Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

660results about How to "Reduce the chance of occurrence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

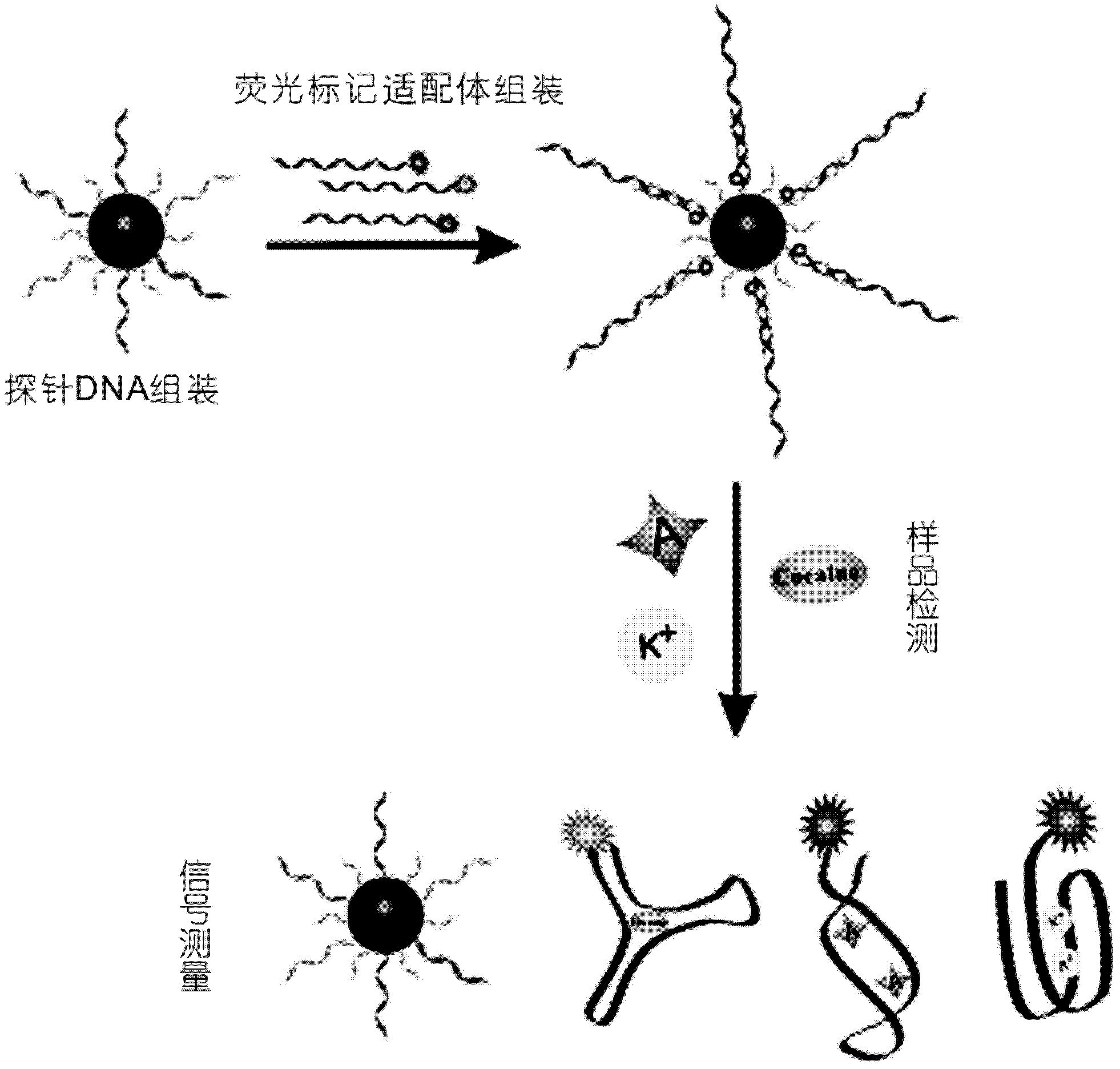

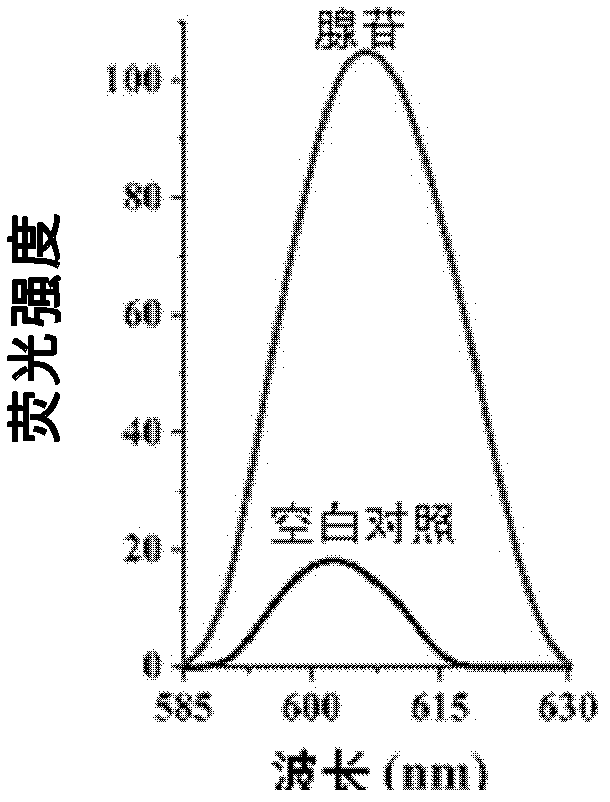

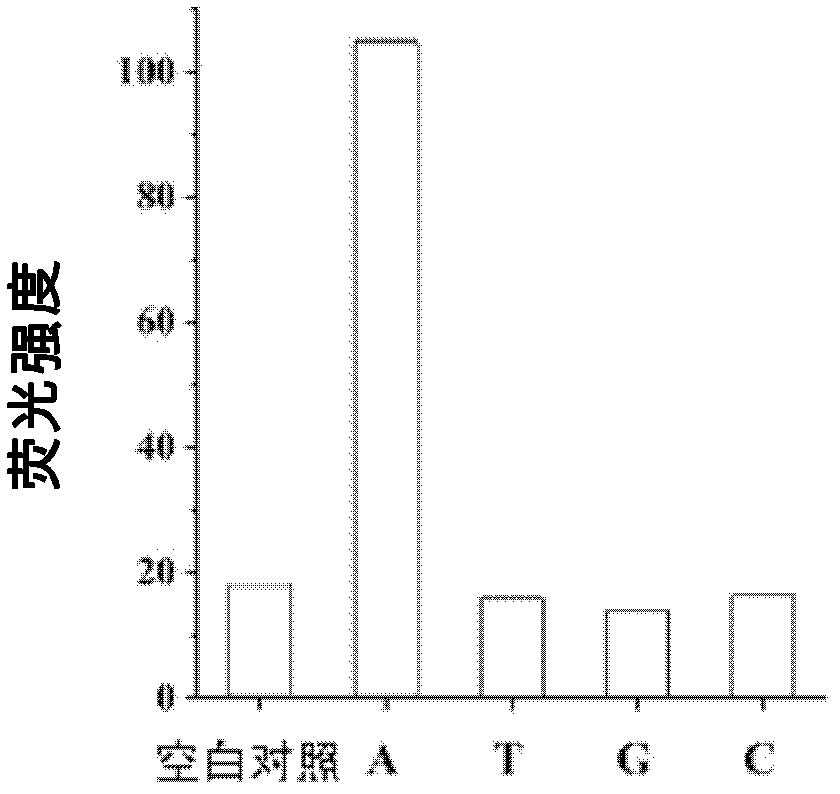

Small molecule probe based on nano-gold and aptamer and preparation method of small molecule probe

InactiveCN102676508AHigh detection sensitivityHigh quenching capacityMicrobiological testing/measurementFluorescence/phosphorescenceAptamerGold particles

The invention discloses a small molecule probe based on nano-gold and aptamer and a preparation method of the small molecule probe. The small molecule probe comprises nano-gold particles, more than one type of sulfydryl modifying deoxyribonucleic acid (DNA) fragment assembled on the nano-gold particles and more than one type of aptamer which is marked by fluorescent groups, and at least a part of fragments of the more than one type of the aptamer are complemented and hybridized with the more than one type of sulfydryl modifying DNA group. The small molecule probe is short in detecting time, simple in operation, high in specificity, good in repeatability, high in accuracy, and the false positive result is effectively reduced. By means of the aptamer technology, a high detection sensibility is achieved, and various molecules can be simultaneously detected.

Owner:华森新科(苏州)纳米技术有限公司

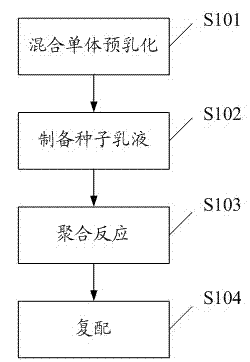

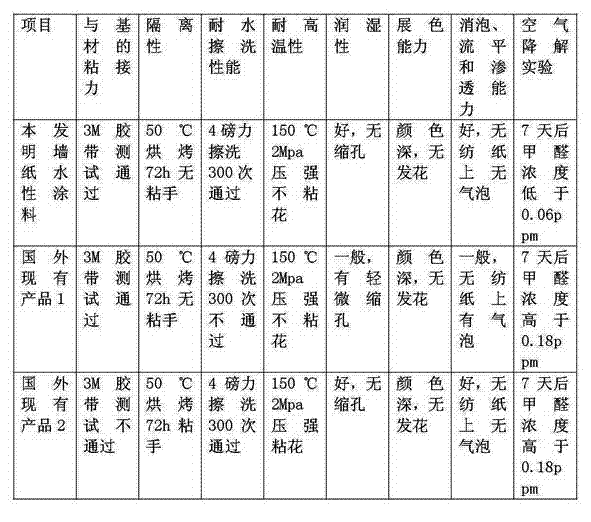

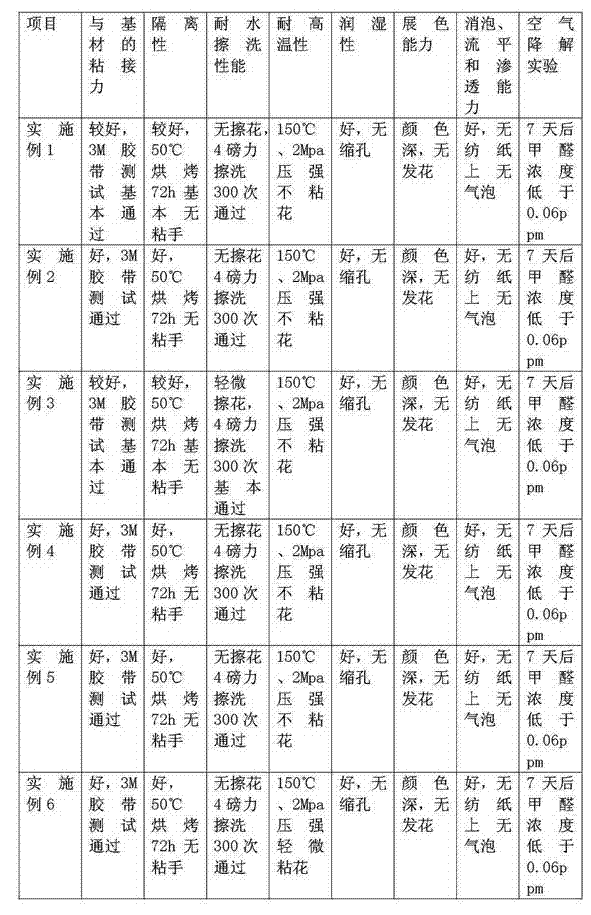

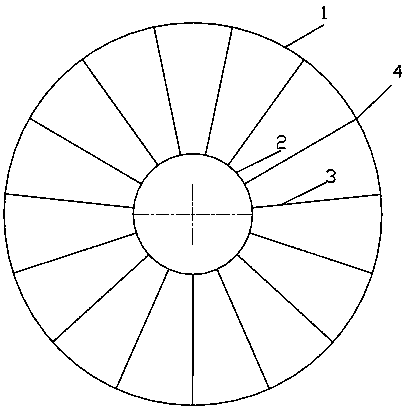

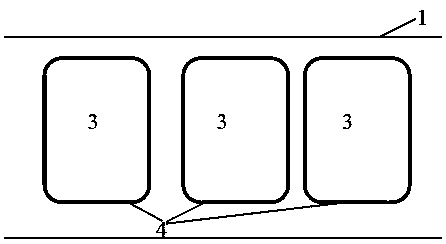

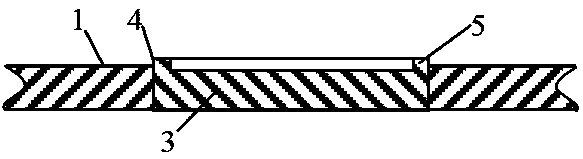

Wallpaper water-based paint, preparation method thereof and wallpaper

The invention discloses wallpaper water-based paint. The wallpaper water-based pain is water-based acrylate emulsion with solid content being 20-40% and the water-based acrylate emulsion is mainly made from a (methyl) acrylate monomer, a functional polymerizable monomer, an emulsifier, a photocatalyst, an initiator and deionized water through an emulsion polymerization method and a sol-gel method. Accordingly, the invention also discloses a method for preparing the wallpaper water-based paint and wallpaper made by adopting the wallpaper water-based paint. The wallpaper water-based paint is obviously improved in wallpaper substrate adaptability, the wallpaper water-based paint has good adhesive force, isolation, wettability and colour developing capability and is resistant to scrubbing and high temperature, defoaming is realized and the hole shrinkage phenomenon of a substrate is avoided; meanwhile, the wallpaper water-based paint also has light degradation property and can purify indoor air.

Owner:佛山市三水灏诚合成树脂有限公司

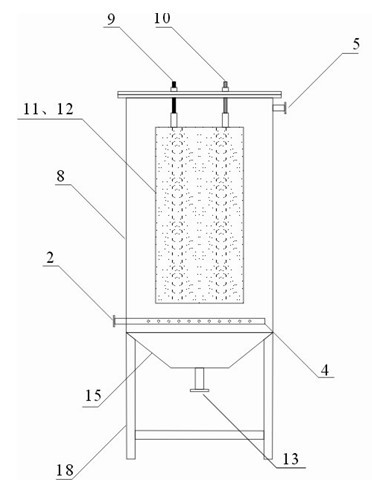

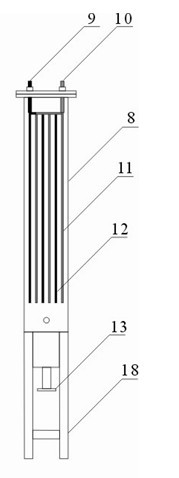

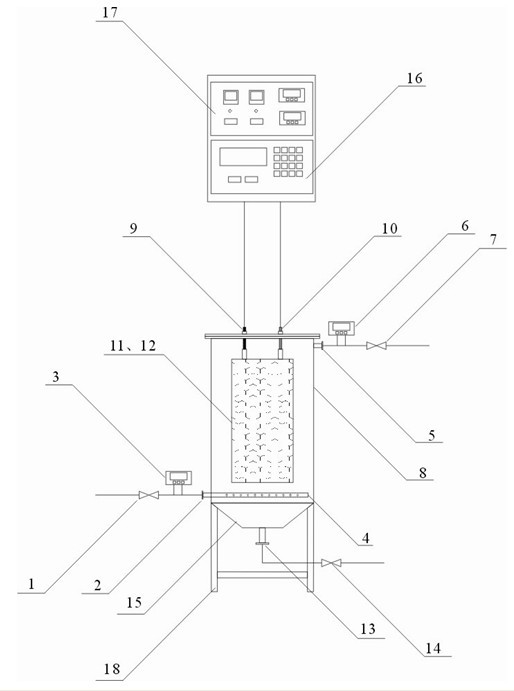

Method and device of electrochemical descaling, corrosion inhibition, sterilization and algae removal for cooling circulating water

InactiveCN102491456AReduce under-deposit corrosionReduce the chance of occurrenceWater/sewage treatment by electrochemical methodsWater/sewage treatment using germicide/oligodynamic-processElectrochemical responseBrown iron oxide

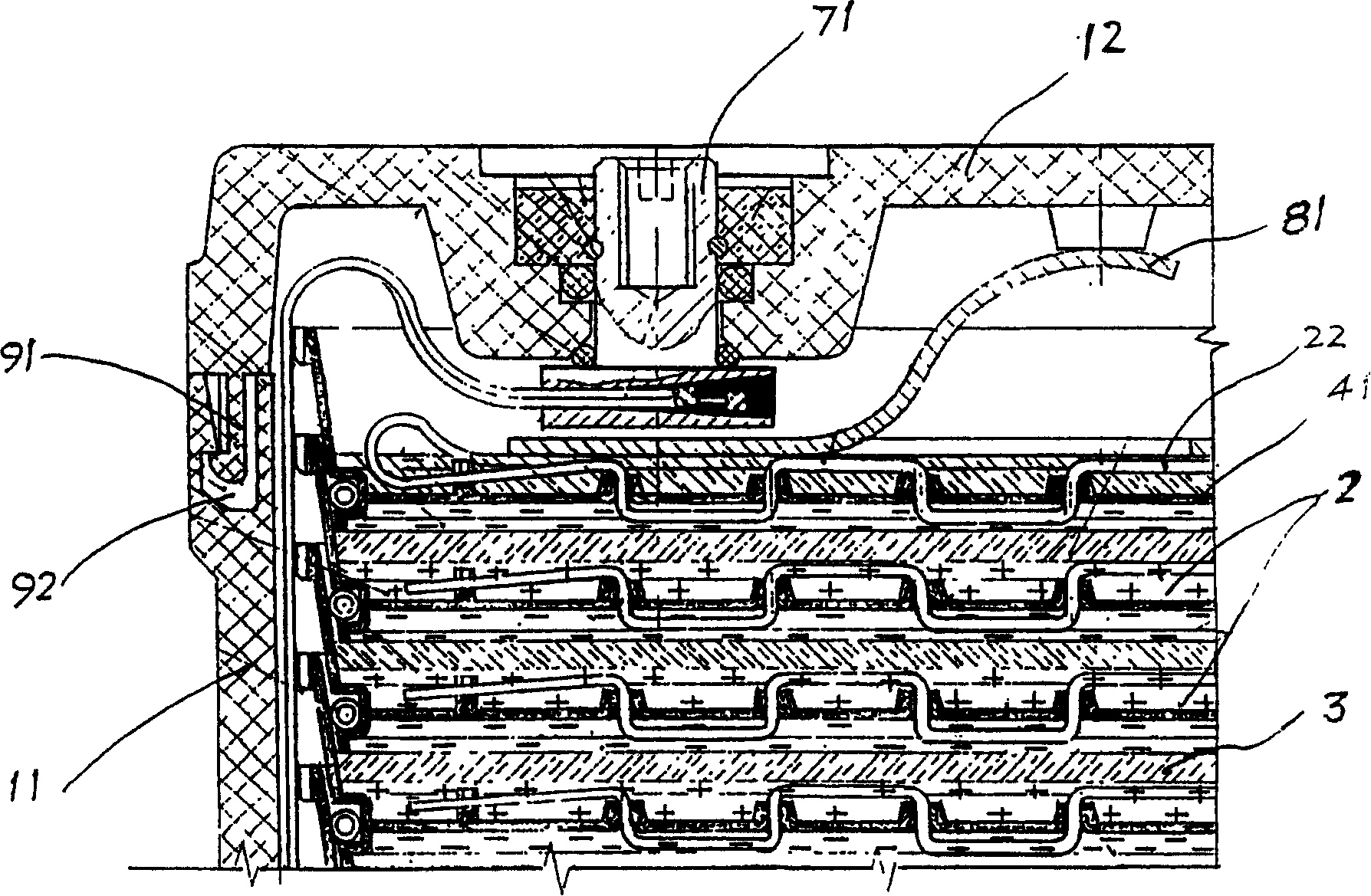

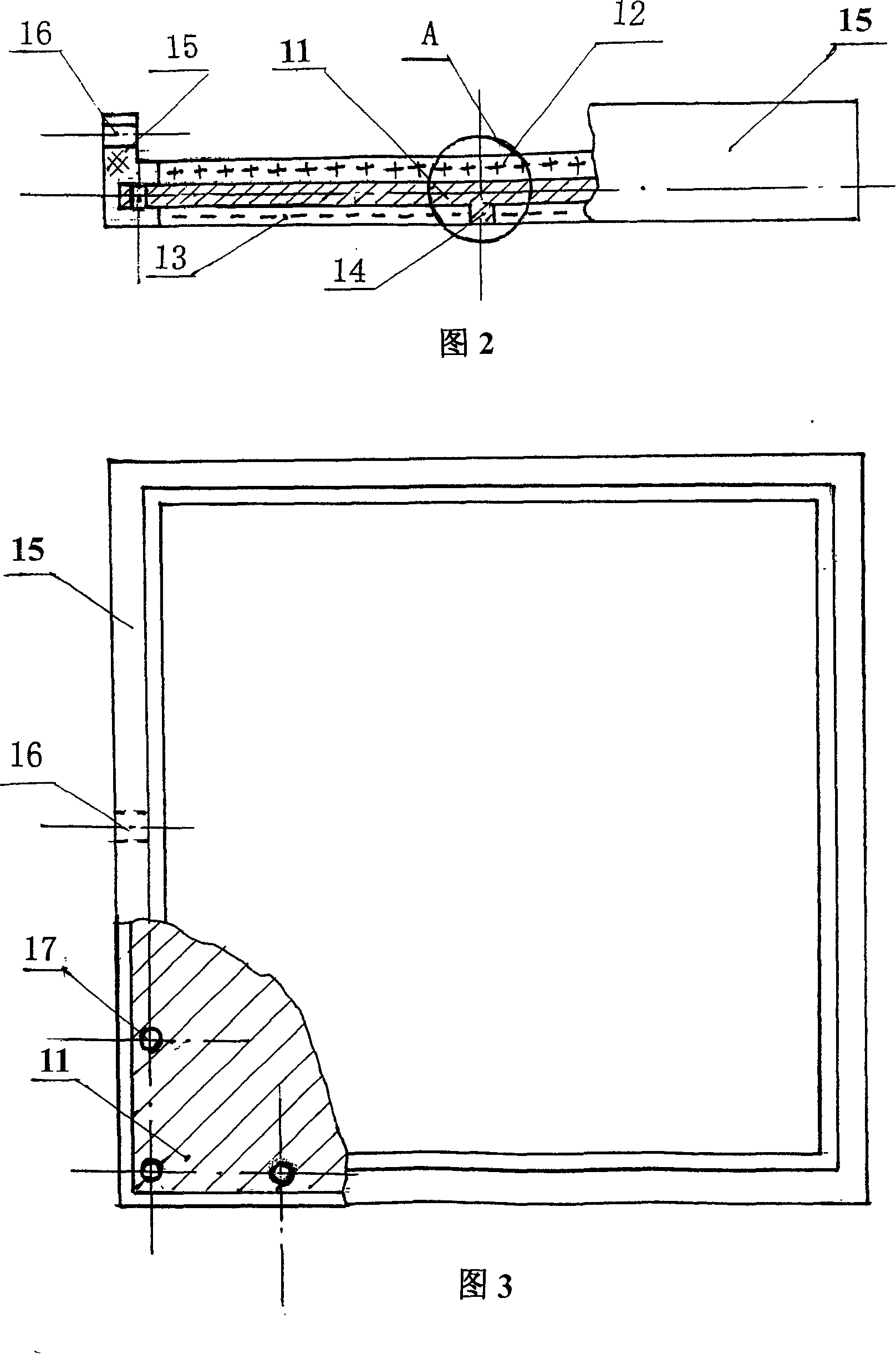

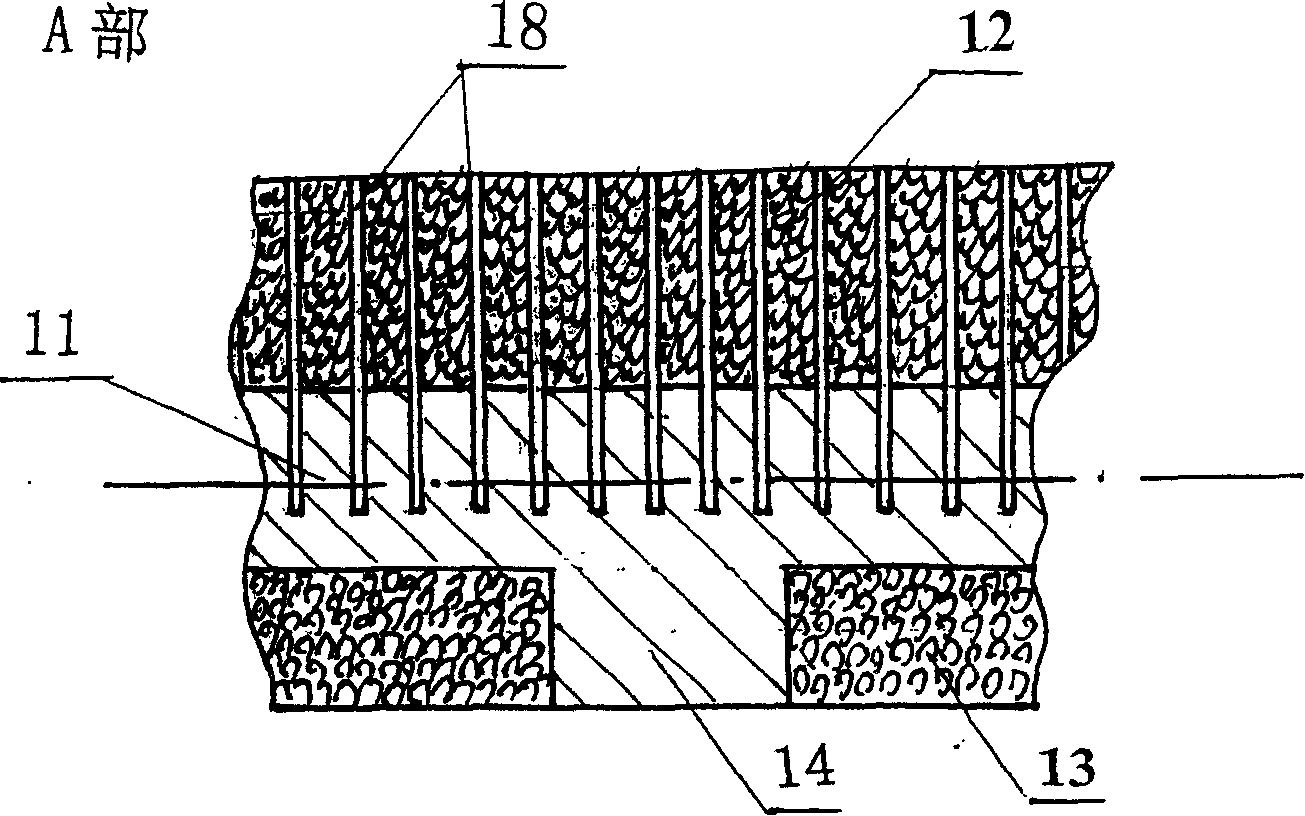

The invention discloses a method and a device of electrochemical descaling, corrosion inhibition, sterilization and algae removal for cooling circulating water, which belong to the field of water treatment and energy saving and emission reduction. A group or multiple groups of cathode plates (11) and anode plates (12) are arranged in an electrochemical reaction chamber (8) of the device. When direct current is loaded, interfaces of the cathode plates and the anode plates are in electrochemical reaction, calcium ions, magnesium ions, ferrous ions, other metal ions, silicate, phosphate and the like in water are settled to form loose needle-like grained stone type mineral crystals. Reactive oxygen, free hydroxyls, ozone and the like are generated at the anode plates (12) to inactivate algae in water, and treated water mixed with the circulating water can keep certain inactivating and restraining functions on algae and bacteria. The device is provided with a residue hopper (15), and when polarities of the anode and the cathode are exchanged, limescale is removed, sinks down to the residue hopper (15) and discharged through a residue discharging pipe (13). When the device is mounted on a circulating water bypass, a compact iron oxide film layer is formed on the tube wall and device wall of a circulating system, so that corrosion is hindered.

Owner:王海峰

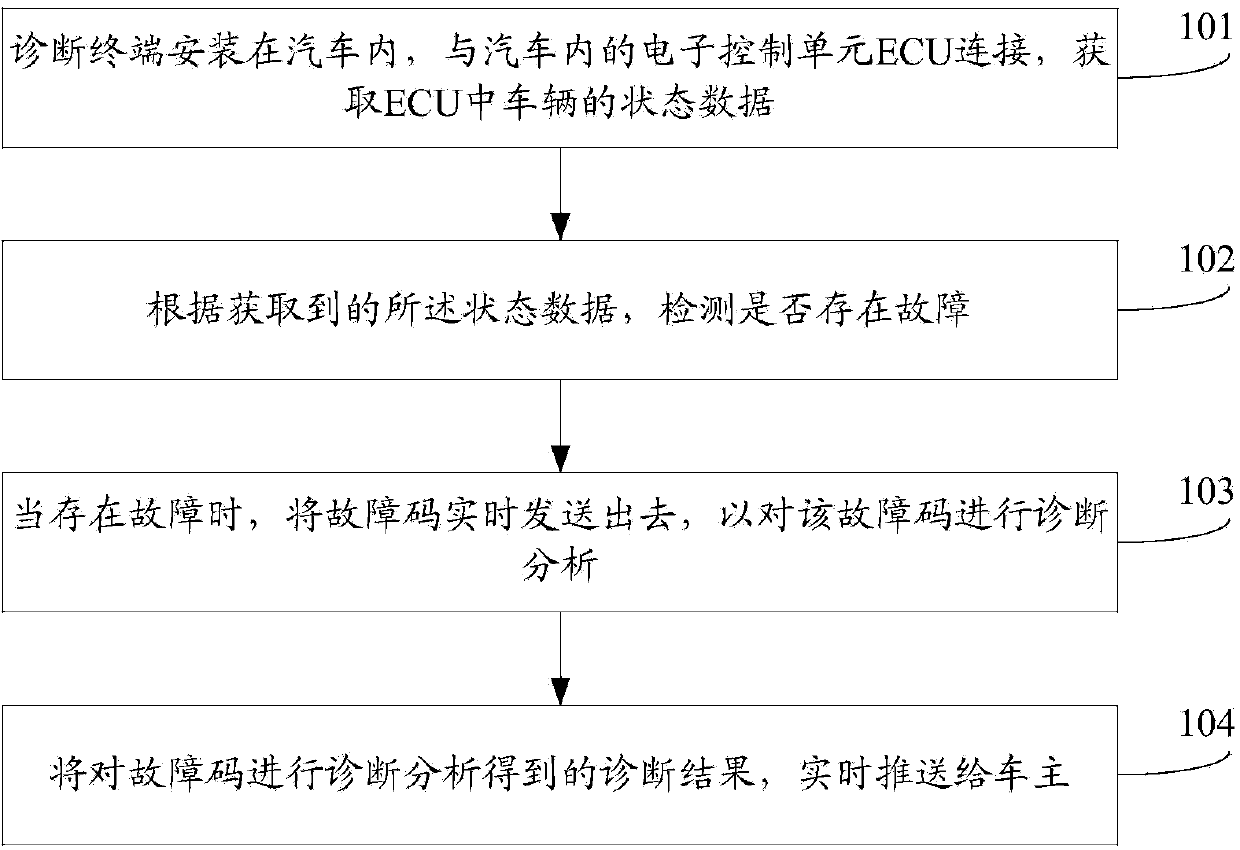

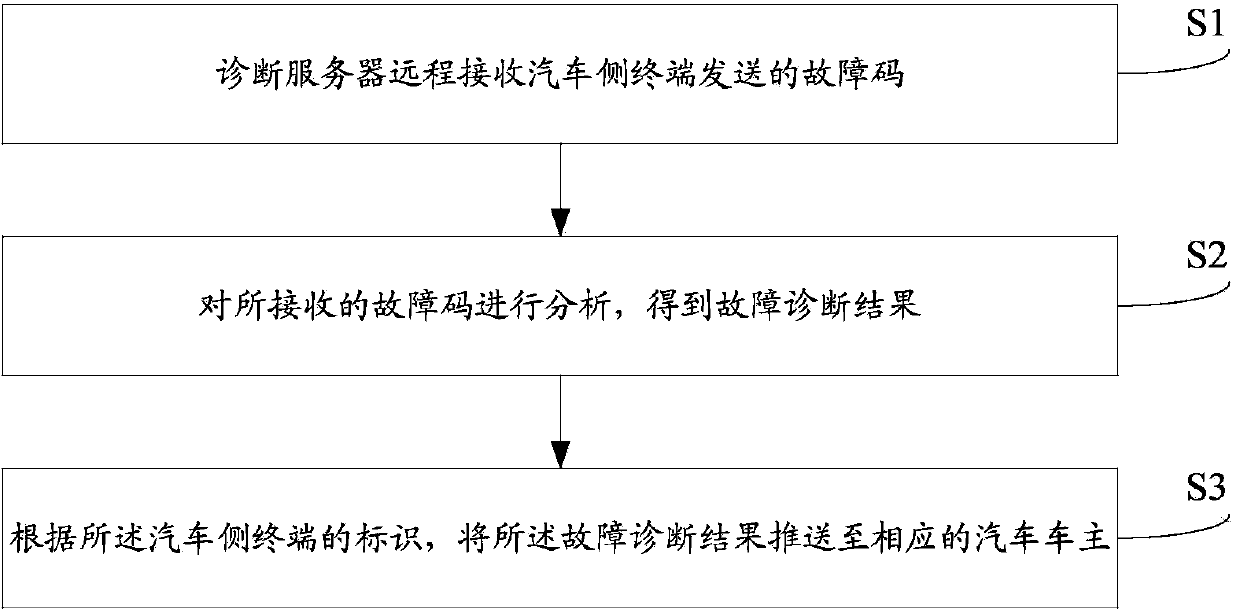

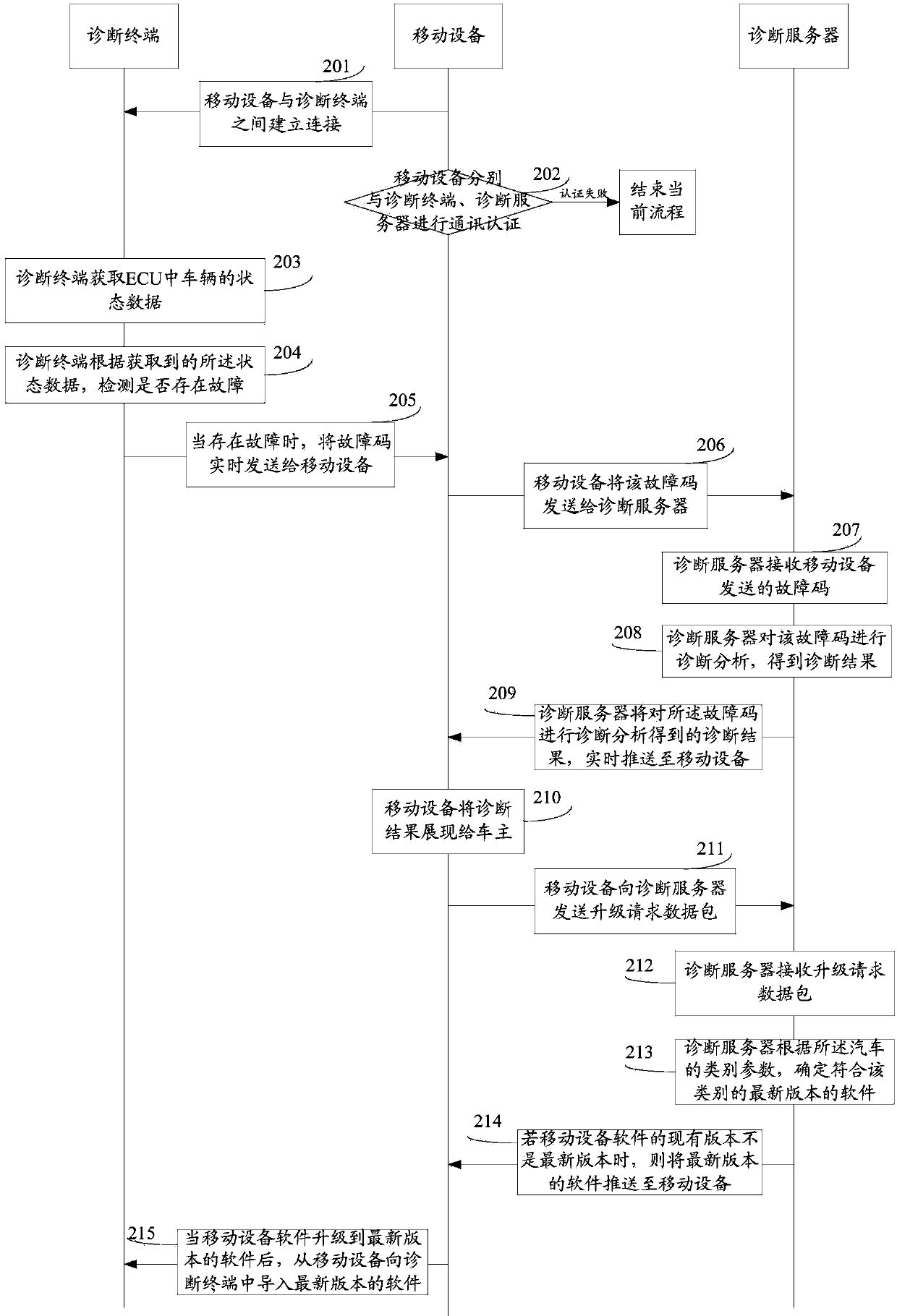

Automobile diagnosis method, server and system

InactiveCN103792093AReduce security risksWaste less timeVehicle testingRegistering/indicating working of vehiclesComputer scienceOccurrence probability

The invention relates to an automobile diagnosis method, server and system. The automobile diagnosis method comprises the following steps that: a diagnosis server receives a fault code sent by an automotive side terminal remotely and records a sending equipment identifier; the received fault code is analyzed to obtain a fault diagnosis result; according to the sending equipment identifier, the fault diagnosis result is pushed to a corresponding automobile owner. According to the technical scheme, the automobile owner can timely obtain an automobile fault situation without the need to drive the automobile to a specific maintenance site and then decides whether the maintenance needs to be carried out based on the obtained fault situation. Therefore, the unnecessary time wasting can be reduced; the automatable potential safety hazard can be effectively reduced; and the accident occurrence probability can also be reduced.

Owner:BEIJING WISELINK SOFTWARE

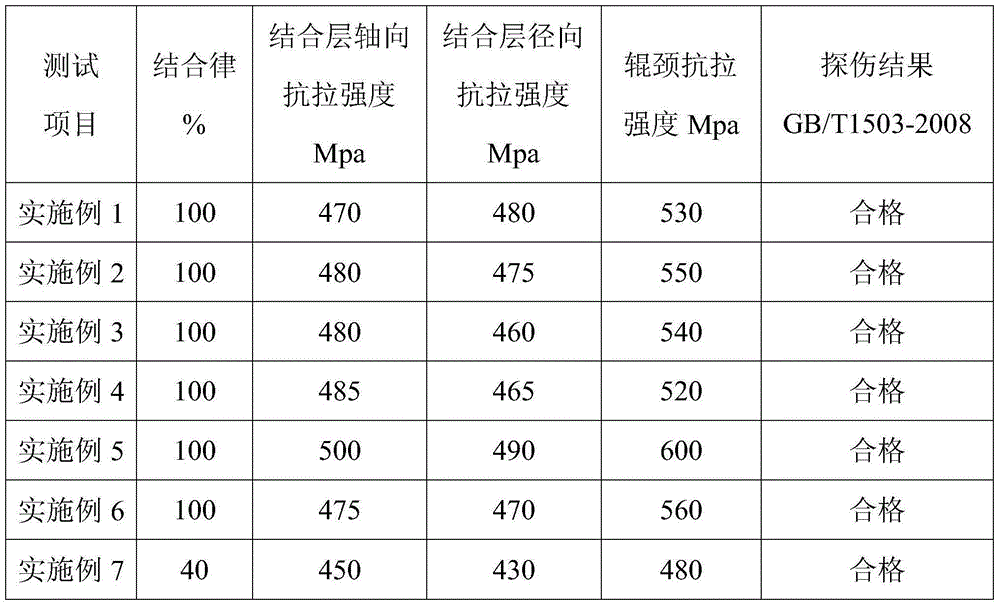

Manufacturing method for high-vanadium high-speed steel composite roll

The invention discloses a manufacturing method for a high-vanadium high-speed steel composite roll suitable for a narrow strip rolling mill. The manufacturing method comprises the steps that an outer layer of a roll body is poured by adopting a centrifugal pouring method, and after the outer layer of the roll body is poured with high-vanadium high-speed liquid steel, inert gas is continuously pumped into a cavity of the outer layer of the roll body; a centrifuge stops rotating when the outer layer temperature of high-vanadium high-speed steel reaches 1220-1280 DEG C, the inert gas is stopped being blown in, and then liquid iron in the core of the roll body is poured through mould closing. According to the manufacturing method for the high-vanadium high-speed steel composite roll, the bonding rate of the high-vanadium high-speed steel of the outer layer and the liquid iron in the core is significantly improved, the binding rate is improved from 40 percent to 100 percent, the bonding strength is improved from about 350 Mpa in the past to about 450 Mpa, and therefore the anti-stripping performance of a roll body bonding layer of the high-vanadium high-speed steel roll is greatly improved; meanwhile, the element amount formed by carbide on the corrosion outer layer of the liquid iron of the core is removed, therefore, roll neck tissues are improved, the tensile strength of the roll neck is improved, and the roll breakage phenomenon in use is effectively and completely eradicated.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Long life high capacity bipolar-type pole plate lead acid battery for electric automobile

InactiveCN101202355AImprove corrosion resistanceReduce the likelihood of feverFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryEngineering

The invention provides a dual-pole polar plate lead-acid accumulator with long service life and high capacity used for an electric vehicle. A polar plate group consists of a dual-pole polar plate, an upper end polar plate, a lower end polar plate and a clapboard; the polar plate group is arranged in a battery frame which presses the polar plate group and gives a suitable pressure to active matter. The invention is technically characterized in that one surface of an anode of a baseplate of the dual-pole polar plate is provided with a conductive needle and one surface of a cathode is provided with a conductive column; furthermore, electrode modification is carried out for the baseplate and the conductive needle. After the modification, the specific capacity of the battery is 45-50Wh / kg, which is improved by 20%-30% compared with the existing normal battery. The design service life is 3-8 years, which is improved 2-3 times compared with the normal battery. The battery is mainly used for electric vehicles, electric bicycles, etc., as power supplies, and can be also used for all sites where the existing normal lead-acid batteries are applied.

Owner:夏振明

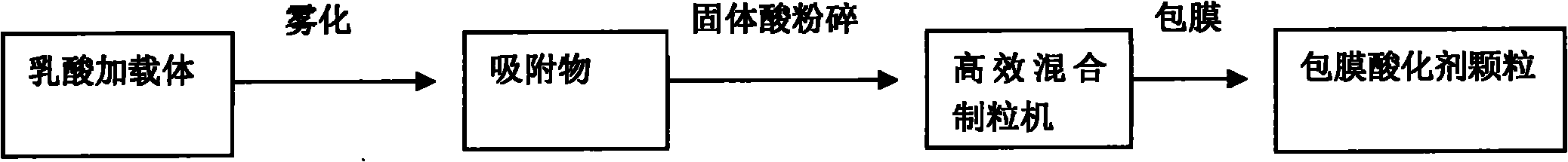

Method for producing coated acidifier granules for feed

ActiveCN101965909ASlow release rateLower pHAnimal feeding stuffAccessory food factorsPeristaltic pumpOrganic acid

The invention relates to a method for producing coated acidifier granules for a feed. The method comprises the following steps of: atomizing and adsorbing lactic acid; placing a proper amount of carbon black into a one-step granulator; spraying the lactic acid into the granulator for atomization and adsorption by a peristaltic pump; crushing citric acid, fumaric acid and malic acid and screening the materials with a 60-mesh sieve; mixing the materials and a lactic acid adsorbate; and adding a coating agent into a high-efficiency mixer granulator for coating and granulating to obtain the finished product. The acidifier prepared by the method is combination of organic acids, so that the releasing of the acidifier can be slowed down. The granules are coated with protective films, so that thecontact with an alkaline substance in the feed is reduced and the acidification effect of the granules is enhanced. The organic acid and other antibacterial substances can be produced by promoting the growth and mass propagation of beneficial bacteria such as lactobacillus and the like, so that the pH value in the gastrointestinal tract is further reduced and the growth of harmful bacteria is suppressed. The organic acid gradually released in the alimentary canal has a complexing effect; and the absorption in small intestine can be promoted after the organic acid is complexed with trace elements in the feed.

Owner:WUXI ZHENGDA POULTRY

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

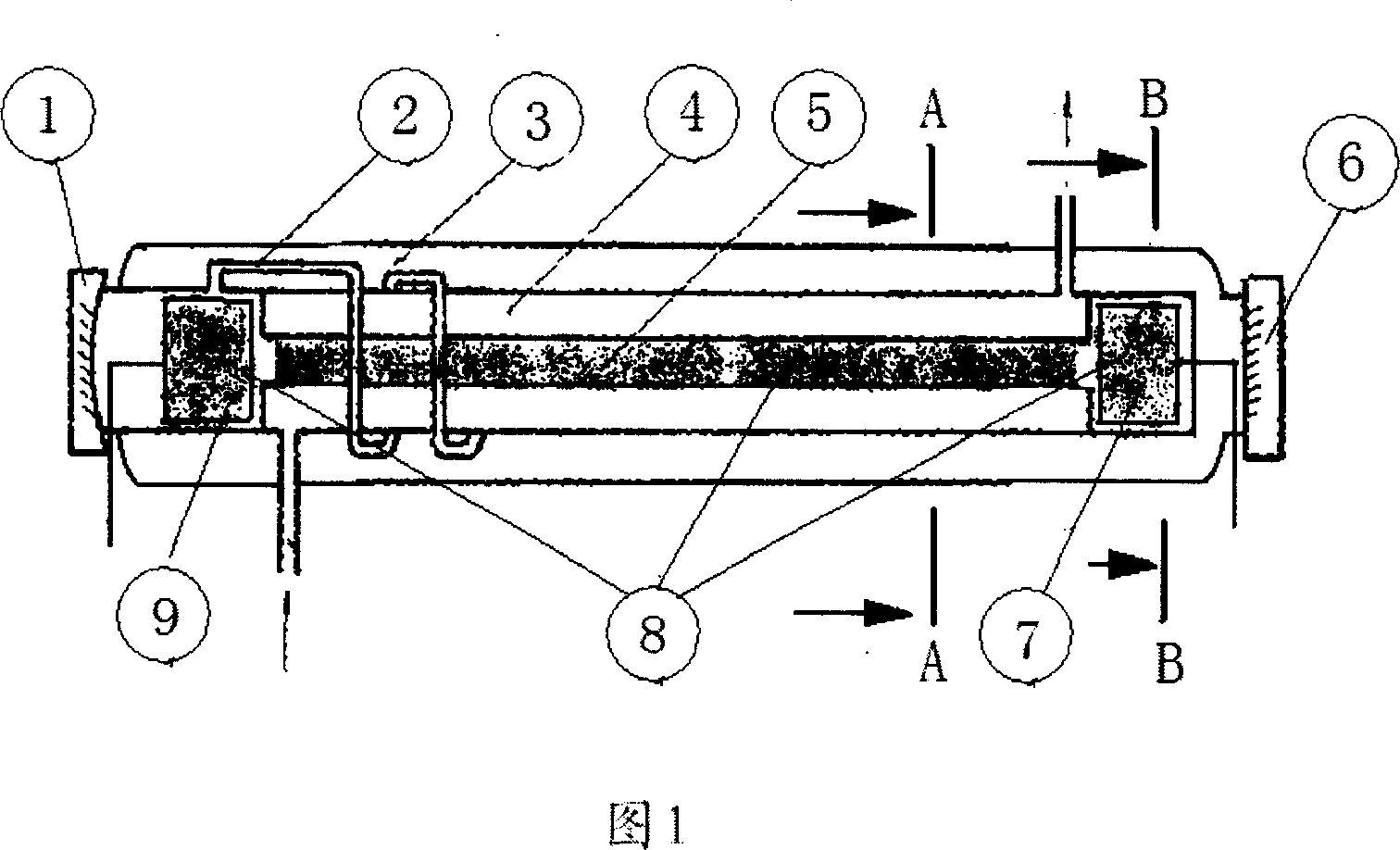

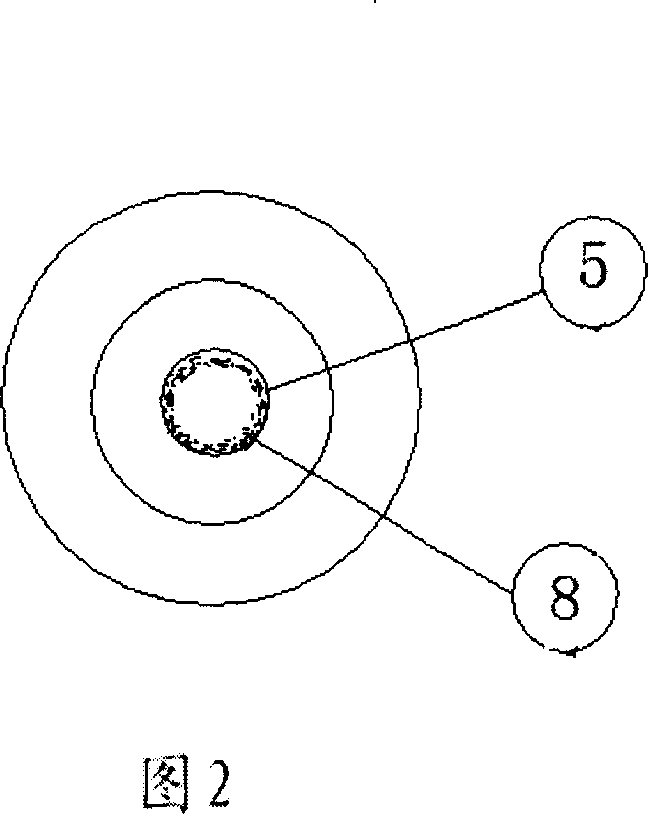

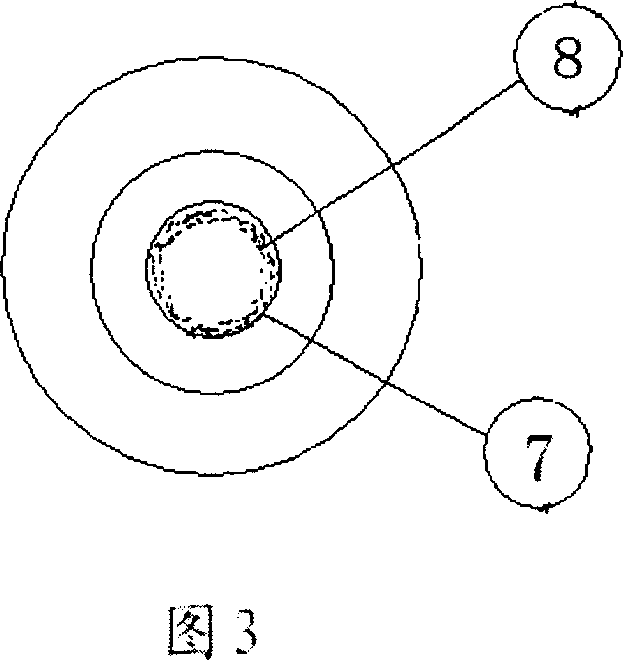

Photocatalytic sealed CO2 laser tube

InactiveCN101060226ARestore concentrationOvercoming activation energyGas laser constructional detailsEpoxyEngineering

The related sealing-type CO2 laser tube comprises: a metal-plated full reflection mirror 1, a muffler 2 set in tube 4 to connect sheath 3 and tube 5, a gas storage sheath 3, a water cooling tube 4 set on top of a discharge tube 5 together in sheath 3, an output mirror 6 together with mirror 1 bonded on ends of laser tube ends by epoxy resin, the TiO2 photo catalyst 8 coated on inner wall of tube 5 and electrodes 7 / 9, and two electrodes 7 / 9 coaxial arranged on ends of tube 5. This invention is simple and convenient, prolongs product life time, reduces cost, and has well social and economic benefits.

Owner:王向阳

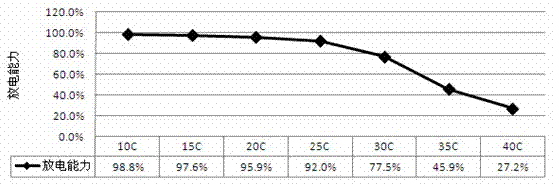

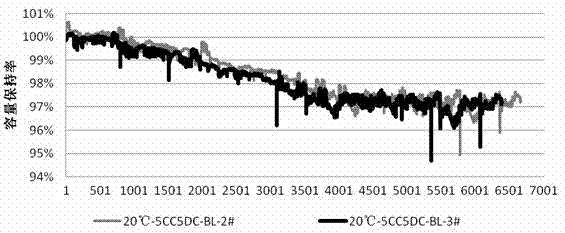

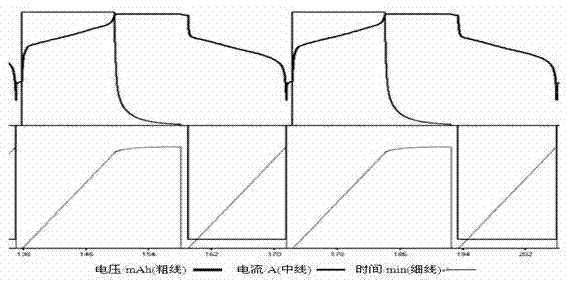

Method for solving gas expansion failure of lithium titanate battery

ActiveCN105449301ALower excitation resistanceLower battery internal resistanceSecondary cells charging/dischargingElectrical batteryEngineering

The invention provides a method for solving gas expansion failure of a lithium titanate battery. The method comprises a formation process and an aging process; the formation process comprises the following steps: firstly, charging for 2 to 20 hours in a constant-current mode by current of 0.01C to 0.1C, charging for 1 to 7 hours in a constant-current mode by current of 0.1C to 0.2C and charging for 0.5 to 1 hour in a constant-current mode by current of 0.2C to 0.5C; secondly, discharging for 3 hours in a constant-current mode by current of 0.5C to 1C, then charging for 3 hours and discharging for 3 hours in a constant-current and constant-voltage mode by current of 0.5C, and repeating the steps of charging for 3 hours and discharging for 3 hours in a constant-current and constant-voltage mode by current of 0.5Cfor 3 to 6 times; and finally, charging for 2 hours and discharging for 2 hours in a constant-current and constant-voltage mode by current of 1C, and repeating final two steps for 3 to 6 times. With such a design, batteries are prevented from expanding, the discharge power of the batteries is increased and a quick charge capacity and good service are realized. The production probability of defective products is low and the process cycle is short.

Owner:DONGFENG COMML VEHICLE CO LTD

Sizing process of fine denier circular hole bright polyamide multifilament

InactiveCN102828369AReduce incidenceImprove flatnessLiquid/gas/vapor removalBeaming machinesPolyamideEngineering

The invention discloses a sizing process of a fine denier circular hole bright polyamide multifilament. By adjusting the technological parameters of four procedures such as warping, sizing, re-beaming and weaving, a good size film is formed on the surface of the fine denier circular hole polyamide filament and is convenient for weaving, the production efficiency is above 95% and a series of problems such as low weaving efficiency of multifilament woolen fabrics of fine denier circular hole bright polyamide multifilament series are solved.

Owner:WUJIANG FUHUA WEAVING

Safe monitoring and protection device for drilling and intelligent protection system of safe monitoring and protection device

ActiveCN104879114AMeet the needs of exploration and developmentAchieve integrationAutomatic control for drillingData transmissionData acquisition unit

The invention relates to the technical field of petroleum drilling safety, in particular to a safe monitoring and protection device for drilling and an intelligent protection system of the safe monitoring and protection device. The safe monitoring and protection device for drilling comprises a data acquisition unit, a control processing unit and a safe protection execution unit; the control processing unit comprises an PLC (programmable logic controller) and an industrial personal computer, the PLC is connected with the industrial personal computer through a serial port; various kinds of sensors of the data acquisition unit acquire on-site operation data and transmit the data to the PLC and the industrial personal computer in real time; the safe protection execution unit comprises a pumping pressure protection mechanism and a runner wagon protection mechanism; a pressure sensor mounted on a vertical pipe or a slurry pump, a winch sensor mounted on a winch barrel and a weight transducer mounted on a deadline anchor output signals to be connected with the PLC; the PLC is in control connection with the pumping pressure protection mechanism and the runner wagon protection mechanism. According to the safe monitoring and intelligent protection device for drilling, the safe protection execution unit comprises a pumping pressure protection sub-system which mainly adopts an active response type safe protection method, and when pumping pressure reaches a set protection value, the pump stops firstly and then pressure relief is performed.

Owner:PUYANG BAIFU REIDE PETROLEUM SCI & TECH CO LTD

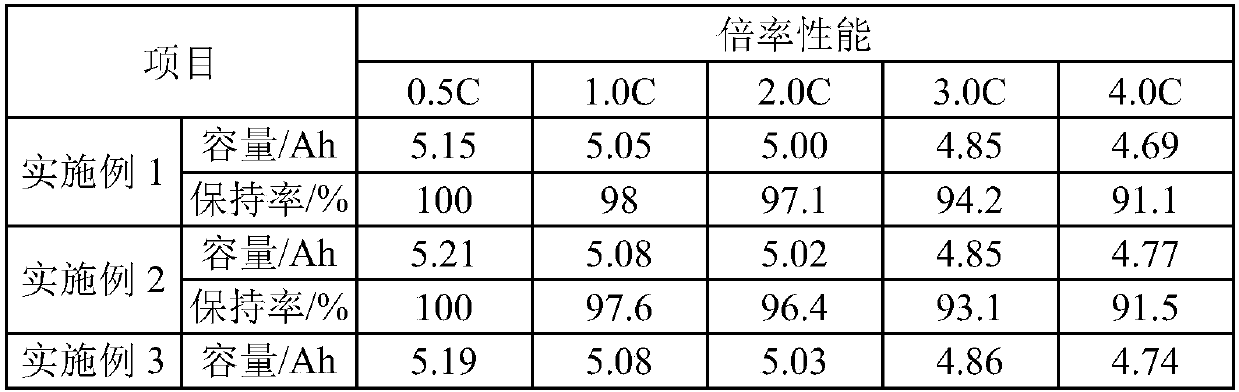

Aluminum fluoride/silver double-coated lithium nickel cobalt manganese oxide positive electrode material and preparation method thereof

ActiveCN107591532AImprove cooling effectImprove conductivityCell electrodesDischarge efficiencyAluminum fluoride

The invention relates to an aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material and a preparation method thereof and belongs to the technical fieldof positive electrode materials for lithium-ion batteries. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has a core-shell structure; a core is lithium nickel cobalt manganese oxide LiNixCoyMn(1-x-y)O2, wherein x smaller than or equal to 1.0 and greater than or equal to 0.5 and y is smaller than or equal to 0.23 and greater than or equal to 0; and a shell of the core-shell structure comprises an inner shell and an outer shell, wherein the inner shell is aluminum fluoride and the outer shell is silver. The aluminum fluoride / silver double-coated lithium nickel cobalt manganese oxide positive electrode material has excellent cycle performance, high initial charge-discharge efficiency and excellent safety performance.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Semiconductor laser multi-chip sintering clamp and sintering method

ActiveCN104966987ASimple structureEasy to operateLaser detailsSemiconductor lasersHeat sinkSemiconductor laser theory

The invention relates to a semiconductor laser multi-chip sintering clamp and a sintering method. The sintering clamp comprises a main body, a lower pressing bar, an upper pressing bar, top blocks with pressing columns and springs. The lower pressing bar and the upper pressing bar are fixed on the main body through fixing screws; the lower pressing bar and the upper pressing bar are provided with holes which are evenly distributed and are used for limiting the top block pressing columns and feeding screws; a spring sleeves the top block pressing column; the bottom of the main body is provided with laser limitation grooves. The sintering method comprises steps of successively placing the tube casings containing heat sinks and COSs in the laser limitation grooves and the positions below the top block pressing columns, transmitting to feeding screws to enable the pressing columns to descend to the bottom and to contact with the COSs, clamping the chip by applying pressure, and performing sintering on the clamp, on which the laser is installed. The pressing column of the invention is of a square structure and maintains no rotation during the pressing down, preventing the displacement of the COS in the installation process and improving the consistency of sintering. At the meantime, the clamp is provided with a plurality of lasers according to the needs, which is high in sintering and easy to industrialization.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

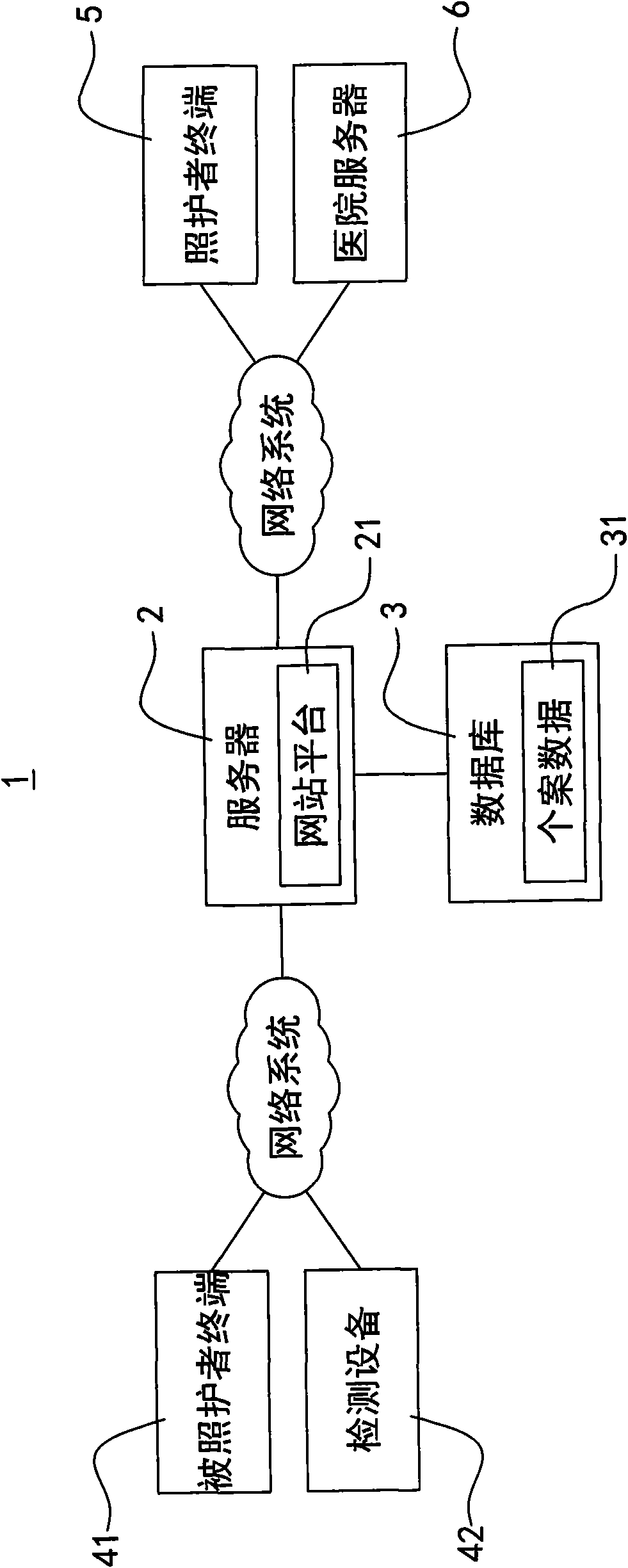

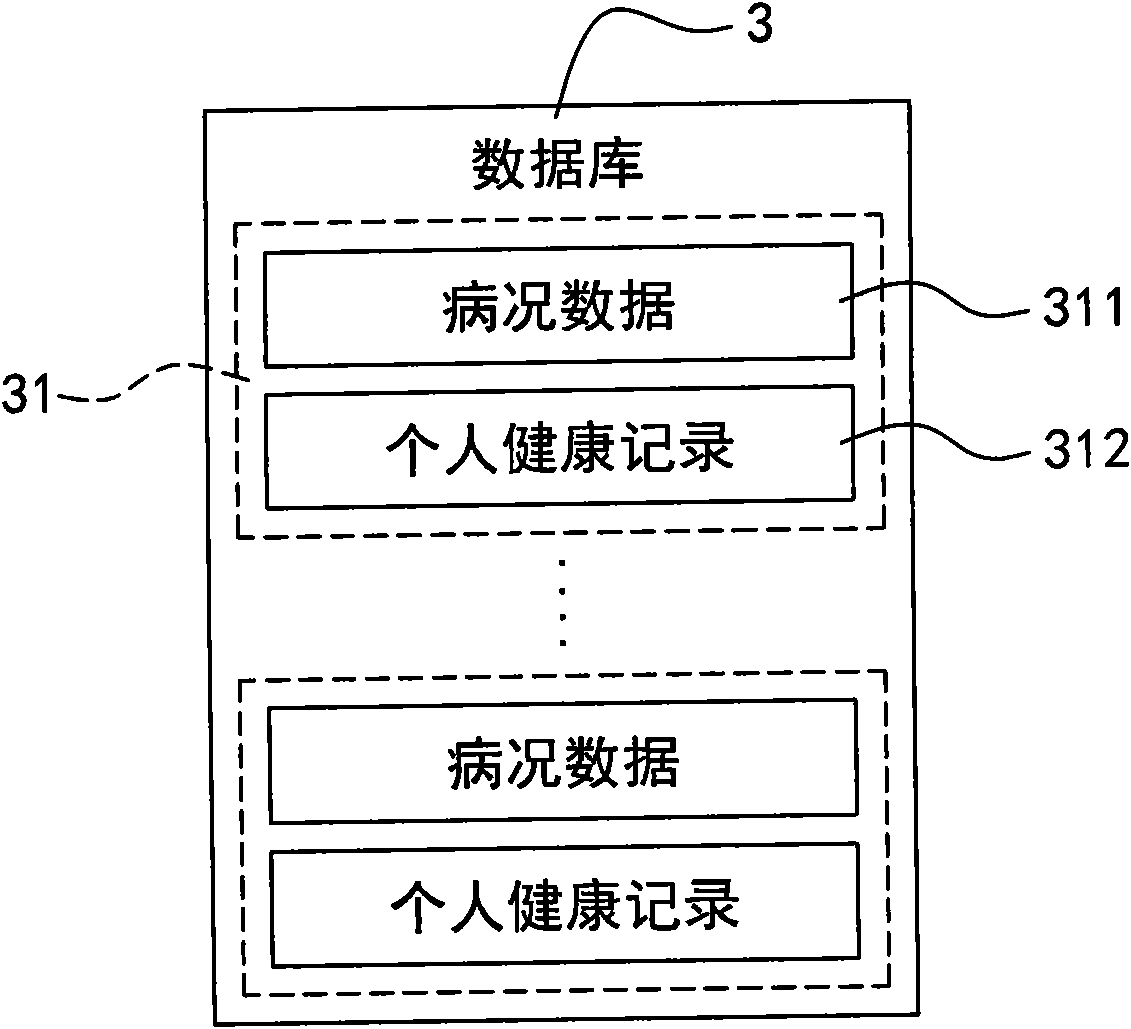

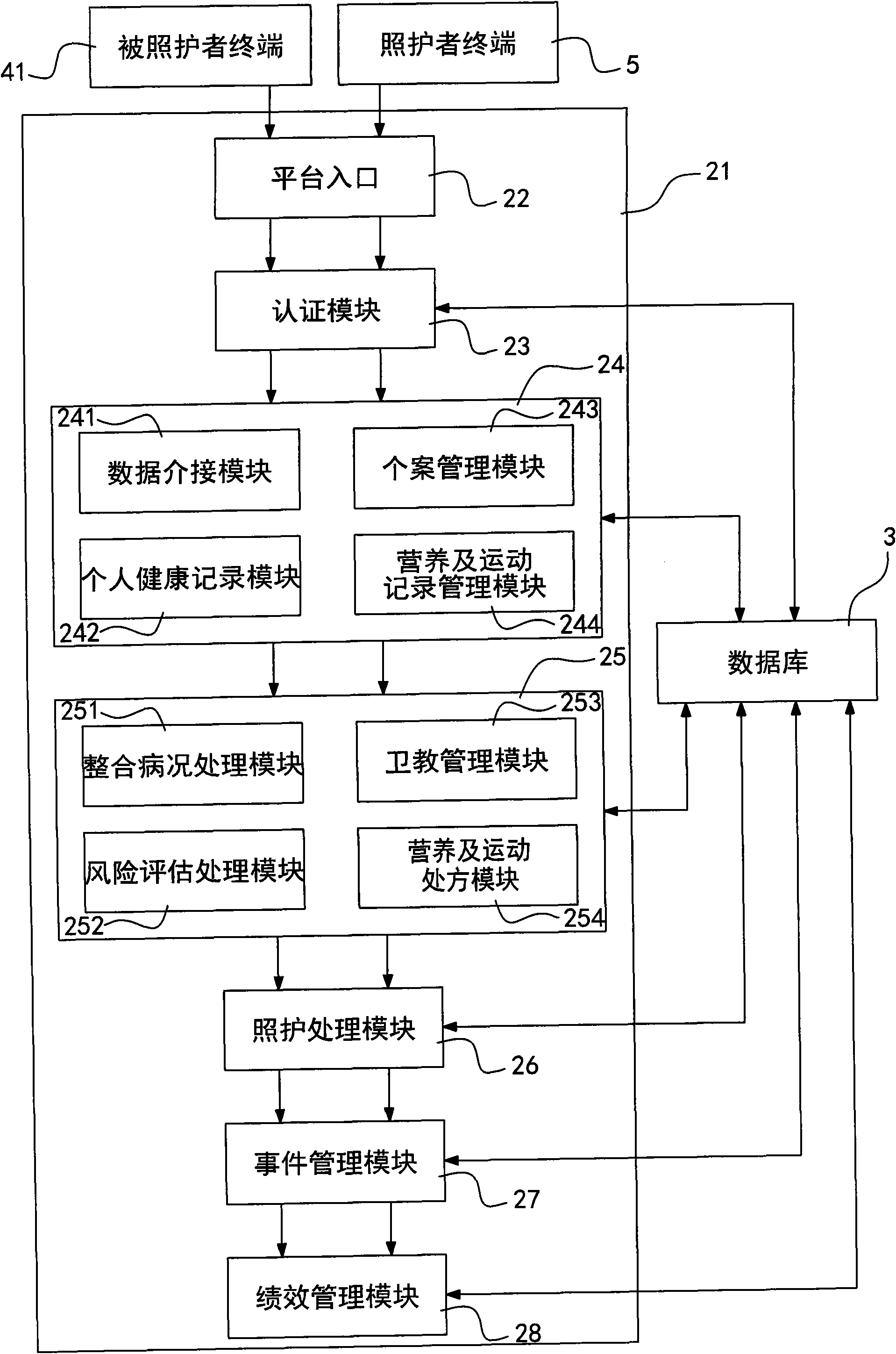

Body condition integral management system as well as management method thereof

InactiveCN102650994AFully integratedReduce the chance of occurrenceSpecial data processing applicationsProcess moduleProgram planning

The invention discloses a body condition integral management system as well as a management method thereof. The integral management system mainly includes a server and a database, wherein a website platform is erected on the server, and both illness condition data and personal health records of at least one attended person are stored in the database. The website platform includes a data source platform, an integration and evaluation platform, an attendance processing module and an incident management module, wherein the data source platform interfaces with, stores and manages the data of the attended person, and the integration and evaluation platform integrates the illness occurring to the attended person, and evaluates the illness possible to occur to the attended person. The attendance processing module makes an individual specific attendance plan targeting the illness occurring to or non-occurring to the attended person, and meanwhile, the incident management module notifies an attending person to manage in case of a particular incident.

Owner:YUEKANG HEALTHCARE MANAGEMENT CONSULTANTS

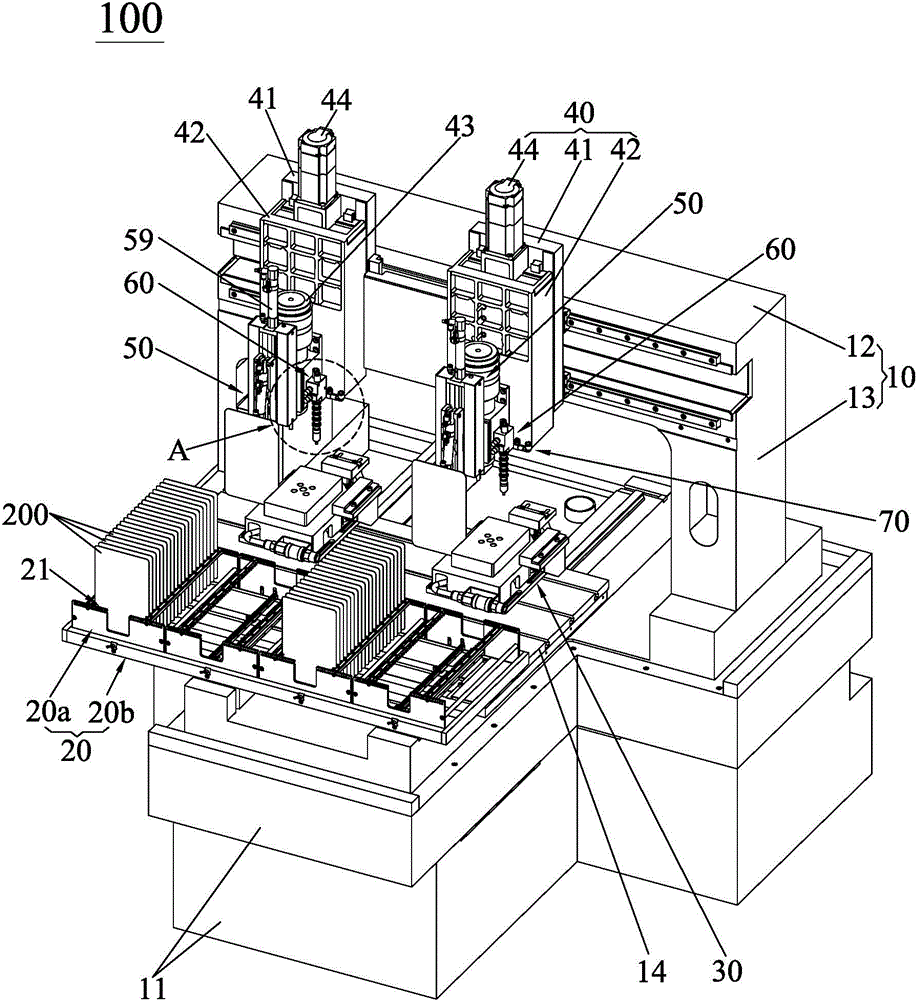

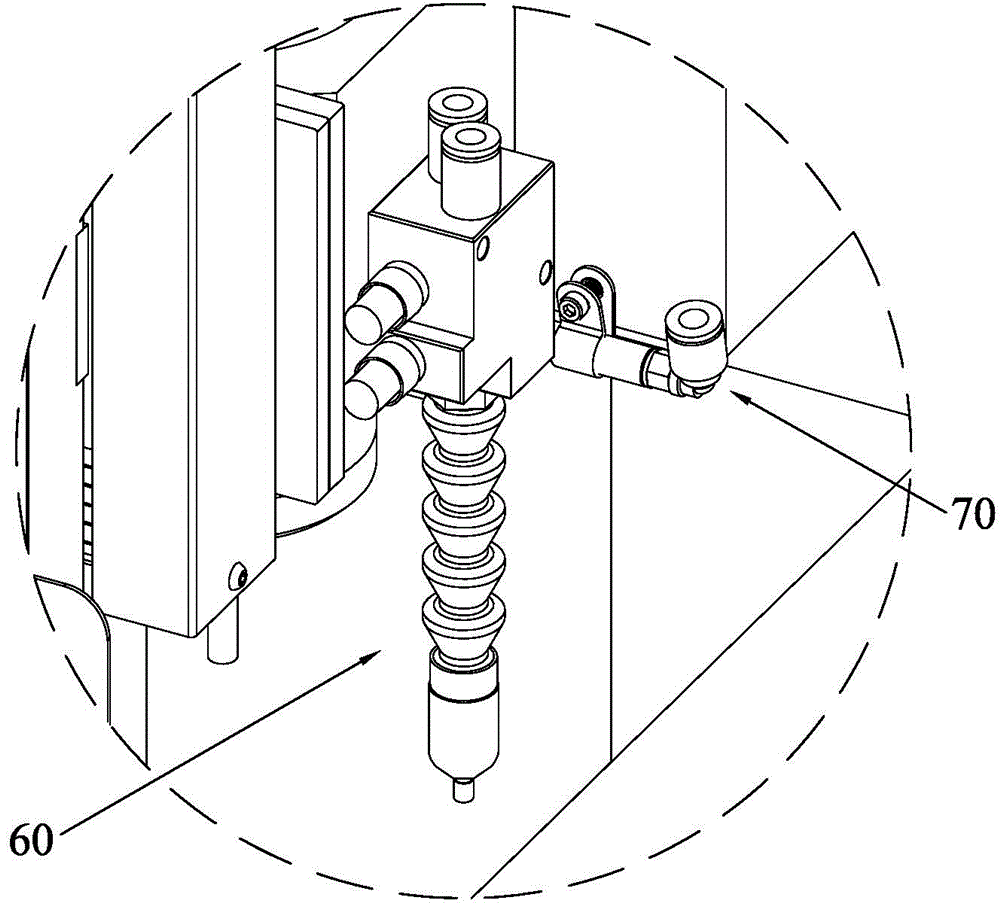

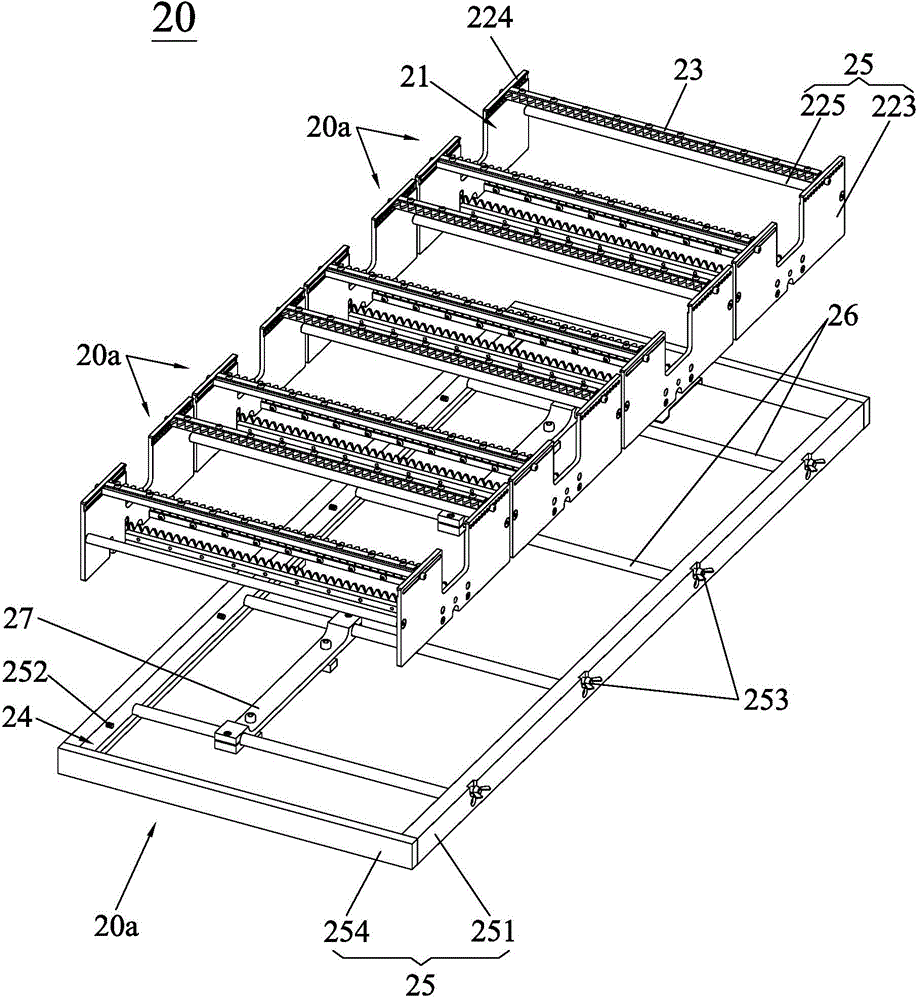

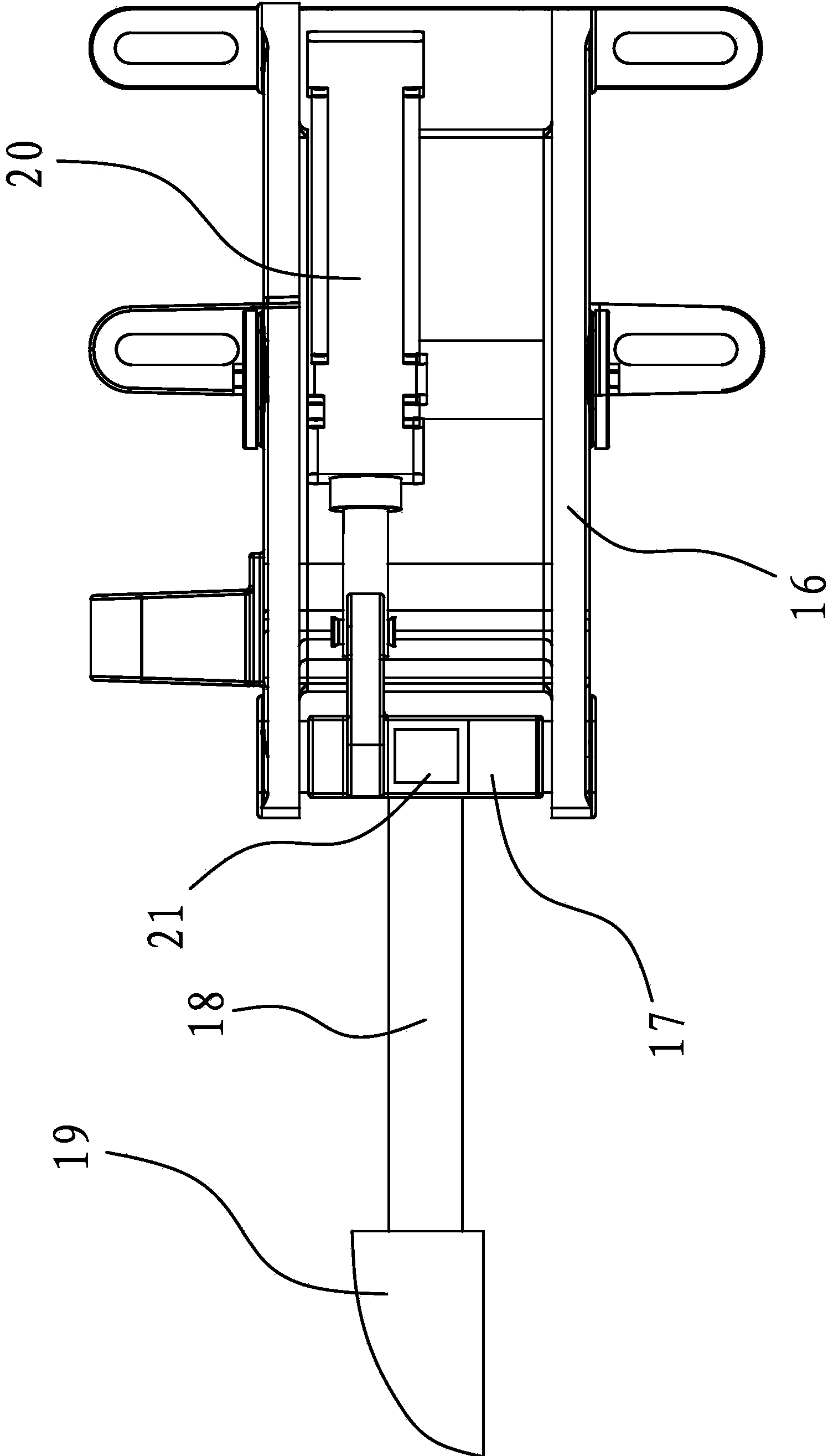

Automatic panel taking, transferring and machining numerical control equipment

ActiveCN104526442ARealize automatic positioningReduce the chance of occurrenceLarge fixed membersPositioning apparatusNumerical controlEngineering

The invention discloses automatic panel taking, transferring and machining numerical control equipment. The equipment comprises a rack, panel box devices, positioning fixtures, handpieces and panel taking and transferring manipulators. The rack comprises a machine tool body, a cross beam and stand columns, and a working platform is arranged on the machine tool body in a sliding mode in the front-back direction of the machine tool body. The panel box devices are installed on the working platform, each panel box device comprises panel boxes, and each panel box is provided with a stacked sorting chamber allowing panels to be arranged in a row in the front-back direction of the machine tool body. The positioning fixtures are installed on the working platform, and each positioning fixture comprises an adsorption platform, positioning plates used for positioning the corresponding panels and a positioning driving assembly used for driving the corresponding positioning plates to slide. The handpieces are installed on the cross beam in a sliding mode in the vertical direction and the horizontal direction of the machine tool body, and the handpieces are hung above the portions corresponding to the positioning fixtures. The panel taking and transferring manipulators are installed on the handpieces and used for transferring the panels between the panel boxes and the positioning fixtures under matching of the handpieces and the working platform so that the panels can be automatically taken out, transferred and machined, and panel machining efficiency and panel machining quality are improved.

Owner:苏州恒远精密数控设备有限公司

Porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and preparation method thereof

InactiveCN102515828AEmission reduction benefits are obviousImprove absorbencySolid waste managementCeramicwareMineralogyMining engineering

The invention relates to a porous heat-insulation material prepared utilizing iron ore surrounding rock and iron tailings and a preparation method of the porous heat-insulation material. The porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings is characterized by being prepared from the following components in percentage by weight: 30-60% of iron tailing powder, 20-50% of iron ore surrounding rock powder, 0.5-10% of foaming agent, 0-1% of cosolvent and 0.1-9% of foam stabilizer by uniformly mixing, then adding water, mixing and pulping, carrying out microwave calcining and cooling. The preparation method of the porous heat-insulation material prepared utilizing the iron ore surrounding rock and iron tailings has high utilization rates of iron ore surrounding rock and iron tailings; and the prepared porous heat-insulation material has low density and excellent heat-insulation performance.

Owner:WUHAN UNIV OF TECH

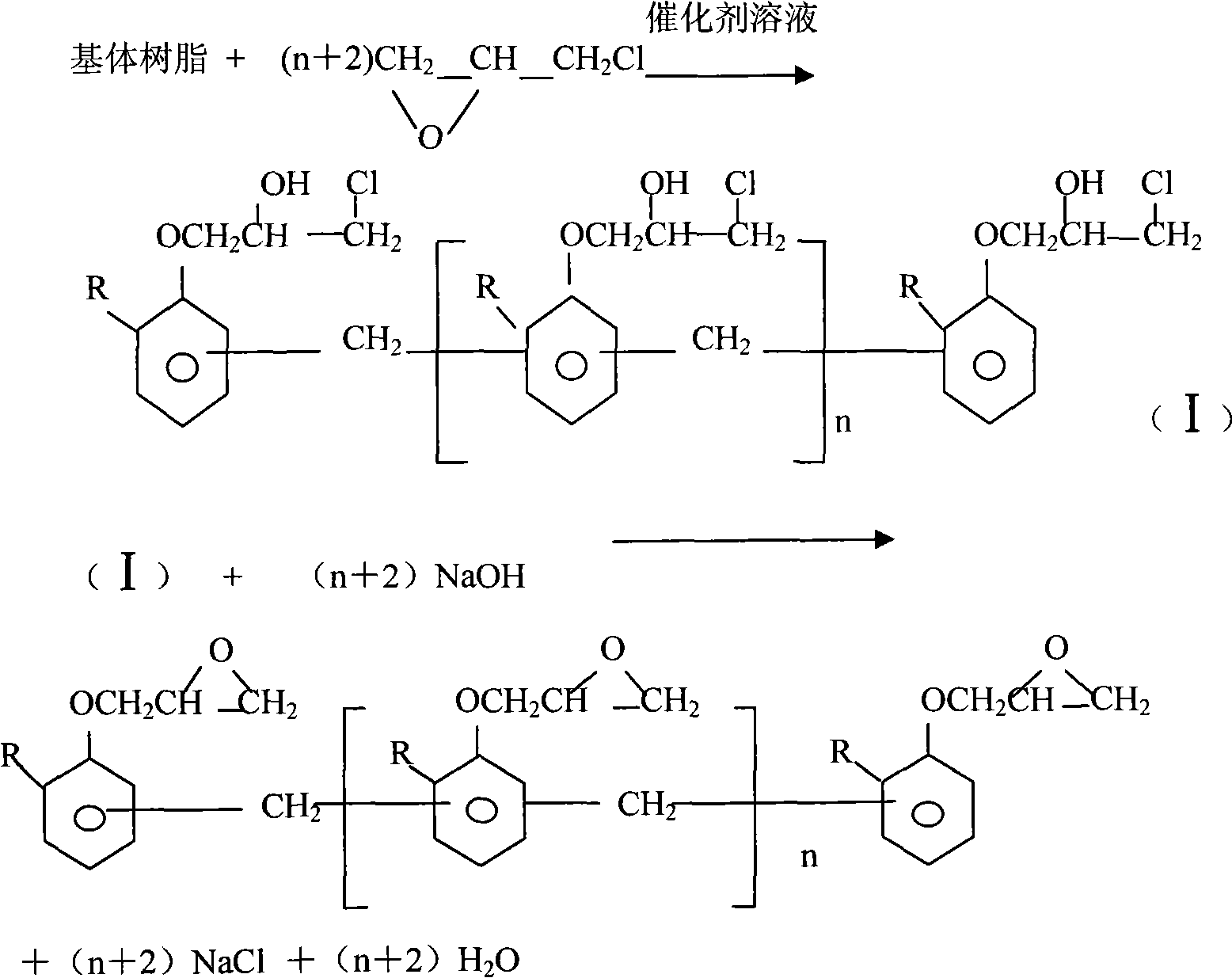

Method for preparing epoxy resins of phenol formaldehyde type

The invention discloses a method for synthesizing phenol formaldehyde epoxy resin with (alkyl)phenolic resin and epoxy chloropropane as raw materials. Base resin and epoxy chloropropane undergo epoxidation reaction under the existence of catalyzer and alkali, and then are refined and processed with post treatment; in this way, phenol formaldehyde epoxy resin can be prepared. The epoxidation technique applied by the invention can effectively reduce the occurrence of side reaction and reduce production of isomerized chlorine and is easy to produce the products with high softening point, high epoxy equivalent weight and low chlorine content and has remarkable effects in improving the stability and heat resistance of the product and in reducing the consumption of the raw materials.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

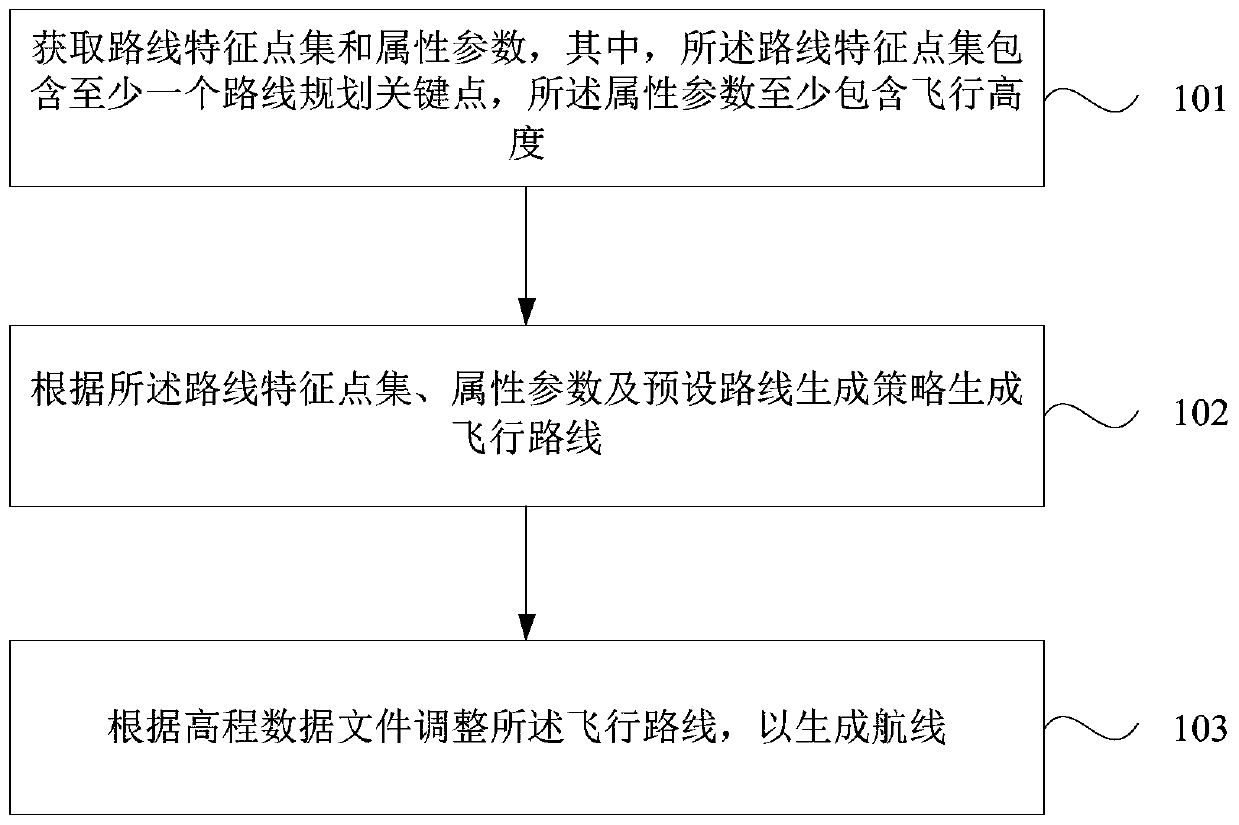

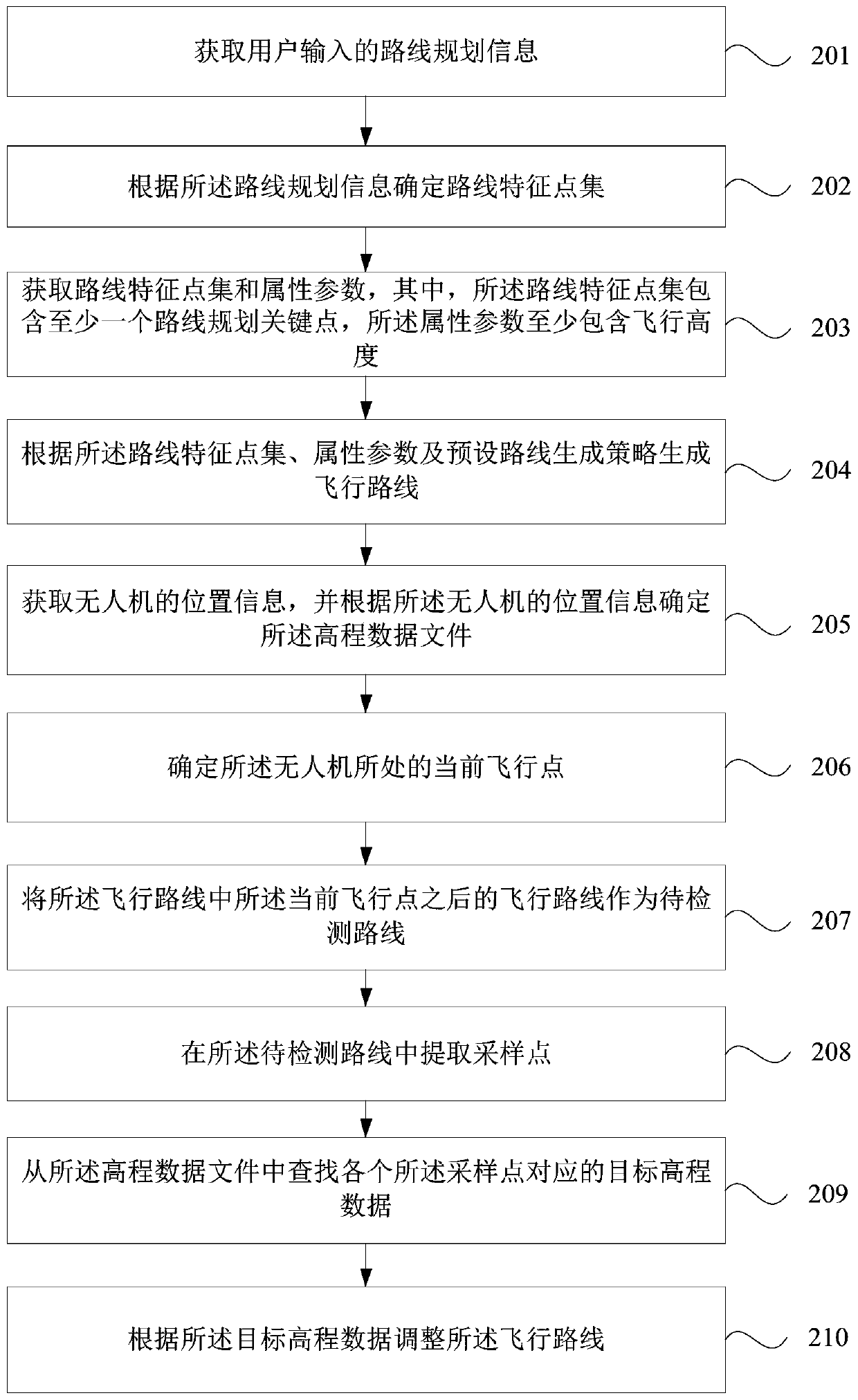

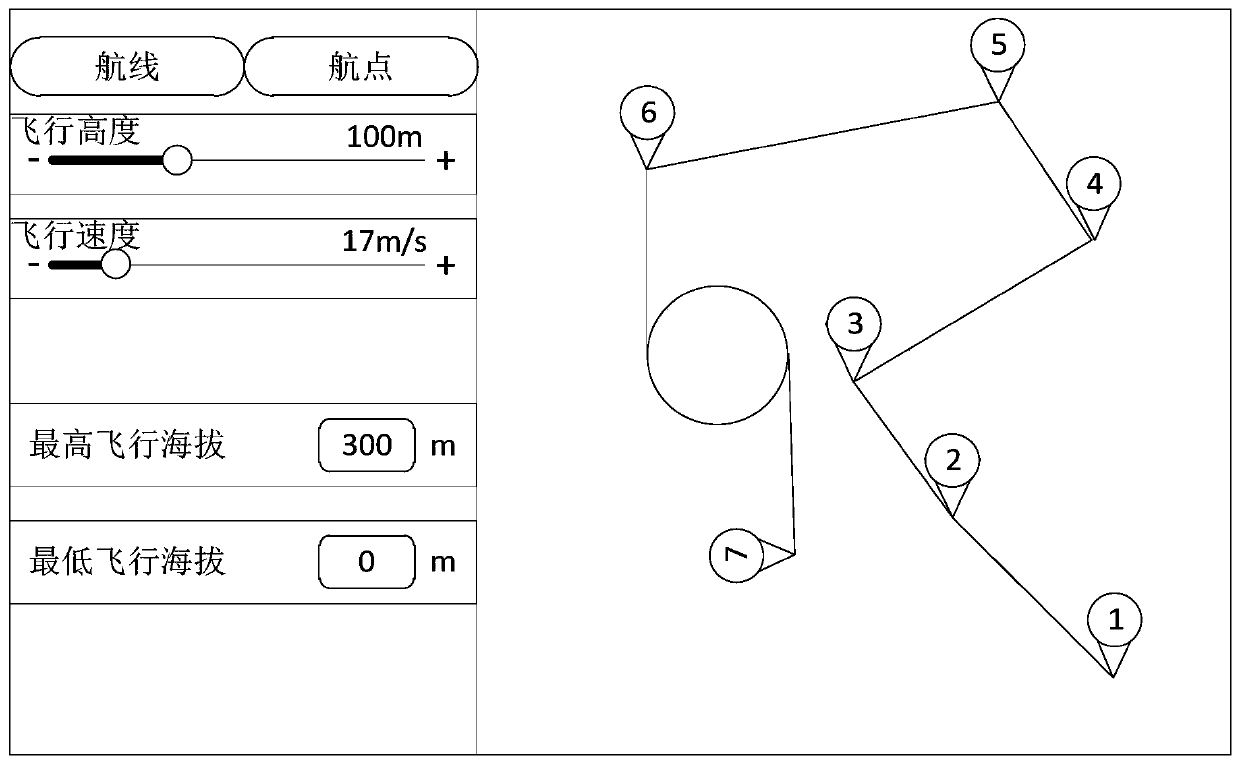

Safe route generation method and device for unmanned aerial vehicle, control terminal and unmanned aerial vehicle

ActiveCN110750106AImprove accuracyImprove securityNavigational calculation instrumentsRemote controlled aircraftFlight heightUncrewed vehicle

The invention discloses a safe route generation method and device for an unmanned aerial vehicle, a control terminal and the unmanned aerial vehicle. The method comprises the following steps of acquiring a route feature point set and attribute parameters, wherein the route feature point set comprises at least one route planning key point, and the attribute parameters at least comprise the flight height; generating a flight route according to the route feature point set, the attribute parameters and a preset route generation strategy; and adjusting the flight route according to an altitude datafile, so as to generate the route. According to the safe route generation method provided by the embodiment of the invention, the elevation data are considered in the flight route formulation, flightobstacles are avoided in the flight control process, and the flight safety of the unmanned aerial vehicle can be improved.

Owner:SHENZHEN AUTEL INTELLIGENT AVIATION TECH CO LTD

Method for dyeing mercerizing wool or mercerizing wool fabric by yellow chrysanthemum flower dye

InactiveCN101117775AReduce the chance of occurrenceImprove uniformityDyeing processSodium bicarbonatePhosphate

The present invention relates to a method of dyeing mercerized wool or mercerized wool fabrics with yellow chrysanthemum paint, which is taken as the paint, and the dyeing method is divided into two steps including ecological pretreatment and subsequent innocuous mordant dyeing: the first step, treatment conditions: baking soda of 1-3 percent of cloth weight, 1-5 percent coconut oil diethanol amide as detergent of 1-5 percent of cloth weight, 0.2-1.0g / L neutral phosphate, temperature 20-60 DEG C, duration 10-60min, bathing ratio 1 to 20-50; the second step, mordant dyeing: the mercerized wool or mercerized wool fabrics with ecological pretreatment is treated with mordant front dyeing, single bathing or post dyeing. The yellow chrysanthemum resources are rich, easy for expanding plantation, with sound dyeing and less damage to mercerized wool during dyeing.

Owner:HAILAN GRP +1

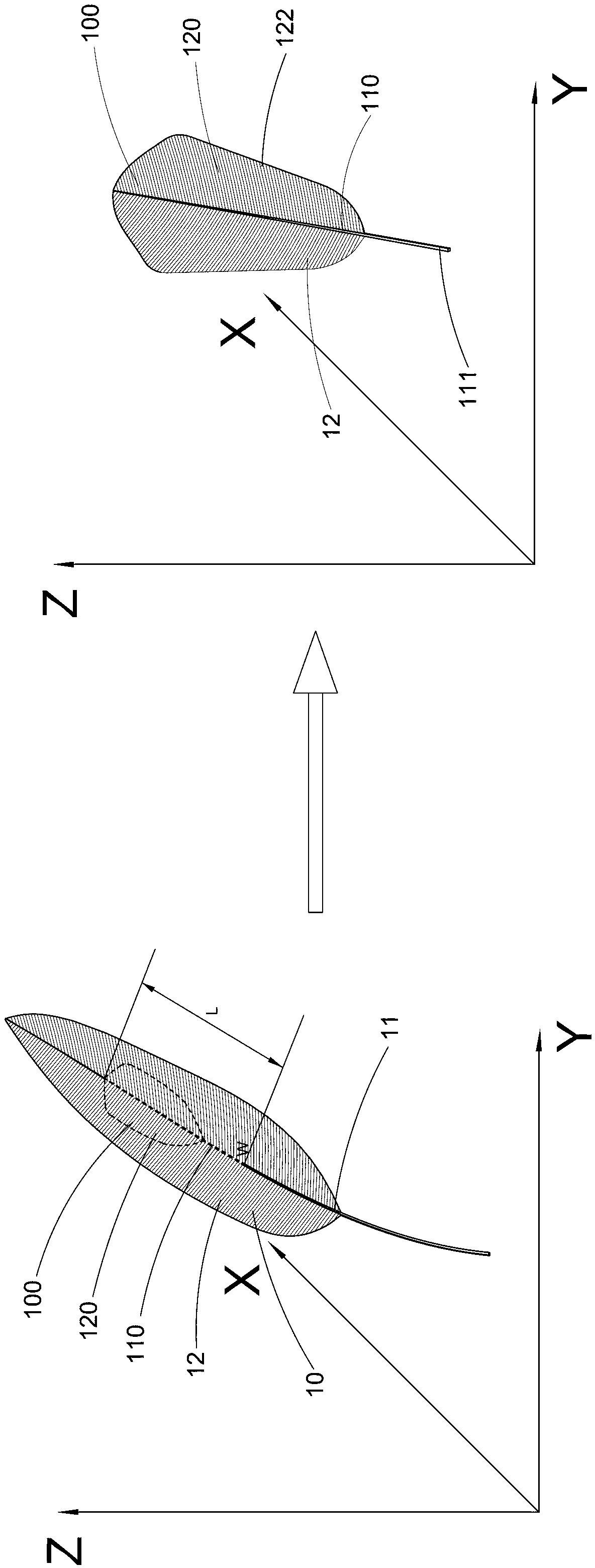

Manufacturing method of badmintons

ActiveCN102989150ARealize automated productionReduce or eliminate manual operationsSport apparatusEngineeringMechanical engineering

The invention discloses a manufacturing method of badmintons. The method comprises the following steps of: (a) molding a flocking shelf with a group of flocking rods and a group of flocking tubes, wherein each flocking tube is respectively and integrally formed at one end of a corresponding flocking rod; (b) installing the flocking shelf at a fixed ball head; and (c) respectively implanting the inserting heads of a group feather blades into corresponding flocking tubes; or after inserting the feather blades into the flocking shelf, the flocking shelf with the feather blades is installed on the ball head. The method further comprises a step (d) that natural feather is cut according to the demands of a cutting model to obtain the feather blades. According to the method, machines are engaged to operate, the production efficiency of the badminton is improved, and the manufactured badminton has a molded flocking shelf, so that stable and accordant conical degree is formed for the badmintons, and the badminton quality is ensured.

Owner:ANHUI SANCAI SPORTS GOODS

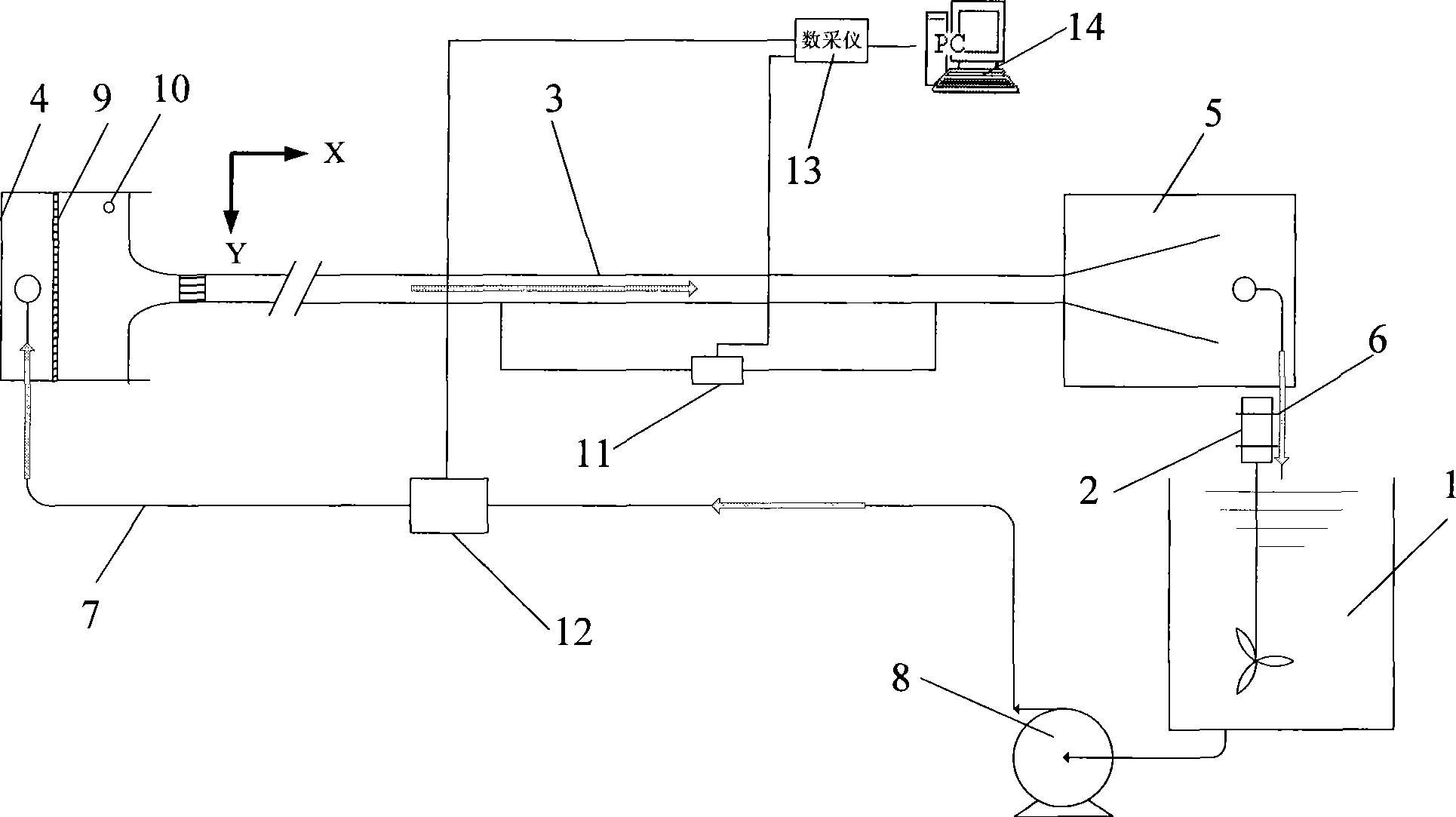

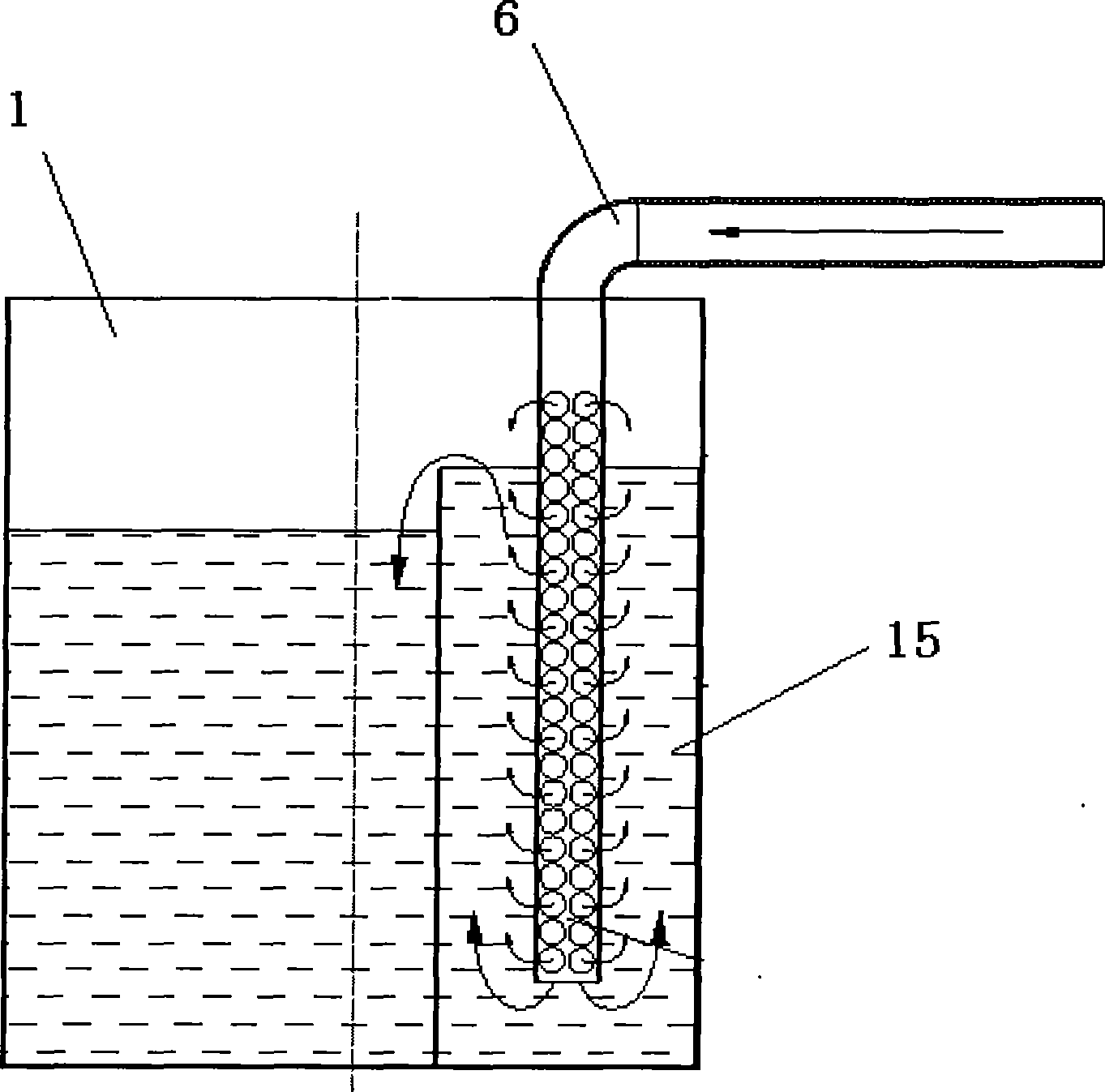

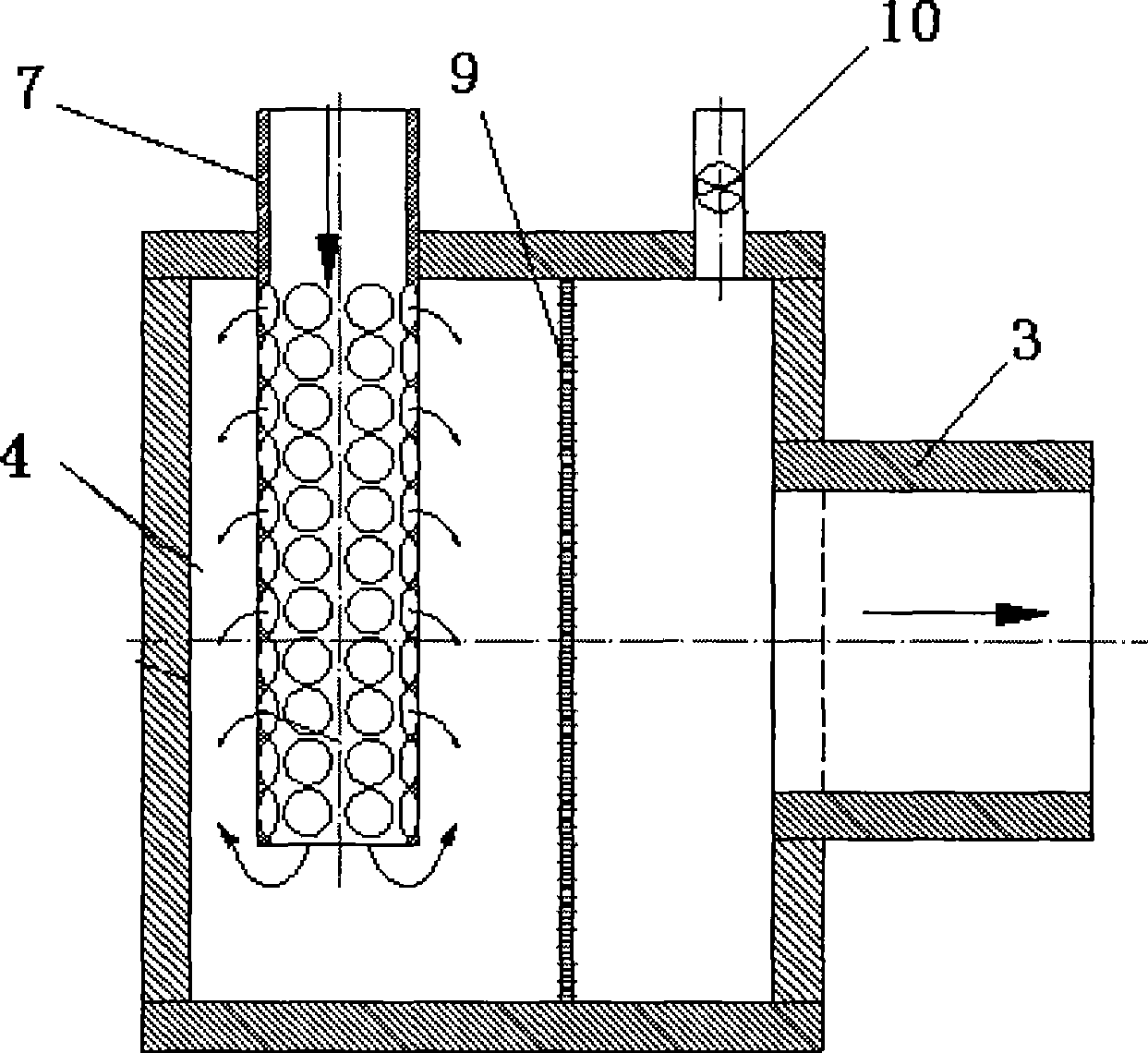

Drag-reduction property experimental apparatus for surfactant solution

InactiveCN101545843AReduce generationSpeed up experimentationFlow propertiesCirculator pumpLiquid storage tank

The invention relates to the field of the research on the drag-reduction property of surfactant solution, in particular to a drag-reduction property experimental apparatus for surfactant solution, comprising a liquid storage tank, a test section, a liquid inlet chamber communicated with the inlet of the test section, a liquid outlet chamber communicated with the outlet of the test section, a liquid outlet pipe communicated with the liquid outlet chamber and the liquid storage tank, a liquid inlet pipe communicated with the liquid storage tank and the liquid inlet chamber and a circulation pump arranged on the liquid inlet pipe. The drag-reduction property experimental apparatus for surfactant solution is characterized in that the liquid outlet pipe extends into the liquid storage tank, and the pipe wall of the extension section of the liquid outlet pipe is provided with a hole.

Owner:XI AN JIAOTONG UNIV

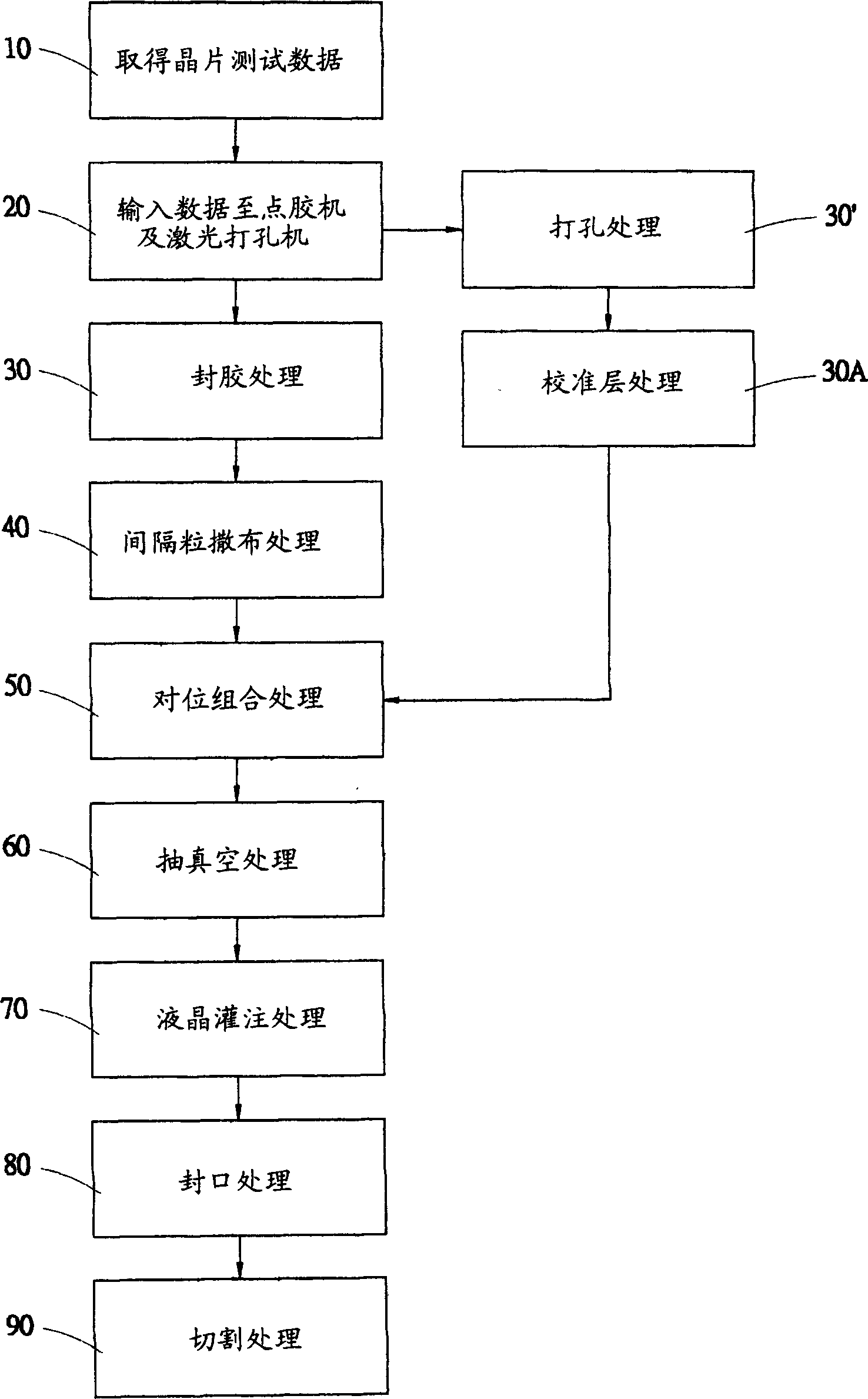

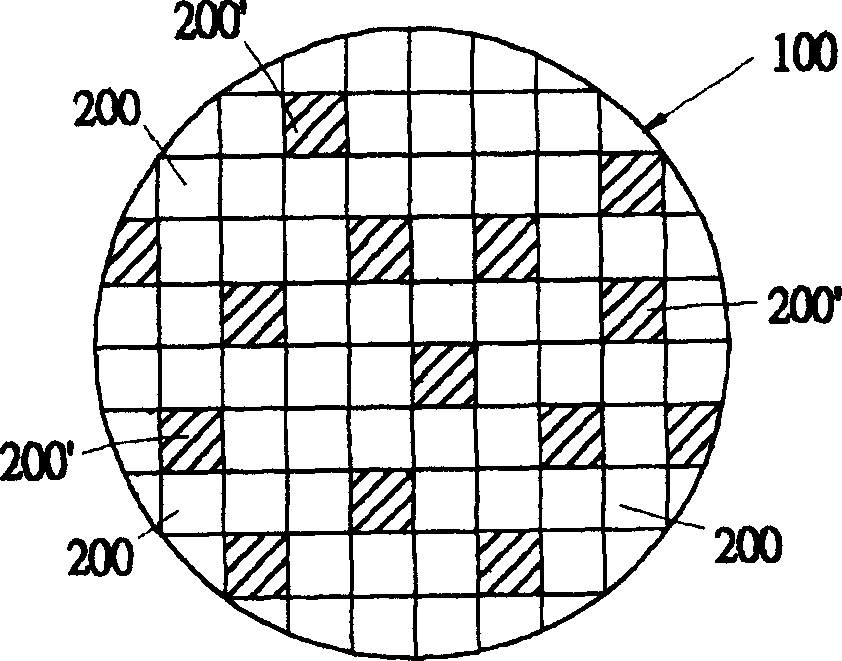

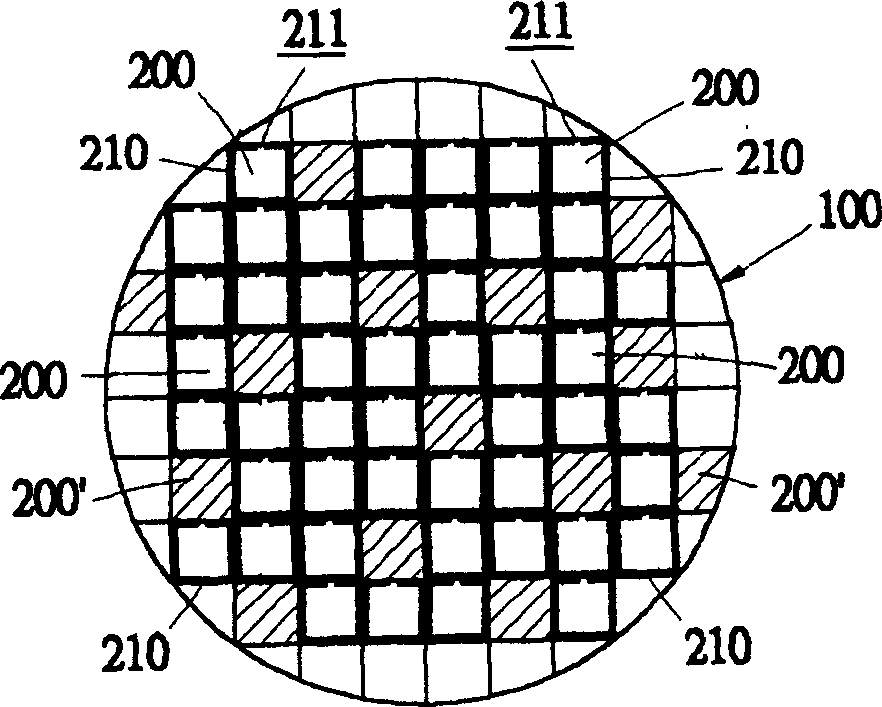

Method for producing miro display

The manufacture of mniature LCD includes testing individual chips on the basic substrate, marking the useless chip after test, inputting the test data into one gluing machine or laser perforator, making glue frame, around the qualified chips in the gluing machine, perforating implanting holes on ITO glass in the positions corresponding to the qualified chips, spreading interval grains to the glued chip checkers, assembling ITO glass sheets onto the chips according to the tested data, injecting liquid crystal via the injecting holes in the ITO glass sheet over the qualified chips so as to make liquid crystal diffuse to between the chips and ITO glass sheet, sealing and cutting to make miniature LCD product with qualified chip. The product is then screened.

Owner:SINGAPORE UNITED PROJECTION

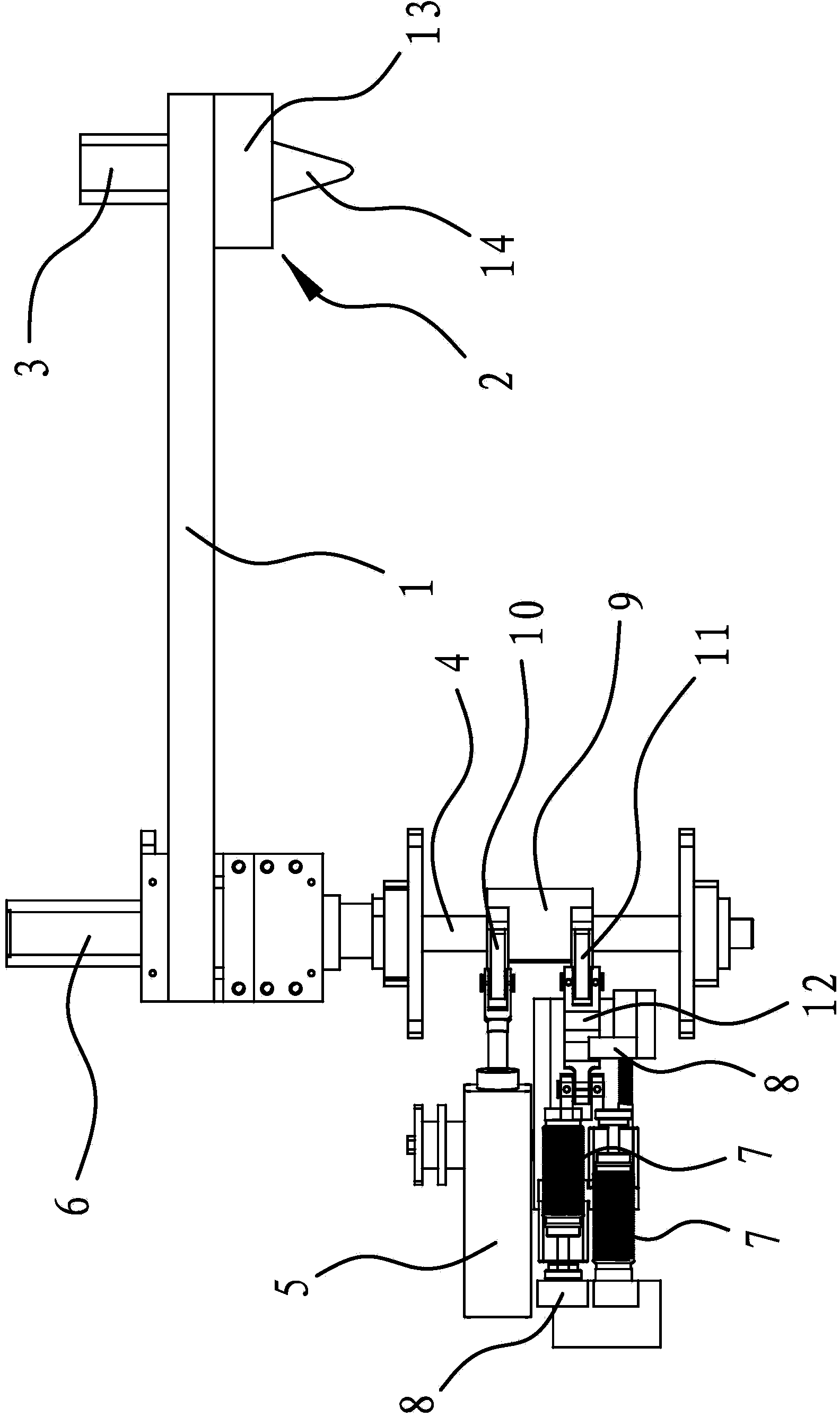

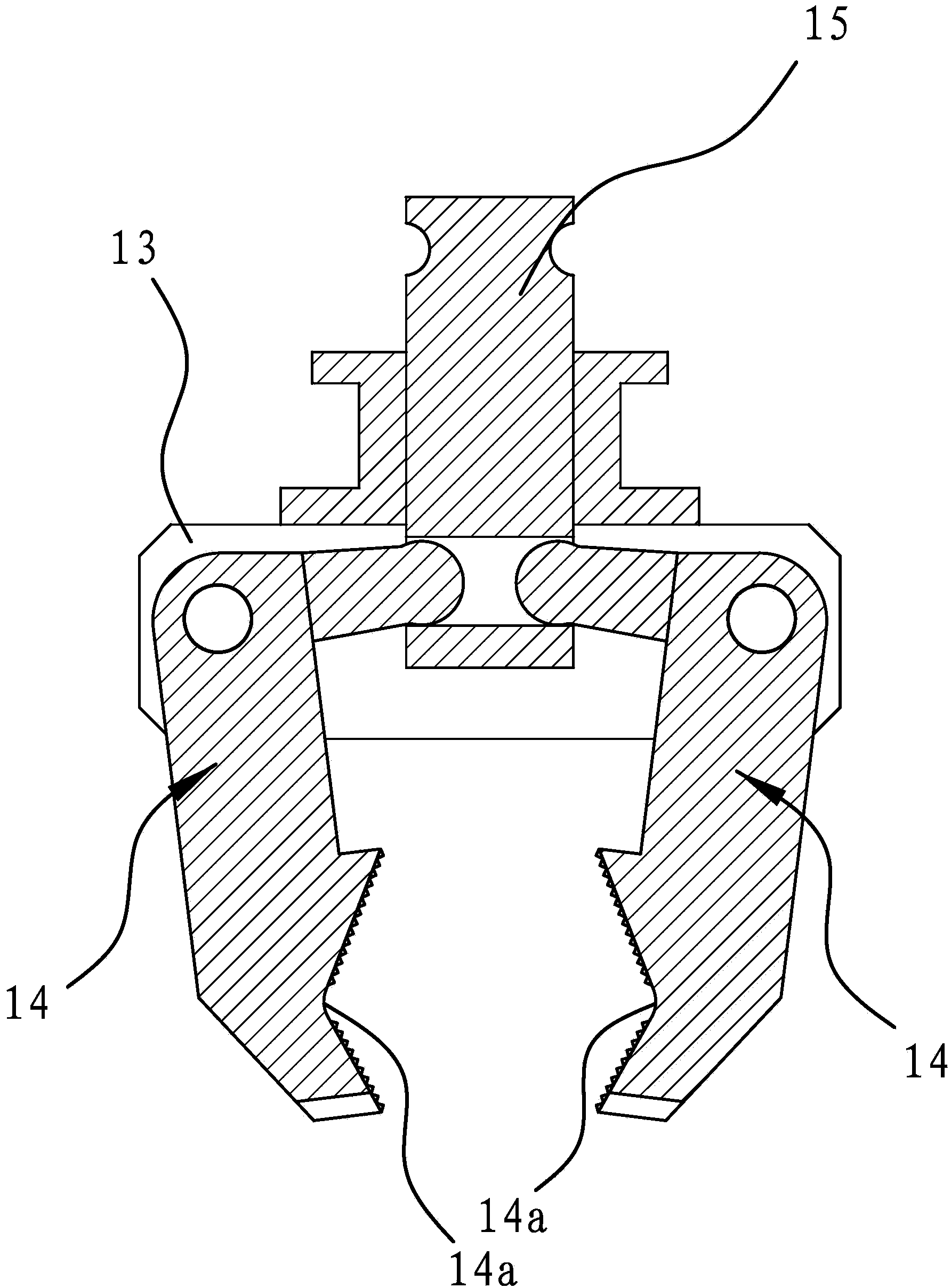

Automatic feeding device of red flushing furnace

The invention provides an automatic feeding device of a red flushing furnace, and belongs to the field of electromechanical technology. The automatic feeding device solves the problems that the labour intensity is heavy and the security is low when the red flushing furnace feeds. The automatic feeding device of the red flushing furnace comprises a material loading mechanical arm and a controller, wherein the material loading mechanical arm comprises an arm which is horizontally arranged, a clamping jaw connected to one end of the arm, a clamping jaw driving piece for driving the clamping jaw to grab or loosen a workpiece, a transmission shaft which is vertically arranged and is fixedly connected to the other end of the arm as well as a transmission shaft driving piece and a lifting driving piece which are both connected with the transmission shaft; an output end of the transmission shaft driving piece is connected with the transmission shaft and can drive the transmission shaft driving piece to rotate through rolling the axis of the transmission shaft driving piece, the lifting driving piece can drive the arm to rise or descend along the vertical direction; the clamping jaw driving piece, the transmission shaft driving piece and the lifting driving piece are all connected with the controller; the controller can respectively control the clamping jaw driving piece, the transmission shaft driving piece and the lifting driving piece to work. The automatic feeding device of the red flushing furnace provided by the invention has the advantages that the degree of automation is high, the service life is long, and the processing quality is high.

Owner:台州英达机械科技有限公司

Electron beam welding method for dense rectangular ring welding lines of outer ring face

ActiveCN109202254ASuitable for mass productionGuarantee welding quality requirementsElectron beam welding apparatusButt jointLap joint

The invention relates to an electron beam welding method for dense rectangular ring welding lines of an outer ring face. According to the electron beam welding method for the dense rectangular ring welding lines of the outer ring face, a thickness-unequal butt joint form increasing the local thickness of the welding part head portion is designed, and a beam flow guiding welding along long edges and lap-joint and step-attenuating beam flow closing welding method is adopted, so that the amount of molten metal is increased, the welding line molding quality is improved, and the process stability and margin are improved; misplaced and lapped U-shaped protective structures are designed inside an outer ring, and injuries by burning on a shaft rod and an inner ring structure are avoided; and a symmetrical welding method is adopted, the welding sequence is designed, a grouped multiple welding manner is adopted, the accumulation effect of dense welding-line welding heat input and stress deformation is reduced, influence of the dense welding-line stress deformation on welding gaps, order difference and the like is reduced, the welding quantity is improved, control of welding deformation and structural size accuracy is facilitated, and the welding finished product rate is increased.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

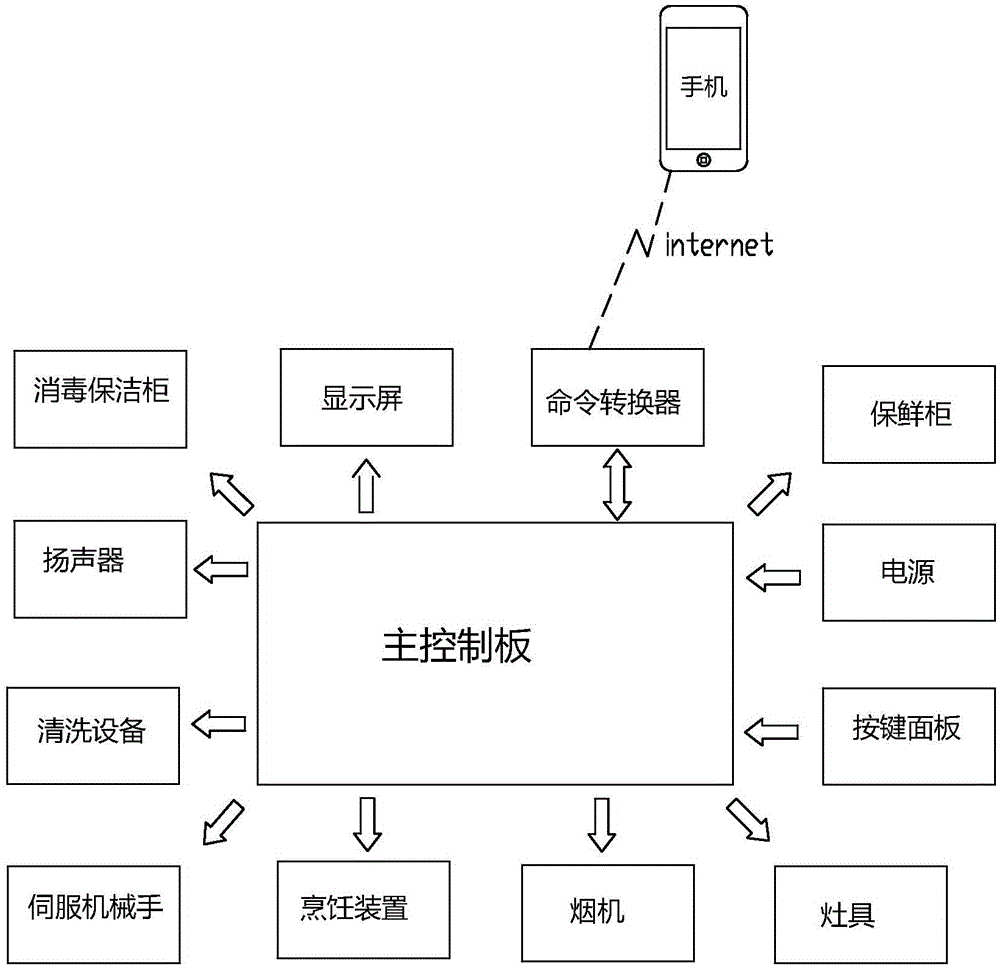

Intelligent kitchen cooking equipment

InactiveCN105030042AGuaranteed nutritionReduce the chance of occurrenceCooking vesselsHuman bodyUncooked Foods

The invention discloses intelligent kitchen cooking equipment. The intelligent kitchen cooking equipment comprises multiple food utensils, a main control panel and a servo manipulator, a button panel, cleaning equipment and a cooking device which are electrically connected with the main control panel; the food utensils are used for containing uncooked food materials and cooked food, and a user types a cooking instruction to the main control panel through the button panel; the main control panel controls the servo manipulator to conduct dosing for the food utensils, clean the cleaning equipment and convey the food materials and controls the cooking equipment to cook the food. According to the intelligent kitchen cooking equipment, one-click cooking from uncooked rice to cooked rice can be achieved by arranging the intelligent cooking elements such as the food utensils, the main control panel, the servo manipulator, the button panel, the cleaning equipment and the cooking device, and great convenience is brought for the user; meanwhile, daily necessary nutrition of human bodies is scientifically guaranteed, and the occurrence probability of diseases is reduced.

Owner:张锡华

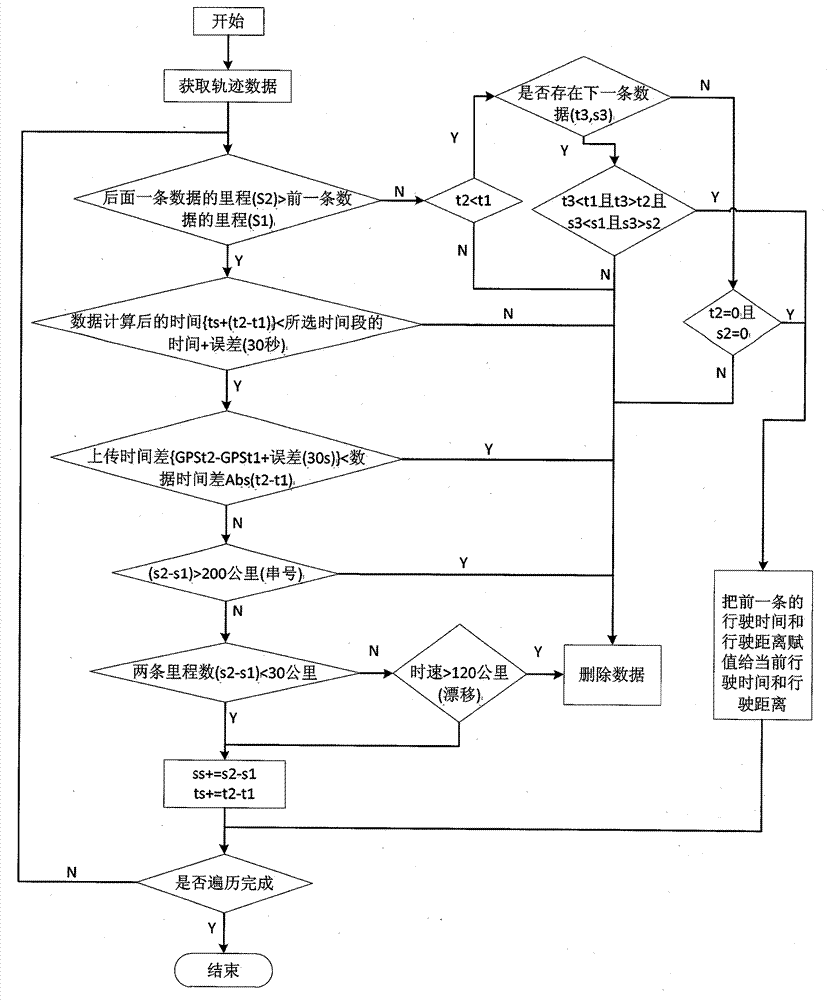

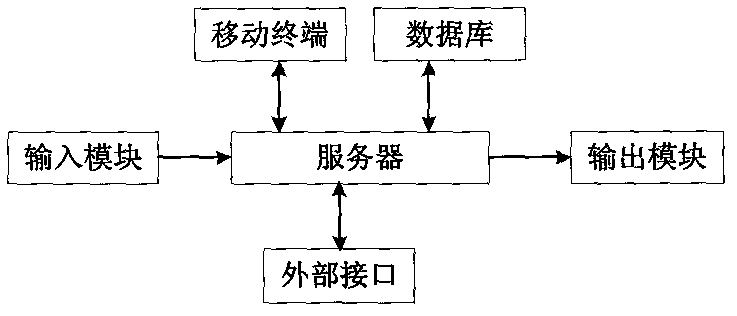

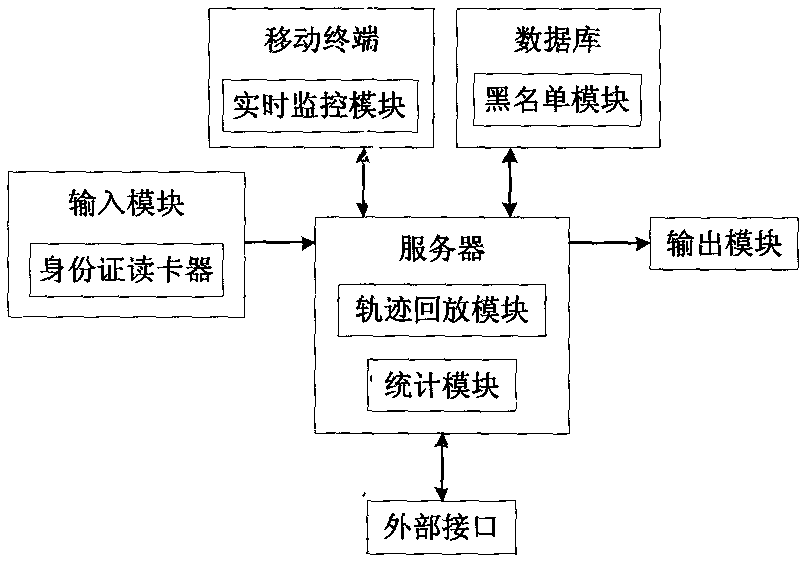

Management system for automobile leasing and renting information

The invention relates to a management system for automobile leasing and renting information. The management system comprises a server and further comprises a mobile terminal, a database, an external interface, an input module and an output module which are connected with the server, wherein the server is used for receiving and processing various instructions; the mobile terminal is arranged on an automobile terminal and is used for sending automobile state information and instruction to the server; the database is used for storing various information in the management system for the automobile leasing and renting information; the external interface is in communication connection with other databases; and the input module is used for receiving an input information instruction of a user, and the output module is used for outputting a processing result of the server. When the management system is used, the identity information of the user is identified by the input module, and then the identity information is compared with the information in the database through the server, so that a leasing company can judge whether the automobile is rented or not. Meanwhile, the management system also has the functions of blacklist warning, one-certificate multi-renting, resource sharing, and the like.

Owner:QUANZHOU HAOJIE INFORMATION TECH DEV

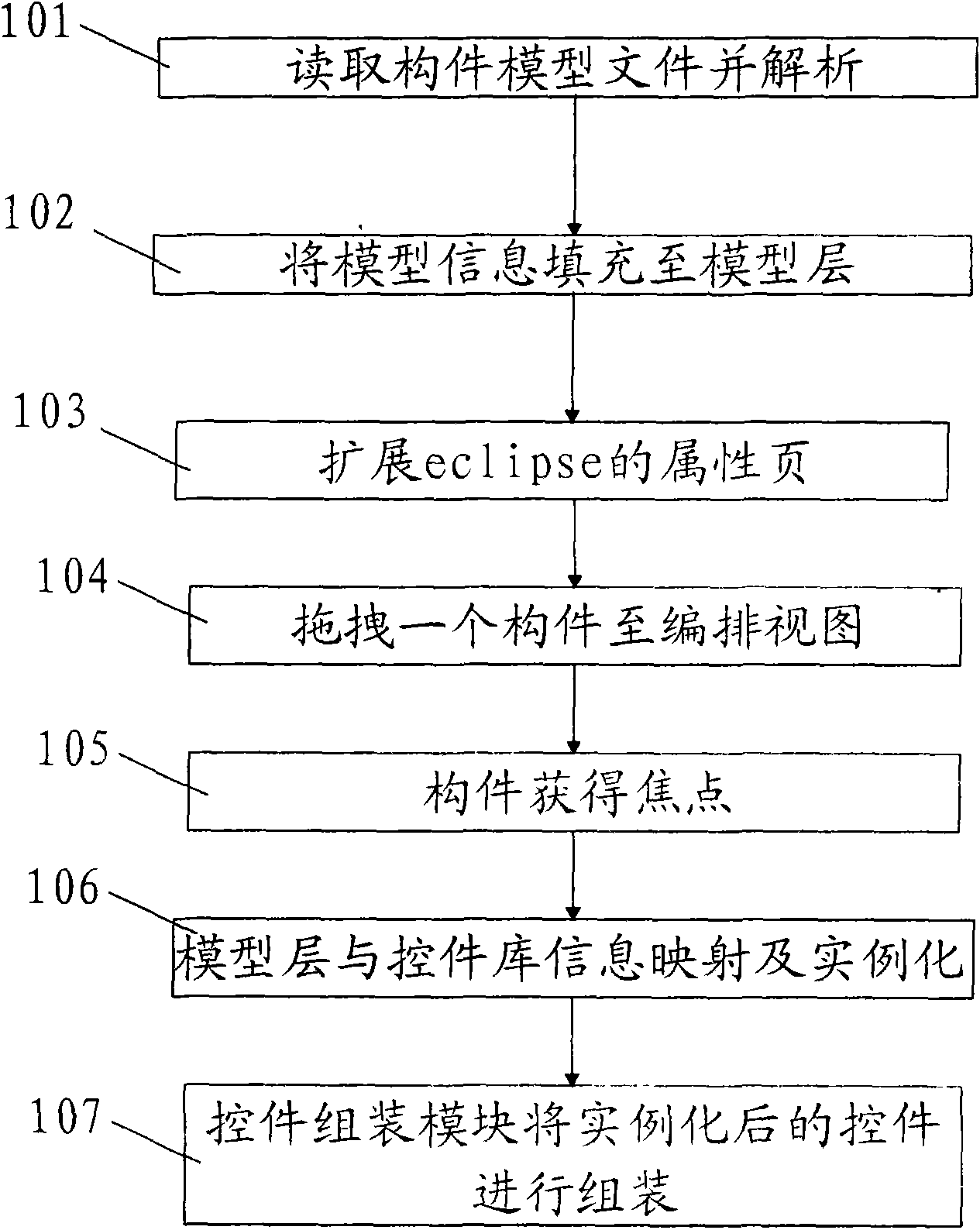

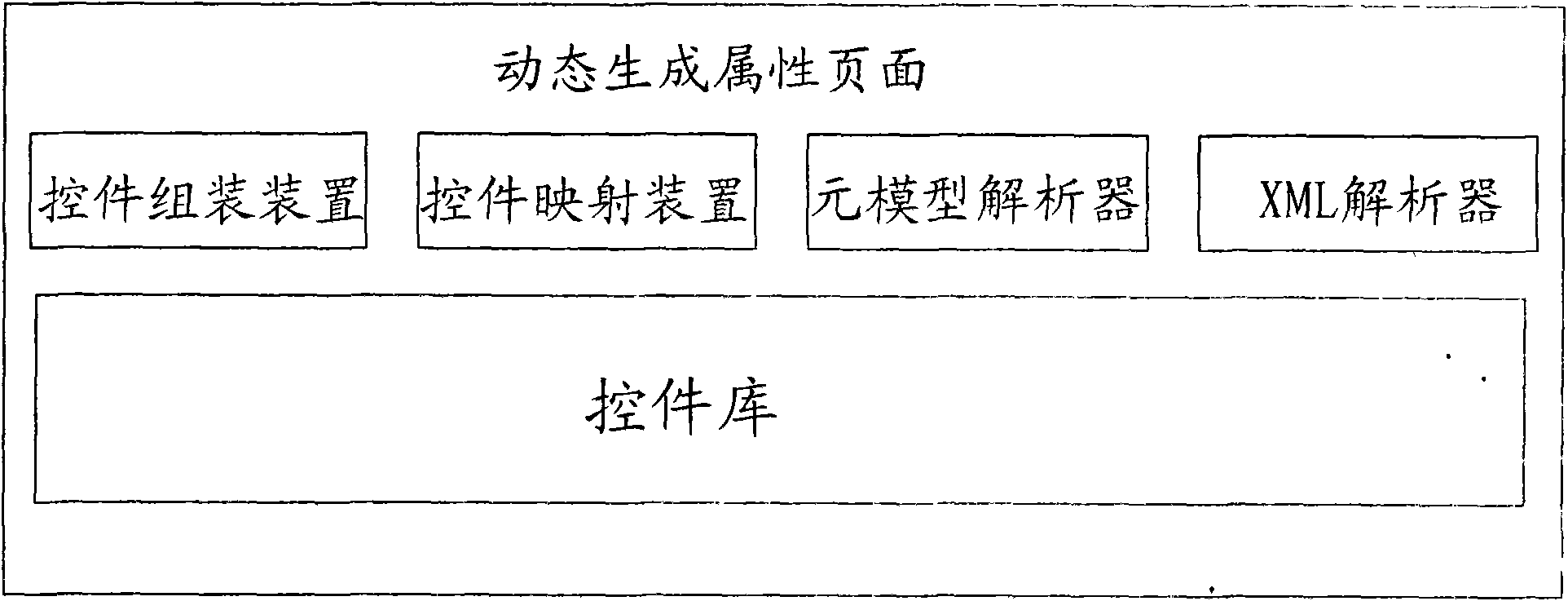

Method and device for dynamically generating property page

ActiveCN101645006AImprove reuseImplement programmingSpecific program execution arrangementsIntegratorDevice form

The invention relates to a method and a device for dynamically generating a property page, belonging to the technical field of dynamic property pages based on Eclipse in a Visual Integrator and comprising an XML resolver, a meta-model resolver, a control component mapping device, a control component assembling device and a control component library, wherein the XML resolver realizes the mutual translation of XML documents and internal information; the meta-model resolver resolves and verifies a constructed model to form an internal data structure of a model layer; the control component mappingdevice finds a corresponding control component entity from the control component library in such a way that the model layer obtains corresponding configuration information by resolving a meta-model,and then establishes a control component instance according to the configuration information; the control component assembling device forms the instantiation control component into corresponding distribution information according to the configuration information, assembles the distribution information and displays the distribution information on the property page; and the control component libraryis defined with control components with fixed length, width and height and provides simple control components and complex control components.

Owner:山东中创软件商用中间件股份有限公司

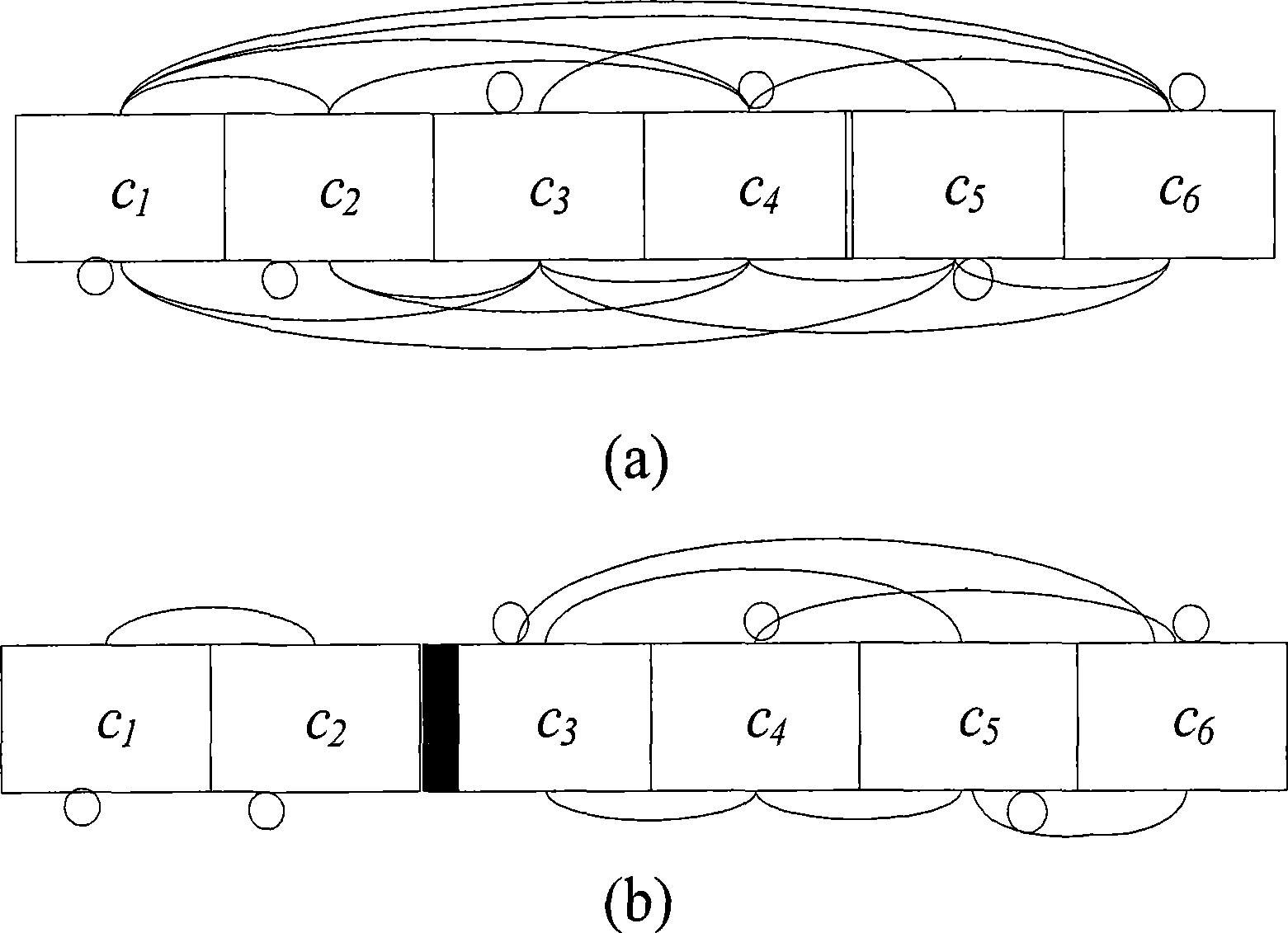

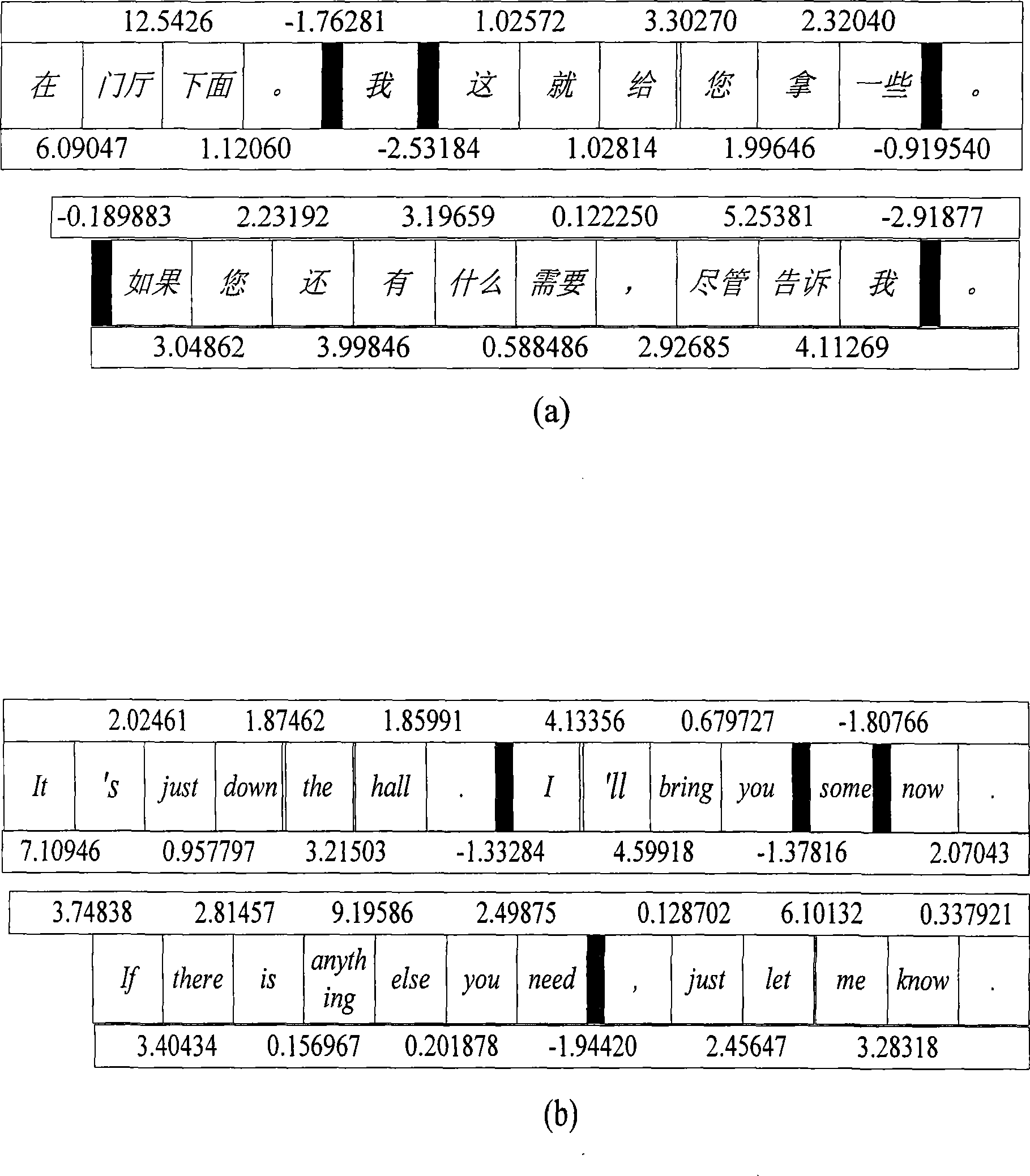

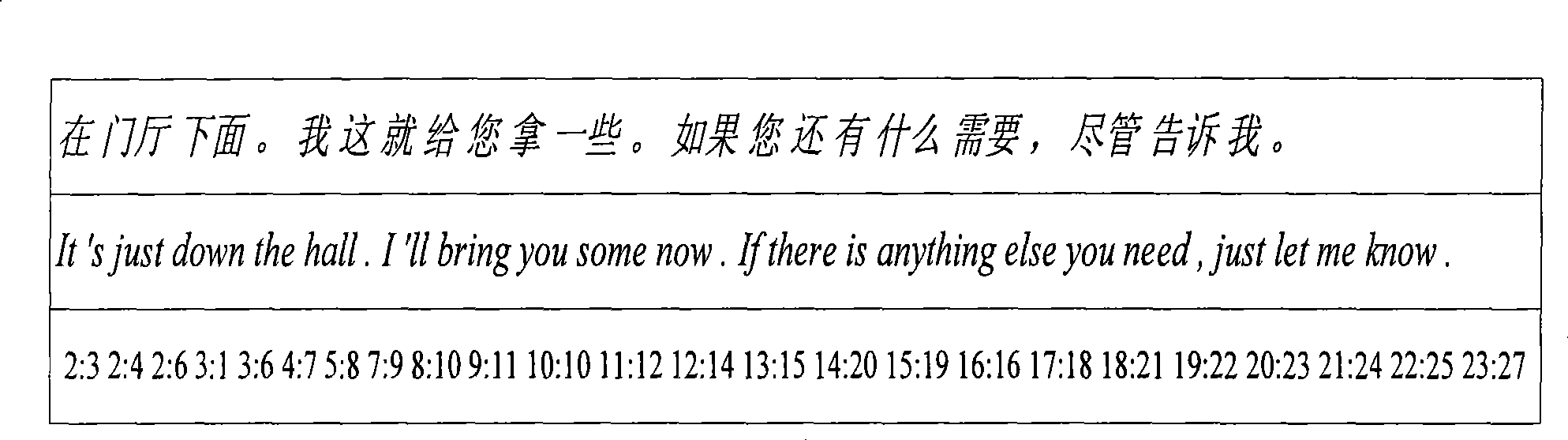

Automatic extraction and filtration method for Chinese-English phrase translation pairs

ActiveCN101482860ANo wasted storage spaceReduce the chance of occurrenceSpecial data processing applicationsSentence pairPrecondition

The present invention provides an automatic abstracting and filtering method in Chinese-English phrase translation. The method of the invention comprises the following steps: extracting the characteristic information which divides the language block and filters the candidate phrase to original Chinese-English double-language sentence pair; confirming the language block division anchor point according to different characteristic information, dividing the original Chinese-English sentence pair to a plurality of single language blocks; extracting the candidate phrase in the language block with the word aligning information of original Chinese-English double-language sentence pair; and filtering the generated candidate phrase according to the characteristic information of generation frequency of candidate phrase for generating the required phrase pair. The invention adopts the phrase abstraction in the traversing language block and is especially useful for the indefinite expanding of empty word thereby effectively settling the requirement to the storing space caused by the overgreat extraction amount of phrase, and effectively filtering many noise phrase. The invention can generate a plurality groups of phrases directly according to the fixation word alignment of present sentence pair thereby increasing the recalling rate of phrase pair under the precondition of satisfying the precision.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com