Application of a Methane Reforming Catalyst in Molten Carbonate Fuel Cell

A technology for molten carbonate and reforming catalysts, applied in physical/chemical process catalysts, battery electrodes, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of unexplained catalyst activity evaluation and high operating temperature , to achieve good anti-alkali poisoning ability, high catalytic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 19.7% Ni catalyst, the preparation method is as follows:

[0041] Weigh 6.0g of Ni (NO 3 ) 2 ·6H 2 O, dissolve it in 2ml deionized water, after the nitrate is completely dissolved, add 5.0g Al 2 O 3 The carrier is impregnated with Ni(NO 3 ) 2In the solution, after the solution was completely adsorbed on the carrier, the carrier with nitrate was placed in an 80°C incubator to dry for 5h. dried Al 2 O 3 Put it into a muffle furnace for calcination, calcined at 450 ℃ for 3 hours, and calcined at a high temperature of 650 ℃ for 3 hours.

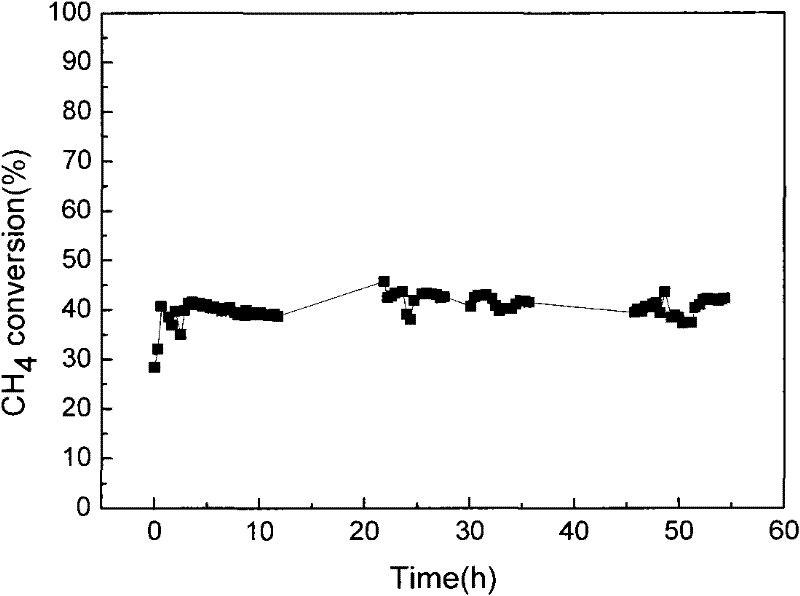

[0042] 1.0 g of the catalyst was weighed into a fixed-bed quartz tube reactor for activity evaluation. The inner diameter of the quartz tube is 10mm and the height is 800mm. The reactor was fed with a mixture of hydrogen and nitrogen (molar ratio of 3:7) at a heating rate of 3 °C / min to 650 °C, continued reduction at 650 °C for 5 h, and then the mixture of hydrogen and nitrogen was switched to methane and water. When evaluated w...

Embodiment 2

[0044] 25% Ni catalyst, the preparation method is as follows:

[0045] Weigh 8.2g Ni (NO 3 ) 2 ·6H 2 O, dissolve it in 2.5 ml of deionized water, and the subsequent steps are the same as in Example 1.

[0046] The catalyst was evaluated for activity in a quartz tube. At 650℃, when S / C=2, the methane conversion rate reaches 73.8%.

Embodiment 3

[0048] 3%Ce+17.7%Ni catalyst by sub-impregnation method, the preparation method is as follows:

[0049] Weigh 0.56g Ce (NO 3 ) 3 ·6H 2 O Prepare 3% Ce catalyst according to the method of Example 1. Then weigh 5.3g Ni (NO 3 ) 2 ·6H 2 O, dissolve it in an appropriate amount of deionized water, and immerse the prepared 3% Ce catalyst in a nickel nitrate solution, and the subsequent steps are the same as those in Example 1. A catalyst impregnated with Ce first and then with Ni was obtained.

[0050] The catalyst was evaluated for activity in a quartz tube. At 650°C, when S / C=2, the methane conversion rate was 73.9%, and the hydrogen yield was 74.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com