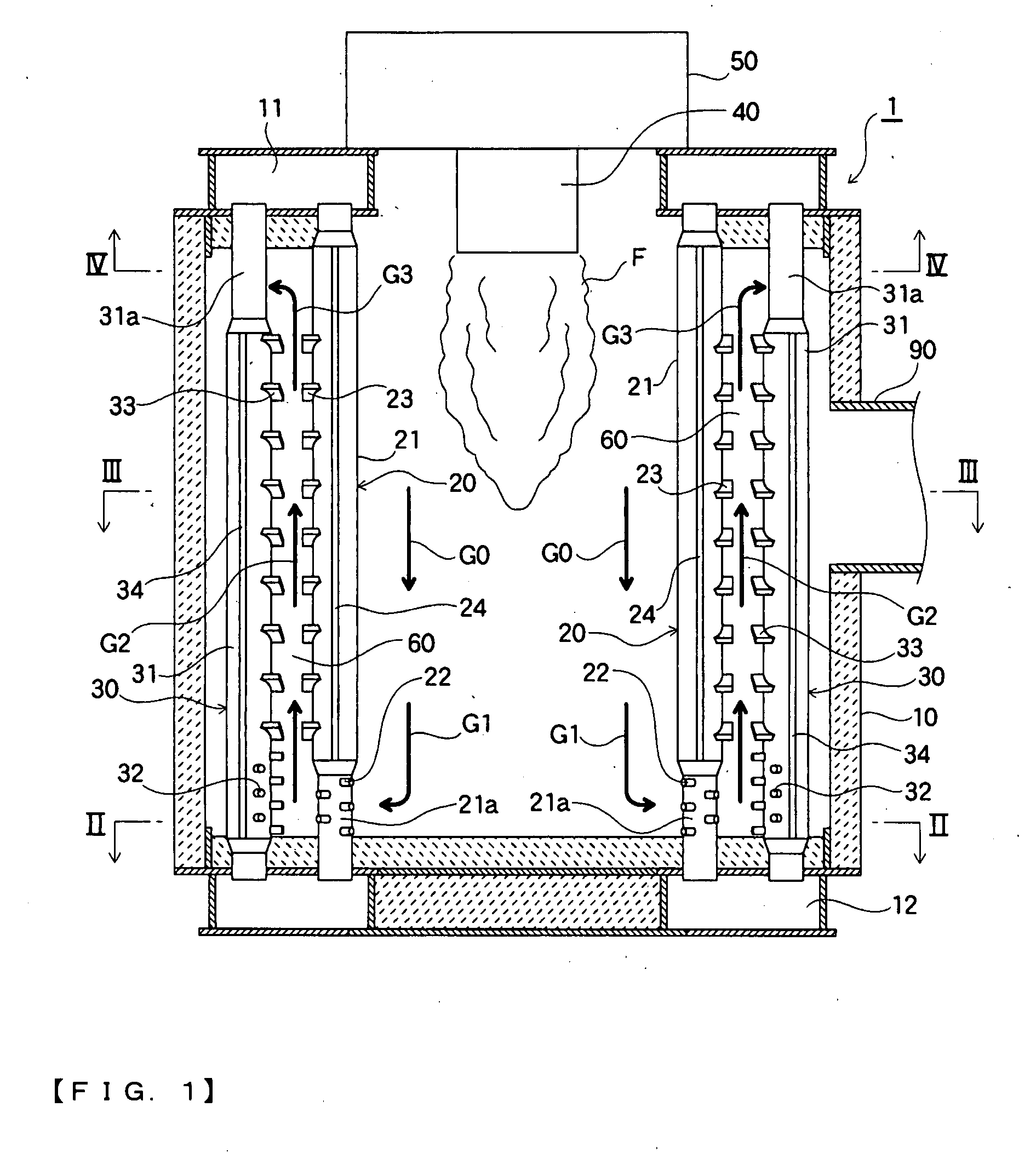

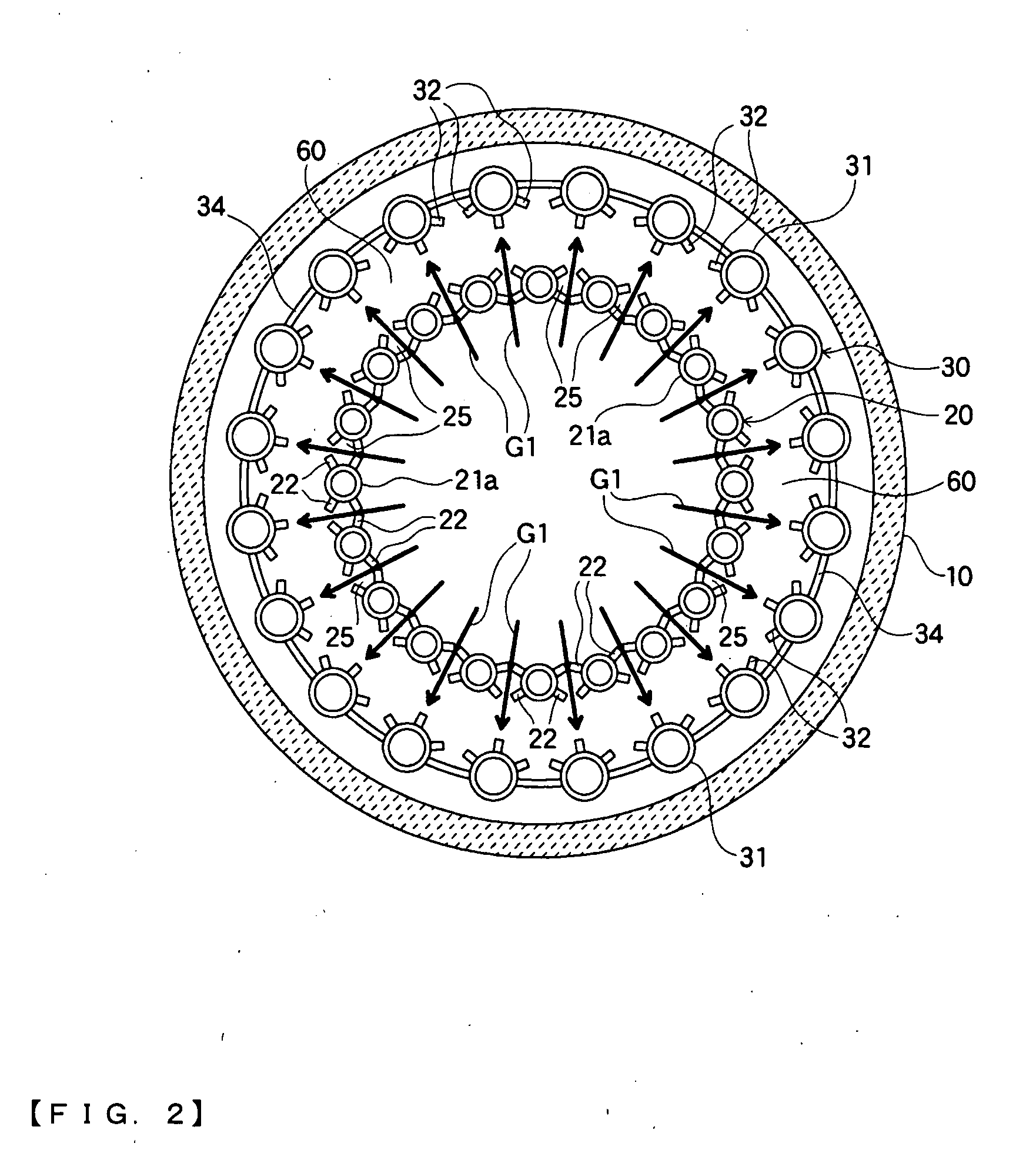

Boiler

ActiveUS7827941B2Increased durabilityReduce generationBoiler water tubesHeat exhanger finsCombustorEngineering

To provide a boiler equipped with a water tube group performing heat recovery effectively and having expansion heating surfaces (fins or the like) of high durability, the present invention provides a boiler (1) including: a boiler body (10) having an inner water tube group (20) and an outer water tube group (30) that are arranged in an annular fashion; and a burner (40) arranged at a central portion of the inner water tube group (20), in which: intervals between adjacent inner water tubes constituting the inner water tube group (20) are closed except for portions where a gas flow passage is provided; and stud fins (22 and 32) are provided on a portion of at least one of the inner water tube group (20) and the outer water tube group (30) in a vicinity of the gas flow passage.

Owner:MIURA COMPANY LIMITED

Heat pipe heat recovery type purification fresh air ventilator

ActiveCN107355937AEfficient heat recoveryReduce energy consumptionEnergy recovery in ventilation and heatingHeat recovery systemsAir volumeFresh air

The invention discloses a heat pipe heat recovery type purification fresh air ventilator. The heat pipe heat recovery type purification fresh air ventilator comprises a heat pipe type heat exchanger. One end of the heat pipe type heat exchanger is arranged in a fresh air duct of a purification fresh air ventilator body, and the other end of the heat pipe type heat exchanger is arranged in an exhaust duct of the purification fresh air ventilator body. In the fresh air duct, a fresh air fan is arranged on one side of the heat pipe type heat exchanger, and a purification module, a sterilization module and an anion sterilization module are sequentially arranged on the other side of the heat pipe type heat exchanger in the wind direction. In the exhaust duct, an exhaust fan is arranged on one side of the heat pipe type heat exchanger, and the fresh air fan and the exhaust fan are in signal connection with a control module. The purification fresh air ventilator adopting a heat pipe type heat recoverer can effectively improve the actual cold-heat exchange efficiency of fresh air and exhaust air, the energy consumption of a heating air conditioning system is greatly reduced, the purification fresh air ventilator can effectively recover heat even though the exhaust amount is half of the fresh air amount, and the effect that fresh air is cooled in summer and heated in winter is ensured.

Owner:SICHUAN JIANYUAN ENERGY SAVING TECH CO LTD

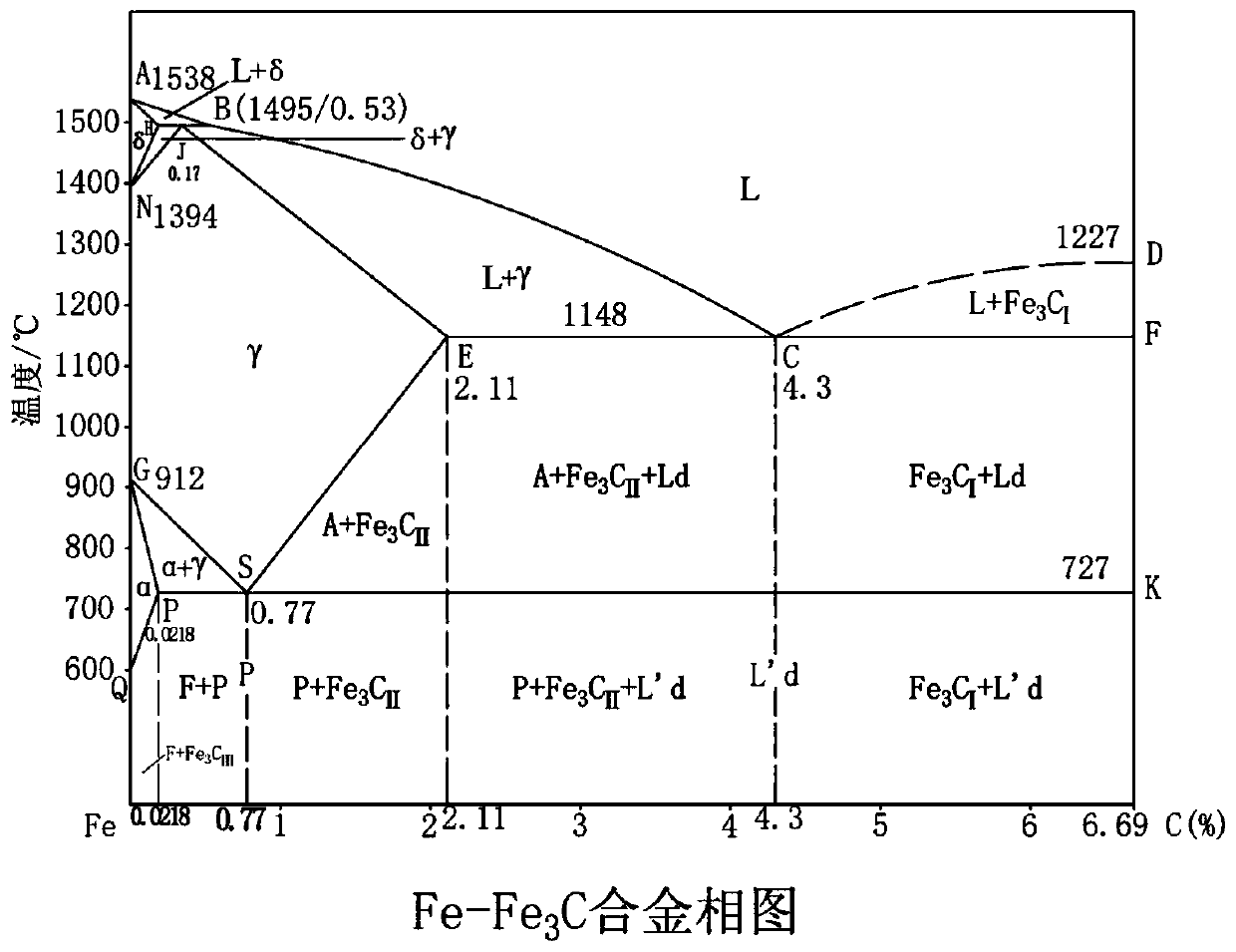

Double-melting-bath organic solid waste blowing gasification device

PendingCN110396435AWon't clogEasy to replaceGasifier mechanical detailsChemical industryHydrogenCombustible gas

The invention discloses a double-melting-bath organic solid waste blowing gasification device, and belongs to the field of organic solid waste harmlessness, quantitative reduction, resource, and energy processing adsorption, and organic matter ultrahigh temperature monoatomic cracking gasification preparation of synthetic gas. According to the double-melting-bath organic solid waste blowing gasification device, a liquid surface adjusting furnace is communicated with the bottom of a vapourizing furnace, and contains 1200 to 1700 DEG C molten iron based alloy liquid covered with a molten liquidstate slag layer; the gas pressure or liquid amount above the liquid level adjusting furnace is increased, so that the molten liquid surface in the vapourizing furnace is raised, a material spray gunis immersed, immersion spraying of organic particles for gasification into the melting bath is carried out, at the same time, gasification agent oxygen gas and oxygen-enriched air are blew into molten, organic matter gasification into synthetic gas rich in CO and hydrogen gas is realized, most inorganic matters enter into molten slag, and are discharged regularly with accumulation of slag liquid;molten iron liquid amount is maintained to be constant, conversion of most organic waste into clean combustible gas is realized, and the obtained clean combustible gas is taken as fuel gas or chemicalproduct synthetic gas.

Owner:杭州吉幔铁氢能科技有限公司

Method and device for recovering molten blast furnace slag sensible heat

ActiveCN103484580ATake advantage ofIncrease temperatureBlast furnace detailsIncreasing energy efficiencyThermal energyCombustion

The invention belongs to the technical field of energy recovery, and particularly relates to a method and device for recovering molten blast furnace slag sensible heat. The process of the method sequentially includes the following steps that (1) blast furnace slag enters a segmented bottom blowing composite molten slag trough, compressed air is blown in from the bottom of the bottom blowing composite molten slag trough, and at the moment a heat accumulator is heated to be within the range from 1100 DEG C to 1250 DEG C; (2) molten slag of which the temperature is reduced to be within the range of 700 DEG C to 800 DEG C enters an old slag processing system through a connecting unit, and then follow-up processing is conducted on slag; (3) when slag stops being discharged from a blast furnace, air is still blown in from the bottom of the bottom blowing composite molten slag trough, and air is heated to be within the range from 800 DEG C to 900 DEG C when passing through the heat accumulator; (4) hot air is used for power generation after being dedusted, and then cooling water replaces heat for production. Compared with the prior art, the method and device have the advantages that through the improvement, heat can be efficiently recovered, the temperature of combustion air by a hot blast heater can be increased, the device and method can be also used for waste heat power generation, and then the purpose of energy reutilization is achieved.

Owner:鞍钢集团工程技术有限公司

Process for producing sterile water for injection from potable water

InactiveUS20010050215A1Shorter treatment timeEasily deployableBiocideLiquid degasificationSubmarineProduct gas

By treating potable water at a temperature of at least 250.degree. C. (482.degree. F.) and at a pressure of at least 4 Mpa (570 psia), can produce pyrogen-free water using treatment times of 0.05 to 5 seconds or less. The addition of an oxidant, in the form of a gas, a liquid, or a solid, further decreases the required treatment time to less than 0.05 second. The reduction in equipment size achieved with this rapid treatment time allows the utilization of treatment units small enough to be easily transported to remote locations or installed in the restricted space environment existing in ships and submarines.

Owner:APPLIED RES ASSOCS INC

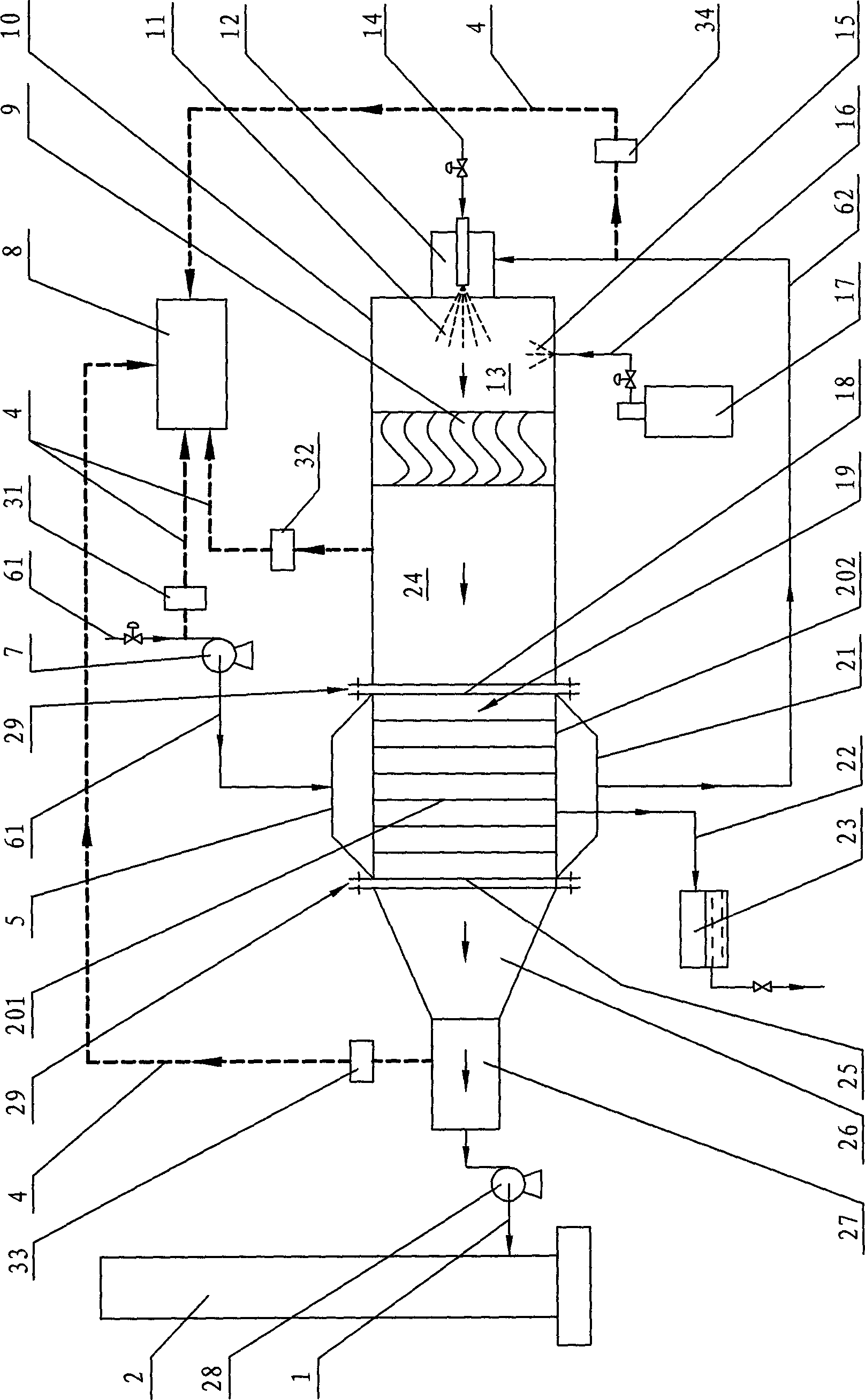

Heat-transfer equipment performance experimental facility

ActiveCN104048908AOperational securityStable for a long period of operationWeather/light/corrosion resistanceMaterial heat developmentAir preheaterGas cylinder

The invention discloses a heat-transfer equipment performance experimental facility to solve the problem that a present experimental facility cannot perform experiments on heat transfer performance, corrosion resistance and mechanical property of an air preheater for gas-gas transfer. The heat-transfer equipment performance experimental facility is provided with parts such as a cylindrical shell (10), a combustor (12), a gas distributor (9), a transition section (26), a flue gas duct (27), a sulfur dioxide gas-bomb (17) and the like. The gas distributor divides an inner cavity of the cylindrical shell into a first cavity (13) and a second cavity (24). An inlet air tube (61), the second cavity, a flue gas duct and an outlet air tube (62) are respectively connected with a data acquisition unit for measuring gas temperature, pressure and flow. Each data acquisition unit is connected with a data processor (8) through respectively data line (4). The heat-transfer equipment performance experimental facility is mainly used for performing experiments on performance of a tubular heating furnace's air pre-heater for gas-gas transfer in the industries of petroleum refining and petrochemical engineering.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Power generating facility

ActiveCN103089341AEfficient use ofHigh outputEnergy industrySteam generation plantsBoiling pointEngineering

To provide a power generating facility for increasing heat utilization efficiency by recovering and utilizing heat from low-temperature exhaust gas of not more than 150 C and increasing steam turbine generation. In a power generating facility provided with heat exchangers (61, 62) for heat exchange between a heat medium and water and a vacuum flasher (63) that supplies steam to a vacuum stage of a steam turbine (41), the amount of generated power is increased by supplying the heat medium to the heat exchangers (61, 62) so as to generate water fluid with a temperature exceeding the water boiling point under vacuum in the vacuum stage, supplying the water fluid to the vacuum flasher (63) so as to produce steam under the vacuum of the vacuum stage, and feeding the steam to the vacuum stage of the steam turbine (41).

Owner:KAWASAKI JUKOGYO KK

Heat recovery system

InactiveUS8266900B2Improve warm-upEfficient heat recoveryInternal combustion piston enginesRecuperative heat exchangersEngineeringInternal combustion engine

A plurality of flat tubes formed as a tube having notches by linearly cutting upper and lower parts from a hollow flat circular doughnut shape are stacked to structure a tube laminate. It is attached to a case so that a notch aligns with the notch and faces upward by an exhaust inflow end plate and that a notch aligns with the notch and faces downward by an exhaust outflow end plate. A cutoff valve is provided at an exhaust outflow end of an exhaust communication tube passing through the center of the tube laminate by heat insulation. While an internal combustion engine is warming up, the cutoff valve is closed to cause the exhaust to flow in gaps of the respective flat tubes from upward to downward as a whole and also a heat exchange medium is caused to flow in the respective flat tubes from downward to upward as a whole to have heat exchanged between the exhaust and the heat exchange medium to recover the exhaust heat.

Owner:THE UNIV OF TOKYO +3

Boiler

ActiveCN101191662AEfficient heat recoveryIncreased durabilityHeat exhanger finsStationary tubular conduit assembliesCombustorEngineering

An object of the present invention is to provide a boiler having a water tube group having an enlarged heat transfer surface (fins, etc.) that efficiently recovers heat and has high durability. The present invention is a boiler (1) comprising a tank body (10) having an inner water pipe group (20) and an outer water pipe group (30) arranged in a ring, and a combustion engine disposed in the center of the inner water pipe group (20). A device (40), characterized in that the adjacent inner water pipes constituting the inner water pipe group (20) are closed except for the part where the gas flow path is provided, and the inner water pipe group near the gas flow path (20) and at least one of the above-mentioned outer water tube group (30) is provided with column fins (22, 32).

Owner:MIURA COMPANY LIMITED

Multifunctional dehumidifying heat pump for swimming pool

InactiveCN112197461AReduce operating costsMake full use ofMechanical apparatusHeat pumpsAir cycleEngineering

The invention provides a multifunctional dehumidifying heat pump for a swimming pool, and relates to the technical field of dehumidifying equipment. The technical problems that in the prior art, the air humidity in a natatorium is high, the energy consumption of a dehumidifier is high, the heat recycling rate is low, and the function is single are solved. The dehumidifying heat pump comprises an air circulation assembly, a refrigerant circulation assembly, a first water circulation assembly, a second water circulation assembly and a control assembly, wherein the refrigerant circulation assembly comprises a first heat exchanger, an indoor condenser, a second heat exchanger and an outdoor condenser, wherein the indoor condenser, the second heat exchanger and the outdoor condenser are arranged in parallel, the two water circulation assemblies communicate with the corresponding heat exchangers for heat recovery so as to meet the requirement for hot water in the natatorium, the control assembly can adjust a parallel refrigerant pipeline where only one of the indoor condenser, the second heat exchanger and the outdoor condenser is located to be a passage at the same time, so that the multifunctional dehumidifying heat pump has multiple functions of dehumidifying and heating, dehumidifying and heating water and dehumidifying and refrigerating, and the multifunctional dehumidifying heat pump is used for improving the functional diversity of the dehumidifying heat pump and effectively recovering heat energy.

Owner:王春喜

Boiler

ActiveUS20120240868A1Prevent heat conductivityPrevent pressure lossBoiler water tubesSpeed sensing governorsHeat transfer tubeEngineering

Owner:MIURA COMPANY LIMITED

Boiler

ActiveUS20080127910A1Increased durabilityReduce NOxBoiler water tubesHeat exhanger finsCombustorEngineering

To provide a boiler equipped with a water tube group performing heat recovery effectively and having expansion heating surfaces (fins or the like) of high durability, the present invention provides a boiler (1) including: a boiler body (10) having an inner water tube group (20) and an outer water tube group (30) that are arranged in an annular fashion; and a burner (40) arranged at a central portion of the inner water tube group (20), in which: intervals between adjacent inner water tubes constituting the inner water tube group (20) are closed except for portions where a gas flow passage is provided; and stud fins (22 and 32) are provided on a portion of at least one of the inner water tube group (20) and the outer water tube group (30) in a vicinity of the gas flow passage.

Owner:MIURA COMPANY LIMITED

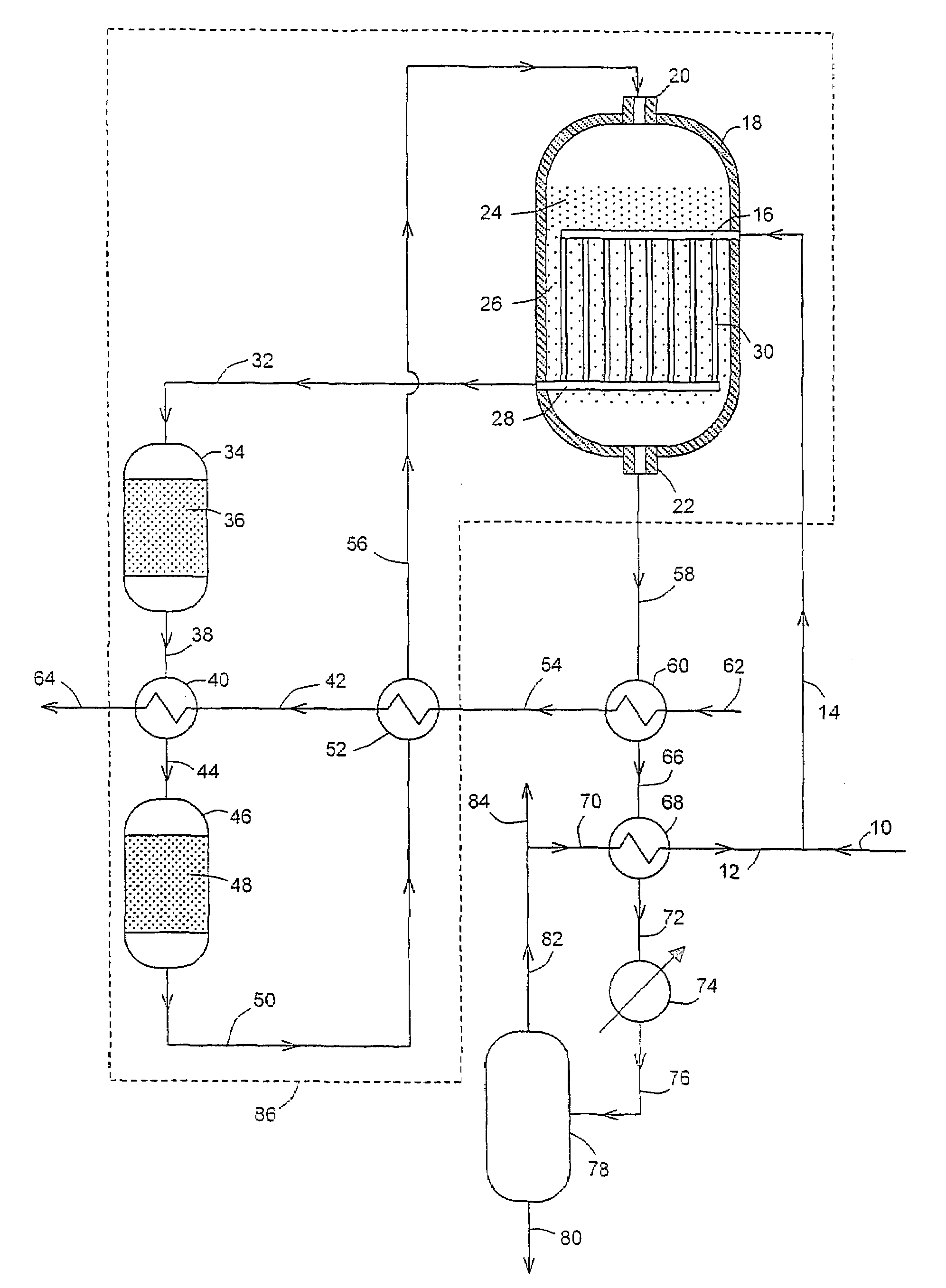

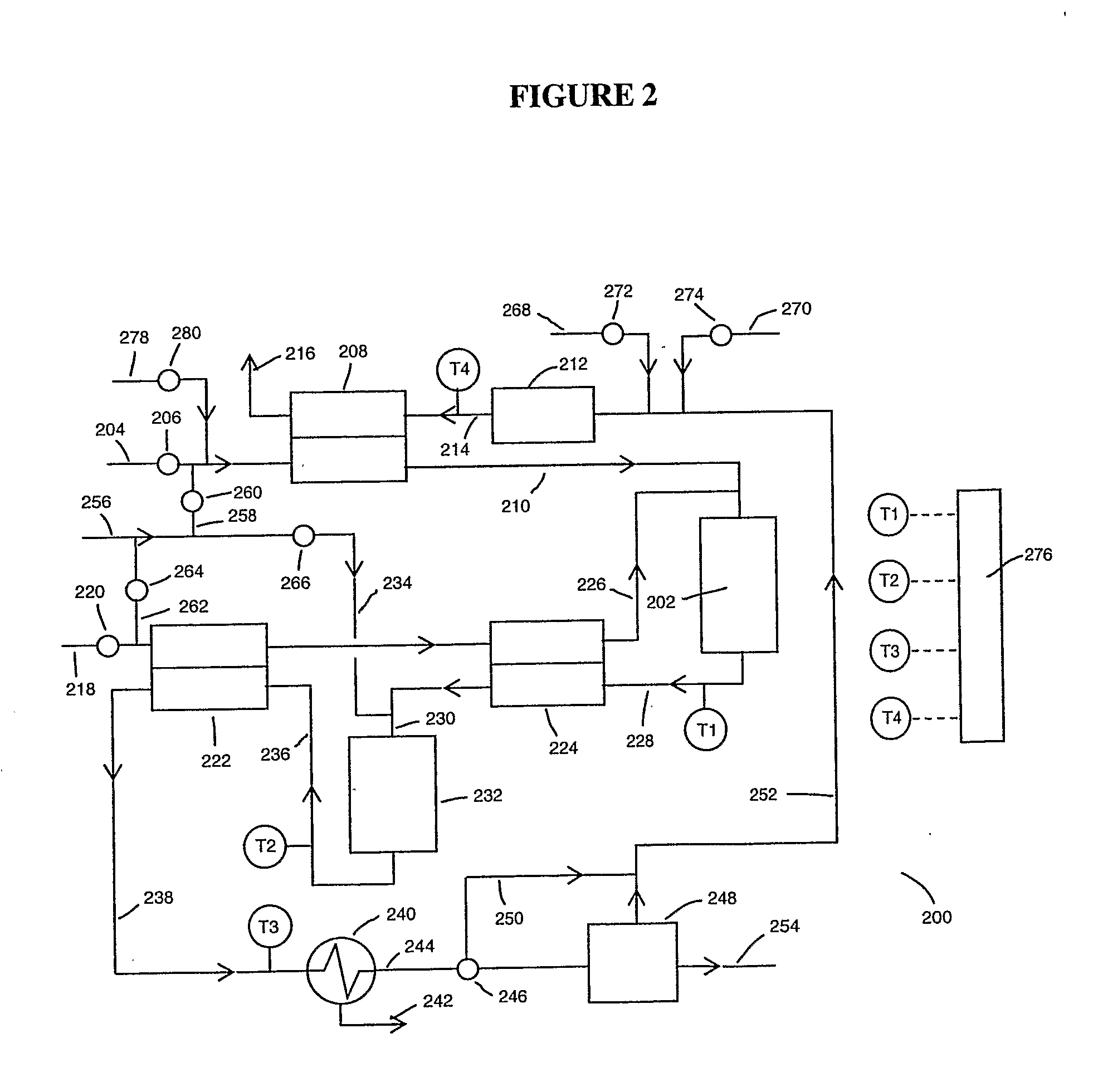

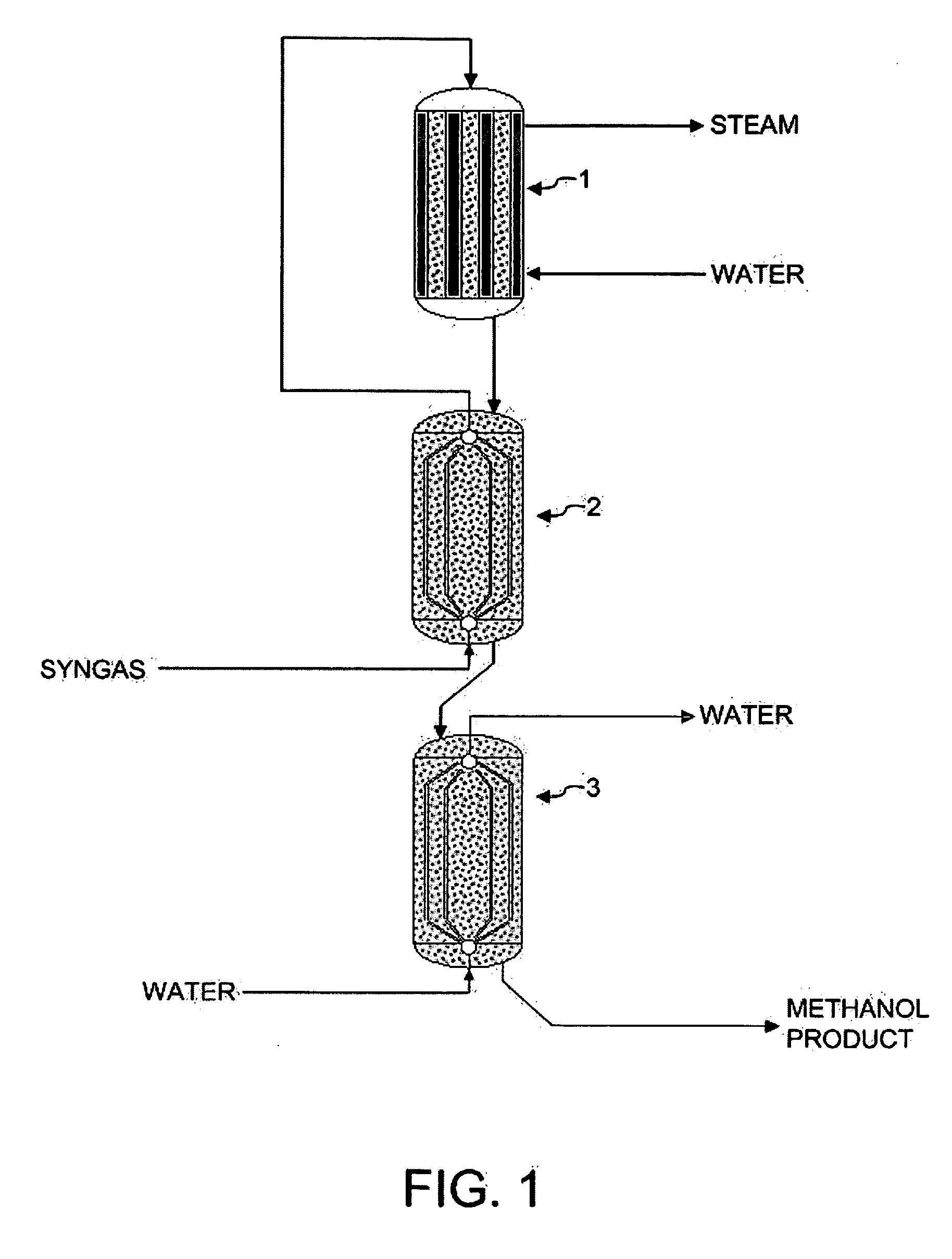

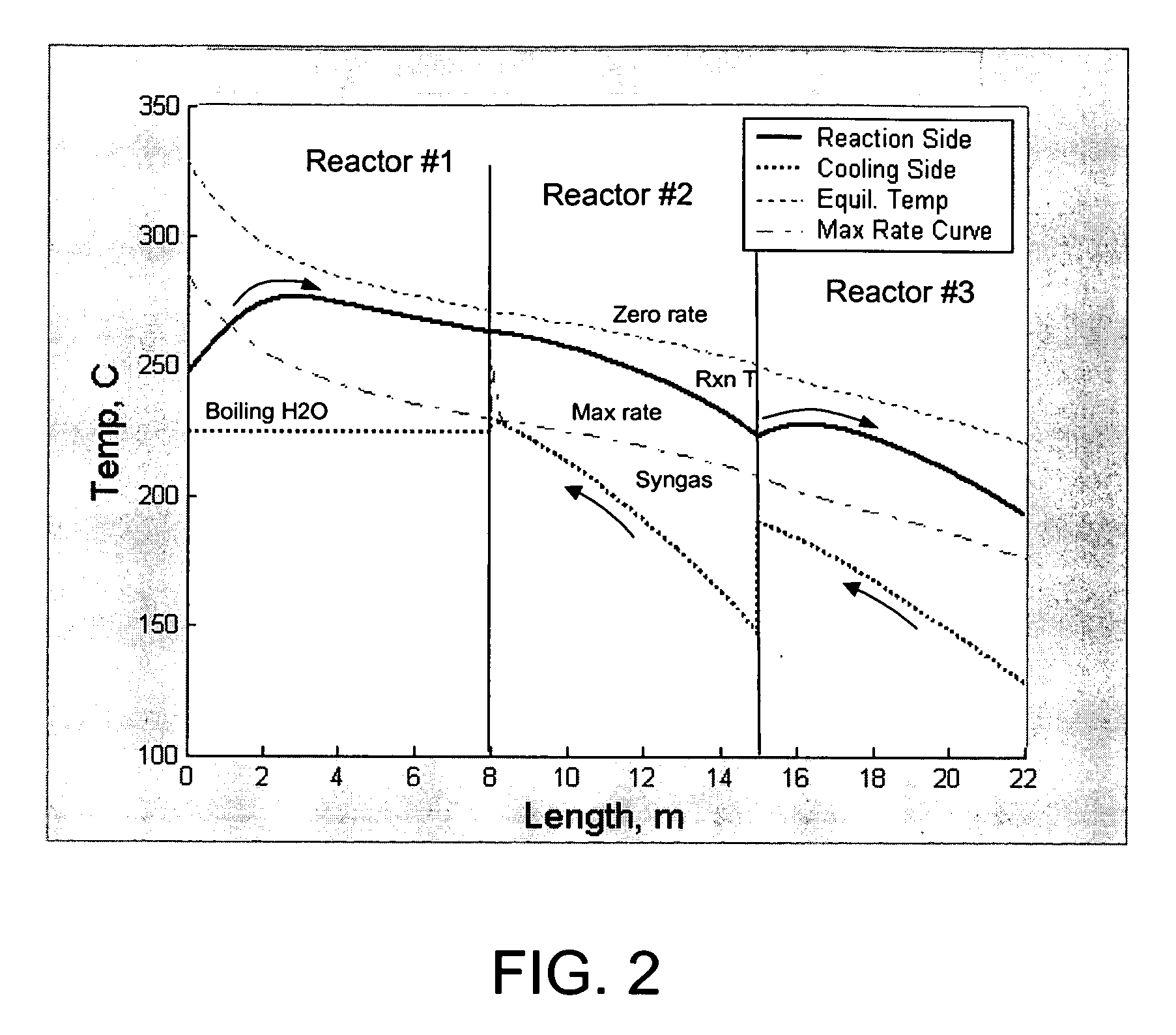

Methanol synthesis and reaction system

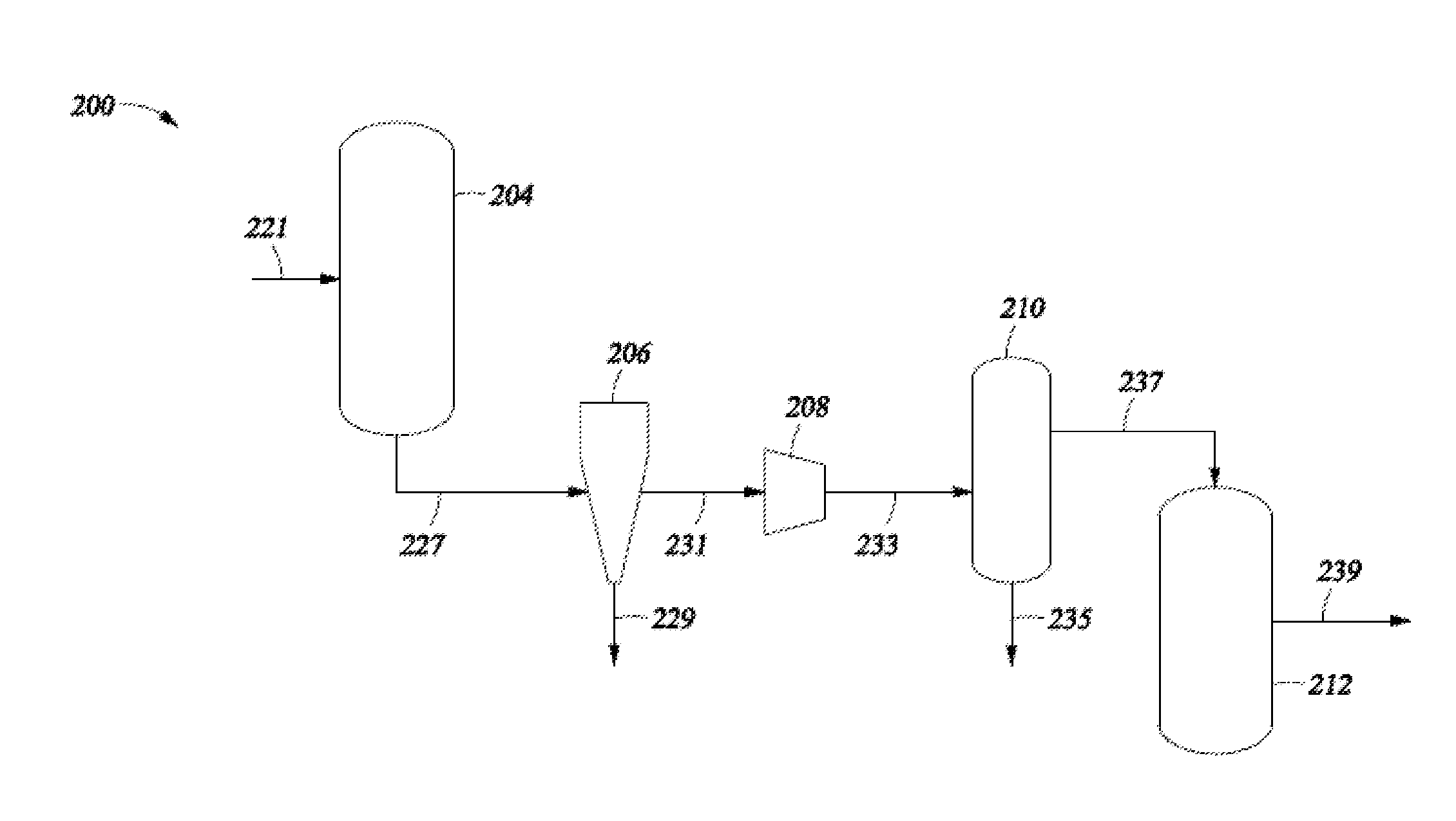

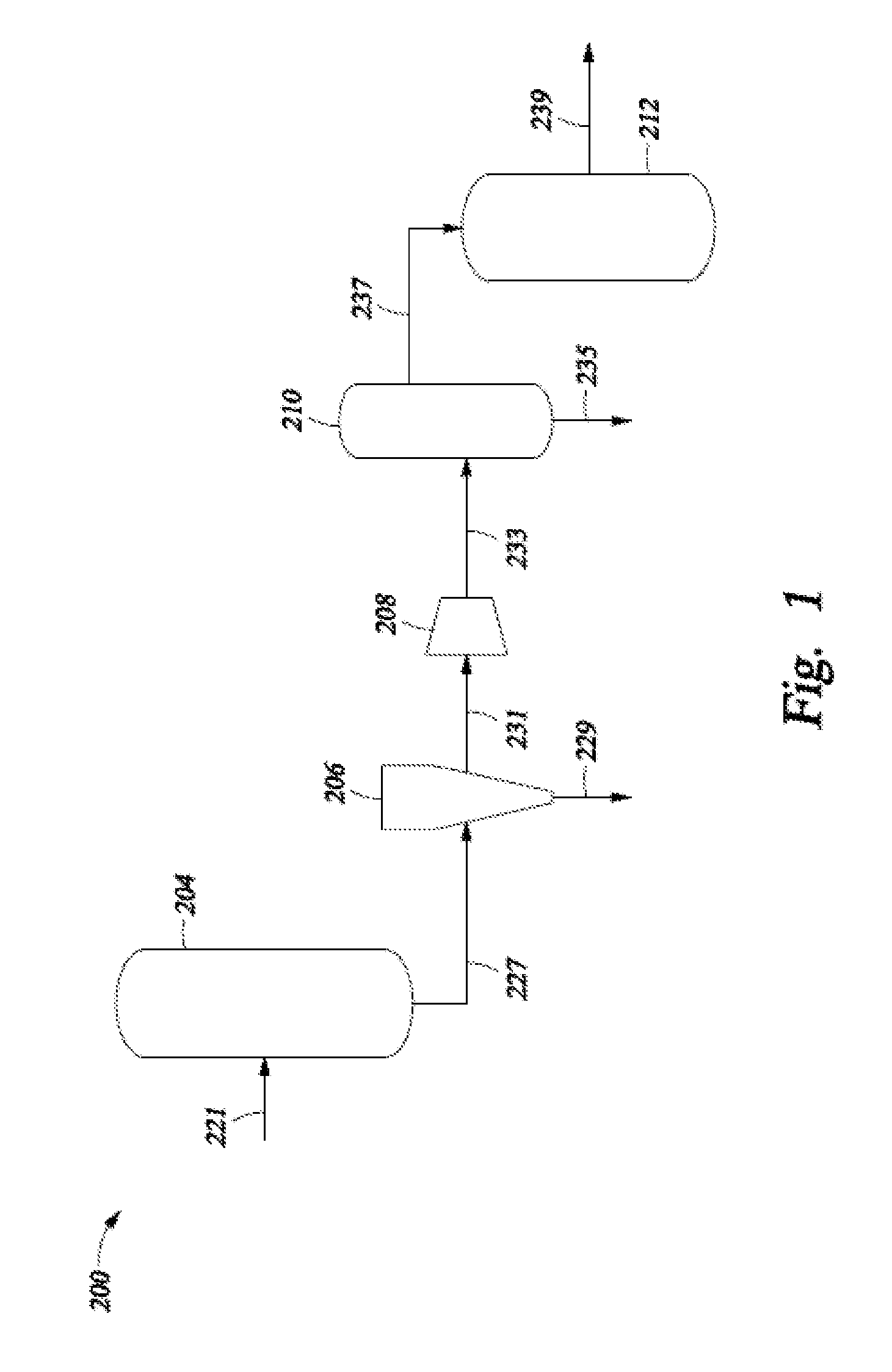

InactiveUS20070043126A1Efficient reaction processEfficient heat recoveryOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasChemistry

This invention is directed to a process for making a methanol product from a synthesis gas (syngas) feed. Preferably, the process uses a reaction system with three reactors. Particular benefits of a three reactor system are provided by arranging each of the reactors in series, with at least one of the reactors being cooled by evaporative cooling.

Owner:EXXONMOBIL CHEM PAT INC

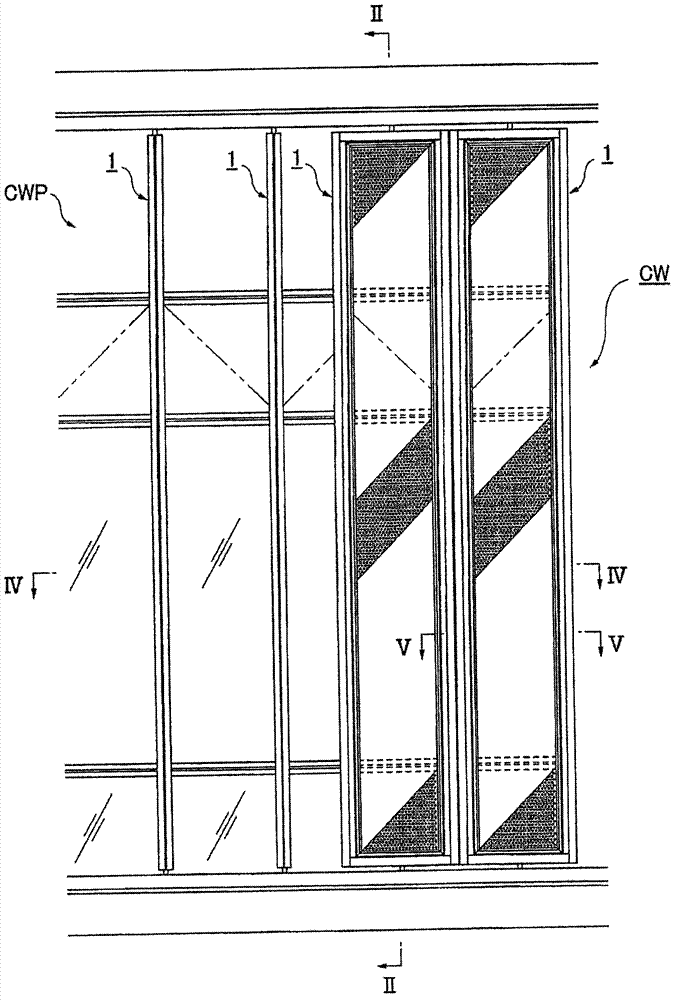

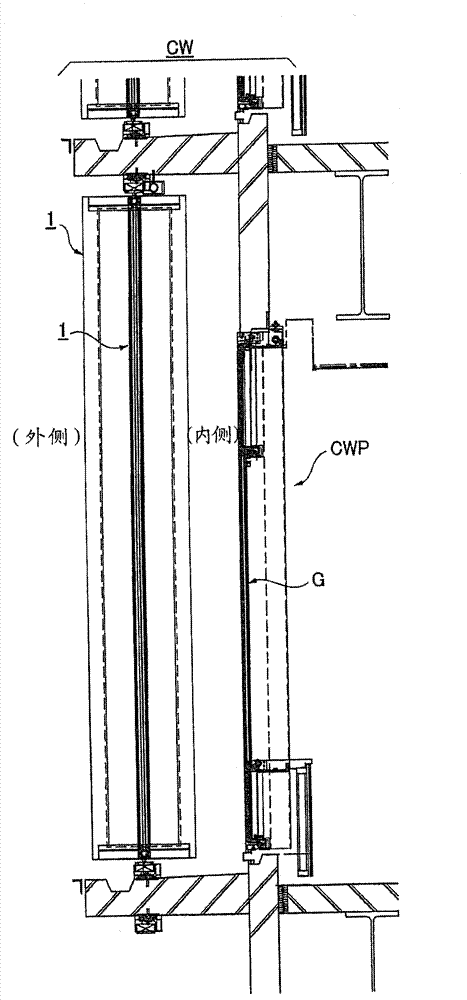

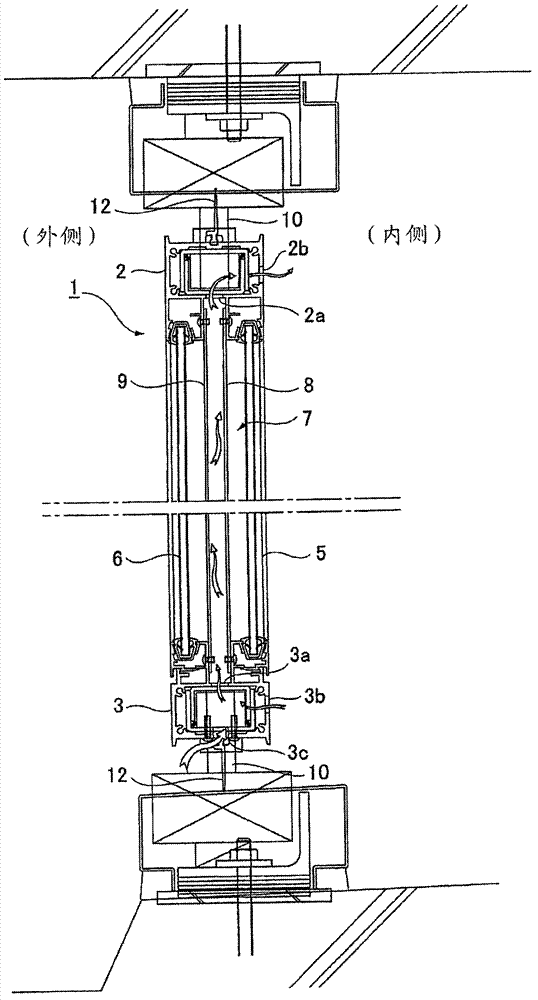

Curtain wall structure

ActiveCN103201438AEasy to inhaleGood environmental performanceSolar heating energySolar heat collector controllersWindow shutterEngineering

to drastically reduce energy consumption by reducing the heat load from solar radiated heat during summer and efficiently absorbing solar radiated heat during winter, while suppressing the reduction in light volume inside a room. [Solution] A curtain wall structure is provided wherein: a plurality of louver units (1, 1...) are arranged at prescribed intervals in a horizontal direction on the outside of a curtain wall panel (CWP); each louver unit (1) has two sheets of glass (5, 6) arranged inside a frame, with an air layer (7) disposed therebetween; two porous panels (8, 9) with a plurality of holes are arranged inside the air layer (7) at intervals and parallel to the two sheets of glass (5, 6); the surface of each porous panel (8, 9) on one sheet of glass (5) side is colored a whitish color and the surface on the other sheet of glass (6) side is colored blackish; air communication ports (2b, 3b) that communicate between the air layer and the louver unit exterior are each disposed on the top and bottom end of the surface on the one sheet of glass (5) side, and the curtain wall structu.

Owner:株式会社骊住集团 +1

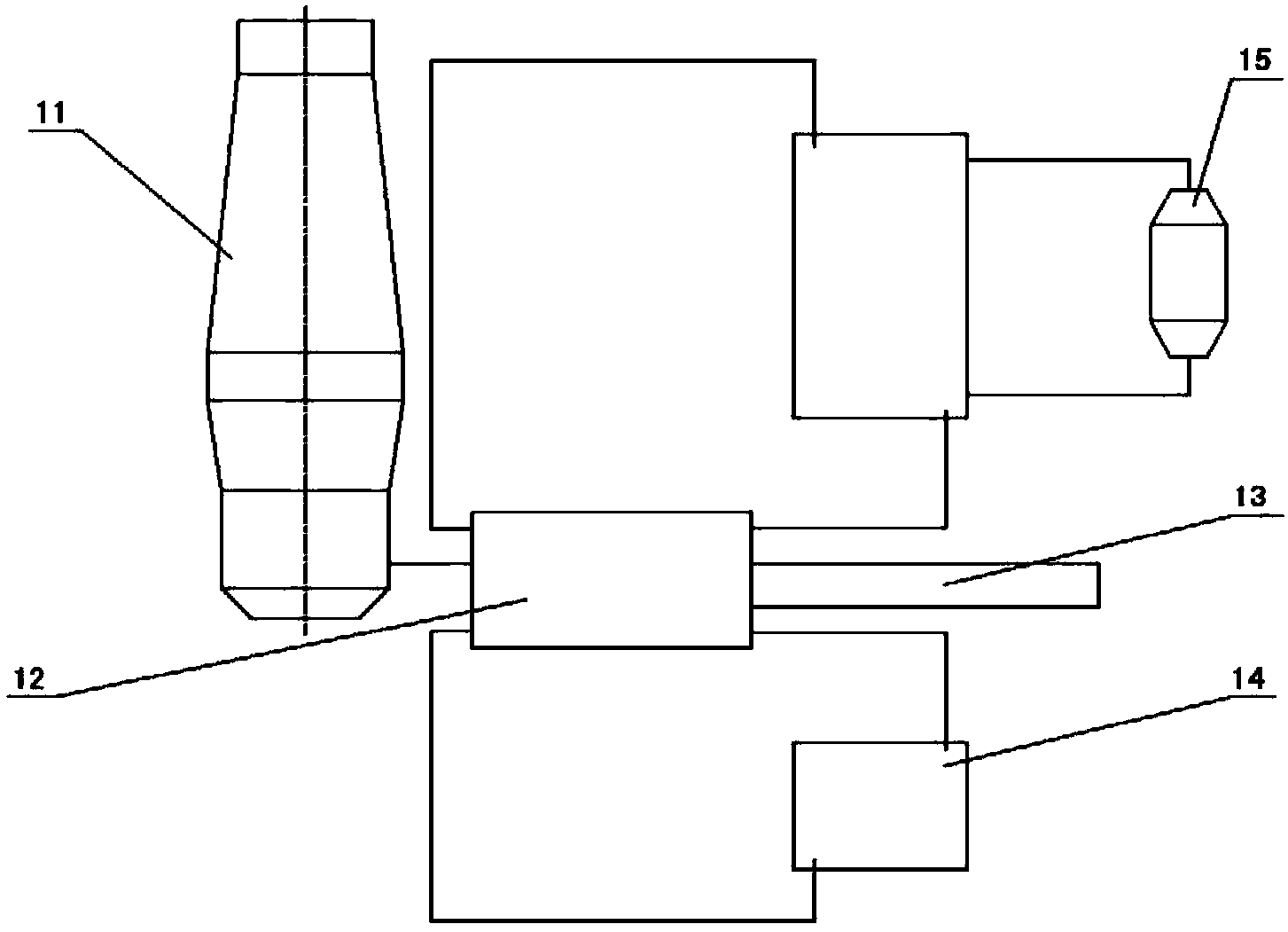

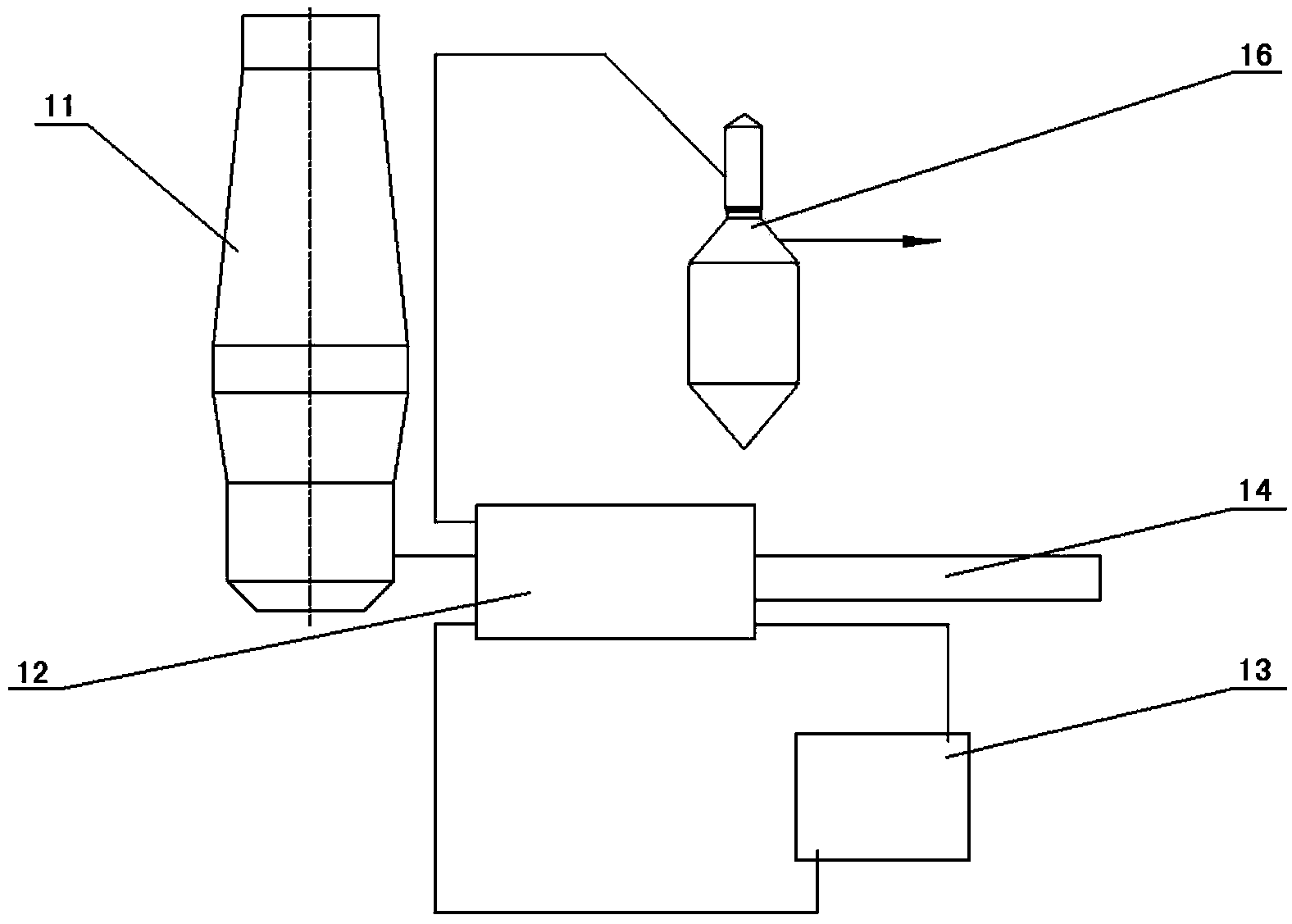

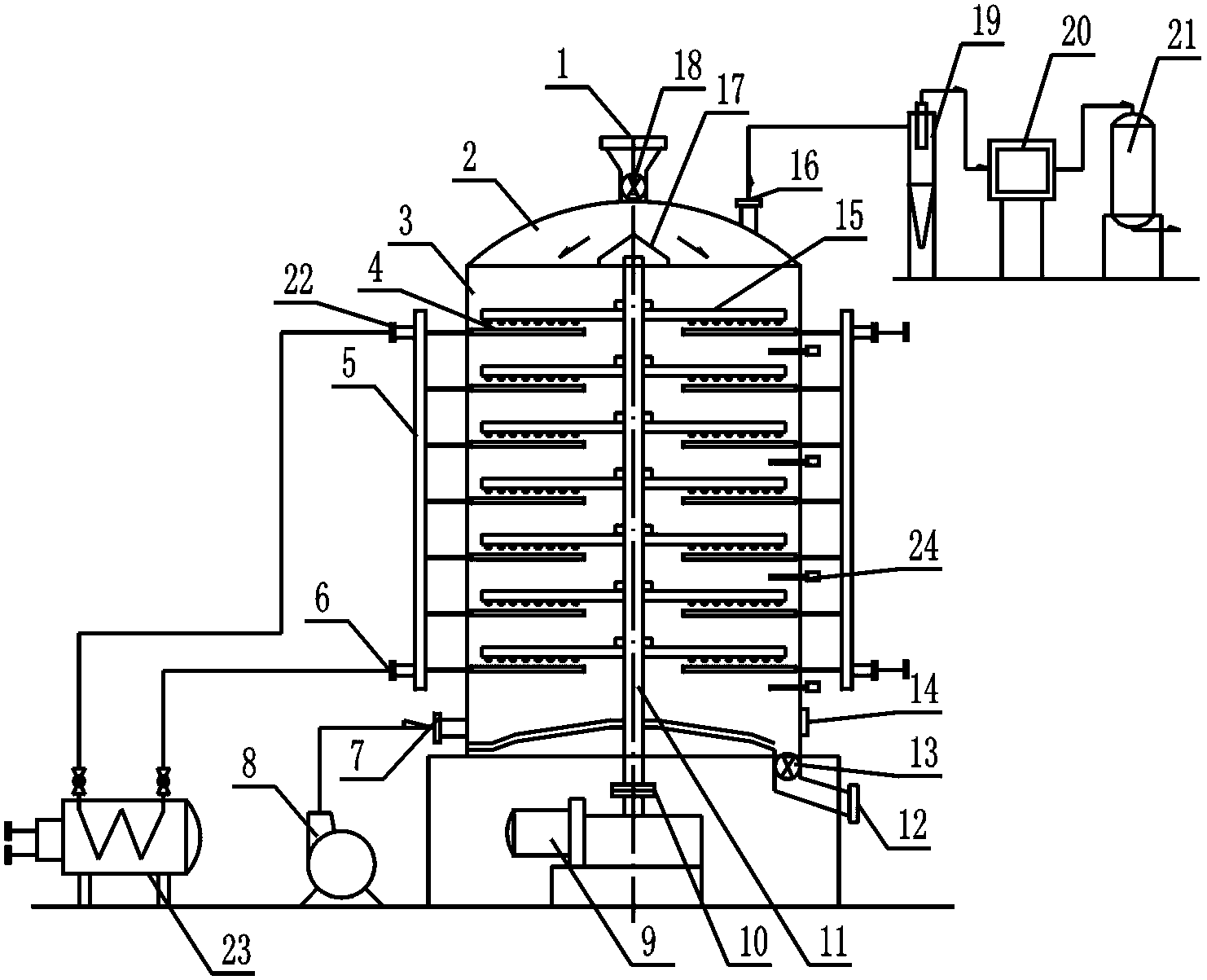

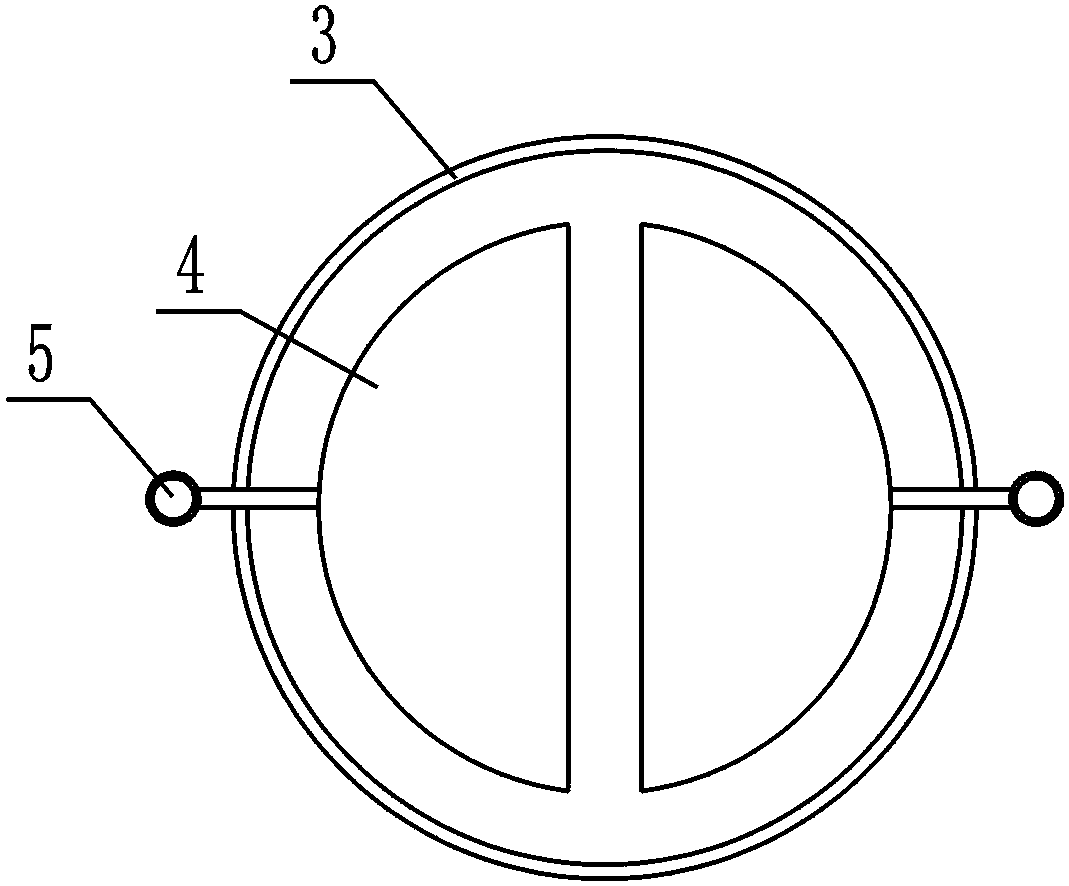

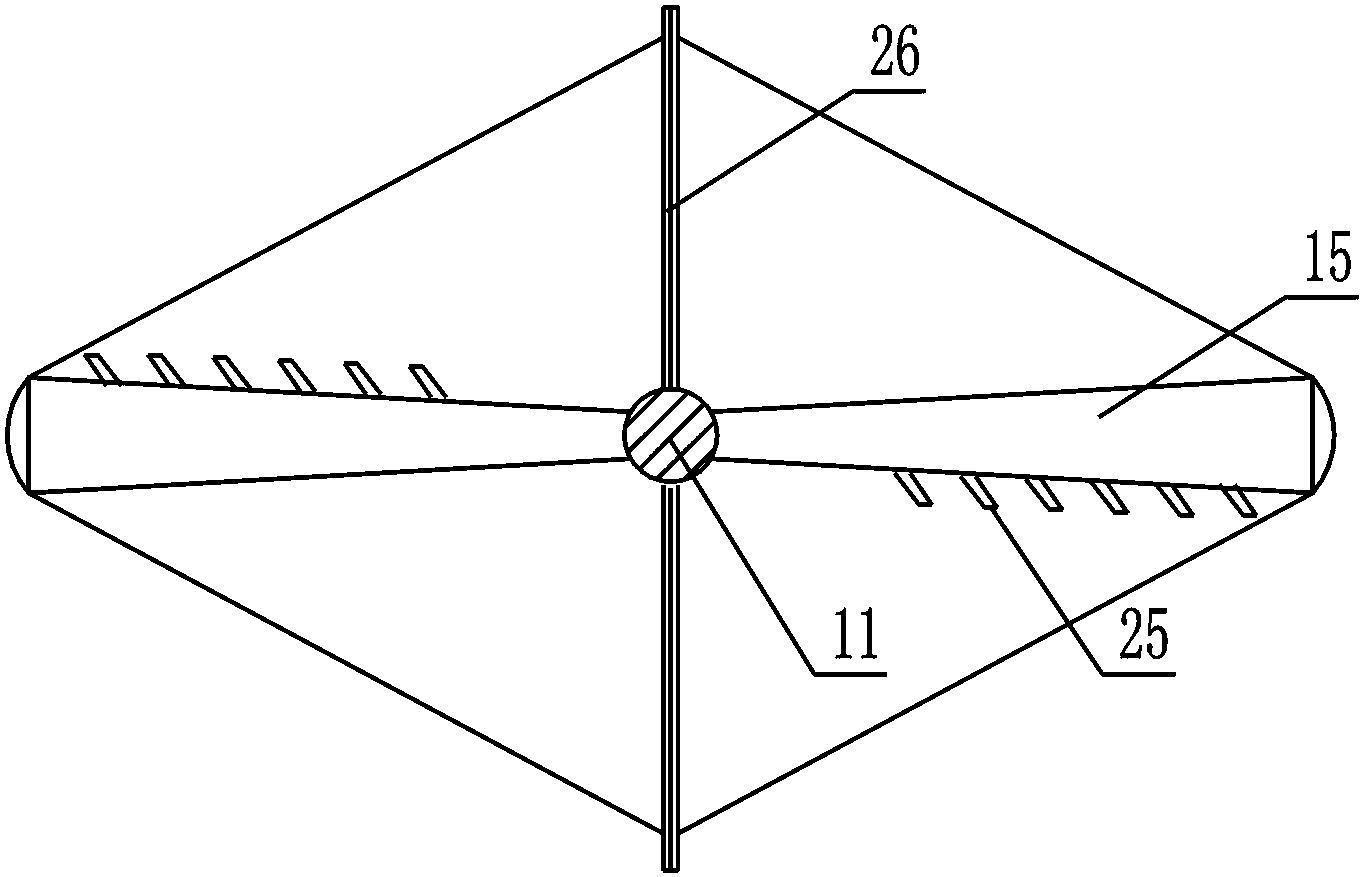

Vertical sludge dryer

InactiveCN103588379AEfficient heat recoveryReduce sludge moisture contentSludge treatment by de-watering/drying/thickeningActivated carbonMoisture

The invention discloses a vertical sludge dryer. The vertical sludge dryer comprises a sealing cap, a tower body, a fixed hot tray, a steam main pipe, a draught fan, a driving device, a rotary arm and a heat recovery boiler, and further comprises a cyclone separator, a plasma dust remover and an activated carbon absorber which are connected sequentially. The vertical sludge dryer is characterized in that the driving device is arranged at the bottom of the tower body and connected with a spindle through a coupler; the rotary arm is mounted on the spindle; a half arm of the rotary arm is fan-shaped; symmetric pull rods are arranged on the rotary arm; the fixed hot tray is semicircular, and communicated with the steam main pipe through a pipe; a conical distributor is arranged at the upper part of the tower body. The vertical sludge dryer is provided with the device for efficiently recovering heat energy, processing waste gases and deodorizing with high automation degree, and utilizes the waste heat to indirectly heat, thereby improving the energy utilization rate, further reducing the moisture content of the sludge and effectively avoiding secondary pollution of the waste gases.

Owner:成都绿源新创环保科技有限公司

High-efficiency air compressor heat recovery system

The embodiment of the invention discloses a high-efficiency air compressor heat recovery system. The system comprises a first compressor, a first heat exchanger, a second compressor, a second heat exchanger, a third compressor, a third heat exchanger, a first three-way valve, a fourth heat exchanger, a second three-way valve, a fifth heat exchanger, a heat preserving water tank, a first drying tower, a second drying tower, a first valve, a second valve, a third valve, a fourth valve, a fifth valve, a sixth valve, a first connecting branch, a seventh valve and an eighth valve. By means of the high-efficiency air compressor heat recovery system disclosed by the embodiment of the invention, the heat recovery can be effectively carried out.

Owner:上海赛捷能源科技有限公司

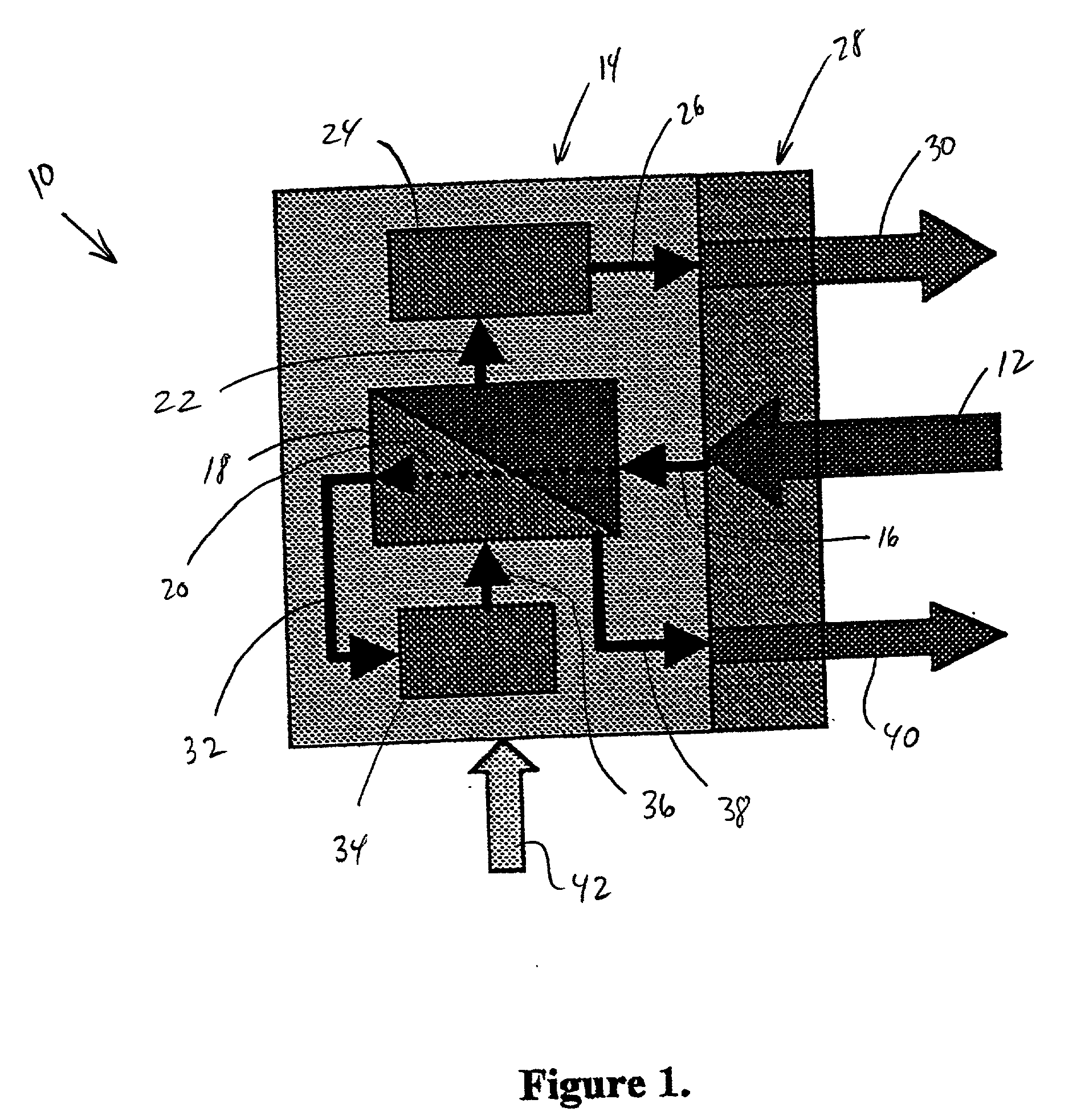

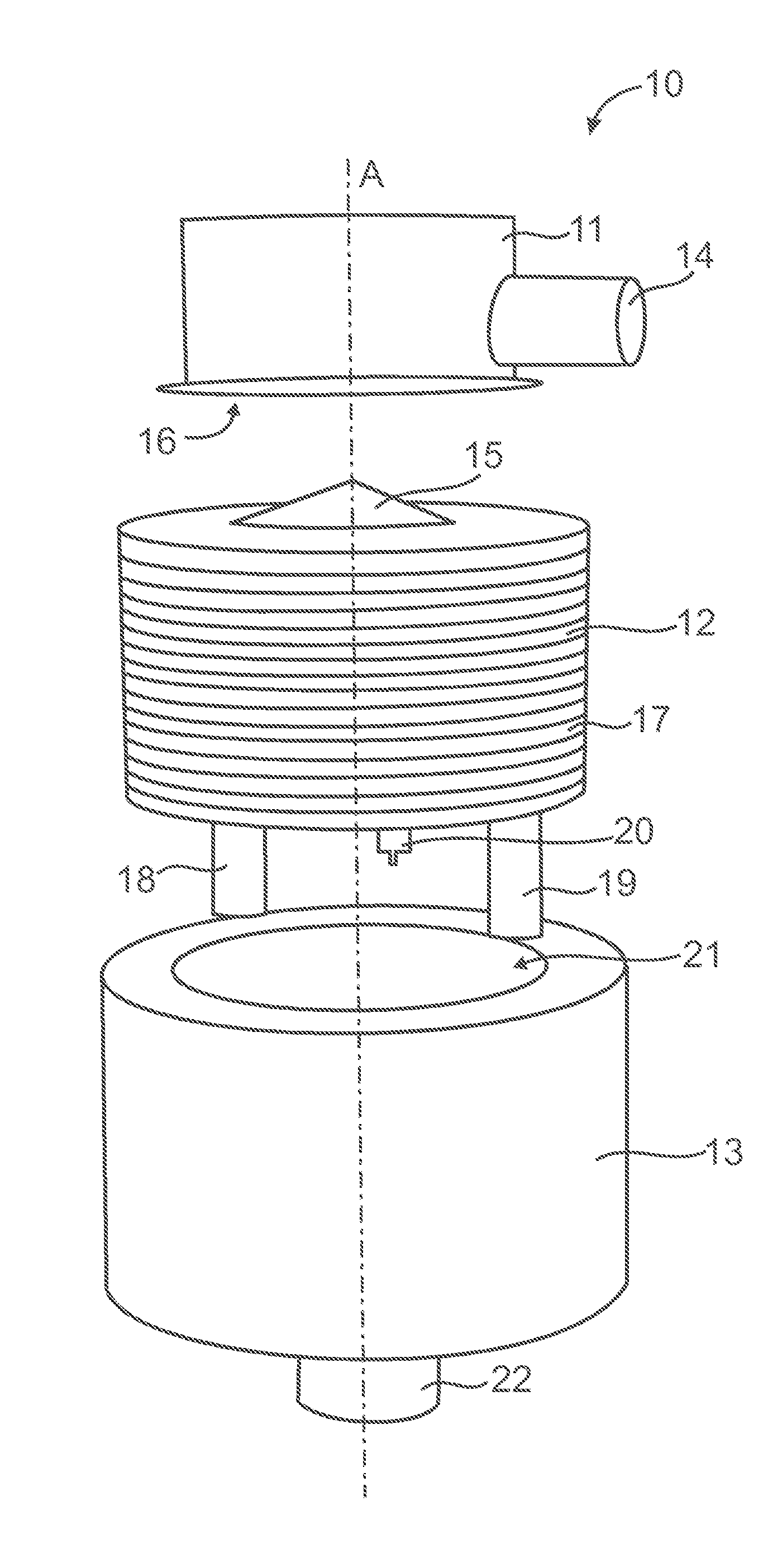

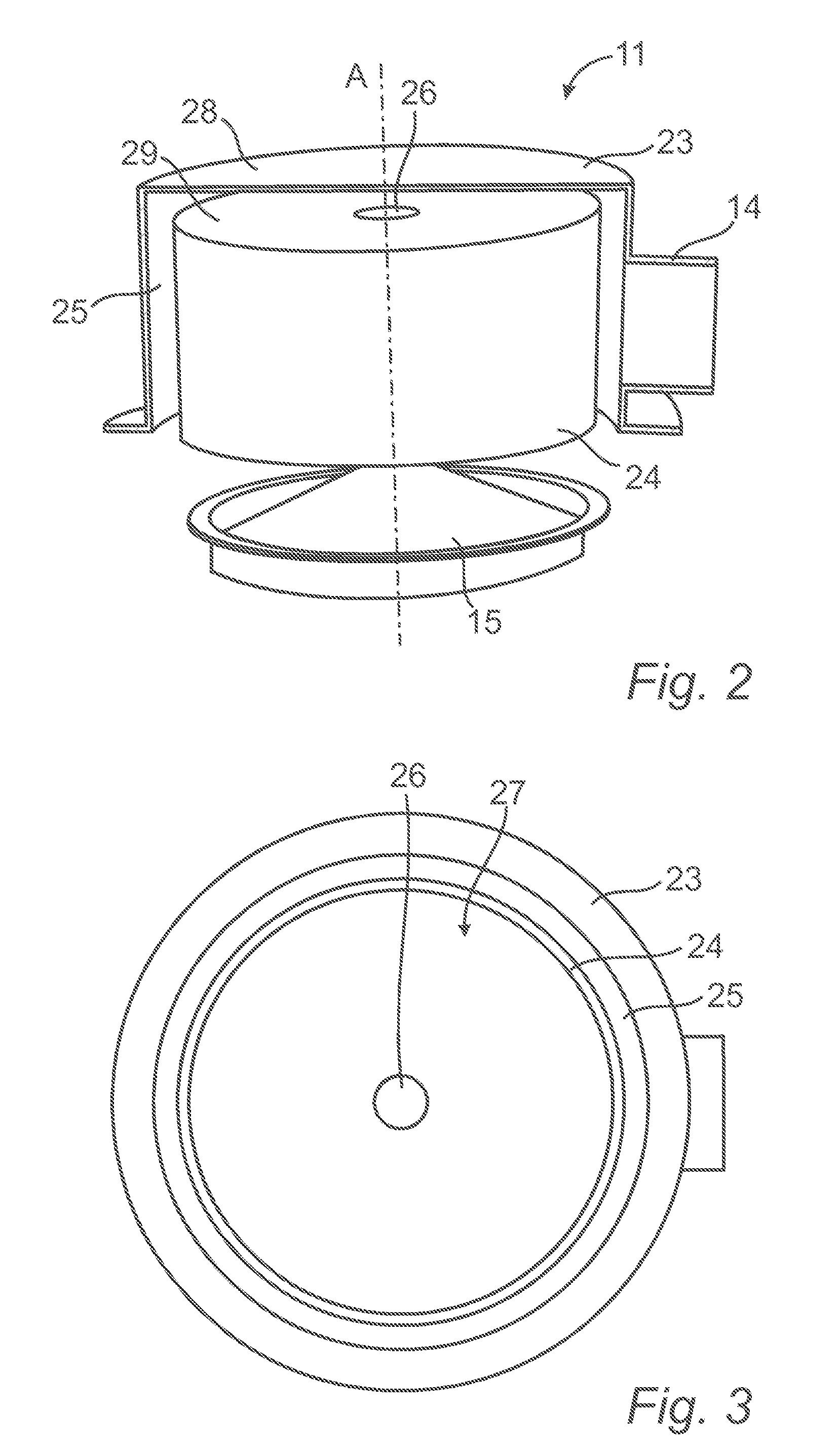

Plate heat exchanger plate for a plate heat exchanger, a plate heat exchanger comprising such plates, a device for heating comprising the plate heat exchanger and a method for heat exchange

ActiveUS20150285560A1Avoid overall overheatingEfficient heat recoveryRecuperative heat exchangersStationary conduit assembliesPlate heat exchangerHeat transmission

A heat exchanger plate for a plate heat exchanger (12) includes a first side, a second side and a centre point (P) through which an imaginary centre axis (A) extends in a direction perpendicular to a plane of the plate. The plate comprises a first port for a first medium, and at least a second port and a third port for a second medium. The plate further comprises a first sealing arranged on the second side around the first port, a second sealing arranged on the second side at a circumference of the plate, and a closed third sealing arranged between the first and second sealings to form a first heat transfer area and a second heat transfer area separated from the first heat transfer area. The second port is arranged in the first heat transfer area and the third port is arranged in the second heat transfer area.

Owner:HEATCORE

Selective Hydrogenation of Alkynyl-Containing Compounds

ActiveUS20130204056A1Efficient heat recoveryEnhance system efficiencyHydrocarbon by hydrogenationChemical industryHeating efficiencyThermal efficiency

A selective hydrogenation method is particularly effective in selectively hydrogenating alkynyl compounds, such as acetylene or methyl acetylene, over alkenyl compounds, such as ethylene. The method produces a relatively high quantity of heat during the selective hydrogenation reaction. This production of heat is, however, quite beneficial in that enough heat is produced such that a substantial portion of the produced heat can be recovered for heat efficiency purposes.

Owner:EXXONMOBIL CHEM PAT INC

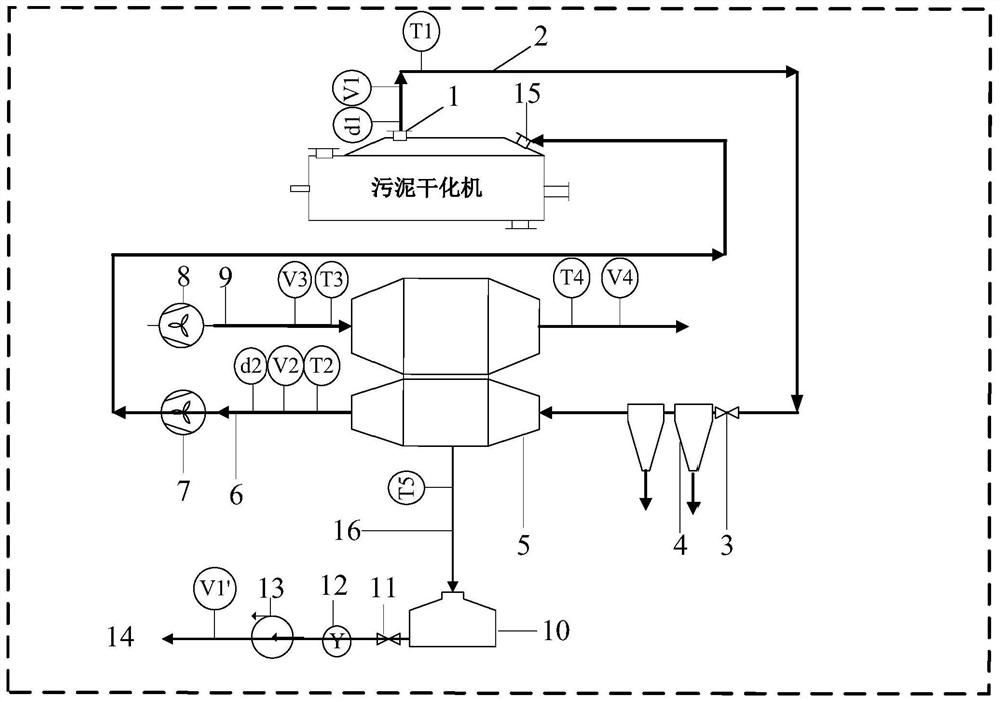

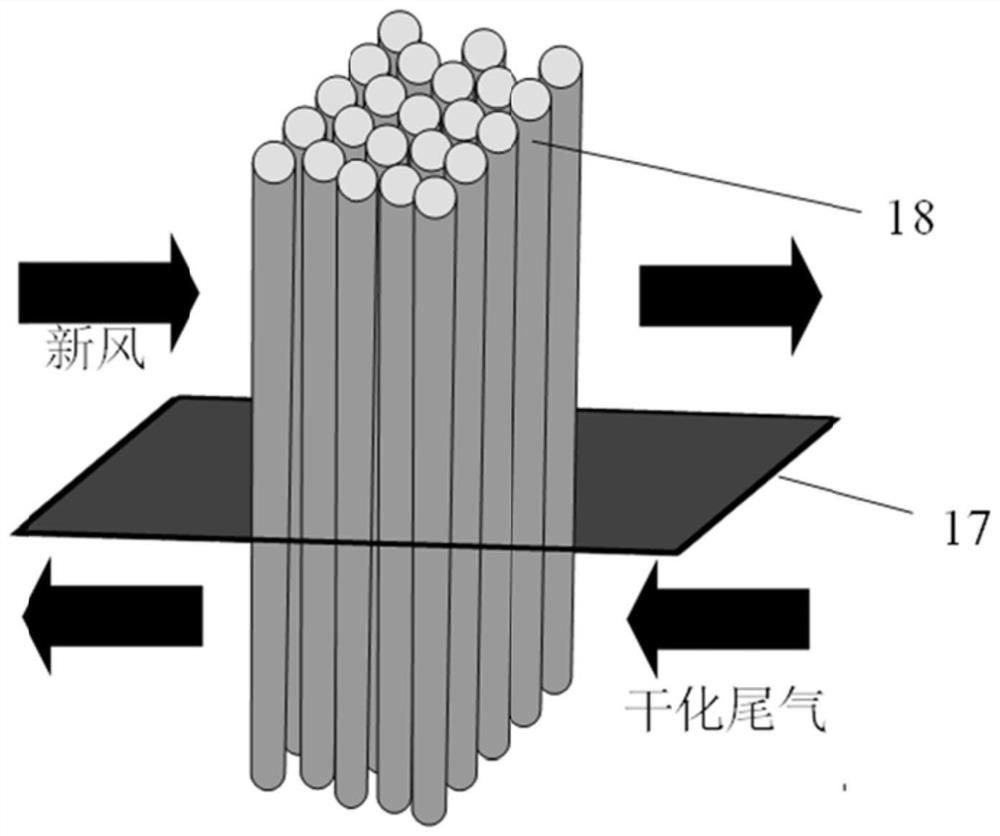

Heat energy recovery system for sludge drying tail gas of paddle dryer and use method of heat energy recovery system

ActiveCN113465422ASolve the problem of difficult energy utilizationEffective heat recoverySludge treatment by de-watering/drying/thickeningIndirect heat exchangersSludgeFresh air

The invention relates to a heat energy recovery system for sludge drying tail gas of a sludge drying incineration plant, in particular to a heat energy recovery system for the sludge drying tail gas of a paddle dryer, which is used for recovering heat of tail gas generated in the drying process of sludge in the paddle dryer by utilizing a two-phase closed thermosiphon and a use method of the heat energy recovery system. When the system runs, the sludge is dried, gas enters the evaporation section of a heat pipe under the action of an induced draft fan, through heat exchange with a working medium in the heat pipe, a large amount of heat released by the tail gas is transferred to the working medium in the heat pipe due to the efficient heat transfer performance of the heat pipe, so that the working medium in the heat pipe is subjected to phase change and ascends to be transferred to the condensation section of the heat pipe and exchange heat with fresh air entering the heat pipe through the induced draft fan; and after heat is transferred to the fresh air, the working medium is liquefied and enters the evaporation section again under the action of gravity, and the working medium circulates in the heat pipe to complete waste heat utilization of the sludge drying tail gas.

Owner:ZHEJIANG UNIV

A kind of intelligent fresh air unit with double plate and double cold source

ActiveCN105444310BImprove performanceImprove heat exchange efficiencyLighting and heating apparatusSpace heating and ventilation detailsPlate heat exchangerBusiness efficiency

The invention relates to a double-plate and double-cold-source intelligent air refresher unit. The double-plate and double-cold-source intelligent air refresher unit comprises a plate type heat exchange unit, a heat pump circulating unit and a spraying unit; the plate type heat exchange unit includes a first plate heat exchanger and a second plate heat exchanger arranged side by side from left to right; the heat pump circulating unit includes a compressor, a cooling condenser, a reheat condenser, an expansion valve and an evaporator; and the spraying unit includes a spraying device, a water collecting tank and a circulating pump. The double-plate and double-cold-source intelligent air refresher unit further comprises a surface cooler; outdoor fresh air reaches an indoor passage, provided with a fresh air-air supply way, after passing through an air supply channel of the first plate heat exchanger, an air supply channel of the second plate heat exchanger, the surface cooler, the evaporator and the reheat condenser in sequence; and indoor returned air is exhausted out of an outdoor passage, provided with a returned air-exhaust air way, after passing through a returned air channel of the second plate heat exchanger, a returned air channel of the first plate heat exchanger and the cooling condenser in sequence. The double-plate and double-cold-source intelligent air refresher unit has the advantages of simple structure, complete functions, stable operation, low cost and high energy-efficiency ratio, and can realize year-round high-efficiency and low-energy-consumption operation.

Owner:HUNDRED TECH CO LTD +1

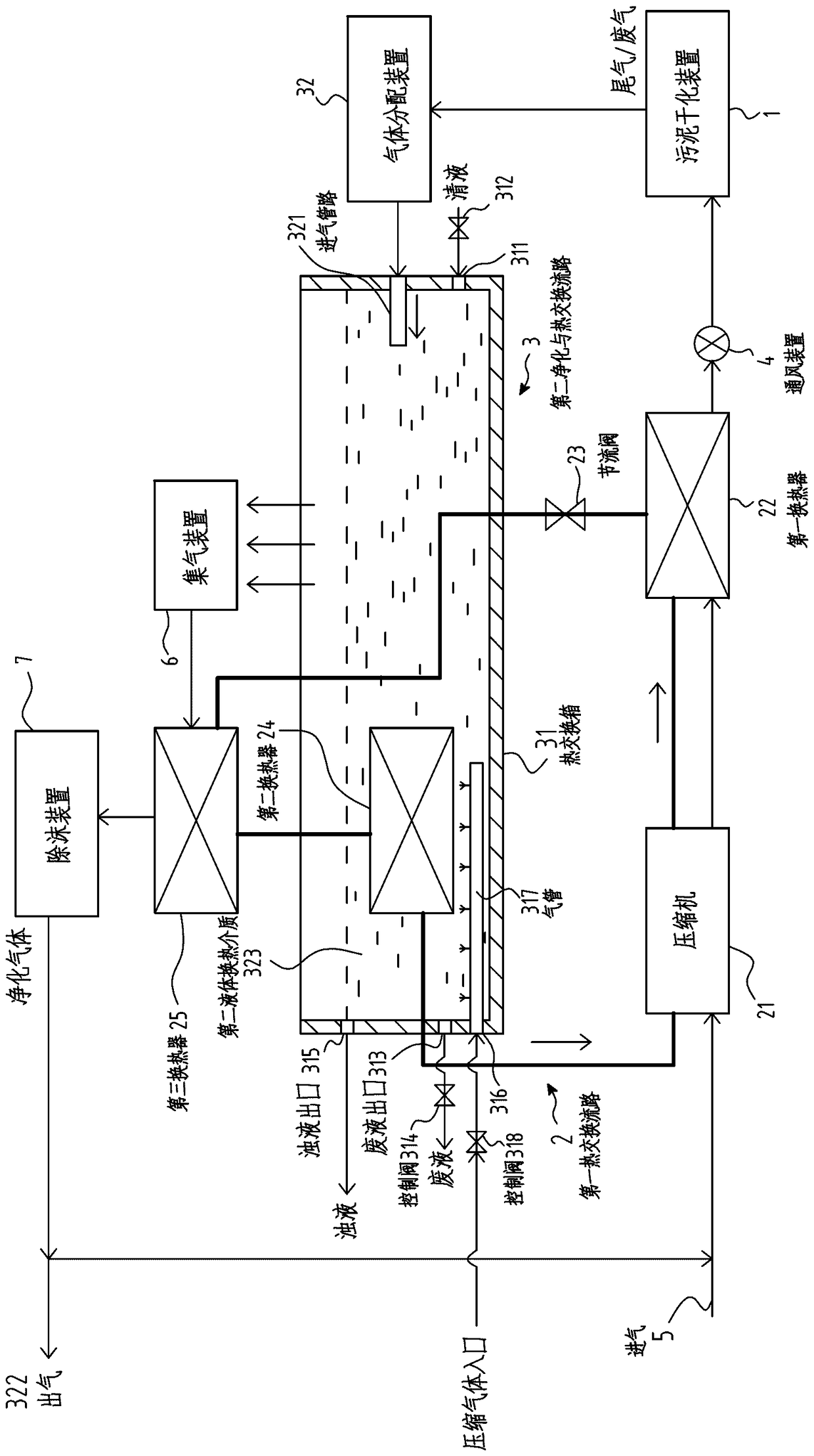

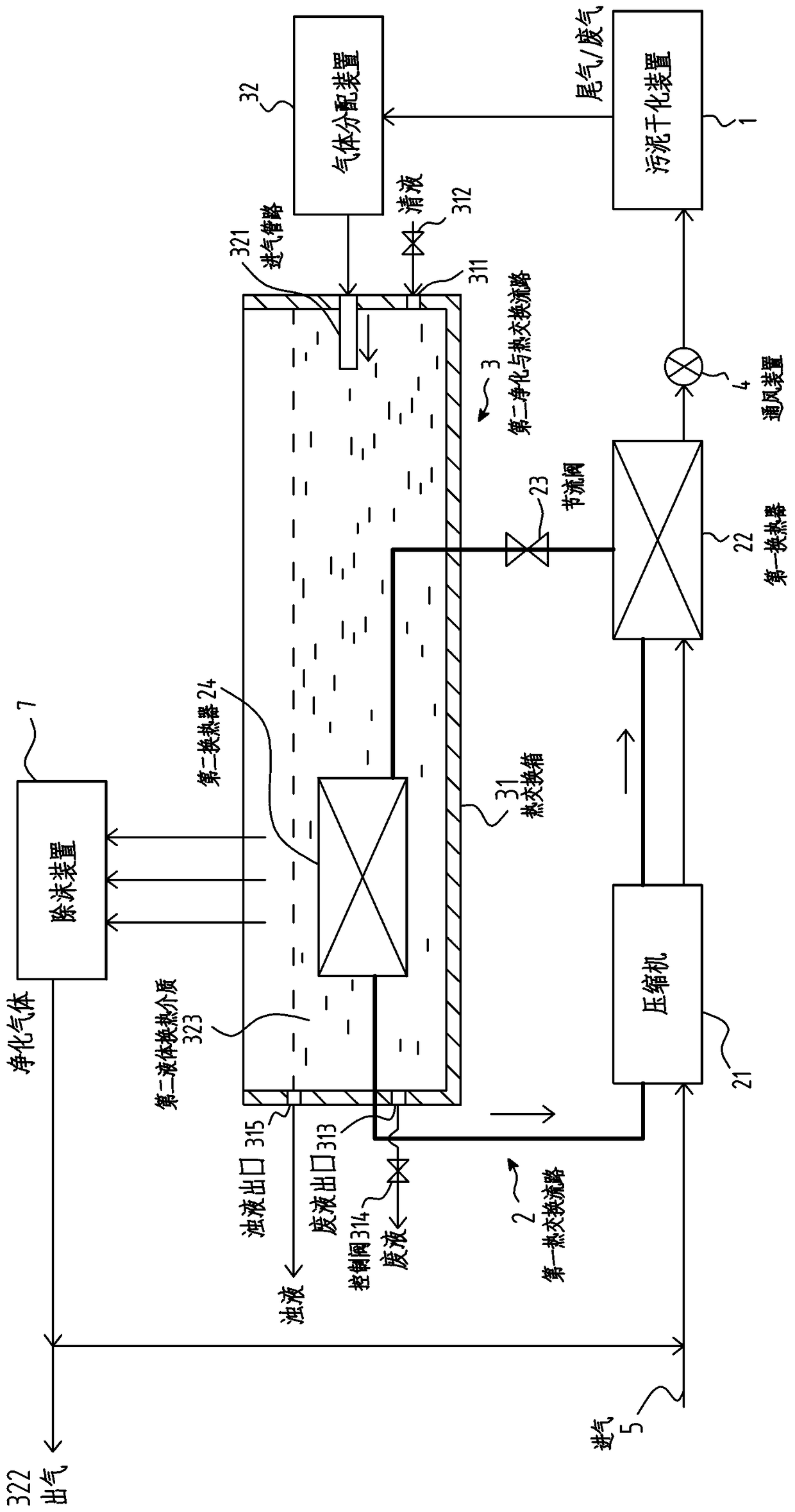

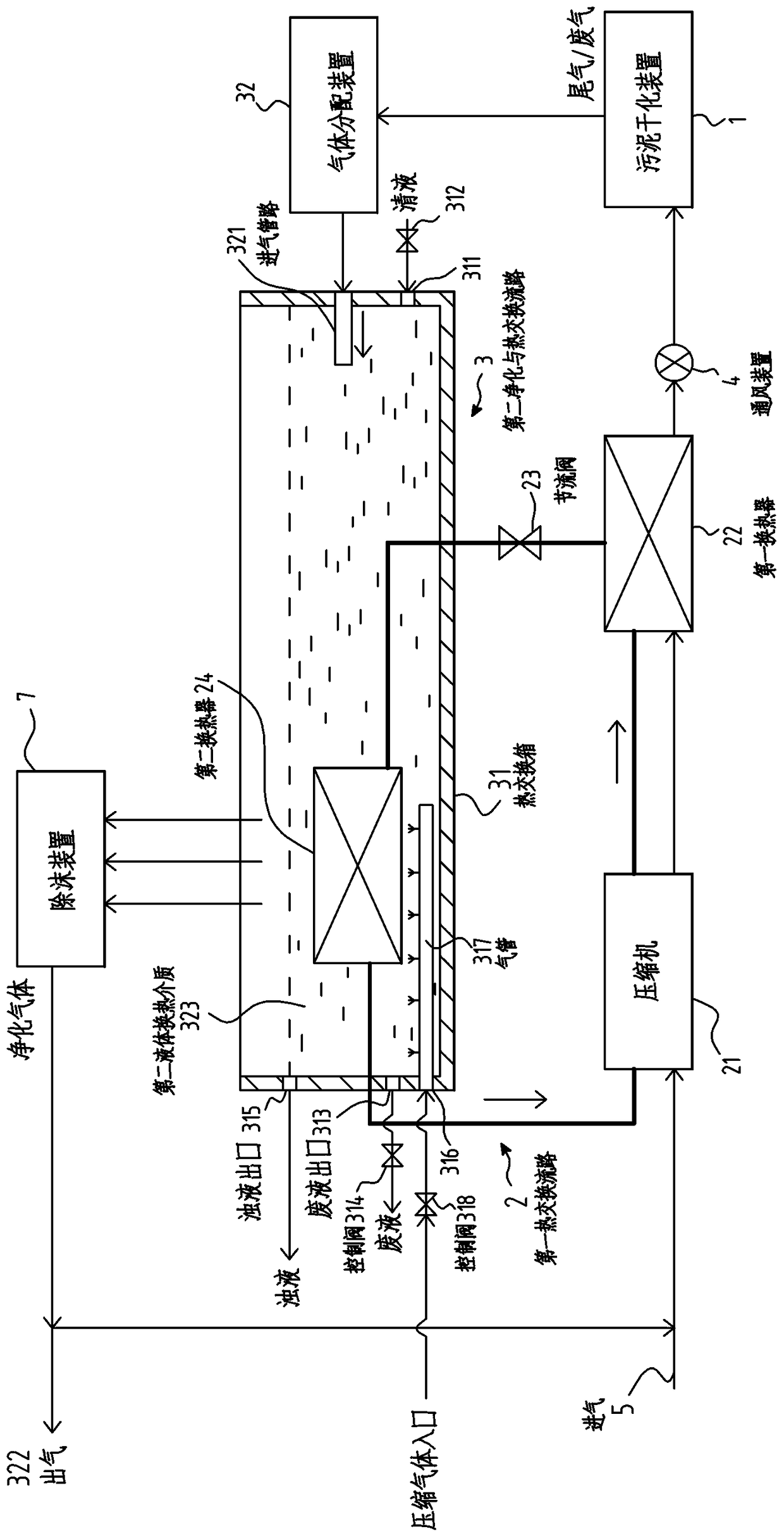

Tail gas purification and heat recovery system and method for sludge treatment

PendingCN109141064AImprove heat recovery efficiencyImprove drying efficiencySludge treatment by de-watering/drying/thickeningHeat pumpsEngineeringRecuperator

The invention relates to a tail gas purification and heat recovery system and method for sludge treatment. The tail gas purification and heat recovery system comprises a first heat exchange flow pathand a second purification and heat exchange flow path and a third gas purification and recovery flow path, ; the first heat exchange flow path comprises a first heat exchanger and a second heat exchanger arranged downstream of the first heat exchanger, and a first heat exchange medium is circulated in the first heat exchange flow path so as to heat treatment gas used for sludge treatment in the first heat exchanger; and the second purification and heat exchange flow path comprises a heat exchange tank containing a second liquid heat exchange medium, the tail gas obtained after sludge treatmentis discharged into the heat exchange tank, is cleaned by a second liquid heat exchange medium in the heat exchange box and transmits heat to the second liquid heat exchange medium so as to be cooled,the second heat exchanger is in heat exchange relation with the second liquid heat exchange medium in the heat exchange box so as to transfer the heat of the second liquid heat exchange medium to thefirst heat exchange medium in the second heat exchanger. According to the third purification gas recovery flow path, through the third gas purification and recovery flow path, at least a part of thetail gas purified by the heat exchange box is guided back to the first heat exchanger through a gas inlet so as to circularly utilize the processing gas.

Owner:广州正晟科技有限公司

High-efficiency catalytic oxidation device

PendingCN108273322AImprove processing efficiencyEfficient heat recoveryDispersed particle filtrationTransportation and packagingCombustorCombustion chamber

The invention discloses a high-efficiency catalytic oxidation device. The high-efficiency catalytic oxidation device comprises a heat exchanger, a catalytic tank and a filter, wherein one end of the filter is a waste gas inlet end, and the other end of the filter is connected with a fan through a first pipe; the fan is connected with the inlet end of the heat exchanger through a second pipe; the outlet end of the heat exchanger is communicated with the catalytic tank through a third pipe; a combustion chamber and a catalytic bed are arranged inside the catalytic tank; a combustor is arranged inside the combustion chamber; the catalytic tank is connected with the heat exchanger; the catalytic bed is arranged on one side of the combustion chamber; the heat exchanger is further connected witha discharge pipe. The high-efficiency catalytic oxidation device is novel in structure design, has the advantages of low wind resistance, high efficiency and high temperature resistance, and improvesthe waste gas treatment efficiency.

Owner:江苏中车云汇科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com