Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Reduction of recycling energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

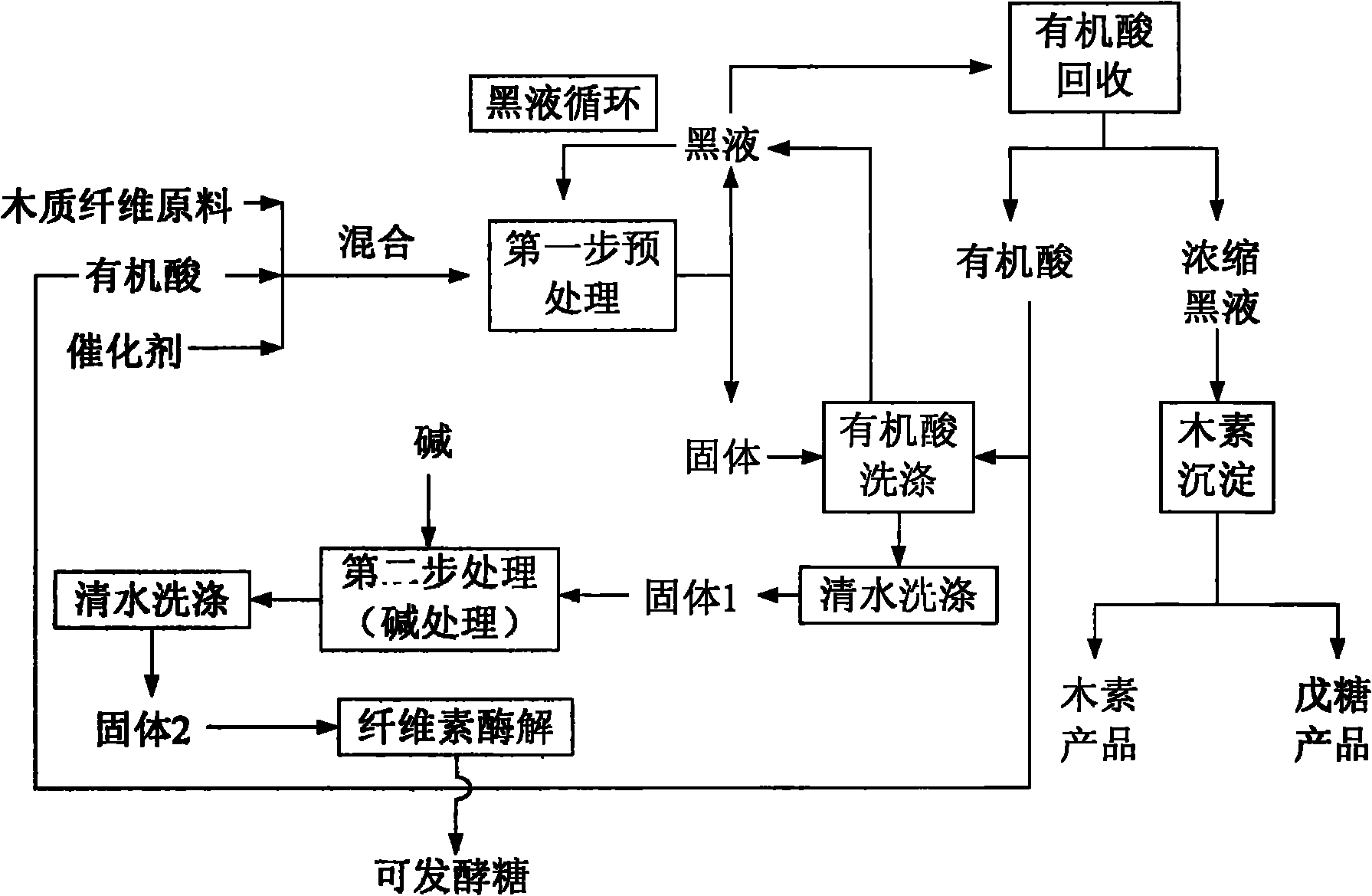

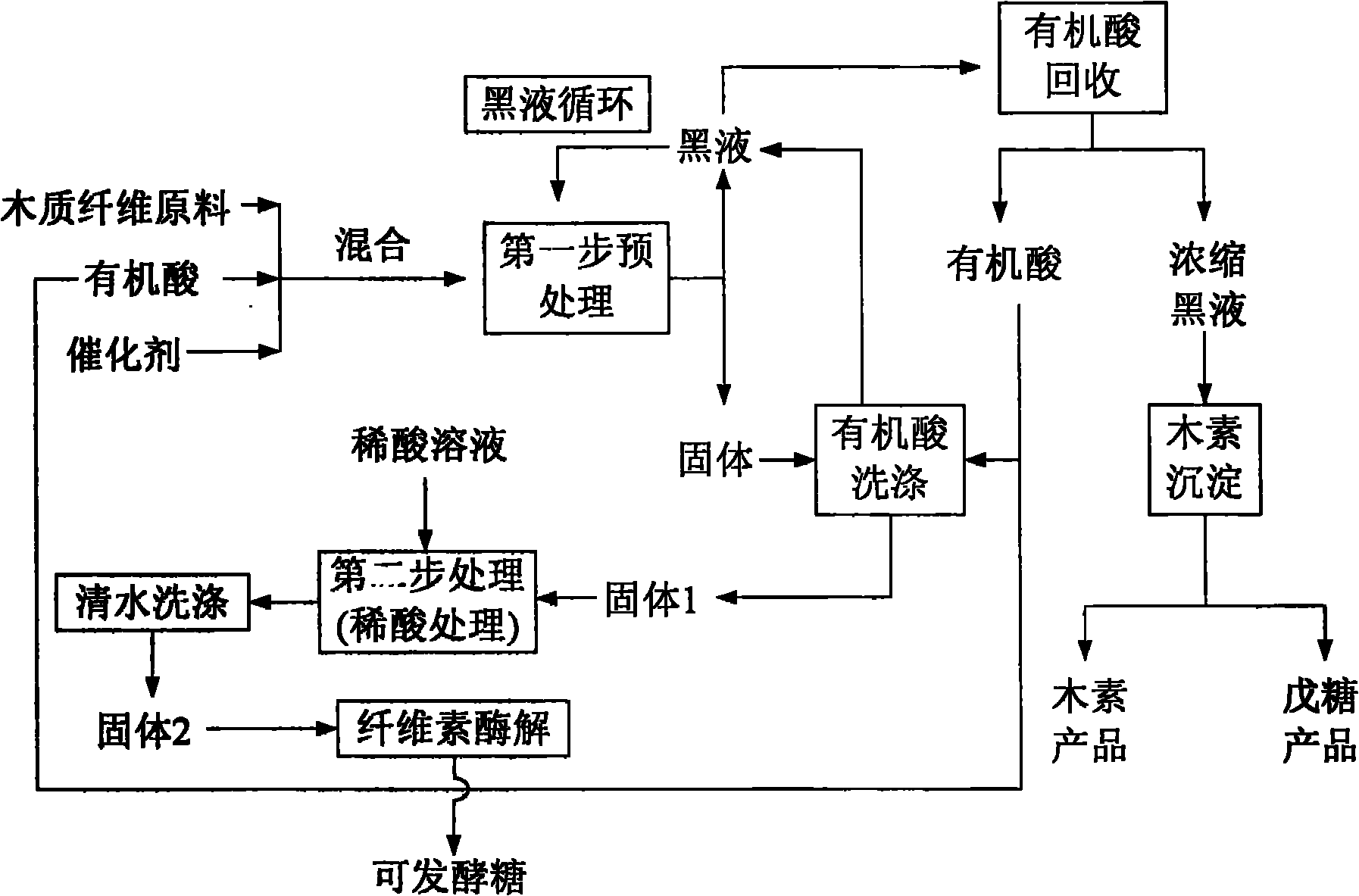

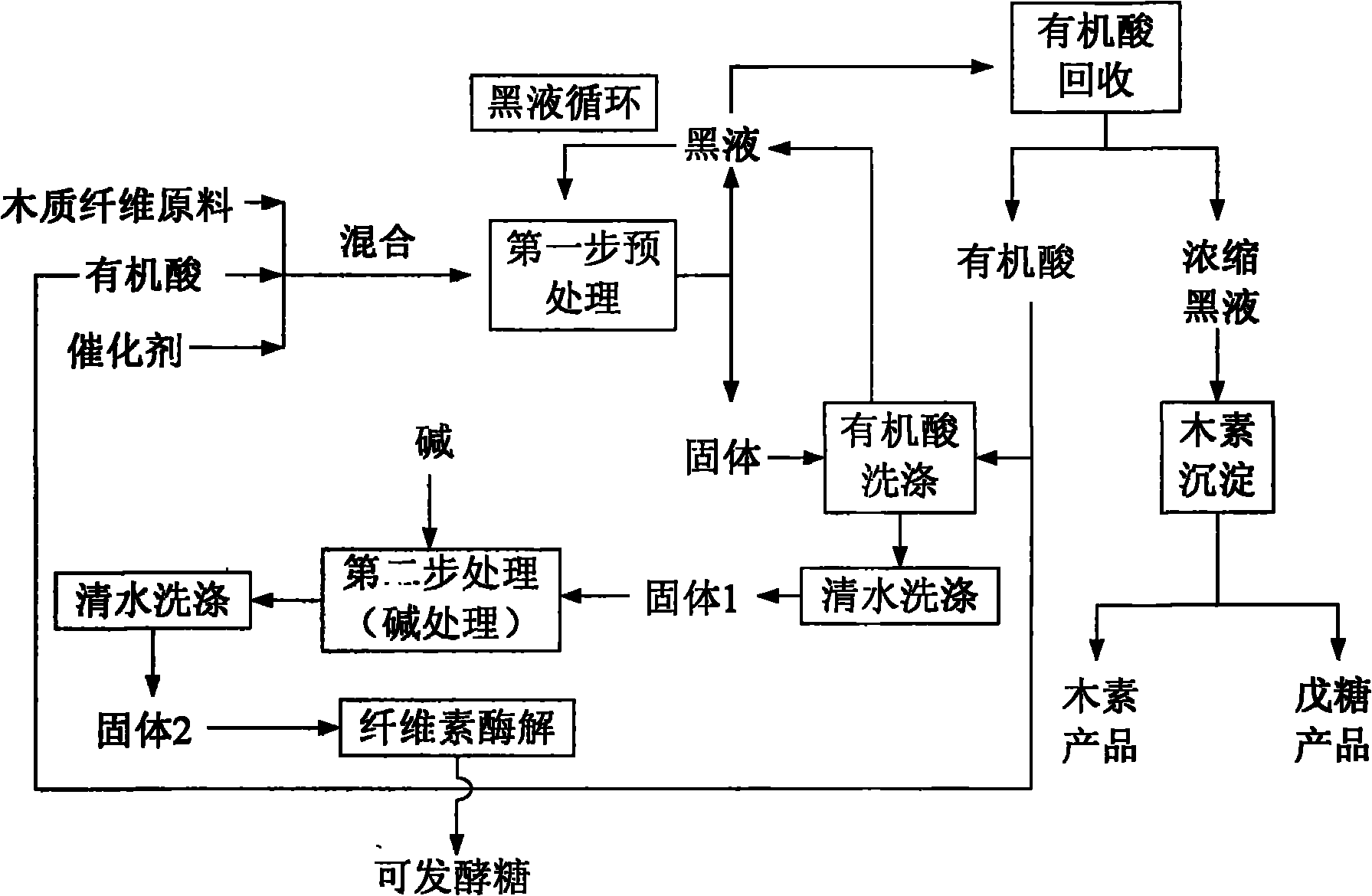

Pretreatment method of wood fiber raw materials

InactiveCN101864683ARealize comprehensive utilizationRealize full-price developmentPretreatment with acid reacting compoundsCelluloseFiber

The invention relates to a pretreatment method of wood fiber raw materials, which belongs to the technical field of biomass chemical engineering. The process comprises the following steps: carrying out the first-step treatment after the wood fiber raw materials are mixed with mixed liquid of an organic acid solution and catalysts to obtain a liquid-solid mixture; separating the obtained liquid-solid mixture to obtain pretreatment black liquid and cellulose solids; washing the obtained cellulose solids by the organic acid solution to obtain washing black liquid and cellulose solids; adopting diluted acid or alkali for carrying out the second-step treatment on the obtained cellulose solids; mixing the obtained pretreatment black liquid and the obtained black liquid to obtain mixed black liquid; circularly using the mixed black liquid in the first-step treatment process; and recovering organic acids, lignin products and syrup solutions from the black liquid in the cyclic use for at least three times. The invention has the advantages that the full-rate development of raw materials can be realized, in addition, the environment-friendly effect can be realized, and the invention conforms to the requirement of modern biorefinery development.

Owner:TSINGHUA UNIV

Composite decarbonizing solution for recovering carbon dioxide in waste gas

InactiveCN101053751ALarge absorption capacityImprove the degree of purificationDispersed particle separationHigh concentrationReaction rate

The invention relates to a composite decarbonization solution for reclaiming the carbon dioxide in the exhaust gas, wherein the component and the mass percent of the composite are that: 20-60 percent of composite amines solution, wherein one or more fast reaction rate amines with a low concentration and one or more slow reaction rate amines with a high concentration are comprised; 5-10 percent of Polyxinolum; 1-5 percent of antioxidant; 1-5 percent of inhibitor; and the rest is water. The invention has the advantage of a large absorbing capability to CO2, a high degree of purification, a light causticity, a little consume of the solution and a lower recycling energy consumption. High concentration CO2 for gas injection oil-recovery can be obtained.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

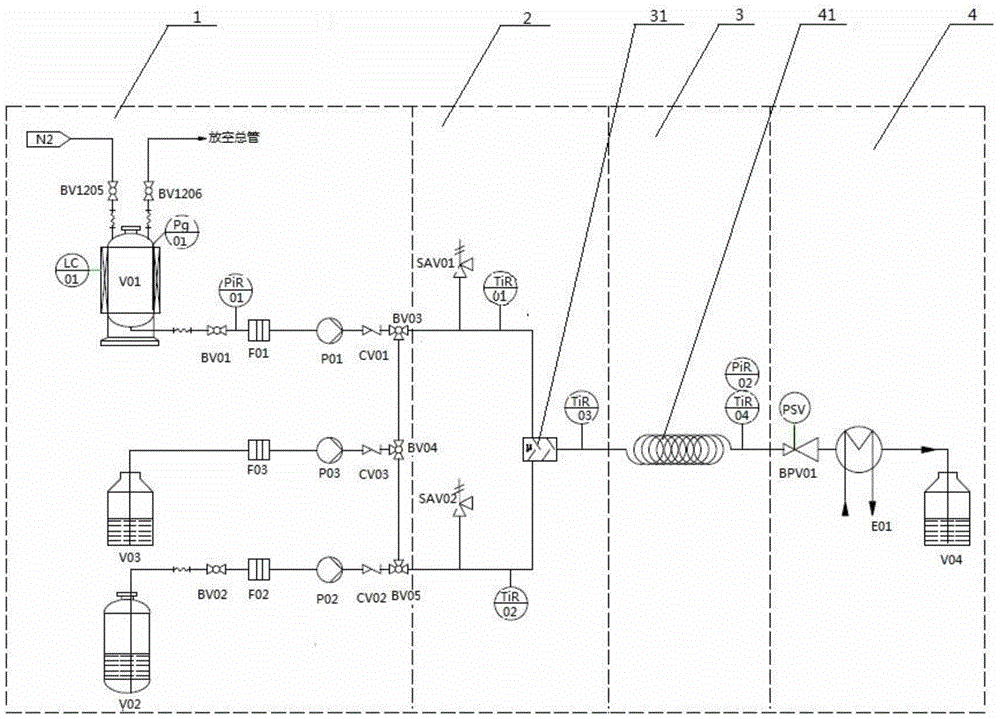

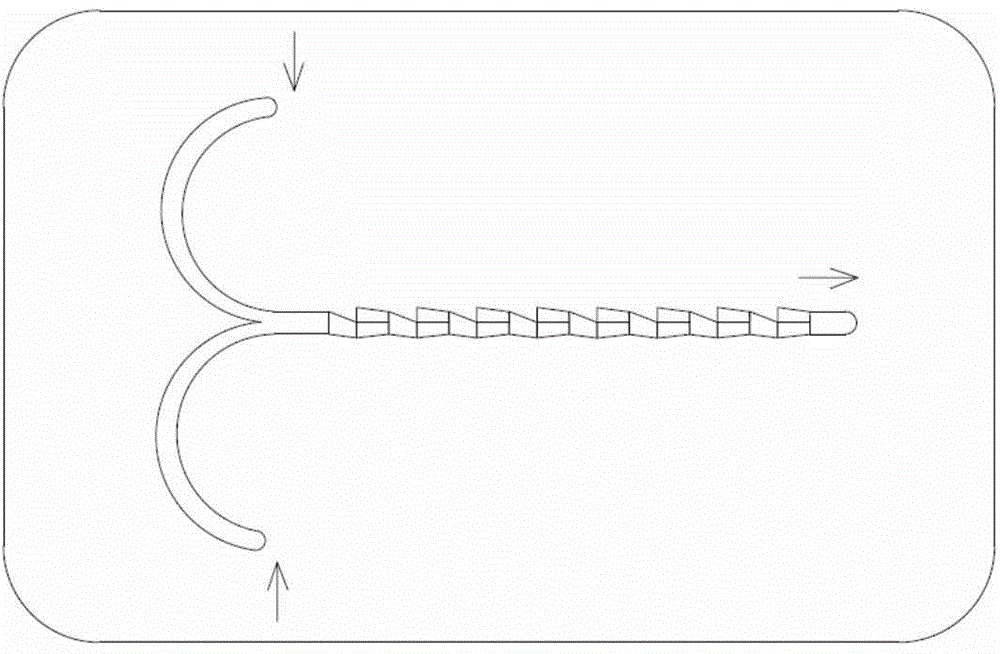

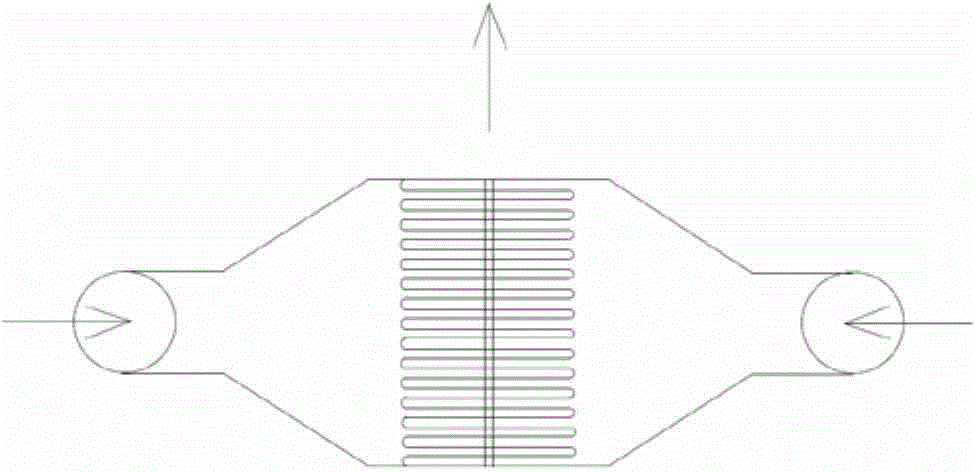

Microreactor device for producing 2-hydroxyethylhydrazine and preparation process

ActiveCN104876833AEthylene oxide accumulationNo accumulationHydrazine preparationMicroreactor2-hydroxyethylhydrazine

The invention discloses a microreactor device for producing 2-hydroxyethylhydrazine and preparation process. The device comprises a feeding system, a mixing system, a reaction system, a backpressure valve, a cooling receiving system, a washing system and an external circulating bathing system, wherein the feeding system comprises a hydrazine hydrate storing tank, an oxirane storing tank and a feeding pump; the mixing system comprises a CPMM or SIMM or Starlam serial micro mixer; the reaction system comprises a rimule reactor section; the pressure of the backpressure valve ranges from 0 to 15MPa; the cooling receiving system comprises a CRMH serial micro heat exchanger and a receiving storing tank; the washing system comprises a washing storing tank and a washing pump which are connected in series; the hydrazine hydrate storing tank or oxirane storing tank, the feeding pump, the micro mixer, the rimule reactor, the backpressure valve, the micro heat exchanger and the receiving storing tank are connected in series; the mixing system, the reaction system and the cooling receiving system are respectively arranged at the circulating bathing system.

Owner:大连微凯化学有限公司

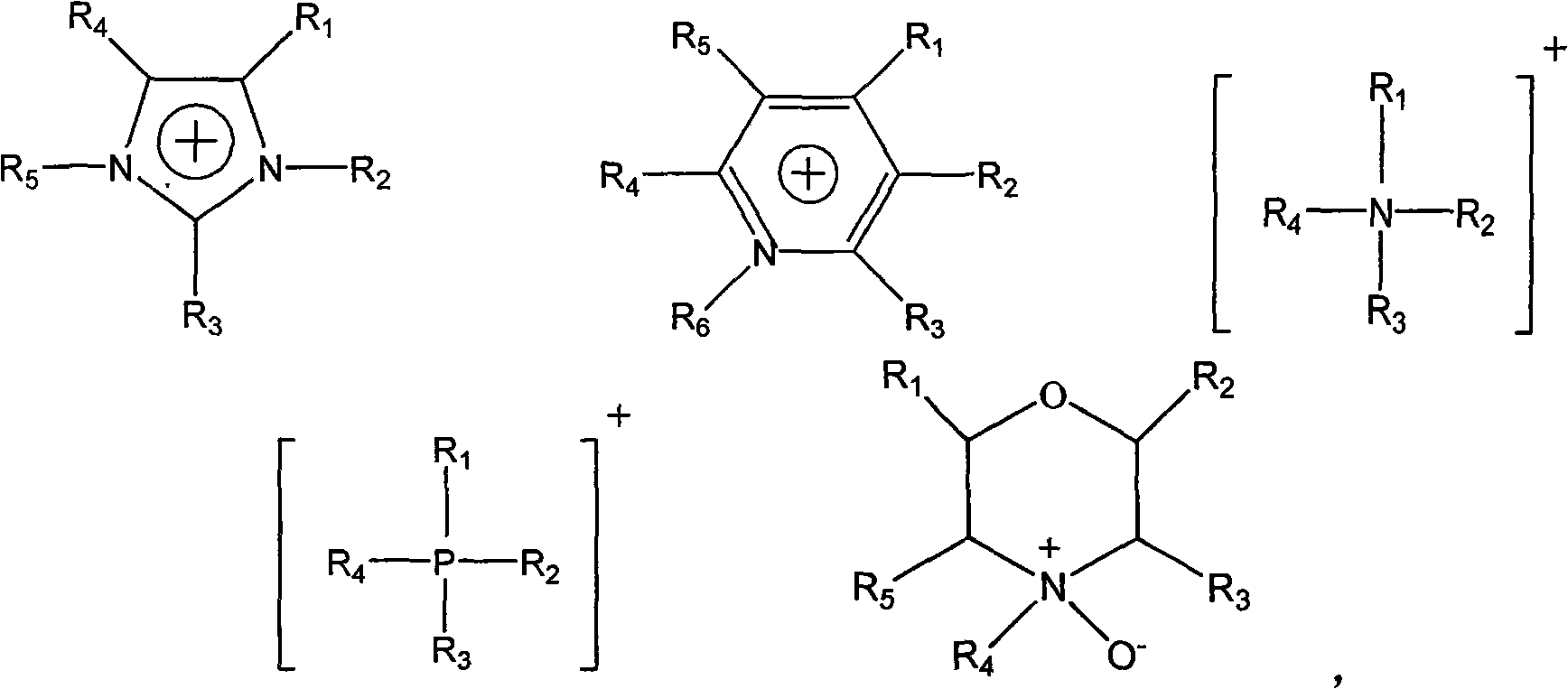

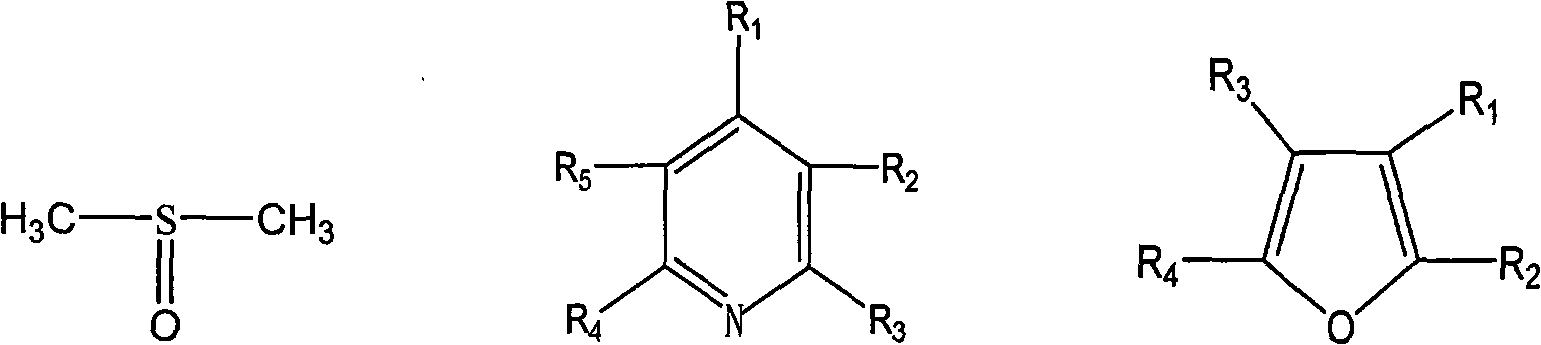

Anti-degradable solvent for dissolving cellulose and preparation method of spinning dope thereof

InactiveCN101654522AHigh degree of polymerizationLow steam pressureArtificial filaments from viscoseBulk chemical productionBoiling pointSolvent

The invention relates to an anti-degradable solvent for dissolving cellulose and a preparation method of spinning dope thereof. The solvent dissolves the cellulose by adding an organic substance to the ionic liquid. The ionic liquid has excellent dissolvability to the cellulose, seriously degrades the regenerated cellulose and is hard to spin filament; the addition of the organic substance can obviously improve polymerization degree of cellulose, and reduce viscosity of the spinning solution. Simultaneously, the compound liquid formed by the ionic liquid and the organic substance has the characteristics of extremely low vapor pressure and high boiling point, and is beneficial to recovering and recycling the compound solvent. Compared with the traditional adhesion method, the method has thecharacteristics of no pollution, simple process, low cost, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

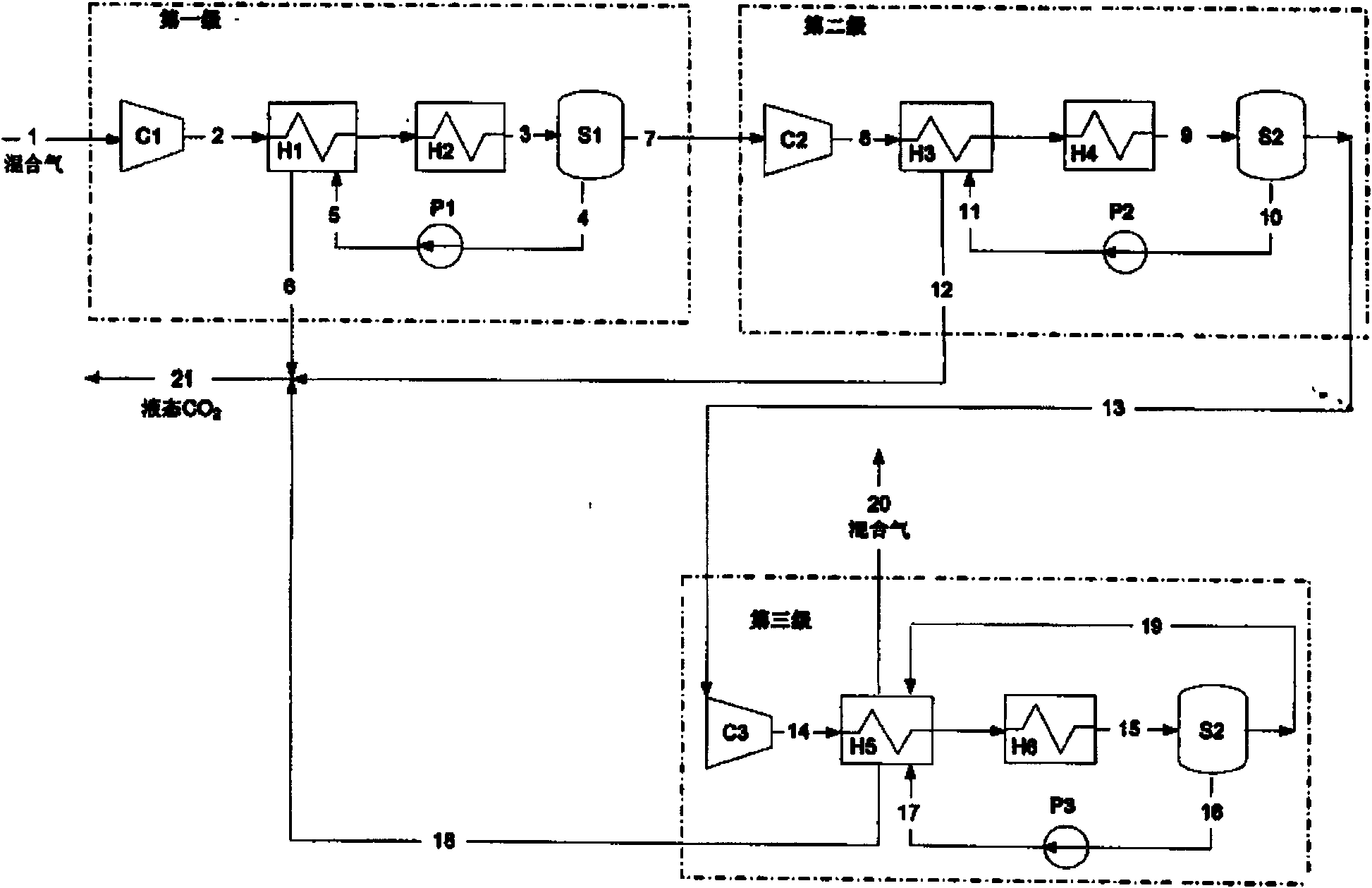

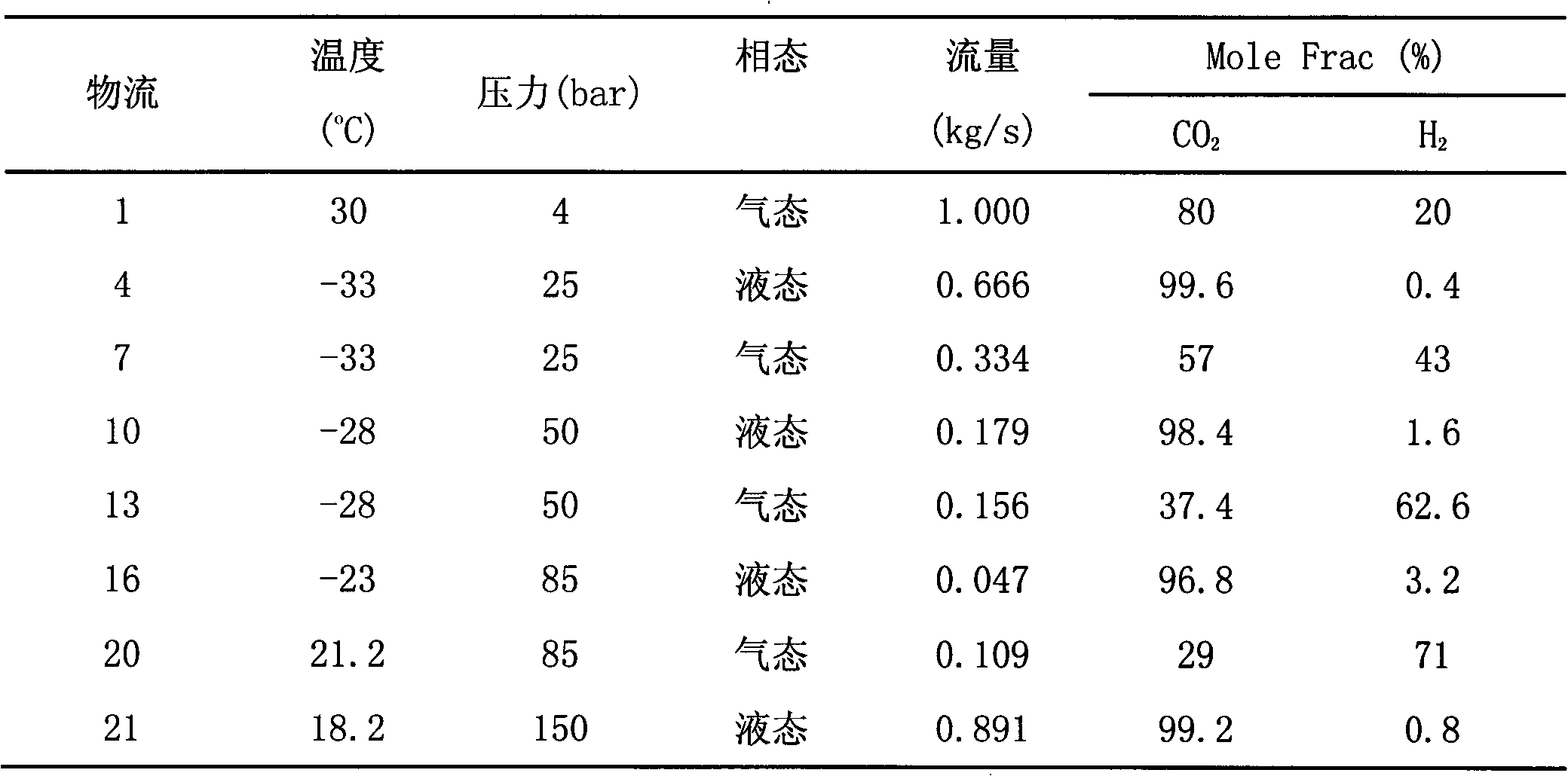

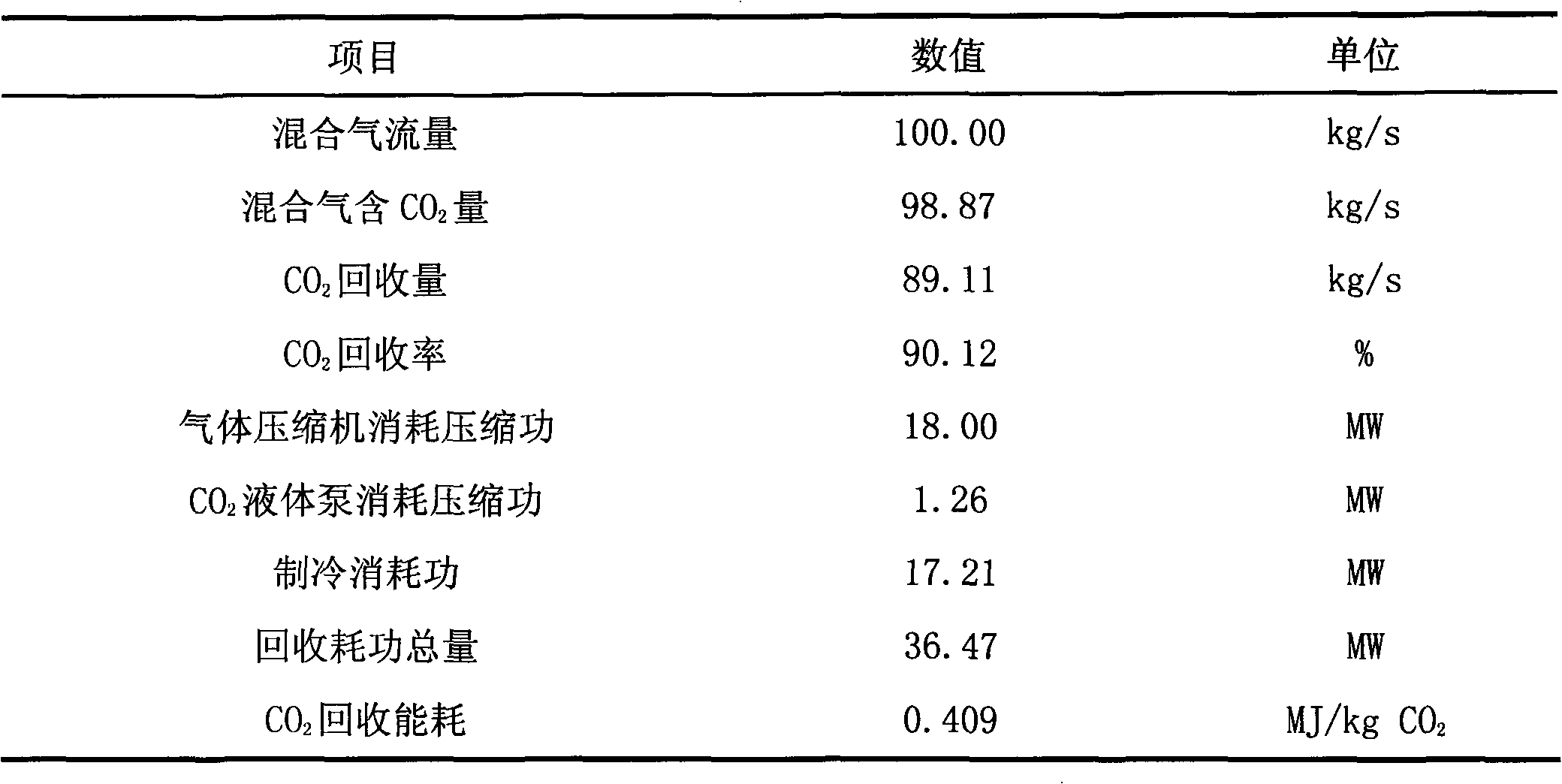

CO2 separation and compression integrated method

InactiveCN101666573AReduction of recycling energy consumptionImprove securitySolidificationLiquefactionCondensation temperatureProduct gas

The invention discloses a CO2 separation and compression integrated method which belongs to the technical field of gas preparation and is used for separating CO2 from gases containing the CO2. The invention improves the phase-transition temperature of CO2 through combining multi-stage compression, multi-stage cooling and multi-stage separation and improving the pressure of gas mixture, ensures a certain separation ratio by adopting a multi-stage separation and multi-stage compression way, and separates most of CO2 in a liquid form from the gas mixture under relatively higher condensing temperature, thereby improving the low-temperature condensing separation method of the CO2, and greatly lowering the energy consumption of recovering the CO2; meanwhile, the whole process does not adopt a chemical solvent, therefore, the lost of equipment is low, the safety is high, and the operation and maintenance cost is greatly lowered. The invention can be widely applied to separate the CO2 from thegas mixture containing the CO2, can produce pure-CO2 products and reduce the emission of greenhouse gases, thereby protecting the human habitat.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for treating waste water in coal chemical industry

InactiveCN102659204AReduction of recycling energy consumptionImprove recycling efficiencyWater/sewage treatment by extractionChemical oxygen demandKetone

The invention relates to a method for treating waste water in coal chemical industry. The method comprises the following steps of: extracting and dephenolizing the waste water which contains phenol, tars, petroleum hydrocarbons and chemical oxygen demand (COD) and is subjected to gasification, coking, destructive distillation, liquefaction and the like in the coal chemical industry and methyl amylene ketone serving as an extracting agent in an extraction tower or a mixed clarificator. By the method, most of pollutants of the tars and the petroleum hydrocarbons can be removed simultaneously, the pollution load of the waste water is reduced, the load of a subsequent biochemical section can be relieved, and the discharge of the waste water can reach the standard or the waste water can be recycled.

Owner:QINGDAO UNIV OF SCI & TECH +1

Drying method of battery pole piece

ActiveCN105932226AImprove efficiencyReduction of recycling energy consumptionCell electrodesPretreated surfacesEngineeringSlurry

The application relates to the field of lithium ion batteries, in particular relates to a drying method of a battery pole piece. The drying method comprises the following steps: coating slurry with N-methyl pyrrolidone as solvent on the pole piece, drying at the temperature of 50-81 DEG C. Based on the saturated vapor pressure theory and the explosion limit theory, the low-temperature drying process is realized through the regulation of the slurry and the coating process parameters, so that the production is in a 100% safe state, and the efficiency of the NMP recycling system is improved, and the NMP recycling energy consumption is greatly lowered.

Owner:UNITED AUTO BATTERY CO LTD

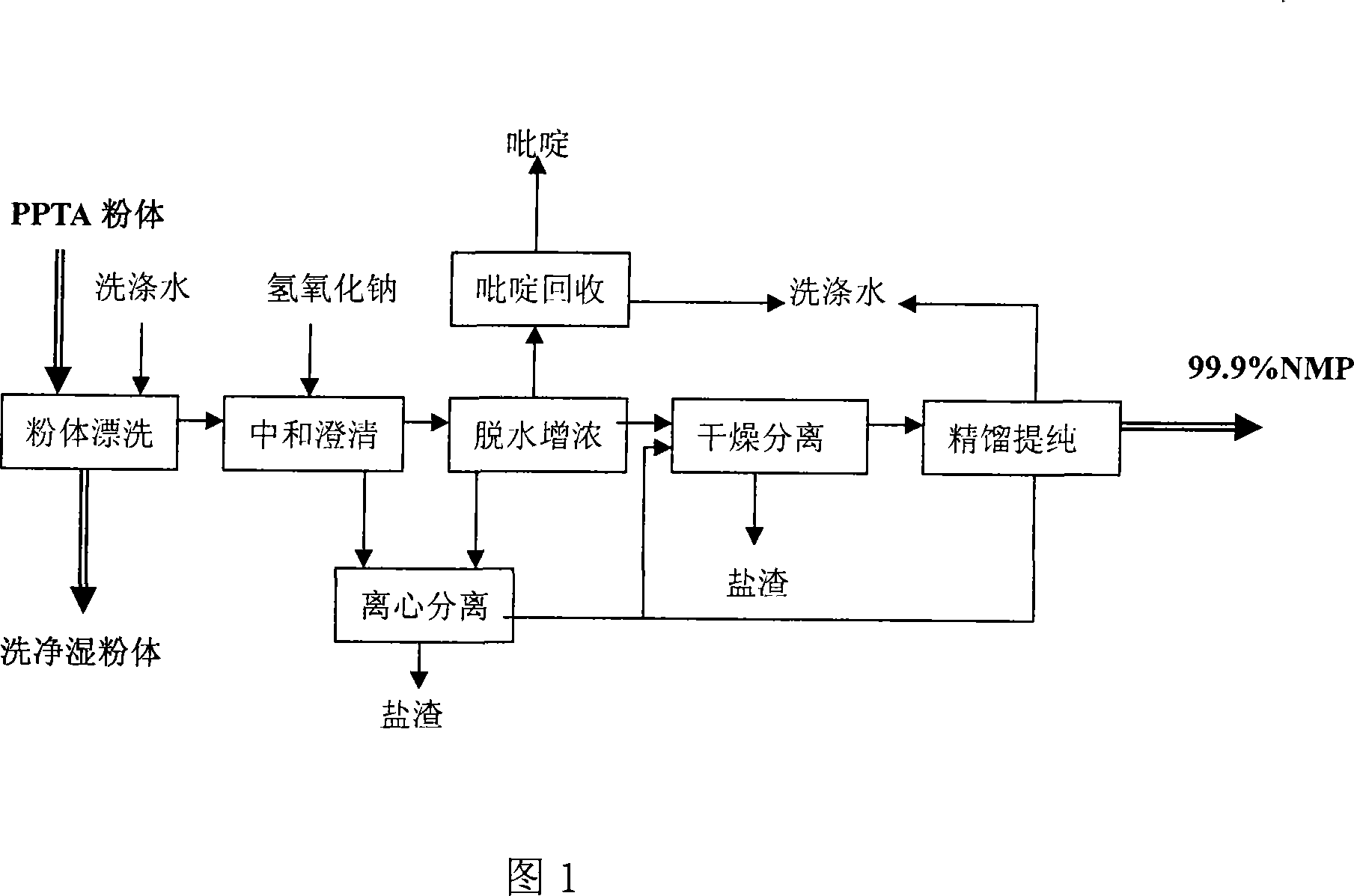

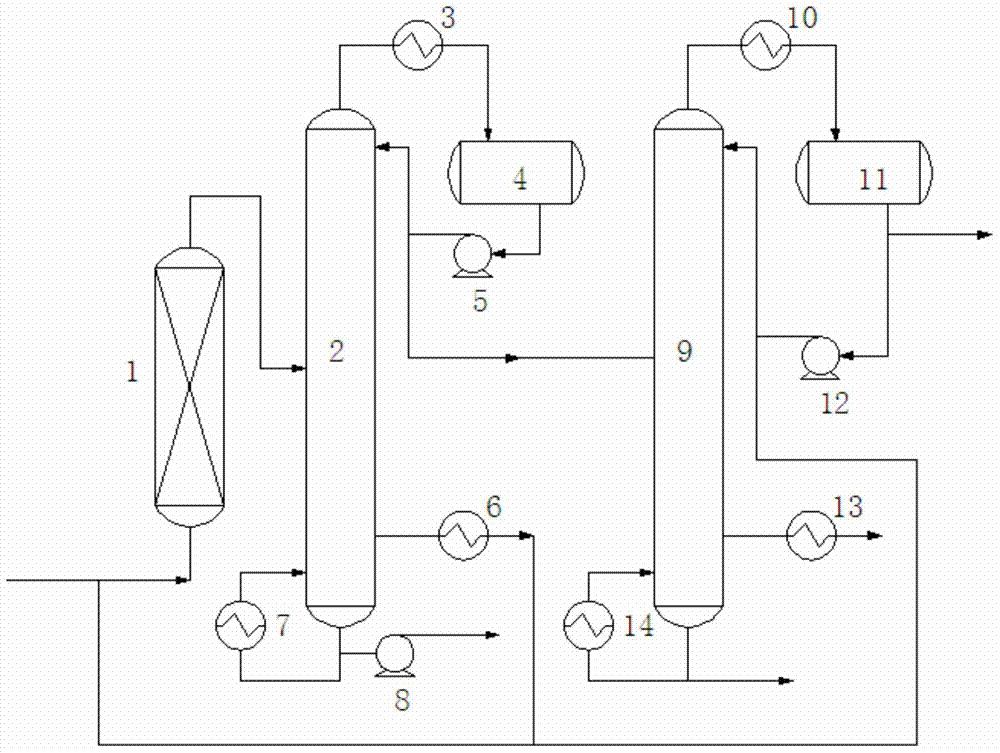

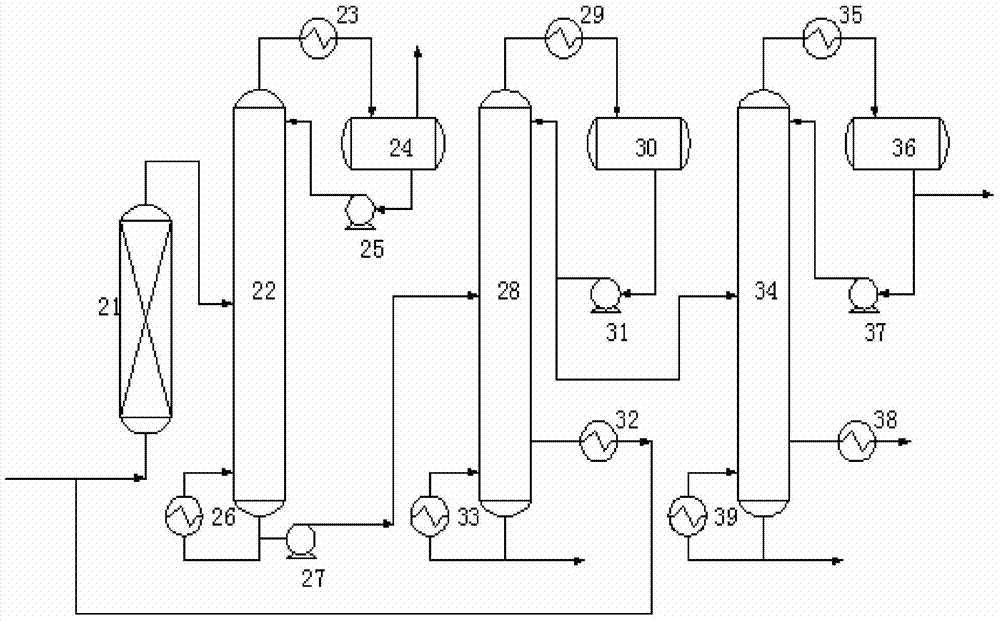

Method for reclaiming solvent from aramid fiber polymeric compound

The solvent recovering process of aramid fiber polymer includes the steps of rinsing, neutralizing, dewatering, separating and purifying. While recovering pyridine, the aramid fiber solvent and assistant are re-used. The technological process is simple and easy in control, and has been applied practically.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

Purification method for coal tar soft pitch

InactiveCN102839008AImprove solubilityHigh yieldWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionPurification methodsCentrifugation

The present invention relates to a purification method for coal tar soft pitch. The method is characterized by comprising: stirring and uniformly mixing coal tar soft pitch with a softening point of 30-60 DEG C and a solvent according to a mass ratio of 1:0.5-1.5 at a temperature of 120-300 DEG C; carrying out thermal and adding the resulting material to a continuous centrifuge; carrying out continuous centrifugation separation at the same temperature to obtain a supernatant and residue; carrying out vacuum distillation on the supernatant; removing the solvent to obtain the purified pitch; and recovering the solvent to reuse. The method of the present invention has the following advantages and effects that a dissolution property of the soft pitch in the solvent and a process yield can be significantly improved, difficulties of mixing and separation are significantly decreased, and operation and maintenance are convenient.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Biomass carbonization treatment method

ActiveCN108893128AAbundant sources of raw materialsLow priceBiofuelsSpecial form destructive distillationSolventChemistry

The invention discloses a biomass carbonization treatment method, and belongs to the field of waste resource utilization. The biomass carbonization treatment method includes steps of (1), drying and smashing biomass to obtain biomass powder; (2), mixing and then heating the biomass powder, acid and catalysts with one another, and completely carbonizing biomass to obtain mixtures; (3), cooling themixtures generated at the step (2) until the temperatures of the mixtures reach the room temperature, adding solvents into the mixtures, carrying out stirring and washing until the acid adsorbed in charcoal is completely dissolved out, and carrying out drying to obtain biomass charcoal and diluted acid or salt. The biomass carbonization treatment method has the advantages that resource recycling and utilization can be carried out on the biomass by the aid of the biomass carbonization treatment method, the biomass carbonization treatment method is high in biomass charcoal yield, charcoal emission can be obviously reduced, and the biomass charcoal obtained by the aid of the biomass carbonization treatment method has an extremely high application value; the biomass carbonization treatment method includes few reaction steps and is low in energy consumption, low-cost carbonization treatment can be carried out on the biomass by the aid of the biomass carbonization treatment method, and the requirements of green chemistry can be met by the biomass carbonization treatment method.

Owner:BEIJING ZFRK ENVIRONMENT &TECH CO LTD

Method and device for preparing isopropyl acetate through reaction of propylene and acetic acid

ActiveCN104744248AReduce the amount of circulating acetic acidHigh processing loadOrganic compound preparationCarboxylic acid esters preparationMaterial consumptionSeparation process

The invention discloses a method for preparing isopropyl acetate through reaction of propylene and acetic acid. The method is characterized by comprising the following steps: (A) mixing an inert component with propylene and acetic acid, and feeding into a fixed bed reactor for reaction; (B) feeding the reacted mixture into a heavy component removal tower for removing heavy components; (C) condensing the tower top product of the heavy component removal tower, feeding into a light component removal tower for further separation, condensing the tower top product of the light component removal tower, feeding back a part of the condensed product to the tower top for backflow, feeding back a part of the condensed part to a reaction system for recycling and reuse, and discharging out an isopropyl acetate product from a side line of the column bottom. By adopting the method, the reaction acid-alkene ratio is reduced, the operation pressure of the reaction system is reduced, the treatment capacity of the heavy component removal tower is increased, the energy consumption is reduced, conventional processes and equipment can be used, propylene which is discharged out at present can be effectively recycled, the material consumption is reduced, the influence caused by discharged propylene to the environment is reduced, the potential safety hazard is eliminated, the separation process procedures are shortened, and the equipment investment is reduced.

Owner:HUNAN ZHONGCHUANG CHEM

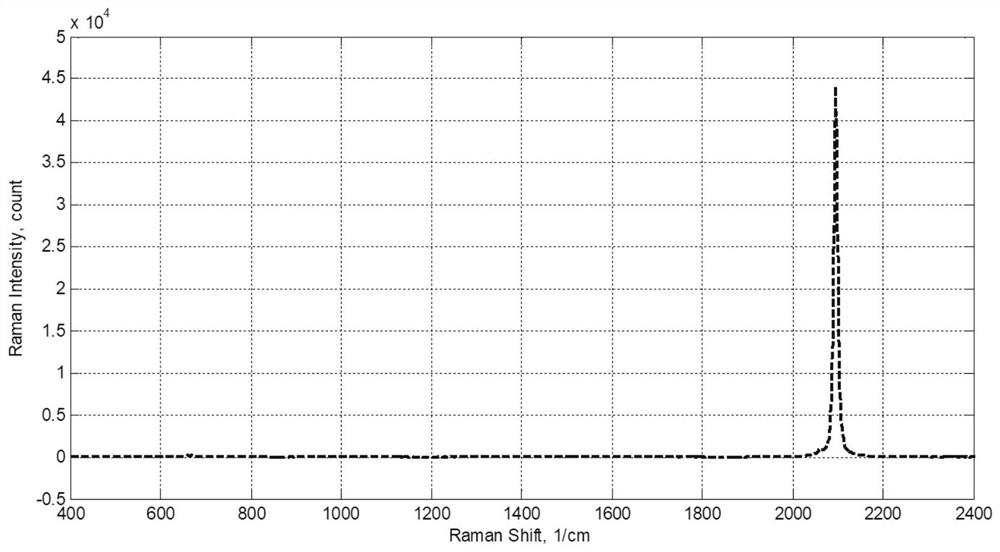

Method and device for preparing adiponitrile

ActiveCN111995547APrecise control ratioImprove stabilityOrganic compound preparationDistillation regulation/controlIsomerizationPtru catalyst

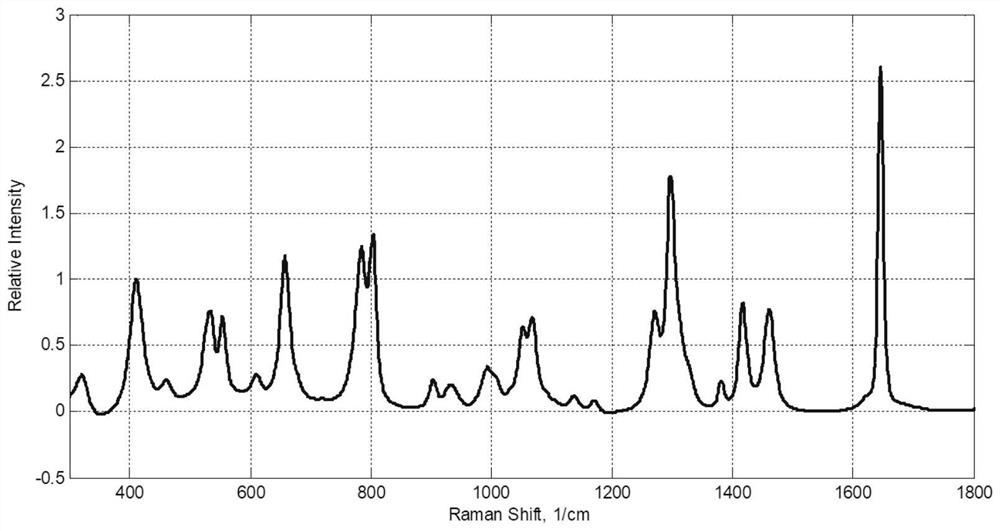

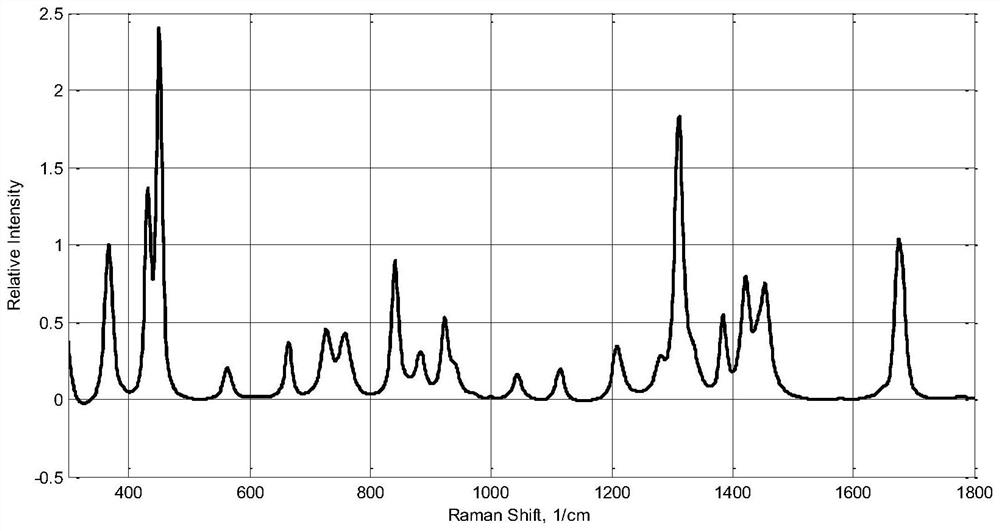

The invention provides a method and a device for preparing adiponitrile. The preparation method comprises the steps of a first hydrocyanation reaction, an isomerization reaction and a second hydrocyanation reaction. According to the method, the contents of specific components in a system is detected by adopting an online Raman spectrum, and reaction conditions are regulated and controlled based ona detection result, so accurate control on materials in each step in the reaction system is realized. The method provided by the invention can reduce the consumption of butadiene, and lower subsequent butadiene recovery energy consumption and equipment investment in the reaction; the content of hydrocyanic acid is monitored in real time, so hydrocyanic acid residues are reduced to a relatively low level, and the operation safety and the stability of a catalyst in the reaction process are improved; and the loss of the catalyst is reduced.

Owner:ZHEJIANG NHU CO LTD +2

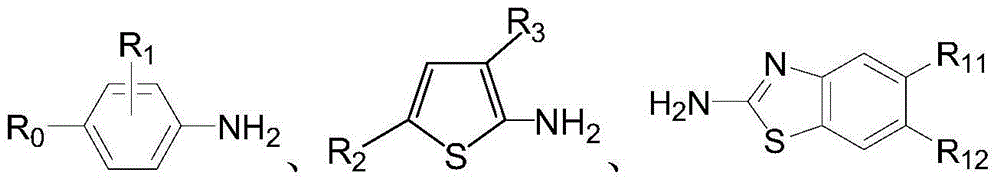

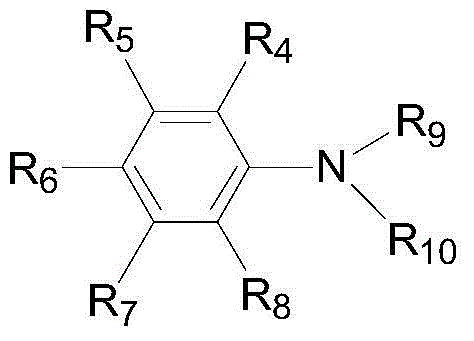

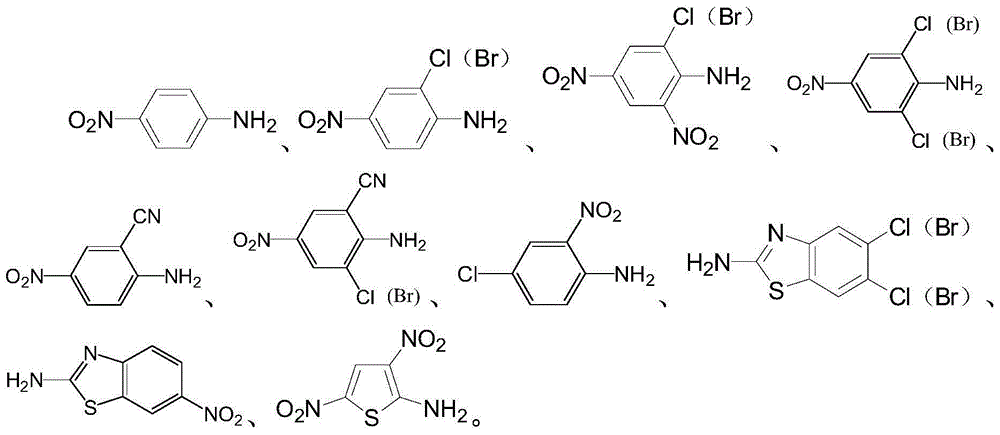

Preparation method of ester group-containing azo disperse dye

The invention discloses a preparation method of an ester group-containing azo disperse dye. The method comprises the following steps: carrying out a coupling reaction on a diazo salt and a coupling component, adding an alkali to the above obtained azo compound material system after the coupling reaction is completed in order to adjust the pH value of the system to 5-7, carrying out heating crystal transformation, and post-processing to obtain a dye filter cake. The pH value of the system is adjusted to 5-7 after the coupling reaction and before the crystal transformation, so hydrolysis of ester groups in the dye product is avoided, the yield of the dye product is improved, and the content of organic matters in wastewater is reduced, thereby the wastewater post-treatment difficulty is reduced.

Owner:ZHEJIANG DIBANG CHEM

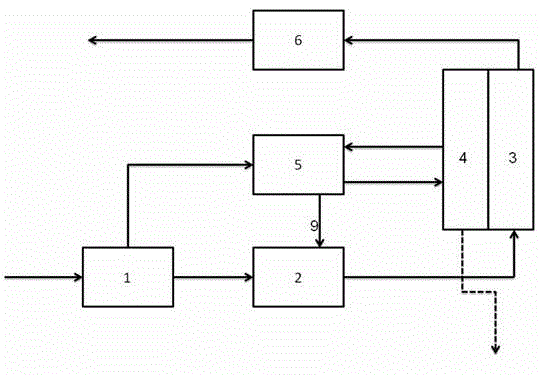

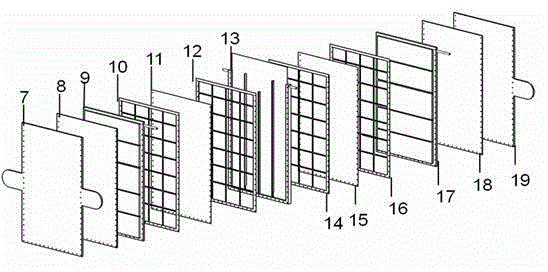

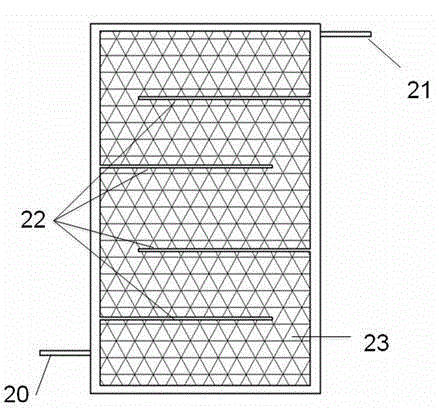

Electrolytic cell for acidic etching liquid in-situ regeneration technology

The invention discloses an electrolytic cell for acidic etching liquid in-situ regeneration technology. The structure of the electrolytic cell comprises a current collector, an expanded graphite current collector, an anode chamber, an anode chamber insulated grid plate, an anion exchange membrane, a cathode chamber insulated grid plate and a cathode chamber; the anode chamber is internally provided with a baffle plate and a porous electrode; the anion exchange membrane adopts AMI-7001 type anion membrane; and the cathode chamber is provided with a baffle plate and a plugged copper plate electrode. Compared with the existing electrolytic cell, the electrolytic cell disclosed by the invention has the characteristics of being simple in structure and convenient to install and expand; and no chlorine gas is generated without polluting the environment since the anode potential is low in the electrolytic process. In the application process, the cell voltage is only 2-2.5V, the current efficiency is high, the energy-saving effect is obvious, and the energy consumption of copper recycle is reduced.

Owner:TIANJIN UNIV

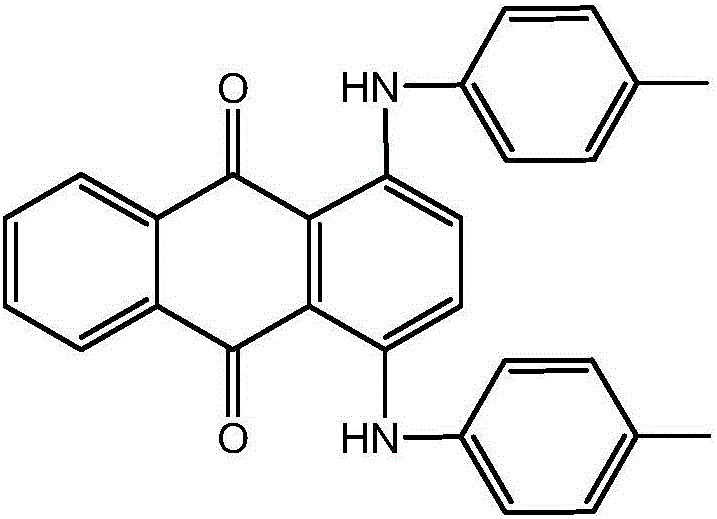

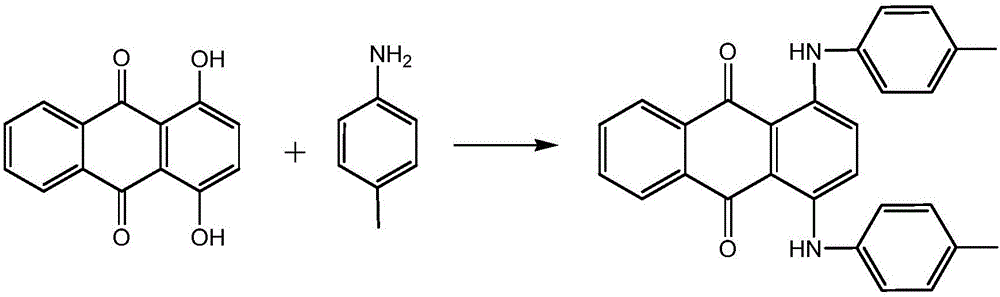

Synthesis method of solvent green 3

ActiveCN106675080AReduction of recycling energy consumptionHigh yieldAnthracene dyesSynthesis methodsAntioxidant

The invention discloses a synthesis method of a solvent green 3. According to the synthesis method, a target product is obtained by taking 1,4-dihydroxy anthraquinone and p-toluidine as raw materials, ethanol as a solvent, boric acid as a catalyst, a 1,4-dihydroxy anthraquinone leuco body as an initiator, sodium hydrogensulfite as an antioxidant and benzene as an azeotrope agent of a system through condensation reaction. According to the synthesis method, the ethanol with a low boiling point is used as the solvent and the solvent green 3 is hardly dissolved in the ethanol, so that the yield of a product is improved and the recycling energy consumption of the solvent is also reduced; the 1,4-dihydroxy anthraquinone leuco body is used as the initiator, has the effect of a reaction initiator and also has a catalytic action in a reaction process; the activity of the 1,4-dihydroxy anthraquinone leuco body can be guaranteed in the presence of the antioxidant, namely the sodium hydrogensulfite, and the initiation and catalysis effects are improved.

Owner:JIANGSU DAOBO CHEM

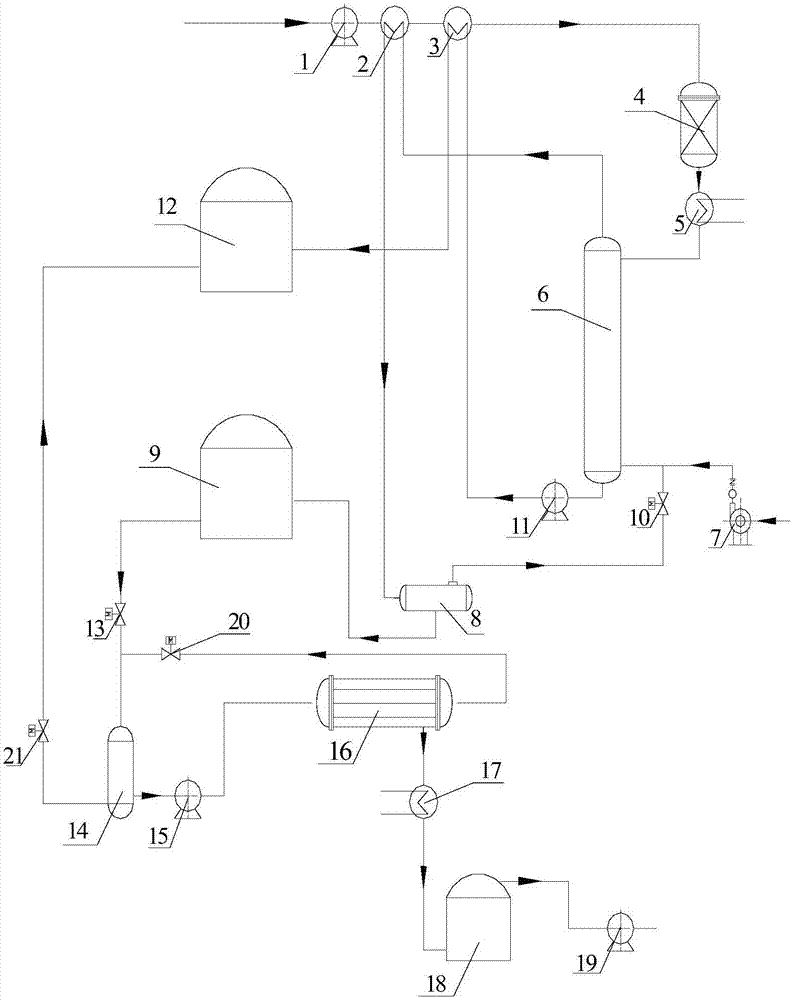

Device and process for recycling methyl alcohol from gas field alcohol-containing sewage based on gas stripping process and vacuum membrane distillation process

ActiveCN106866368AShort processSimple processOrganic compound preparationWater contaminantsReboilerMembrane distillation

The invention relates to a device and a process for recycling methyl alcohol from gas field alcohol-containing sewage based on a gas stripping process and a vacuum membrane distillation process. A complex process route of performing gas stripping first to obtain a dilute methyl alcohol solution with fewer impurities and then concentrating the dilute methyl alcohol solution through vacuum membrane distillation is adopted. The device and the process have the beneficial effects that related equipment such as a complex rectifying tower, a reboiler and a reflux tank is not needed, so that equipment investment is greatly reduced; the integrated process does not generate methyl alcohol reflux, so that repeated heating of reflux and tower bottoms is avoided, raw materials are sufficiently heated by waste heat of a methyl alcohol product and tower bottom water; waste heat of raw materials heated at a gas-stripping section provides energy for phase change of vacuum membrane distillation, so that methyl alcohol recycling energy consumption is greatly reduced and economic benefits are improved; the problems that content of impurities of alcohol-containing sewage of the raw materials is relatively high and the solution pollutes the hydrophobic microporous membrane are avoided, and the service life of the membrane is prolonged; the gas stripping process and the vacuum membrane distillation composite process are integrated, so that recycling efficiency is improved, and content of methyl alcohol in alcohol-containing sewage is reduced.

Owner:CHANGZHOU UNIV

Recovery method of fiber reinforced composite material

ActiveCN111333905ARealize full resource recyclingLow reaction temperatureSulfur compoundsCarbon preparation/purificationEconomic benefitsFiber-reinforced composite

The invention relates to a recovery method of a fiber reinforced composite material. The method comprises: (1), mixing a fiber reinforced composite material and acid, performing heating, and carryingout solid-liquid separation to obtain a modified fiber and a filtrate; and (2), carbonizing the filtrate obtained in the step (1) to obtain a carbon material. Resin of the fiber composite material isdissolved through microwave-enhanced acid and the fiber surface is subjected to chemical oxidation treatment, so that the resin material is dissolved in a sulfuric acid solution, and thus the fiber and the resin material are separated to obtain the fiber material. According to the method, full resource recycling of the fibers and the resin material is achieved through microwaves under the action of biomass or the catalyst, and the recycling energy consumption is greatly reduced through the low reaction temperature; and the method is short in route, easy to operate, low in energy consumption and wide in application range and has great economic benefits and environmental benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

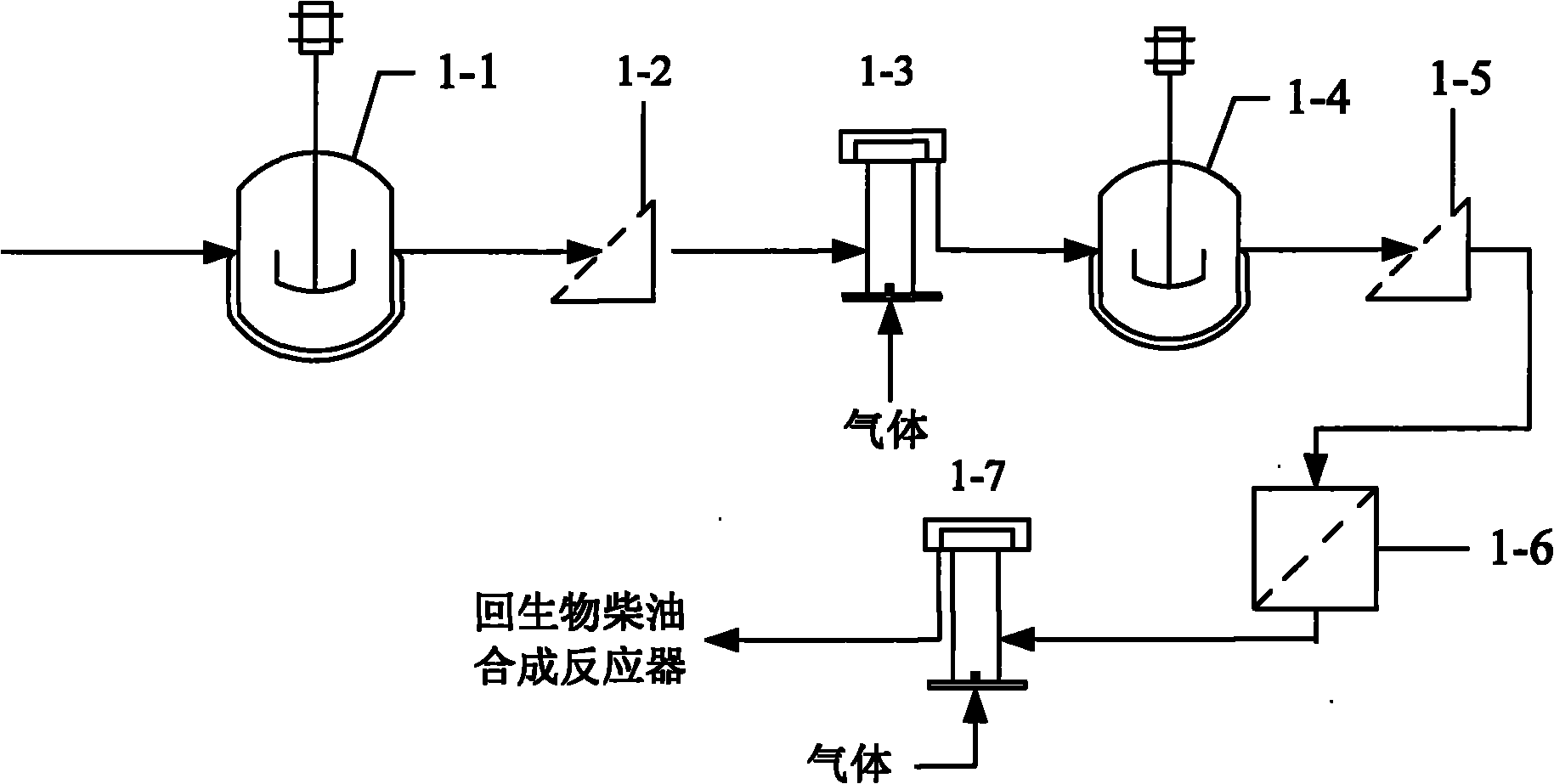

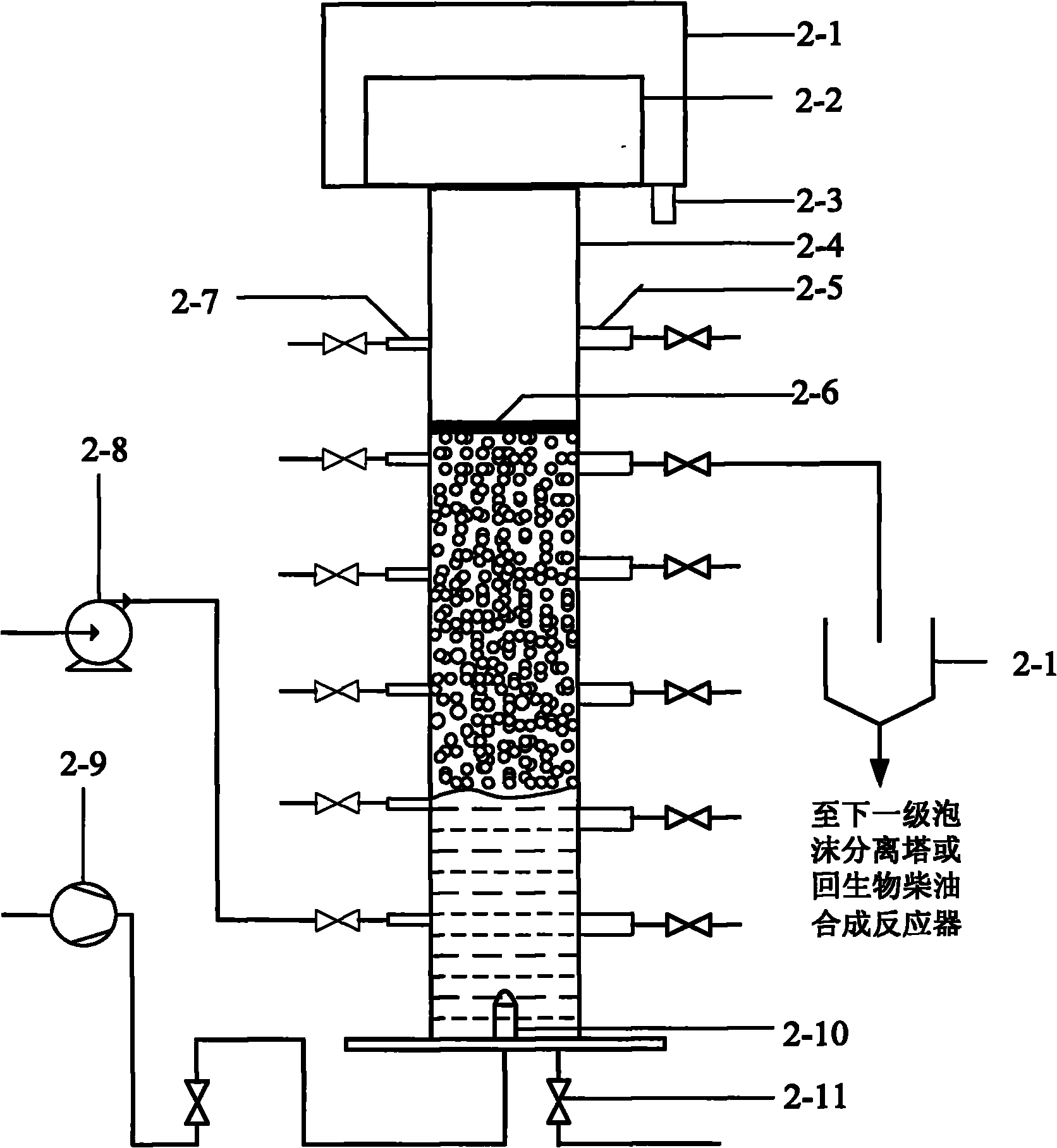

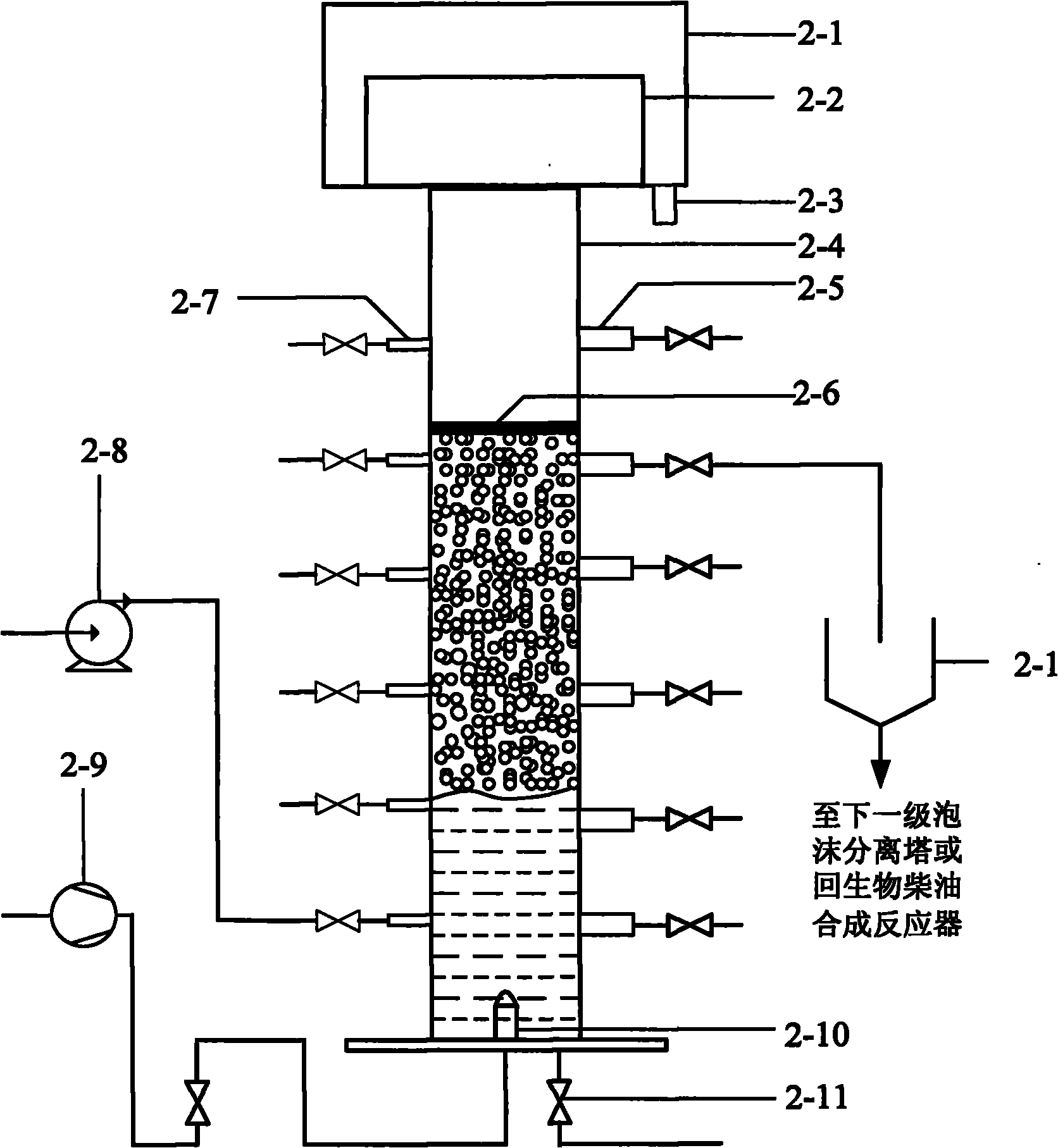

Method and device for recovering and/or enriching aqueous-phase mobilized lipases

ActiveCN102021155AAchieve recyclingRecycling and Enrichment RealizationHydrolasesBiodieselContinuous operation

The invention discloses a method and a device for recovering and / or enriching aqueous-phase mobilized lipases. In the method provided by the invention, a gas is introduced into solution to be recovered and / or enriched, and the lipases in the solution are recovered and / or enriched by foam separation; and the method is particularly applicable to the recovery and / or enrichment of the aqueous-phase mobilized lipases in the bioenzymic production of biodiesel. The method provided by the invention can effectively recover and enrich the lipases in an aqueous phase and keep the activity of the lipases, has the advantages of low energy consumption and low cost, and is easy to amplify and operate. In addition, the invention also provides the device used for the method. The device can be used independently, or a plurality of devices can be connected in series for use so as to realize batch type or continuous operations.

Owner:TSINGHUA UNIV

Method for recycling lithium manganate anode materials of waste lithium ion battery

InactiveCN110396598AReduce the impactEfficient recyclingWaste accumulators reclaimingProcess efficiency improvementActivated carbonManganate

The invention provides a method for recycling lithium manganate anode materials of a waste lithium ion battery. The method comprises the following steps of (1) carrying out ultrasonic concussion treatment on a lithium manganate anode piece with N-methyl pyrrolidone, and filtering to obtain precipitate; (2) calcining, cooling, grinding and sieving the precipitate to obtain the lithium manganate anode materials; (3) leaching the obtained lithium manganate anode materials by using a mixed solution of sulfuric acid and hydrogen peroxide, and filtering to obtain leachate; (4) activating the surfaceof carbon cloth, and placing the leachate and activated carbon cloth in a closed container at the same time for thermostatic hydrothermal reaction; and (5) after the reaction is finished, taking outthe carbon cloth, washing with deionized water, and drying in a vacuum drying oven to obtain a carbon cloth material with lithium manganate crystal on the surface. According to the method for recycling the lithium manganate anode materials in the waste lithium ion battery, the lithium manganate anode materials are recycled by adopting the ultrasonic concussion method, the materials are recycled byadopting the hydrothermal method, a traditional process is replaced, the environmental influence is reduced, and the recovery energy consumption is reduced.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

Preparation method of lily aldehyde

ActiveCN106699534ASimple process routeLow costOrganic compound preparationCarbonyl compound preparationNitrobenzeneDichloromethane

The invention provides a preparation method of lily aldehyde. The method comprises steps as follows: tert-butylbenzene, a solvent and a catalyst are combined and stirred and mixed at a certain temperature; the solvent is any one of dichloromethane, chloroform, nitrobenzene and 1,2-dichloroethane; the catalyst is composition of Lewis acid and an acidic substance providing protons; the certain temperature ranges from subzero 60 DEG C to 40 DEG C; 2-methacrylaldehyde is dropwise added after mixing, and the mixture is kept at the constant temperature continuously after 2-methacrylaldehyde is dropwise added; 2-methacrylaldehyde is dropwise added for 2.5-3.5 h. By means of the method, the yield of lily aldehyde is high and can reach 50%-73%; the recovery rates of the solvent and tert-butylbenzene are high, the cost is saved, and the recovery rate of the solvent is 95%-98% while the recovery rate of tert-butylbenzene is 93%-98%.

Owner:SHANDONG NHU PHARMA

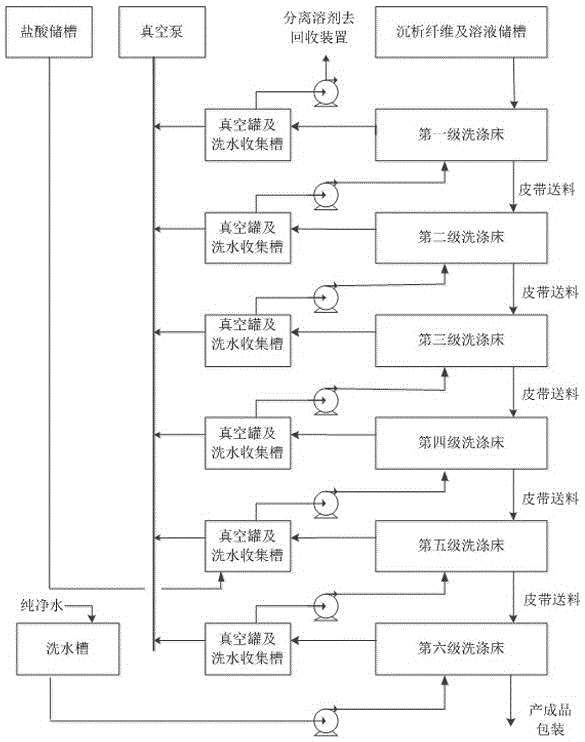

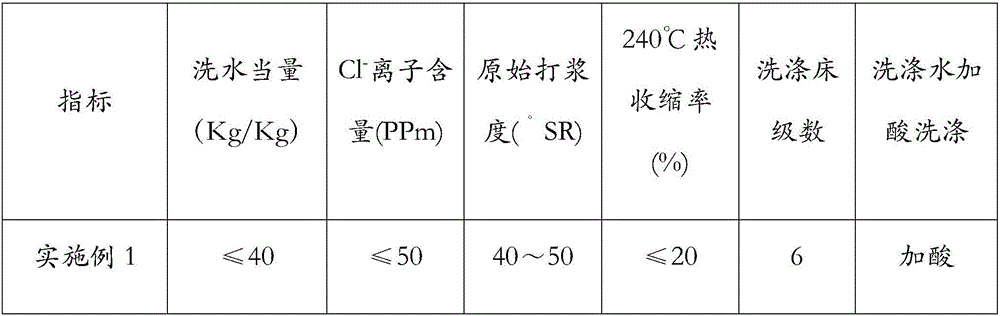

Method for washing meta-aramid fibrid

ActiveCN106367827AIncrease penetration rateAccelerated Diffusion DissolutionArtificial filament washing/dryingOligomerHydrolysate

The invention relates to the technical field of special synthesized fiber manufacturing, and in particular to a method for washing meta-aramid fibrid. The method comprises the following steps: performing continuous washing for six stages in sequence, from the sixth time of washing, performing countercurrent washing with pure water, recycling separated washing water for a former washing stage, and adding acid into washing water of the fourth stage to the first stage so as to acidify the fiber in an acid washing solution, so that the caked surface of the fiber is loosed, the infiltration rate of the washing water is increased, and diffusion dissolution of Cl- and chlorizated salts in the washing water in the fiber is accelerated; meanwhile, oligomers in the acid washing solution can be subjected to acidolysis and can be decomposed into acid hydrolysate which can be dissolved in the washing water, so that the product quality can be improved. By adopting the method, the content of Cl- ions of a fibrid product obtained by using the method can be less than or equal to 50PPm, the original beating degree of the fibrid product can be 35-50 DEG SR, the thermal shrinkage rate of the fibrid product at 240 DEG C is less than or equal to 20%, and the washing water equivalent of the fibrid product on a dry basis Kg is less than or equal to 40Kg.

Owner:四川辉腾科技股份有限公司

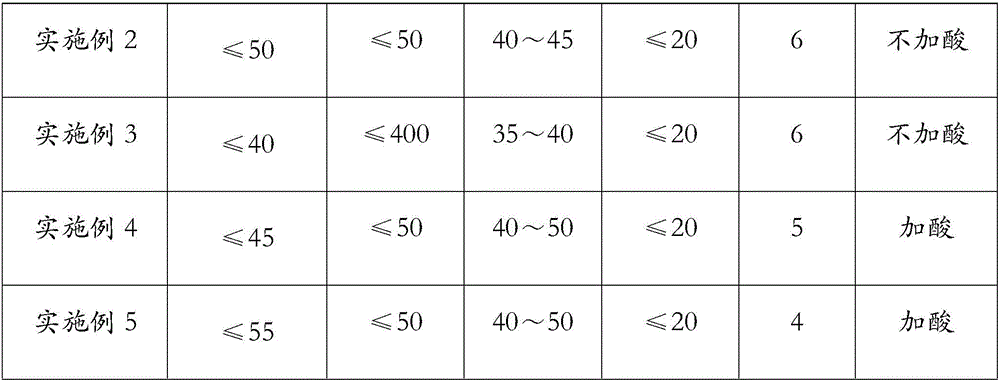

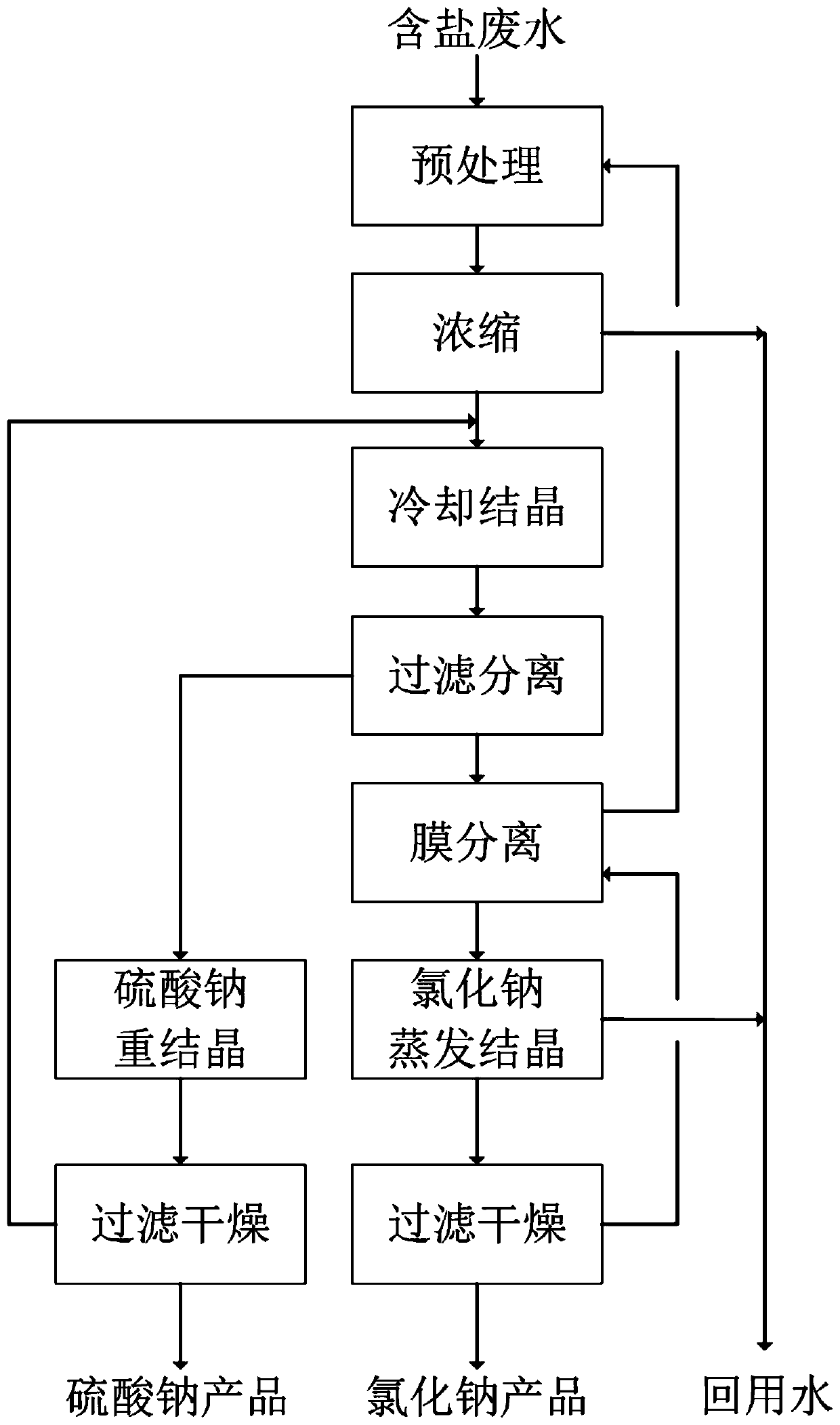

Method for separating salt from high-sulfur low-chlorine salt-containing wastewater

InactiveCN111348794AHigh recovery rateImprove separation efficiencyWater contaminantsWater softeningPhysical chemistryWastewater

The invention provides a method for separating salt from high-sulfur low-chlorine salt-containing wastewater. According to the method, sodium sulfate and sodium chloride in the salt-containing wastewater are sequentially separated and enriched through cooling crystallization and membrane separation on the basis of a phase diagram principle, and meanwhile, sodium sulfate and sodium chloride products available for sale and reuse water are obtained by combining the procedures of pretreatment, concentration, sodium chloride evaporative crystallization, sodium sulfate recrystallization, filtrationdrying and the like. According to the method provided by the invention, sodium sulfate and sodium chloride in the high-sulfur low-chlorine salt-containing wastewater are completely recycled in the form of a single product, the separation effect is good, the purity of the obtained product is high, meanwhile, water is completely recycled, near-zero emission is realized, and the method is a real, efficient and environment-friendly recycling process; moreover, the separation method is low in energy consumption, high in efficiency, simple to operate, capable of treating high-sulfur low-chlorine salt-containing wastewater from different sources, high in universality and suitable for large-scale industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

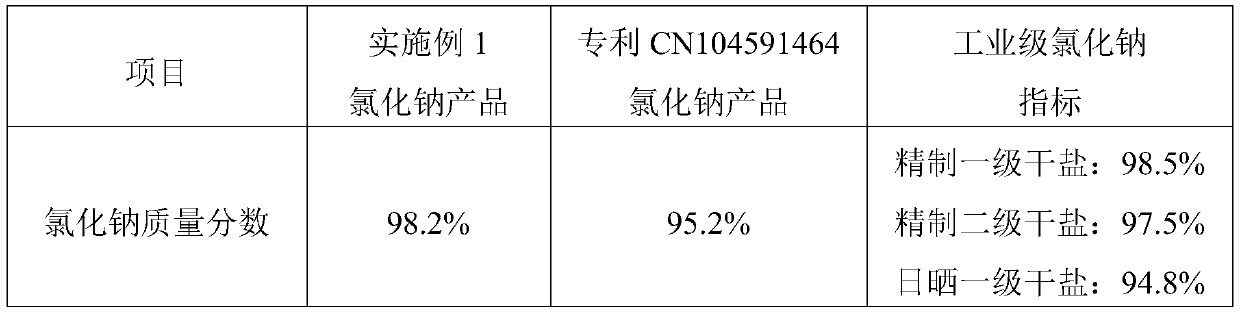

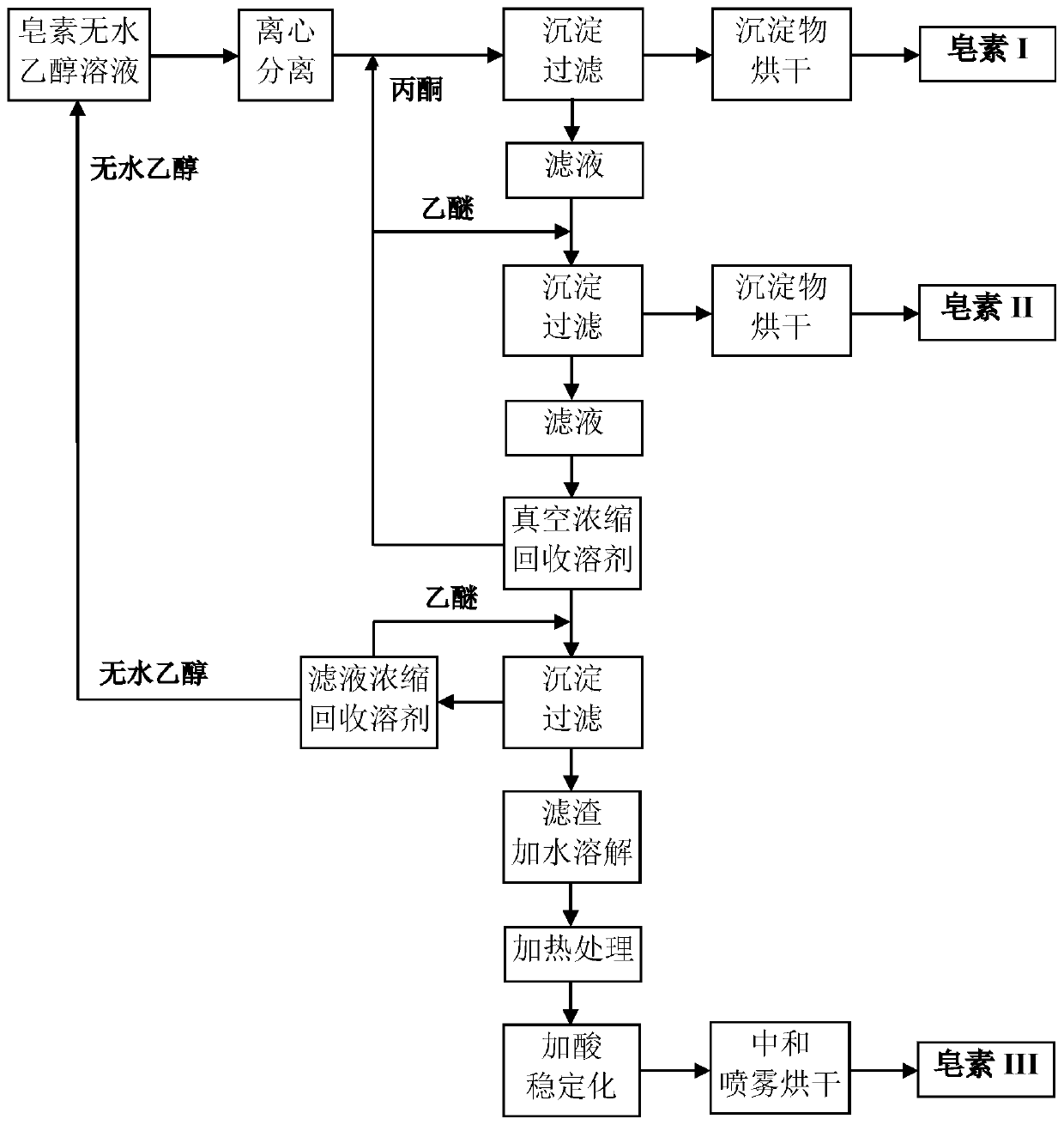

Saponin separation and stabilization method

ActiveCN111298710AReduce concentrationReduce surface tensionTransportation and packagingGlycosidesCritical micelle concentrationSaporin

The invention belongs to the technical field of high-quality utilization of plant extracts, and particularly relates to a saponin separation and stabilization method. The saponin separation and stabilization method comprises the following steps: crude saponin is used as a raw material and filtering by absolute ethyl alcohol, obtained filtrate I is subjected to acetone precipitation separation to obtain saponin I, obtained filtrate II is subjected to acetone / diethyl ether precipitation separation to obtain saponin II, obtained filtrate III is further subjected to diethyl ether precipitation separation, obtained precipitation filter residues are dissolved in water and then subjected to heat treatment and acid stabilization treatment, and thus saponin III is obtained. According to the method,after the crude saponin is filtered by absolute ethyl alcohol, acetone, acetone / diethyl ether and diethyl ether are sequentially used for fractional purification so that three saponin products with different properties can be obtained at the same time, and a basis is provided for refined and high-quality utilization of saponin; in addition, saponin obtained through diethyl ether precipitation issubjected to stabilizing treatment and the stability is remarkably improved, the critical micelle concentration and surface tension of saponin are remarkably reduced, and the quality of saponin products is improved.

Owner:BEIJING FORESTRY UNIVERSITY

Dephenolizing method for phenol-containing wastewater

InactiveCN106698776AReduction of recycling energy consumptionImprove recycling efficiencyWater contaminantsMultistage water/sewage treatmentRefluxDistillation

The invention provides a dephenolizing method for phenol-containing wastewater. The dephenolizing method for the phenol-containing wastewater comprises the following steps: a, mixing phenol-containing wastewater and an extracting agent which takes methyl terschyl ether as a main body and extracting in an extracting tower or a multi-stage mixer-settler to obtain a solvent phase and a raffinate aqueous phase; b, rectifying the solvent by a rectification process and recycling the solvent and coarse phenol, wherein the rectifying tower theoretical stage is 15 to 25, the reflux ratio is 0.1 to 1, the operating pressure is 0.1 to 0.91 MPa, the tower top operating temperature is 50 to 90 DEG C, and the tower bottom temperature is 150 to 300 DEG C; c, distilling the raffinate aqueous phase by a distillation solvent recovery process and recycling residual extracting solvent, wherein the tower top temperature is 62 to 90 DEG C, the tower bottom temperature is 100 to 130 DEG C, and the amount of a material which is distilled from the top of the tower is 1.5 to 5 percent of that of a fed material; d, recycling the extracting solvent. The dephenolizing method for the phenol-containing wastewater has the beneficial effects that the process flow is simple; the equipment investment is low; the solvent recycling energy consumption is low; the recycling rate of the phenol is high.

Owner:YANCHENG OUHUA CHEM IND

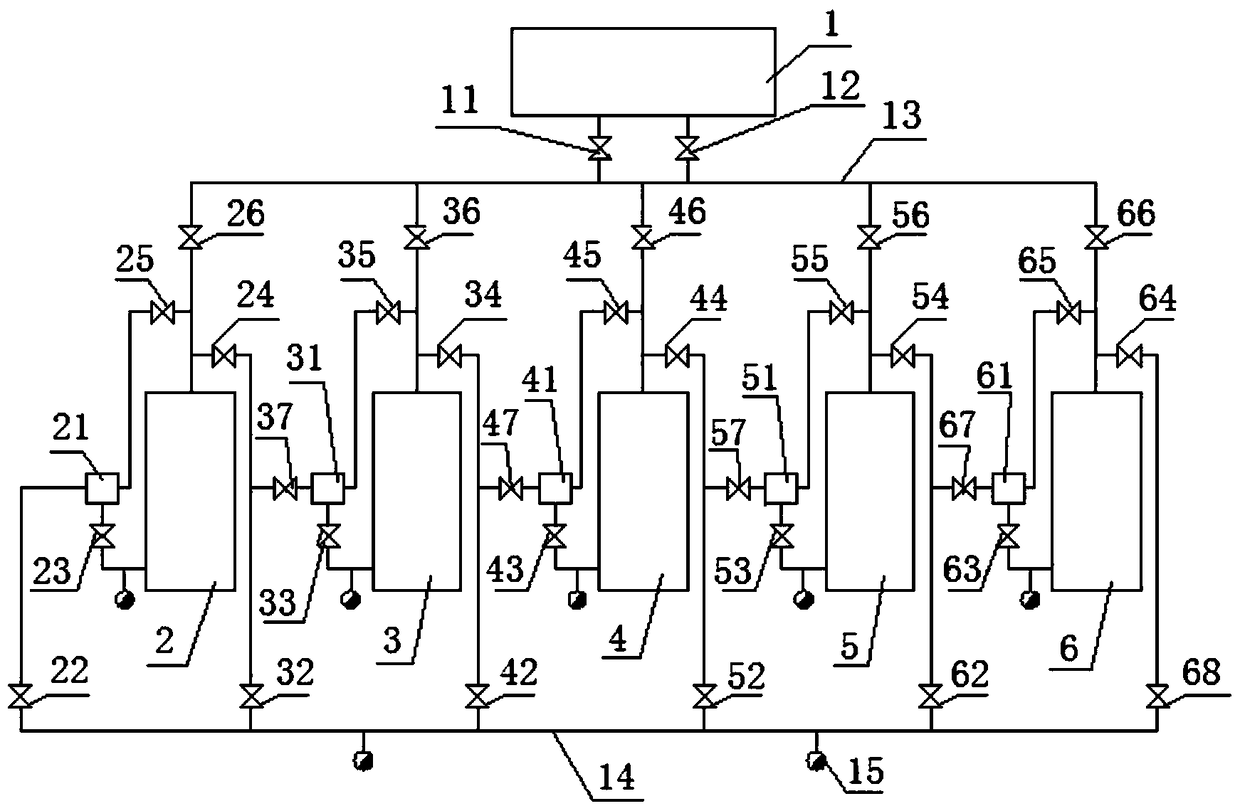

An autoclave system for the production of phosphogypsum autoclaved bricks

InactiveCN105291257BAchieve recyclingReduction of recycling energy consumptionCeramic shaping apparatusPressure riseBrick

The invention discloses a still kettle system for producing ardealite steam-pressing bricks. The still kettle system comprises a heat main steam source collecting box, a still kettle A, a still kettle B, a still kettle C, a still kettle D, a still kettle E, a steam source distribution pipe, a dead steam distribution pipe, a steam-steam pumping pipe A, a steam-steam pumping pipe B, a steam-steam pumping pipe C, a steam-steam pumping pipe D and a steam-steam pumping pipe E, wherein the main steam source collecting box is connected with the steam source distribution pipe through a steam source main valve A and a steam source main valve B; inlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam source distribution pipe and the dead steam distribution pipe; outlets of the still kettle A, the still kettle B, the still kettle C, the still kettle D and the still kettle E are connected with the steam-steam pumping pipe A, the steam-steam pumping pipe B, the steam-steam pumping pipe C, the steam-steam pumping pipe D and the steam-steam pumping pipe E. Dead steam of the still kettles are subjected to temperature rise and pressure rise respectively through the steam-steam pumping pipes and then is gathered into the dead steam distribution pipe, therefore the dead steam can be recycled instead of being discharged, the recycling effect is better, and the maximum recycling and reusing purposes are achieved.

Owner:GUIZHOU KAILIN GRP CO LTD

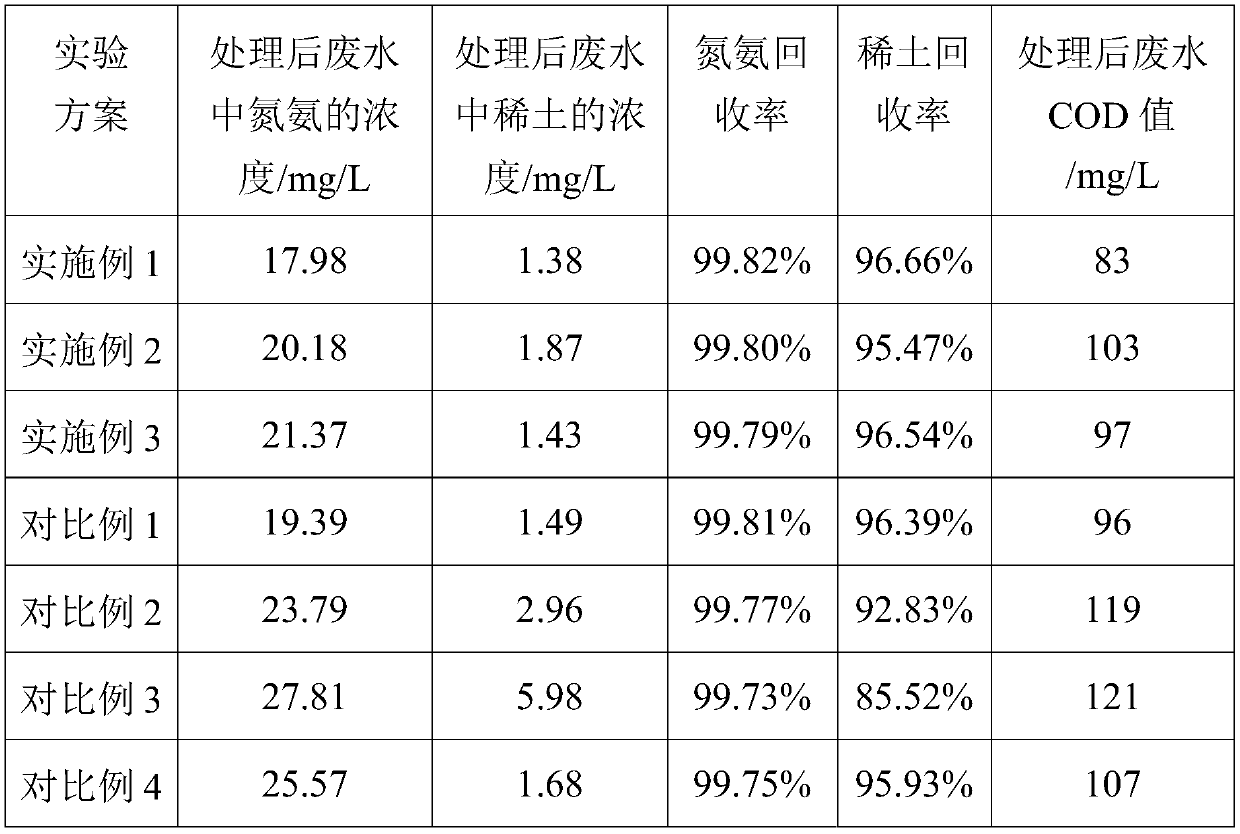

Rare earth wastewater treatment and recovery process

ActiveCN110776128AFiltration system is stableReduce solubilityWater contaminantsTreatment involving filtrationMicropore FilterAmmoniacal nitrogen

The invention discloses a rare earth wastewater treatment and recovery process, wherein rare earth wastewater is filtered by a quartz sand filter, a microporous filter and an ultrafiltration device, and then is subjected to rare earth and nitrogen ammonia enrichment, rare earth recovery, nitrogen ammonia absorption and other operations, so that the enrichment of the rare earth ions and the nitrogen ammonia in the rare earth wastewater, the recovery of the rare earth ions and the nitrogen ammonia and the standard discharge of the wastewater are achieved. According to the invention, through thenanofiltration device, the enrichment of rare earth and nitrogen ammonia in a waste liquid is realized, the treatment load of rare earth and nitrogen ammonia recovery is reduced, the recovery energy consumption is reduced, and the recovery efficiency and the recovery rate are improved; by stripping and adding the agent into the filtrate to recover ammonia nitrogen, the recovery rate of ammonia nitrogen is improved; the stability of the whole filtering system is realized through the three-stage filtering of quartz sand filtering, microporous filtering and ultrafiltration; and the rare earth wastewater treatment and recovery process is simple to operate and low in treatment cost, and is suitable for industrial production.

Owner:盛和资源(江苏)稀土有限公司

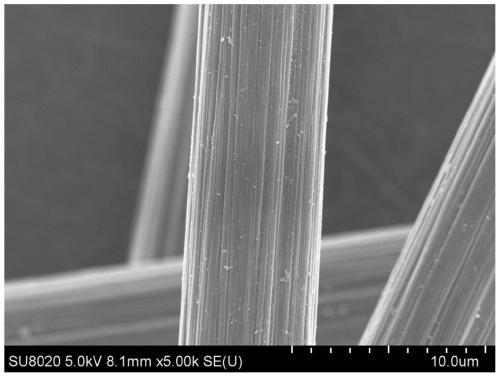

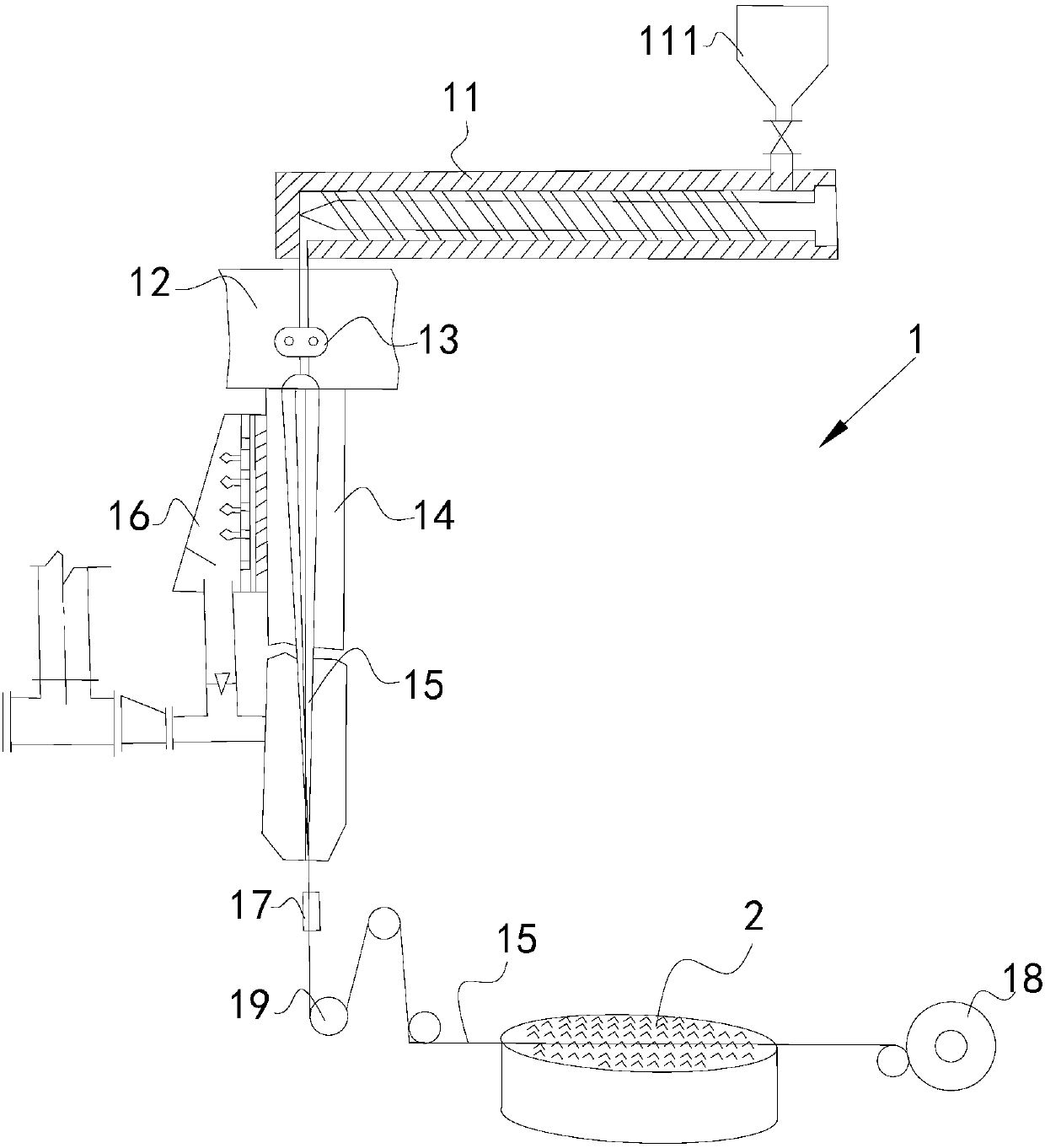

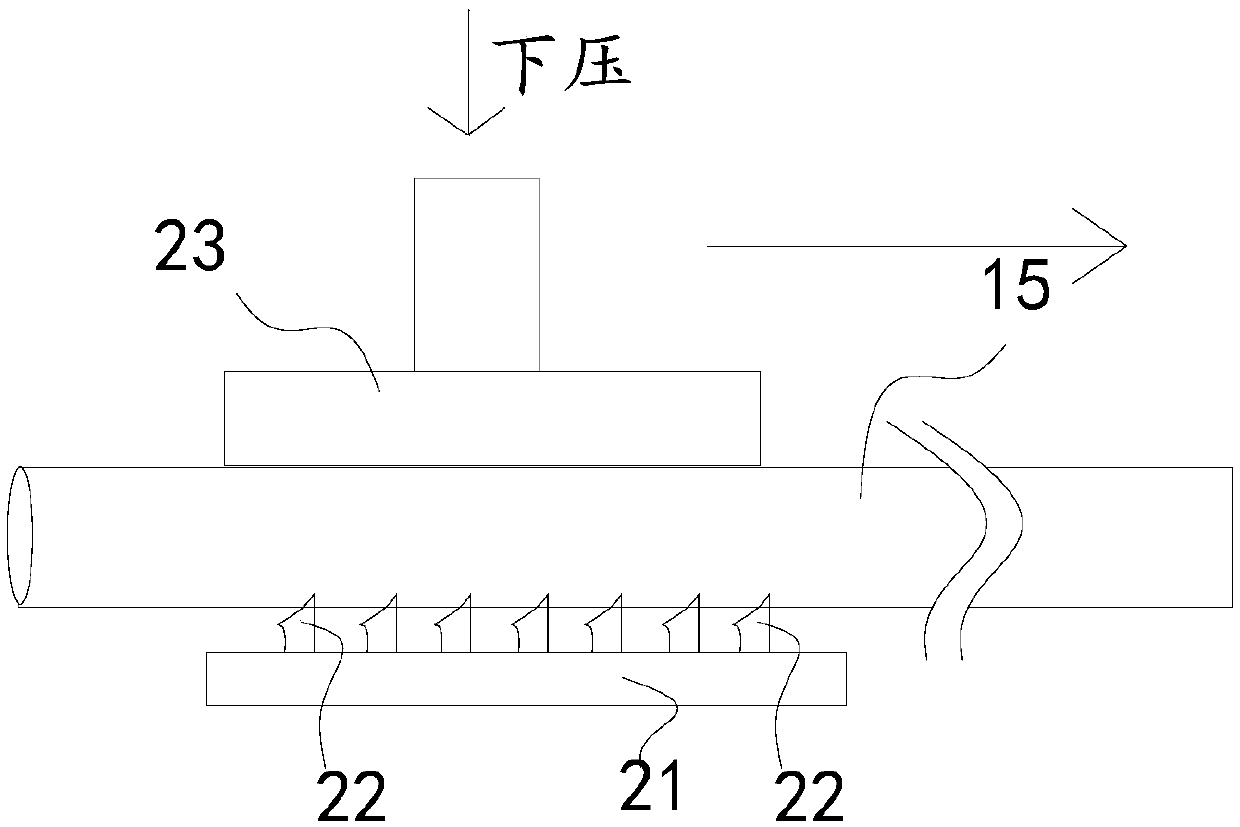

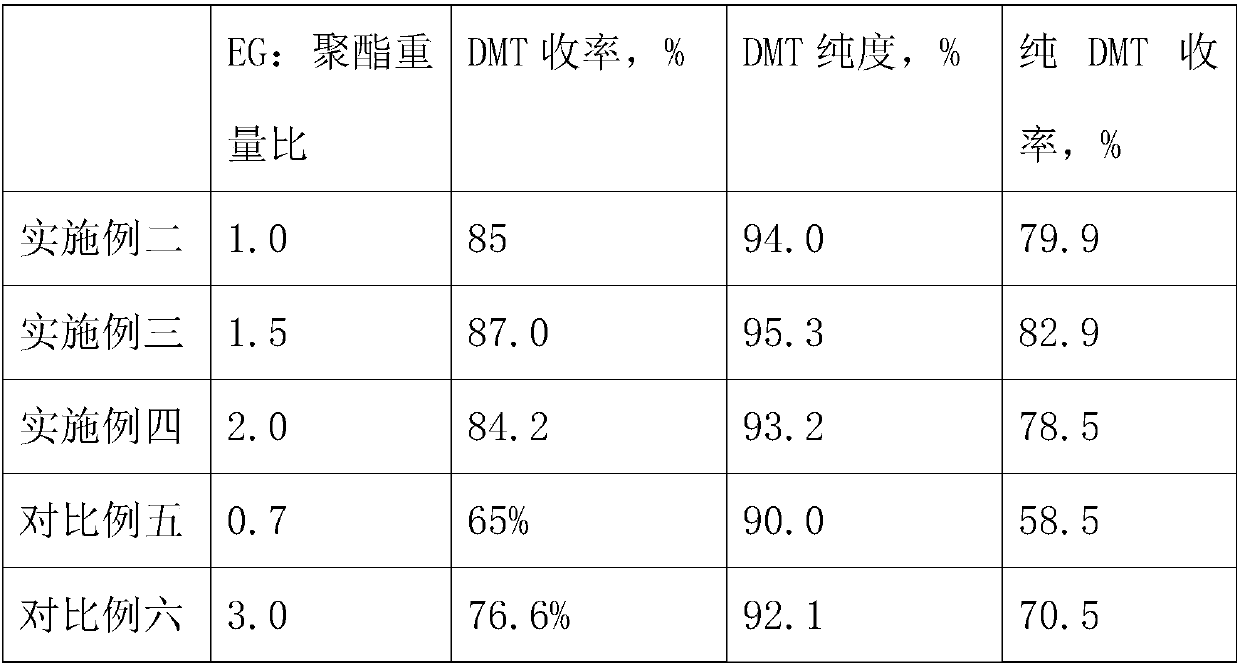

Polyester material recovery and surface mechanical etching method

ActiveCN108103613AReduce energy consumptionReduction of recycling energy consumptionTextile/flexible product manufactureMonocomponent polyesters artificial filamentCvd grapheneChemistry

The invention relates to the technical field of polymer processing and provides a polyester material recovery and surface mechanical etching method. The method comprises steps as follows: alcoholysis:a recovered polyester material and EG (ethylene glycol) are added to an alcoholysis kettle in a weight ratio of the polyester material to EG being 1:(1.0-2.0) for alcoholysis; impurity removal: an alcoholysis product is filtered by a filter; exchange reaction: methanol is added to the filtered alcoholysis product for an ester exchange reaction, and an ester exchange product is obtained; extraction of DMT; spinning: purified DMT is prepared into graphene / polyester fiber with a composite spinning technology; mechanical etching: fine holes are etched in the surface of the prepared graphene / polyester fiber. Energy consumption for polyester recovery can be reduced, more functional ingredients can be exposed on the surface of the graphene / polyester fiber, and the functional ingredients in the graphene / polyester fiber can better perform the performance.

Owner:福建赛隆科技有限公司

Emamectin benzoate purifying method

ActiveCN106008628AHigh reaction yieldIncrease productionSugar derivativesChemical industryBenzoic acidAbamectin

The invention relates to an emamectin benzoate purifying method which comprises the following steps: pretreating a methylamino abamectin extract; performing macroporous resin adsorption and dichloroethane analysis; performing reduced pressure distillation of the obtained analysis liquid to remove dichloroethane; adding an isopropyl acetate solution and dissolving; adding a sodium chloride saturated solution, and sufficiently stirring; standing, separating water and filtering with an ultrafiltration membrane to obtain methylamino abamectin refined liquid; and performing a salt forming reaction between the refined liquid and a benzoic acid solution. In the invention, the methylamino abamectin extract is purified by use of the macroporous resin, the purity of the product emamectin benzoate of the salt forming reaction between the methylamino abamectin and benzoic acid is not less than 90%, the yield of the salt forming reaction between the purified methylamino abamectin and benzoic acid is increased by 6%, and the output and economic benefits are increased; and moreover, acetone is not adopted for recrystallization, the solvent loss is reduced, and the solvent recycling energy consumption is lowered.

Owner:NINGXIA TAIYICIN BIOTECH CO LTD

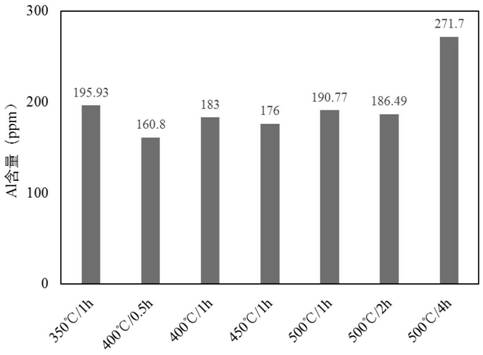

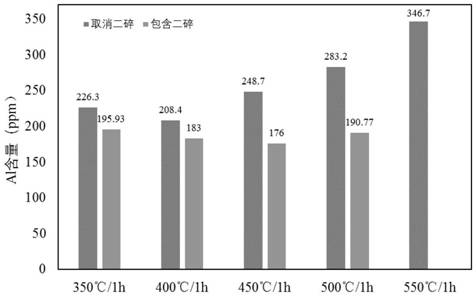

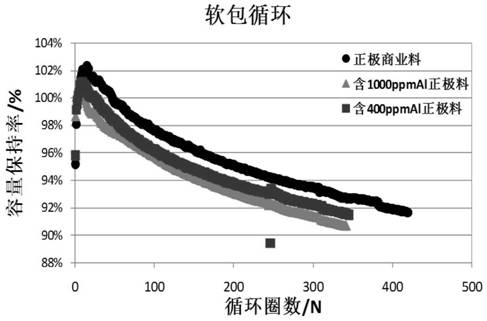

Low-energy-consumption and low-Al-content recovery method for lithium iron phosphate positive plate

ActiveCN112234272AReduce energy consumptionLow Al contentPositive electrodesWaste accumulators reclaimingLithium iron phosphateCrusher

The invention provides a low-energy-consumption and low-Al-content recovery method for a lithium iron phosphate positive plate. The method comprises the following steps of firstly, crushing a to-be-recycled positive plate into coarse particles by using a crusher to obtain a crushed material with the particle size of 1-15mm; heating the primary crushed material to 350-500 DEG C in an inert atmosphere, keeping the temperature for 0.5-2 hours, cooling and discharging to obtain a calcined material; crushing the calcined material into powder by using a crusher to obtain a secondary crushed materialof which the D50 is 50-80 microns; and finally, grading the secondary crushed material by using an airflow grading machine to obtain the positive electrode material of which the Al content is less than 200ppm. Through primary crushing, calcining, secondary crushing and airflow grading, the positive electrode material can be separated and recycled from the aluminum foil; and in the process, low-energy-consumption and low-Al-content recovery of the positive electrode material can be realized by controlling process parameters such as the size of the primary crushed particles, the calcining temperature and time and the particle size of the secondary crushed particles.

Owner:HUAZHONG UNIV OF SCI & TECH

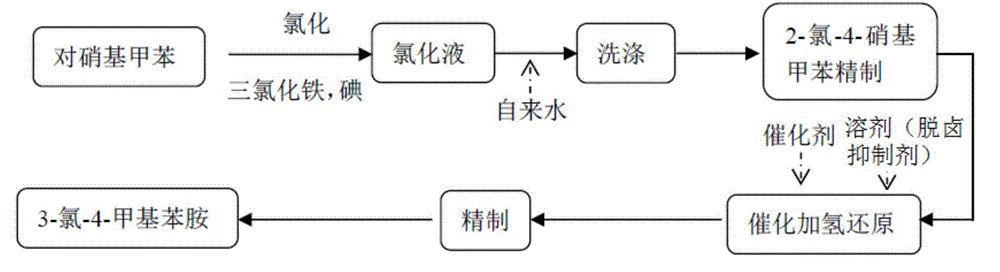

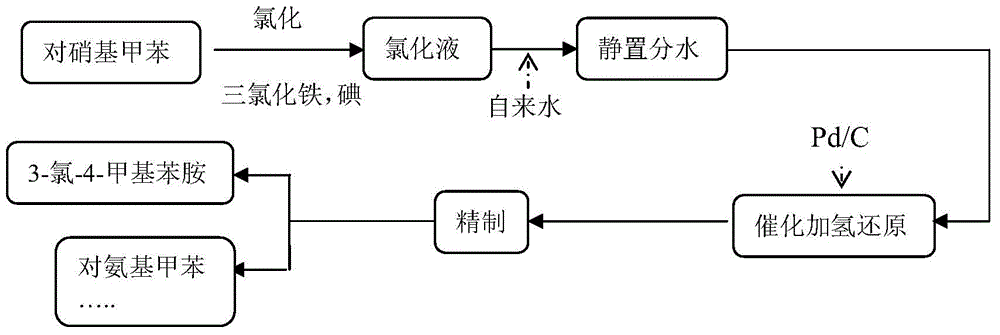

Method for synthesizing 3-chloro-4-methylaniline

ActiveCN104370747AAdjust output at any timeSimple production processOrganic compound preparationAmino compound preparationMethylanilineHydrogen atmosphere

A method for synthesizing 3-chloro-4-methylaniline is disclosed and comprises: taking a 4-nitrotoluene chlorination liquid as an initial raw material, standing for separating water, so as to obtain a mixture mainly containing 2-chloro-4-nitrotoluene, 4-nitrotoluene and dicloronitrotoluene, directly conveying to a hydrogenation reaction kettle without performing refining purification processing, and performing catalytic hydrogenation reaction under the conditions of not using organic solvents and dehalogenation inhibiters and under the effect of a carbon-supported palladium catalyst, and performing rectification separation on the fully-reacted reduced liquid to obtain 3-chloro-4-methylaniline. A preparation method of the carbon-supported palladium catalyst comprises: firstly processing active carbon in hydrogen atmosphere at 200-800 DEG C, then using a NaBr or KBr solution for dipping to enable Br ion to be supported on the active carbon surface, filtering and washing until no Br ion is detected out; then dipping the processed active carbon in a H2PdCl4 solution, after complete dipping, adjusting the pH value of the solution to 7.0, fully stirring for reaction, filtering and washing with deionized water until no chlorine ion is detected out; and finally performing reduction in hydrogen atmosphere at 30-400 DEG C to obtain the carbon-supported palladium catalyst.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com