Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261 results about "Molten carbonate fuel cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molten-carbonate fuel cells (MCFCs) are high-temperature fuel cells that operate at temperatures of 600 °C and above. Molten carbonate fuel cells (MCFCs) are currently being developed for natural gas, biogas (produced as a result of anaerobic digestion or biomass gasification), and coal-based power plants for electrical utility, industrial, and military applications. MCFCs are high-temperature fuel cells that use an electrolyte composed of a molten carbonate salt mixture suspended in a porous, chemically inert ceramic matrix of beta-alumina solid electrolyte (BASE). Since they operate at extremely high temperatures of 650 °C (roughly 1,200 °F) and above, non-precious metals can be used as catalysts at the anode and cathode, reducing costs.

Energy efficient gas separation for fuel cells

InactiveUS20020142208A1Improve efficiencyReduce the ratioFuel cell heat exchangeFused electrolyte fuel cellsEngineeringDelivery system

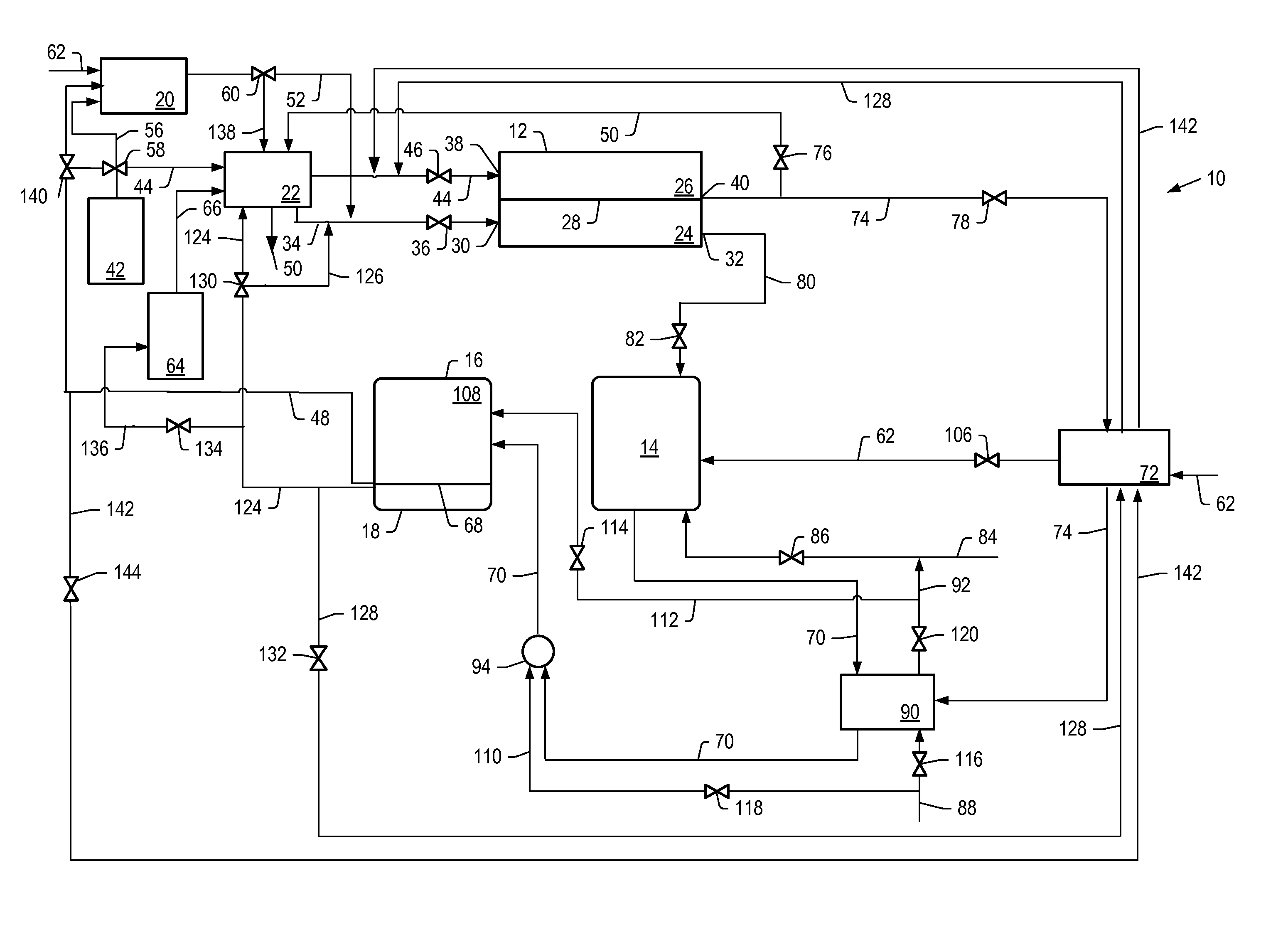

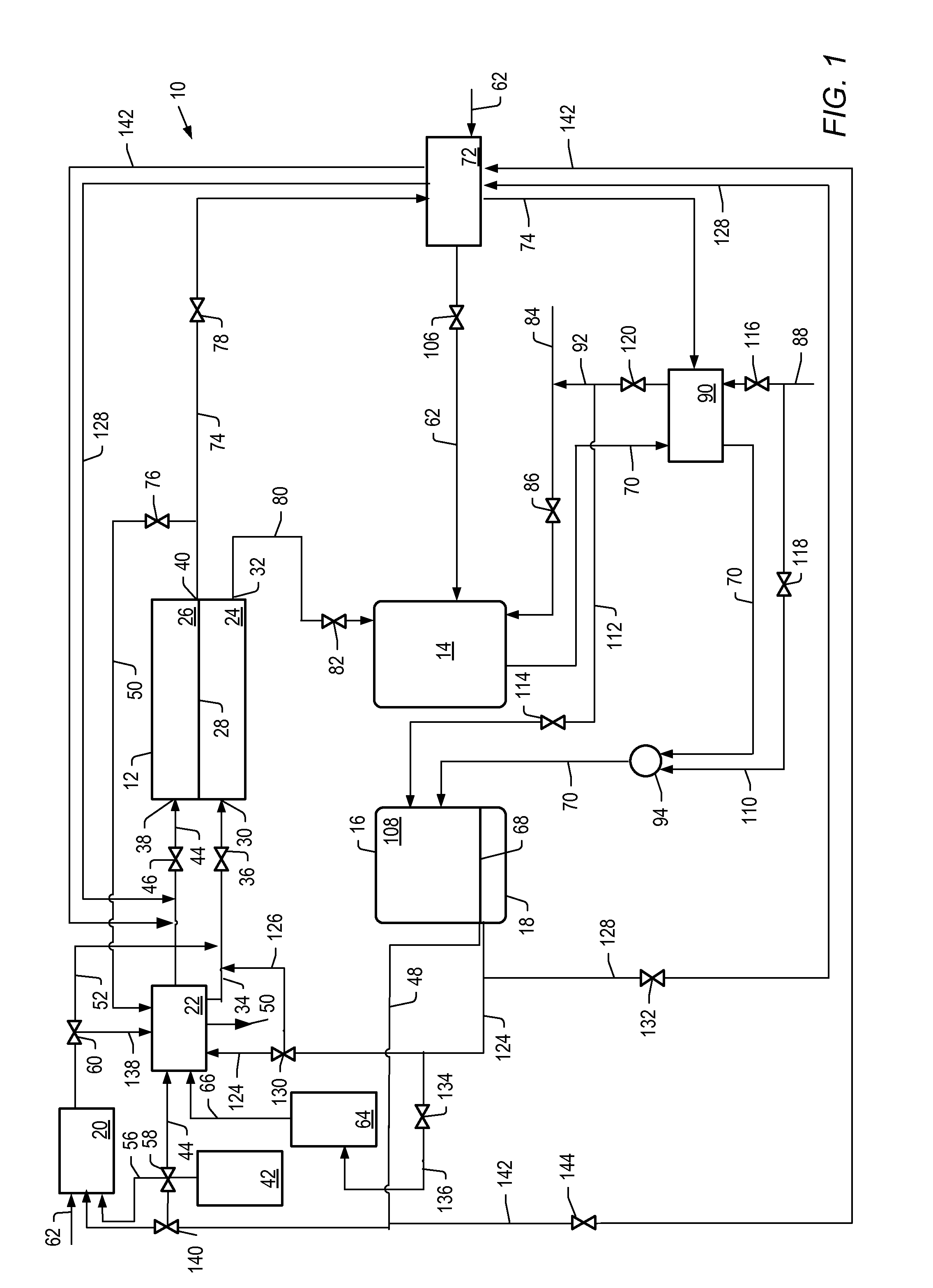

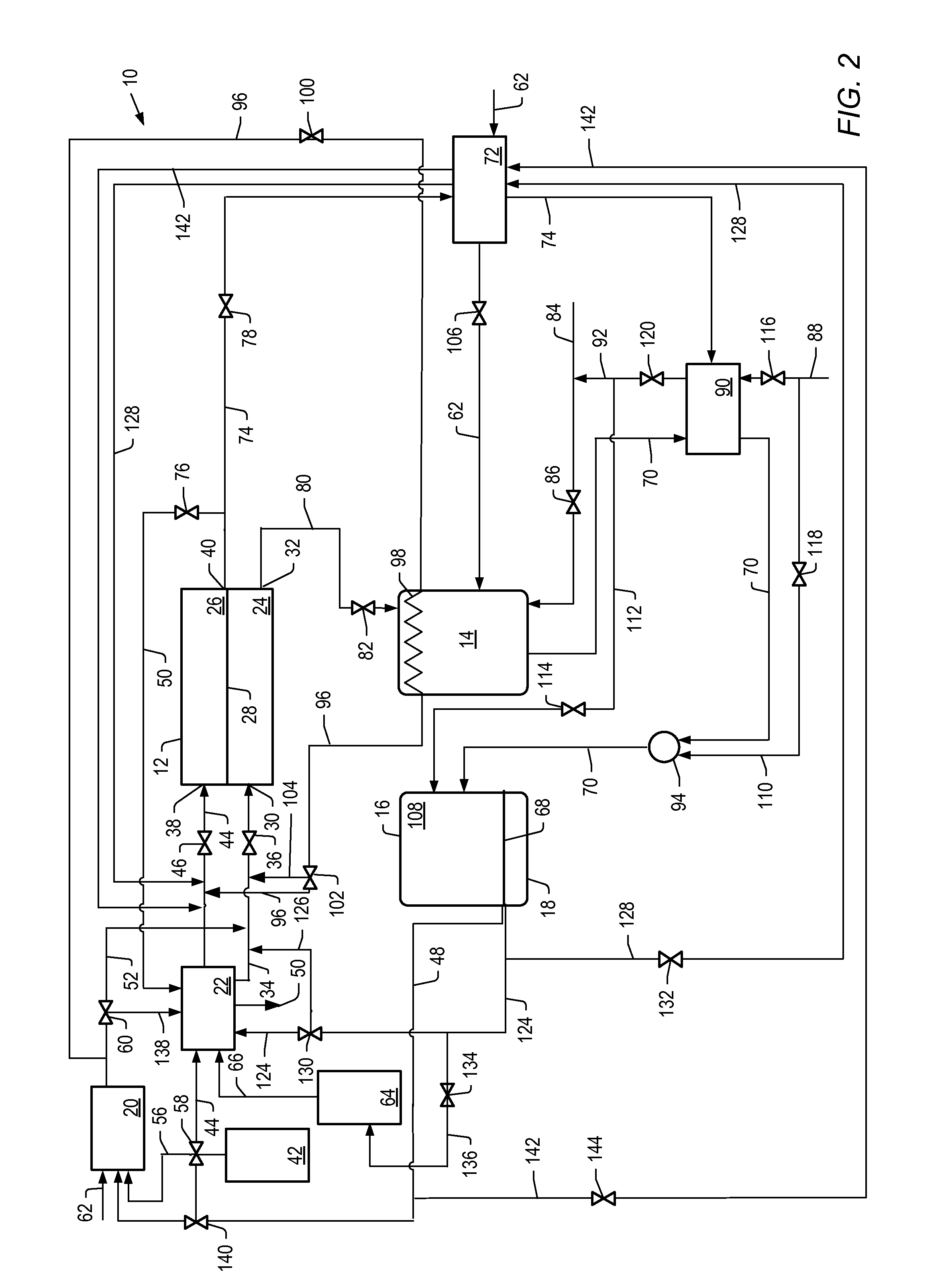

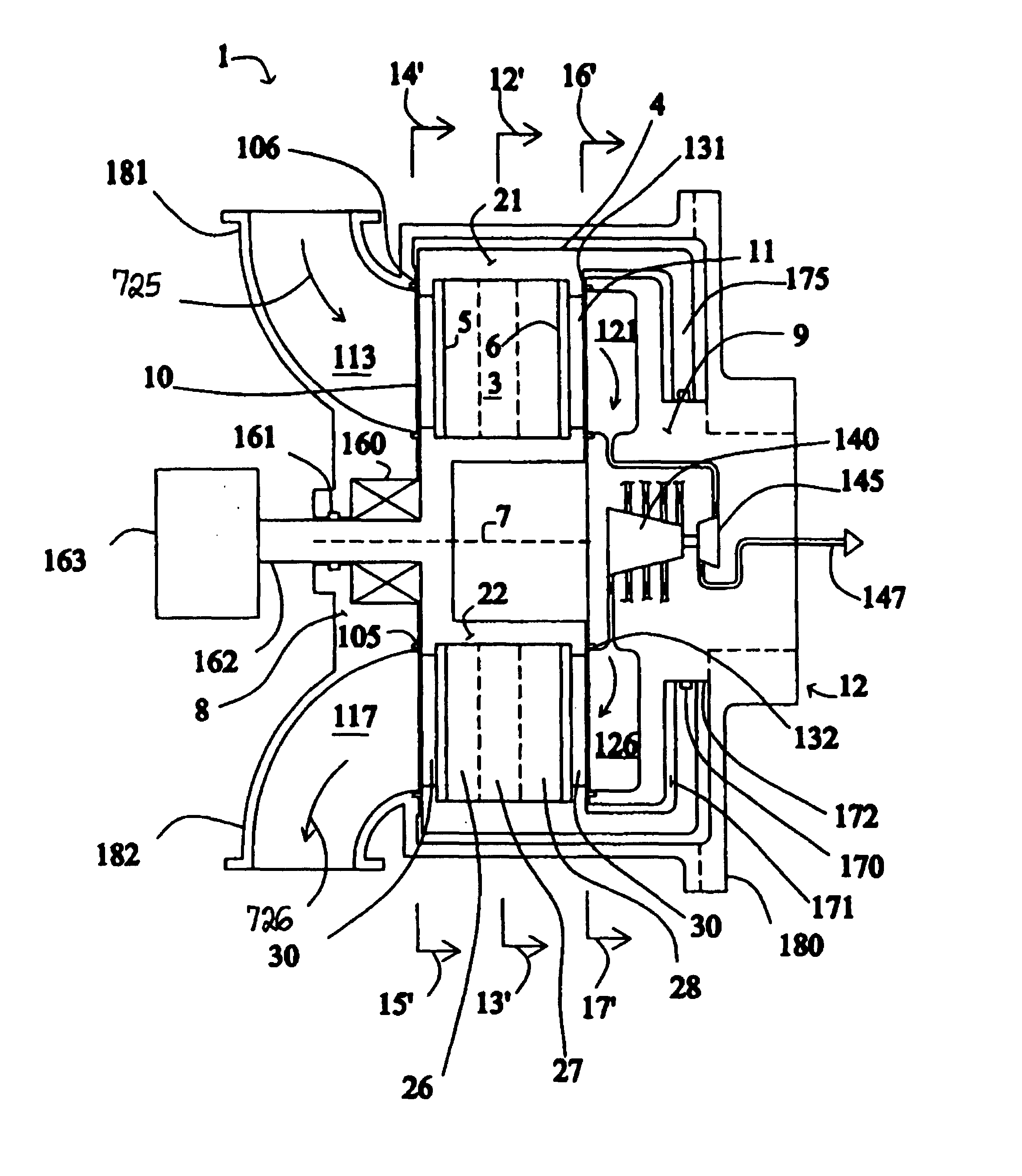

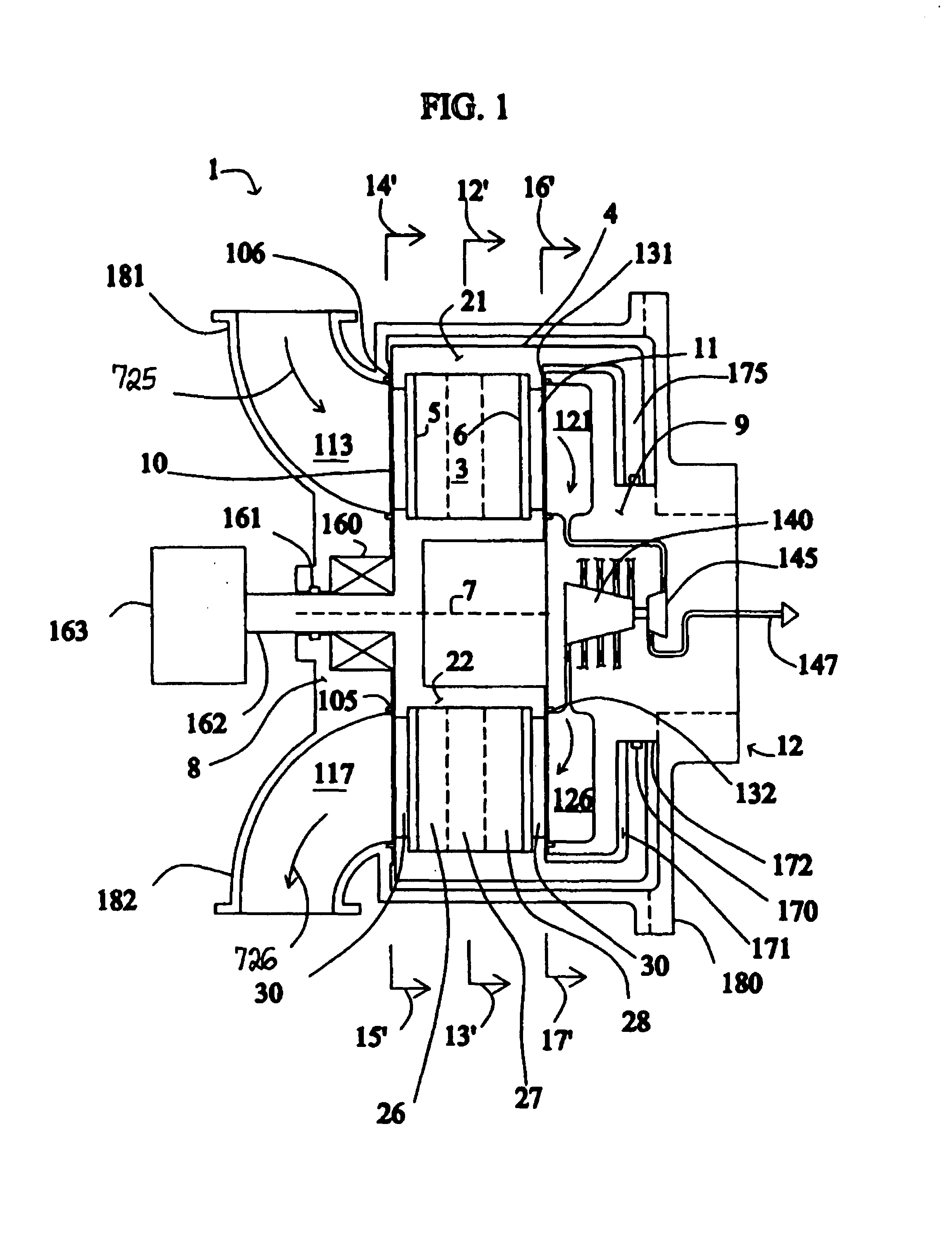

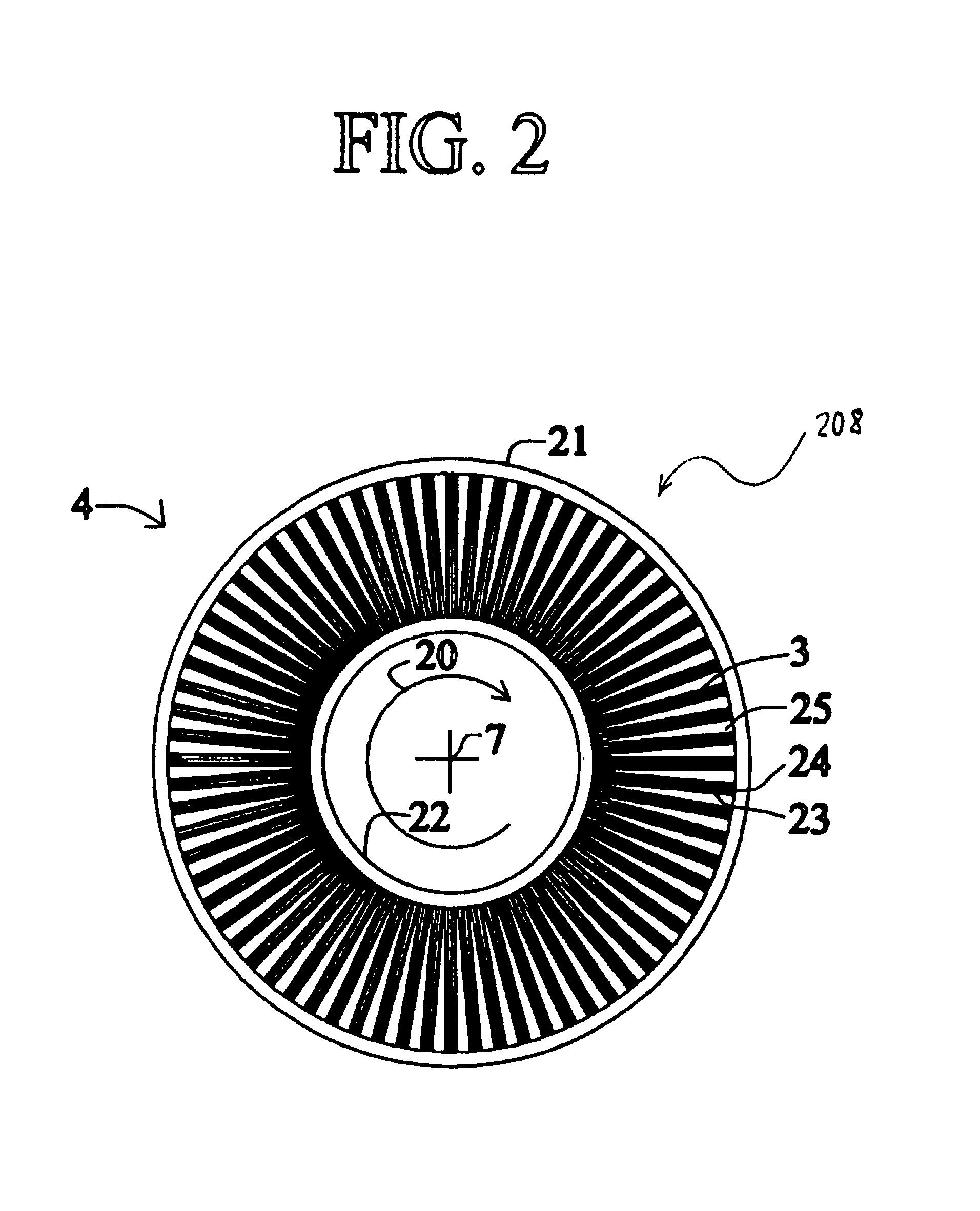

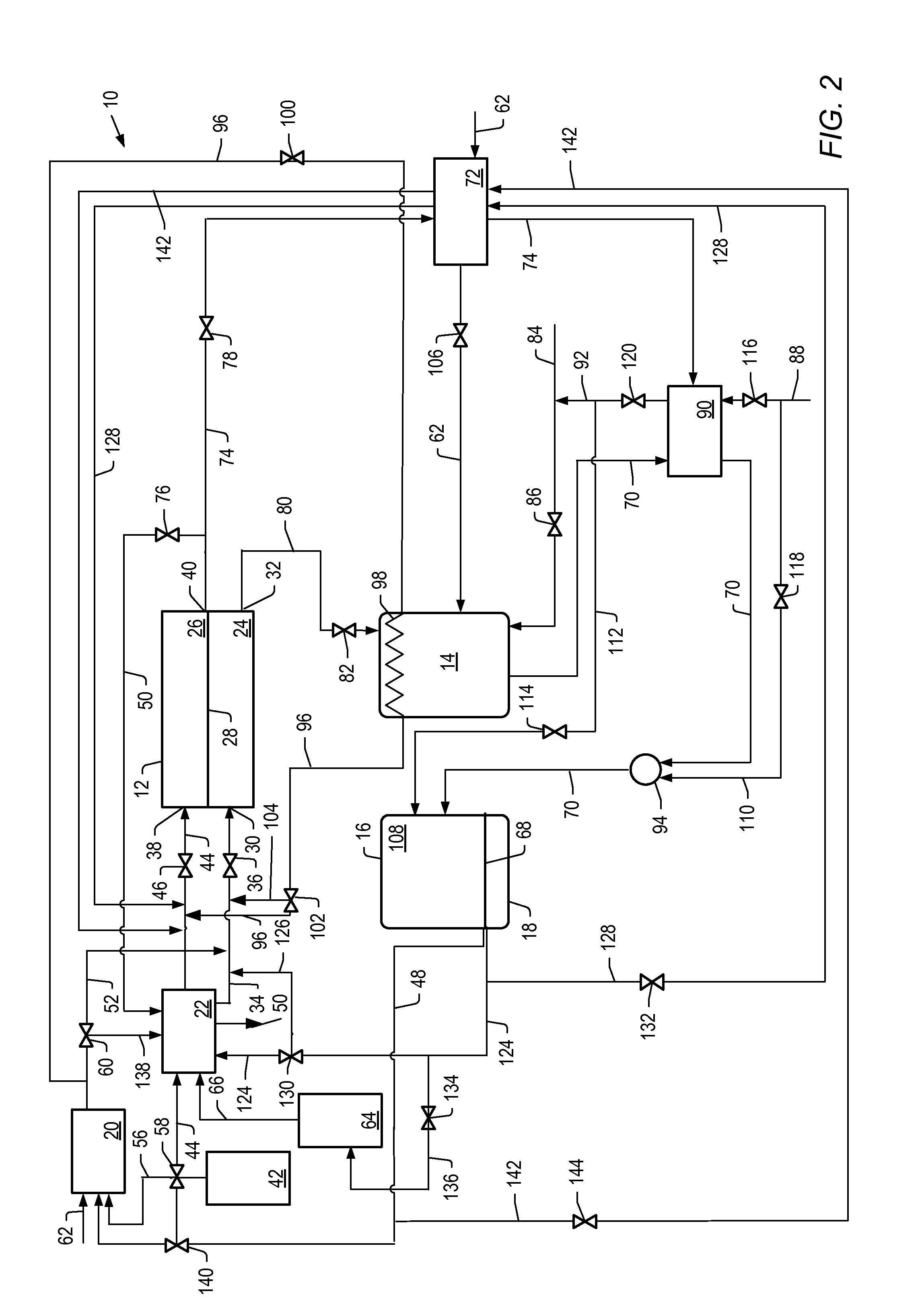

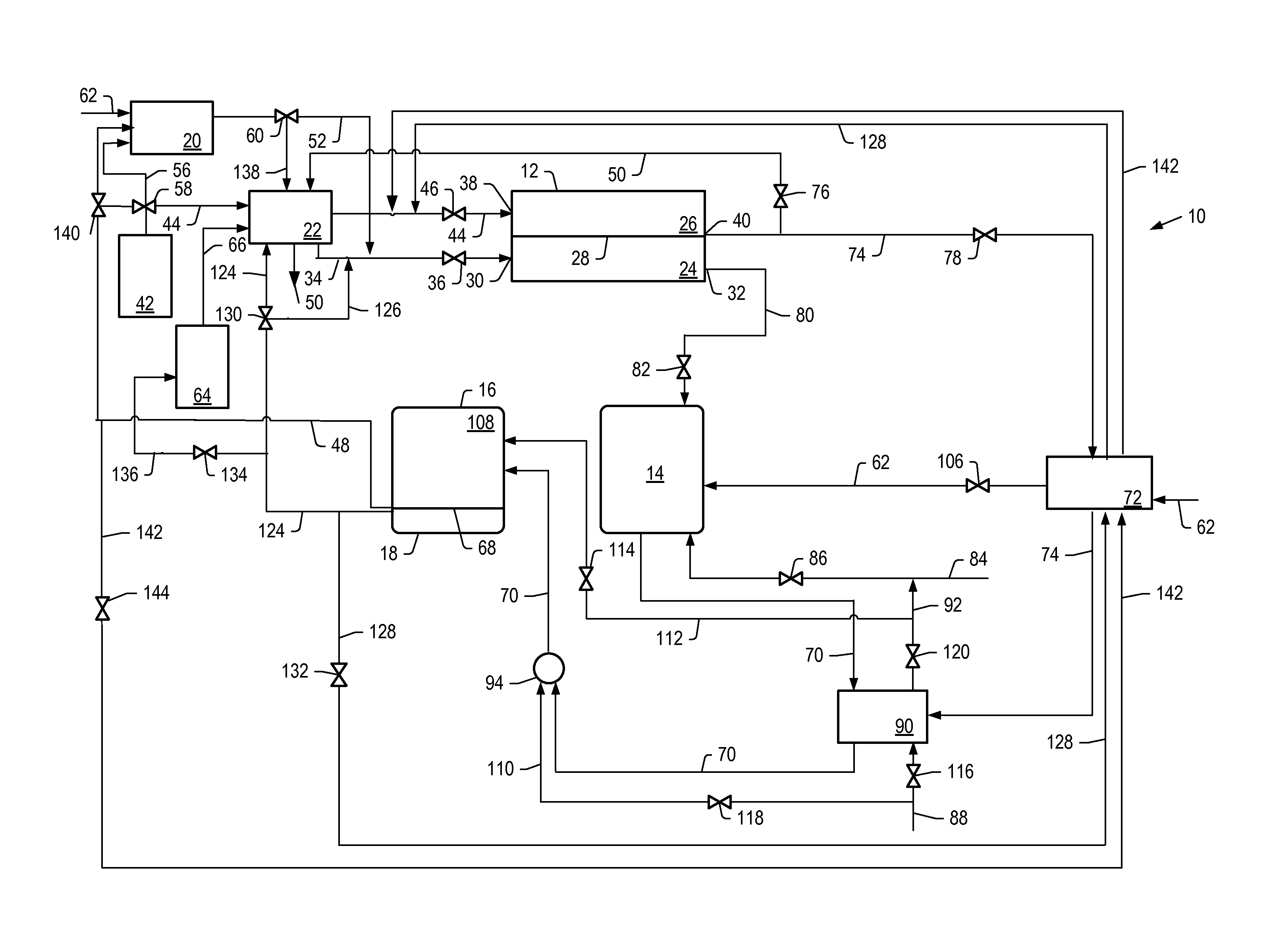

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

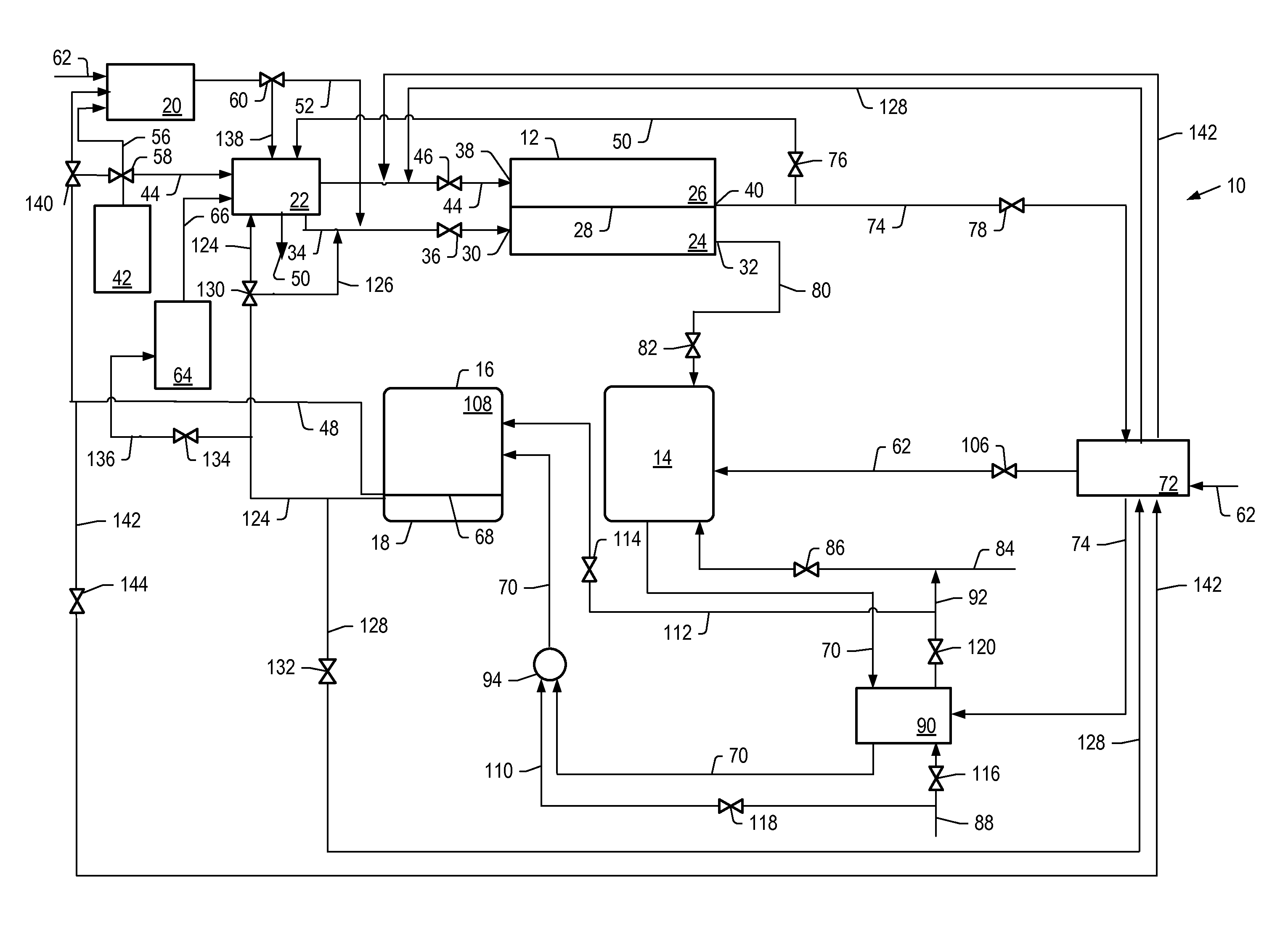

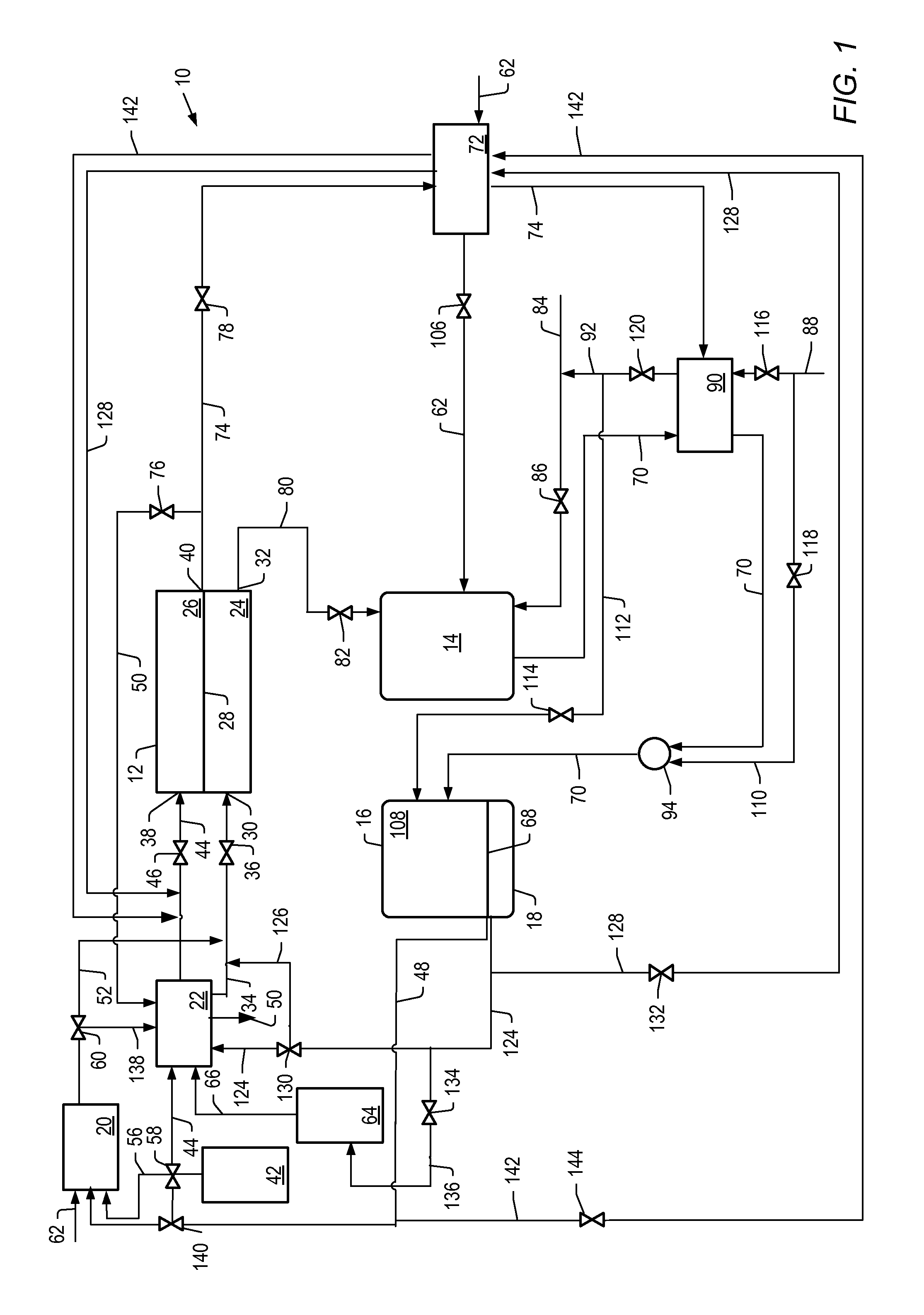

Systems and processes of operating fuel cell systems

InactiveUS20110111315A1Well mixedFuel cell auxillariesFused electrolyte fuel cellsSteam reformingFuel cells

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

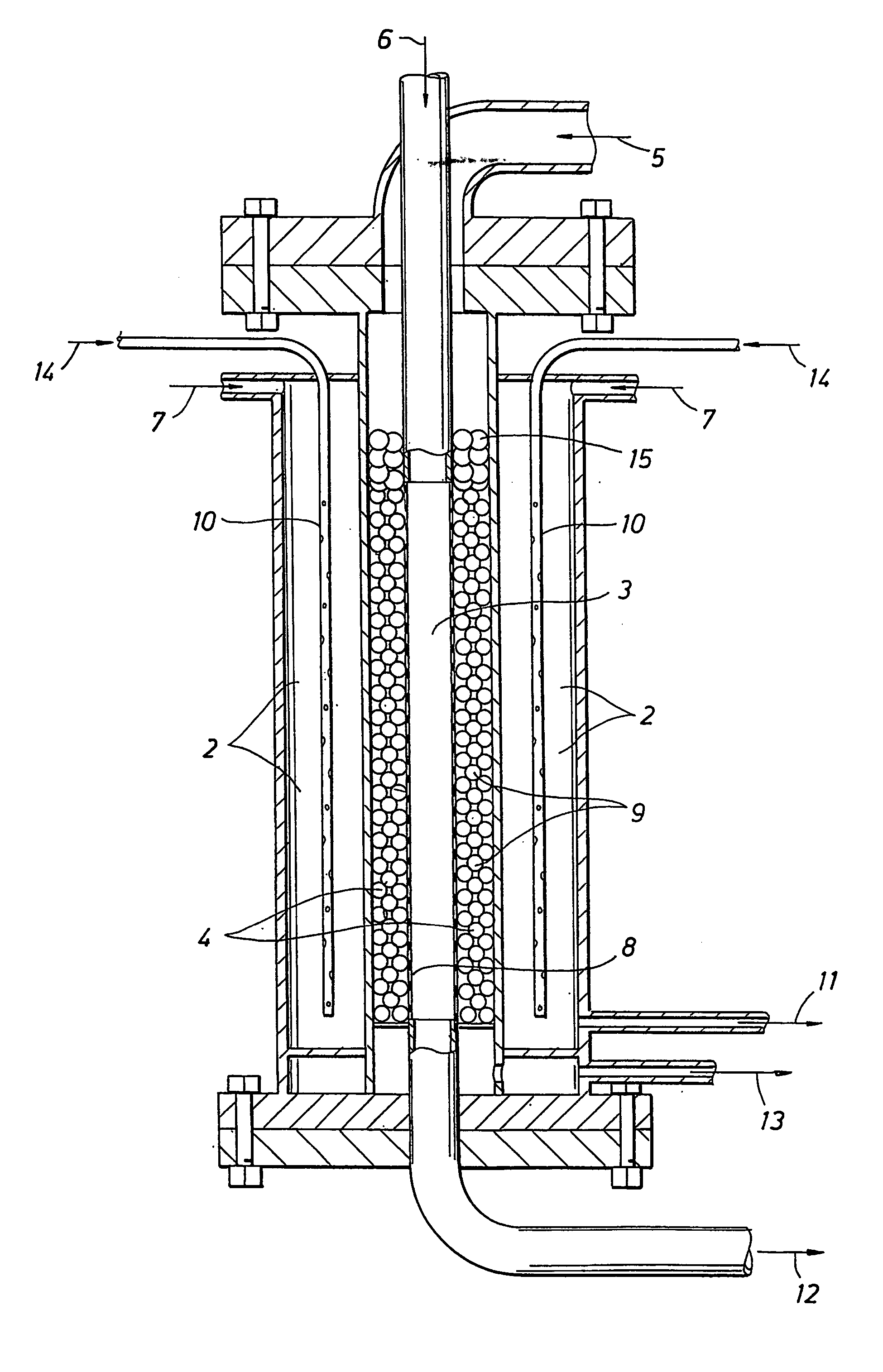

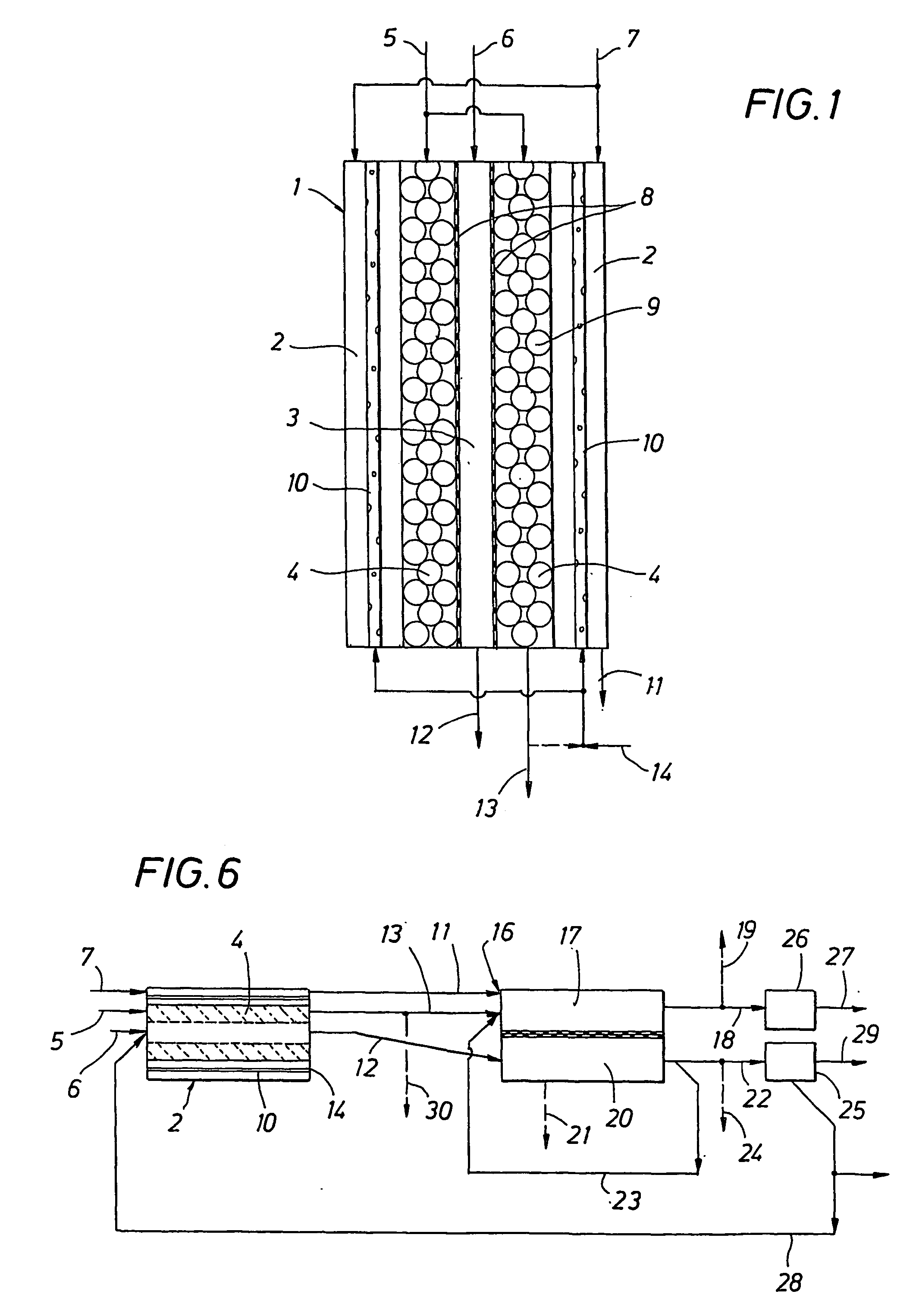

Apparatus and process for production of high purity hydrogen

InactiveUS20060248800A1High purityEnhanced overall recoveryCarbon compoundsIndirect carbon-dioxide mitigationSteam reformingCombustion chamber

The invention relates to a new and improved process and apparatus for the production of high purity hydrogen by steam reforming. The apparatus is an integrated flameless distributed combustion-membrane steam reforming (FDC-MSR) or reactor for steam reforming of a vaporizable hydrocarbon to produce H2 and CO2, with minimal CO, and minimal CO in the H2 stream. The flameless distributed combustion drives the steam reforming reaction which pro-vides great improvements in heat exchange efficiency and load following capabilities. The reactor may contain multiple flameless distributed combustion chambers and multiple hydrogen-selective, hydrogen-permeable, membrane tubes. The feed and reaction gases may flow through the reactor either radially or axially. A further embodiment of the invention involves producing high purity hydrogen by dehydrogenation using an integrated FDC-membrane de-hydrogenation reactor. A still further embodiment of the invention involves a zero emission hybrid power system wherein the produced hydrogen is used to power a high-pressure internally manifolded molten carbonate fuel cell. In addition, the design of the FDC-SMR powered fuel cell makes it possible to capture good concentrations of CO2 for sequestration or use in other processes.

Owner:SHELL OIL CO

Energy efficient gas separation for fuel cells

InactiveUS7087331B2Intuitive effectFully purifiedFuel cell heat exchangeFused electrolyte fuel cellsDelivery systemSolid oxide fuel cell

An electrical current generating system is disclosed that includes a fuel cell operating at a temperature of at least about 250° C. (for example, a molten carbonate fuel cell or a solid oxide fuel cell), a hydrogen gas separation system or oxygen gas delivery system that includes a compressor or pump, and a drive system for the compressor or pump that includes means for recovering energy from at least one of the hydrogen gas separation system, oxygen gas delivery system, or heat of the fuel cell. The drive system could be a gas turbine system. The hydrogen gas separation system or the oxygen gas delivery system may include a pressure swing adsorption module.

Owner:AIR PROD & CHEM INC

Hydrogen recycle for high temperature fuel cells

InactiveUS20040197612A1Improve efficiencyImprove sustainabilityGas treatmentRegenerative fuel cellsOxygenContamination

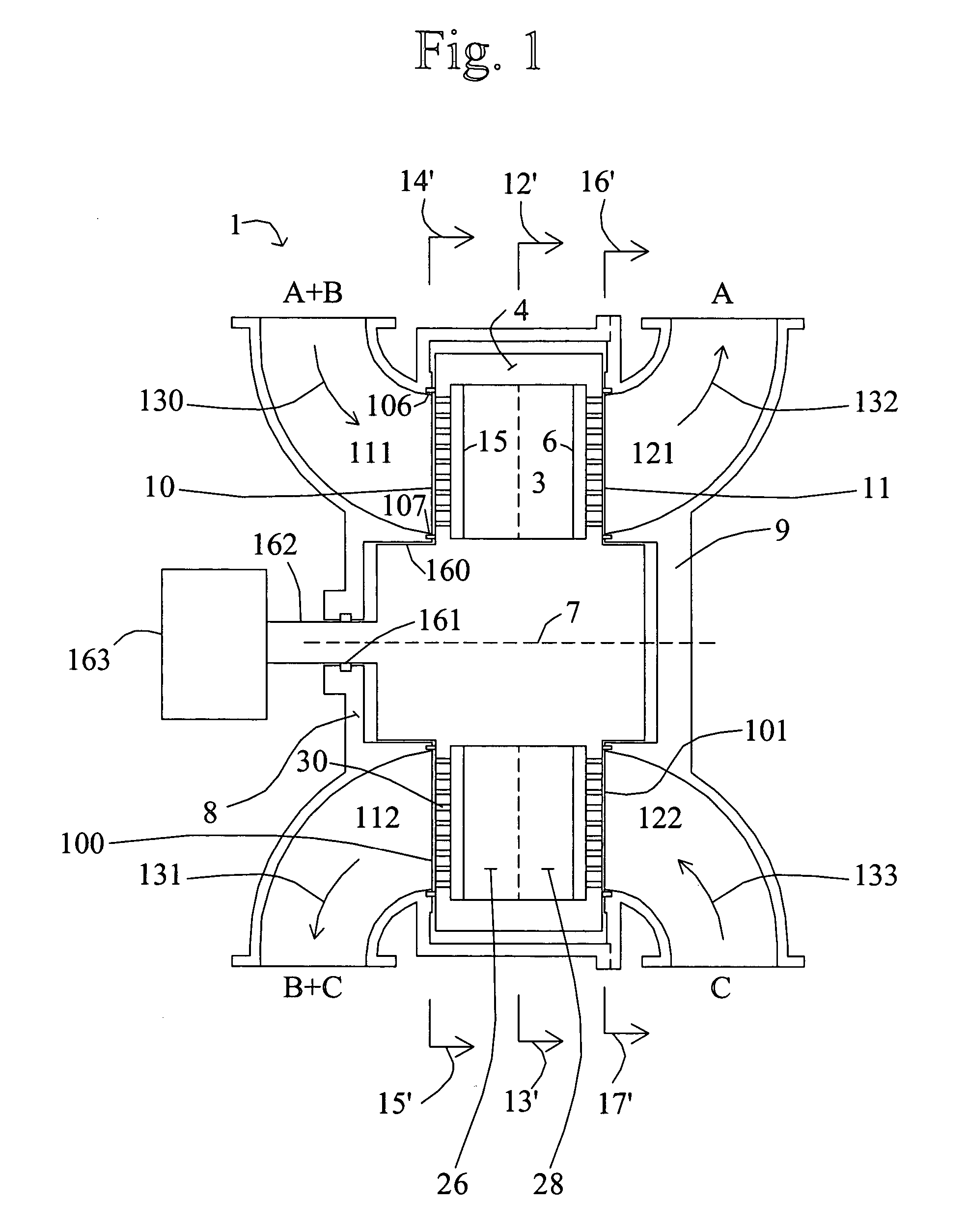

High temperature fuel cell electrical generation systems are provided that are adapted to enable selective generation of electrical power, and / or hydrogen fuel, and / or useable heat, allowing flexible operation of the generation system. In such embodiments, the high temperature fuel cell may be either a MCFC or a SOFC. The disclosed systems relate to high temperature fuel cells exploiting gas separation devices in which a first gas mixture is to be separated so that a first product of the separation is enriched in a first component, while a second component is mixed with a displacement purge stream to form a second gas mixture, with provision to prevent cross contamination of purge gas components into the first product stream. The process may be applied to hydrogen (component A) enrichment from syngas mixtures such as fuel cell anode exhaust, where dilute carbon dioxide (component B) is to be rejected such as to the atmosphere or for recycle to the fuel cell cathode in the case of molten carbonate fuel cells, by purging with cathode exhaust oxygen-depleted air (as component C).

Owner:QUSIR TECH

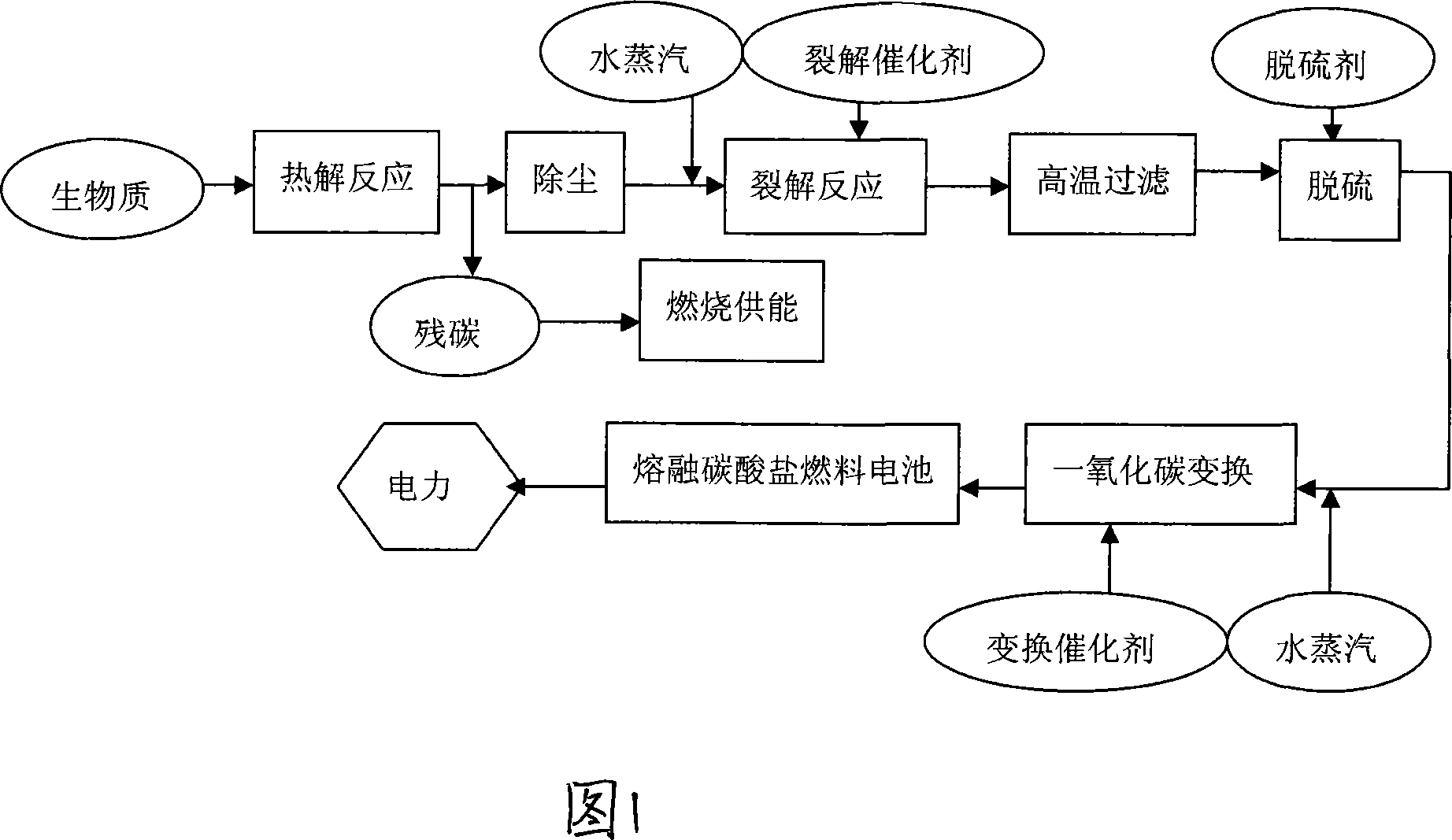

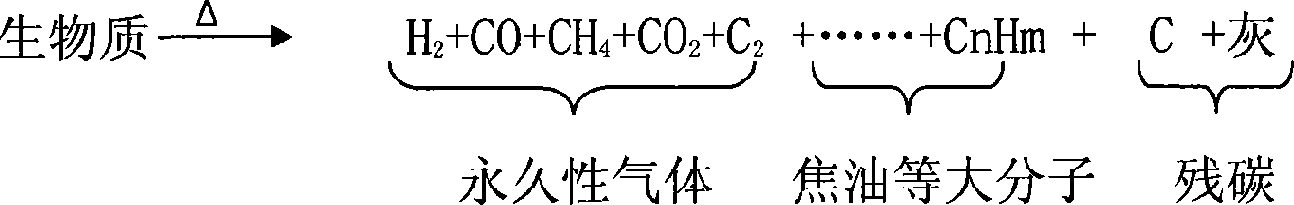

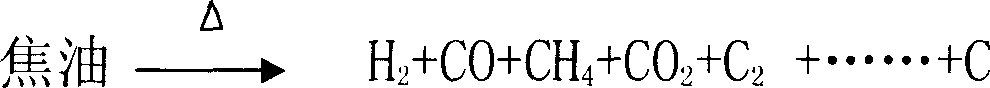

Biomass hydrogen energy electric generation method

InactiveCN101098022AIncrease profitOptimize layoutEnergy inputFused electrolyte fuel cellsElectricityHydrogen

A biomass hydrogen energy generating method is characterized in that using biomass thermal chemical hydrogen generating method to convert biomass into clean high-temperature hydrogen-abundant fuel gas, which can be directly used in fusion carbonate fuel battery without purification to generate electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Systems and processes for operating fuel cell systems

The present invention is directed to systems and processes of operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen from a high temperature hydrogen-separation device to a molten carbonate fuel cell, wherein the high temperature hydrogen-separation device comprises one or more high temperature hydrogen-separating membranes; mixing at least a portion of hydrocarbons to be provided to, or provided to, a first reformer with anode exhaust from the molten carbonate fuel cell; at least partially reforming some of the hydrocarbons in the first reformer to produce a steam reforming feed; and providing the steam reforming feed to a second reformer, wherein the second reformer comprises the high temperature hydrogen-separation device or the second reformer is operatively coupled to the high temperature hydrogen-separation device, and the high temperature hydrogen-separation device is configured to produce at least a portion of the stream comprising molecular hydrogen provided to the molten carbonate fuel cell.

Owner:SHELL OIL CO

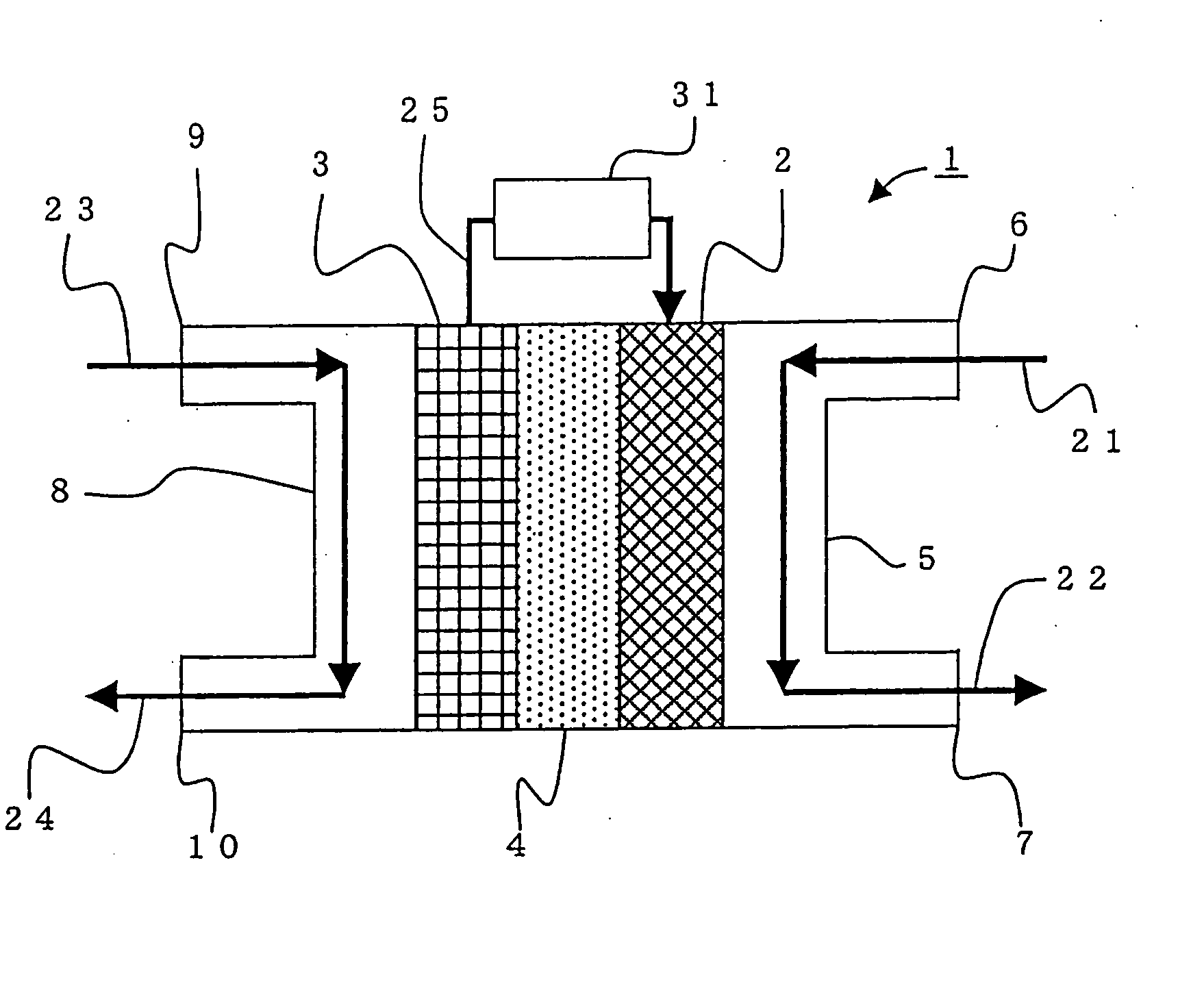

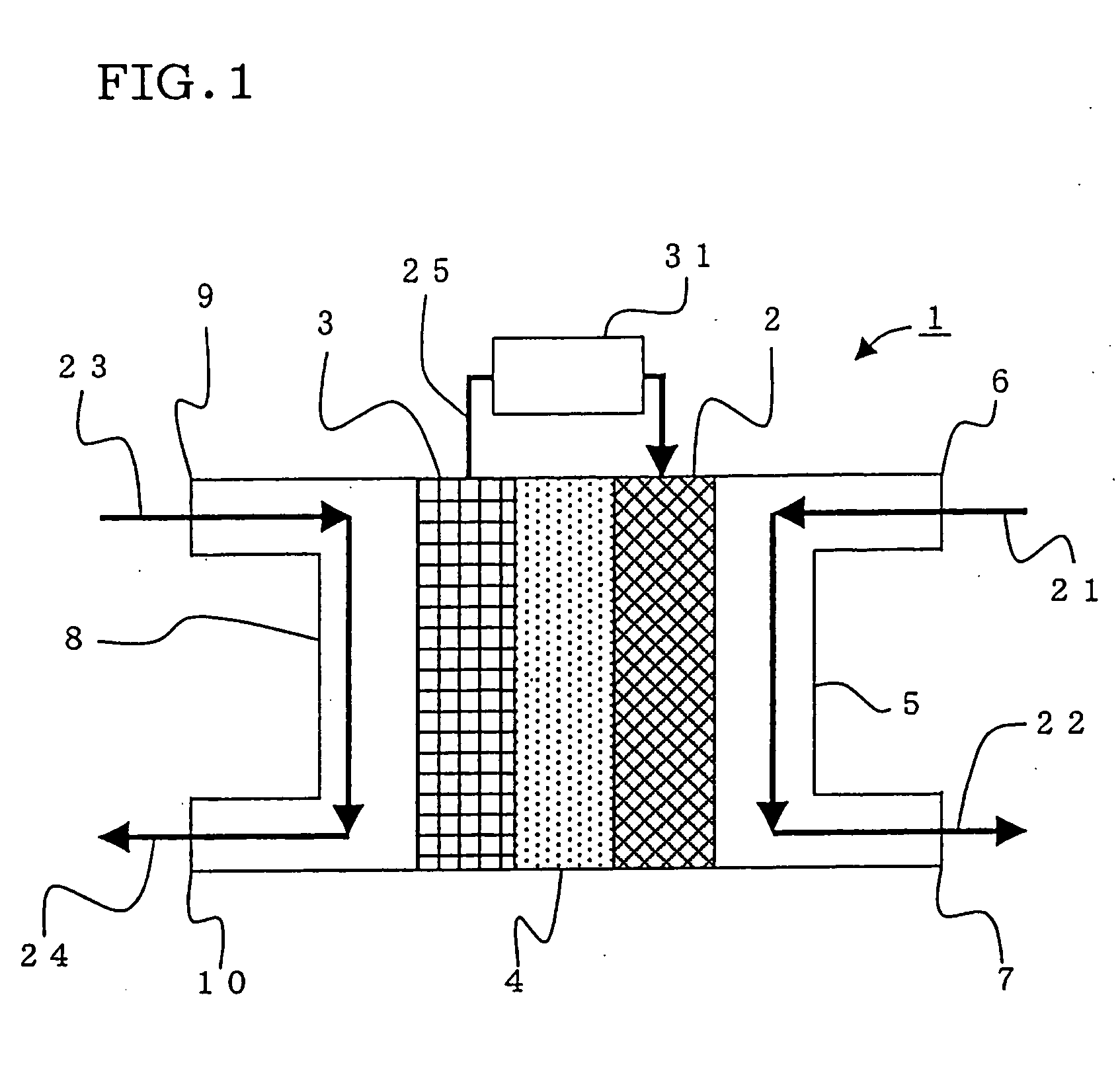

Fuel cell, operating method thereof, sintering furnace, and power generator

InactiveUS20060127718A1Increase carbon dioxide concentrationEfficient heatingHydrogen separationChemical industryFuel cellsMetallurgy

A molten carbonate fuel cell, operating method of the fuel cell, sintering furnace equipped with the fuel cell, and power generator, wherein a cathode gas with a high carbon dioxide concentration can be obtained without a process of increasing the carbon dioxide concentration, and the heat of furnace exhaust gas can be effectively reclaimed and the fuel consumption can be reduced. The cathode gas is a gas containing a furnace exhaust gas discharged from an industrial furnace for heating materials, a mixed gas of the furnace exhaust gas and a gas for cathode use or a preheated gas for cathode use, which is a gas for cathode use preheated using the furnace exhaust gas as a heating source, or the preheated gas for cathode use, and the carbon dioxide concentration of the cathode gas is 0.1-50 vol %.

Owner:NGK INSULATORS LTD

Systems and processes of operating fuel cell systems

The present invention is directed to systems and processes for operating molten carbonate fuel cell systems. A process for operating the molten carbonate fuel cell includes providing a hydrogen-containing stream comprising molecular hydrogen to a molten carbonate fuel cell anode; heating a hydrocarbon stream, at least a majority of which is comprised of hydrocarbons that are liquid at 20° C. and atmospheric pressure, with a heat source comprising an anode exhaust from the molten carbonate fuel cell anode; contacting at least a portion of the heated hydrocarbon stream with a catalyst to produce a steam reforming feed comprising gaseous hydrocarbons, hydrogen, and at least one carbon oxide; separating at least a portion of the molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode as at least a portion of the stream comprising molecular hydrogen.

Owner:SHELL OIL CO

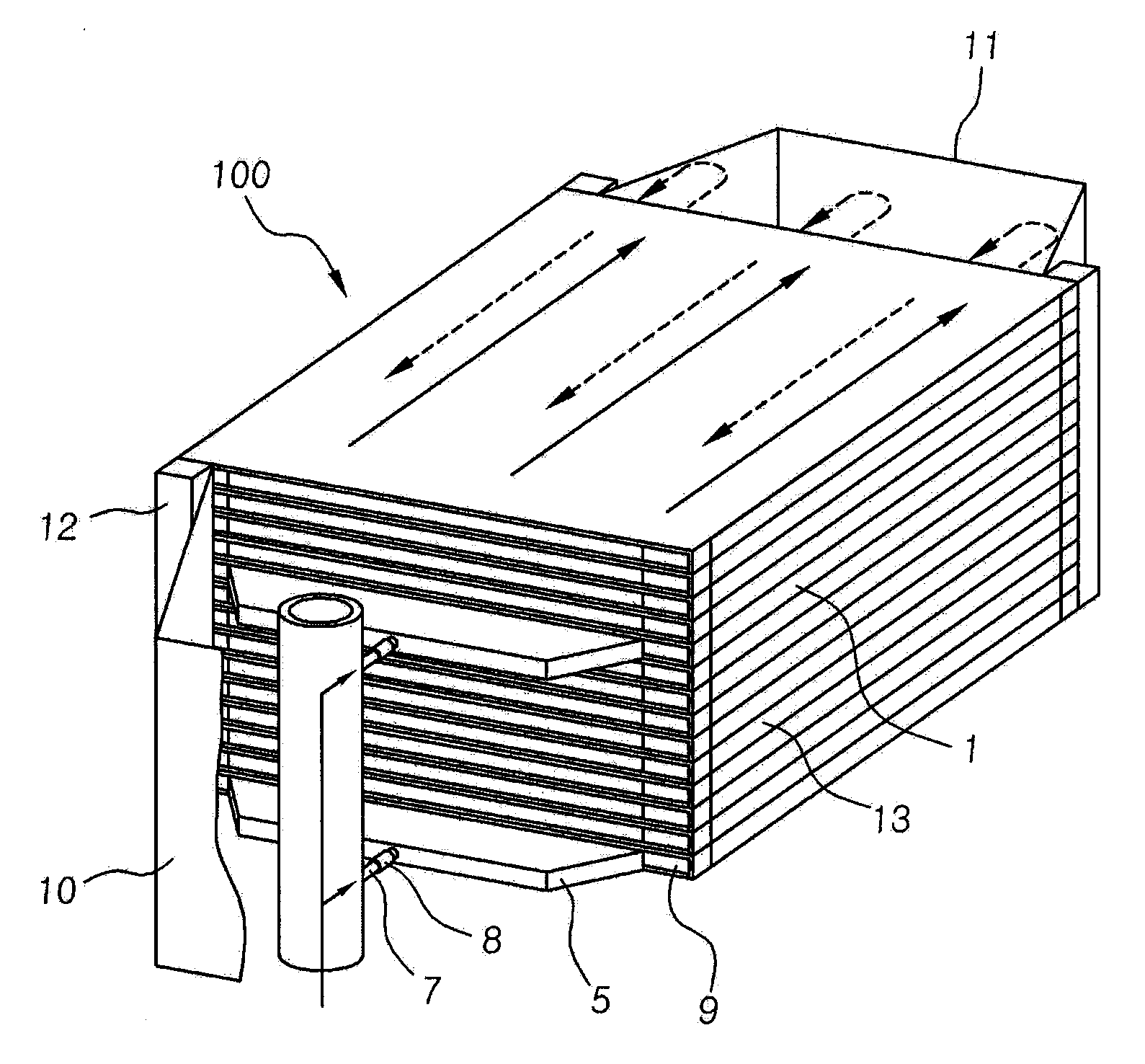

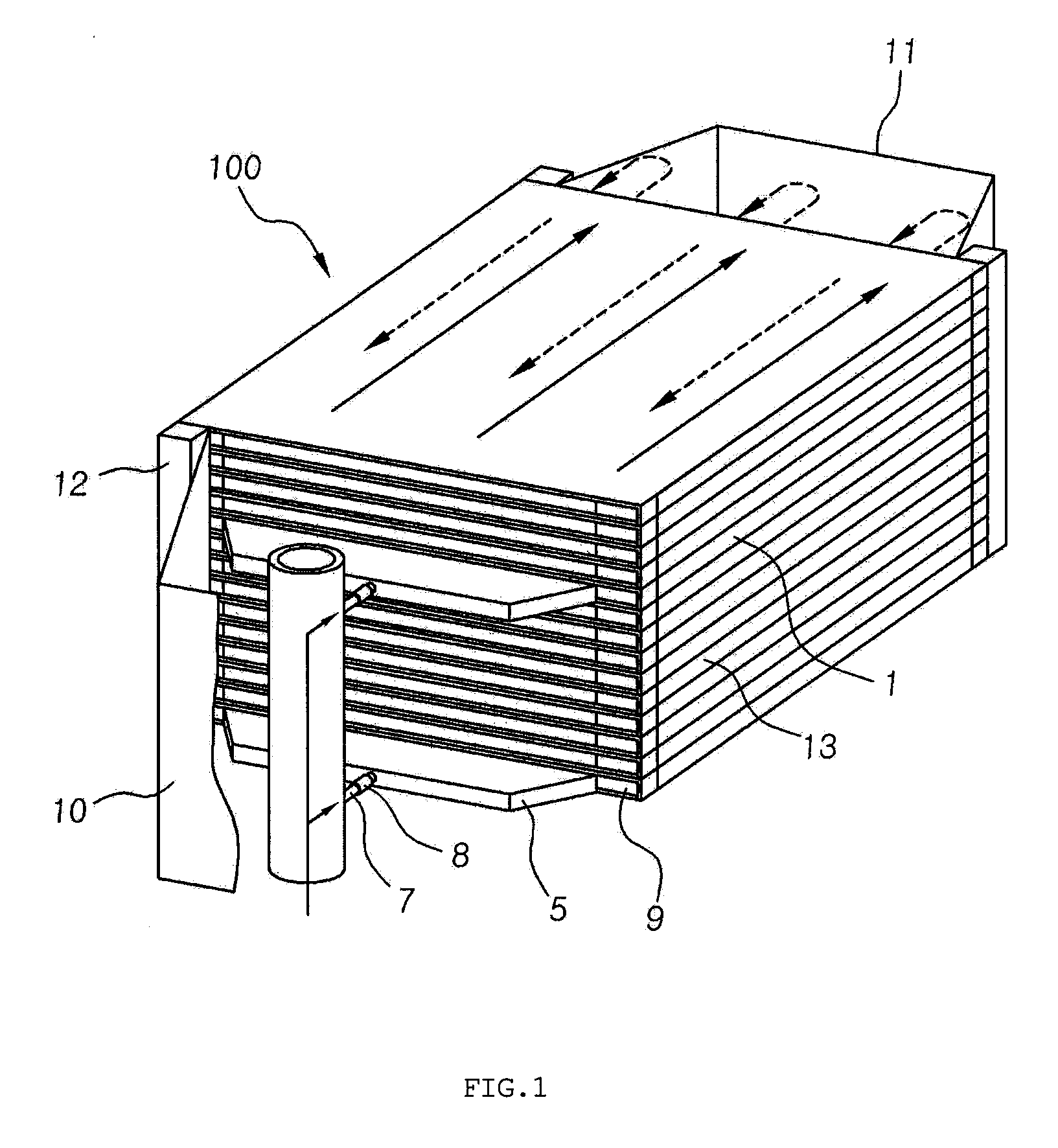

Molten Carbonate Fuel Cell Provided with Indirect Internal Steam Reformer

InactiveUS20070184310A1Controlled heatingSimple system constructionHydrogenFuel cells groupingSteam reformingOperational costs

A molten carbonate fuel cell, which is provided with an indirect internal steam reformer to efficiently control heat and simplify the system construction and has a simple structure to reduce production cost and efficiently controls heat to reduce operational cost and increase operational efficiency, is disclosed. The molten carbonate fuel cell of the present invention has a plurality of unit cells each including a porous matrix plate which is interposed between an anode plate and a cathode plate and is filled with an alkali carbonate electrolyte, the unit cells being stacked on top of another; at least one indirect internal steam reformer interposed between the stacked unit cells and reforming a fuel to hydrogen through a reforming reaction and supplying the hydrogen to the unit cells; a fuel manifold air-tightly installed at an inlet of both the indirect internal steam reformer and the unit cells and receiving a fuel supply pipe therein to supply the fuel to the indirect internal steam reformer; and a reformed fuel manifold air-tightly installed at an outlet of both the indirect internal steam reformer and the unit cells and supplying the hydrogen produced by the indirect internal steam reformer to the unit cells.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

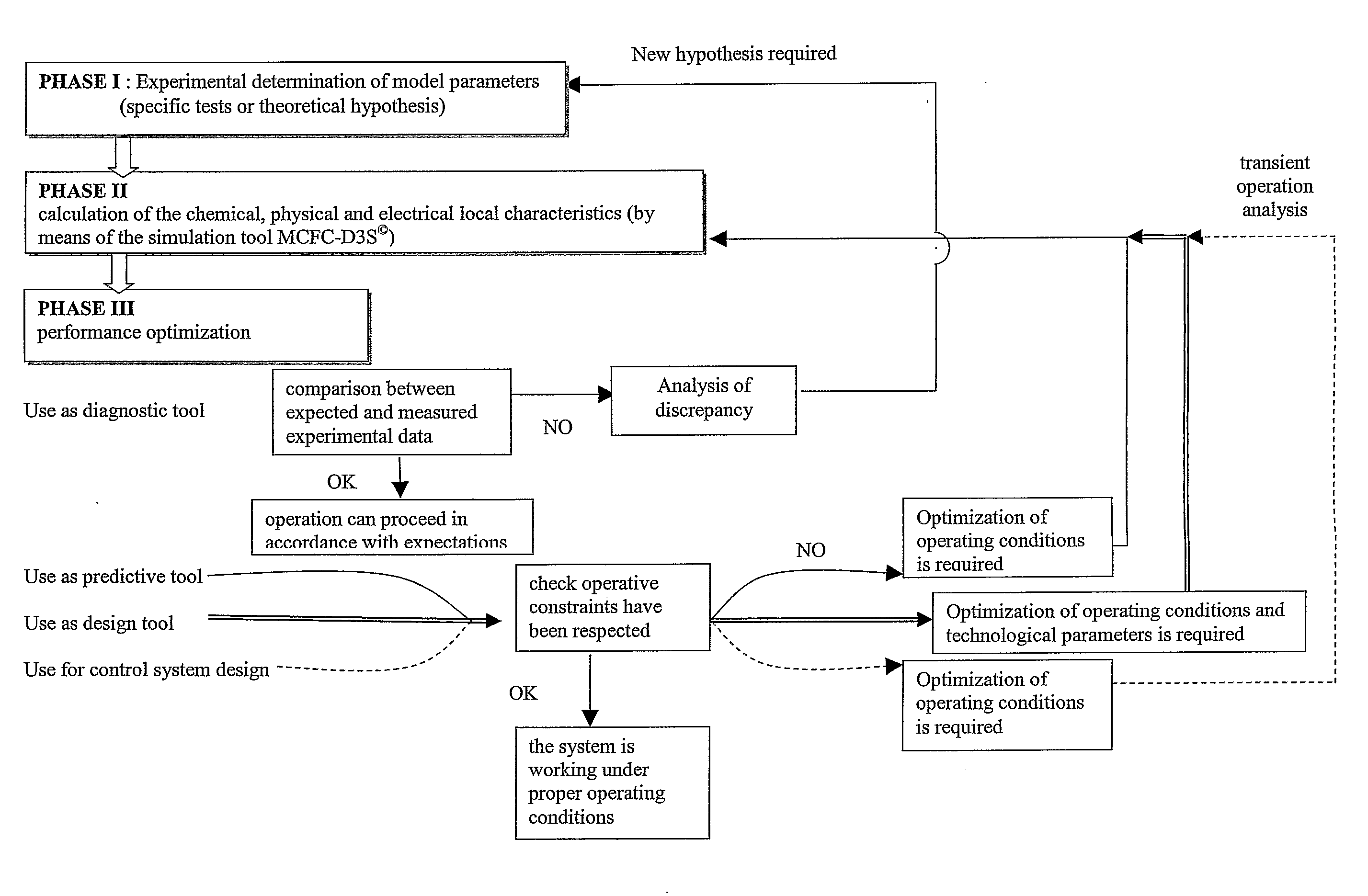

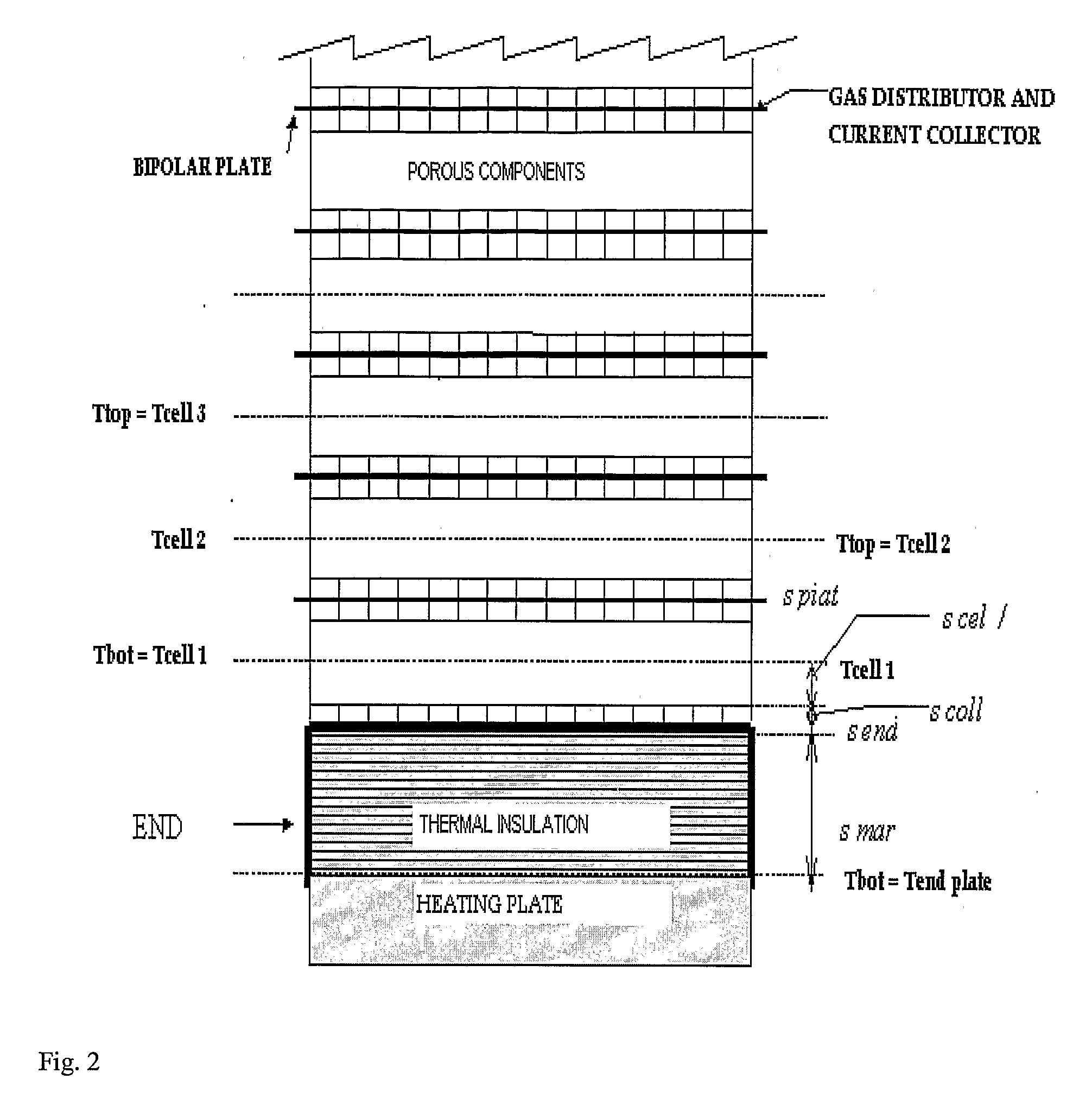

Method and System of Operating Molten Carbonate Fuel Cells

A molten carbonate fuel cell stack and a method of operating a molten carbonate fuel cell stack, which fuel cell comprises a porous anode, a carbonate-comprising matrix and a porous cathode, wherein the anode section is supplied with a hydrogenous gas and the cathode section is supplied with a gaseous mixture comprising oxygen and carbon dioxide, the fuel cell is operated at a temperature in a range of about 823-973 K, with the carbonate of the carbonate-comprising matrix being in a fluid state, oxygen and carbon dioxide are reacted at the cathode, yielding carbonate ions which move from the cathode to the anode generating an electric voltage between the anode and the cathode and an electrical current circulating in the external circuit and water that has been formed is led away from the fuel cell together with carbon dioxide, comprising sampling the temperature of inlet of the reactants, sampling the temperature of outlet of reactants, sampling the current density and voltage sampling the flow rate and gas composition of the inlet and outlet gases analyzing the sampled temperature, current density, voltage flow rates and gas composition, and regulating the inlet flow rate such as the pressure drop between inlet and outlet is below 20 mbar and the temperature in each element of a cell of the stack is below 973K.

Owner:PARODI FILIPPO +2

Systems and processes for operating fuel cell systems

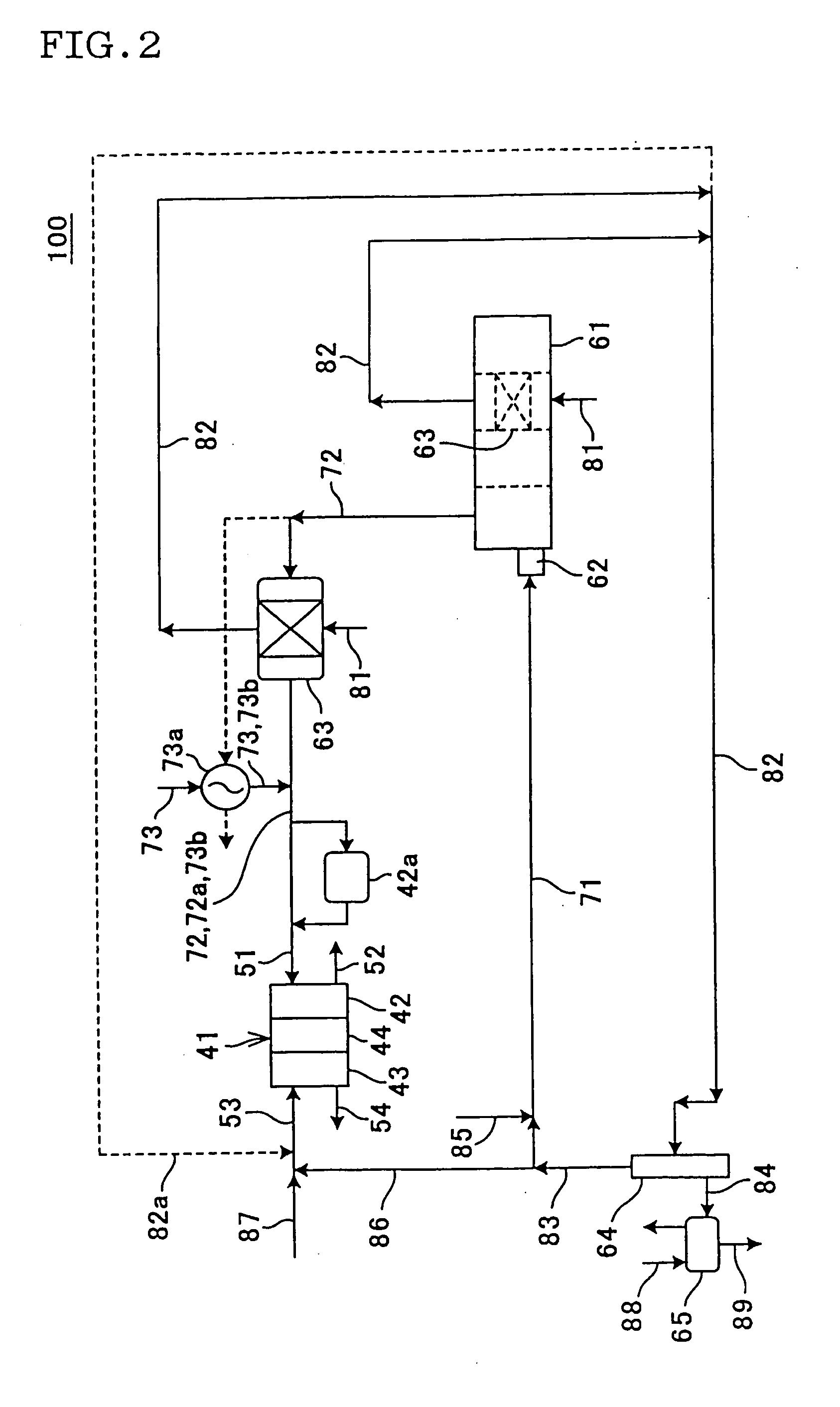

InactiveUS20110111314A1Well mixedRegenerative fuel cellsHydrogen/synthetic gas productionSteam reformingFuel cells

Processes and systems for operating molten carbonate fuel cell systems are described herein. A process for operating a molten carbonate fuel cell system includes providing a hydrogen-containing stream comprising molecular hydrogen to an anode portion of a molten carbonate fuel cell; controlling a flow rate of the hydrogen-containing stream to the anode such that molecular hydrogen utilization in the anode is less than 50%; mixing anode exhaust comprising molecular hydrogen from the molten carbonate fuel cell with a hydrocarbon stream comprising hydrocarbons, contacting at least a portion of the mixture of anode exhaust and the hydrocarbon stream with a catalyst to produce a steam reforming feed; separating at least a portion of molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode.

Owner:SHELL OIL CO

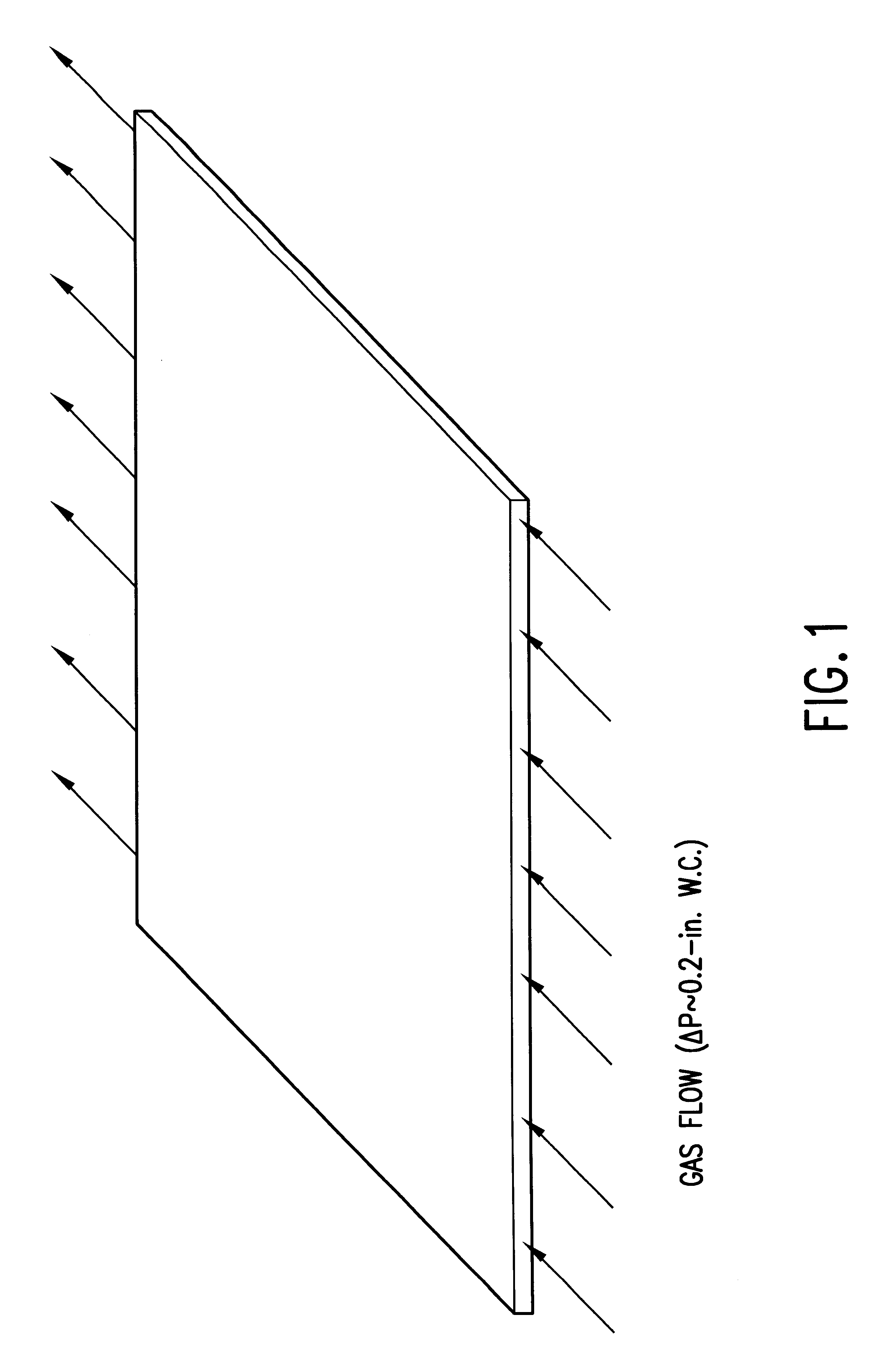

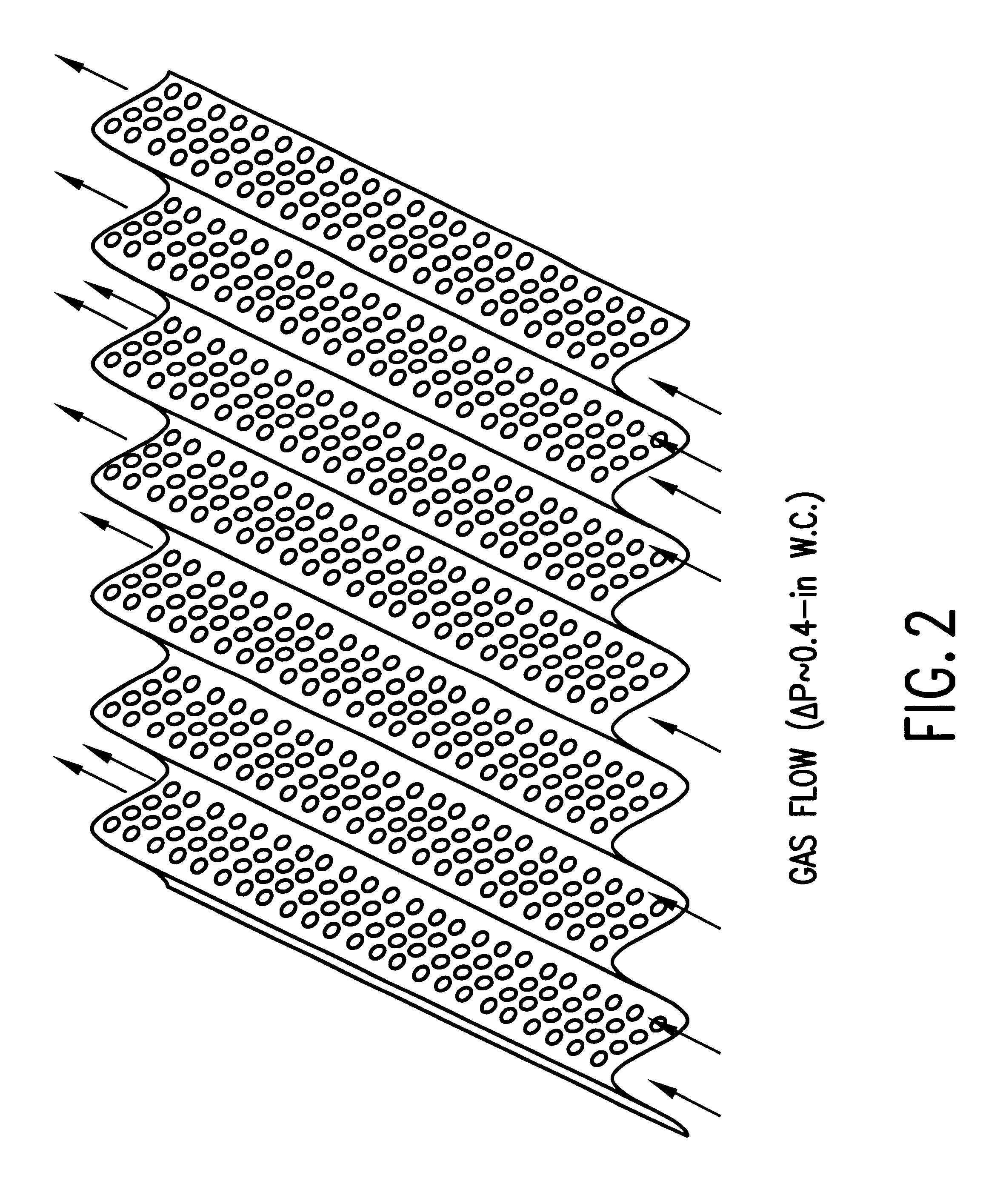

Alternative electrode supports and gas distributors for molten carbonate fuel cell applications

InactiveUS6379833B1Low costInexpensive, lightweight, and durableFuel cells groupingCell electrodesPorosityFuel cells

A molten carbonate fuel cell having an anode electrode, a cathode electrode, and an electrolyte matrix disposed between the anode electrode and the cathode electrode. An electrode support constructed of a high porosity reticulated foam material is disposed on an anode electrode face of at least one of the anode electrode and the cathode electrode facing away from the electrolyte matrix and forming a plurality of pores. An electrolyte is disposed within at least a portion of the plurality of pores, whereby at least a portion of the electrolyte flows into the electrolyte matrix during initial conditioning of the fuel cell.

Owner:INST OF GAS TECH

Deferential Presssure Control Method for Molten Carbonates Fuel Cell Power Plants

InactiveUS20070224467A1Low efficiencyWithout riskFuel cells groupingFuel cell auxillariesFuel cellsPower station

A molten carbonate fuel cell System in which the fuel cell stack(s) is (are) enclosed within a containment vessel and in which a burner exhaust is used to control the system operating pressure is described. Moreover, highly reliable, simple and low-cost differential pressure control method never affected by service interruption or troubles in control valves or other components is disclosed. Excluding differential control valves and reducing the cost by guiding the anode, cathode and vessel exhaust gases to the inlet of a catalytic burner forward the containment vessel and mixed therein so that the pressure of these gases are equal to each other, this fuel cell system guarantees dynamic pressure balancing between the vessel and reactants to prevent leakage of the reactants from the fuel cell stack and avoid an excessive differential pressure between the fuel cell and the vessel and between the anode and the cathode.

Owner:ANSALDO FUEL CELLS SPA

Improvement of carbon efficiencies in hydrocarbon production

InactiveCN101426885AHydrocarbon from carbon oxidesFinal product manufactureAtmospheric airInternal combustion engine

This invention relates to a method of producing liquid hydrocarbons, preferably internal combustion engine fuels, using feedstocks of coal or methane. Depending on the nature of the feedstock it is subjected to a gasification and / or reforming process and / or water gas shift process which produces a syngas that is rich in carbon dioxide and hydrogen rather than carbon monoxide and hydrogen as in the conventional process. The carbon dioxide and hydrogen are combined in a Fischer Tropsch process to produce desired hydrocarbons and water. The energy requirements of the gasification / reforming process to produce a syngas that is rich in carbon dioxide and hydrogen is considerably less than the energy requirements for gasification / reforming process for producing the conventional carbon monoxide rich syngas. This reduction in energy consumption reduces considerably the quantities of carbon dioxide released into the atmosphere compared to conventional processes that are based on carbon monoxide rich syngas. Unreacted CO2-rich syngas can be recirculated or can also be used, in molten carbonate fuel cells, or to generate energy or steam in turbine processes such as IGCC.

Owner:UNIVERSITY OF THE WITWATERSRAND

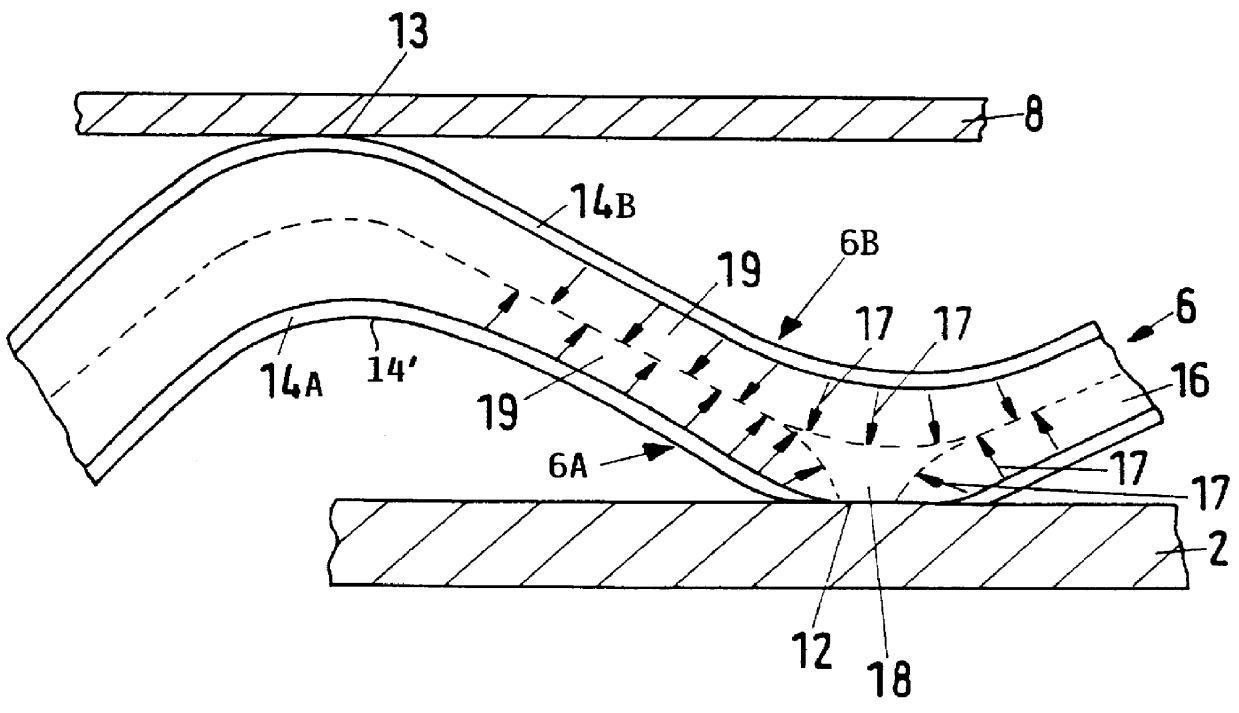

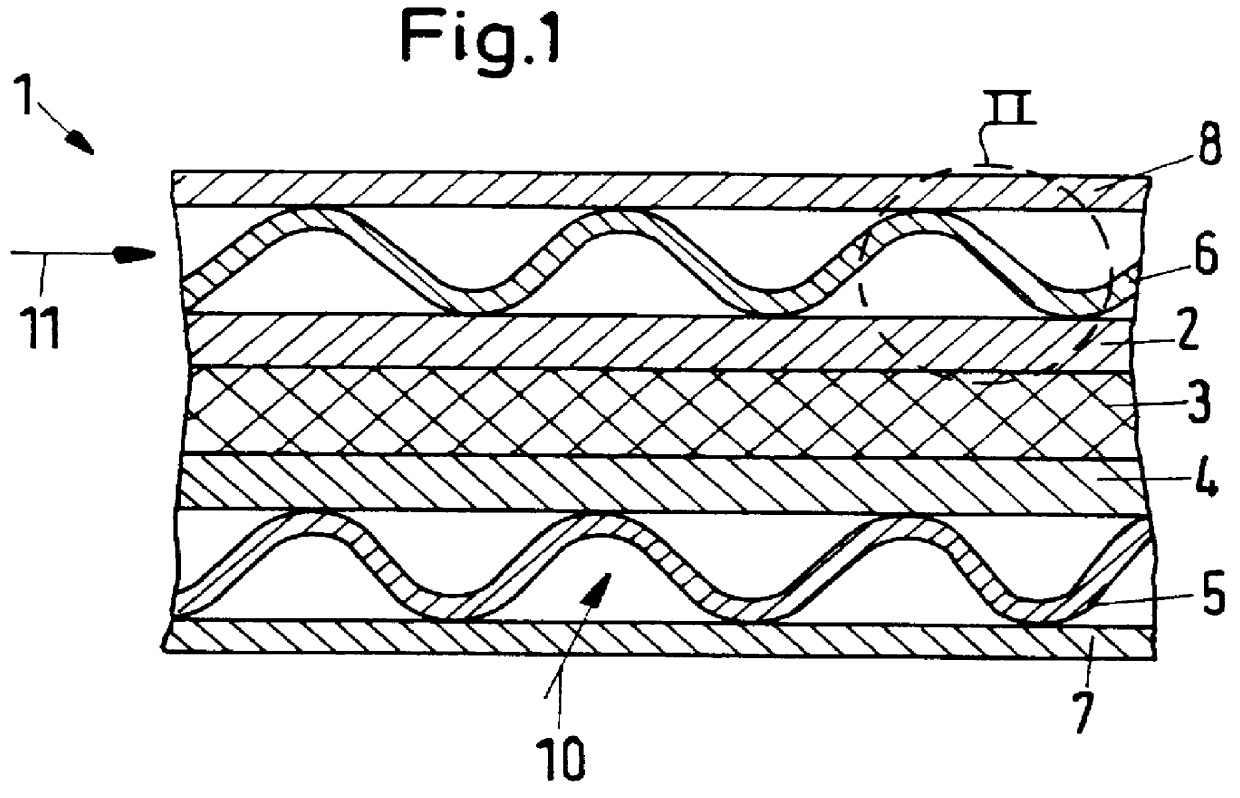

Current collector for a fuel cell and method of making the same

InactiveUS6117580AEffective corrosion protectionAccelerate the lossFuel cells groupingFinal product manufactureFuel cellsMolten carbonate fuel cell

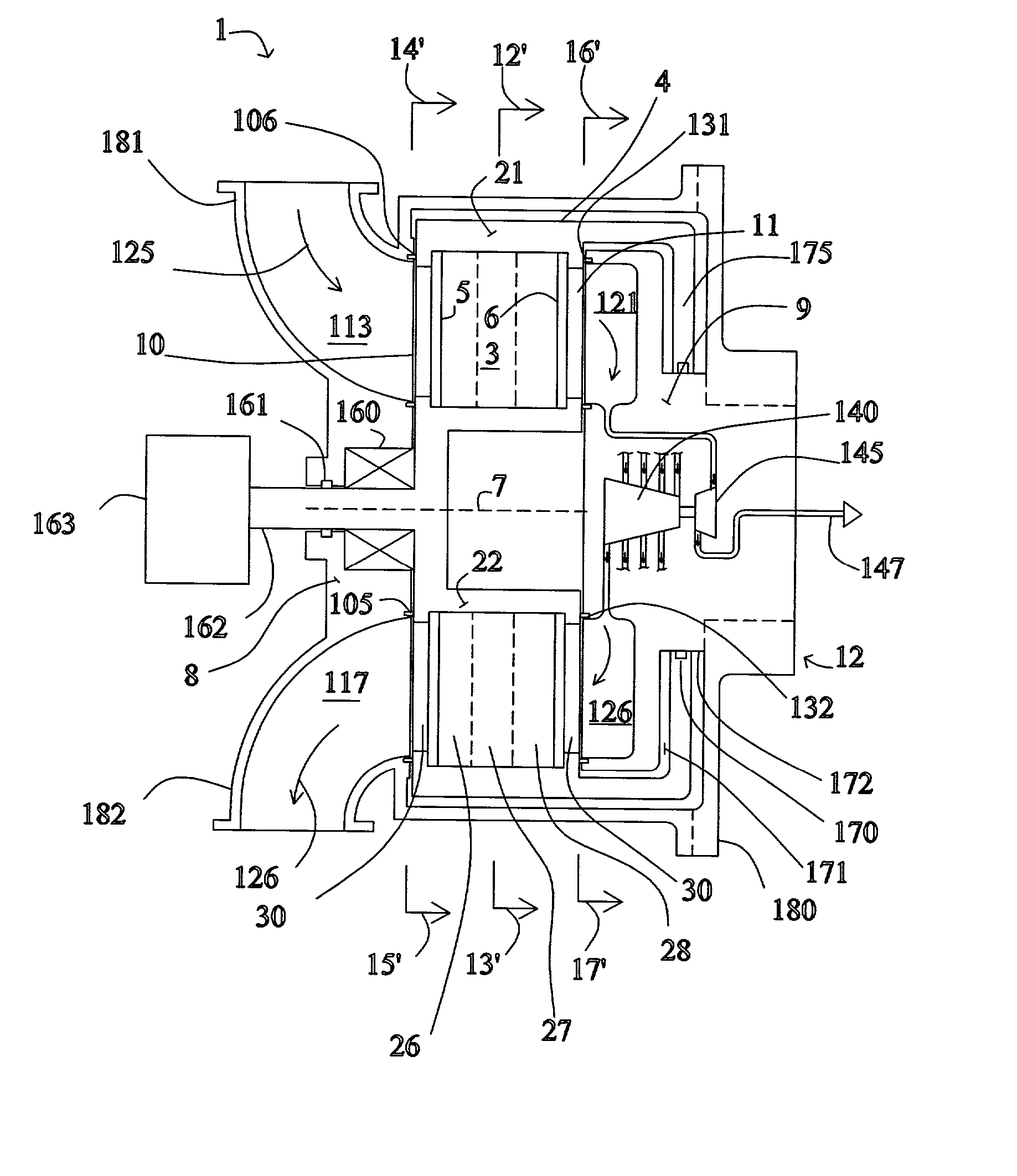

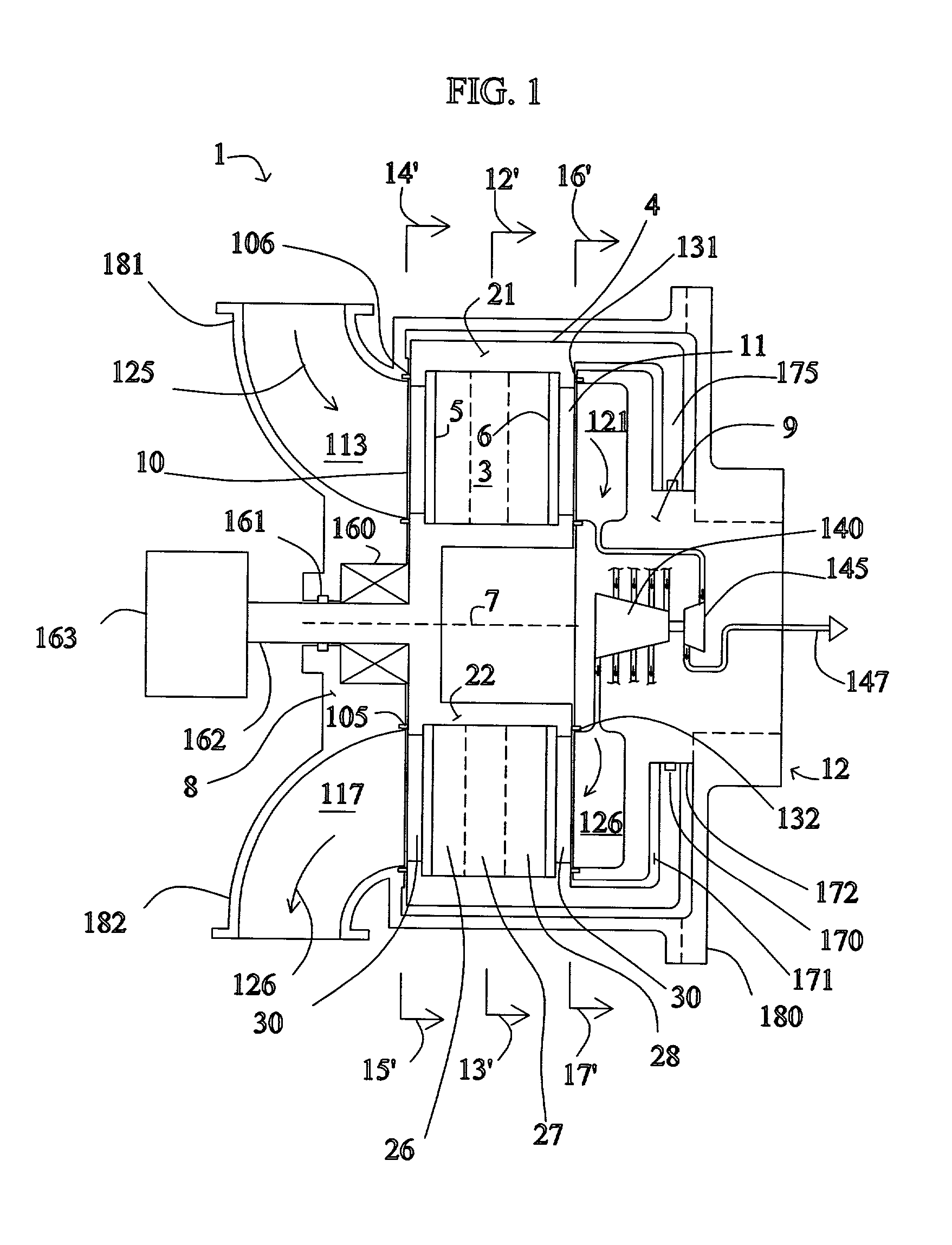

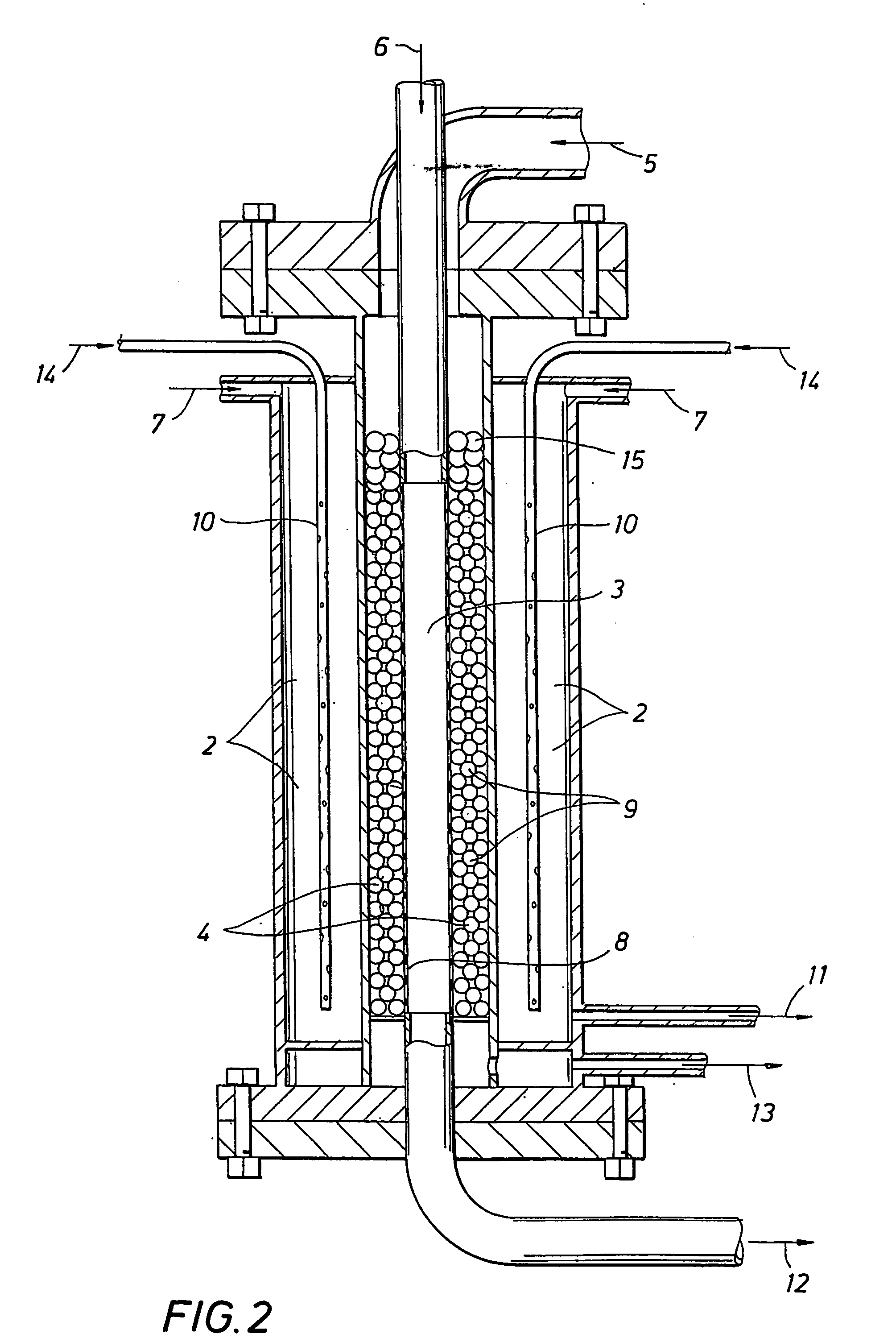

A molten carbonate fuel cell is constructed of plural stacked individual cell units, that each respectively include a porous, electrolyte saturated matrix (3) sandwiched between a cathode (2) and an anode (4), and current collectors (5, 6) respectively arranged between the anode (4) and a first separator plate (7), and between the cathode (2) and a second separator plate (8). Especially the cathode current collector (6) includes a stainless steel core (16) that is coated on at least one surface with an aluminum-containing layer (14). Preferably both surfaces of the stainless steel core (16) are coated with aluminum-containing layers (14A, 14B), except for a contact area (12) at which the stainless steel core (16) directly contacts the cathode (2). The aluminum-containing layer (14) prevents or minimizes the occurrence of an oxidation reaction that would otherwise lead to significant loss of the electrolyte.

Owner:DAIMLER AG

Coal chemical poly-generation process and system

InactiveCN102850172ASave energyEliminates water gas shift processFinal product manufactureChemical industryCoalChemistry

The invention belongs to the field of coal chemical, and discloses a coal chemical poly-generation process and a coal chemical poly-generation system. According to the invention, coke and oxygen-rich gas obtained after low-rank coal upgrading conversion and quicklime are adopted as raw materials; calcium carbide is prepared by using an oxygen heat method; and acetylene is produced with a dry-method acetylene production process. Part of calcium carbide residue containing calcium hydroxide is outputted as a by-product, and another part of the calcium carbide residue containing calcium hydroxide is calcined and prepared into calcium oxide, which is then recycled as a calcium carbide preparation unit raw material. High-purity CO furnace gas produced by the calcium carbide preparation unit is added into the oxygen-rich gas, such that molten carbonate fuel cell raw material is prepared and electricity generation can be carried out. Further, heat contained in discharged gas of fuel cell recovered with a heat recovery technology and heat produced after combustion thereof are respectively used for providing heat for a steam Rankine cycle, a raw material preheating unit, a drying unit, and a calcining unit. Steam Rankine cycle condensed water is pump-pressurized; heat contained in fuel cell tail gas, combustion unit tail gas, calcining unit discharged water, and drying unit discharged water are recovered; and steam generation is carried out. With the process and the system provided by the invention, energy cascade utilization is realized.

Owner:BEIJING UNIV OF CHEM TECH

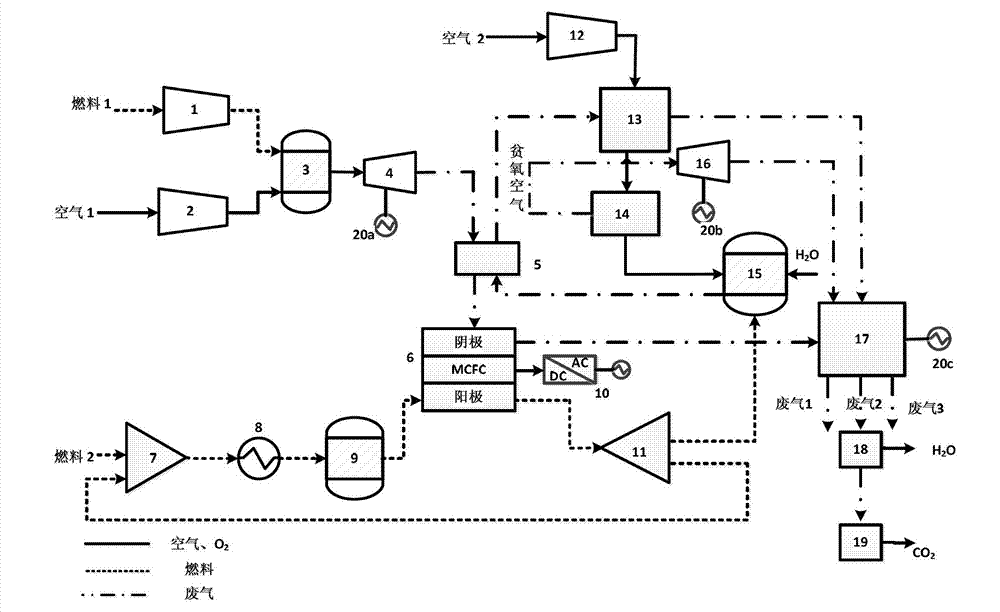

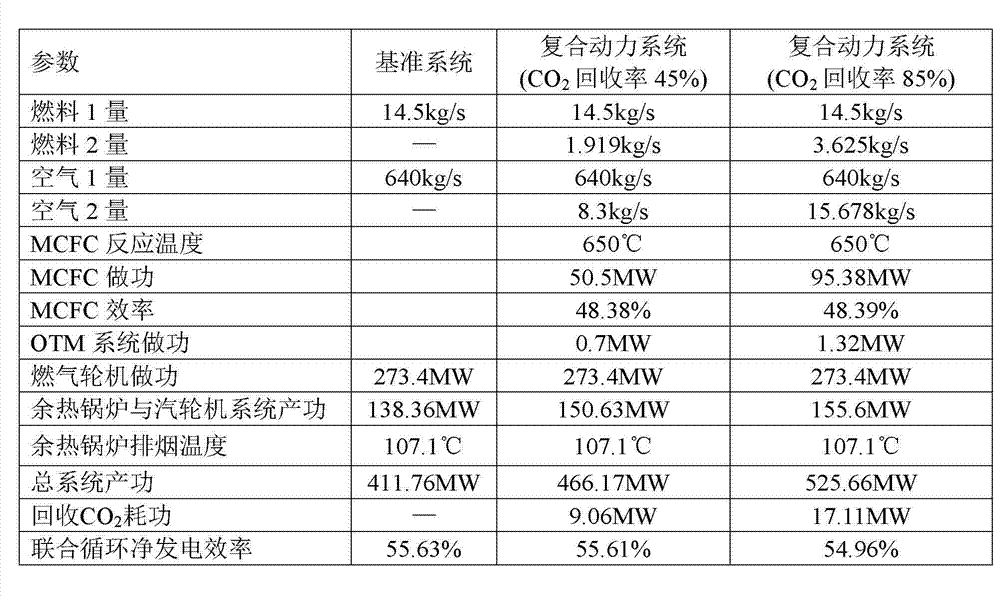

System and method for capturing coal-fired power plant CO2 by use of molten carbonate fuel cell

ActiveCN104847424AEmission reductionReduction of recycling energy consumptionDispersed particle separationSteam engine plantsFuel cellsCombustion chamber

The invention belongs to the technical fields of coal-fired power plant CO2 capture and utilization and in particular relates to a system and a method for capturing coal-fired power plant CO2 by use of a molten carbonate fuel cell. The following scheme is put forward by taking a conventional coal-fired power plant not recovering CO2 as a reference system, namely a system composed of the conventional coal-fired power plant, the molten carbonate fuel cell, an independent air separation unit, a waste heat boiler and steam turbine unit and a CO2 recovery unit and used for capturing the coal-fired power plant CO2 by use of the molten carbonate fuel cell, and a method of the system; as a result, the problem of relatively low efficiency after large-amount CO2 emission of the coal-fired power plant and CO2 capture, and CO2 emission reduction of the coal-fired power plant and low-energy consumption CO2 recovery are realized. Besides, the high-temperature exhaust heat of MCFC and a rear combustion chamber are utilized thoroughly, and therefore, the system is enabled to have relatively high efficiency in CO2 recovery.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

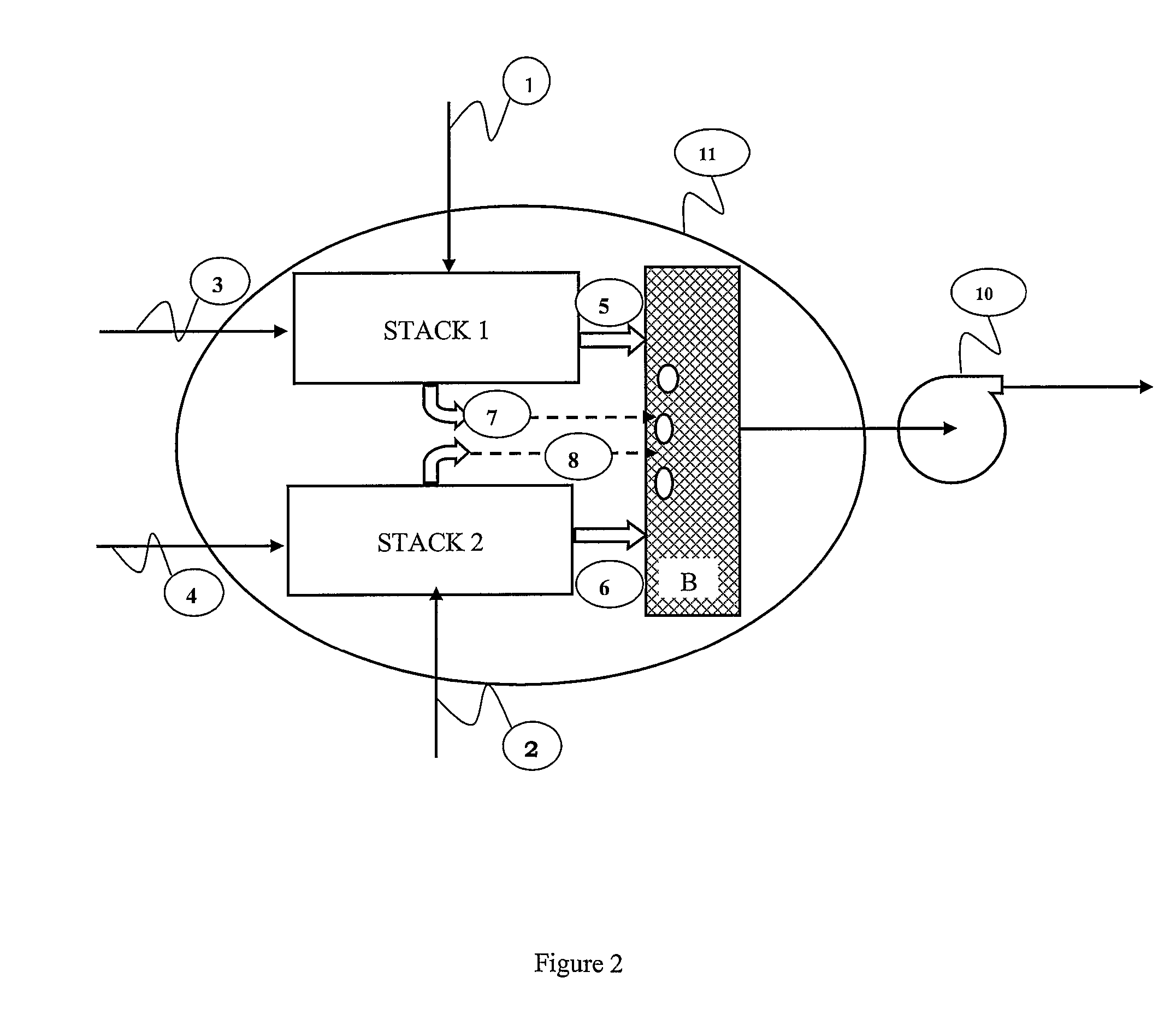

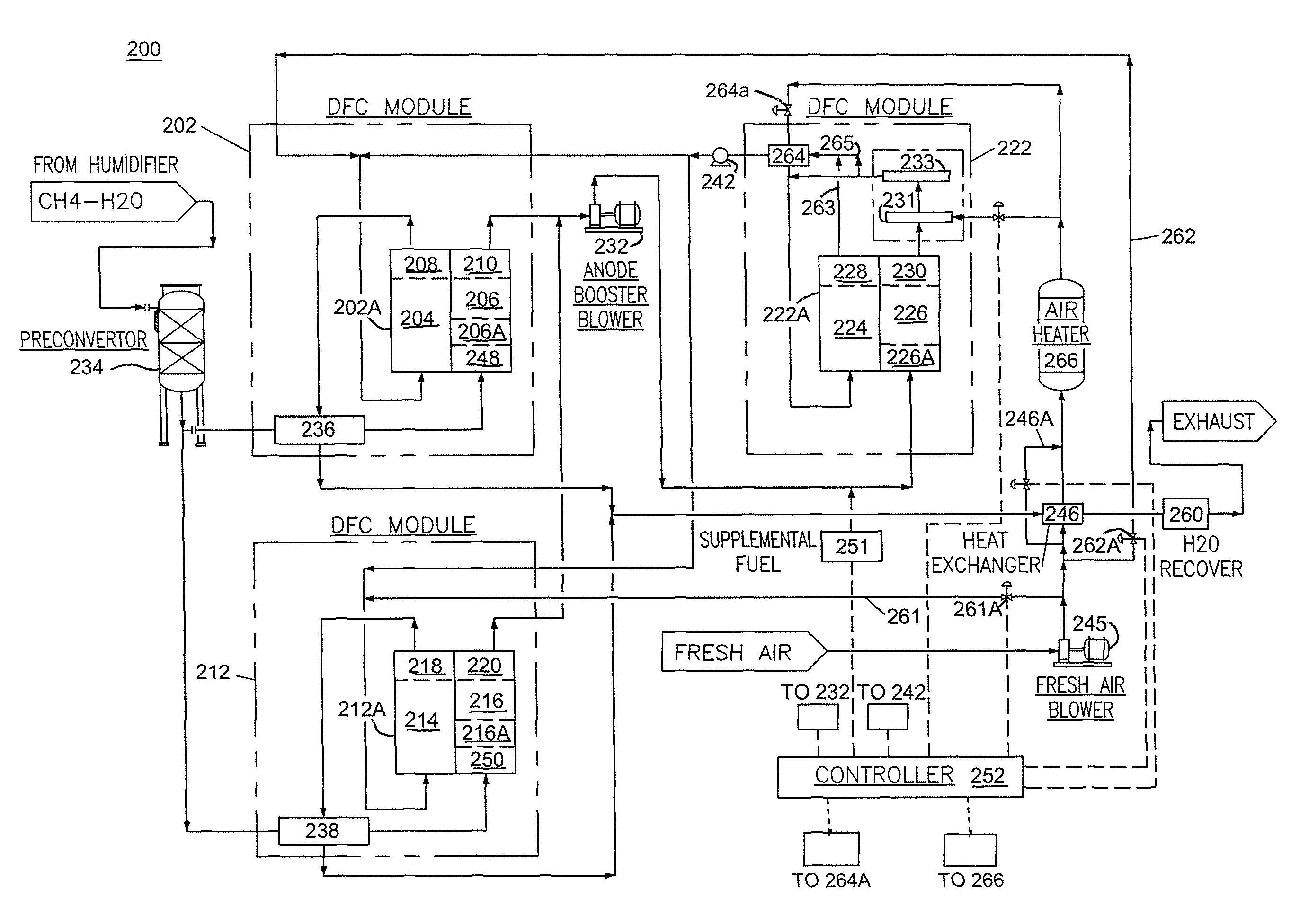

High-efficiency dual-stack molten carbonate fuel cell system

Owner:FUELCELL ENERGY INC

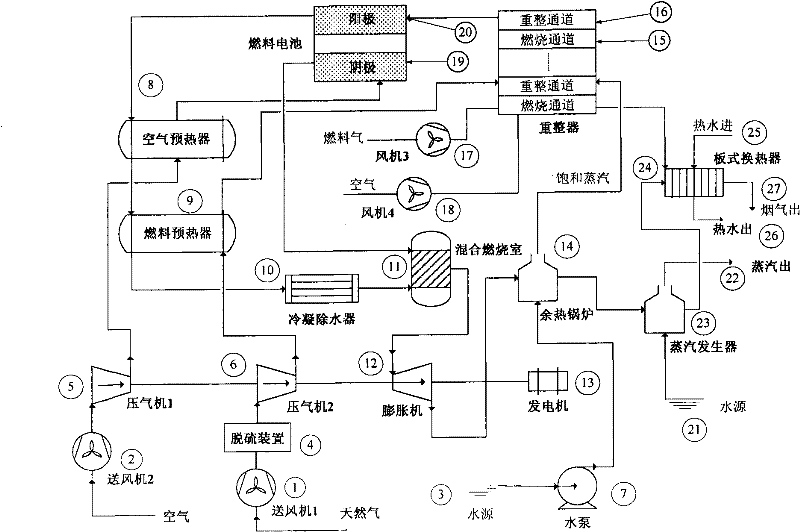

Combined heat and electricity generation system with fuel cell and gas turbine

ActiveCN102456898AIncrease profitEasy to control working conditionsFuel cell heat exchangeOther heat production devicesCombustionFuel cells

The invention discloses a combined heat and electricity generation system formed by the combination of a fuel cell and a gas turbine. The system comprises a feeding subsystem, a preheating subsystem, a fuel cell subsystem, a reforming subsystem, a gas turbine power generation subsystem and a waste heat utilization subsystem. A mixing combustion subsystem is provided between the fuel cell subsystem and the gas turbine power generation subsystem, and the subsystems are mutually connected with each other to form the combined heat and electricity generation system of cycle combination. According to the invention, the supercharged melted carbonate fuel cell is organically combined with the micro gas turbine to form the quality-exchanged combined cycle system, the power density of the system is high, and the waste heat recycle is fully and effectively carried out, so the whole energy utilization rate is improved as possible.

Owner:ENN SCI & TECH DEV

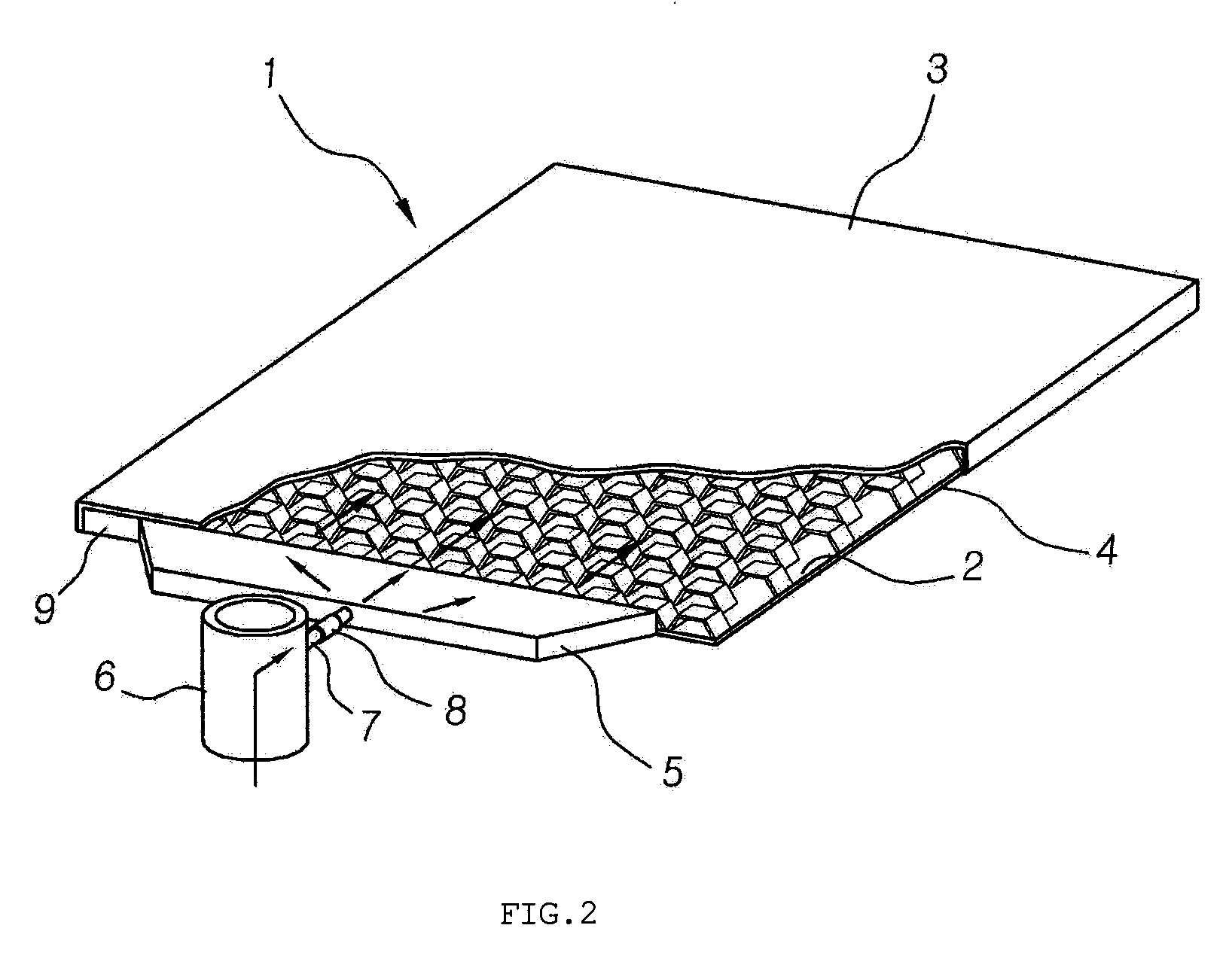

Design of fuel cell and electrolyzer for small volume, low cost and high efficiency

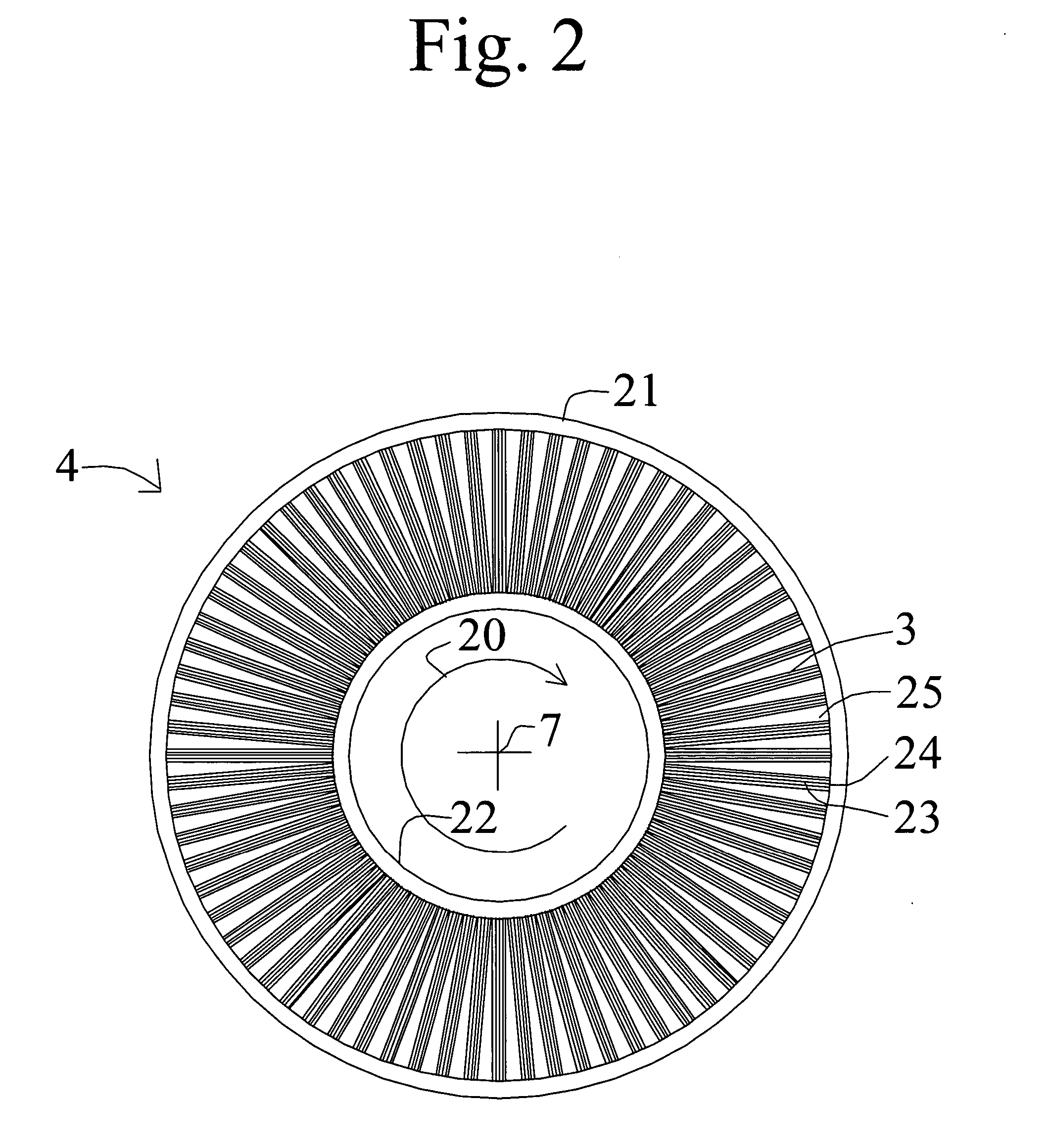

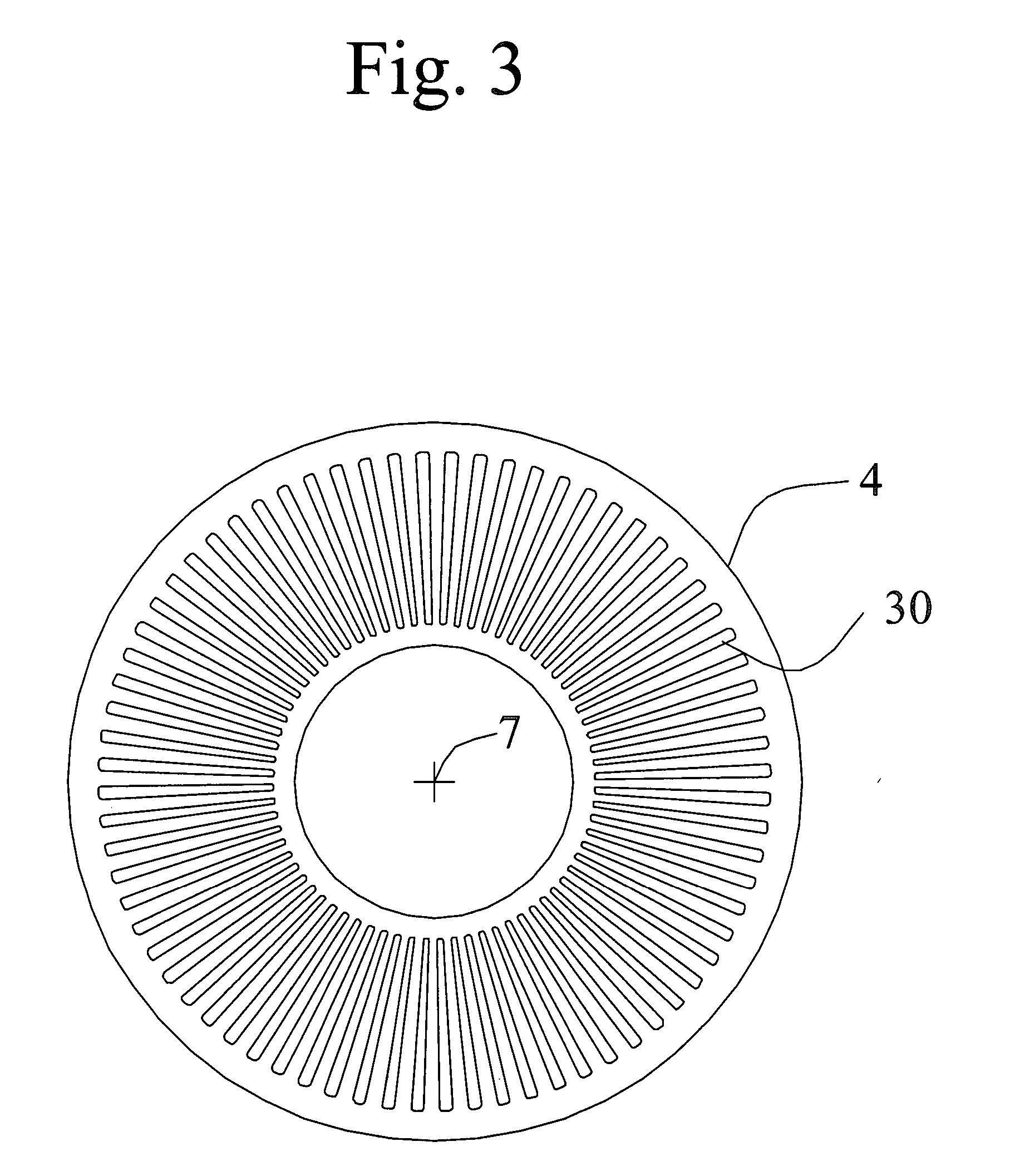

InactiveUS20070231669A1Improve scalabilityImprove output performanceCellsFuel cells groupingElectrochemical responseO-Phosphoric Acid

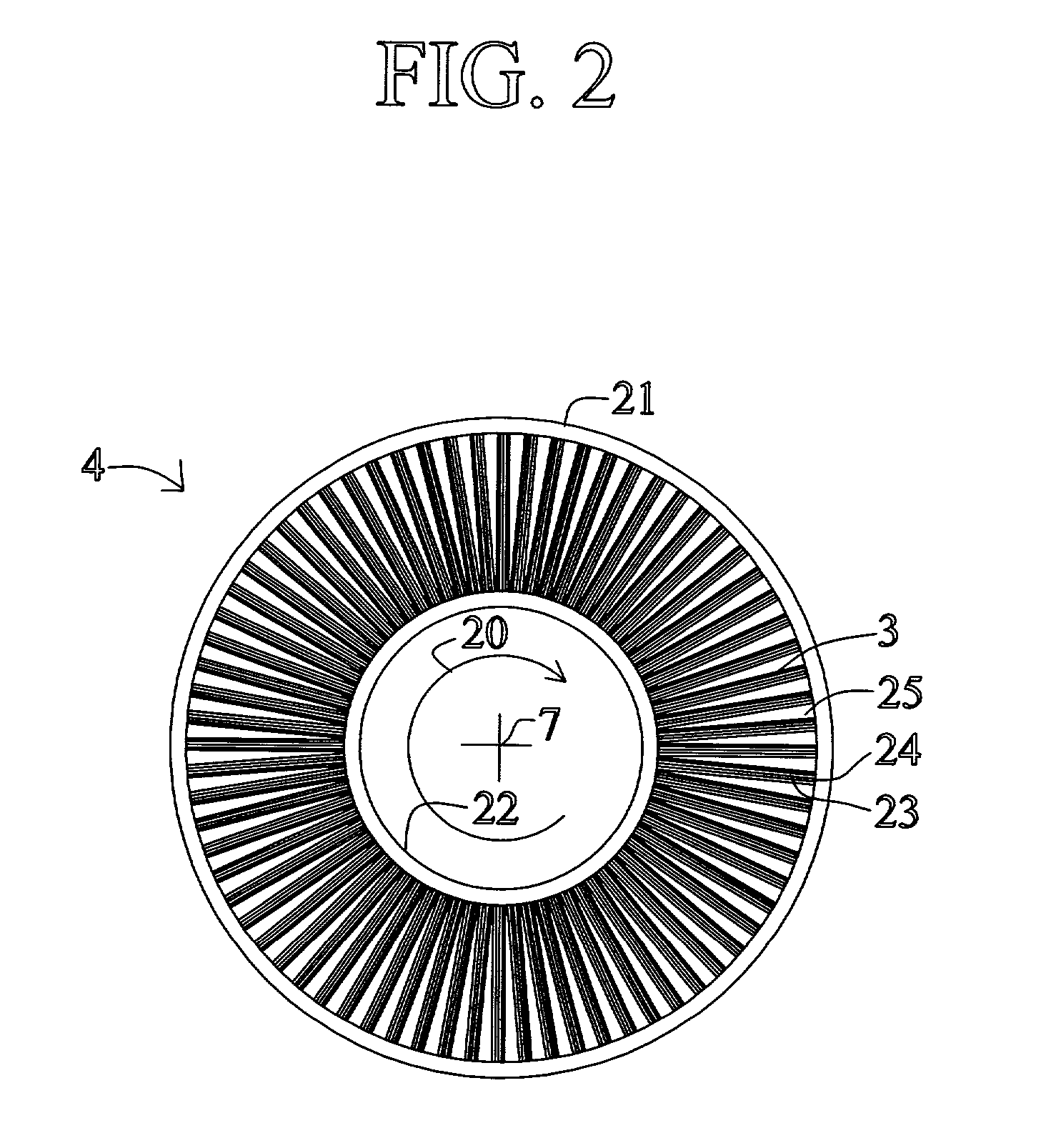

An electrochemical fuel cell designed for a large electrochemical reaction surface area per unit volume for high power density and high efficiency. The fuel cell is designed for counter propagating reactants flow for uniform reaction rate over the whole reaction area. This design is scalable and a single cell can be built with output power level ranging from a few watts to several megawatts. The cell does not require bipolar plates and is lightweight. The design has been demonstrated with proton exchange membrane as an electrolyte for the electrochemical reaction, however, the design is adaptable for other types of fuels and fuel cells with other electrolytes including all types of polymer electrolytic fuel cells, alkaline fuel cells, phosphoric acid fuel cells, molten carbonate fuel cells, solid oxide fuel cells and all their subcategories as well. The fuel cell is adaptable for use as an electrolyzer as well.

Owner:GHOSH CHUNI LAL

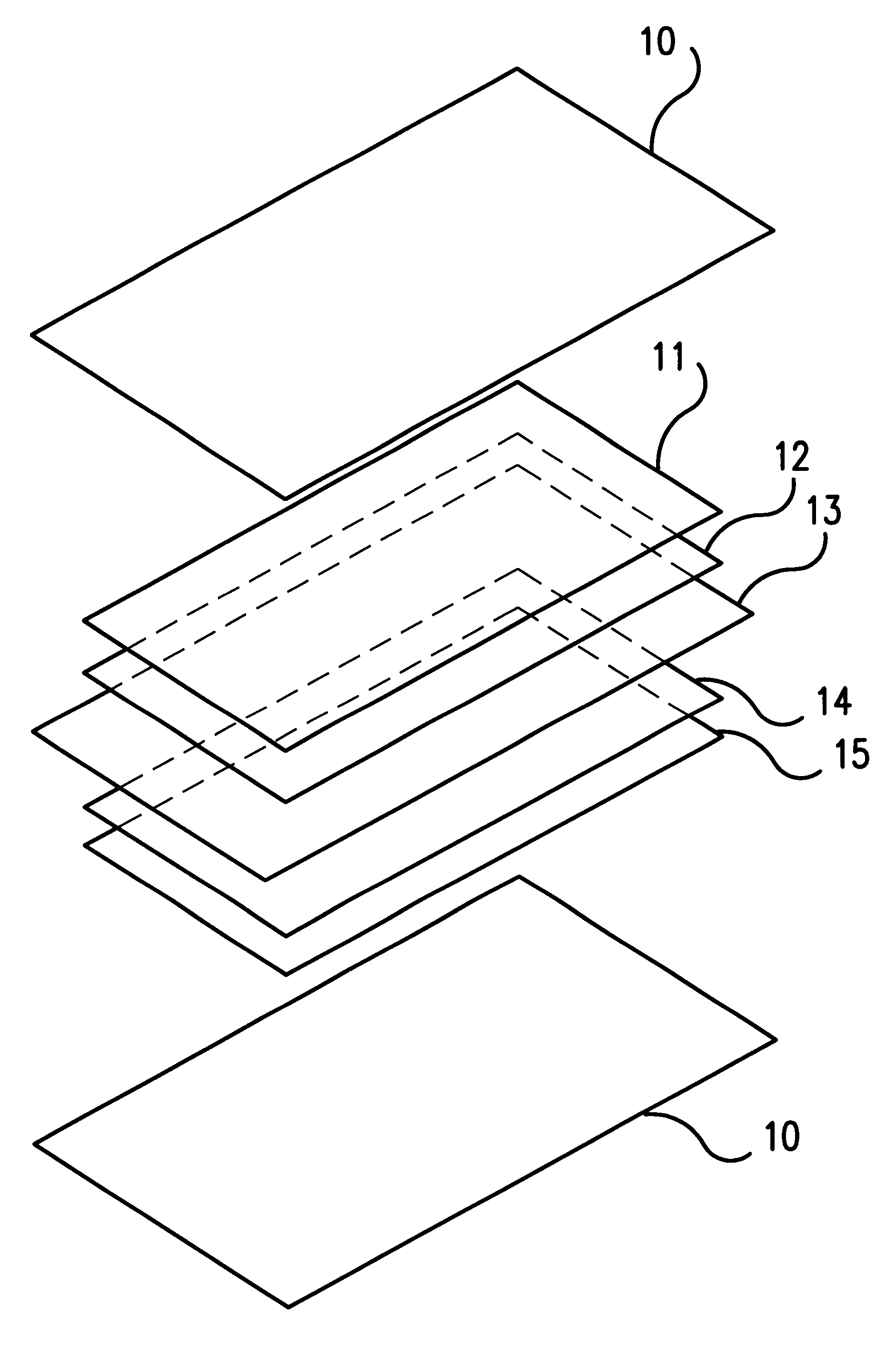

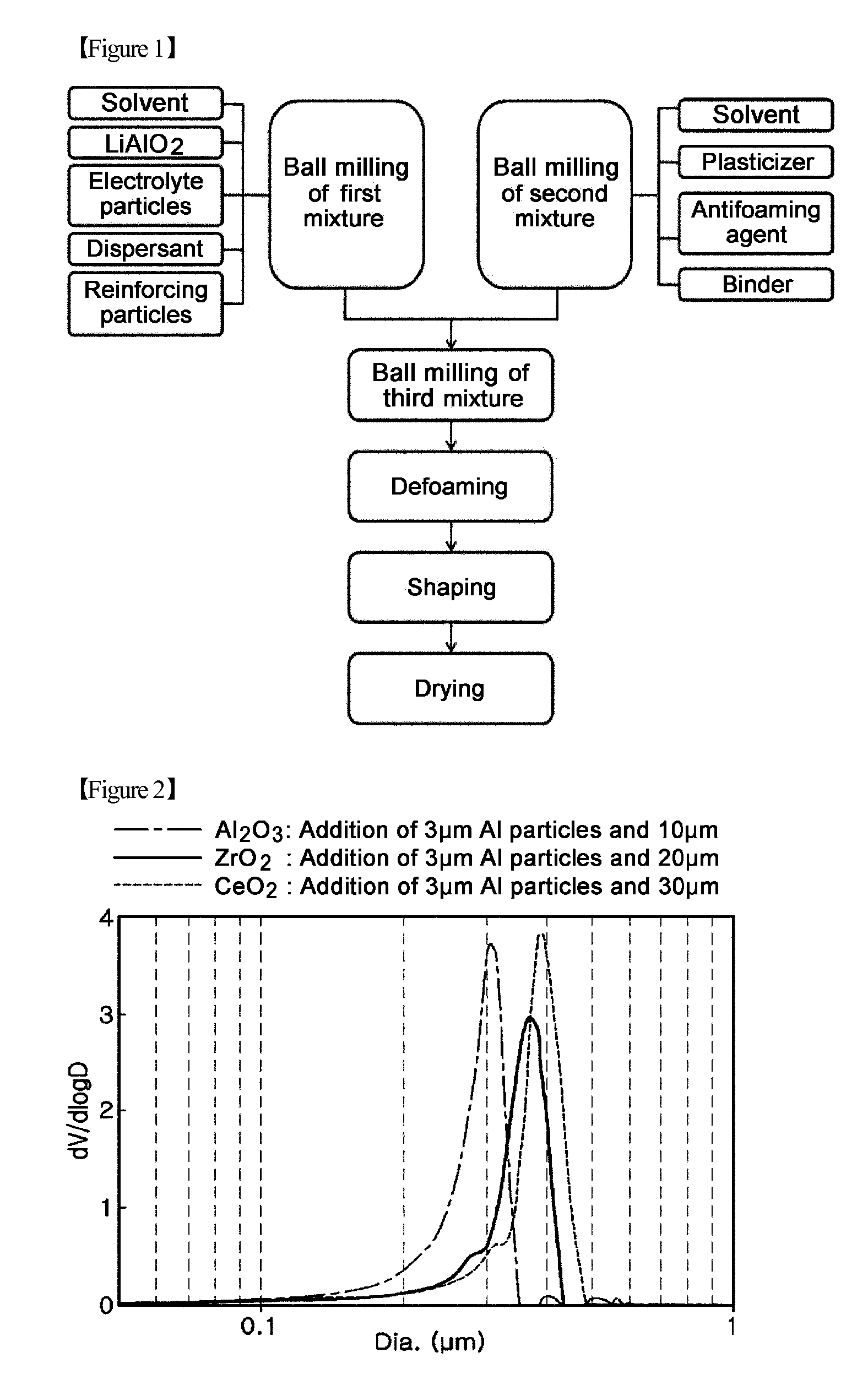

Reinforced matrix impregnated with electrolytes for molten carbonate fuel cell and fabrication method thereof

ActiveUS20110287333A1Improving performance and lifetimeEasy to operateElectrolyte holding meansFinal product manufactureFuel cellsMolten carbonate fuel cell

The present invention relates to an electrolyte-impregnated, reinforced matrix for molten carbonate fuel cells and a manufacturing method thereof. According to the invention, the electrolyte-impregnated matrix, which comprises both the electrolyte and the reinforcing particles including a metal and an oxide, is manufactured by adding the electrolyte, as required per unit cell of a fuel cell, and the reinforcing particles including the metal and the oxide, to a slurry during the matrix preparation step, and subjecting the resulting slurry to a tape casting process. By doing so, the matrix stacking operation is facilitated, and the matrix manufacturing process is simplified. In addition, cracking caused by the difference in thermal expansion coefficient between an electrolyte sheet and the matrix can be suppressed, and thermal shock occurring during operation of the fuel cell stack can be reduced, thus improving the performance and lifetime of the fuel cell.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Reinforced matrix for molten carbonate fuel cell using porous aluminum support and method for preparing the molten carbonate fuel cell comprising the reinforced matrix

ActiveUS7678470B2No worry about fracture or crackLow costElectrolyte holding meansFinal product manufactureMolten carbonate fuel cellLithium aluminate

Disclosed is a reinforced matrix for a molten carbonate fuel cell comprising a porous aluminum support and a lithium aluminate tape-cast on the porous aluminum support. Further, disclosed is a method for preparing the molten carbonate fuel cell comprising the reinforced matrix comprising steps of tape-casting a lithium aluminate on a porous aluminum support so as to prepare a reinforced matrix (S1), making a unit cell or a stack of the unit cells using the reinforced matrix (S2) and heat treating the unit cell or the stack so as to oxidize aluminum in the support into lithium aluminate (S3). According to the present invention, the method is simple and economic, and the mass production of the matrix is easy, and strength of the matrix can be increased effectively and therefore there is no worry about fracture or crack.

Owner:KOREA INST OF SCI & TECH

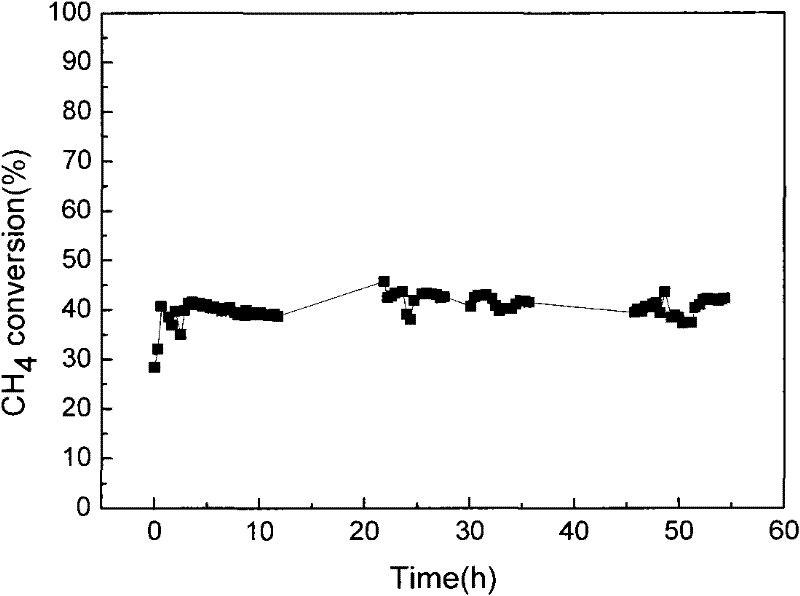

Nickel-based reforming catalysts

InactiveUS8575063B2Long catalyst lifeImprove stabilityHydrogenOther chemical processesStructural stabilityCarbonate

The present invention relates unique pore structures in nickel supported on alumina with the negligible formation of macropores. Incorporation of additional elements stabilizes the pore structure of the nickel supported on alumina. Additional element(s) were then further added into the nickel-supported materials. These additional element(s) further stabilize the pore structures under heating conditions. The improvements of pore structure stability under heating conditions and negligible presence of macropores limit the sintering of nickel metal to a mechanism of impeded diffusion. The negligible presence of macropores also limits the deposition of alkali metal hydroxide(s) / carbonate(s) on the outer shell of the catalyst pellet in the molten carbonate fuel cells. Both the negligible presence of macropores and improvement in pore structure stability allow for prolonging the catalyst life of these nickel supported on alumina catalysts of the present invention for reforming hydrocarbons.

Owner:HE HONGYING

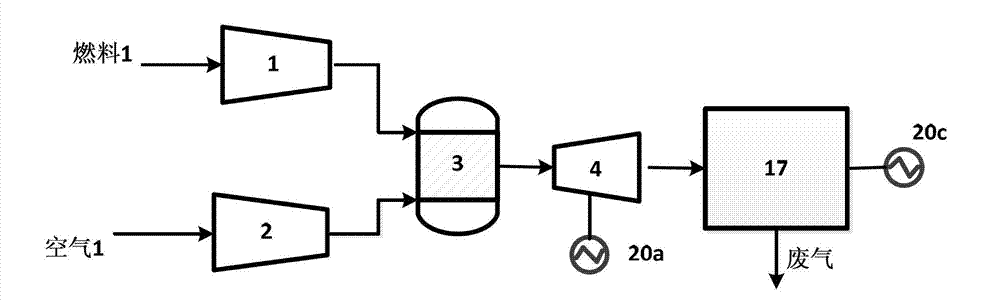

Hybrid power system using normal pressure MCFC (molten carbonate fuel cell) to recover CO2 in exhaust gas of gas turbine

ActiveCN103206307AGas turbine plantsFused electrolyte fuel cellsCombustion chamberMolten carbonate fuel cell

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Integrated gasification molten carbonate fuel cell power generating system

An integrated gasification molten carbonate fuel cell power generating system comprises an air separation device. An outlet of the air separation device is connected with an inlet of a gasification furnace. An outlet of the gasification furnace is connected with a waste heat recovery device through a high-temperature heat exchanger, a particulate removal device, a desulfurization device, a mercury removal device, and a water-steam conversion device, and then connected with an anode inlet of a molten carbonate fuel cell. The output of the molten carbonate fuel cell is connected with an AC power grid or an electric appliance through a DC / AC converter. Synthesis gas from the gasification furnace is subjected to heat recovery after passing through the high-temperature heat exchanger, is introduced into the high-temperature molten carbonate fuel cell after being subjected to gas purification. Moreover, air is firstly pressurized by a compressor, then is heated by the high-temperature heat exchanger and a low-temperature heat exchanger, and then is used for driving a turbine to generate electricity, and heat is made makes a full use to be converted into electrical power. By adopting the system, the heat utilization rate is increased and the efficiency is improved.

Owner:HUANENG TIANJIN COAL GASIFICATION POWER CO LTD

High-efficiency molten carbonate fuel cell system and method

ActiveUS9478819B2Maintain thermal balanceCost-effectiveFuel cells groupingFuel cell auxillariesFuel cellsMolten carbonate fuel cell

A high efficiency fuel cell system comprising a topping fuel cell assembly comprising a topping cathode portion and a topping anode portion; and a bottoming fuel cell assembly comprising a bottoming cathode portion and a bottoming anode portion, wherein the bottoming anode portion receives anode exhaust output from the topping anode portion and the topping cathode portion receives cathode exhaust from the bottoming cathode portion, and wherein the topping fuel cell assembly has a greater number of fuel cells than the bottoming fuel cell assembly so that the topping fuel cell assembly utilizes more fuel than the bottoming fuel cell assembly.

Owner:FUELCELL ENERGY INC

Application of a Methane Reforming Catalyst in Molten Carbonate Fuel Cell

InactiveCN102299345AEasy to prepareConditions are easy to controlCell electrodesMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementMolten carbonate fuel cell

The invention discloses the application of a methane reforming catalyst in a molten carbonate fuel cell. The catalyst comprises an active component nickel with a content of 4-25 wt%, a rare earth element catalytic promoter with a content of 0-10 wt%, Alumina carrier with a content of 65-96 wt%. The preparation method of the catalyst is simple, can be operated under the conditions of medium temperature and low water-to-carbon ratio, has high reactivity, strong carbon deposition resistance and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Systems And Processes Of Operating Fuel Cell Systems

Processes and systems for operating molNISSAN CHEMICAL IND LTD ten carbonate fuel cell systems are described herein. A process for operating a molten carbonate fuel cell system includes providing a hydrogen-containing stream comprising molecular hydrogen to an anode portion of a molten carbonate fuel cell; controlling a flow rate of the hydrogen-containing stream to the anode such that molecular hydrogen utilization in the anode is less than 50%; mixing anode exhaust comprising molecular hydrogen from the molten carbonate fuel cell with a hydrocarbon stream comprising hydrocarbons, contacting at least a portion of the mixture of anode exhaust and the hydrocarbon stream with a catalyst to produce a steam reforming feed; separating at least a portion of molecular hydrogen from the steam reforming feed; and providing at least a portion of the separated molecular hydrogen to the molten carbonate fuel cell anode.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Natural gas melting carbonate fuel cell generation system

InactiveCN101051690AImprove conversion efficiencyHigh purityFuel cell heat exchangeFuel cellsWater vapor

The power generation system of fuel cell includes three subsystems: adsorption-enhanced subsystem for reforming vapor and methane; fuel cell subsystem of molten carbonate, and subsystem for cyclic utilizing carbon dioxide and tail gas. Through gas inlet pipe and gas outlet pipe, the three subsystems are connected. Combining with MCFC power generation system, the invention uses adsorption-enhanced subsystem for reforming vapor and methane instead of traditional reforming vapor and methane to constitute power generation system of fuel cell of natural gas and molten carbonate. Advantages are: simple system and low energy consumption.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com