Method and system for preparing propylene

A technology of propylene and propane, applied in the field of propylene preparation, can solve the problems of large investment, high energy consumption, unstable operation of the device, etc., and achieve the effects of reducing energy consumption, reducing load and improving operation stability of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

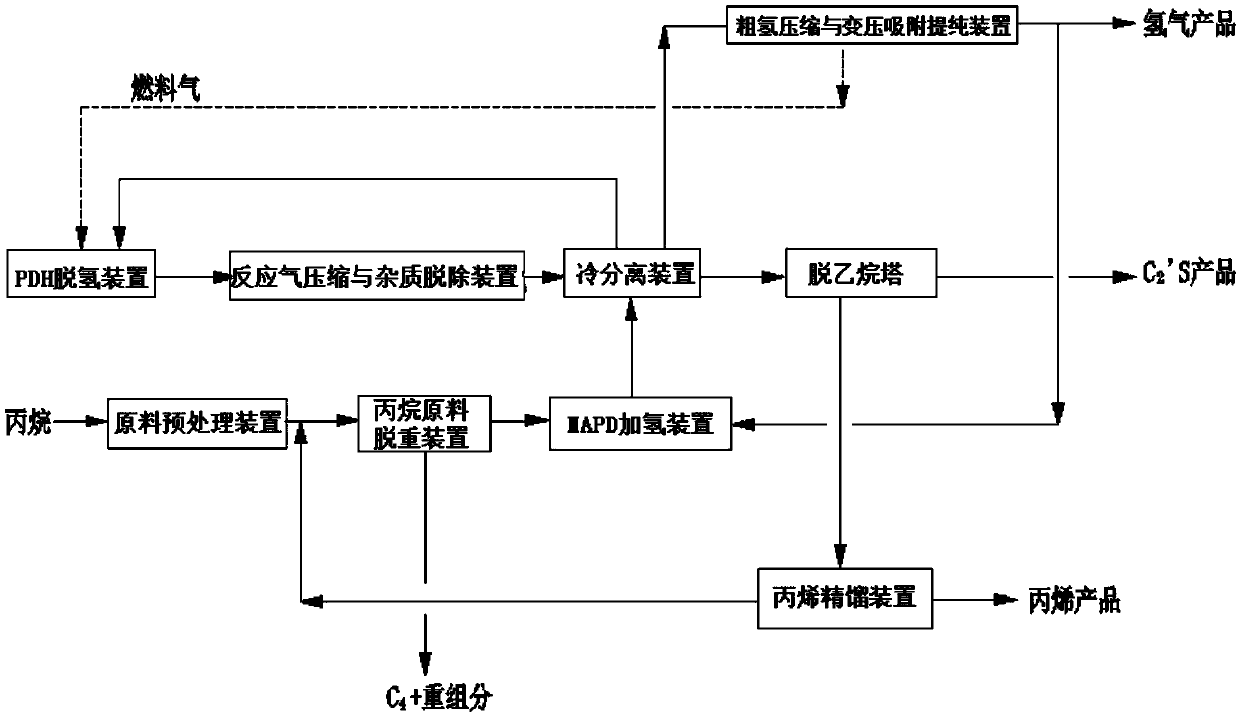

[0064] Such as figure 1As shown, the fresh propane raw material of 99.28 kg is removed after nitrogen oxides, heavy metals and water, and then introduced into a heavy removal device for heavy components such as carbon four. The content of methyl acetylene in the fresh propane raw material is 120ppmmol, The content of propadiene is 50 ppm mol. The deheavy treated material is then introduced into the MAPD hydrogenation unit for MAPD hydrogenation treatment to remove impurities such as methyl acetylene and propadiene. The hydrogen distribution amount of the MAPD hydrogenation treatment is 1.7. The hydrotreated liquid C was then 3 The material is introduced into the cold separation device, and becomes gaseous C after heat exchange treatment in the cold separation device. 3 The material is introduced into the PDH dehydrogenation unit for PDH dehydrogenation treatment. The material after dehydrogenation treatment is compressed, dechlorinated, dried, and desulfurized, and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com