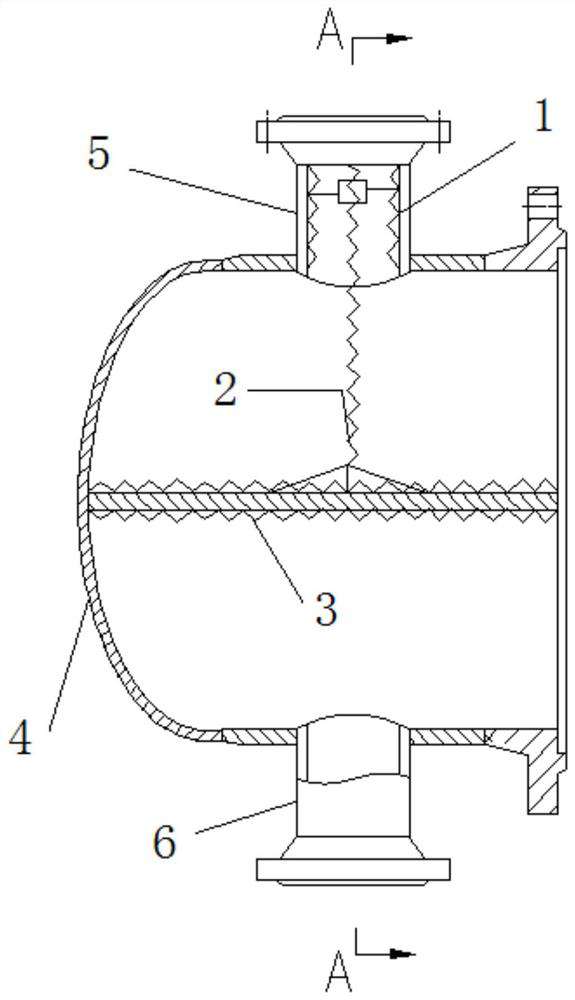

Self-cleaning head cover and heat exchange equipment

A heat exchange equipment and self-cleaning technology, which is applied in the field of head covers, can solve the problems of easy fouling and under-scaling corrosion, and achieve the effects of improving the total heat transfer coefficient, strong anti-corrosion ability, and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

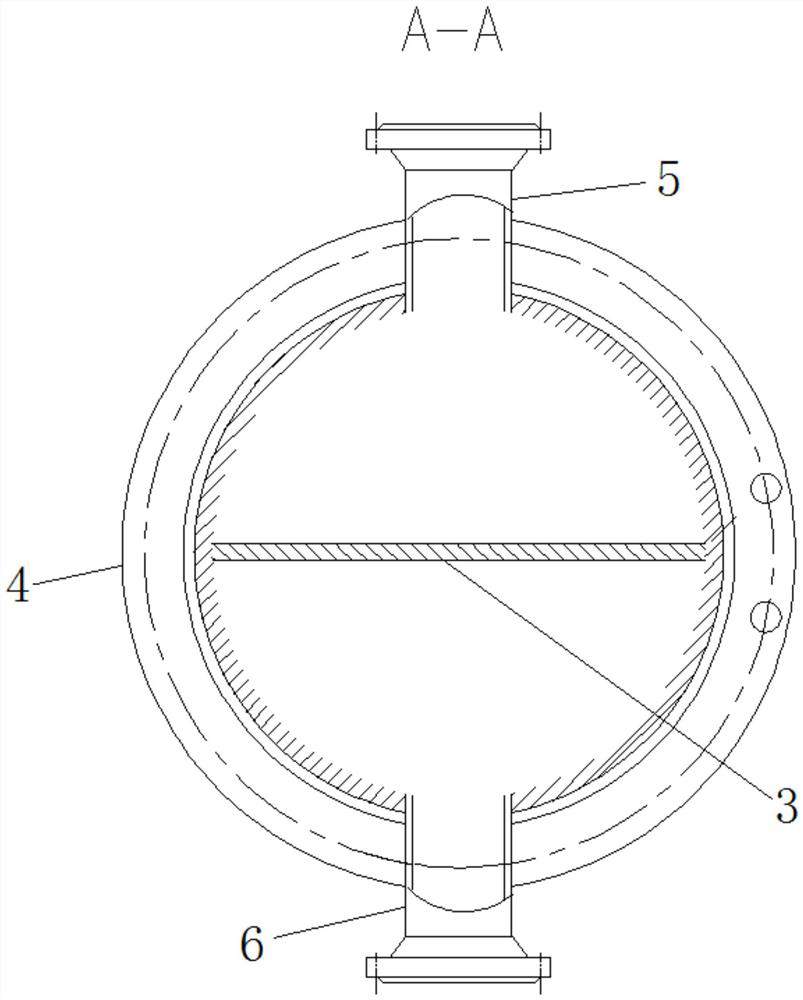

Method used

Image

Examples

Embodiment approach

It is reduced by more than 10%, which increases the energy-saving effect of coal chemical industry. The self-cleaning head cover in this application can reduce or reduce labor and

Chemical cleaning to prevent equipment damage and scaling corrosion, easy installation, no need to change the equipment body, safe and reliable. SH type self-cleaning

The washing head cover has a very obvious effect of enhancing the turbulence, which can effectively improve the turbulence performance and prevent the scaling of the pipe wall, sludge deposition and corrosion.

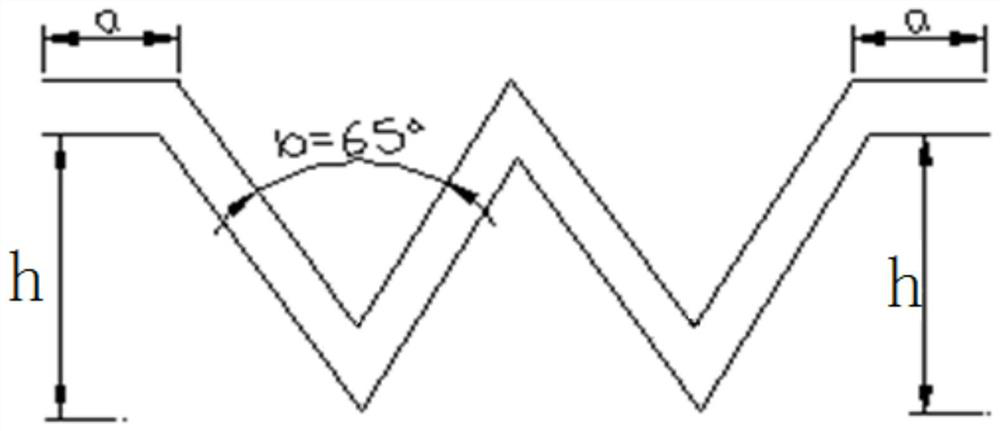

Theoretical calculations and experimental data strongly support this. From low flow to high flow, low Reynolds number to high Reynolds number

Anti-scaling and anti-corrosion calculations were carried out.

The self-cleaning head cover of the present application strengthens scale and anti-corrosion data:

[0039]

[0040]

[0041] Reynolds number Re: ρvd / n and U / ( / L), the ratio of flow rate to flow rate. The flow velocity U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com