Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

599 results about "Fischer–Tropsch process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Fischer–Tropsch process is a collection of chemical reactions that converts a mixture of carbon monoxide and hydrogen into liquid hydrocarbons. These reactions occur in the presence of metal catalysts, typically at temperatures of 150–300 °C (302–572 °F) and pressures of one to several tens of atmospheres. The process was first developed by Franz Fischer and Hans Tropsch at the Kaiser-Wilhelm-Institut für Kohlenforschung in Mülheim an der Ruhr, Germany, in 1925.

Fischer-Tropsch process in the presence of nitrogen contaminants

InactiveUS20050154069A1Organic compounds purification/separation/stabilisationHydrocarbon from carbon oxidesNitrogenPre conditioning

A Fischer-Tropsch process in the presence of nitrogen is provided wherein the Fischer-Tropsch catalyst retains at least 50% of its original activity and about the original C5+ selectivity. A process for pre-conditioning a Fischer-Tropsch catalyst such that no more than 50% of the original catalyst activity is lost while the resultant catalyst retains about its original C5+ selectivity.

Owner:SYNTROLEUM

Distillate fuel blends from Fischer Tropsch products with improved seal swell properties

InactiveUS6890423B2Hydrocarbon by isomerisationCatalytic naphtha reformingPolymer scienceEngineering

The invention provides distillate fuel blend components with improved seal swell and lubricity properties obtained from Fischer Tropsch products. The blends contain a highly paraffinic distillate fuel component and distillate-boiling alkylcycloparaffins and / or distillate-boiling alkylaromatics. The invention further provides processes for obtaining such blends using the products of Fischer Tropsch processes. Finally, the invention provides methods for improving seal swell and lubricity properties for distillate fuels.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

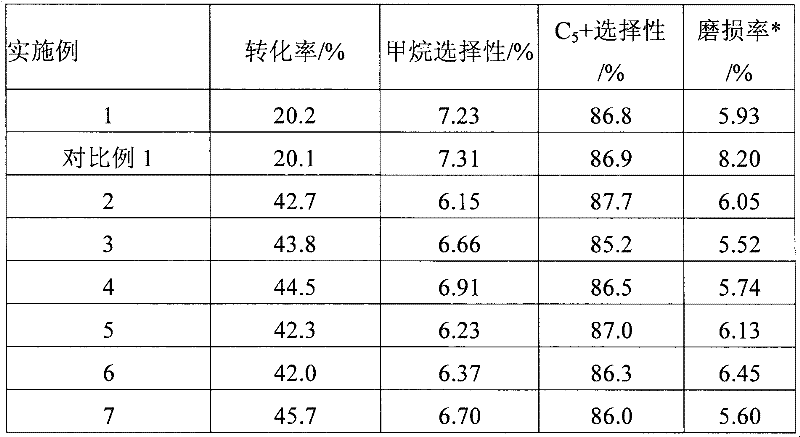

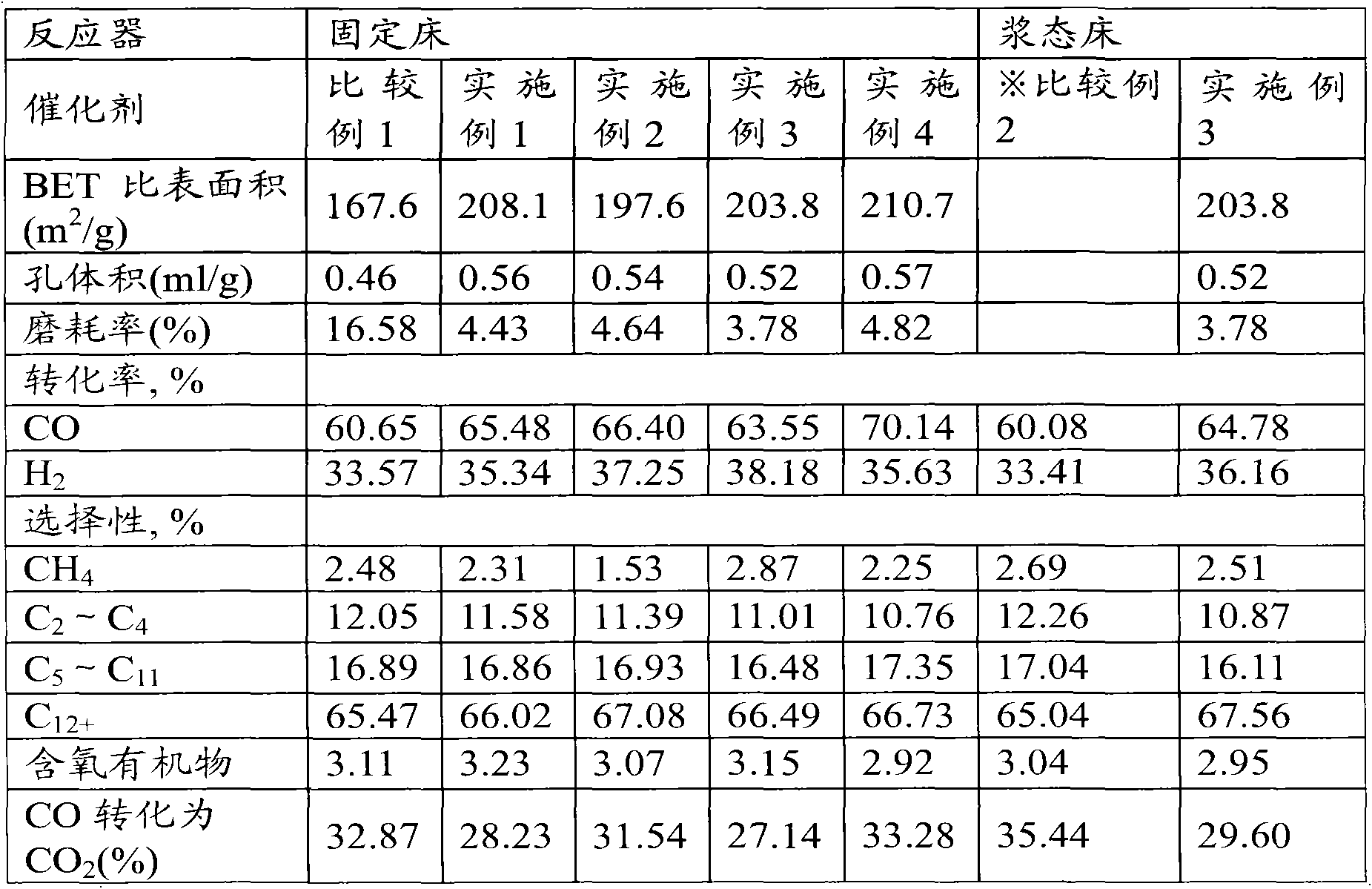

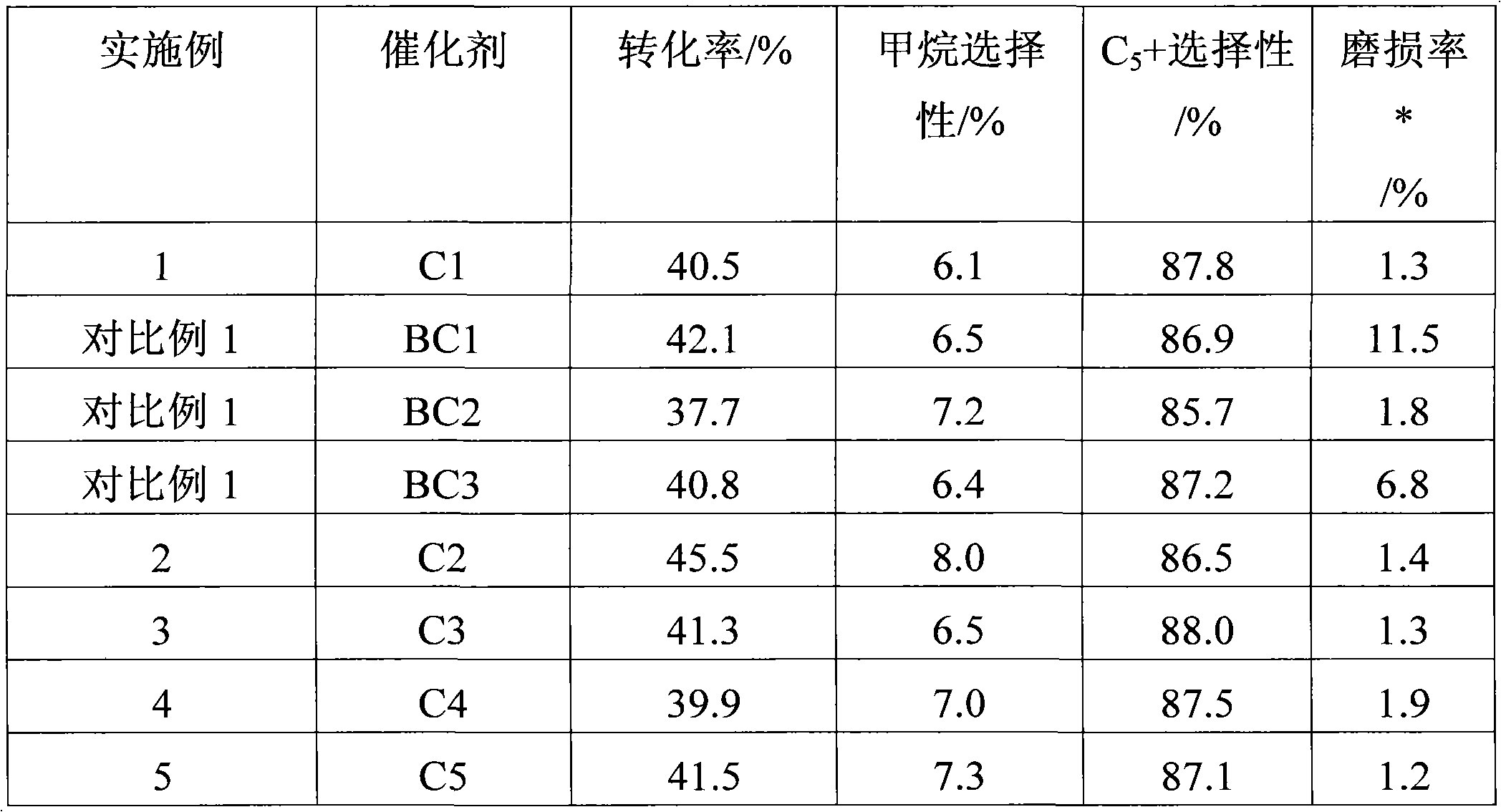

Fischer-Tropsch synthesis catalyst by taking modified alumina as carrier and application thereof

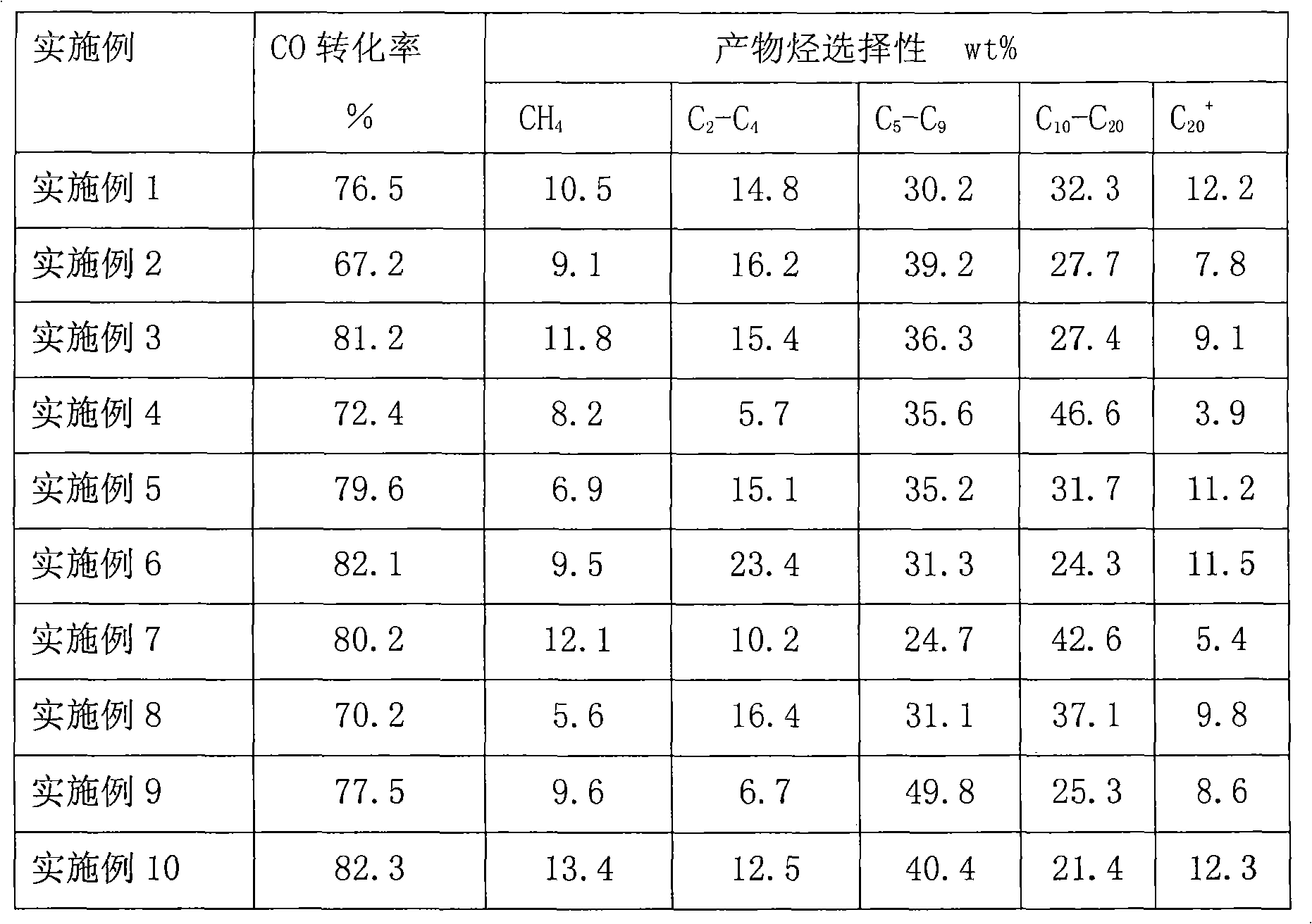

ActiveCN102441393AHigh activityHigh selectivityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsComponent LoadHigh activity

The invention relates to Fischer-Tropsch synthesis catalyst by taking modified alumina as a carrier and application thereof; the catalyst contains the carrier and an active metal component loaded on the carrier and selected from iron and / or cobalt, wherein the carrier is alumina modified by the metal component containing one or more auxiliaries of zinc, cobalt and nickel; based on oxide and the carrier, the content of the metal component containing one or more auxiliaries of zinc, cobalt and nickel is 0.5-15% by weight; and a preparation method of the modified alumina comprises the following steps of: (1) preparing an aqueous solution containing alkali and the metal component containing one or more auxiliaries of zinc, cobalt and nickel; (2) dipping the alumina by using the solution prepared in the step (1); and (3) drying and roasting the alumina dipped in the step (2). Compared with the prior art, on the premise of keeping the high activity and the high selectivity, the wearable property of the catalyst provided by the invention is obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch processes and catalysts using stabilized supports

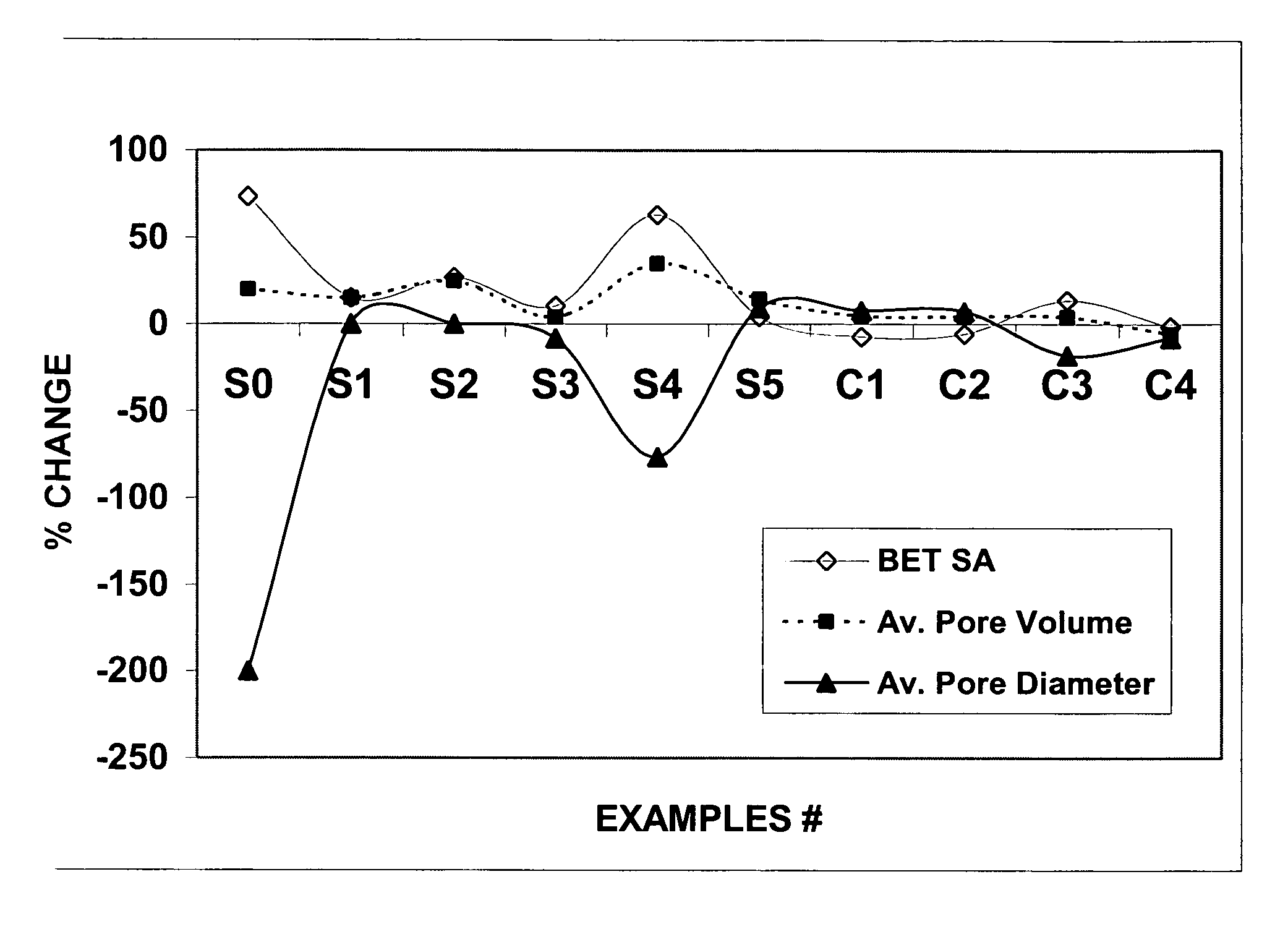

ActiveUS7071239B2Good hydrothermal stabilityImprove stabilityCatalyst carriersOrganic compound preparationSlurryHYDROSOL

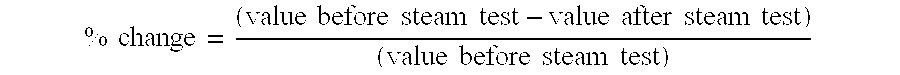

A catalyst and method for producing hydrocarbons using a catalyst support having an improved hydrothermal stability, such as under Fischer-Tropsch synthesis conditions. The stabilized support is made by a method comprising treating a boehmite material in contact with at least one structural stabilizer. Contacting the boehmite with at least one structural stabilizer can include forming a mixture comprising the boehmite material and at the least one structural stabilizer. The mixture can be a sol or a slurry. The treating preferably includes drying or spray drying the mixture, and calcining in an oxidizing atmosphere to obtain the stabilized support. Preferred structural stabilizers can include an element, such as cobalt, magnesium, zirconium, boron, aluminum, barium, silicon, lanthanum, oxides thereof, or combinations thereof; or can include precipitated oxides, such as a co-precipitated silica-alumina.

Owner:CLARIANT INT LTD

Method of preparing cobalt-base Fischer-Tropsch synthetic catalyst

InactiveCN1454714AHigh reactivityHigh selectivityCatalyst activation/preparationHydrocarbonsActive componentHYDROSOL

The invention is a manufacturing method for cobalt Fischer-Tropsch synthesis catalyst. It produces silica gel carrier through sol-gel method, the silica gel carrier is surface mollified by amine liquor, and then the active component cobalt is loaded on to the silica gel surface through isopyknic pickling process. There gets the mollified cobalt silicon catalyst through drying and baking. The reaction activity and selection are enhanced greatly through the mollifying of amine, the operation life is long, and the manufacturing method is simple.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Fischer-Tropsch processes and catalysts made from a material comprising boehmite

ActiveUS7012104B2Improve performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPseudoboehmiteCatalytic metal

A hydrothermally-stable catalyst, method for making the same, and process for producing hydrocarbon, wherein the catalyst is used in synthesis gas conversion to hydrocarbons. In one embodiment, the method comprises depositing a compound of a catalytic metal selected from Groups 8, 9, and 10 of the Periodic Table on a support material comprising boehmite to form a composite material; and calcining the composite material to form the catalyst. In other embodiments, the support material comprises synthetic boehmite, natural boehmite, pseudo-boehmite, or combinations thereof.

Owner:CLARIANT INT LTD

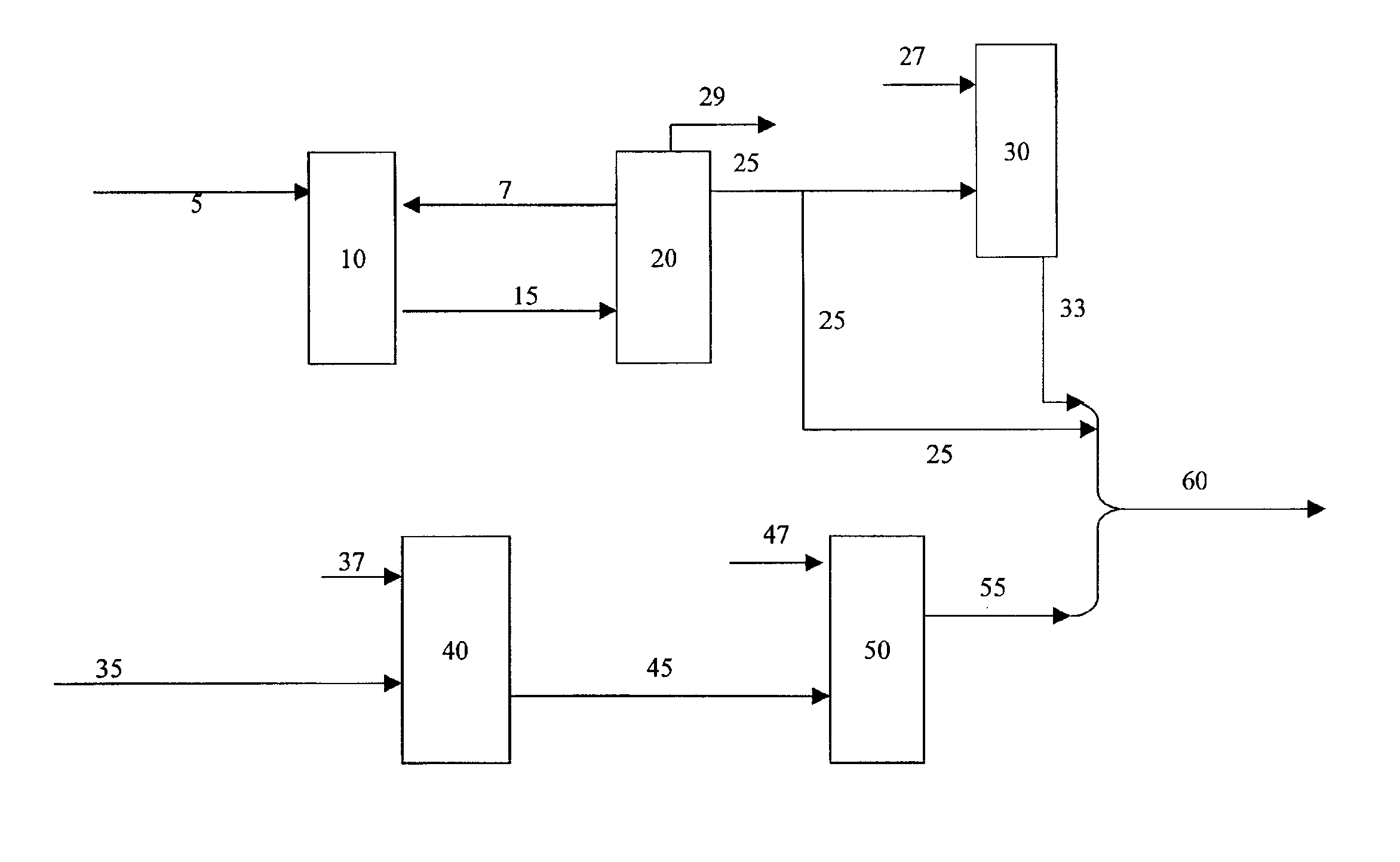

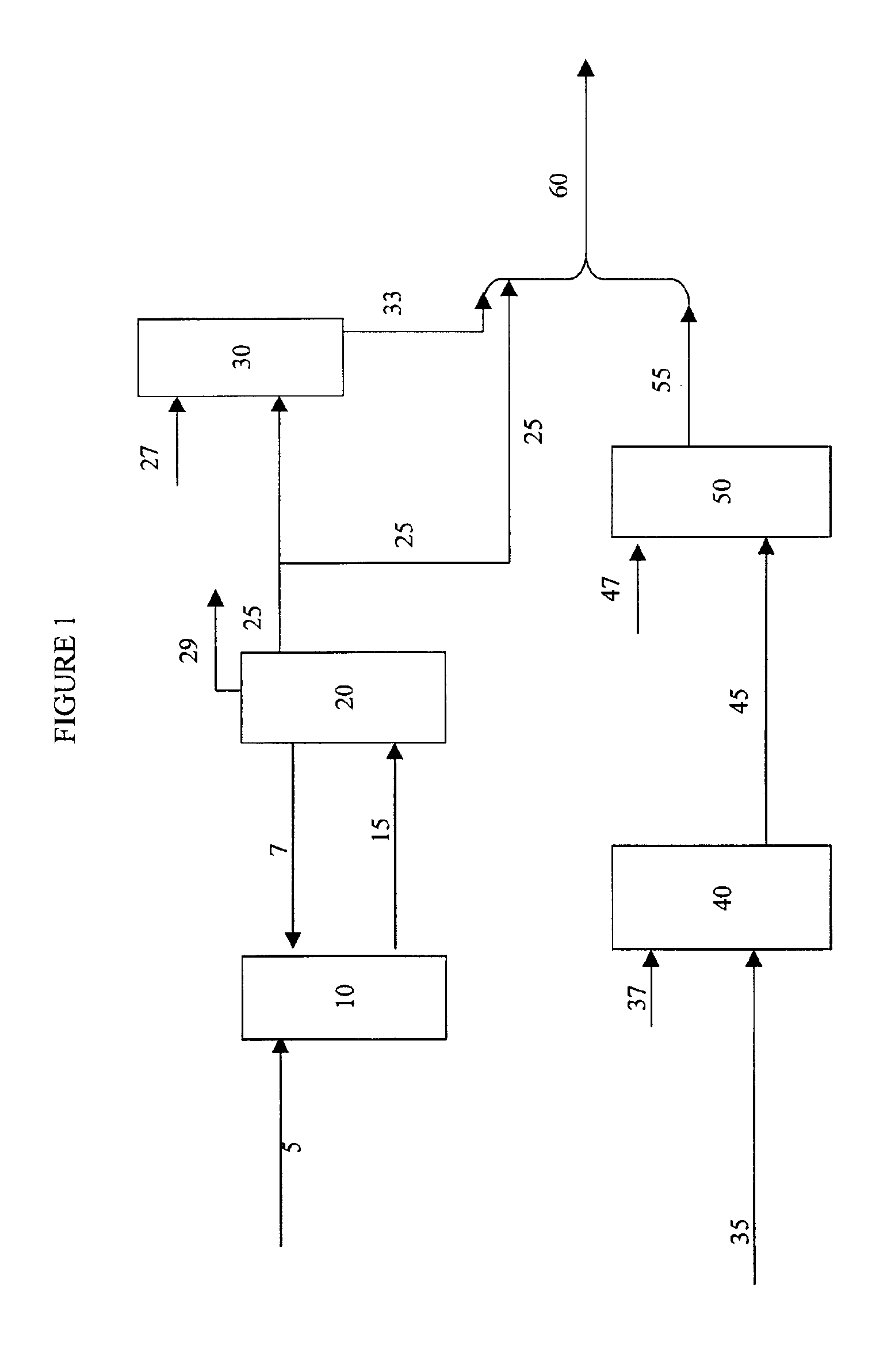

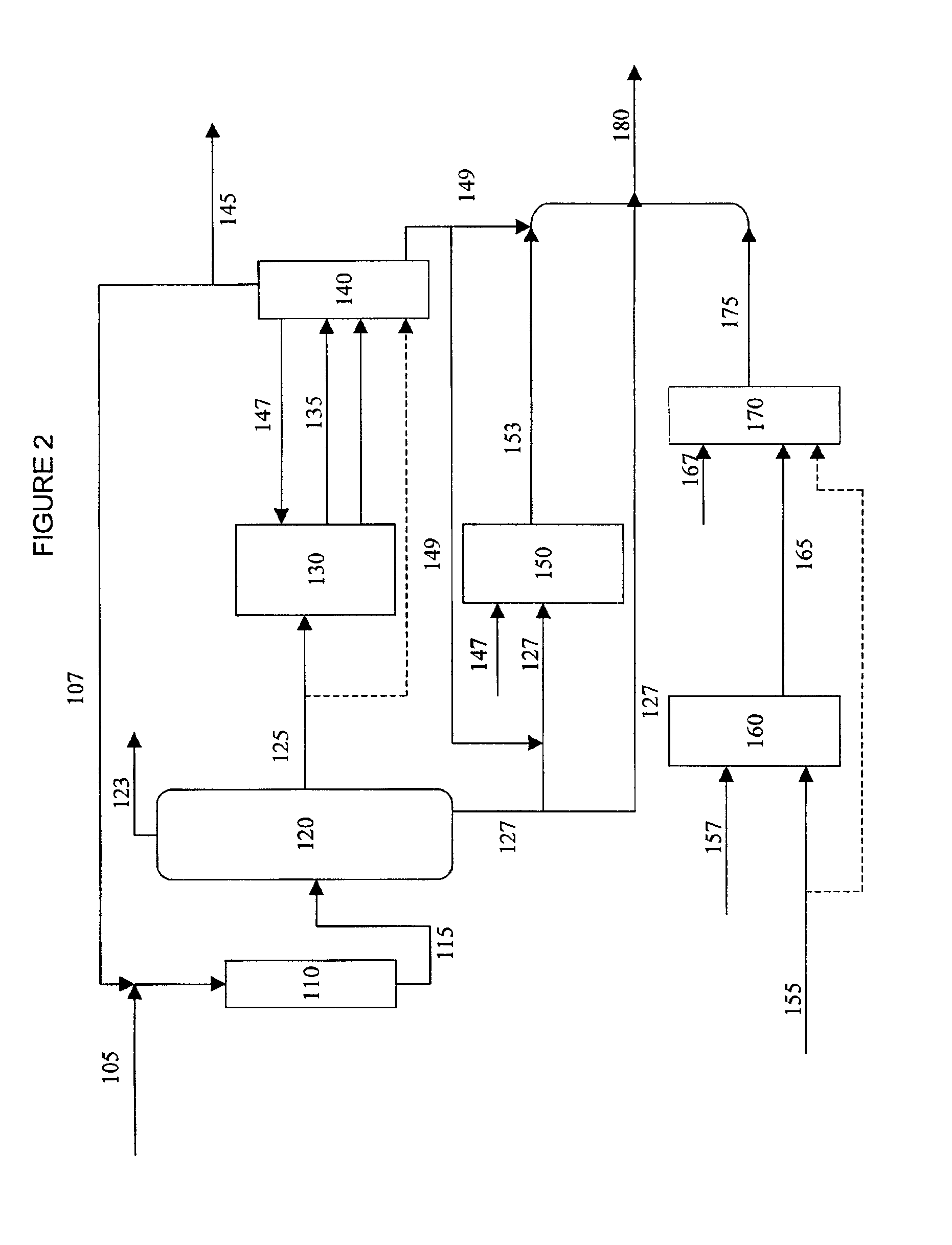

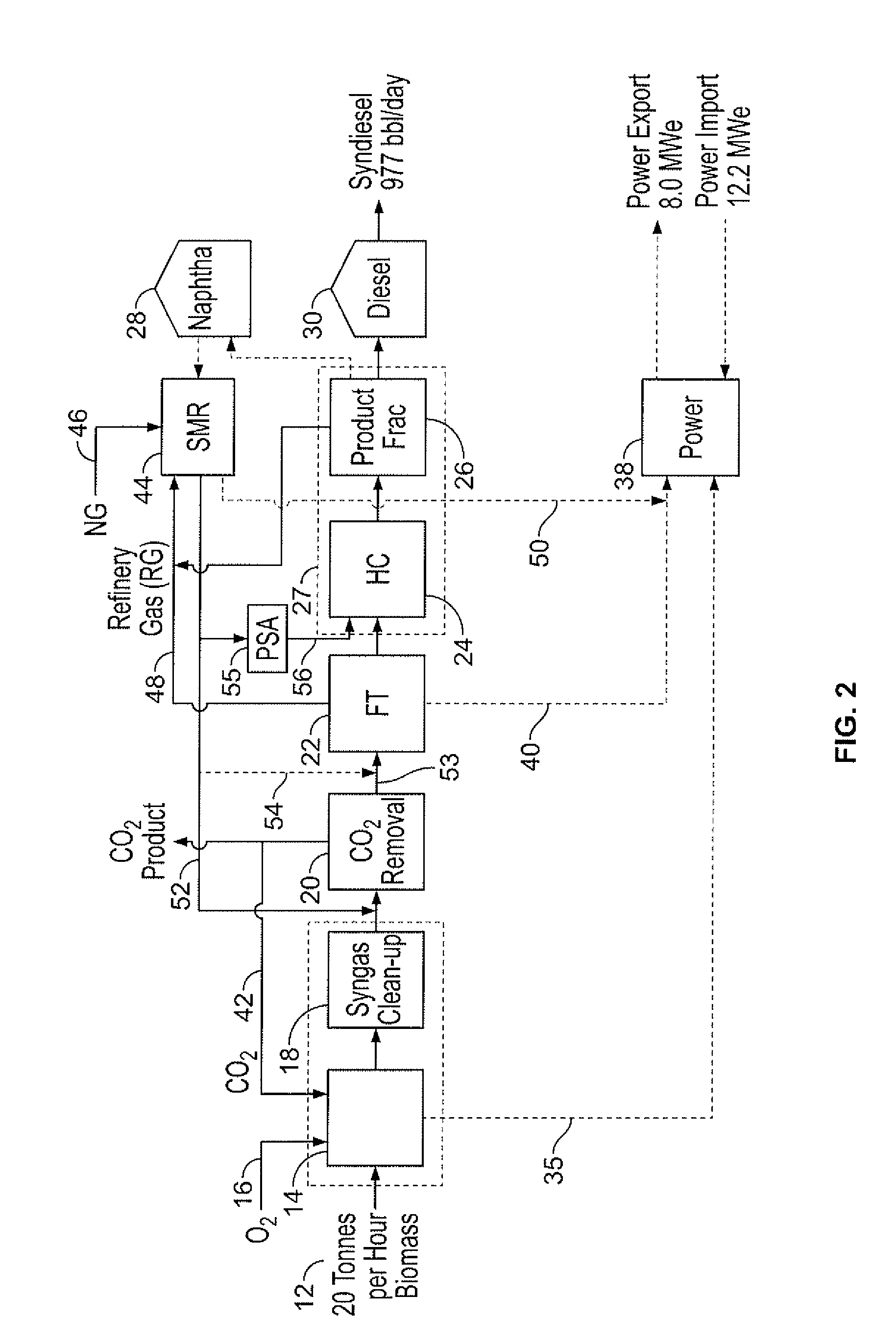

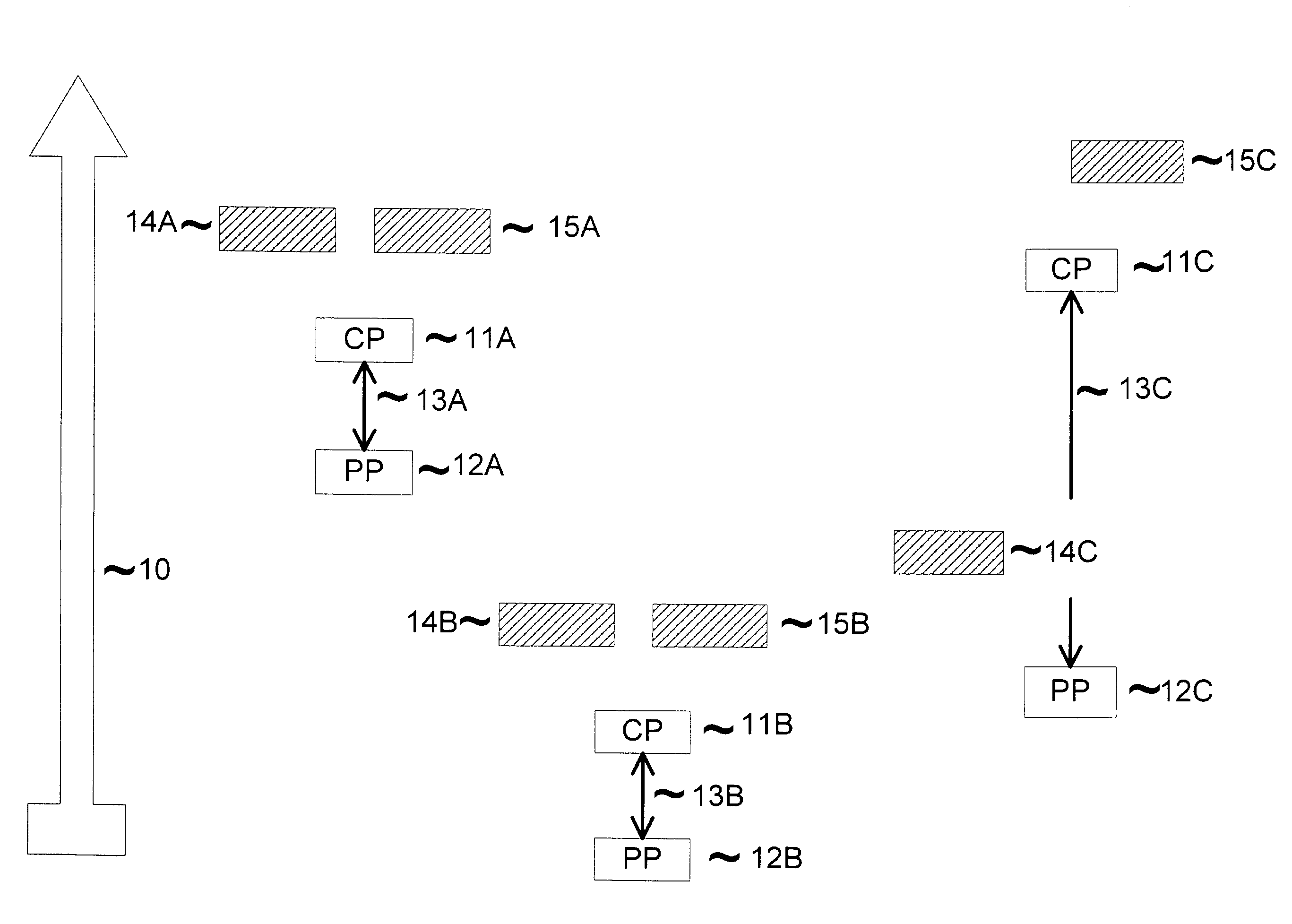

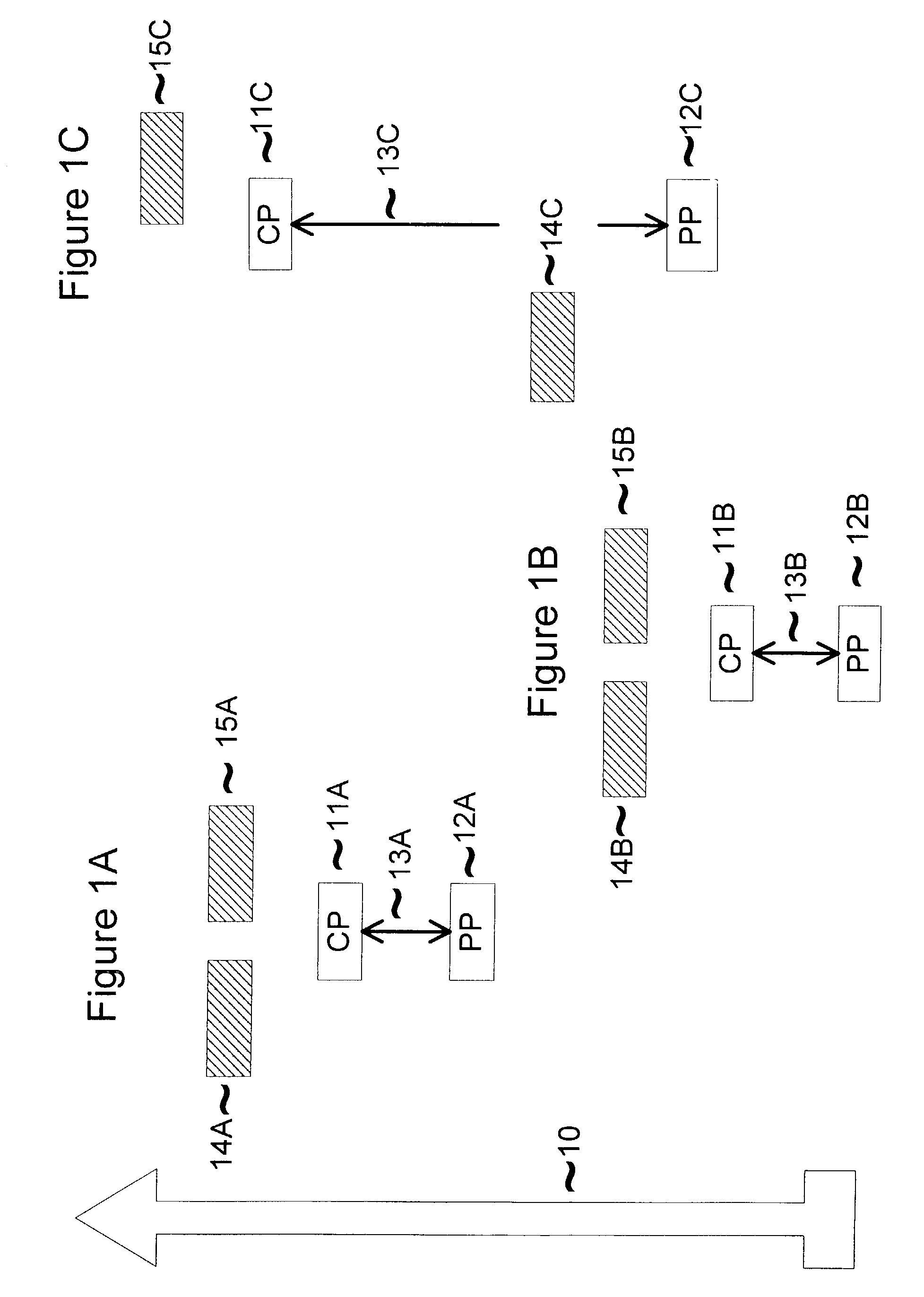

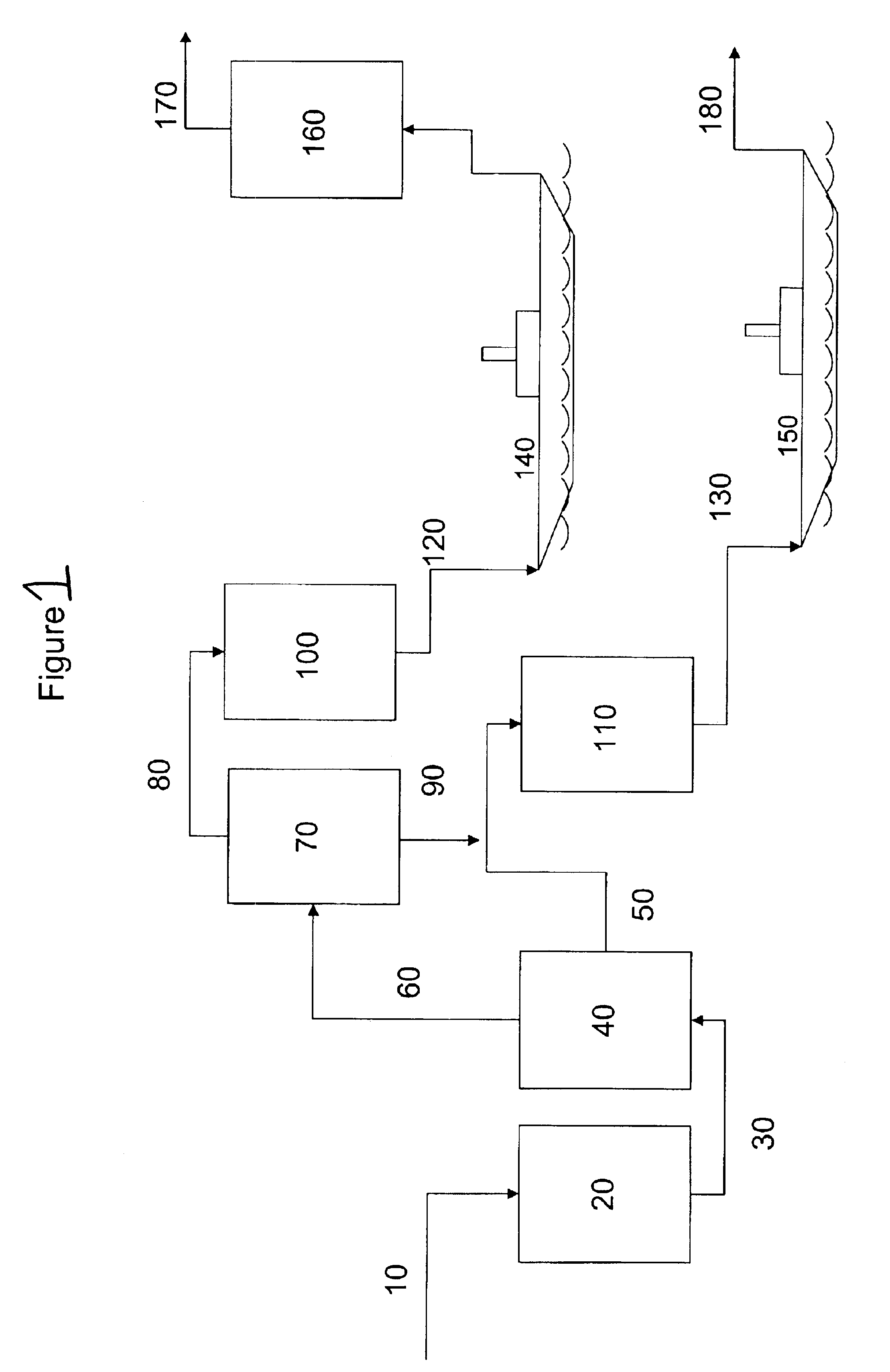

Enhancement of fischer-tropsch process for hydrocarbon fuel formulation

ActiveUS20120208902A1Increase productionIncrease conversionsBiofuelsGas modification by gas mixingSyngasNaphtha

An enhanced Fischer-Tropsch process for the synthesis of sulfur free, clean burning, green hydrocarbon fuels, examples of which include syndiesel and aviation fuel. Naphtha is destroyed in a hydrogen generator and recycled as feedstock to a syngas (FT) reactor in order to enhance the production of syndiesel from the reactor. A further variation integrates a second hydrogen generator capturing light hydrocarbon gas for conversion to hydrogen and carbon monoxide which supplements the Fischer-Tropsch reactor. The result is a considerable increase in the volume of syndiesel formulated. A system for effecting the process is also characterized in the specification.

Owner:EXPANDER ENERGY

Reduction method for iron-based catalyst for Fischer-Tropsch synthesis in fixed bed

ActiveCN103071543AReduce carbon depositionHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionHydrogenFixed bed

The invention discloses a reduction method for an iron-based catalyst for Fischer-Tropsch synthesis in a fixed bed. The method comprises the following steps: adding the iron-based catalyst into a fixed bed reactor; and introducing gaseous hydrocarbon or mixed gas of hydrogen and gaseous hydrocarbon into the fixed bed reactor for reduction reaction to reduce the iron-based catalyst. The reduction method has the advantages that (1) the reduced catalyst has a little carbon deposit, so the catalyst has high activity and stability; (2) the product selectivity of the catalyst can be effectively modulated, and the selectivity for C5-30 in products is high; and (3) the reduced catalyst has a little carburization, so the catalyst has high wear resistance.

Owner:SYNFUELS CHINA TECH CO LTD

Iron base catalyzer through Fischer-Tropsch synthesis and preparation method

InactiveCN1562471AReduce manufacturing costReduce preparation energy consumptionHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMicrosphereSlurry

A Fe-base catalyst with high antiwear performance, activity and stability for the Fischer-Tropsch synthesis contains Fe, Zn, Cu, K and SiO2. It is prepared through proportionally mixing sodium carbonate solution as precipitant with the mixed solution of iron nitrate, zinc nitrate and copper acetate, depositing to obtain deposit slurry, adding the mixed solution of potassium silicate and silicon sol, spray drying and calcining.

Owner:中科合成油淮南催化剂有限公司

Cobalt group catalyst synthesized with fischer tropsch process, production method and application thereof

InactiveCN101269329AHigh reactivityHigh selectivityHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionActive componentMetal

The invention relates to a fischer-tropsch cobalt-based catalyst composed of an active component and a carrier, wherein, the metal cobalt accounts for 5-35 percent, and the carrier accounts for 65-95 percent of the catalyst which is made by a method of impregnation. The fischer-tropsch cobalt-based catalyst has the advantages of improving the reactivity of the catalyst and optimizing the distribution of products as well as increasing the selectivity for C5<+>; besides, the fischer-tropsch cobalt-based catalyst has simple process and is suitable for mass industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for conversion of atmospheric carbon dioxide into useful materials

A method for converting carbon dioxide in a gaseous environment, including air into useful materials by use of renewable energy sources which comprises:(1) extracting carbon dioxide from a gaseous source using a sorbent such as sodium hydroxide, calcium hydroxide, or potassium hydroxide;(2) utilizing wind power, solar power, or other renewable energy sources to regenerate said sorbent by membrane cell electrolysis or other similar method, simultaneously producing hydrogen (H2) gas;(3) releasing carbon dioxide from said sorbent; and(4) utilizing the Fischer Tropsch process, Mobil process, ICI process, or related or similar processes to convert carbon oxides to a hydrocarbon concomittantly with or after effecting the reverse water-gas shift reaction to convert said CO2 and H2 gas into carbon monoxide for reaction in said Fischer Tropsch process, Mobil process or ICI process.

Owner:KAPLAN THOMAS PROGER

Co-Zr catalyst for Fischer-Tropsch synthesis and its prepn and application

InactiveCN1398669AImprove stabilityReduced inactivation rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalChemistry

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Process for producing hydrocarbons from syngas

The invention pertains to a lean process for the production of hydrocarbons in which a tail gas is subjected to shift conversion, carbon dioxide removal, and then to purification in a PSA to obtain a hydrogen stream comprising more than 99 vol % hydrogen. The Fischer Tropsch process is a single-stage process. The hydrogen stream can be used to upgrade the Fischer-Tropsch hydrocarbons.

Owner:SHELL OIL CO

Synthetic fuel with reduced particulate matter emissions and a method of operating a compression ignition engine using said fuel in conjunction with oxidation catalysts

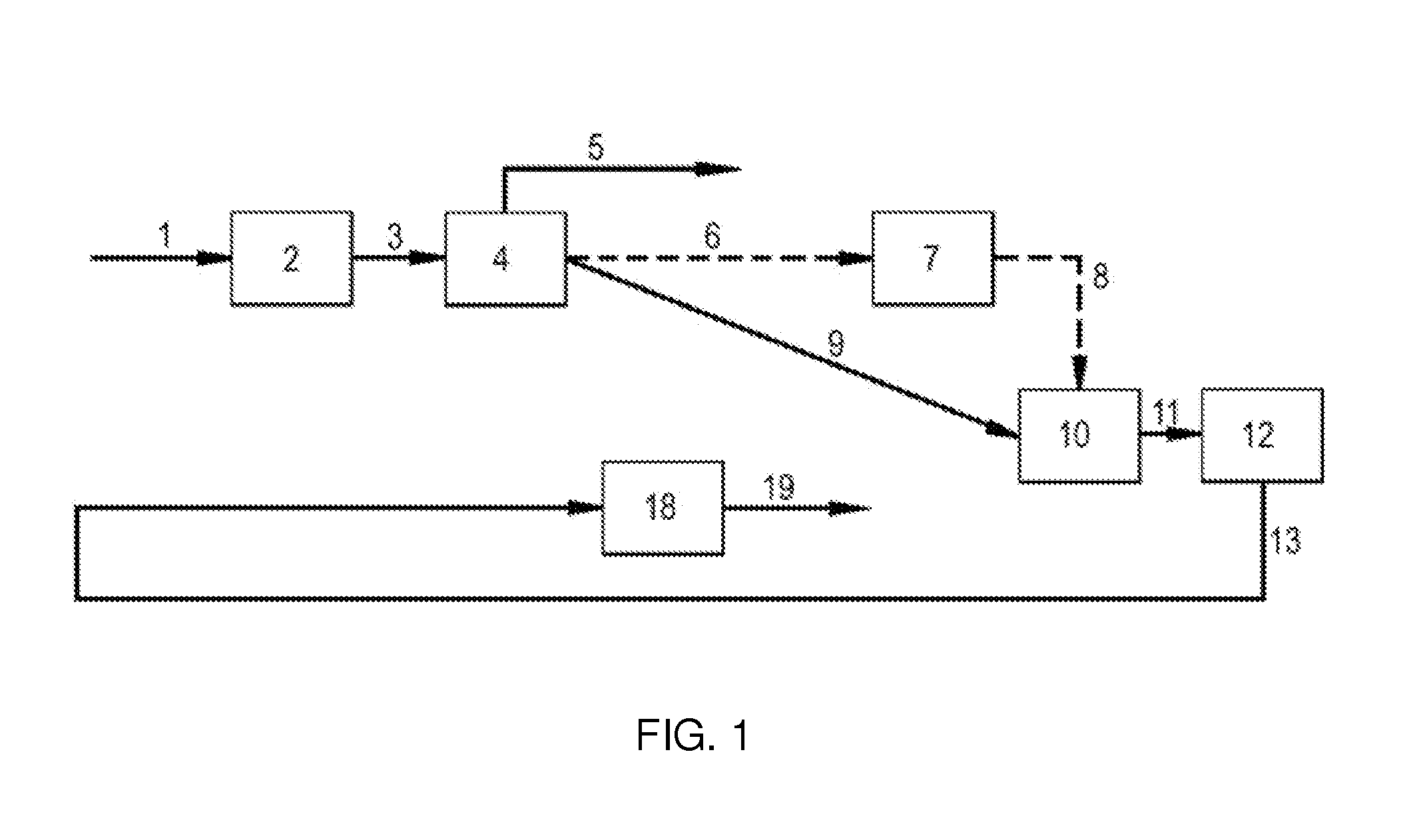

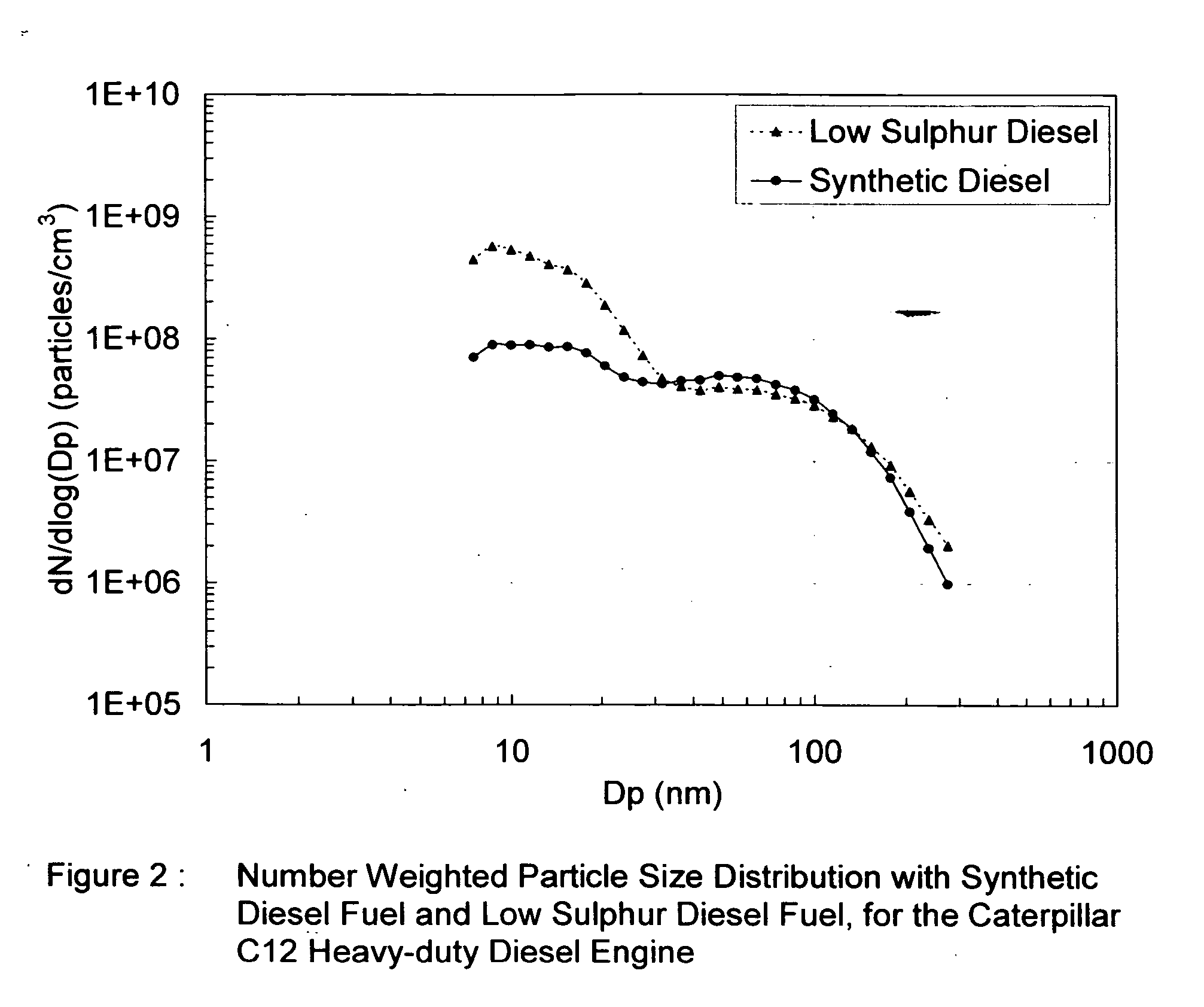

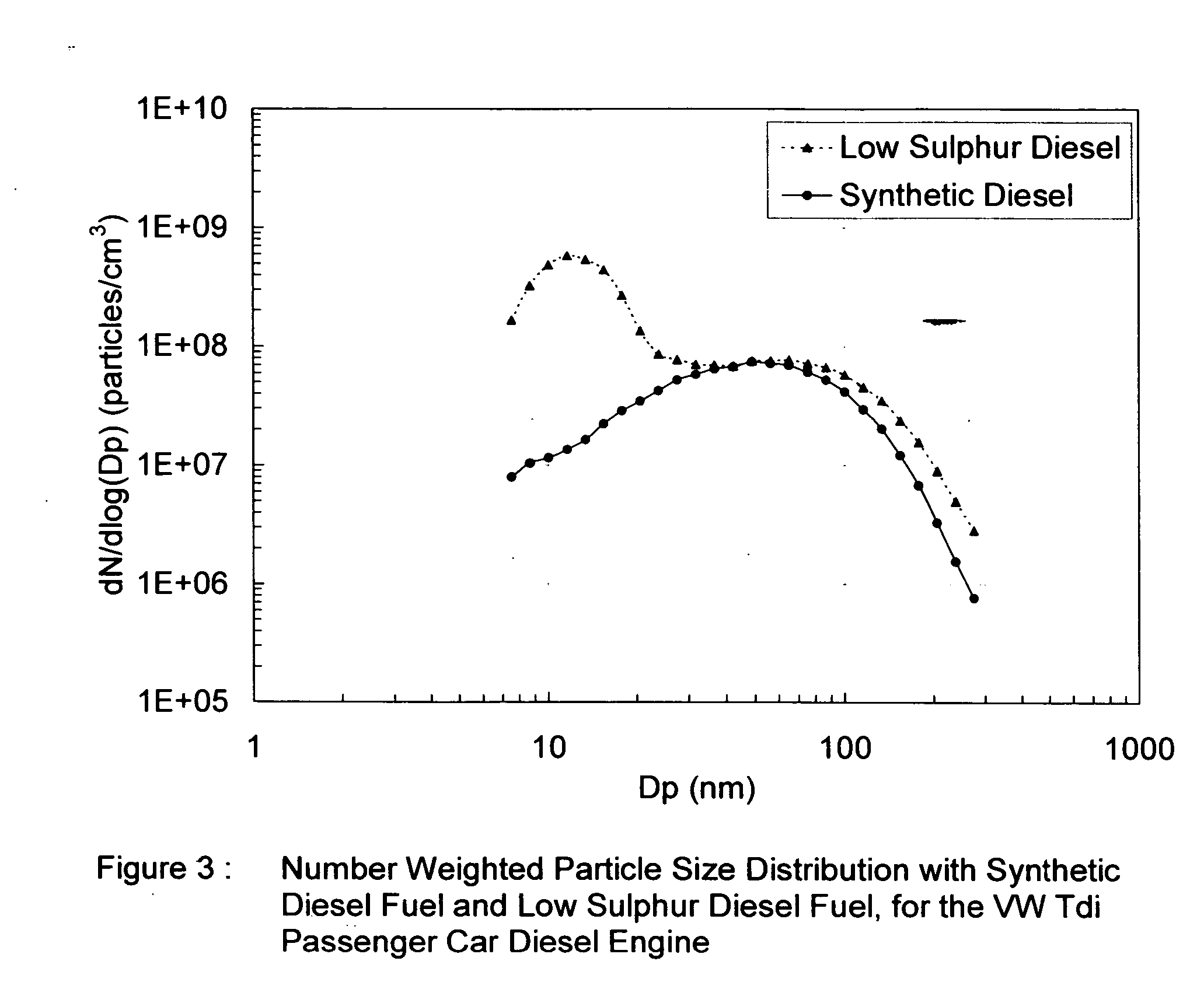

InactiveUS20050154240A1Improve conversion efficiencyEmission reductionSolid fuelsLiquid carbonaceous fuelsParticulatesCarbon number

The invention provides a compression ignition engine fuel derived from a Fischer-Tropsch process, which fuel has a generally increasing iso:n paraffins ratio with increasing paraffin carbon number at least between C9 to C18, less than 0.05% m / m sulphur, and less than 10% by mass aromatics. The fuel may have on average more than 0.9 alkyl branches per paraffinic molecule as measured by H+ NMR analysis. The invention also provides a method for operating a compression ignition engine to produce low particulates emissions, which method comprises combusting the fuel with oxygen or an oxygen containing gas in the engine. Yet further the invention provides a method of improving the conversion efficiency of oxidation catalysts used in conjunction with compression ignition engines, said method including combusting the fuel in the compression ignition engine in the presence of said oxidation catalysts and in oxygen or an oxygen containing gas.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

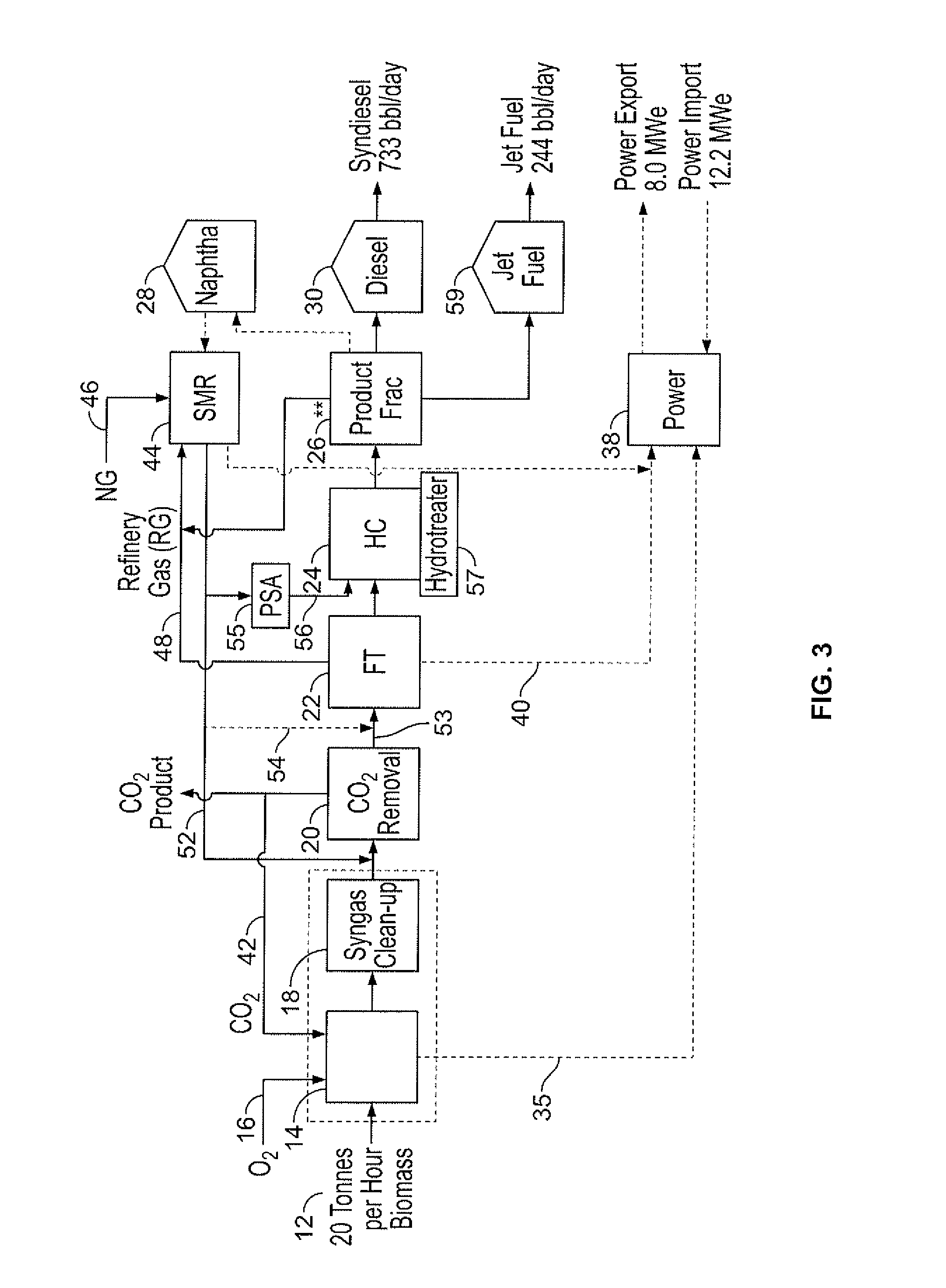

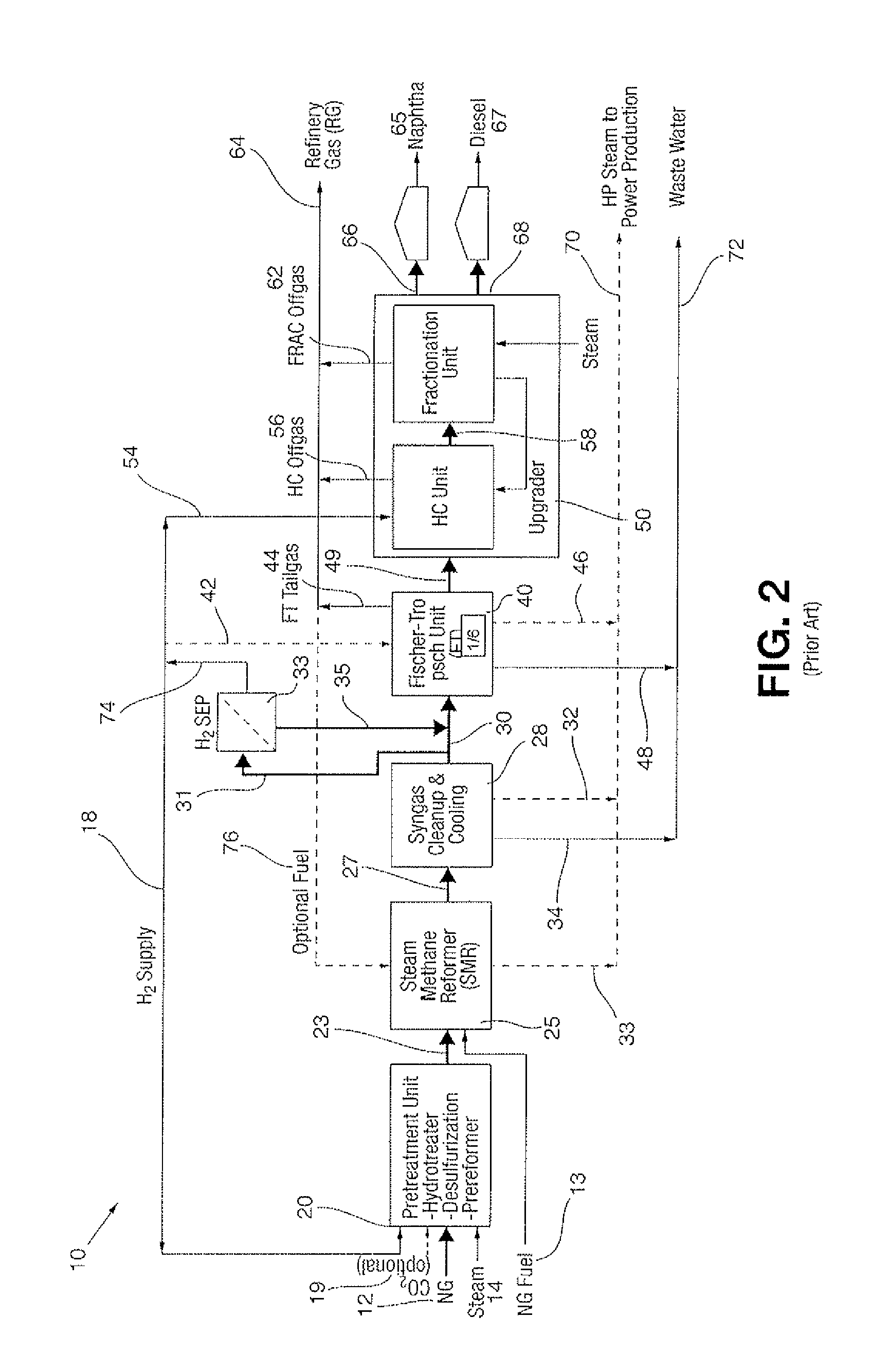

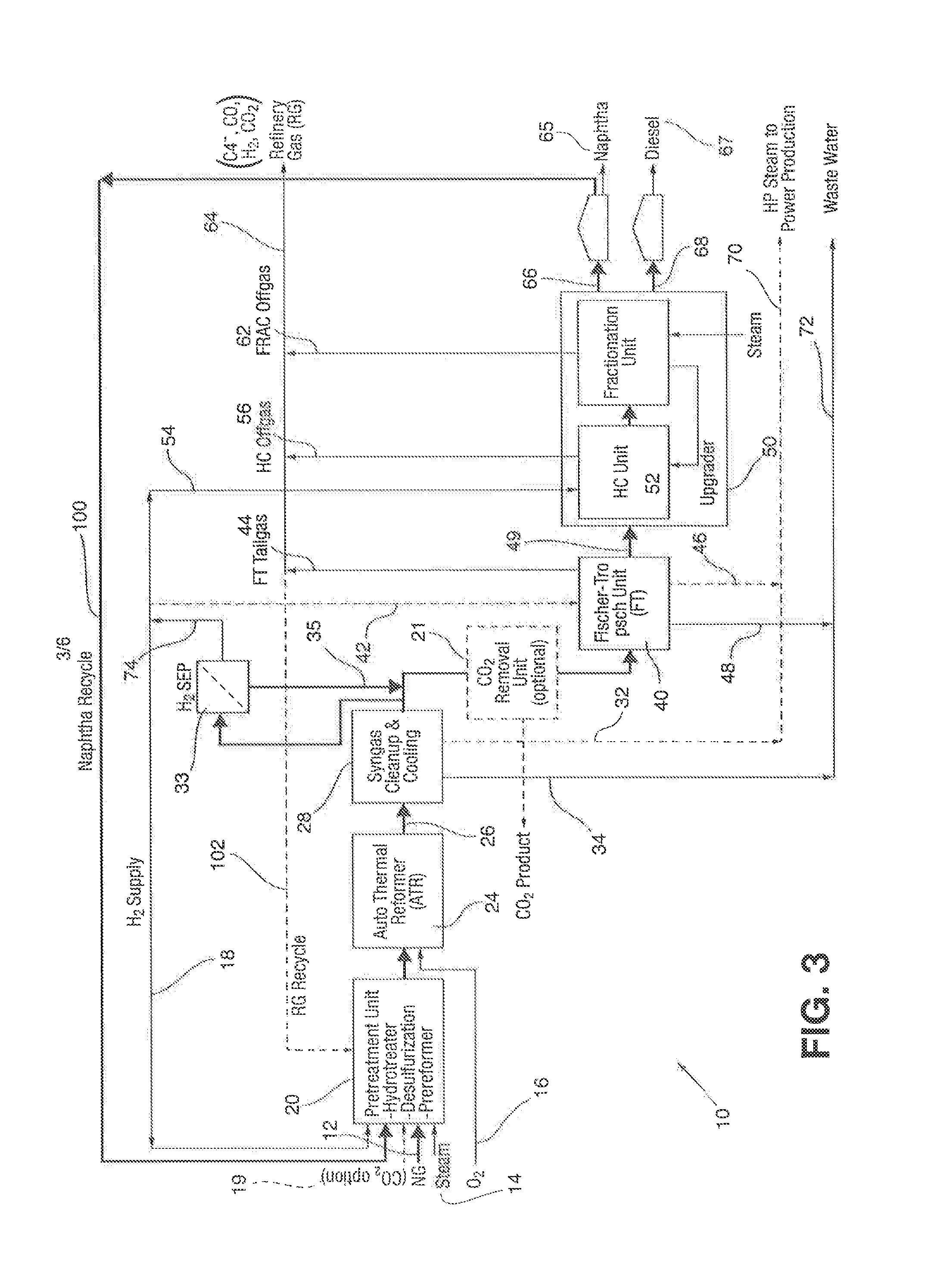

Enhancement of Fischer-Tropsch process for hydrocarbon fuel formulation in a GTL environment

ActiveUS8889746B2Increase productionRaise the ratioHydrogenOrganic compound preparationSyngasNaphtha

An enhanced Fischer-Tropsch process for the synthesis of sulfur free, clean burning, hydrocarbon fuels, examples of which include syndiesel and aviation fuel. Naphtha is destroyed in a syngas generator and recycled as feedstock to an Fischer-Tropsch (FT) reactor in order to enhance the production of syndiesel from the reactor. The process enhancement results is the maximum production of formulated syndiesel without the formation of low value by-products.

Owner:EXPANDER ENERGY

Precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and preparation method and application thereof

ActiveCN101884926AHigh specific surface areaIncrease the areaCatalyst activation/preparationLiquid hydrocarbon mixture productionPrecipitationIon

The invention relates to a precipitated iron catalyst for Fischer-Tropsch synthesis reaction, and a preparation method and application thereof. The preparation method comprises the following steps of: (a) feeding ferric salt solution, aid saline solution, the solution of precipitator and a small amount of solution of silicon compounds in a form of concurrent flow into a precipitation reactor; (b)performing coprecipitation reaction on the mixture under certain process conditions in the reactor, and fast cooling, filtering and rinsing pulp obtained after the precipitation reaction is finished;(c) adding a silicon compound binder into a filter cake obtained after the rinsing, adding a nitric acid into the filter cake to adjust pH and performing secondary filtration; (d) performing secondary pulping on the obtained filter cake with de-ionized water or the mixed solution of the de-ionized water and the required aid saline solution; and (e) performing spray-drying molding and baking on the obtained catalyst pulp. The catalyst prepared by the method of the invention has high specific surface area, proper pore volume, high wear strength, high sphericity and smooth surface.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

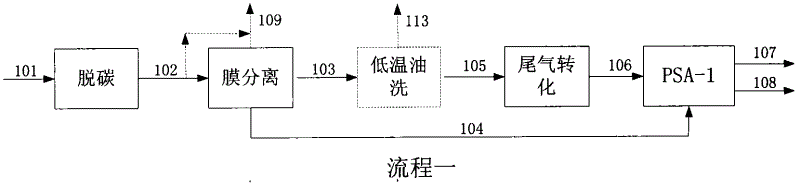

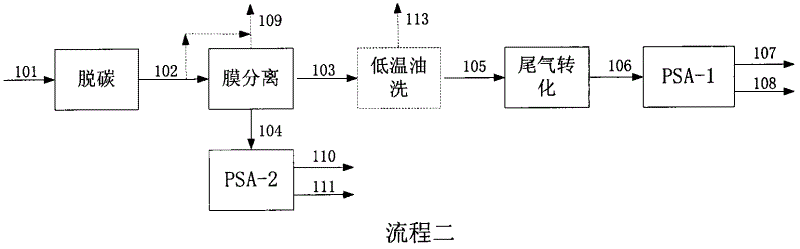

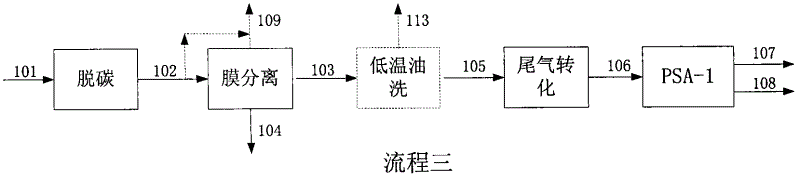

Method for processing Fischer-Tropsch synthesis tail gas

ActiveCN102614763AIncrease added valueAchieve different production goalsDispersed particle separationBy chemical separationLiquid gasDecarburization

The invention relates to a method for processing Fischer-Tropsch synthesis tail gas, which comprises the steps of decarburization, membrane separation, low temperature oil washing, tail gas conversion and pressure swing adsorption(PSA). The method is characterized in that tail gas from a Fischer-Tropsch synthesis apparatus is passed through a decarburization unit for removing CO2 component; decarburization tail gas is sent to a membrane separation unit for recovering hydrogen, membrane separation penetration gas with rich hydrogen is boosted and then sent to a PSA unit for hydrogen production, also can be returned to the Fischer-Tropsch synthesis apparatus after boosting, the membrane separation unit can be returned to the Fischer-Tropsch synthesis apparatus according to the required gas with any H2 / CO proportion, membrane separation non-penetration gas can be passed through a low temperature oil washing unit for recovering liquefied gas component and then sending to a tail gas conversion unit, and also can be sent to the tail gas conversion unit directly for hydrogen production; in the tail gas conversion unit, oil washing dry gas or membrane separation non-penetration gas are conversed, methane and hydrocarbons components are conversed to crude synthetic gas; the conversed crude synthetic gas converses CO and H2O to CO2 and H2, the conversed gas after decarburization removes CO2 to obtain hydrogen rich gas, the hydrogen rich gas is passed through the PSA unit for recovering hydrogen, hydrogen in the PSA unit can be used for whole plant, the analytic gas can be used as fuel gas.

Owner:SYNEFUELS CHINA

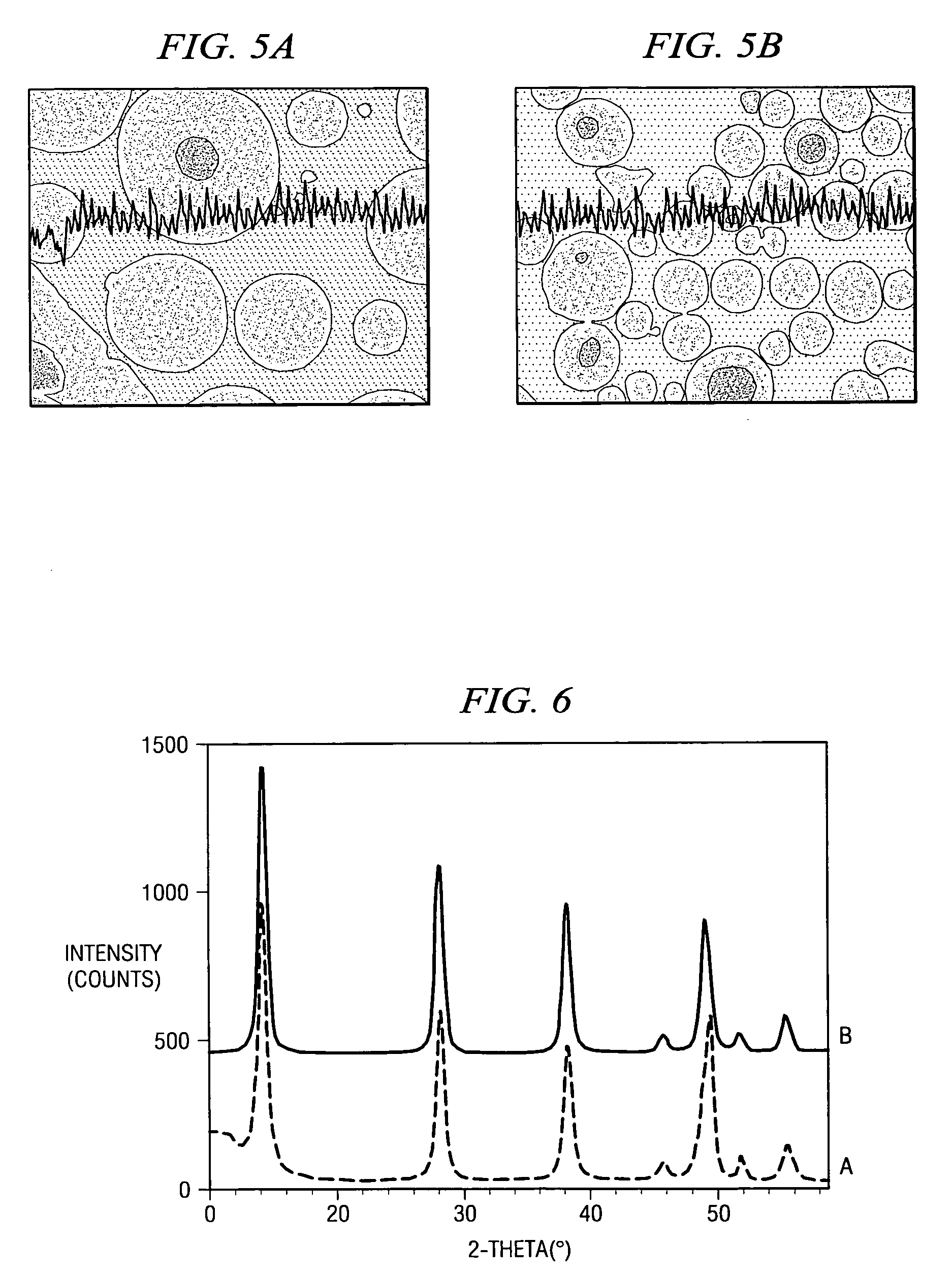

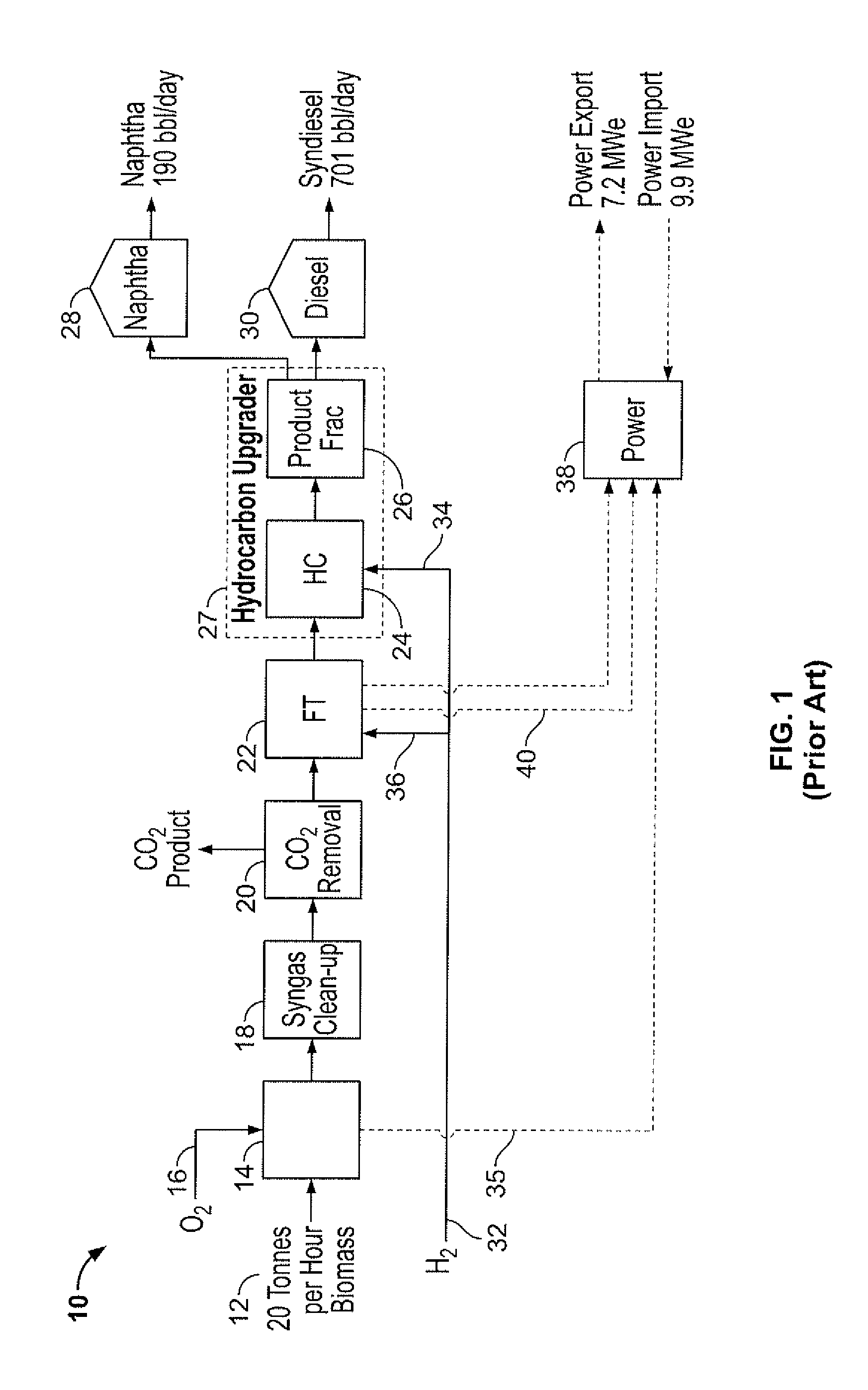

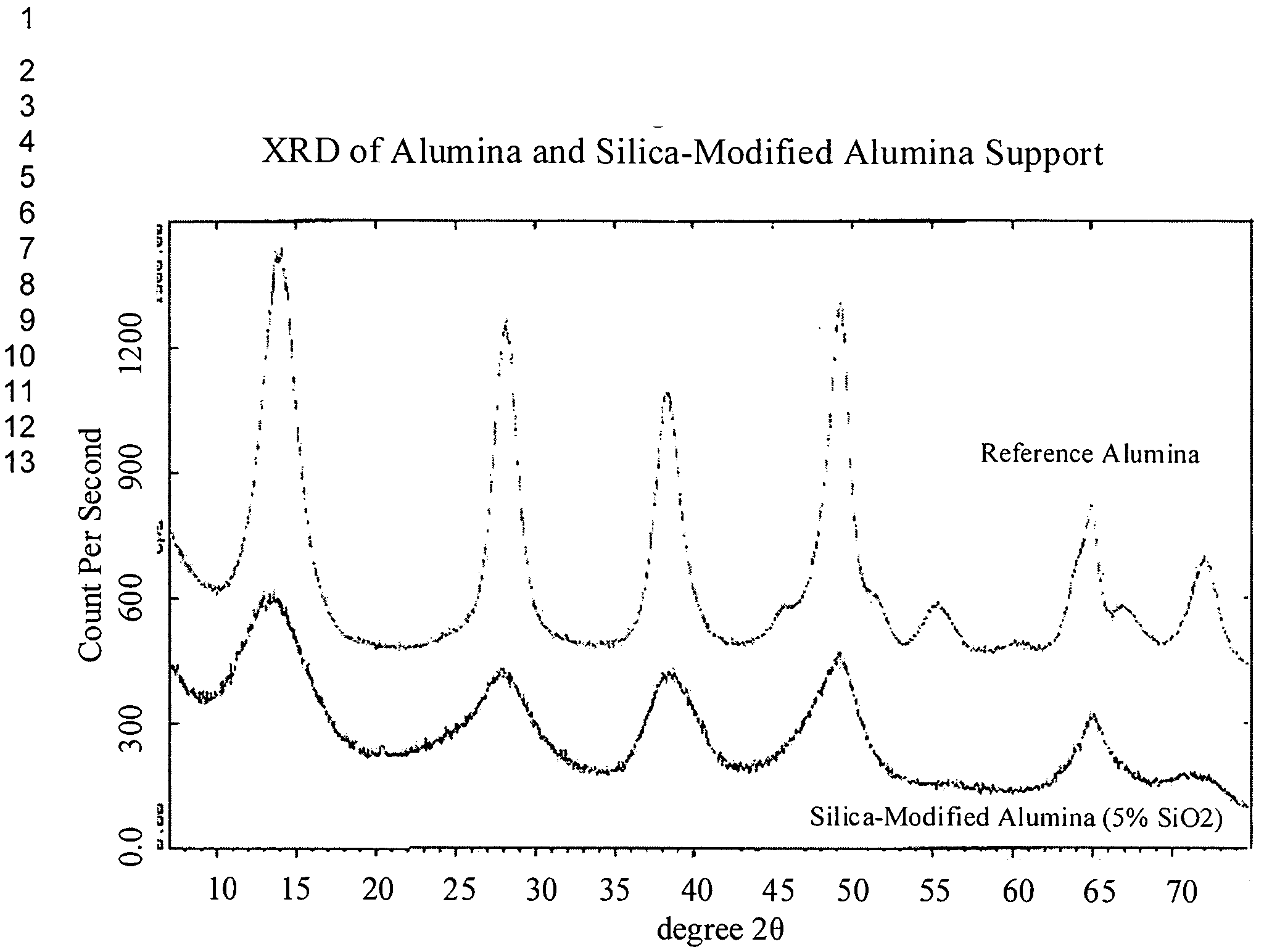

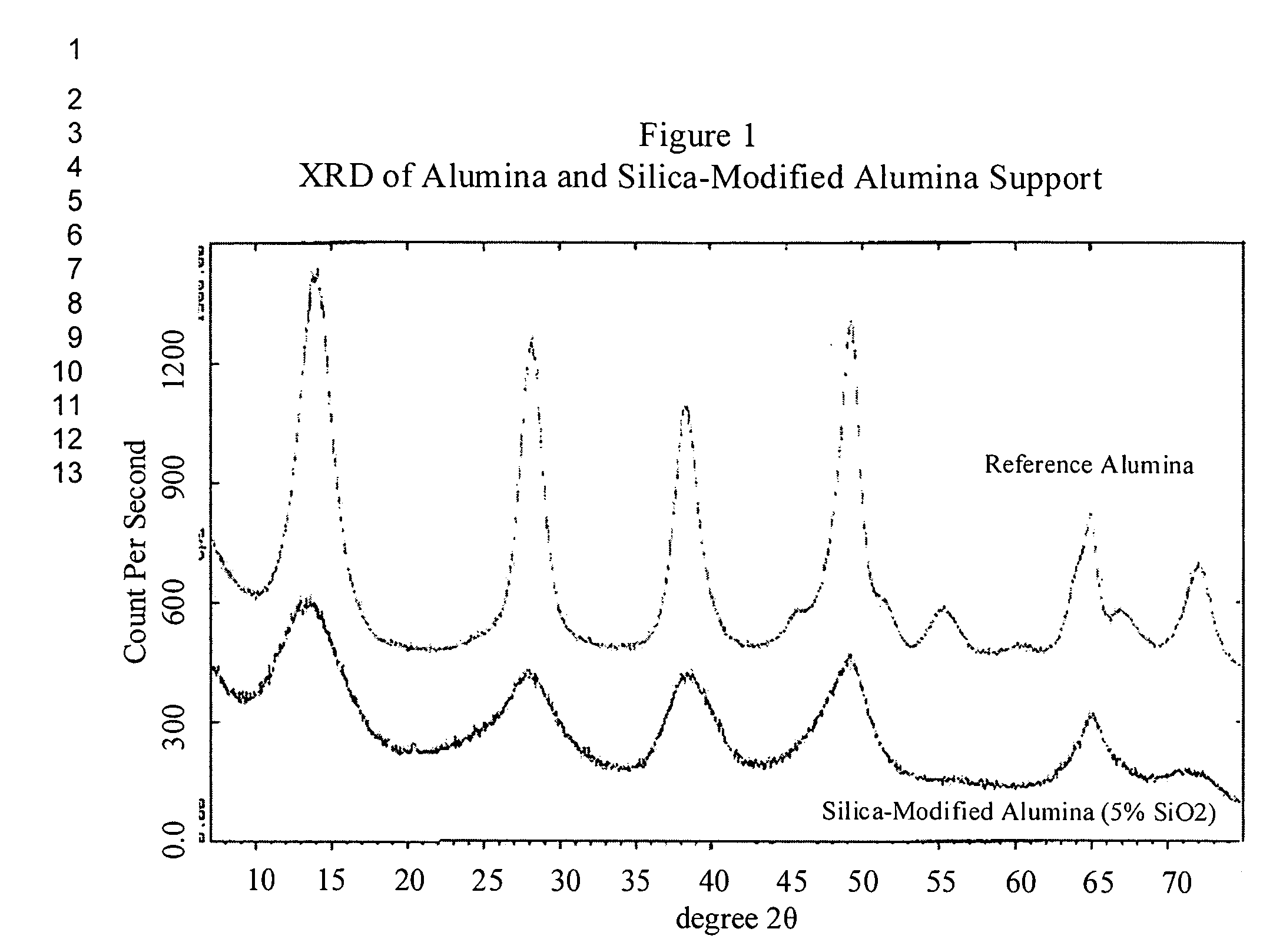

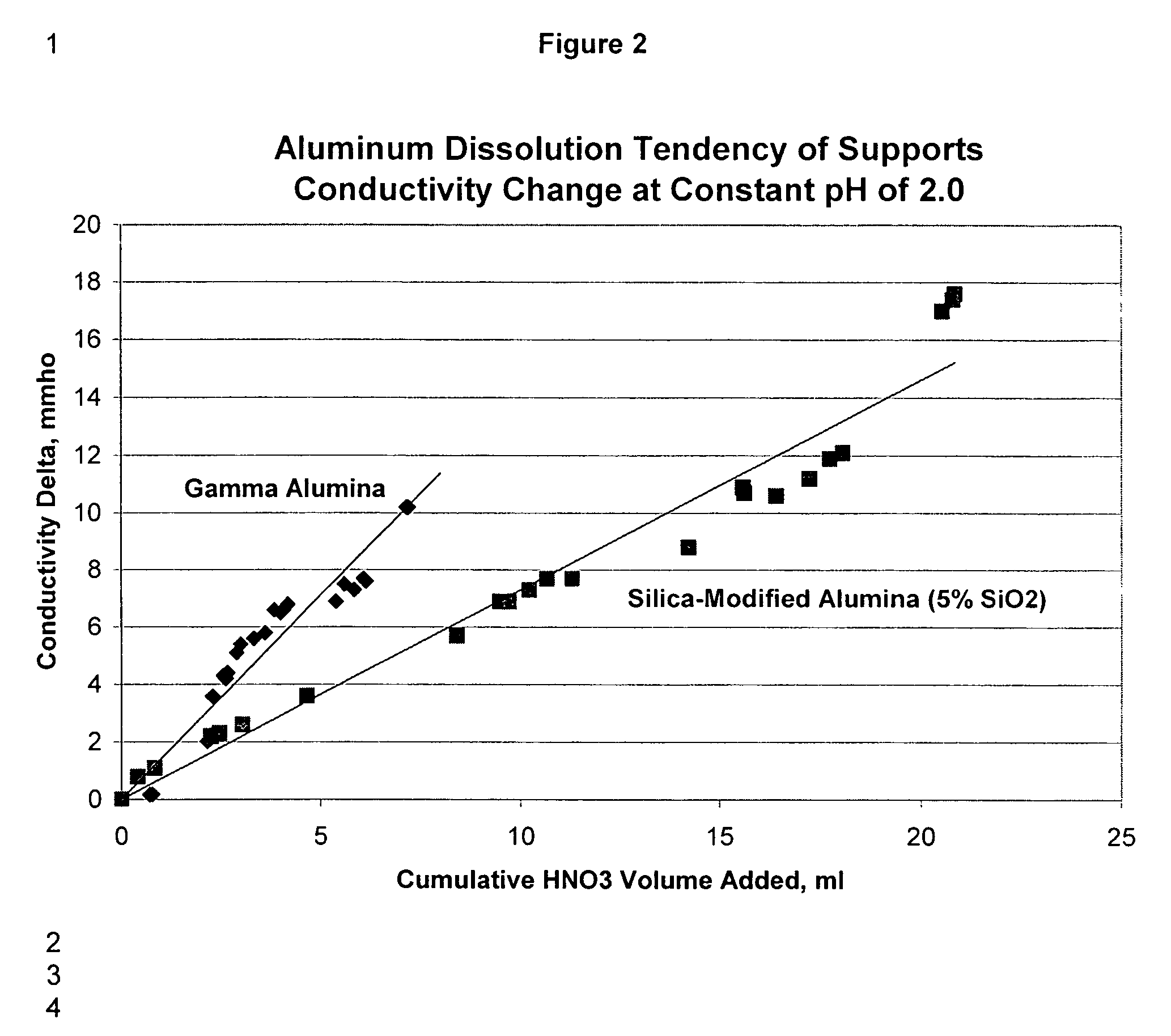

Homogeneous modified-alumina Fischer-Tropsch catalyst supports

InactiveUS7348293B2Other chemical processesCatalyst activation/preparationHigh resistanceAlkali metal oxide

A homogeneous, amorphous catalyst support comprising a modifying-metal-oxide and a base-metal oxide, the catalyst support having a Surface to Bulk modifying-metal / base-metal atomic ratio of from about 0.6 to about 1.3 and exhibiting an X-ray diffraction having broader line width and lower intensity than is exhibited by the base-metal oxide is disclosed. More specifically, a homogeneous, amorphous silica-modified-alumina catalyst support useful in the Fischer-Tropsch process is disclosed. A silica-modified-Alumina catalyst support of the present invention maintains the desirable properties of alumina and exhibits higher resistance to acid than unmodified alumina.

Owner:CHEVROU USA INC

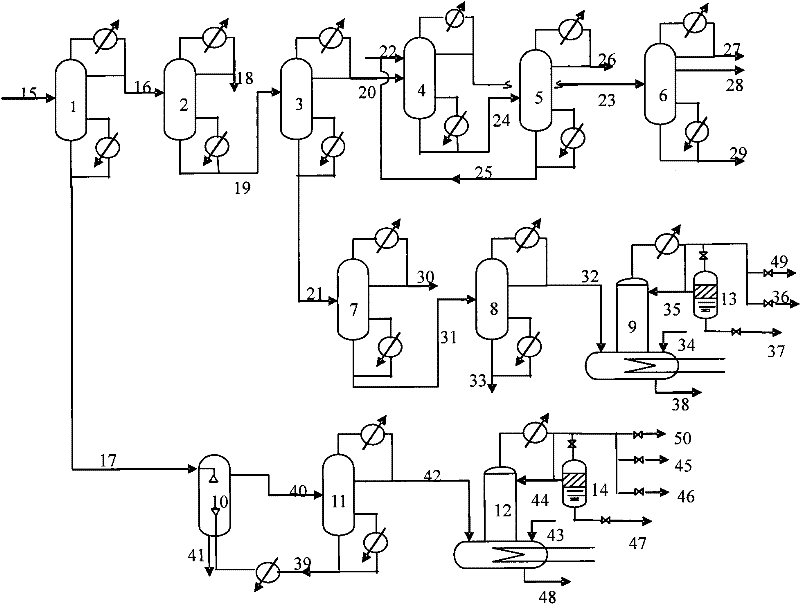

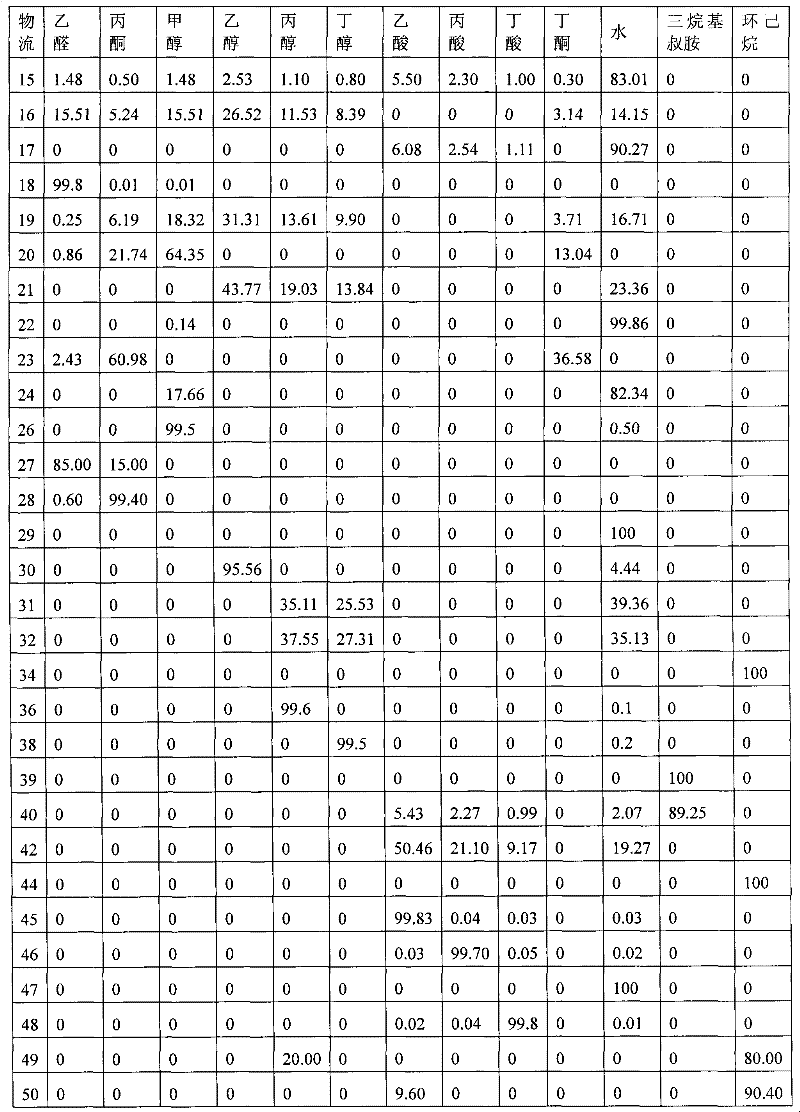

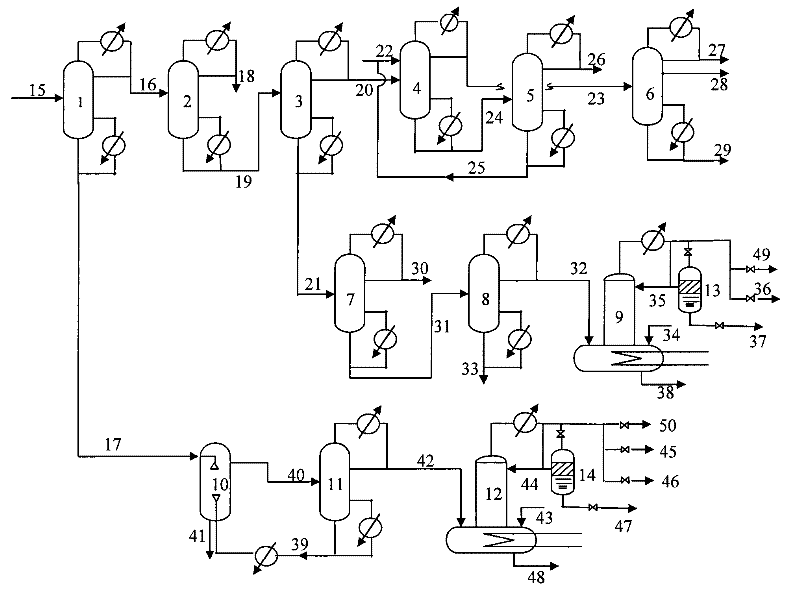

Separating and recovering method for organic oxygen-containing compounds in Fischer-Tropsch synthesis water phase

InactiveCN102442882AReach salesMeet application requirementsOrganic compound preparationHydroxy compound preparationCarboxylic acidOxygen

The invention relates to method and equipment system for separating and recovering organic oxygen-containing compounds in a Fischer-Tropsch synthesis water phase. The equipment system is integrated by adopting twelve towers including a mixed acid cutting tower, an acetaldehyde rectifying tower, a methanol / ethanol dividing tower, a methanol extraction rectifying tower, a methanol rectifying tower, an acetaldehyde removing tower, an ethanol tower, a propanol concentration extracting tower, a propanol intermittent azeotropic distillation tower, a carboxylic acid extraction tower, a carboxylic acid intermittent rectifying tower and an extraction agent recovering tower matched with the carboxylic acid extraction tower for use. By applying the method and equipment system disclosed by the invention, more than ten kinds of organic oxygen-containing compounds such as acetaldehyde, acetone, methanol, ethanol, normal propyl alcohol, normal butanol, acetic acid, metacetonic acid, butyric acid, butanone and the like can be separated from raw materials; and the products can respectively reach the industrial purity. The method and equipment provided by the invention are economic, effective and reasonable; and according to the method and equipment, efficiency of Fischer-Tropsch synthesis industrial enterprises can be greatly increased, production cost is reduced and goal of clean production can be achieved.

Owner:SYNFUELS CHINA TECH CO LTD

Systems and methods of improving diesel fuel performance in cold climates

InactiveUS7354462B2Reduce yieldIncrease cetane numberNon-fuel substance addition to fuelCombustion enginesParaffin waxPetroleum product

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

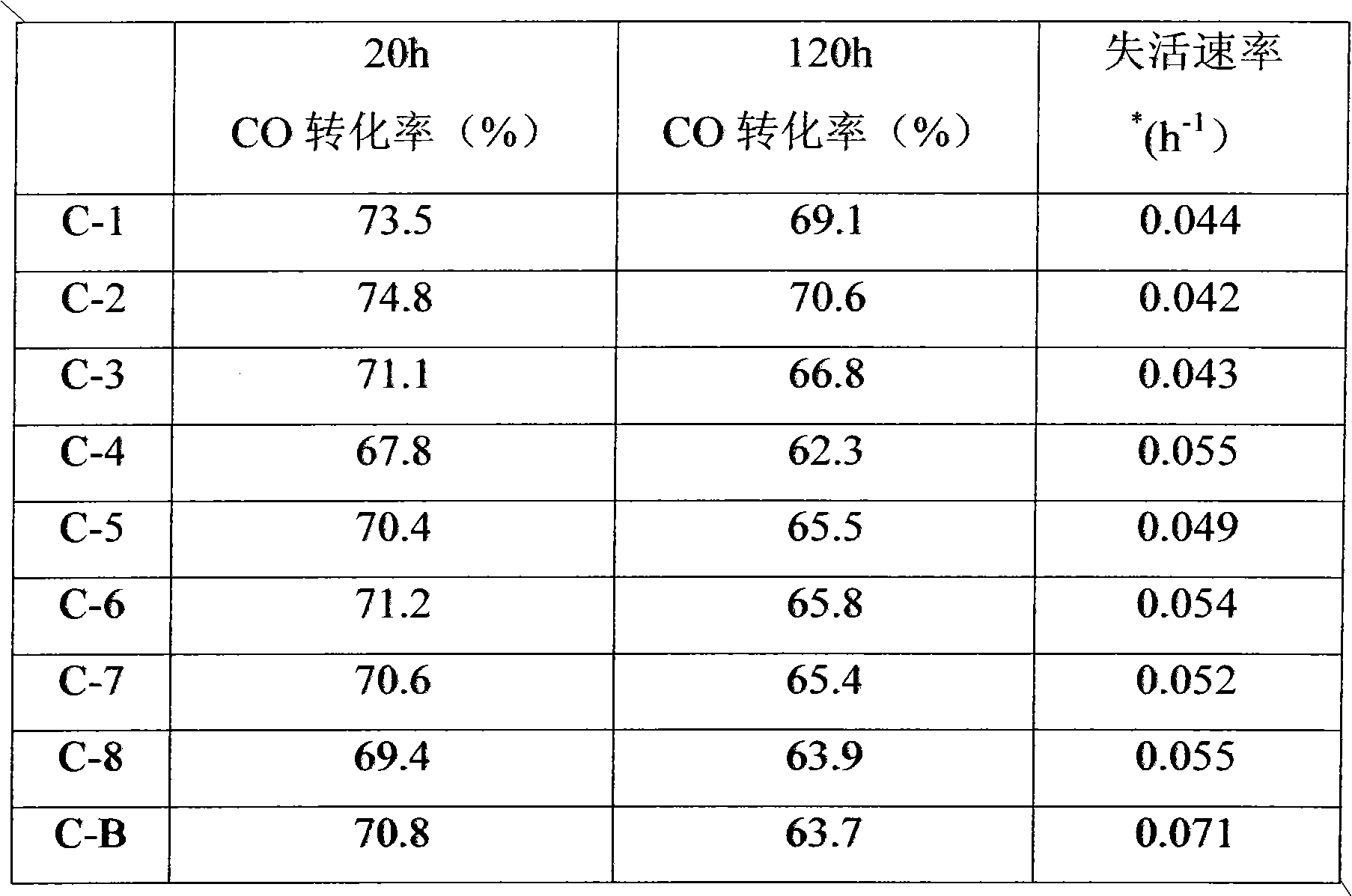

Fischer-Tropsch synthesis catalyst, its preparation and application

ActiveCN103203238AImprove wear resistanceHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsDivalent metalHigh wear resistance

The invention relates to a Fischer-Tropsch synthesis catalyst, its preparation and application. The catalyst contains a carrier and an active metal component that is loaded on the carrier and is selected from iron and / or cobalt. The catalyst is characterized in that, the carrier is a surface modified porous heatproof inorganic oxide molded carrier composed of silicon and one or more divalent metal components selected from the IIA group, the VIII group, the IB group and the IIB group. In terms of elements and based on the carrier, the content of silicon is 0.3-3.5 wt%, and the content of the divalent metal components is 0.2-2.0 wt%. Compared with the prior art, the catalyst provided in the invention has high wear resistance, and also has high activity and selectivity at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of stable olefinic fischer tropsch fuels with minimum hydrogen consumption

The present invention relates to a stable, low sulfur, olefinic distillate fuel blend component derived from a Fischer-Tropsch process and a process for producing this stable, low sulfur, olefinic distillate fuel blend component. The stable, low sulfur, olefinic distillate fuel comprises olefins in an amount of 2 to 80 weight percent, non-olefins in an amount of 20 to 98 weight percent wherein the non-olefins are predominantly paraffins, oxygenates in an amount of less than 1 weight percent, and sulfur in an amount of less than 10 ppm by weight. A distillate fuel comprising the above blend component forms less than 5 ppm peroxides after storage at 60° C. for four weeks.

Owner:CHEVROU USA INC

Process for producing middle distillates by hydrocracking of feedstocks obtained by the fischer-tropsch process in the presence of a catalyst comprising an IZM-2 solid

ActiveUS20110180455A1Shorten the timePromote formationTreatment with plural serial cracking stages onlyMolecular sieve catalystsAlkaneChemical composition

The invention relates to a process for producing middle distillates from a paraffinic feedstock produced by Fischer-Tropsch synthesis, implementing a hydrocracking / hydroisomerisation catalyst comprising at least one hydro-dehydrogenating metal selected from the group formed by the metals from group VIB and from group VIII of the periodic table and a substrate comprising at least one crystallised IZM-2 solid having a chemical composition, expressed on an anhydrous base, in terms of oxide moles, by the following general formula: XO2:aY2O3:bM2 / nO, wherein X represents at least one tetravalent element, Y represents at least one trivalent element and M is at least one alkali metal and / or an alkaline earth metal of valency n, a and b representing respectively the number of moles of Y2O3 and M2 / nO and a is between 0 and 0.5 and b is between 0 and 1.

Owner:ENI SPA +1

Fischer-tropsch catalysts using multiple precursors

InactiveUS7056857B2Easy to fallImprove catalytic performanceOther chemical processesCatalyst activation/preparationCatalytic metalBoron

Owner:CONOCOPHILLIPS CO

Method for preparing long-life cobalt-based catalyst for Fischer-Tropsch synthesis

ActiveCN101920200AInhibitory responseSuppress generationCatalyst activation/preparationLiquid hydrocarbon mixture productionSurface modificationFischer–Tropsch process

The invention discloses a method for preparing a long-life cobalt-based catalyst for Fischer-Tropsch synthesis. The method comprises the following steps of: performing surface modification on a silica gel carrier; and loading a metal aid and an active ingredient Co by adopting an immersion method, wherein the surface modification method for the silica gel carrier is to perform immersion treatmentby using acid solution of sugar. Compared with similar catalysts, the catalyst for Fischer-Tropsch synthesis prepared by the method has the advantages of reducing the reaction between the carrier andthe active ingredient in the processes of preparing and using the catalyst, and showing better stability in the reaction process, along with long service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

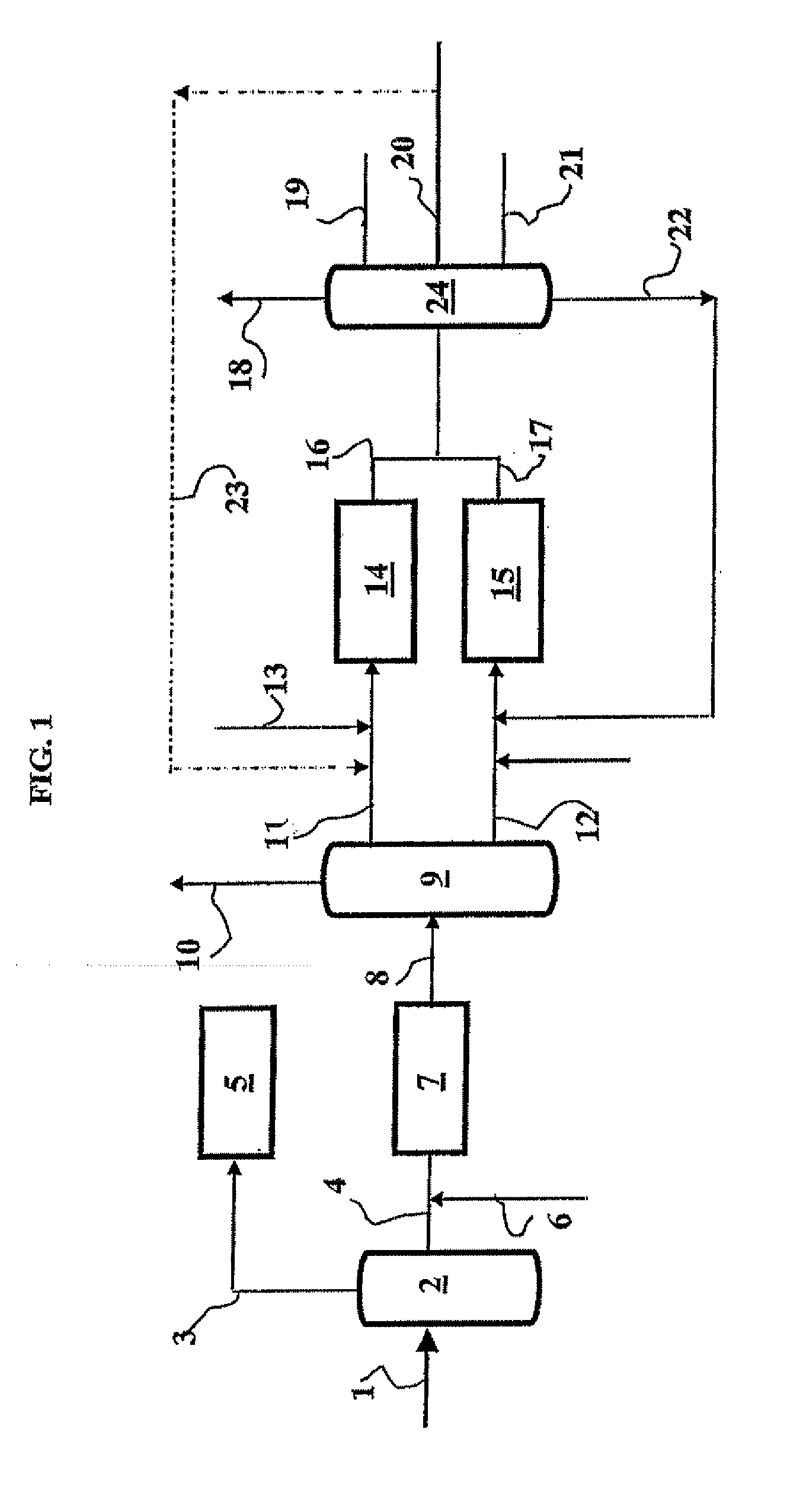

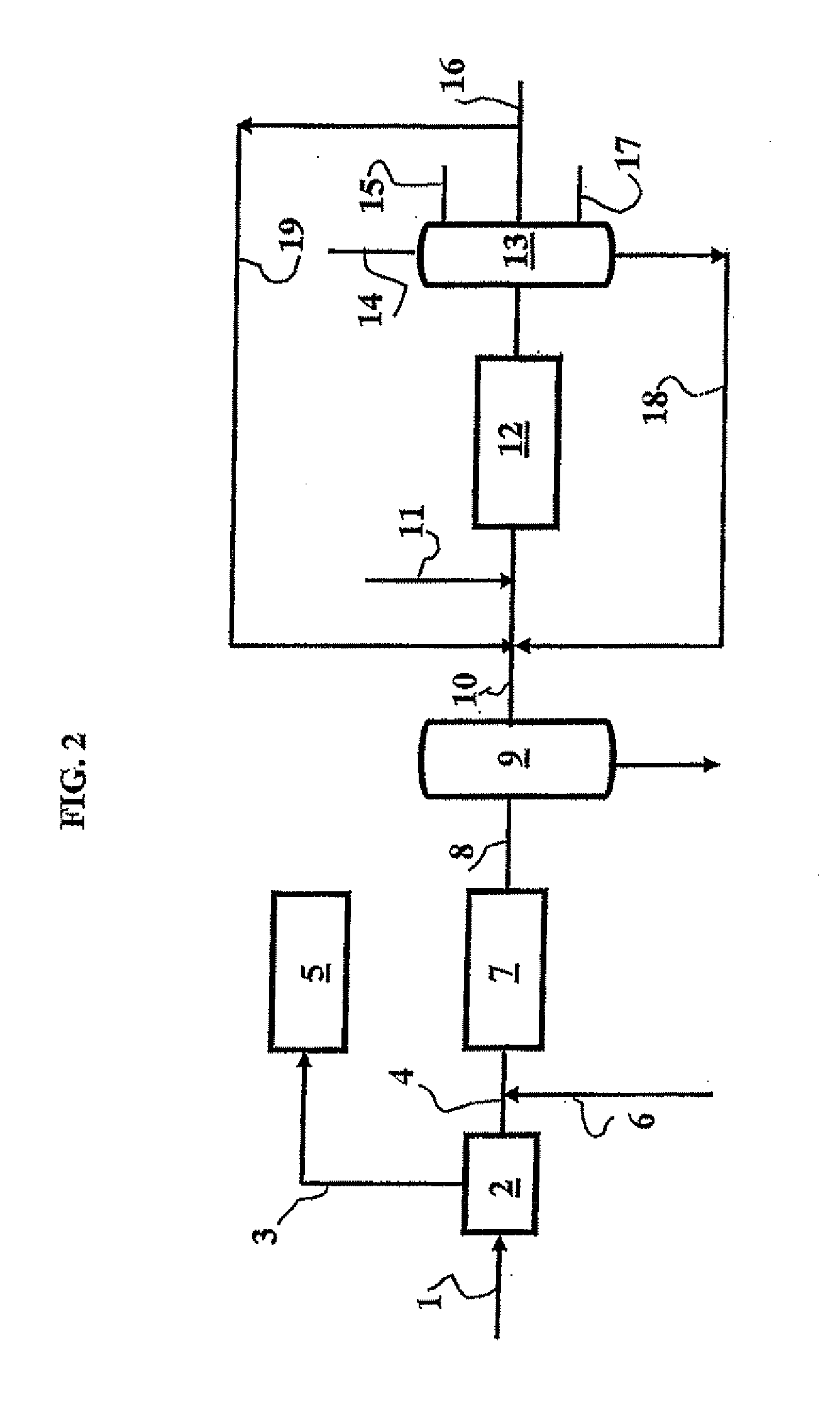

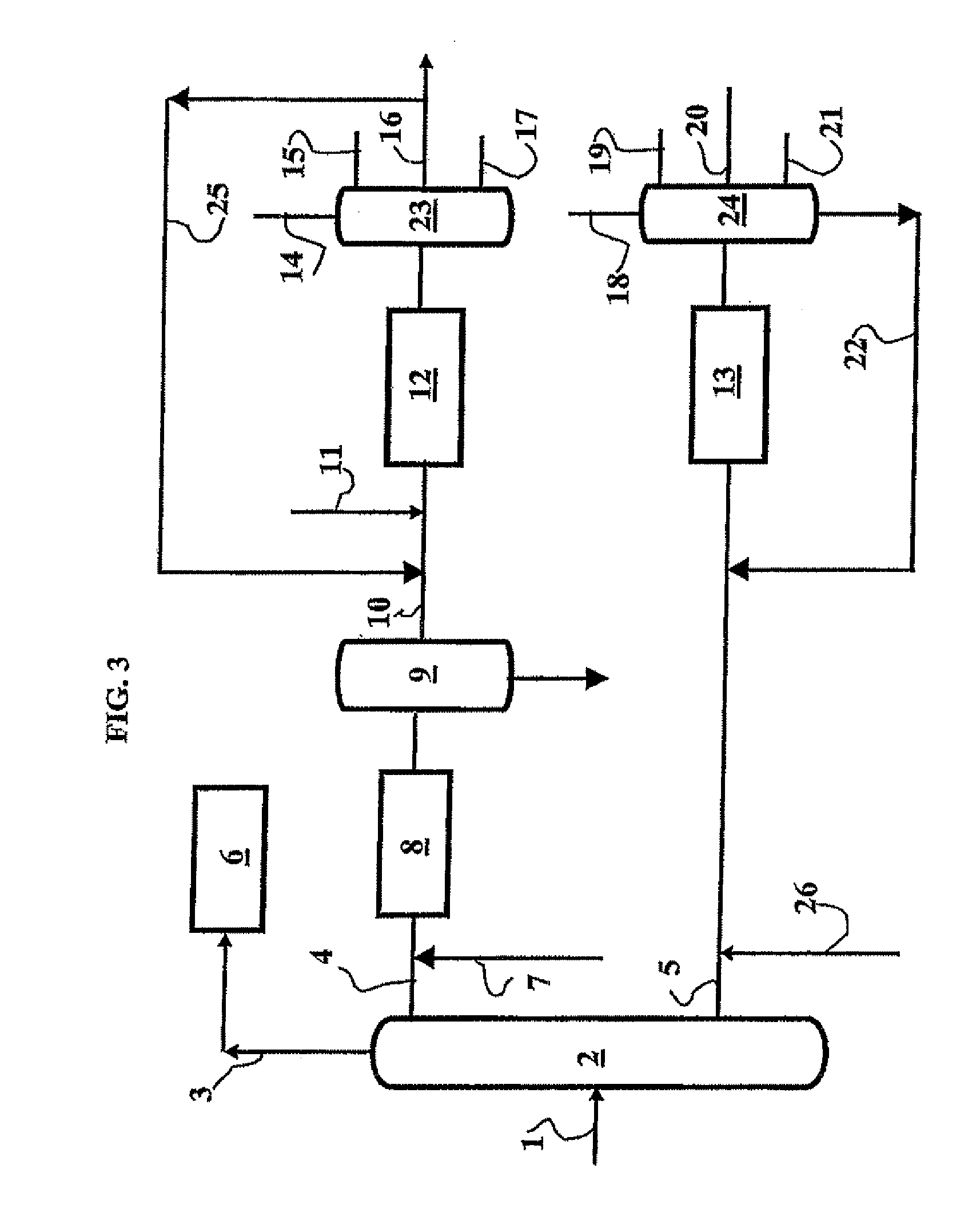

Two stage Fischer-Tropsch synthesis method

ActiveCN1948438AHigh yieldSeverity GuaranteeLiquid hydrocarbon mixture recoveryAlkaneSynthesis methods

This invention relates to a synthesis method of fischer-tropsch. Its preparation includes (a) Synthesis gas material enters into the first fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under the action of accelerant, (b) Segregating the first grade reaction product and letting parts of end gas return to the first fischer-tropsch reactor for recycling, and then letting C1-C4 alkanes containing in other surplus end gas to transform into synthetic gas.(c) Mixing the end gas transformed at step (b) and the second fischer-tropsch synthesis reaction circulation gas, and then entering the second fischer-tropsch synthesis reactor to conduct fischer-tropsch synthesis reaction under accelerant. (d) Segregating the second fischer-tropsch synthesis reaction product, and most of the gas returning to the second fischer-tropsch synthesis reactor for circulating reaction, and then evacuating other end gas. The transformation efficiency of CO+H2 is higher than 96% and the yield of methyl hydride is lower than 3%, and the yield of unit space-time of accelerant reaches 185 g / kg*h.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Process for maximizing 371.degree. C.+ production in fischer-tropsch process

InactiveUS6458857B1Maximize productionLightweight productionOrganic compound preparationOxygen compounds preparation by reductionProduction rateNaphtha

A hydrocarbon synthesis (HCS) process wherein a Fischer-Tropsch reactor is operated to maximize the selectivity to 371.degree. C.+ boiling fraction while minimizing the production of less valuable products such as light gases (C.sub.1 -C.sub.4), naphtha and diesel fractions. Inventive modes of operation to offset the effects of catalyst deactivation and maximize selectivity to 371.degree. C.+ boiling fraction are utilized including (a) reducing gas inlet velocity to maintain an optimal CO conversion level, (b) introducing additional active catalyst until a maximum loading is reached, and (c) increasing reactor temperature until productivity reaches a predetermined cut-off level.

Owner:EXXON RES & ENG CO

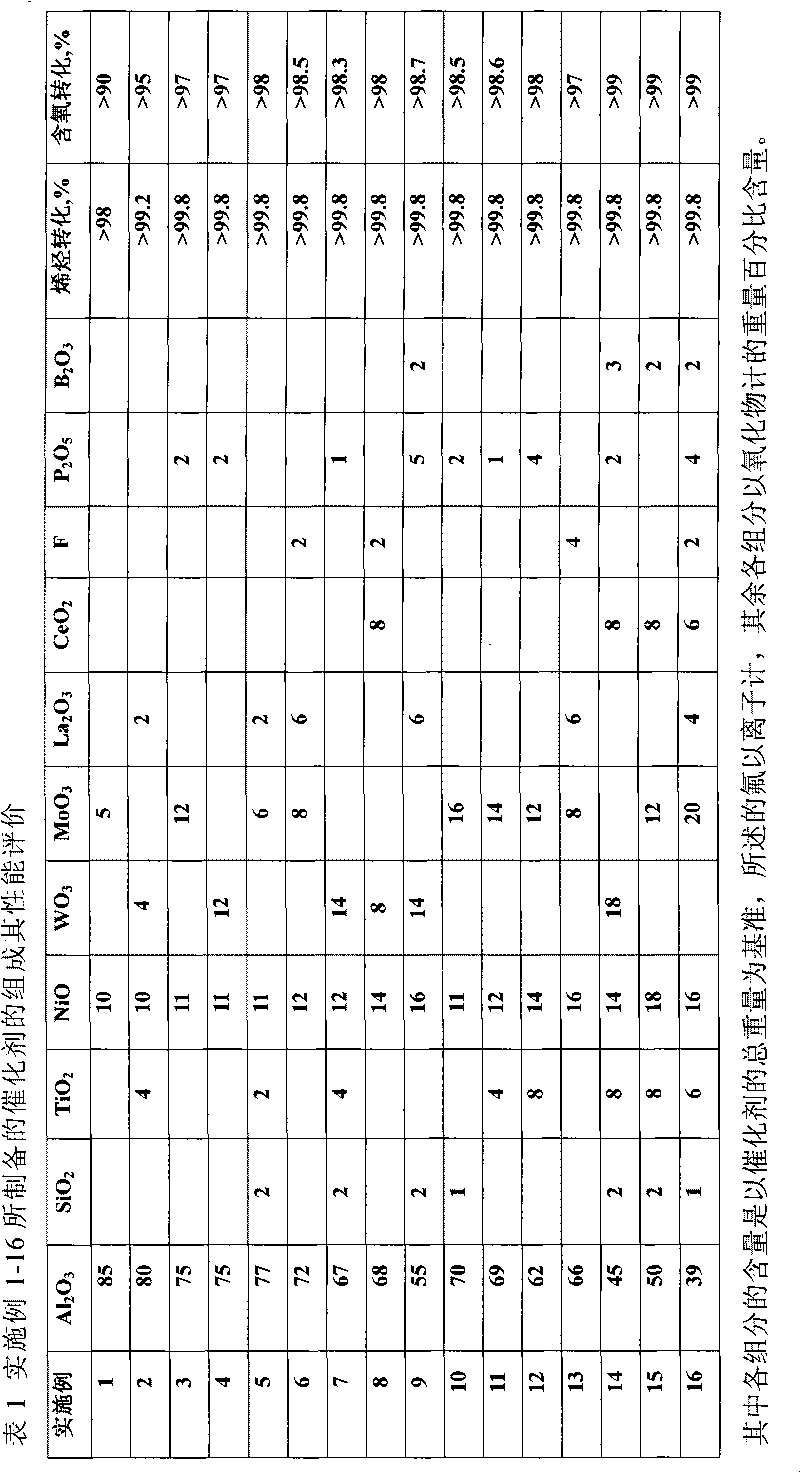

Catalyst for hydrogenation of Fischer-Tropsch synthesis oil, preparation method as well as application thereof

ActiveCN101733119AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCeriumLanthanide

The invention relates to a catalyst for hydrogenation of Fischer-Tropsch synthesis oil, which is characterized in that lanthanide metal lanthanum and / or cerium, and / or non-metallic element phosphorus and / or boron and / or fluorine which are used as cocatalysts are added into active component nickel and tungsten and / or molybdenum, and the catalyst comprises the following components in percentage by weight: 10-18% of nickel oxide, 1-20% of tungsten oxide or molybdenum oxide, 0-15% of silicon oxide and / or titanium oxide; 0-10% of lanthanum oxide and / or cerium oxide; 0-10% of phosphorus pentoxide and / or boron oxide and / or fluorine oxide and 35-89% of aluminum oxide. The preparation method of the catalyst comprises the steps of preparing carriers, soaking active components and adding cocatalyst components. The catalyst of the invention is suitable for the hydrogenation process of oil products having high olefin content and containing a certain amount of oxygen compounds, is especially suitable for hydrogenation of Fischer-Tropsch synthesis oil products, and has the advantages of high hydrogenation activity, good catalyst stability and the like.

Owner:SYNFUELS CHINA TECH CO LTD

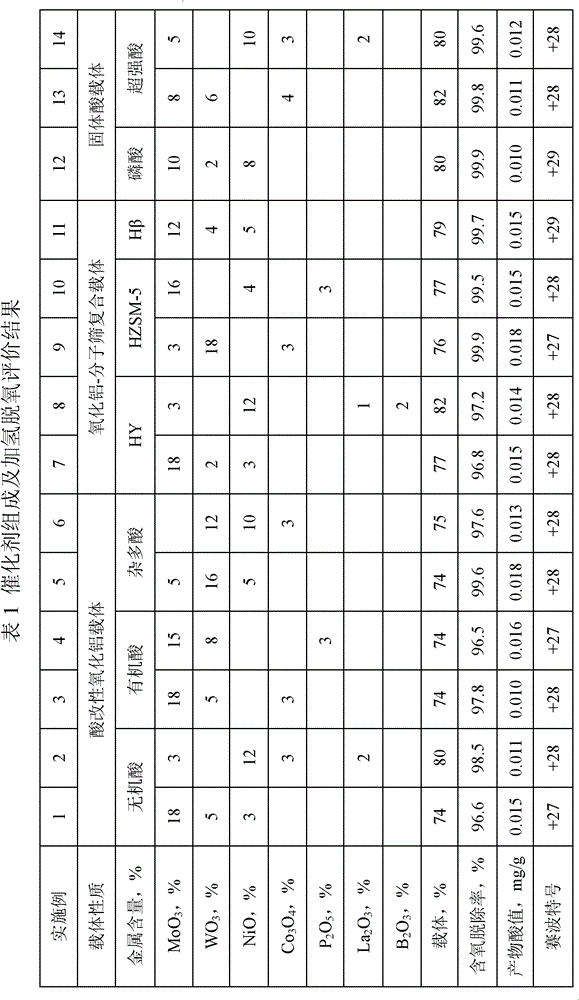

Hydrodeoxygenation catalyst for Fischer Tropsch synthesis oil and preparation method and application of hydrodeoxygenation catalyst

ActiveCN102794181AMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureSolid acid

The invention discloses hydrodeoxygenation catalyst for Fischer Tropsch synthesis oil. The catalyst consists of one or more of Mo, W and Ni which are used as main catalytic reactive metal components, a carrier and IIIA-group, VA-group, VIII-group or lanthanide-series and other acid catalytic active components, wherein the carrier is an acid modified alumina carrier, a compounded carrier containing a molecular sieve and alumina or a solid acid carrier or a combination of more of the acid modified alumina carrier, the compounded containing the molecular sieve and alumina and the solid acid carrier. The invention also discloses a preparation method for the catalyst and the application of the catalyst to a hydrodeoxygenation process of the Fischer Tropsch synthesis oil; by using the catalyst, organic oxygenated chemicals in the Fischer Tropsch synthesis oil can be effectively subjected to hydro-conversion under the conditions that the reaction temperature is 150 to 350 DEG C, pressure is 2 to 10 MPa, weight hourly space velocity (WHSV) is 0.3 to 5.0h<-1>, and the volume ratio of hydrogen to oil is 300 to 2,000; the removal rate of the organic oxygenated chemicals is more than 96.0 percent, and a product is low in acid value and high in chromaticity; and compared with the conventional catalyst, the catalyst has the advantages of obviously reducing the reaction temperature and reducing energy consumption.

Owner:SYNFUELS CHINA TECH CO LTD

Micro-ball iron-based catalyst for Fischer-Tropsch synthesis and its preparation and use

ActiveCN1583259AEasy to prepareGood sphericityHydrocarbon from carbon oxidesCatalyst activation/preparationNitrateCerium nitrate

A microspherical Fe-base catalyst for slurry-bed Fischer-Tropsch synthesis contains Fe, Ce, Cu, K and SiO2. Its preparing process includes such steps as preparing the deposit slurry from the mixed solution of iron nitrate, cerium nitrate, copper acetate, and sodium carbonate, adding the mixed solution of K2C2O4 and silica sol, spray drying, and calcining.

Owner:SYNFUELS CHINA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com