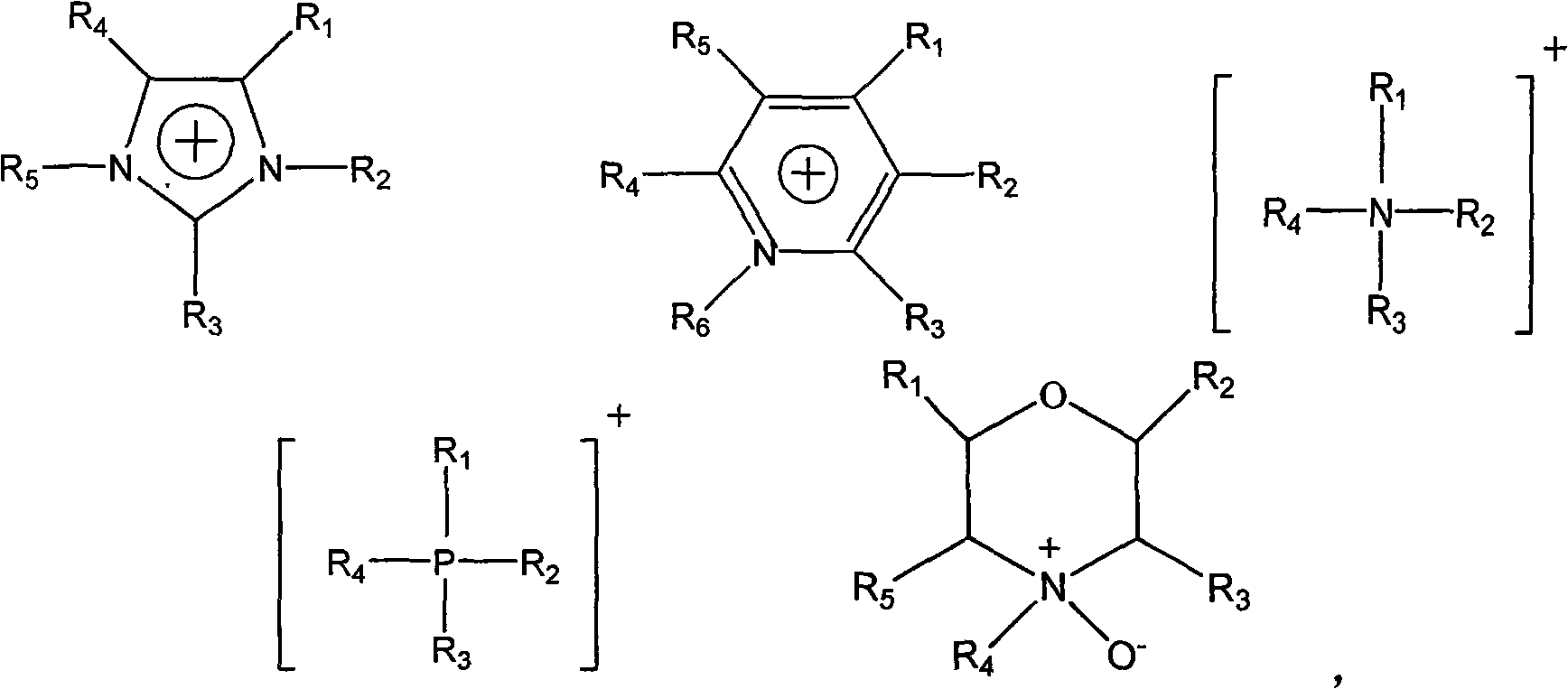

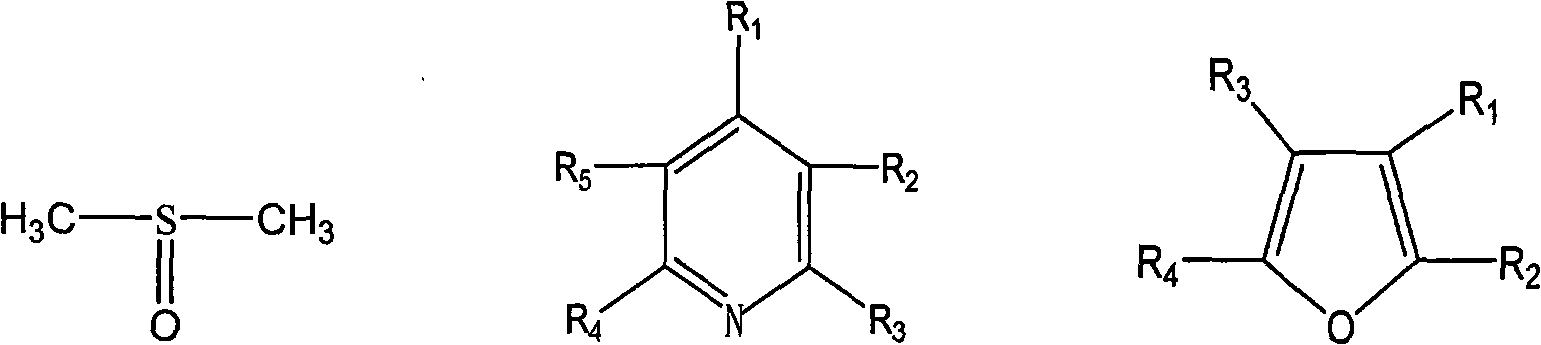

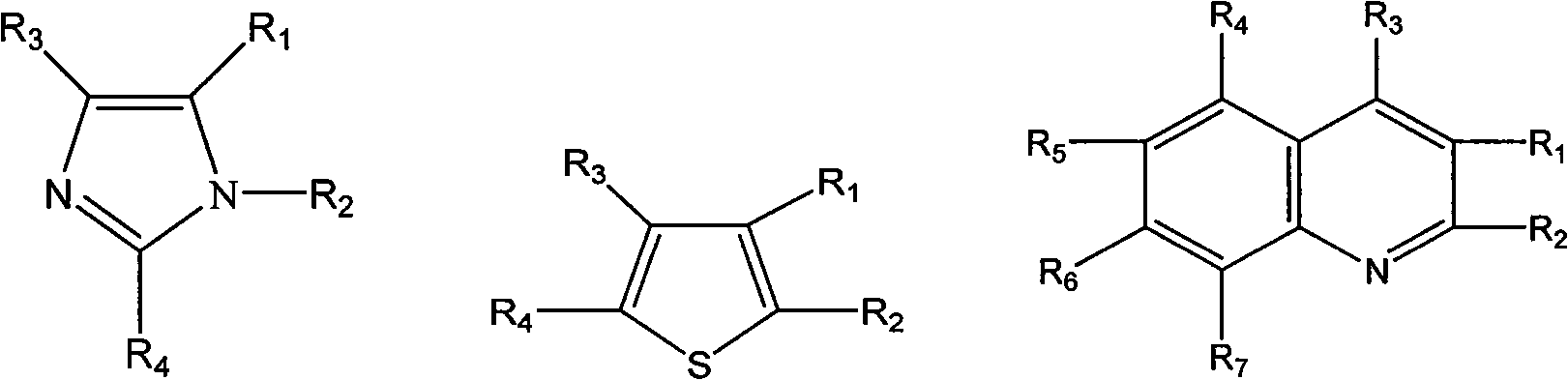

Anti-degradable solvent for dissolving cellulose and preparation method of spinning dope thereof

A technology for dissolving cellulose and spinning dope, which is applied in the production of artificial filaments made of viscose and bulk chemicals. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Stir 10 g of BmimCl (1-butyl-3-methyl-imidazolium chloride) after vacuum drying in an oil bath at 90°C for 30 minutes. After the solution becomes transparent and clear, add cotton with a degree of polymerization of 500 after vacuum drying. 1g of staple fiber, continue to stir at 90°C for 7 hours to dissolve the cellulose, keep the whole process sealed, then filter, defoam, and finally obtain a light yellow spinning fiber with a concentration of 10%, a viscosity of 160Pa.s, and a degree of polymerization of 188 stock solution.

example 2

[0020] Stir 15g of EmimAc (1-ethyl-3-methyl-imidazole acetate) and 3g of pyridine in a 90°C oil bath for 30 minutes after vacuum drying, and after the solution becomes transparent and clear, add the degree of polymerization after vacuum drying 2g of 500 cotton linter short fibers, continue to stir at 90°C for 7h to dissolve the cellulose, keep the whole process sealed, then filter, defoam, and finally obtain a concentration of 10%, a viscosity of 220Pa·s, and a degree of polymerization of 240 Milky white spinning dope.

example 3

[0022] Stir 5g of BmimBr (1-butyl-3-methyl-imidazolium bromide) and 10g of DMSO after vacuum drying in an oil bath at 90°C for 30 minutes. 0.75g of short cotton linters, continue to stir at 90°C for 7h to dissolve the cellulose, keep the whole process sealed, filter, and defoam to finally obtain a milky white spinning fiber with a concentration of 5%, a viscosity of 330Pa.s, and a degree of polymerization of 380. Silk stock solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com