Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127 results about "Fluoromethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluoromethane, also known as methyl fluoride, Freon 41, Halocarbon-41 and HFC-41, is a non-toxic, liquefiable, and flammable gas at standard temperature and pressure. It is made of carbon, hydrogen, and fluorine. The name stems from the fact that it is methane (CH₄) with a fluorine atom substituted for one of the hydrogen atoms. It is a seldom used fluorocarbon.

Multi-element mixed working substance adapted to double temperature preparation of single-unit vapor compression type refrigerator

The invention relates the multicomponent mixed working substance used for preparing dual-temperature by single-machine vapor compression refrigerator. The low temperature is between -60- -40Deg.C and the high temperature is between -25- 10Deg.C. The multicomponent mixed working substance comprises lower boiling working substance and high boiling working substance. The lower boiling working substance comprises tetrafluoromethane, ethylene, ethane, fluoroethylene, trifluoromethane, fluoromethane, hydrofluoeic ether, carbon dioxide, difluoromethane and penfluoroethane; the high boiling working substance comprises trifluoro-thane, hydrofluoeic ether, propylene, propane, perfluoropropylamine, propadiene, cyclopropane, difluo-monochloromethane, penta-monochloroethane, perfluoroethane, difluoroethane, isobutene, butane, butylenes, isobutylene, sevofluoropropane, hexafluoropropane, penfluoropropane and tetrachloromonofluoroethane.

Owner:XI AN JIAOTONG UNIV

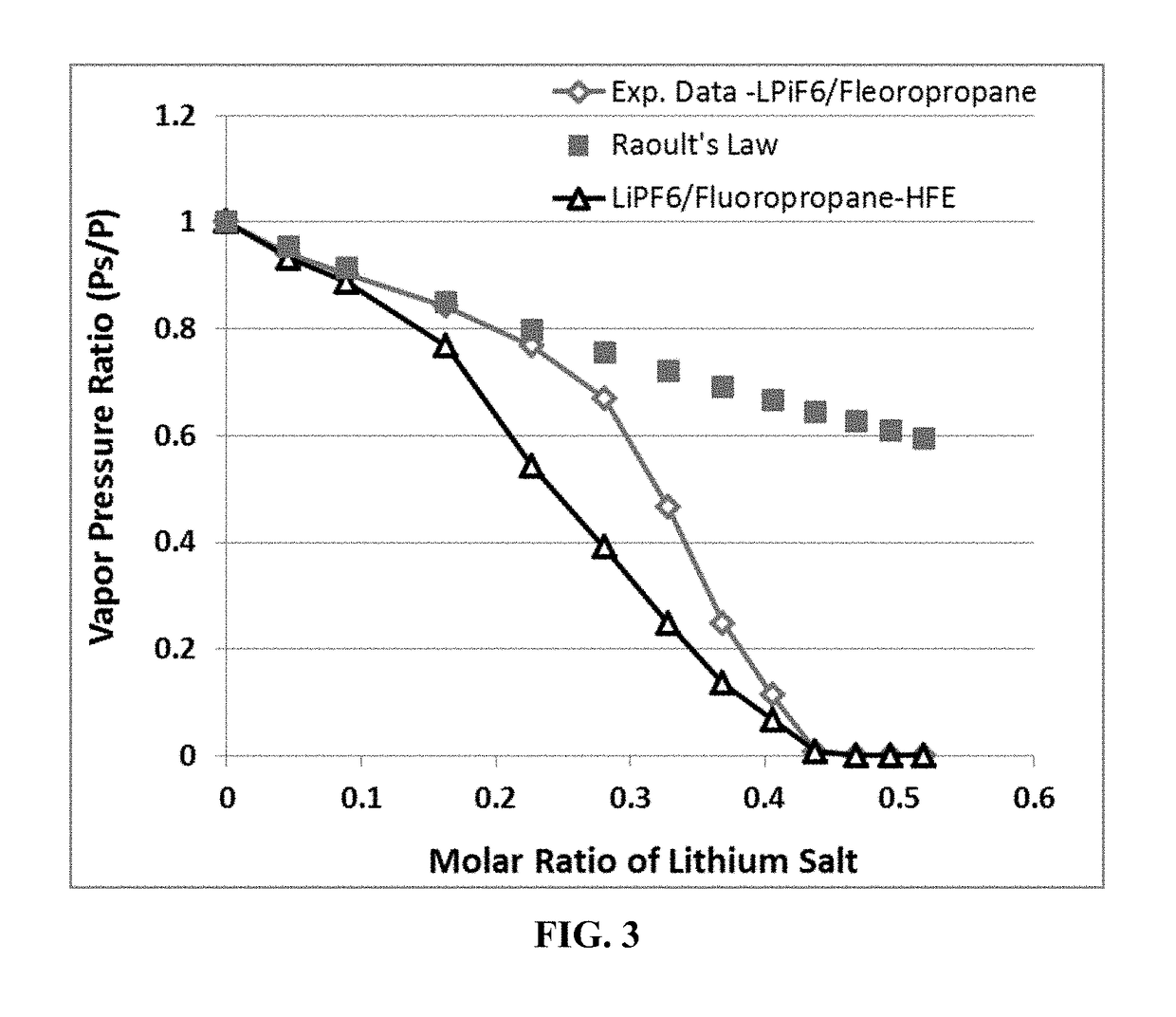

Non-flammable Electrolyte Containing Liquefied Gas and Lithium Secondary Batteries Containing Same

ActiveUS20180375156A1Flammability of any liquefied gas solvent can be effectively suppressedImprove solubilityOrganic chemistryCell electrodesElectrolytic agentDifluoroethyne

A rechargeable lithium cell comprising a cathode, an anode, an optional ion-permeable membrane disposed between the anode and the cathode, a non-flammable salt-retained liquefied gas electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in or mixed with a liquefied gas solvent having a lithium salt concentration greater than 1.0 M so that the electrolyte exhibits a vapor pressure less than 1 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquefied gas solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the liquefied gas solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquefied gas solvent is selected from methane, fluoromethane, difluoromethane, chloromethane, dichloromethane, ethane, fluoroethane, difluoroethane, tetrafluoroethane, chloroethane, dichloroethane, tetrachloroethane, propane, fluoropropane, chloropropane, ethylene, fluoroethylene, chloroethylene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Working medium for heat cycle, composition for heat cycle system, and heat cycle system

ActiveCN107614652AFully playLow greenhouse potentialHeat-exchange elementsCompression machinesKryptonEngineering

This working medium for a heat cycle contains trifluoroethylene and a first component comprising at least one substance selected from carbon dioxide, fluoromethane, trifluoroiodomethane, methane, ethane, propane, helium, neon, argon, krypton, xenon, nitrogen, and ammonia.

Owner:ASAHI GLASS CO LTD

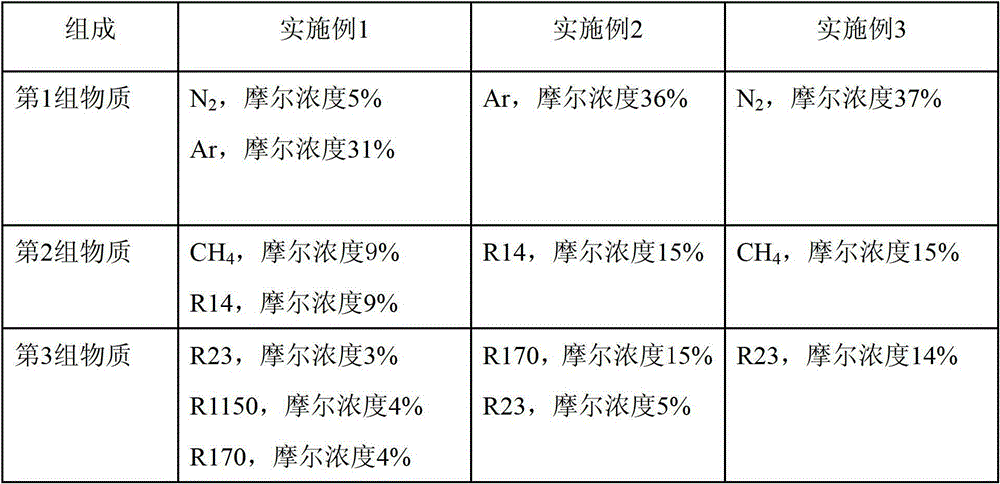

Multi-element mixed refrigerant suitable for cryogenic regions of -130 to -180 DEG C

ActiveCN102719226AIncrease concentrationReduce concentrationHeat-exchange elementsHexafluoropropylenePerfluorobutane

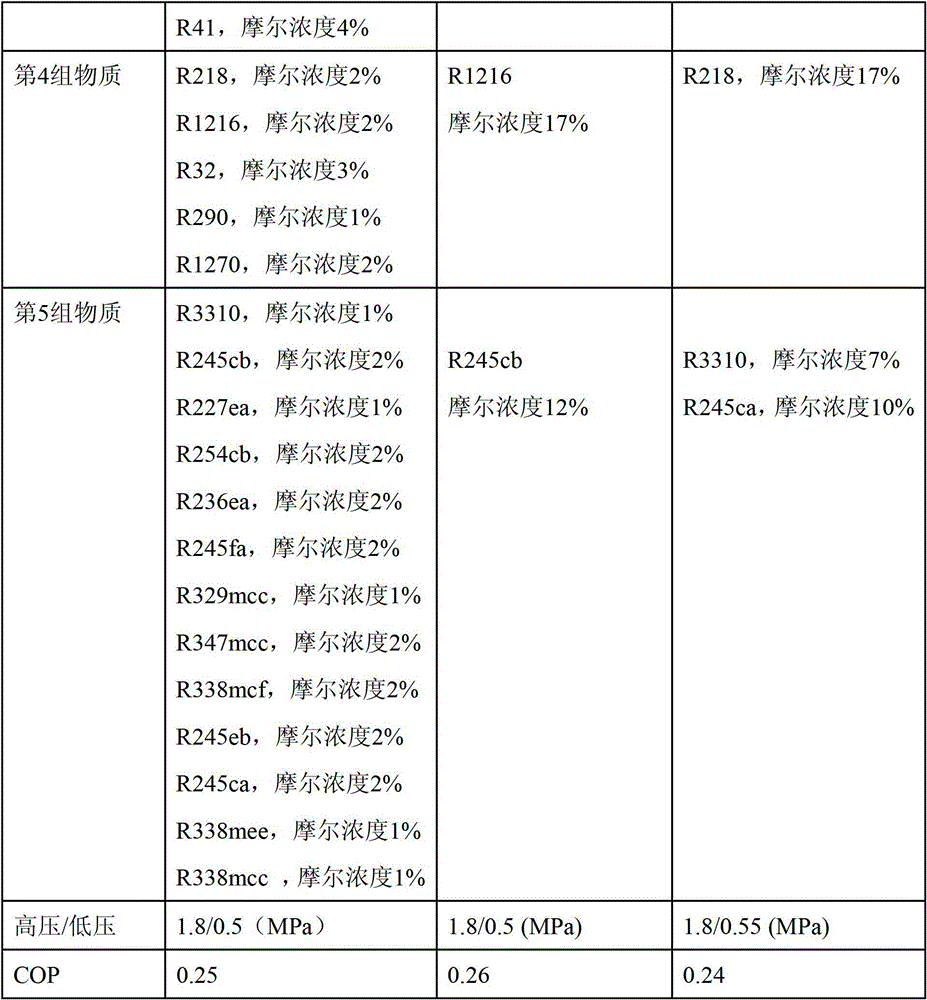

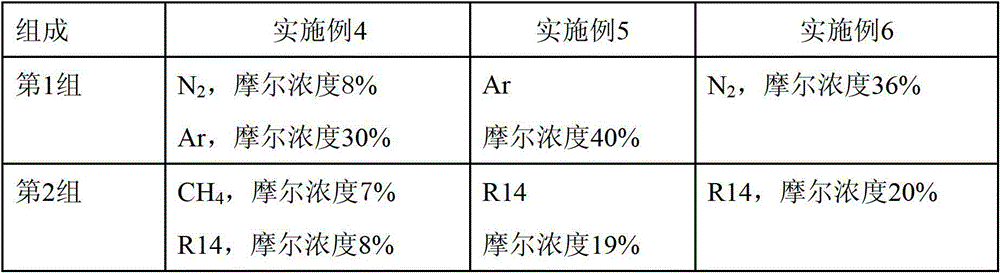

A multi-element mixed refrigerant suitable for cryogenic regions of -130 to -180 DEG C comprises five groups of substances: 1) the combination of at least two of nitrogen, argon, neon or alkyl; 2) tetrafluoromethane and methane or the combination thereof; 3) trifluoromethane, ethane, ethylene and fluoromethane or the combination of at least two thereof; 4) perfluoropropane, difluoromethane, propane, propylene and hexafluoropropylene or or the combination of at least two thereof; 5) 1,1,1,2,2-perfluoropropane, 1,1,1,2,3,3,3-heptafluoropropane, perfluoro-n-butane, 1,1,2,2-tetrafluoropropane, 1,1,1,2,3,3-hexafluoropropane, 1,1,1,3,3-perfluoropropane, 1,1,1,2,2,3,3,4,4-nonafluorobutane, 1,1,1,2,2,3,3-sevofluorobutane, 1,1,1,2,2,4,4,4-perfluorobutane, 1,1,2,3-perfluoropropane, 1,1,2,2,3-perfluoropropane, 1,1,1,2,3,4,4,4-perfluorobutane and 1,1,1,2,2,3,3,4-perfluorobutane or the combination of at least two thereof. The multi-element mixed refrigerant can achieve refrigeration of -130 to -180 DEG C safely and efficiently, the greenhouse effect is low and no ozone layer is destroyed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Selective oxygen-free etching process for barrier materials

InactiveUS7129171B2High selectivitySemiconductor/solid-state device manufacturingOxygenNitrous oxide

A method of etching a barrier layer in an integrated circuit (IC) wherein said barrier layer is composed of silicon nitride or silicon carbide. The method comprises receiving an etched IC structure having an exposed barrier layer. The method then proceeds to apply an etchant gas mixture comprising a nitrous oxide (N2O) gas and a fluoromethane (CH3F) gas. The etchant gas mixture provides a relatively high selectivity between the barrier layer to an adjacent dielectric layer.

Owner:LAM RES CORP

Method for preparing fluoromethane

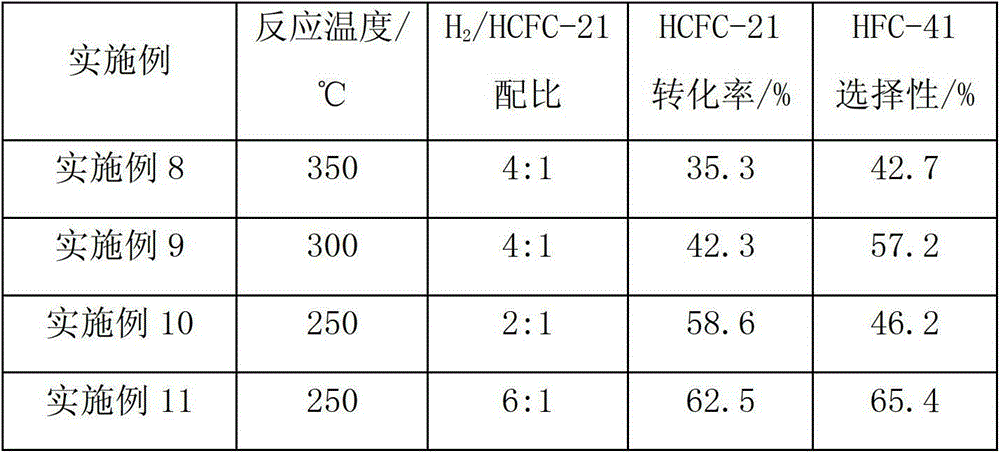

InactiveCN104016829ANovel synthetic method of HFC-41Simple production processPreparation by dehalogenationHydrogenCarbide

The invention provides a method for preparing fluoromethane. In the presence of a catalyst, CHxClyF (x is equal to 0, 1 and 2, and y is equal to 3, 2 and 1) and hydrogen are subjected to hydrodechlorination reaction so as to generate HFC-41, the catalyst is selected from a self-loaded type Ni catalyst, a loaded type Pd catalyst, a loaded type Pt catalyst, a loaded type Rh catalyst or a metal carbide catalyst, and the metal carbide catalyst is selected from Mo2C, WC or W2C. The method provided by the invention is simple in process route, safe in production and environmentally friendly.

Owner:SINOCHEM LANTIAN +1

Method for preparing ultrapure fluoromethane

InactiveCN103910600AFast adsorption rateSuitable for mass productionHalogenated hydrocarbon preparationMolecular sieveActivated carbon

The invention provides a method for preparing ultrapure fluoromethane through an adsorption process. Impurities in crude fluoromethane are removed by adopting A-type molecular sieve and / or active carbon with the particle size of 1.5-3.0mm, and the A-type molecular sieve and active carbon are activated before use. Highly pure fluoromethane with the purity of above 99.99 even 99.9999% can be obtained through the preparation method, and the prepared ultrapure fluoromethane can be used in the semiconductor / electron industry as an etching gas.

Owner:SINOCHEM LANTIAN +1

Separation equipment and separation process for HF (Hydrogen Fluoride) in difluoromethane reaction gas

InactiveCN104888574ASimple structureReduce energy consumptionChlorine/hydrogen-chlorideDispersed particle separationIon contentPollution

The invention discloses separation equipment for HF (Hydrogen Fluoride) in a difluoromethane reaction gas. The equipment comprises an HF absorption tower, a falling film absorber, a water scrubber, an alkali scrubber and circulating pumps arranged on the water scrubber and the alkali scrubber. The invention further discloses a separation process for HF in the difluoromethane reaction gas. The separation process comprises the following steps: introducing the difluoromethane reaction gas which flows through a reflux tower into the HF absorption tower, feeding 98wt% concentrated sulfuric acid in an elevated tank through the tower top of the HF absorption tower, and feeding a mixed gas absorbed by the HF absorption tower into the falling film absorber; then feeding the mixed gas into the water scrubber, circulating until the hydrochloric acid concentration is about 32%, and collecting; and recycling concentrated sulfuric acid in a tower kettle of the HF absorption tower to an anhydrous hydrogen fluoride production device. The HF absorption tower for removing HF is simple in structure, operates at a normal temperature and pressure, and is low in energy consumption; concentrated sulfuric acid, which contains a certain amount of HF and is obtained by the HF absorption tower, is fed into the anhydrous hydrogen fluoride production device so as to be reused, so that wastes of raw materials are reduced; the hydrochloric acid obtained by the process is high in quality, the fluorine ion content is not more than 50ppm, and the environment pollution is reduced.

Owner:JIANGSU SANMEI CHEM

N2O-containing low temperature mixing working substance for cascade refrigeration system

InactiveCN101434831ADestruction will notSmall slip temperatureHeat-exchange elementsHexafluoroethaneBoiling point

The invention relates to a cascade refrigeration system low-temperature mixed refrigerant which is applicable to the temperature area of 180-220K and contains N2O, and a preparation method thereof; the low-temperature mixed refrigerant comprises one or two components of low-boiling point refrigerant N2O(R744A), ethane (R170), fluoromethane (R23), hexafluoroethane (R116), fluoromethane (R41), and CO2 (R744) and is formed by physical mixing at normal temperature. The low-temperature mixed refrigerant damages no ozonosphere, has low greenhouse effect potential, meets the requirement of environmental protection, has suitable thermal parameters and excellent circulation performance, and can optimize and design the new refrigerant system by the existing cascade low-temperature compressor. The mixed refrigerant can be used for replacing the refrigerant in the existing cascade refrigeration low-temperature system.

Owner:XI AN JIAOTONG UNIV

Method for etching inclined shoulder type side wall in large scale integrated circuit logic device

ActiveCN101202229AGood for filling growthReduce the chance of occurrenceSemiconductor/solid-state device manufacturingVery large scale integrated circuitsEtching

The invention discloses an etching method used for a shoulder-style side wall of a logic component of an ultra large scale integrated circuit, adopting a plasma-drying etching method to remove most of silicon oxide and silicon nitride medium films to form a side wall. The method includes the following steps: step A, main etching of top silicon nitride: adjusting electrode power, cavity pressure and flow proportion of reaction gases to raise isotropy etching trends so as to acquire an inclined top shoulder form of the side wall; step B, over-etching of silicon nitride: regulating proportions of fluoromethane and oxygen to get a high selection ratio of 16:1 to 22:1 between silicon nitride and silicon oxide. The invention adopts the method of raising the gradient of the top shoulder of the side wall to solve the problem of holes in the following PMD settlement process caused by the continuous reduction of the space between polysilicon grids so as to enhance the reliability of the component.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Mixed working medium containing fluoroethane and trifluoroethylene

ActiveCN111849420AReduced greenhouse effect potentialPromote environmental protectionChemical industryHeat-exchange elementsHexafluoropropyleneTrifluoroiodomethane

The invention discloses a mixed working medium containing fluoroethane and trifluoroethylene, and belongs to the field of power engineering and engineering thermophysics. The mixed working medium containing fluoroethane and trifluoroethylene comprises the first component trifluoroethylene and the second component fluoroethane, and other one or two compounds must be mixed into the first component trifluoroethylene and the second component fluoroethane. When a ternary mixture is formed, any one of pentafluoroethane, difluoromethane, trifluoroiodomethane and hexafluoropropylene needs to be added;when a quaternary mixture is formed, two of pentafluoroethane, difluoromethane, trifluoroiodomethane, hexafluoropropylene, propane and dimethyl ether need to be added, but any two of propane, dimethyl ether and difluoromethane are not added at the same time. Compared with R-404A, the greenhouse effect potential of the multi-component mixed working medium provided by the invention is greatly reduced. The condensation pressure of the mixed working medium is equivalent to that of the R-404A, and the mixed working medium has the technical advantage that main related systems or components of the current R-404A continue to be used. Compared with the R-404A, the mixed working medium has higher heat conduction capacity and lower flow resistance, and further optimization and improvement of a heatexchanger are facilitated. The refrigeration cycle performance coefficient of the mixed working medium is higher than that of the R-404A, and the energy-saving significance is achieved.

Owner:DALIAN UNIV OF TECH

Fluoromethane production process and product

ActiveCN101023051AEfficient separationHigh purityPreparation by halogen replacementBulk chemical productionHydrogen fluorideDistillation

Methyl chloride and hydrogen fluoride are reacted in a gas phase in the presence of a fluorination catalyst and the resulting mixture, containing fluoromethane and hydrogen chloride, is fed to a distillation column for separation and purification of the fluoromethane and hydrogen chloride as the overhead fraction. It is thus possible to efficiently produce high purity HFC-41 which is suitable for use as a semiconductor etching gas.

Owner:株式会社力森诺科

Selective oxygen-free etching process for barrier materials

ActiveUS20050079725A1High selectivitySemiconductor/solid-state device manufacturingNitrous oxideOxygen

A method of etching a barrier layer in an integrated circuit (IC) wherein said barrier layer is composed of silicon nitride or silicon carbide. The method comprises receiving an etched IC structure having an exposed barrier layer. The method then proceeds to apply an etchant gas mixture comprising a nitrous oxide (N2O) gas and a fluoromethane (CH3F) gas. The etchant gas mixture provides a relatively high selectivity between the barrier layer to an adjacent dielectric layer.

Owner:LAM RES CORP

Method for pretreating and regenerating catalysts used in a process for making fluoroiodoalkanes

ActiveUS20090137852A1Reduce length of induction periodCatalyst regeneration/reactivationChemical recyclingAlkaneHydrogen fluoride

A process for the preparation of a fluoroiodoalkane represented by the structural formula CF3(CF2)n—I, wherein n is 0 or 1. The process has the step of reacting a source of iodine with a compound represented by the structural formula CF3(CF2)n—Y, wherein Y is selected from H, Cl, Br and COOH and wherein n is 0 or 1. The reaction is carried out at a temperature from about 100° C. to about 750° C. and at a pressure from about 0.001 to about 100 atm for a contact time from about 0.001 second to about 300 hours in the presence a catalyst. The catalyst is subject to one or both of the following: (a) treating the catalyst prior to the reaction via contact with a gas selected from the group consisting of hydrogen fluoride, trifluoromethane, hydrogen, hydrogen iodide, iodine, fluorine, and oxygen, wherein the contact is carried out at a temperature and for a contact time sufficient to reduce the length of the induction period of the catalyst; and (b) treating the catalyst after the reaction via contact with a gas selected from the group consisting of hydrogen fluoride, hydrogen, fluorine, oxygen, or air at a temperature and for a contact time sufficient to regenerate the catalyst.

Owner:HONEYWELL INT INC

Fluorination catalyst for preparing difluoromethane or monochlorodifluoromethane, preparation method and application

ActiveCN102527414AHigh activityExtended service lifePhysical/chemical process catalystsChemical recyclingPtru catalystChloride

The invention relates to a fluorination catalyst for preparing difluoromethane or monochlorodifluoromethane, a preparation method and an application and belongs to the catalyst preparation technology. An antimonial chloride and a promoter are mixed to be the fluorination catalyst, wherein the promoter comprises metal sulfates and a carrier; the weight percentage of the antimonial chloride to the promoter is (50-70):(30-50); the weight percentage of the carrier to the metal sulfates is (80-90):(10-20); and the obtained fluorination catalyst is used for preparing the difluoromethane or monochlorodifluoromethane. The fluorination catalyst provided by the invention is low in preparation cost and is used for preparing the difluoromethane or monochlorodifluoromethane; the operation process is simple and the condition is mild; the purity of the difluoromethane or monochlorodifluoromethane reaches up to 99%; the corrosion to equipment is small; the service life is long; the service life of the reaction equipment of the difluoromethane is increased from 2-6 months to more than 6-18 months; and the service life of the reaction equipment of the monochlorodifluoromethane is increased from 12-18 months to more than 24-36 months.

Owner:LINHAI LIMIN CHEM

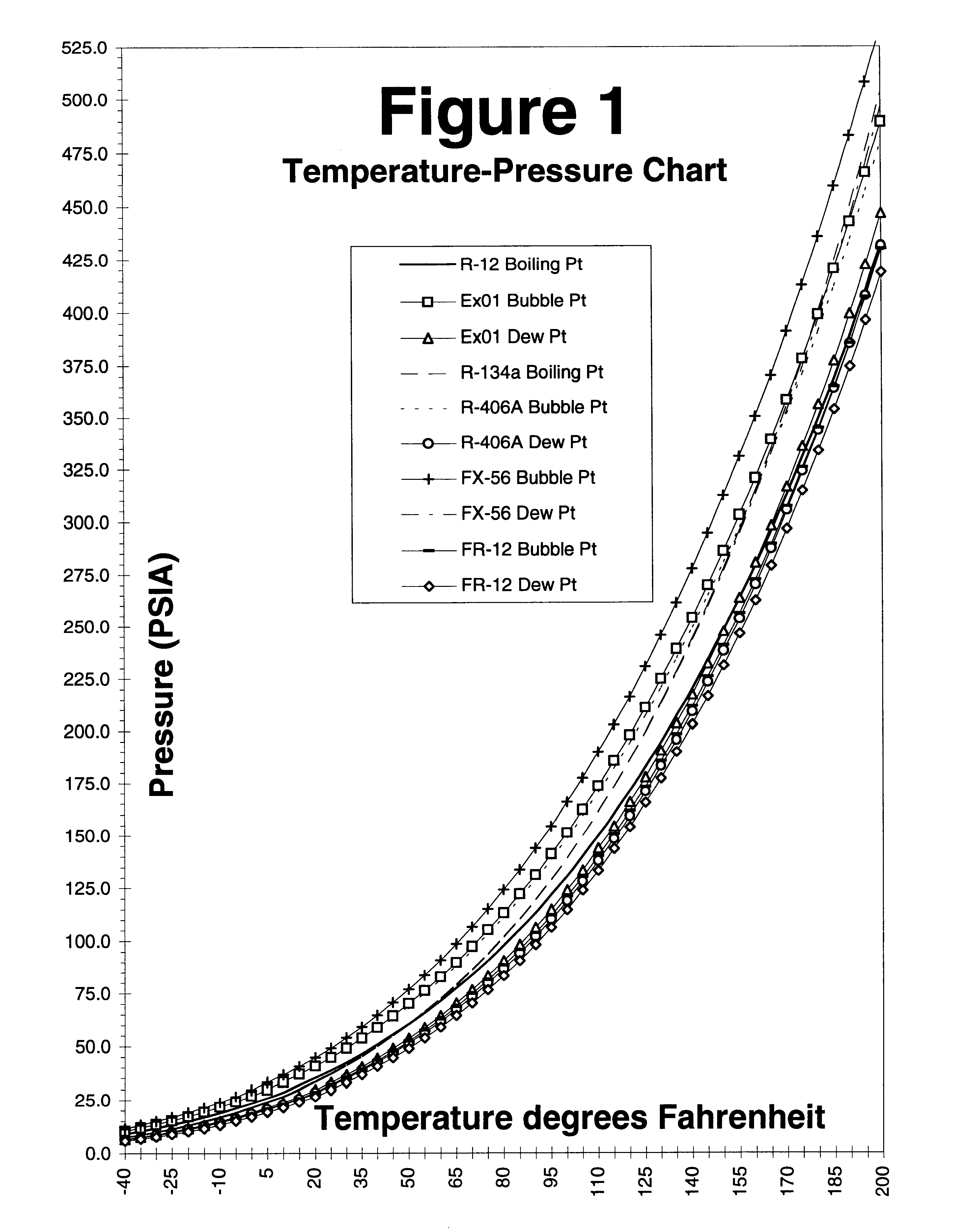

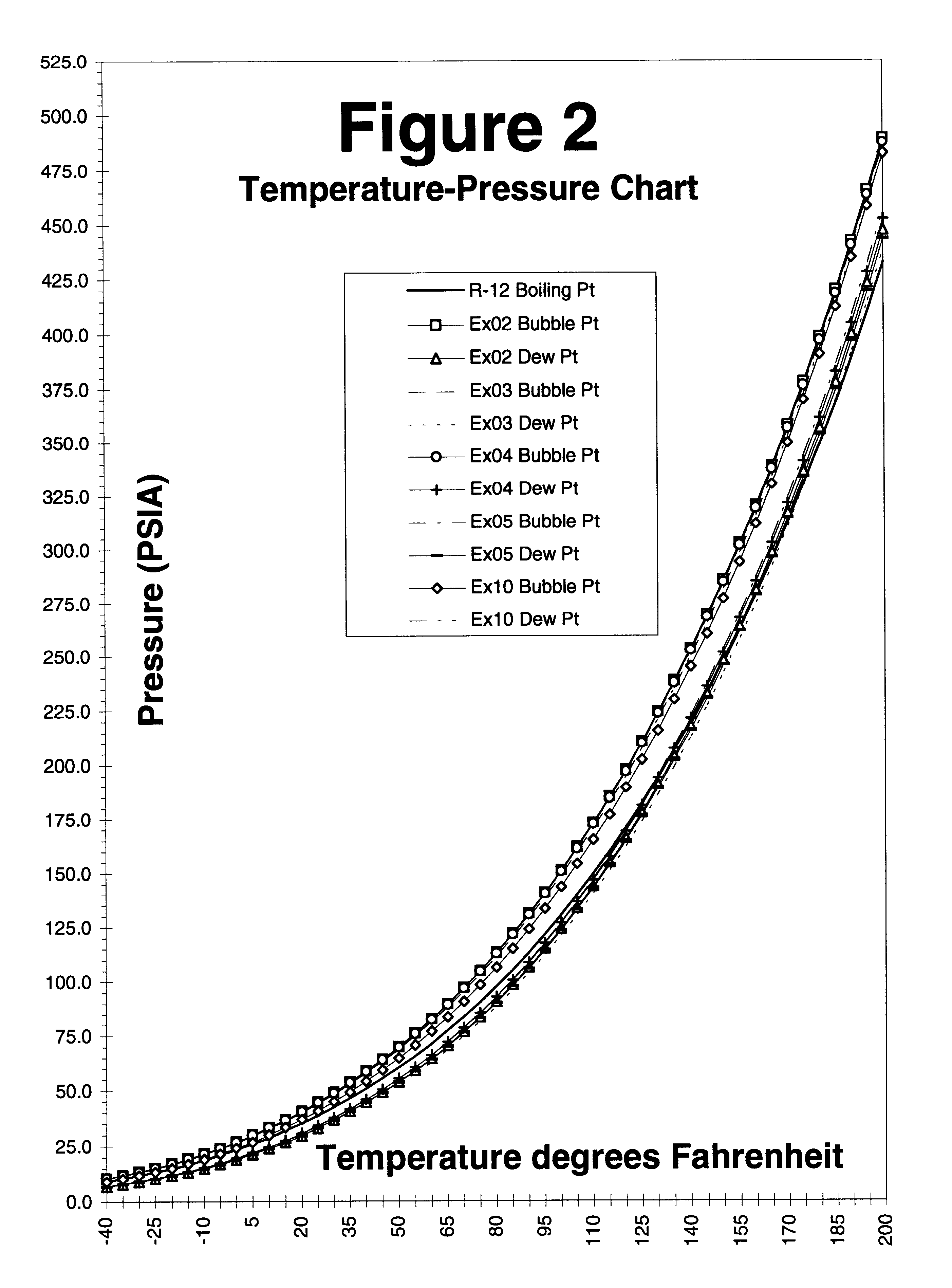

Environmentally safer replacement refrigerant for freon 12-based refrigeration systems

InactiveUS6565766B1Low vapor pressureAvoid damageCompression machines with non-reversible cycleHeat-exchange elementsDichlorodifluoromethaneEngineering

An apparatus and method wherein ozone layer-damaging dichlorodifluoromethane is substituted with a mix of less environmentally damaging refrigerants chlorodifluoroethane and tetrafluoroethane in dichlorodifluoromethane-based air-cooling systems. While less environmentally damaging than dichlorodifluoromethane, the substitute refrigerant has a temperature-pressure relationship similar to that of dichlorodifluoromethane, making the substitute refrigerant suitable for use with dichlorodifluoromethane-based air-cooling systems. The substitute refrigerant can be used alone or in combination with dichlorodifluoromethane. In either event, it is mixed with a relatively small percentage of a hydrophobic lubricating oil which is compatible with both the substitute refrigerant and with dichlorodifluoromethane.

Owner:KENNETH B RUELLO

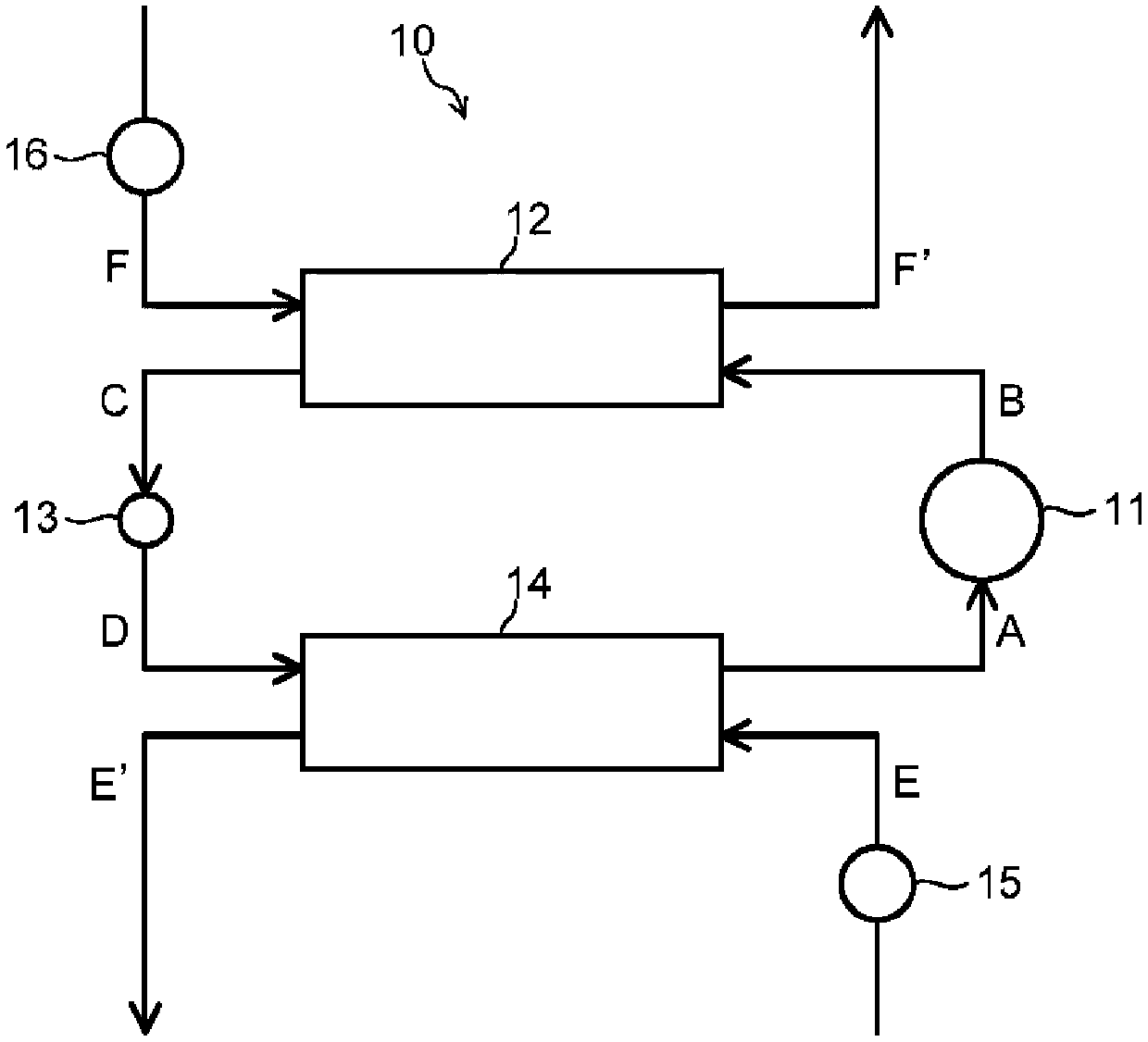

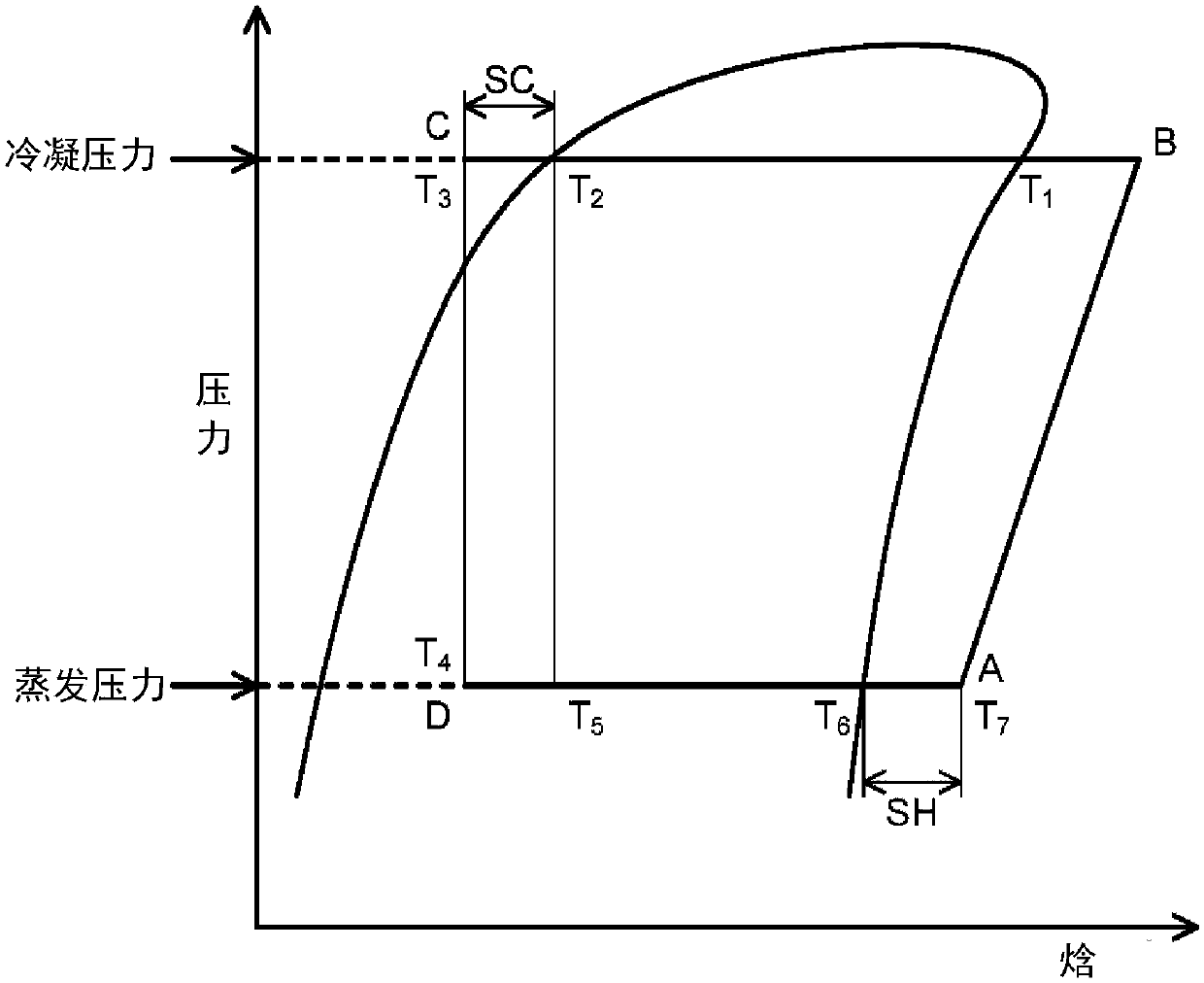

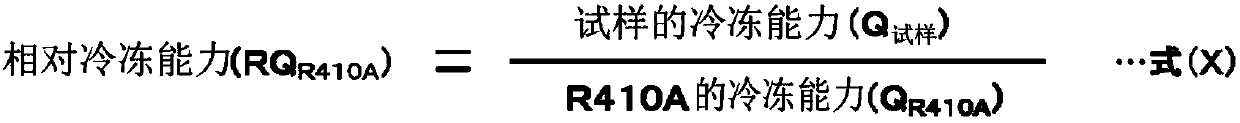

Test chamber

PendingCN108779941AFree from damageMechanical apparatusPreparing sample for investigationHexafluoroethaneEngineering

Owner:WEISS UMWELTTECHNIK GMBH

Method for preparing high purity tetrafluoromethane through combination of rectification and adsorption

InactiveCN102399126AContinuous and stable purificationSolve the disadvantages of unstable purificationHalogenated hydrocarbon separation/purificationHydrogen fluoridePhysical chemistry

The invention discloses a method for preparing high purity tetrafluoromethane through combination of rectification and adsorption. The method is mainly characterized in that: equipment for generating tetrafluoromethane continuously supplies the tetrafluoromethane, and fluorochloromethane and potassium bifluoride are subjected to gas-phase reaction to form the tetrafluoromethane. In the method for preparing the high purity tetrafluoromethane, a raw material preparation system, a tetrafluoromethane gas preparation system and a liquefying and gasifying system for the tetrafluoromethane purified through combination of rectification and adsorption. The method has the advantages that: the product has high yield and high purity (99.0-99.9 percent), has a few impurities which are easy to separate; and besides the product, other harmful and toxic byproducts are absent, the operation is convenient, and the method is an ideal technology for preparing the high purity tetrafluoromethane.

Owner:TIANJIN TAIYUAN INDAL GAS

Compositions

ActiveUS11136482B2Reduce environmental impactImprove propertiesOther chemical processesNon-surface-active detergent compositionsVinyl fluorideEthylene

The invention provides a composition comprising 1,1-difluoroethene (R-1132a), difluoromethane (R-32), 2,3,3,3-tetra-fluoropropene (R-1234yf), optionally carbon dioxide (CO2, R-744), and, optionally, 1,1,2-trifluoroethene (R-1123).

Owner:MEXICHEM FLUOR S A DE CV

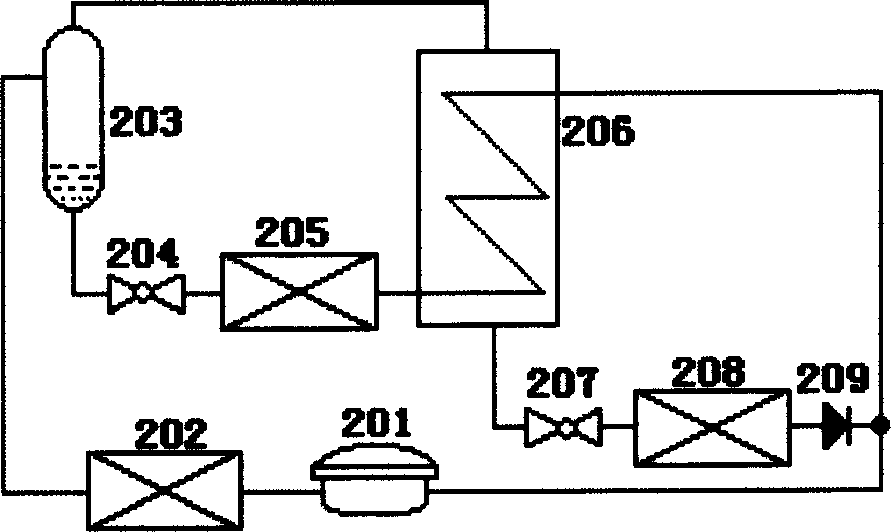

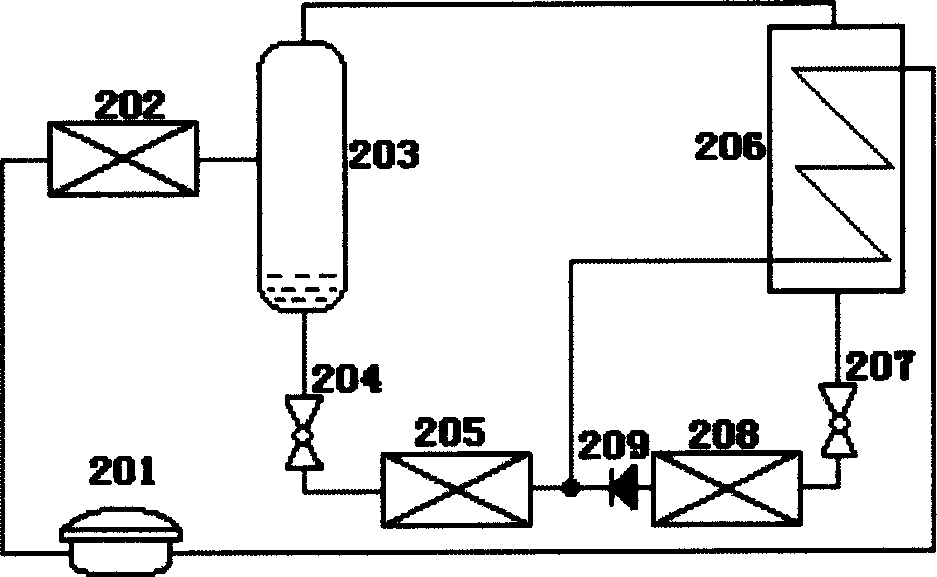

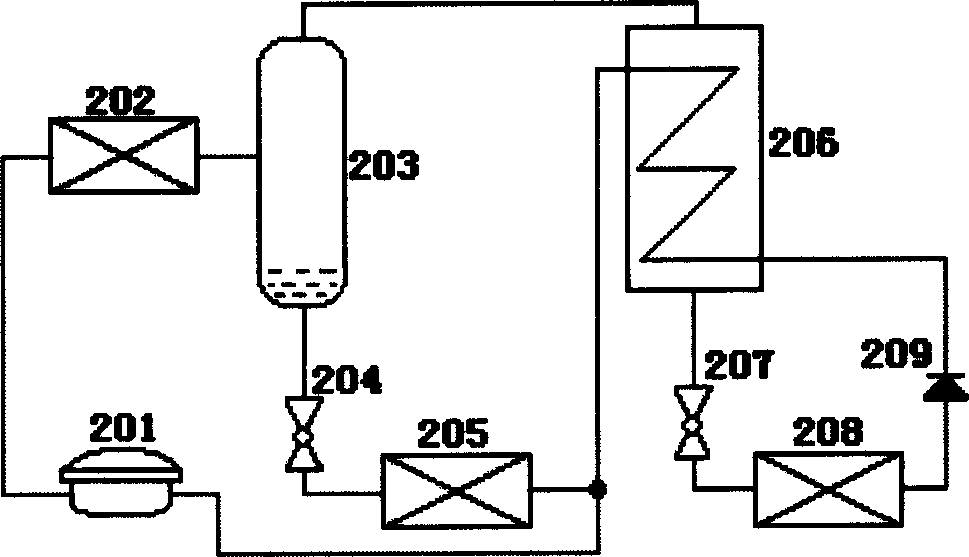

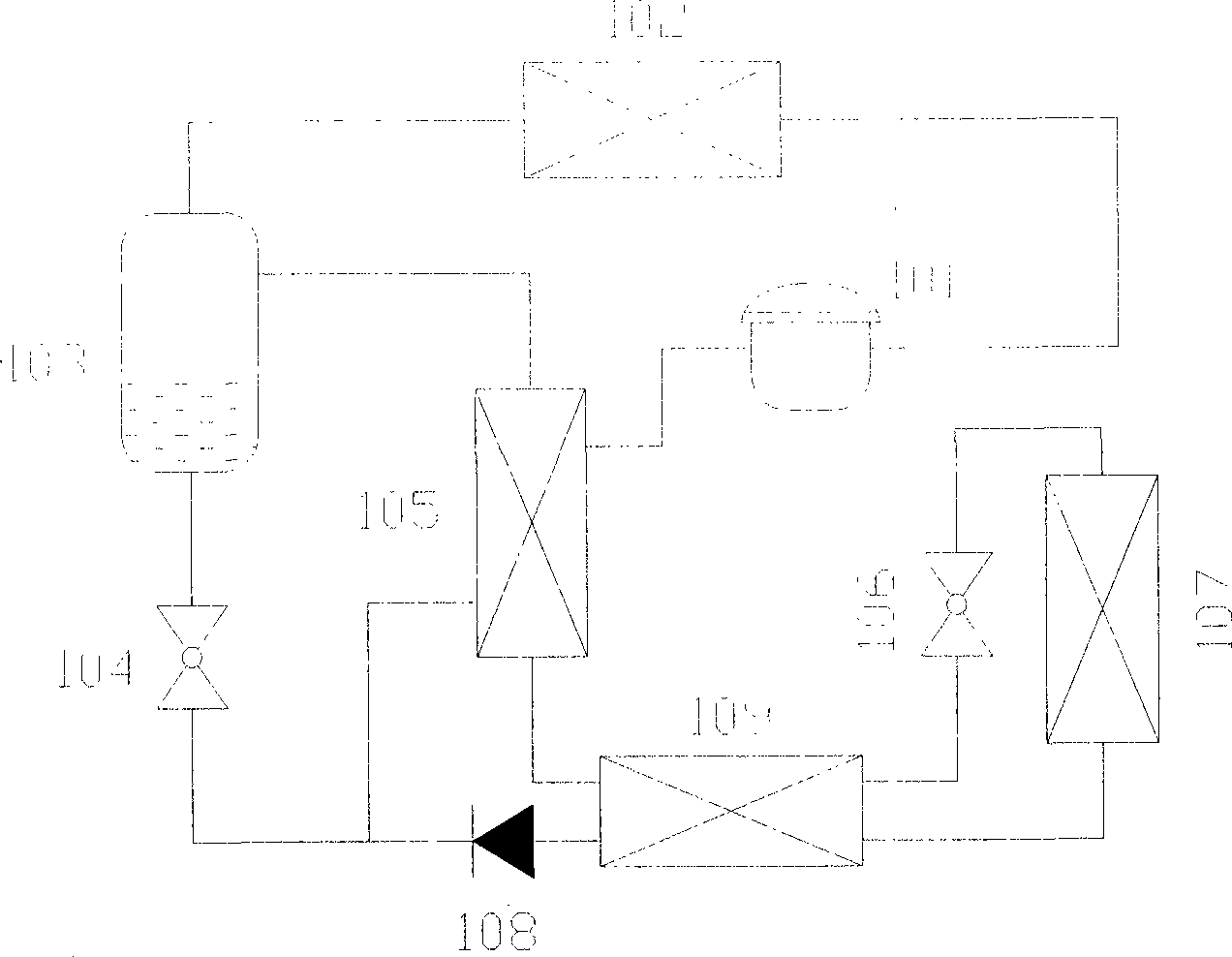

Rectification control system and rectification control method for preparing electronic-grade monofluoromethane

ActiveCN114870416AOptimizing Purification PrecisionProcess control/regulationDistillation regulation/controlControl systemProcess engineering

The invention relates to the field of intelligent manufacturing of electronic-grade gas, and particularly discloses a rectification control system and a rectification control method for preparing electronic-grade fluoromethane. The rectification control system comprises a premixer, a reactor, a separating tower, a water washing tower, an alkaline washing tower, a drying tower, a rectifying tower and a rectification control tower system, according to the rectifying tower control system, an intelligent control method based on the artificial intelligence technology is used for dynamically regulating and controlling the pressure and temperature of a rectifying tower so as to optimize the purification precision of electronic-grade fluoromethane from a control end.

Owner:FUJIAN DEER TECH CORP

Mixed working substance containing N*O in auto-cascade circulatory system

InactiveCN101445718AAchieve refrigerationConsumption potential zeroHeat-exchange elementsHexafluoroethaneSubstance use

The invention discloses a mixed working substance containing N2O in an auto-cascade circulatory system. The working substance consists of 15-50% of a first group substance by mass fraction and a second group substance in balancing amount, wherein, the first group substance is N2O or a compound formed by N2O and one or more of ethane, trifluoromethane, hexafluoroethane, fluoromethane, carbon dioxide and ethylene. Compared with the prior working substance used for the auto-cascade circulatory system, the mixed working substance provided by the invention has the following advantages: the mixed working substance provided by the invention can effectively realize the refrigeration of a temperature range of 200-240K; the ozone depletion potential (ODP) of N2O (R744A) equals to zero, and the global warming potential (GWP) thereof is relatively low; and as N2O is a natural substance which can be easily obtained, and other refrigerants matched with N2O are reasonably priced, the use of the mixed refrigerant can reduce the cost for companies.

Owner:HENAN XINFEI ELECTRICAL EQUIP +1

Environment-friendly and energy-saving refrigerator refrigerant

ActiveCN104974717AEnvironmentally friendlyReduce flammabilityChemical industryHeat-exchange elementsDichlorodifluoromethaneEngineering

The invention discloses a high efficient refrigerator refrigerant with a low global warming potential (GWP) value. The refrigerant comprises the following components in percentage by weight: 2 to 15% of 1,1,1,2-tetrafluoroethane (CF3CH2F, R134a), 0 to 80% of fluoroethane (C2H5F, R161), and 5 to 98% of dimethyl ether (C2H6O, DME). The ozone depression potential (ODP) of the mixed refrigerant is 0, the GWP value is less than 120, the environmental performance is excellent, moreover the unit-quality COP (coefficient of performance) of the refrigerant is better than that of R12 (dichlorodifluoromethane, namely freon); and at the same time, the unit-volume refrigerating capacity of the refrigerant is equivalent to R12, the slippage temperature is small, the evaporation and condensing pressures are approximate to those of R12, the refrigerant has the advantages of low displacement cost, energy saving, and environment-friendliness, and thus the refrigerant can be used to displace R12 in the long term.

Owner:TAIYUAN UNIV OF TECH

Process for preparing difluoromethane by gas phase method

InactiveCN110818526AAvoid dischargeReduce unit consumptionChlorine/hydrogen-chloride purificationPhysical/chemical process catalystsProcess engineeringReaction system

The invention discloses a process for preparing difluoromethane by a gas phase method, and relates to the field of difluoromethane production processes. The process for preparing the difluoromethane by the gas phase method comprises seven process steps. After the technical scheme is adopted, the beneficial effects of the invention are as follows: the process is suitable for large-scale production;most of HCFC-31 is recovered by a heavy component recovery tower and then returns to the reaction system again to participate in the reaction, so that the unit consumption of dichloromethane is reduced, meanwhile, the HCFC-31 is prevented from being directly discharged into the atmosphere from the tower kettle of a rectifying tower, the problem of environmental pollution is solved, the safety ofthe device is improved, and the economic benefit is remarkable.

Owner:福建省清流县东莹化工有限公司

Catalyst for preparing vinyl fluoride through gas phase removal of HF by virtue of 1,1-difluoroethane as well as preparation method and application of catalyst

ActiveCN109174139AChange active siteImprove anti-carbon performancePhysical/chemical process catalystsPreparation by hydrogen halide split-offActivated carbonMetal chloride

The invention provides a catalyst for preparing vinyl fluoride through gas phase removal of HF by virtue of 1,1-difluoroethane as well as a preparation method and application of the catalyst. The catalyst is prepared by the steps of preparing a precursor from a carrier and an active component, and carrying out roasting and trifluoromethane fluorination, wherein the carrier is activated carbon, andthe active component is metal chloride or metal nitrate. The prepared catalyst is applied to the preparation of vinyl fluoride by virtue of 1,1-difluoroethane, the anti-carbon performance of the catalyst is remarkably improved, and the service life of the catalyst is prolonged; and meanwhile, the selectivity of reaction for preparing vinyl fluoride from 1,1-difluoroethane at low temperature and the conversion rate of 1,1-difluoroethane(R152a) are relatively high.

Owner:SHANDONG DONGYUE CHEM

Environment-friendly refrigeration composition

ActiveCN106147716AReduce chargeSave resourcesHeat-exchange elements1,3,3,3-TetrafluoropropeneBoiling point

The invention discloses an environment-friendly refrigeration composition. The environment-friendly refrigeration composition is prepared from, by molar percent, 50-70% of fluoromethane and 30-50% of a second component selected from one or two or three of trans-1,3,3,3-tetrafluoropropene, 2,3,3,3-tetrafluoropropene and f-methyl methyl ether; the boiling point of the refrigeration composition is -50--75 DEG C, and the GWP value is smaller than or equal to 300. The refrigeration composition is low in GWP value, excellent in refrigeration performance, low in flammability, high in safety and suitable for replacing HFC-23 for refrigeration.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH +1

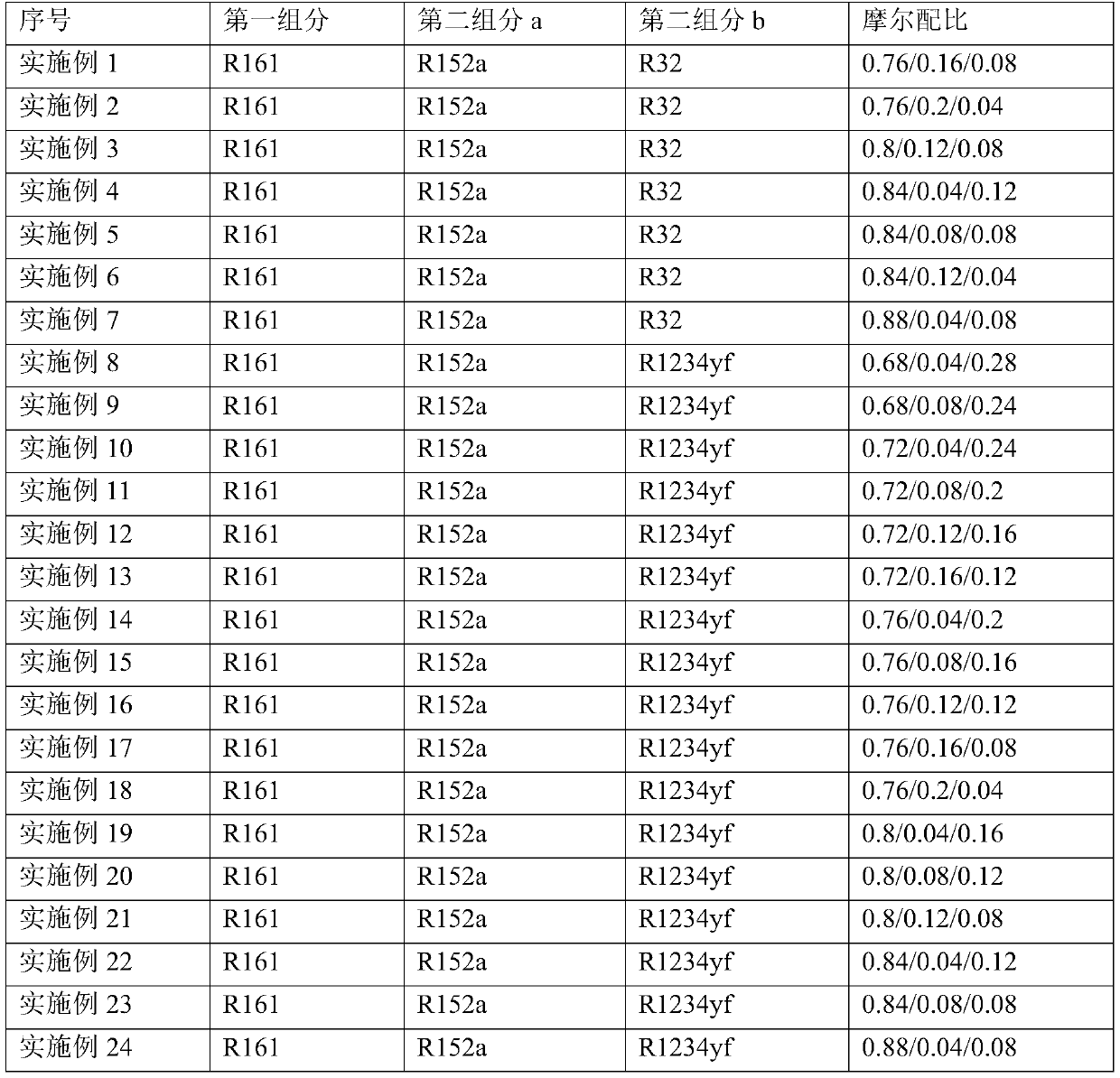

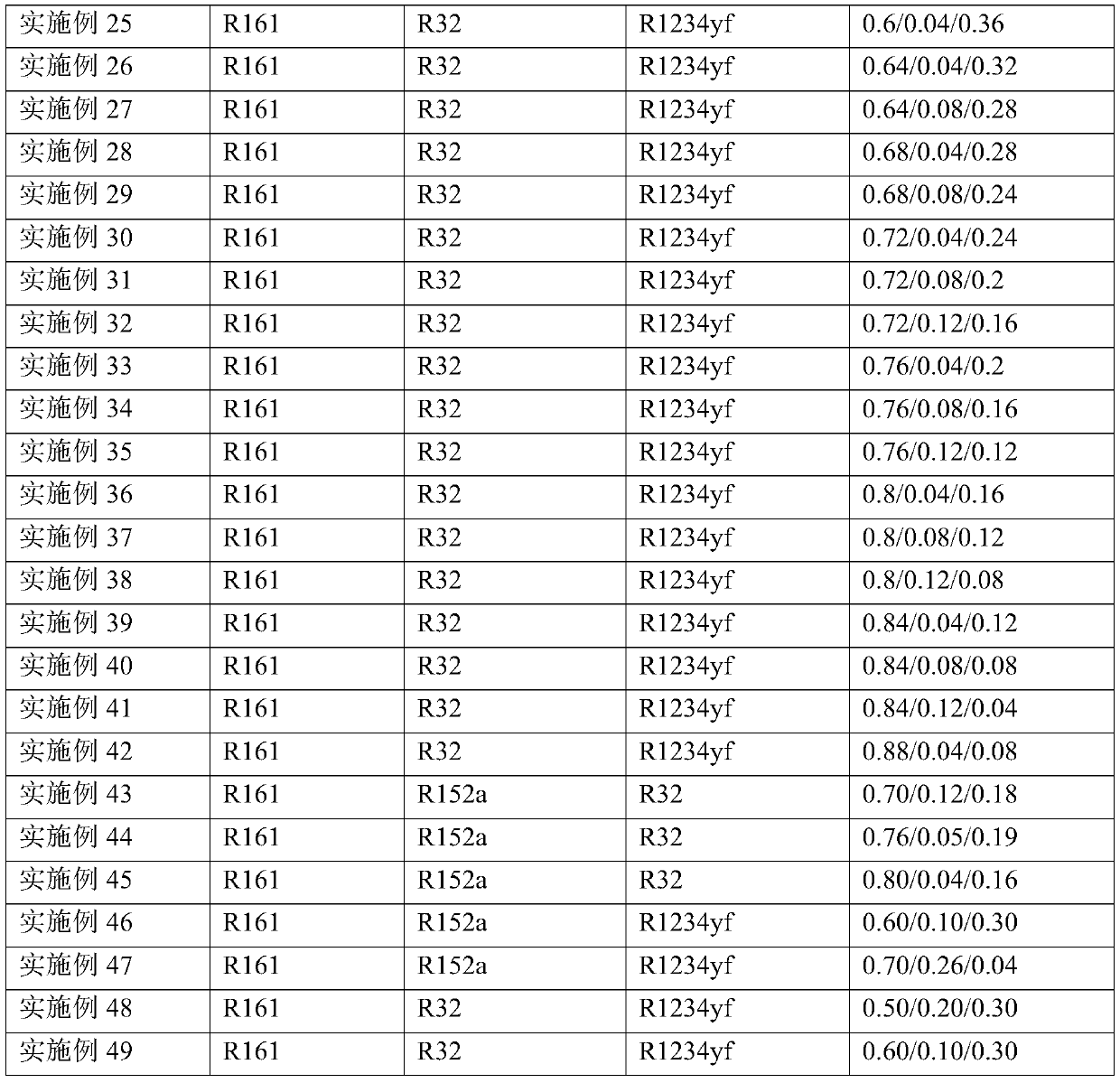

Ternary refrigeration composition and refrigeration device comprising same

ActiveCN111423852ALow GWPLow flammability ratingCompression machines with non-reversible cycleChemical industryDifluoroethyneRefrigeration

The invention provides a ternary refrigeration composition and a refrigeration device comprising the same. The ternary refrigeration composition is composed of a first component and a second component, the first component is fluoroethane, and the second component is selected from any two of 1, 1-difluoroethane, difluoromethane and 2, 3, 3, 3-tetrafluoropropene. According to the present invention,the environmental protection property and the thermodynamic property of fluoroethane are similar to those of R290 while the combustibility of fluoroethane is lower than R290, and fluoroethane and thesecond component with the combustibility of class 2 or 2L are used together, so that the refrigeration composition can have characteristics of low GWP, good thermodynamic property and low combustibility grade, and the use safety is improved; the ternary refrigeration composition has an ODP value of zero, and does not cause damage to the ozone layer even after long-term use. Therefore, the ternaryrefrigeration composition has lower GWP, ODP is 0, the combustibility is 2 types, and the capacity and the energy efficiency of a unit are equivalent to those of a unit using an R290 refrigerant whenthe ternary refrigeration composition is applied.

Owner:GREE ELECTRIC APPLIANCES INC

Drop-in Substitutes for dichlorodifluoromethane refrigerant

A group of known refrigerants, (R-227ea, R-124, R-134a, R-143a, R-125, R-E125, R-E143a, R-E227ca2, R-254cb, R-600a, R-142b, R-22, R-290, R-E170, R-1270, R-1216, R-218, R-C318, R-C270), that may be combined in novel ways to produce several excellent “drop-in” substitutes for refrigerants R-12 or R-500. The performance of the preferred “drop-in” substitutes for R-12 or R-500 of the present invention often exceeds that of the refrigerant being replaced, while maintaining acceptable oil circulation with existing mineral oils used in R-12 or R-500 refrigeration and air conditioning systems.

Owner:GOBLE GEORGE H

Coolant

The invention relates to a refrigerant for a cooling device, a test chamber for conditioning air, and a use of the refrigerant for conditioning air in a test space of the test chamber. The cooling device comprises a cooling circuit with at least one heat exchanger, the refrigerant undergoing a phase transition in the heat exchanger, the refrigerant being a refrigerant mixture composed of a mass fraction of carbon dioxide (CO2), a mass fraction of difluoromethane (CH2F2) and a mass fraction of at least one other component, wherein the mass fraction of carbon dioxide in the refrigerant mixture is 5 to 65 mass percent, the mass fraction of difluoromethane being up to 68 mass percent, the other component being trifluoroiodomethane (CF3I), fluoromethane (CH3F), ethane (C2H6), 1,1-difluoroethene(C2H2F2), ethene (C2H4), fluoroethene (C2H3F), ethyne (C2H2), propane (C3H8), propene (C3H6) and / or fluoroethane (CH2FCH3), the mass fraction being up to 55 mass percent.

Owner:WEISS UMWELTTECHNIK GMBH

Fluoromethane production process and product

ActiveCN100562510CEfficient separationHigh purityPreparation by halogen replacementBulk chemical productionHydrogen fluorideDistillation

To provide a method for efficiently producing HFC-41 having high purity and usable as an etching gas for semiconductor and provide a product produced by the method. The method for producing fluoromethane comprises reacting methyl chloride with hydrogen fluoride in gaseous phase in the presence of a fluorination catalyst to obtain a mixture containing the fluoromethane and hydrogen chloride, introducing the mixture into a distillation column, separating the fluoromethane and hydrogen chloride as a column top fraction and purifying the fluoromethane.

Owner:RESONAC CORPORATION

Refrigerant and applications thereof

ActiveCN104974718AEnvironmentally friendlyReduce flammabilityChemical industryHeat-exchange elementsDichlorodifluoromethaneEngineering

The invention discloses a high efficient refrigerator mixed refrigerant with a low global warming potential (GWP) value. The refrigerant comprises the following components in percentage by weight: 2 to 15% of 1,1,1,3,3-pentafluoropropane (C3H3F5, R245fa), 0 to 20% of fluoroethane (C2H5F, R161), and 65 to 98% of dimethyl ether (C2H6O, DME). The ozone depression potential (ODP) of the refrigerant is 0, the GWP value is less than 120, the environmental performance is excellent, moreover, the refrigerating capacity of the refrigerant in unit quality or unit volume is equivalent to R12 (dichlorodifluoromethane, namely freon), the COP (coefficient of performance) of the refrigerant is slightly higher than that of R12; and at the same time, the evaporation and condensing pressures of the refrigerant is approximate to those of R12, so the refrigerant can be directly injected into the refrigerating system that uses R12 originally, and has the advantages of low replacement cost, energy saving, and environment-friendliness.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com