Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

493results about How to "Improve anti-carbon performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of SSZ-13 loaded Cu-Fe catalyst for selectively catalyzing and eliminating NOx by ammonia

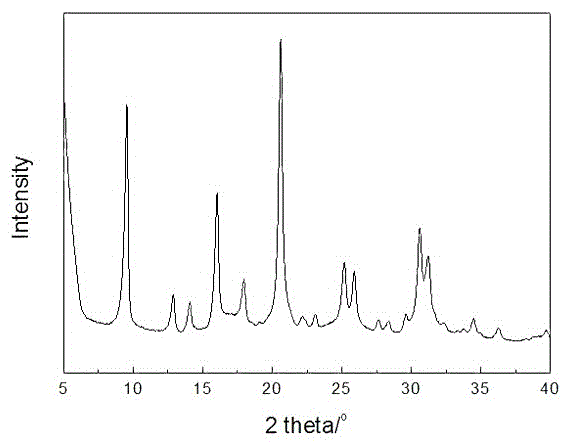

InactiveCN102614908AImprove anti-carbon performanceStable activityMolecular sieve catalystsDispersed particle separationIonIon exchange

The invention provides a preparation method of a SSZ-13 loaded Cu-Fe catalyst for selectively catalyzing and eliminating NOx by ammonia. The catalyst is used for catalyzing and eliminating nitrogen oxides. A micropore SSZ-13 molecular sieve carrier with high specific surface area (400-550 m2 / g) is prepared by using a soft template method. And then by using a mixed solution of ferric chloride and copper chloride as well as a SSZ-13 molecular sieve ion exchanging method, the SSZ-13 molecular sieve loaded Cu-Fe composite catalyst is prepared. According to the invention, within a wide temperature range (150-550 DEG C), high catalytic eliminating effect and higher stability are obtained for a pollutant with high airspeed (120, 000 mL. (g.h)-1 - 1-360,000 mL.(g.h)-1), high O2 concentration (10vl.%-20v1.%), high H2O content (5wt%-10wt%) and low concentration NO (300-1000 ppm). After a hydrocarbon compound (300-1000 ppm propylene) is added to a reaction system, the catalyst prepared by the preparation method provided by the invention has the advantages of high carbon deposition resistance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

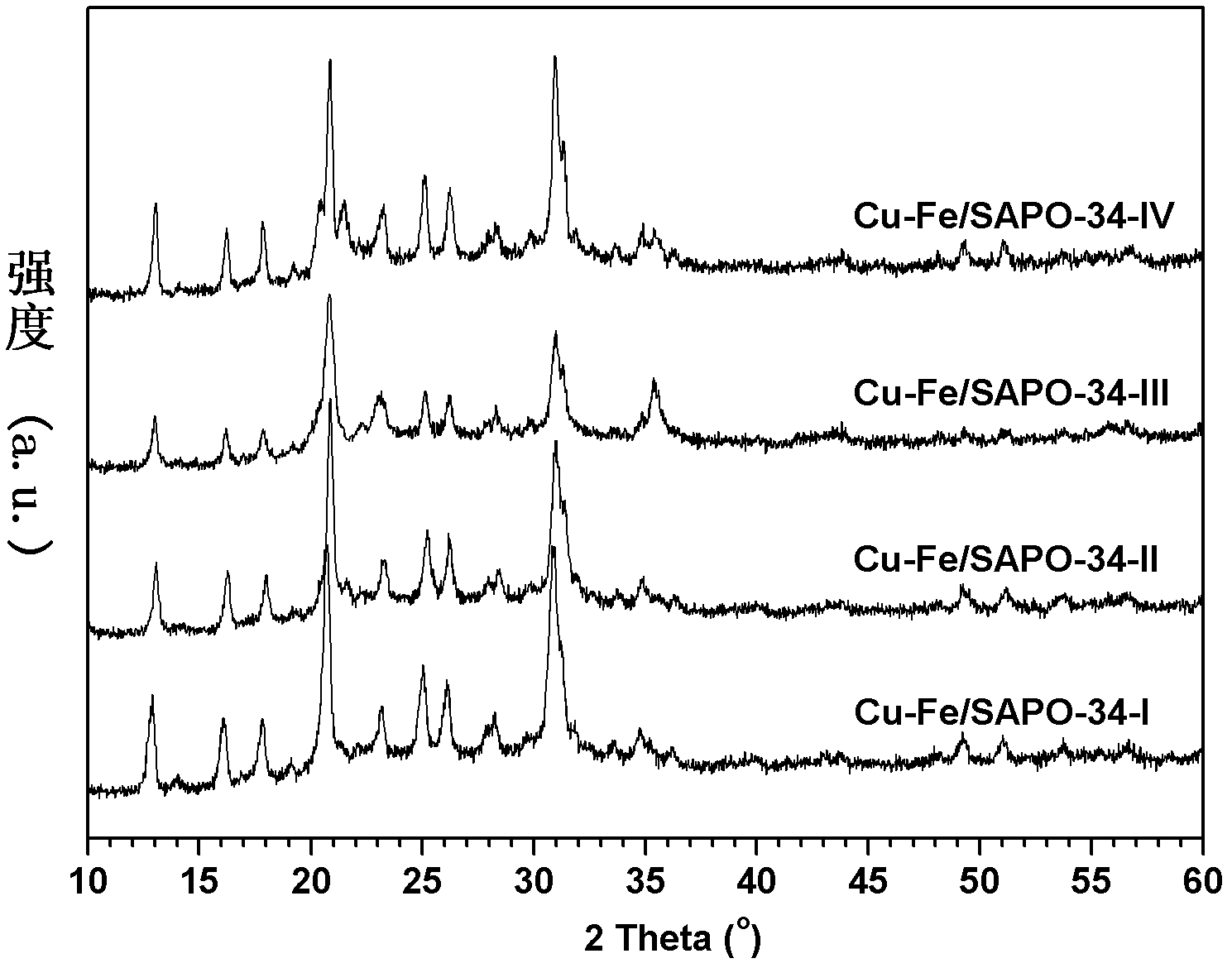

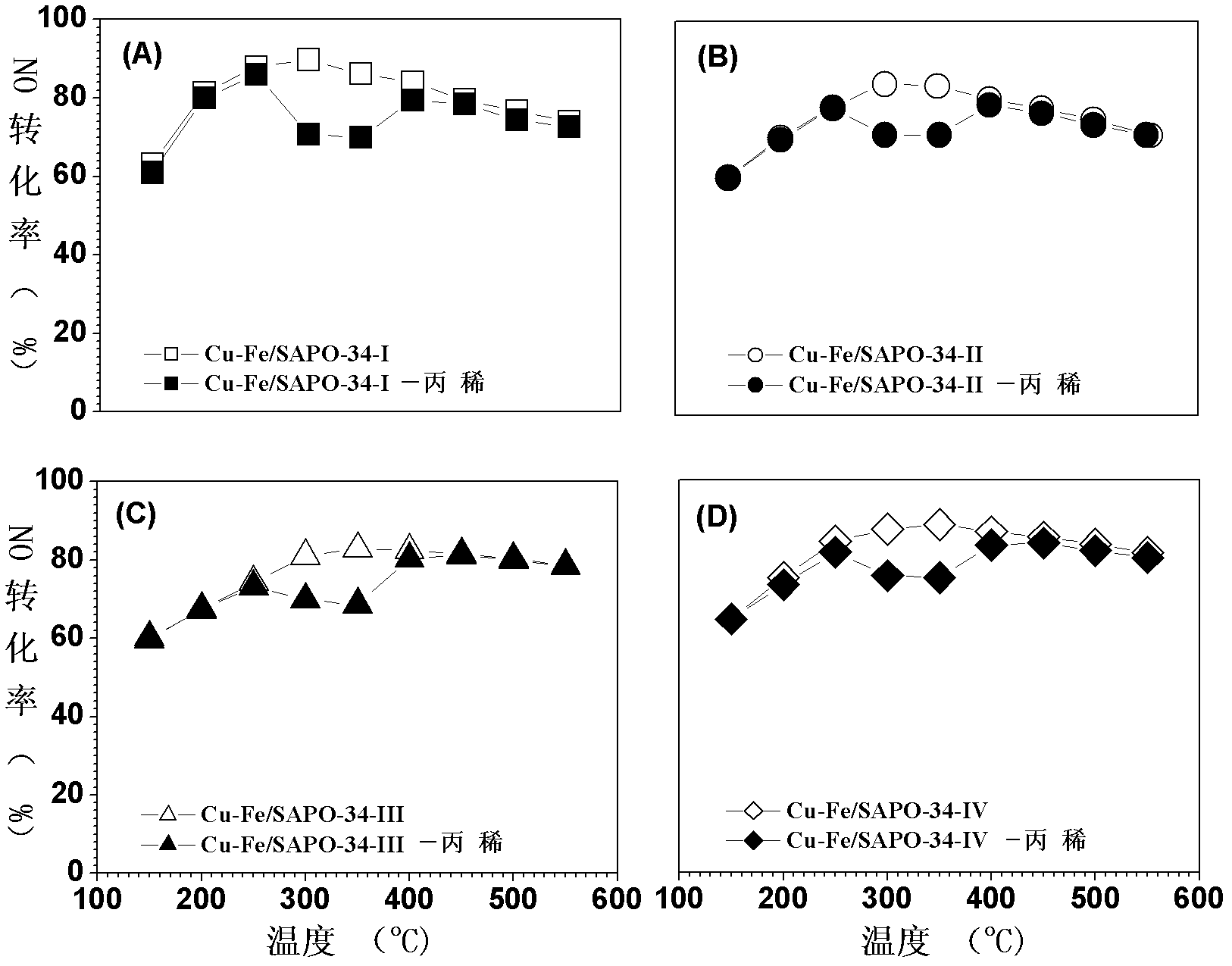

Ammonia-selective preparation method of SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx

InactiveCN102614910AHigh activityImprove anti-carbon performanceNitrous oxide captureMolecular sieve catalystsMolecular sieveCopper chloride

The invention relates to an ammonia-selective preparation method of an SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx. The catalyst is used for catalytically removing oxynitrides. A soft template method is used for preparing the SAPO-34 micropore molecular sieve carrier with high specific area (400-550m<2> / g); and an iron chloride-copper chloride mixed solution and an SAPO-34 molecular sieve ion-exchange method are utilized to prepare the SAPO-34 molecular sieve supported Cu-Fe composite catalyst. In a wide temperature range (150-550), the invention has high catalytic removal effect and high stability for pollutants with high air speed (120000-360000mL.(g.h)<-1>), high O2 concentration (10-10 vl.%), high H2O content (5-10 wt%) and low NO concentration (300-1000ppm). After adding hydrocarbons (300-1000ppm of propylene) into the reaction system, the catalyst provided by the invention has high anti-carbon performance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

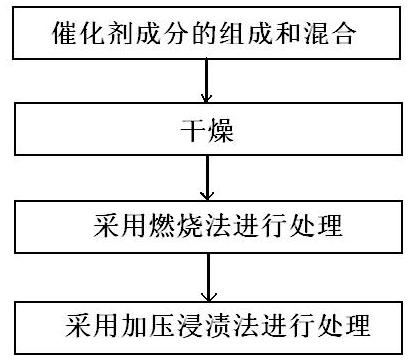

Catalyst used in complete methanation of synthesis gas at high temperature and preparation method thereof

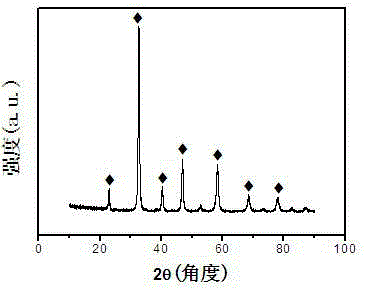

ActiveCN102527405AHigh methanation activityHigh hydrothermal stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasPtru catalyst

The invention discloses a catalyst used in complete methanation of synthesis gas at high temperature, and the catalyst comprises the following ingredients in percentage by weight: 10-30wt% of nickel, 11-20wt% of lanthanum, 1-5wt% of cerium, 0.1-2wt% of one or a plurality of manganese, lithium and vanadium and the balance of aluminium oxide, wherein the sum of the weight percentages of all the ingredients is 100%. The preparation method of the catalyst comprises the following steps: (1) combining and mixing catalyst ingredients; (2) drying to obtain a fusant; (3) heating the fusant to 600-800DEG C at the heating speed of 1-4DEG C per minute, and roasting at the temperature of 600-800DEG C for 6-8 hours to obtain particulate matters; and (4) grinding and screening the particulate matters, and processing by a pressure impregnation method to obtain a target product. The catalyst has the positive effects that the prepared catalyst is suitable for being operated and applied under the condition of high temperature, high pressure and high airspeed, and the equipment has higher material processing capability. The catalyst not only can be used for gas with high heating value and coal-derived natural gas in production and used for methanating CO tail gas of the industrial electric furnace but also can be used for purifying and separating synthesis gas and small amounts of CO and CO2.

Owner:EAST CHINA UNIV OF SCI & TECH

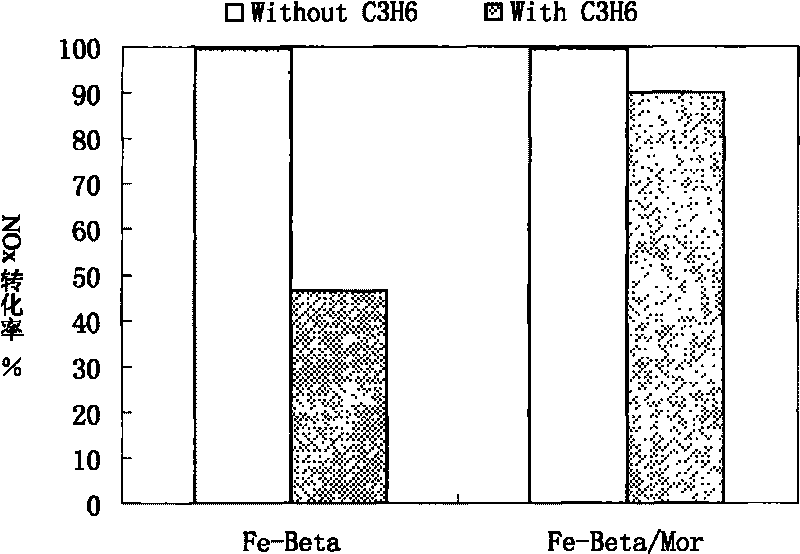

Fe molecular sieve composite catalyst and preparation method thereof

ActiveCN101711991AHigh catalytic activityInhibition of adsorptionMolecular sieve catalystsDispersed particle separationIon exchangeMordenite

The invention relates to a Fe molecular sieve composite catalyst, which comprises an active component Fe, a catalyst carrier Beta and a mordenite. A preparation method comprises the following steps of: 1, performing ion exchange on a Si / Al H-Beta molecular sieve and FeCl2; 2, removing Cl ions in the solution, and drying the obtained filter cake and roasting the filter cake in a muffle furnace to obtain the Fe / Beta molecular sieve catalyst; 3, placing the Fe / Beta molecular sieve catalyst in the water, adding the mordenite, and roasting the mixture to obtain the Fe / Beta / Mor molecular sieve composite catalyst; 4, dissolving the Fe / Beta / Mor molecular sieve into the de-ionized water, and adding concentrated nitric acid to obtain coating serum; and 5, dipping a Cordierite honeycomb ceramic carrier in the serum, blowing a residual liquid, and after drying the mixture in the shade, drying and roasting the mixture. The catalyst can efficiently purify NOx in the tail gas of a diesel vehicle, a lean-burning gasoline car and a lean-burning natural gas vehicle, and has the characteristics of environment protection and highly efficient catalytic activity.

Owner:TSINGHUA UNIV

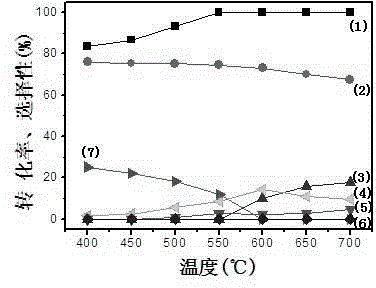

Catalyst used for direct preparation of light olefin from synthetic gas, preparation method and application thereof

InactiveCN103157489ALow priceLow costHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasAlkane

The invention relates to a catalyst used for direct preparation of light olefin from synthetic gas, a preparation method and an application thereof. According to the invention, a parallel flow precipitation method is used to highly disperse Fe and auxiliary agents on surfaces of self-made alkaline carriers, and thus a catalyst load is low, a preparing technology is simple and a cost is lower than that of product with a same type. When the catalyst is used for direct preparation of the light olefin from the synthetic gas, a CO conversion rate can reach 75-85 % under a one-way catalytic condition of the synthetic gas, an alkene-alkane ratio can reach 4.5-6.0 in organic gas products, an alkene weight is 50-60 % and more than 98% of the liquid product is water. The catalyst is good in abrasion resistance and pressure resistance, and can be used for slurry beds and fixed beds. A reaction technology of the catalyst is that the temperature is 200-500 DEG C, a pressure is 0-5 MPa, and an air speed of the synthetic gas is 600-2400 <-1>.

Owner:SHANXI LUAN MINING GRP +1

Ni-based catalyst adopting core-shell structure and used in DRM (dry reforming of methane) and preparation method

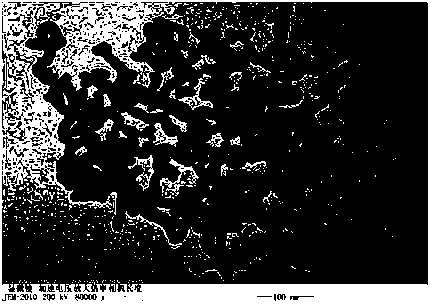

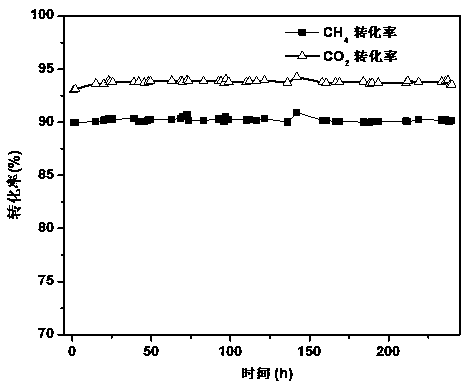

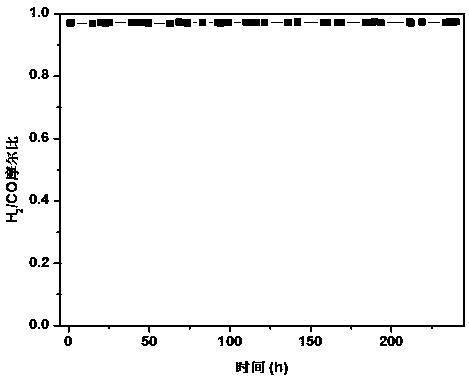

InactiveCN107552054AImprove anti-sinteringImprove anti-carbon performanceHydrogenMetal/metal-oxides/metal-hydroxide catalystsGas compositionReaction temperature

The invention discloses a Ni-based catalyst adopting a core-shell structure and used in DRM (dry reforming of methane) and a preparation method. A Ni-MOx@SiO2 (M is Zr, La and Ce) multi-core core-shell material is prepared with a reversed-phase microemulsion method with nickel nitrate, zirconium nitrate and the like as precursor salt. The additive amount of metal oxide in the catalyst is 1%-5% ofthe weight of the catalyst and the additive amount of nickel is 5%-10% of the weight of the catalyst. The sintering resistance and carbon deposit resistance of the catalyst are remarkably enhanced dueto addition of the metal oxide. The catalyst shows high activity, high stability and extremely high carbon deposit resistance and sintering resistance under the reaction conditions of normal pressure, reaction gas composition CH4:CO2 being 1.05:1, the air speed being 1,8000 ml.gcat<-1>.h<-1> and the reaction temperature being 800 DEG C. The catalyst has the advantages of being simple to prepare,free of secondary pollution to the environment, low in cost, high in catalytic efficiency and the like.

Owner:NANCHANG UNIV

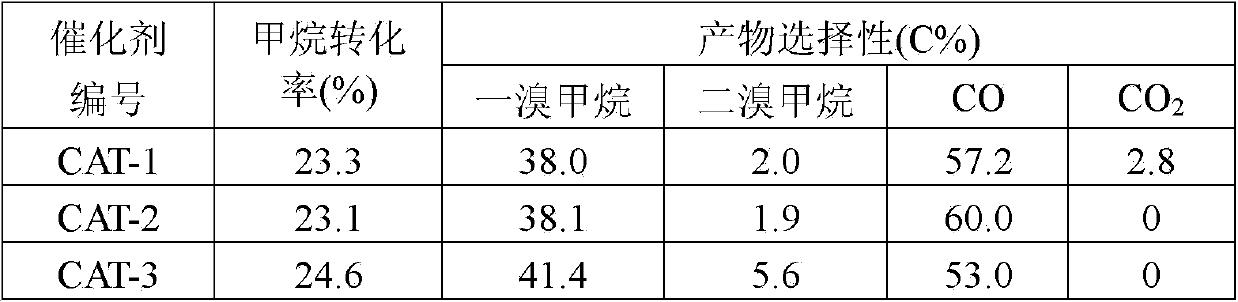

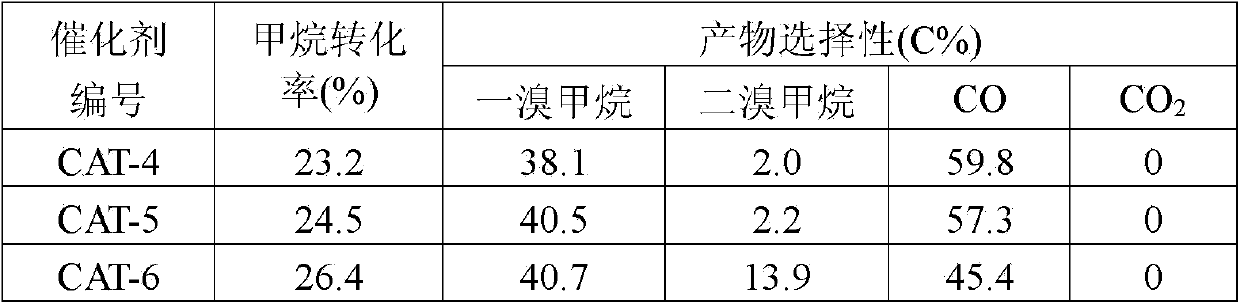

Catalyst used for preparation of bromomethane and CO through methane bromination-oxidation, and preparation method and application thereof

InactiveCN104209134AImprove performanceNo carbon depositCatalyst activation/preparationCarbon monoxideActive componentOxygen

The invention provides a catalyst used for the preparation of bromomethane and CO through methane bromination-oxidation. The catalyst contains a main active component and a carrier, wherein the main active component is one or more selected from FePO4, Fe3P2O7 and Fe3(P2O7)2, the carrier is one or more of TiC-SiC and TiO2-SiC, and the content of the main active component in the catalyst is 1.0-50.0wt%. The catalyst is prepared through the steps of supporting an impregnation liquid containing the main active component onto the carrier through an impregnation technology, drying and roasting, and the catalyst can catalyze a mixture comprising methane, oxygen and an aqueous solution of HBr converted into bromomethane and CO in a high activity and high selectivity manner under reaction conditions comprising normal pressure and a temperature of 400-800DEG C. The catalyst has the advantages of good performances, on obvious inactivation in a continuous reaction process carried out for above 1400h, and no carbon deposition on the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of thermometal methanation catalyst with high-temperature resistance

InactiveCN102513116AReasonable ratioImprove stabilityGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsMethanation

The invention relates to a preparation method of a thermometal methanation catalyst with high-temperature resistance, which comprises the following steps of: taking alumina as a vector, taking nickel oxide as a main active component, taking cobalt oxide as a second active component, taking lanthanum oxide as an adjuvant and mixing the above oxides evenly by adopting a double-hydrolyzing homogeneous-phase coprecipitation method of inorganic salt so as to prepare the methanation catalyst by filtering, washing, drying and calcining. The dispersion of each component in the catalyst is uniform, the stability and the coagulating resistance are good, the quick methanation of the catalyst can be realized by mixing with raw gas, and the catalyst can have the function of effectively resisting coagulation and accumulation in a high-temperature environment generated in the quick reaction process and has favorable catalytic capability at the temperature of 500 to 700 DEG C. The preparation method has short technological process, reasonable mixture ratio of materials and full and accurate data, is easy to operate and is a very ideal preparation method of the thermometal methanation catalyst with high-temperature resistance.

Owner:TAIYUAN UNIV OF TECH

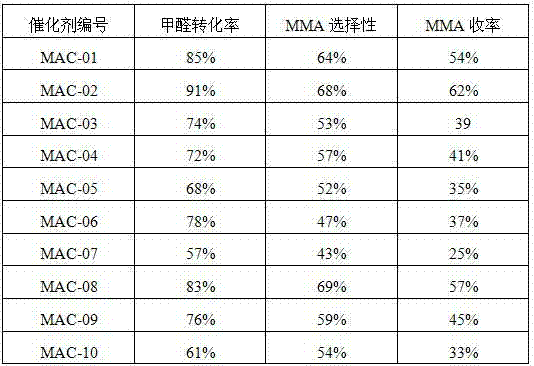

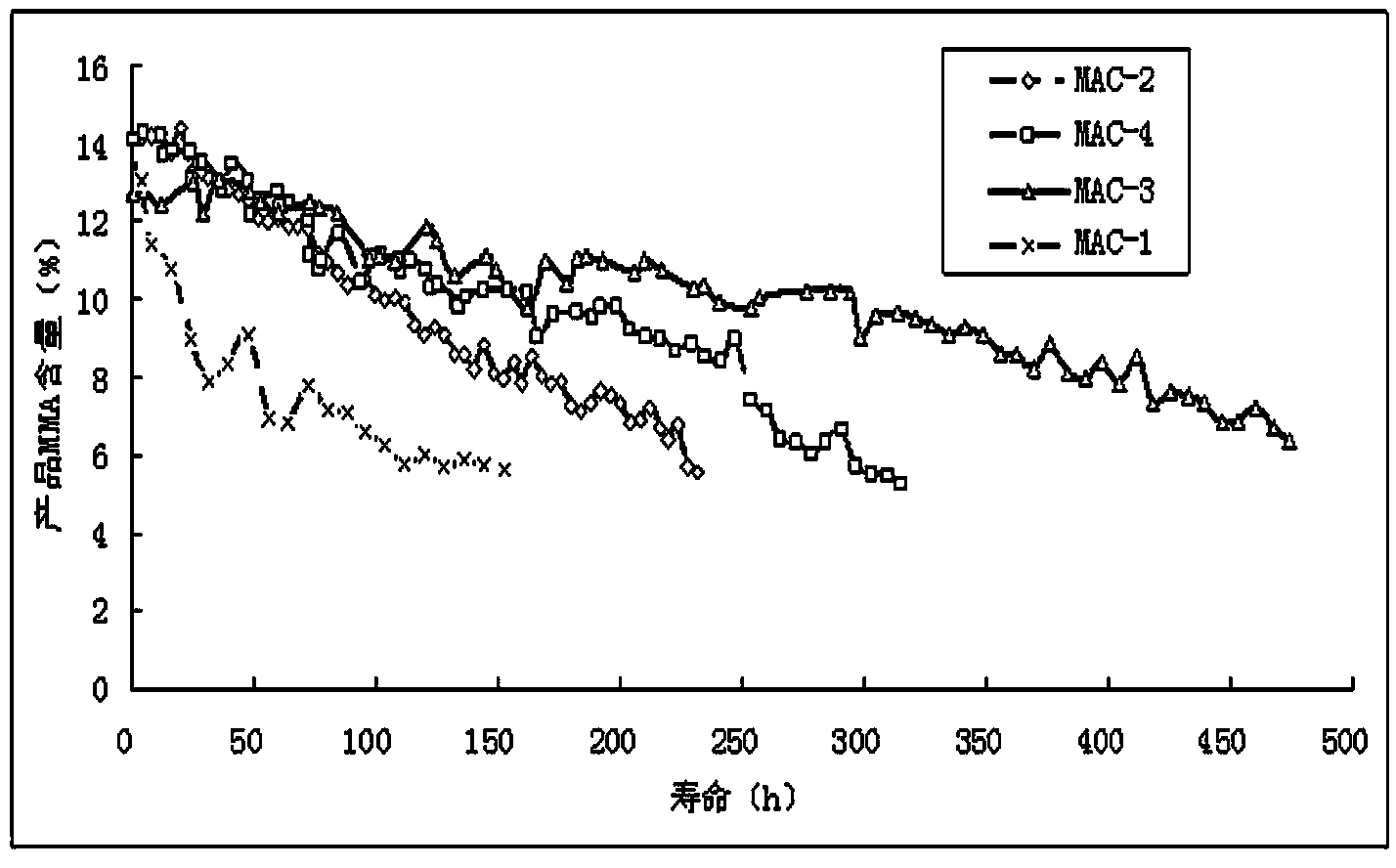

Catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and preparation method of catalyst

ActiveCN102962062ALarge specific surface areaImprove physicsOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention discloses a catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and a preparation method of the catalyst. The catalyst mainly comprises a main active component, an activated auxiliary and a carrier, wherein the main active component is Cs, the activated auxiliary is selected from one or more of Sb, Nb and Ag, and the carrier is a nanometer SiO2 / Al2O3-ZrO2 composite carrier; and metered by oxides and according to mass percentage, the main active component Cs accounts for 5%-20%, the activated auxiliary accounts for 1%-5%, and the balance is the carrier. Simultaneously, the invention discloses a preparation method of the catalyst. The catalyst provided by the invention is good in activity, selectivity and stability, simple in manufacture technology, suitable for large-scale industrialized application and environment-friendly.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

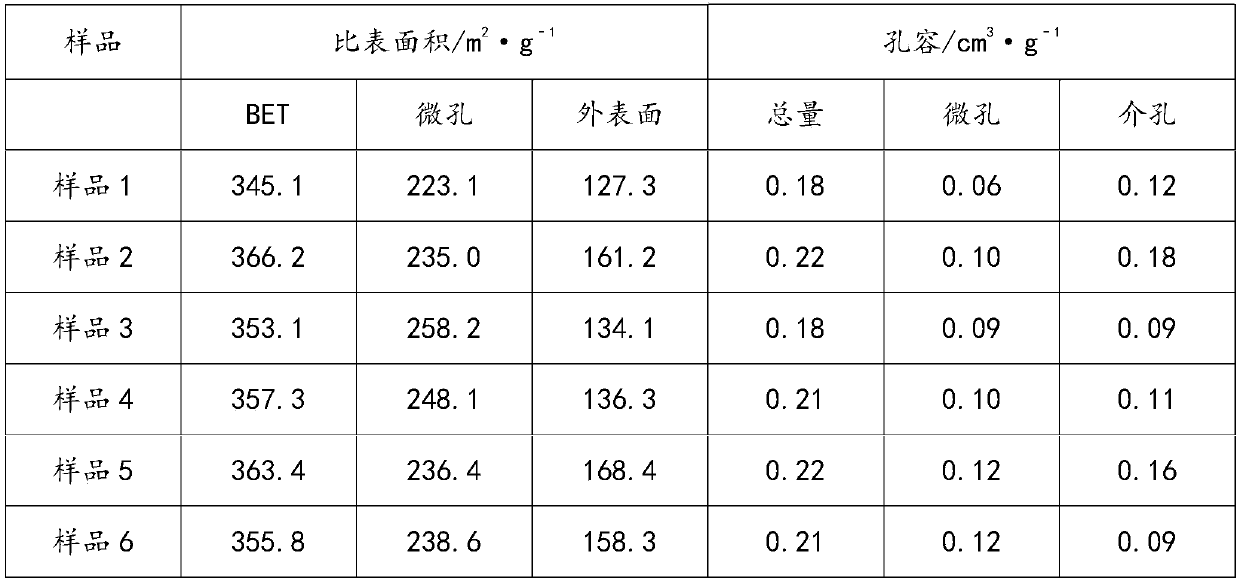

Alumina support with dual apertures and preparation method thereof

ActiveCN1689703AHigh activityImprove anti-carbon performanceCatalyst carriersCeramicwareHalogenNitrogen

The present invention is alumina carrier with double holes and its preparation process. The carrier contains alumina in 95-99.9 wt% of carrier and halogen element in 0.1-5 wt%, and has acid amount of 0.2 mmol / g. The preparation process of the carrier includes mixing alumina precursor with pore expander, forming and roasting the alumina precursor at 600-850 deg.c for 1-10 hr. The pore expander includes one kind nitrogen containing compound except acid and one kind one halide. The alumina carrier with double holes has low acid amount and may be used widely as carrier for heavy oil hydrogenating catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of alkene epoxidation catalyst as well as catalyst prepared thereby

ActiveCN107930610AHigh reactivityReduce surface acidityOrganic chemistryMolecular sieve catalystsComposite oxideKinetic diameter

The invention relates to a preparation method of an alkene epoxidation catalyst. The preparation method of the alkene epoxidation catalyst comprises the following steps: (1) preparing titanium silicongel; (2) performing pore-enlarging treatment on the titanium silicon gel by using organic amine or liquid ammonia, drying and roasting to obtain titanium silicon composite oxide; (3) optionally performing alcohol solution treatment on organic alkali metal salt; and (4) optionally performing gas phase silanization treatment. The pore diameter of the catalyst prepared by the method is adjustable, so that the catalyst has higher activity on epoxidation reaction of olefin molecules with different kinetic diameter; and the catalyst is subjected to two-step modification, the surface acidity of thecatalyst is effectively reduced and the catalyst has higher epoxidation product selectivity.

Owner:WANHUA CHEM GRP

Method for preparing hierarchically porous ZSM-5 molecular sieve for methanol to propylene

ActiveCN108046288AShorten micropore channel lengthImprove diffusivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystIon exchange

The invention discloses a method for preparing a hierarchically pore porous ZSM-5 molecular sieve for methanol to propylene. The method comprises the steps as follows: a, mixing an aluminum source, asilicon source, an alkali source and a ZSM-5 molecular sieve seed crystal with water to form a gel; b, pre-crystallizing the gel in a reactor at 80-140 DEG C for 6-48 h; c, quenching a pre-crystallized product obtained in step b, adding an organic template, heating the pre-crystallized product containing the template to 100-180 DEG C for crystallization reaction, performing solid-liquid separation, washing and drying on a crystallized product after the reaction to obtain molecular sieve original powder; d, placing the molecular sieve original powder obtained in step c in an ammonium salt solution for ion exchange to obtain an ammonia-type ZSM-5 molecular sieve, and then performing calcination to obtain the HZSM-5 molecular sieve. The prepared molecular sieve catalyst has good propylene selectivity and good carbon deposition resistance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

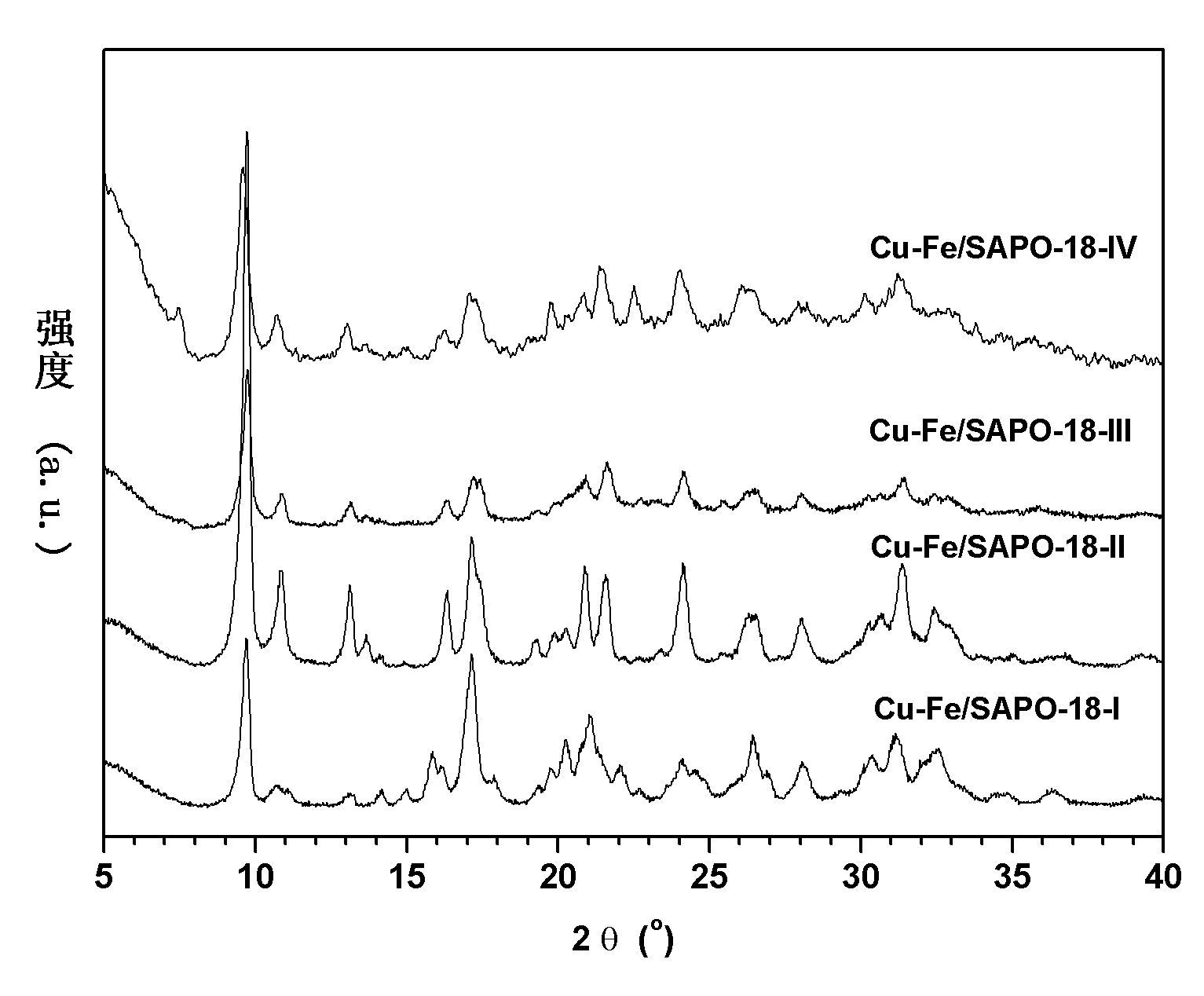

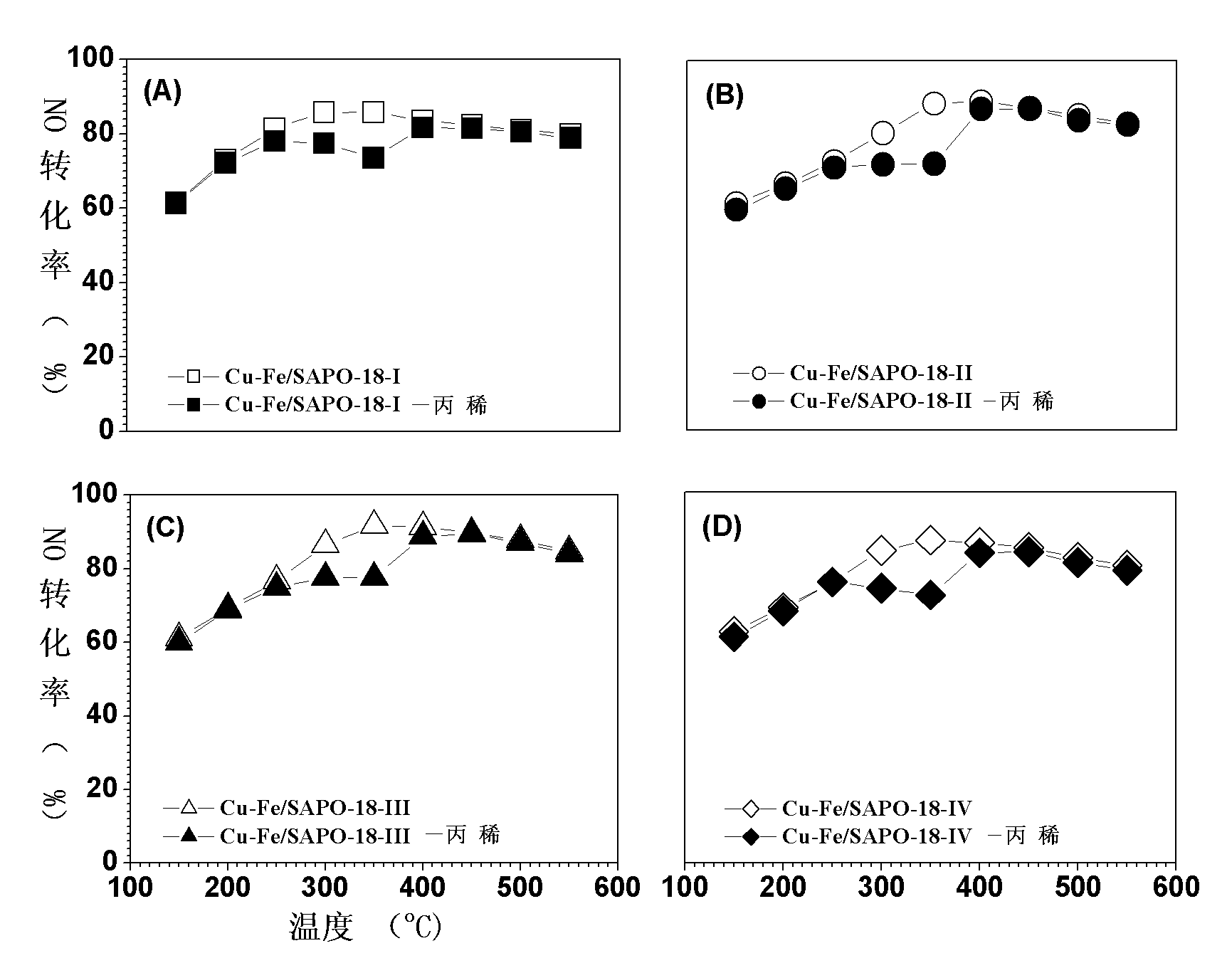

Preparation method of SAPO-18-carried Cu-Fe catalyst for ammonia-selective catalytic elimination of NOx

InactiveCN102626653AImprove anti-carbon performanceHigh activityMolecular sieve catalystsDispersed particle separationMolecular sieveHigh carbon

The invention discloses a preparation method of a SAPO-18-carried Cu-Fe catalyst for ammonia-selective catalytic elimination of NOx. The SAPO-18-carried Cu-Fe catalyst is used for selective catalytic elimination of nitric oxides. The preparation method is characterized in that SAPO-18 foraminate molecular sieve carriers having high specific surface areas of 400 to 550m<2> / g are prepared by a soft template synthesis method; and a FeCl3-CuCl2 mixed solution and the SAPO-18 foraminate molecular sieve carriers are prepared into the SAPO-18-carried Cu-Fe catalyst by an ion exchange method. In a wide temperature range of 150 to 550 DEG C, the SAPO-18-carried Cu-Fe catalyst has high catalytic elimination effects on pollutants having a high airspeed of 120000 to 360000mL.(g.h)<-1>, a high O2 concentration of 10 to 20vl.%, high H2O content of 5 to 10wt% and a low NO concentration of 300 to 1000ppm, and has high stability. After adding a hydrocarbon (300 to 1000ppm of propylene) into a reaction system, the SAPO-18-carried Cu-Fe catalyst has high carbon deposition resistance and high hydrothermal stability.

Owner:BEIJING UNIV OF TECH

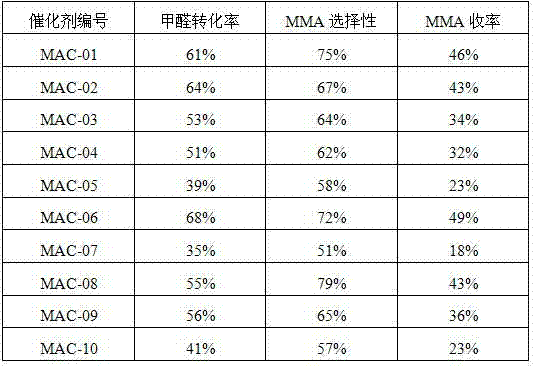

Water resistant catalyst for aldol condensation as well as preparation method and application thereof

ActiveCN103551148AGood physical and mechanical propertiesIncrease resistance to poisoningOrganic compound preparationCarboxylic acid esters preparationPtru catalystPropanoic acid

The invention discloses a water resistant catalyst for aldol condensation. The water resistant catalyst comprises a main active ingredient, an active agent and a carrier, wherein the main active ingredient is one or more selected from oxides or salts of Cs; the active agent is one or more selected from oxides or salts of Sb, Nb, Ag, Al and Zr; the carrier comprises SiO2 and a carrier aid; the carrier aid is one or more selected from Al2O3, ZrO2, diatomite and kaolin; the SiO2 is hydrophobic nano SiO2; or (2) the catalyst is subjected to water-resistant treatment. The water resistant catalyst is used for aldol condensation, has the characteristics of high activity, high selectivity and long service life, is especially used for synthesizing methyl methacrylate through formaldehyde and methyl propionate. With calculation of methyl propionate, the selectivity of methyl methacrylate is 94 percent, and the single service life of the catalyst is over 400 hours. The catalyst is simple in preparation method and is suitable for industrial application.

Owner:HAO HUA CHENGDU TECH

Biomass pyrolysis gasification multifunctional iron-based catalyst and preparation method thereof

ActiveCN103394356AImprove stabilityImprove anti-sintering and anti-carbon abilityGas purification with selectively adsorptive solidsMetal/metal-oxides/metal-hydroxide catalystsMuffle furnacePyrolysis

A biomass pyrolysis gasification multifunctional iron-based catalyst and a preparation method thereof are disclosed. The preparation method is characterized by comprising the following steps: (1) carrier pretreatment: placing CaO in a muffle furnace for calcining, then grinding and screening to prepare CaO carrier particles; (2) introduction of a main active component: mixing the CaO carrier particles with a Fe(NO3)3.9H2O solution, stirring and immersing, drying, calcining and grinding; (3) introduction of an auxiliary active component: mixing the sample prepared by the step (2) with a Ce(NO3)3.6H2O solution, stirring, immersing, drying, placing the obtained sample in a muffle furnace for calcining, placing the calcined sample in a dryer to cool to room temperature, grinding, then mixing the obtained powder with a Zr(NO3)4.5H2O solution, stirring, immersing, drying, then placing the sample in a muffle furnace for calcining, then placing the calcined sample in a dryer to cool to room temperature, and then grinding; and (4) shaping of the catalyst: performing shaping on the obtained catalyst, and screening to obtain the catalyst finished product.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Preparation method of catalyst for carbon dioxide reforming of methane to produce synthesis gas

InactiveCN103566936AFast preparationOvercoming inactivation problemsHydrogenCatalyst activation/preparationCooking & bakingCobalt

The invention discloses a preparation method of a catalyst for carbon dioxide reforming of methane to produce synthesis gas. The preparation method comprises the following steps: mixing lignite active carbon with ammonia water according to a proportion and performing closed immersion to obtain modified lignite active carbon; placing the modified lignite active carbon in a closed pressurized temperature control reaction kettle; performing hydrothermal reaction at certain temperature and under certain voltage; naturally cooling and drying to prepare ammonia water modified lignite active carbon; finally performing ultrasonic immersion treatment on the ammonia water modified lignite active carbon and cobalt nitrate solution under certain pressure and drying and baking to prepare the catalyst. The catalyst prepared by the method has the advantages of readily available raw materials, good catalytic activity, long life and easiness in industrial production.

Owner:SHANXI LUAN MINING GRP

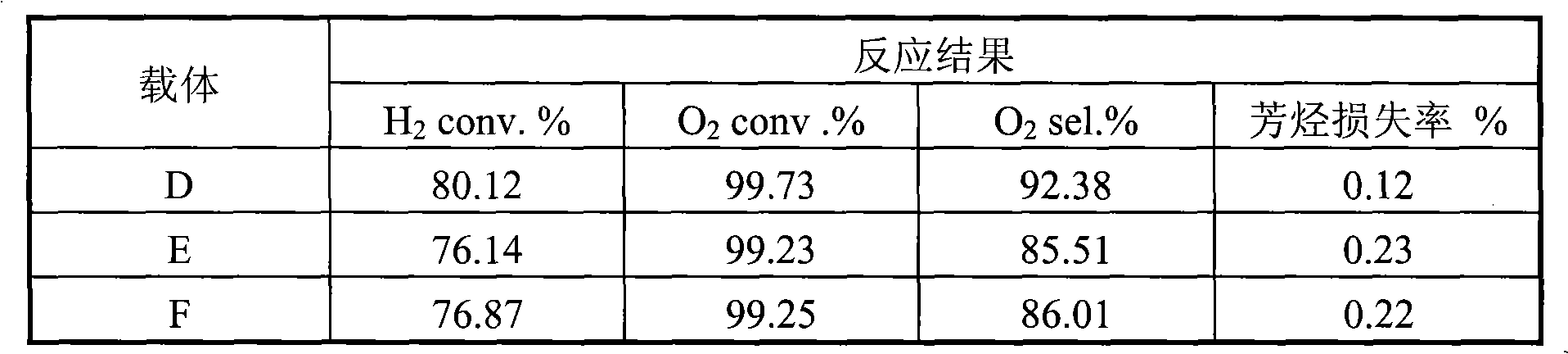

Catalyst for H2 selective oxidation in styrene production

ActiveCN101491758AImprove combustion activityImprove anti-carbon performanceCatalyst activation/preparationHydrocarbonsIridiumAlkaline earth metal

The invention relates to a catalyst for hydrogen selective oxidation reaction during phenyl ethylene production, and mainly solves the problems of low using efficiency and short service life of the catalyst, and high raw material loss in the prior art. The catalyst for the hydrogen selective oxidation reaction during the phenyl ethylene production comprises a kernel of an inert carrier and a layered composite carrier which is combined on the kernel and consists of an outer layer of a porous coating material, wherein the outer layer of the layered composite carrier is loaded with at least one platinum series metal selected from ruthenium, rhodium, palladium, osmium, iridium and platinum, at least one dressing agent selected from alkali metals and alkaline-earth metals, and an assistant catalyst selected from one of IVA compounds and at least one of lanthanide series compounds. The technical proposal solves the problems well, and the catalyst can be applied in the industrial production of the hydrogen selective oxidation reaction in a process of producing phenyl alkene by ethylbenzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

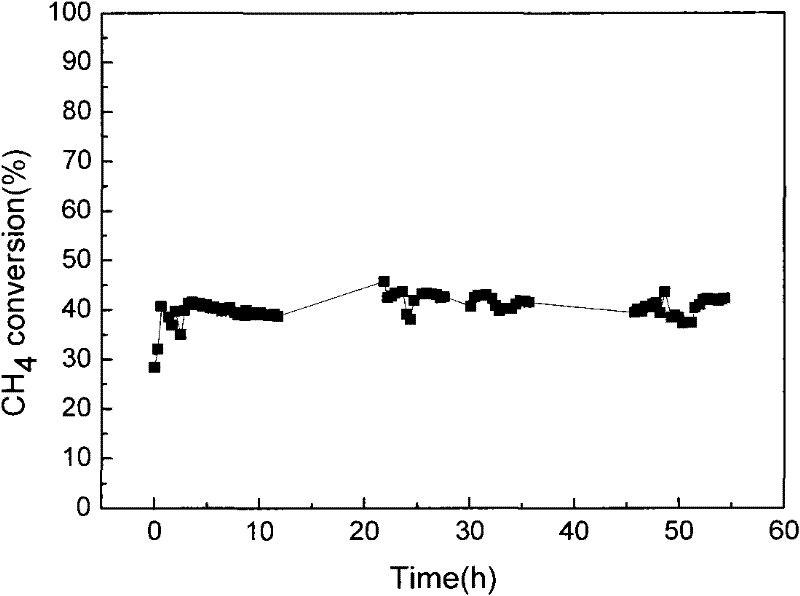

Catalyst for producing synthesis gas by catalytic partial oxidation of methane and preparation thereof

ActiveCN101279271AHigh selectivityReduce manufacturing costHydrogenCarbon monoxideNickel catalystPartial oxidation

The present invention provides a catalyst for preparing a compound gas by methane catalyzing partial oxidation and a preparation method thereof. The catalyst relates to a loading type catalyst which is added with a cerium oxide-based compound accessory ingredient and a noble metal ruthenium; wherein, the content of nickel is 5 to 15 percent (weight percent, the same below), the content of the cerium oxide-based compound accessory ingredient is 0.1 to 5 percent, the content of ruthenium is 0.1 to 0.2 and the rest is the content of a carrier. The catalyst has excellent reaction property; the methane converting rate as well as the selectivity of CO and H2 is all higher than 95 percent; besides, the stability is excellent.

Owner:PETROCHINA CO LTD

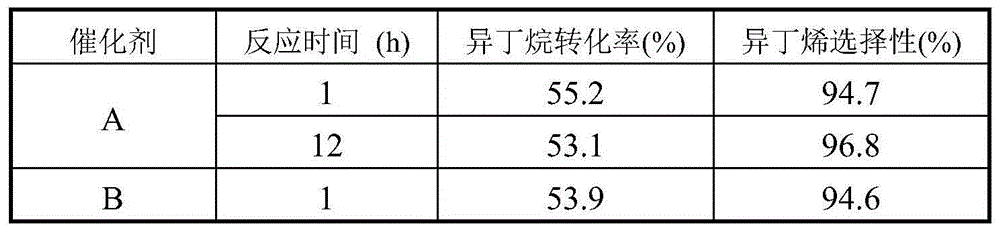

Catalyst used for producing olefin through low-carbon alkane dehydrogenation, and preparation method thereof

ActiveCN105582919AImprove anti-sintering performanceGood performance and stableHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsLow activityAlkane

The invention relates to a catalyst used for producing olefin through low-carbon alkane dehydrogenation, and a preparation method thereof. The invention mainly aims at solving the problems of low activity and poor stability of dehydrogenation catalysts prepared with prior arts. The low-carbon alkane dehydrogenation catalyst provided by the invention is prepared through an impregnation precipitation method, and comprises the following components, by weight: (a) 0.1-5 parts of Pt or oxide thereof, (b) 0.1-5 parts of Sn or oxide thereof, (c) 0.1-5 parts of alkali metal or oxide thereof, (d) 0.1-5 parts of Fe, Co, Ni, Cu, Zn or oxide thereof, (e) 0.1-10 parts of a Ce-La-O solid solution, and (f) 80-99 parts of a carrier Al2O3. With the above technical scheme, the problems are well solved. The catalyst can be applied in industrial productions for producing low-carbon olefin through low-carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of a Methane Reforming Catalyst in Molten Carbonate Fuel Cell

InactiveCN102299345AEasy to prepareConditions are easy to controlCell electrodesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMolten carbonate fuel cell

The invention discloses the application of a methane reforming catalyst in a molten carbonate fuel cell. The catalyst comprises an active component nickel with a content of 4-25 wt%, a rare earth element catalytic promoter with a content of 0-10 wt%, Alumina carrier with a content of 65-96 wt%. The preparation method of the catalyst is simple, can be operated under the conditions of medium temperature and low water-to-carbon ratio, has high reactivity, strong carbon deposition resistance and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

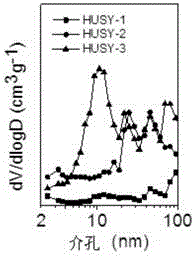

Preparation of hydrodeoxygenation isomerization catalyst and application thereof in preparation of diesel oil from illegal cooking oil

ActiveCN105126898AImprove anti-carbon performanceReduce manufacturing costMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveDeposition precipitation

The invention discloses a hydrodeoxygenation isomerization catalyst, which includes a hydrodeoxygenation catalyst of an ultrastable Y molecular sieve loaded metal and a hydroisomerization catalyst of a molecular sieve loaded noble metal. The ultrastable Y molecular sieve has a microporous-mesoporous composite pore system, and the metal selected from Zn, Ni and Cu is loaded by means of deposition precipitation so as to obtain the hydrodeoxygenation catalyst. The hydroisomerization catalyst adopts the microporous molecular sieve SAOP-11, SAPO-31, SAPO-34, HZSM-5, HZSM-22 or HBEA as the carrier, and the noble metal selected from Pt, Pd and Ru are loaded on the molecular sieve through impregnation method, thus obtaining the hydroisomerization catalyst. The invention also puts forward application of the hydrodeoxygenation isomerization catalyst in preparation of high cetane number diesel oil from illegal cooking oil. The mixed catalyst has high activity and anti-carbon deposition capacity, and the obtained diesel oil product has the advantages of high cetane number and low freezing point.

Owner:EAST CHINA NORMAL UNIV

Method for preparing 2,6-dimethylnaphthalene by catalyzing naphthalene alkylation reaction with CoAPO-11 molecular sieve

InactiveCN102746101AEasy to separateGood acid catalytic performanceMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveSolvent

The invention provides a method for preparing 2,6-dimethylnaphthalene by catalyzing naphthalene alkylation reaction with CoAPO-11 molecular sieve, relates to a method for preparing 2,6-dimethylnaphthalene, and is used for solving the problems that the traditional catalyst cannot simultaneously have high activity and high selectivity of 2,6-dimethylnaphthalene. The method comprises the steps of: activating the CoAPO-11 molecular sieve synthesized by an electrical heating method or microwave heating method for 2h, then mixing with naphthalene, alkylation reagents and solvent to prepare raw material liquid, and carrying out alkylation reaction to obtain 2,6-dimethylnaphthalene. According to the invention, the synthesized CoAPO-11 molecular sieve has higher catalytic reaction activity on naphthalene alkylation reaction, and higher selectivity of 2,6-dimethylnaphthalene; and the method is suitable for preparing 2,6-dimethylnaphthalene.

Owner:HEILONGJIANG UNIV

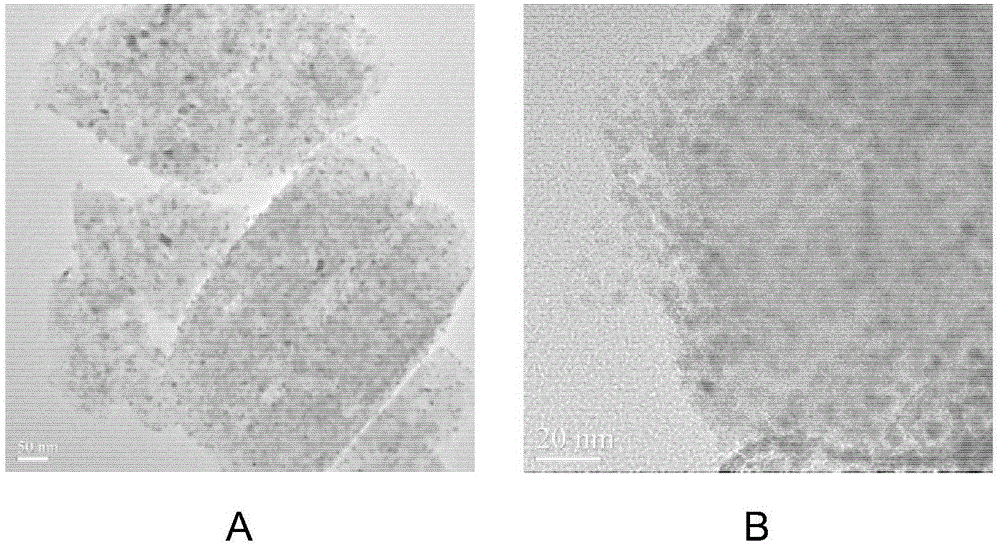

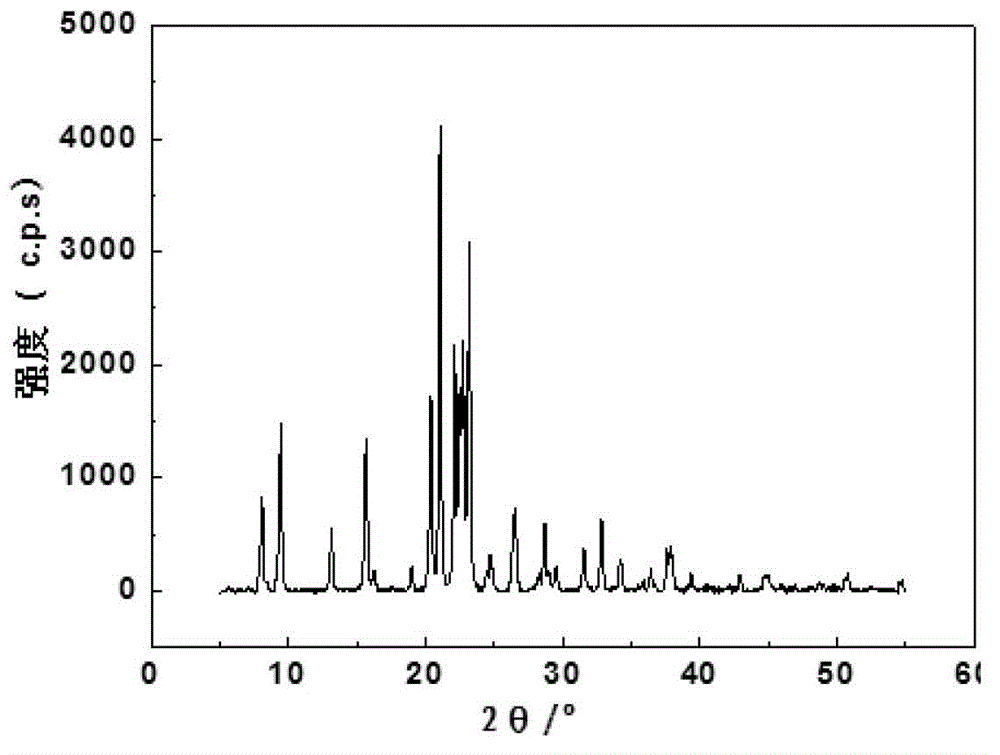

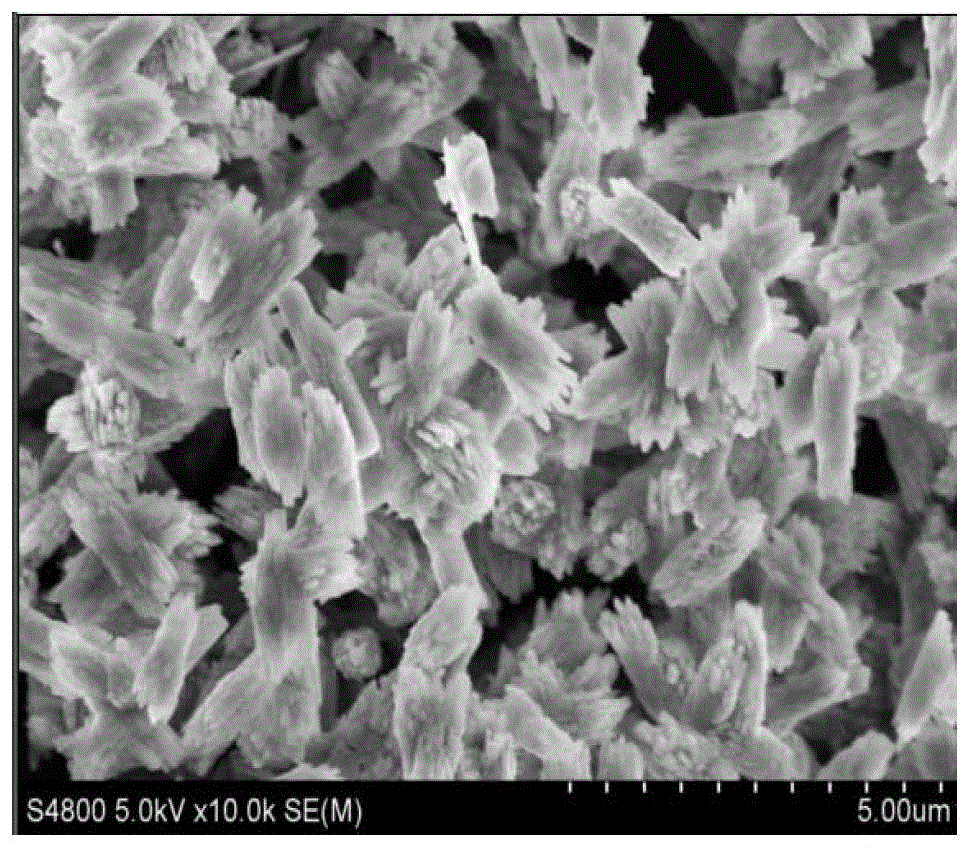

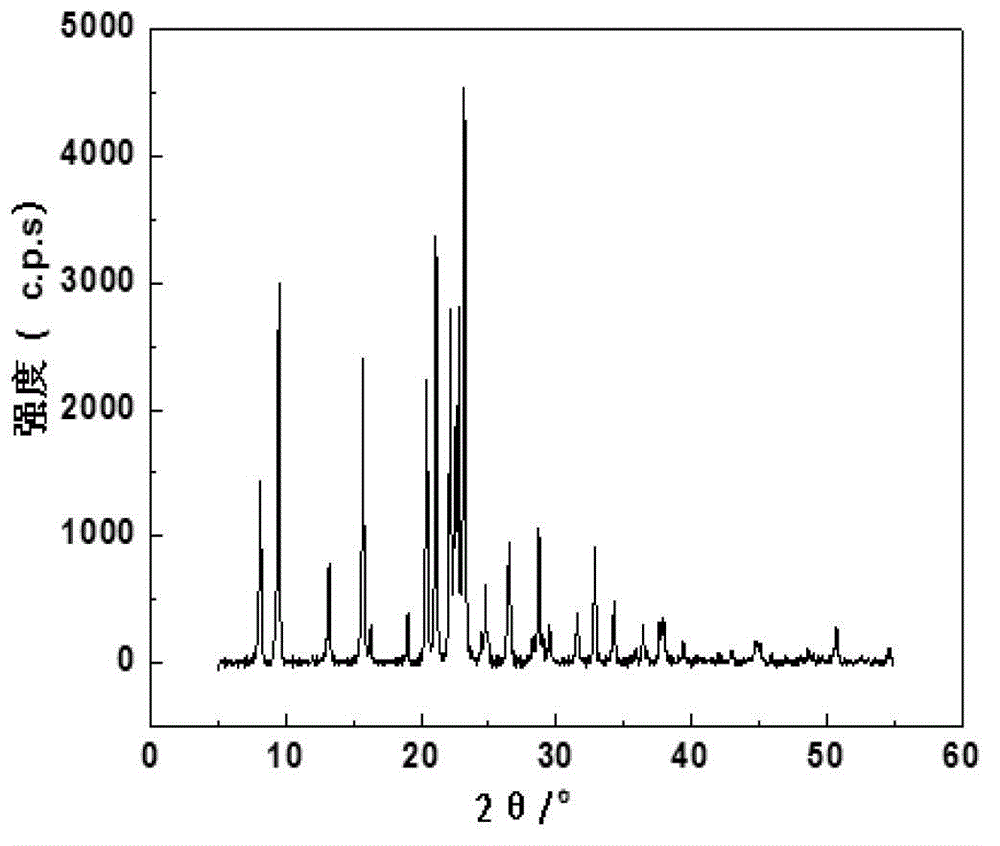

Nanoscale sheet-SAPO-34 molecular sieve and synthetizing method thereof

InactiveCN104986780ASimple processLow costMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesBoehmiteMolecular sieve

The invention belongs to the technical field of synthesis of a molecular sieve material, and relates to a nanoscale sheet-SAPO-34 molecular sieve and a synthetizing method thereof. The nanoscale sheet-SAPO-34 molecular sieve is mainly prepared from synthetizing an aluminum source, a phosphorus source, a silicon source, a formwork agent and water, wherein the aluminum source is pseudo-boehmite; the formwork agent is a composite formwork agent consisting of a first formwork agent and a second formwork agent; the molar ratios of the components forming sol are shown as follows: 1 part of Al2O3 is used as a standard, 0.8-1.2 parts of P2O5, 0.2-1.0 part of SiO2, 2-4 parts of the first formwork agent, 0.1-0.2 part of the second formwork agent, and 20-100 parts of H2O. According to the nanoscale sheet-SAPO-34 molecular sieve and the synthetizing method thereof, disclosed by the invention, a composite phosphorus source and a composite formwork agent are adopted, a hydrothermal method is adopted for one-step synthetizing SAPO-34 sheet-nanometer crystals, the process is simple, and cetyl trimethyl ammonium bromide(CTAB) is a frequently-used surfactant for industrial use, and is low in cost. The thickness of the prepared SAPO-34 molecular sieve is only scores of nanometers, and the diffusion path of molecules is obviously shortened.

Owner:青岛理健新材料科技有限公司

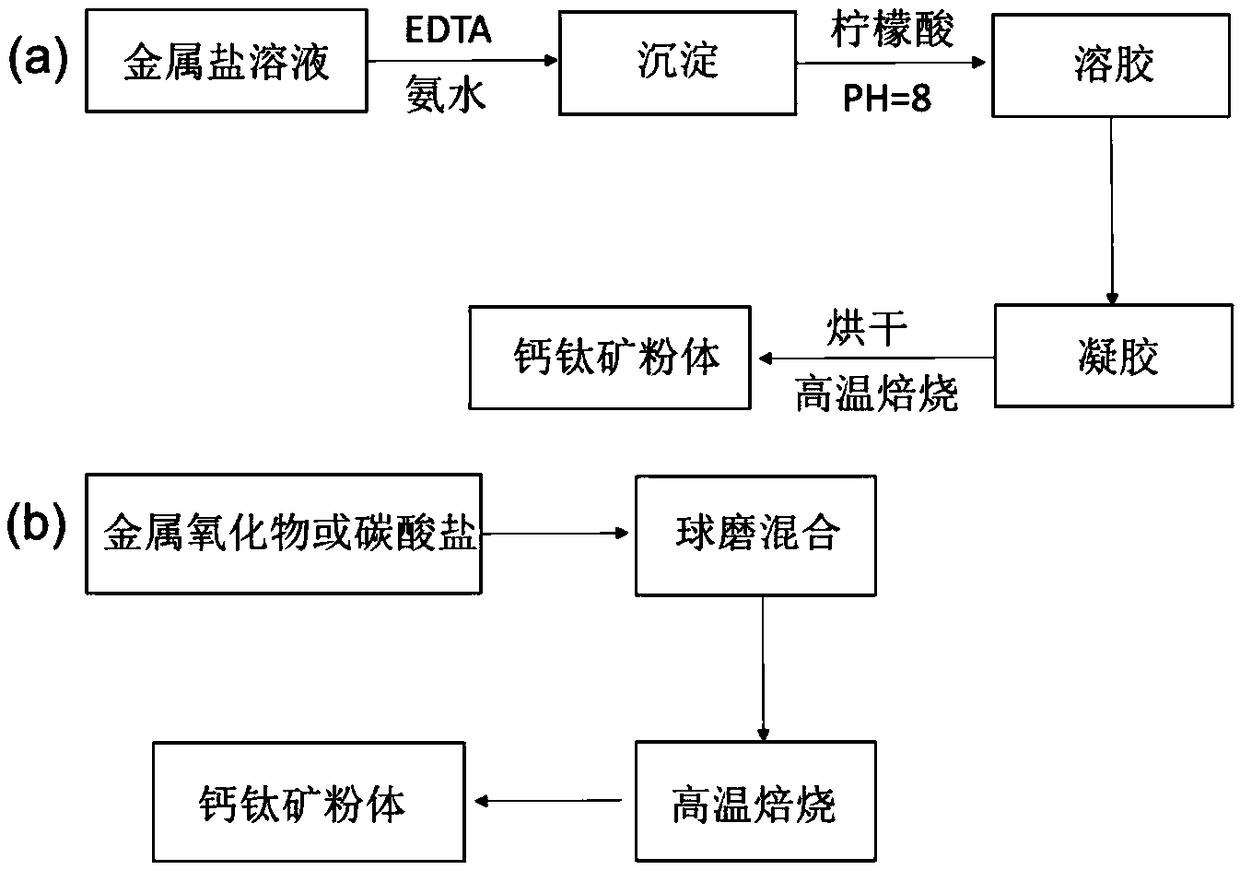

Lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and method for preparing catalyst

InactiveCN102941099AHigh catalytic activityImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen selectivityEvaporation

The invention discloses a lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and a method for preparing the catalyst. The chemical formula of the catalyst is La1-xCaxFe1-yCoyO3, wherein the x is in a range of 0.1 to 0.5, and the y is in a range of 0.1 to 0.5. The method for preparing the catalyst includes that corresponding metal salt is dissolved in deionized water according to a molar ratio of metal ions to be prepared into a salt solution, citric acids are added according to a molar ratio of the citric acids and the metal ions, citric acids and polyethylene glycol 400 are added in a salt solution according to a molar ratio of the citric acids and the polyethylene glycol, uniform complexes are obtained after stirring, and then the complexes are subjected to evaporation concentration, drying and calcining to obtain the lanthanum calcium iron cobalt calcium titanium ore type catalyst. The lanthanum calcium iron cobalt calcium titanium ore type catalyst for oxidizing and reforming ethanol and the method for preparing the catalyst have the advantages that the manufacture process is simple, and the obtained catalyst has good reactivity and high hydrogen selectivity, and excellent stability and anti-carbon deposition capabilities simultaneously.

Owner:TIANJIN UNIV

Cu-SSZ-13/M-AlPO composite molecular sieve catalyst, preparation method and applications thereof

ActiveCN108014843AImprove anti-carbon performanceImprove thermal stabilityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsButeneMethanol

The invention relates to a Cu-SSZ-13 / M-AlPO composite molecular sieve catalyst, a preparation method and applications thereof. In the prior art, the stability of the methanol-to-olefin catalyst is nothigh, the selectivity of ethylene, propylene and butylene in low-carbon olefins is low, and the yield is low. A purpose of the present invention is mainly to solve the problems in the prior art. According to the technical scheme of the present invention, the Cu-SSZ-13 / M-AlPO composite molecular sieve catalyst is used, and comprises, by weight, a) 10-100% of a Cu-SSZ-13 / M-AlPO composite molecularsieve, and b) 0-90% of a binder. With the technical scheme, the problems in the prior art are well solved. The obtained catalyst of the present invention can be used in the industrial production of methanol-to-olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

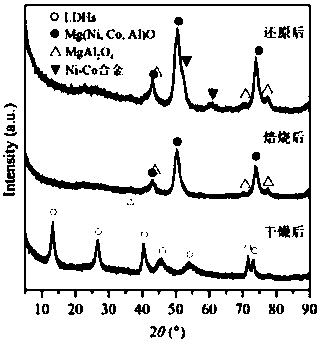

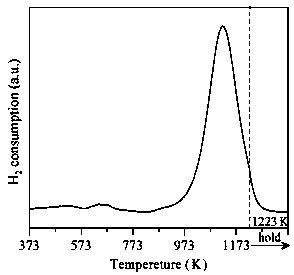

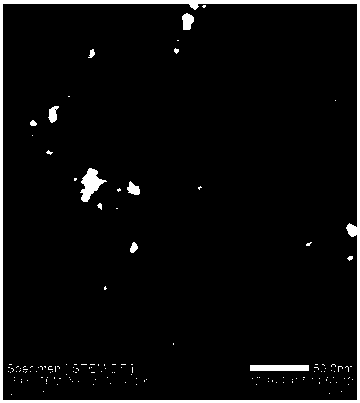

Supported uniform nickel-cobalt (Ni-Co) alloy catalyst and preparation method thereof

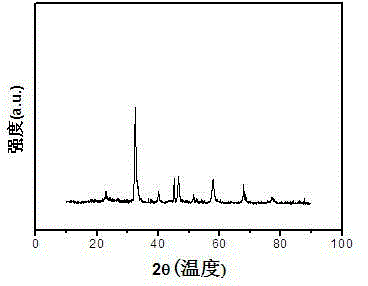

InactiveCN108380218AGood dispersionEvenly dispersedHydrogenHydrogen/synthetic gas productionActive phaseCobalt

The invention belongs to the field of catalysts for the preparation of synthesis gas by reforming hydrocarbons, and particularly relates to a supported uniform nickel-cobalt (Ni-Co) alloy catalyst anda preparation method thereof. The catalyst provided by the invention is prepared from the active phase of a Ni-Co alloy nano particle and a high-specific-surface-area Mg(Al)O composite oxide support.The preparation method comprises the following steps of firstly, synthesizing a Ni-Co-Mg-Al LDHs (Layered Double Hydroxides) lamellar composite hydroxide as a precursor by adopting a coprecipitationmethod, afterwards, obtaining a Mg(Ni,Co,Al)O oxide solid solution through roasting treatment, next, reducing through high-temperature hydrogen to in situ generate the Ni-Co alloy nano particle. The Ni-Co alloy nano particle of the supported uniform Ni-Co alloy catalyst is highly dispersed on the surface of the support, and the supported uniform Ni-Co alloy catalyst has the characteristics of being single in structure, uniform in composition, small in particle size which is approximately 8nm and high in metal-support interaction, and the like, and shows favorable catalytic activity, stabilityand anti-carbon performance to the reforming reaction of methane and carbon dioxide.

Owner:FUZHOU UNIV

Low-carbon alkane dehydrogenation catalyst preparation method

ActiveCN107486195ACluster controllableHigh dehydrogenation activityHeterogenous catalyst chemical elementsCatalystsAlkaneDehydrogenation

The invention discloses a low-carbon alkane dehydrogenation catalyst preparation method, which comprises: dissolving a high-valent chromium precursor in a reducing agent solution, impregnating into an alumina-based carrier, carrying out a reaction for 0.5-20 h at a temperature of 30-200 DEG C, washing, filtering, drying, impregnating into an aid, drying, and calcining to obtain the low-carbon alkane dehydrogenation catalyst. According to the present invention, the Cr cluster can be controlled; and the catalyst with the moderate Cr dispersion degree is obtained through the in-situ reduction method, such that the acid quantity of the acid B on the catalyst surface is reduced, the utilization efficiency of the active atom Cr is improved, and the dehydrogenation activity, the selectivity and the anti-carbon-deposition performance of the catalyst are improved.

Owner:PETROCHINA CO LTD +1

Perovskite catalyst, preparation method thereof and in-situ testing method of perovskite catalyst

InactiveCN108654592AHighly dispersed and stable dispersedImprove anti-coking performanceChemical analysis using catalysisHydrogenRare-earth elementAlkaline earth metal

The invention discloses a novel solid catalyst material for methane carbon dioxide reforming reaction, a corresponding widely-applicable preparation method and a simply and easily operated testing andreacting process. According to the perovskite catalyst, a substrate is a perovskite material which includes in-situ precipitated B-site doped metal nano-particles and an A site short of positive ions. The in-situ precipitated B-site high-activity metal nano-particles for catalyzing cover the surface of the substrate, the A site is any one of a rare earth element and an alkali-earth metal element,and a B-site substrate is doped transition metal with various valence states. The perovskite catalyst can provide good catalytic performances, and carbon deposit and catalyst deactivation caused by carbon deposit in reforming reaction are avoided. The in-situ precipitated-in-situ reaction preparation and testing method has the advantages of simplicity in operation, practicability, high efficiencyand novelty. The method has a good application prospect in a preparation and testing process of the catalyst.

Owner:HUAZHONG UNIV OF SCI & TECH

Catalyst for use in preparation of propylene by olefin cracking

InactiveCN102069007AIncrease surface areaIncrease active centerMolecular sieve catalystsHydrocarbonsMolecular sieveWater vapor

The invention discloses a catalyst for use in the preparation of propylene by olefin cracking, and a preparation method thereof. The catalyst is prepared by using molecular sieve raw powder of which the silicon to aluminum (molar) ratio is smaller than 300 as an active main body and by uniformly mixing the molecular sieve raw powder, silica sol and / or alumina sol and a template agent, forming by crystallization, drying, roasting, performing hydro-thermal treatment with high-temperature water vapor, and modifying by using rare earth metal and / or phosphorus as a modifier. The modifier comprises the following components in percentage by weight: 0.2 to 8 percent of rare earth metal, 0.1 to 5 percent of non-metal phosphorus and the balance of molecular sieve. The catalyst has high activity and stability and high propylene selectivity, and can be used in the field of propylene production industry.

Owner:王伟跃

Platinum catalyst supported on double-oxide composite carrier and preparation method and application of platinum catalyst

ActiveCN104148060APropylene selectivity is highImprove the ability to resist carbon depositionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsDouble oxideSol-gel

The invention discloses a platinum catalyst supported on a double-oxide composite carrier and a preparation method and an application of the platinum catalyst. The catalyst takes TiO2-Al2O3 double oxides as a carrier; the supported active component is Pt; the mass percentage content of Pt is 0.5-1.5%. The preparation method comprises the following steps: preparing the TiO2-Al2O3 double-oxide carrier by using a sol-gel method, subsequently dipping the obtained carrier into a chloroplatinic acid solution, drying and roasting, thereby obtaining the Pt / TiO2-Al2O3 catalyst. The catalyst disclosed by the invention is applicable to preparation of propylene by propane dehydrogenation in the presence of hydrogen atmosphere; and due to addition of TiO2, the acting forces between an active center and the product and a reactant are changed, so that the selectivity and the anti-carbon capability of propylene are improved, and relatively good reaction stability of the catalyst under the high temperature is ensured.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com