Modified reinforced geopolymer gelling material and preparation method thereof

A cementing material and enhanced technology, which is applied in the field of modified and enhanced geopolymer cementing material and its preparation, can solve the problems of chemical stability and other problems, and achieve the effect of high mechanical strength and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

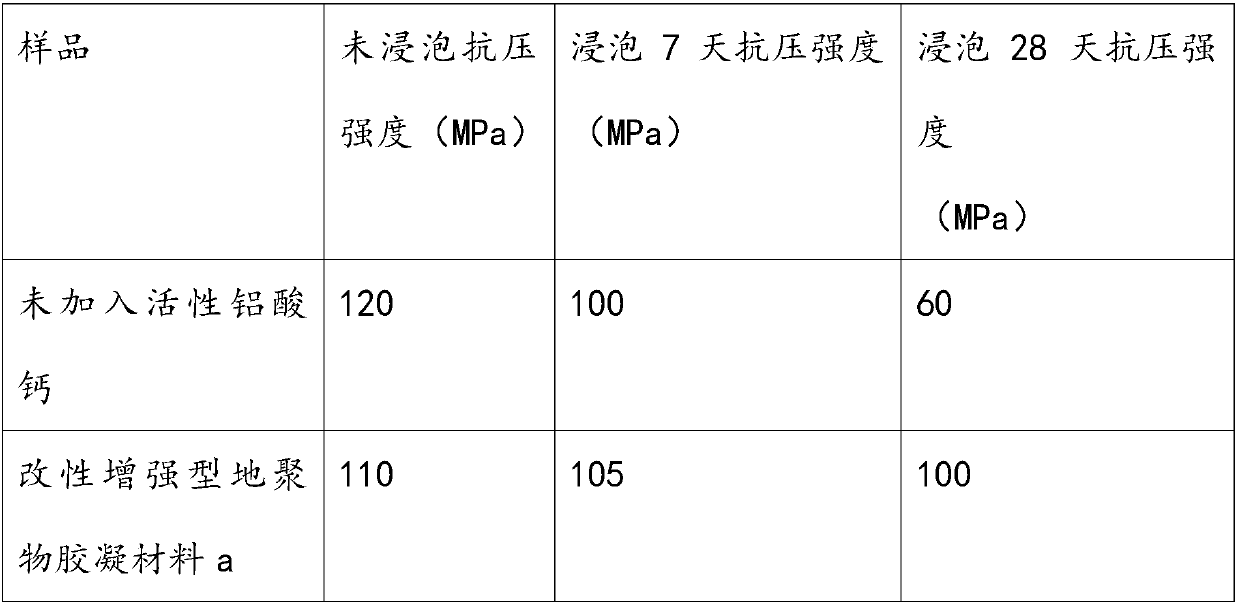

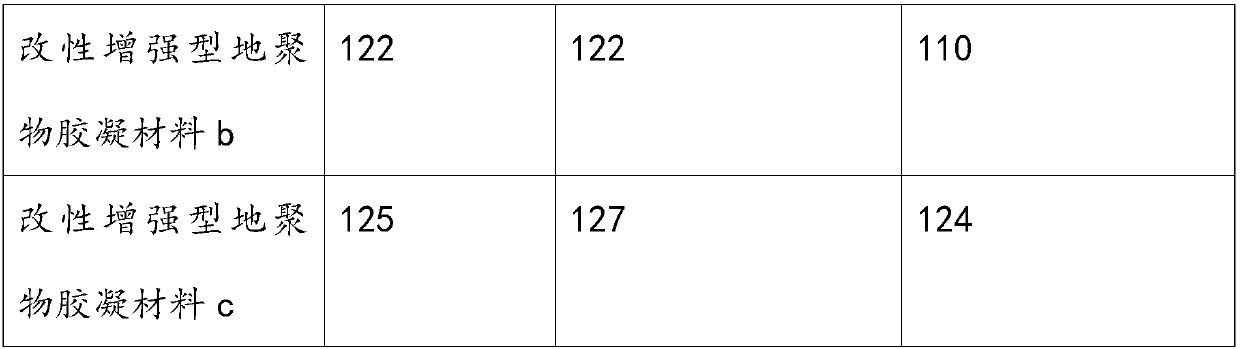

Examples

Embodiment 1

[0022] 1) Calcining high-quality kaolin at 750°C, 30 parts of metakaolin with a particle size of 0.1-100 microns, 10 parts of first-grade fly ash with a particle size of 0.1-100 microns, and 105-grade slag with a particle size of 0.1-100 microns 5 parts, 10 parts of water-quenched electric furnace steel slag with a particle size of 0.1-100 microns, 4 parts of silica fume with a particle size of 0.1-100 microns, and 2 parts of silicon dioxide are mixed in proportion and ground to obtain a compound silicon-aluminum powder;

[0023] 2) Take 40 parts of the compound silicon-aluminum powder obtained in step 1), and 2 parts of the condensed phosphoric acid obtained by secondary condensation of aluminum tripolyphosphate at 450°C for 4 hours, and then spray, dry, crush and sieve Aluminum and 5 parts of active calcium aluminate are mixed and ground to obtain compound powder;

[0024] 3) Dissolving 5 parts of sodium hydroxide into 70 parts of liquid sodium silicate with a solid content ...

Embodiment 2

[0027] 1) Calcining high-quality kaolin at 800°C, 25 parts of metakaolin with a particle size of 0.1-100 microns, 15 parts of first-grade fly ash with a particle size of 0.1-100 microns, and 105-grade slag with a particle size of 0.1-100 microns 8 parts, 7 parts of water-quenched electric furnace steel slag with a particle size of 0.1-100 microns, 5 parts of silica fume with a particle size of 0.1-100 microns, and 1.5 parts of silicon dioxide are mixed in proportion and ground to obtain a compound silicon-aluminum powder;

[0028] 2) Take 50 parts of the compound silicon-aluminum powder obtained in step 1), and 4 parts of the condensed phosphoric acid obtained by secondary condensation of aluminum tripolyphosphate at 450°C for 4 hours, and then spray, dry, crush and sieve Aluminum and 10 parts of calcium aluminate cement are mixed and ground to obtain compound powder;

[0029] 3) Dissolving 10 parts of sodium hydroxide into 60 parts of liquid sodium silicate with a solid conte...

Embodiment 3

[0032] 1) Calcining high-quality kaolin at 850°C, 20 parts of metakaolin with a particle size of 0.1-100 microns, 20 parts of first-grade fly ash with a particle size of 0.1-100 microns, and 105-grade slag with a particle size of 0.1-100 microns 10 parts, 5 parts of water-quenched electric furnace steel slag with a particle size of 0.1-100 microns, 6 parts of silica fume with a particle size of 0.1-100 microns and 1 part of silicon dioxide are mixed in proportion and ground to obtain a compound silicon-aluminum powder;

[0033] 2) Take 60 parts of the compound silicon-aluminum powder obtained in step 1), and 6 parts of condensed phosphoric acid obtained by secondary condensation of aluminum tripolyphosphate at 450°C for 4 hours, and then spray, dry, crush and sieve Aluminum, 8 parts of activated calcium aluminate, and 7 parts of calcium aluminate cement are mixed and ground to obtain compound powder;

[0034] 3) Dissolve 7 parts of sodium hydroxide and 8 parts of potassium hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com