Method and device of electrochemical descaling, corrosion inhibition, sterilization and algae removal for cooling circulating water

A cooling cycle, sterilizing and algae-killing technology, applied in the direction of electrochemical water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high energy consumption, under-scale corrosion, and limited scale-inhibiting effect, and achieve Reduce the probability of occurrence and reduce the effect of under-deposit corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

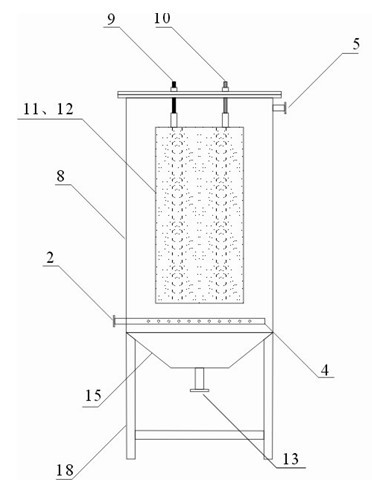

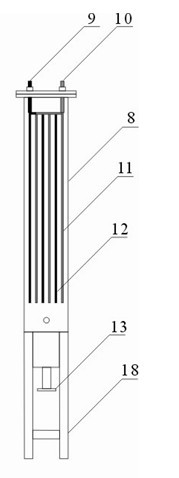

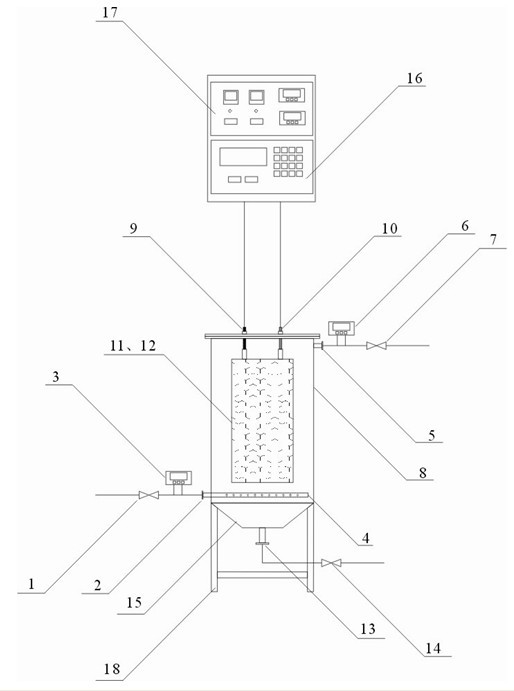

Image

Examples

example 1

[0061] The cooling water open circuit circulation system of a chemical factory enterprise, the circulation pool volume is 2850m 3 , using two sets of this device for processing, with a processing capacity of 1.0 m 3 / h. Taiwan, the water from the circulating pool is lifted into the equipment through the water pump, and is discharged into the circulating pool after treatment. It runs continuously for 50 days. The water quality parameters in the circulating pool are shown in Table 1.

[0062]

example 2

[0064] In the water ring vacuum pump cooling water circulation system of an enterprise, after installing this device and running for 60 days, the discharged scale was analyzed, and the composition is shown in Table 2.

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com