Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223 results about "Commercial software" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Commercial software, or seldom payware, is a computer software that is produced for sale or that serves commercial purposes. Commercial software can be proprietary software or free and open-source software.

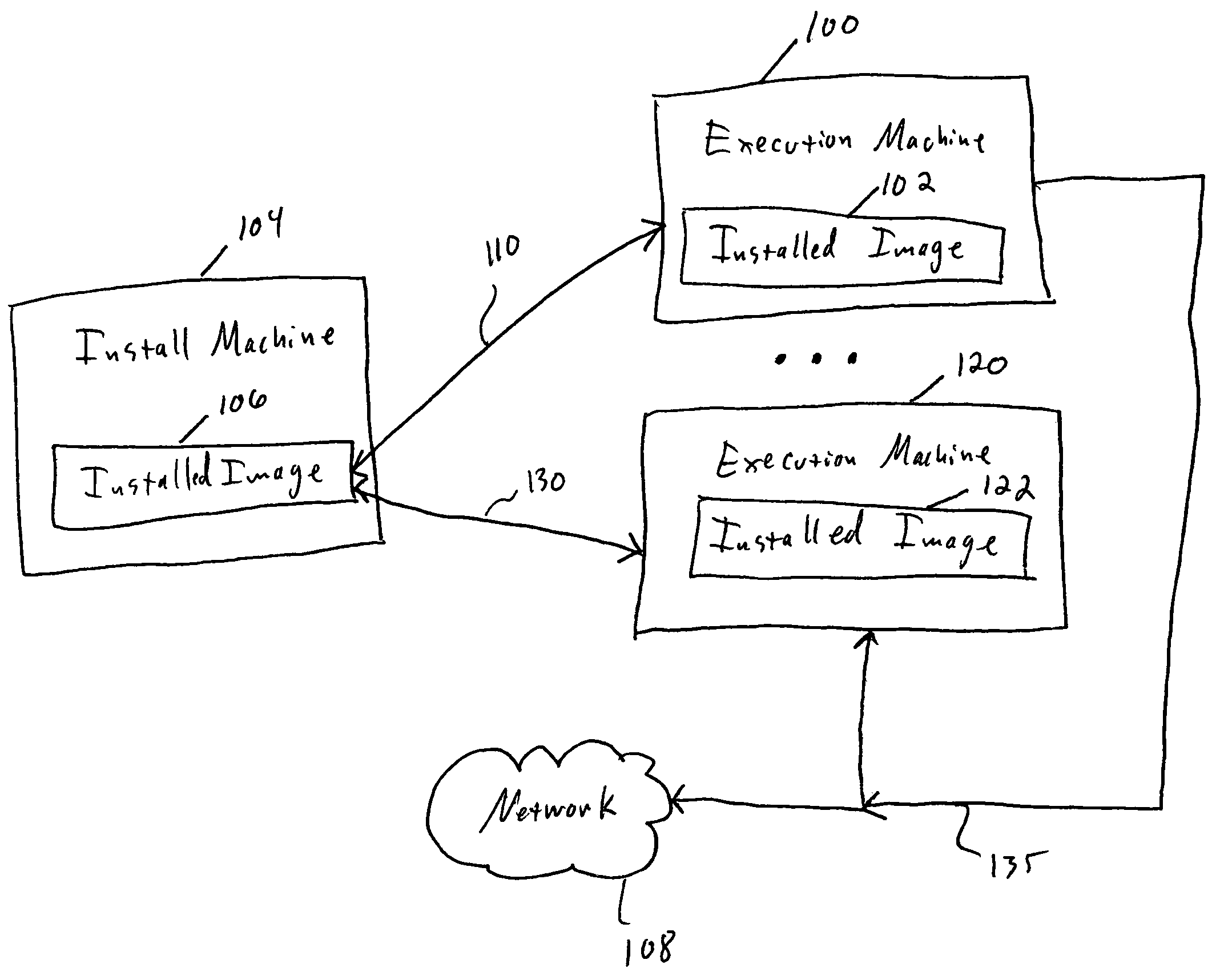

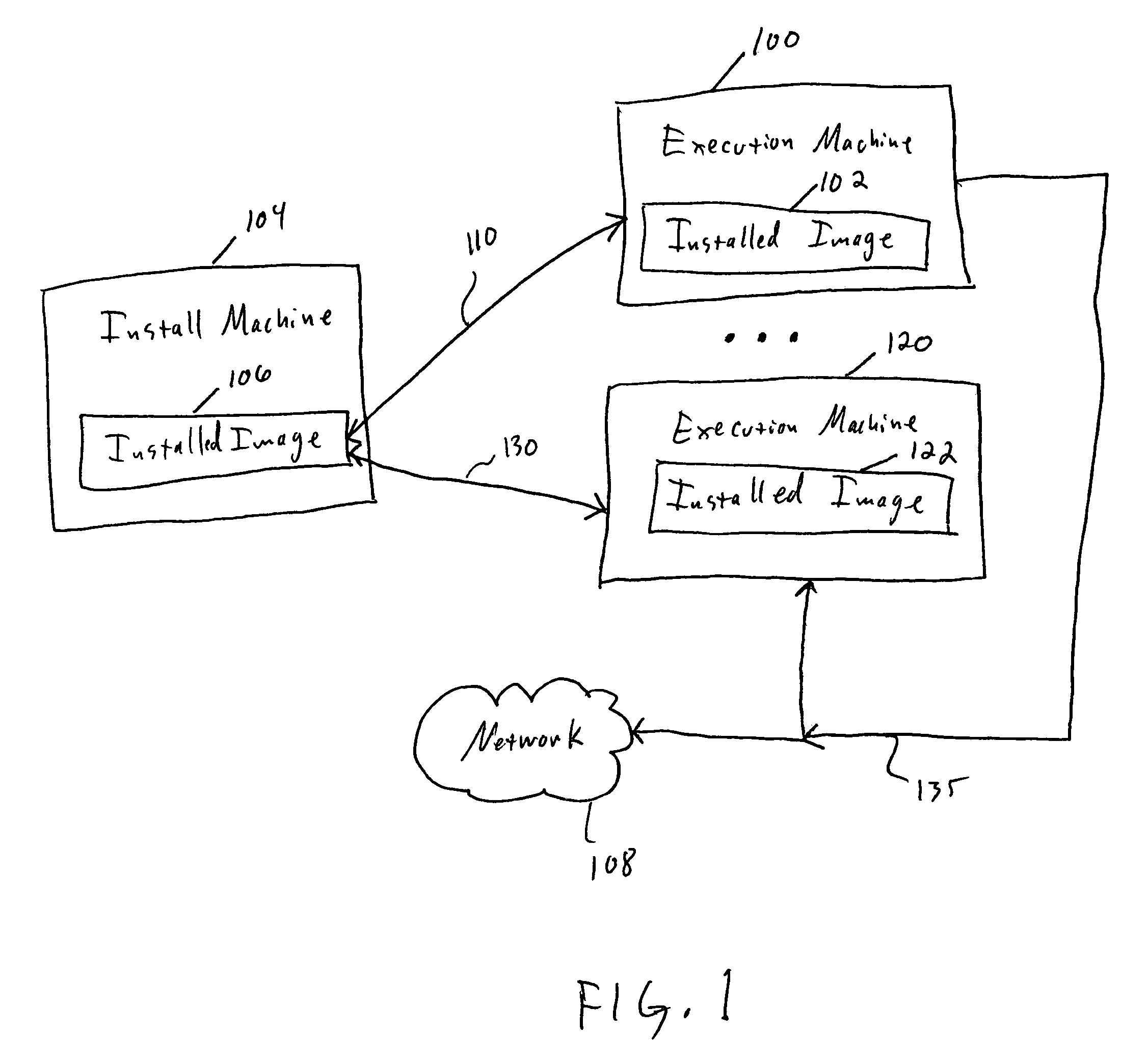

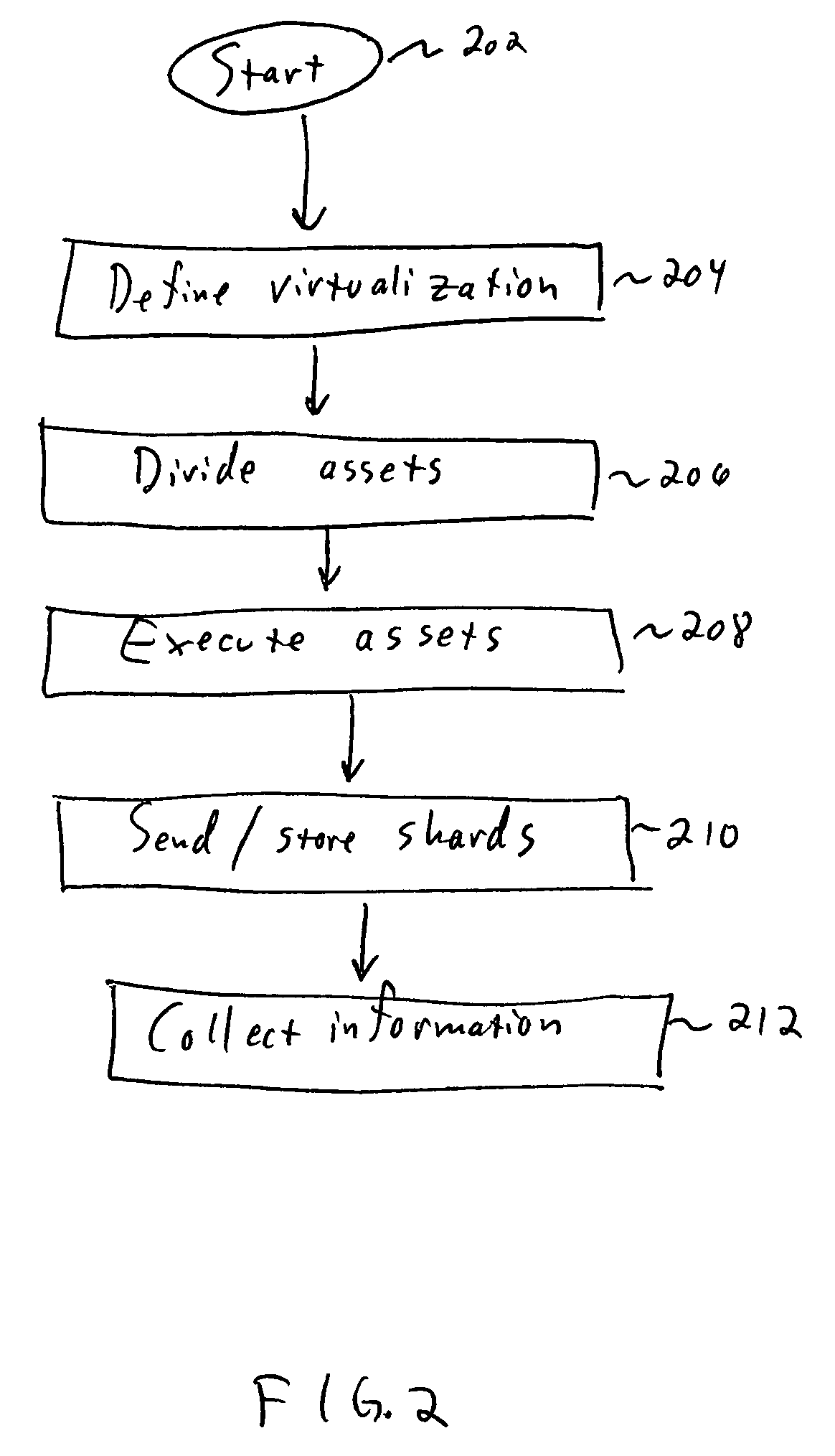

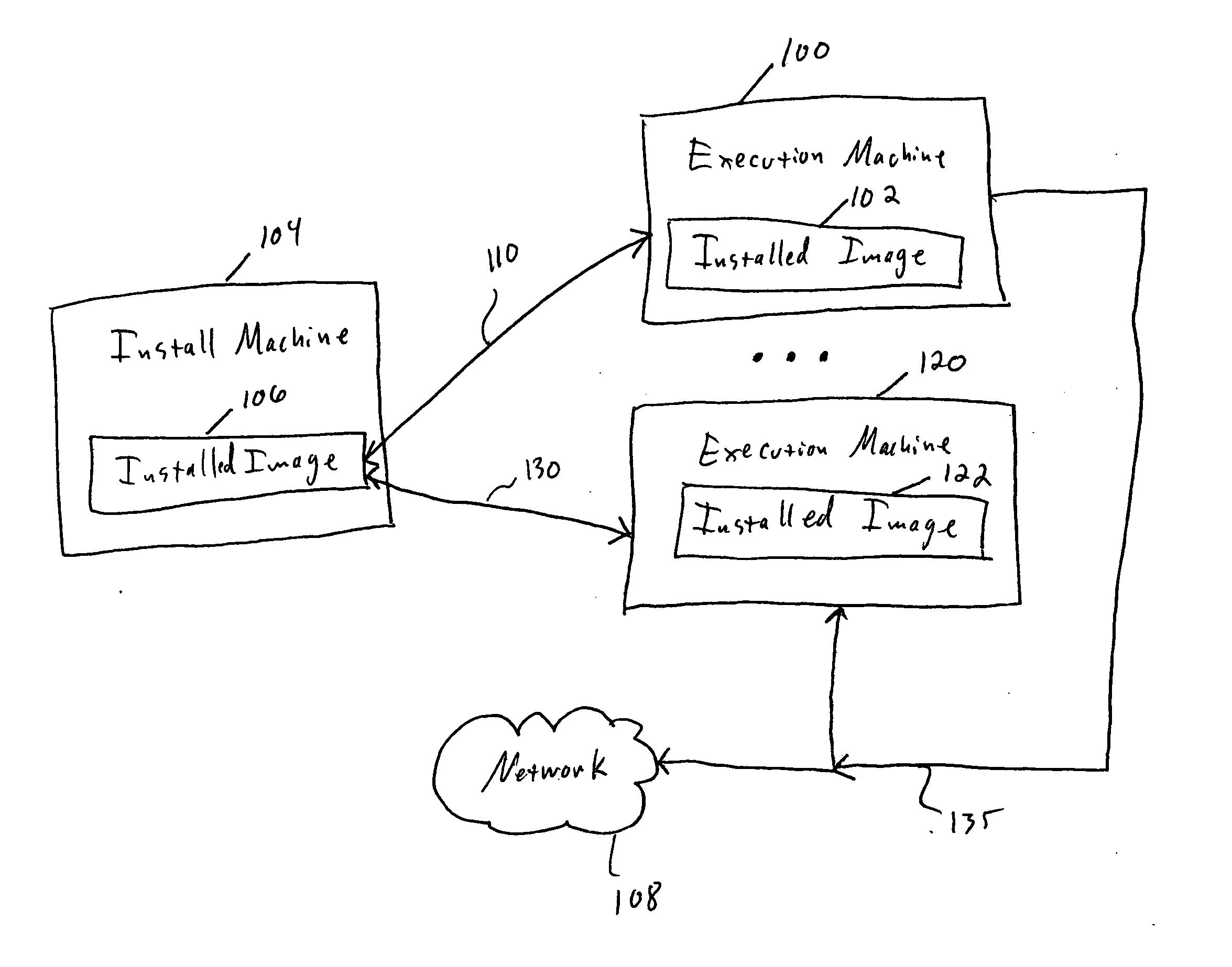

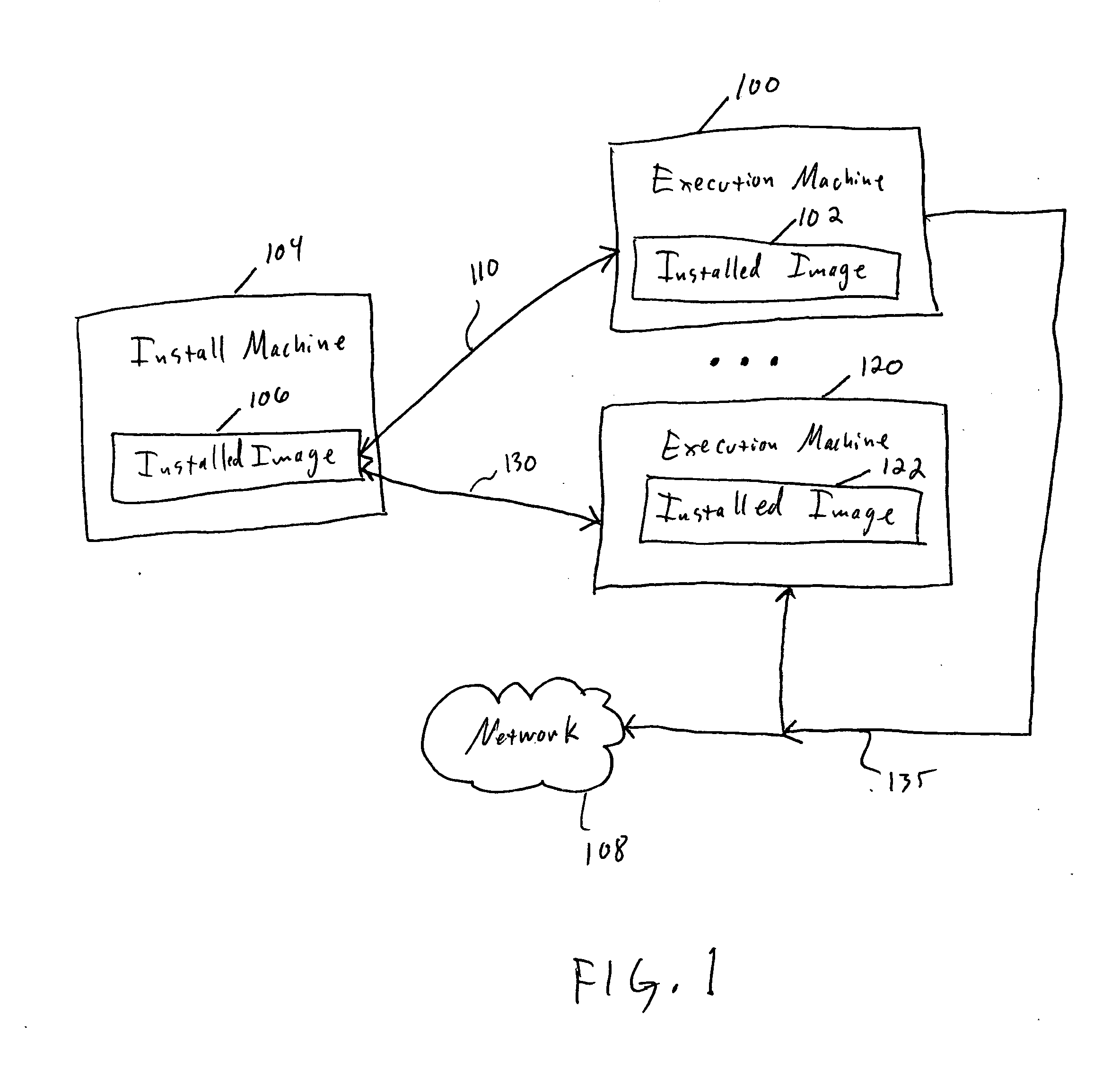

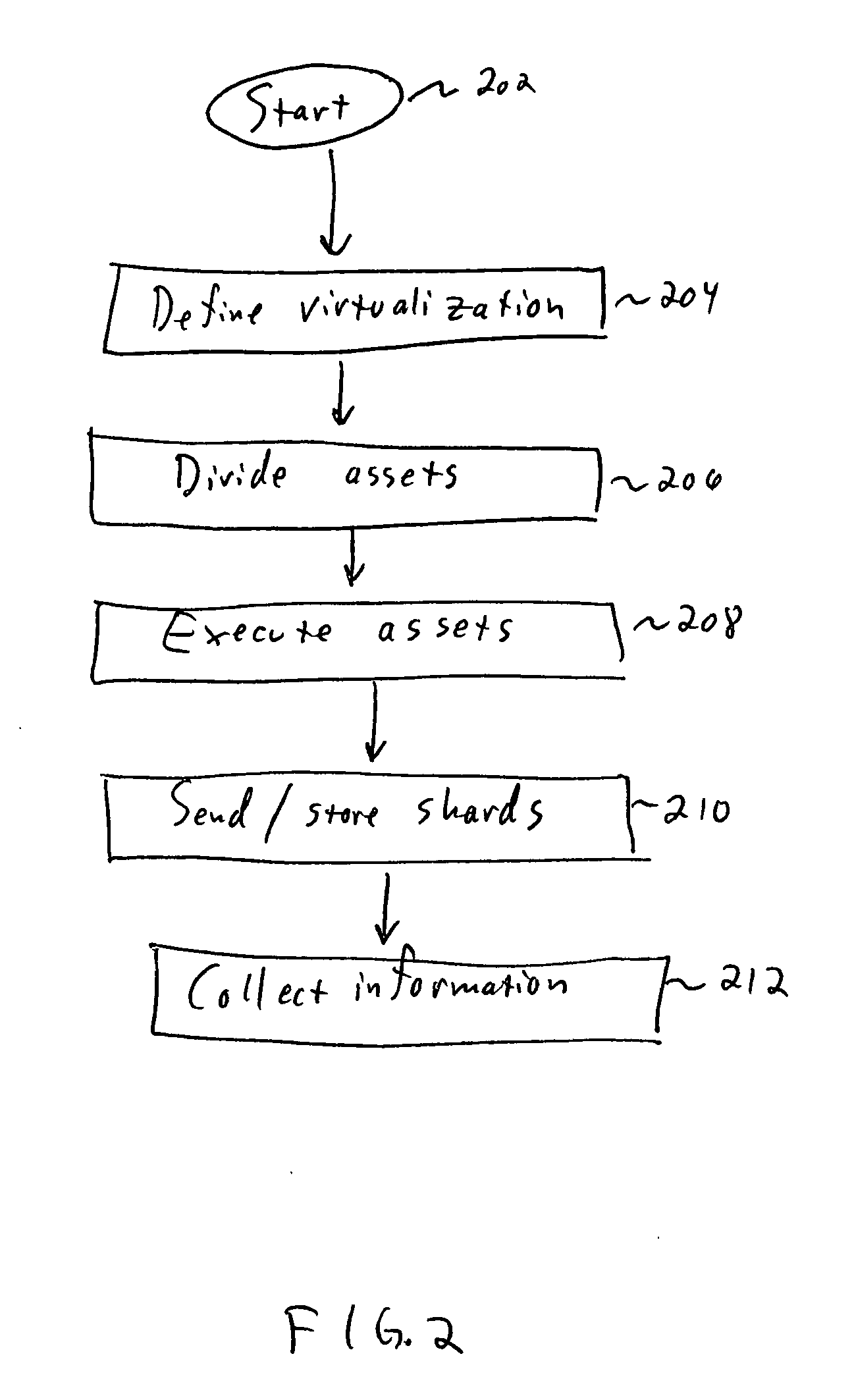

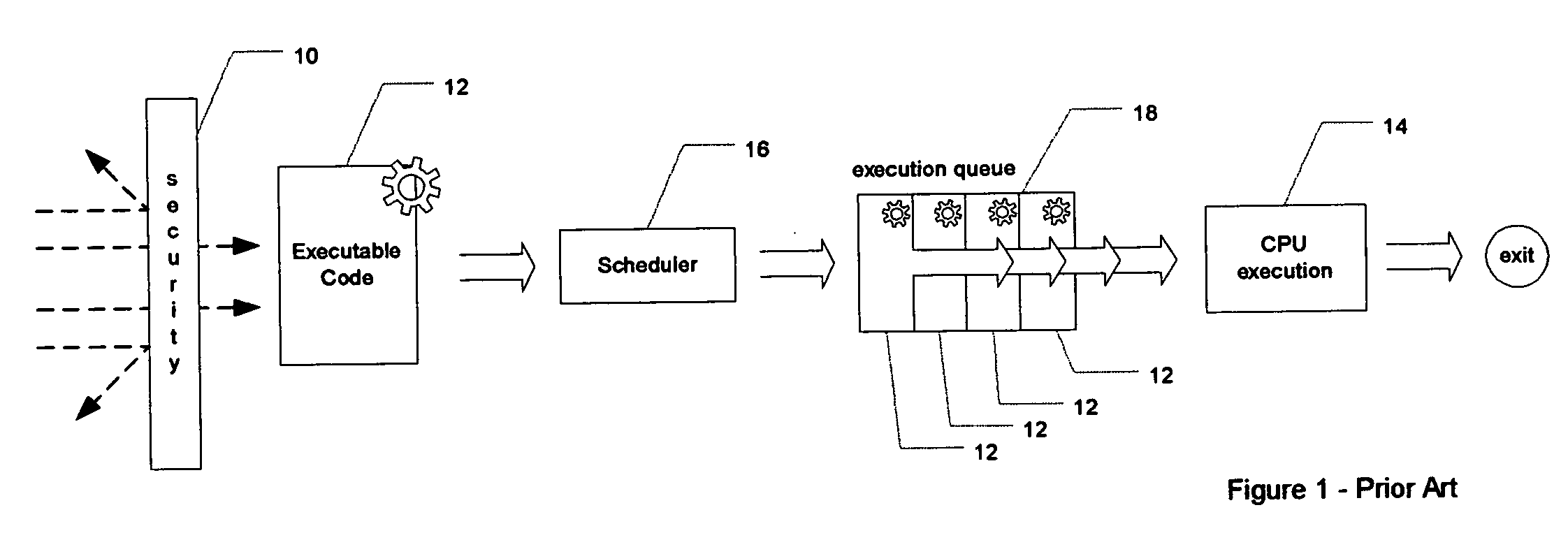

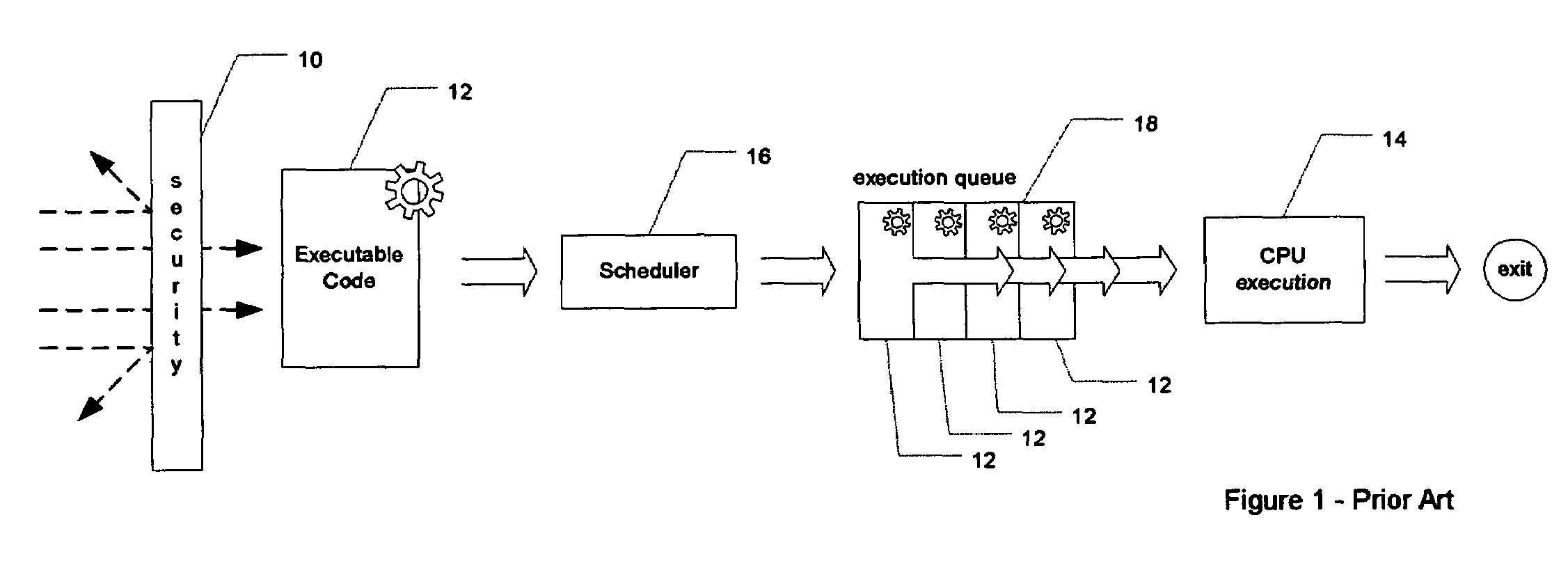

Method and apparatus for simplifying the deployment and serviceability of commercial software environments

InactiveUS7506338B2Component can be removedEliminate redundancyDigital data processing detailsUnauthorized memory use protectionComputer hardwareMaintainability

Owner:INT BUSINESS MASCH CORP

Method and apparatus for simplifying the deployment and serviceability of commercial software environments

InactiveUS20060047974A1Component can be removedEliminate redundancyDigital data processing detailsUser identity/authority verificationComputer hardwareCommercial software

Owner:IBM CORP

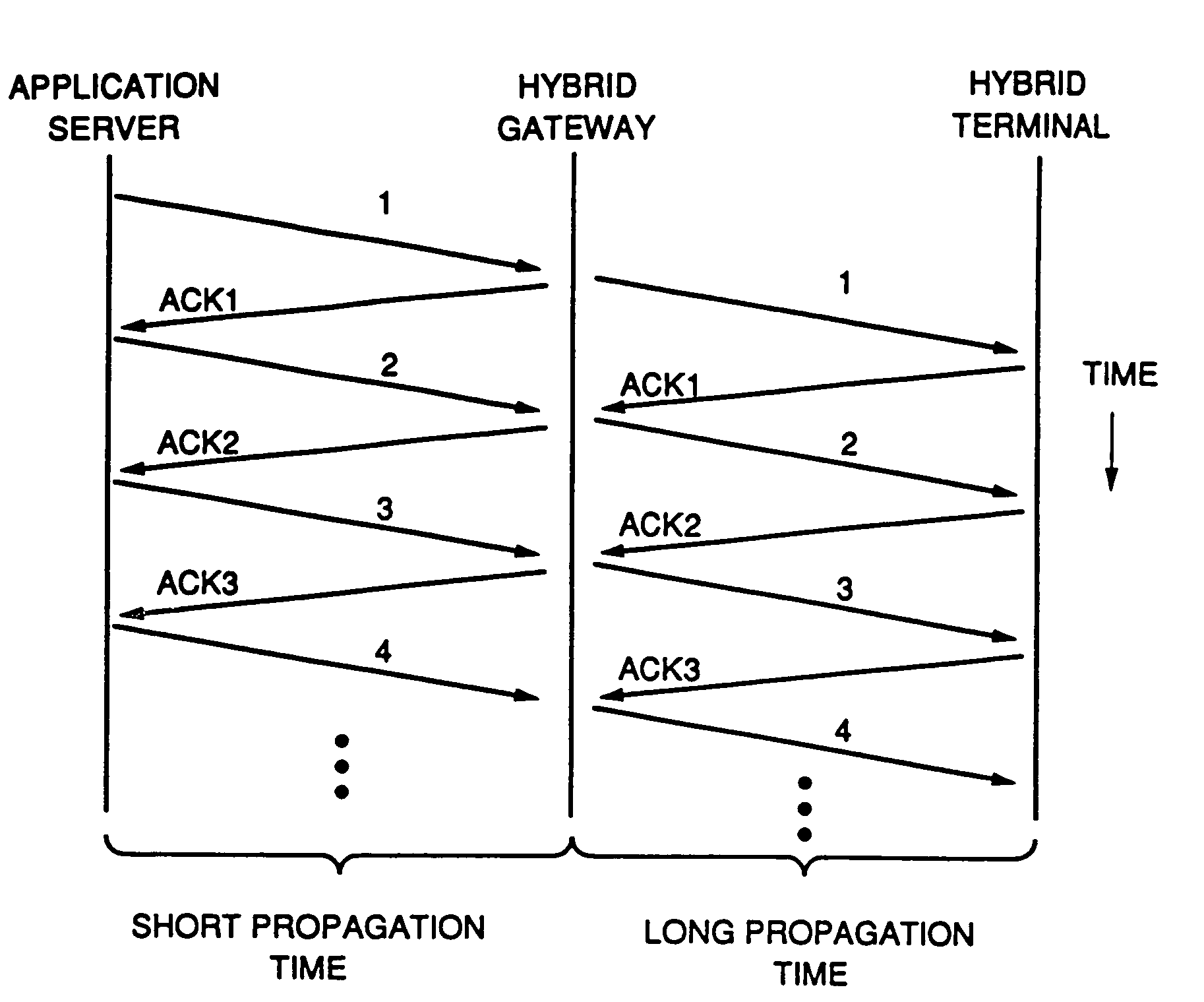

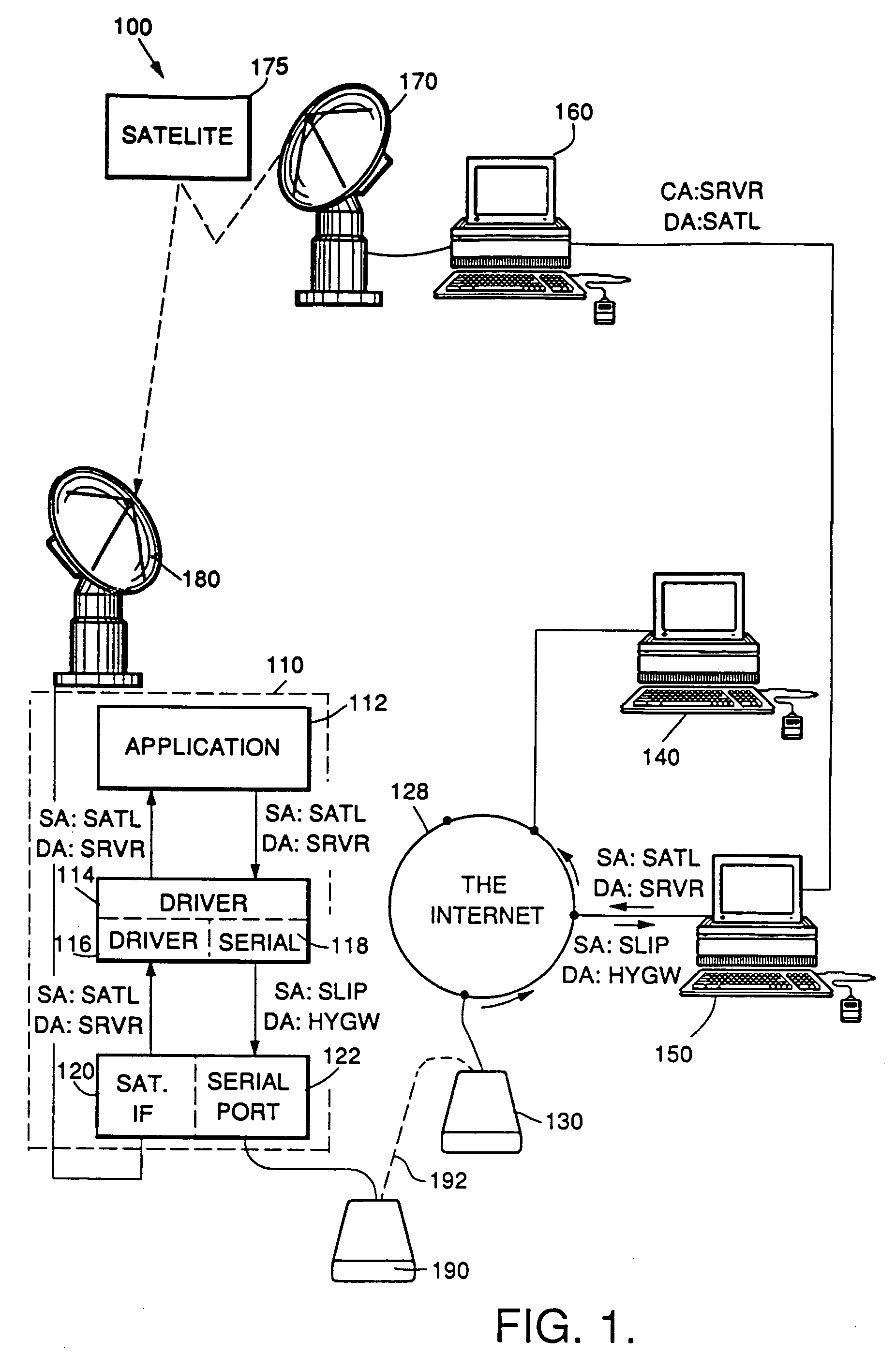

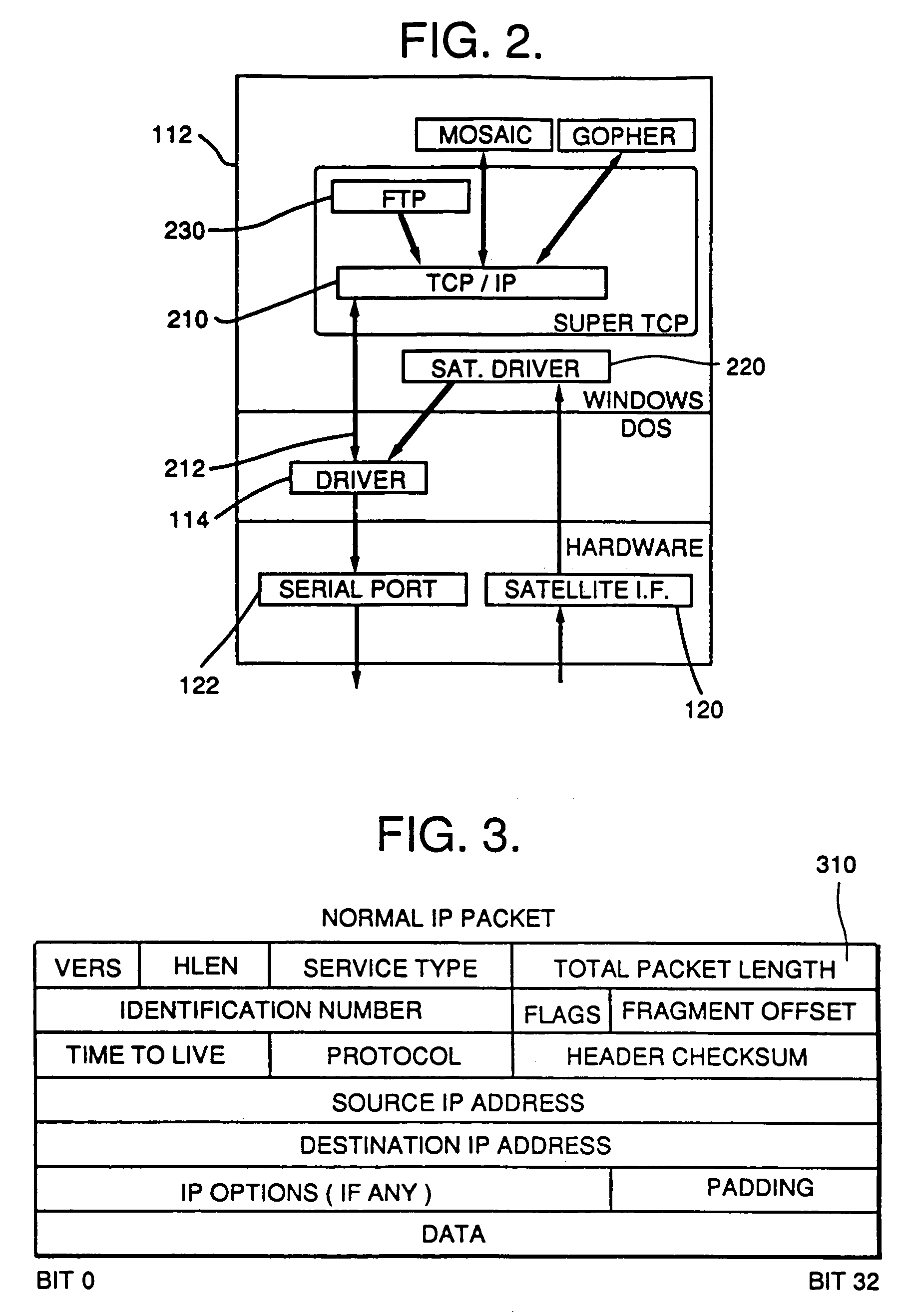

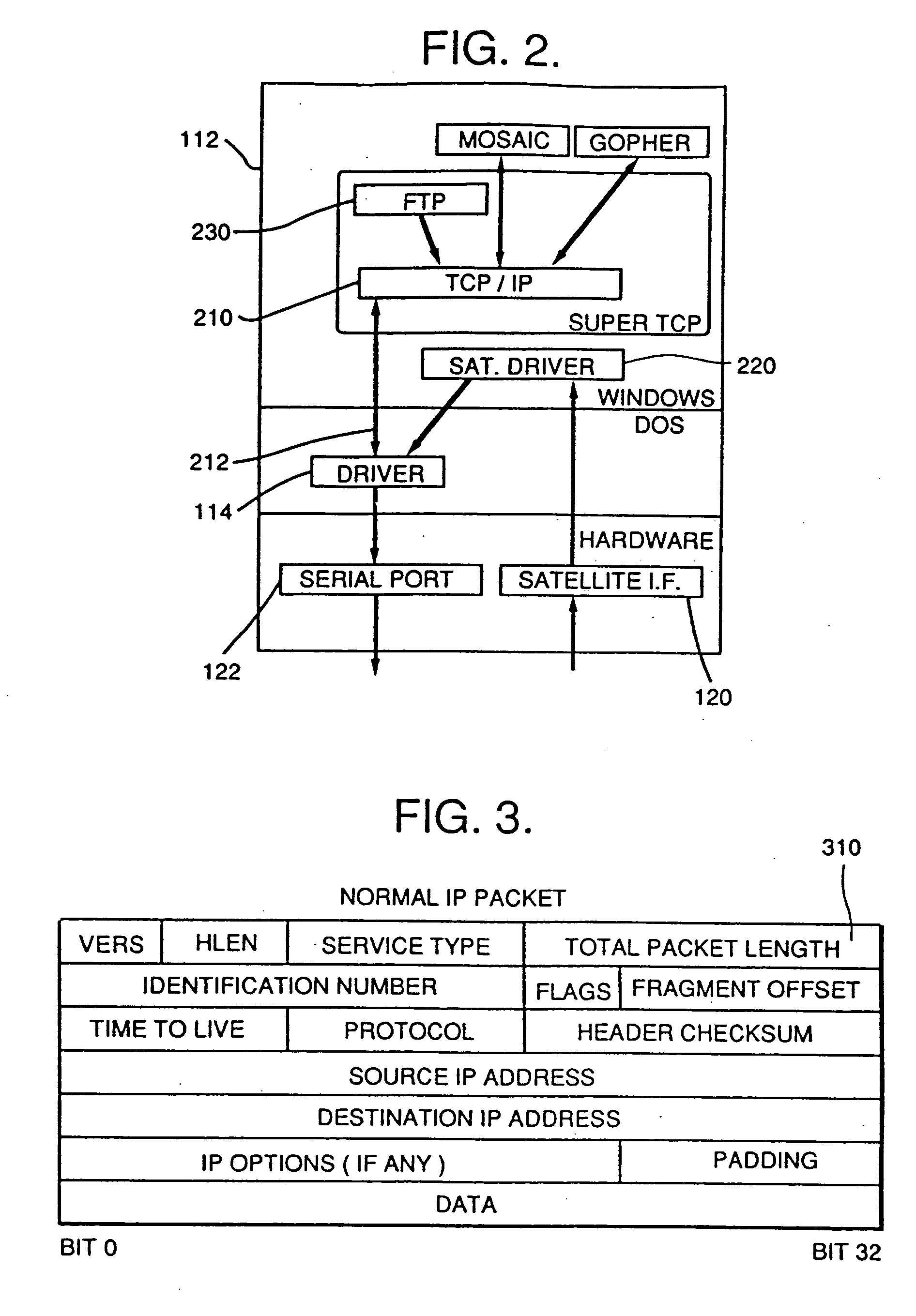

Network system with TCP/IP protocol spoofing

InactiveUS7337233B2Multiple digital computer combinationsRadio transmissionPropagation delayCommercial software

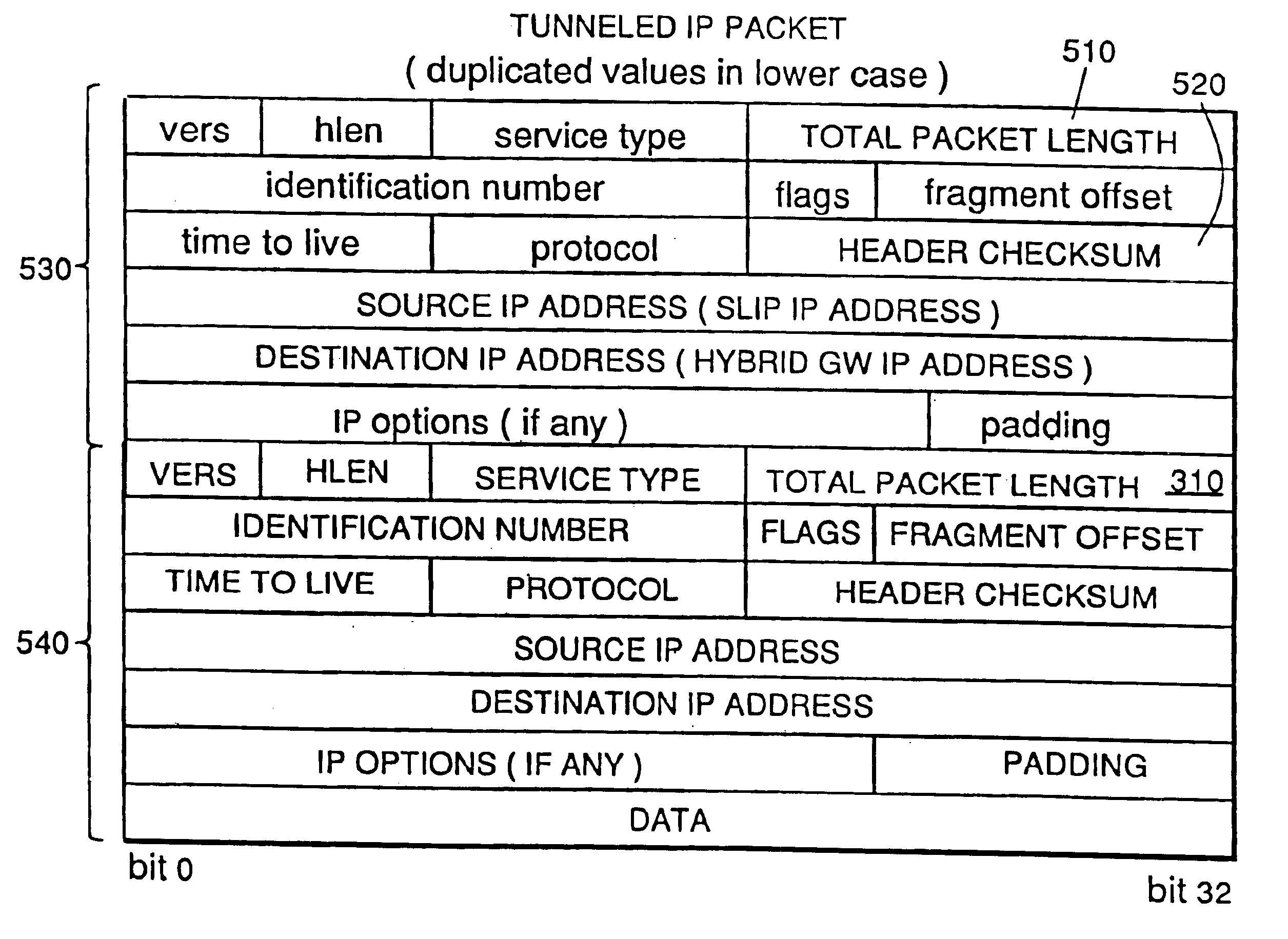

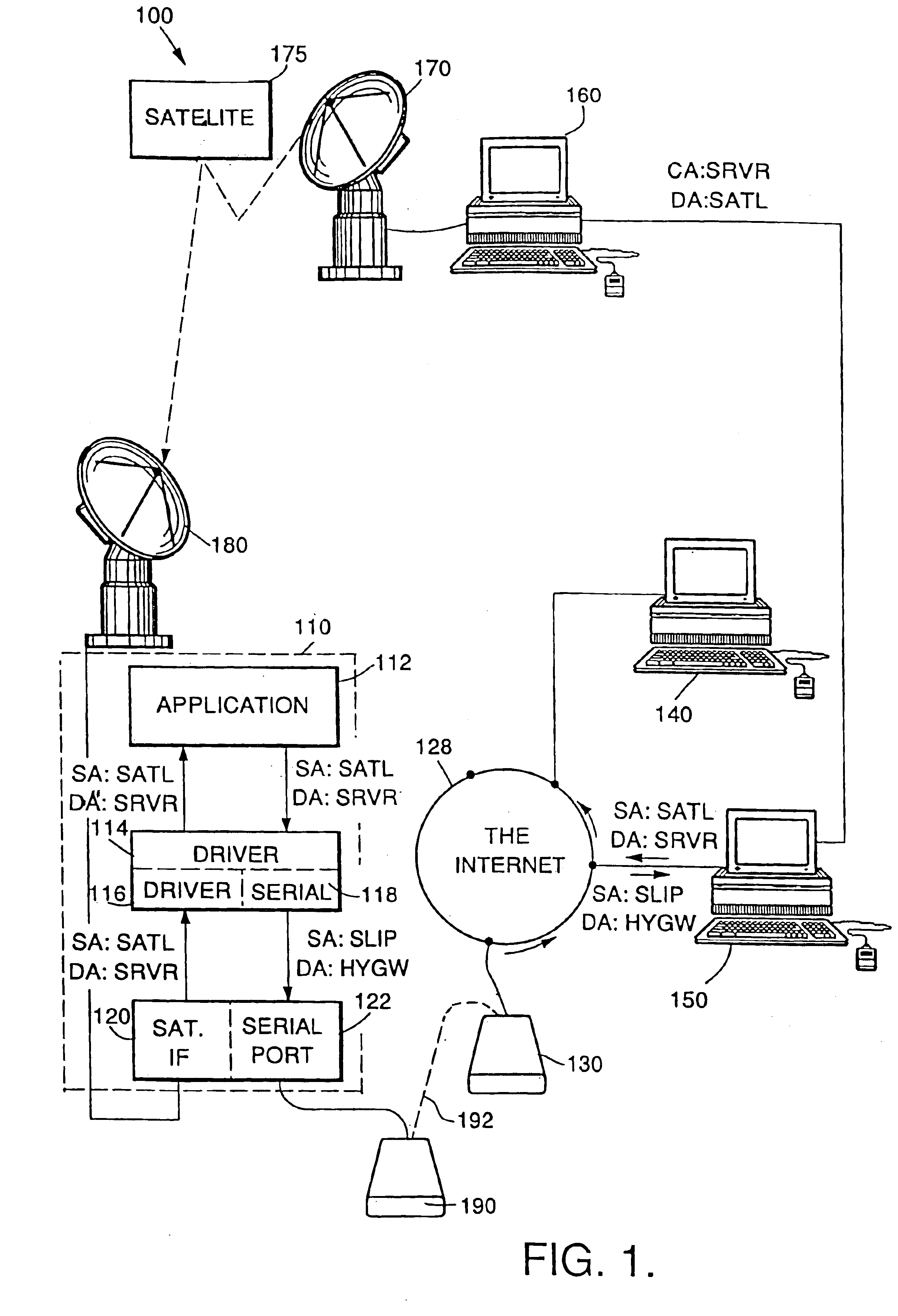

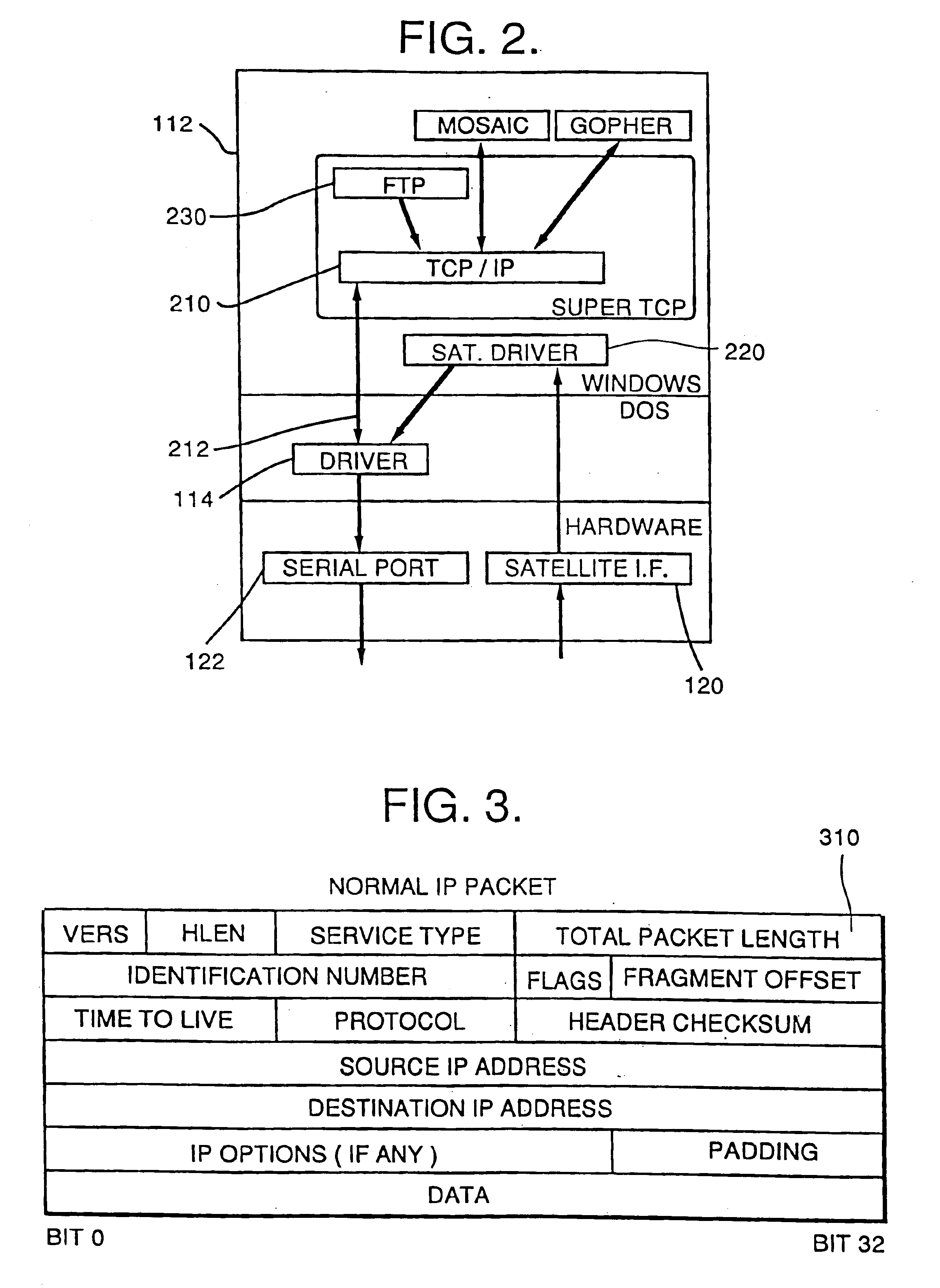

A system in which a personal computer sends messages into a TCP / IP network using a conventional dial-up link and downloads data from the TCP / IP network using a high-speed one-way satellite link. A preferred embodiment uses a conventional SLIP provider to connect to the TCP / IP network and uses a commercial software TCP / IP package that has a standard driver interface. A spoofing protocol compensates for the long propagation delays inherent to satellite communication.

Owner:HUGHES NETWORK SYST

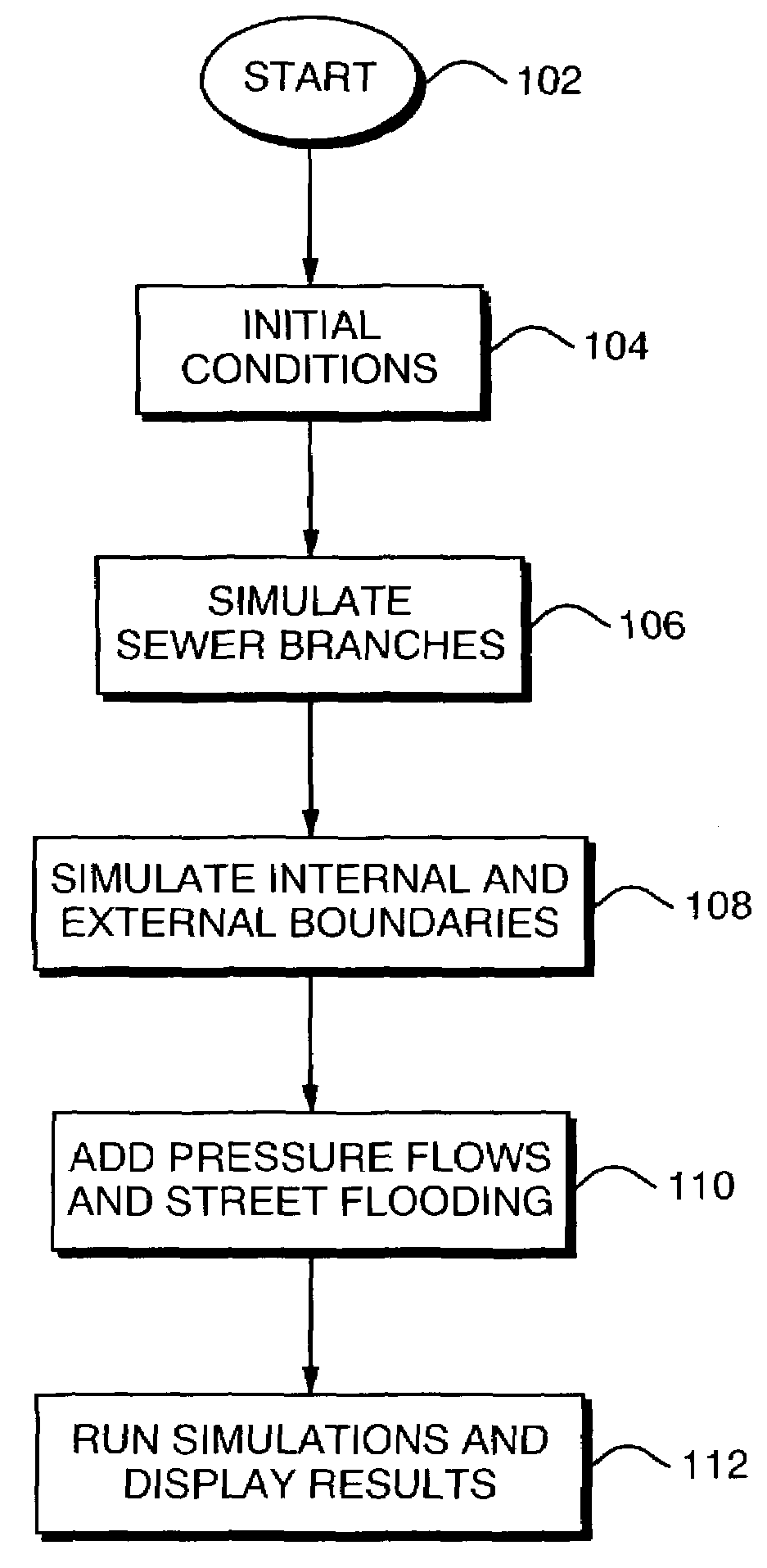

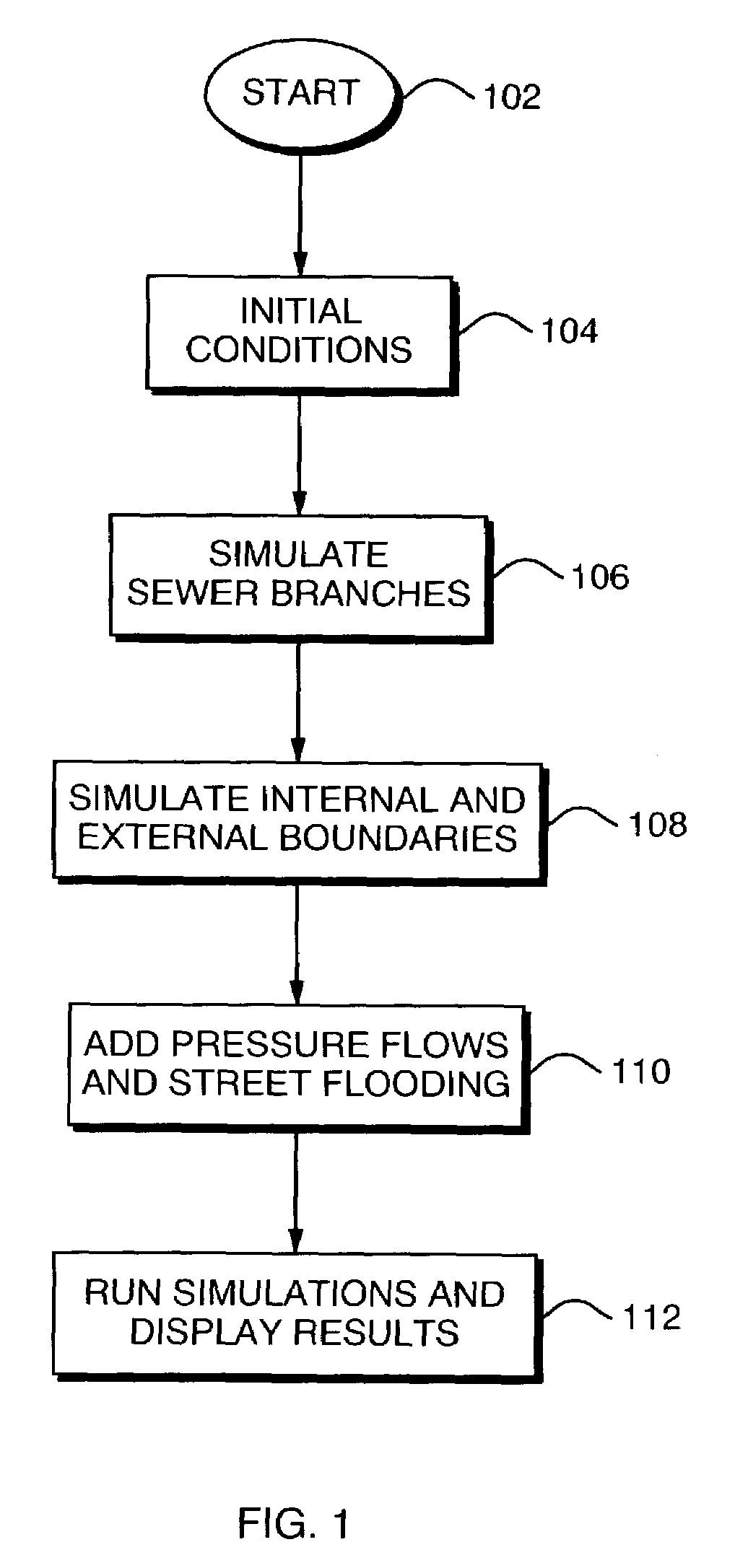

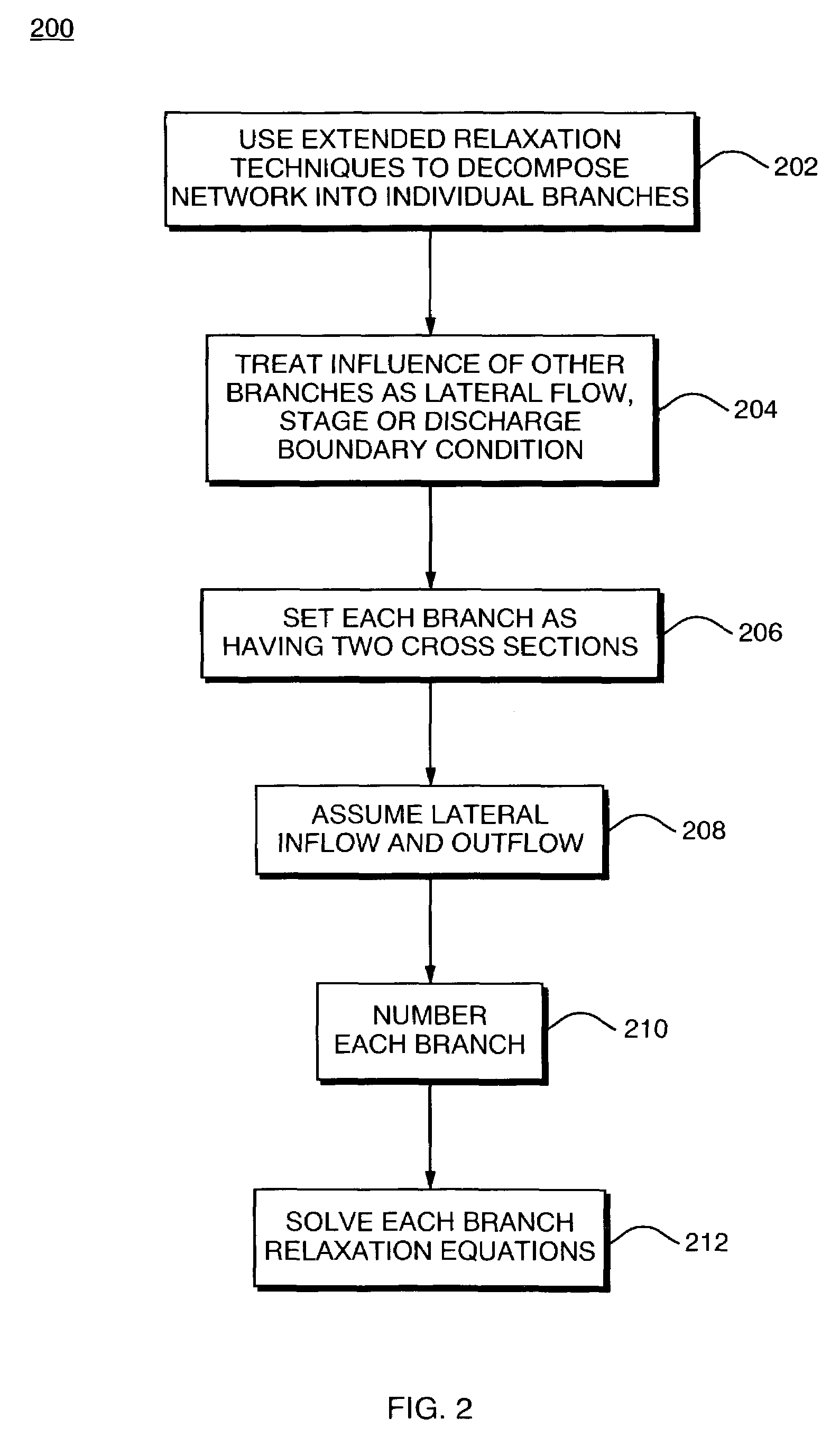

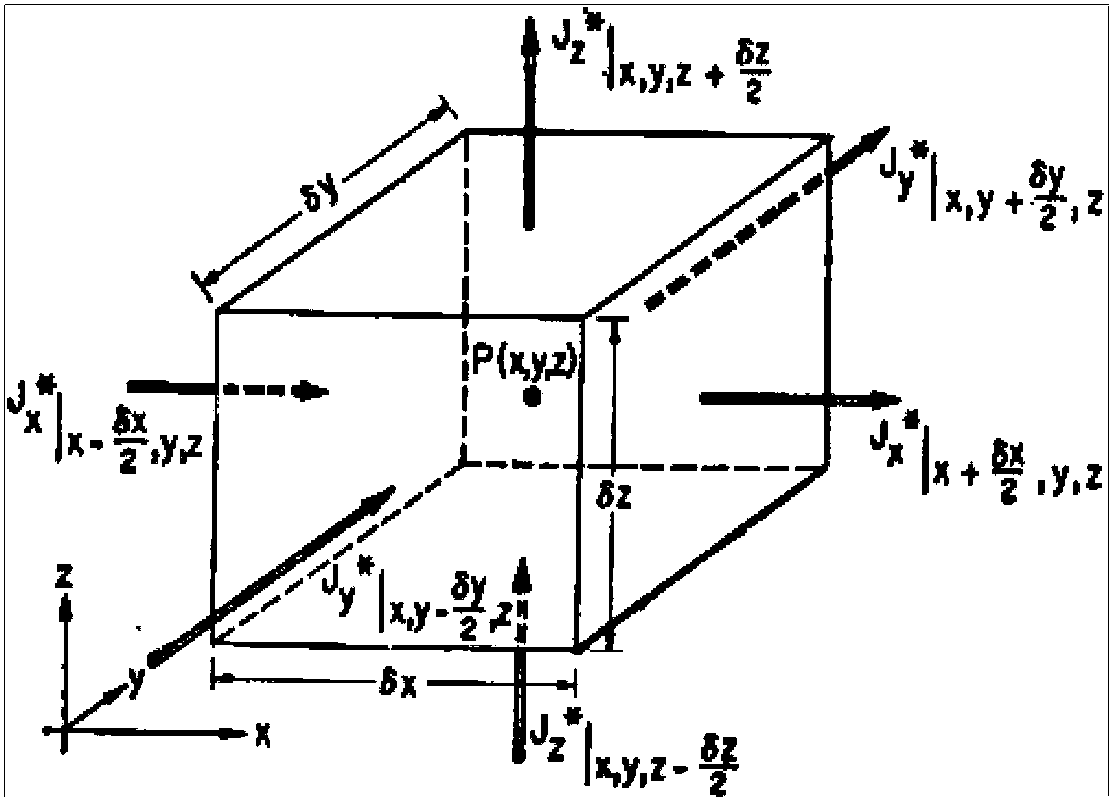

Method and system for developing a numerical dynamic sanitary sewer and storm water drainage simulation model

ActiveUS7039565B1Geometric CADComputation using non-contact making devicesSoftware systemCommercial software

An hydraulics software system for a one-dimensional hydrodynamic numerical model for modeling unsteady flows in sewer and storm water urban drainage systems is provided. The inventive software uses as a numerical model, an implicit four-point, finite-difference solution technique to solve the one-dimensional Saint-Venant equations. The software is designed to select that numerical model, or equation that best describes, or best exhibits the behavior of each of the various structures and flows encountered in complex hydrodynamic systems such as a sewer and storm water drainage systems. Local partial initial modification for subcritical and supercritical transcritical flows is provided. Relaxation for pipe / channel networks are included for achieving computational performance and robustness for commercial software for practical use in water resource engineering.

Owner:BENTLEY SYST INC

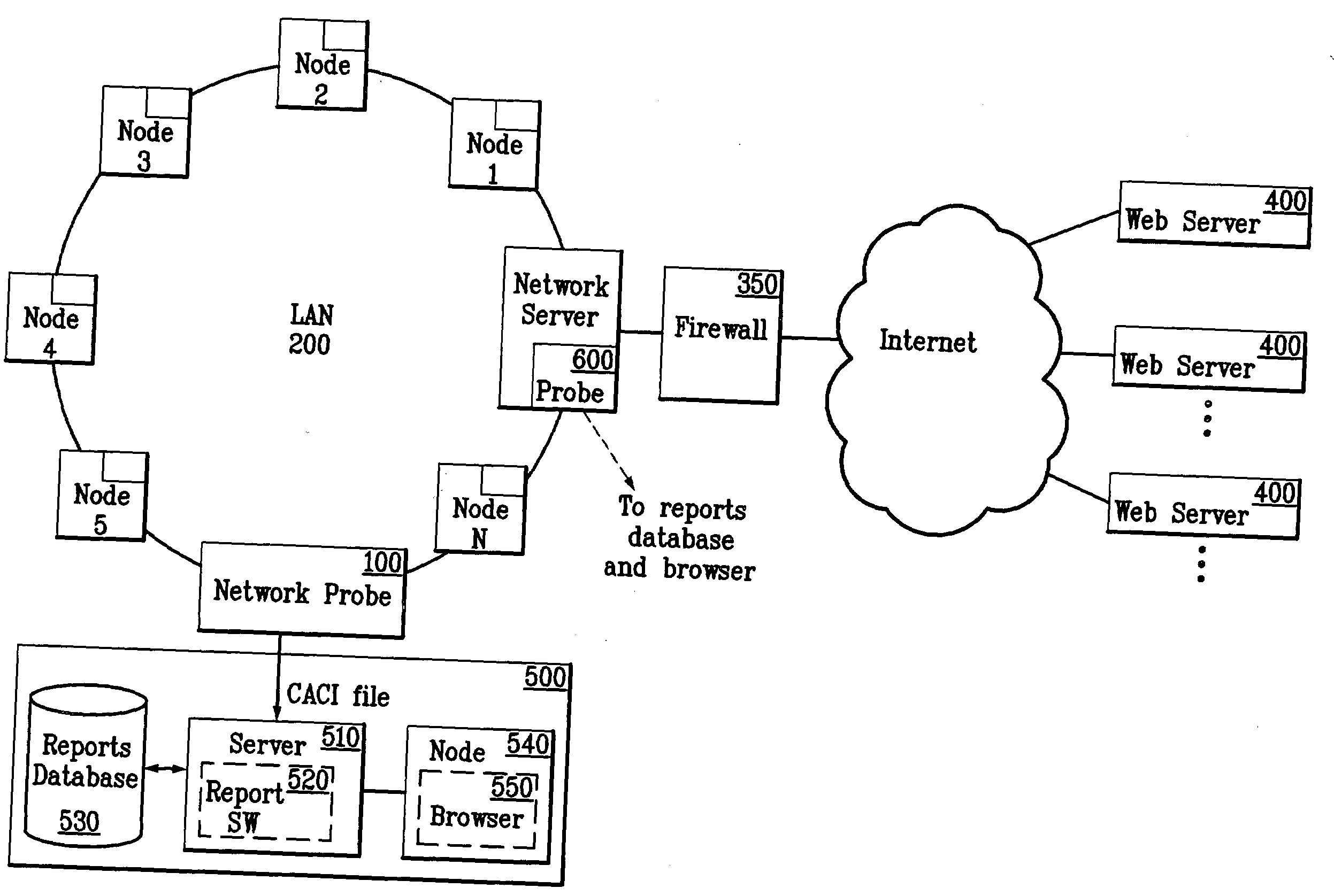

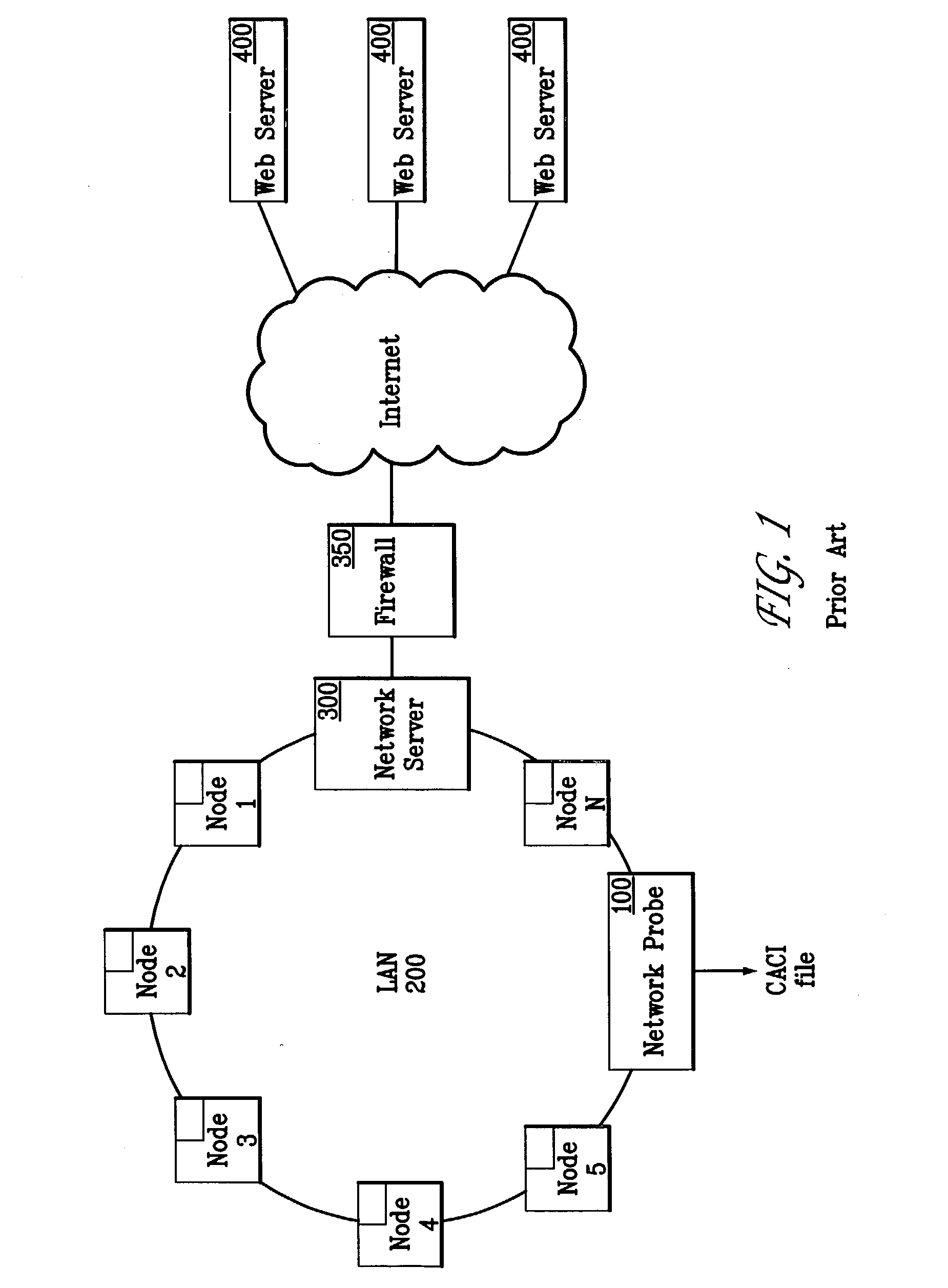

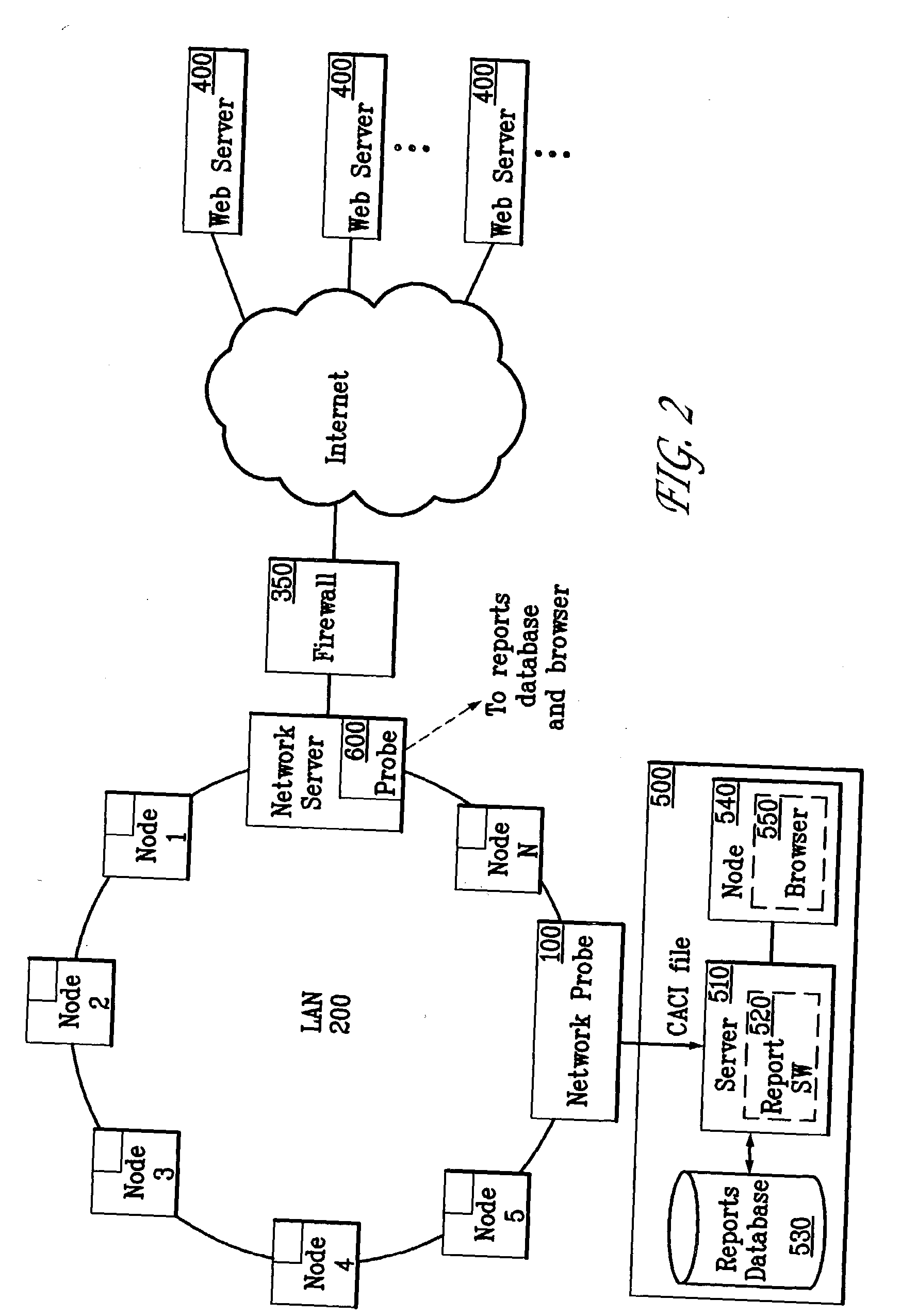

Internet traffic tracking and reporting system

InactiveUS20040073533A1Digital data processing detailsWebsite content managementTraffic capacityInternet traffic

A reporting system and method that works with conventional network management systems to provide long term tracking capability for all network conversations with data provided by, e.g., a company owned commercial software system. The conventional network management system gathers the data frames and a data file is exported after a collection of network conversations that contains only the information needed for reporting. Such information may include, e.g., times, dates, computer addresses, and counters. This data is captured by the reporting system of the invention, filtered, normalized, and stored in a database in such a fashion that unique searches may be applied to the stored data to provide the network administrator with detailed information concerning the usage of the data by particular individuals, the usage of certain data ports, and how much traffic to a specific site on the Internet is generated by network users.

Owner:J&J CONSUMER

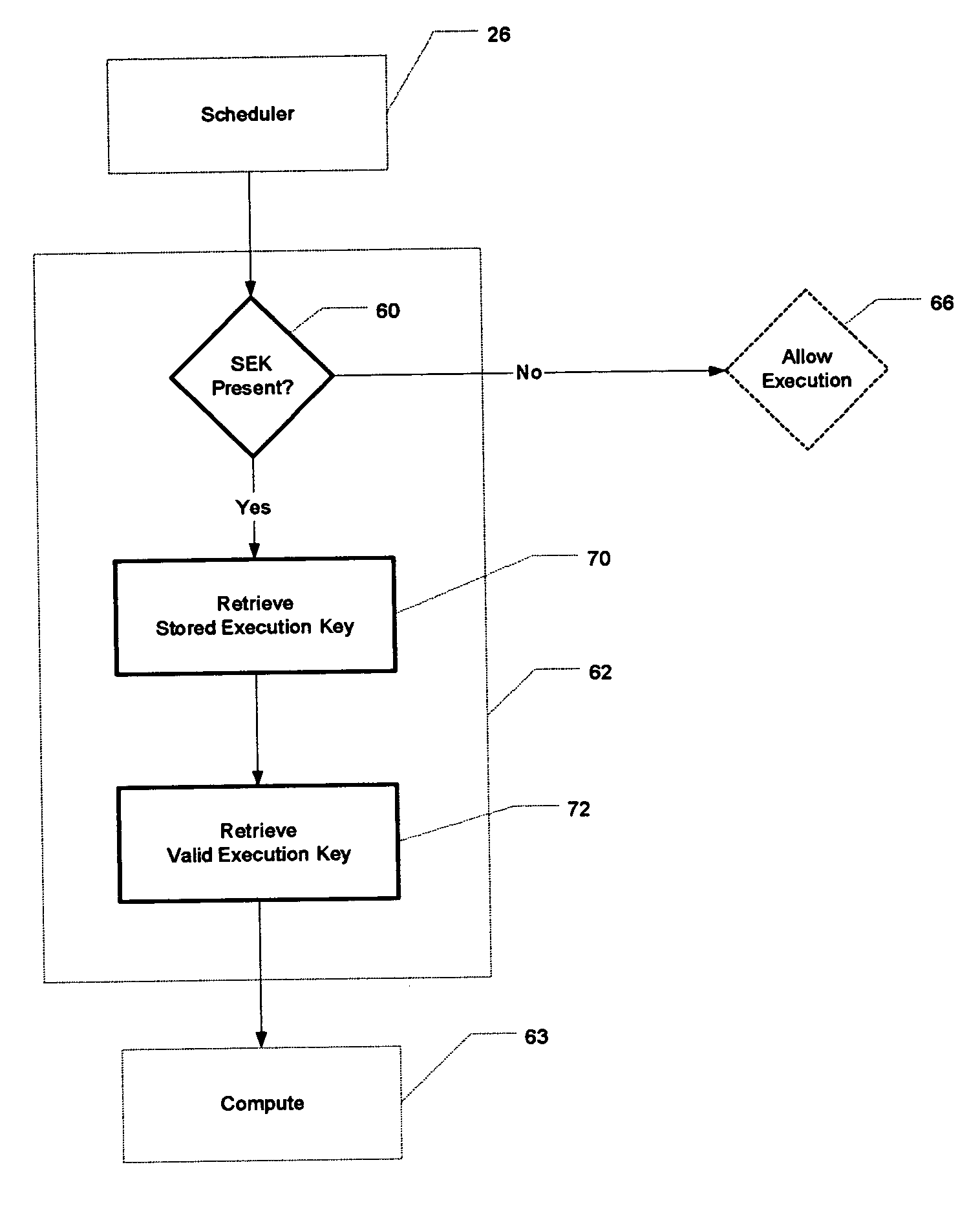

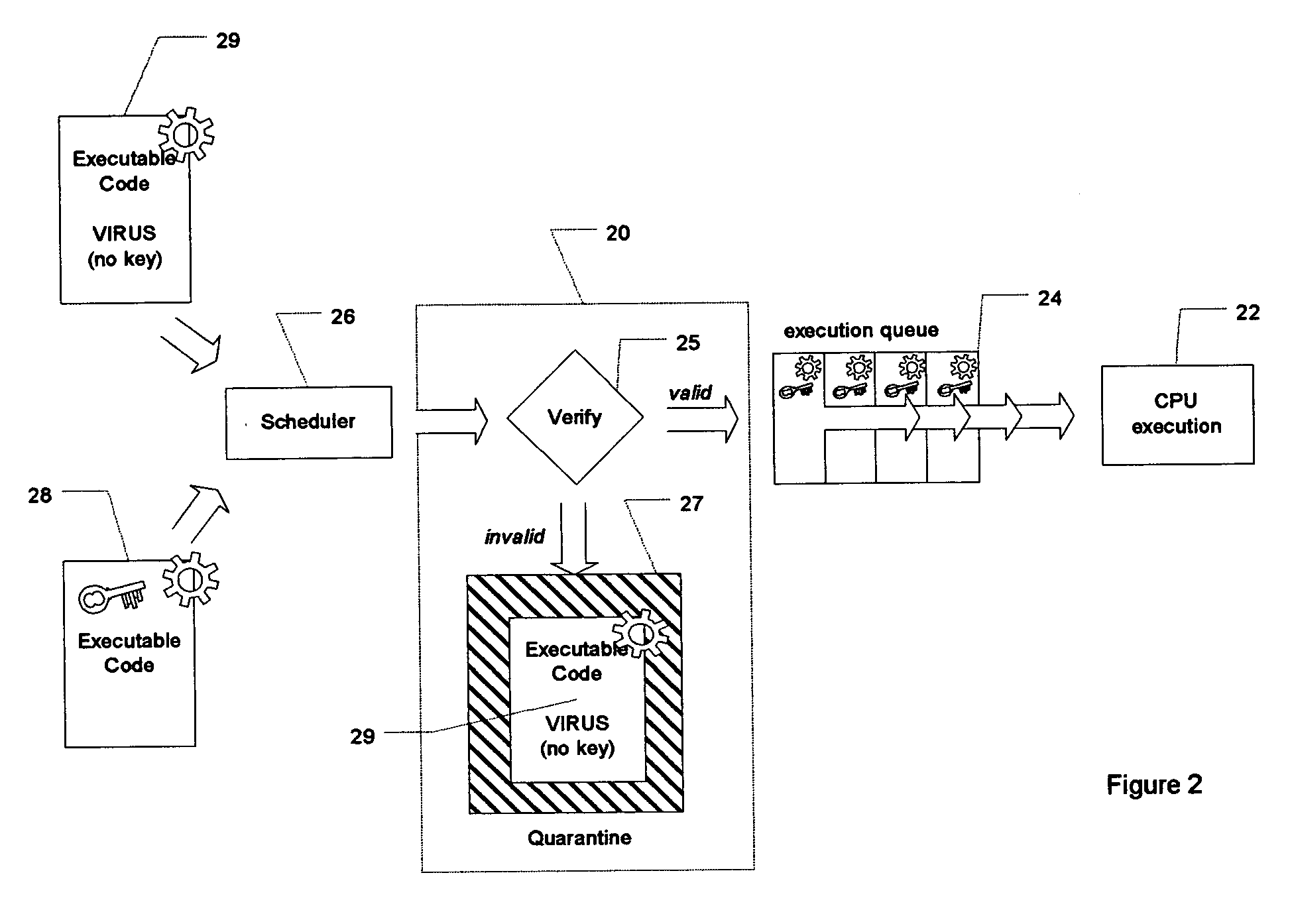

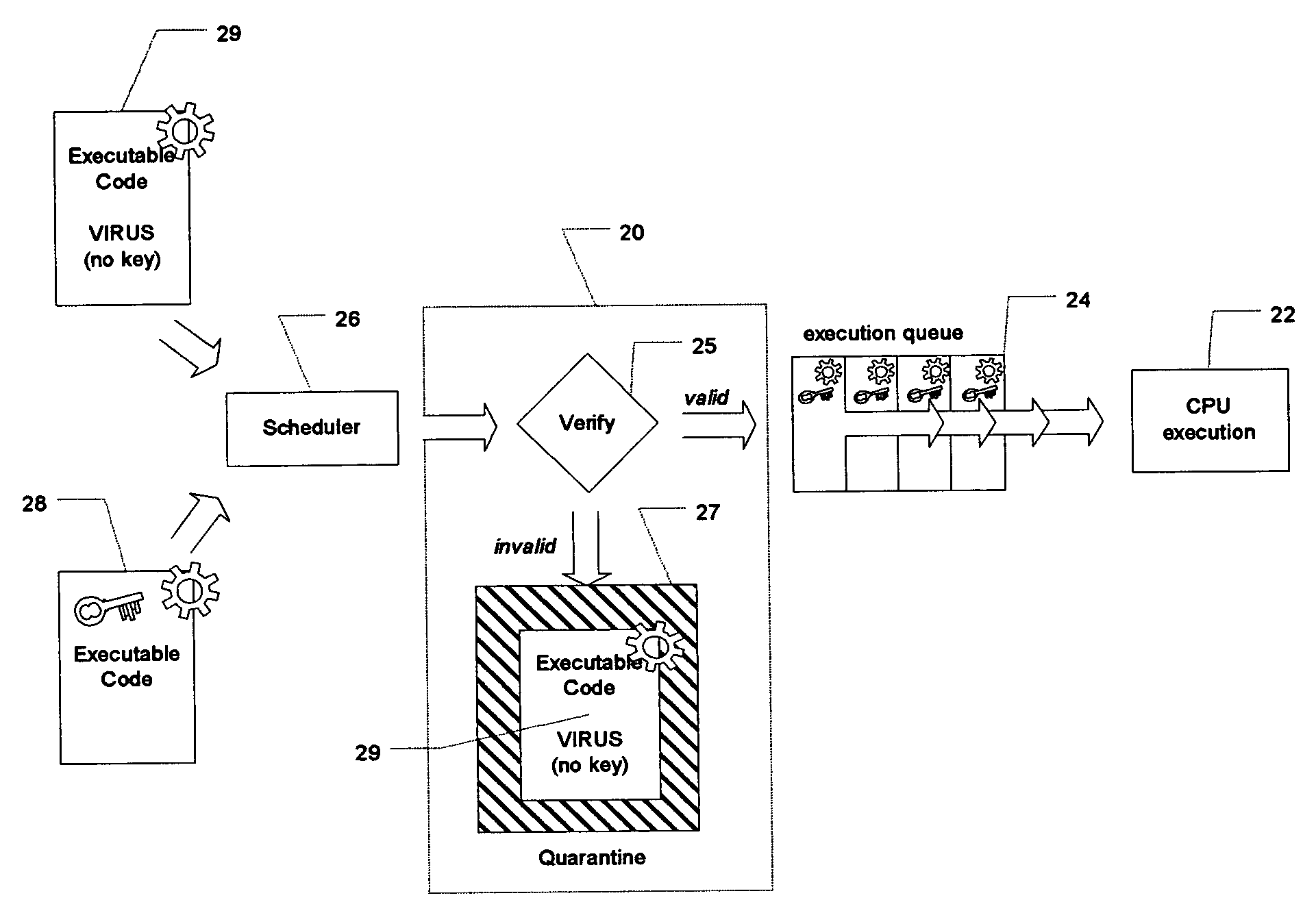

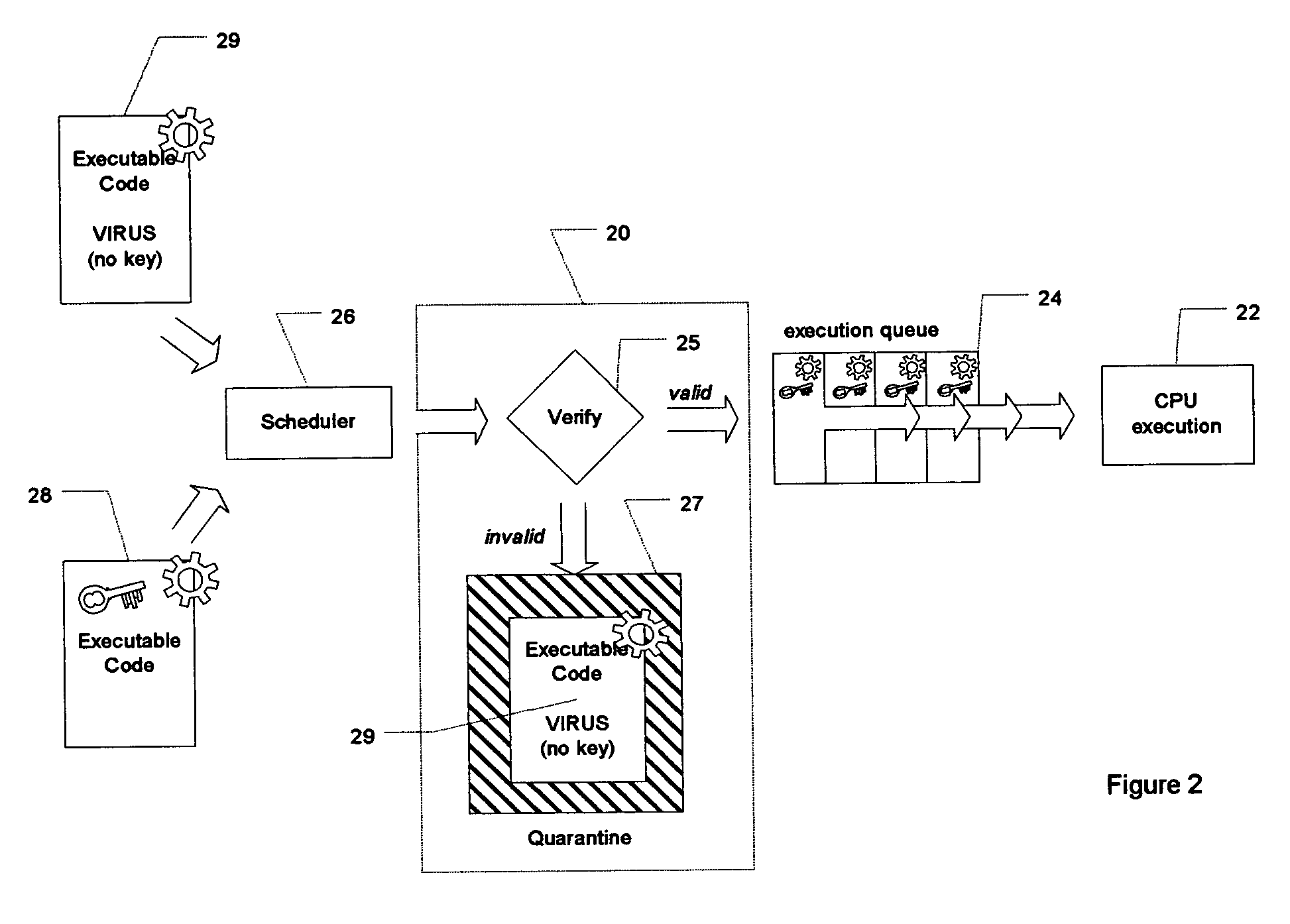

Pre-emptive anti-virus protection of computing systems

ActiveUS20060031937A1Reduce problem sizeImprove efficiencyMemory loss protectionDigital data processing detailsAnti virusOperational system

A system is provided that strongly inhibits infection and spread of computer viruses. Valid executable software files and supporting files, even files provided by mass-released commercial software, are associated with a numeric key that is unique to each individual computer running the software. For a file to be processed by the central processing unit (CPU) of the computer, the presence of a valid key must first be verified. Every valid executable file, including files relating to the operating system and application layer code, is provided with a unique key. Thus, viruses that attempt to gain access to the CPU to perform unauthorized actions, including replication, are prevented due to lack of a valid execution key. Execution keys are generated locally on each individual computer using a variety of methods. Execution keys can be regenerated if the security of a computer system has been compromised, or appears to have been compromised.

Owner:DIGITAL GUARDIAN LLC

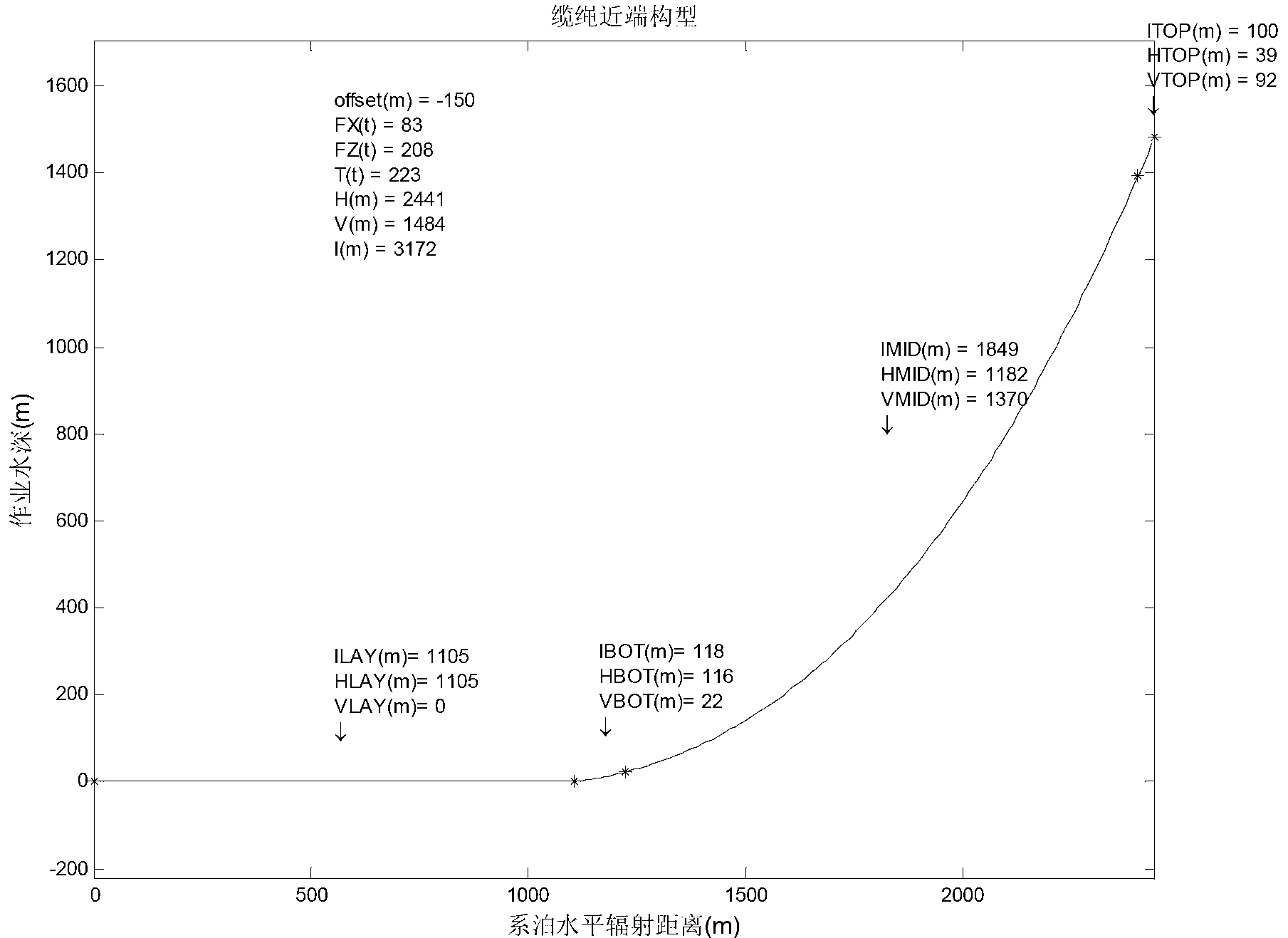

Structural design optimization method for deepwater catenary mooring rope

ActiveCN103295078AExcellent level of recovery characteristicsRealize optimal selectionForecastingMooring systemMarine engineering

The invention relates to a structural design optimization method for a deepwater catenary mooring rope. The method aims at an 'anchor chain-steel rope-anchor chain' three-section combined deepwater catenary mooring rope, structural parameters of length of each section of the rope, top pretension, mooring horizontal radiation distance and the like are determined through iterative computation by giving consideration to specific requirements of design specifications on various indicators under the condition of given rope specifications, operating water depth and allowable limit horizontal offset of a floating body, and accordingly horizontal restoration characteristics of the rope reaches optimum under the condition of controlling total steel consumption and mooring load, and then structure types and stress situations of the rope under different states are computed to bring convenience to type selection of mooring equipment. Compared with existing commercial software such as mooring analysis software MOSES and SESAM, the method has the advantages of oriented design, high practicality, high convergence speed and the like, achieves optimal selection of various design parameters and can be used for preliminary scheme design and performance evaluation of deepwater floating type platform catenary mooring systems.

Owner:CHINA NAT OFFSHORE OIL CORP +1

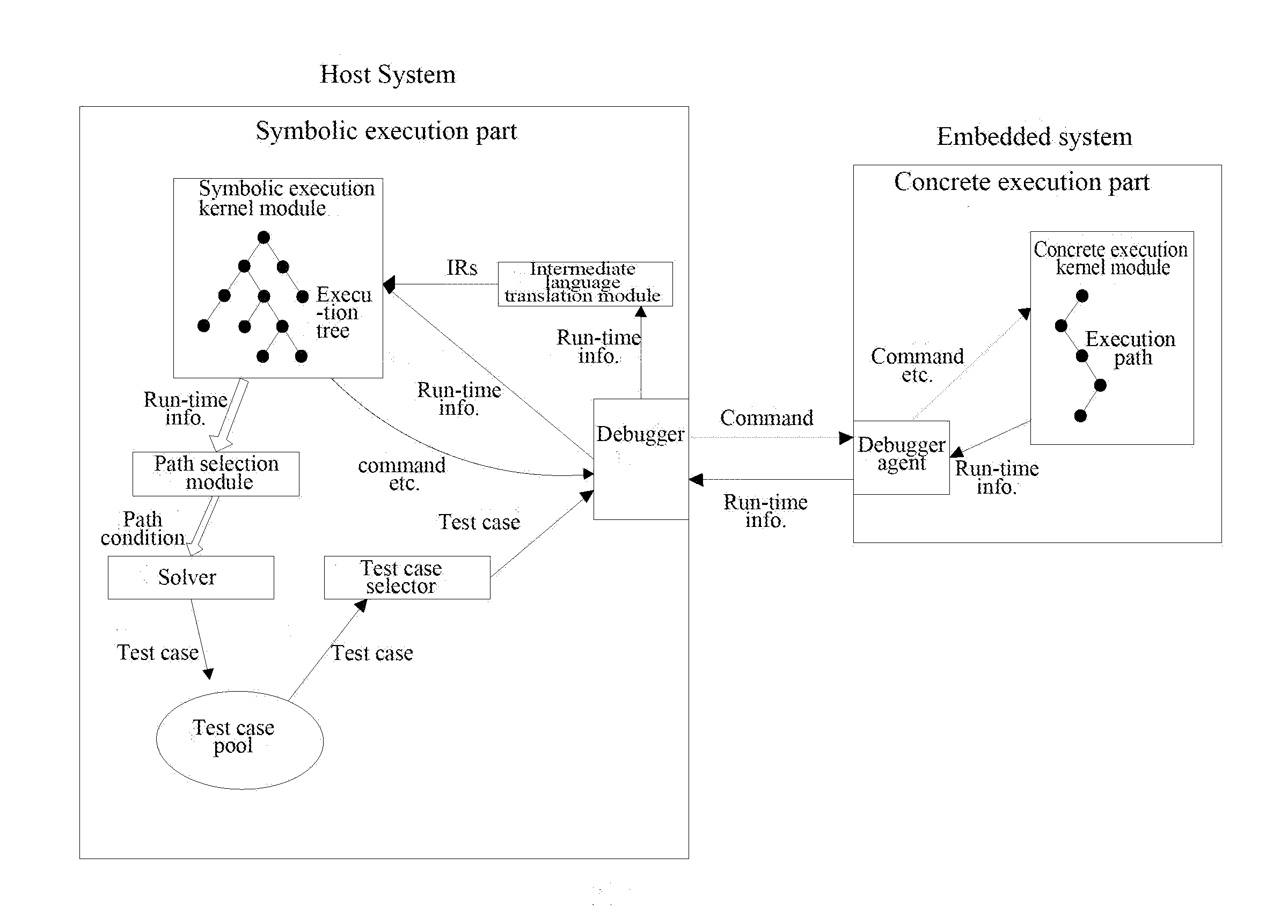

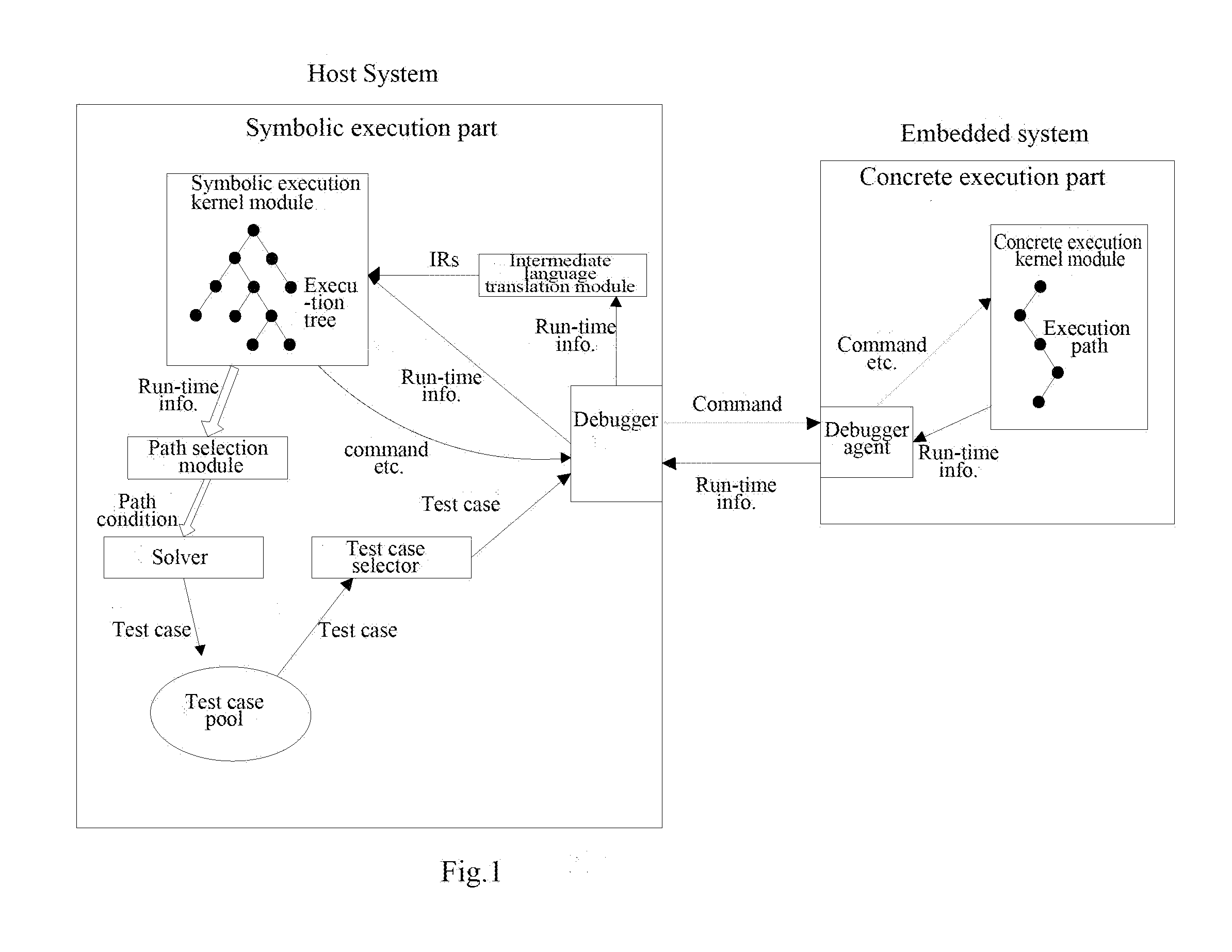

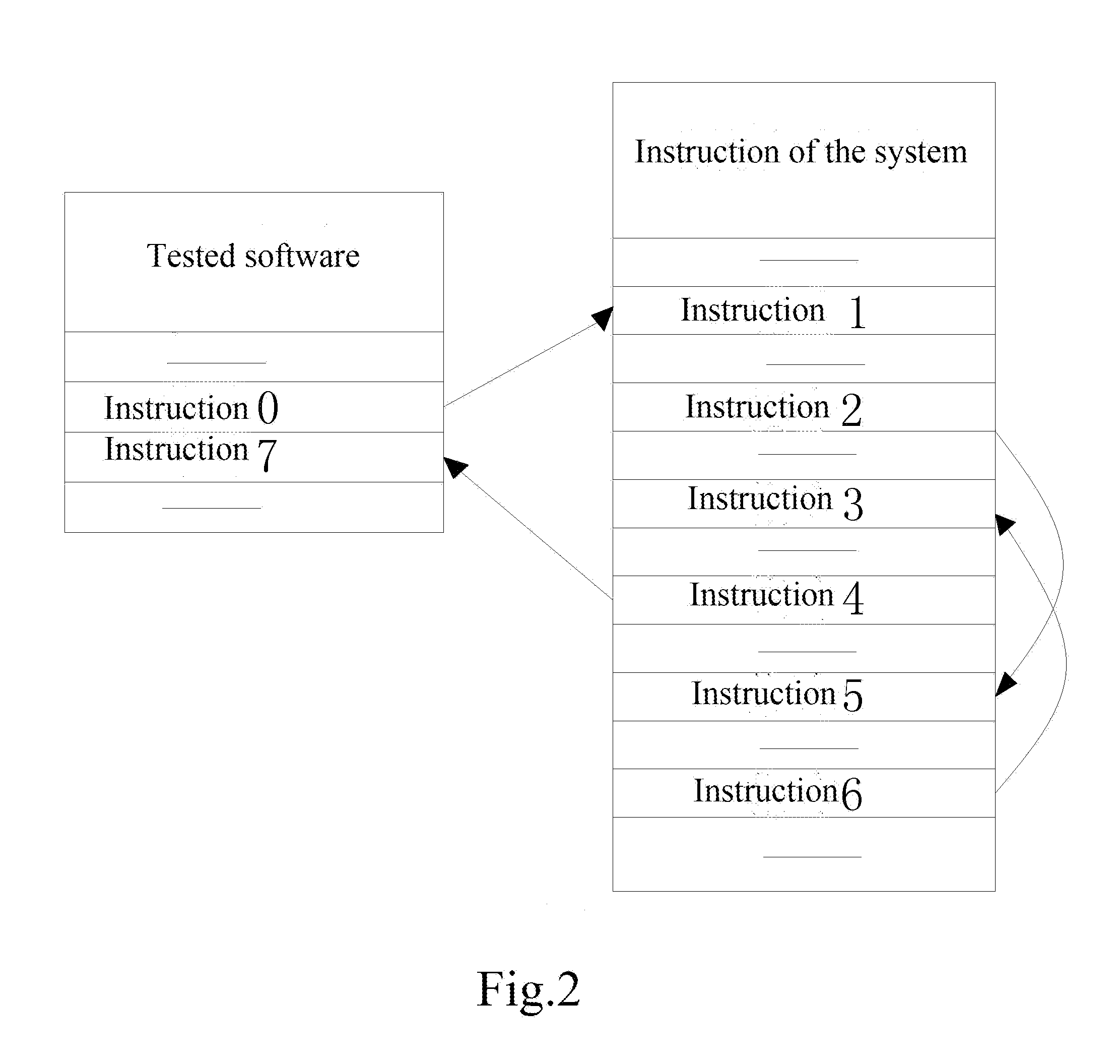

Device for automatically generating test cases for embedded software and method thereof

ActiveUS20170010956A1Reduce capacityEasy to useSoftware testing/debuggingCommercial softwarePath condition

A device and a method are provided to automatically generate test case for embedded software. This invention is in software test field, including symbolic execution kernel module, path selection module, solver, debugger, concrete execution kernel module and debugger agent module. The tested software and test cases are uploaded from the host system to the embedded system through debugger and debugger agent. The concrete execution kernel module starts the tested software. The symbolic execution kernel module captures the run-time information of the tested software through the debugger. When the tested software operates on the symbol source, the symbolic execution kernel module marks the symbol source, tracks the symbol propagation, generates path condition and sends the path condition to path selection module. This invention can automatically generate test cases for embedded software, which doesn't need the source code of the tested software and can be conveniently used for commercial software.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

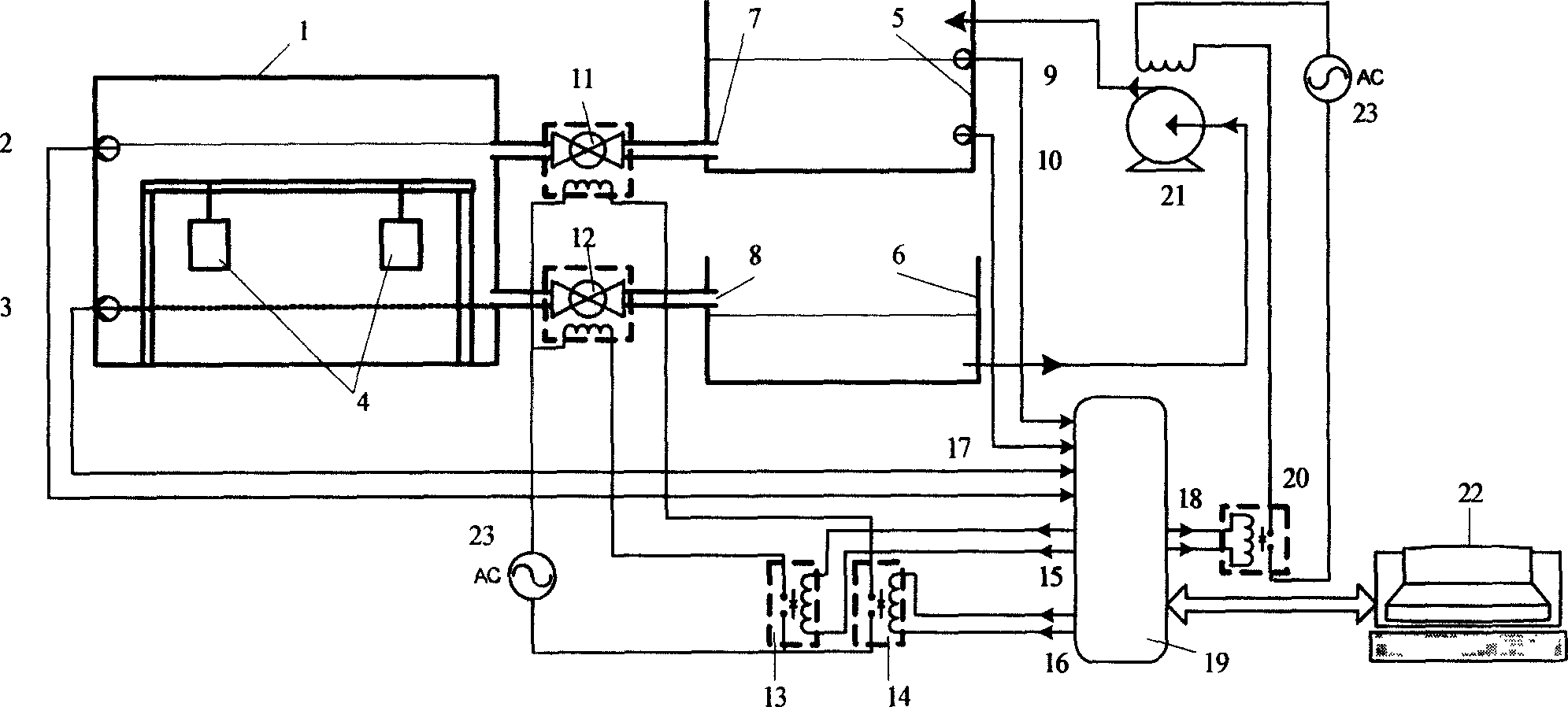

Automatic wetting and drying cycle apparatus for corrosion test sample

This invention relates to erosion test sample automatic wet and dry recycle device, which is characterized by the following: comprising erosion test water tank, low tank and high tank controlled by water-in electricity magnetic valve, water in relay, drainage electricity magnetic valve, drainage relay, high level liquid sensor, low level sensor, data collection control board, water pump and relay, computer and data input and output commercial software.

Owner:OCEAN UNIV OF CHINA

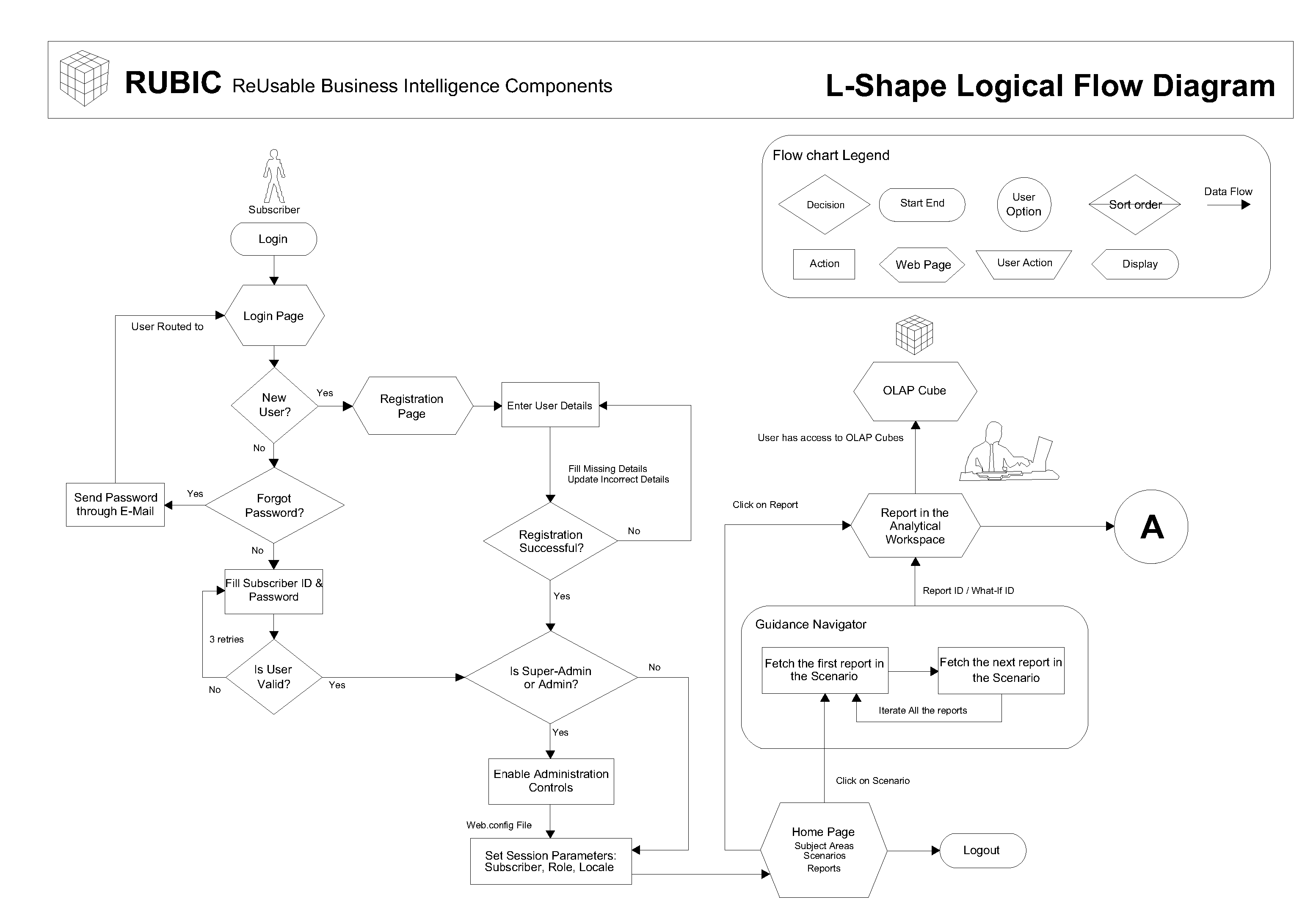

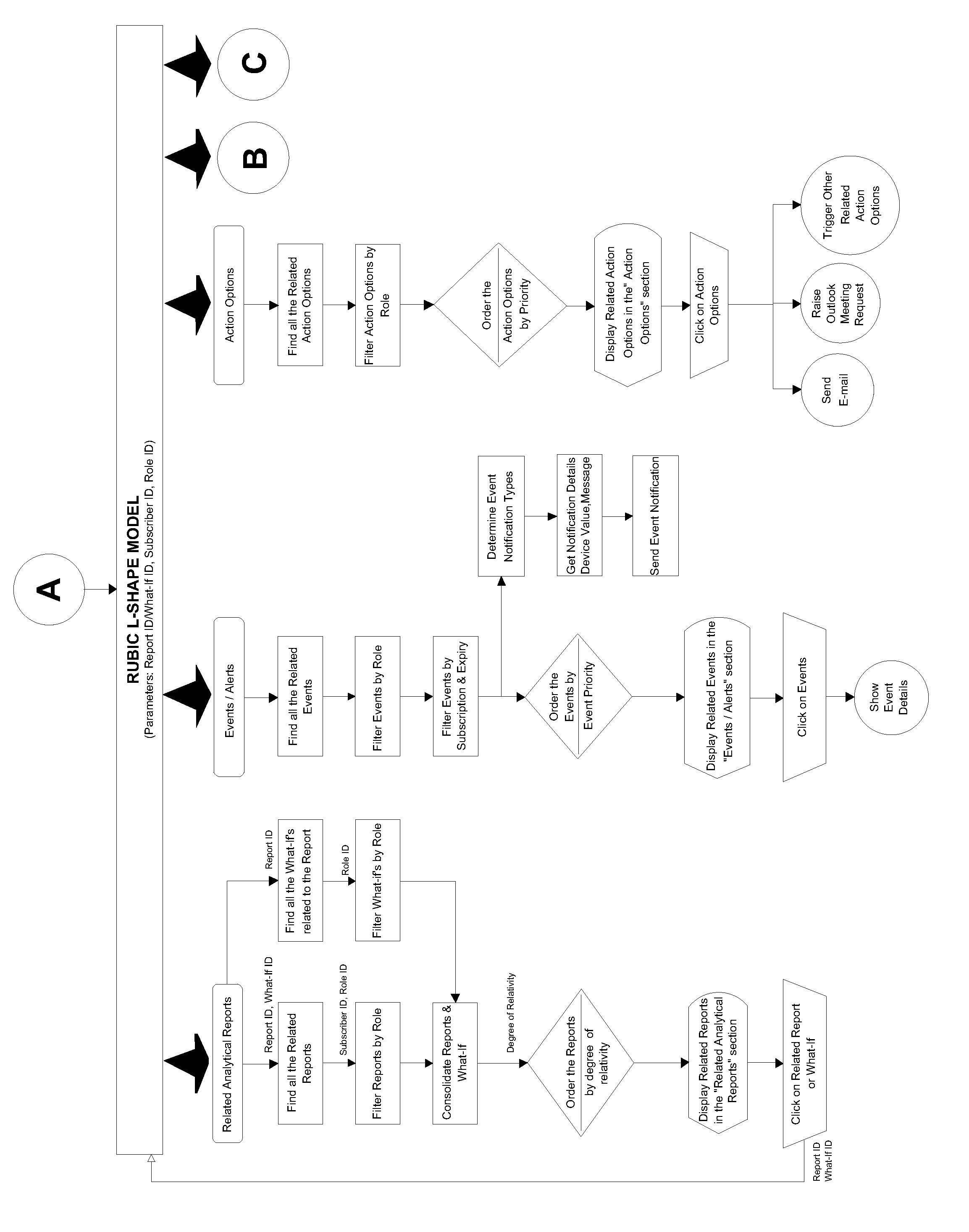

Method and system for generating an analytical report including a contextual knowledge panel

InactiveUS20070250466A1Digital data information retrievalSpecial data processing applicationsDisplay deviceData science

Described is a method and system for producing and displaying a required analytical report based on user-determined rule-set, selectively including contextual information that is specifically linked to the analytical report. Certain report-attributes, e.g., role ID, subscriber ID, and report ID / what-if ID, which are characteristic of the required report, are inputted into a user's system / framework to obtain outputs specific to the required analytical report by narrowing down / filtering the selection from available contextual information to obtain specific contextual information used for selective display. The method includes specific steps to use filter / narrow-down choices, considering what-if and different possible scenarios. The method can be part of commercial software that is tailored to the user's requirements and sold as a package. The analytical report might include contextual metadata, associated analytics for a particular analysis scenario, event alerts and operational metadata as part of a contextual knowledge panel. The display may have an L shaped configuration.

Owner:MINDTREE CONSULTING PVT

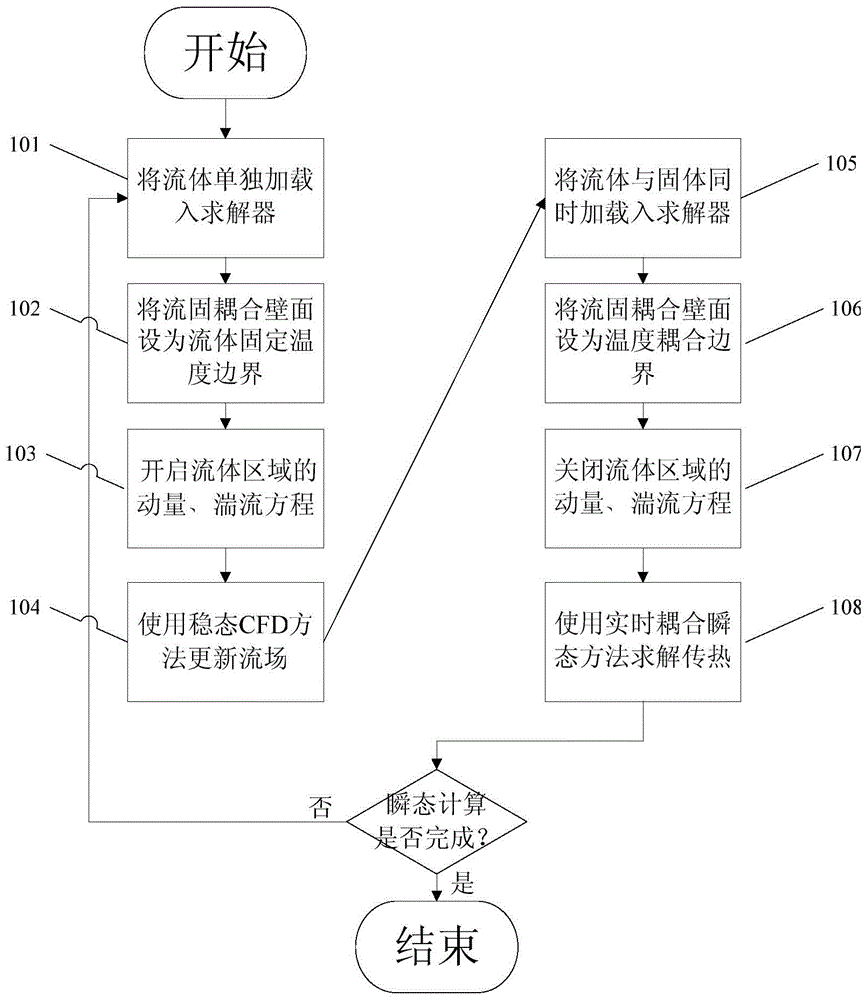

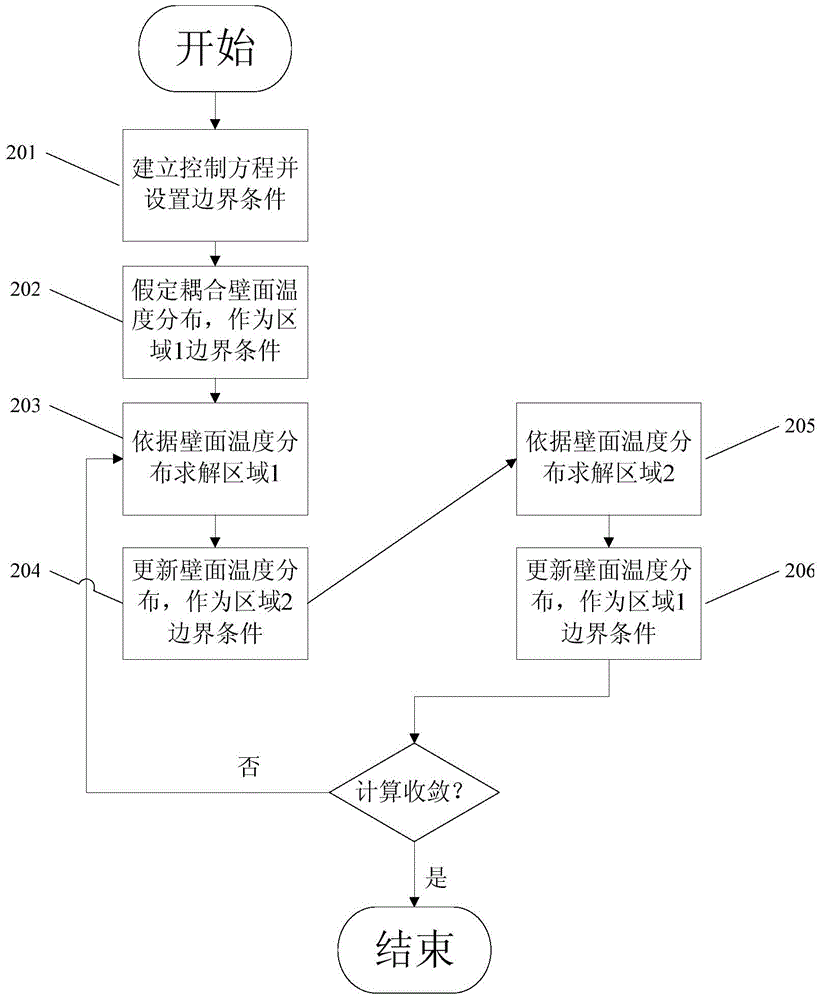

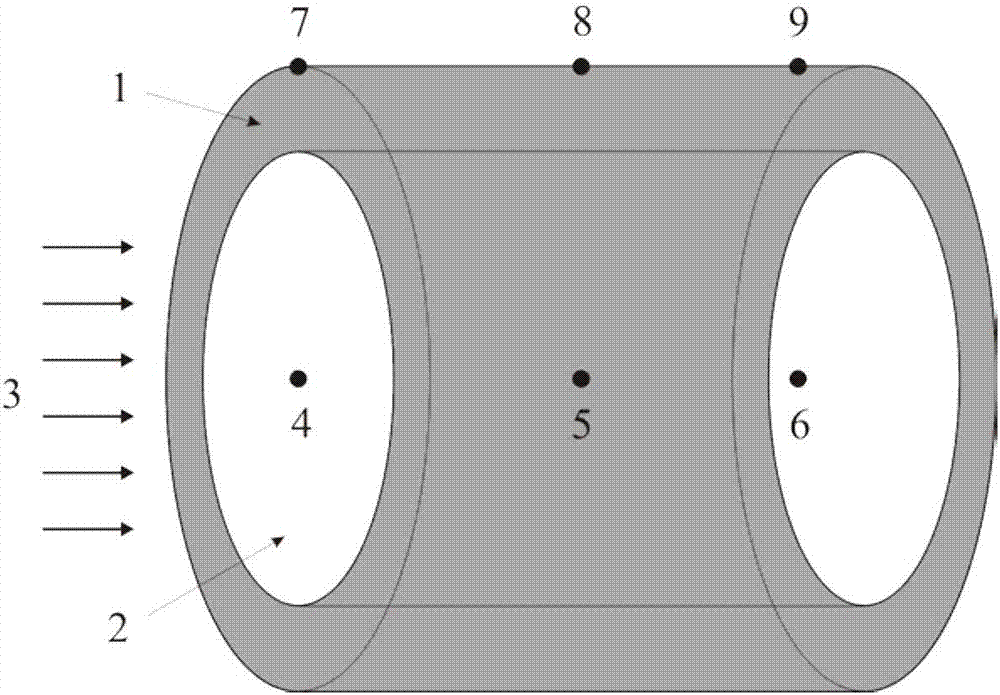

Loose coupling modeling method for fluid-solid coupling heat transfer

The invention provides a loose coupling modeling method for fluid-solid coupling heat transfer. The loose coupling modeling method is characterized in that the transient change process of a flow filed is ignored, and the global transient heat transfer process is assumed to be performed in a quasi-stable-state flow field. The method comprises the specific calculation procedures that 1, the flow field is updated, wherein only fluid is taken as a solving object, the fluid-solid coupling wall surface is set as a fixed temperature boundary of the fluid, and the flow field is solved through a stable-state CFD algorithm; 2, transient heat transfer is calculated, wherein the fluid and solid are both taken as the solving object, the fluid-solid coupling wall surface is set as a heat transfer coupling boundary, a momentum equation and a turbulent flow equation of the fluid are closed, and transient heat transfer is calculated until the flow field is updated for the next time and / or calculation stops; 3, the first step and the second step are repeated, wherein flow field updating and transient heat transfer calculating are alternately performed until the time arrives at the transient heat transfer termination moment. For the forced-convection heat transfer process of air in a pipe, by comparing the modeling method with a tight coupling calculation result of Fluent commercial software, the absolute error is 1 K or below, the calculation efficiency is improved by one order of magnitude, and the engineering calculation requirement is met.

Owner:BEIHANG UNIV

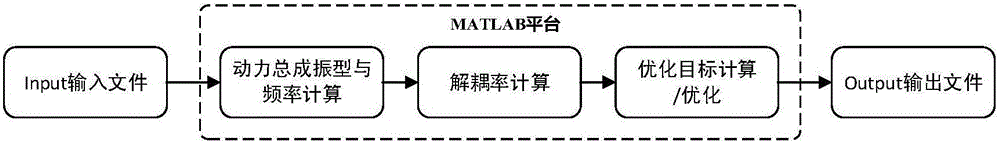

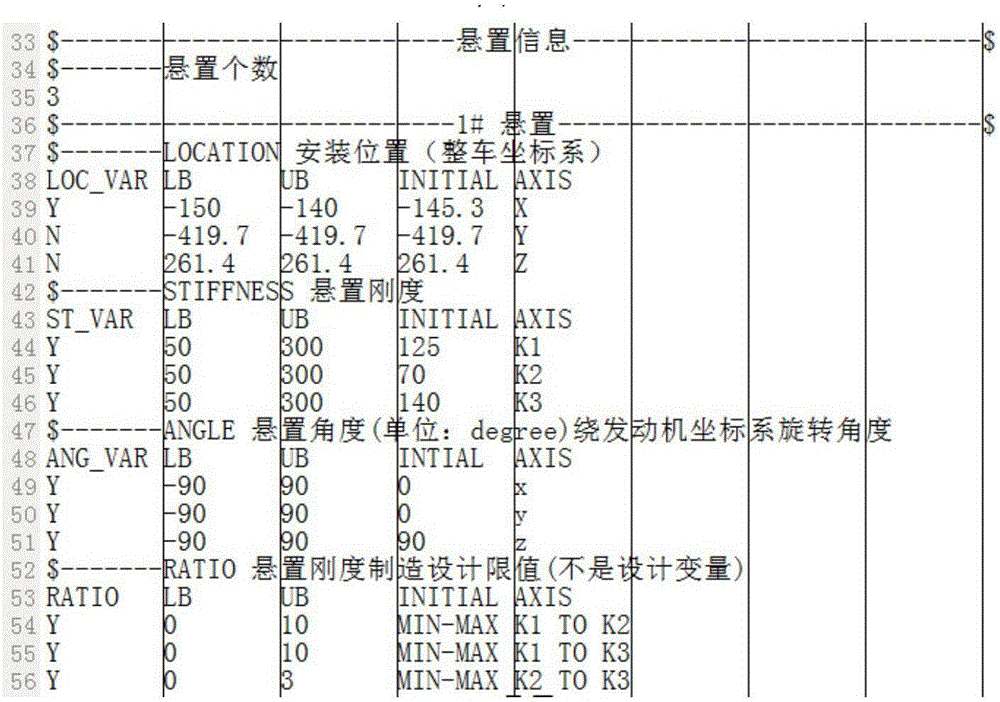

Quick design optimization method of power assembly suspension decoupling

ActiveCN105808828AAvoid mismatchImprove analysis efficiencyGeometric CADSpecial data processing applicationsCommercial softwareProcess engineering

The invention puts forward a quick design optimization method of power assembly suspension decoupling. MATLAB (matrix laboratory) programming and a computing platform are adopted to realize the computation of the modal frequency and the decoupling rate of a power assembly six-degree-of-freedom rigid body; on the premise that a plurality of targets are fully considered, a modal frequency target model, a modal decoupling target model and a suspension rigidity manufacture target model are established; and finally, a target function is defined and optimized, and meanwhile, the installation position, the rigidity and the installation angle of a suspension system can be subjected to optimal design. The quick design optimization method does not depend on traditional commercial software, analyzes the power assembly suspension decoupling and greatly improves analysis efficiency. In addition, the quick design optimization method fully considers the installation position, the rigidity and the installation angle in a suspension optimization design process, enriches an optimal design variable, and provides rich solving resources for the power assembly design of a finished automobile concept design stage. Meanwhile, frequency avoidance and suspension manufacture constraints in a design process are considered, and the mismatching of a later period power assembly under the working situation of the finished automobile is avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

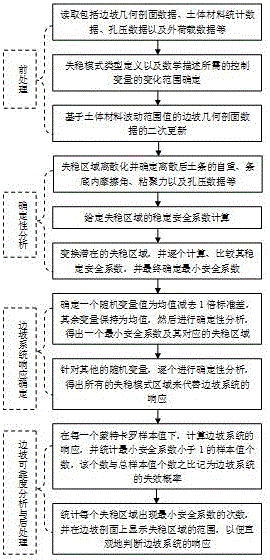

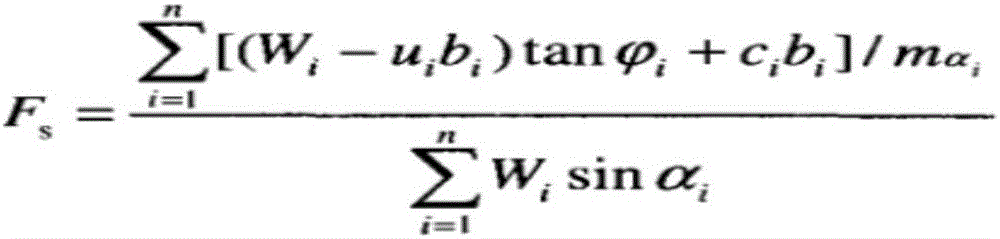

A method for developing slope stability reliability analysis software under spatial variation characteristics

ActiveCN106021853AFill in the calculation gapStrong engineering application valueSpecial data processing applicationsInformaticsSlope stability analysisCommercial software

The invention belongs to the technical field of slope stability analysis software development and relates to a method for developing slope stability reliability analysis software under spatial variation characteristics. The method comprises the steps of on the basis of preprocessed data input, performing slope discretization and integration analysis to obtain a safety coefficient of a specific instability mode; performing a certain number of times of minimum safety coefficient search and determining main instability areas; finally realizing slope stability reliability analysis software development based on multiple main instability modes through the Monte Carlo sampling method. The method gives full consideration to system features brought by the spatial variation characteristics of soil mass materials, fills up the blank of system feature calculation caused by spatial variation characteristics in conventional commercial software, and has a high engineering application value and a good commercial prospect.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

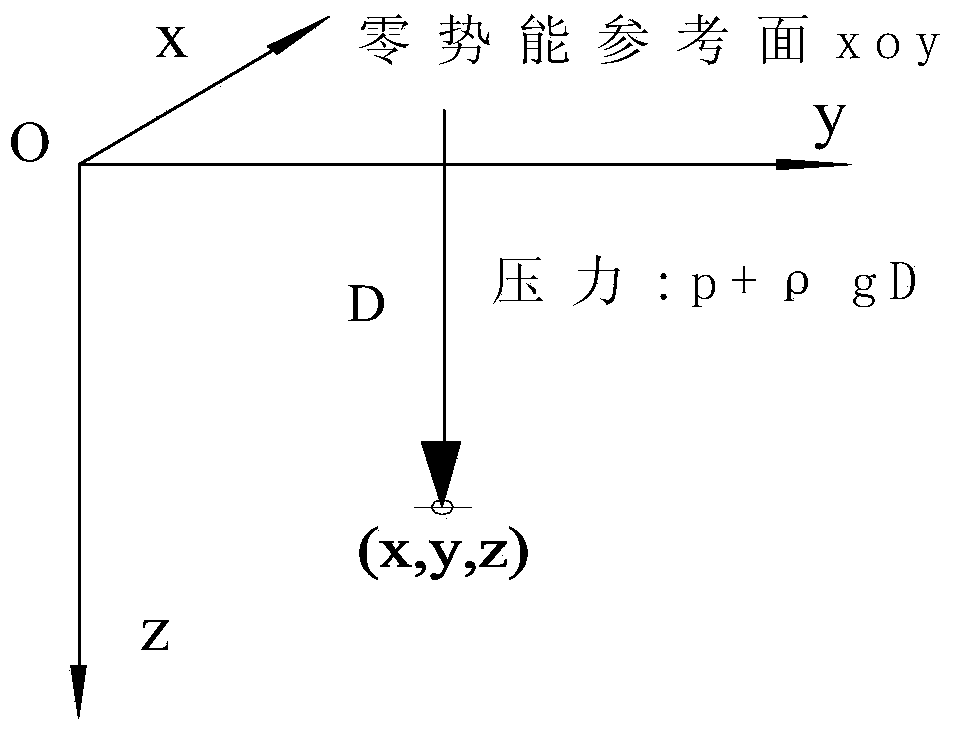

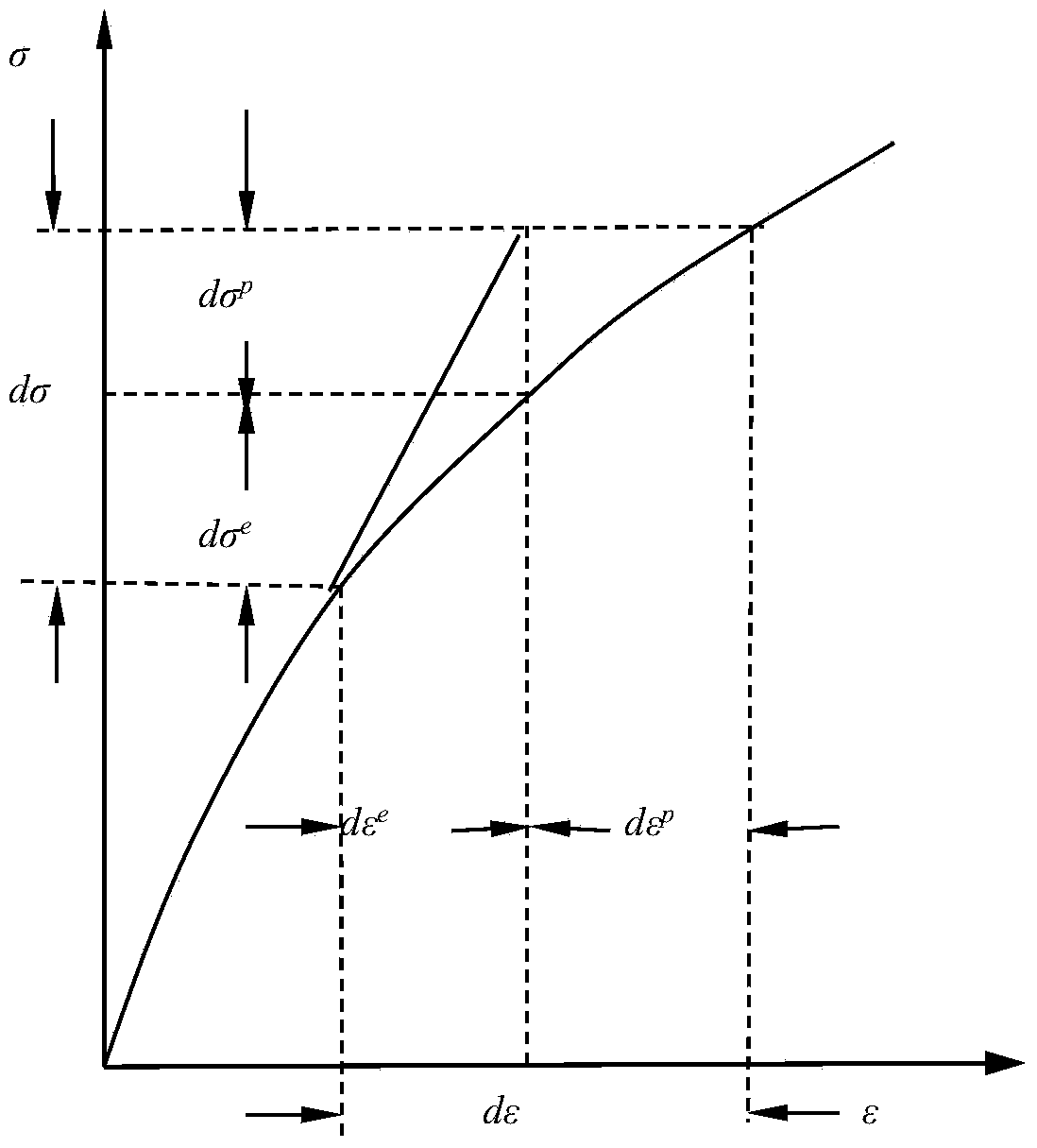

Method for calculating oil field casing damage under fluid-solid coupling effect

InactiveCN104318032APrecise prevention and controlSpecial data processing applicationsMathematical modelElastic plastic

The invention discloses a method for calculating oil field casing damage under the fluid-solid coupling effect. The method is based on a fluid-solid coupling theory, research is performed through a method of combining indoor experiments, numerical calculation and theoretical analysis; a seepage flow mathematical model in the petroleum reservoir exploitation process and a stress field calculation mathematical model are established according to the fluid mechanics theory and the elastic-plastic theory, and an elastic-plastic constitutive model of reservoir rock is established according to indoor experiment analysis; and a fluid-solid coupling mathematical model is established by means of the effective stress principle. According to the fluid-solid coupling mathematical model and the solving thinking, a numerical simulation method for reservoir fluid-solid coupling ground stress prediction and casing damage prevention is established on the basis of existing commercial software; with a Qudi oilfield typical block as an example, the concrete method for oil field casing damage prediction and prevention under the fluid-solid coupling effect is given, detailed measures are provided, and the method is of great application value for improving oil field casing damage conditions and prolonging service life of an oil well.

Owner:SOUTHWEST PETROLEUM UNIV

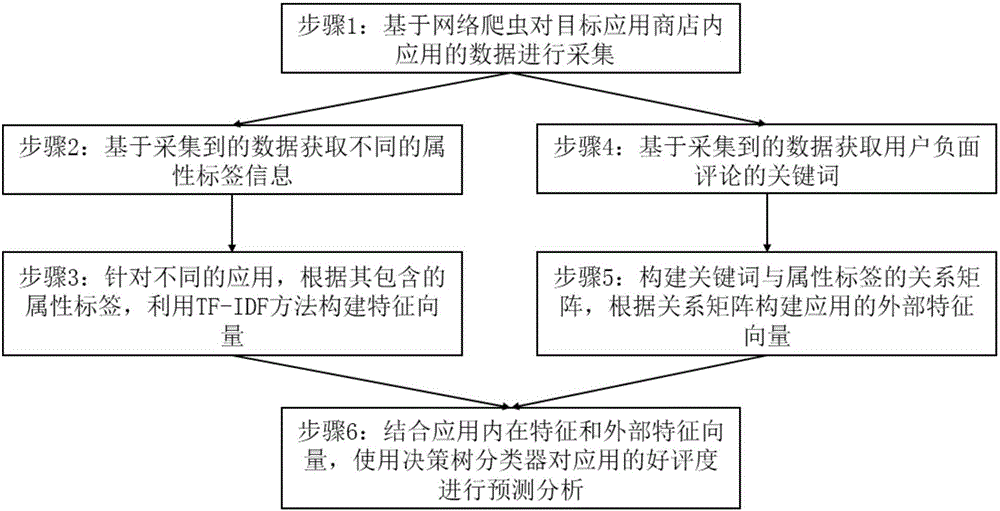

Mobile application software performance prediction method based on attributes

InactiveCN105787662APracticalWeb data indexingCharacter and pattern recognitionFeature vectorCommercial software

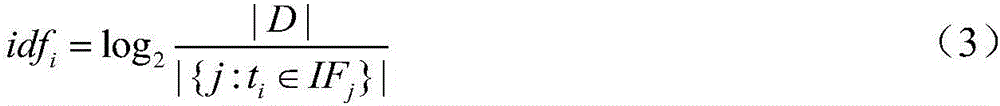

The present invention discloses a mobile application software performance prediction method based on attributes. The objective of the invention is to solve the technical problem that a mobile application software performance prediction method in the prior art is poor in practicability. A network crawler program is employed to collect commercial software application attribute information; different attribute tags are extracted based on the collected software application attribute information; internal feature vectors based on a word frequency inverse document frequency method are built aiming at each application; existing user comment information is processed; the negative comment content in the comment is extracted and words having the highest frequencies of occurrence are selected in order and taken as negative comment key words; constructing the relation matrix between the negative key words and the application attribute tags according to the relation of the negative comment and the application attributes; the external features of the application expressed by the key words are derived through adoption of the relation matrix of the key words and the application feature vectors; a decision tree classifier is used through combination of the inherent features and the external features of the application; and the features of the application is subjective to classification learning and prediction. The mobile application software performance prediction method based on attributes is high in practicality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

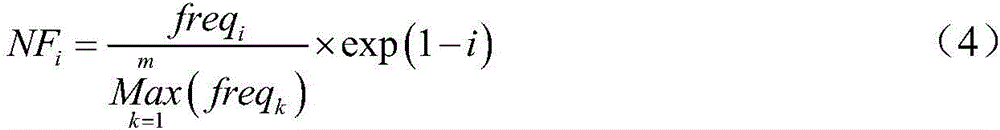

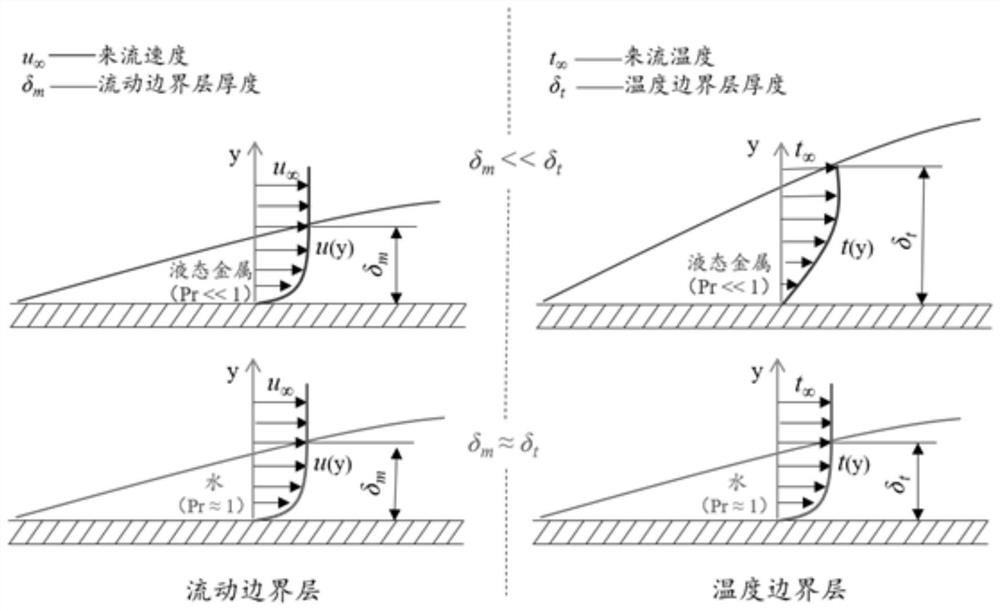

Liquid metal flow heat transfer calculation method

ActiveCN113095004AOvercome limitationsImprove rationalityDesign optimisation/simulationSpecial data processing applicationsCommercial softwareLiquid state

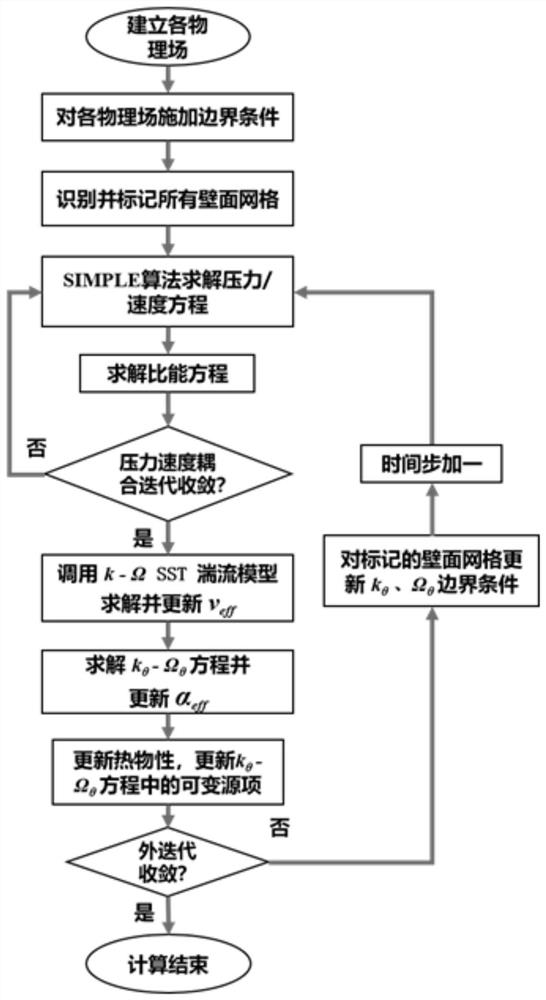

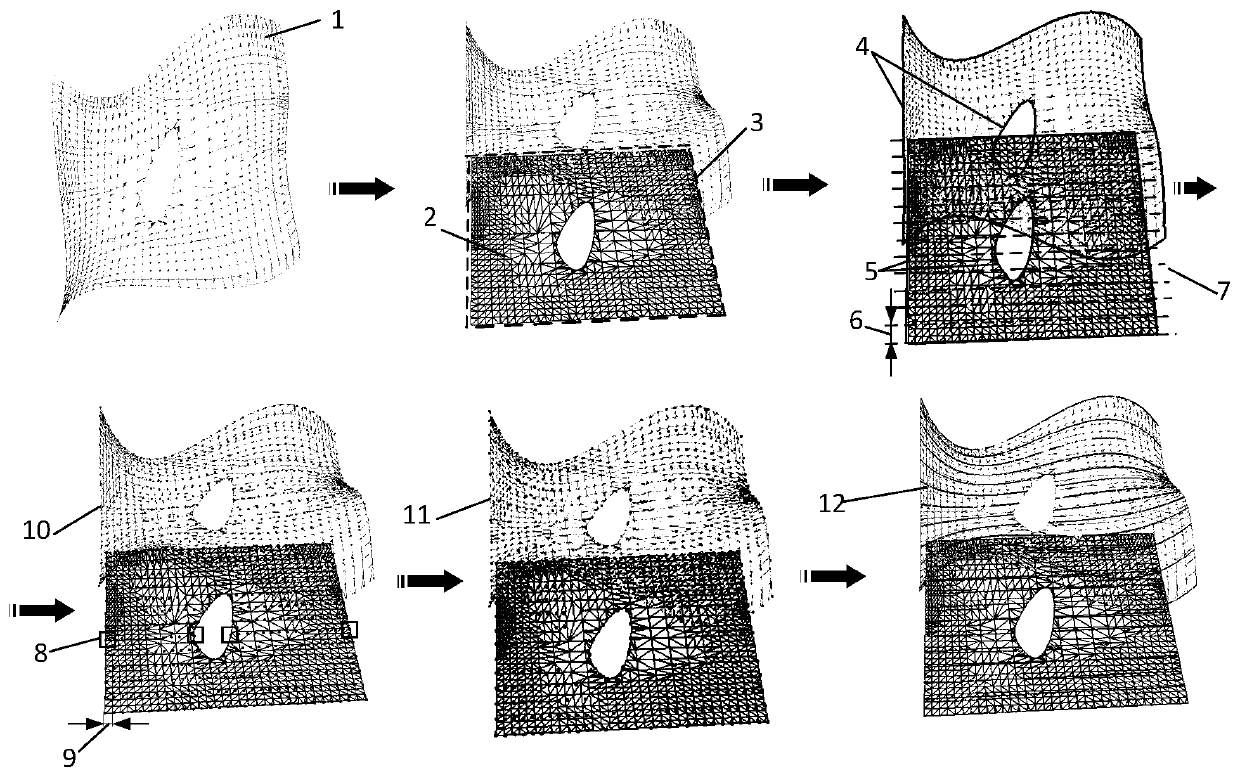

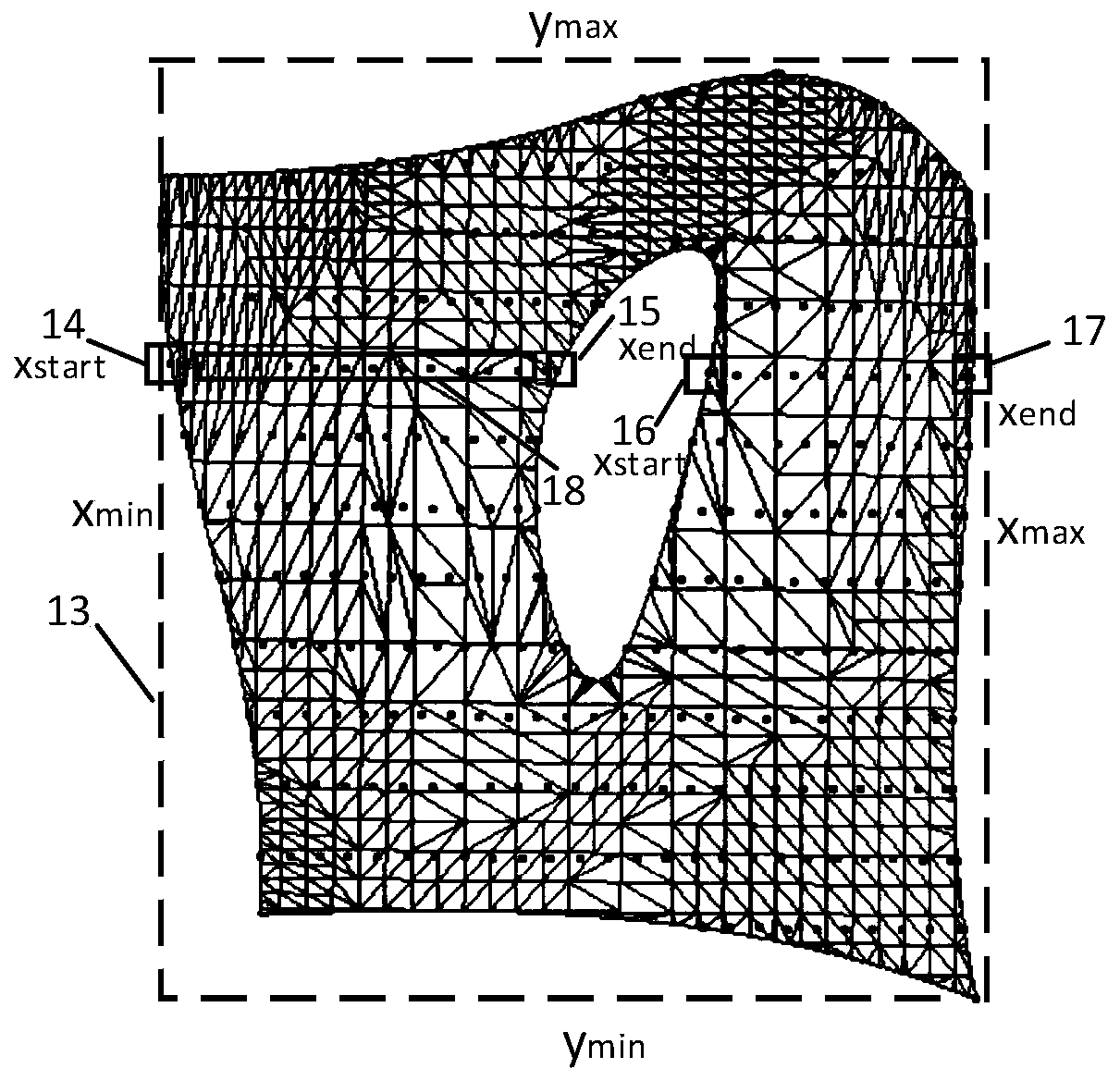

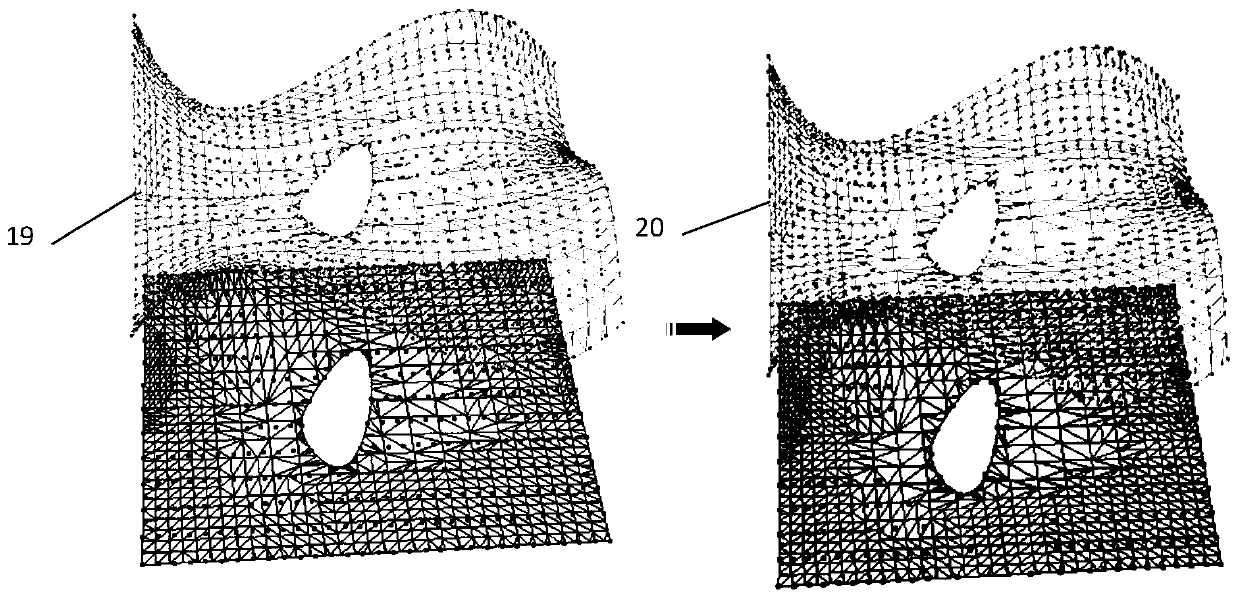

The invention discloses a liquid metal flow heat transfer calculation method. The method comprises the following steps that 1, establishing physical fields needed for solving in OpenFOAM; 2, applying boundary conditions to each physical field, and marking wall surface grids; 3, solving a mass and momentum conservation equation through pressure-velocity coupling iteration, and solving a specific energy equation; 4, judging whether coupling iteration converges or not, and determining to return to the step 3 or carry out the next step; 5, updating effective viscosity and thermal diffusivity in momentum and specific energy equations based on a k-omega-k theta-omega theta turbulent flow heat exchange model; 6, updating physical properties and variable source items in each equation; 7, updating the pulsation temperature square mean value k theta and the unit dissipation rate omega theta on the marked wall surface grid, judging whether external iteration convergence exists or not, and determining to return to the step 3 to continue calculation or finish calculation. According to the method, the problem that an advanced turbulence heat exchange model, which is low in precision despite high theoretical property and complex in solution, is difficult to implement and apply in commercial CFD software when a traditional constant-value turbulence Prandtt number vortex diffusion model is used for calculating the liquid metal flow heat transfer phenomenon is solved.

Owner:XI AN JIAOTONG UNIV

Curved surface model path planning method applied to laser surface etching

ActiveCN110039186ASmall amount of calculationReduce intermediate stepsLaser beam welding apparatusCommercial softwarePath generation

The invention discloses a curved surface model path planning method applied to laser surface etching. The method is characterized in that a three-dimensional curved surface model which is establishedin commercial software and is stored into an stl format serves are an input, a scanning path formed by a three-dimensional point set is used as an output, and the precision and the calculation amountof path planning are controlled by using a plurality of parameters, wherein the relevant parameters comprise a path point x direction distance parameter dx, a path point y direction distance parameterdy and a vertex sparse parameter delta k. According to the method, the direct three-dimensional path generation on the non-closed stl curved surface is realized, and compared with a traditional method in which the curved surface is firstly layered, and then plane path planning is carried out, the curved surface model path planning method has the advantages that a middle step is omitted, and the calculation amount is greatly reduced.

Owner:无锡超通智能制造技术研究院有限公司

Boundary processing technology of WENO difference method

ActiveCN104268322AReduce template sizeSpecial data processing applicationsRunge–Kutta methodCommercial software

The invention provides a boundary processing technology when the flow field calculation is performed by a WENO difference method. The consistent high accuracy can be achieved when the flow field calculation is performed and the complicated boundary can be processed. The boundary processing technology mainly comprises step 1, grid division, wherein grids are divided into an internal area and a boundary area, the boundary area only comprises a layer of grids, and accordingly the complicated calculation of the boundary area DG is minimized; step 2, space dispersion, wherein the space dispersion is performed on the internal area by the WENO finite difference method; step 3, boundary processing, wherein the space dispersion is performed on the boundary area by a DG method; step 4, coupling processing, wherein the coupling is performed on the boundary processing portion and the internal area and the derivative information is provided by the boundary area through DG polynomial approximation; step 5, time dispersion, wherein the time dispersion is displayed by a TVD-Runge-Kutta method; step 6, post-processing, wherein the visual stimulation is performed on a flow field result through commercial software such as Tecplot or Paraview.

Owner:BEIHANG UNIV

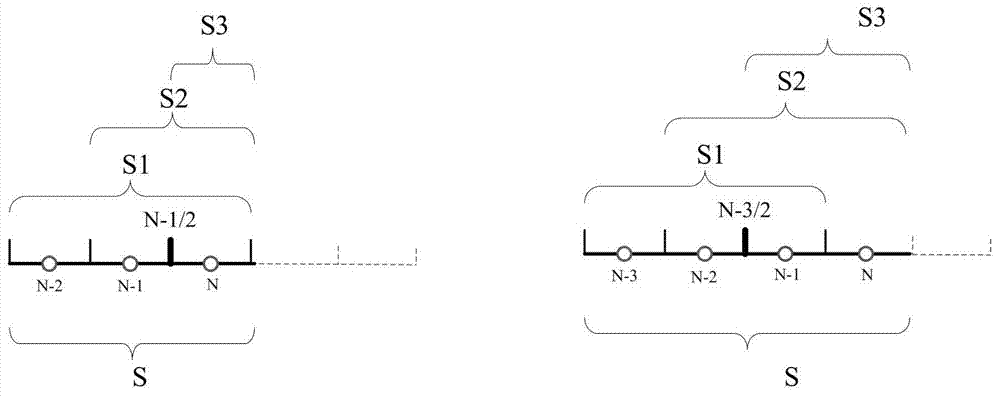

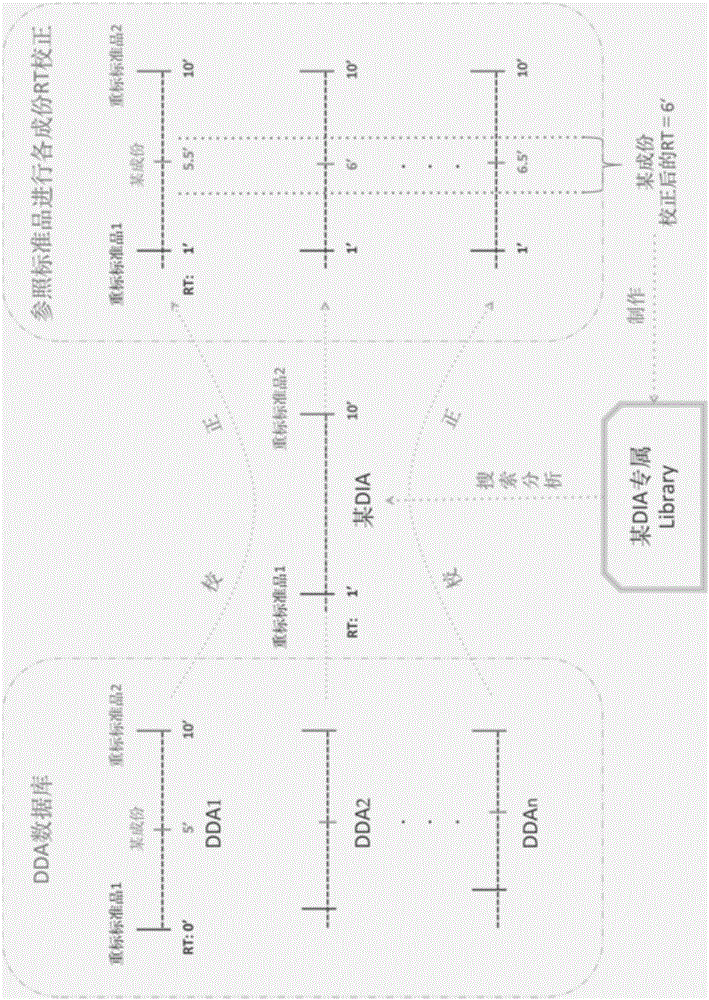

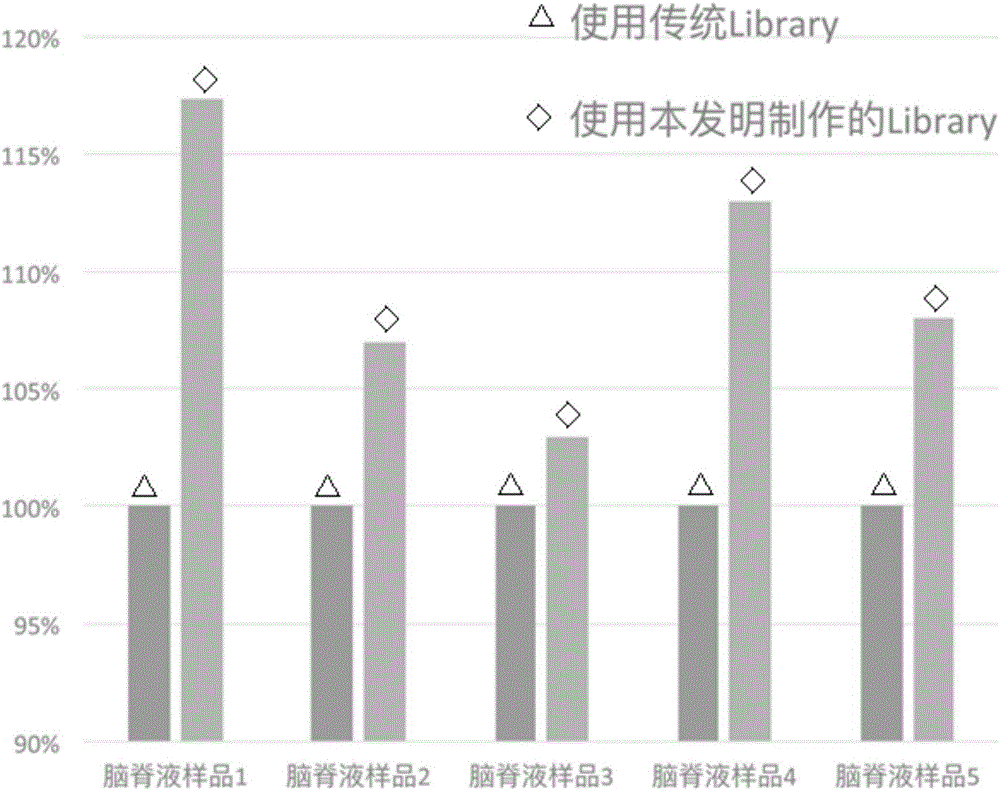

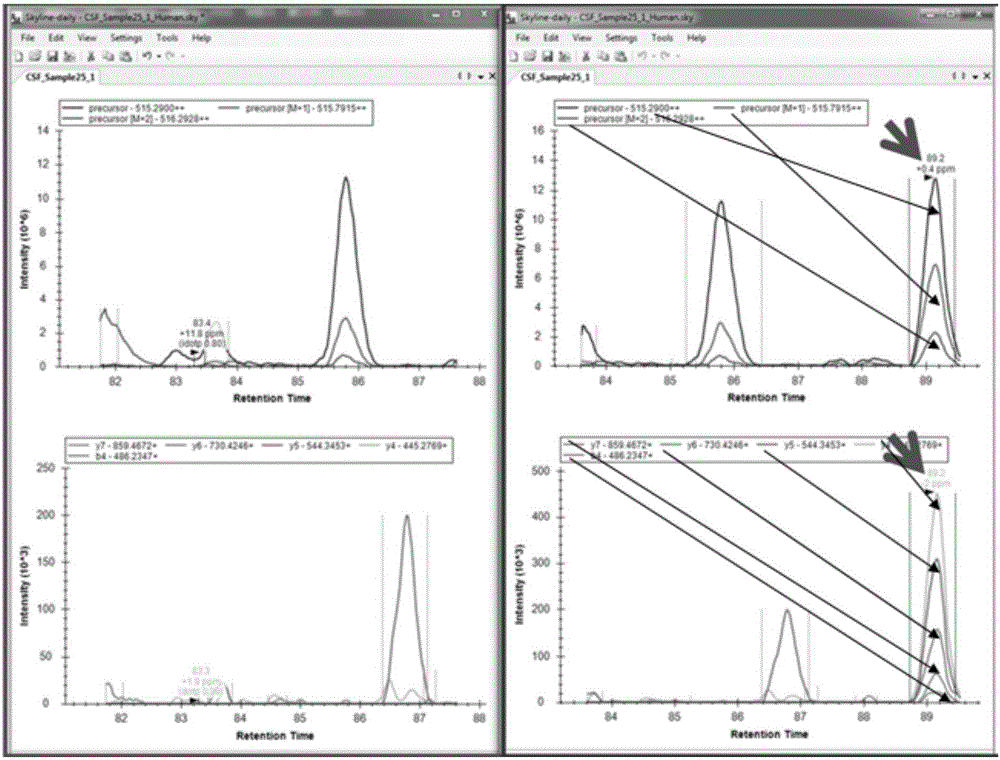

Method for analyzing non-data-dependent acquisition mode mass spectral data and application thereof

ActiveCN106290684AA large number of detectionAccurate quantitative analysisComponent separationGas phaseData file

The invention provides a method for analyzing non-data-dependent acquisition mode mass spectral data, comprising the steps of mixing standard ones not present and heavily isotope-labeled among a plurality of analysis samples into samples under test; analyzing the samples by jointly using gas or liquid chromatography and mass spectrometry; acquiring the standard samples heavily isotope-labeled from data acquired in various DDA modes, and mass spectral information of ingredients in the samples under test, and making corresponding mass spectral database files; searching for mas spectral information of the standard samples heavily isotope-labeled from data acquired in various DIA modes; making mass spectral database files suitable for the analysis of data files acquired in each DIA mode; searching DIA data by using mass spectral data commercial software to obtain qualitative and quantitative results of the ingredients of each sample. The mass spectral DIA analysis method provided herein is a brand-new method, ingredients can be massively detected in samples, and the ingredients can be more accurately and quantitatively analyzed.

Owner:PROTEINT (TIANJIN) BIOTECHNOLOGY CO LTD

An integration method of multiple prediction results of power load probability density

ActiveCN109558975ASmall continuous rank probability lossImprove forecast accuracyBiological neural network modelsForecastingSystems analysisPower system scheduling

The invention relates to an integration method of multiple prediction results of power load probability density, and belongs to the technical field of power system analysis. According to the method, aplurality of probability density or quantile probability prediction models are obtained through training of a plurality of three-class regression models set by different hyper-parameters, and the output of the quantile prediction models is converted into a probability density model conforming to Gaussian distribution through Gaussian distribution assumption of loads and a least square method. A probability density prediction integration method is adopted, a probability density prediction optimal integration model is constructed based on the trained probability density prediction model and result, the weights of different probability density prediction methods are determined, and therefore the probability loss of the continuous grade of the final integration prediction model is minimum. The method is finally converted into a quadratic programming problem, the global optimal integrated weight is quickly searched by utilizing mature commercial software, the probability density short-termload prediction precision is improved, and the dispatching operation cost of the power system is further reduced.

Owner:TSINGHUA UNIV

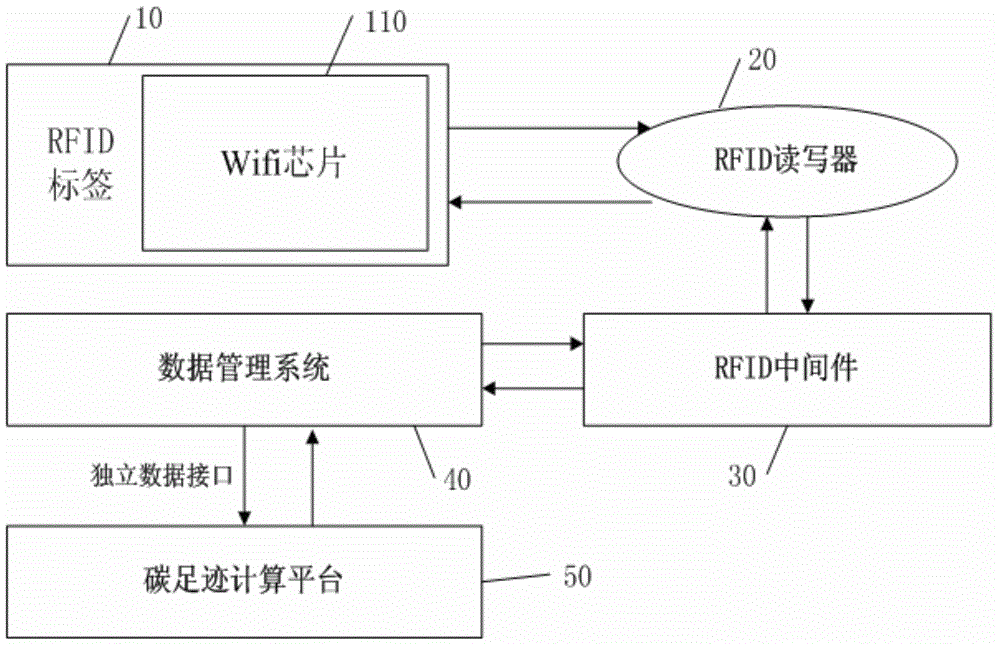

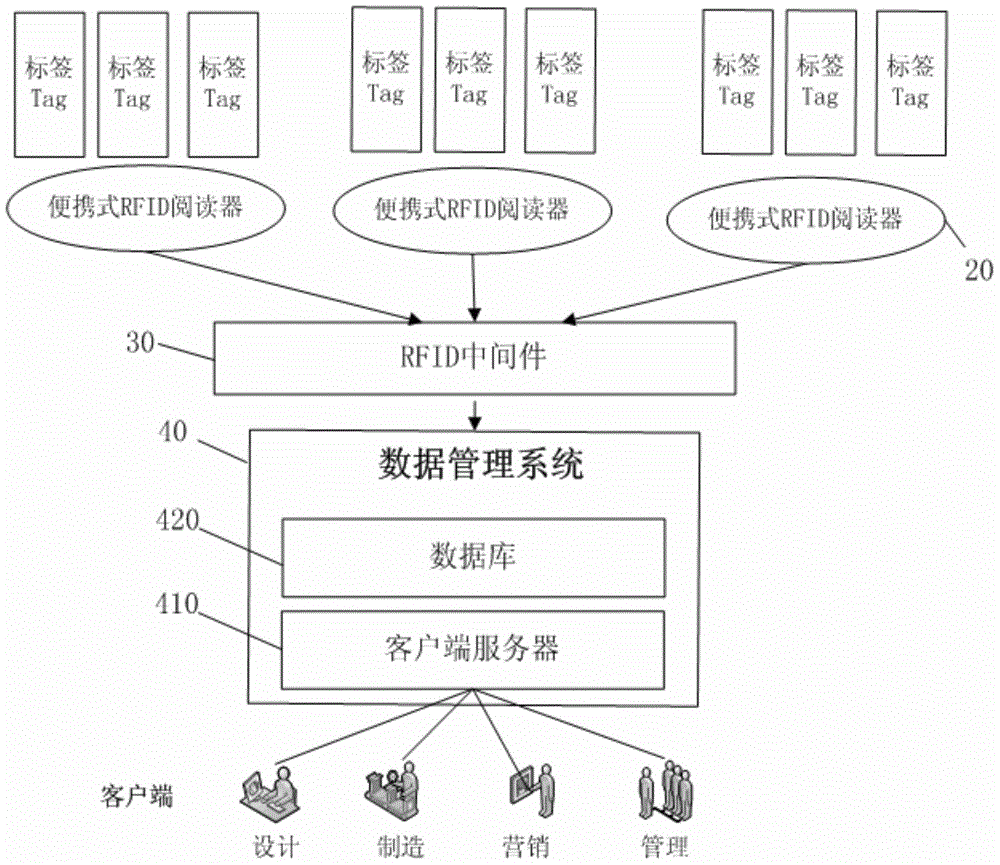

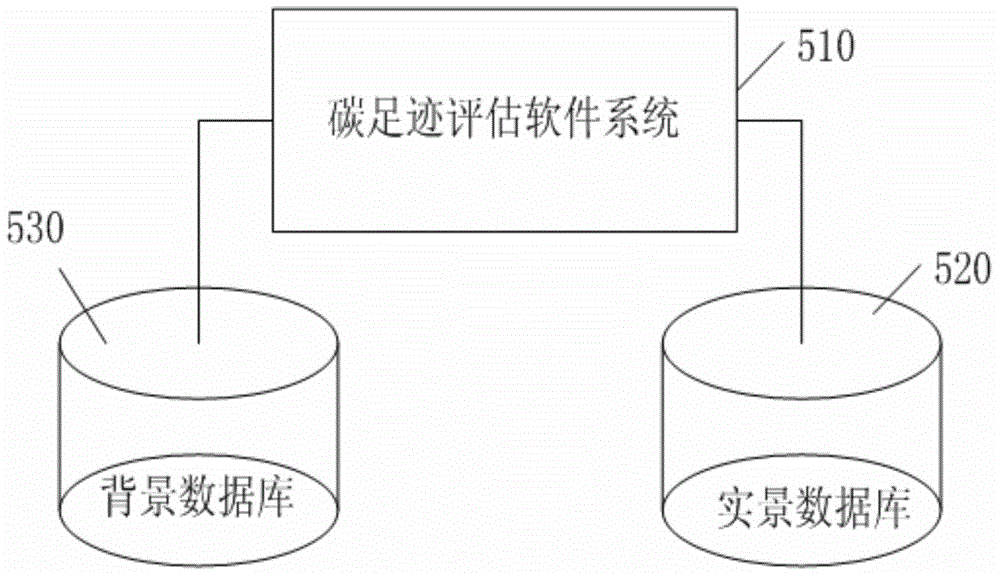

Automatic acquisition and management system of supply chain carbon footprint information

ActiveCN104834988AQuick understandingRealize automatic collectionCo-operative working arrangementsTechnology managementCarbon footprintCommercial software

The present invention belongs to the technical field of energy saving and environmental protection, and discloses an automatic acquisition and management system of supply chain carbon footprint information, comprising an RFID tag, an RFID portable reader-writer, a data management system, and a carbon footprint assessment platform system, wherein the RFID tag is used for recording carbon footprint information of an outsourcing component and a product; the RFID portable reader-writer reads the information of the RFID tag; the data management system is connected with the RFID portable reader-writer through a wireless network, and automatically acquires and stores the carbon footprint information of the outsourcing component; the carbon footprint assessment platform system calculates carbon footprint of the enterprise product by using a carbon footprint assessment commercial software built in the platform and data of a database, and feeds a result back to the data management system through an independent data interface, so as to achieve that the result can be inquired by a plurality of clients and can be fed back to the RFID tag during sale of the product. The automatic acquisition and management system of the present invention is suitable for acquisition and management of carbon footprint information of the product by the enterprise.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Pre-emptive anti-virus protection of computing systems

ActiveUS7712135B2Reduce problem sizeImprove efficiencyMemory loss protectionDigital data processing detailsAnti virusOperational system

A system is provided that strongly inhibits infection and spread of computer viruses. Valid executable software files and supporting files, even files provided by mass-released commercial software, are associated with a numeric key that is unique to each individual computer running the software. For a file to be processed by the central processing unit (CPU) of the computer, the presence of a valid key must first be verified. Every valid executable file, including files relating to the operating system and application layer code, is provided with a unique key. Thus, viruses that attempt to gain access to the CPU to perform unauthorized actions, including replication, are prevented due to lack of a valid execution key. Execution keys are generated locally on each individual computer using a variety of methods. Execution keys can be regenerated if the security of a computer system has been compromised, or appears to have been compromised.

Owner:DIGITAL GUARDIAN LLC

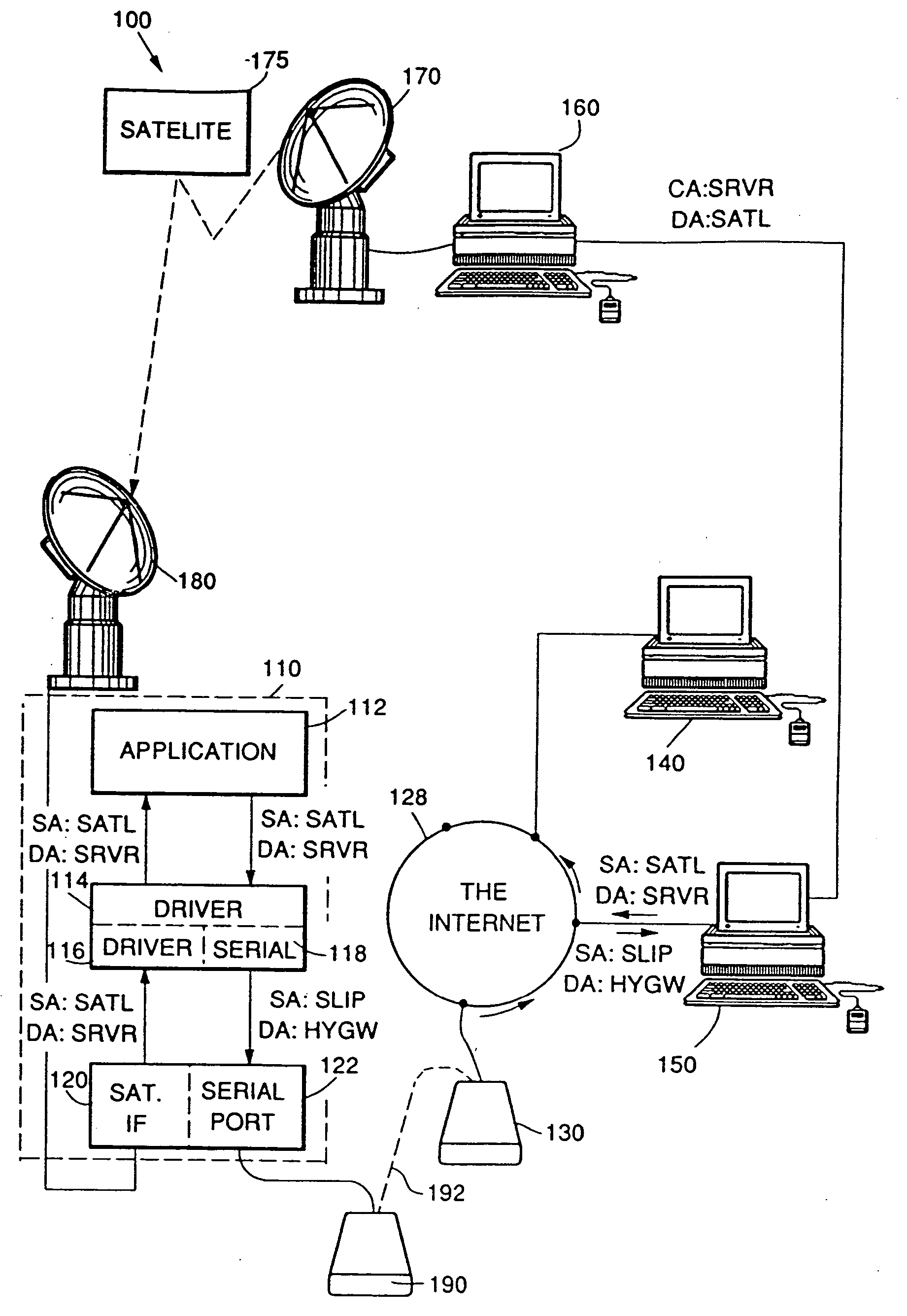

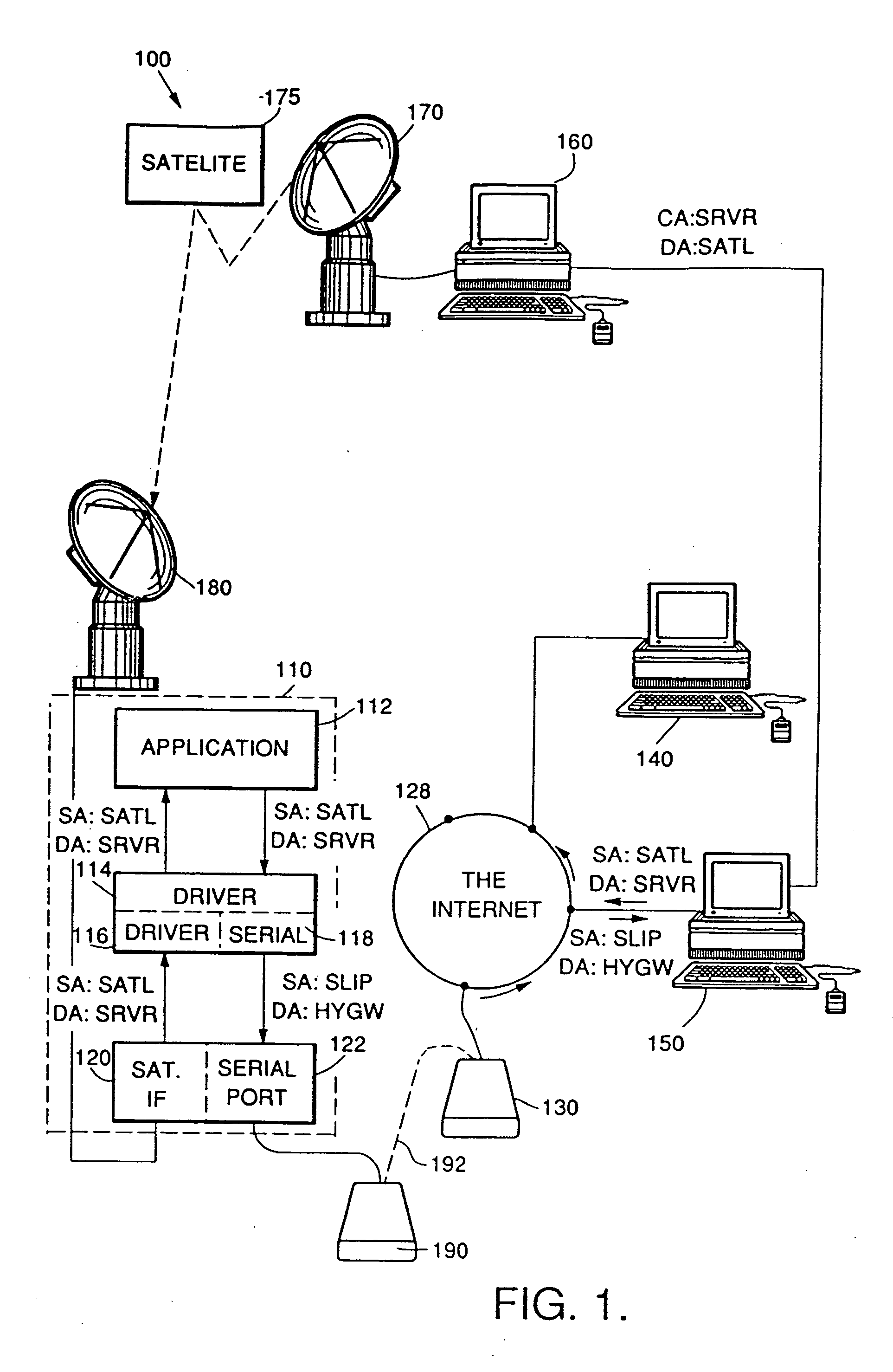

Apparatus and method for hybrid network access

InactiveUS20050053082A1Error prevention/detection by using return channelTransmission systemsPropagation delayMix network

Owner:PERFORMANCE PROXY RES

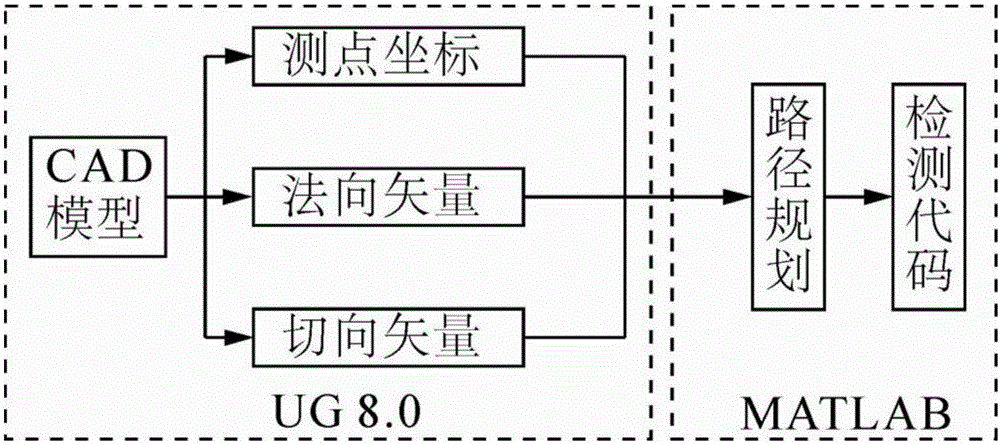

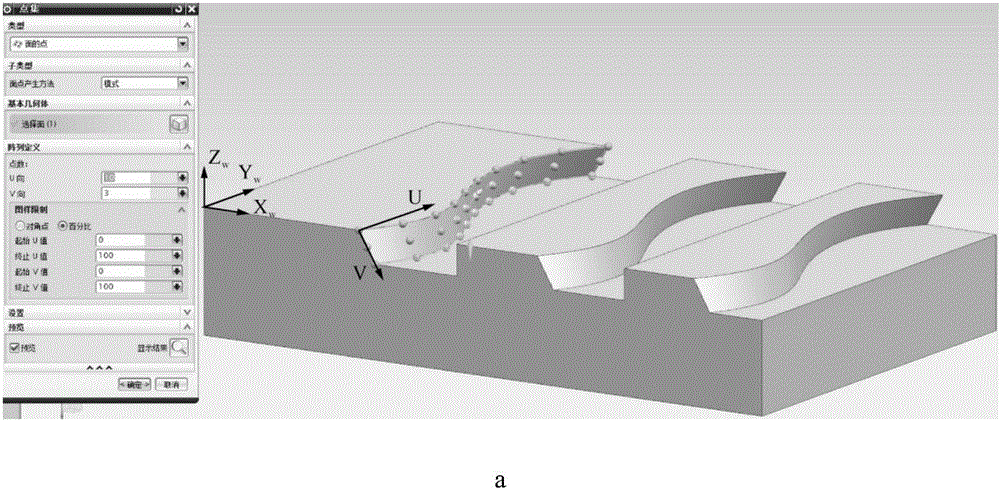

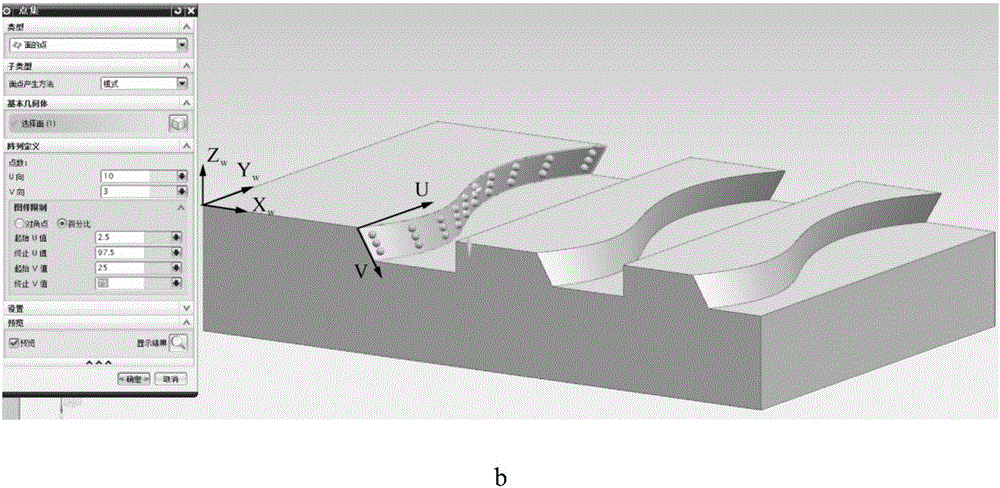

Complex surface on-machine test method of five-axis machining center

ActiveCN104985482AReduce scrap rateIncrease productivityMeasurement/indication equipmentsCommercial softwareRead through

The invention discloses a complex surface on-machine test method of a five-axis machining center. The complex surface on-machine test method includes the following steps that the detection point is planned through a solid modeling technology based on commercial software UG NX8.0, and the coordinates, the normal vector and the tangential vector of the surface detection point are obtained; the coordinates, the normal vector and the tangential vector of the detection point are read through commercial visual digital software, and the detection path is planned; the surface is detected through the detection path, and a corresponding on-machine detection code is generated according to the type of the five-axis machining center. By means of the method, when a workpiece is machined, the workpiece does not need to be conveyed to a detection device from a machine tool, and the quality of the workpiece can be detected at any time in the machining process; meanwhile, by means of obtained results, positioning and machining correction of the workpiece are guided, production efficiency of the machining process is improved, occurring errors are detected in real time as early as possible at low time cost, and the scrap rate of the workpiece is reduced.

Owner:TIANJIN UNIV

Apparatus and method for access to network via satellite

InactiveUS6839770B1Multiple digital computer combinationsRadio transmissionAccess networkPropagation delay

A system in which a personal computer sends messages into a TCP / IP network using a conventional dial-up link and downloads data from the TCP / IP network using a high-speed one-way satellite link. A preferred embodiment uses a conventional SLIP provider to connect to the TCP / IP network and uses a commercial software TCP / IP package that has a standard driver interface. A spoofing protocol compensates for the long propagation delays inherent to satellite communication.

Owner:PERFORMANCE PROXY RES

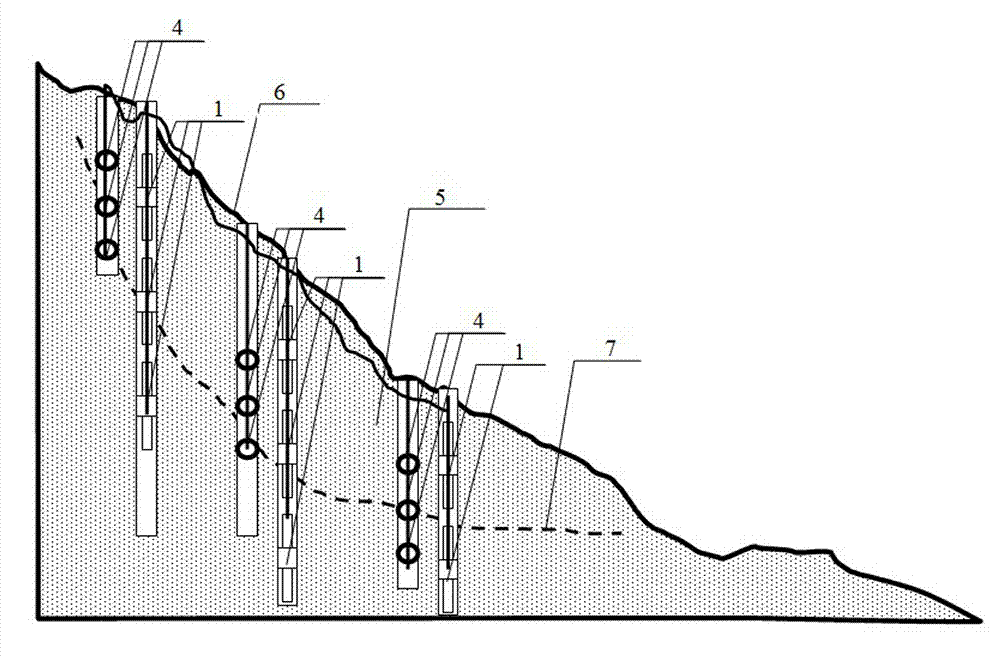

Slide-face type remote three-dimensional digital pre-warning method and system for stability of high slope

ActiveCN102968884AImprove securityTimely preventive measuresAlarmsSoftware systemPore water pressure

The invention provides a slide-face type remote three-dimensional digital pre-warning method and a slide-face type remote three-dimensional digital pre-warning system for the stability of a high slope. The method comprises the following steps: establishing a stability three-dimensional numerical model of a high slope in a construction area according to the physical mechanics parameters of the rocks and soil in the high slope, hydrogeological and engineering geological features in the high slope area, meteorological data and FLAC3D (Fast Lagrangian Analysis Of Continua In 3 Dimensions) technology; establishing a three-dimensional visual safety pre-warning platform based on a VTK (Visualization Tool Kit) commercial software system; acquiring real-time offsetting slipping monitoring data of the slide face of the high slope and the ambient pore water pressure data of the slide face; transmitting the data to a remote computer, and loading to the stability three-dimensional numerical model of the high slope; analyzing the actually-measured data by the model, and comparing with the data of the model, so as to generate a sliding stability grading pre-warning parameter of the high slope; displaying and grading the safety pre-warning through the three-dimensional visual safety pre-warning platform; and transmitting the pre-warning information to cell phones of relative personnel in the form of short messages through a short message module which is linked with the remote computer, thus accomplishing the slide-face type stability remote three-dimensional digital pre-warning of the high slope.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

Method and system for remote three-dimensional digital safety early warming for tunnel construction landslide

The invention establishes a construction area tunnel excavation three-dimensional strain numerical model based on tunnel construction areal geology reconnaissance documents and an FLAC3D (Fast Lagrangian Analysis of Continua in 3-D) technology, establishes an intelligent displacement back analysis model based on a difference evolution method and establishes a three-dimensional visualization safety early warming platform based on a VTK (Visualization Tool Kit) commercial software system. The method comprises the following steps: acquiring real-time monitoring data of tunnel initial convergence displacement; transmitting the real-time monitoring data to a user computer; analyzing the obtained real-time monitoring displacement data by using the tunnel excavation three-dimensional strain numerical model and the intelligent displacement back analysis model; carry out displacement normal and back analysis by using the difference evolution method; displaying through the visualization safety early warming platform; analyzing and comparing real-time monitoring displacement values with a surrounding rock convergence deformation threshold obtained from the normal and back analysis; and subsequently carrying out graded early warming about the deformation stability of a tunnel supporting structure, wherein the early warming information is transmitted to cell phones of relevant on-site construction and ground management personnel through a short message module connected with a computer through a cell phone short message, so as to accomplish the remote three-dimensional digital safety early warming for tunnel construction landslides.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

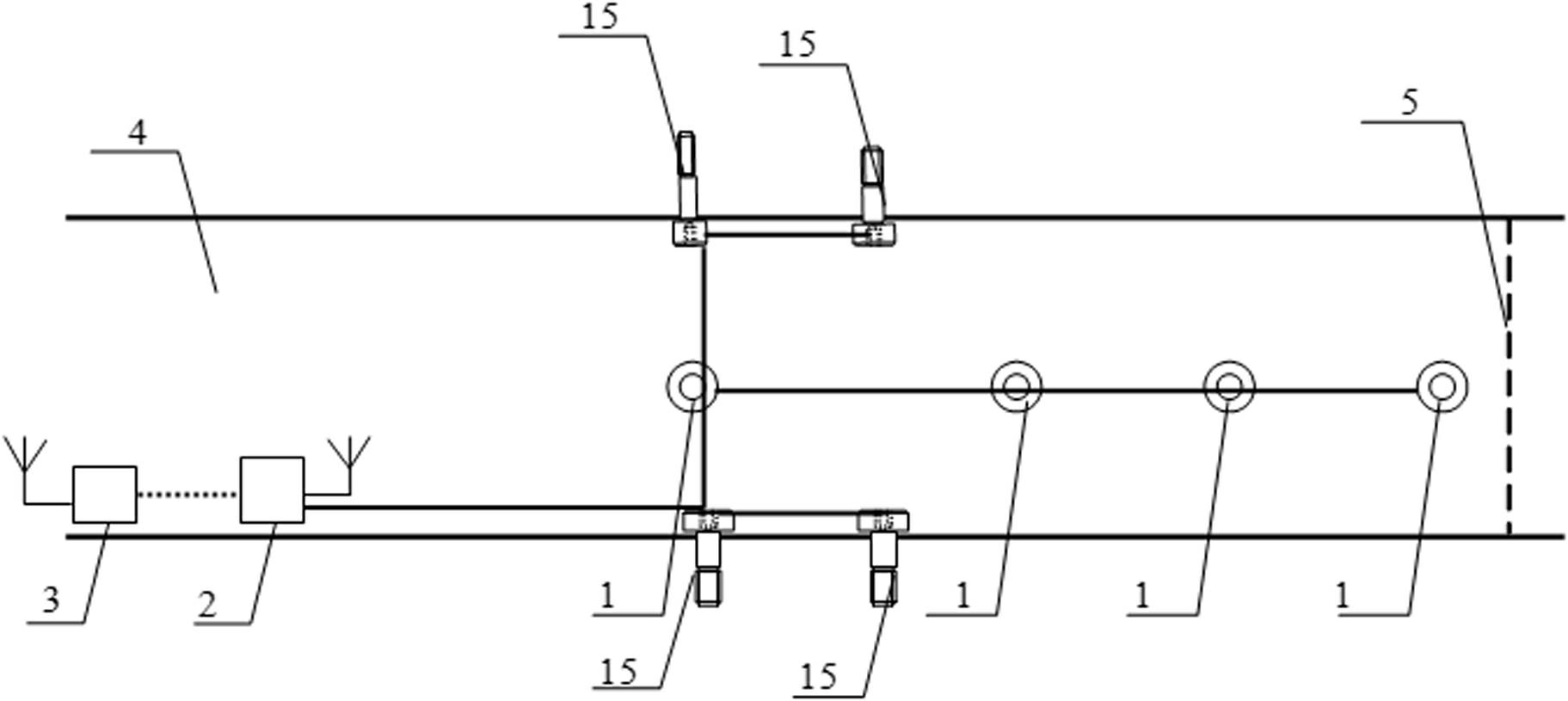

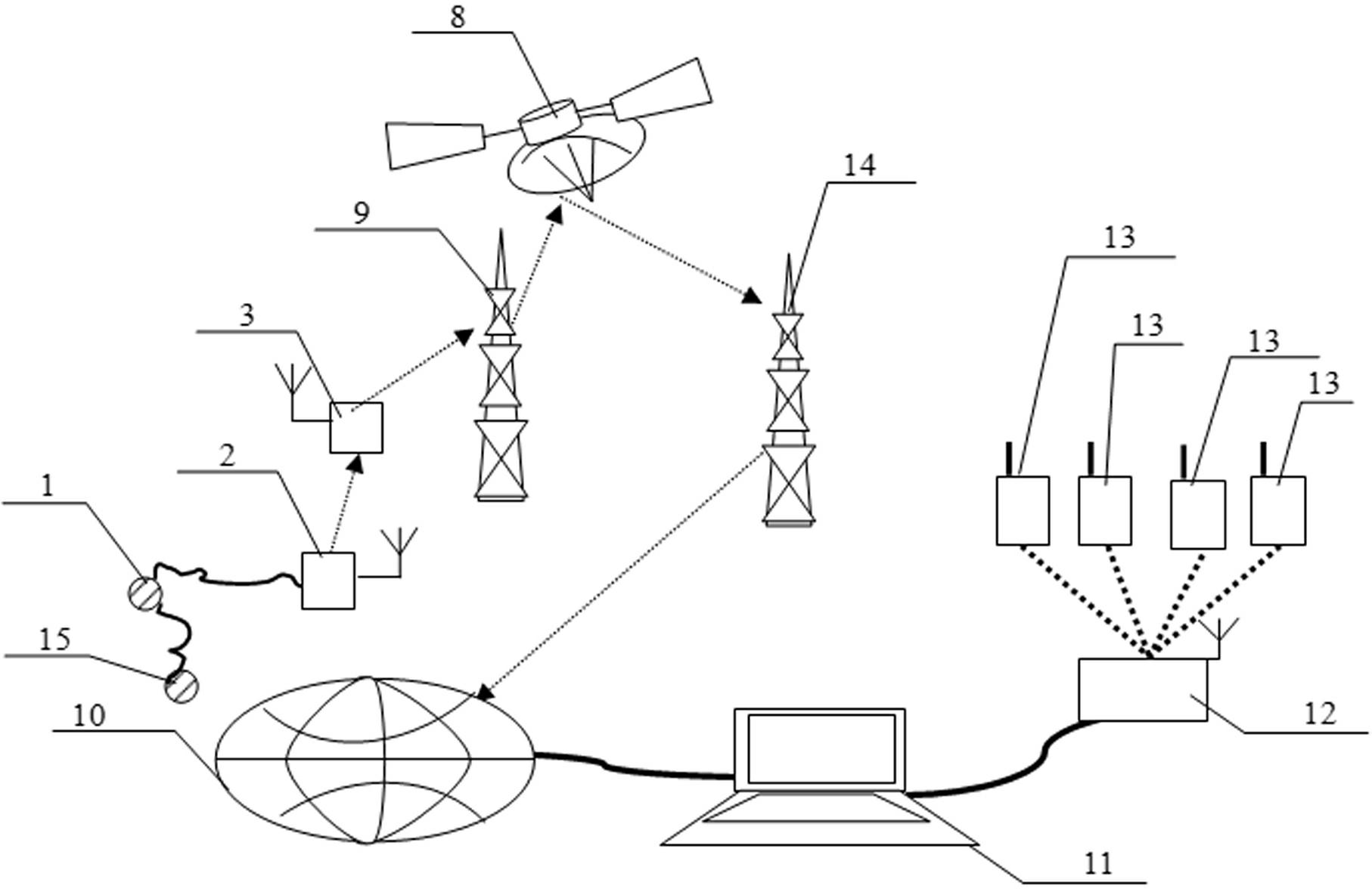

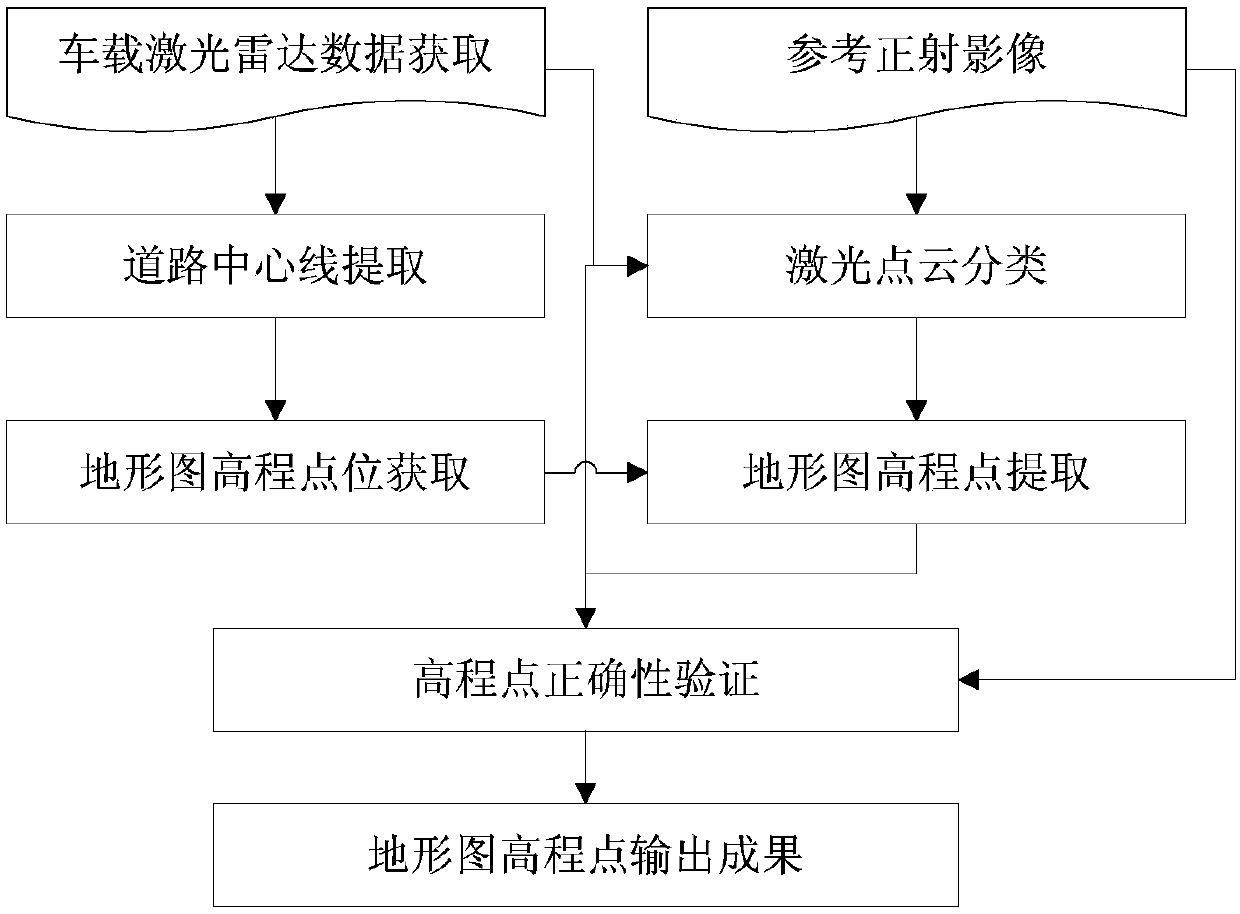

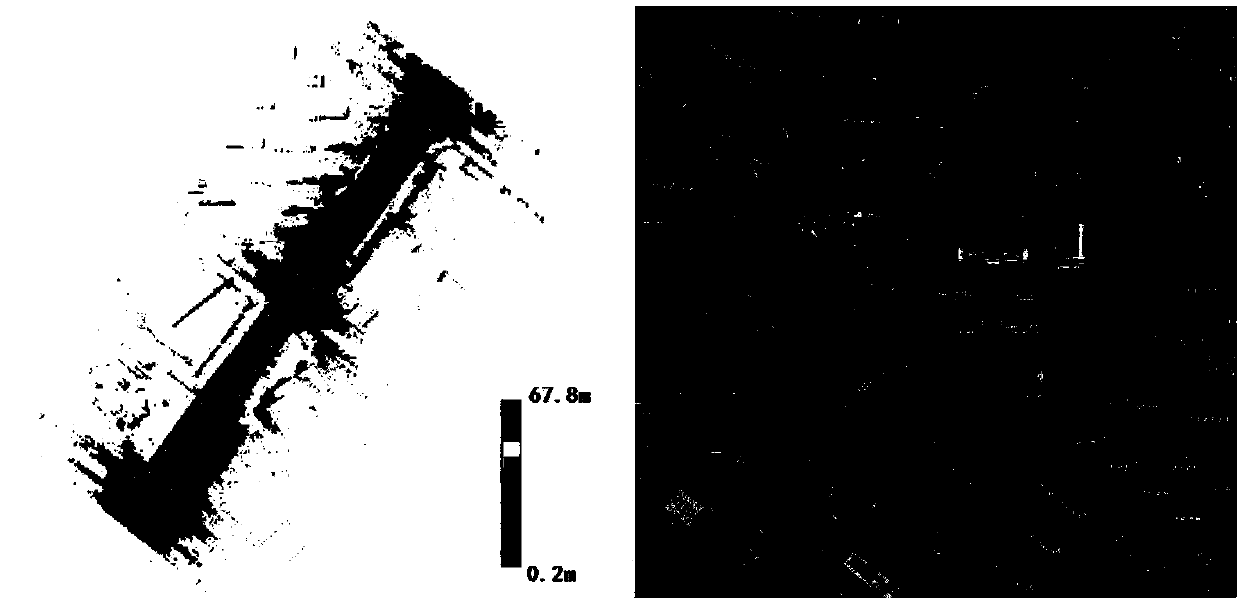

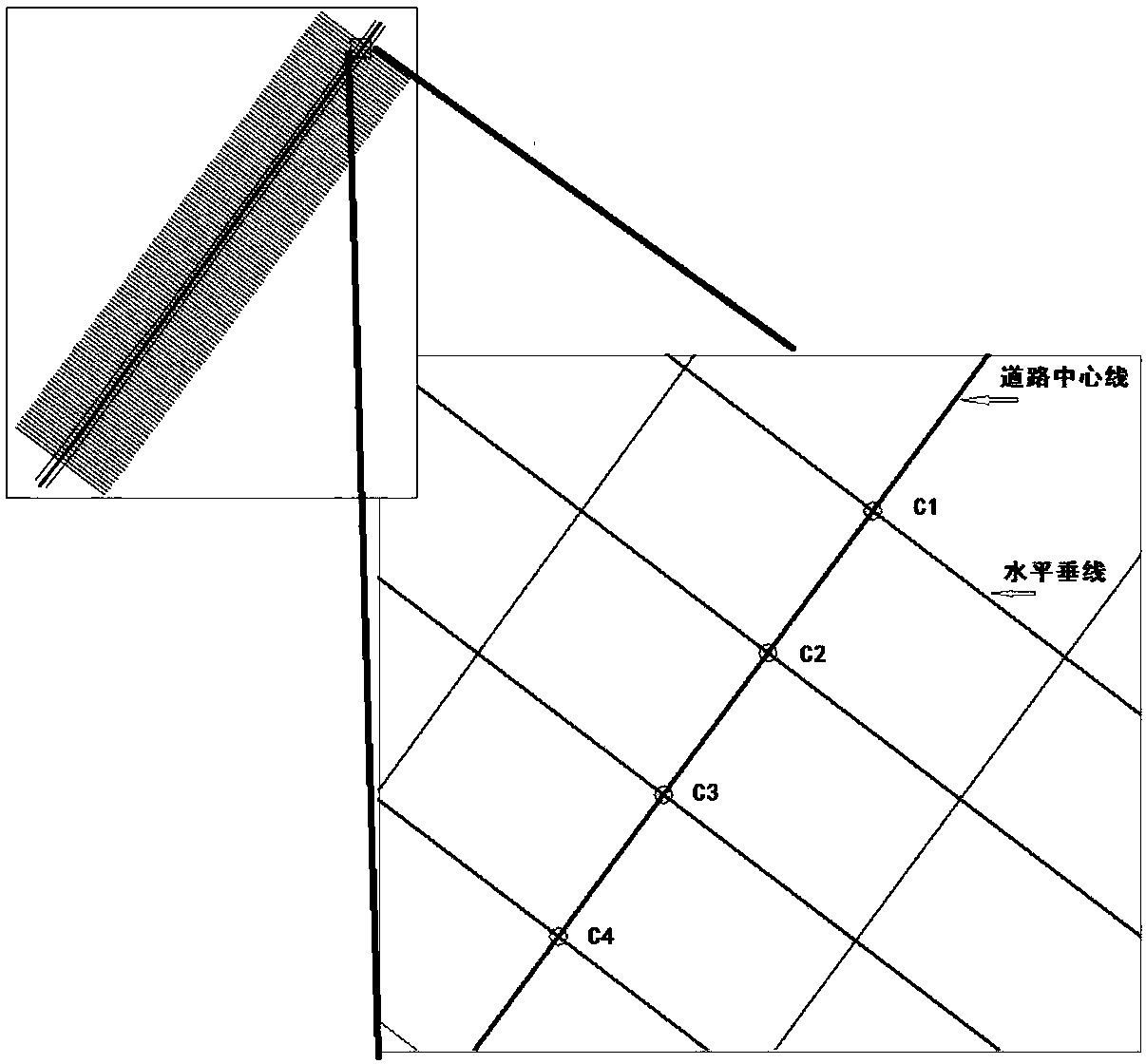

Method for automatically extracting elevation point of road topographic map based on vehicle-borne LiDAR data

The present invention discloses a method for automatically extracting an elevation point of a road topographic map based on vehicle-borne LiDAR data. The method comprises a step of obtaining vehicle-borne LiDAR point cloud data and classifying surface points and non-surface points with commercial software and a step of extracting a road center line according to a trajectory line of vehicle-borne scanning, determining a position of an elevation point to be extracted, and thus obtaining elevation point three-dimensional coordinates needed by the road topographic map. Compared with the prior art,the method provided by the invention has the advantages that a method of topographic map elevation point automatic acquisition and elevation value automatic acquisition suitable for vehicle-borne laser point cloud is invented and used, and the elevation point required for a road area topographic map can be extracted according to vehicle-borne laser point cloud data.

Owner:南京市测绘勘察研究院股份有限公司

Remote intelligent monitoring and three-dimensional early warning method and system for stress stability of deep foundation pit

The invention establishes a three-dimensional numerical model for the excavation stress stability of a deep foundation pit in a construction area based on parameters including rock-soil physical mechanics parameters of the deep foundation pit, hydrogeology and engineering geology conditions of a deep foundation pit area, fender post design strength, specifications and dimensions, and the like as well as an FLAC3D technology, and establishes a deep foundation pit three-dimensional visual safety pre-warning platform on the basis of a VTK (Visualization Tool Kit) commercial software system. A method disclosed by the invention comprises the following steps of: acquiring horizontal displacement of a foundation pit slope crest and the fender posts, I steel support axial force and real-time monitoring data of soil pore water pressure around the fender posts through a gradient meter, an axial force meter and a pore water pressure meter, transmitting to a remote monitoring and data processing host, comparing real-time mechanics data with a model threshold value by using the three-dimensional numerical model for the excavation stress stability of the deep foundation pit, and displaying and performing graded safety early warning on warning-exceeding parameters through the deep foundation pit three-dimensional visual safety pre-warning platform; and transmitting all early warning information to mobile phones of relevant personnel, and transmitting early warning information to an audible-visual alarm installed on the working surface of a construction site for performing audible-visual alarming.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

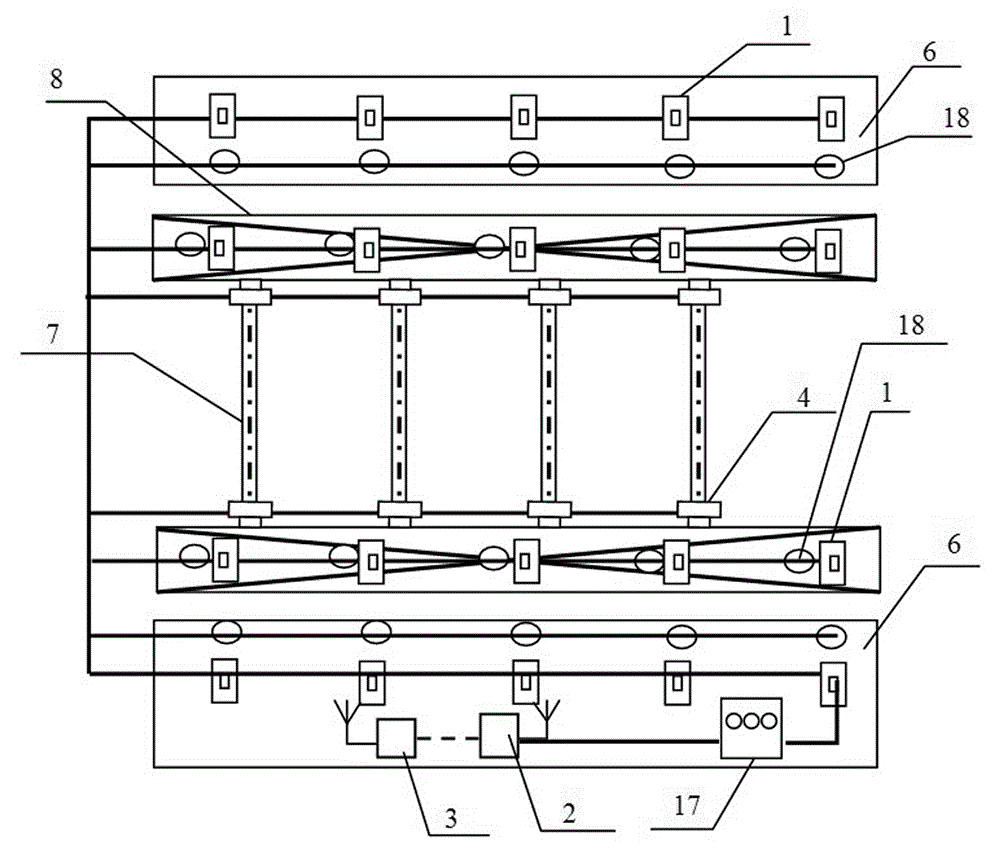

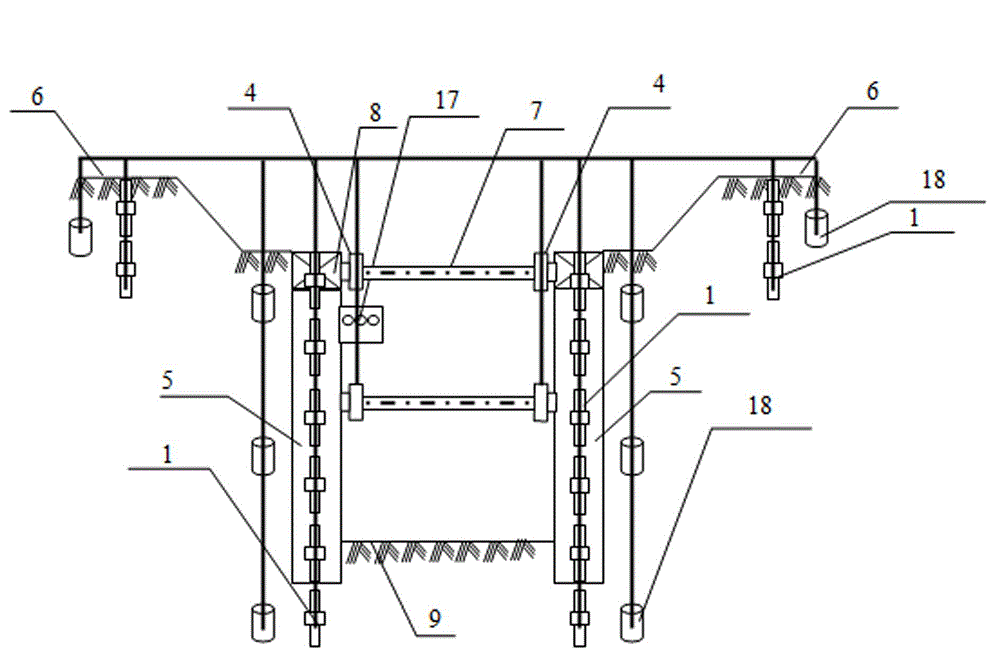

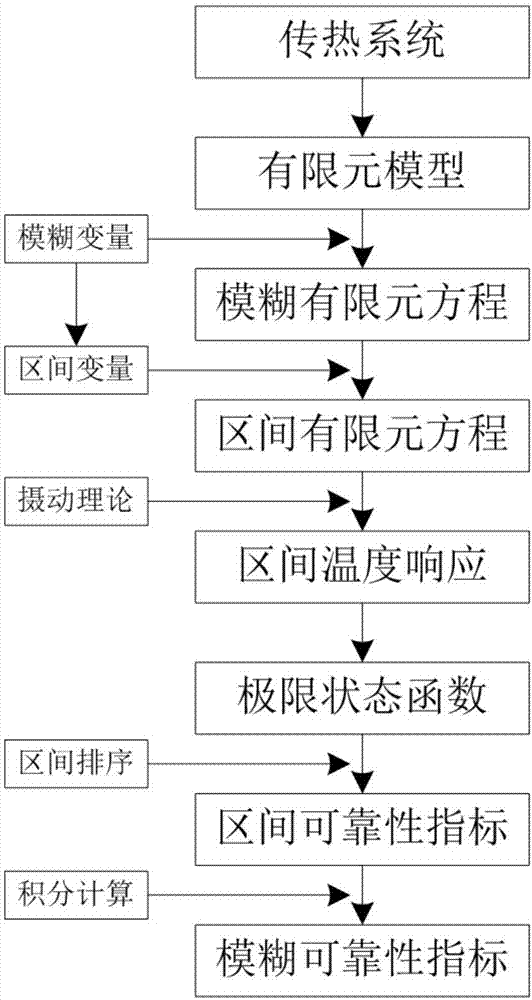

Reliability analysis method for heat transfer system containing fuzzy parameters

ActiveCN106897520ATake full advantage of interval computing technologyThe calculation result is accurateGeometric CADDesign optimisation/simulationTemperature responseElement modeling

The invention discloses a reliability analysis method for a heat transfer system containing fuzzy parameters. The method comprises the following steps that: carrying out the finite element modeling of a heat transfer system; utilizing a fuzzy variable to represent uncertain input parameters, and establishing the fuzzy finite element equation of the heat transfer system; selecting a cut set level, and converting the fuzzy variable into an interval variable so as to obtain one group of interval finite element equations; utilizing a perturbation theory to solve the interval finite element equations to obtain the upper and lower bounds of interval temperature response; according to the temperature response, establishing an ultimate state function which represents system reliability, and calculating the upper and lower bounds of the ultimate state function; utilizing an interval sorting method to process the ultimate state function to obtain an interval reliability index under each cut set level; and carrying out integral computation on the interval reliability index under the cut set level, and finally, obtaining the fuzzy reliability index of the heat transfer system. On a premise that calculation efficiency is guaranteed, by use of the method, the fuzzy reliability calculation accuracy of the heat transfer system can be effectively improved, which can not be realized by general commercial software.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com