Ammonia-selective preparation method of SAPO-34 supported Cu-Fe catalyst for catalytically removing NOx

A SAPO-34, selective technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., to achieve high anti-coking performance, high hydrothermal stability, and stable catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

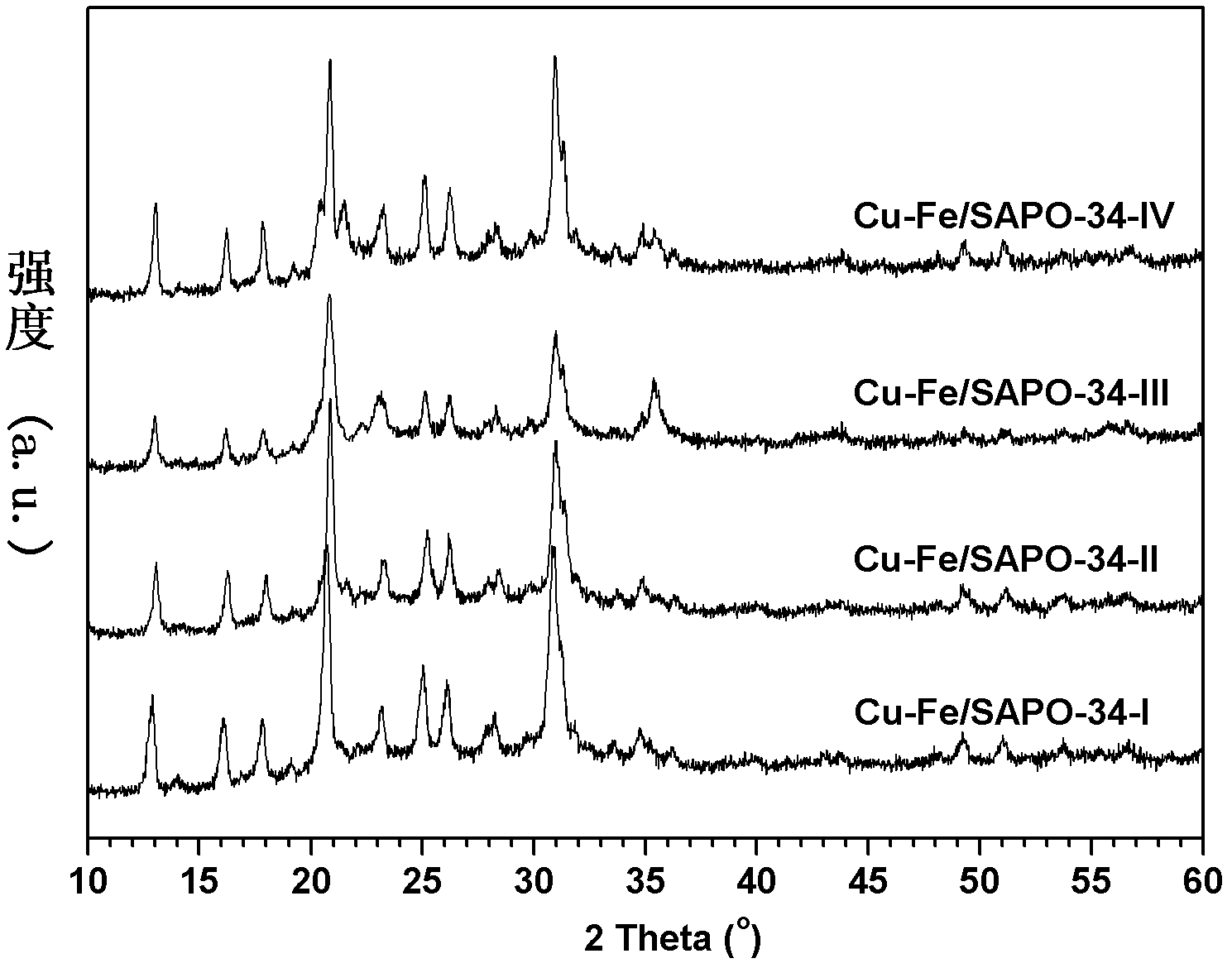

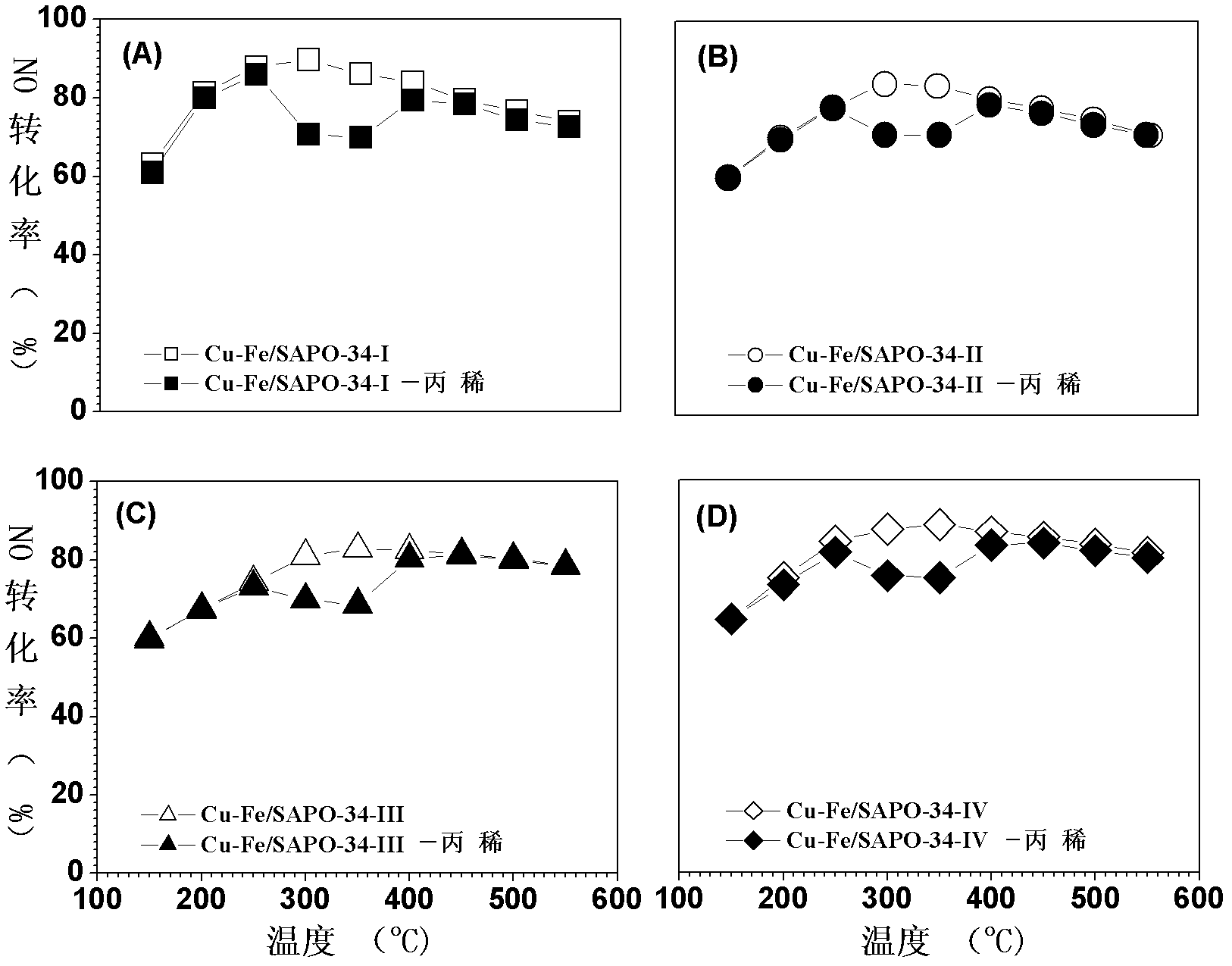

Embodiment 1

[0020] (1) Preparation of SAPO-34

[0021] Aluminum isopropoxide (Al(OC 3 h 7 ) 3 ), phosphoric acid solution and concentrated hydrochloric acid solution were dissolved in water to form a solution, and stirred evenly, and stood at room temperature for 5 days, then added silica sol to the above solution, and stirred evenly, then added tetraethylammonium hydroxide solution, stirred evenly , finally obtain the sol composition ratio (molar molecular weight ratio) as follows:

[0022] 1.39 (TEA) 2 O:0.2SiO 2 : 1.0Al 2 o 3 : 0.88P 2 o 5 : 0.21HCl

[0023] The above sol was left at room temperature for 5 days, and then the sol was added to a stainless steel reactor lined with polytetrafluoroethylene, heated to 200°C, and kept at a constant temperature for 80 hours. The solid product was then filtered, washed and dried in air at 30°C. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 400° C. for 15 hours in an oxygen atmos...

Embodiment 2

[0030] (1) Preparation of SAPO-34

[0031] Aluminum isopropoxide (Al(OC 3 h 7 ) 3 ), phosphoric acid solution and concentrated hydrochloric acid solution were dissolved in water to form a solution, and stirred evenly, and stood at room temperature for 7 days, then added silica sol to the above solution, and stirred evenly, then added tetraethylammonium hydroxide solution, stirred evenly , finally obtain the sol composition ratio (molar molecular weight ratio) as follows:

[0032] 1.11 (TEA) 2 O: 0.33SiO 2 : 1.0Al 2 o 3 : 0.71P 2 o 5 : 0.17HCl

[0033] The above sol was left at room temperature for 7 days, and then the sol was added to a stainless steel reactor lined with polytetrafluoroethylene, heated to 220°C, and kept at a constant temperature for 90 hours. The solid product was then filtered, washed and dried in air at 50°C. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 500° C. for 18 hours in an oxygen atm...

Embodiment 3

[0040] (1) Preparation of SAPO-34

[0041] Aluminum isopropoxide (Al(OC 3 h 7 ) 3 ), phosphoric acid solution and concentrated hydrochloric acid solution were dissolved in water to form a solution, and stirred evenly, and stood at room temperature for 8 days, then added silica sol to the above solution, and stirred evenly, then added tetraethylammonium hydroxide solution, stirred evenly , finally obtain the sol composition ratio (molar molecular weight ratio) as follows:

[0042] 0.83(TEA) 2 O: 0.31SiO 2 : 1.0Al 2 o 3 : 0.66P 2 o 5 : 0.16HCl

[0043] The above sol was left at room temperature for 8 days, and then the sol was added to a stainless steel reactor lined with polytetrafluoroethylene, heated to 230°C, and kept at a constant temperature for 100 hours. The solid product was then filtered, washed and dried in air at 70°C. In order to remove the template agent and other impurities, the obtained solid matter was calcined at 500° C. for 18 hours in an oxygen atm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com