Curved surface model path planning method applied to laser surface etching

A surface etching and path planning technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of less related algorithms, and achieve the effect of less calculation, moderate quantity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and embodiments.

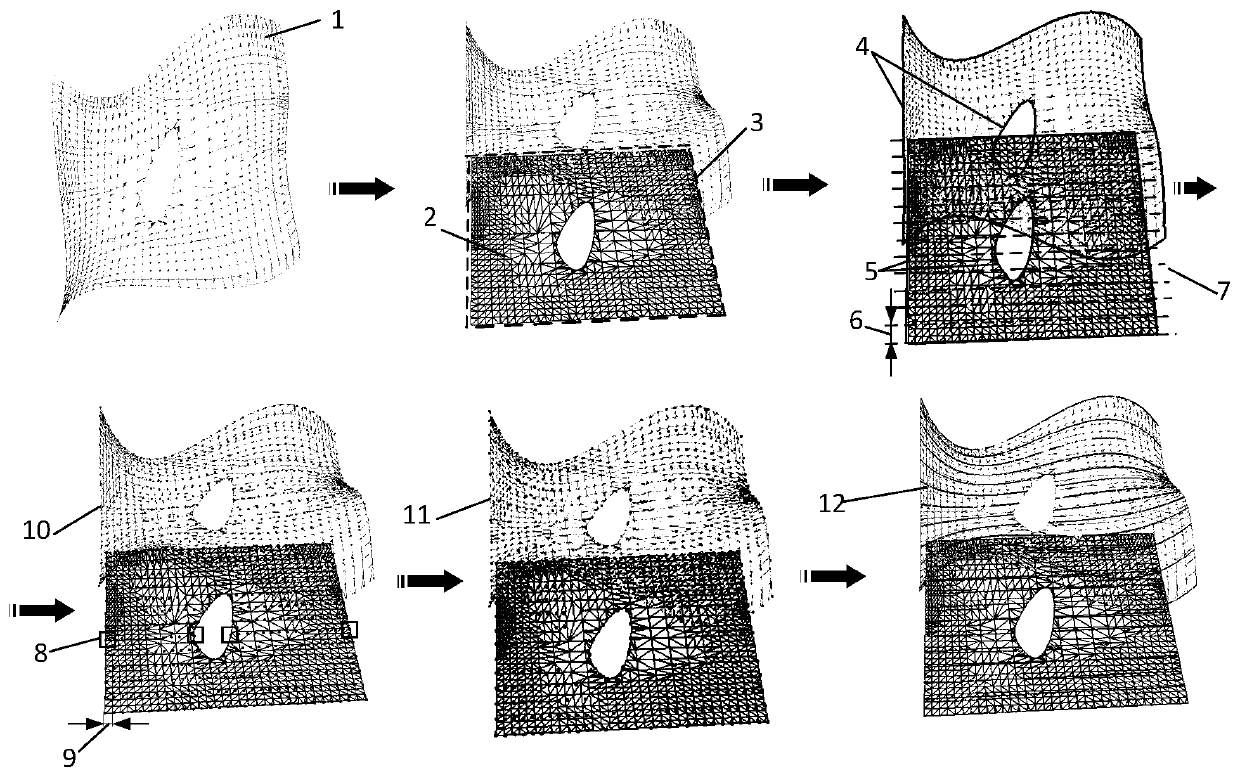

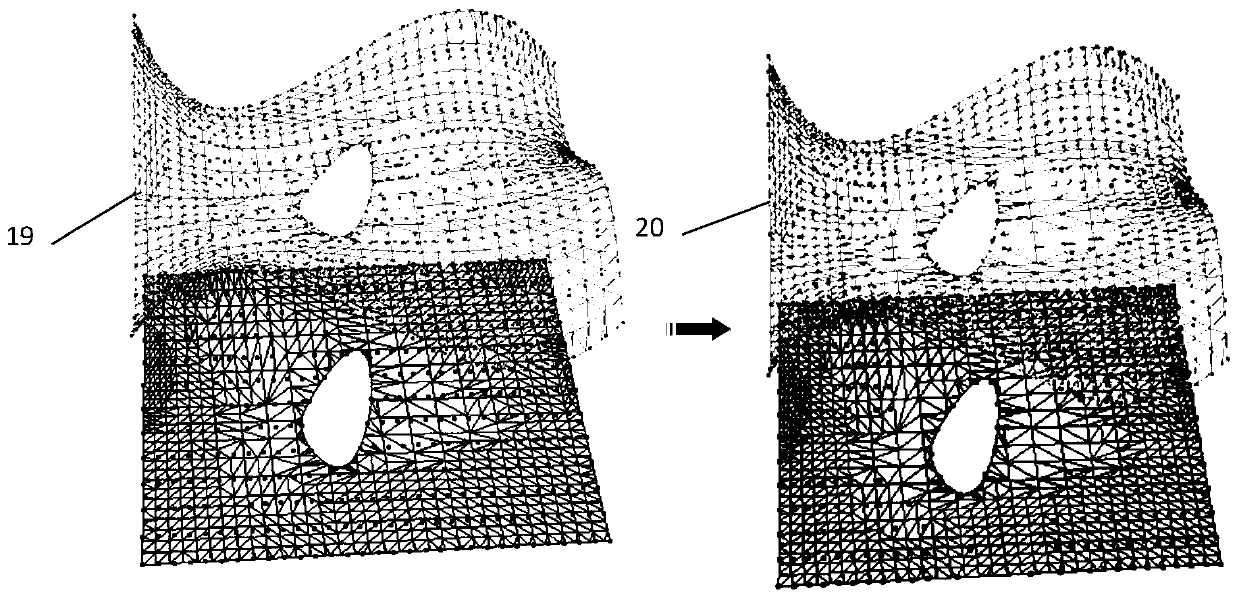

[0037] like figure 1 Shown: the present invention provides a surface model path planning method applied to laser surface etching, the method takes a three-dimensional curved surface 1 as an input, a three-dimensional scanning path 12 on the curved surface as an output, and uses multiple parameters to control the accuracy of the path planning and operation volume. The parameters include the vertical distance of the waypoint 7 and the horizontal distance of the waypoint 9. In addition, the sparse parameter map cannot be represented.

[0038] The steps of path planning are as follows:

[0039] 1) Form a bounding box

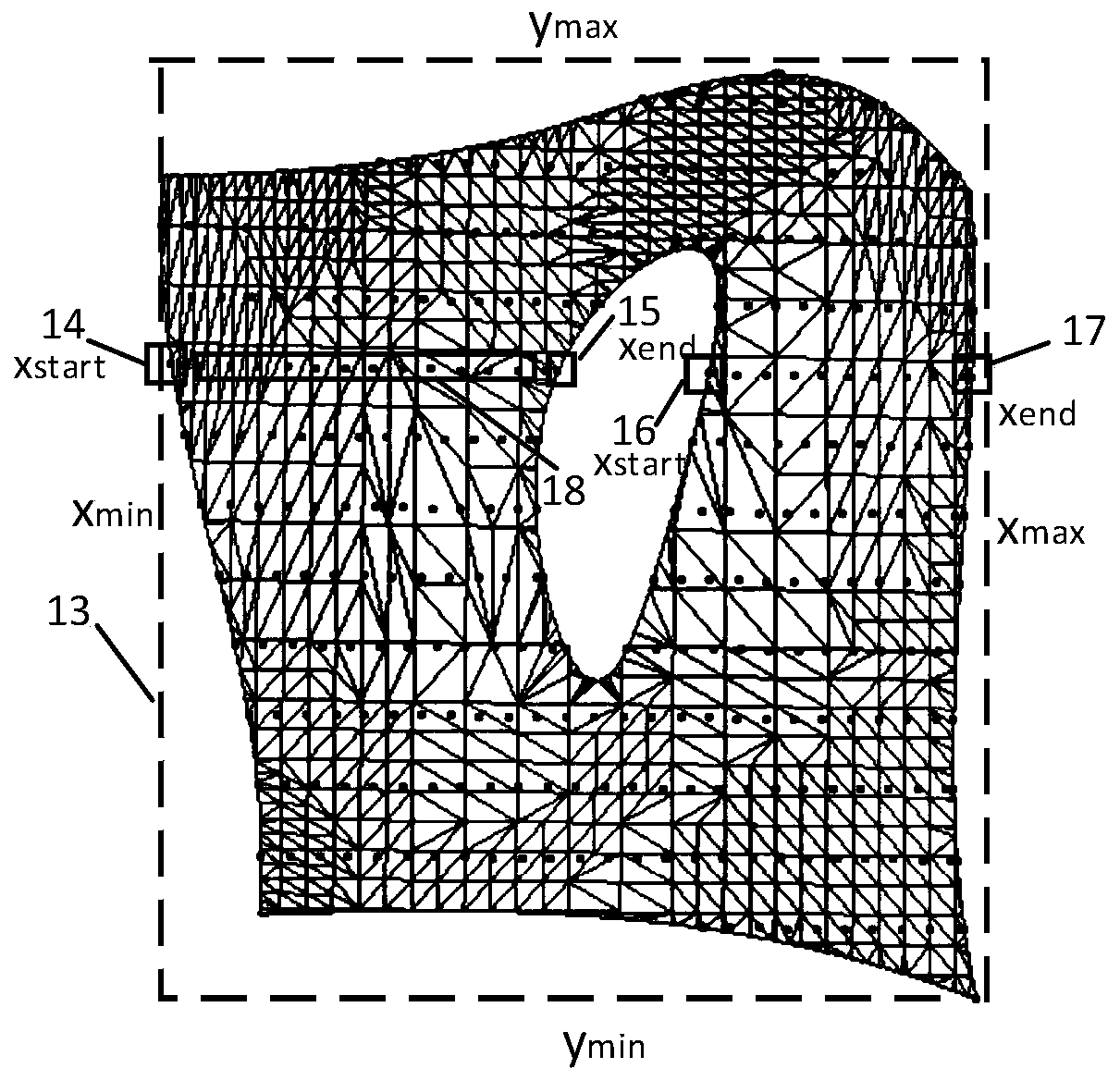

[0040] Project the three-dimensional surface 1 to form a bounded plane 2 consisting of a series of triangles, and find the extent x of the bounded plane 2 min , x max , y min and y max , forming a rectangular bounding box 3 to enclose it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com