CO2 separation and compression integrated method

A CO2 and separation rate technology, applied in the field of CO2 separation and compression integration, can solve the problems of high energy consumption, low phase transition temperature, freezing equipment, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

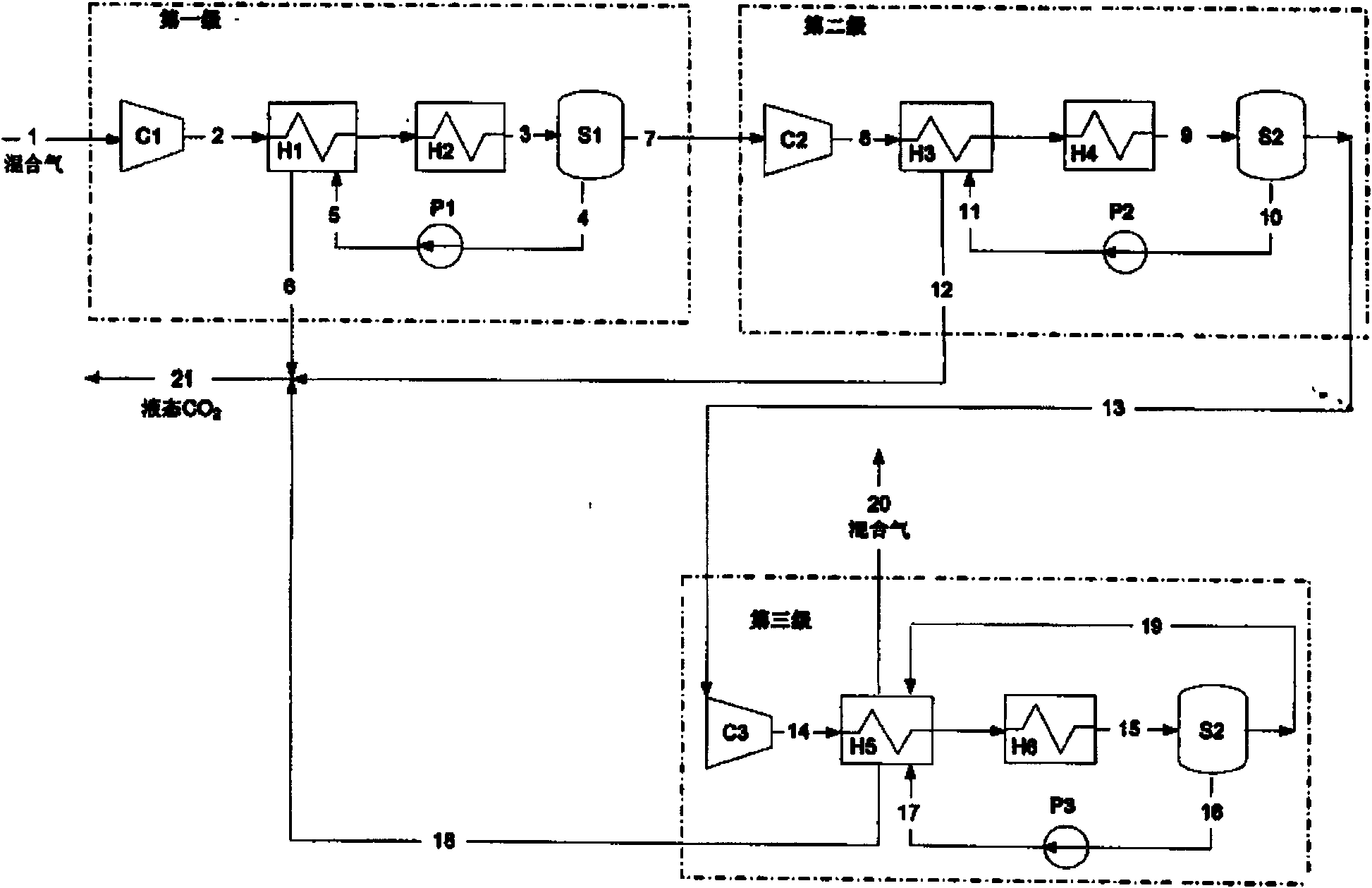

Method used

Image

Examples

Embodiment 1

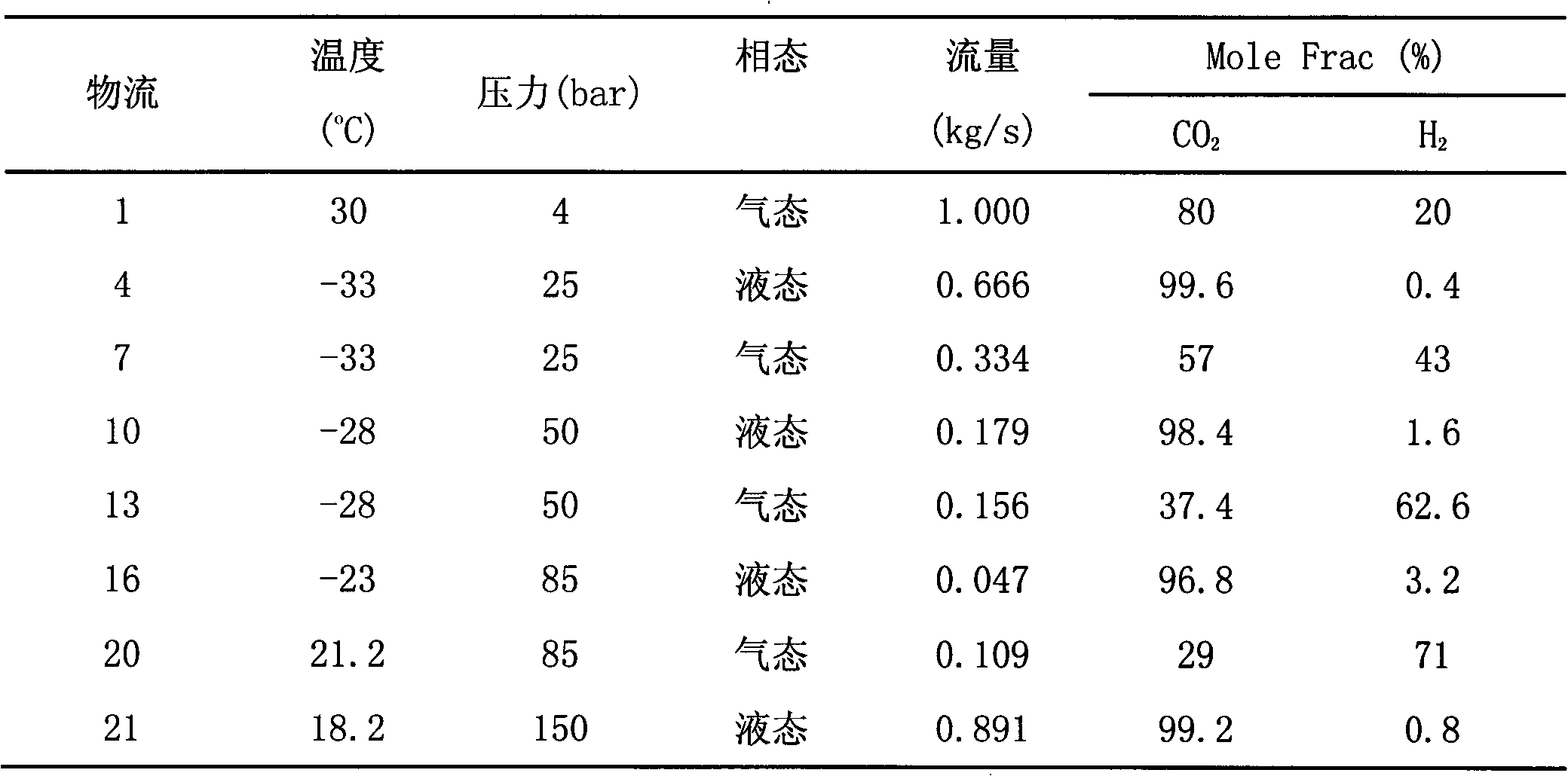

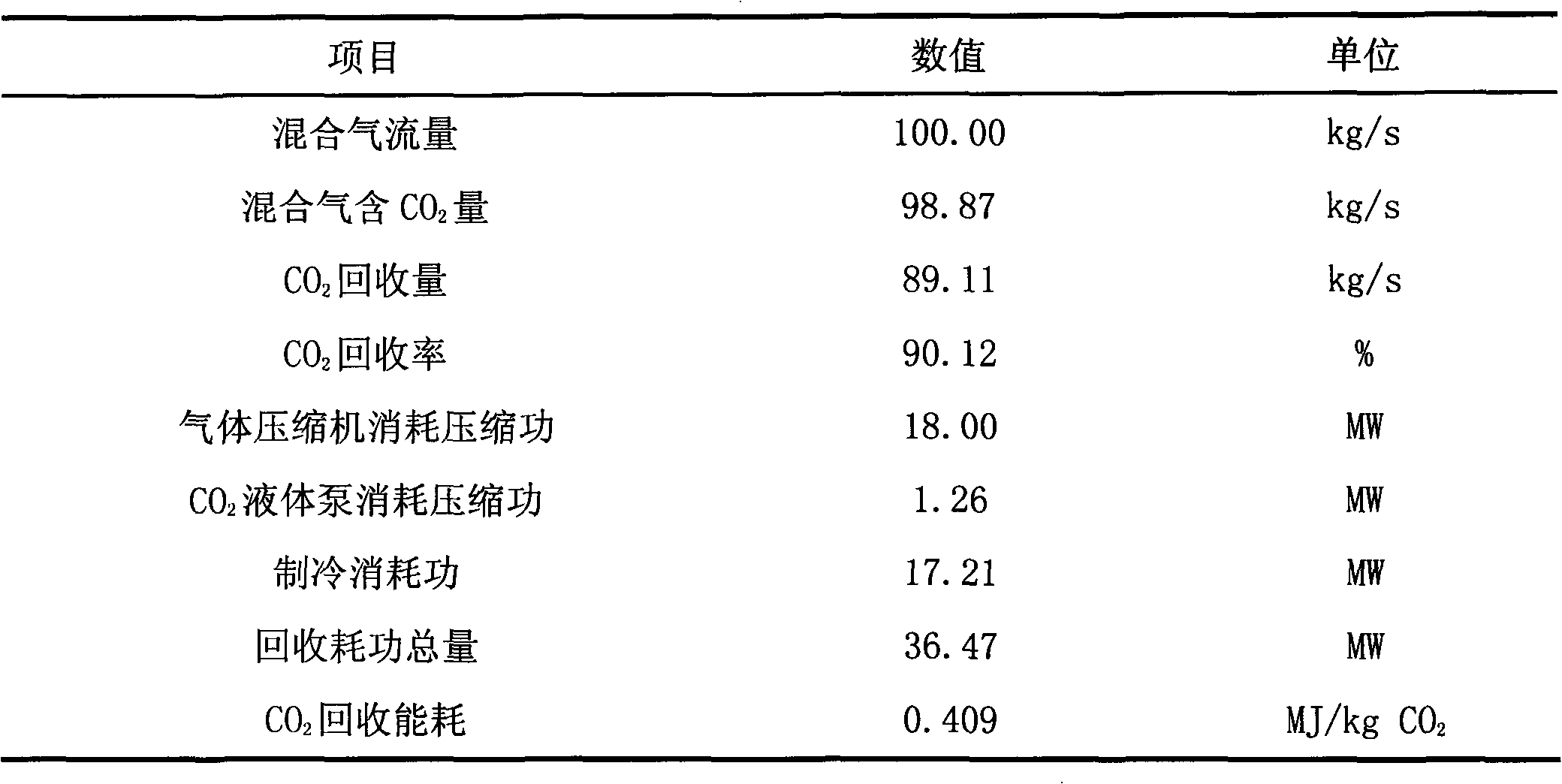

[0021] The computer simulation was carried out using commercial software (Aspen plus Version 11.1), in which Table 1 shows the parameter table of the main logistics.

[0022] In this simulation, the CO 2 and H 2 The mixed gas of 80% and 20% respectively is used as the research object, and the analysis adopts CO 2 The characteristics of material flow and energy consumption when the separation and compression integration method is used for separation. This kind of H 2 and CO 2 The mixed gas as the main component is often found in the shift gas after the coal gasification synthesis gas undergoes shift reaction. Generally speaking, its CO 2 The concentration can reach about 40%, the corresponding H 2 The concentration can reach about 60%; if another clean energy production process (such as PSA hydrogen production process), 70-90% of the H 2 Extract it to get CO 2 CO with a concentration of about 70-85% 2 / H 2 mixed composition.

[0023] The main calculation in the simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com