Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116 results about "Propadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propadiene or allene is the organic compound with the formula H₂C=C=CH₂. It is the simplest allene or compound with two adjacent carbon double bonds, and can also be identified as allene. As a constituent of MAPP gas, it has been used as a fuel for specialized welding.

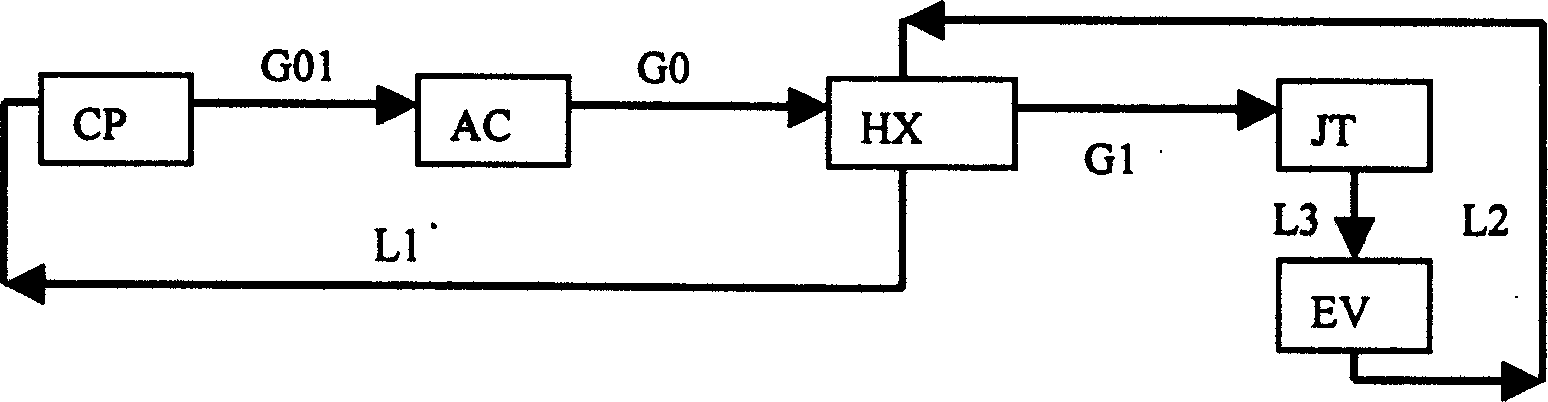

Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

The invention relates the multicomponent mixed working substance used for preparing dual-temperature by single-machine vapor compression refrigerator. The low temperature is between -60- -40Deg.C and the high temperature is between -25- 10Deg.C. The multicomponent mixed working substance comprises lower boiling working substance and high boiling working substance. The lower boiling working substance comprises tetrafluoromethane, ethylene, ethane, fluoroethylene, trifluoromethane, fluoromethane, hydrofluoeic ether, carbon dioxide, difluoromethane and penfluoroethane; the high boiling working substance comprises trifluoro-thane, hydrofluoeic ether, propylene, propane, perfluoropropylamine, propadiene, cyclopropane, difluo-monochloromethane, penta-monochloroethane, perfluoroethane, difluoroethane, isobutene, butane, butylenes, isobutylene, sevofluoropropane, hexafluoropropane, penfluoropropane and tetrachloromonofluoroethane.

Owner:XI AN JIAOTONG UNIV

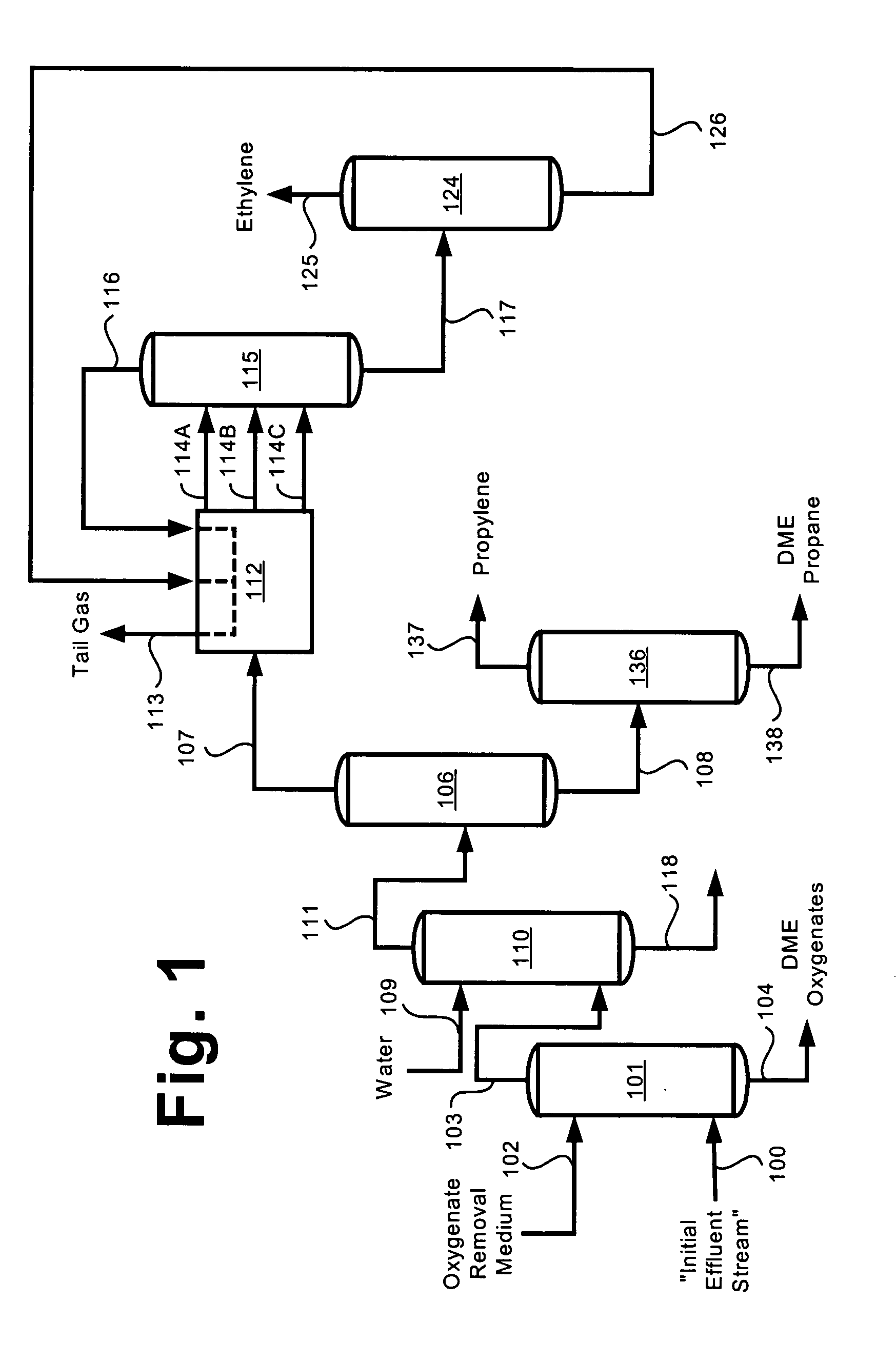

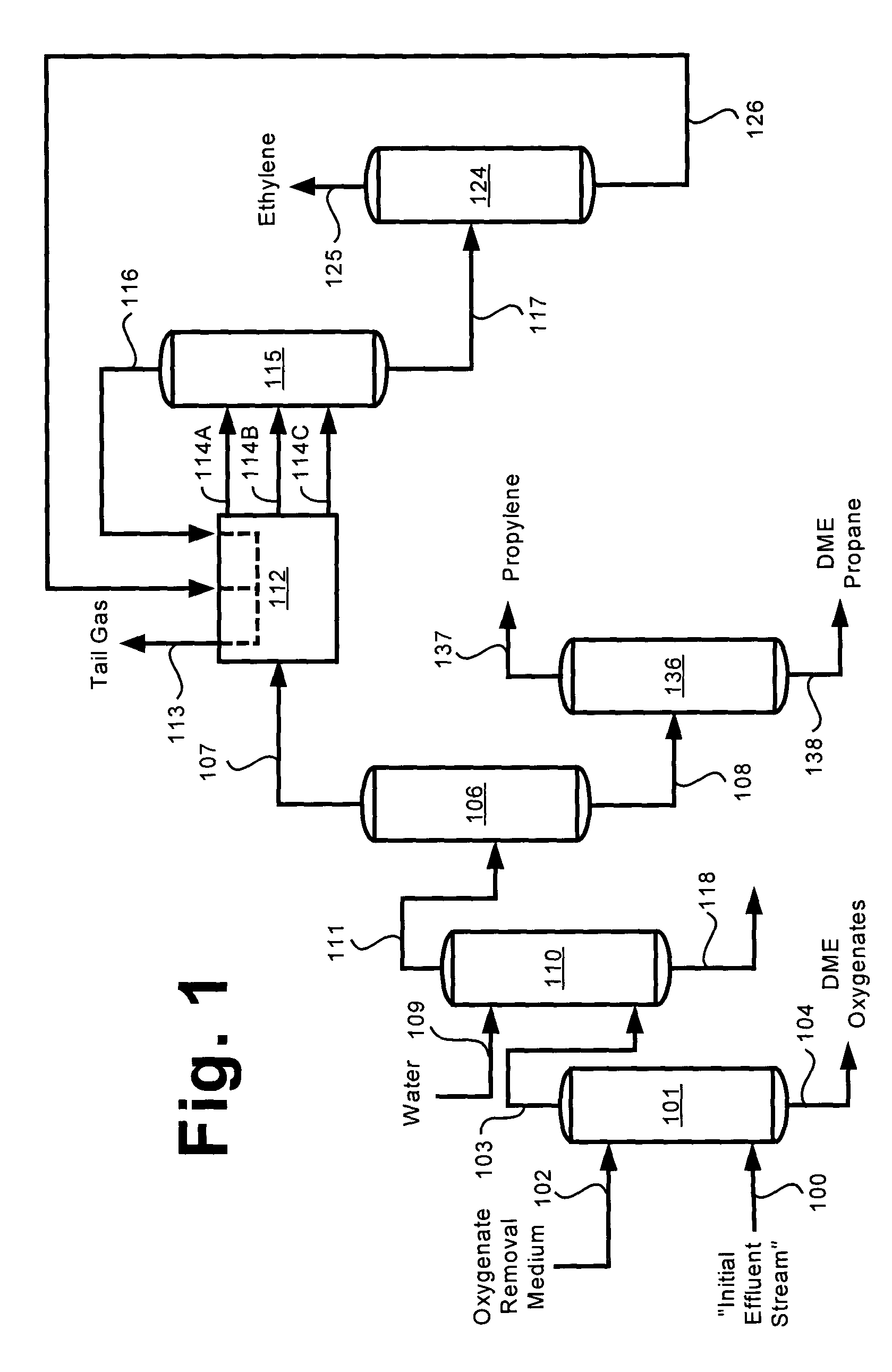

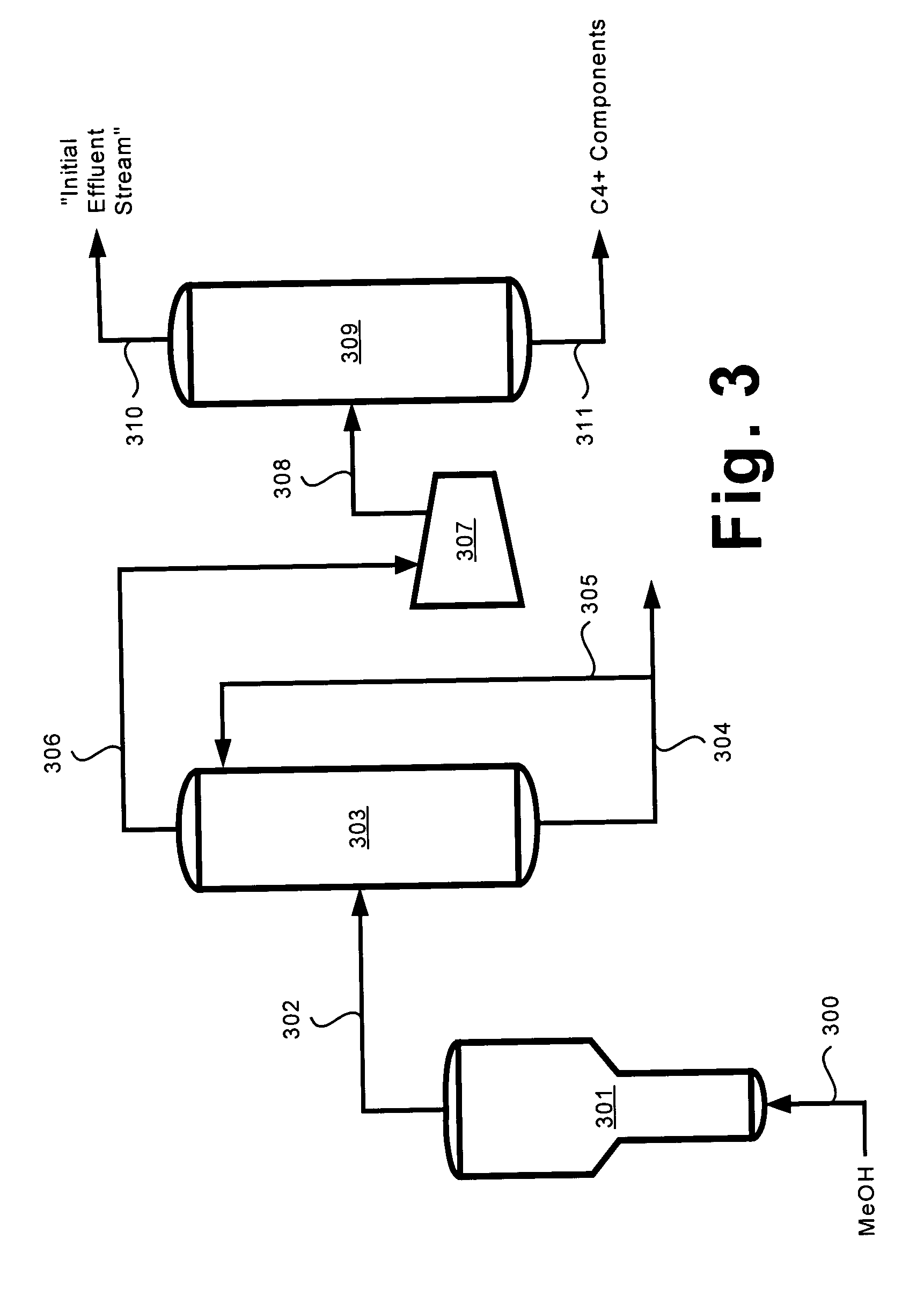

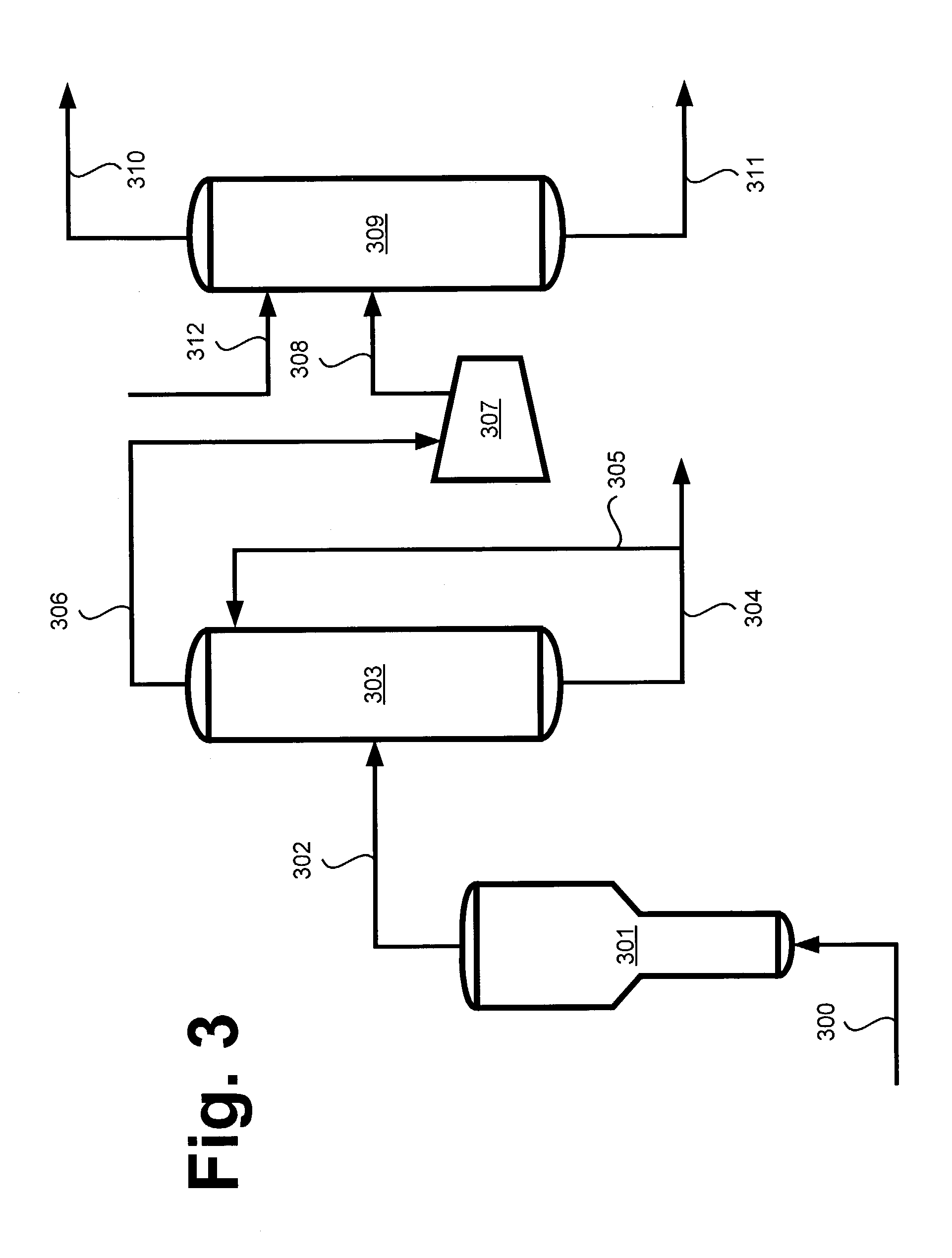

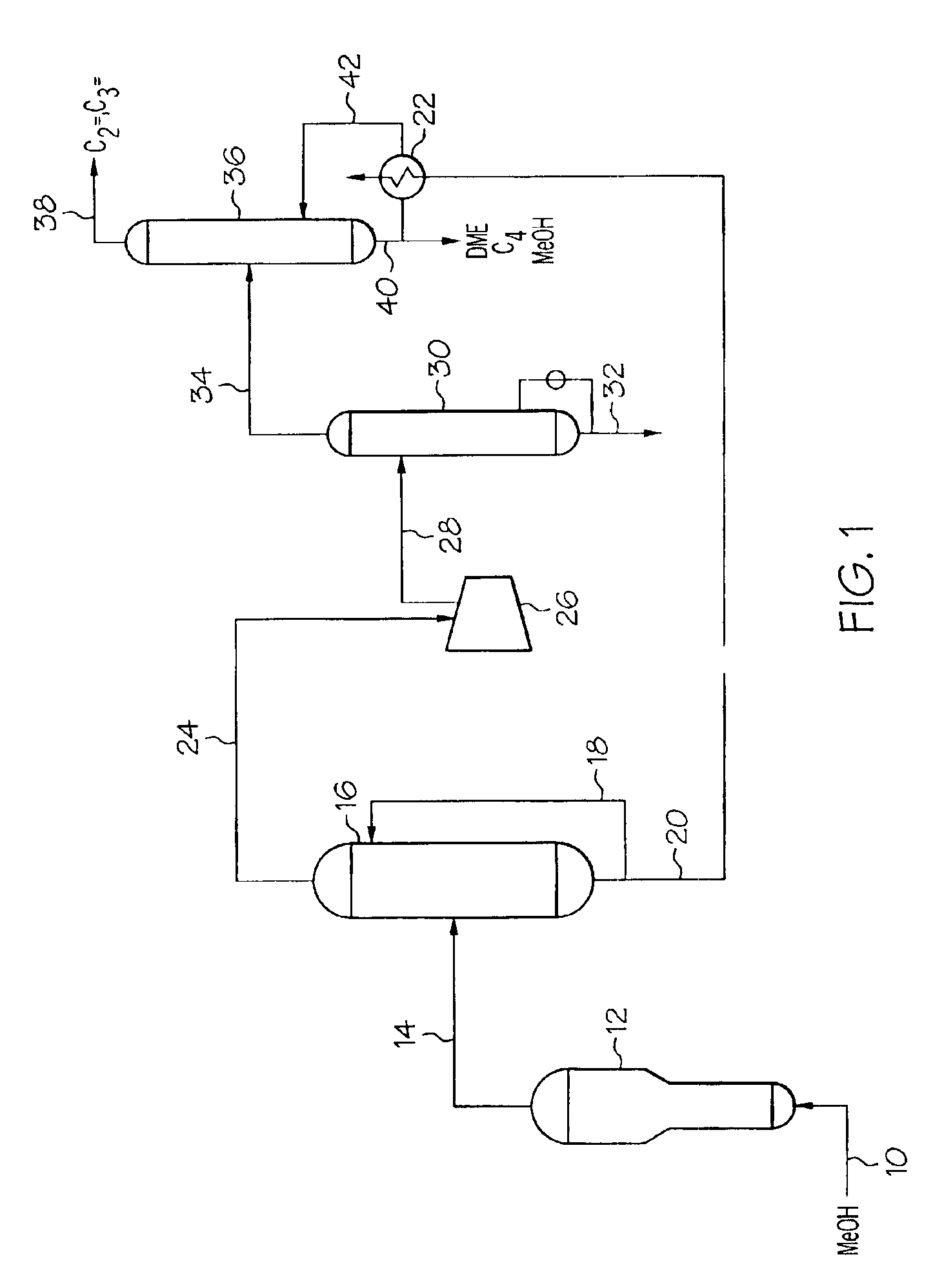

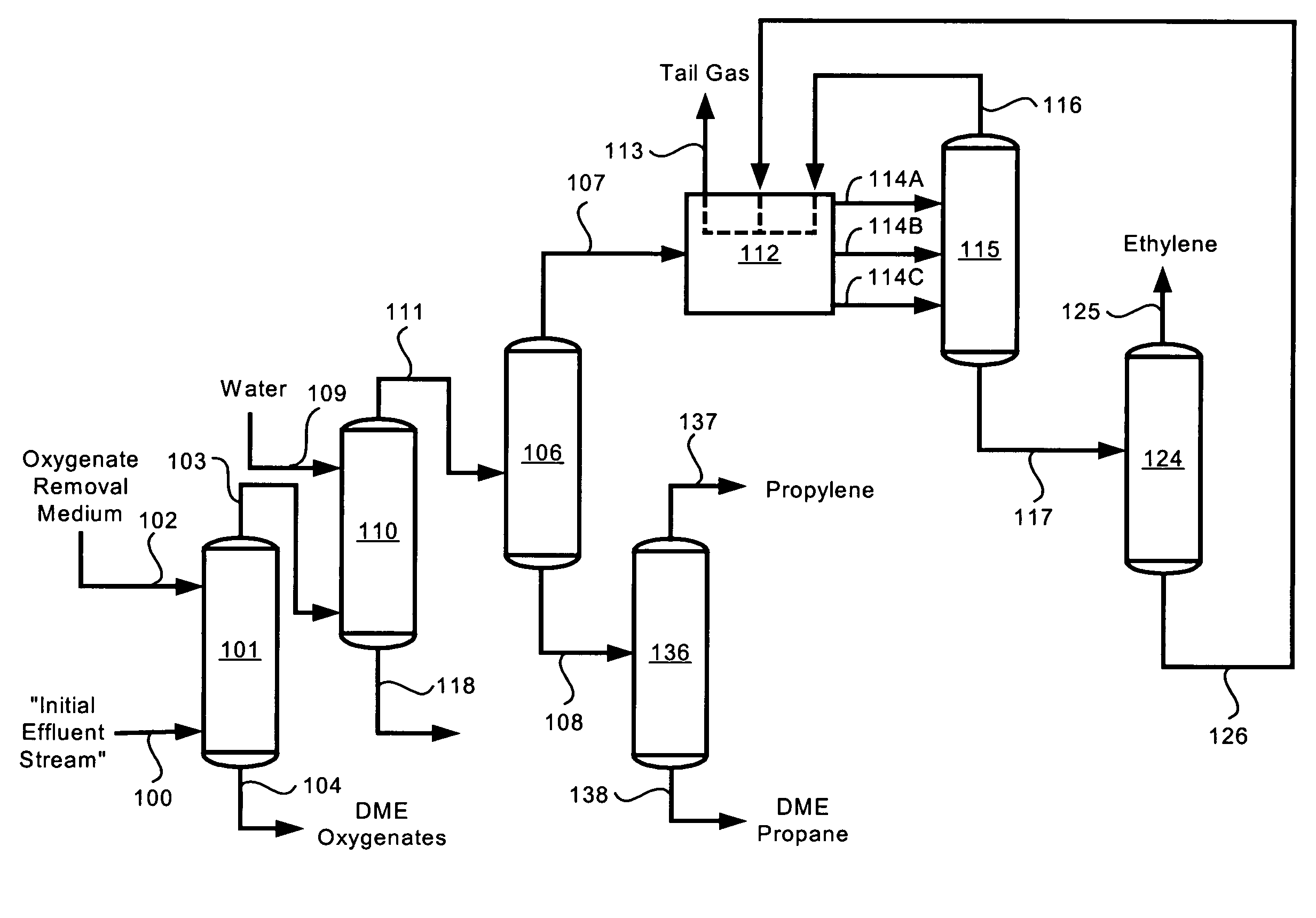

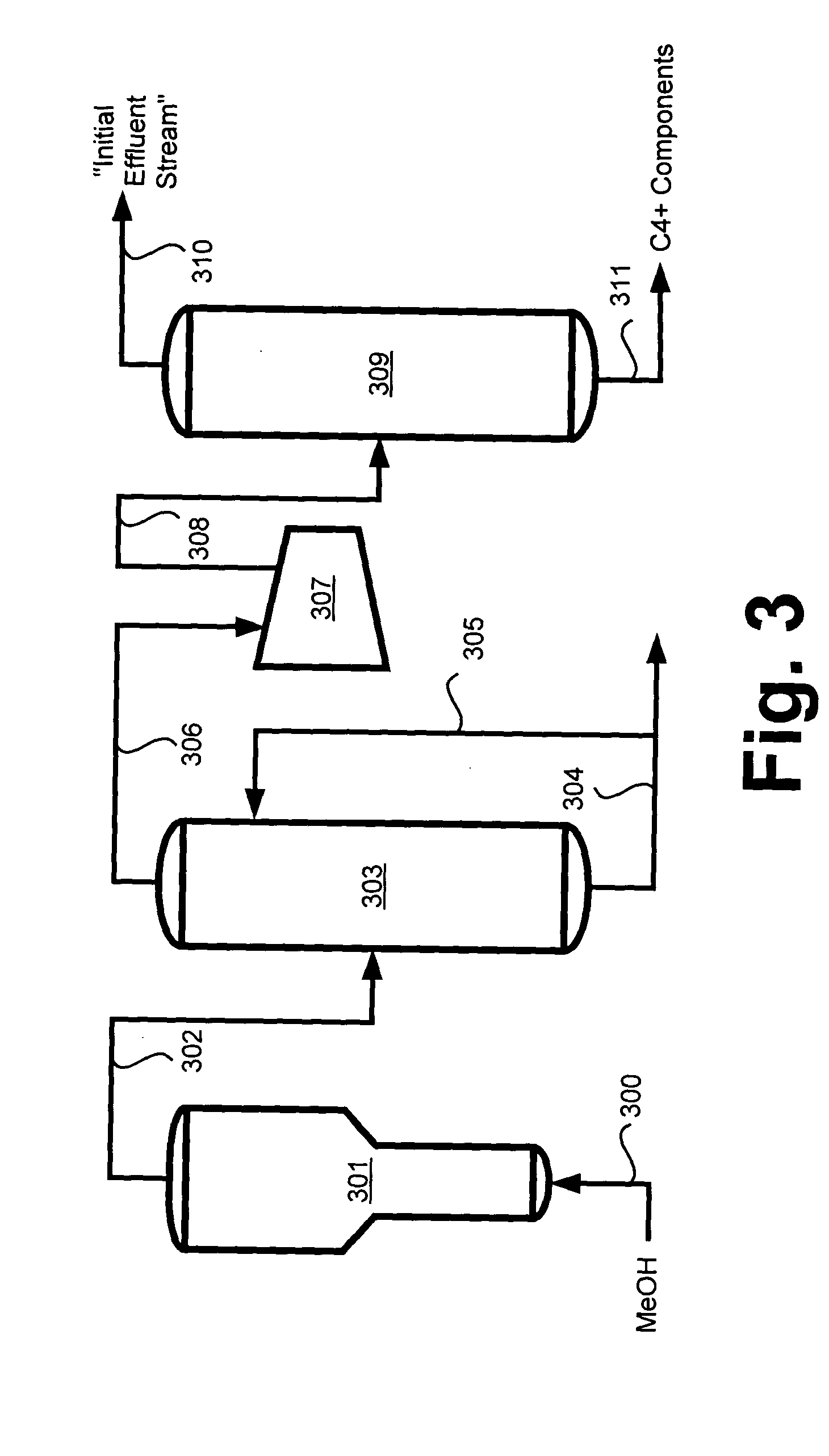

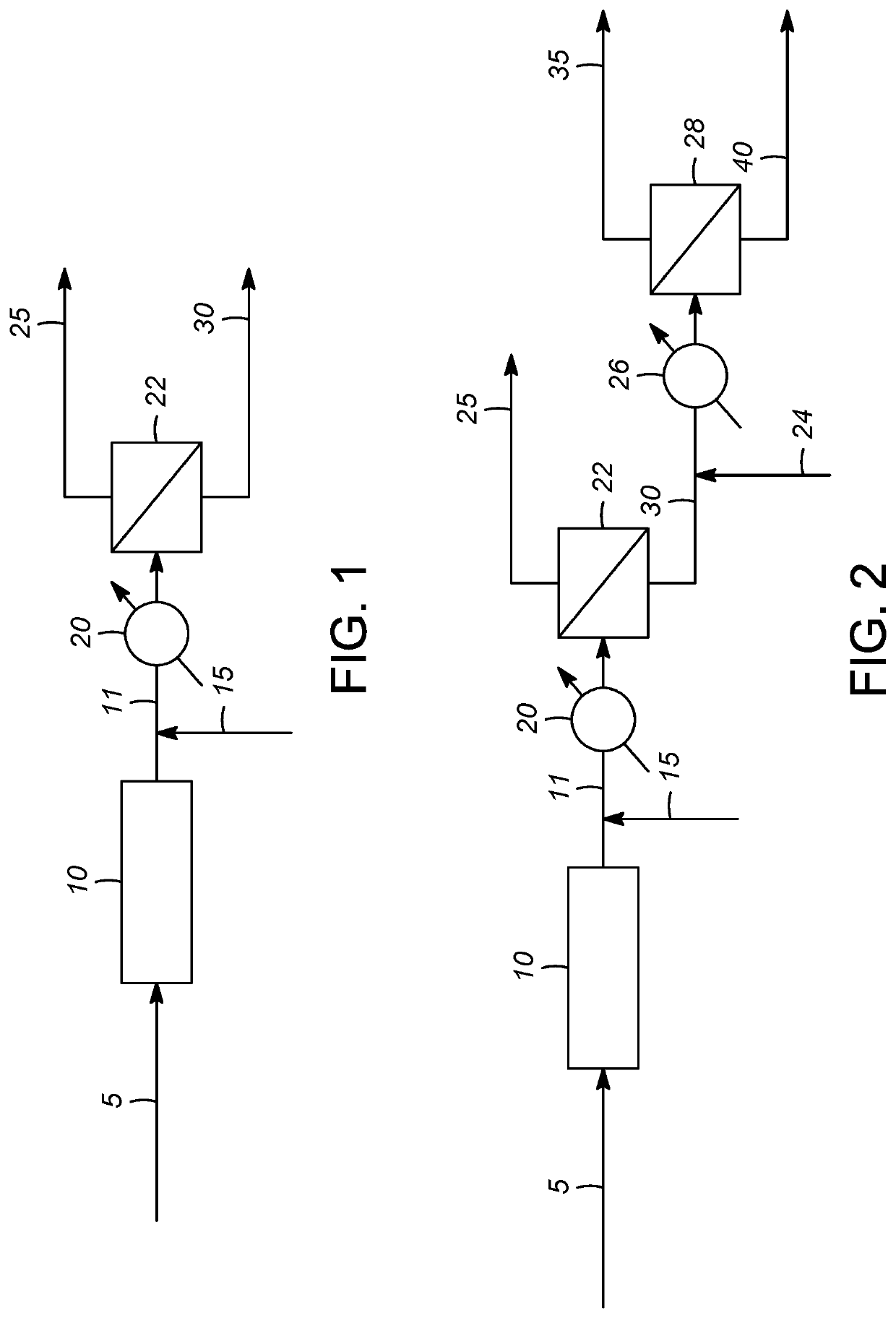

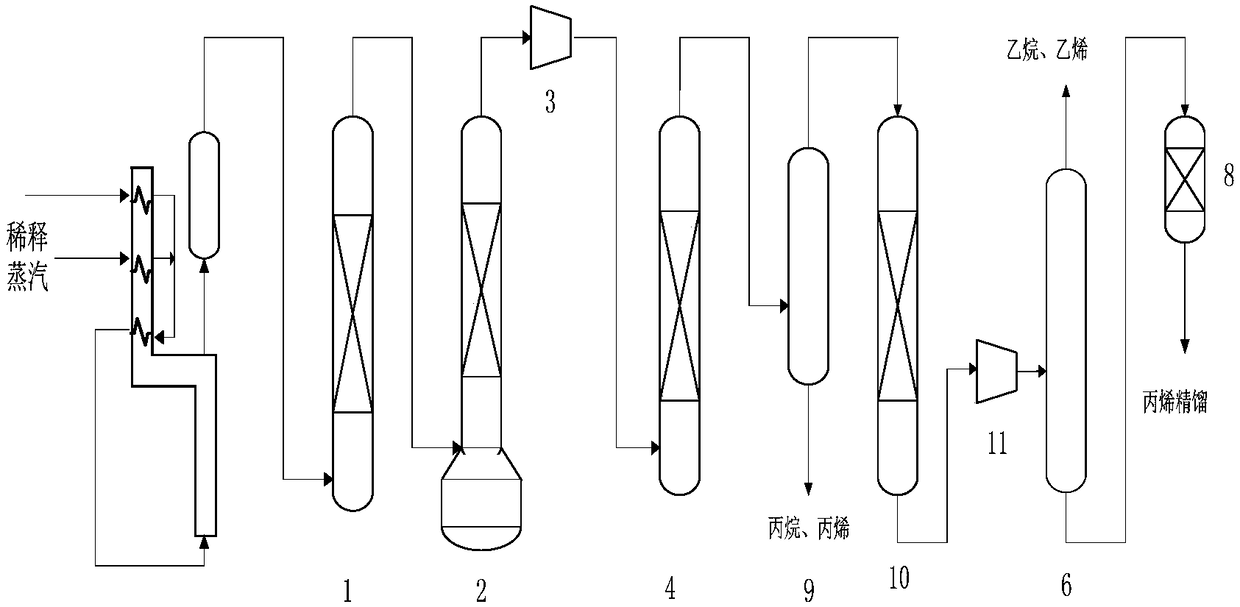

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS20050033104A1Efficient removalMinimizing equipment countHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

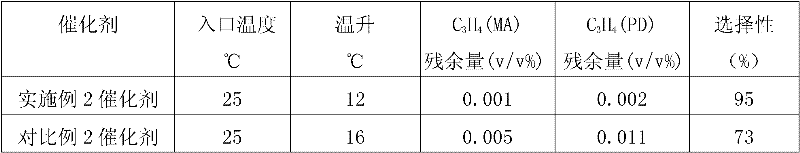

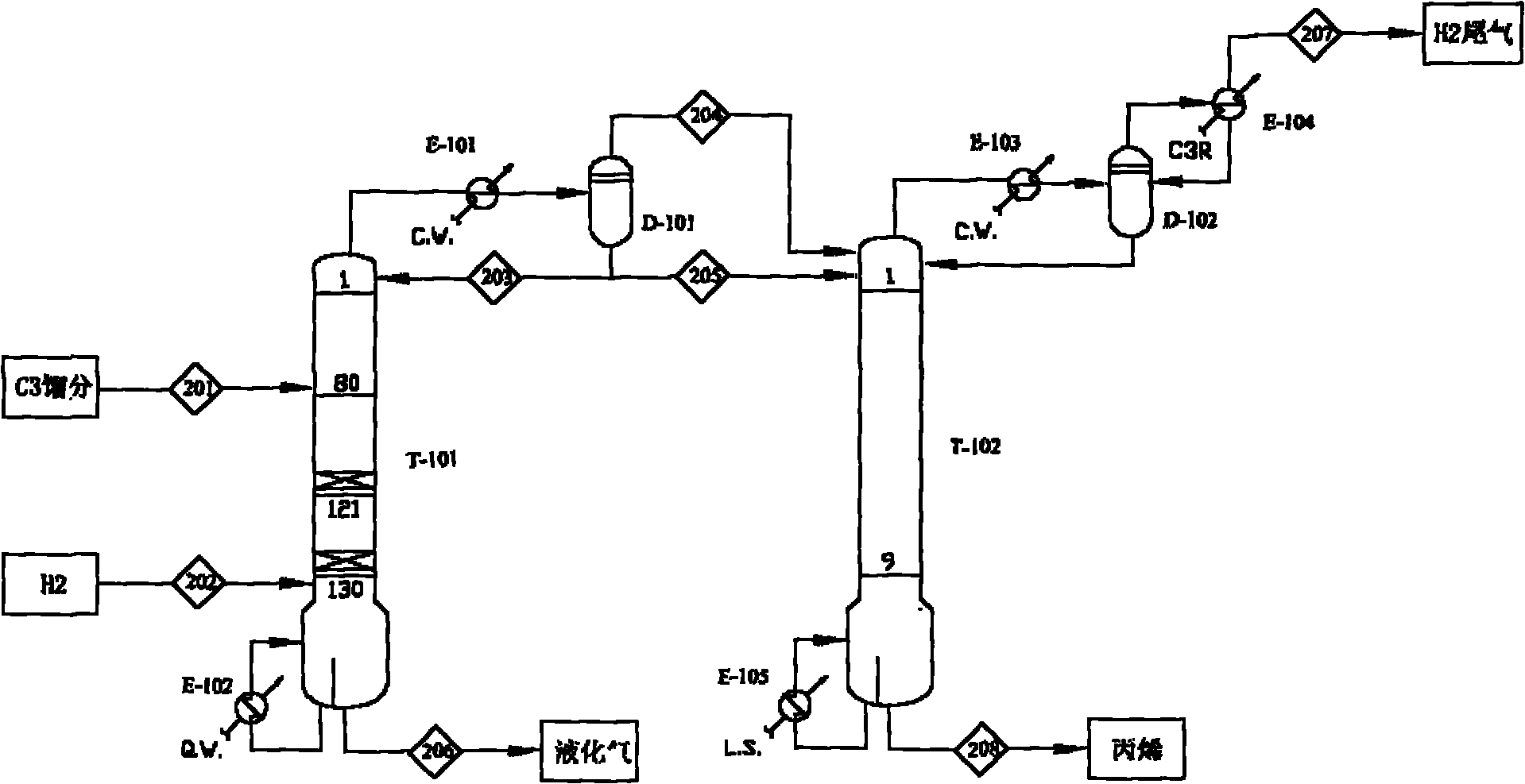

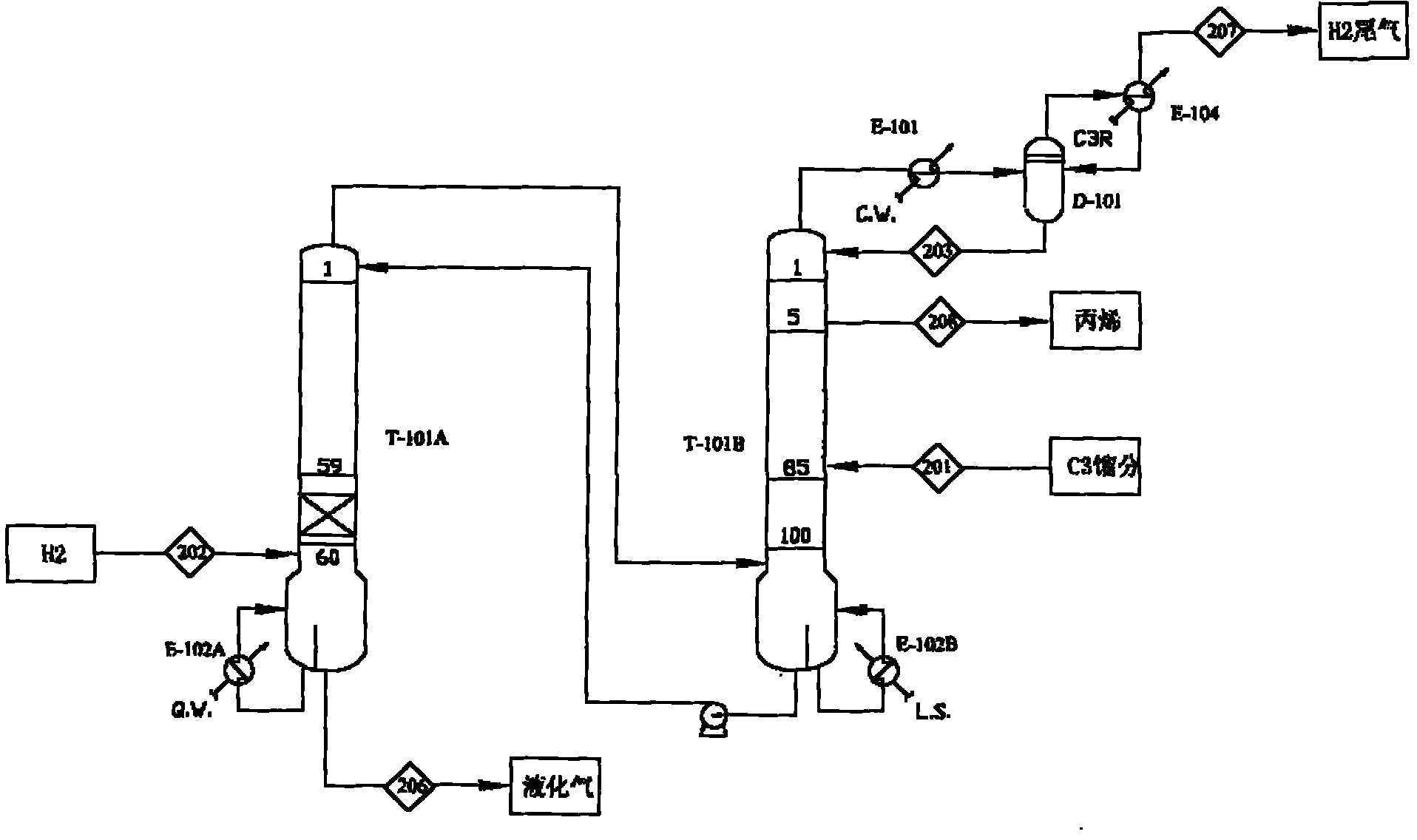

Selective hydrogenation method for C3 fraction

ActiveCN102206132ALower trend for deep hydrogenationEnhanced catalytic reaction selectivityHydrocarbon purification/separationHydrocarbonsPolymer metalFixed bed

The invention relates to a selective hydrogenation method for a C3 fraction. The method is characterized in that: an adiabatic bed reactor is provided with a Pd-Ag catalyst, the Pd-Ag catalyst contains Al2O3 used as a carrier, 0.2-0.4% of Pd and preferable 0.05-0.2% of Ag based on 100wt% of the catalyst, the specific surface area of the catalyst is 15-100 m<2> / g, the pore volume of the catalyst is 0.3-0.6 mL / g, and the catalyst forms an organic polymer metal complex during preparation process; and the hydrogenation process conditions are as follows: the inlet temperature of the fixed bed reactor is 10-50 DEG C, the reaction pressure is 2.5-3.5 MPa, the liquid phase volume space velocity is 5-100 h<-1> and the mol ratio of hydrogen to propyne and propadiene is (1-5):1. The selective hydrogenation method provided by the invention improves the hydrogenation activity and selectivity, greatly broadens the reaction space velocity range, greatly improves the running safety and efficiency of an apparatus and greatly improves economical benefits of the apparatus.

Owner:PETROCHINA CO LTD

Direct epoxidation process using modifiers

The invention is a process for epoxidizing an olefin with hydrogen and oxygen in the presence of a noble metal-containing titanium or vanadium zeolite and a modifier selected from the group consisting of carbon monoxide, methylacetylene, and propadiene. The process results in significantly reduced alkane by-product formed by the hydrogenation of olefin compared to processes that do not use the carbon monoxide, methylacetylene, and / or propadiene modifier.

Owner:LYONDELL CHEM TECH LP

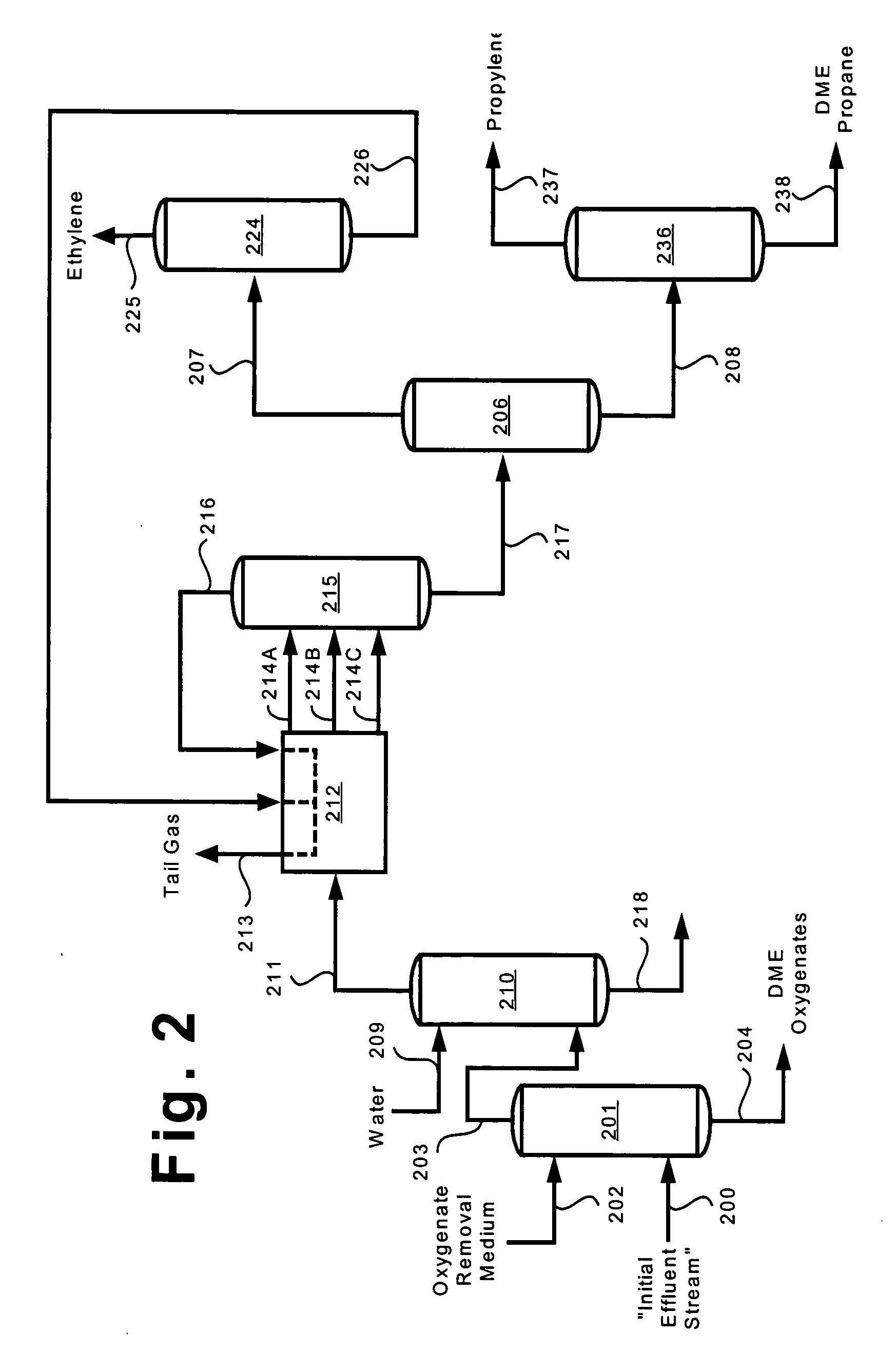

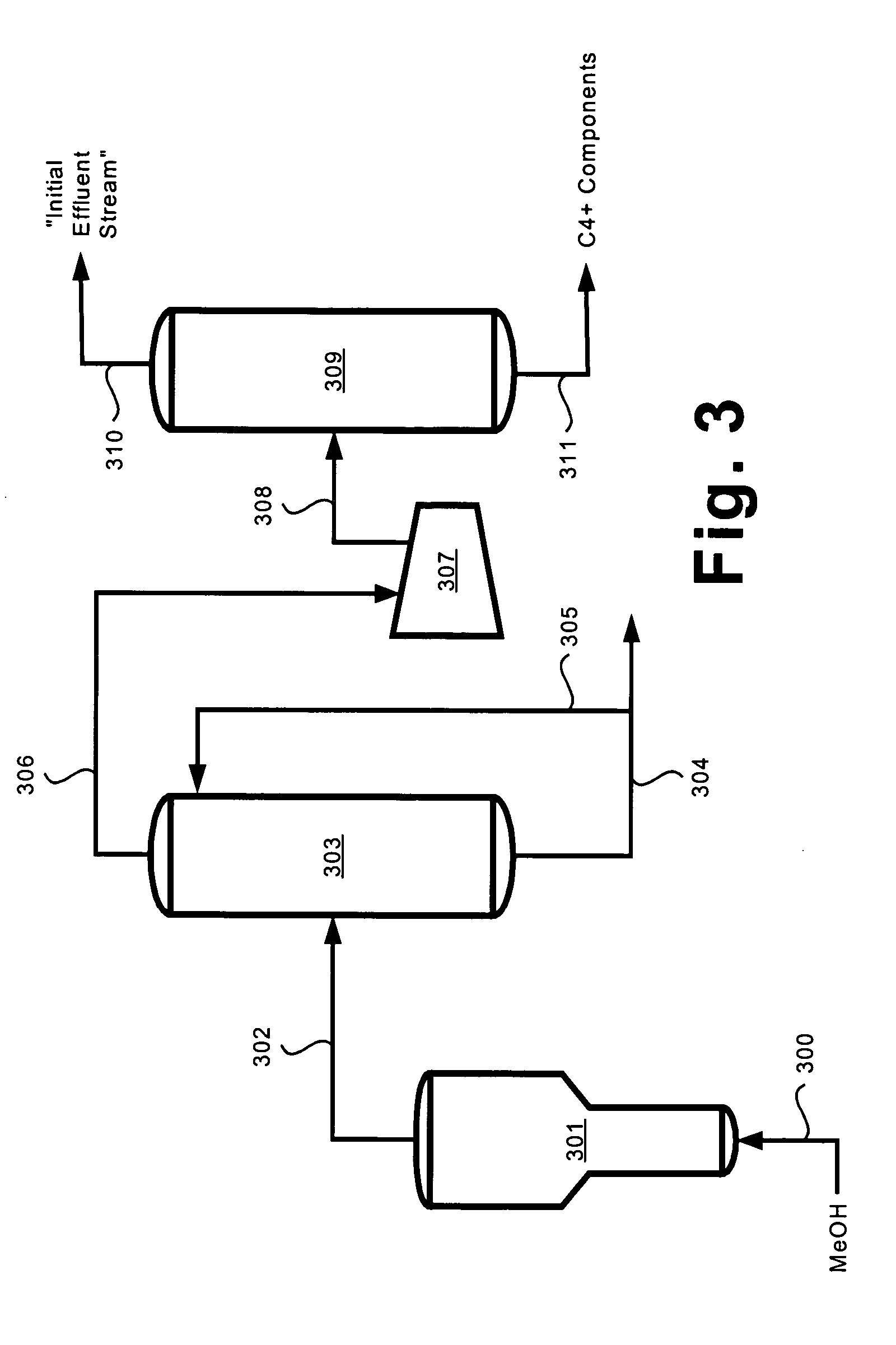

Recovery of ethylene and propylene from a methanol to olefin reaction system

ActiveUS20050033103A1Efficient removalMinimizing equipment countLiquid hydrocarbon mixture productionHydrocarbonsPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

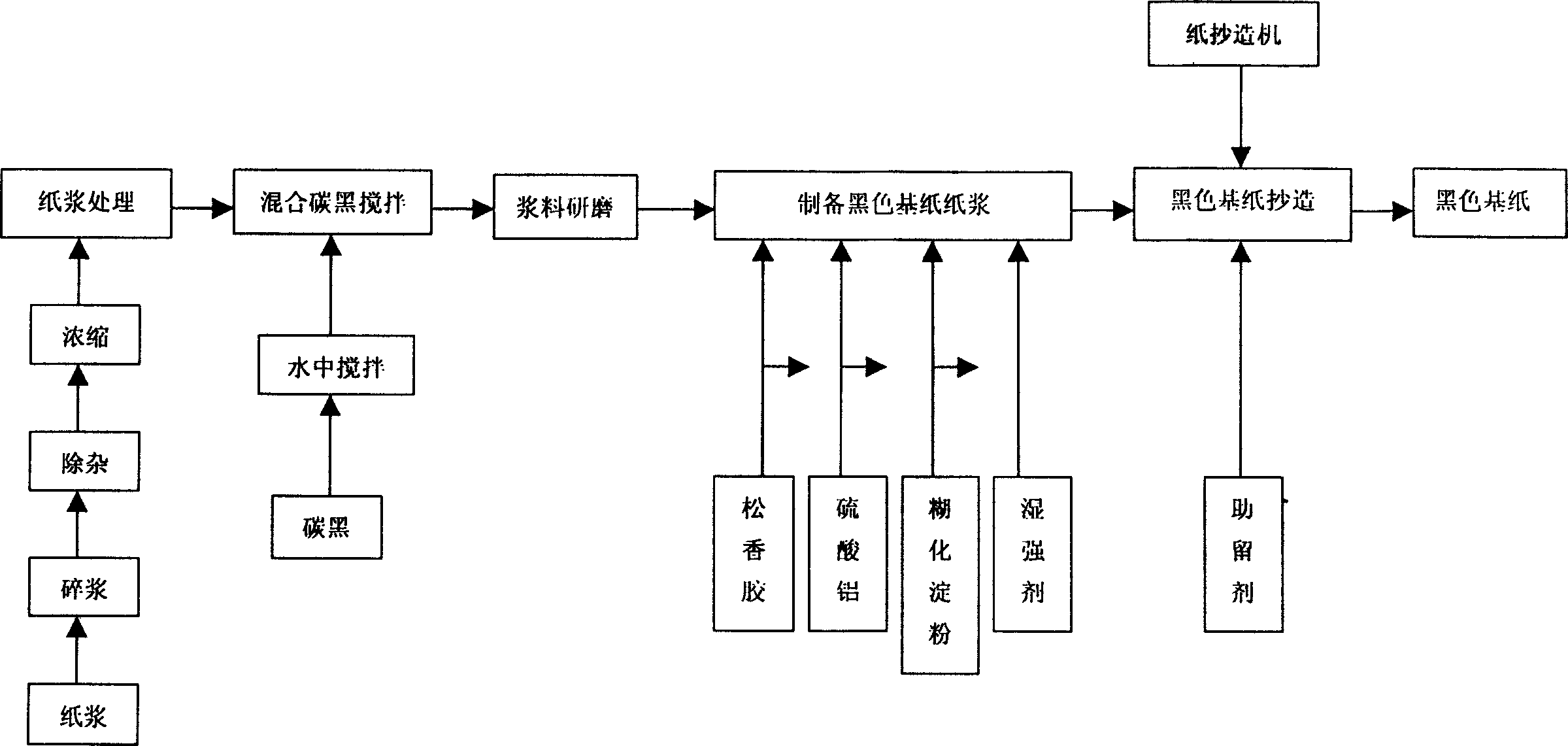

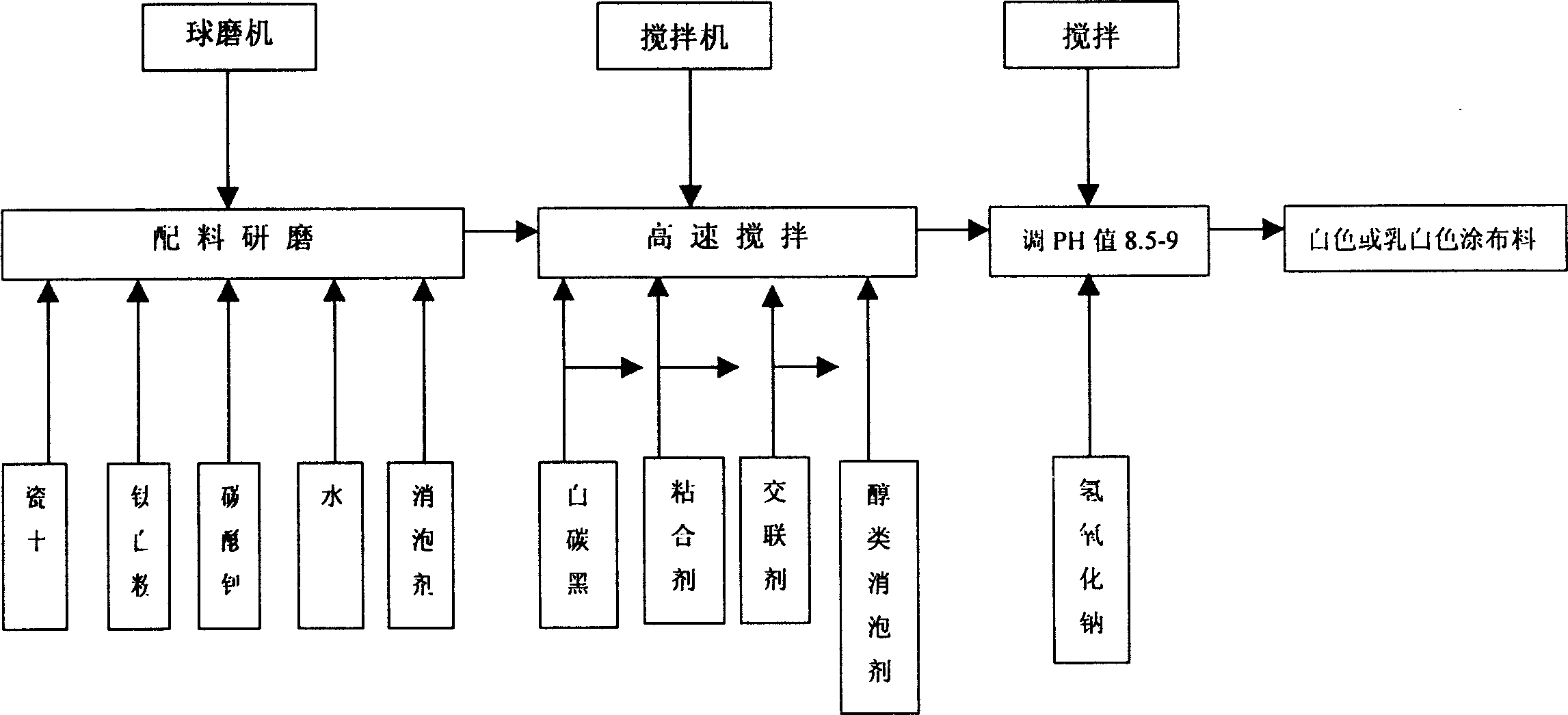

Xuan paper imitation water writing paper and its making method

A water writing paper simulating the Xuan paper is composed of black base paper and coated white layer, and is prepared through making black base paper, preparing white paint and coating. Said black base paper contains pulp fibres, black pigment, adhesive, acid salt, dry strnegthening agent, and wet strengthening agent. Said white paint paint contains white pigment, disperser, adhesive (butadiene-styrene or propadiene styrene emulsion and PVA), cross-linking agent and regulator. Its advantages are low cost, clear tracing and cyclic use.

Owner:徐洁

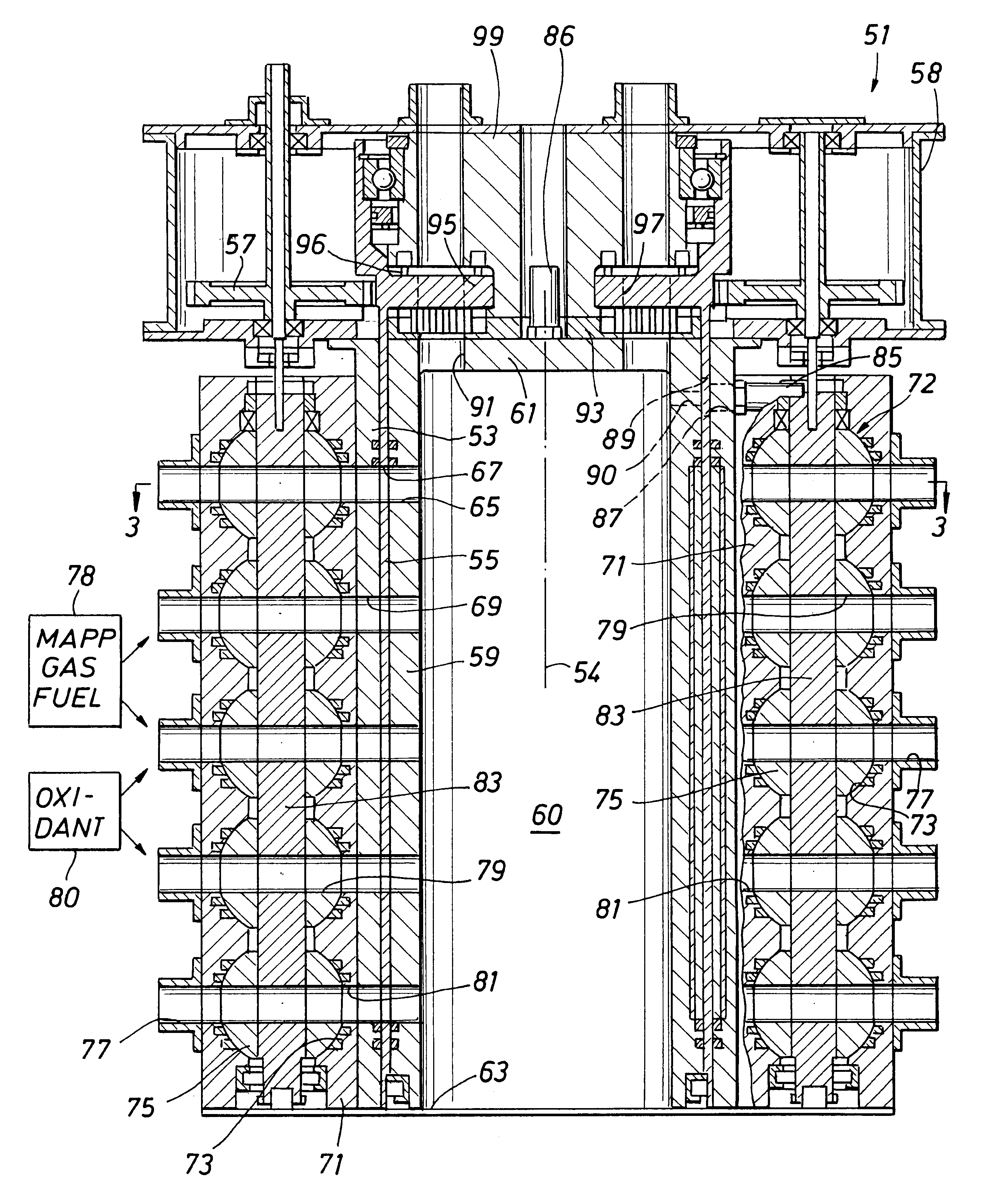

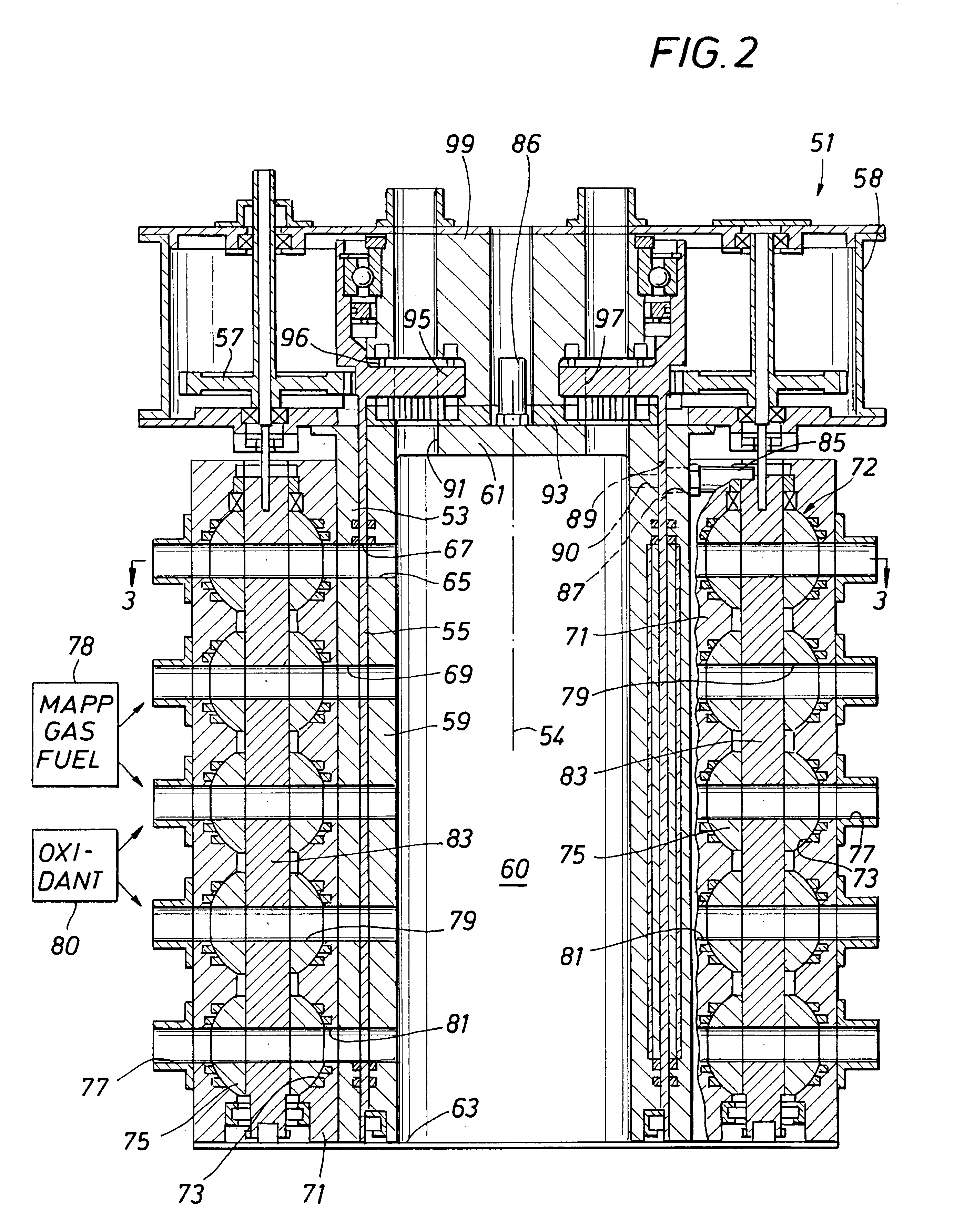

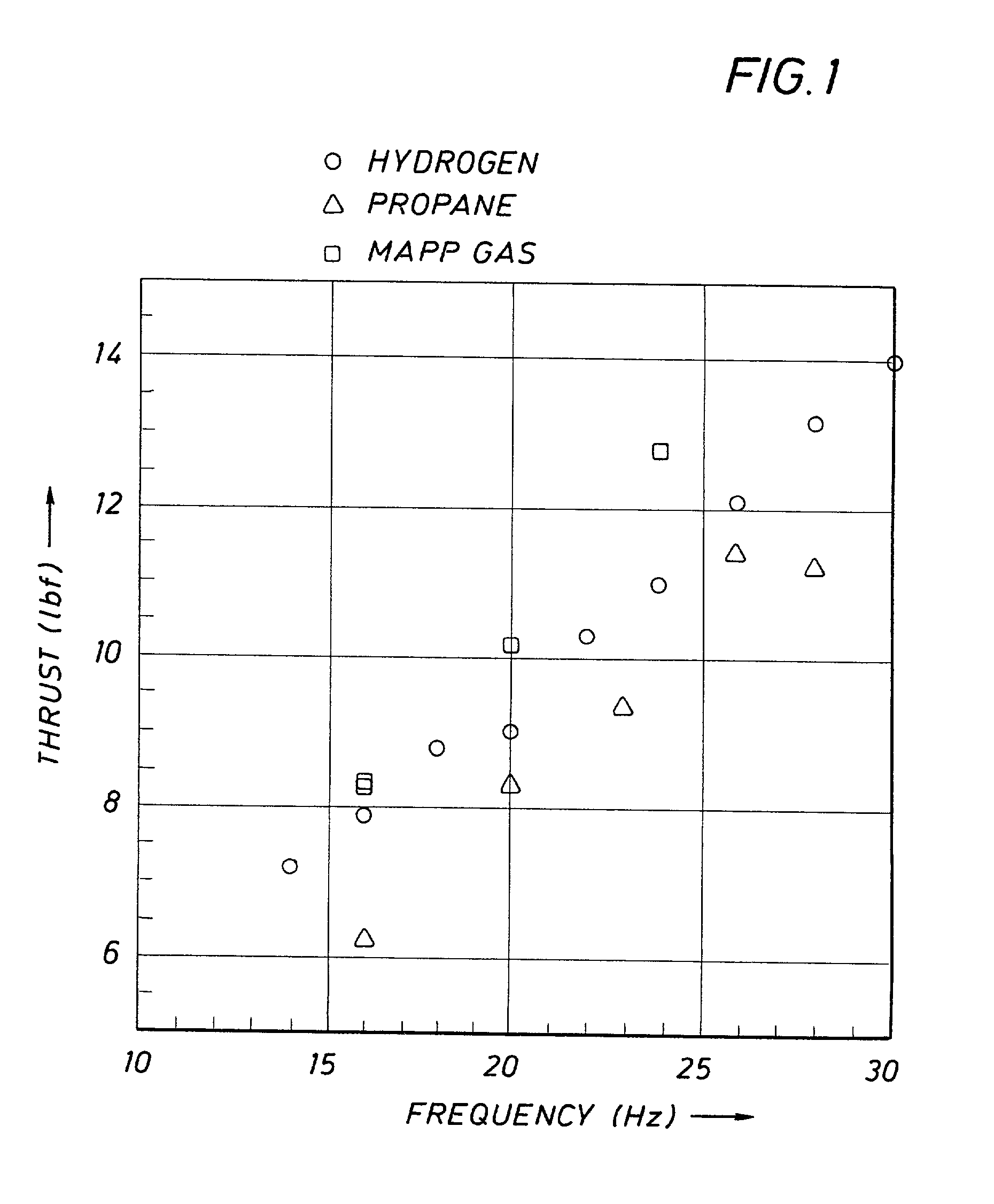

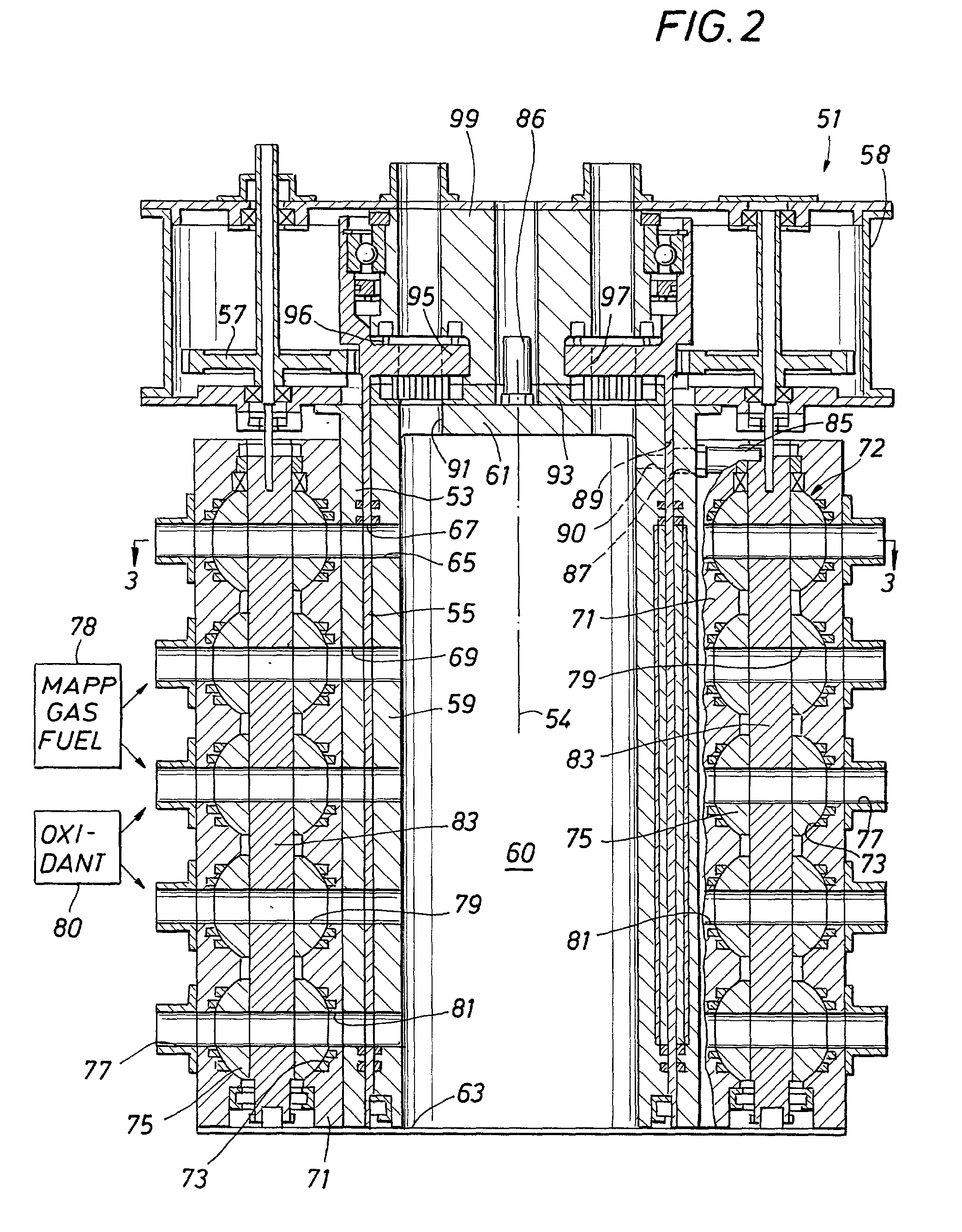

MAPP gas fuel for flight vehicles having pulse detonation engines and method of use

A fuel containing methylacetylene-propadiene, commonly referred to as MAPP gas, produces thrust in a flight vehicle having a pulse detonation engine. The MAPP gas fuel of this invention may be used alone or combined with other conventional fuels such as hydrogen, JP-4, JP-5, JP-10, kerosene or any other suitable hydrocarbon fuel. Such hydrocarbon containing fuel includes, but is not limited to, acetylene, methane, ethylene, propane, butane or liquified petroleum gas. MAPP gas fuel is mixed with an oxidant containing oxygen or air and ignited. The detonation wave created produces thrust for the flight vehicle. A method of powering a flight vehicle having a pulse detonation engine with MAPP gas fuel is also disclosed.

Owner:LOCKHEED MARTIN CORP

Mapp gas fuel for flight vehicles having pulse detonation engines and method of use

A fuel containing methylacetylene-propadiene, commonly referred to as MAPP gas, produces thrust in a flight vehicle having a pulse detonation engine. The MAPP gas fuel of this invention may be used alone or combined with other conventional fuels such as hydrogen, JP-4, JP-5, JP-10, kerosene or any other suitable hydrocarbon fuel. Such hydrocarbon containing fuel includes, but is not limited to, acetylene, methane, ethylene, propane, butane or liquified petroleum gas. MAPP gas fuel is mixed with an oxidant containing oxygen or air and ignited. The detonation wave created produces thrust for the flight vehicle. A method of powering a flight vehicle having a pulse detonation engine with MAPP gas fuel is also disclosed.

Owner:LOCKHEED MARTIN CORP

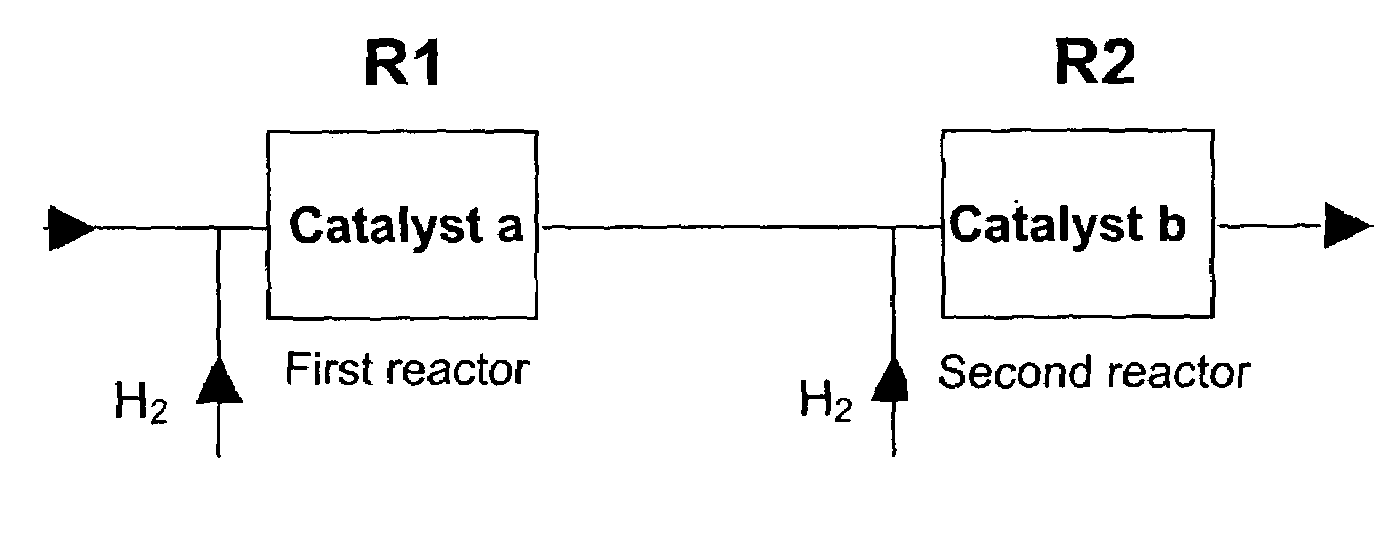

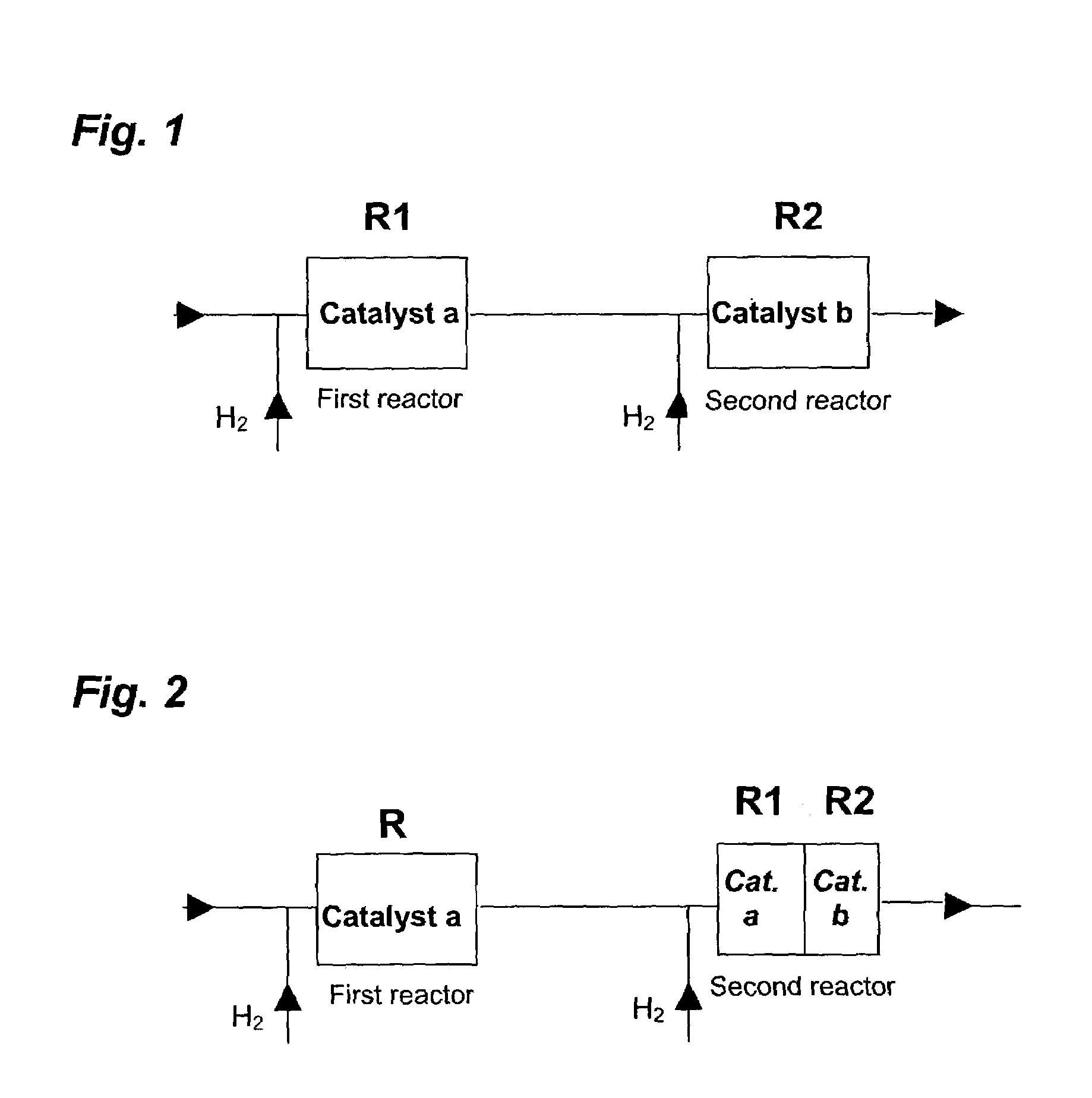

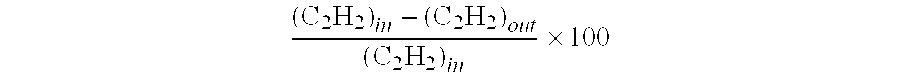

Dual bed process using two different catalysts for selective hydrogenation of acetylene and dienes

InactiveUS7038097B2Many solutionsMaintains and improves conversionHydrocarbon by hydrogenationHydrocarbon purification/separationOligomerHydrogen

It has been discovered that a dual bed process using two different catalysts for the selective hydrogenation of acetylene and / or methyl acetylene (MA) and / or propadiene (PD) in a light olefin-rich feedstream can be accomplished with less selectivity to making oligomers (green oil) as compared with existing commercial technologies, if a low oligomers selectivity catalyst is used first in the process. A palladium catalyst may be used as a second, sequential catalyst to further hydrogenate acetylene and / or MAPD while consuming at least a portion of the balance of the hydrogen present. The first catalyst should be different from the second catalyst.

Owner:EXXONMOBIL CHEM PAT INC

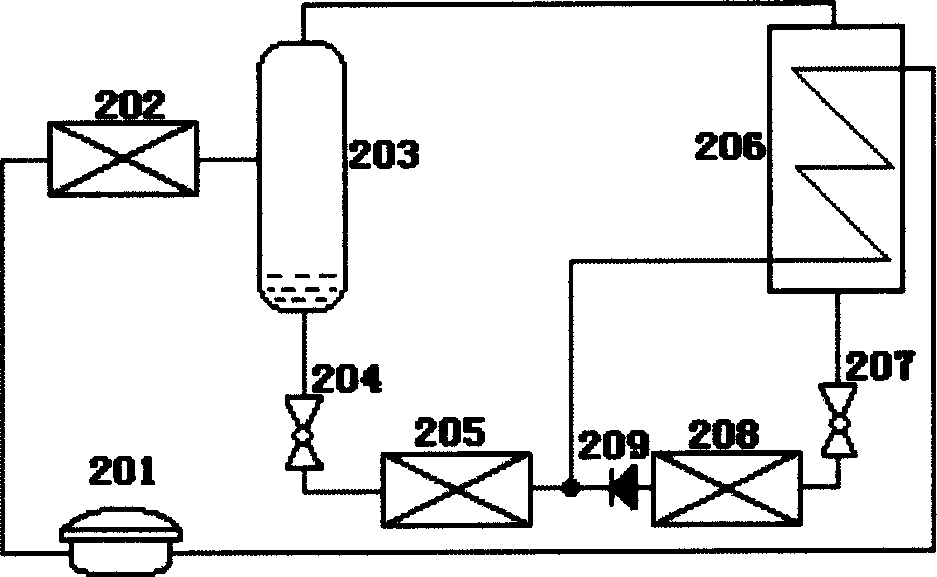

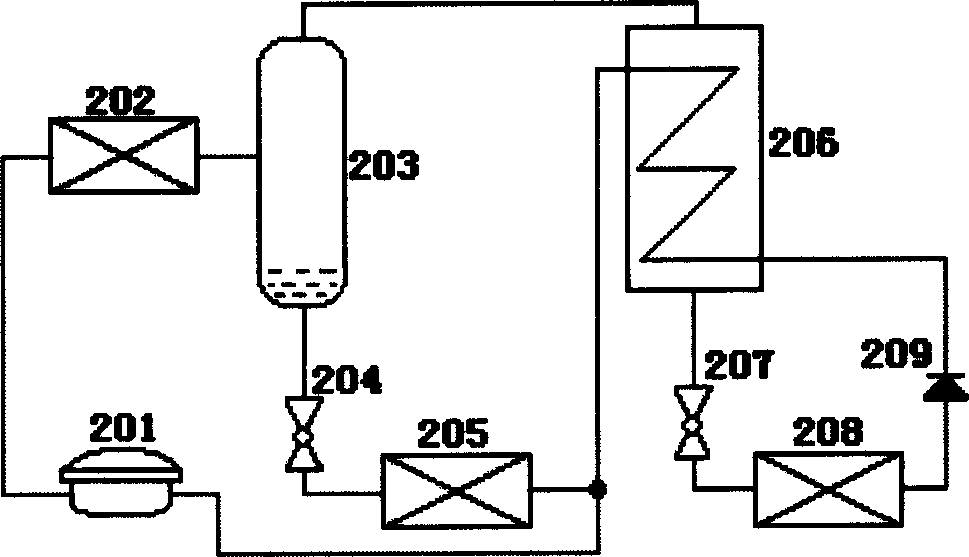

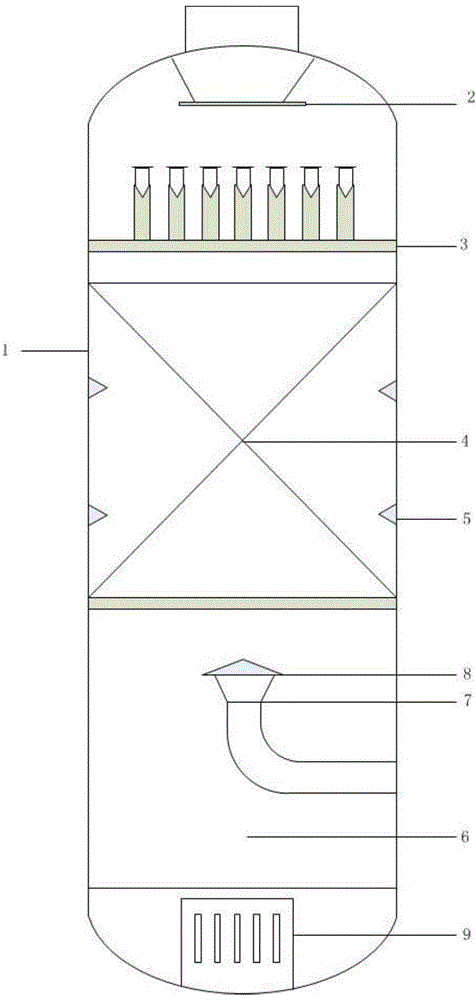

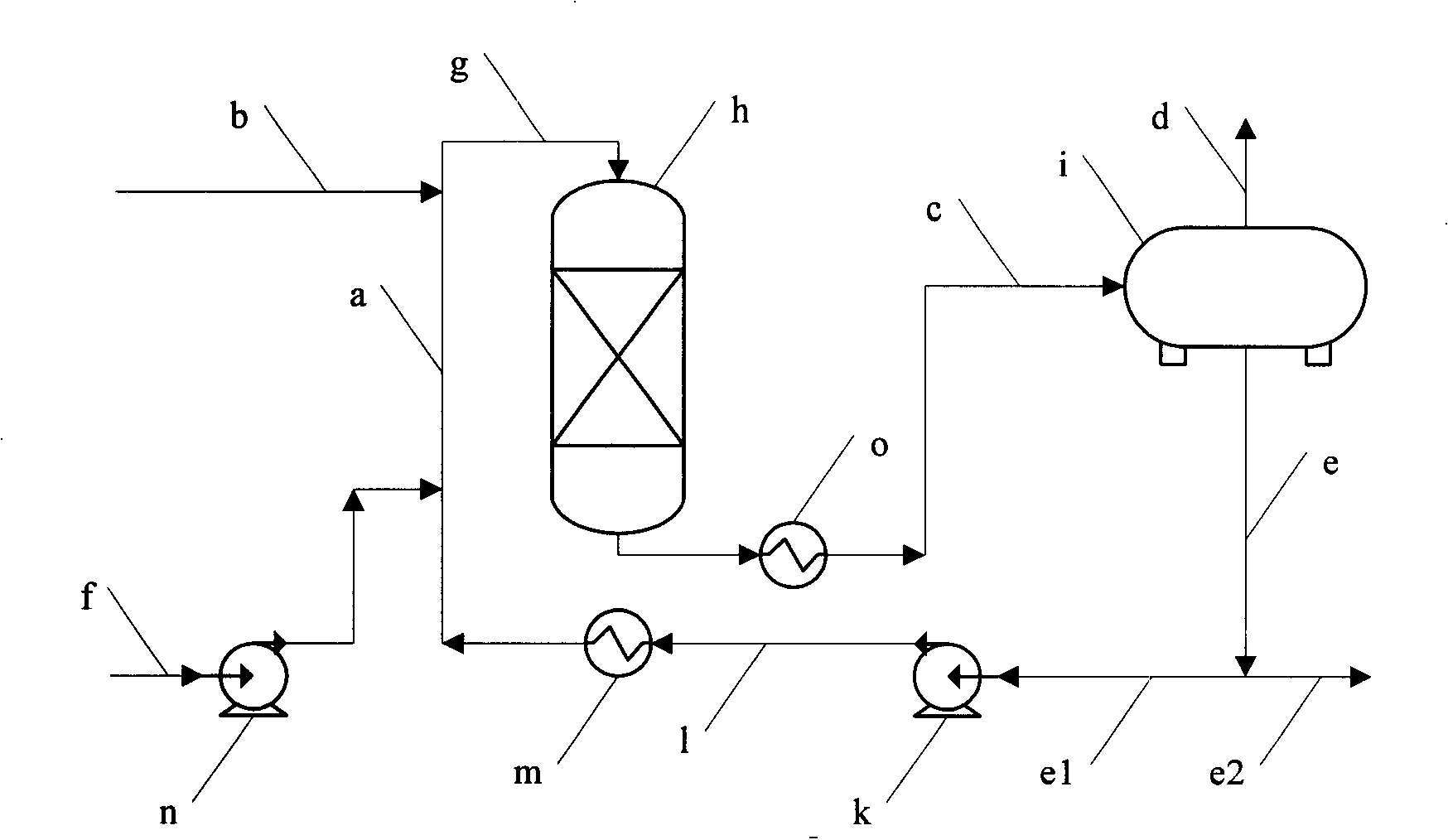

Fixed bed hydrogenation reactor and application method thereof

ActiveCN105582854AEasy to operateImprove the efficiency of refining reactionHydrocarbon by hydrogenationRefining by selective hydrogenationSeparation technologyHydrogenation reaction

The invention discloses a fixed bed hydrogenation reactor and an application method thereof. In the fixed bed hydrogenation reactor, a gas-liquid phase product pre-separation technology with gas phase withdrawal in an axial center position is employed, wherein a plurality layers of baffle plates are arranged on the inner wall of the reactor, thereby improving operation stability of the hydrogenation system, improving gas-liquid distribution status in the reactor and eliminating wall flow, deflected flow and the like defects. The reactor, when being used in a reaction process of C3 fraction liquid-phase selective hydrogenation to remove methyl acetylene (MA) and propadiene (PD), can not only increase the MAPD hydrogenation purification reaction efficiency of a propadiene material but also is low in residual hydrogen, so that separation load in a down-stream propylene rectification column is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS7074971B2Efficient removalCount is minimizedEther separation/purificationOrganic compound preparationPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that the best separation of these components is realized when DME is selectively removed in a first separation step, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

Heat-integrated high pressure system for separation of byproducts from an olefin stream

InactiveUS6864401B2Large temperature differenceIncrease temperature differenceChemical industryDistillation purification/separationButeneFractionating column

The present invention is a heat-integrated process for obtaining an ethylene and propylene enriched stream from an oxygenate to olefin reactor. The process comprises providing an effluent stream from an oxygenate to olefins reactor. The effluent stream comprises ethylene, propylene and one or more byproducts selected from the group consisting of propane, methyl acetylene, propadiene, dimethyl ether, acetaldyhyde and butylene. The process further includes quenching the effluent stream with the quench medium to provide an olefin stream. The olefin stream is separated into a heavy fraction and a remaining fraction. The remaining fraction is directed to a distillation column which separates the remaining fraction into a first fraction comprising a majority of both ethylene and a propylene and a second fraction comprising at least a majority of one or more heavier fraction. The bottoms of the distillation column is reboiled by the quench medium. The separation step allows the bottoms of the distillation column to be reboiled at a lower temperature.

Owner:EXXONMOBIL CHEM PAT INC

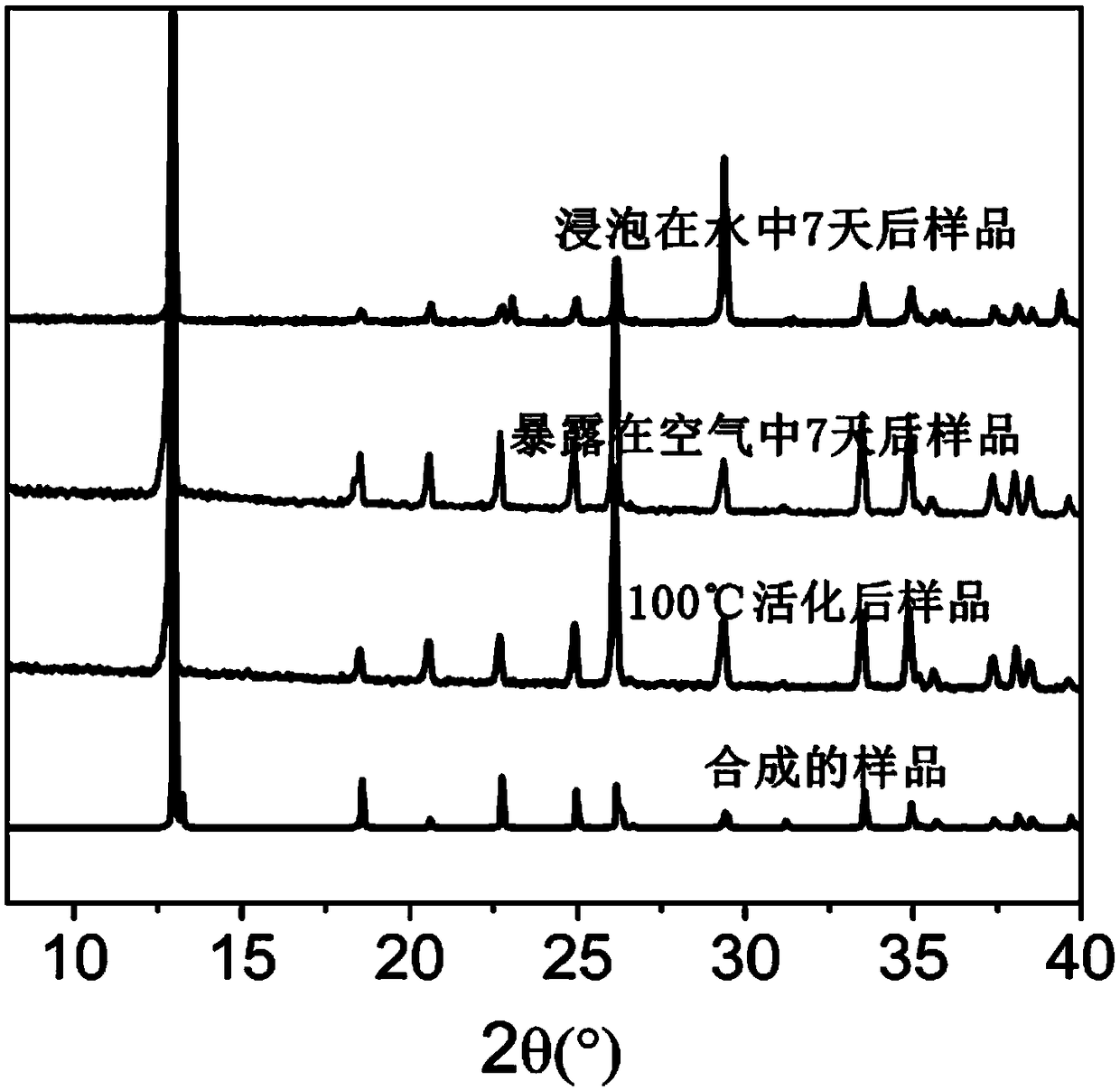

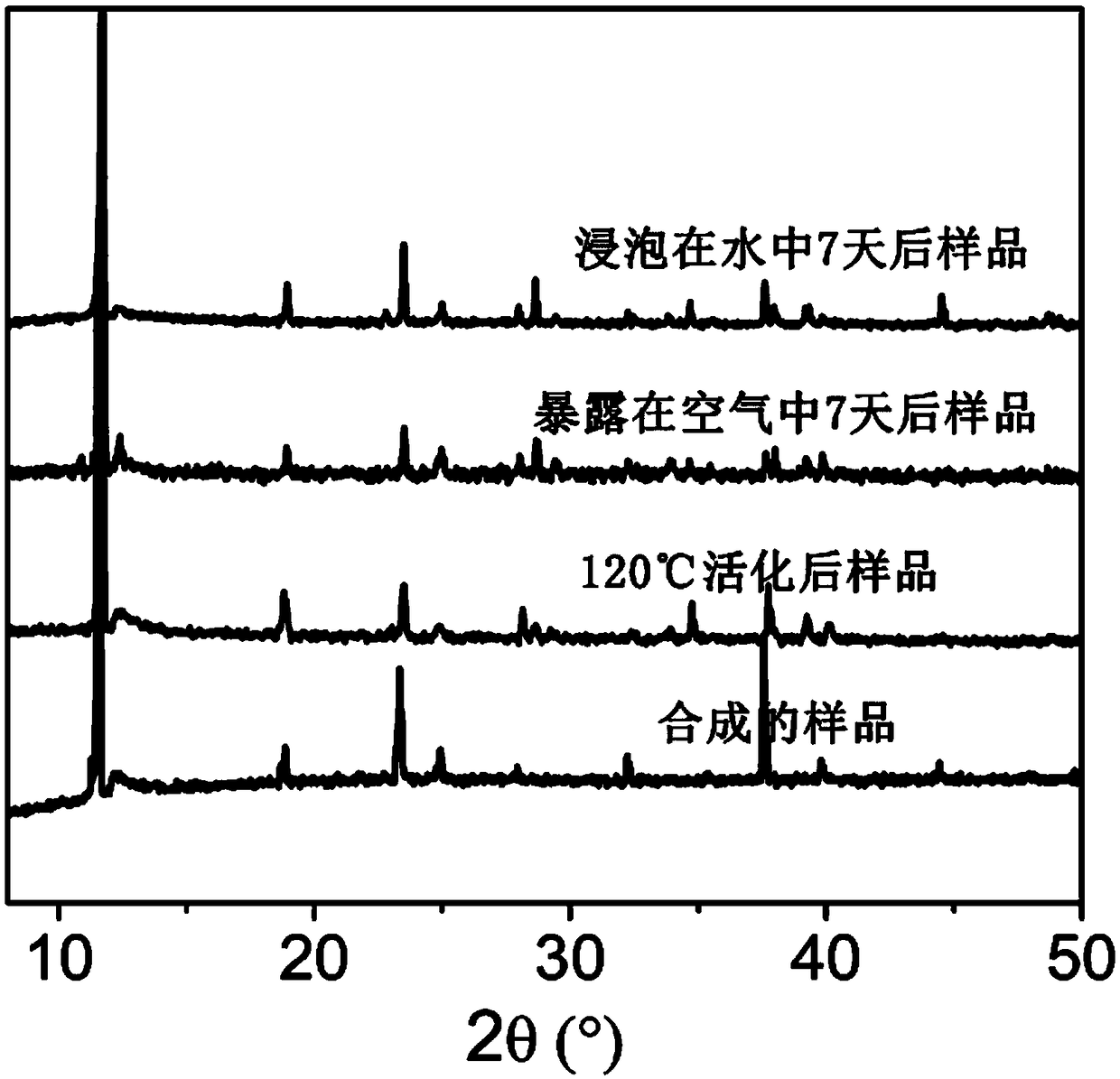

Method for adsorption separation of propylene, propyne, propane and propadiene

ActiveCN109293467AStable structureImprove performanceGas treatmentOther chemical processesAlkaline earth metalSorbent

The invention discloses a method for separating propylene, propyne, propane and propadiene from a mixed gas. The method comprises: separating a mixed gas containing propylene, propyne, propane and propadiene by using a metal organic framework material as an adsorbent to obtain the gases of each single component, wherein the structural general formula of the metal organic framework material is [M(C4O4)(H2O)].1.5H2O, M is a metal ion, and transition metal ions or alkaline earth metal ions and squaric acid form a three-dimensional network structure through a coordination bond or intermolecular force. According to the present invention, the metal organic framework material has excellent adsorption separation selectivity to propylene, propyne, propane and propadiene, further has characteristicsof cheap and easily available raw materials, simple preparation process, low cost, good regeneration property and good repeatability, can maintain the original adsorption effect after vacuum or heating regeneration, and has broad industrial application prospects.

Owner:ZHEJIANG UNIV

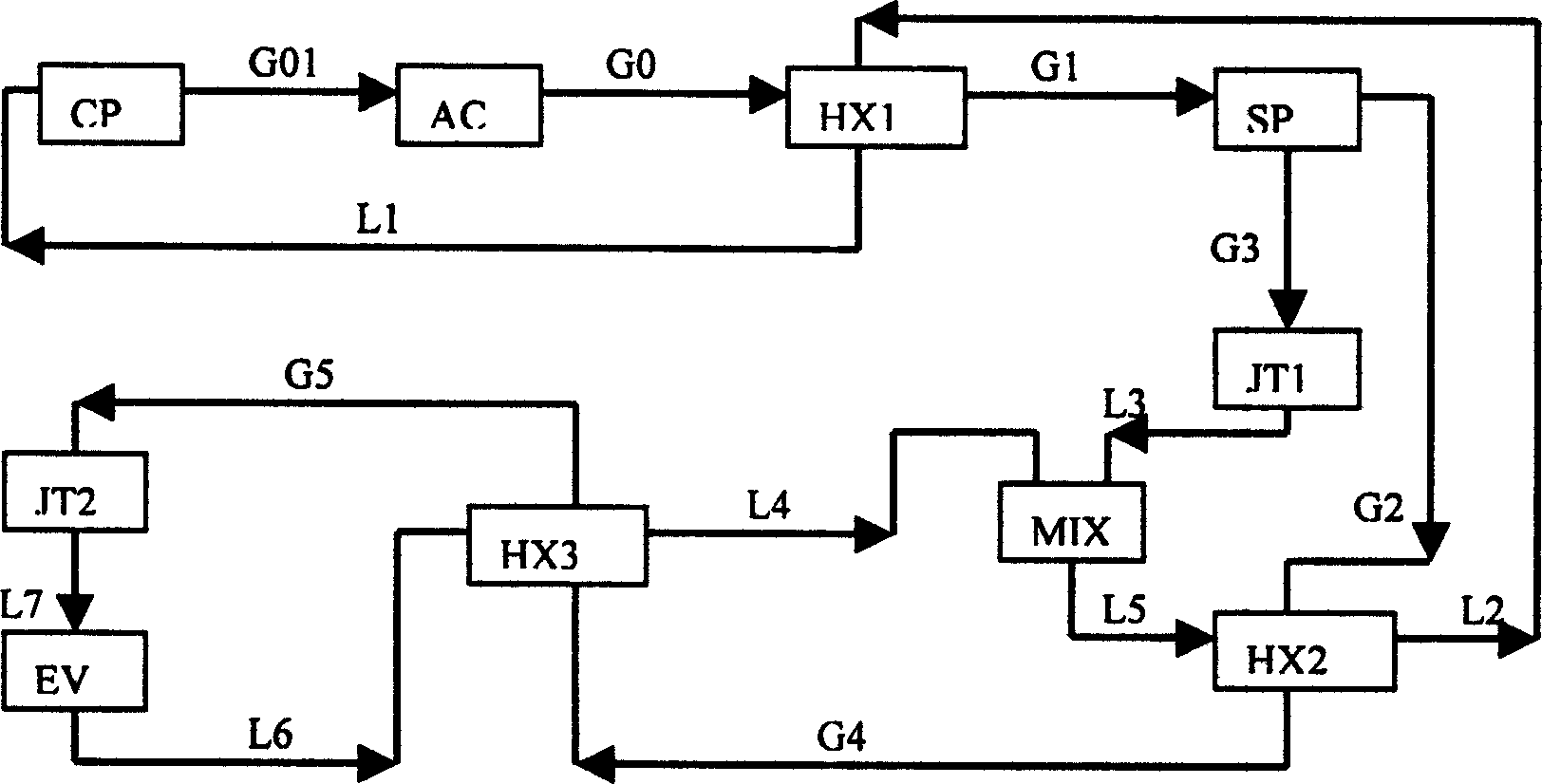

Multicomponent mixed work medium throttling refrigerant applicable to medium-low temperature zone

The multicomponent mixed work medium throttling refrigerating agent applicable to medium-low temp. zone includes five groups of substances, the sum of their mole concentration is 100%, in which first group includes methane, krypton or mixture, total mole concentration is 5%-45%, second group includes tetrafluoromethane, nitrogen trifluoride or mixture, total mole concentration is 15%-55%; fourth group includes propylene, propane, perfluoropane, 1,1,1-trifluoroethane, 1,1-bifluoroethane, fluoroethane, propadiene, cyclopropane, or mixture, total mole concentration is 5%-25%; fifth group includes 1-butylene, isobutane, 2-methylbutane, 1-pentene, 3-methyl-1-butylene, 2-methylpentane, 2-butylene, isobutylene, n-butane, perfluorobutane, n-pentane or mixture, total mole concentration is 5%-25%.

Owner:中科赛凌(北京)科技有限公司

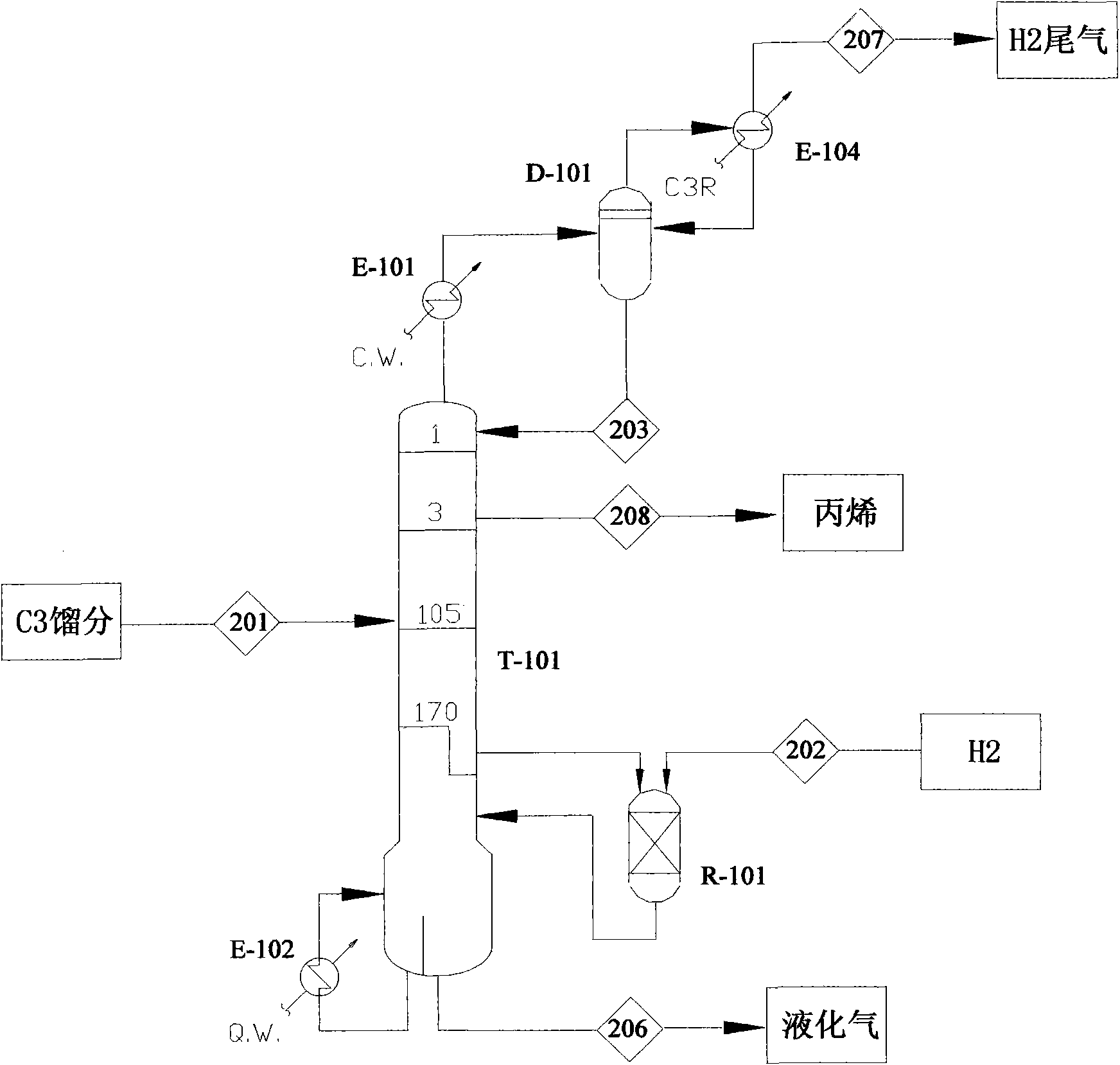

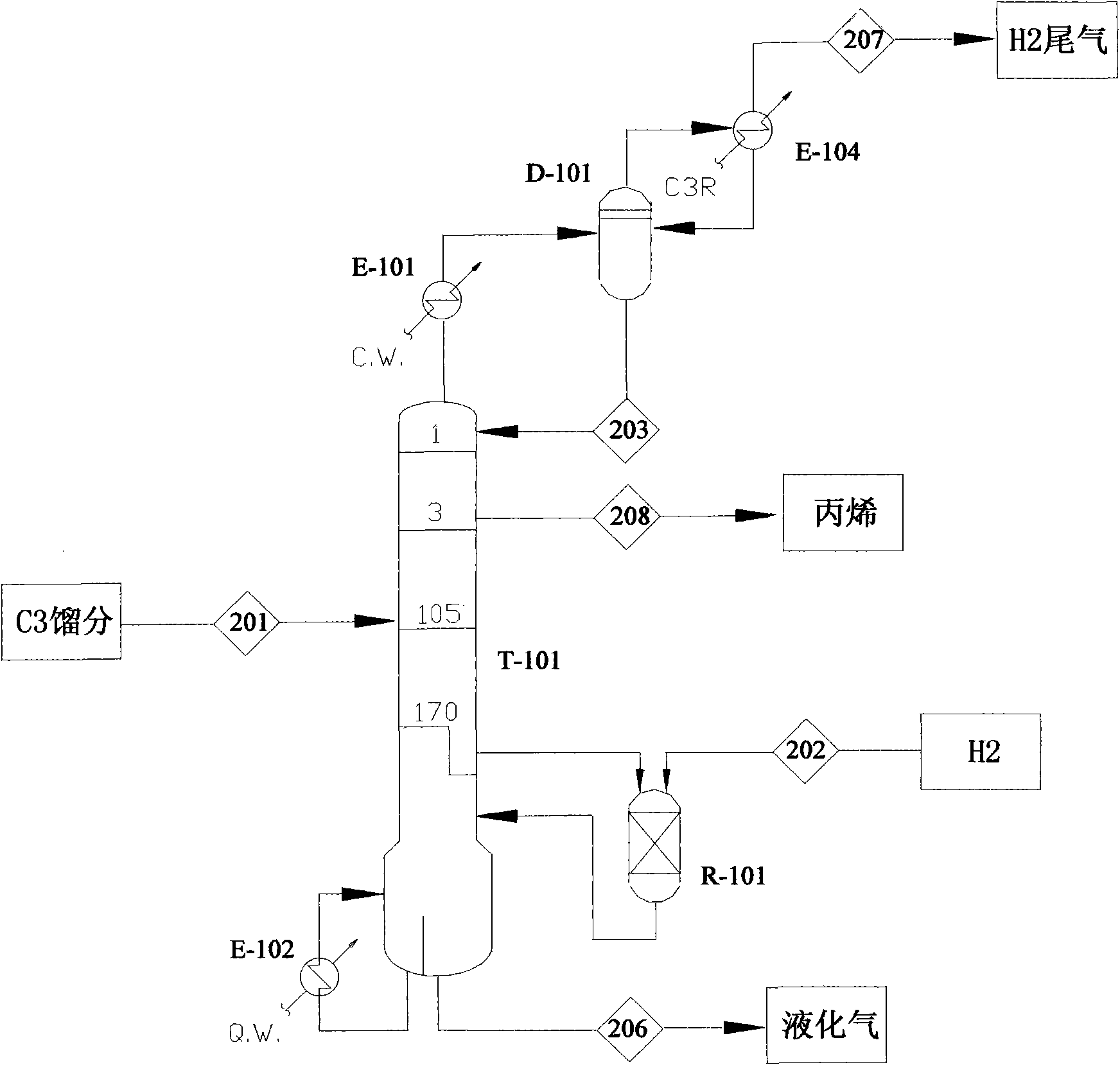

Catalytic rectification method for removing MAPD by selective hydrogenation

ActiveCN102040446AHigh conversion selectivityLow inactivation effectHydrocarbon by hydrogenationGaseous fuelsHydrogenTower

The invention provides a catalytic rectification method for removing methyl acetylene and propadiene (MAPD) by selective hydrogenation. The method comprises the following steps of: placing a catalytic rectification member below a C3 fraction feeding position of a propylene rectification tower, introducing hydrogen into the tower from the lower part of the catalytic rectification member, and making the hydrogen upwards flow through the catalytic rectification member; and directly feeding the C3 fraction containing the MAPD into the propylene rectification tower or feeding the C3 fraction whichis pre-transformed through a first MAPD reactor into the propylene rectification tower to perform catalytic rectification and remove MAPD, directly recovering propylene meeting the polymerization level requirement from a lateral line, or recovering the material from the top of the tower, and removing light components to obtain polymerization level propylene, wherein the molar fraction of the MAPDin the tower can be directly reduced to below 0.1 to 2 percent. The method is characterized in that: by using the characteristic of low concentration of the propylene in the propylene rectification tower, the probability of side reaction of transforming the propylene into propane can be reduced, the selectivity of MAPD transformation is improved, and the purpose of high propylene yield is fulfilled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Wear-resistant rubber

The invention discloses a wear-resistant rubber. The wear-resistant rubber comprises, by weight, 60-100 parts of polyurethane rubber, 60-100 parts of natural rubber, 40-50 parts of nitrile rubber, 40-50 parts of silicone rubber, 20-30 parts of brominated butylene rubber, 3-5 parts of sulfur, 2-4 parts of an antioxidant, 3-5 parts of nanometer zinc oxide, 5-10 parts of propadiene siloxane, 20-30 parts of magnesium oxide, 10-20 parts of carbon black and 5-10 parts of ethyl carbamate. All above raw materials have synergistic effects, so compared with common rubbers, the wear-resistant rubber prepared in the invention has the advantages of excellent wear resistance, high mechanical strength, good fireproof property and good corrosion resistance.

Owner:NANTONG HONGTU RUBBER & PLASTIC

Dimethyl ether fuel compositions and uses thereof

The present invention provides useful fuel compositions which may be produced substantially from renewable resources, such as biomass, to provide green fuel compositions, methods, and systems. In some embodiments, fuel compositions include dimethyl ether and one or more C2 or larger alcohol, such as ethanol, 1-propanol, 2-propanol, 1-butanol, 2-butanol, isobutanol, or tert-butanol. In some embodiments, fuel compositions include dimethyl ether and one or more C2 or larger hydrocarbons, such as propane, propylene, propyne, and propadiene, n-butane, isobutane, isobutylene, 1-butene, 2-butene, or 1,3-butadiene. Methods of making these novel DME-based fuel compositions, particularly from biomass-derived syngas, are described. Various applications and methods of using the fuel compositions, such as portable cylinder fuels for camping, are disclosed. Additionally, principles of burner design for these fuel compositions are disclosed herein.

Owner:MAVERICK BIOFUELS

Recovery of ethylene and propylene from a methanol to olefin reaction system

InactiveUS7208650B2Efficient removalEfficient separationHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionPropadieneDimethyl ether

The present invention provides new highly-efficient separation processes and systems for separating polymerization-grade ethylene and propylene from an initial effluent stream comprising ethane, ethylene, propylene, dimethyl ether, and one or more of propane, acetylene, methyl acetylene, propadiene, methane, hydrogen, carbon monoxide, carbon dioxide and C4+ components. In one embodiment, the initial effluent stream is provided from a methanol-to-olefin reaction system. It has been discovered that an efficient separation of these components is realized when DME is partially removed in a first separation step comprising methanol and water washing steps, followed by separation of the remaining components in additional separation steps.

Owner:EXXONMOBIL CHEM PAT INC

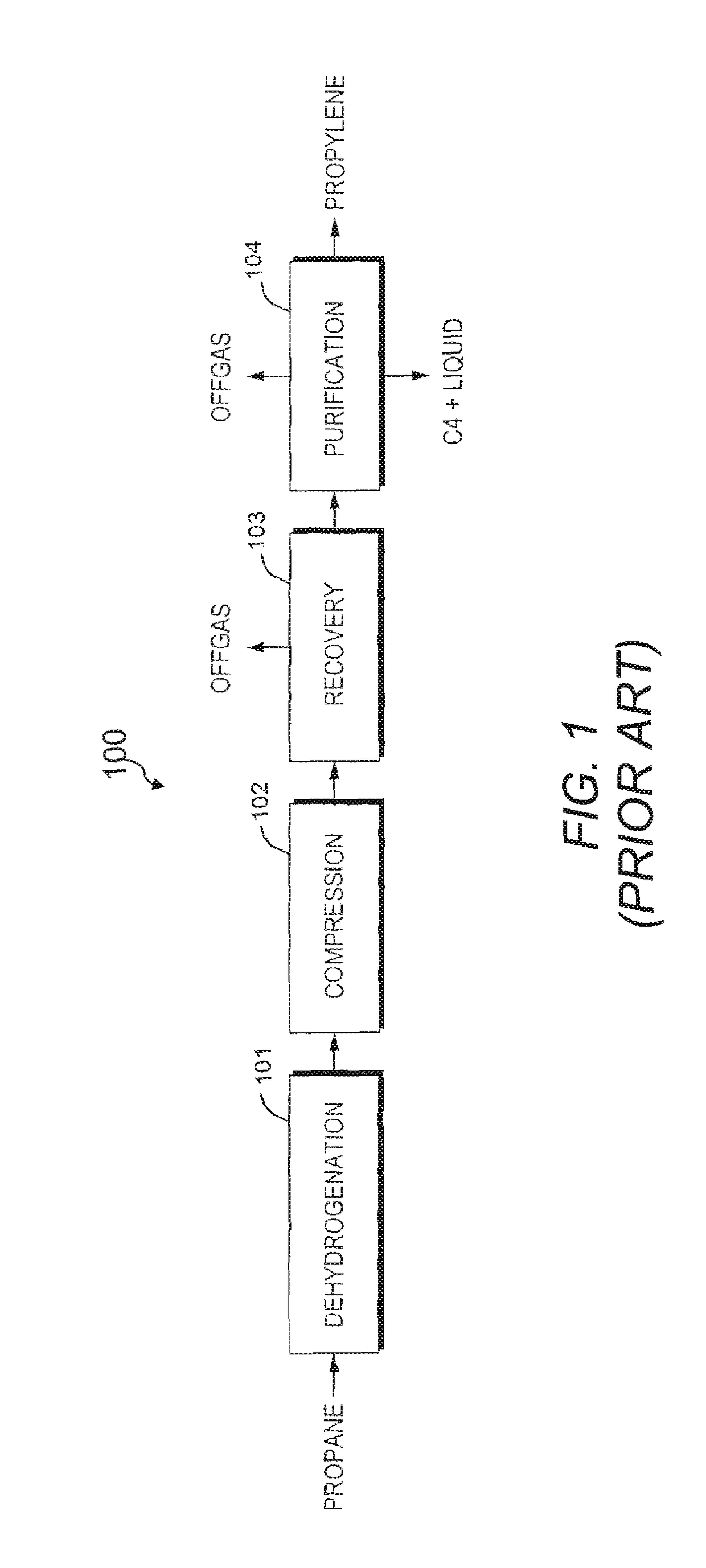

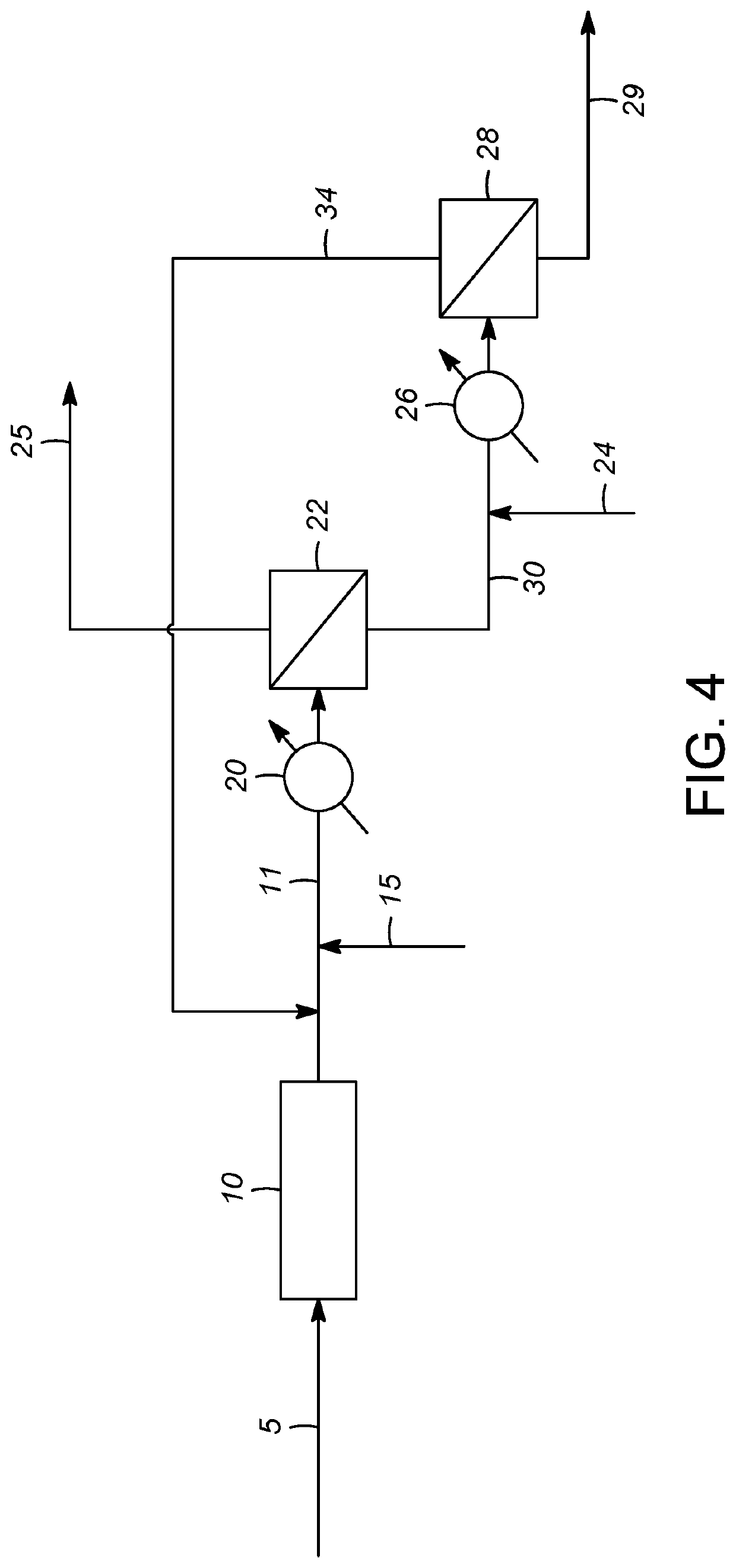

Method for improving propane dehydrogenation process

ActiveUS20170305814A1Operational securityExcessive pressureHydrocarbon by hydrogenationDistillation purification/separationReactor systemHydrogen

A propane dehydrogenation and propylene purification process in which a stream comprising propylene, propane, and methyl acetylene and propadiene (MAPD) is mixed with a hydrogen stream then reacted in at least three distinct reaction zones in a hydrogenation reactor system where MAPD is hydrogenated by a high-selectivity hydrogenation catalyst in a first reaction zone, and a second and a third reaction zones each have a low-selectivity hydrogenation catalyst to remove unreacted hydrogen. The outlet stream leaving the hydrogenation reactor system is MAPD-free and can be fed to a splitter column, which now mainly serves to separate propylene from propane. Various embodiments of reaction zone arrangements in a single or multiple reactors are also provided.

Owner:NAT INDZATION CO

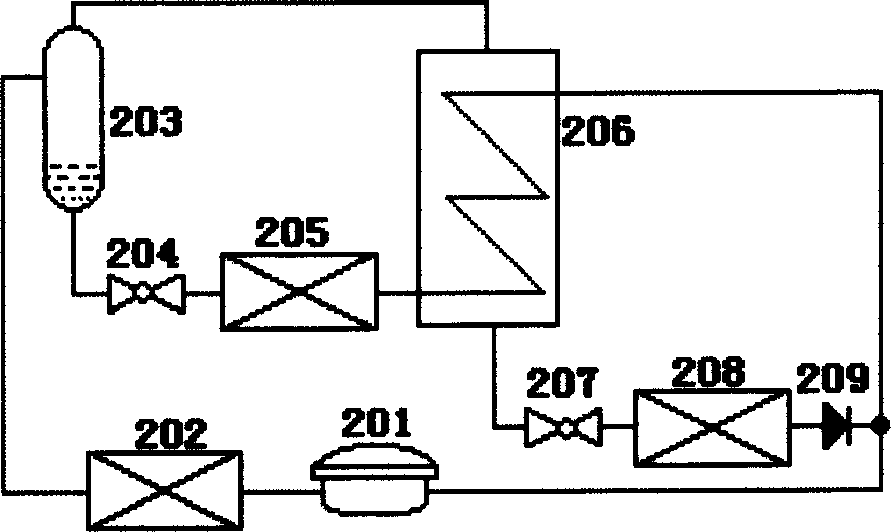

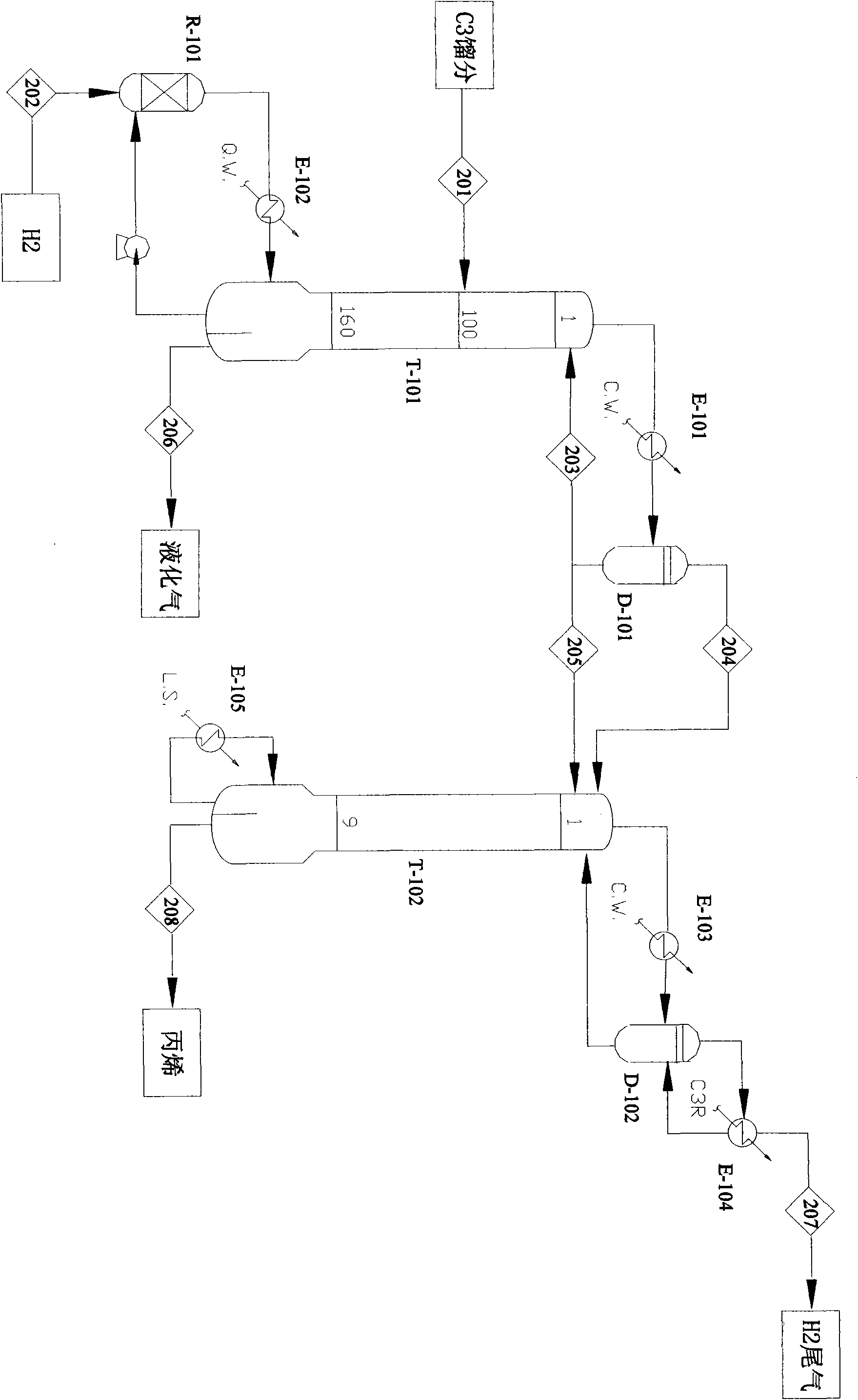

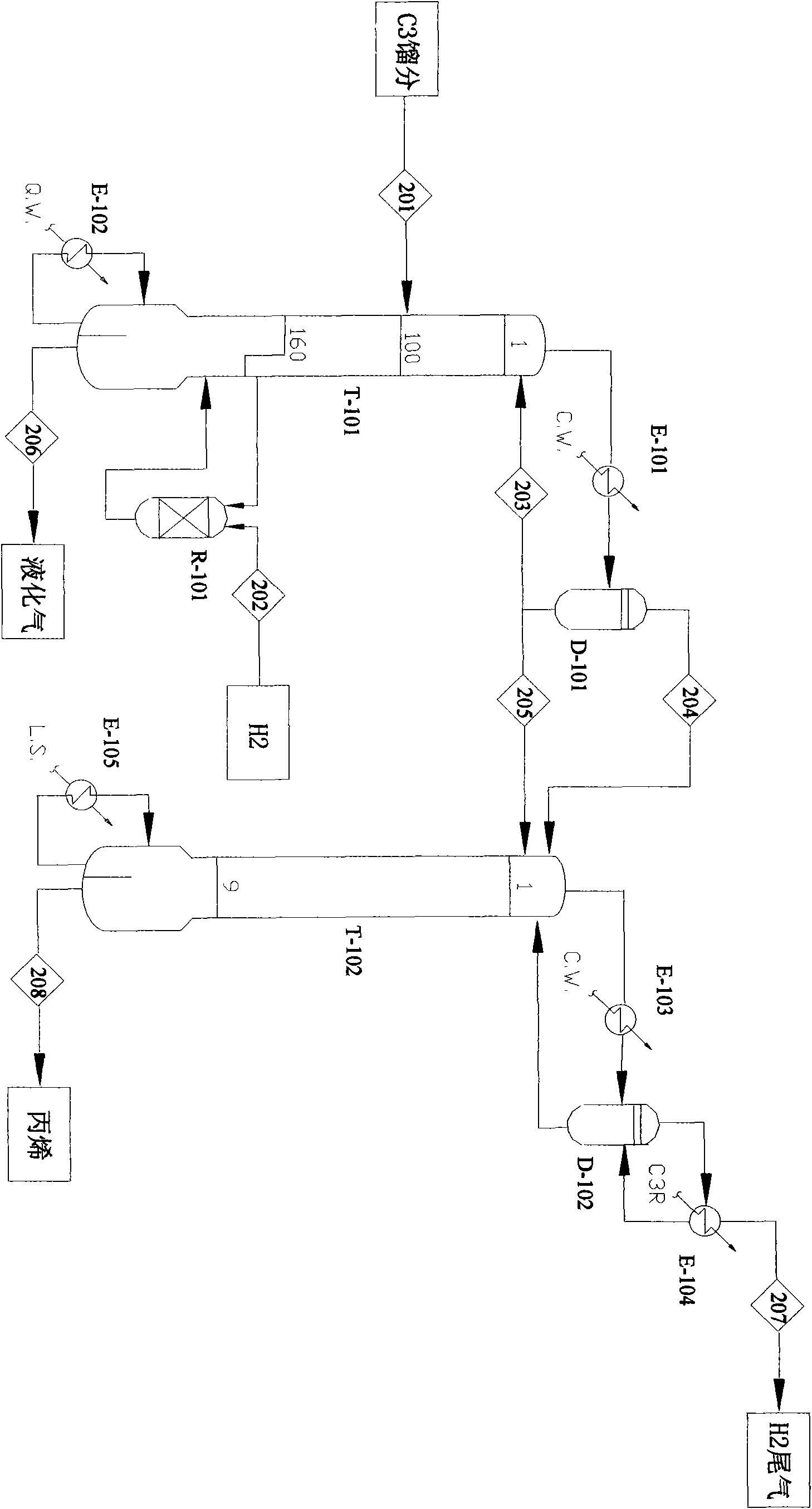

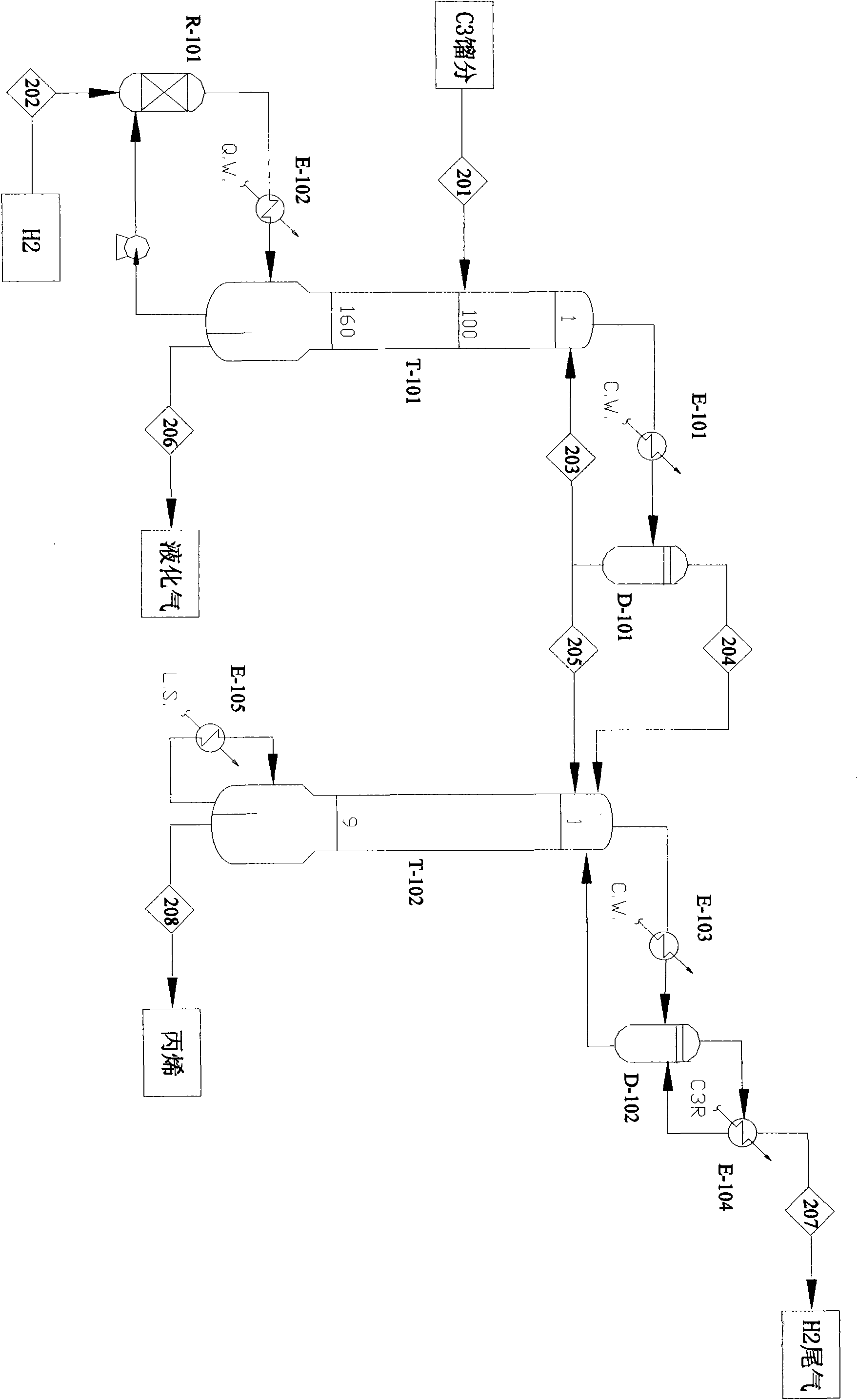

Process of carrying out reaction, rectifying and coupling to selectively hydrogenate to remove MAPD (Methylacetylene Propadiene)

ActiveCN101993327AEasy to switchImprove efficiencyDistillation purification/separationHydrocarbonsHydrogenPropadiene

The invention discloses a process for carrying reaction, rectifying and coupling to selectively hydrogenate to remove MAPD (Methylacetylene Propadiene) from refined propylene. A C3 fraction directly enters a propylene rectification tower or enters the propylene rectification tower after being pre-transformed by a first MAPD reactor; the MAPD is enriched into a stripping section and a tower kettlein the propylene rectification tower; and liquid is collected from a higher MAPD concentration position in the propylene rectification tower, is mixed with hydrogen to enter a second MAPD reactor andthen return to the propylene rectification tower. The treatment of the C3 fraction realizes the effective separation of the propylene and the MAPD, thereby increasing the selectivity of converting the MAPD into the propylene and realizing the purpose of increasing the yield of the propylene. In addition, the requirement of catalyst activity in the MAPD converting process is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene-containing composition

InactiveUS20050033013A1Shorten the counting processLow production costOrganic chemistryOxygenateOxygen compound

The present invention provides a new propylene-containing compositions, which preferably are suitable for polymerization disposition. The propylene-containing compositions include propylene, propane, dimethyl ether and one or more of ethylene, ethane, methanol, acetylene, methyl acetylene, propadiene, C4+ hydrocarbons and water. The propylene-containing composition can be derived from an oxygenate to olefin reaction system without expending resources on propane / propylene separation.

Owner:EXXONMOBIL CHEM PAT INC

Detection method of cis-trans isomer in cis-propenyl phosphonic acid and related impurity thereof

A detection method of cis-trans isomers in cis-propenyl phosphonic acid and related impurities thereof is applicable to the field of pharmaceutical analysis, and the method comprises the following steps and conditions: the chromatographic conditions are that the chromatographic column is a C-18 column of 4.6 mm*250 mm*5.0 microns; the flow velocity is 1.0 ml / min; an ultraviolet detector has a detection wavelength of 225 nm and a sample size of 10 microliters; the mobile phase is 50 mmol / L dipotassium hydrogen phosphate aqueous solution-methanol; preparing a test solution by dissolving 0.1 microliters of test samples in the mobile phase, diluting to 25 ml, and filtering; introducing 10 microliters of the test solution, recording a spectrum, wherein the retention time for cis-propenyl phosphonic acid is 12.3 min, the relative retention value of its cis-trans isomers is 1.15, and the relative retention value of propadiene phosphonic acid is 0.38, and calculating the contents of various impurities by an area normalization method; in the mobile phase, the 50 mmol / L dipotassium hydrogen phosphate aqueous solution contains 2% of tetrabutylammonium hydroxide aqueous solutions; the concentration of the tetrabutylammonium hydroxide aqueous solution is 55%. According to the invention, the method is used for the detection of cis-trans isomers in cis-propenyl phosphonic acid and related impurities thereof, and the repeatability, the sensitivity, and the accuracy all meet the requirements.

Owner:NORTHEAST PHARMA GRP

Process of carrying out reaction, rectifying and coupling to selectively hydrogenate to remove MAPD (Methylacetylene Propadiene)

ActiveCN101993327BEasy to switchImprove efficiencyDistillation purification/separationHydrocarbonsHydrogenPropadiene

The invention discloses a process for carrying reaction, rectifying and coupling to selectively hydrogenate to remove MAPD (Methylacetylene Propadiene) from refined propylene. A C3 fraction directly enters a propylene rectification tower or enters the propylene rectification tower after being pre-transformed by a first MAPD reactor; the MAPD is enriched into a stripping section and a tower kettlein the propylene rectification tower; and liquid is collected from a higher MAPD concentration position in the propylene rectification tower, is mixed with hydrogen to enter a second MAPD reactor andthen return to the propylene rectification tower. The treatment of the C3 fraction realizes the effective separation of the propylene and the MAPD, thereby increasing the selectivity of converting the MAPD into the propylene and realizing the purpose of increasing the yield of the propylene. In addition, the requirement of catalyst activity in the MAPD converting process is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Membrane process for olefin separation

A process is provided to separate a hydrocarbon stream comprising a mixture of light olefins and light paraffins, the process comprising sending the hydrocarbon stream through a pretreatment unit to remove impurities selected from the group consisting of sulfur compounds, arsine, phosphine, methyl acetylene, propadiene, and acetylene to produce a treated hydrocarbon stream; vaporizing the treated hydrocarbon stream to produce a gaseous treated hydrocarbon stream; adding liquid or vapor water to the gaseous treated hydrocarbon stream; then contacting the gaseous treated hydrocarbon stream to a membrane in a membrane system comprising one or more membrane units to produce a permeate stream comprising about 96 to 99.9 wt % light olefins and a retentate stream comprising light paraffins.

Owner:UOP LLC

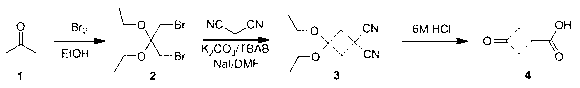

Synthesis method of 3-oxocyclobutanecarboxylic acid

InactiveCN103232340AReduce usageSimple process routePreparation from nitrilesSodium iodideSynthesis methods

The invention provides a synthesis method of a medical intermediate 3-oxocyclobutanecarboxylic acid. A target product 3-oxocyclobutanecarboxylic acid is obtained by adopting acetone, bromine and malononitrile as raw materials, adopting ethanol, DMF (dimethyl formamide) and water as solvents, adopting sodium iodide as an activating agent and tetrabutylammonium bromide (TBAB) as a phase transfer catalyst through three-step reaction. By measurement of H-nuclear magnetic resonance, a mass spectrum, the high-efficiency gas chromatography and a melting point, the synthesized final product is proved to be the 3-oxocyclobutanecarboxylic acid, the purity of 3-oxocyclobutanecarboxylic acid is 99 to 99.2 percent, and the yield of 3-oxocyclobutanecarboxylic acid is 52 to 68 percent. The synthesis method is simple in process route, short in production period and low in synthesis cost; meanwhile, the application of highly toxic products such as osmium tetroxide and propadiene can be avoided, and the process is more moderate, more reliable and safer; and the solvents such as the ethanol, the DMF and the methylbenzene can be recycled in the reaction process, so that the emission and processing costs of toxic reagent can be reduced, the national environmental protection can be achieved, and a good industrialized production prospect can be realized.

Owner:LANZHOU WOJIN ENVIRONMENT PROTECTION SCI & TECH CO LTD

Method to purify olefin-containing hydrocarbon feedstocks

A process for purifying an olefin-containing hydrocarbon feedstock comprising the steps of:(a) passing the said hydrocarbon feedstock in the presence of hydrogen over a first catalyst bed material comprising nickel deposited on a support material wherein said nickel is present as both nickel oxide and metallic nickel(b) recovering the feedstock having a substantially reduced acetylenics (in particular methylacetylene) and allenes (in particular propadiene) content.

Owner:TOTAL RES & TECH FELUY

Selective hydrogenation method for C3 fraction

InactiveCN108250020AModerate reactivityGreat operating flexibilityHydrocarbon purification/separationHydrocarbonsHydrogen atmospherePropadiene

The invention relates to a selective hydrogenation method for a C3 fraction. The C3 fraction used as a hydrogenation raw material undergoes hydrogen distribution, and is selectively hydrogenated by anFe-Co catalyst to convert methylacetylene (MA) and propadiene (PD) in the material into propylene. The carrier of the catalyst is a high temperature-resistant inorganic oxide, the active components of the catalyst at least contain Fe and Co, and 100 mass% of the catalyst contains 9-15 mass% of Fe and 3-4 mass% of Co; and the specific surface area of the catalyst is 10-300 m<2> / g, and the pore volume is 0.2-0.65 ml / g, wherein Fe and Co are loaded on the carrier in an impregnating manner, and the Fe and Co supported carrier is calcined, and is reduced in a hydrogen atmosphere to prepare the catalyst. Reaction conditions are as follows: the inlet temperature is 30-50 DEG C, the pressure is 1.5-3.5 MPa, the liquid space velocity is 15-120 h<-1>, and a ratio of hydrogen / MAPD is 1-10. The catalyst has the advantages of good hydrogenation activity, excellent olefin selectivity, high olefin increment and good long-period running performance, and has a lower cost than a precious metal Pd catalyst.

Owner:PETROCHINA CO LTD

Direct epoxidation process using modifiers

The invention is a process for epoxidizing an olefin with hydrogen and oxygen in the presence of a noble metal-containing titanium or vanadium zeolite and a modifier selected from the group consisting of carbon monoxide, methylacetylene, and propadiene. The process results in significantly reduced alkane by-product formed by the hydrogenation of olefin compared to processes that do not use the carbon monoxide, methylacetylene, and / or propadiene modifier.

Owner:LYONDELL CHEM TECH LP

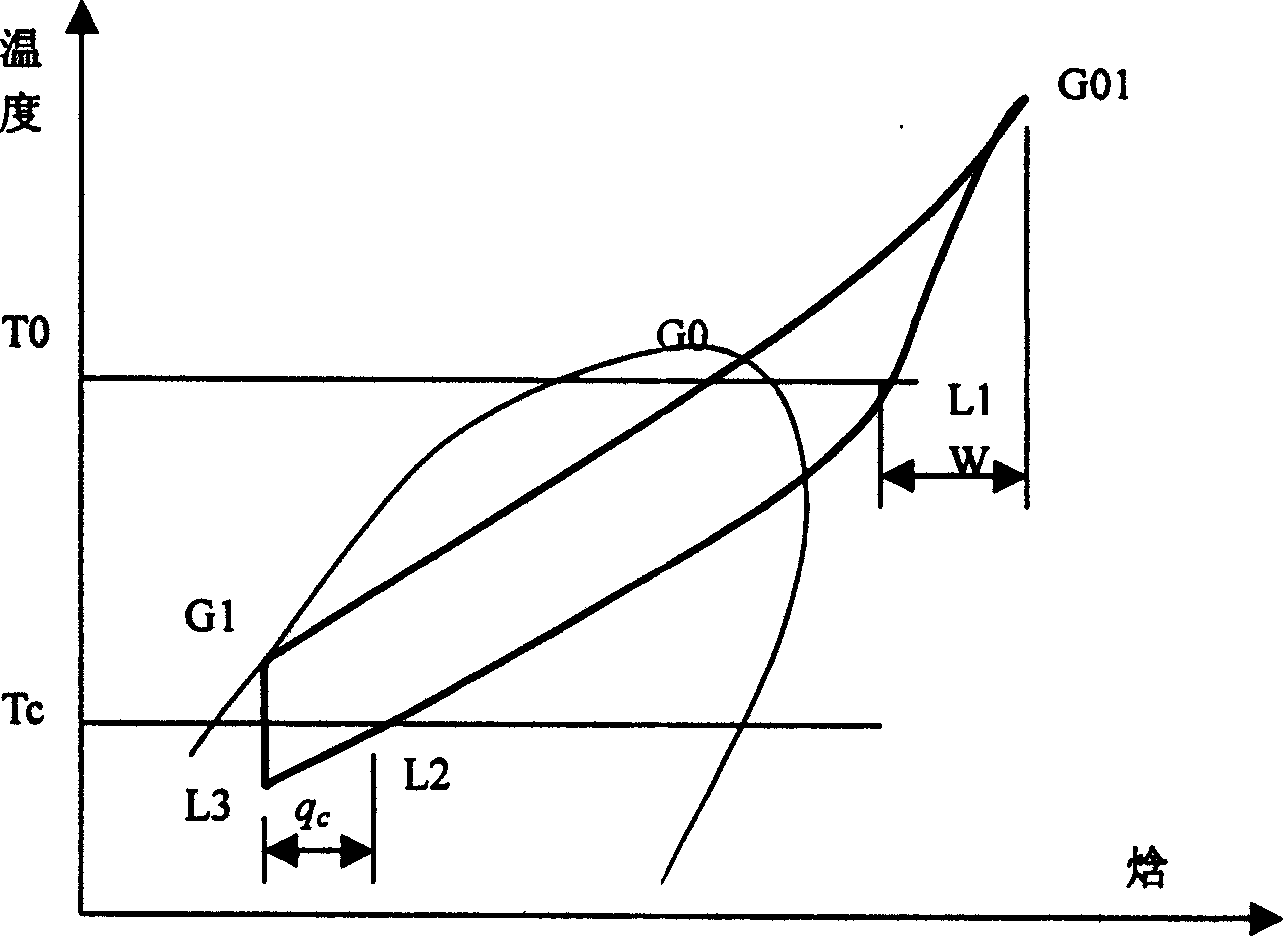

Method for liquid phase selective hydrogenation of C3 hydrocarbons

ActiveCN101139242BIncrease temperatureAvailable heatHydrocarbon by hydrogenationGas phaseHydrogenation reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

Sealing rubber strip for automobile window and preparation method of sealing rubber strip

The invention discloses a sealing rubber strip for an automobile window. The sealing rubber strip is made of the following materials in parts by weight: 22-26 parts of polyvinyl chloride, 40-45 parts of ethylene-propylene-diene-terpolymer rubber, 6-10 parts of paraffin, 7-11 parts of poly propadiene siloxane, 12-15 parts of tert-Butylhydroquinone, 18-20 parts of diisobutyl phthalate, 9-14 parts of sulfydryl acid ester, 8-12 parts of lauryl alcohol polyoxyethylene, 6-12 parts of sodium fluosilicate, 2-4 parts of coal gangue, 15-20 parts of carbon black, 2-3 parts of trichlorofluoromethane, 4-8 parts of sodium alcohol ether sulfate, 6-11 parts of aluminum borate crystal whisker, 12-14 parts of silicic acid hydrate, 9-15 parts of sodium antimonate, 3-8 parts of diisopropylamine and 7-11 parts of glyceryl tristearate. The sealing rubber strip of the automobile window is provided with bubbles inside and is good in elasticity, good in corrosion resistance and aging resistance, and long in service life.

Owner:芜湖天鸿汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com