Manufacturing method for high-vanadium high-speed steel composite roll

A technology of composite roll and manufacturing method, which is applied in the field of roll manufacturing, can solve problems such as difficulty in guaranteeing bonding quality, high melting point of vanadium oxide, and low strength of roll journal, so as to improve bonding rate, increase vanadium absorption rate, and reduce vanadium The effect of oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

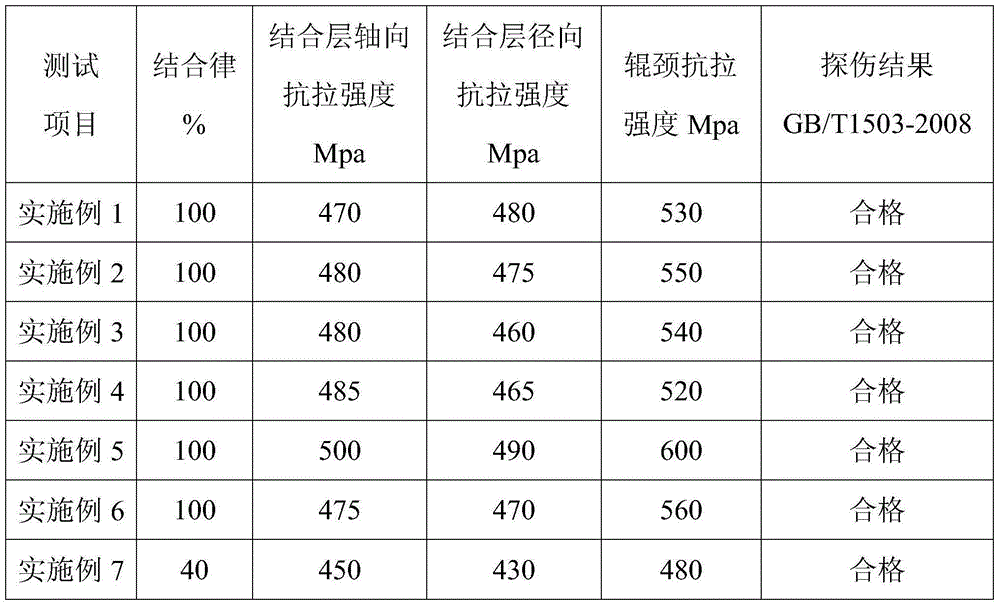

Examples

Embodiment 1

[0056] A method for manufacturing a high-vanadium high-speed steel composite roll, comprising the following process steps:

[0057] A. Modeling, the roll body model adopts a metal mold with paint sprayed inside, the roll neck model adopts quartz sand clay modeling, and the bottom box is connected to the overflow pipe;

[0058] B. Smelting raw materials: In the intermediate frequency furnace, the outer high-vanadium high-speed steel raw materials, the transition layer ductile iron molten iron raw materials, and the core ductile cast iron molten iron raw materials are respectively smelted;

[0059] (1) The chemical composition and weight percentage of the high-vanadium high-speed steel in the outer layer are C2.0%, Cr4.0%, Ni0.7%, Mo4.3%, V8.0%, W2.0%, Nb2. 5%, Re0.08%, P≤0.04%, S≤0.04%, Mn≤0.5%, Si1.5%, and the rest is Fe; the melting temperature of the outer high-vanadium high-speed steel is 1600-1650°C.

[0060] After smelting, the high-vanadium high-speed molten steel in th...

Embodiment 2

[0074] The preparation process is basically the same as that of Example 1, the difference being that in step C, the pouring temperature of the outer layer of high-vanadium high-speed steel is 1420-1450°C.

Embodiment 3

[0076] The preparation process is basically the same as that of Example 1, with the difference that: in step C, the pouring temperature of the transition layer molten iron is 1500-1550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com