Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

605results about How to "Improve reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

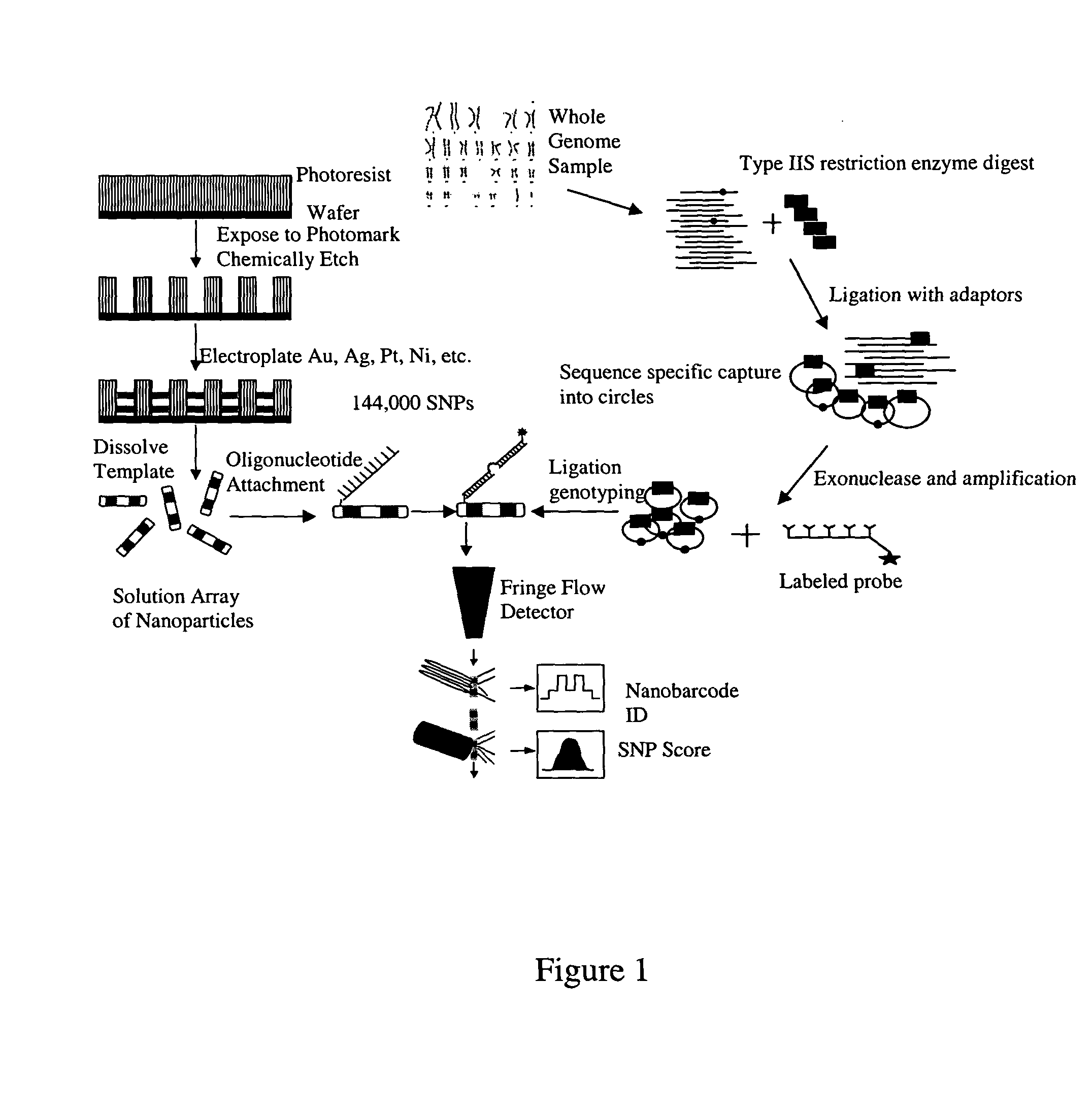

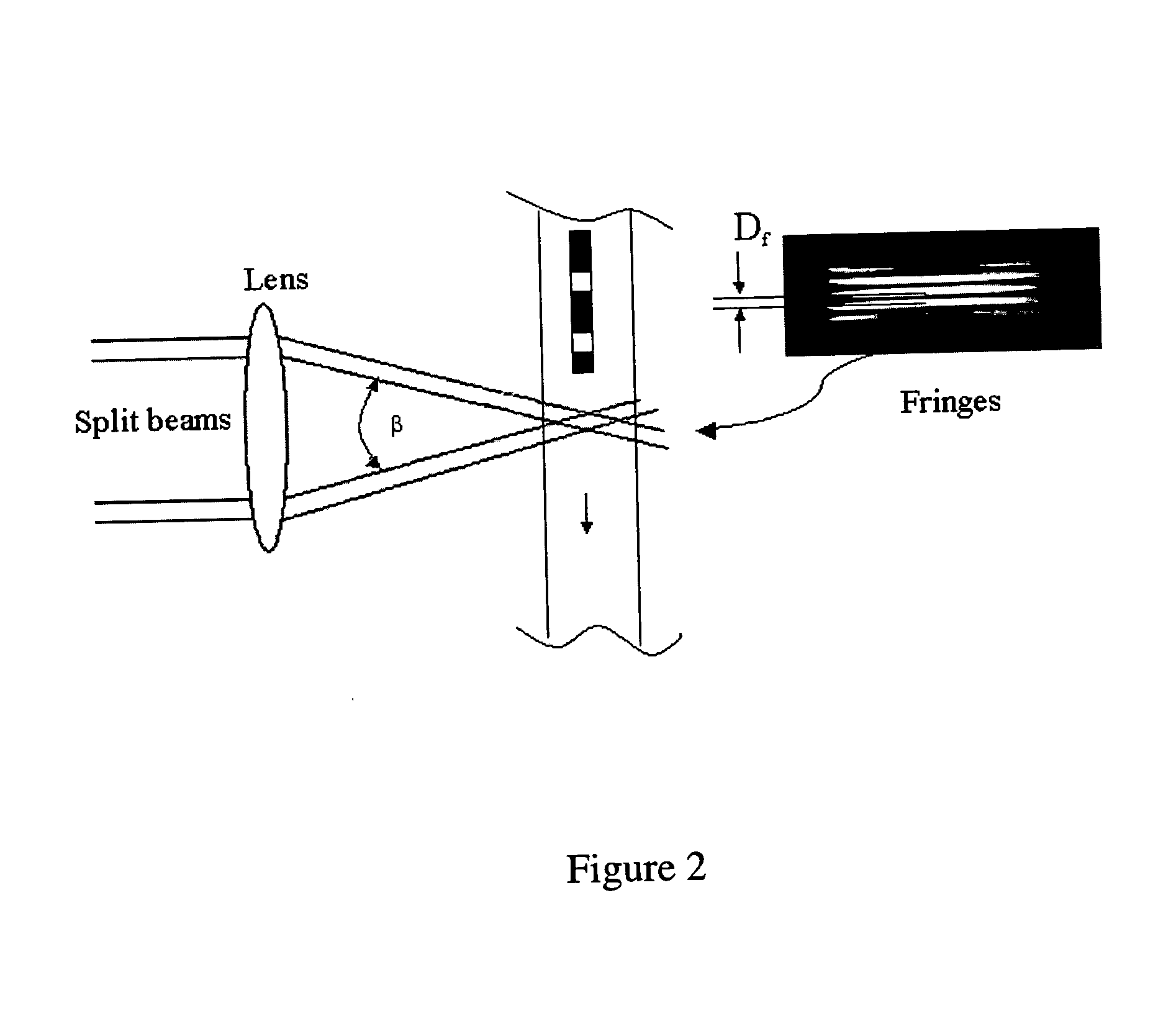

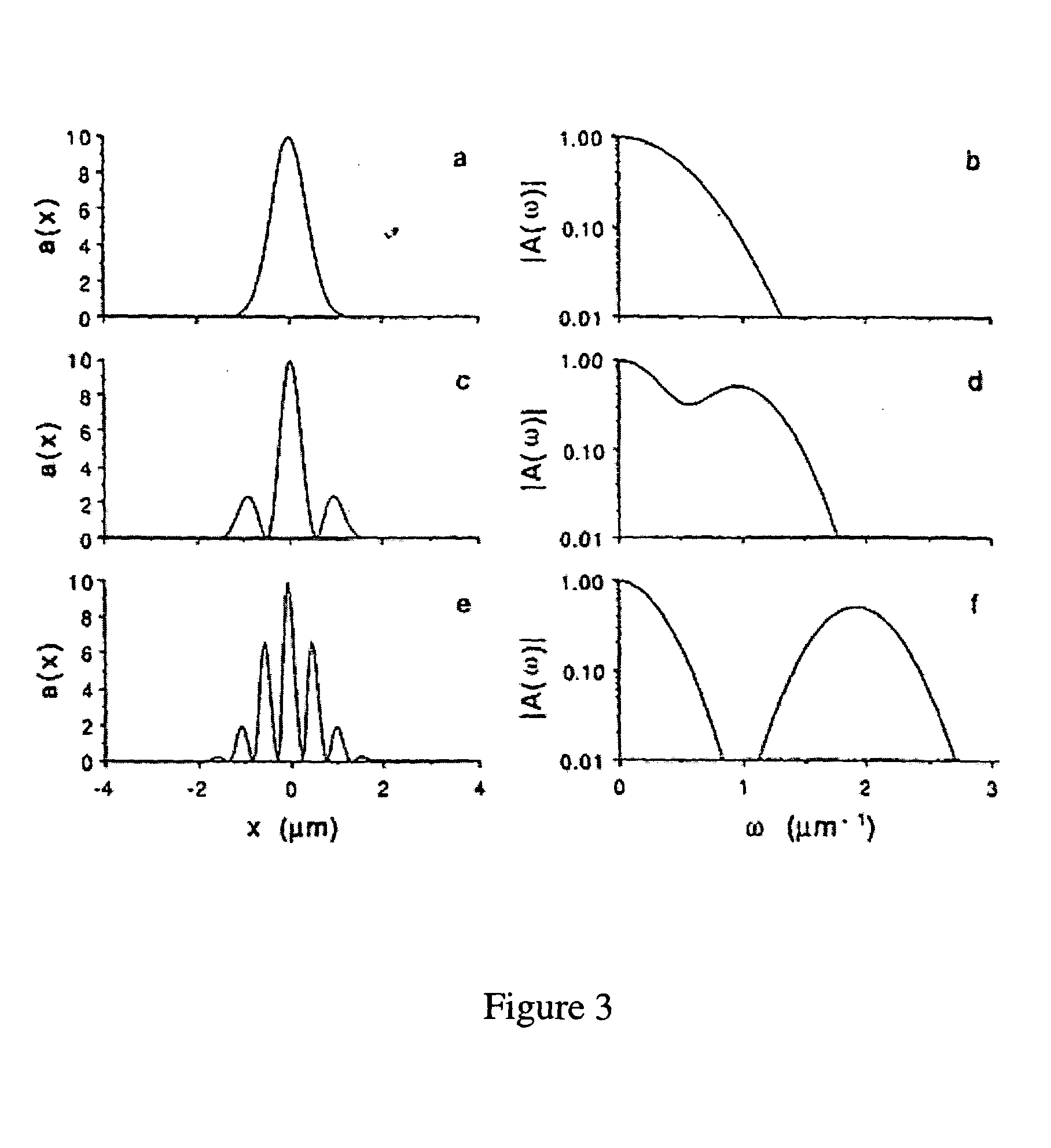

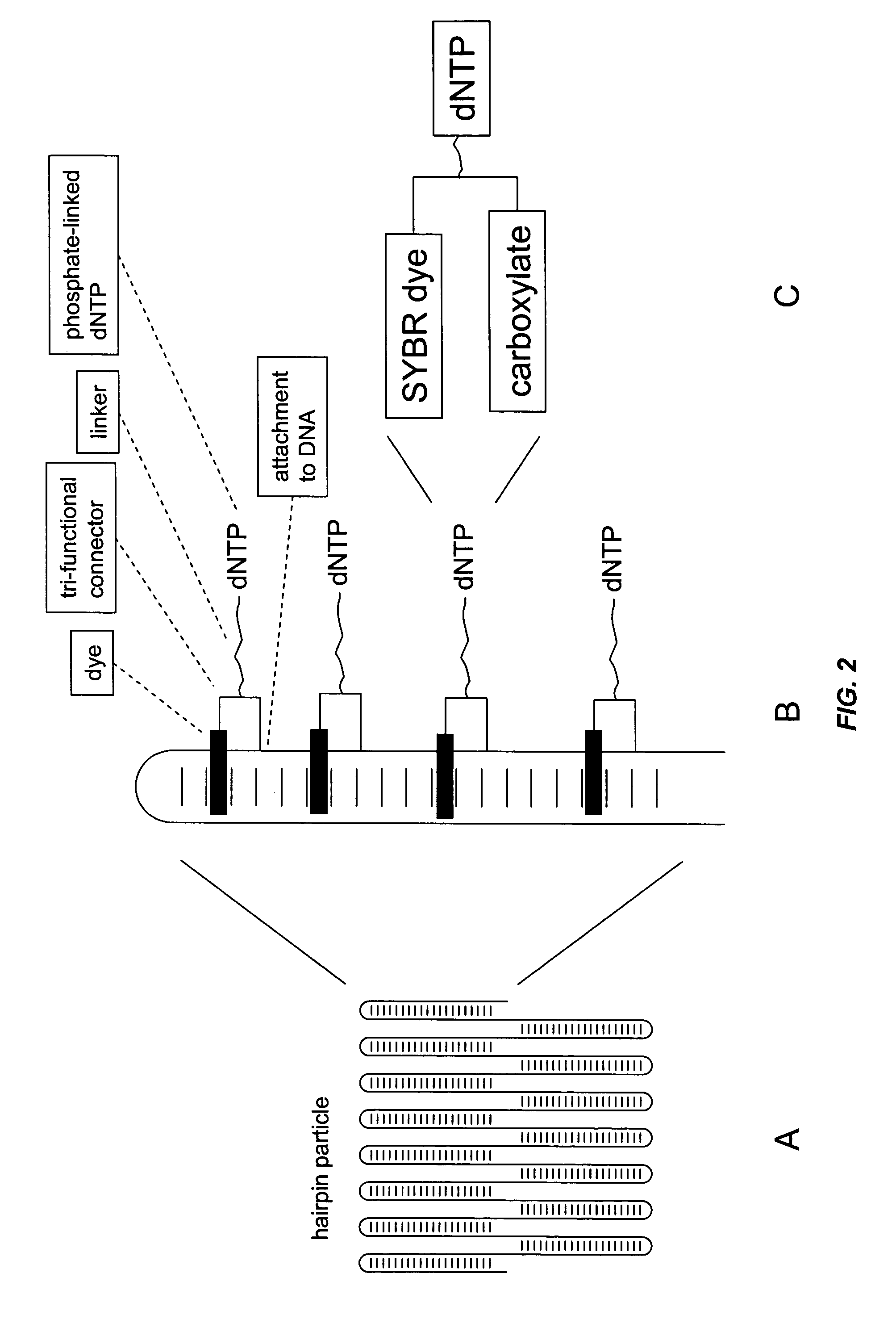

Universal selective genome amplification and universal genotyping system

InactiveUS20050019776A1Enriches SNPsImprove reuseMicrobiological testing/measurementFermentationSmall fragmentGenomic DNA

The invention relates to methods for isolating and amplifying small fragments of genomic DNA for genotyping polymorphisms in human populations.

Owner:COMPLETE GENOMICS INC

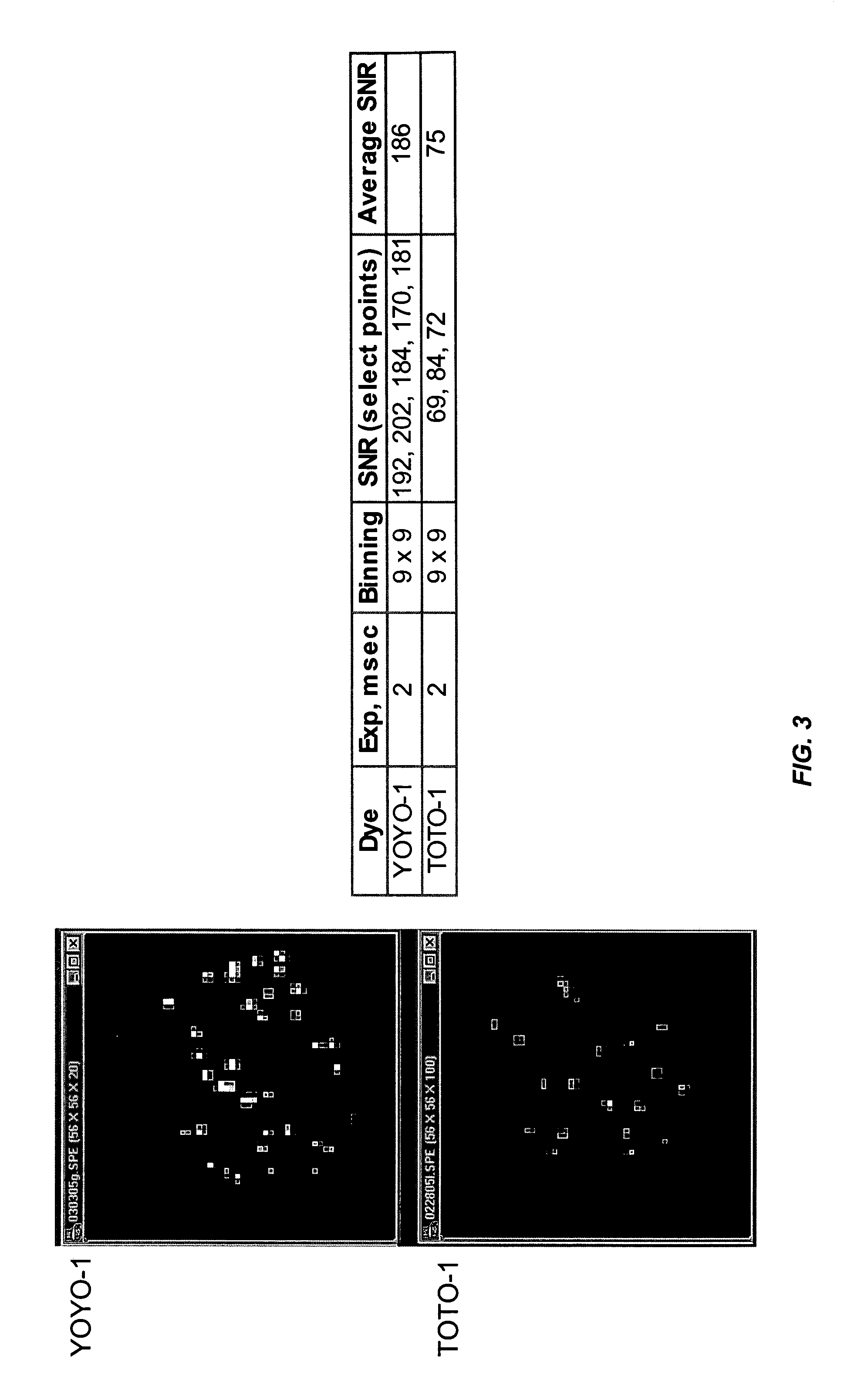

Field-switch sequencing

ActiveUS7462452B2Low costImprove reuseSugar derivativesMicrobiological testing/measurementPhosphatePolymerase L

Owner:PACIFIC BIOSCIENCES

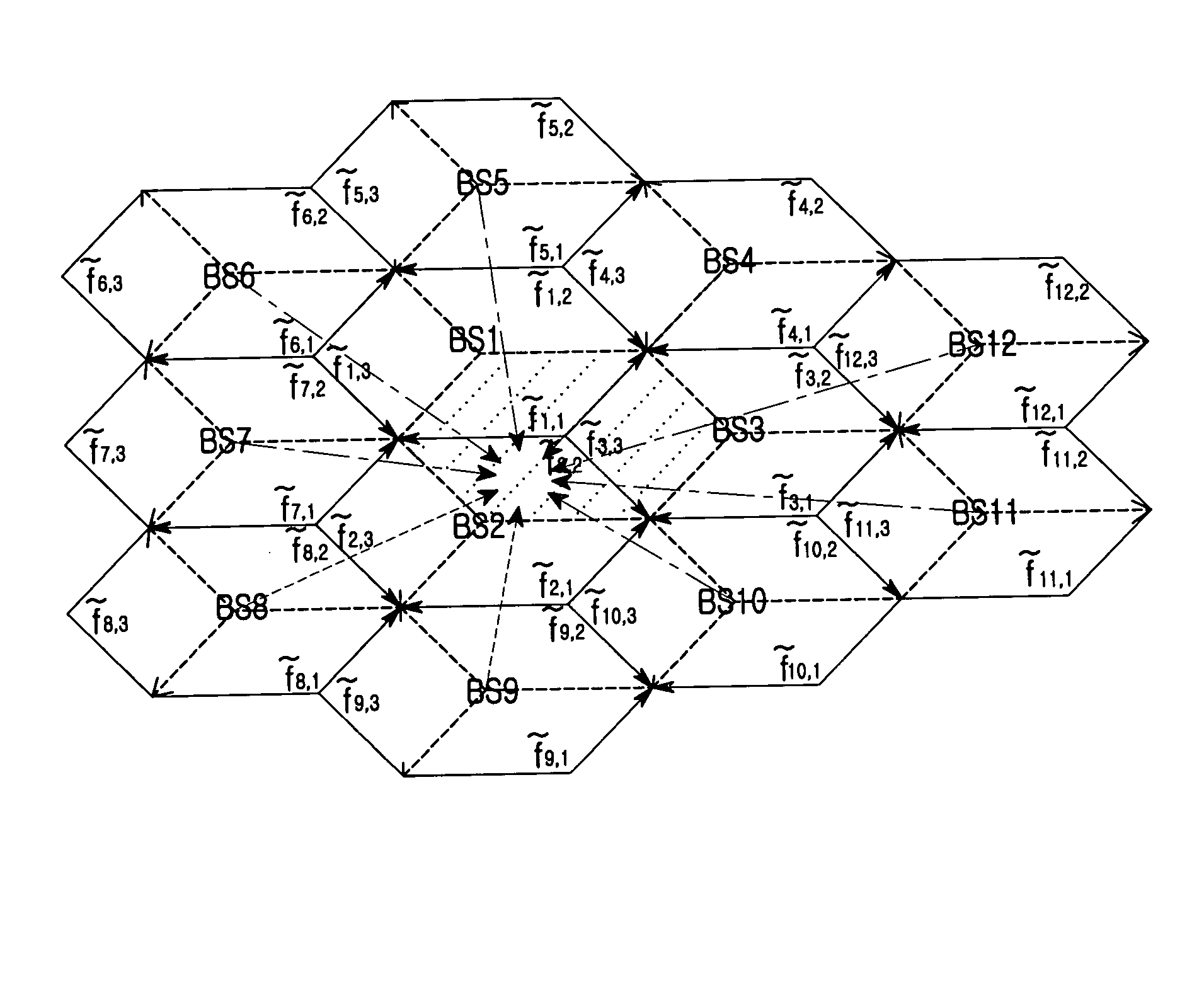

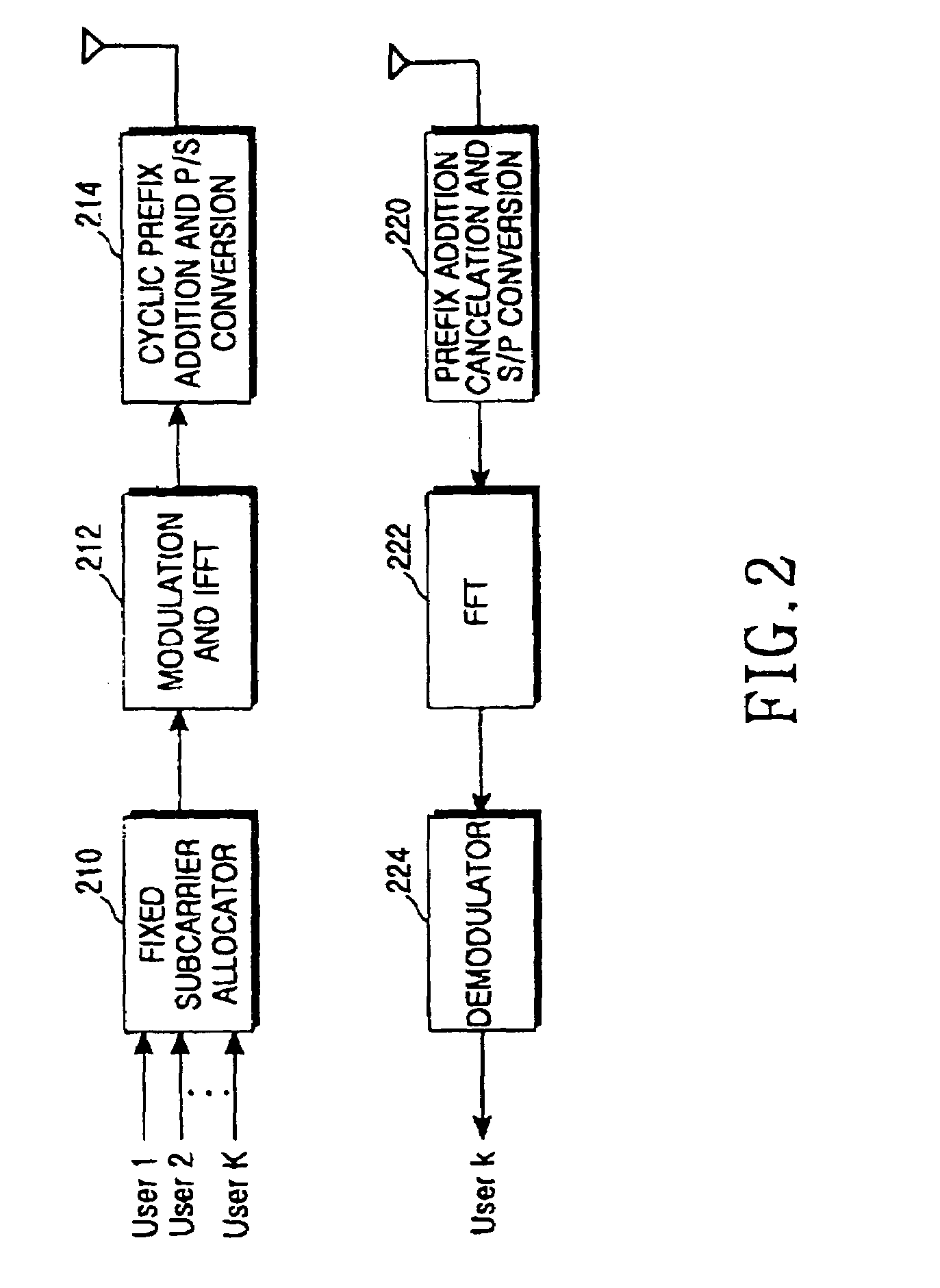

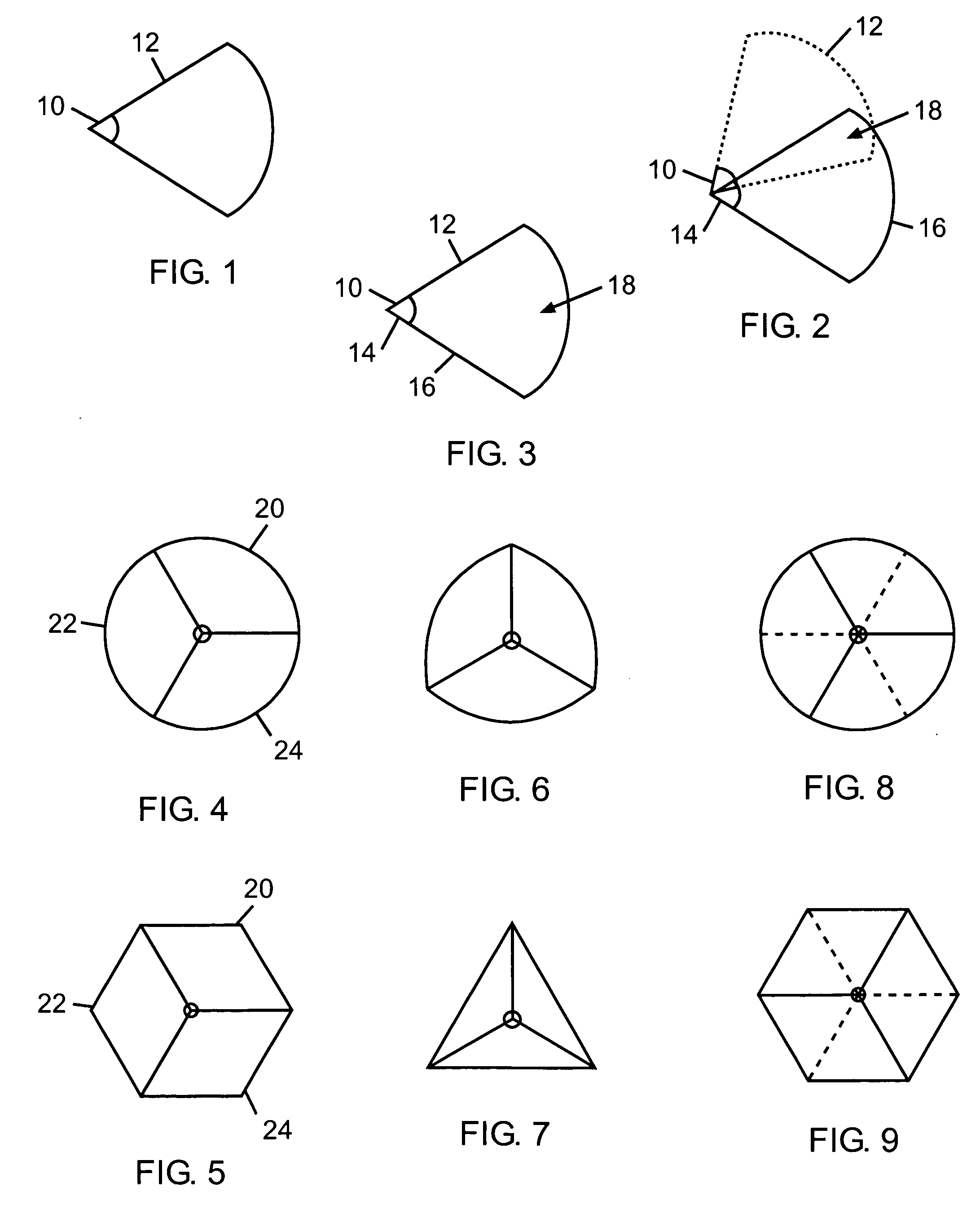

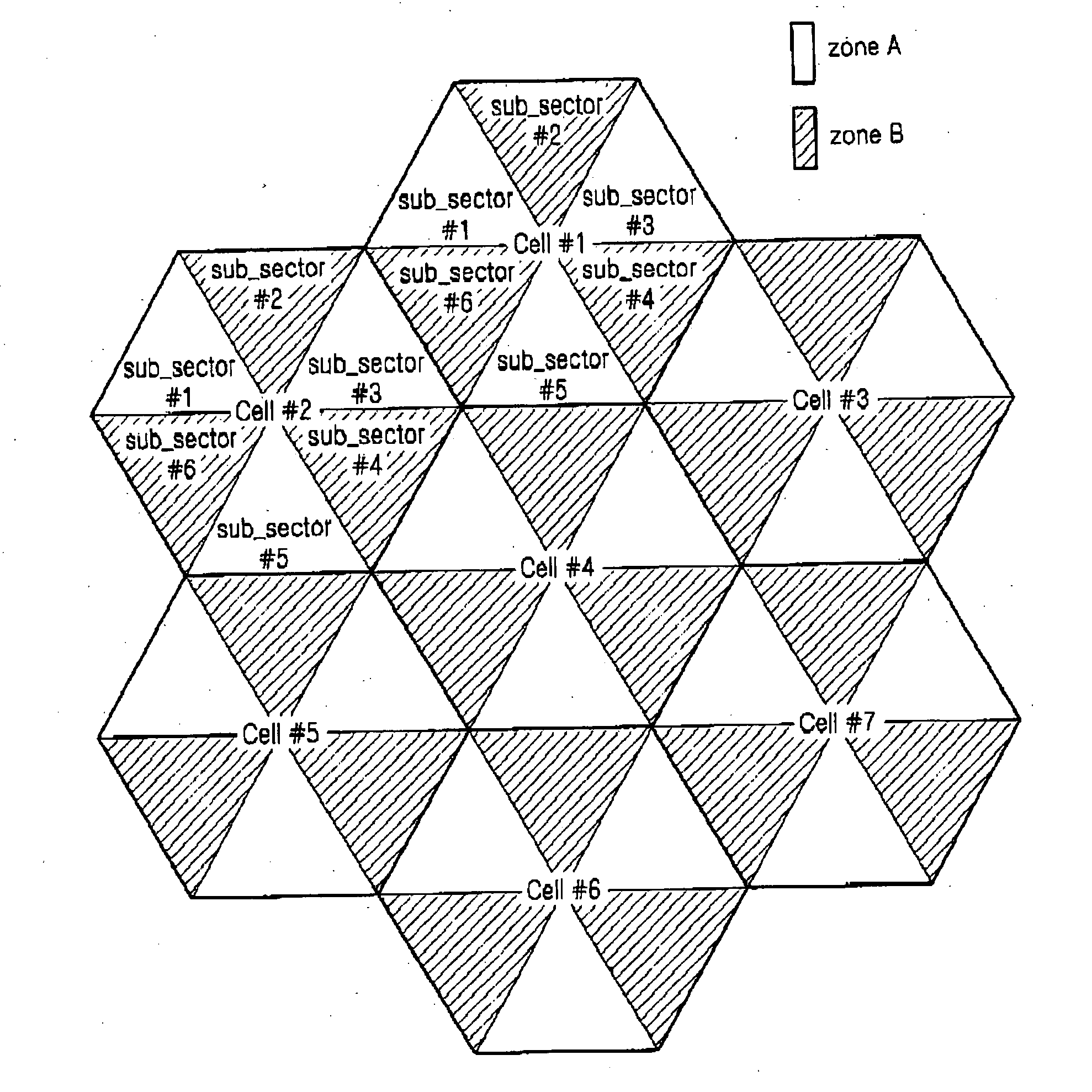

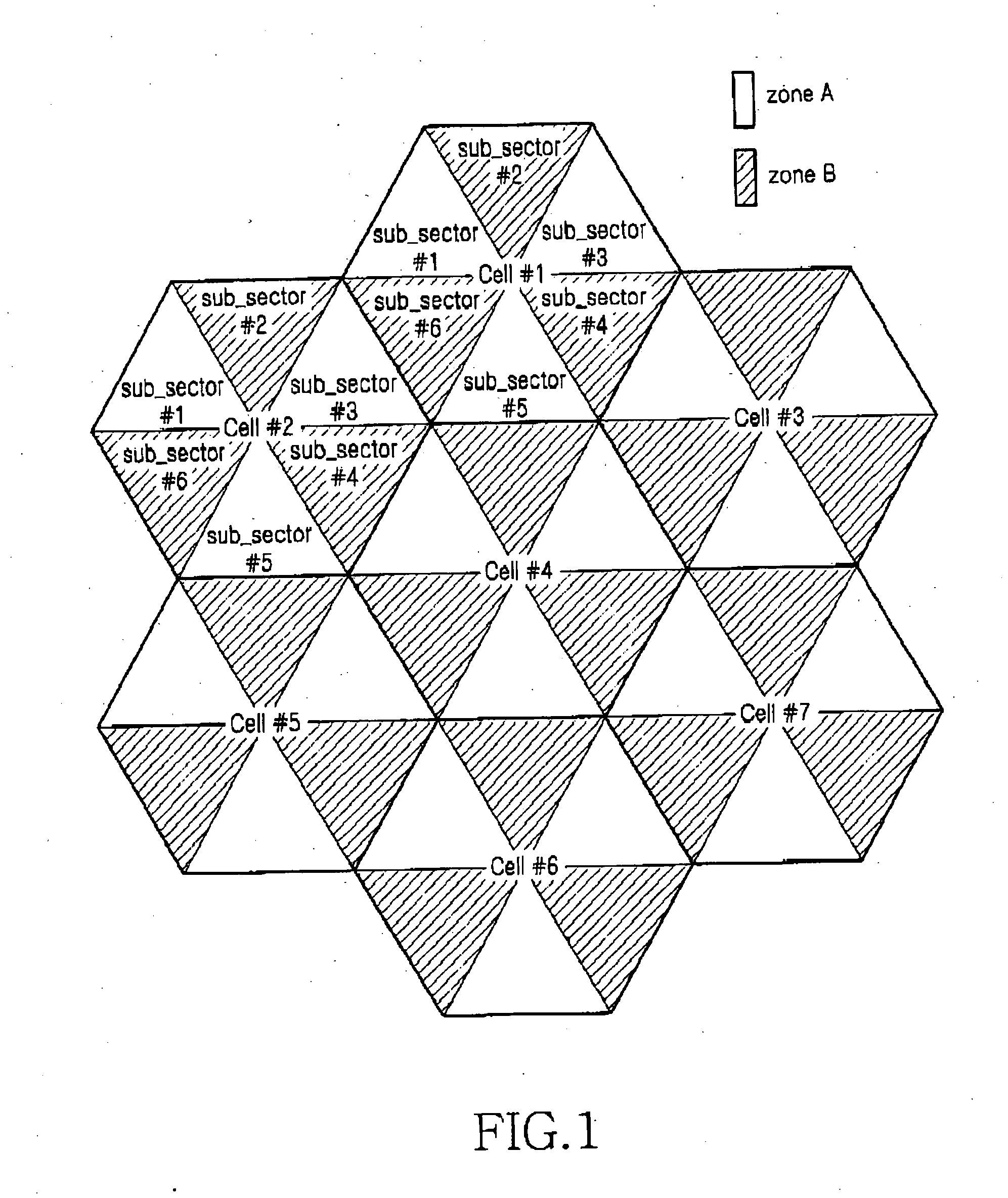

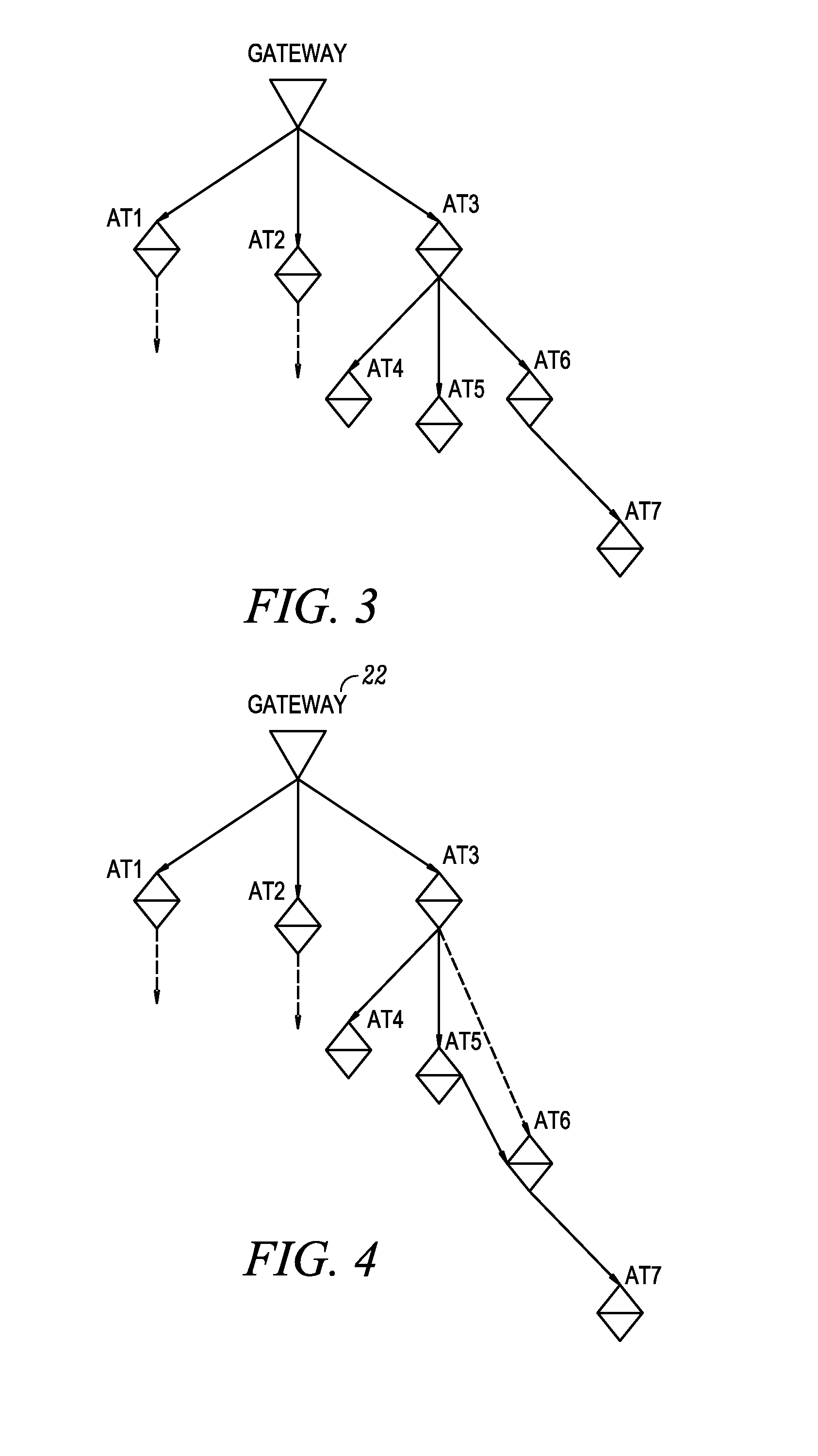

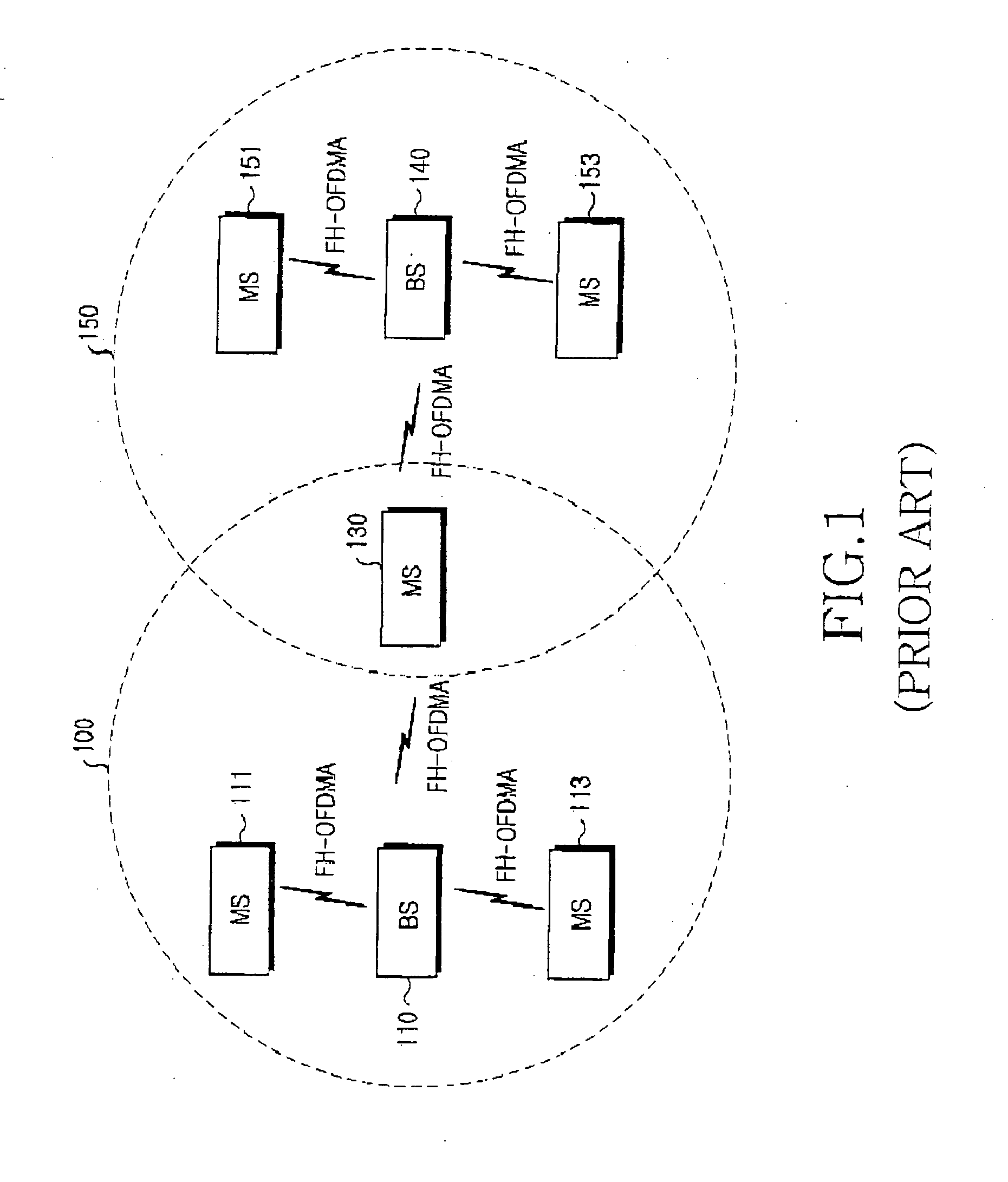

Apparatus and method for allocating resources of a virtual cell in an OFDM mobile communication system

ActiveUS7069009B2Improve efficiencyIncrease powerEnergy efficient ICTSite diversityCommunications systemVirtual cell

A virtual cell management apparatus and method using sectors in an orthogonal frequency division multiplexing mobile communication system including a cell structure having cells each comprised of a plurality of sectors, the cells performing data communication with mobile terminals within a corresponding cell through at least one subchannel having orthogonality. The method comprises forming a virtual cell with a particular one of sectors constituting a particular cell and sectors of two other cells neighboring the particular sector; transmitting, by three base stations forming the virtual cell, an interference measurement value and a channel parameter estimation value from a mobile terminal located in the virtual cell to a base station controller that controls the virtual cell, thereby allocating wireless resource including frequency bandwidth, initial bits, subcarriers and refined bits in the virtual cell; transmitting the allocated wireless resource to the three base stations so that the base stations allocate a same subchannel to each mobile terminal located in the virtual cell; and transmitting same data over the allocated subchannel.

Owner:SAMSUNG ELECTRONICS CO LTD

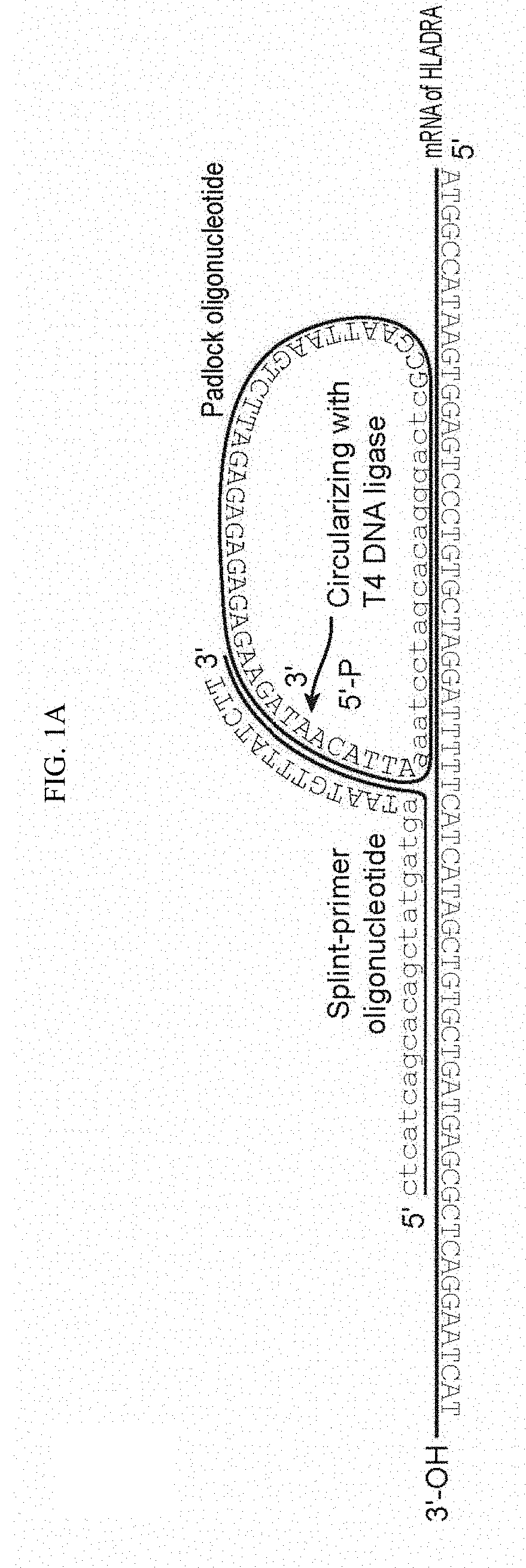

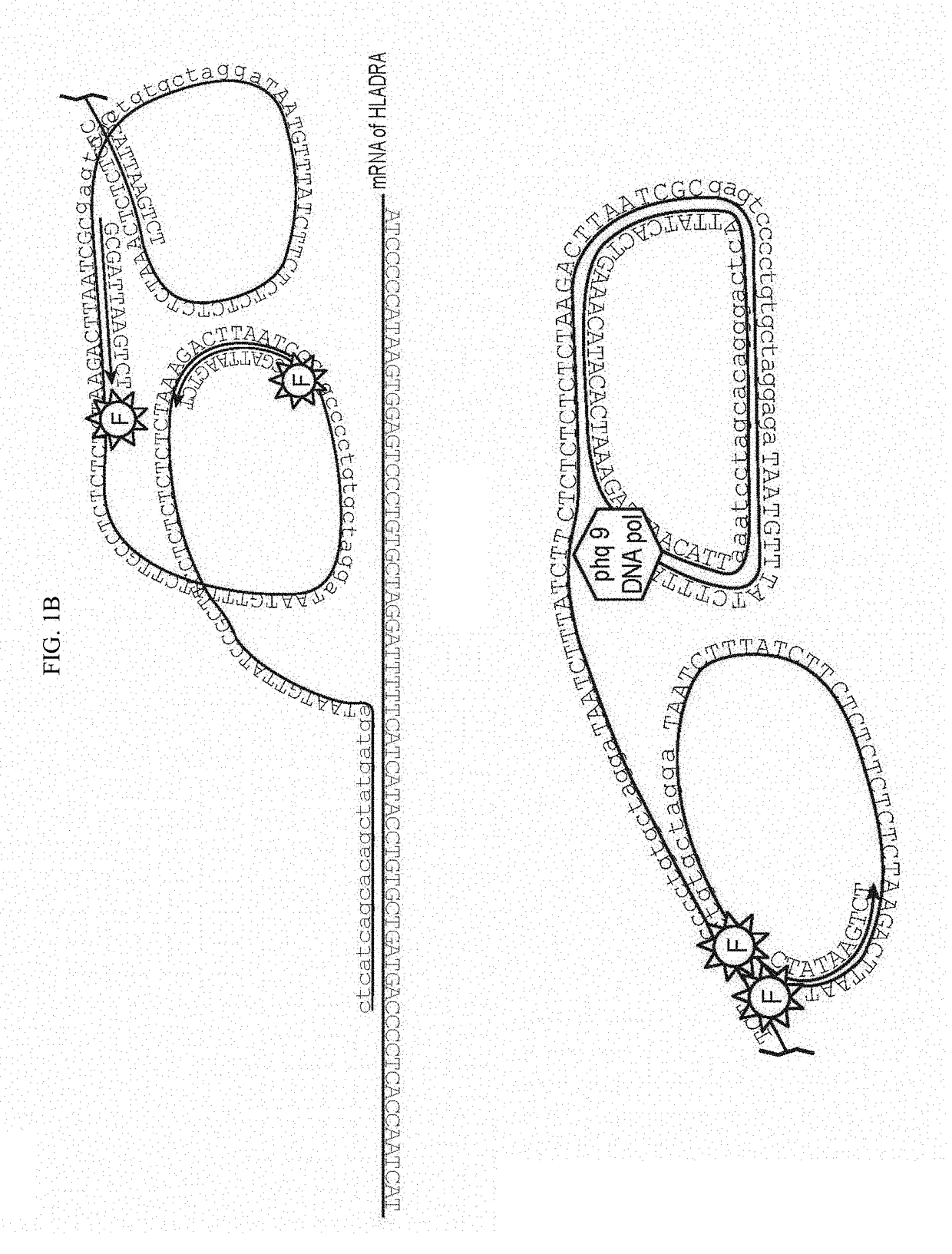

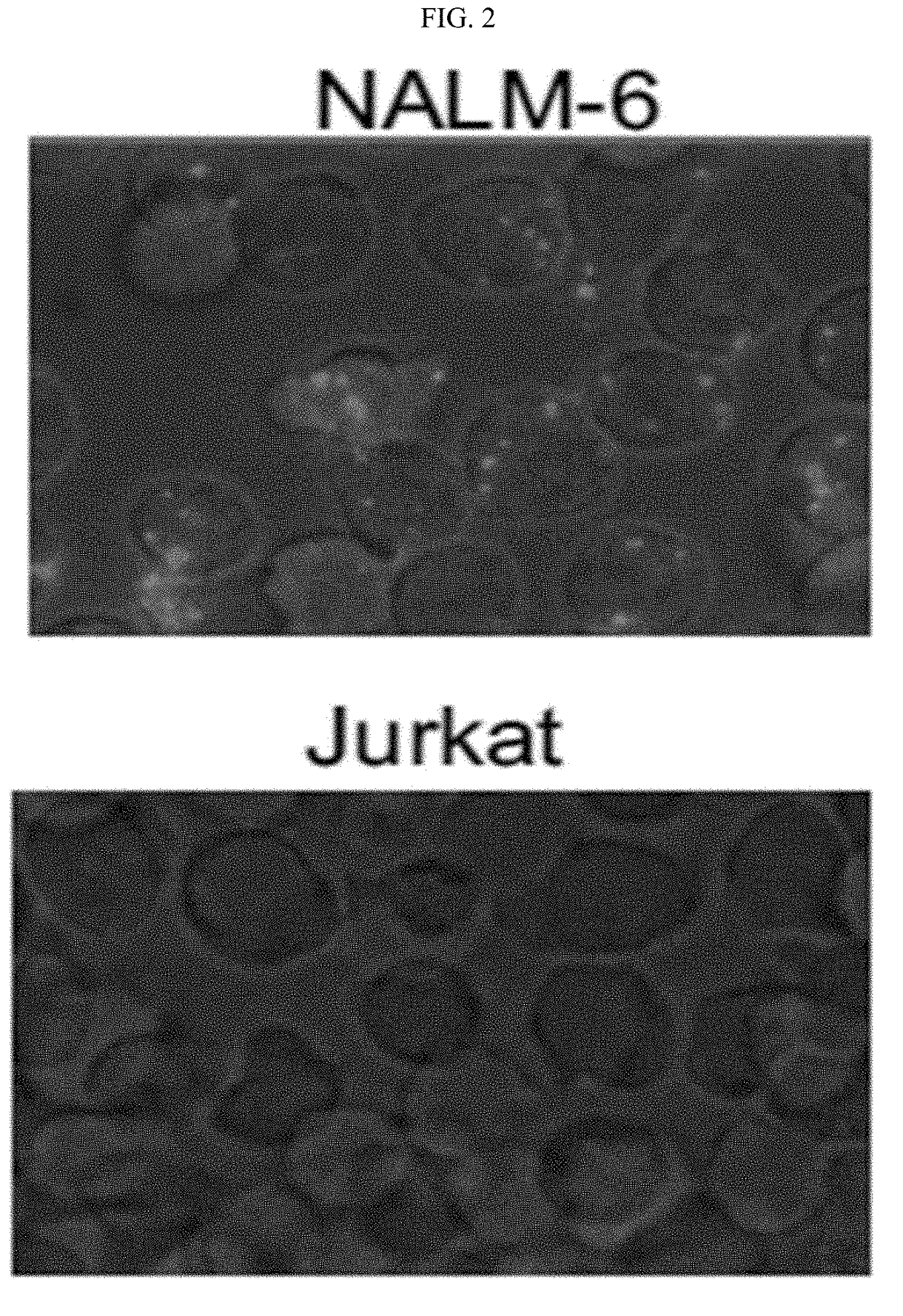

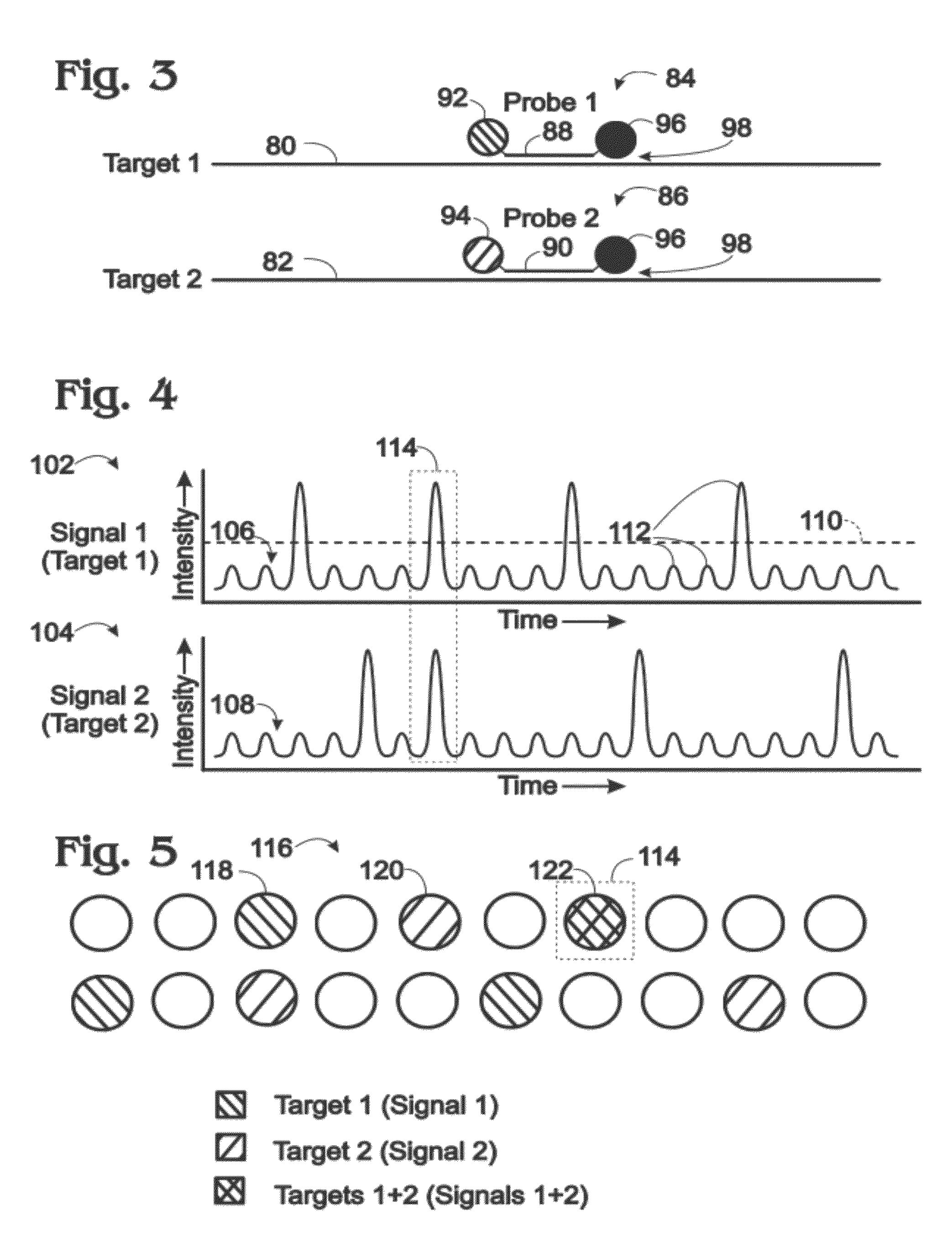

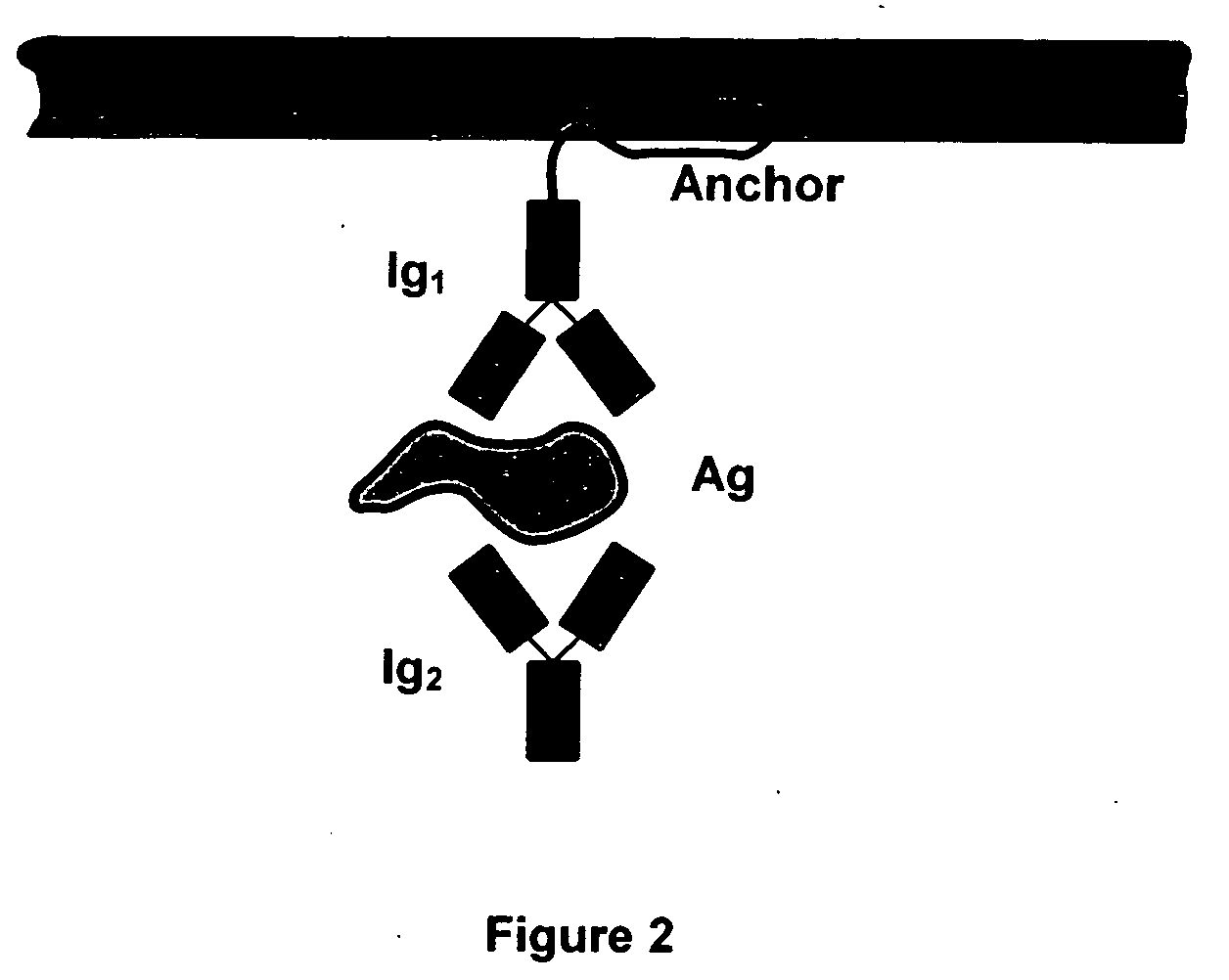

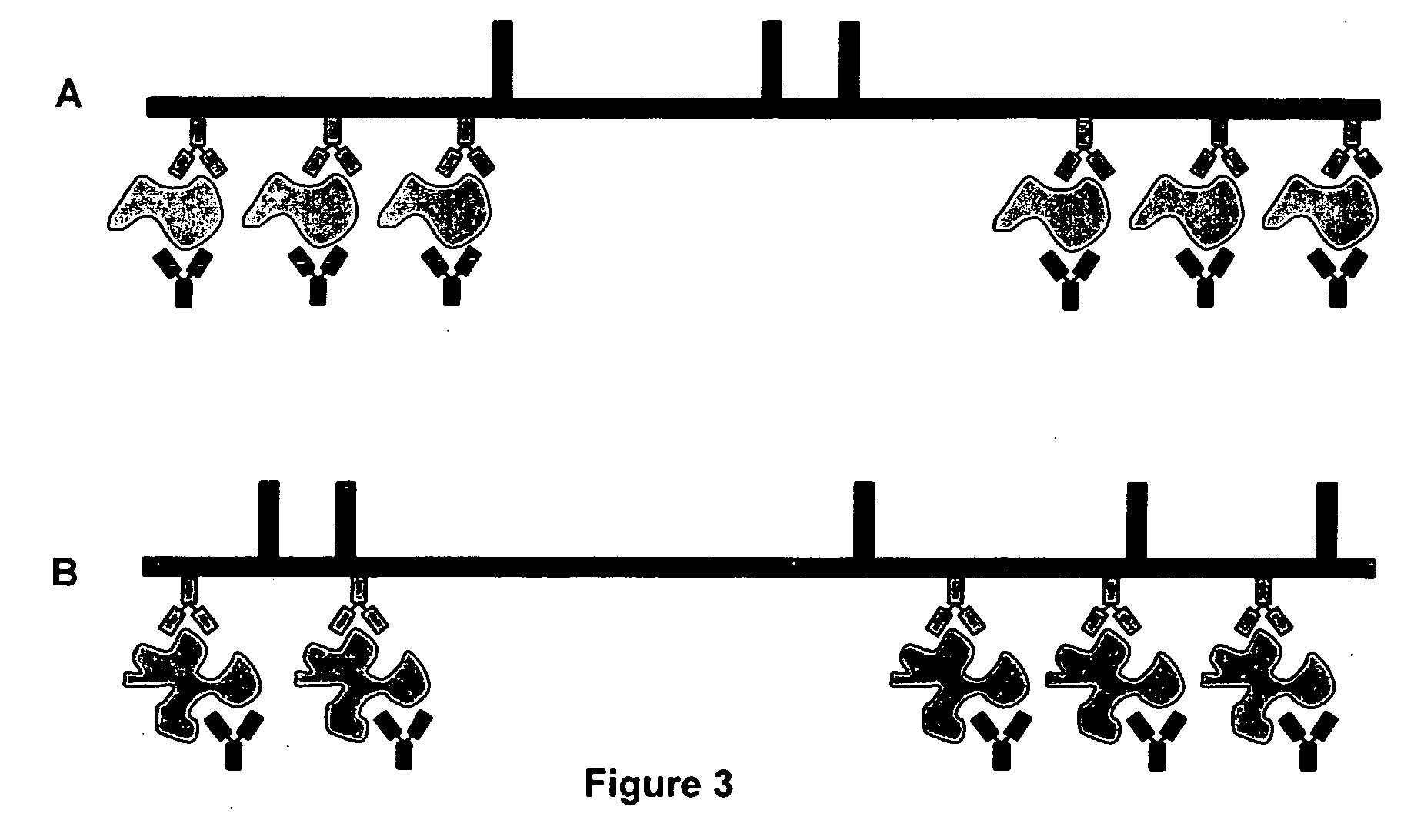

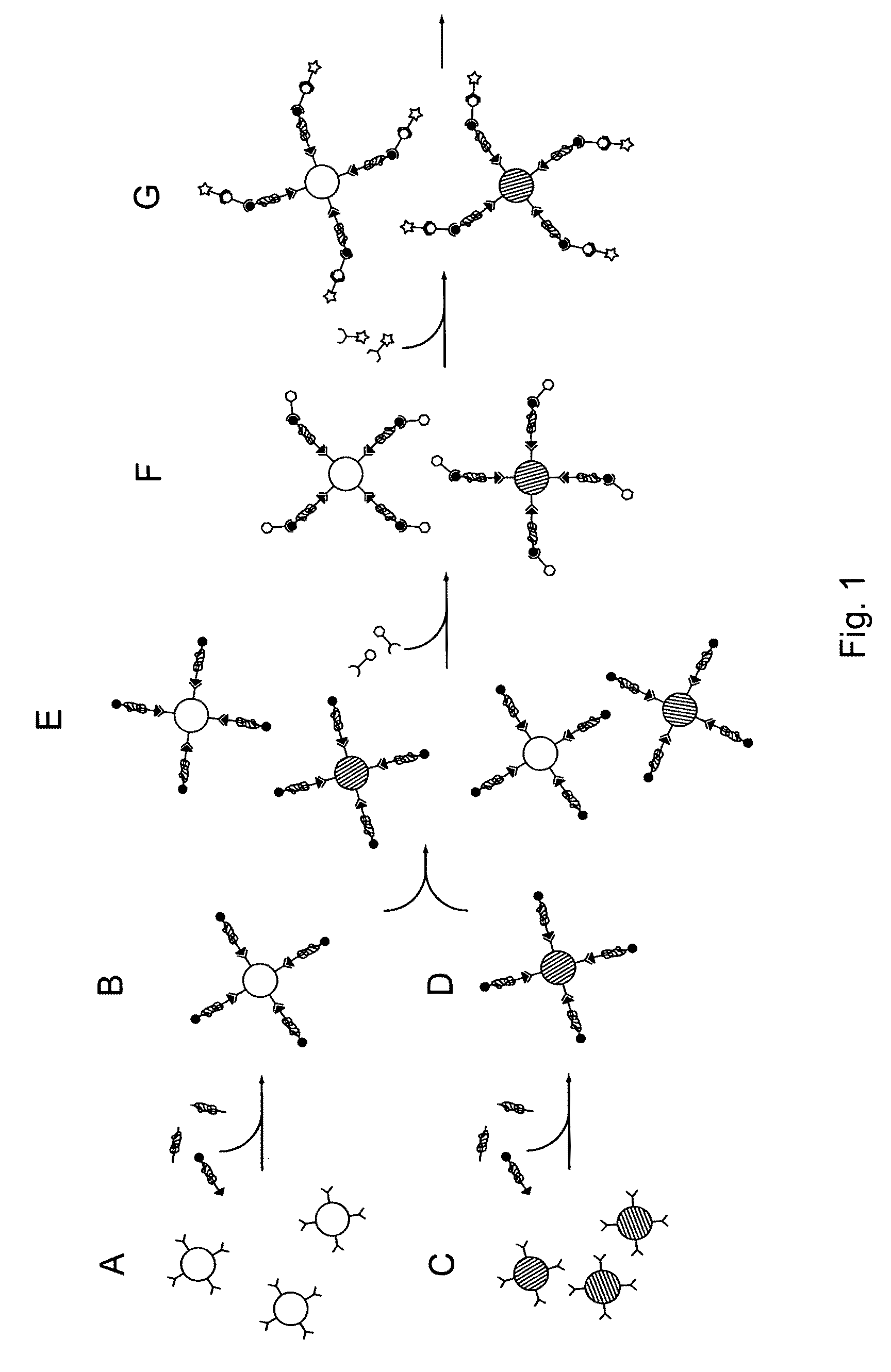

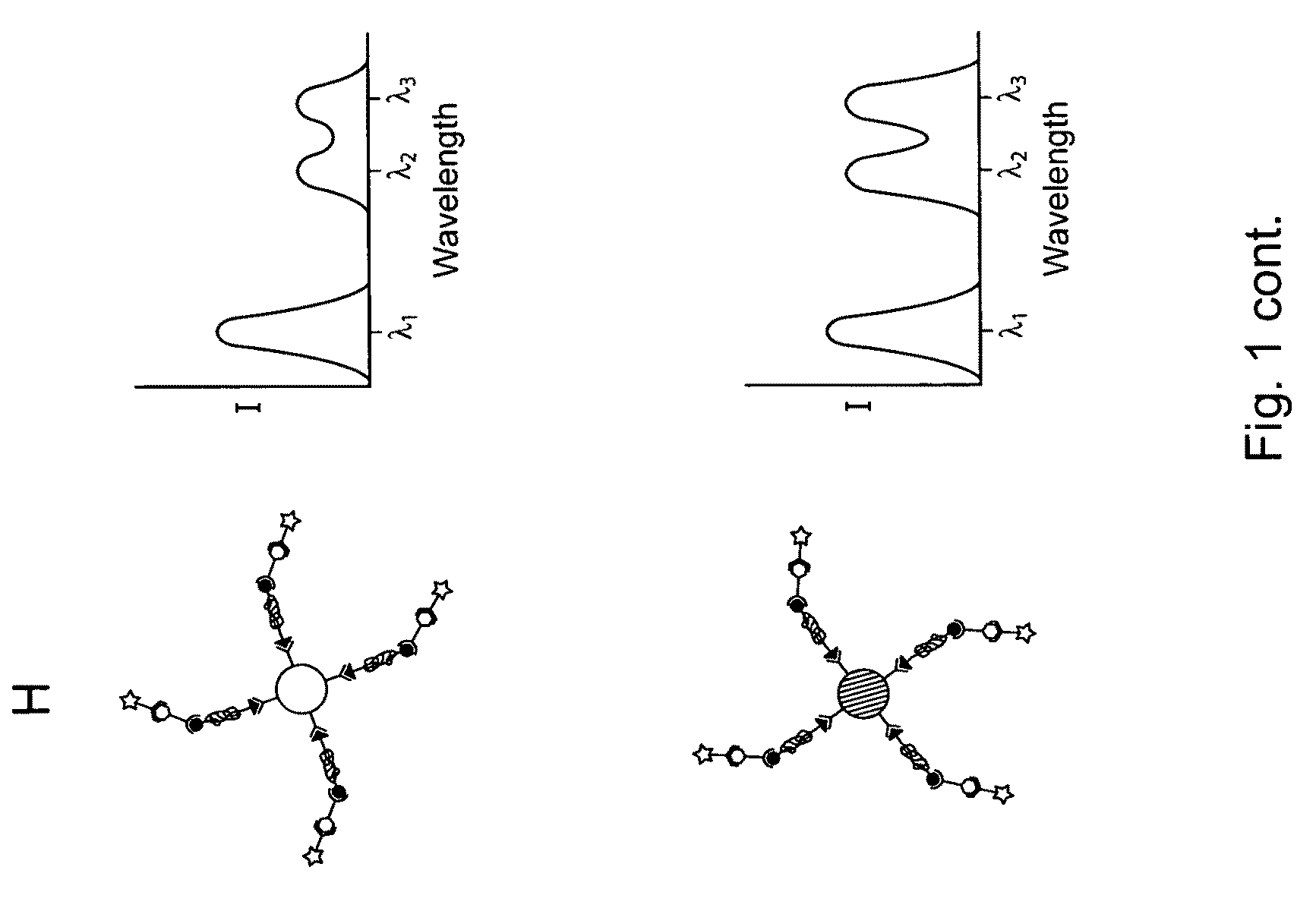

Multiplexed single molecule RNA visualization with a two-probe proximity ligation system

ActiveUS20190055594A1Minimizing chanceReduce the numberMicrobiological testing/measurementMaterial analysisFlow cytometryBioinformatics

SNAIL provides cost-efficient detection of specific nucleic acids in single cells, and may be combined with flow cytometry to simultaneously analyze large numbers of cells for a plurality of nucleic acids, e.g. at least one, to up to 5, up to 10, up to 15, up to 20 or more transcripts can be simultaneously analyzed, at a rate of up to about 50, 100, 250, 500 or more cells / second. The methods require only two primers for amplification, and may further include a detection primer.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

High throughput sequence-based detection of snps using ligation assays

ActiveUS20090215633A1Compromise reliabilityEasy to detectSugar derivativesMicrobiological testing/measurementHigh throughput sequenceOligonucleotide

Method for the detection the presence or absence of one or more target sequences in one or more samples based on oligonucleotide ligation assays with a variety of ligatable probes containing identifiers and the subsequent identification of the identifiers in the amplicons or ligated probes using high throughput sequencing technologies.

Owner:KEYGENE NV

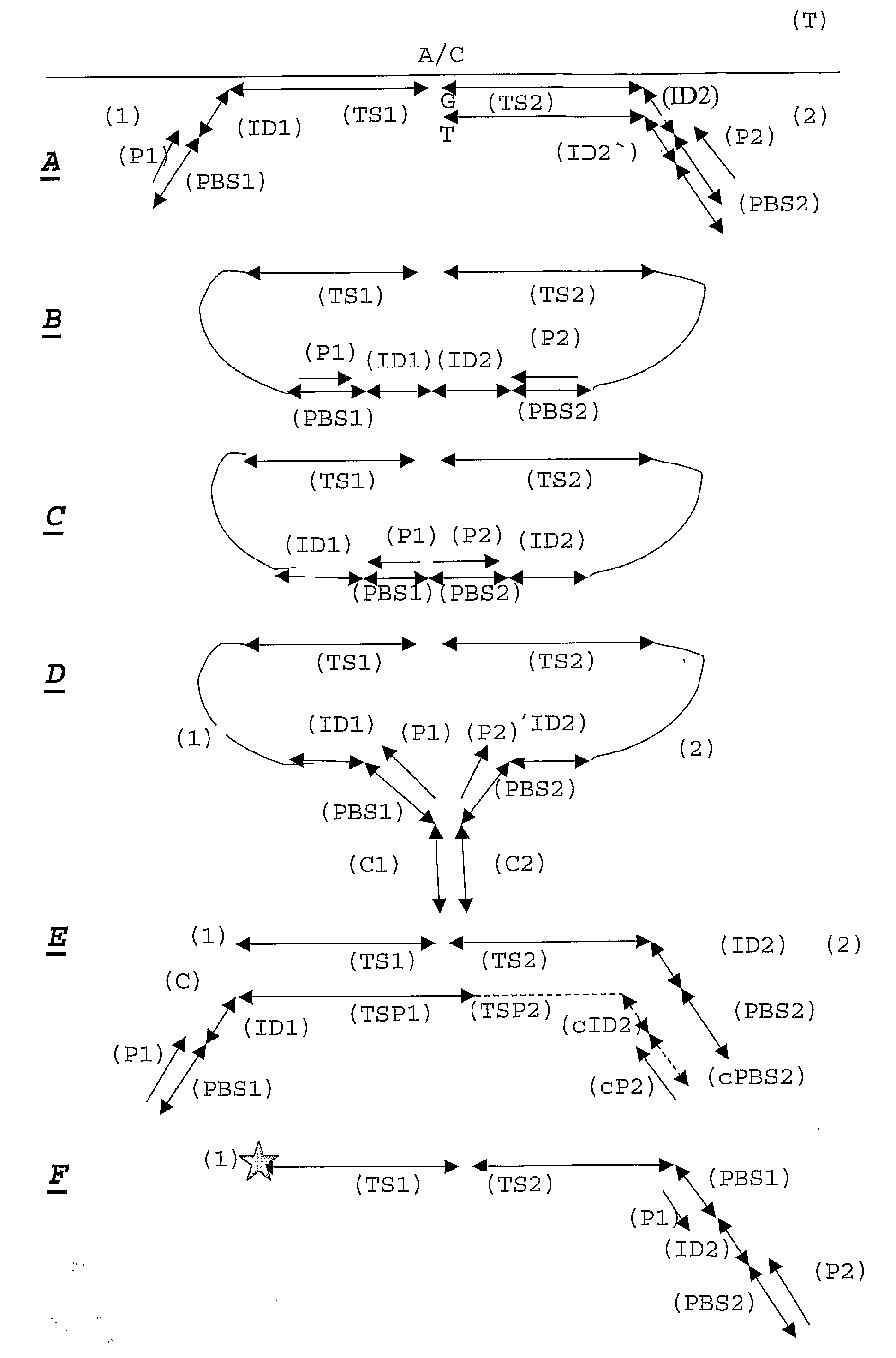

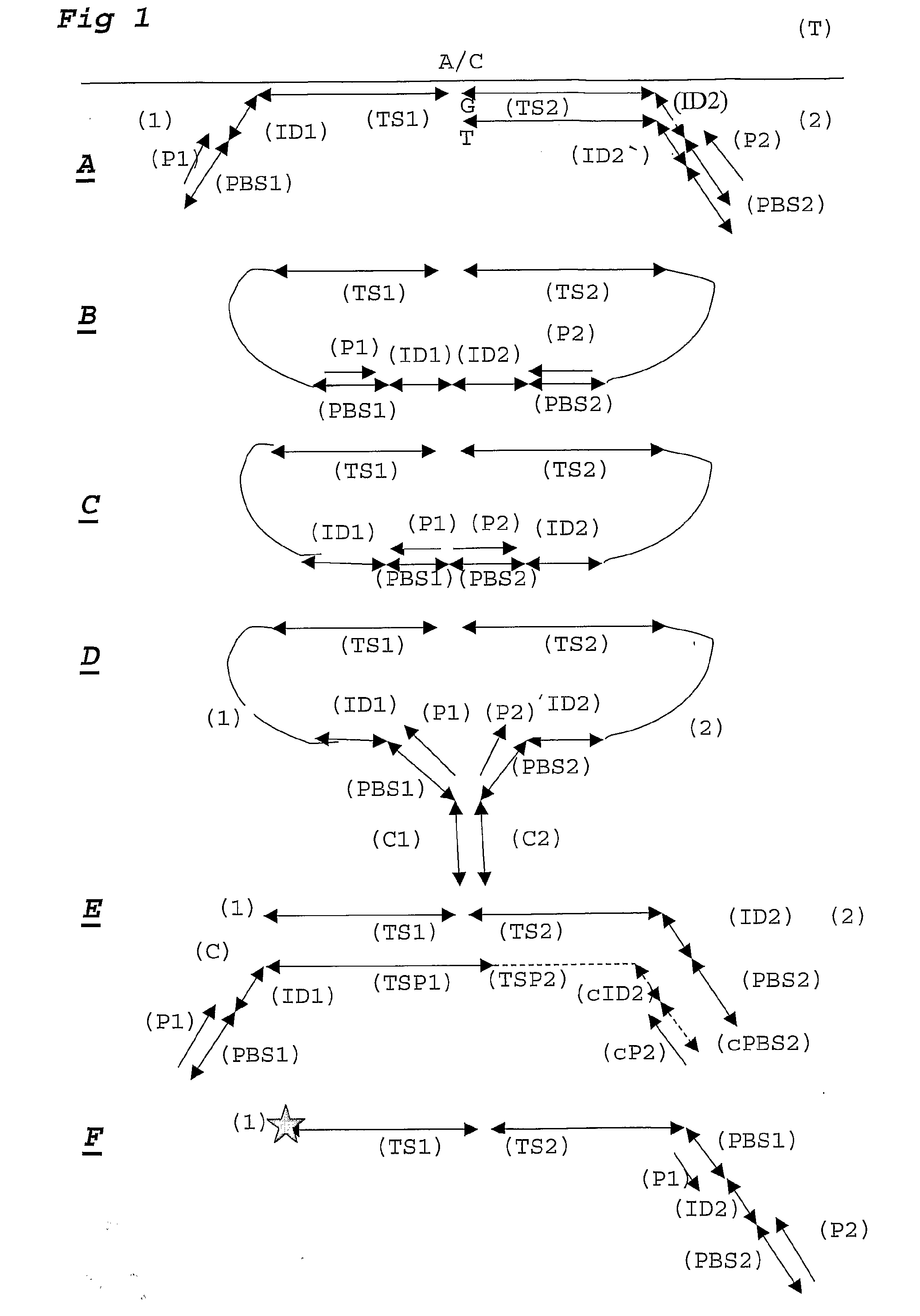

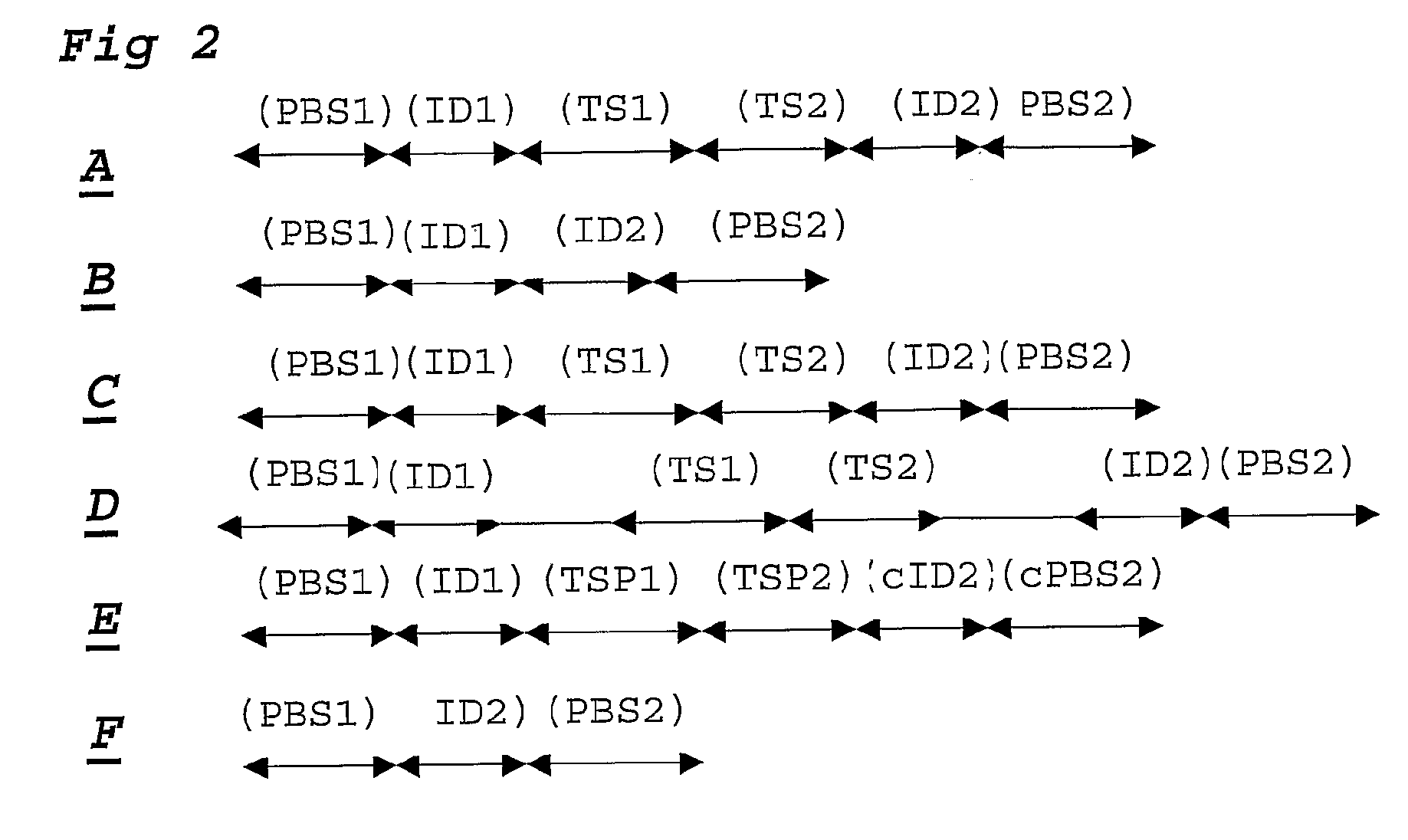

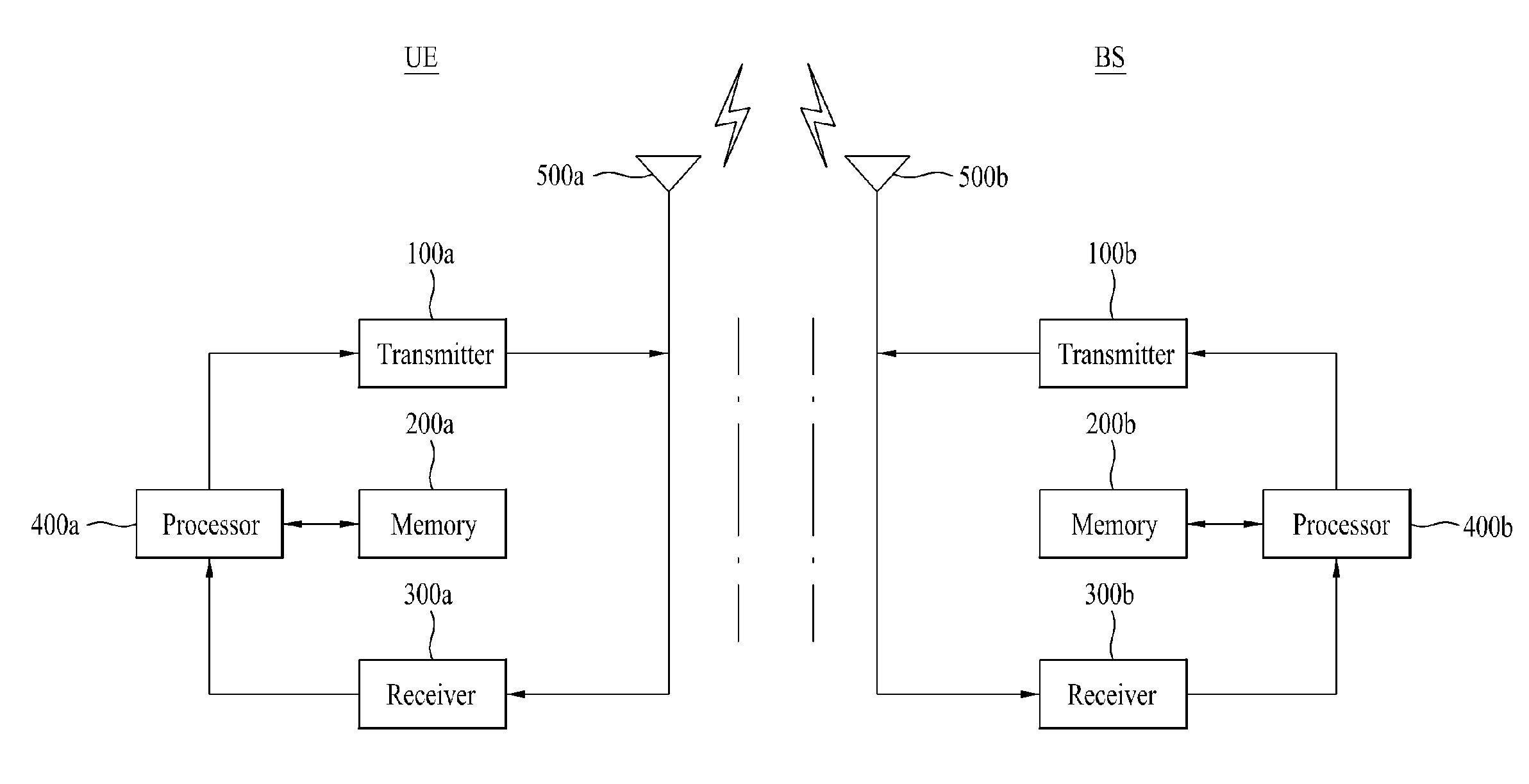

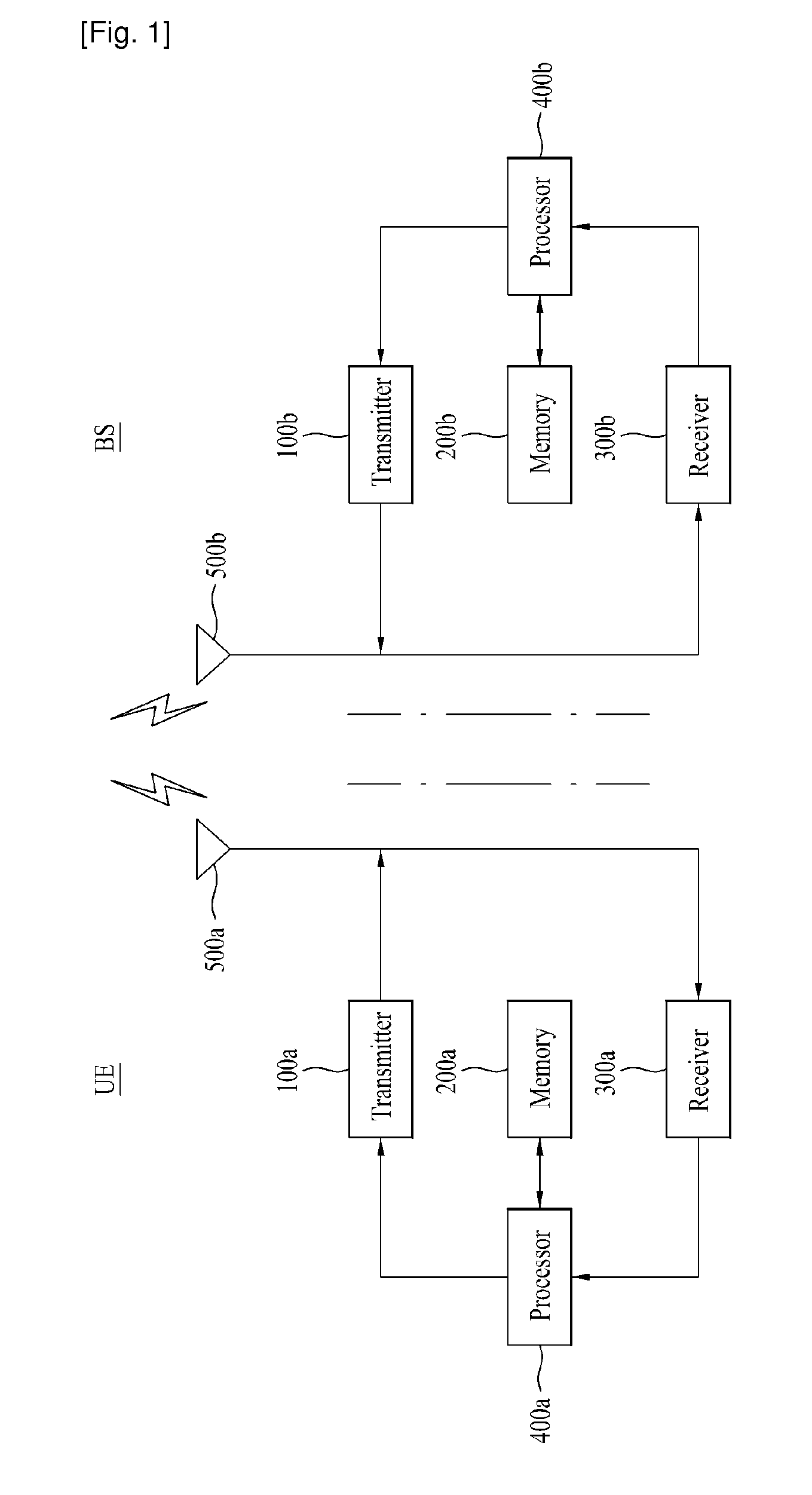

Method and user equipment for measuring interference, and method and base station for receiving interference information

ActiveUS20120315859A1Improve reuseImprove accuracyTransmission path divisionTransmission monitoringUser equipmentRadio resource

A method and apparatus for providing information indicating radio resources for multi-cell interference measurement at a BS so that a UE can more accurately measure interference are disclosed.

Owner:LG ELECTRONICS INC

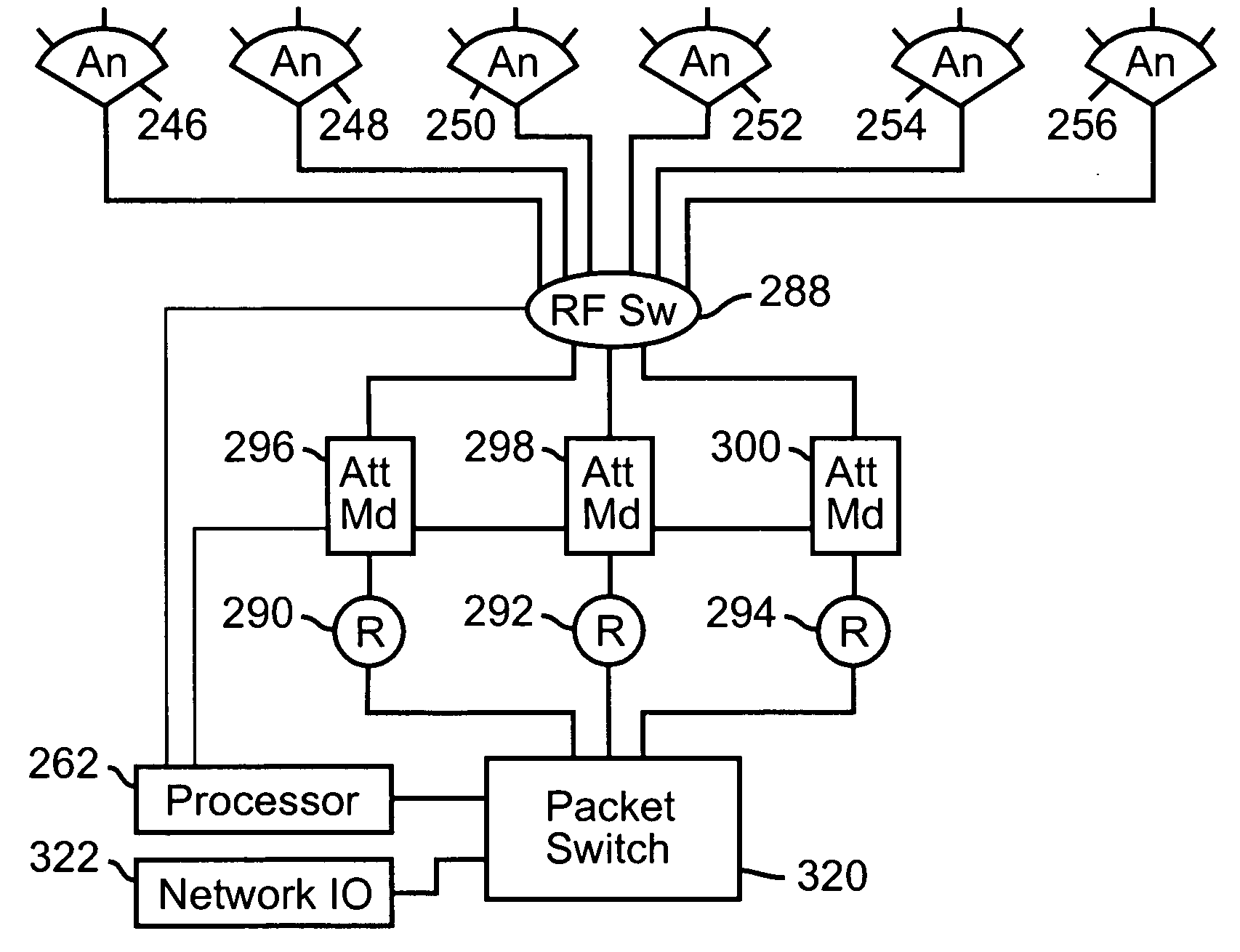

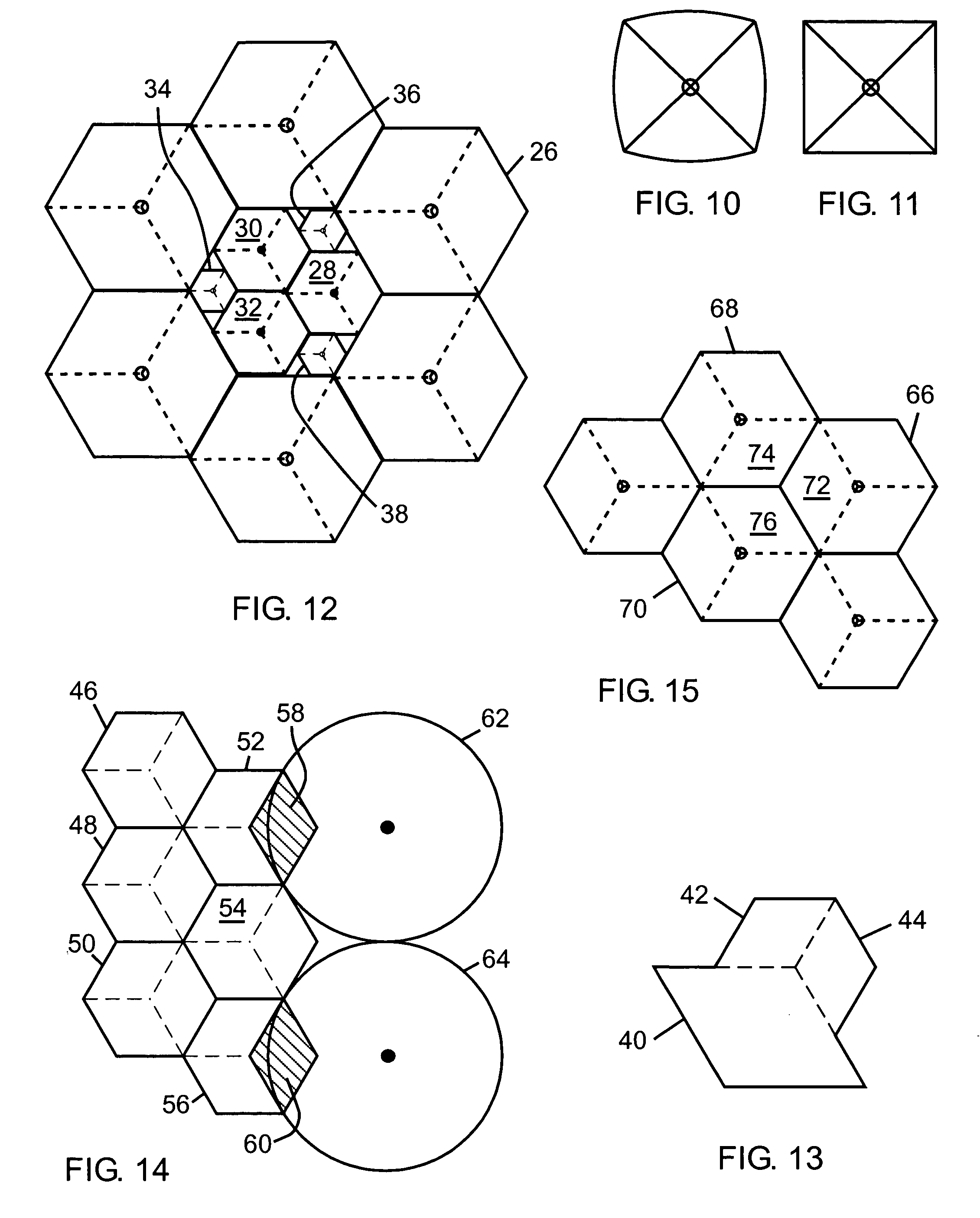

Methods and apparatus for high throughput multiple radio wireless cells and networks

InactiveUS20050003763A1Minimize interferenceImprove data throughputSite diversitySpatial transmit diversityUltrasound attenuationWireless

Methods and apparatus for high throughput wireless cells and networks are described. The wireless cells may be equipped with multiple radios. Antennas may be arranged into overlapping and non-overlapping patterns. Channels may be assigned to foster servicing clients, and inter-cell communication. Attenuation may be used to decrease interference. Networks may be formed using a variety of methods and apparatus.

Owner:ROTANI

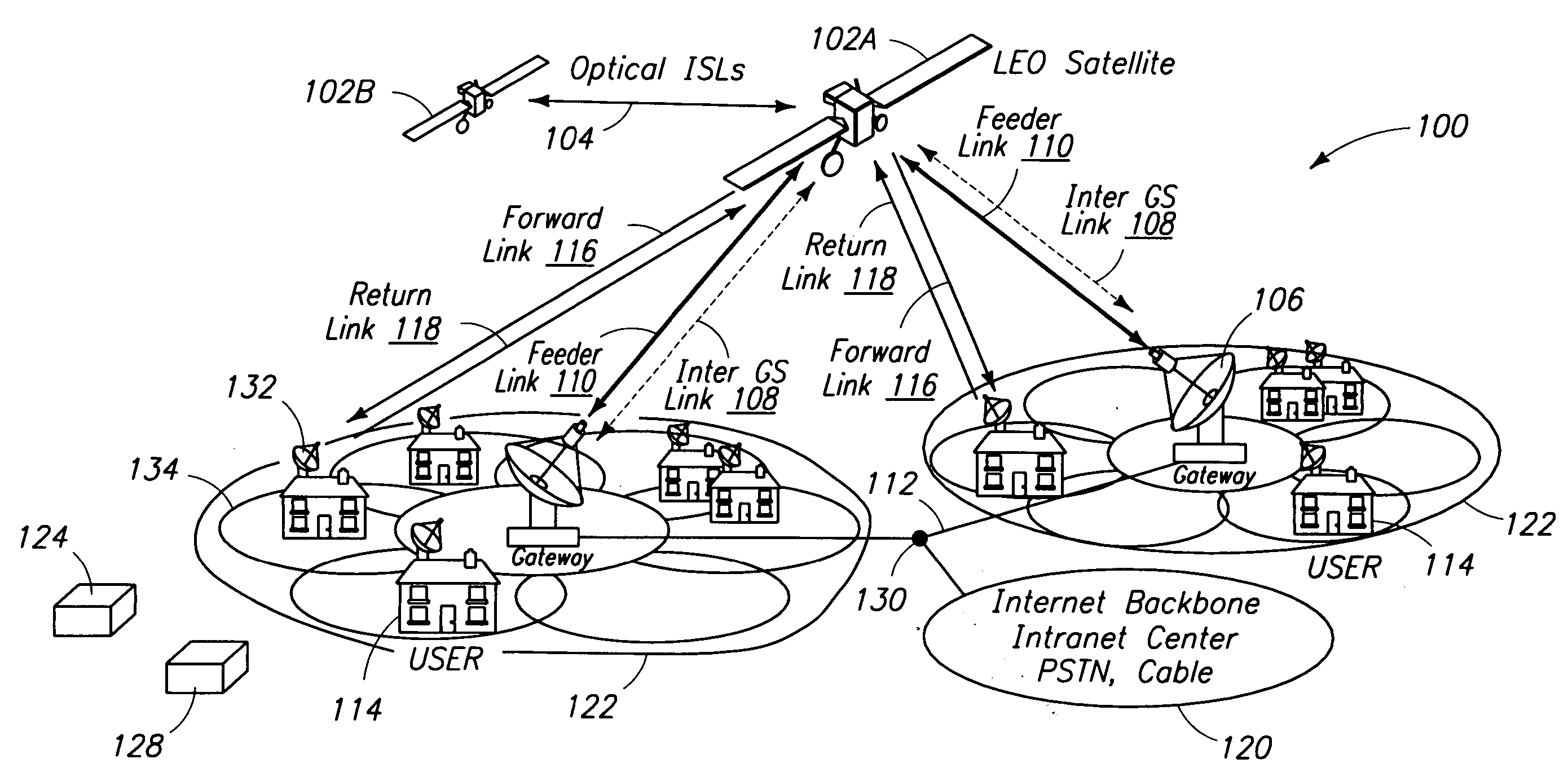

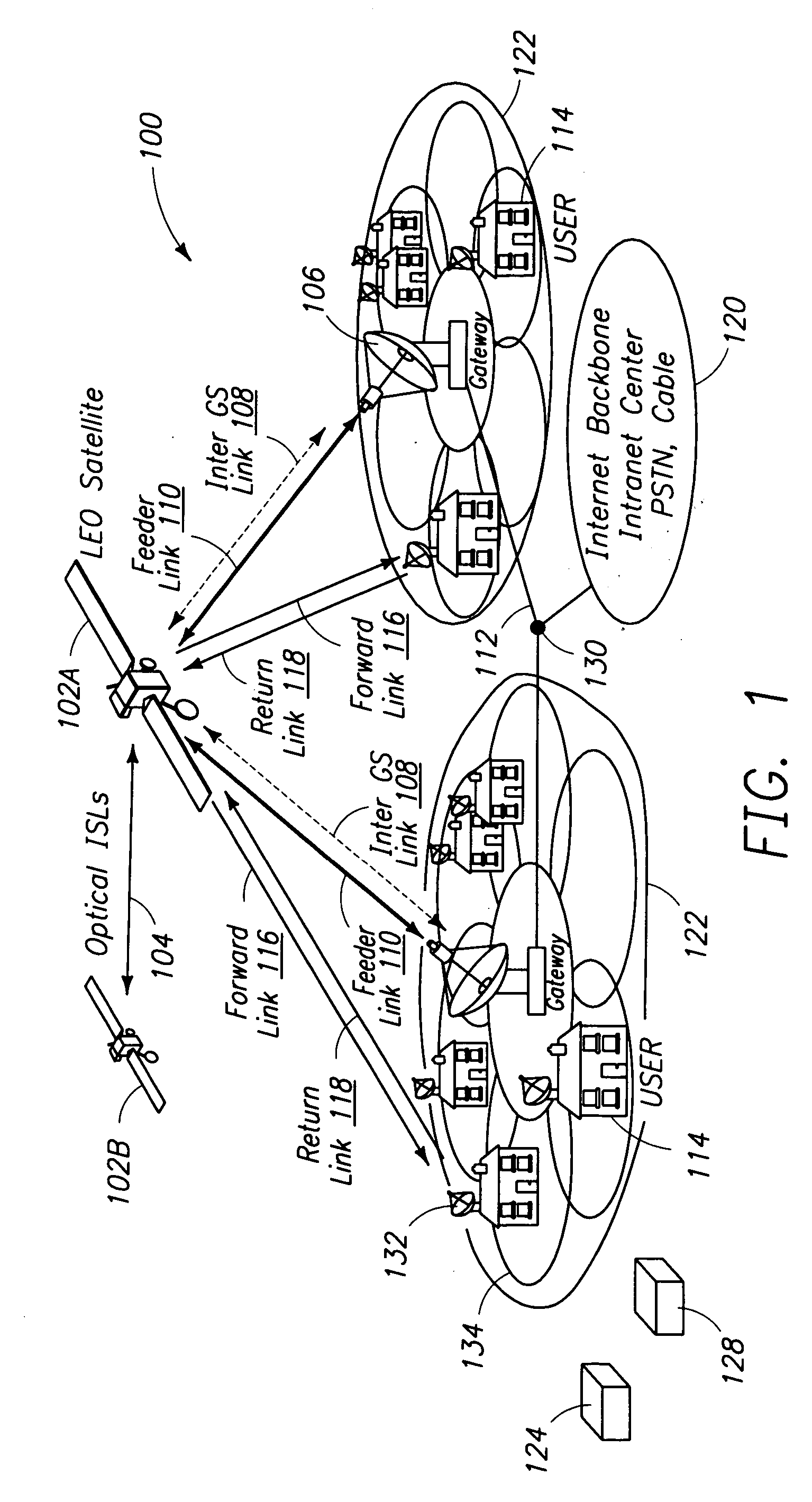

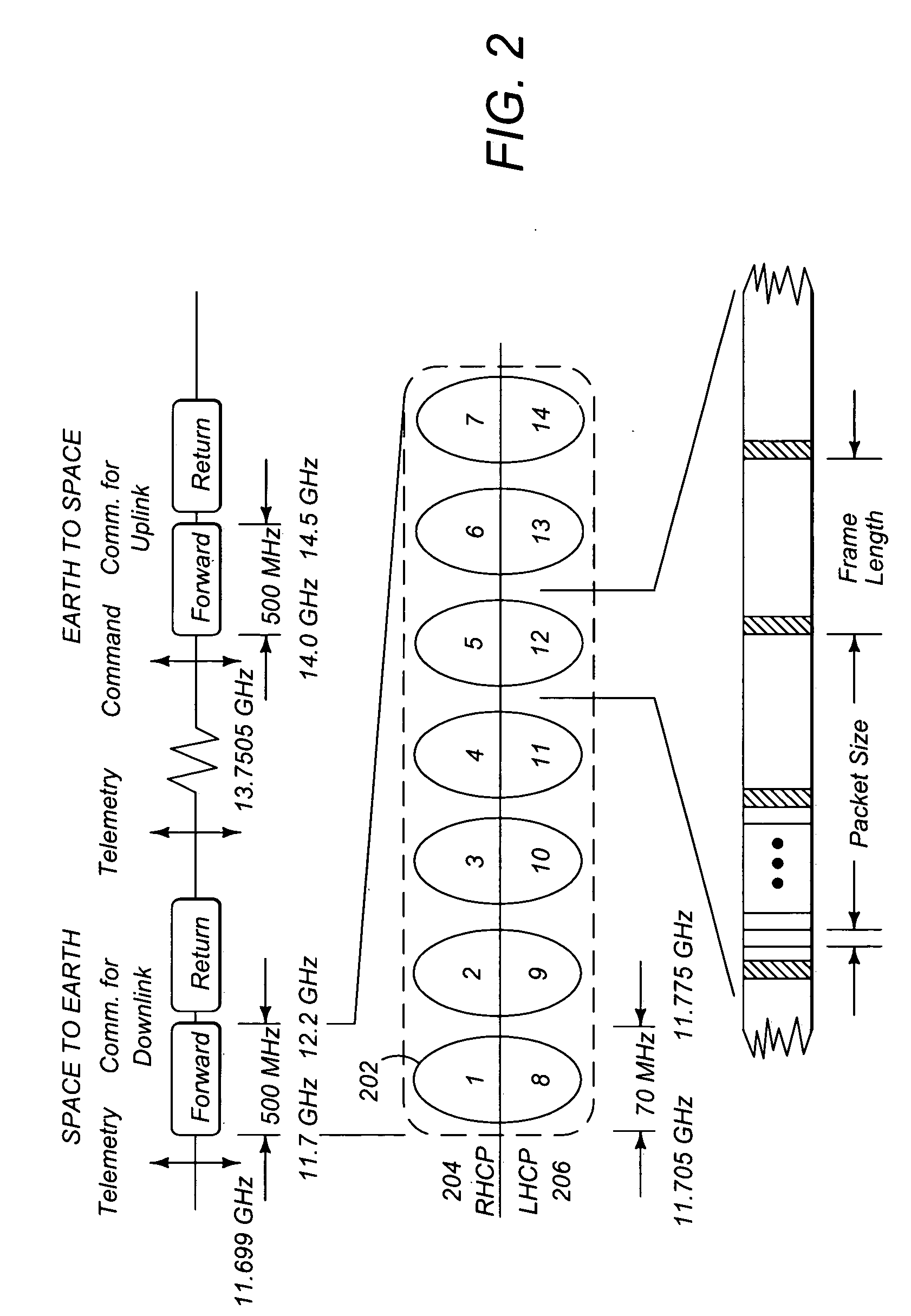

Method and apparatus for providing wideband services using medium and low earth orbit satellites

InactiveUS20040110467A1High data rate serviceReduce distractionsActive radio relay systemsSubstation equipmentHigh elevationLow earth orbit

A method and apparatus for mitigating communications interference between satellite communications systems in different orbits is disclosed. The method comprises the steps of evaluating a geometrical relationship between a second ground station and the satellites in the second satellite constellation, and directing communications between the second ground station and the second satellite according to the evaluated geometrical relationship. In one embodiment communications are handed over from a first satellite to another satellite when the first satellite is no longer at the highest elevation angle of visible satellites. In another embodiment, handover occurs when the first satellite drops below a minimum elevation angle.

Owner:THE DIRECTV GRP INC

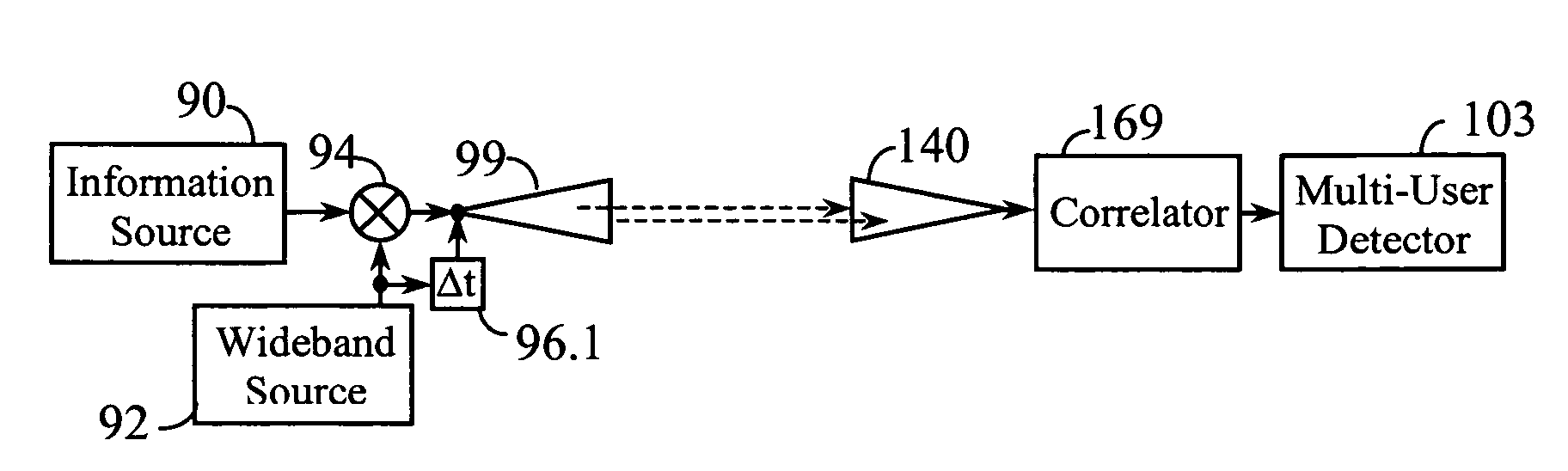

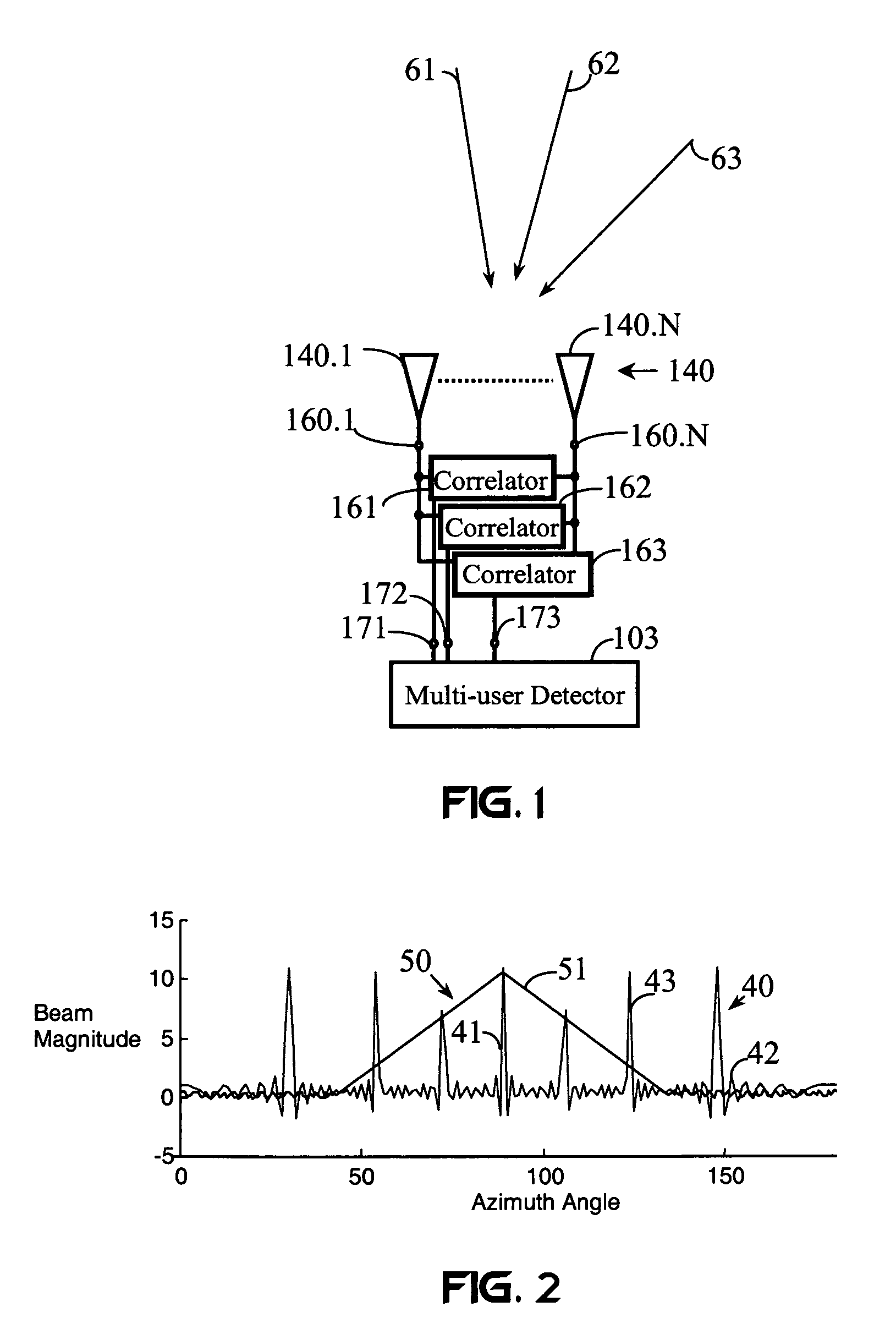

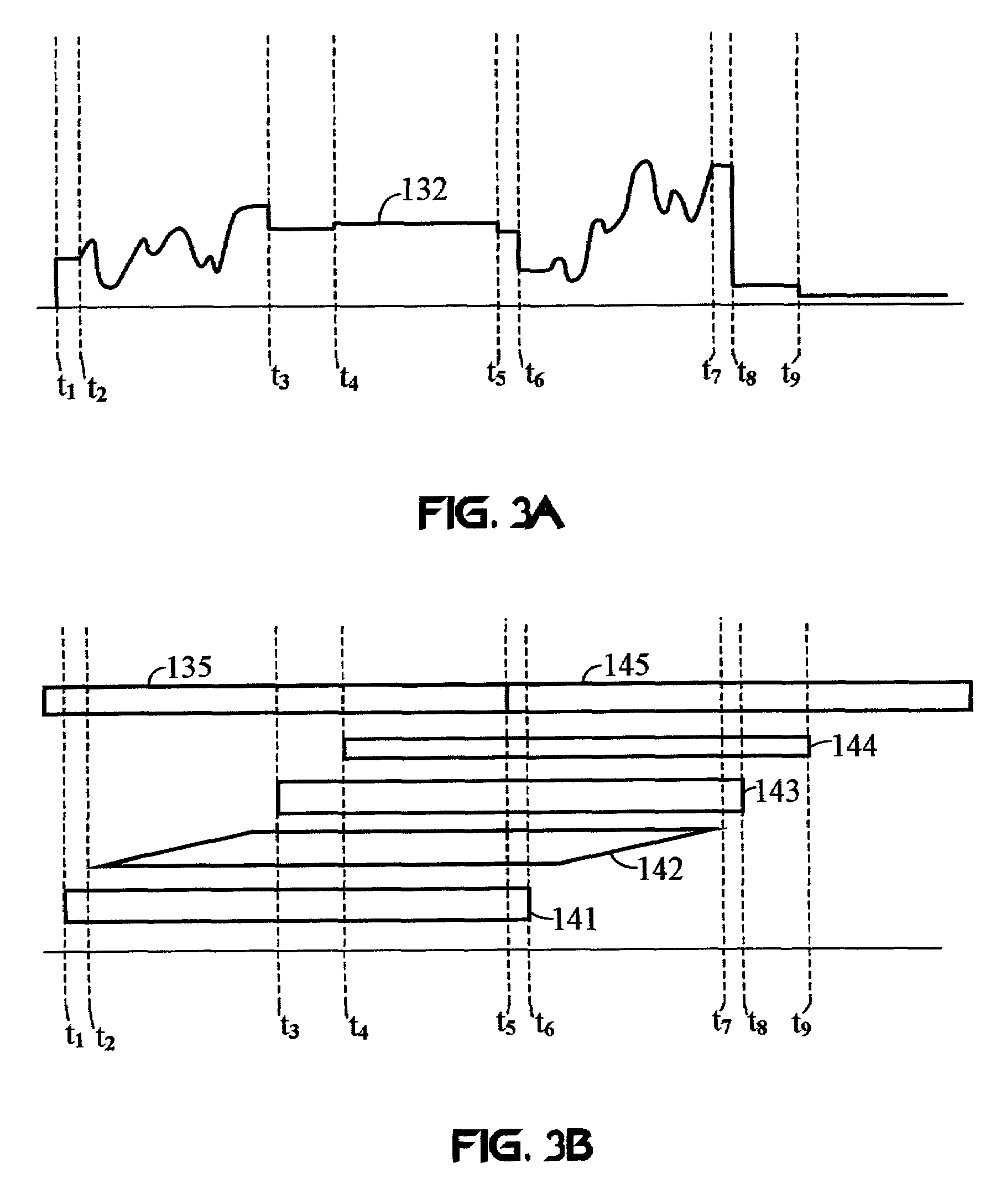

Spread spectrum communication method and system using diversity correlation and multi-user detection

ActiveUS7391804B2Ensures separabilityOptimize processSpatial transmit diversityModulated-carrier systemsReceiver diversityEngineering

A communication system transmits and receives a plurality of spread-spectrum signals having differences in at least one diversity parameter. The signals are highly correlated when their diversity parameters are similar, and the signals are uncorrelated when at least one diversity parameter is different. Any combination of a transmitter, a receiver, and a communication channel may diversity-encode the signals to effect differences in their diversity parameters. A receiver diversity-decoder compensates for differences in a diversity-parameter of at least one received signal to make the signal highly correlated with at least one other received signal. A correlator combines at least two of the received signals to recover an embedded information signal. The communication system enables the use of true-noise signals for spreading information signals, provides simplified receiver designs, and enables antenna arrays to spatially process spread-spectrum signals.

Owner:S AQUA SEMICONDUCTOR LLC

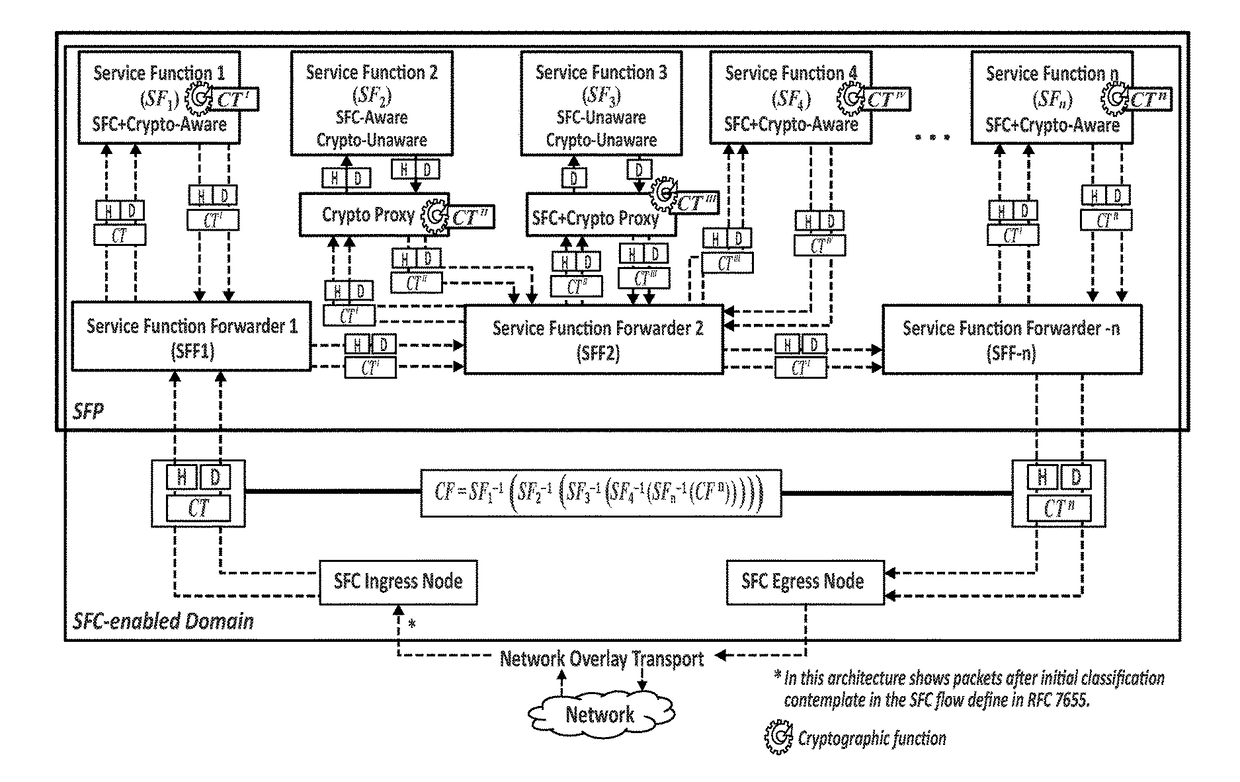

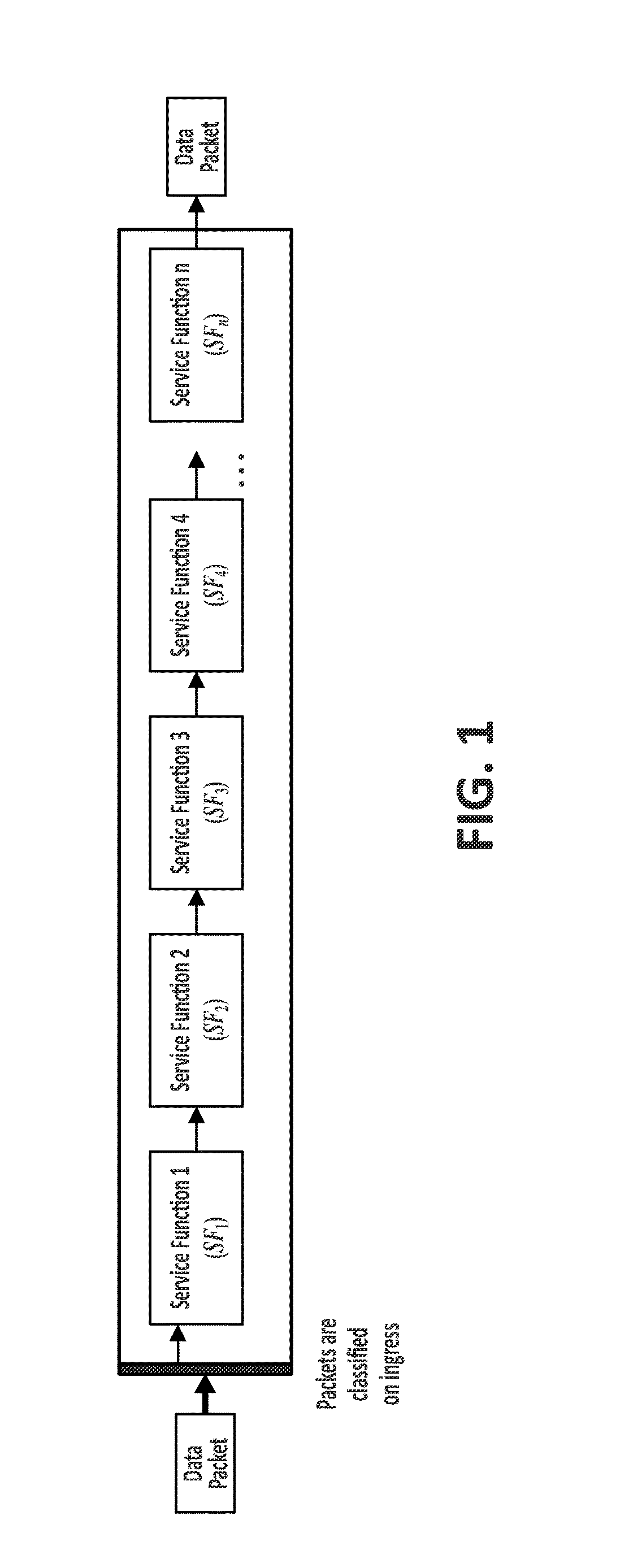

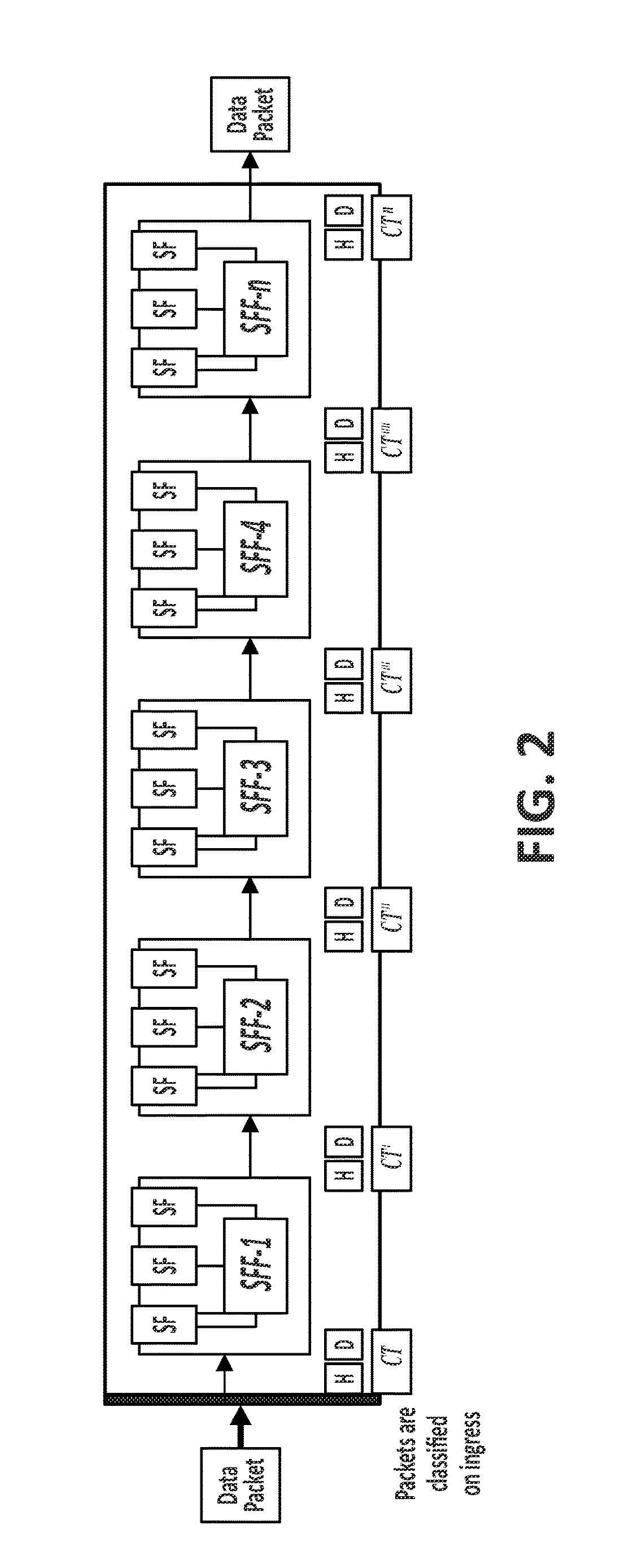

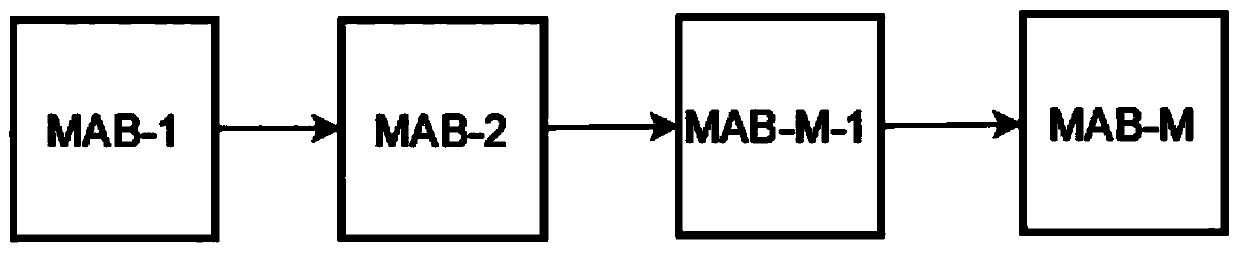

Method to assure correct data packet traversal through a particular path of a network

ActiveUS20170295021A1Improve scalabilityImprove reuseMultiple keys/algorithms usageEncryption apparatus with shift registers/memoriesNetwork packetEncrypted function

The method comprising, in a network based on a chain of individual Service Functions, SFs, that are composed to implement Network Services, NSs: assigning, at an ingress node of a network architecture, to at least one data packet received by said ingress node from the network, a unique cryptographic tag; processing said assigned unique cryptographic tag using a cryptographic function specific to each Service Function, SF; and verifying, at a given point of the network architecture, said processed unique cryptographic tag by applying a cryptographic verification function composed by the inverse functions of the cryptographic functions associated to the SFs traversed by the at least one data packet.

Owner:TELEFONICA SA

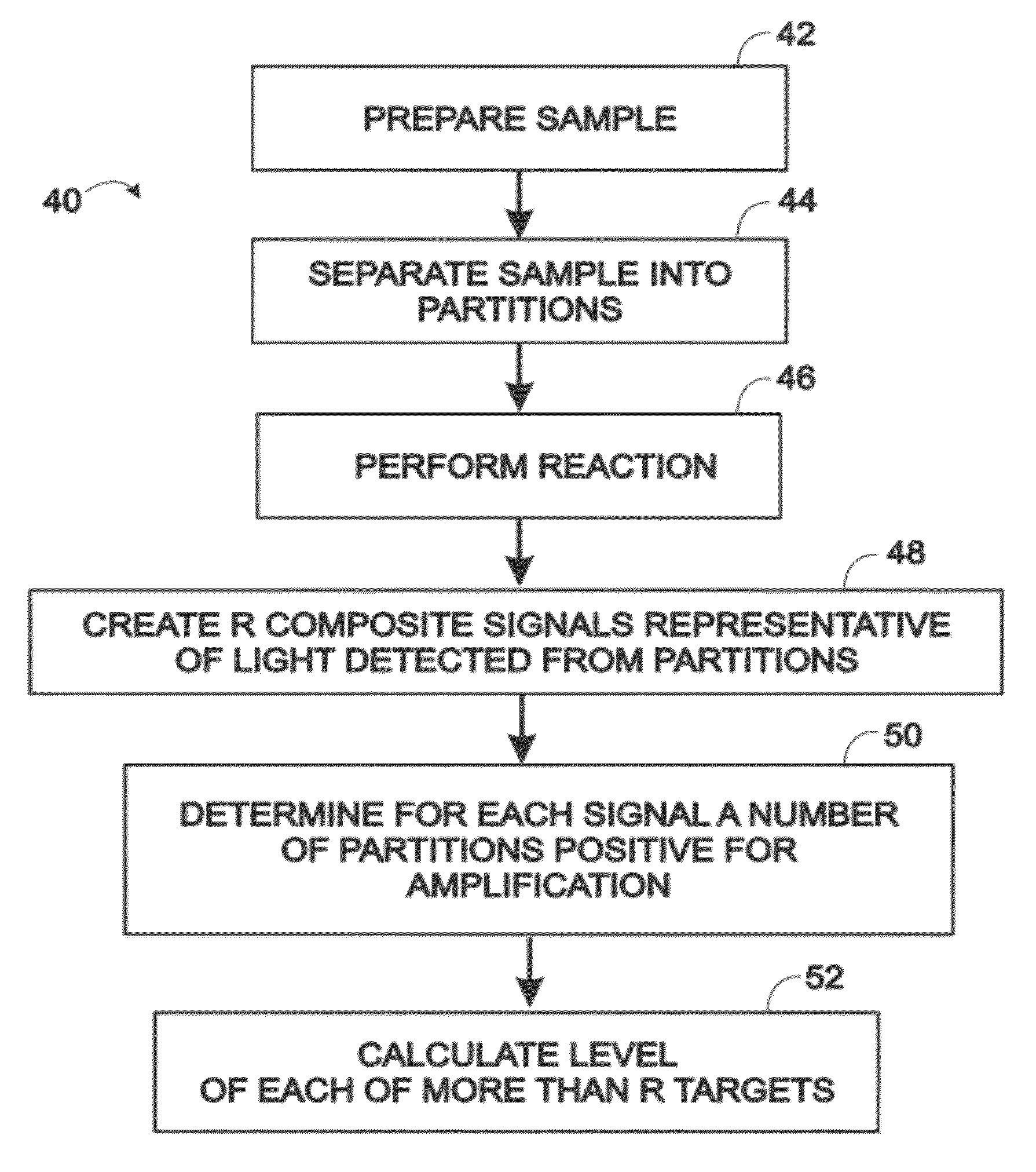

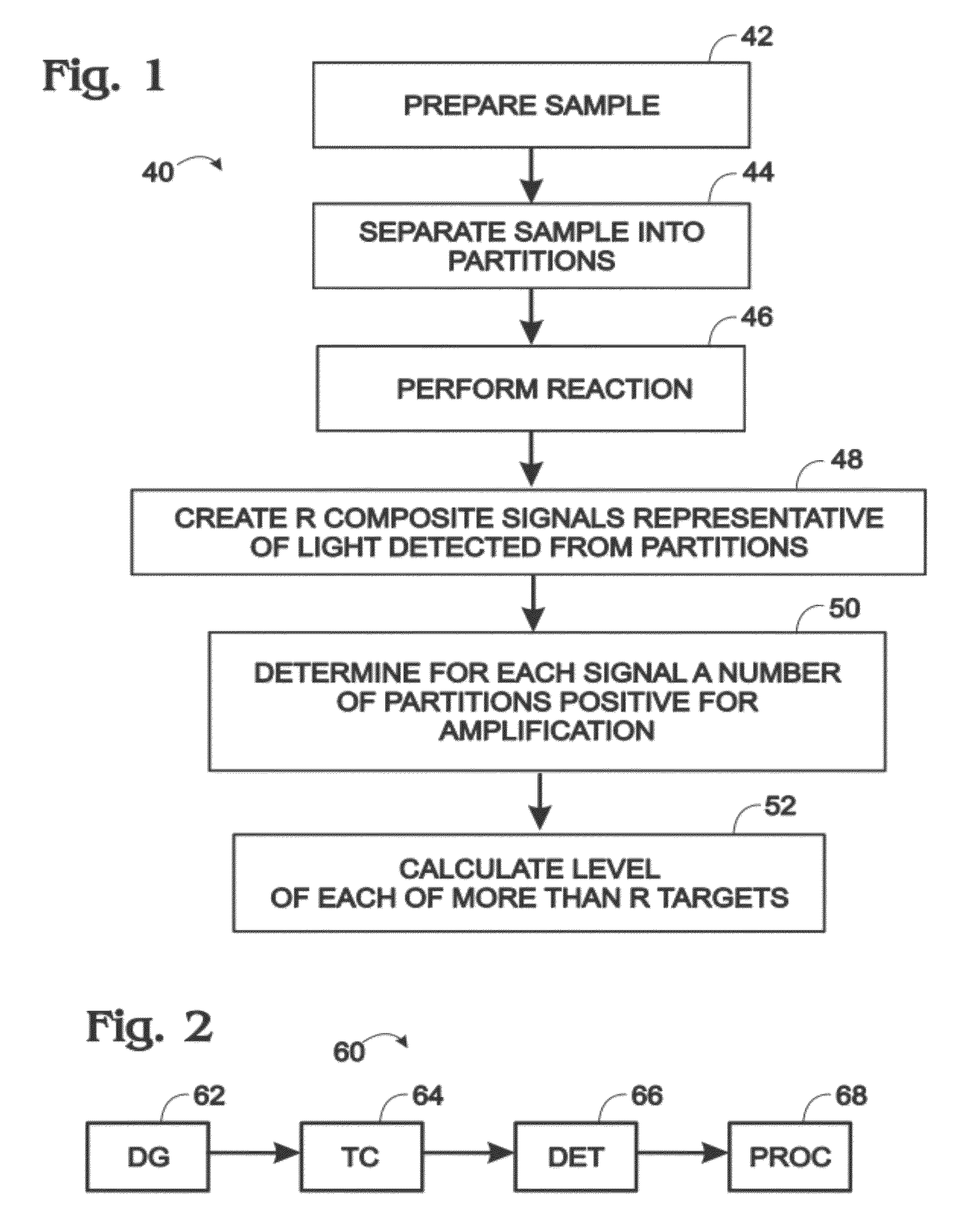

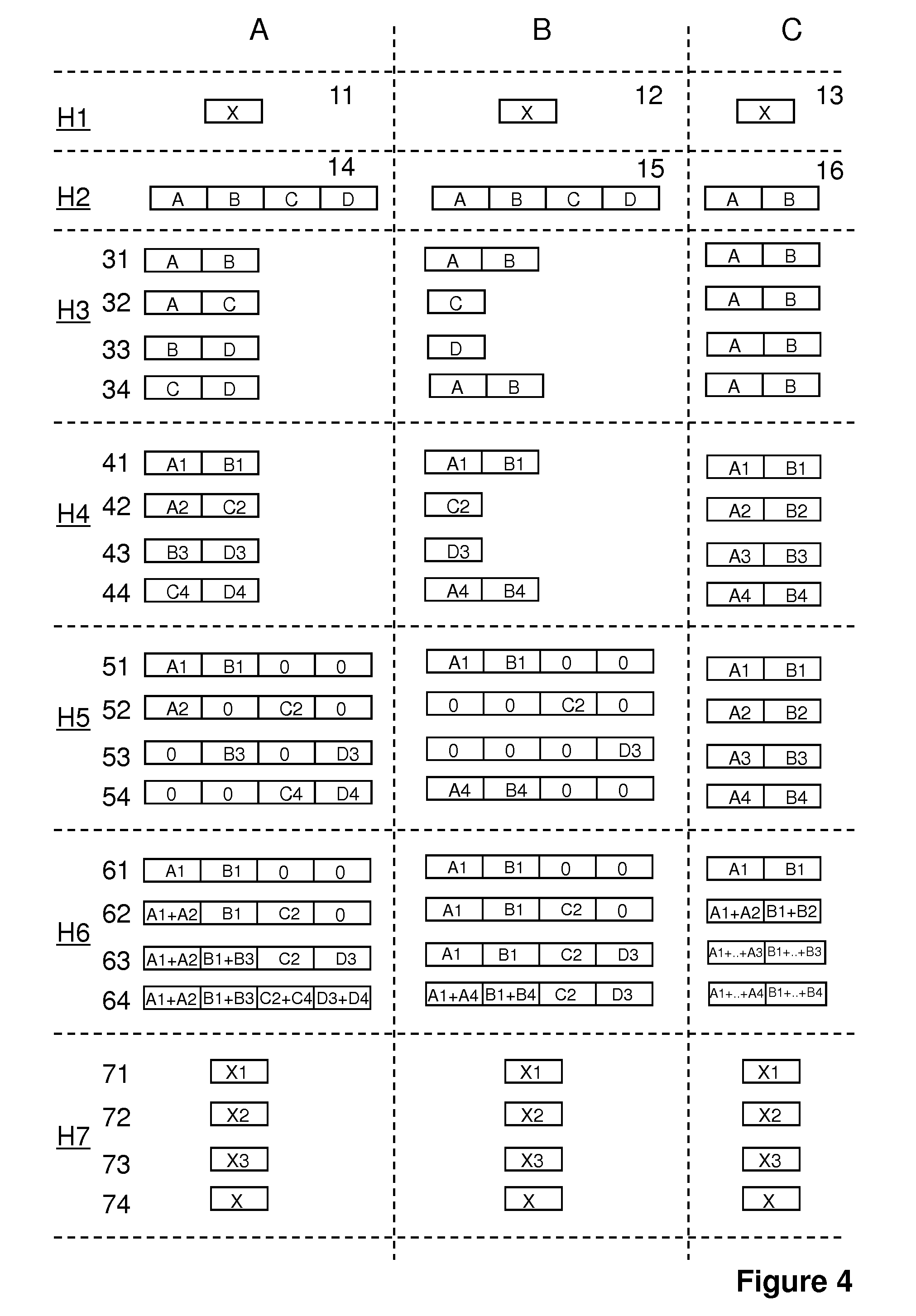

Multiplexed digital assays with combinatorial use of signals

ActiveUS20120329664A1Increase the number ofImprove reuseNucleotide librariesMicrobiological testing/measurementAlgorithmSignaling system

Owner:BIO RAD LAB INC

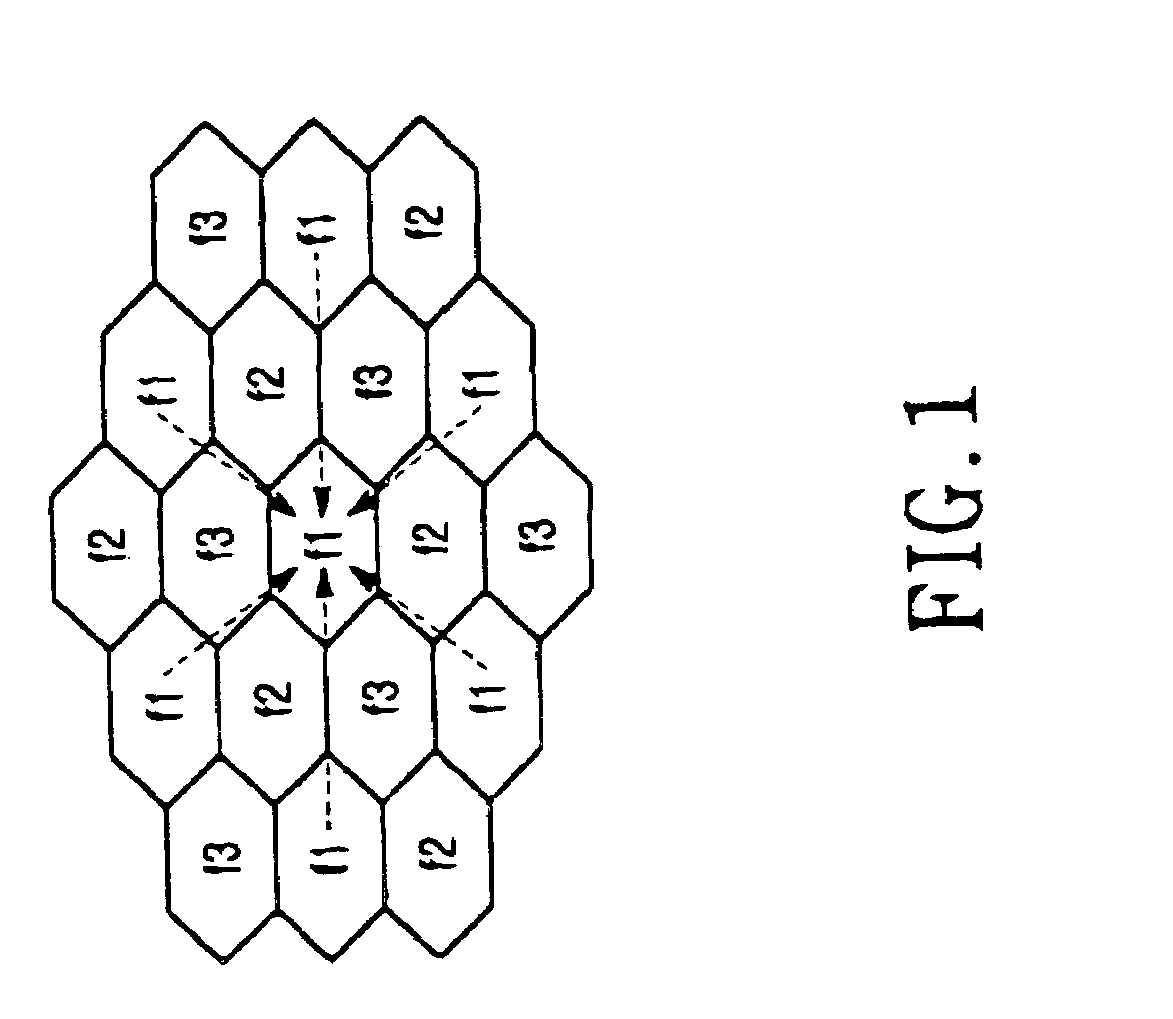

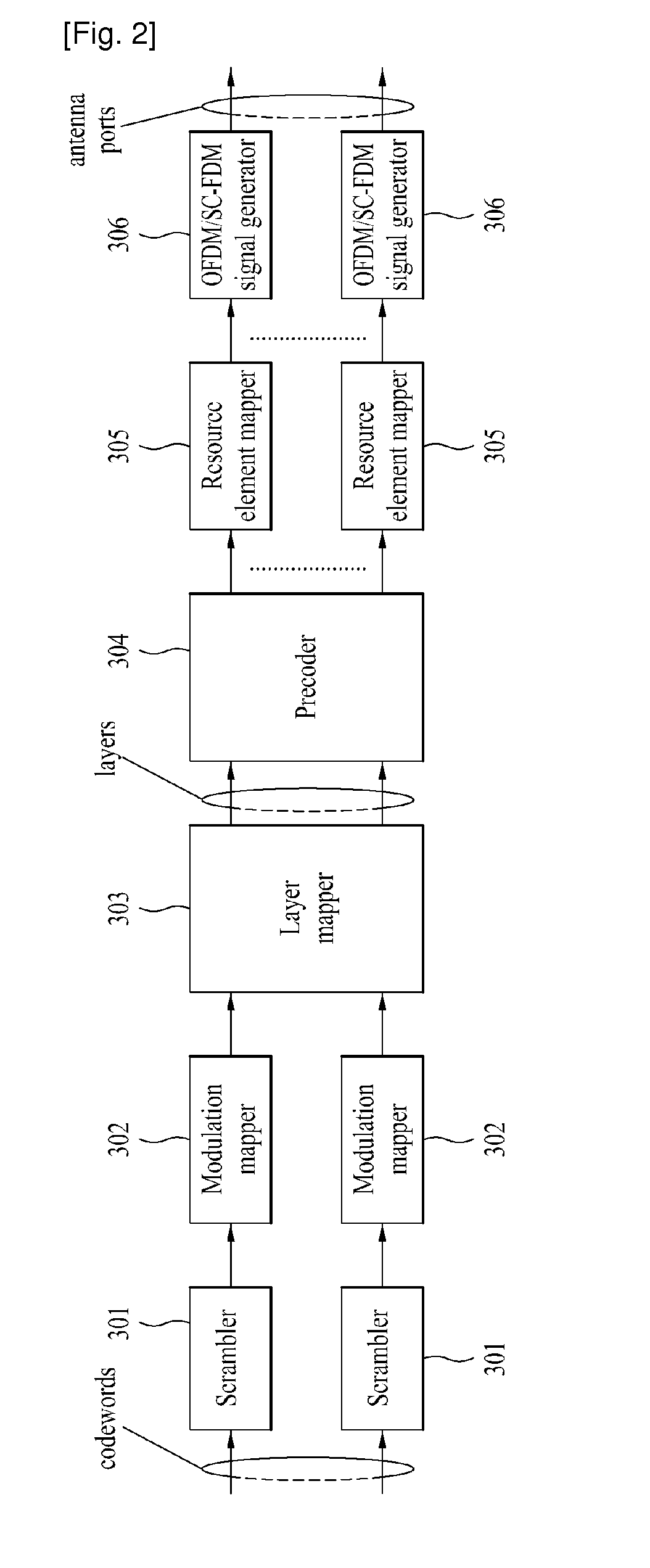

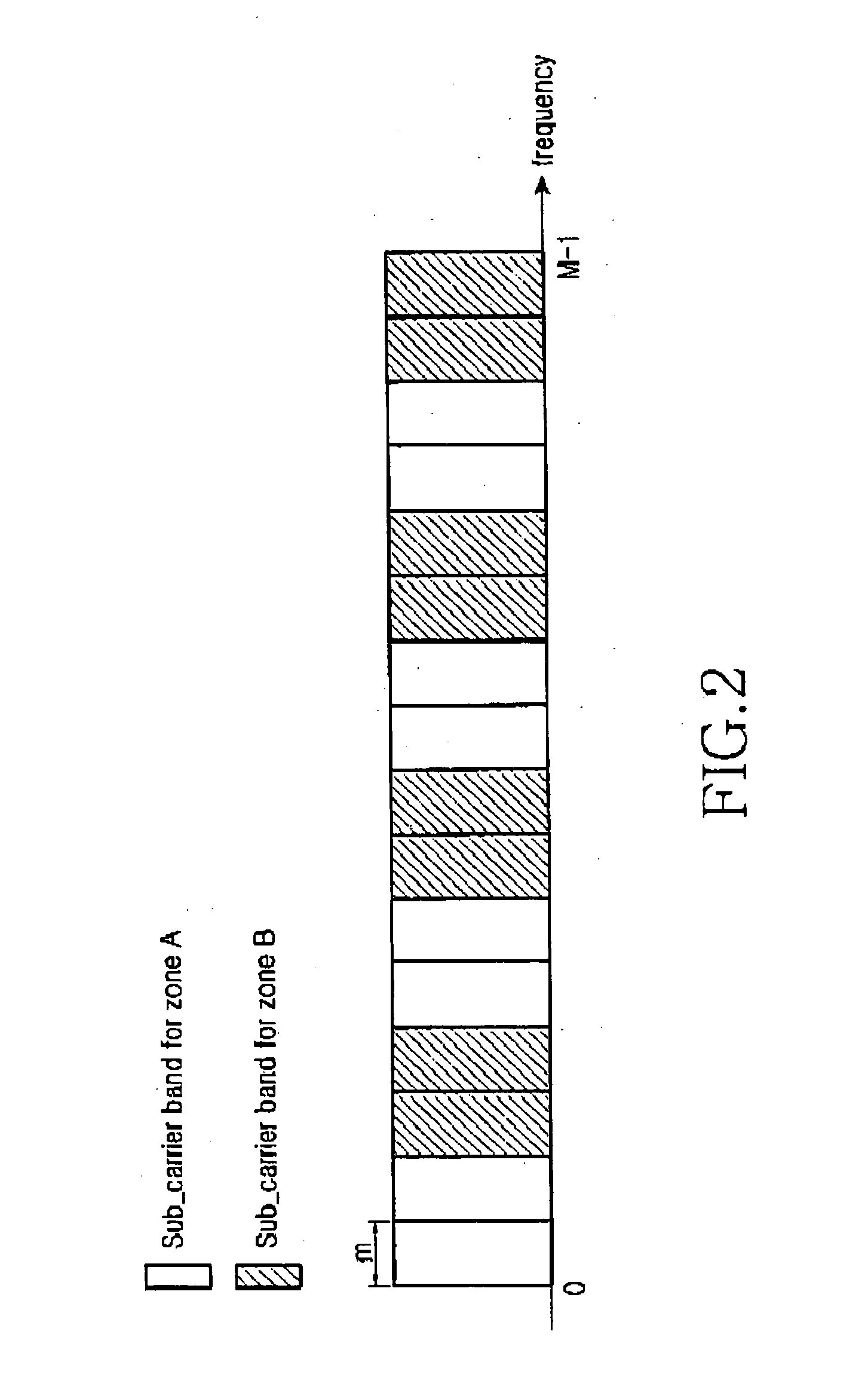

Method for allocating resources in a multicarrier system and transmission apparatus using the same

ActiveUS20060109865A1Interference minimizationImprove reuseNetwork traffic/resource managementTime-division multiplexCarrier signalEngineering

In an orthogonal frequency division multiplexing (OFDM) mobile communication system, an apparatus and method allocates resources for data transmission and transmits / receives user data using the allocated resources. A full subcarrier band allocable for one cell is divided into a plurality of subcarrier regions. Subcarriers selected from subcarriers existing in one of the plurality of subcarrier regions are allocated for each of a plurality of sectors constituting the cell. The subcarriers are allocated such that subcarriers existing in different subcarrier regions are allocated for neighboring sectors in the cell.

Owner:SAMSUNG ELECTRONICS CO LTD

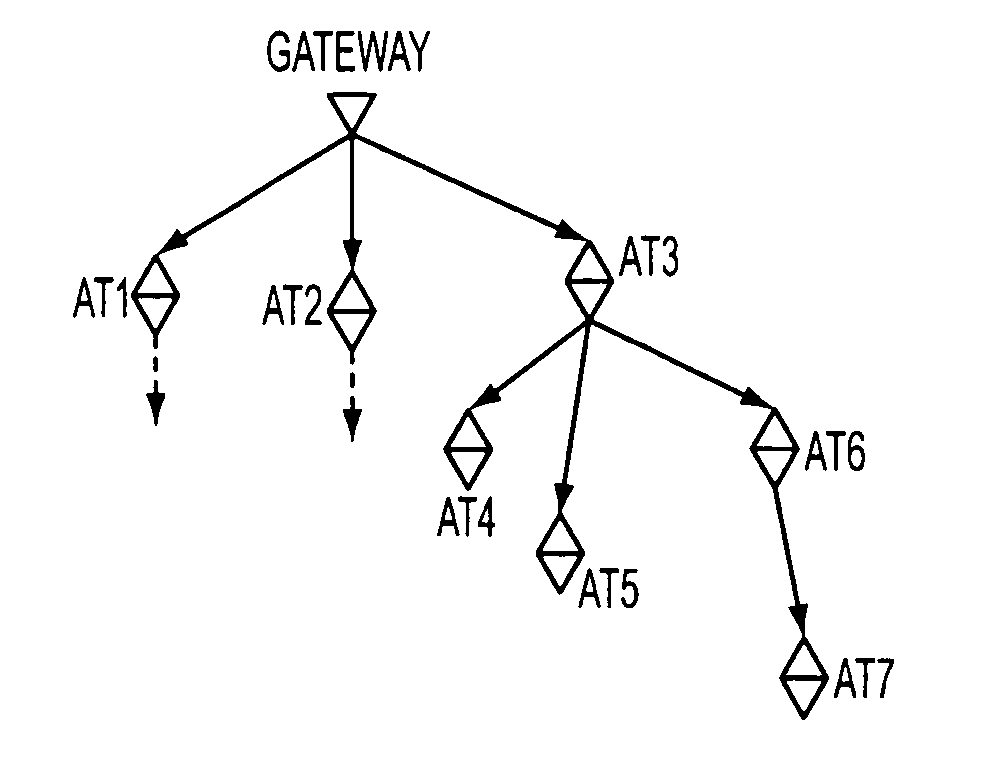

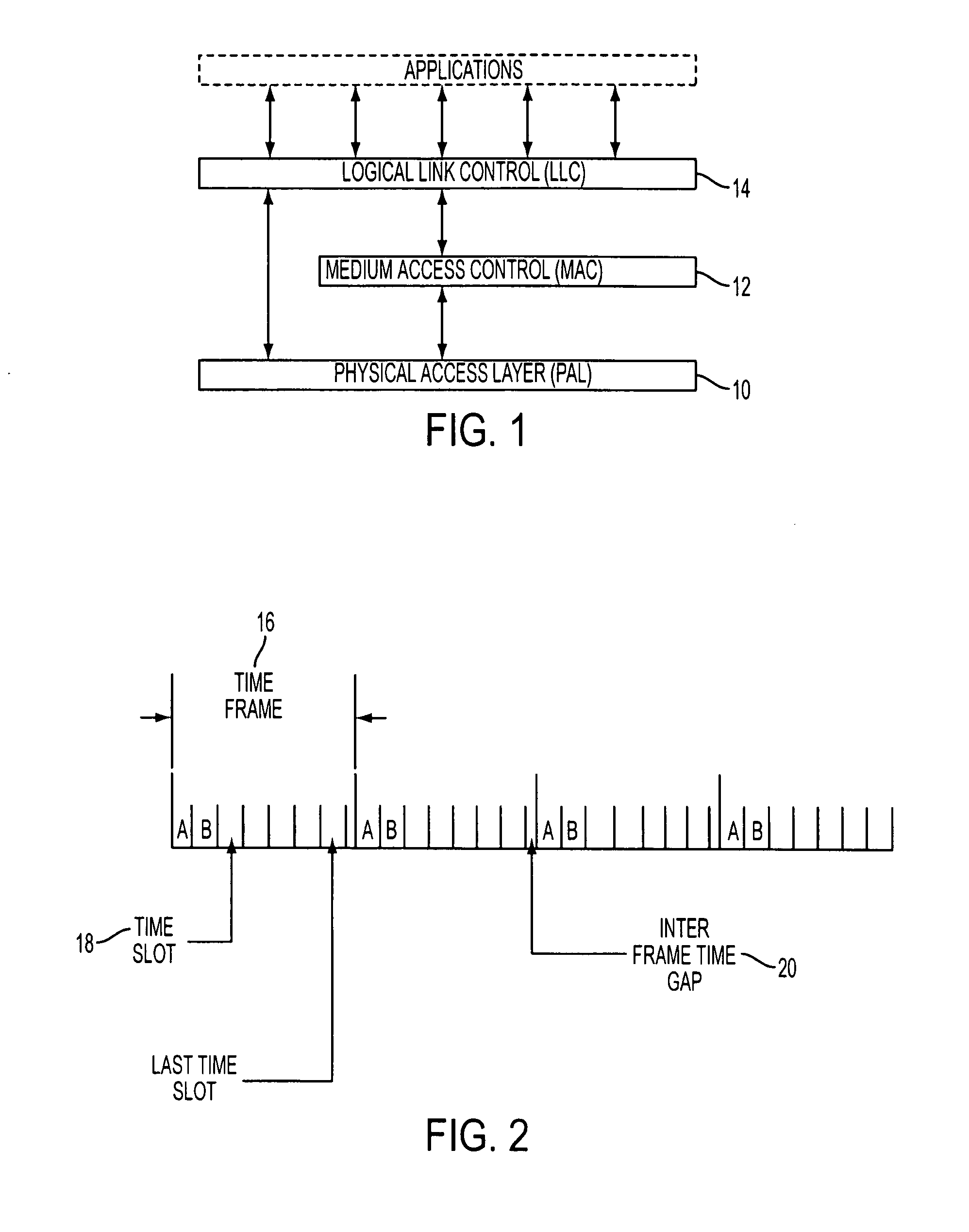

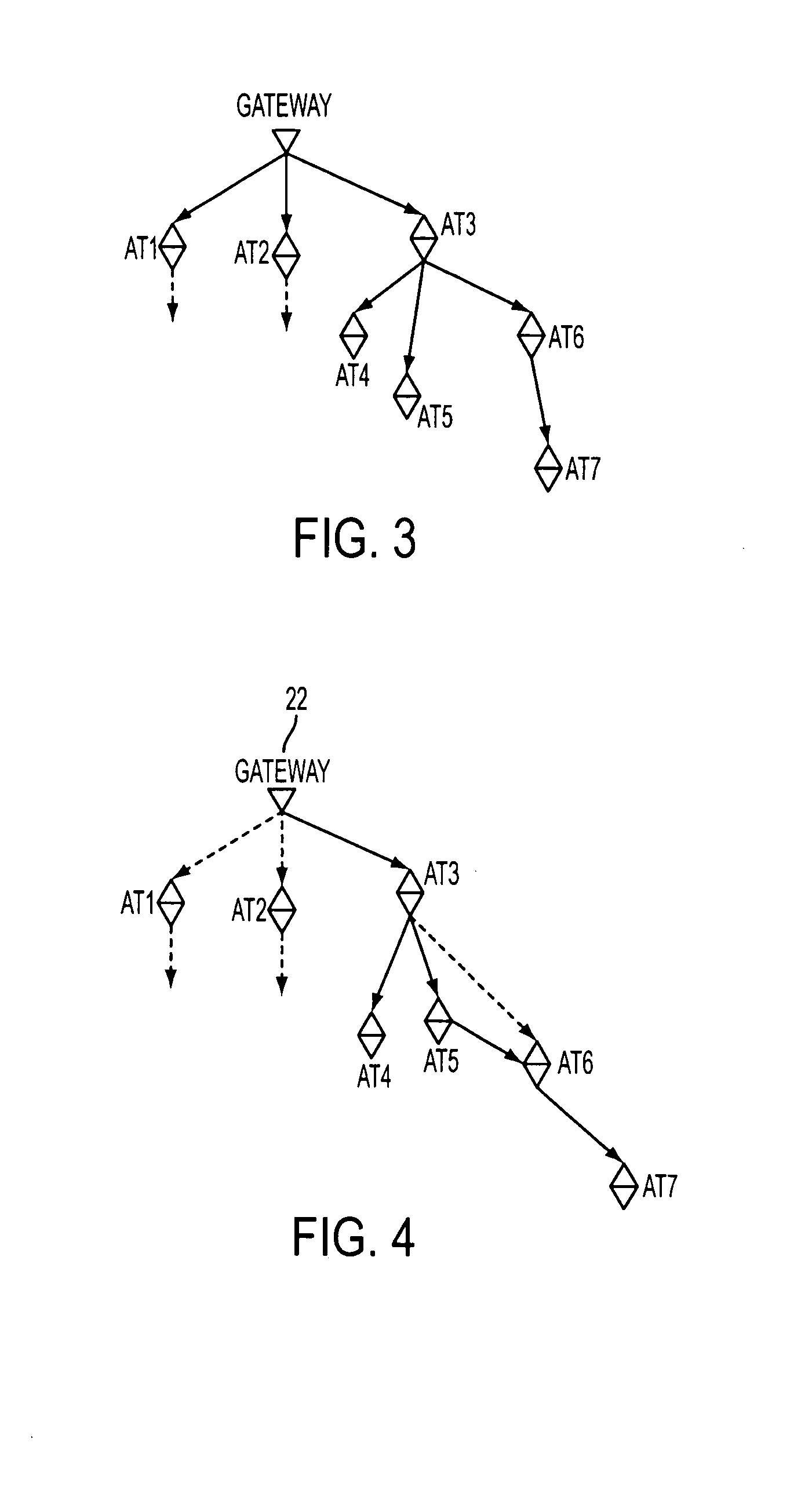

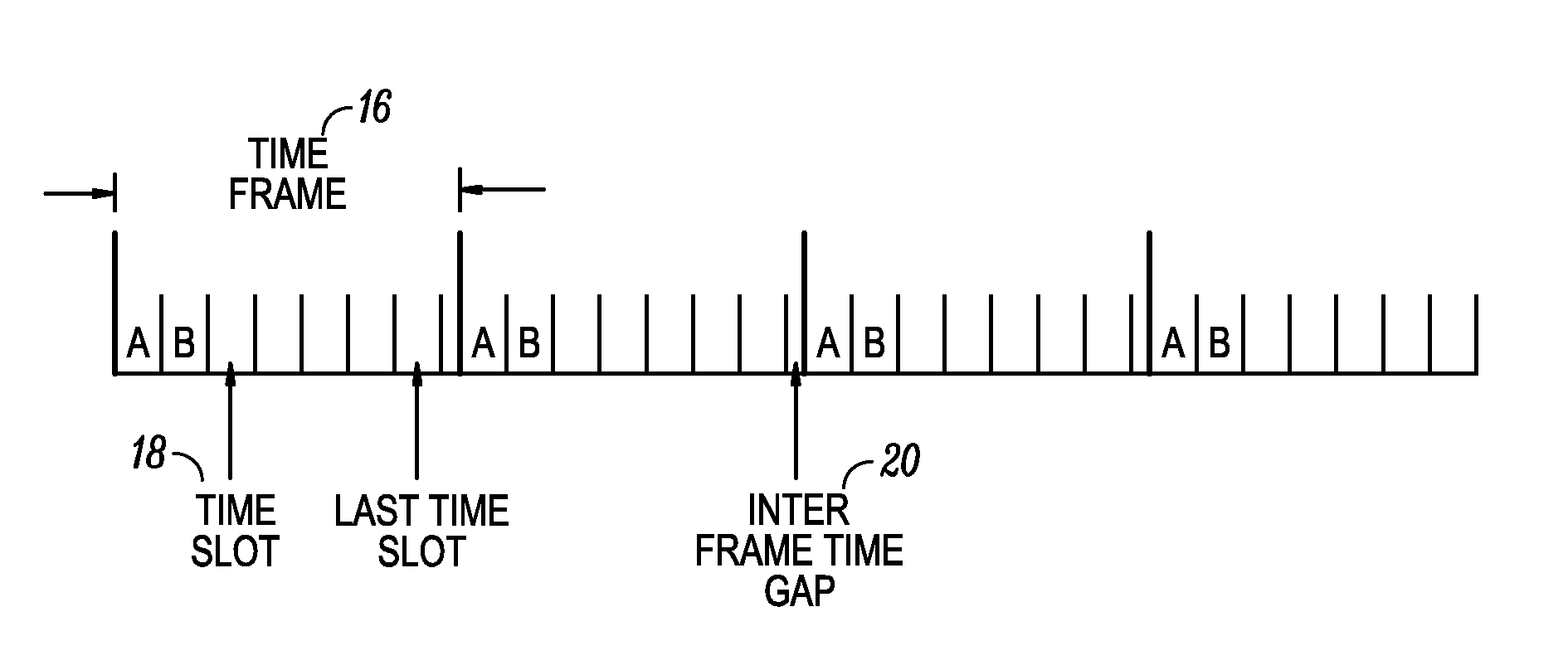

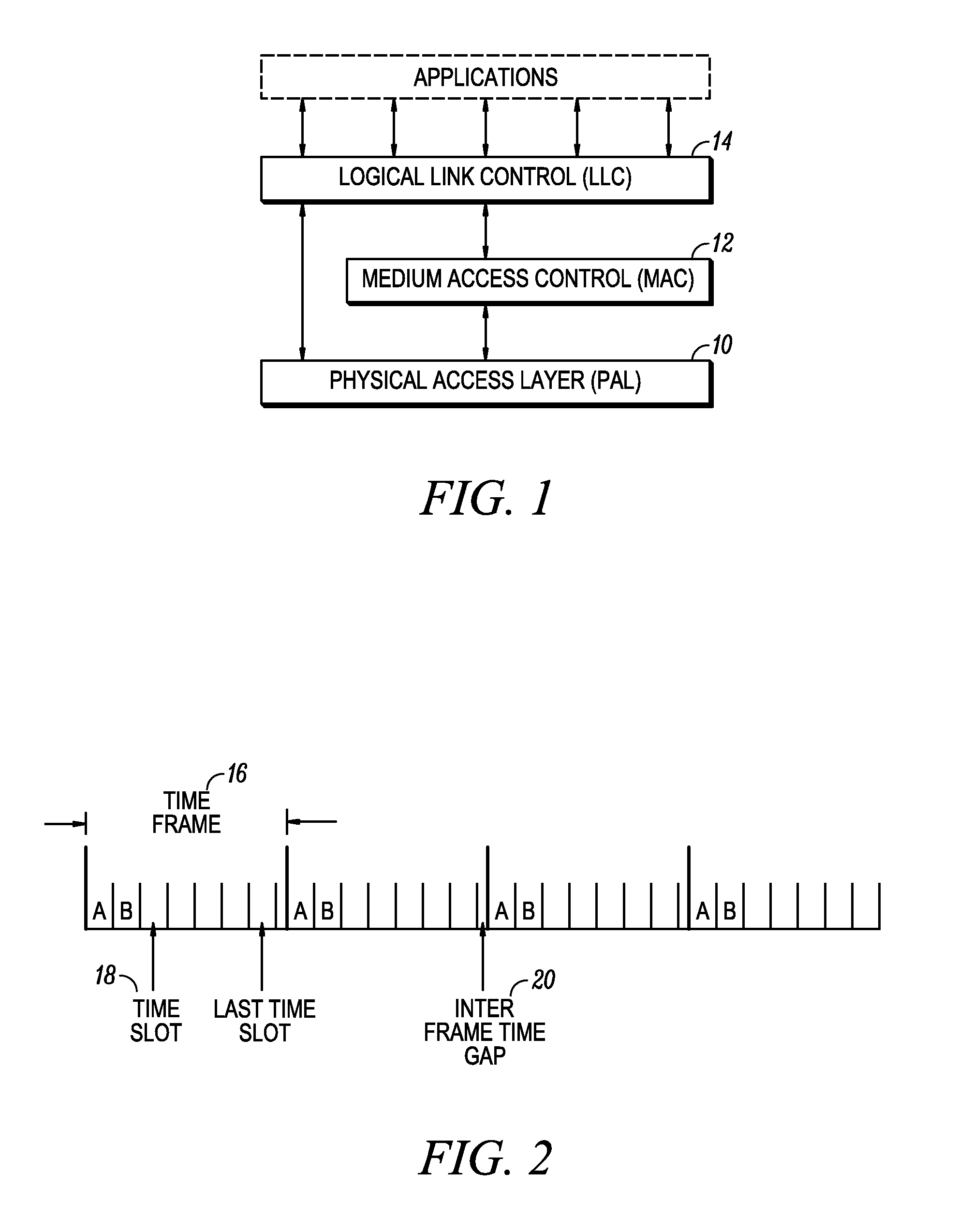

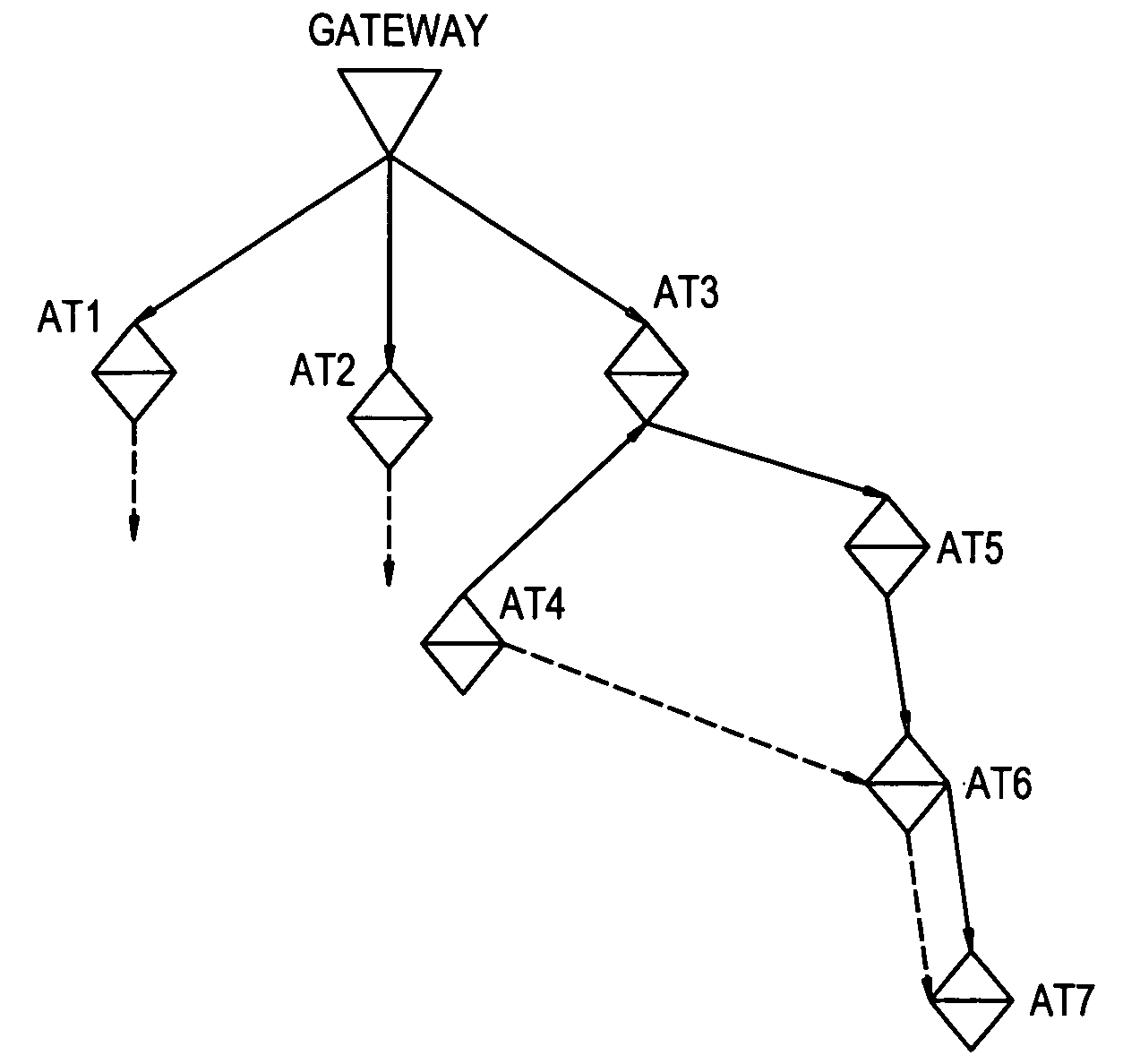

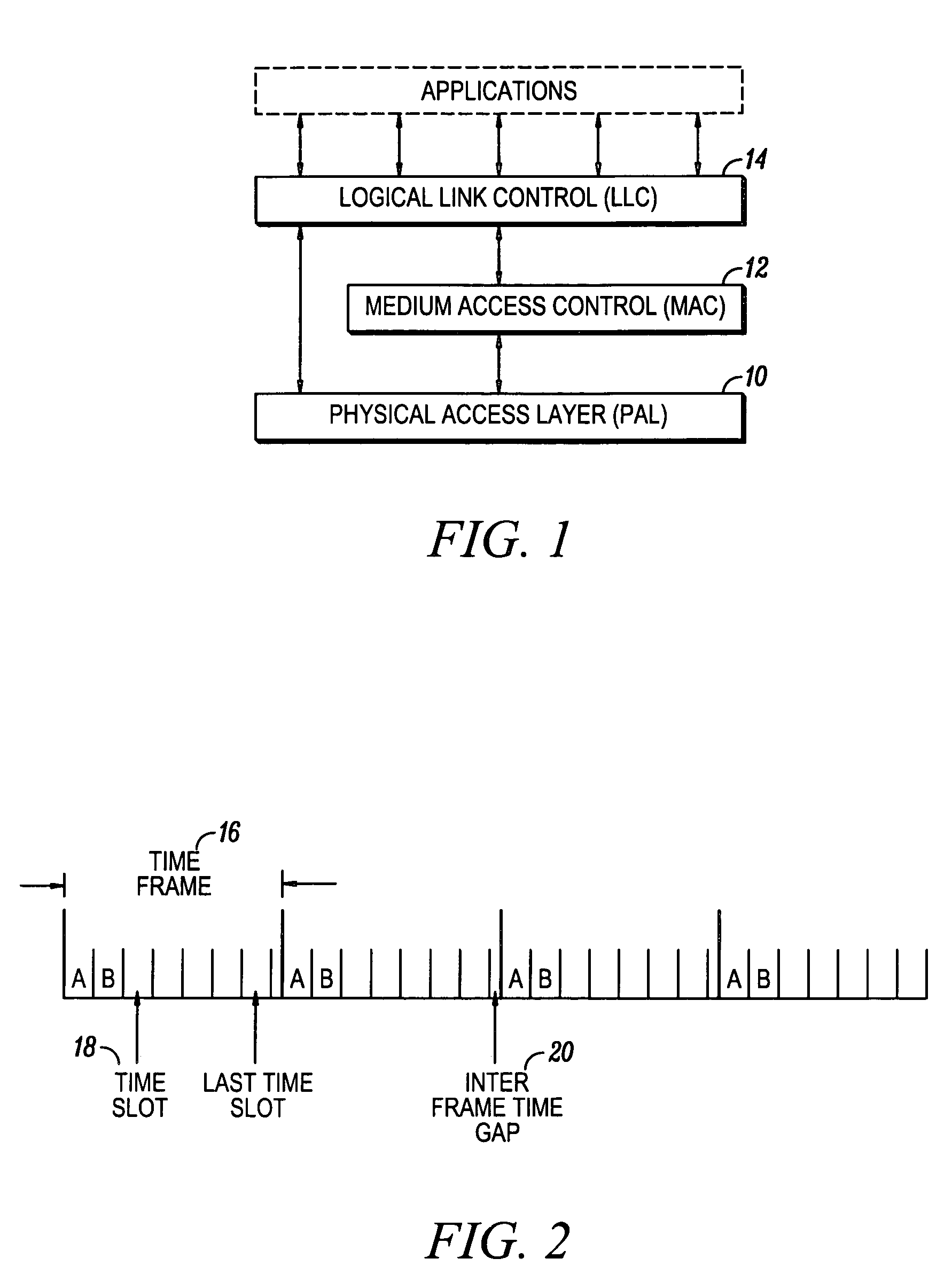

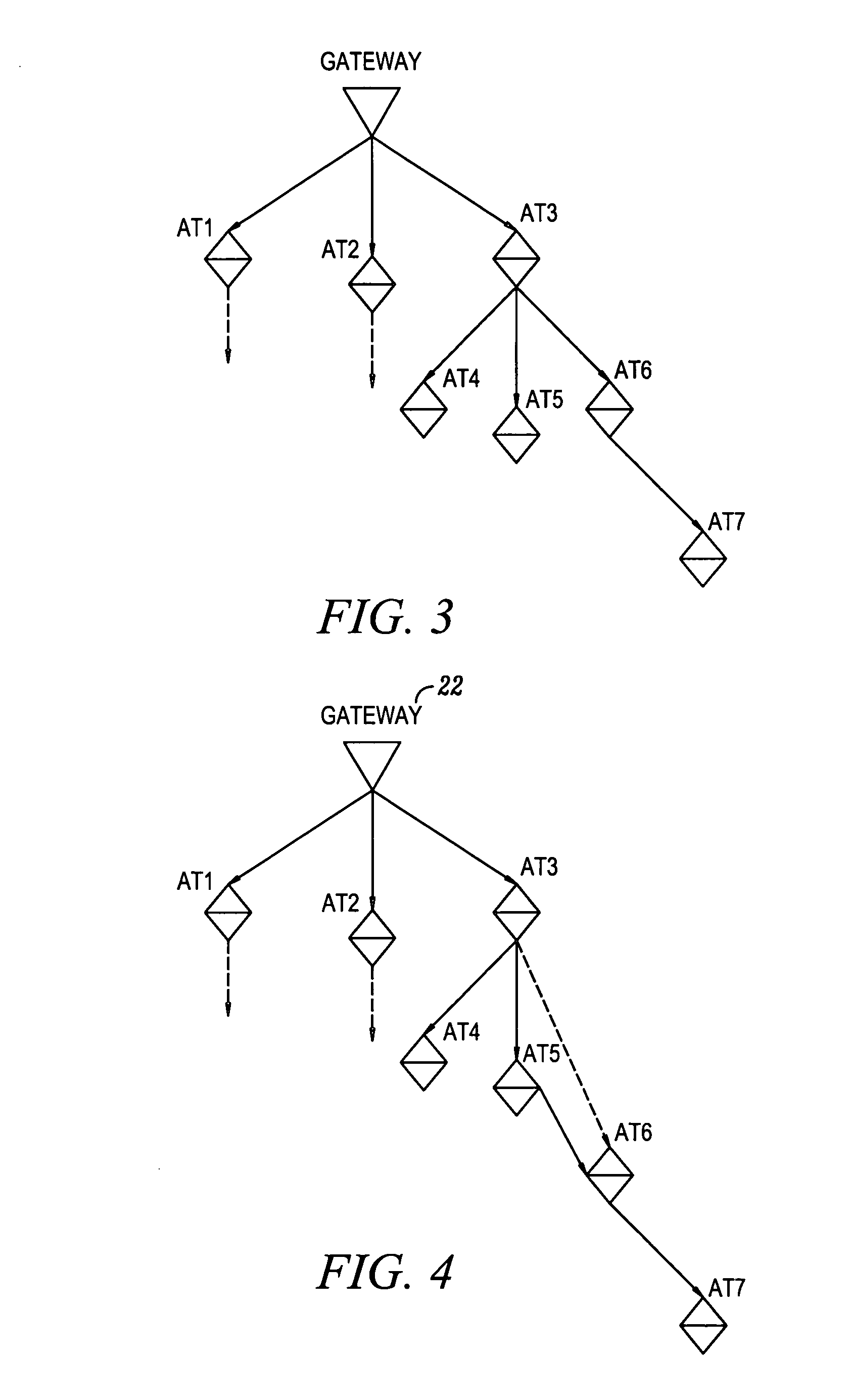

Time division protocol for an ad-hoc, peer-to-peer radio network having coordinating channel access to shared parallel data channels with separate reservation channel

InactiveUS7079509B2Improve throughputImprove reliabilityPower managementEnergy efficient ICTRadio networksQuality voice

A novel protocol for an ad-hoc, peer-to-peer radio network that provides collision-free channel access with an emphasis on improving geographic reuse of the frequency spectrum. The protocol of the invention is executed on the reservation or control channel, and provides a method for allocating data transactions on the data channels. The system of the invention utilizes multiple parallel data channels that are coordinated by a single reservation channel. The transceiver of the system employs two modems to solve the channel reliability issues with multiple channel designs, where one is dedicated as a receive-only modem for gathering channel usage information on the reservation channel. High quality voice, video and data may be transmitted. The reservation channel implements a time division multiple access algorithm with dynamic slot allocation. In a distributed manner, nodes determine geographic reuse of slots based on channel quality extracted from the modem. Signal quality calculations are used to determine the likelihood of a slot reuse causing destructive interference within a node's neighborhood. Requests for slot usage are compared with the known traffic pattern and accepted or rejected by nodes within RF signal range based on the signal quality calculations.

Owner:ARRIS ENTERPRISES LLC

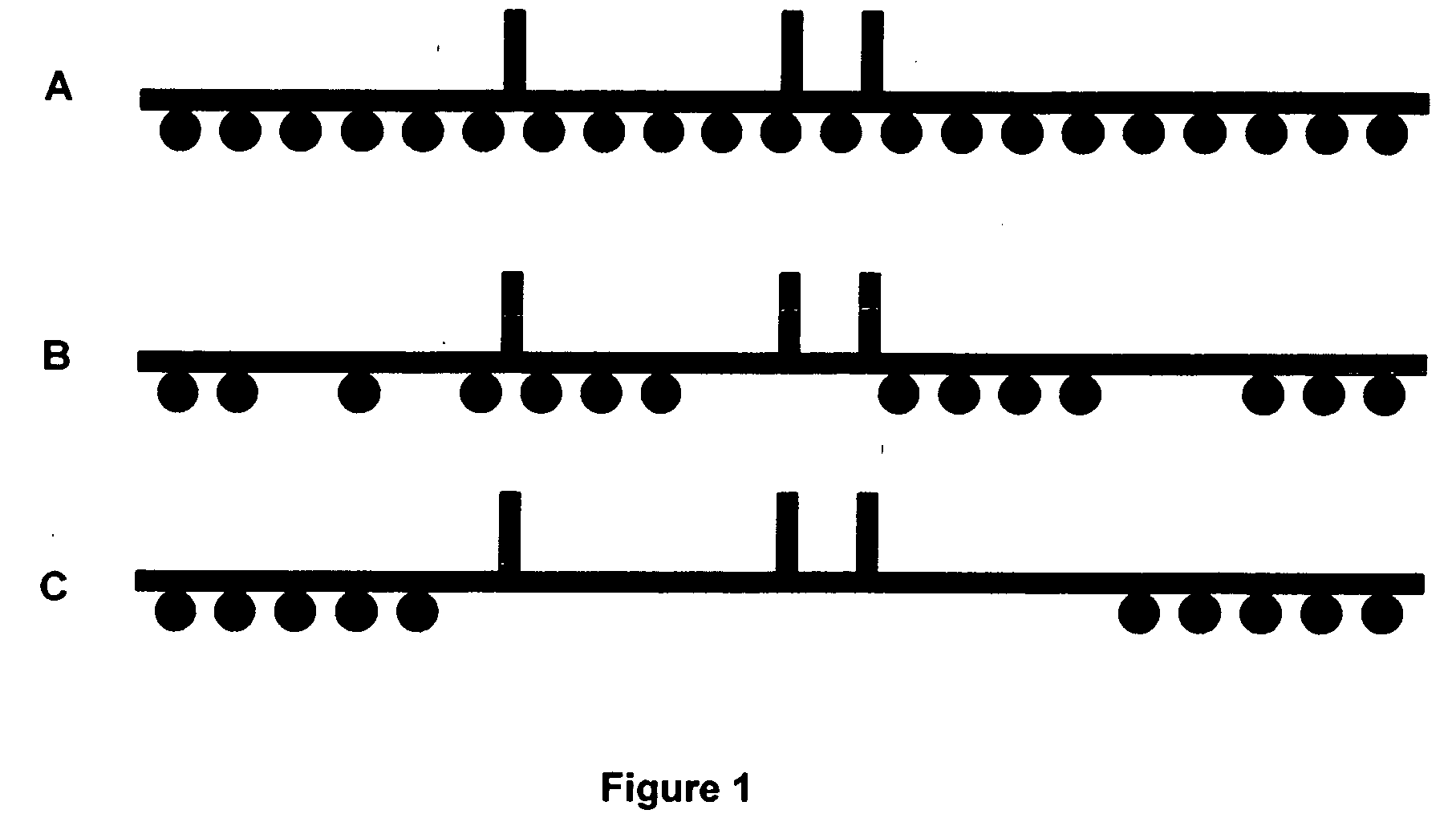

Detection and quantification of analytes in solution using polymers

InactiveUS20050153354A1Improve reuseSugar derivativesMicrobiological testing/measurementAnalyteVirus

Owner:PATHOGENETIX

Time division protocol for an ad-hoc, peer-to-peer radio network having coordinating channel access to shared parallel data channels with separate reservation channel

InactiveUS7099296B2Improve throughput and reliabilitySignificant to useEnergy efficient ICTPower managementFrequency spectrumModem device

A novel protocol for an ad-hoc, peer-to-peer radio network that provides collision-free channel access with an emphasis on improving geographic reuse of the frequency spectrum. The protocol of the invention is executed on the reservation or control channel, and provides a method for allocating data transactions on the data channels. The system of the invention utilizes multiple parallel data channels that are coordinated by a single reservation channel. The transceiver of the system employs two modems to solve the channel reliability issues with multiple channel designs, where one is dedicated as a receive-only modem for gathering channel usage information on the reservation channel. High quality voice, video and data may be transmitted. The reservation channel implements a time division multiple access algorithm with dynamic slot allocation. In a distributed manner, nodes determine geographic reuse of slots based on channel quality extracted from the modem. Signal quality calculations are used to determine the likelihood of a slot reuse causing destructive interference within a node's neighborhood. Requests for slot usage are compared with the known traffic pattern and accepted or rejected by nodes within RF signal range based on the signal quality calculations.

Owner:ARRIS ENTERPRISES LLC

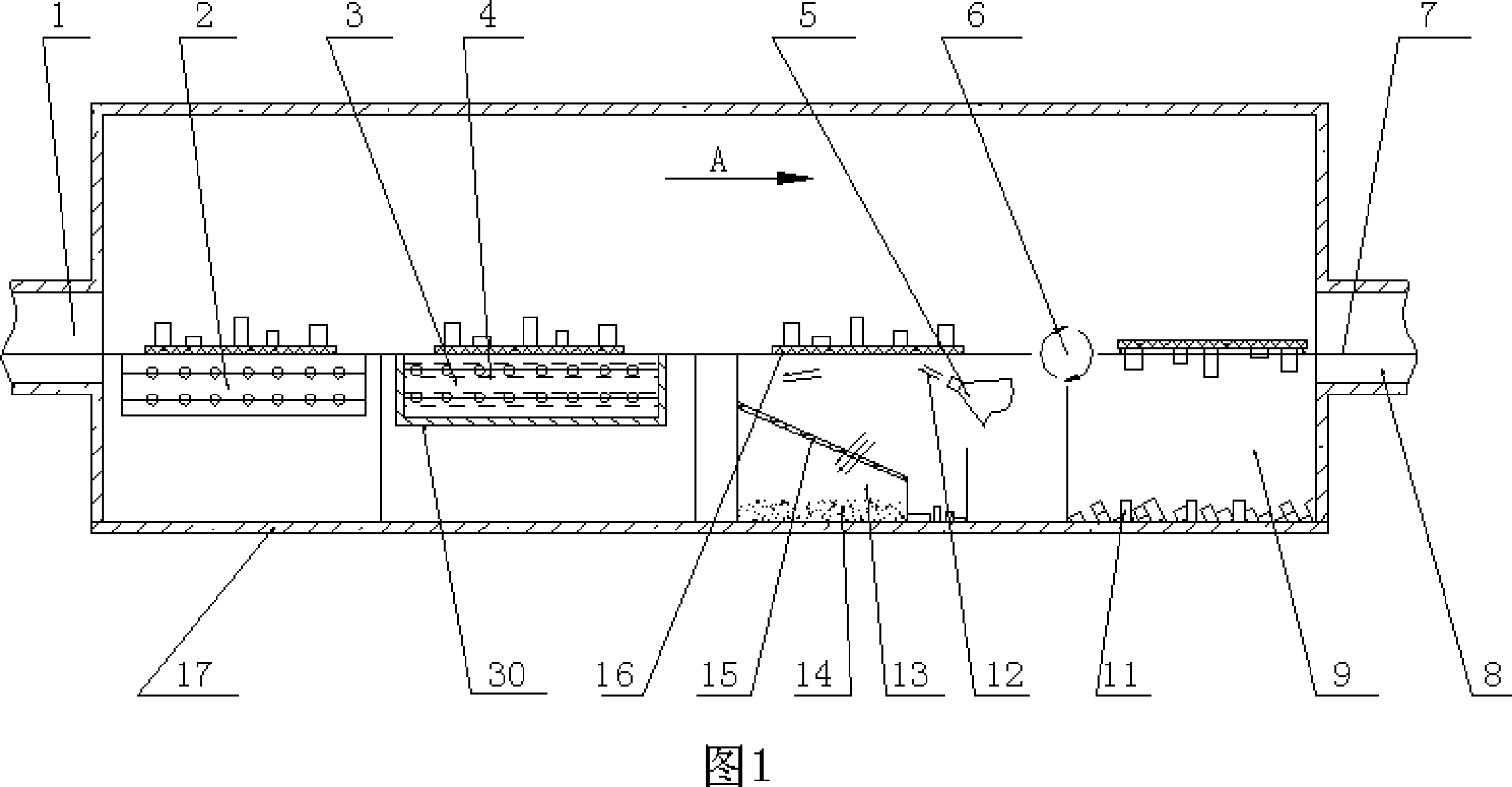

Circuit board element and welding flux separating and recovery method and device thereof

InactiveCN101112728AReduce thermal shockImprove uptimeSolid waste disposalSoldering auxillary devicesRecovery methodEngineering

The invention relates to recycle and reuse technology of electronic castoff, in particular to a method and a device to remove the element and separate the welding material from the circuit board. The invention discloses the method and the device which separates and recycles the welding material and removes the elements on the circuit board with high efficiency. The technic proposal of the invention adopts the melting welding material as the heating medium and heats the welding pots on the welding surface of the circuit board; the welding material is separated from the circuit board by utilizing the special nozzle to spray high-temperature high-pressure gas; finally, the circuit board is turned over and vibrated, separating the element from the circuit board. The invention has the beneficial effects that the element is subject to small heat impact during the removal process, the element after removal has high intact rate and repeated ratio, and the new impurity is not brought in during the removal process. The invention has the advantages of complete separation of welding pot, high removal ratio of elements, low energy consumption, environment-friendship, etc.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

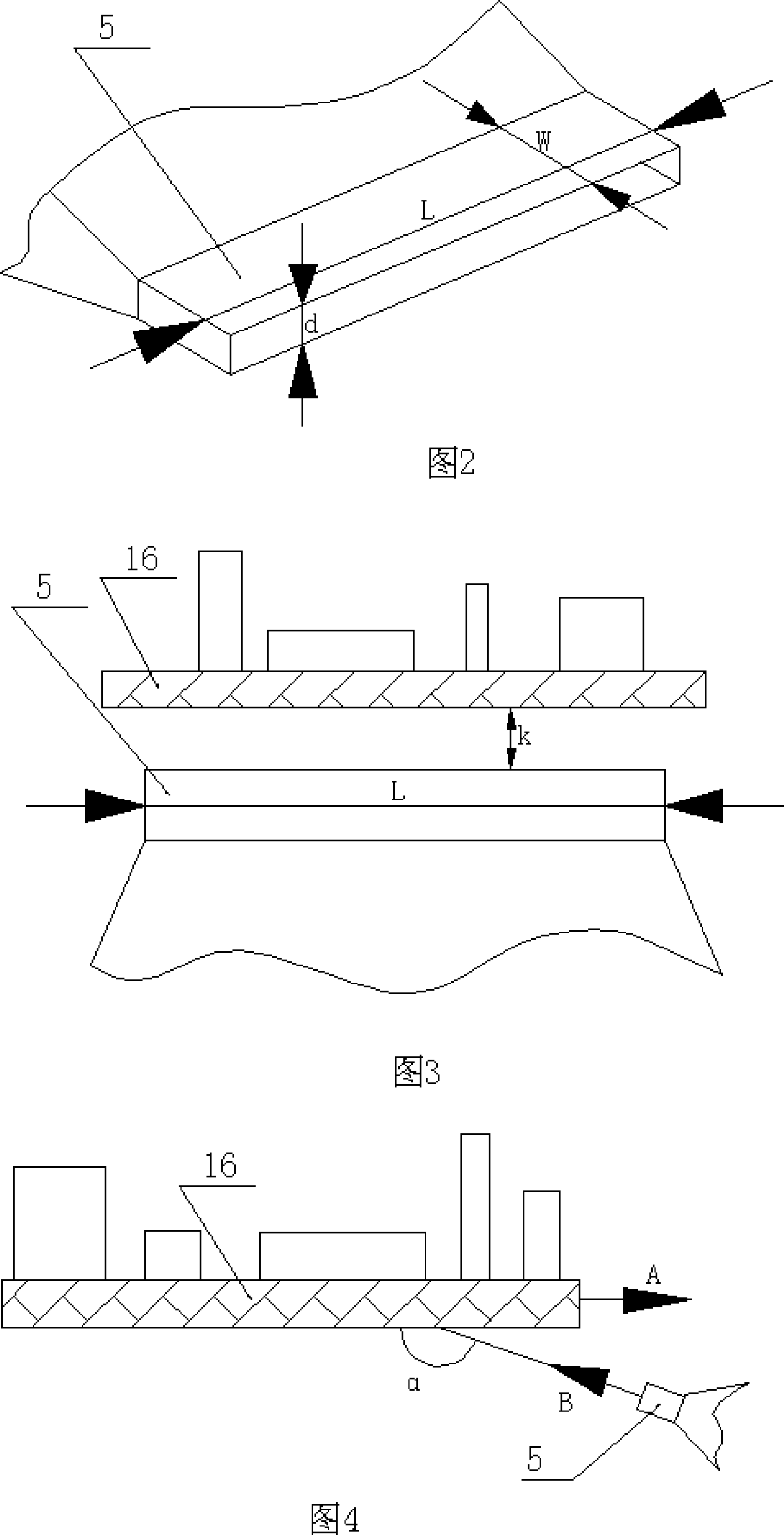

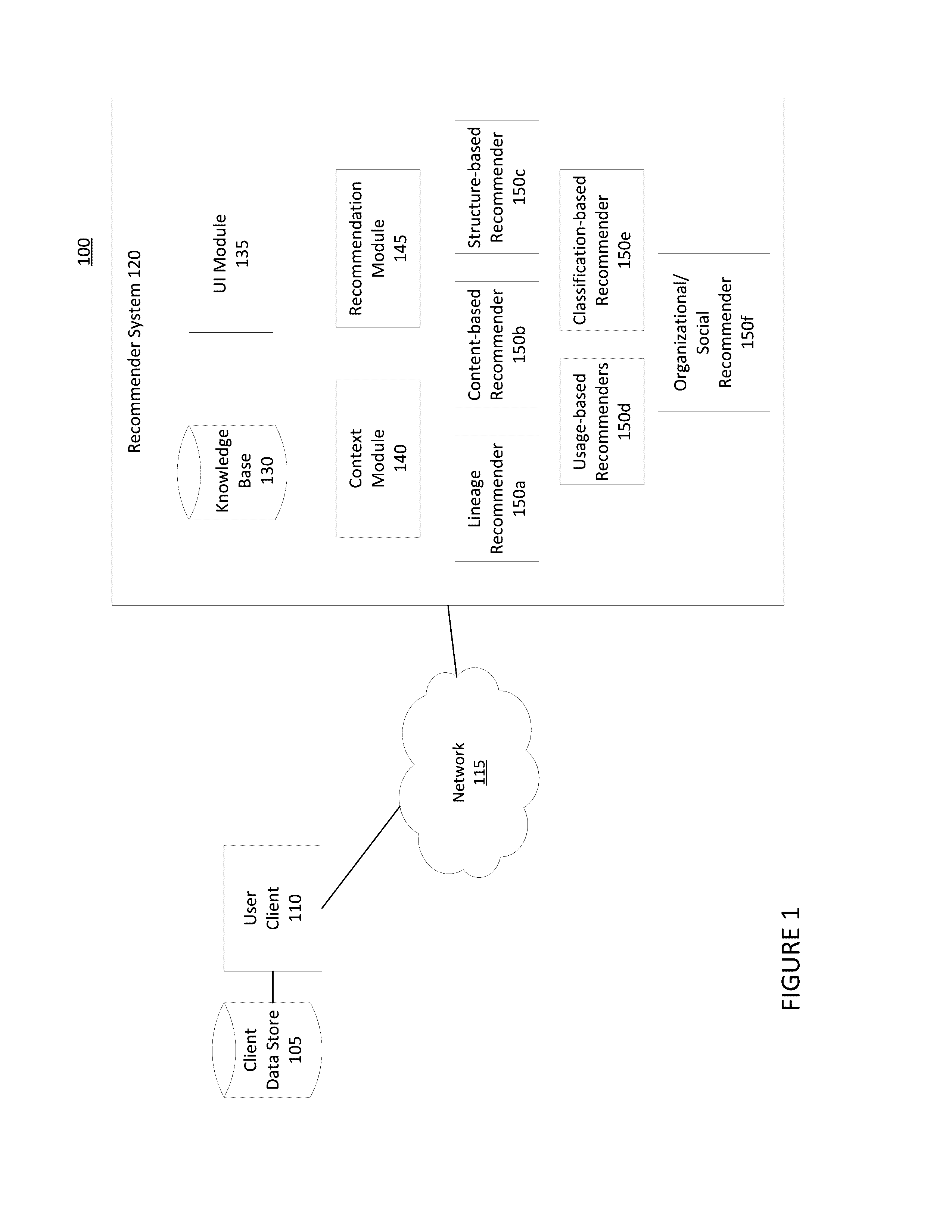

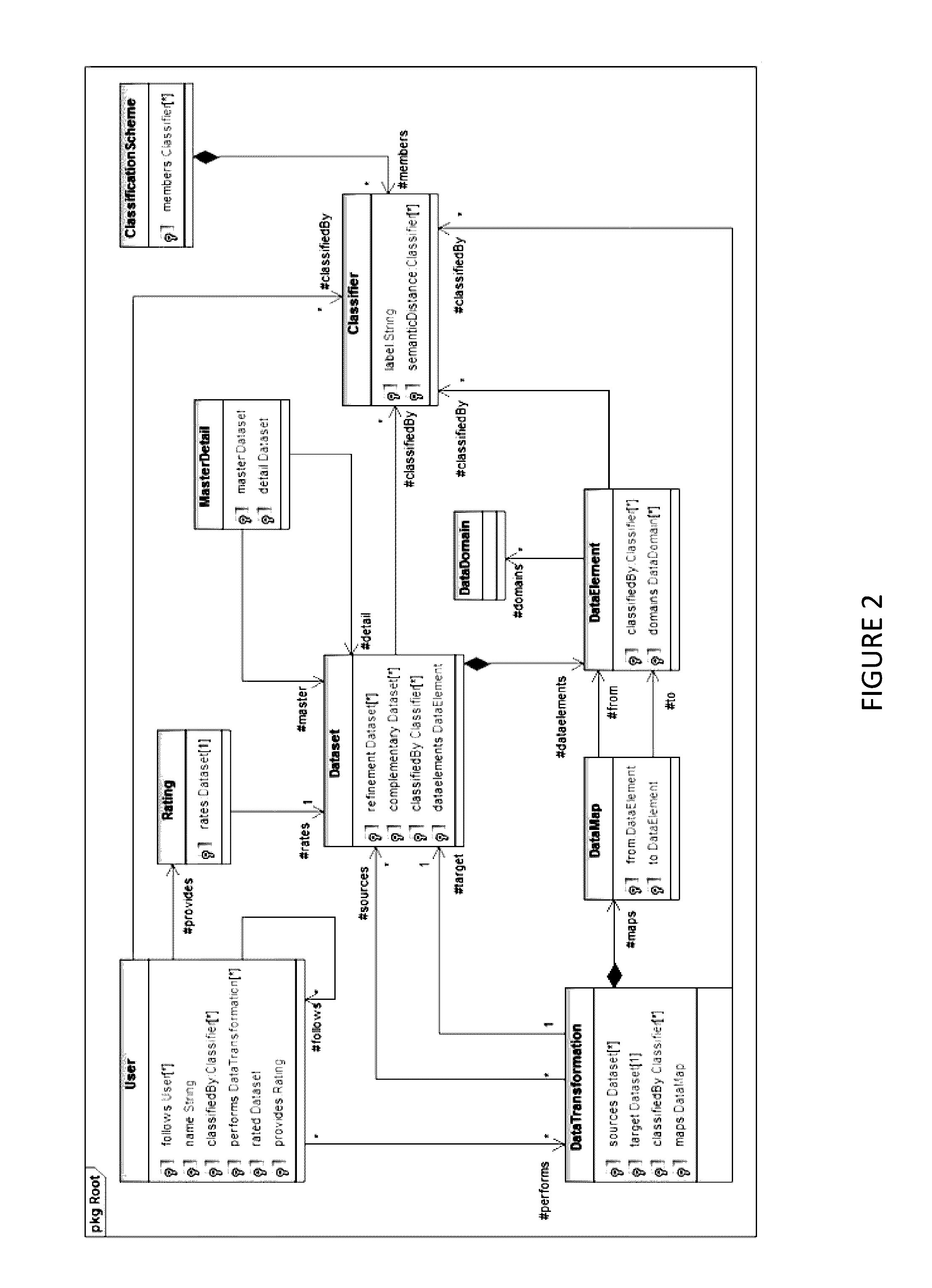

Interactive recommendation of data sets for data analysis

InactiveUS20160328406A1Shorten the timeIncrease awarenessDigital data information retrievalSpecial data processing applicationsData setData profiling

A data analysis platform provides recommendations for datasets for analysis. Given a user selected dataset, for example resulting from a search,automatically identifies other datasets based a variety of different types of relationships, including lineage, structural, content, usage, classification, and organizational / social. Datasets for each type of relationship are identified and scored for relevance, and ranked. Selected ones of the ranked data sets are presented in a recommendation interface. As the user selects from recommended dataset, additional datasets are automatically recommended based in inferences made according to the selected dataset and relationship.

Owner:INFORMATICA CORP

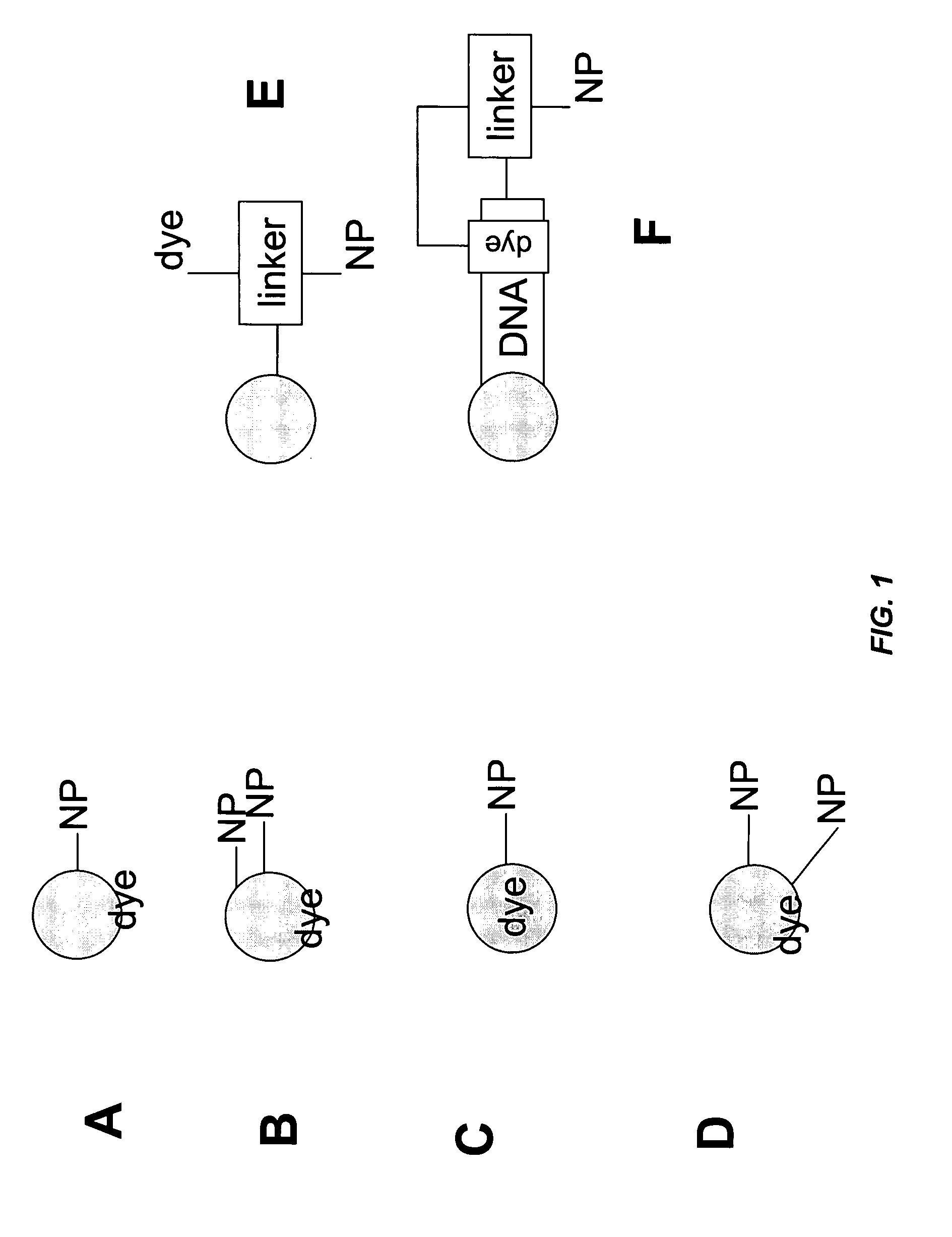

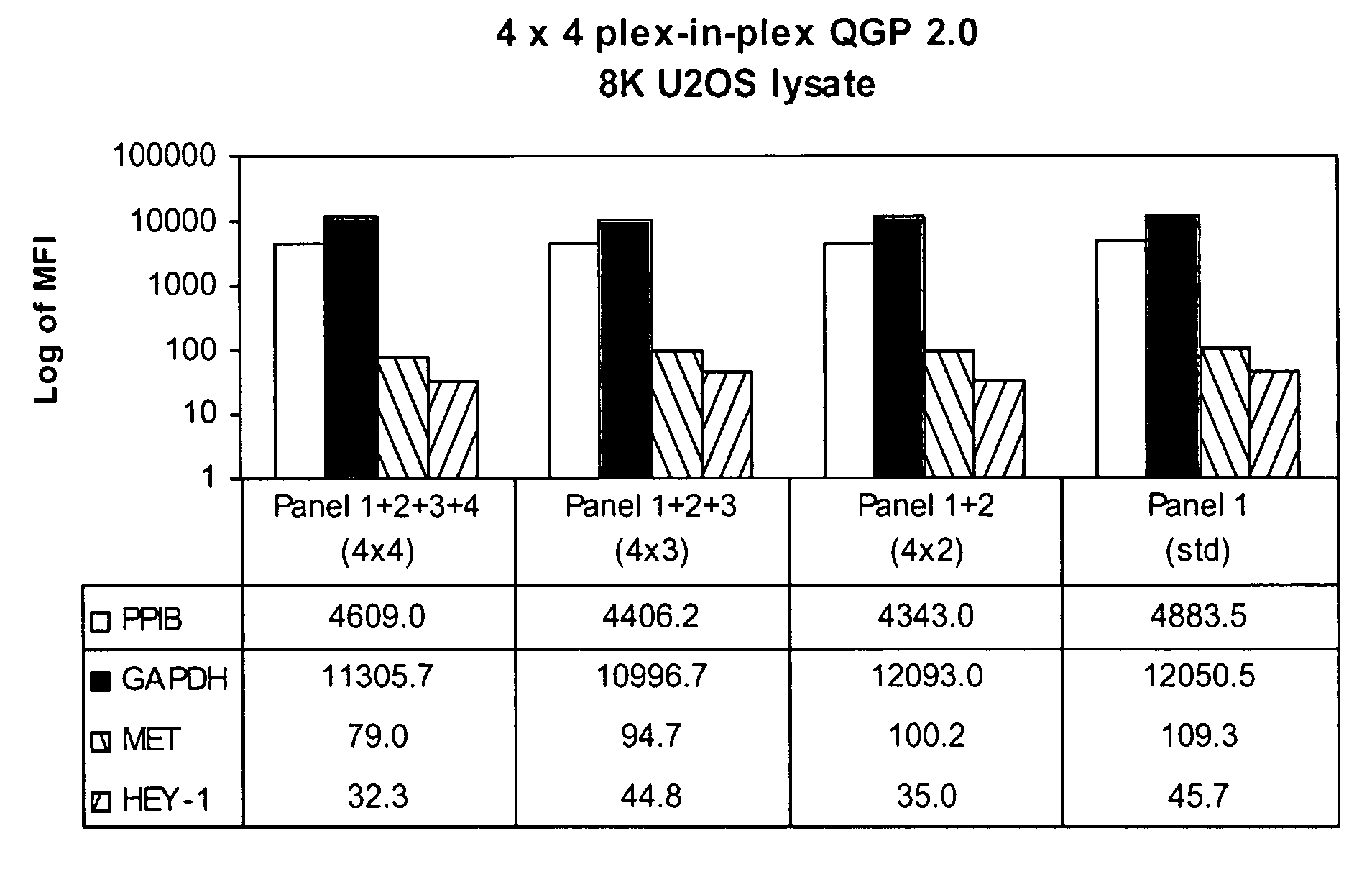

Highly multiplexed particle-based assays

ActiveUS20090131269A1Improve reuseBioreactor/fermenter combinationsBiological substance pretreatmentsMultiplexingAnalyte

Methods are provided for detecting and optionally quantitating multiple analytes, including nucleic acid and / or polypeptide analytes, in particle-based assays that can be highly multiplexed. Compositions, systems, and kits related to the methods are also featured.

Owner:AFFYMETRIX INC

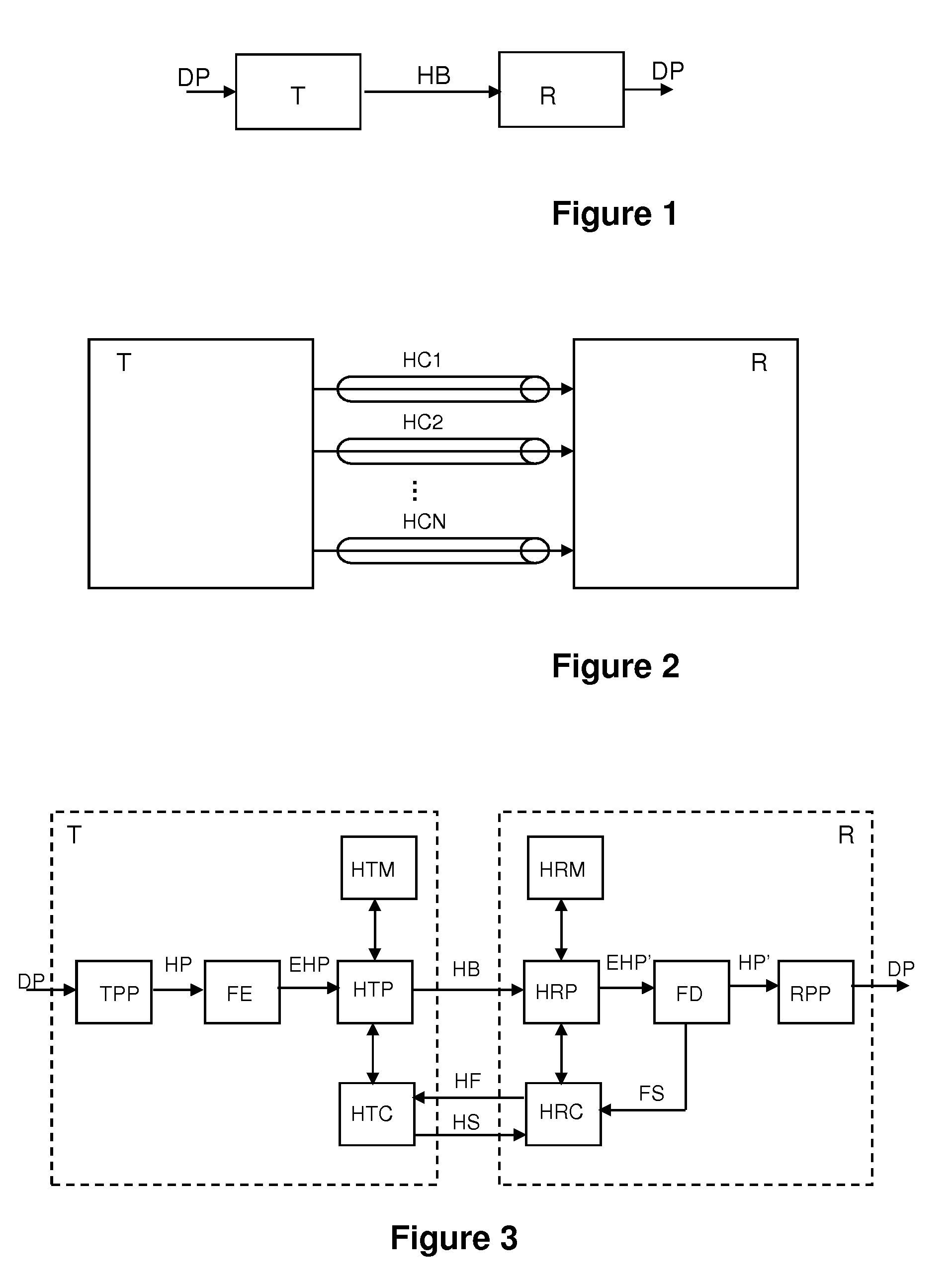

Method and system for memory management in a HARQ communications system

ActiveUS20090228755A1Optimize amount of memoryImproving memory reuseError prevention/detection by using return channelCode conversionTransmitterMemory management

A method is provided for memory management in a communications system using a HARQ error control mechanism, in which a transmitter establishes a plurality of HARQ channels with a receiver. The method includes determining whether each received encoded HARQ packet needs to be combined with an encoded HARQ packet already stored in HARQ memory. In case a received encoded HARQ packet does not need to be combined, the method determines whether there is a free memory space available in the HARQ memory for storing that received encoded HARQ packet, and if so, allocating that free memory space for storage of that received encoded HARQ packet. If not, the method determines whether a certain amount of memory space can be forced to be freed, and if so, de-allocates it and then allocates it for storage of that received encoded HARQ packet, that packet is sent to an FEC decoder.

Owner:SEQUANS COMMUNICATIONS

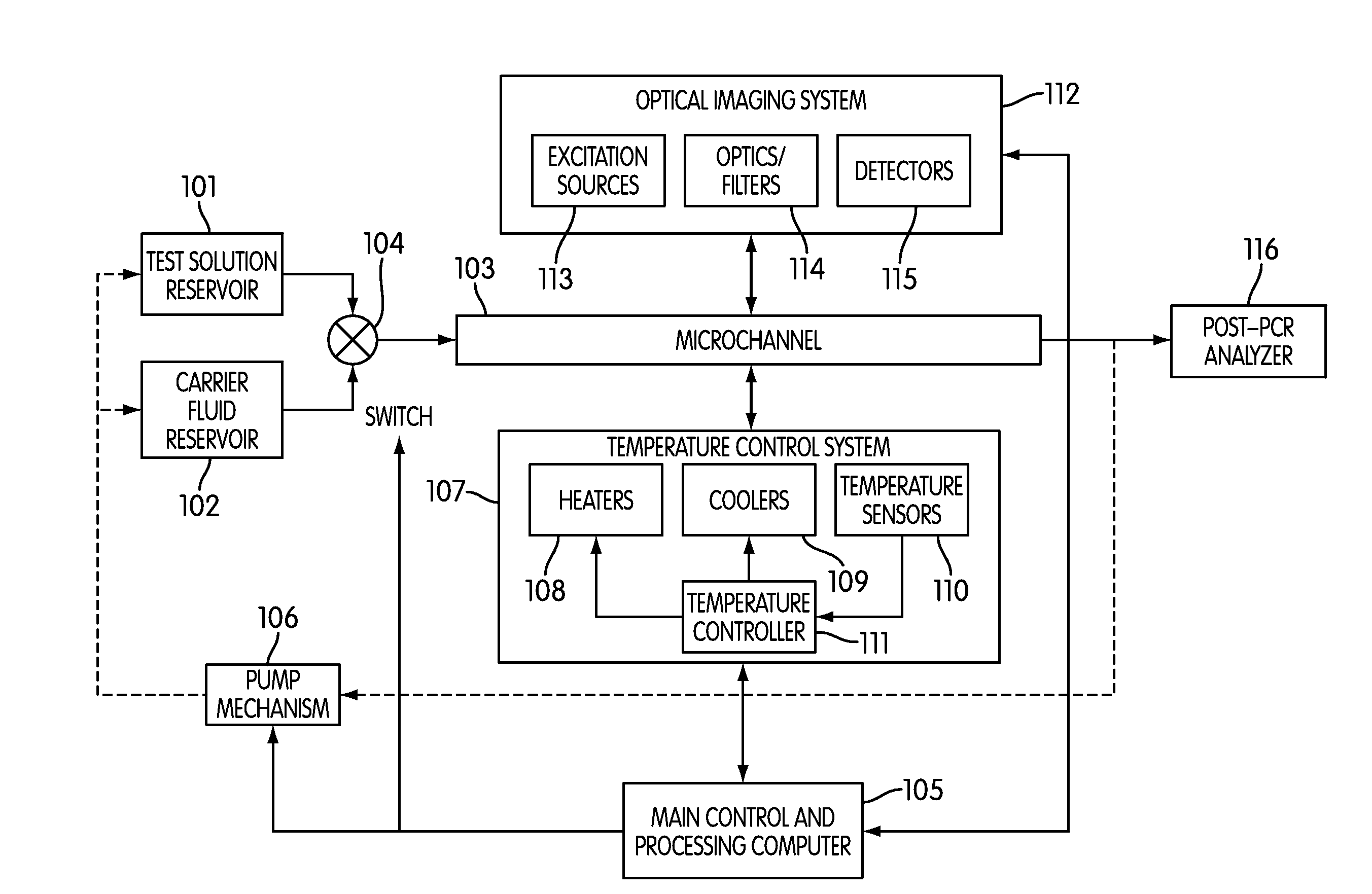

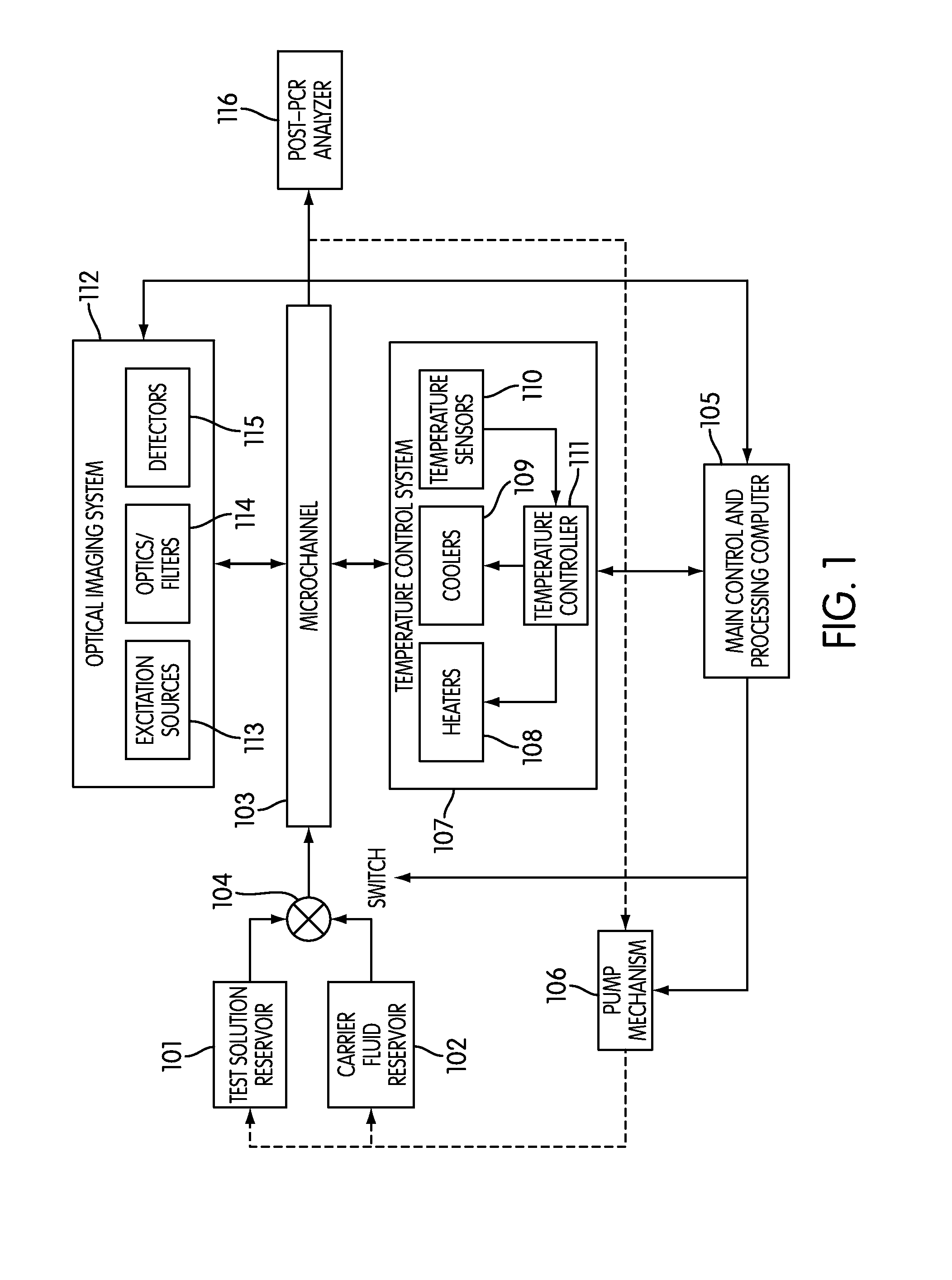

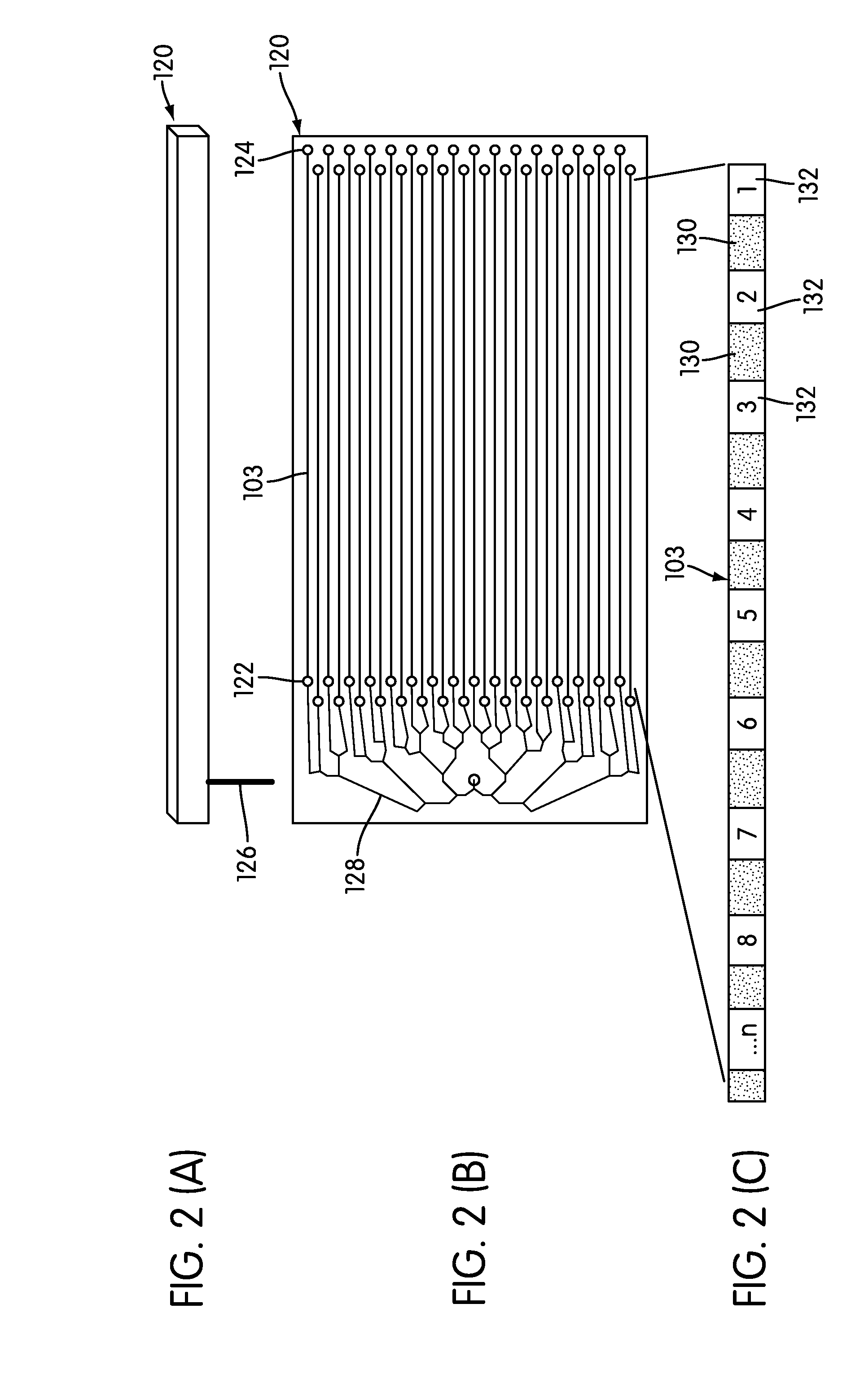

Device and method for digital multiplex PCR assays

ActiveUS20090143233A1Improve reuseIntuitive interpretationHeating or cooling apparatusMicrobiological testing/measurementFluorescenceTest bolus

A method and device for digital multiplex PCR assays employ a microfluidic chip for performing real-time, continuous flow PCR within microchannels of the chip. A stream of sample material is introduced into each microchannel and alternating boluses of assay-specific reagents and buffer are introduced into the stream to form sequentially configured test boluses. A PCR procedure is performed on the test boluses followed by a thermal melt procedure. During the thermal melt procedure, fluorescent output is detected and fluorescence vs temperature data is collected and compared to expected normal correlations. The results, positive or negative, are converted to digital format, with positive results designated as “1” and negative results designated as “0”, or vice versa.

Owner:CANON US LIFE SCIENCES INC

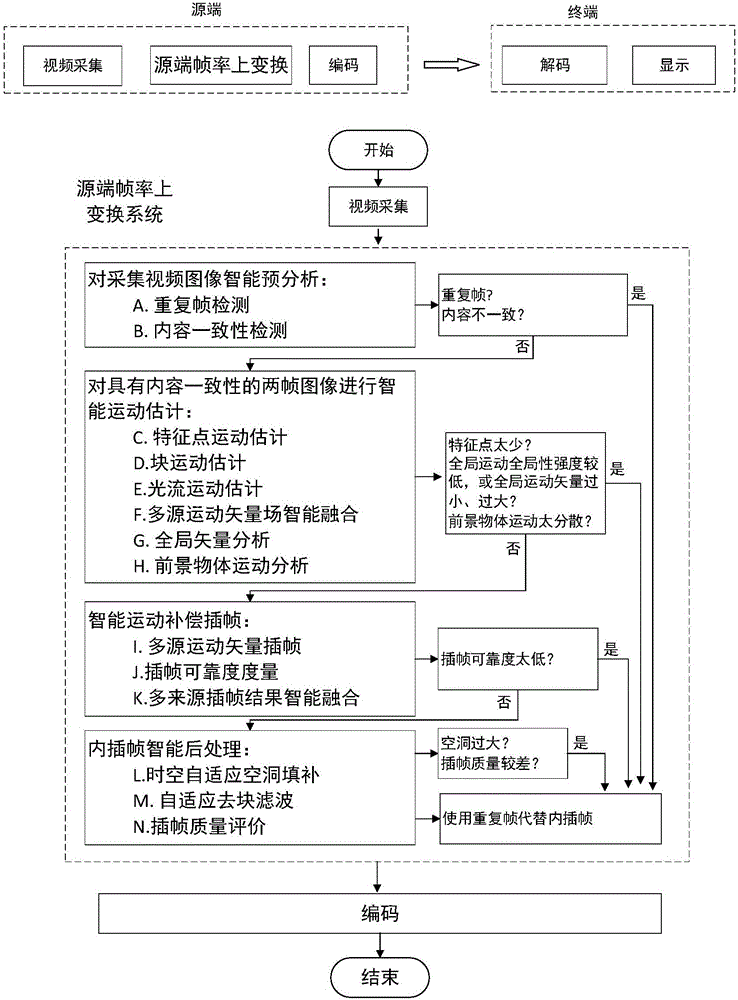

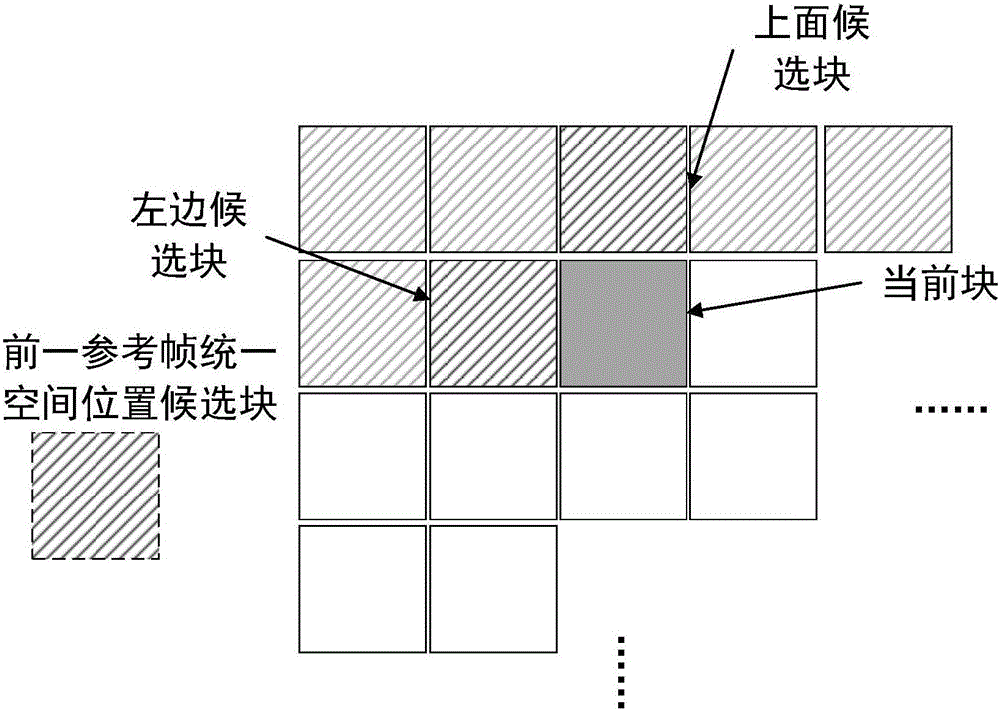

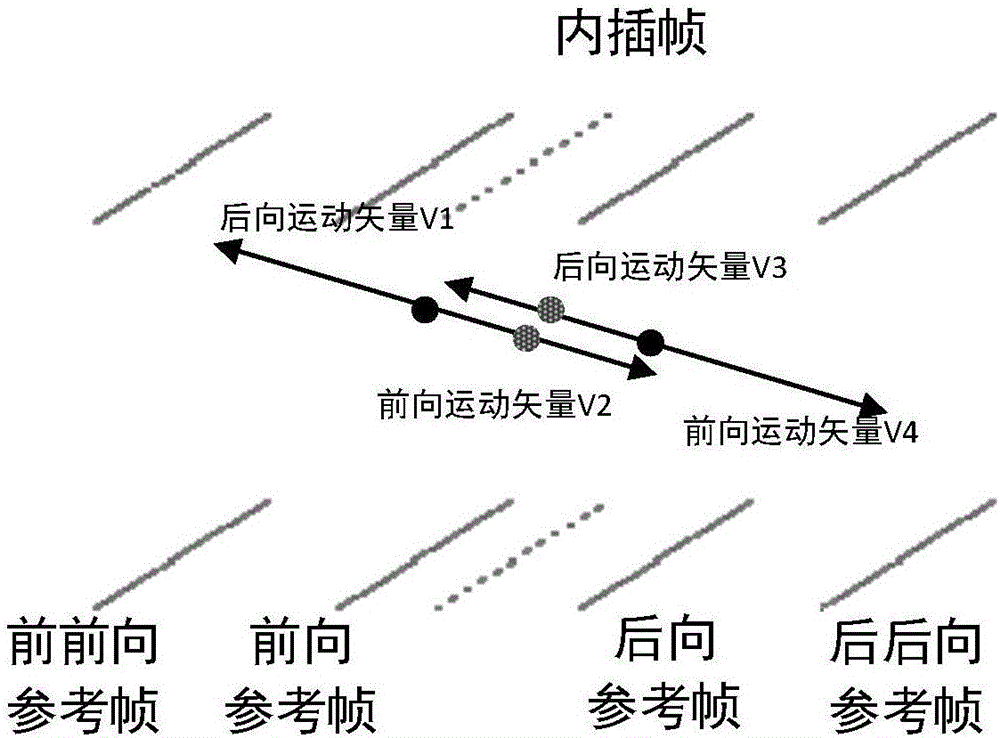

Video frame rate up-conversion method and system for improving motion fluency intelligently

ActiveCN106210767AImprove fluidity of movementImprove viewing experienceSelective content distributionImaging qualityBlock effect

The present invention discloses a video frame rate up-conversion method and system for improving motion fluency intelligently. The method comprises a first step of pre-analyzing two frames of continuous original video image; a second step of performing motion estimation on the two frames of image; a third step of calculating a new interpolated frame between the two frames of original image according to estimated motion information; a fourth step of performing post processing like hole filling, block-effect filling, image quality evaluation on the interpolated frame image; and a fifth step of according to information of the four previous steps, determining whether to replace the interpolated frame with a repeated frame. On the basis of the method, the present invention provides a video frame rate up-conversion system for improving motion fluency intelligently. Due to the frame rate up-conversion, stream of each processing module is controlled, so that high reuse and high parallelism of the information of all modules are realized. Through adoption of the method and system, high quality video frame rate improvement is realized at a source end, and the video motion fluency is improved intelligently.

Owner:SHANGHAI JIAO TONG UNIV

Time division protocol for an ad-hoc, peer-to-peer radio network having coordinating channel access to shared parallel data channels with separate reservation channel

InactiveUS7133391B2Improve throughput and reliabilitySignificant to usePower managementEnergy efficient ICTFrequency spectrumModem device

A novel protocol for an ad-hoc, peer-to-peer radio network that provides collision-free channel access with an emphasis on improving geographic reuse of the frequency spectrum. The protocol of the invention is executed on the reservation or control channel, and provides a method for allocating data transactions on the data channels. The system of the invention utilizes multiple parallel data channels that are coordinated by a single reservation channel. The transceiver of the system employs two modems to solve the channel reliability issues with multiple channel designs, where one is dedicated as a receive-only modem for gathering channel usage information on the reservation channel. High quality voice, video and data may be transmitted. The reservation channel implements a time division multiple access algorithm with dynamic slot allocation. In a distributed manner, nodes determine geographic reuse of slots based on channel quality extracted from the modem. Signal quality calculations are used to determine the likelihood of a slot reuse causing destructive interference within a node's neighborhood. Requests for slot usage are compared with the known traffic pattern and accepted or rejected by nodes within RF signal range based on the signal quality calculations.

Owner:ARRIS ENTERPRISES LLC

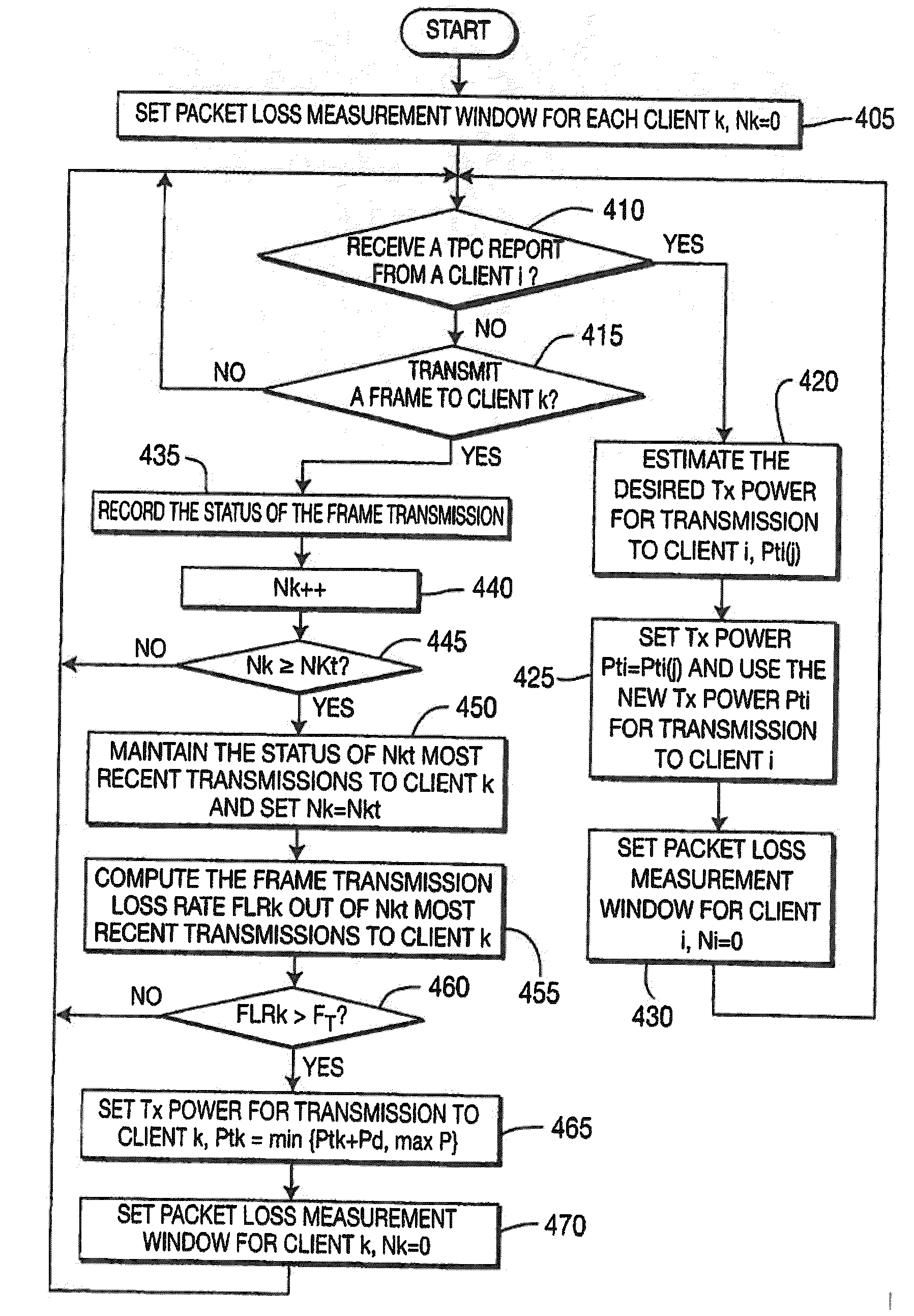

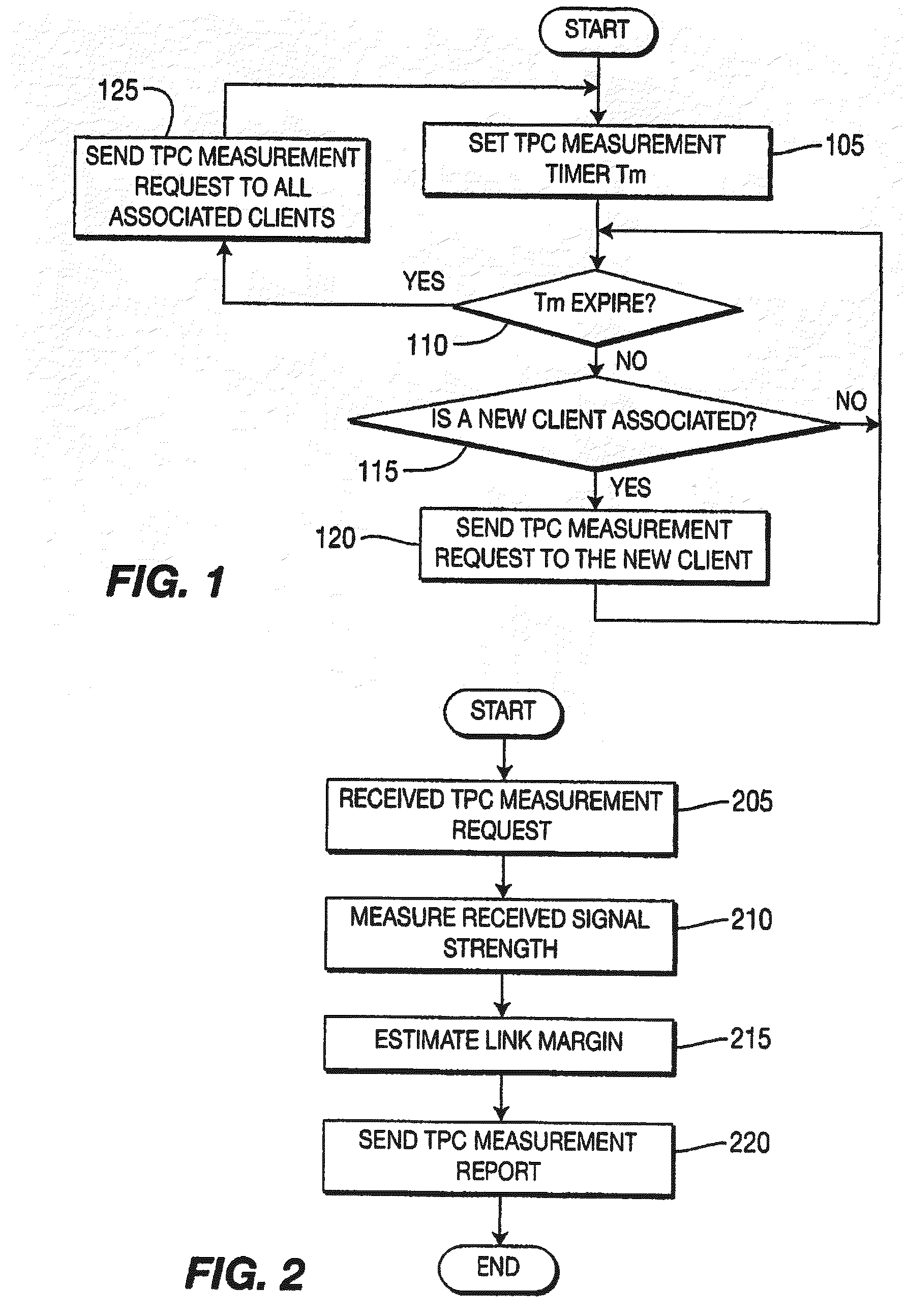

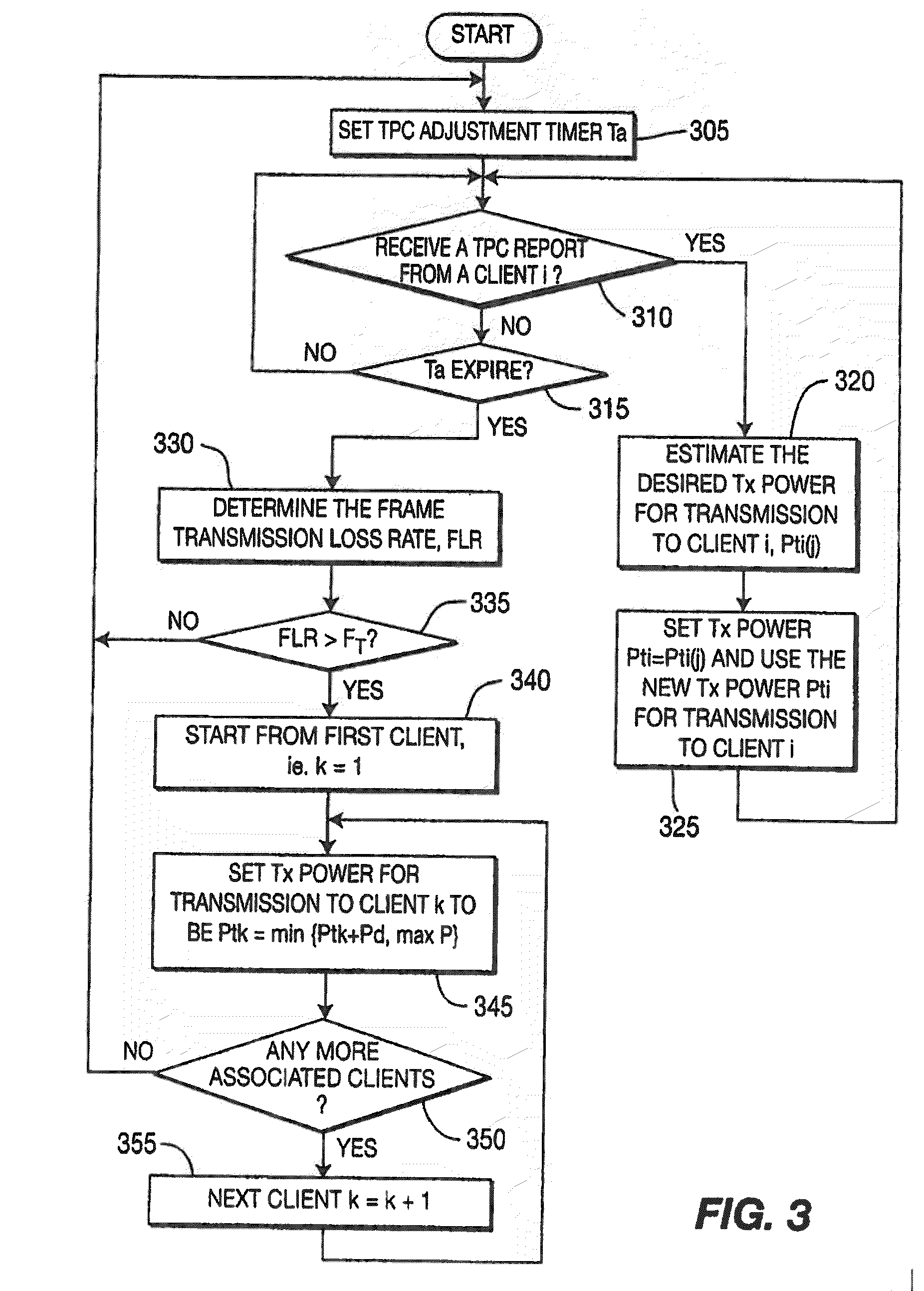

Method and apparatus for transmit power control in wireless networks

ActiveUS20110167291A1Improve communicationIncrease channel reusePower managementVolume/mass flow measurementData transmissionVIT signals

A method and apparatus are described including receiving, by a transmitter, a report from an associated client, setting and using a downlink transmit power level responsive to the report for data transmissions to the associated client, determining a downlink data loss rate and adjusting the downlink transmit power level responsive to the downlink data loss rate, wherein said report includes received signal strength, client transmit power level and one of link margin and receiver sensitivity. Also described are a method and apparatus including receiving, by a receiver, a request for a report, transmitting the requested report, receiving an instruction to use an uplink transmit power level, setting and using the uplink transmit power level, determining an uplink data loss rate and adjusting the uplink transmit power level responsive to the uplink data loss rate, wherein said report includes said received signal strength, client transmit power level and one of said link margin and said receiver sensitivity.

Owner:INTERDIGITAL CE PATENT HLDG

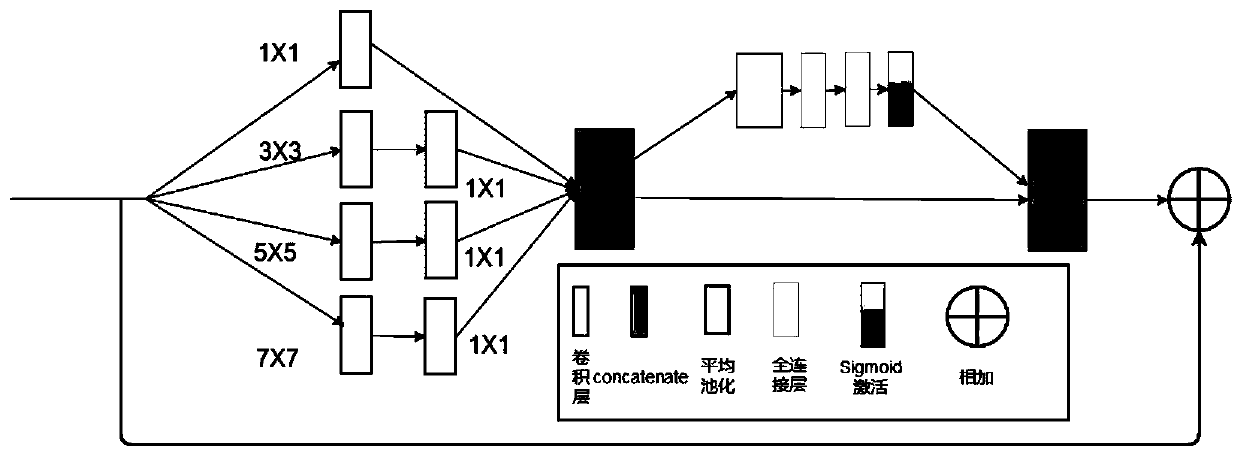

Image super-resolution method based on multi-scale attention convolutional neural network

ActiveCN110415170AEfficient extraction and utilization of featuresAvoid the interference of redundant informationImage enhancementImage analysisInstabilityReusability

The invention discloses an image super-resolution method based on a multi-scale attention convolutional neural network. By using a multi-scale structure and an attention mechanism, the convolutional neural network can extract rich information in an image, and importance distinguishing can be performed on extracted features, so that important information and interference information can be distinguished in learning of the convolutional neural network, and the learning efficiency is improved. A dense connection mode and a residual connection mode are used, so that the back propagation of the gradient is enhanced, the problem of instability of the gradient is avoided, the reusability of the features is enhanced, the features in the low-resolution image are fully utilized, the training speed of the model is increased, and the parameters of the model are further reduced. Besides, a sub-pixel convolution layer method is used in an image amplification stage, learned pixel values are filled into a high-resolution image according to a certain rule without calculation, so that the operation is concentrated in a small-scale stage, the operation amount is reduced, and the image reconstructionspeed is improved.

Owner:WUHAN UNIV

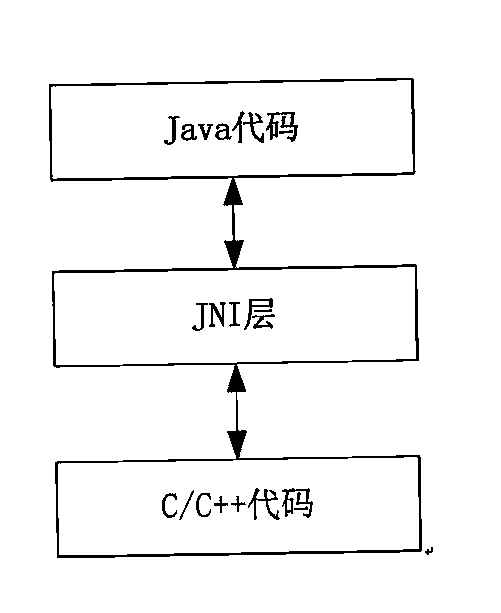

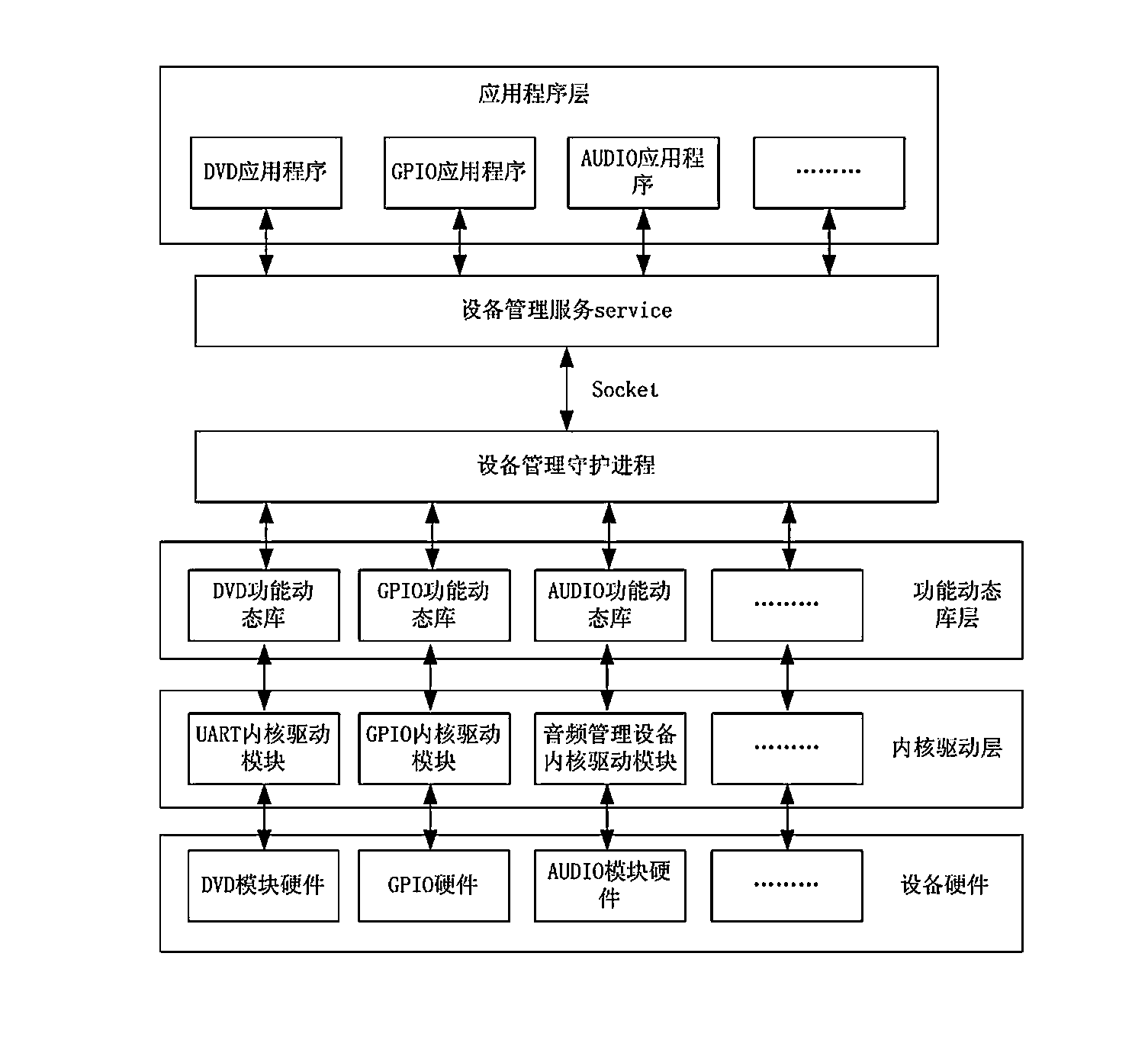

Device management framework based on android platform

InactiveCN103488478AEasy to controlEasy to manageSpecific program execution arrangementsApplication procedureFunctional interface

The invention discloses a device management framework based on an android platform. The device management framework comprises an application program layer, a management service module, a management daemon process module, a function dynamic depot layer and an inner core drive layer, wherein the application program layer is used for realizing calling an interface of the device management framework; the management service module is used for converting the function interface into a command call, and transmitting a command by using a Local Socket client end of a Socket in an Android; the management daemon process module receives the command by using a Local Socket service end of the Socket in the Android, analyzes the command, and calls the function dynamic depot layer according to the analysis result; the function dynamic depot layer is used for packaging an interface which is interactive with the inner core drive layer; the inner core drive layer is used for providing a standard operation interface of a Linux operating system to be called by the function dynamic depot layer, and operating each hardware device.

Owner:XIAMEN YAXON NETWORKS CO LTD

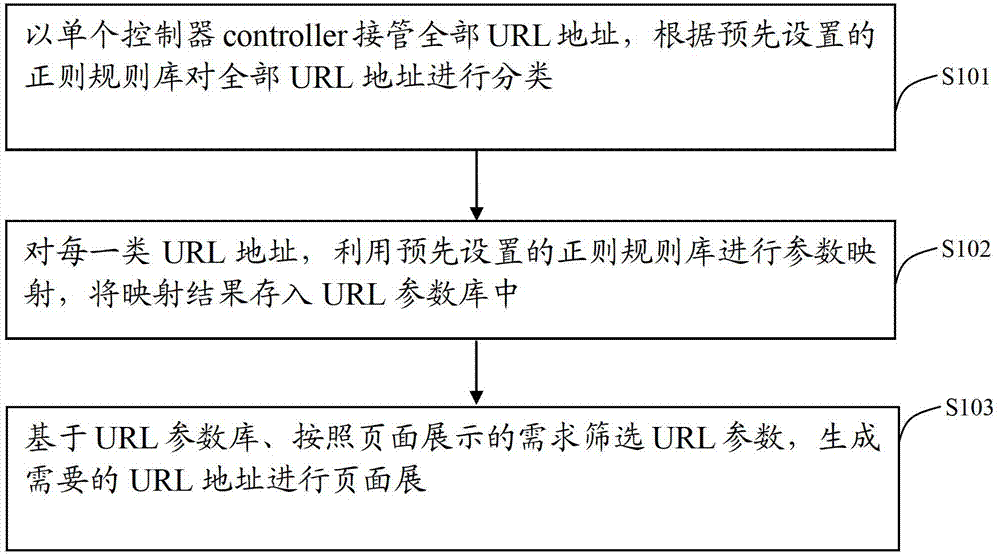

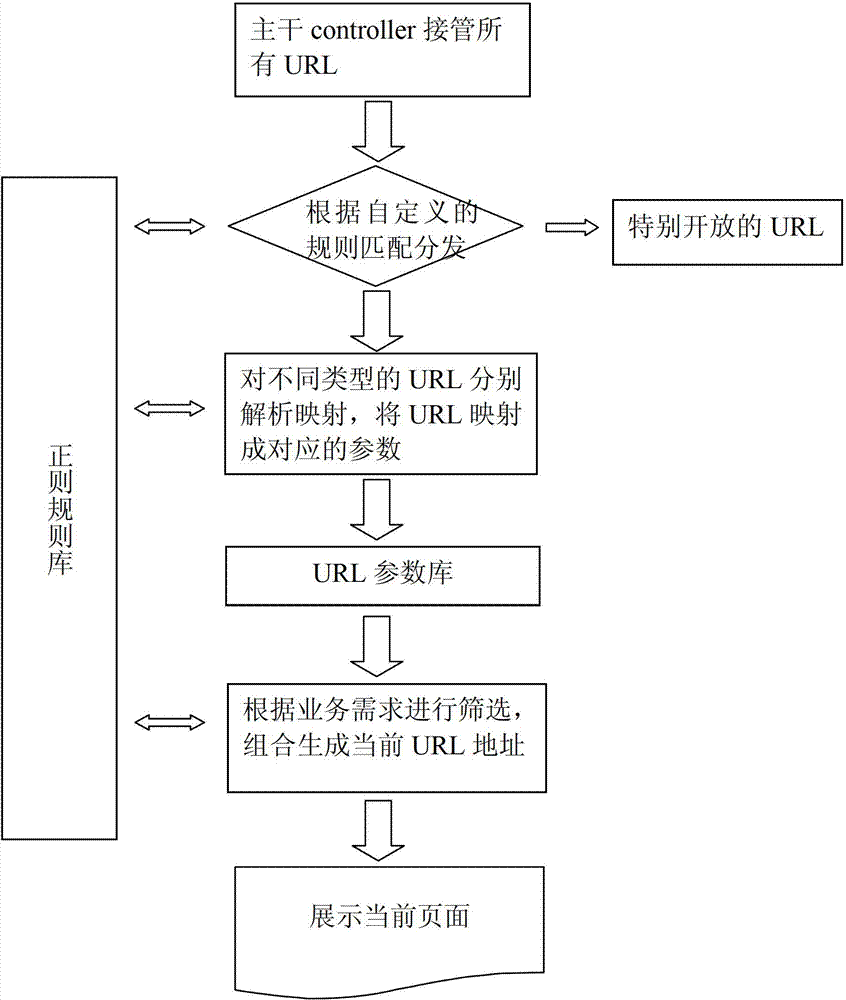

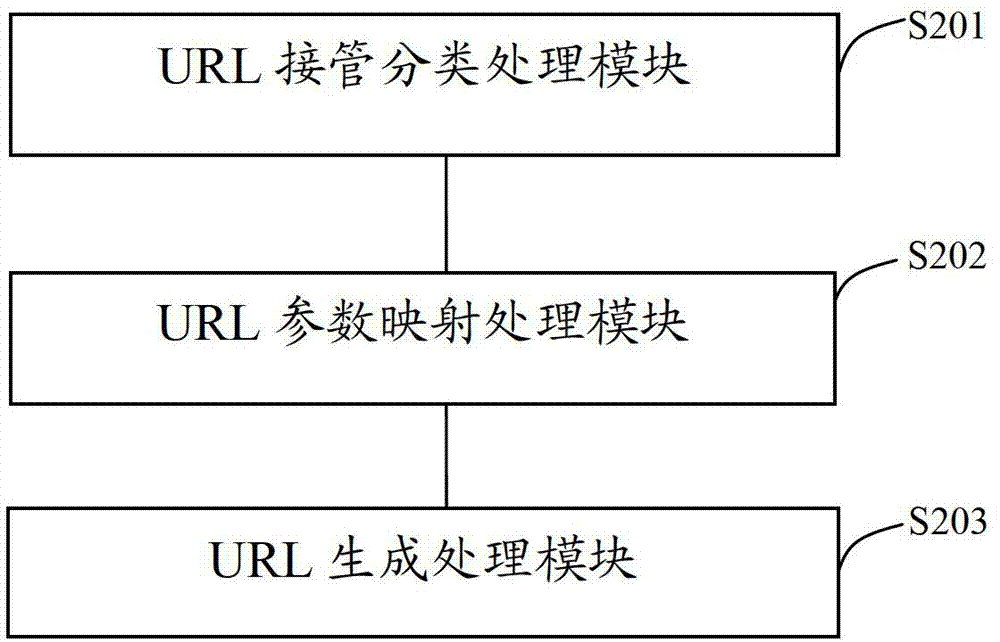

Dynamic matching method and dynamic matching device of uniform resource locator (URL)

ActiveCN102902780ASimplify complexityImprove good performanceSpecial data processing applicationsUniform resource locatorMatching methods

The invention discloses a dynamic matching method and a dynamic matching device of a uniform resource locator (URL). The method includes utilizing a single controller to take over all URL addresses, classifying all URL addressed according to a preset regular rube base, utilizing the regular rule base to conduct parameter mapping on the URL addresses in each class, storing the mapping result into a URL parameter base and screening the URL parameter according to page display requirements based on the URL parameter base to generate required URL addresses to conduct page display. The method and the device reduce the number of the controller in the system, simplify code complexity, conduct screening and combination on conditions that the parameter corresponds to according to business requirements when a new URL is generated, retain required condition, remove needless conditions, conduct automatic arrangement and splicing according to regular rule definition sequence in combination, dynamically generate a unique URL address, improve code reuse rate and page display flexibility and reduce maintenance cost.

Owner:WUBA

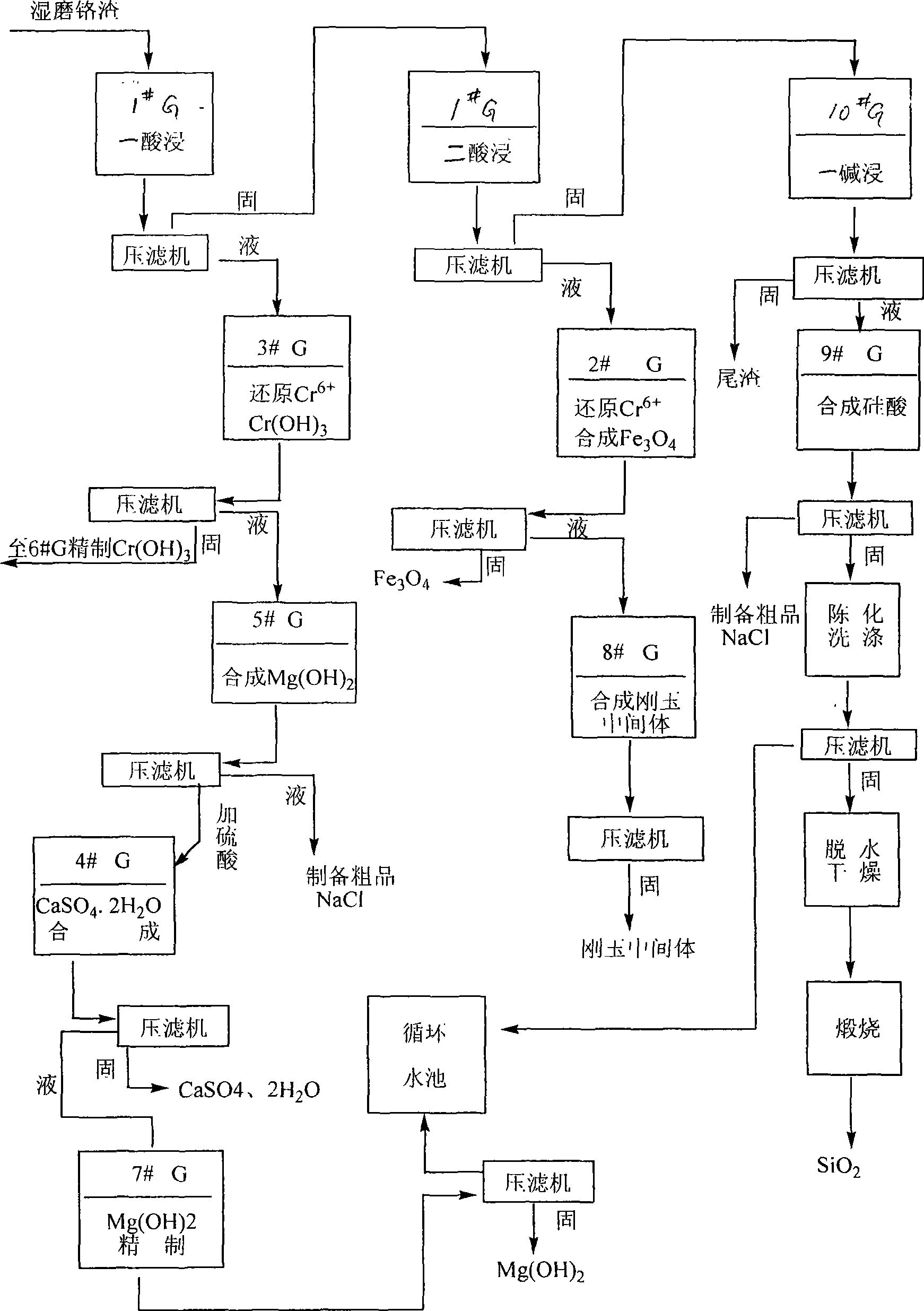

Chromic slag wet method detoxifcation and resource comprehensive utilization new technique

InactiveCN101380510ADetoxify thoroughlyAchieve detoxificationCalcium/strontium/barium sulfatesFerroso-ferric oxidesAmmonium hydroxideHexavalent chromium

A new harmless comprehensive utilization technique for wet processing chromic slag comprises steps as follows: ball milling chromic slag to 80-200 meshes, adding water to prepare slurry, immersing the slurry in hydrochloric acid solution, regulating the pH to 5-6, performing solid-liquid separation with filter press, in the immersion liquid after separation, the hexavalent chrome is reduced to trivalent chromium, adding sodium hudroxide aqueous solution, regulating the pH to 4-6, roughly preparing chromic hydroxide, adding sulfuric acid into filtrate, regulating the pH to 5-6, removing the calcium coprecipitated with magnesium in the rest filtrate, preparing the 2-water calcium sulphate whisker, adding alkali to the filtrate after filter-pressing to regulate the pH to 9-12 to synthesize super-fine magnesium hydroxide powder; the solution after filter-pressing is concentrated to prepare sodium chloride. The main contents of extracts within the chromic slag treated by wet processing all can meet primary, secondary or even accredited national or ministerial standard. The technique can thoroughly detoxicate Cr<6+> in chromic slag and can prepare nine products, includiing chromic hydroxide, magnesium hydroxide, ammonium hydroxide, silicon dioxide, magnetic ferrous ferricoxide, 2-water calcium sulphate, corundum intermediate, sodium chloride, and tailings-chromite; and the extracts after processing chromic slag have high quality.

Owner:杨恩清 +1

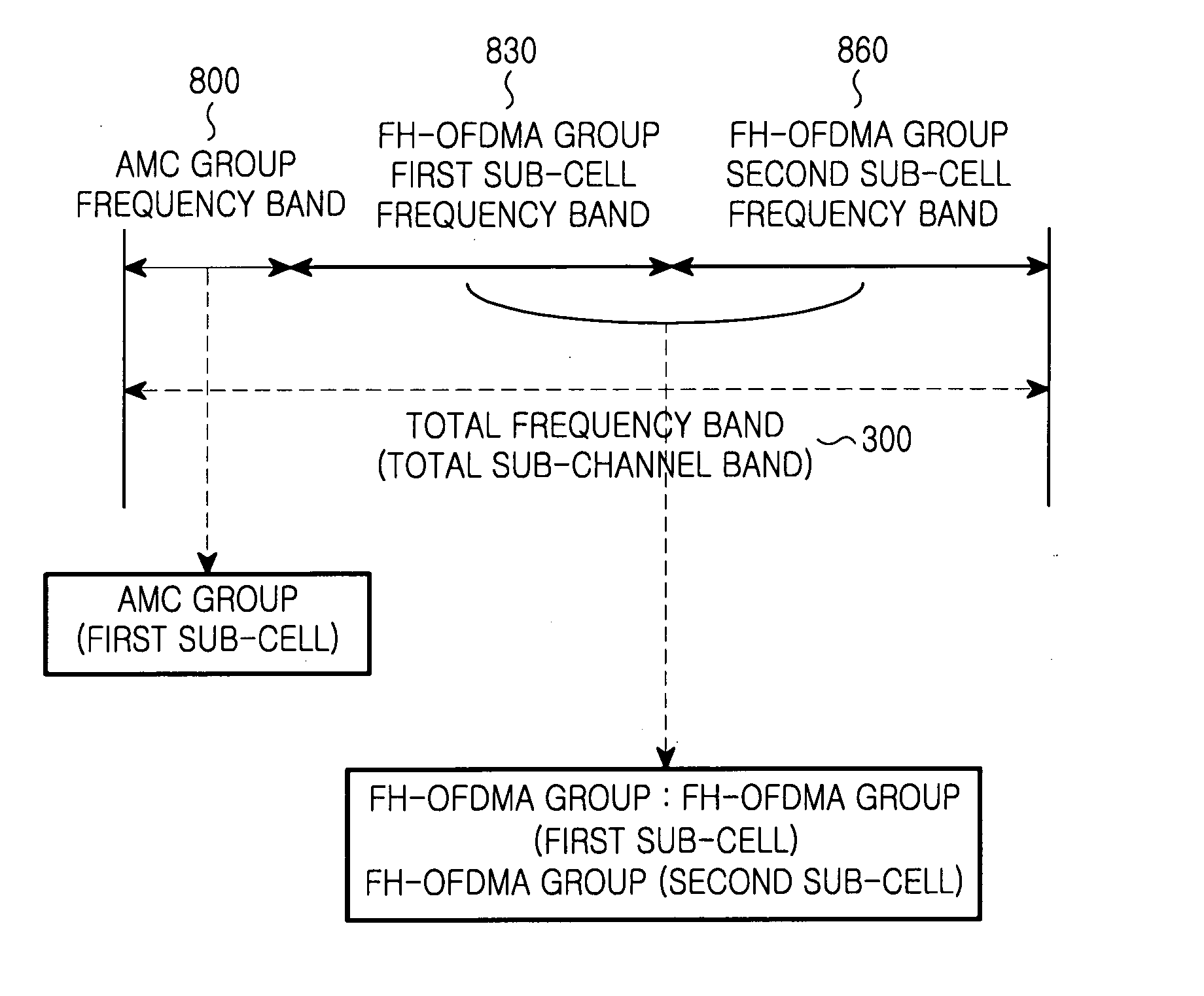

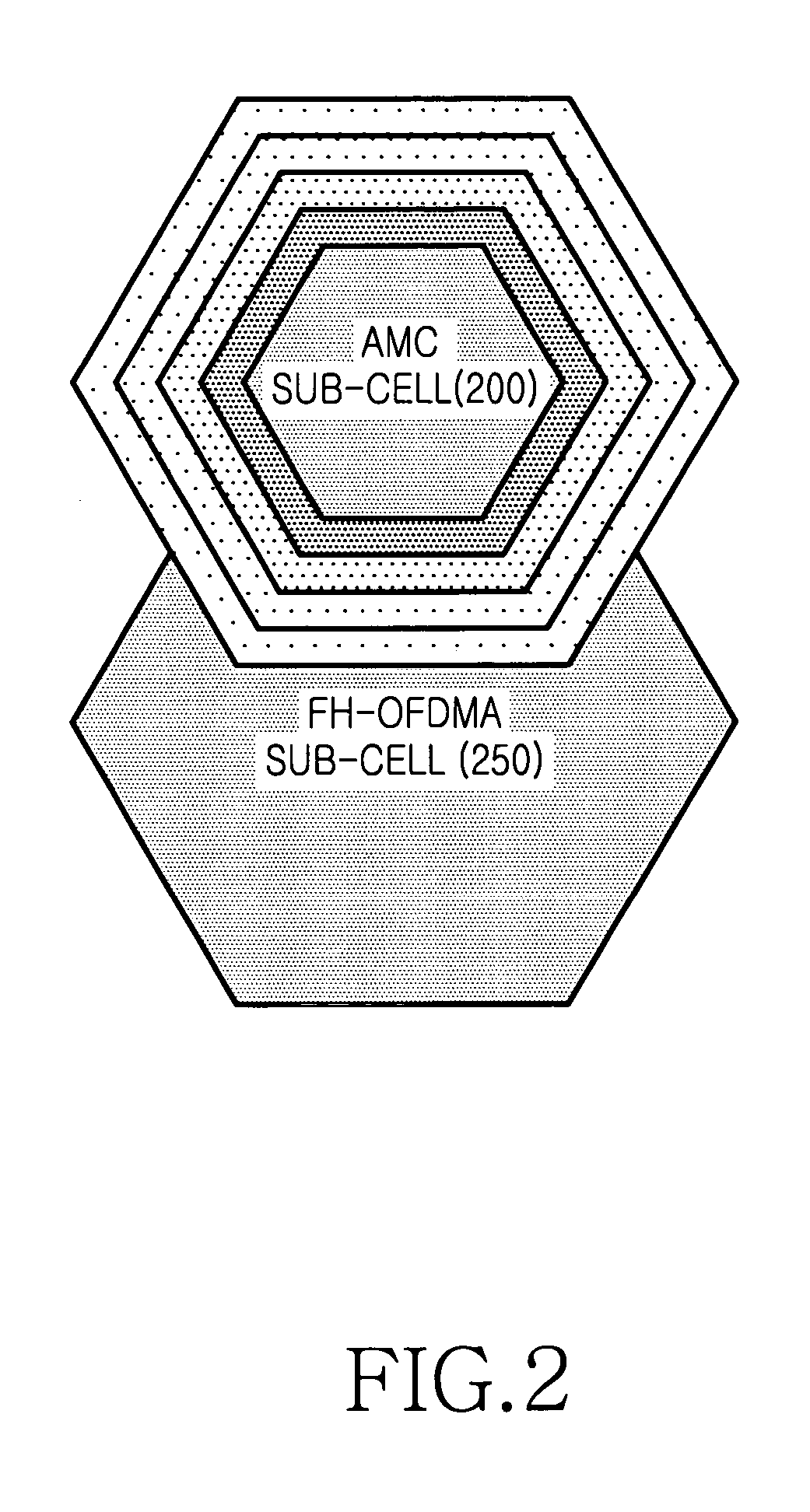

Method for transmitting a signal using a precise adaptive modulation and coding scheme in a frequency hopping-orthogonal frequency division multiple access communication system

InactiveUS20060018365A1Improve data transfer rateImprove reuseChannel coding adaptationMulti-frequency code systemsCommunications systemCarrier signal

A method of transmitting a signal by using an Adaptive Modulation and Coding scheme in a Frequency Hopping-Orthogonal Frequency Division Multiplexing Access communication system capable of dividing total frequency bands into a plurality of sub-carrier bands and including a plurality of sub-channels, which are sets of predetermined sub-carrier bands, and a plurality of cells. The method includes the steps of allocating a predetermined number of sub-channels as AMC sub-channels per each cell matching with predetermined conditions in order to apply the AMC scheme to the AMC sub-channels, and allocating remaining sub-channels except for the AMC sub-channels as FH-OFDMA sub-channels in order to apply an FH-OFDMA scheme to the FH-OFDMA sub-channels.

Owner:SAMSUNG ELECTRONICS CO LTD +1

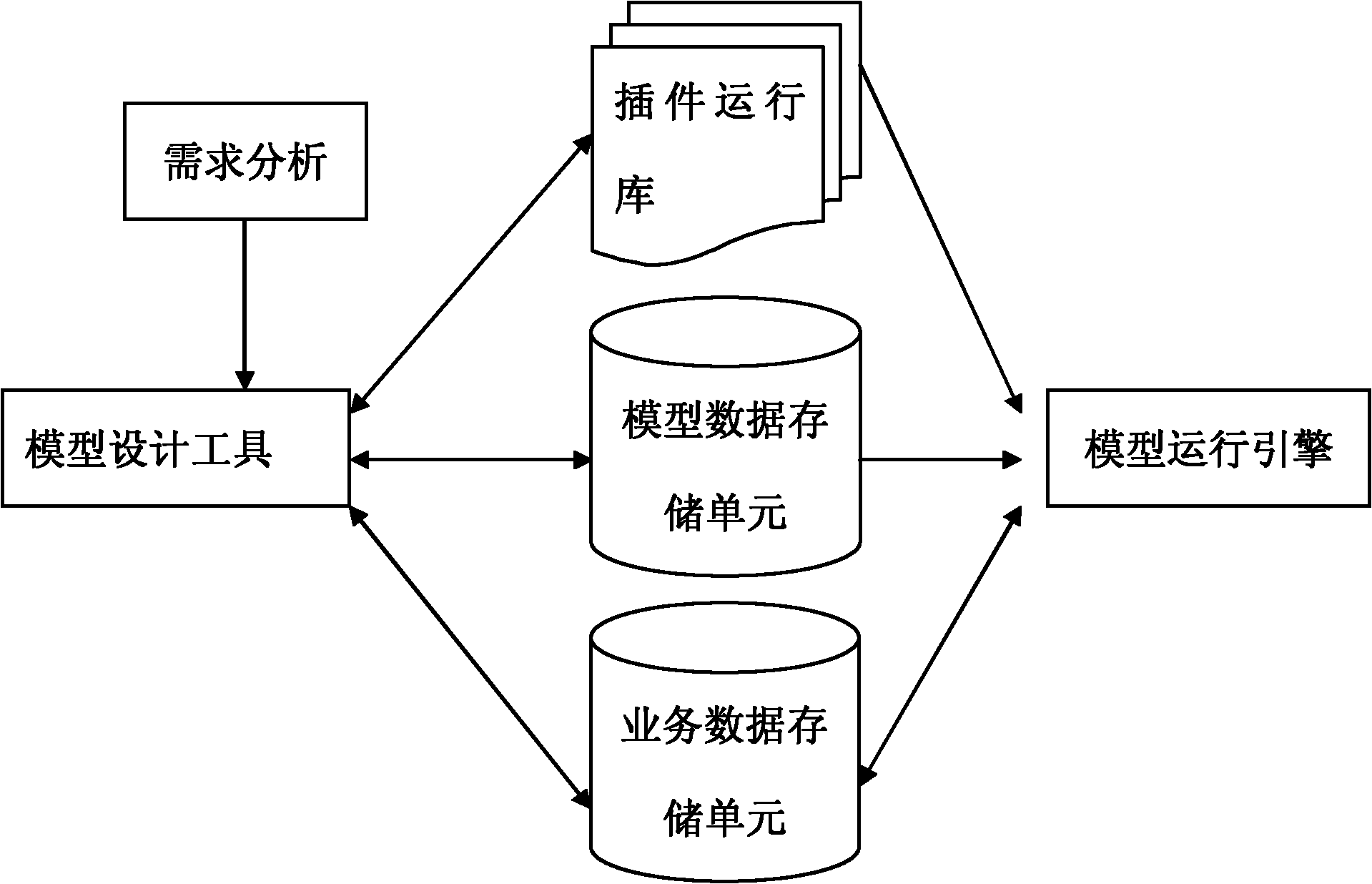

System and method for expanding model driving development capability by applying plug-in

ActiveCN102033743ASolve the problem of insufficient description abilityExpandable and flexibleSpecific program execution arrangementsModel descriptionStationary model

The invention relates to a system and method for expanding the model driving development capability by applying a plug-in. In the system and the method, a'model and plug-in' combined mode is provided to describe and establish a software system, firstly a model designing tool is used for establishing basic model description of the software system and then establishing a plurality of reusable plug-pin model for further describing a basic model object, the plug-in model can be expanded randomly on various basic model objects, and the plug-in can complete a software function with any complexity, therefore, the expansion of the model driving development capability is realized. By utilizing the invention, the technical problems of the existing model driving development method that because a fixed model is adopted, the describing capability of complex service system is poor, and the software system with the model driving development can not be established, expanded and maintained visually and dynamically under the operating state and the like are solved. The system developed by using the method has the advantages that the development complexity degree is low, the development speed is fast, the reusable degree of technology is high, the expansion is flexible, the maintenance is convenient and the reliability is high.

Owner:广州翼风信息科技股份有限公司

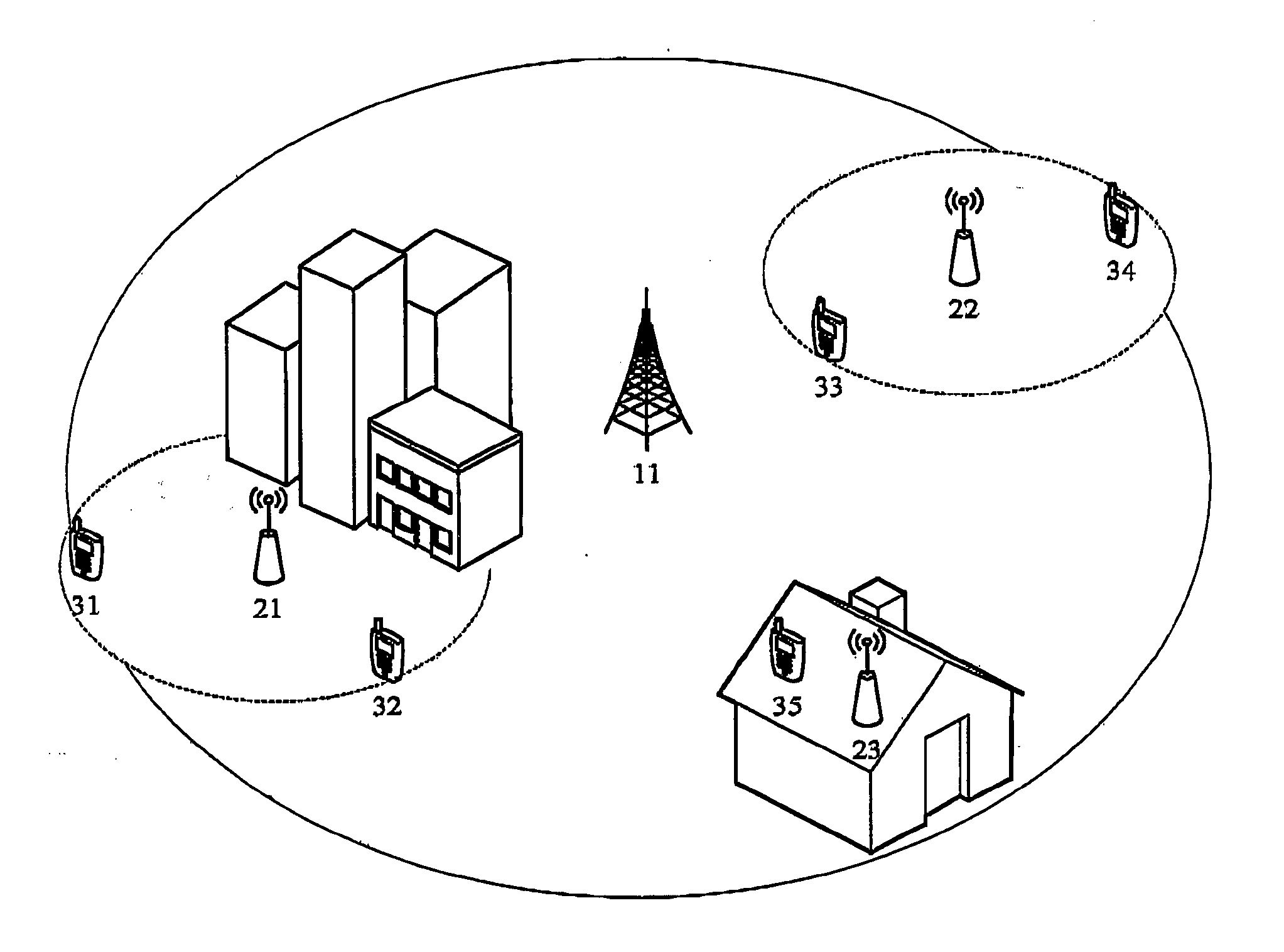

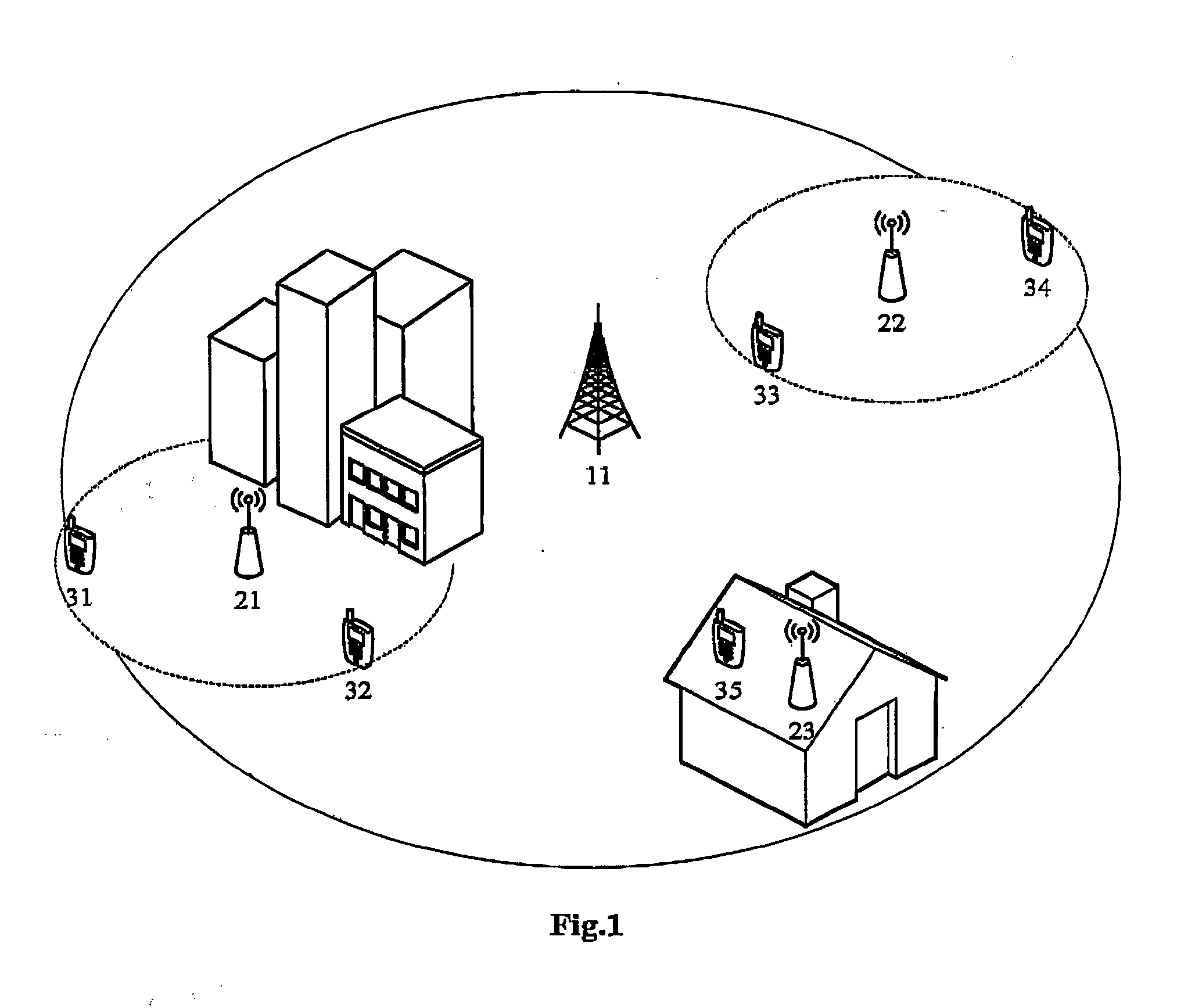

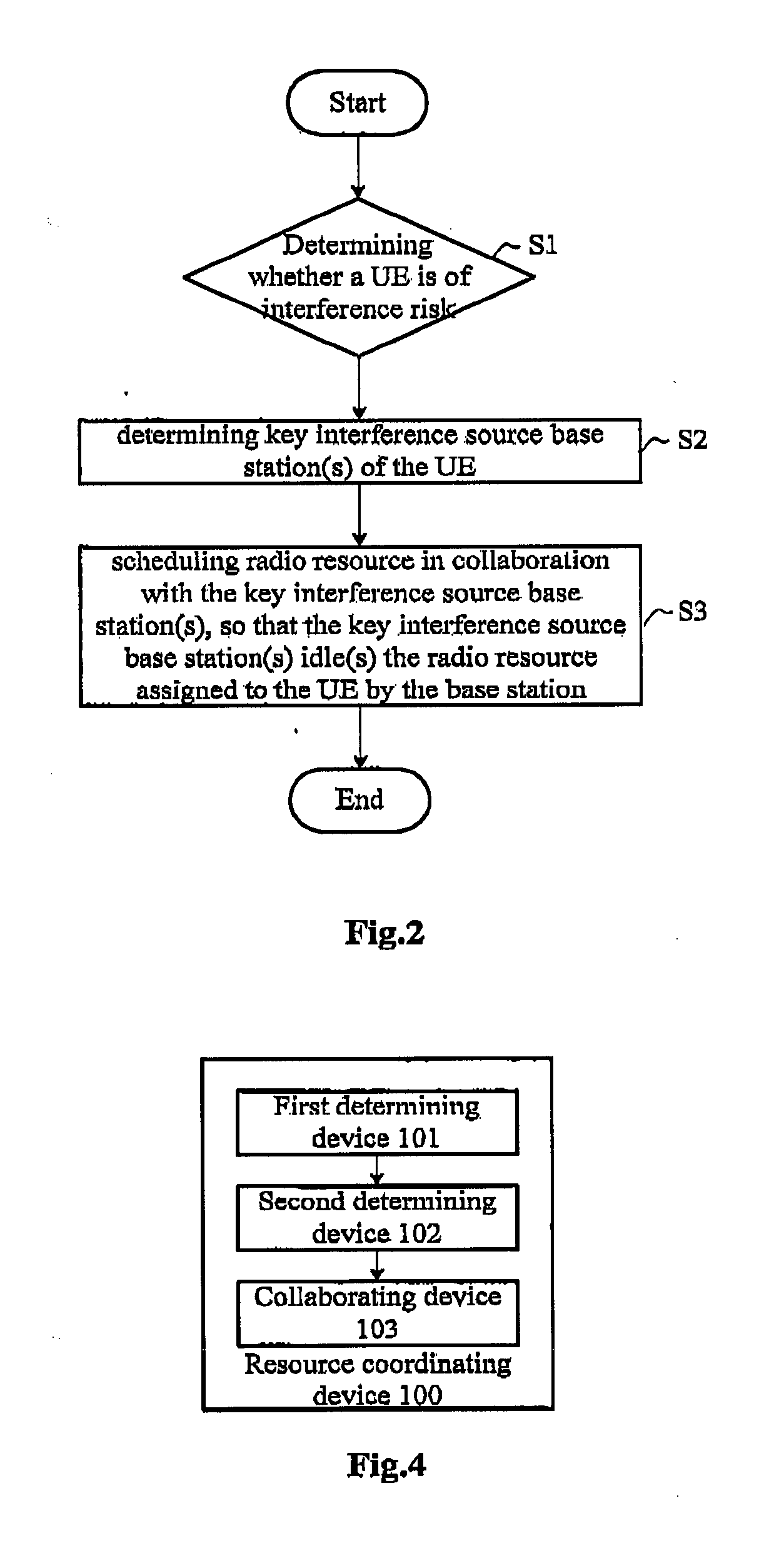

Method and device for inter-cell interference coordination

InactiveUS20130084907A1Effective avoidance of inter-cell interferenceCollision of control signals between Macro and small cells is avoidedRadio transmissionTransmission noise suppressionRadio resourceBackward compatibility

To address the problem of inter-cell interference, the present invention proposes a method for inter-cell interference coordination and a device thereof. In one embodiment of the present invention, there is provided a method of coordinating radio resource in a base station of wireless communication network, comprising the steps of: S1 determining whether a UE is of interference risk; if the UE is of interference risk, then S2 determining key interference source base station(s) of the UE; S3, scheduling radio resource in collaboration with the key interference source base station(s), so that the key interference source base station(s) idle(s) the radio resource assigned to the UE by the base station. With the method and device provided in the present invention, effective avoidance of inter-cell interference may be achieved, and every cell may fully reuse resource to accomplish reuse gain, while UE backward compatibility may also be supported.

Owner:ALCATEL LUCENT SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com