Method for detecting and classifying fabric defects

A classification method and defect detection technology, applied in the field of image recognition, can solve problems such as inability to classify defects, and achieve the effect of reducing correlation and saving computation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

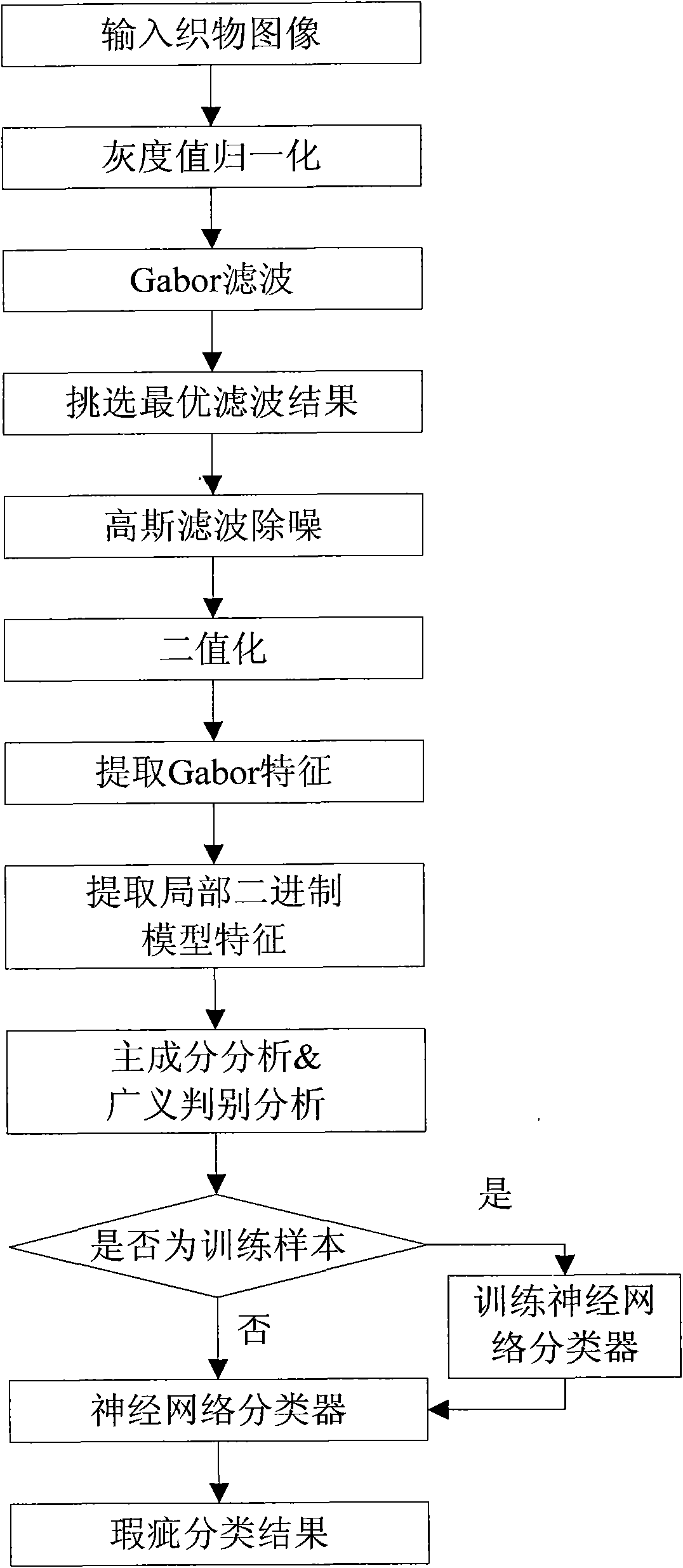

[0022] refer to figure 1 , the present invention proposes a method for automatic detection and classification of fabric defects, and its implementation steps include the following:

[0023] Step 1: Use an ordinary industrial camera to obtain grayscale images of fabric defects with a resolution of 256*256.

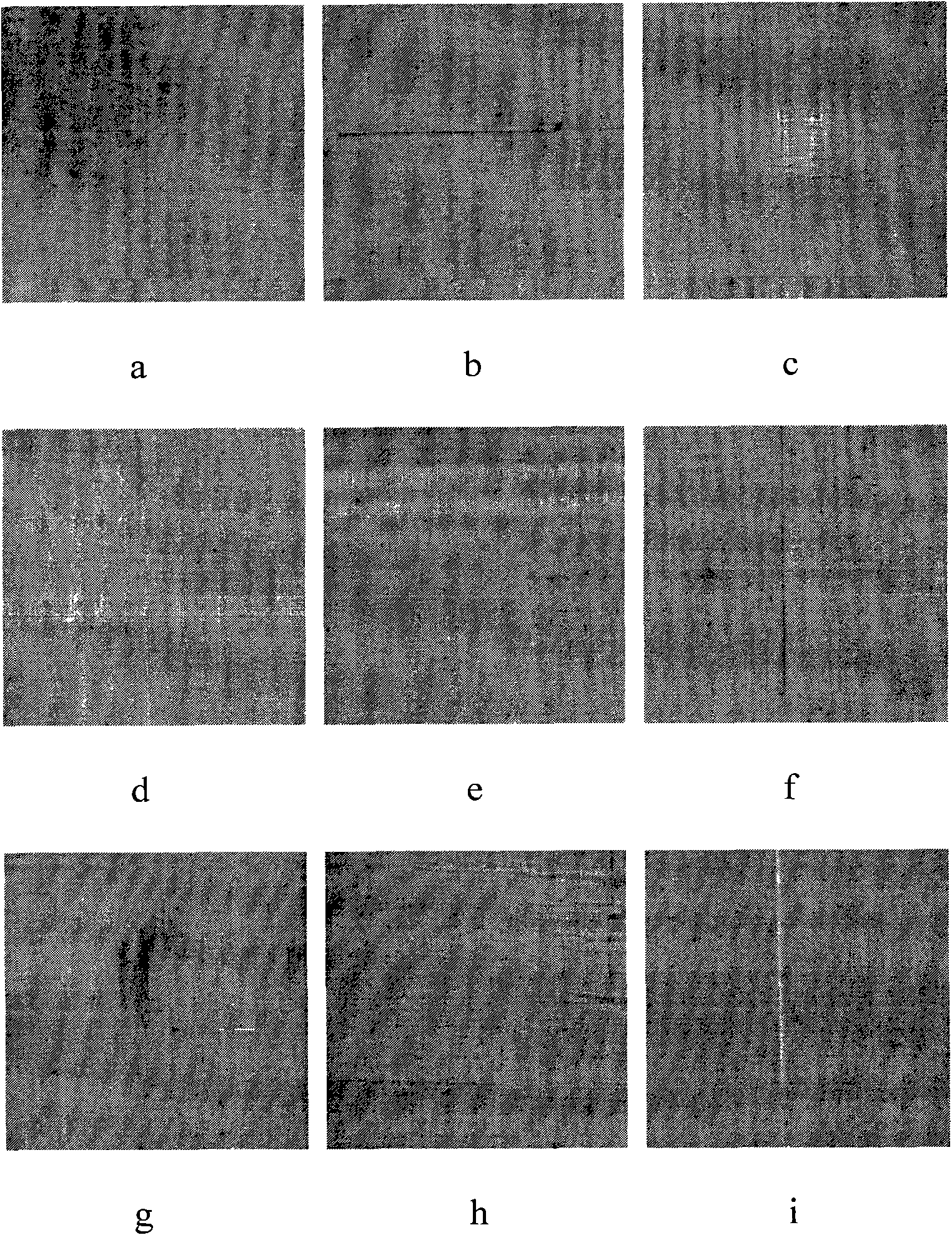

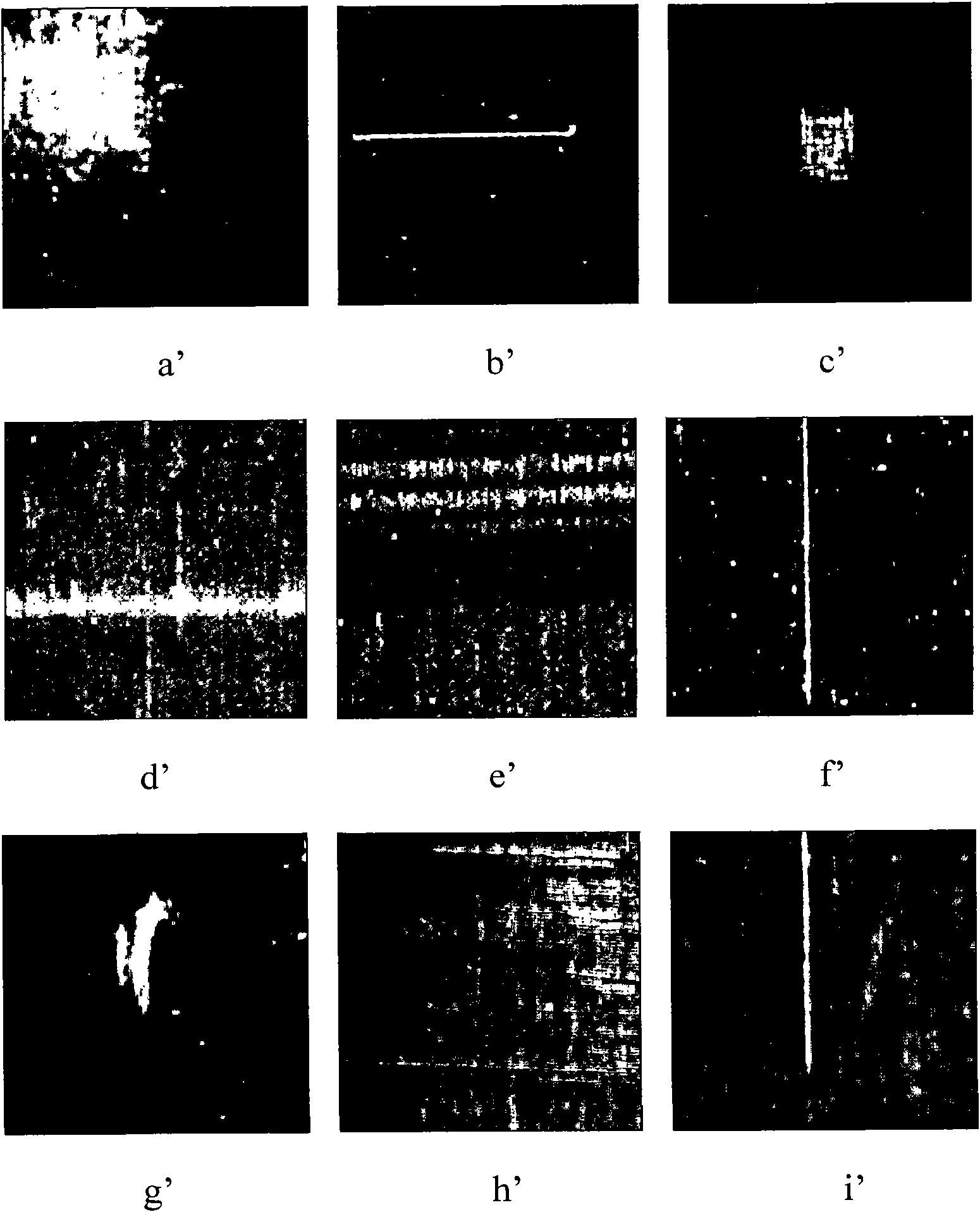

[0024] The present invention uses industrial cameras to obtain fabric pictures from the fabric inspection production line, selects the flaw pictures, and collects 9 common types of fabric flaws, such as figure 2 , each category includes 80 pictures, all of which are 8-bit grayscale images with a size of 256*256. For each category, 75% of the pictures randomly selected are used as training samples, and all pictures are used for testing.

[0025] Step 2: Normalize the pixel gray values of the fabric gray image so that all pixel values in an image have zero mean and a standard deviation of 1.

[0026] Input the grayscale fabric image I, the grayscale value of each pixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com