Electrolytic cell for acidic etching liquid in-situ regeneration technology

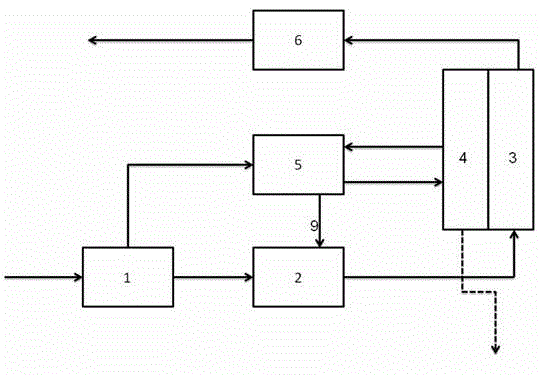

An acid etching solution and in-situ regeneration technology, which is applied in the field of electrolytic cells, can solve the problems of high cost, high operating voltage, and easy precipitation of hydrogen and chlorine, and achieves the advantages of convenient installation and capacity expansion, simple structure, and reduced energy consumption of copper recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

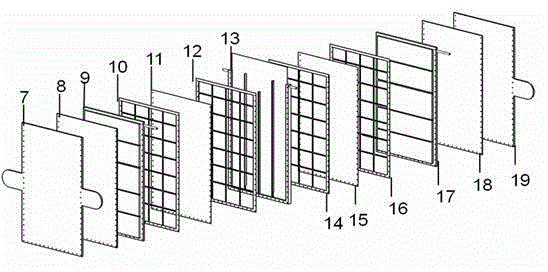

[0015] Below in conjunction with accompanying drawing, the present invention is further described as follows:

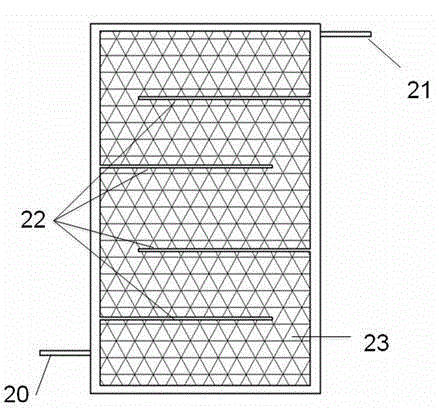

[0016] In this electrolytic cell, the metal current collectors 7 and 19 at both ends are made of metal titanium, and the size is 15*10*0.2 cm; the expanded graphite current collectors 8 and 18 are 15*10* 0.5cm; close to the expanded graphite current collector is the anode chamber 9, 17 with anode electrodes, the anode chamber is made of PVC plastic material, its size is 15*10*2cm, the anode chamber includes 4 horizontally arranged folding Flow plate, the length of the baffle plate in the anode chamber is 10cm, the lower end of one side of the anode chamber is provided with a liquid inlet, and the upper end of the other side is provided with a liquid outlet, and the diameter of the inlet and outlet is 8mm; the one close to the anode chamber is the anode The room insulation grid plate 10,14, its material is PVC plastics, and its size is 15*10*0.2 cm, wherein each grid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com