Catalyst for synthesis of methyl methacrylate by formaldehyde and methyl propionate and preparation method of catalyst

A technology for methyl methacrylate and methyl propionate, which is applied in the field of catalysts for synthesizing methyl methacrylate, can solve problems such as low reaction activity, and achieve the effects of simple preparation method, improved activity, and improved anti-poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

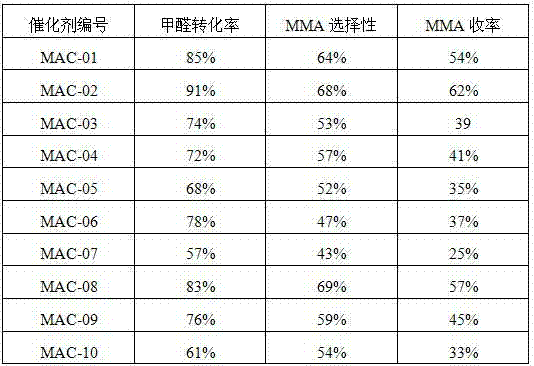

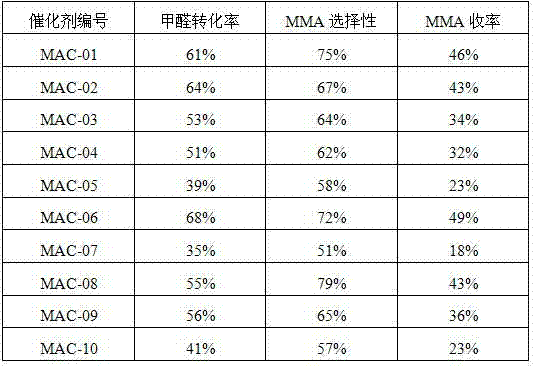

Examples

Embodiment 1

[0033] The catalyst of this embodiment consists of 20% active component, 5% coagent and 75% carrier. The active component is cesium acetate with a content of 20% of cesium oxide in the catalyst, the active agent is silver nitrate with a content of 5% of silver oxide, and the carrier is composed of 88% silicon dioxide, 10% activated alumina and 2% composition of zirconia. The preparation method is as follows:

[0034] (1) Weigh 36.3g of cesium acetate and dissolve it in deionized water to make an aqueous solution;

[0035] (2) Weigh nano-SiO 2 88g, pseudo-boehmite 14g, ZrO 2 2g, after mixing evenly, add the solution prepared in step (1) for kneading, extruding, drying at 100°C for 4 hours, and calcining at 500°C for 4 hours to obtain a catalyst precursor;

[0036] (3) Weigh 7.7gAgNO 3 , add deionized water to dissolve and make a solution;

[0037] (4) Weigh 100 g of the catalyst precursor prepared in step (2) and immerse in the aqueous solution prepared in step (3), immer...

Embodiment 2

[0039] The catalyst of this embodiment consists of 15% active component, 2% coagent and 83% carrier. The active component is cesium nitrate equivalent to 15% cesium oxide content in the catalyst, the active auxiliary agent is silver nitrate equivalent to 2% silver oxide content, and the carrier is composed of 89% silicon dioxide, 10% activated alumina and 1% composition of zirconia. The preparation method is as follows:

[0040] (1) Weigh 49.98g CsNO 3 Add deionized water to dissolve and make an aqueous solution;

[0041] (2) Weigh nano-SiO 2 178g, pseudoboehmite 28g, ZrO 22g, after mixing evenly, add the solution prepared in step (1) for kneading, extruding, drying at 100°C for 4 hours, and calcining at 500°C for 4 hours to obtain a catalyst precursor;

[0042] (3) Weigh 3.0gAgNO 3 , add deionized water to dissolve and make a solution;

[0043] (4) Weigh 100 g of the catalyst precursor prepared in step (2) and immerse in the aqueous solution prepared in step (3), immer...

Embodiment 3~5

[0045] The catalyzer of embodiment 3~5 is made up of 10% active ingredient, 1% coagent and 89% carrier. The active component is cesium nitrate equivalent to 10% cesium oxide in the catalyst, and the active additives are silver nitrate and SbCl 3 1. Niobium oxalate, calculated as oxide, the mass percentage is 1.0%, and the carrier is composed of 75% silicon dioxide, 20% activated alumina and 5% zirconia. The preparation method is as follows:

[0046] (1) Weigh 46.6gCsNO 3 Add deionized water to dissolve and make an aqueous solution;

[0047] (2) Weigh nano-SiO 2 225g, pseudo-boehmite 86g, ZrO 2 15g, after mixing evenly, add the solution prepared in step (1) for kneading, extruding, drying at 100°C for 6 hours, and calcining at 400°C for 4 hours to obtain a catalyst precursor;

[0048] (3) Weigh 1.2gAgNO respectively 3 , 1.3gSbCl 3 Dissolve 1.5g niobium oxalate in water to make 3 solutions;

[0049] (4) Weigh 80g of the catalyst precursor prepared in step (2), immerse in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com