Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Low intrinsic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

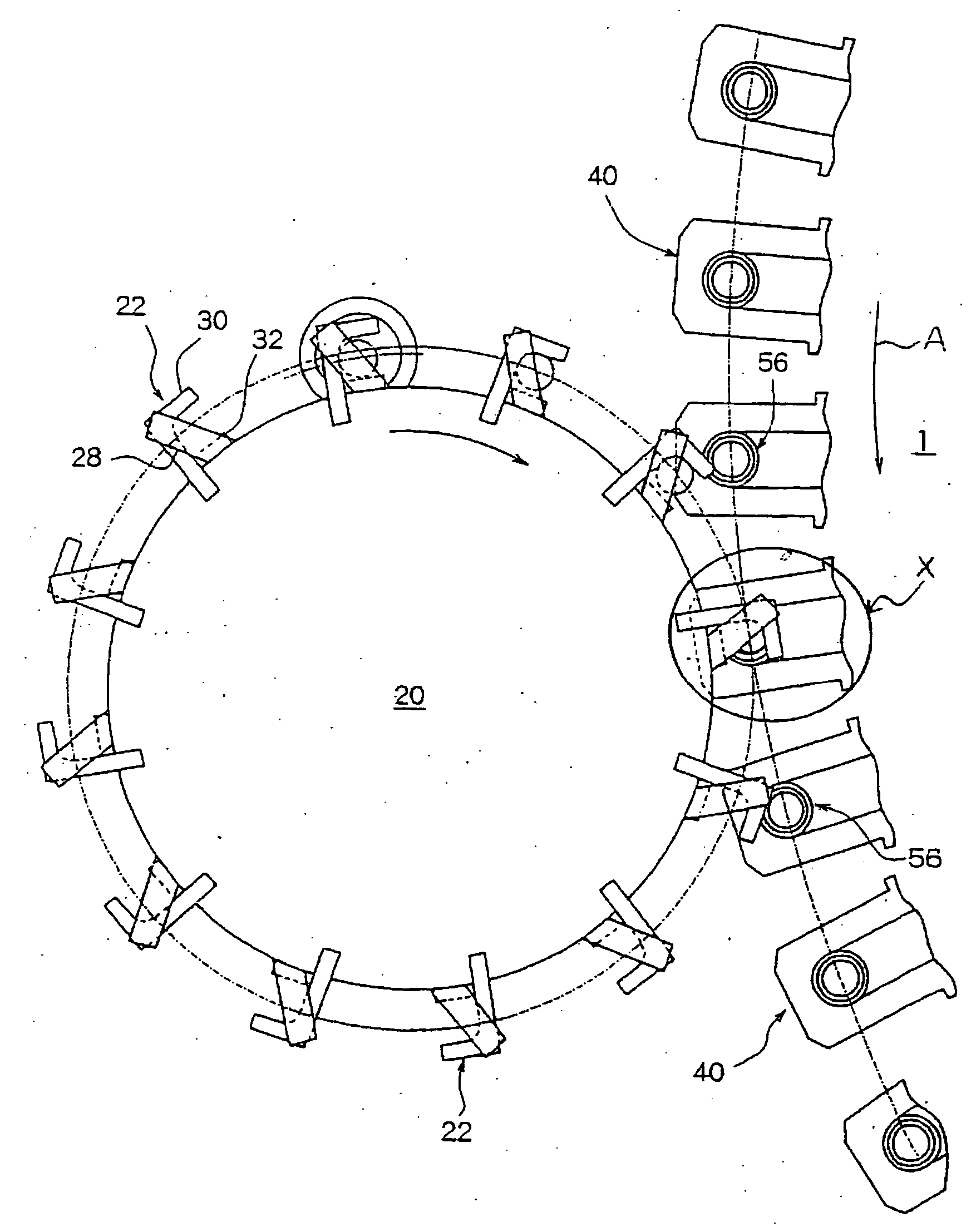

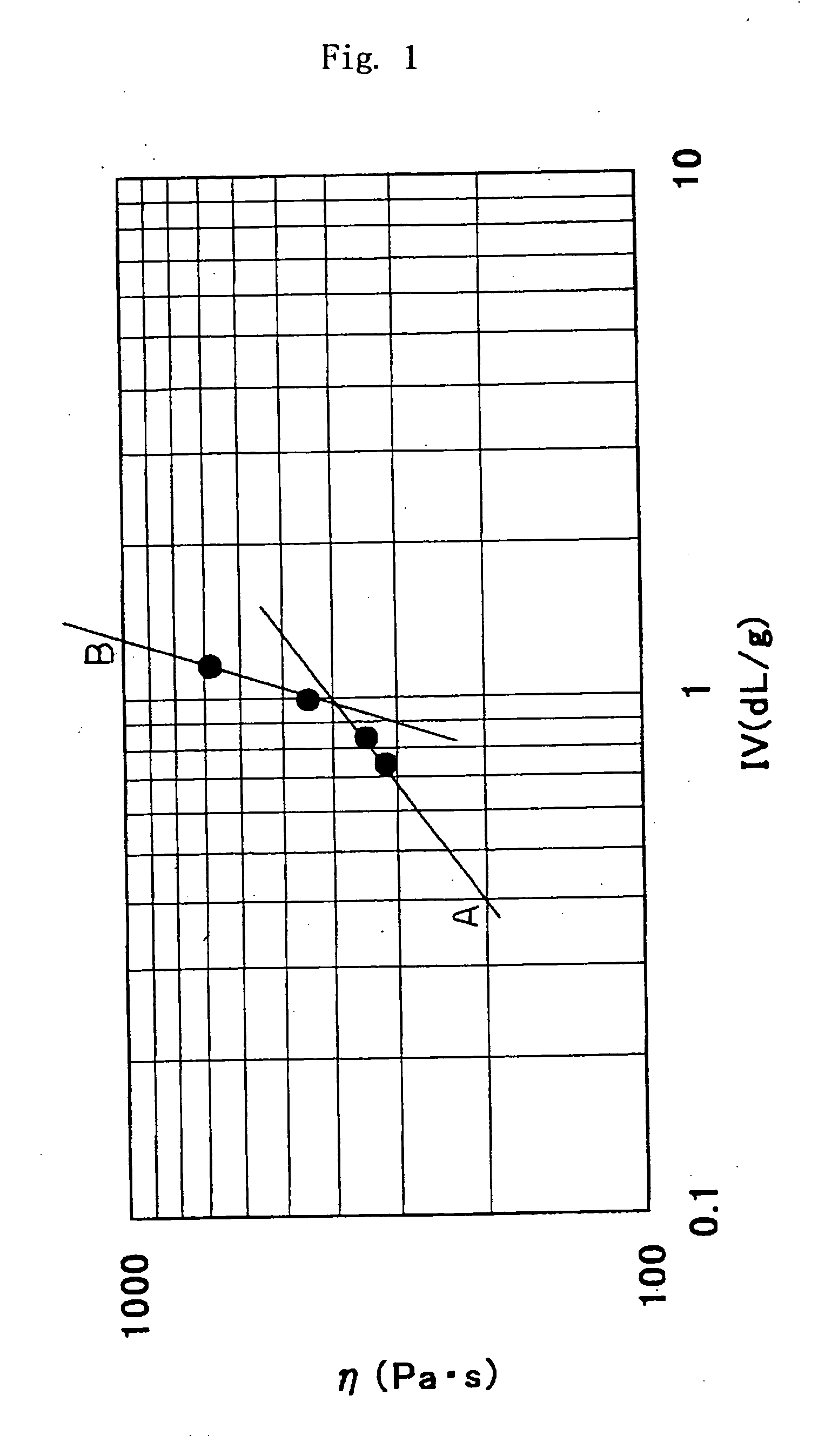

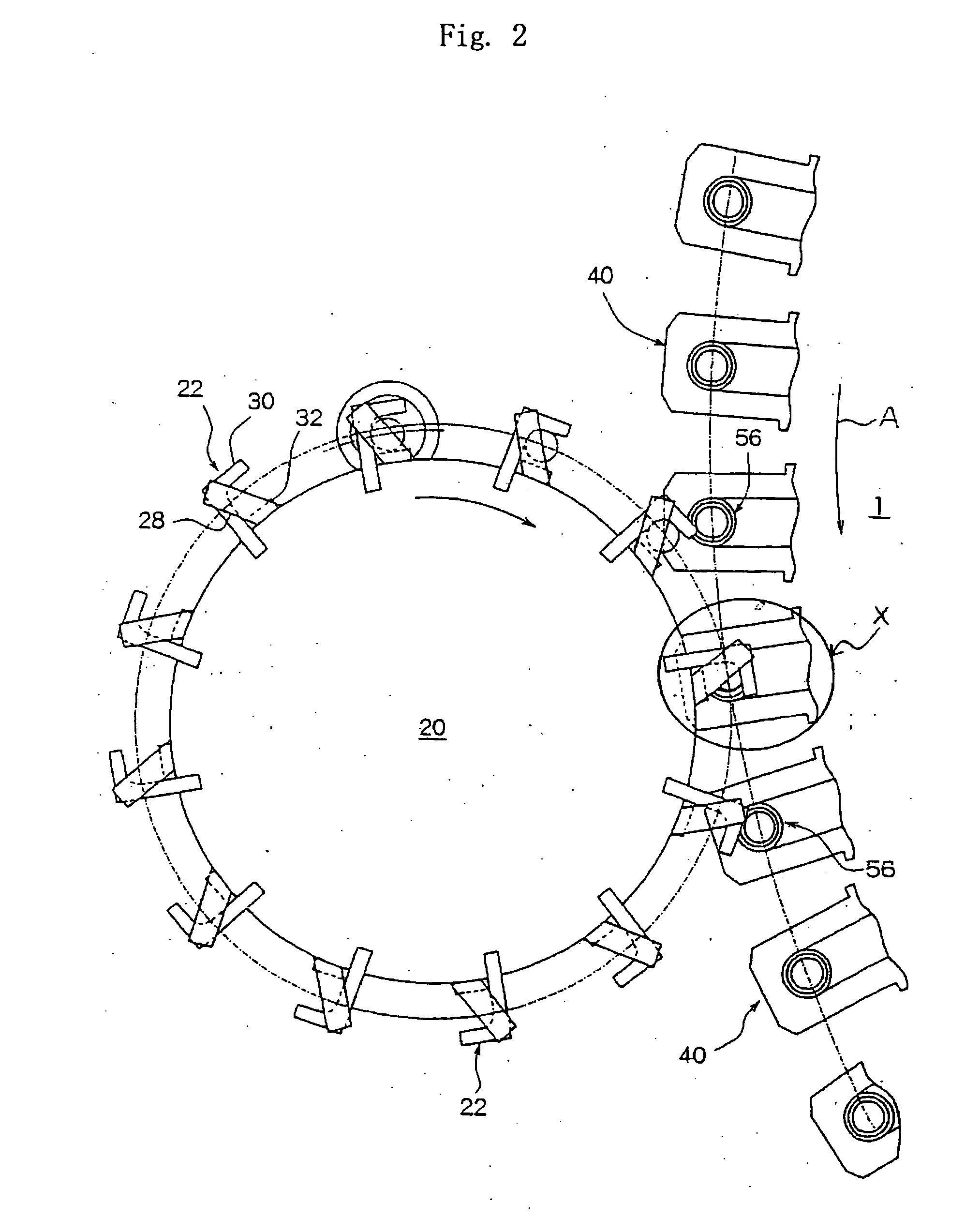

Resin composition

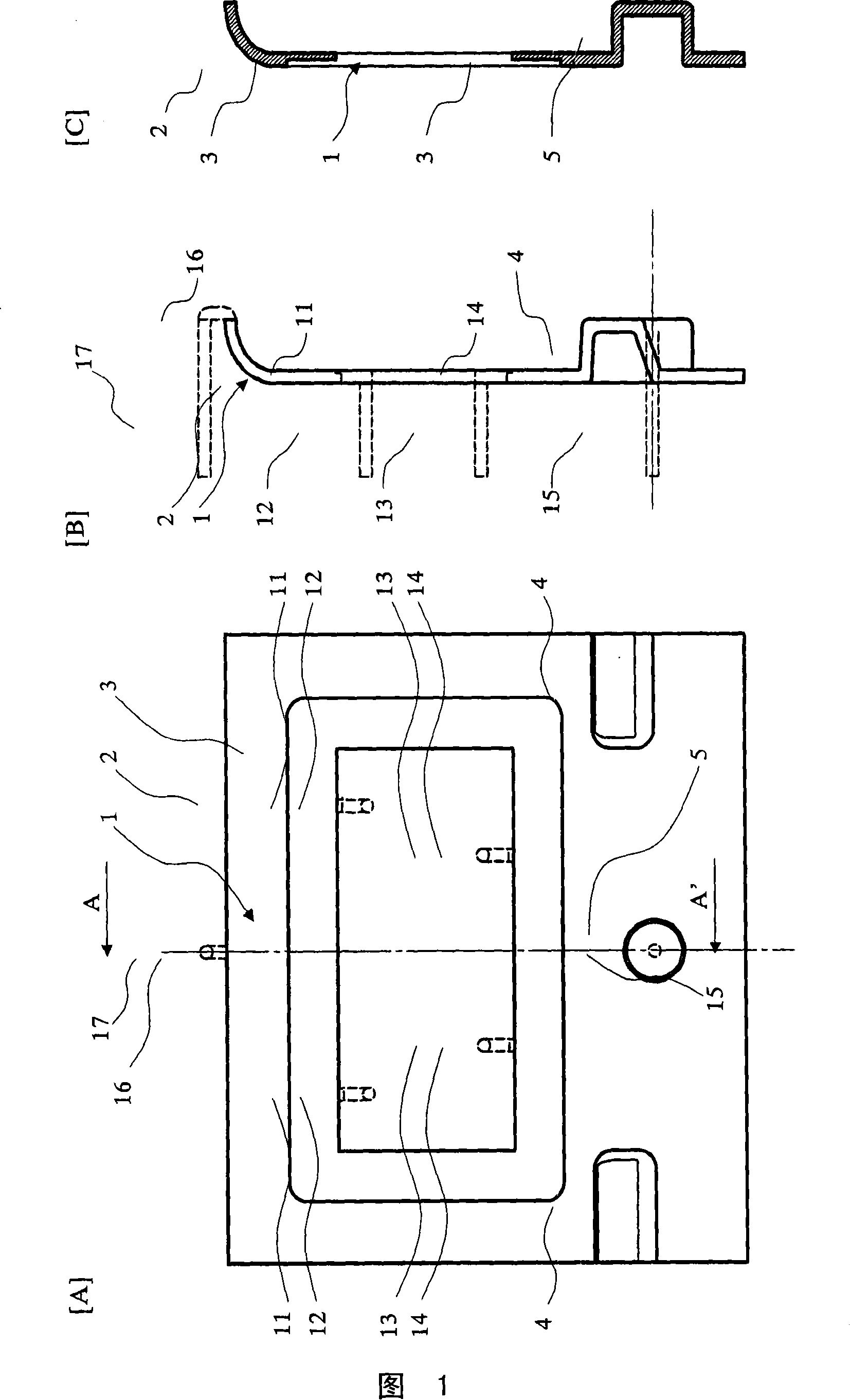

ActiveCN101142277ALow intrinsic viscosityHigh degree of polymerizationPolyethylene terephthalateFilling materials

Disclosed is a resin composition comprising an aromatic polycarbonate and a polyethylene terephthalate, which has high chemical resistance and is excellent in impact resistance, heat resistance, stiffness and thermal stability while maintaining good fluidability. Also disclosed is a molded article produced from the resin composition. Further disclosed is a process for production of a vehicle exterior material. The resin composition comprises 50 to 100 wt% of a resin component and 0 to 50 wt% of an inorganic filler (component D), the resin component comprising (i) an aromatic polycarbonate having a specified viscosity average molecular weight (component A) and (ii) a polyethylene terephthalate having a specified inherent viscosity (IV), a specified terminal carboxyl group content and a specified ratio of a weight average molecular weight (Mw) to a number average molecular weight (Mn) (Mw / Mn) (component B), provided that (iii) the ratio by weight of the total amount of the components A and D to the amount of the component B [(A+D) / B] falls within the range from 60 / 40 to 85 / 15.

Owner:TEIJIN KASEK KK

Method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol

The invention discloses a method for processing and preparing resistant starch by Pullulanase cooperated with acid alcohol, comprising the following steps: heating starch milk of which the weight concentration is 10-45% and the pH value is 3.5-6.5 to 40-70 DEG C, adding Pullulanase of which the dosage is 1-40ASPU per gram of starch, and keeping for 8-48hrs; inactivating enzymes, assisting by acid alcohol processing, cooling, filtering, drying, crushing and sieving to obtain the product. The invention takes starch as a raw material, adopts the biological technology and acid alcohol processing means, thus greatly improving the content of the resistant starch, simplifying the process for preparing the resistant starch, effectively enhancing the yield, and lowering energy consumption. The obtained product not only has the function of dietary fiber, but also has the characteristics of fat substitute, and can be widely used as functional food materials and biochemical drug carriers.

Owner:SOUTH CHINA UNIV OF TECH

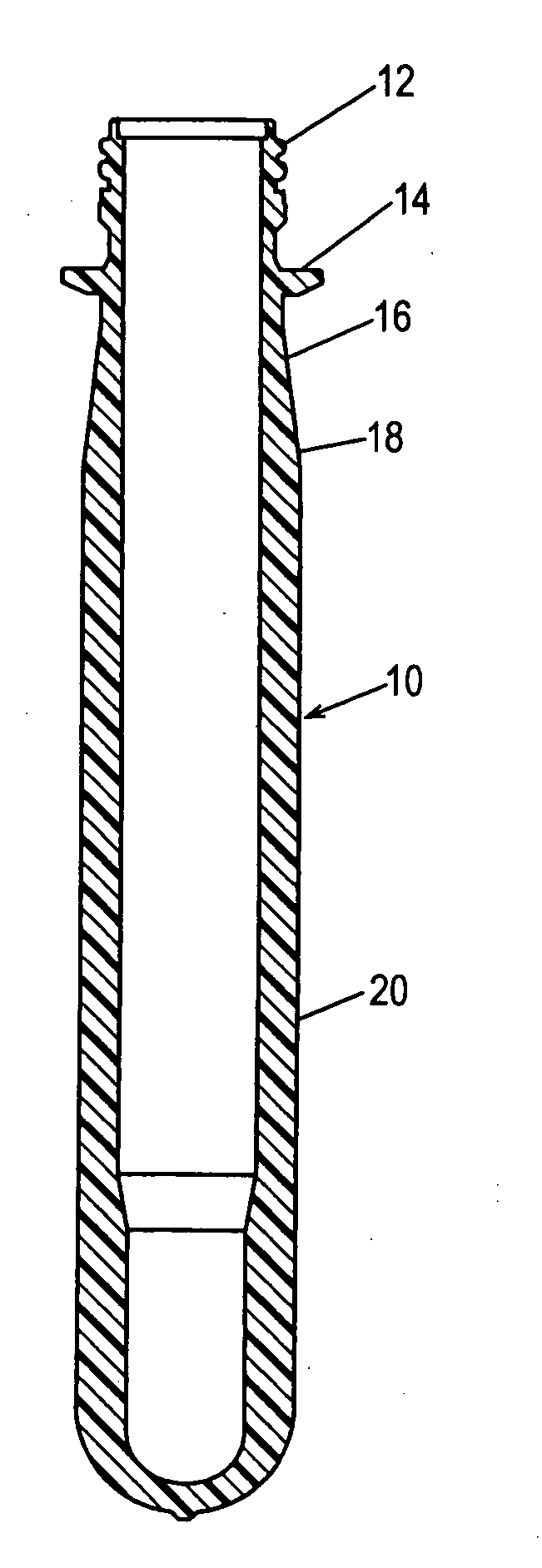

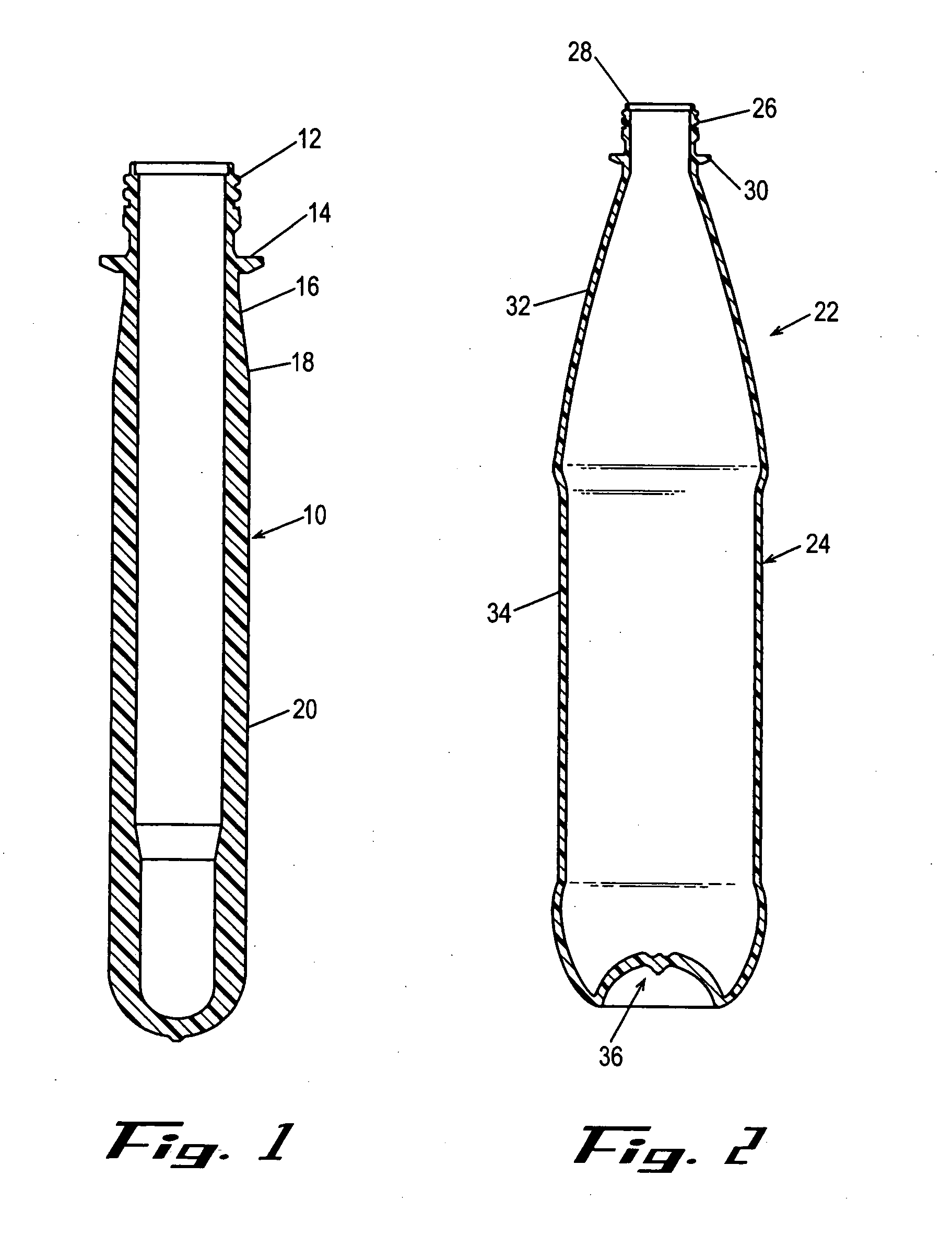

PET with stress cracking resistance, preform and container made therewith and method

InactiveUS20050153084A1Reduce molecular weightLow intrinsic viscositySynthetic resin layered productsThin material handlingPolyesterCrack resistance

A preform comprising an open-ended mouth forming portion, an intermediate body forming portion, and a closed base forming portion comprising a stress cracking resistant polyester composition comprising poly(ethylene terephthalate) based resin and an impact modifier. The preform is blow molded to form a corresponding container. Polyester compositions and methods are also disclosed. The impact modifier improves the stress cracking resistance of low IV PET such that the containers perform similar to those made of high IV PET.

Owner:THE COCA-COLA CO

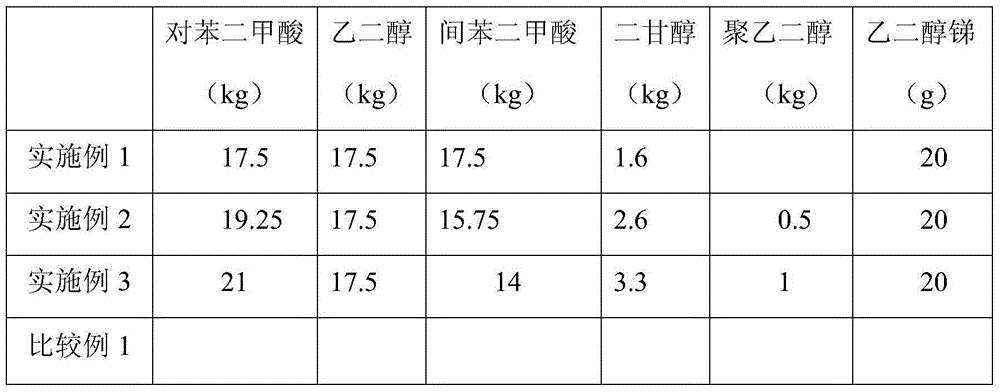

A preparing method of low-melting point polyester used for manufacturing terylene sewing threads

InactiveCN104558560ALow intrinsic viscosityReduced crystallization performanceAdhesivesSolventPolymerization catalysts

The invention relates to a preparing method of low-melting point polyester used for manufacturing terylene sewing threads. The method includes: 1) performing esterification by adopting terephthalic acid, ethylene glycol, isophthalic acid, and a straight-chain monomer having double hydroxyl reaction functional groups except the ethylene glycol; and 2) under the existence of a condensation polymerization catalyst, performing further esterification and pre-condensation polymerization, and performing condensation polymerization under a vacuum condition of 0.1-2 KPa. The melting point and the intrinsic viscosity of a polyester product prepared by the method are lower than that of conventional polyester. Compared with present low-melting point polyester, the intrinsic viscosity and the crystallization property of the product prepared by the method are low, and dissolution performance when the product is used for producing an adhesive used for solvent type bonded threads is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified meta-aramid, preparation method thereof and hollow fiber membrane

ActiveCN109456476AImprove stabilitySimple preparation processMembranesSemi-permeable membranesPolymer scienceChloride

The invention discloses a modified meta-aramid polymer and a preparation method thereof. Metaphenylene diamine, 2-(4-aminophenyl)-5-aminobenzimidazole and various diamine monomers such as halogenateddiamine monomers are poly-condensed with isophthalic chloride by a low-temperature solution polycondensation method to form the modified meta-aramid polymer, wherein the isophthalic chloride is repeatedly added into reaction solution. The invention further discloses a preparation method for preparing a hollow fiber membrane by the prepared meta-aramid polymer. The prepared modified meta-aramid polymer keeps original excellent performances, further has low intrinsic viscosity and good chlorine resistance and is more applicable to spinning of the hollow fiber membrane, the prepared membrane is more easily preserved in a dry state, and the preparation method is simple, easy to operate and suitable for industrial production and has an excellent market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

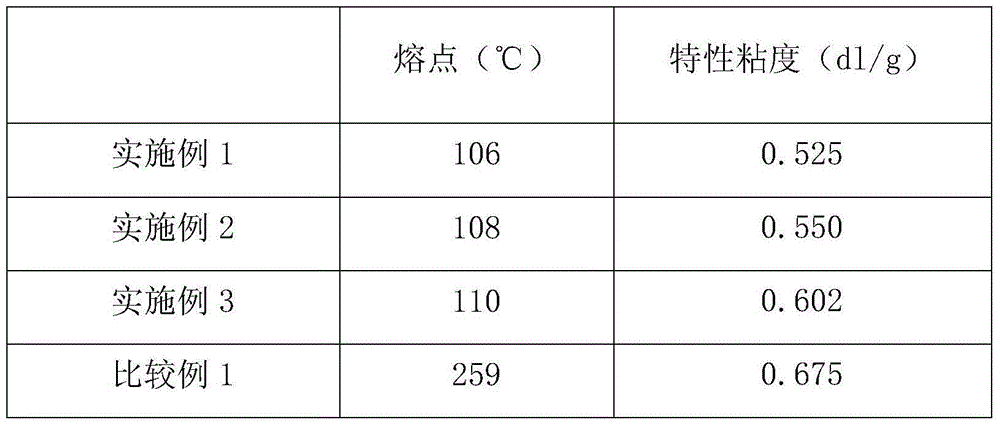

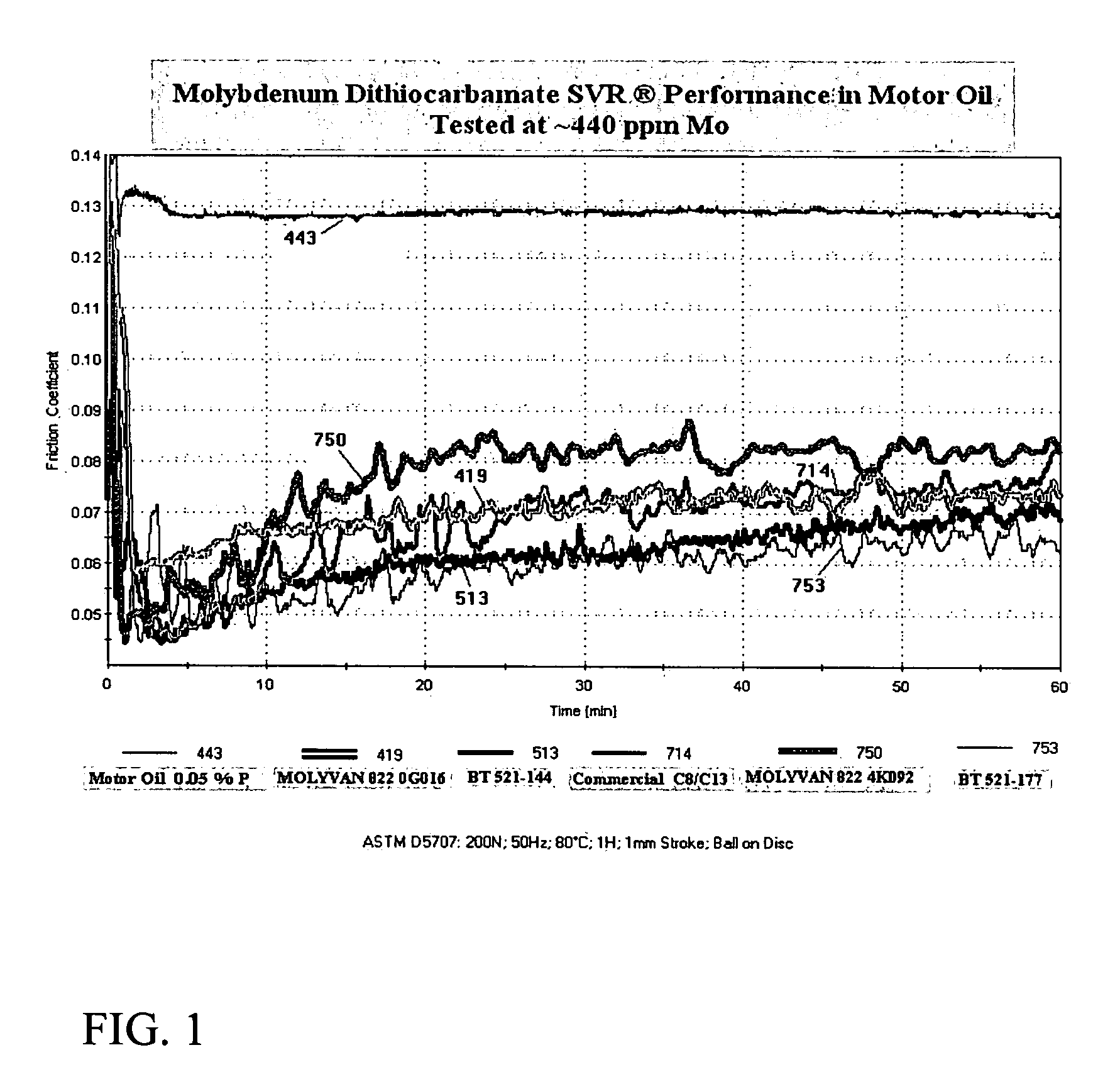

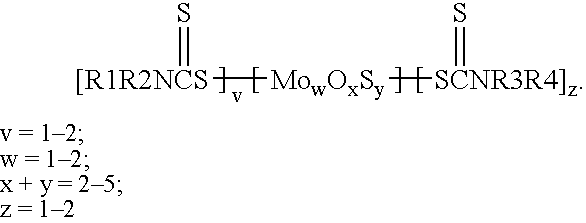

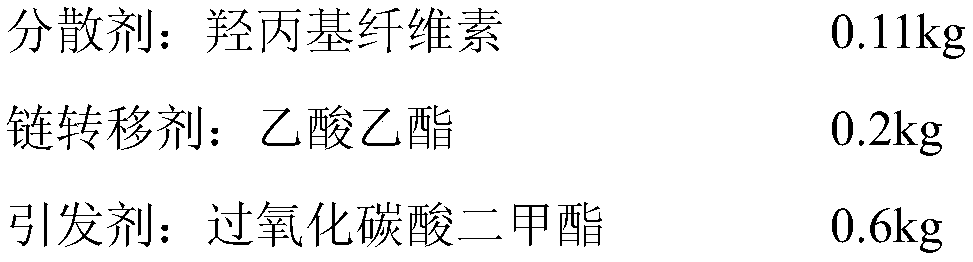

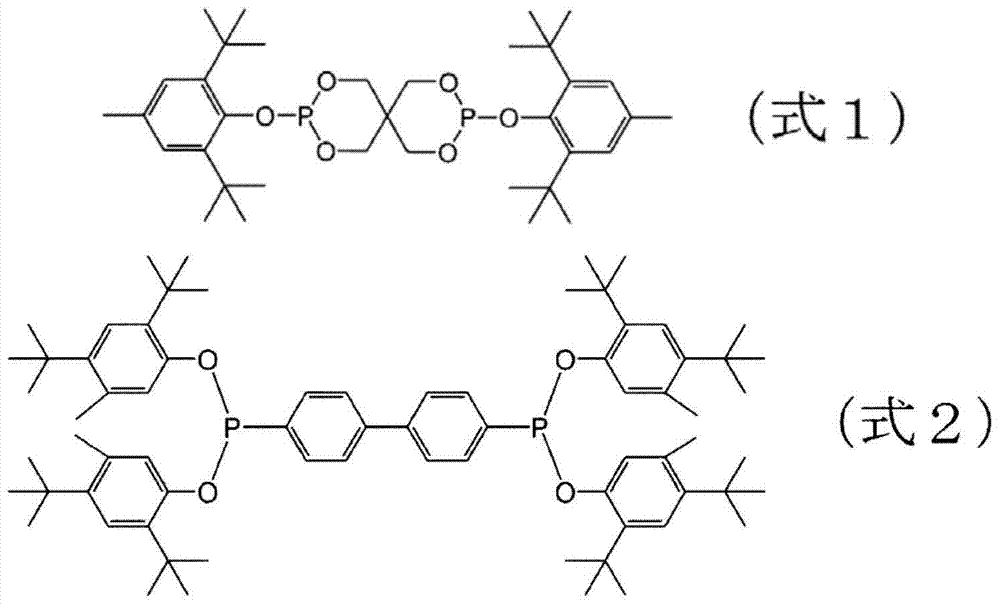

Molybdenum dialkyldithiocarbamate compositions and lubricating compositions containing the same

ActiveUS20060199745A1Improve solubilityHigh molybdenum contentAdditivesGroup 6/16 element organic compoundsSolubilityViscosity

Thie invention relates to a novel asymmetrical, secondary dialkylamine-based molybdenum dithiocarbamate with improved friction reducing performance, viscosity and solubility, and lubricating compositions containing the same. The compounds are produced from asymmetrical dialkylamine of the formula R1-NH-R2 where R1 and R2 are different, and are independently selected from alkyl groups C3 to C19. In a preferred embodiment, R3 and R4 are different and are independently selected from alkyl groups C3 to C19. The molybdenum dithiocarbamates can be represented by the following formula:

Owner:VANDERBILT CHEM LLC

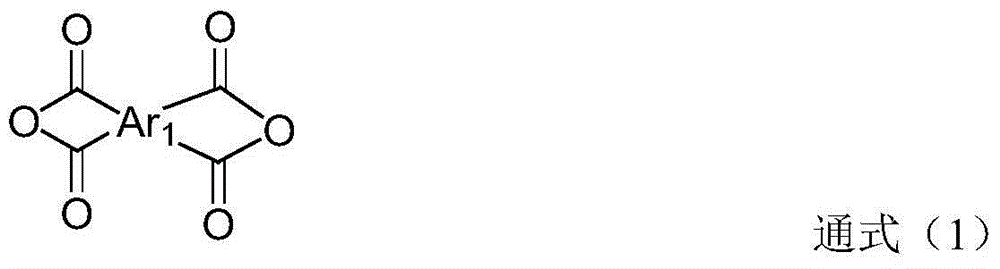

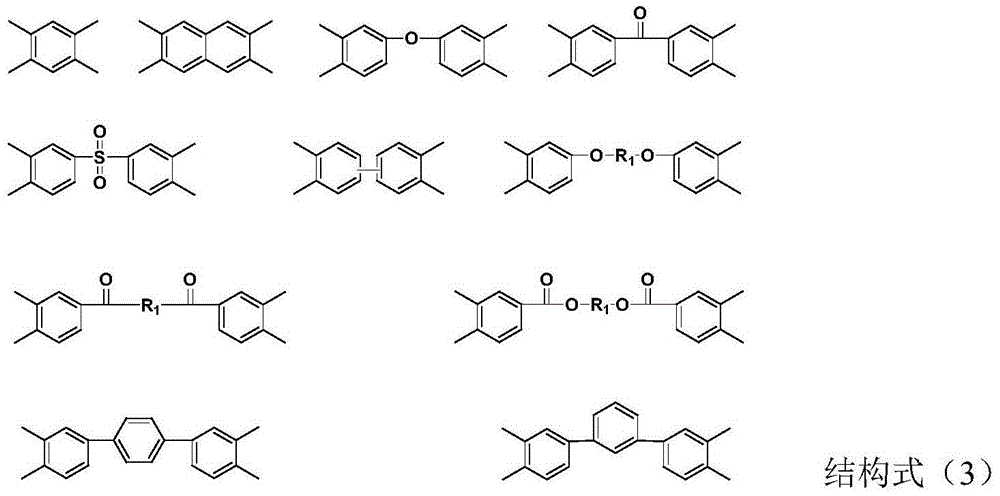

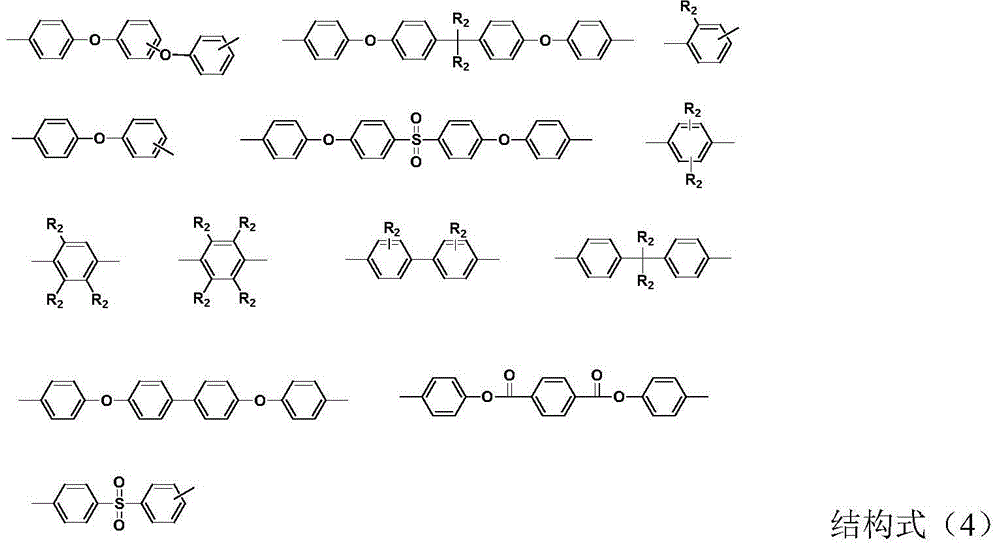

Preparation method for polyamide acid solution

ActiveCN105622936ALow intrinsic viscosityControl molecular weightMonocomponent synthetic polymer artificial filamentChemistryFiber

The invention relates to a preparation method for a polyamide acid solution for preparing polyimide fibers, and is used for mainly solving the problems in the prior art that when a two-step method is adopted for preparing polyimide fibers, the polyamide acid solution has unstable viscosity control and too large viscosity in the preparation process to cause spinning difficulty. The problems are relatively well solved by adopting the technical schemes that the preparation method comprises the following steps: a) proportioning diamine and tetracarboxylic dianhydride according to the total molar ratio of 1 to X; b) under the protection of an inert gas, stirring diamine at low temperature to be completely dissolved in an organic solvent; and c) slowly adding tetracarboxylic dianhydride with the Y quantity ratio to the solution with the feeding time of 20-60 minutes, after the feeding is finished, continuing to carry out a reaction for 30-120 minutes, adding tetracarboxylic dianhydride with the Z quantity ratio to the reaction system, continuing to carry out a reaction for 0.5-10 hours, and thus obtaining the polyamic acid solution which can be used for industrial production of polyimide materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

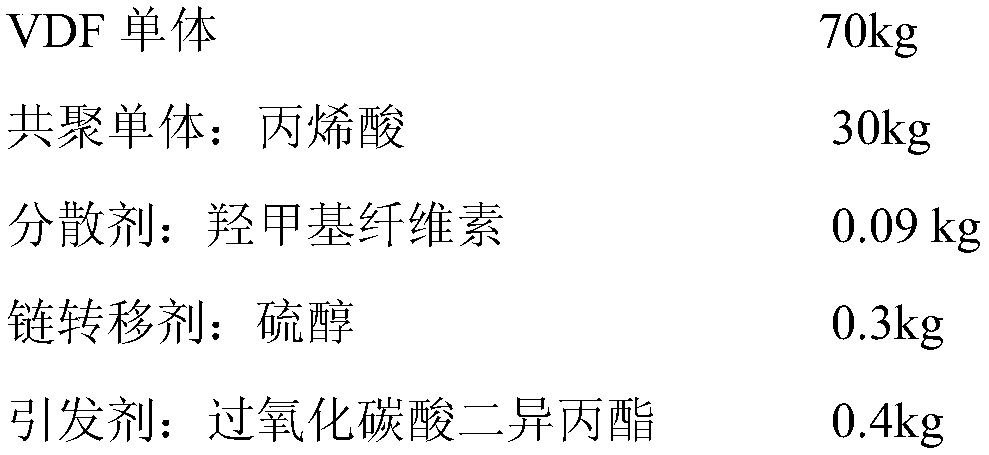

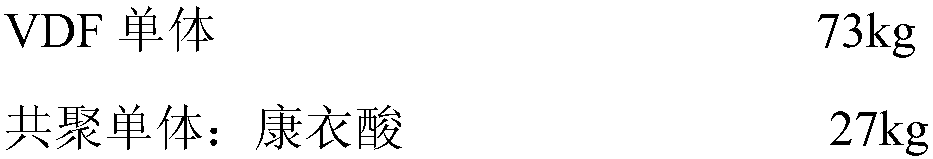

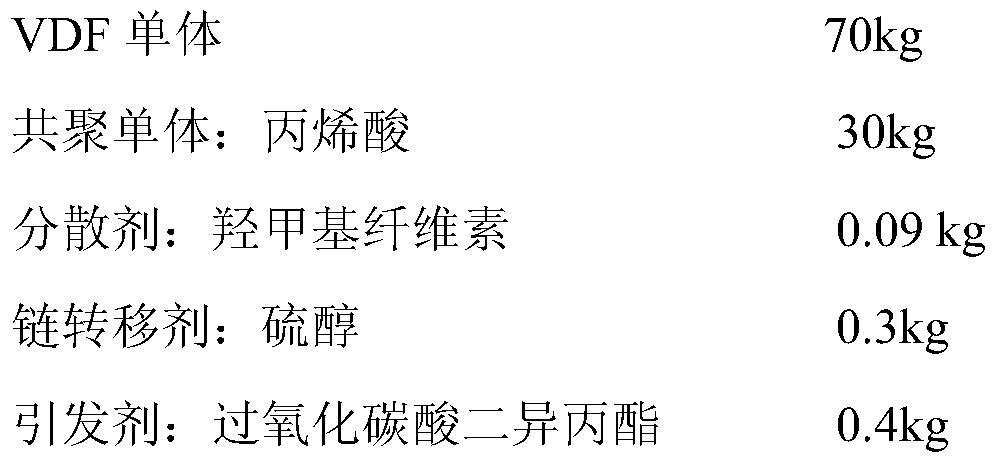

Preparation method of hydrophilic polyvinylidene fluoride resin

ActiveCN108467451AEasy to operateThe polymerization reaction process is mild and stableWater contaminantsWater/sewage treatment bu osmosis/dialysisFiltration membraneReaction temperature

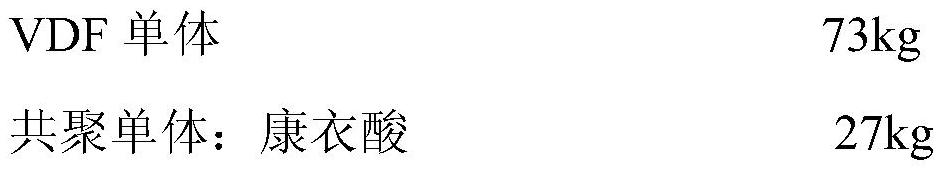

The invention discloses a preparation method of hydrophilic polyvinylidene fluoride resin. The preparation method comprises the steps that 1, 200-400 parts of deionized water, 60-90 parts of VDF monomers, 10-50 parts of comonomers, 0.05-1.5 parts of dispersing agents, 0.1-0.5 part of chain transfer agents and 0.1-1.0 part of initiator react with one another at the stirring rotating speed of 50-80rpm, and a suspension polymerization product is obtained, wherein the reaction temperature ranges from 20 DEG C to 40 DEG C, the reaction time is 12-24 hours, and the reaction pressure is 2.0-4.5 Mpa;2, the suspension polymerization product obtained in the first step is washed, centrifugally dehydrated and dried to obtain the hydrophilic polyvinylidene fluoride resin product. The method is simplein process and suitable for industrialization. An ultra-filtration membrane prepared from the obtained product has relatively good hydrophilicity, relatively high membrane flux, long service life andgood metal ion removal effects.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +2

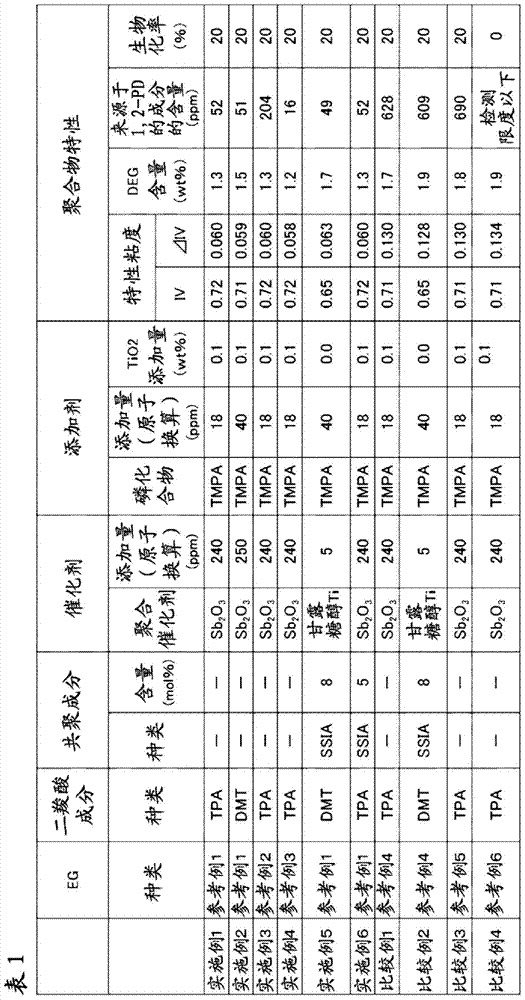

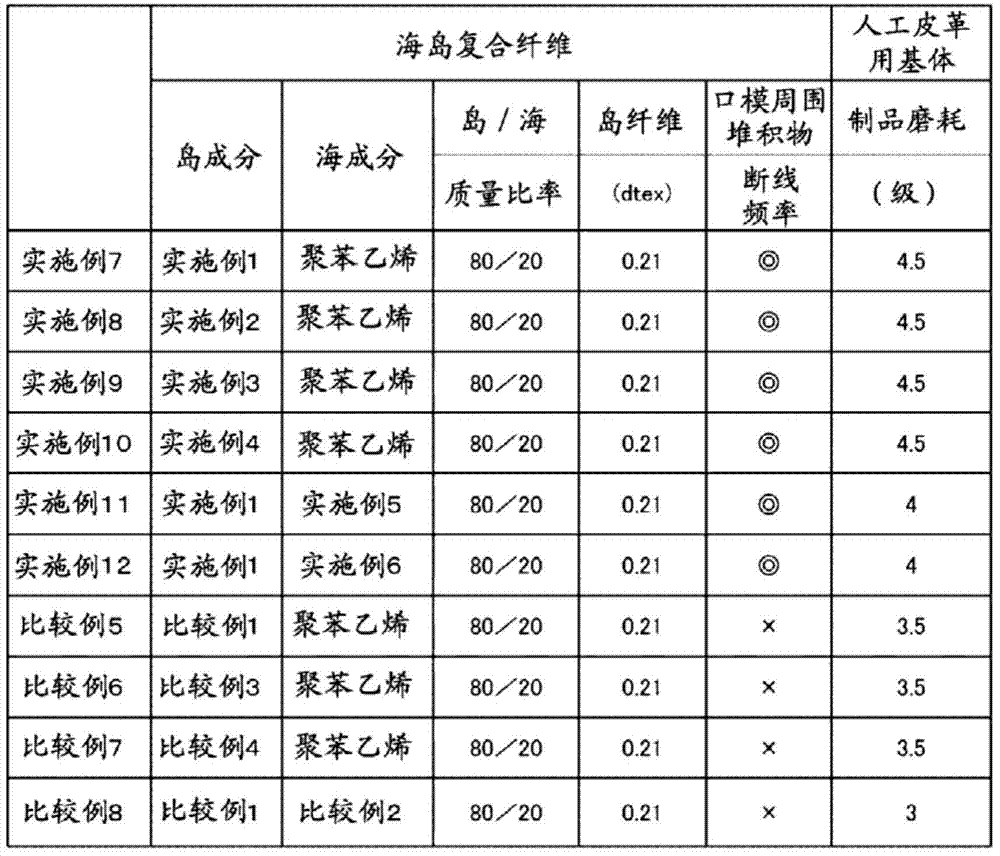

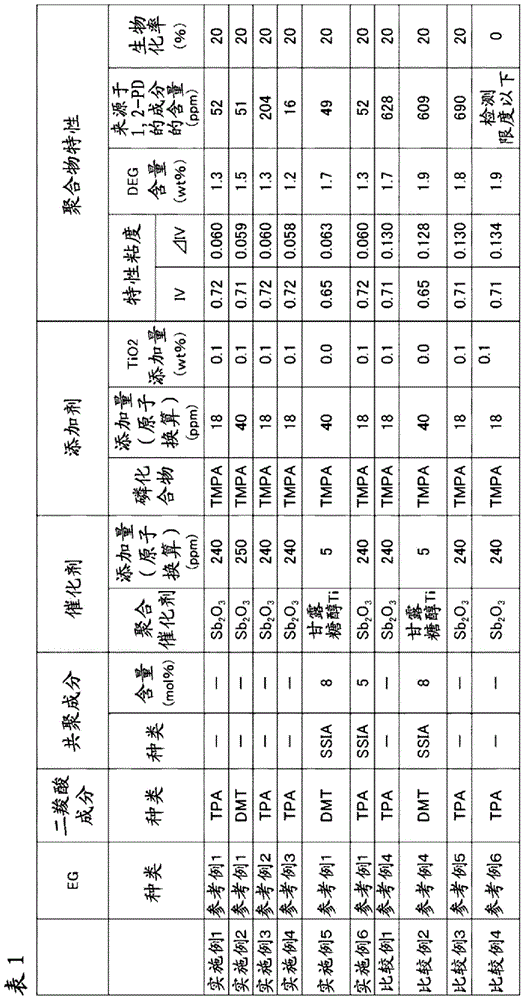

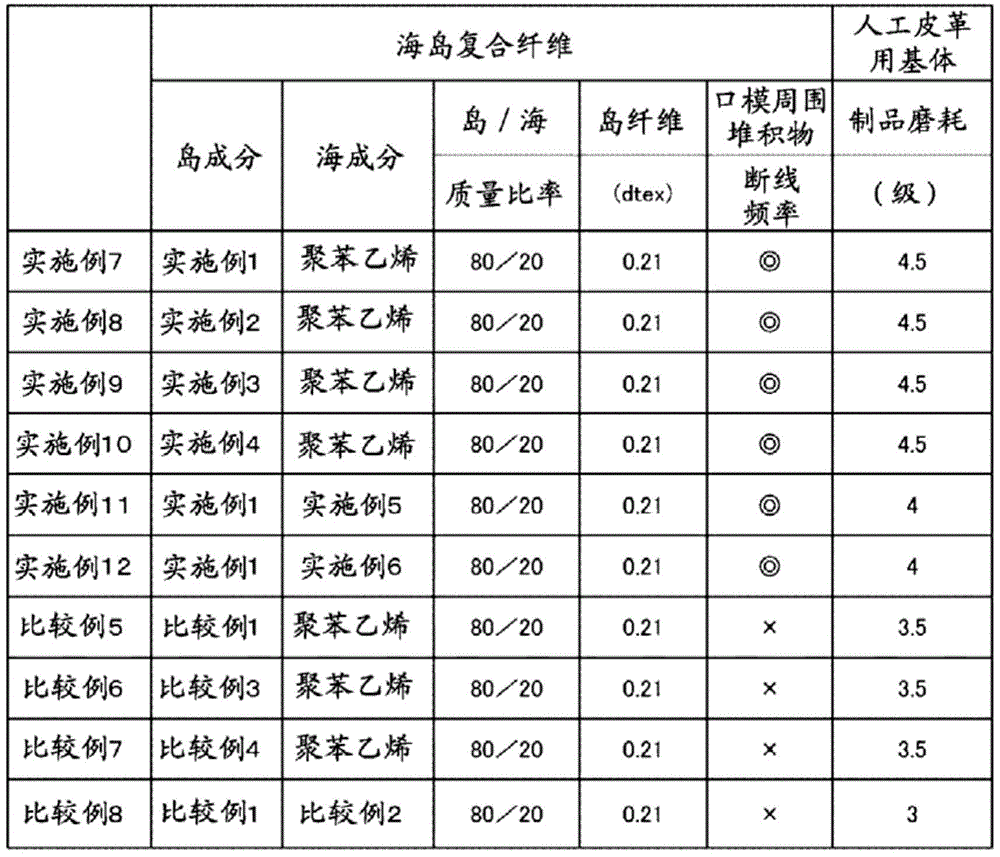

Base for artificial leather

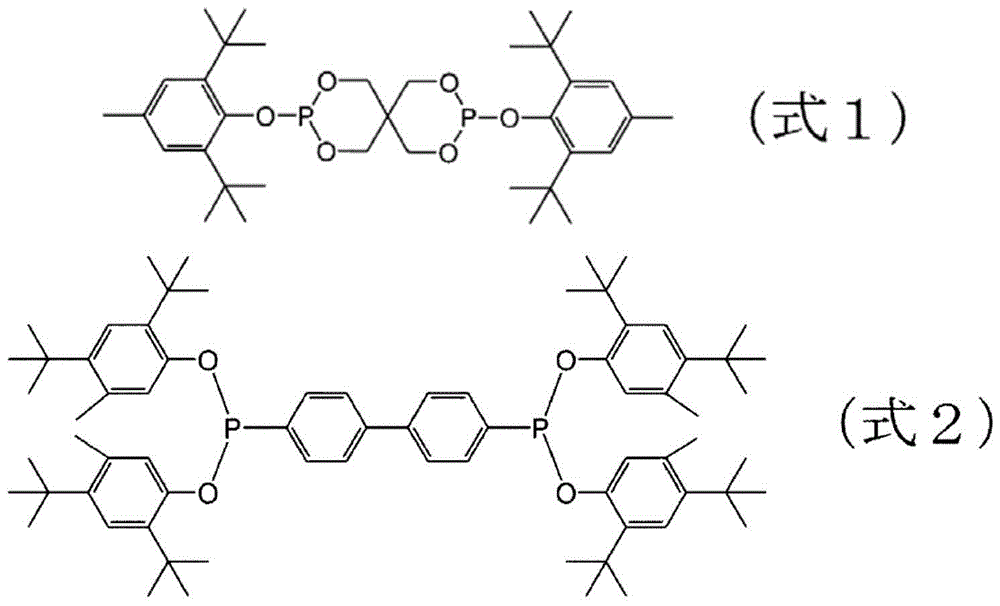

ActiveCN104520486AImprove abrasion resistanceLower intrinsic viscosityMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberPolyester

To provide a base for artificial leather, which uses a polyester that exhibits excellent heat resistance during melt molding. Namely, to provide composite fibers which are formed of a polyester that is suppressed in decrease of the intrinsic viscosity during melt molding. A base for artificial leather, which is formed of a polyester that is configured from an elastic polymer and a fiber entangled body that is mainly composed of ultrafine fibers having a fiber diameter of 0.01-10 mum. The polymer which constitutes the ultrafine fibers is a polyester that is obtained from a diol and a dicarboxylic acid and / or an ester-forming derivative thereof, said polyester containing 15-500 ppm of a component that is derived from 1,2-propane diol.

Owner:TORAY IND INC

Composite material based on polyethylene glycol terephthalate and preparation method thereof

ActiveCN107141728AReduced interfacial free energy for nucleationLow intrinsic viscosityElastomerBlood Collection Tube

The invention discloses a composite material based on polyethylene glycol terephthalate and a preparation method thereof. The composite material comprises the following raw materials in parts by weight: 90-99.5 parts of a PET material I and 0.5-10 parts of a PET material II. The PET material I is prepared from the following steps of: pre-heating a PET material, wherein the pre-heating temperature is 60-100 DEG C and the pre-heating time is 2-6h, then feeding the PET material into a crystallization kettle to be stirred and crystallized to obtain the PET material I, wherein the temperature is 110-160 DEG C and the crystallization time is 2-6h; the PET material is prepared from the following steps: feeding 80-98 parts by weight of the PET material, 1-20 parts of a polyolefin elastomer, 0.02-6 parts of a nucleating agent and 0.02-5 parts of an auxiliary agent into a twin-screw extruder; melting and blending the components; and extruding and granulating the components to obtain the PET material II. The composite material based on polyethylene glycol terephthalate prepared by the method has the characteristics of good crystallization property, high crystallization rate and moderate viscosity, has a good processing characteristic and an excellent comprehensive performance, and meets the demand on a high-performance PET vacuum blood collection tube.

Owner:宁波萱群材料科技有限公司

Modified meta-aramid, preparation method thereof and hollow fiber membrane

ActiveCN109456477AImprove stabilitySimple preparation processSemi-permeable membranesMembranesHollow fibre membranePolymer science

The invention discloses a modified meta-aramid polymer and a preparation method thereof. Metaphenylene diamine, alkyl diamine H2N-M-NH2 and various diamine monomers such as halogenated diamine monomers are poly-condensed with isophthalic chloride by a low-temperature solution polycondensation method to form the modified meta-aramid polymer, wherein the isophthalic chloride is repeatedly added intoreaction solution. The invention further discloses a preparation method for preparing a hollow fiber membrane by the prepared meta-aramid polymer. The prepared modified meta-aramid polymer keeps original excellent performances, further has low intrinsic viscosity and good chlorine resistance and is more applicable to spinning of the hollow fiber membrane, the prepared membrane is more easily preserved in a dry state, and the preparation method is simple, easy to operate and suitable for industrial production and has an excellent market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

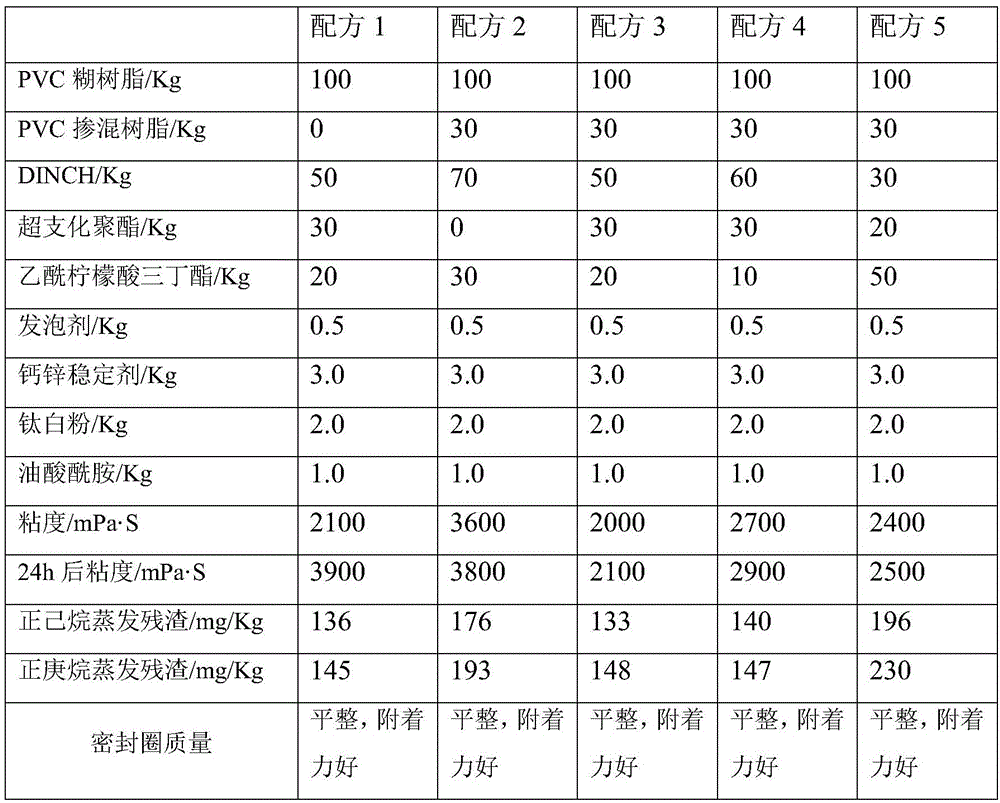

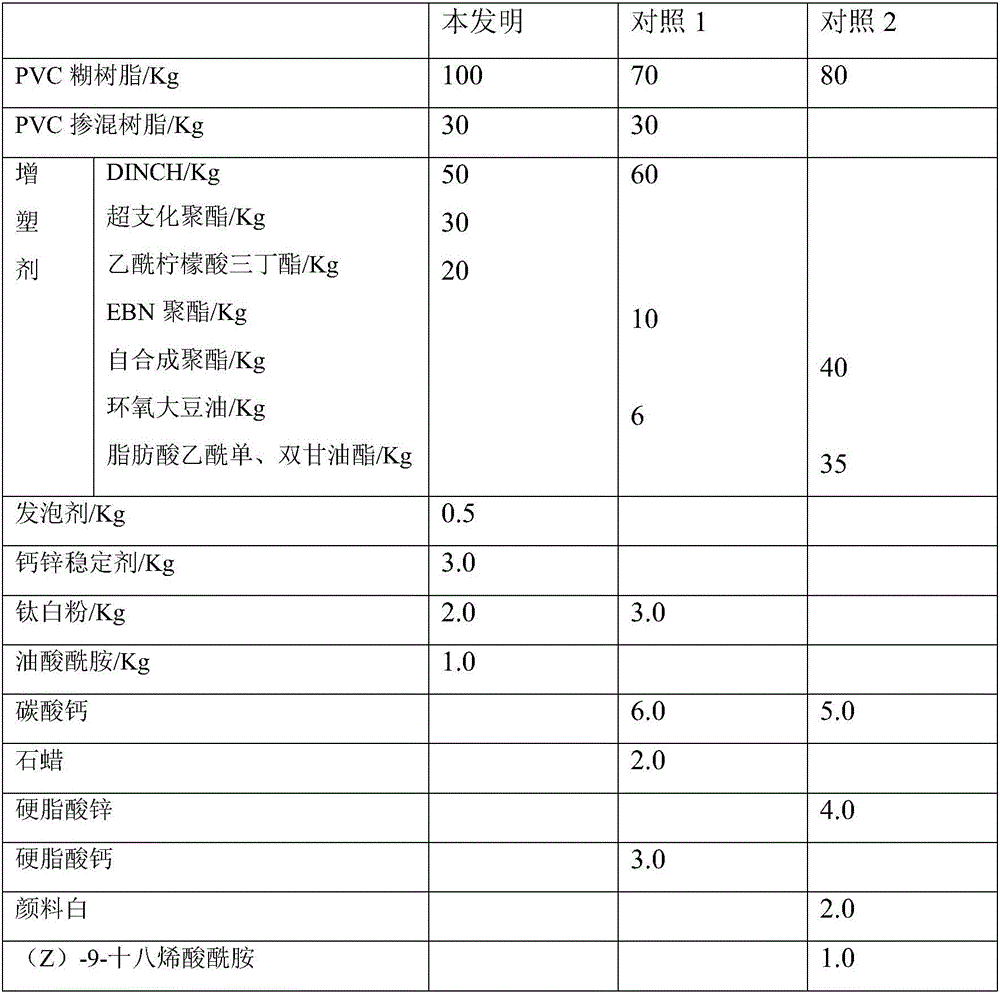

Low-migrated-amount PVC bottle cap sealant and preparation method thereof

ActiveCN105754260AIncreased free volumeImprove athletic characteristicsHyperbranched polyesterPolyvinyl chloride

The invention discloses a low-migrated-amount PVC bottle cap sealant and a preparation method thereof. The low-migrated-amount PVC bottle cap sealant is formed by combination of PVC paste resin, PVC blend resin, a DINCH plasticizer, a hyperbranched polyester plasticizer, acetyl tributyl citrate, a foamer, a calcium-zinc stabilizer, titanium dioxide and oleamide. The low-migrated-amount PVC bottle cap sealant does not contain phthalic ester plasticizers at all, and the viscosity and the viscosity stability of the low-migrated-amount PVC bottle cap sealant meet the requirements of the rubber patch process. The migrated amount of a seal ring manufactured by the sealant is lower than 150 mg / Kg in n-hexane and n-heptane simulative material, reaching the international advanced level and satisfying the requirement on food safety.

Owner:JIANGNAN UNIV

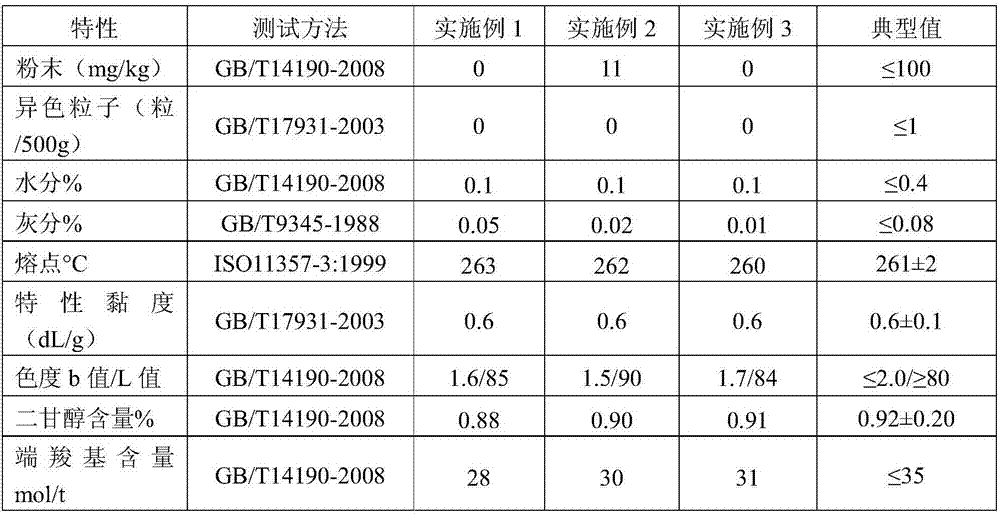

Polyester with excellent heat resistance and method for producing same

ActiveCN103502303AImprove heat resistanceSuppress generationOrganic compound preparationHydroxy compound separation/purificationPolyesterHeat resistance

To provide polyester which has excellent thermostability with only a small reduction in intrinsic viscosity during melt molding. A polyester obtained from a dicarboxylic acid, and / or an ester-forming derivative thereof, and a diol which is characterized by the fact that it contains 15 to 500 ppm of a 1,2-propanediol-derived component.

Owner:TORAY IND INC

Ultrafine denier polyester fiber FDY filament and preparation method thereof

ActiveCN107245768AReduce bloatPromote crystallizationMelt spinning methodsMonocomponent polyesters artificial filamentChemistryPolyester

The present invention relates to an ultrafine denier polyester fiber FDY filament and a preparation method thereof, wherein a spinning melt comprises a saturated fatty acid metal salt and a polyester according to a mass ratio of the saturated fatty acid metal salt to the polyester of 0.0005-0.002:1, the post-filtration pressure during spinning is 125-155 kg / cm<2>, the extrusion expansion ratio of the spinning melt is 1.25-1.35, and the saturated fatty acid metal salt has the carbon atom number of 12-22, the melting point of 100-180 DEG C, and the dynamic viscosity of less than or equal to 1 Pa.s. According to the present invention, the saturated fatty acid metal salt is added to the spinning melt so as to provide the effect of the addition of the lubricant, such that the post-filtration pressure during the spinning is effectively reduced so as to effectively reduce the outlet expansion, and the product has the good shape retention effect; and the saturated fatty acid metal salt can be used as the nucleating agent to increase the fiber curing speed so as to further improve the fiber shape retention effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

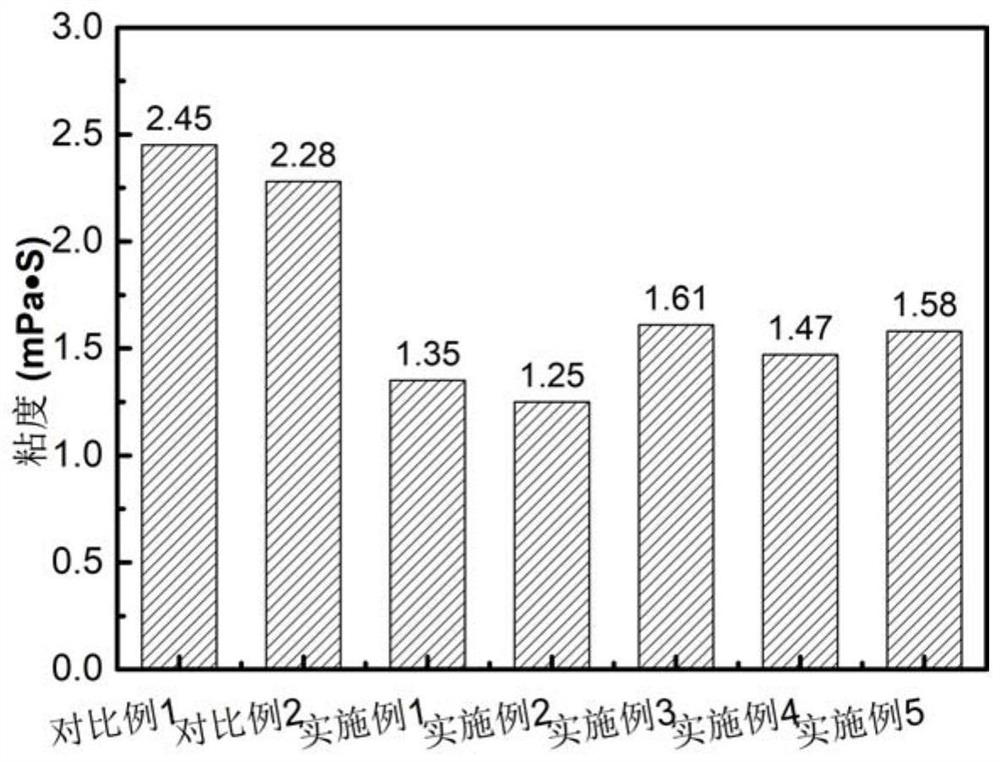

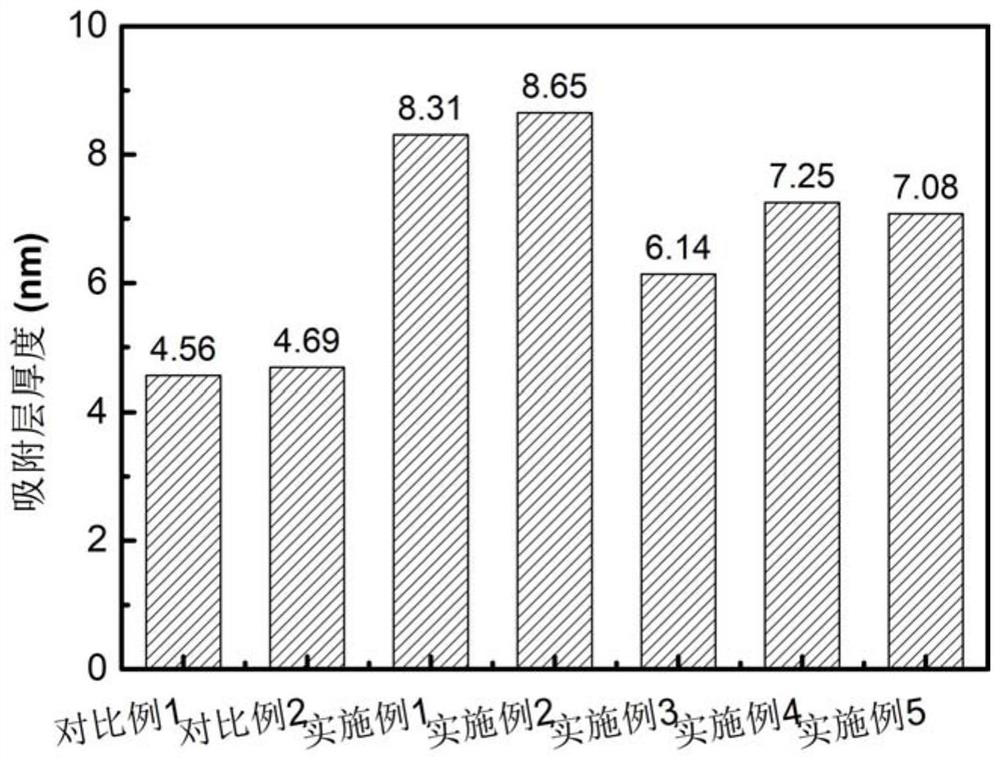

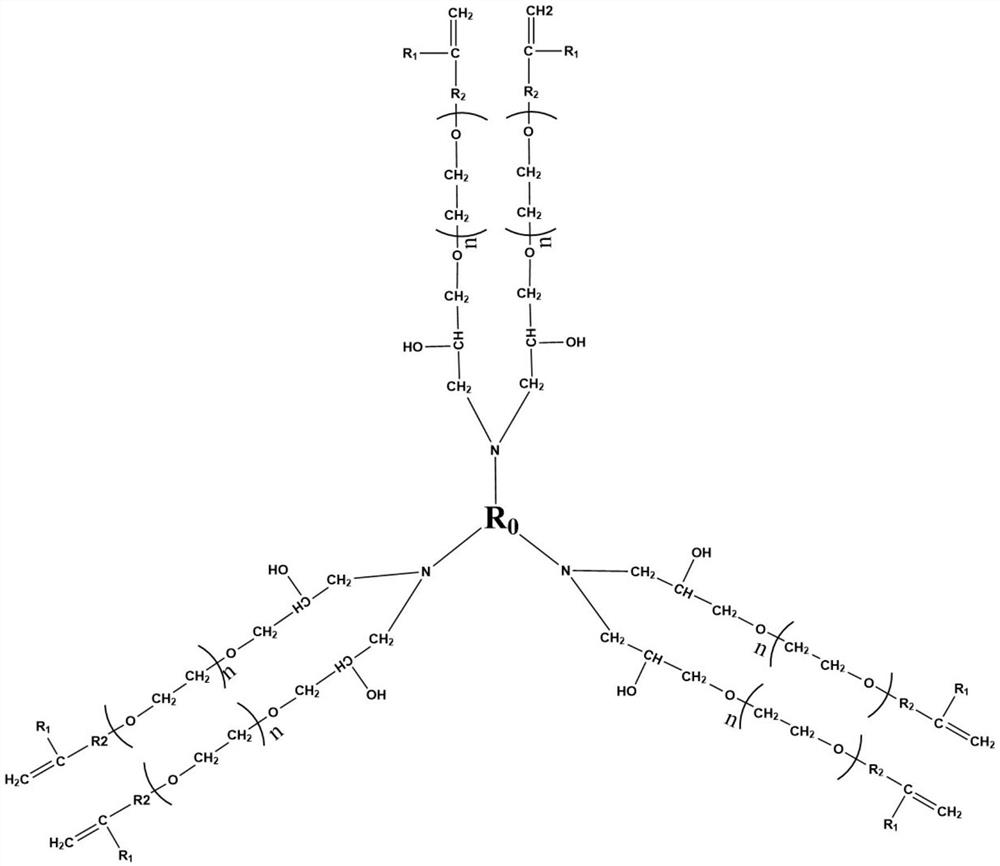

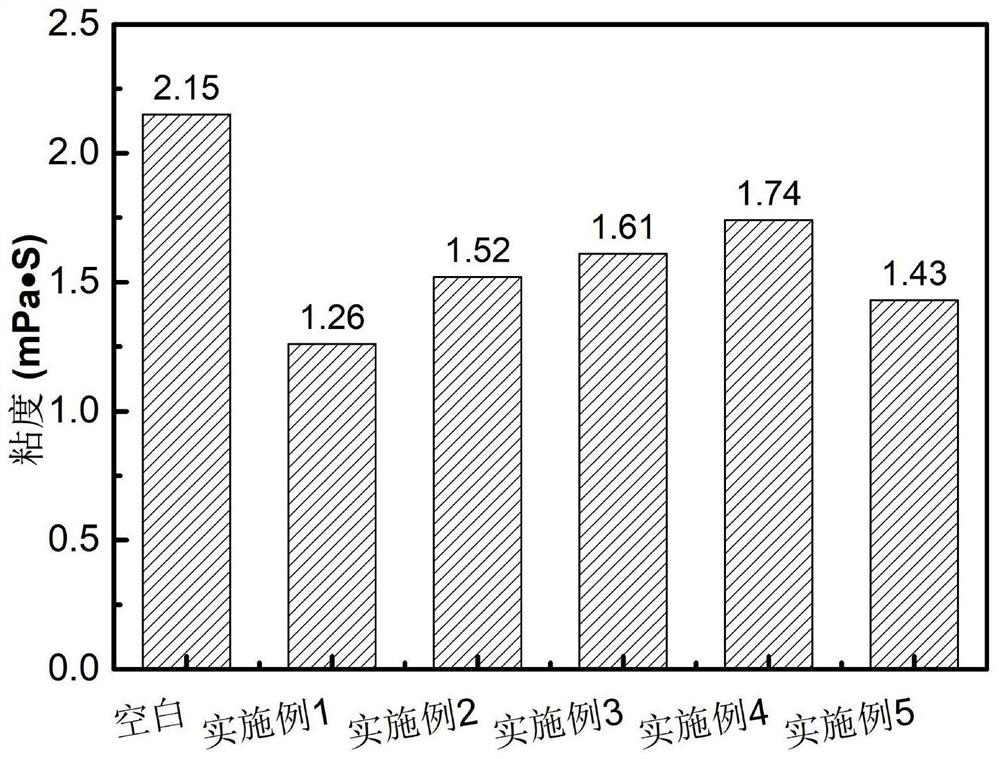

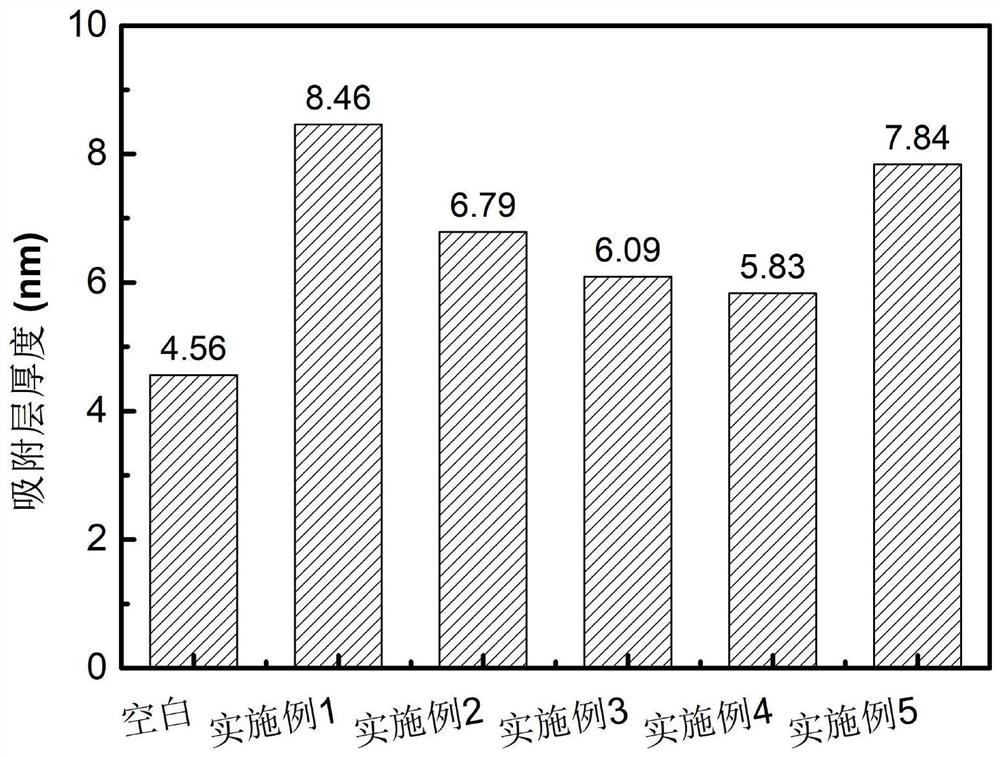

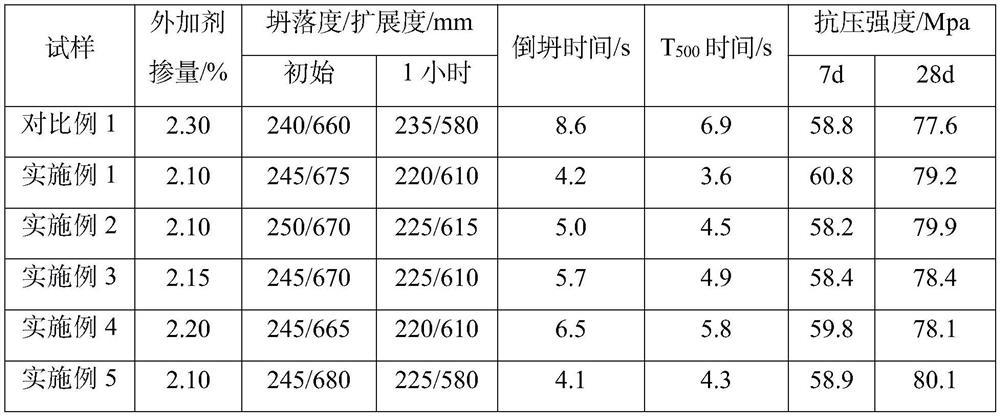

Vinyl-terminated hyperbranched polymer, viscosity-reducing type polycarboxylic acid water reducing agent with hyperbranched structure and preparation methods of vinyl-terminated hyperbranched polymer and viscosity-reducing type polycarboxylic acid water reducing agent

ActiveCN113372549AGood dispersionReduce dosageSolid waste managementPolymer scienceFunctional monomer

The invention discloses a vinyl-terminated hyperbranched polymer, a viscosity-reducing type polycarboxylate water reducing agent with a hyperbranched structure and preparation methods of the vinyl-terminated hyperbranched polymer and the viscosity-reducing type polycarboxylate water reducing agent, and belongs to the technical field of concrete admixtures. The viscosity-reducing type polycarboxylate water reducing agent with the hyperbranched structure is composed of the following raw materials in percentage by mass: 3 to 18 percent of unsaturated carboxylic acid, 1 to 10 percent of unsaturated anhydride, 0 to 1 percent of unsaturated phosphate, 75 to 93 percent of unsaturated polyether, 1 to 6 percent of a hyperbranched functional monomer, 0.1 to 1 percent of an initiator and 0.2 to 3.0 percent of a chain transfer agent. The prepared water reducing agent has the characteristics of special branched topological molecular structure, low intrinsic viscosity and the like, effectively weakens the intermolecular chain winding effect of the polycarboxylic acid water reducing agent, improves the dispersing performance of the water reducing agent, and reduces the dosage of the water reducing agent; and the thickness of an adsorption layer on the surface of a cementing material particle is increased, the thickness of a solvation layer on the surface of the particle is reduced, free water is released, and the viscosity of the high-strength concrete is reduced.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Triangular profiled polyester fiber HOY filament and preparation method thereof

ActiveCN106835337AReduce bloatPromote crystallizationMelt spinning methodsFilament-forming treatmentCarbon numberPolyester

The invention relates to a triangular profiled polyester fiber HOY filament and a preparation method thereof. A spinning melt includes saturated fatty acid metal salt and polyester in the mass ratio of (0.0005.0.002):1; the pressure after filtering at a spinning moment is 85.125kg / cm<2>; a die swell ratio of the spinning melt is 1.20.1.32; the saturated fatty acid metal salt is the metal salt with the carbon number of 12.22, the melting point at 100-180 DEG C and dynamic viscosity less than or equal to 1Pa.s. According to the invention, the saturated fatty acid metal salt is added into the spinning melt, and equivalently, a lubricating agent is added, so that the pressure after filtering at the spinning moment is effectively reduced, the outlet expansion is effectively reduced and the product has an excellent shape-preserving effect; and meanwhile, the saturated fatty acid metal salt also can be used as a nucleating agent; the curing speed of the fiber can be increased; the shape-preserving effect of the fiber is further improved.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

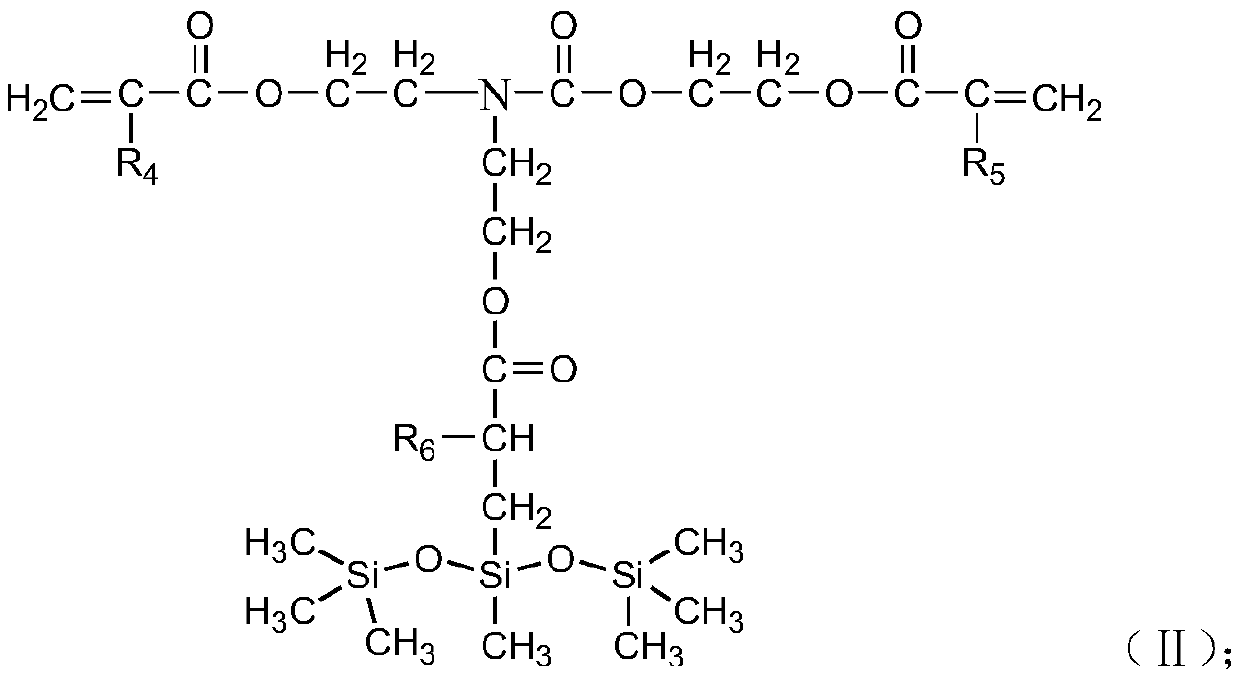

High-strength and high-toughness waterborne antifouling metal baking paint and preparation method thereof

ActiveCN109824837AImprove heat resistanceImprove cold resistanceAntifouling/underwater paintsPaints with biocidesCross-linkEpoxy

The invention discloses high-strength and high-toughness waterborne antifouling metal baking paint and a preparation method thereof, and discloses an epoxy-hyperbranched organic silicon modified acrylic acid polyurethane resin and preparation method thereof. The high-strength and high-toughness waterborne antifouling metal baking paint comprises the epoxy-hyperbranched organic silicon modified acrylic acid polyurethane resin, polyester resin, saturated polyester polyols, cross-linking agents, adhesion promoters, wetting leveling agents, ethylene glycol tert-butyl ether, neutralizers, catalysts, flash rust inhibitors, defoaming agents and the balance water. The invention further discloses a preparation method of the high-strength and high-toughness waterborne antifouling metal baking paint.The waterborne antifouling metal baking paint has the advantages that the paint is high in hardness and toughness, resistant to water, chemistry, oil, abrasion, weather and salt fog and the like. Thepaint film performance of the waterborne metal baking paint is greatly improved, and use range is greatly widened.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

Homogeneous hyper-viscous polyester and preparation method thereof

The invention relates to homogeneous hyper-viscous polyester and a preparation method thereof. The method comprises the following steps of: controlling the mechanism of adding a catalyst during a synthesis process to obtain low-viscous polyester with an intrinsic viscosity of 0.300-0.500 dL / g, and then performing solid phase thickening on the low-viscous polyester to obtain the homogeneous hyper-viscous polyester with an intrinsic viscosity of 0.85-1. 15dL / g, an intrinsic viscosity deviation less than or equal to 0.02dL / g and a molecular weight distribution index of 2.5, wherein the catalyst is added when the average polymerization degree of an intermediate product in a polymerization reaction reaches 8-17; the pre-reaction of the solid-phase thickening is divided into four stages which are a first stage, a second stage, a third stage, and a fourth stage, the corresponding temperatures are 190-195 DEG C,195-210 DEG C, 210-220 DEG C and 220-230 DEG C respectively. The preparation methodof the homogeneous hyper-viscous polyester obviously reduces the content of oligomer in a product, and the prepared polyester has high quality and excellent popularization value.

Owner:ZHEJIANG UNIFULL IND FIBER +1

Substrate for artificial leather

ActiveCN104520486BImprove abrasion resistanceLower intrinsic viscosityMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberPolyester

The present invention provides a substrate for artificial leather using polyester excellent in heat resistance during melt molding. That is, there is provided a conjugate fiber containing polyester having a small decrease in intrinsic viscosity during melt molding. A matrix for artificial leather, which is composed of a fiber complex mainly composed of ultrafine fibers with a fiber diameter of 0.01 to 10 μm and an elastic polymer. The polymer constituting the ultrafine fibers is composed of dicarboxylic acid and / or its ester The polyester obtained from the forming derivative and diol contains 15 to 500 ppm of a component derived from 1,2-propanediol in the polyester.

Owner:TORAY IND INC

A kind of preparation method of hydrophilic polyvinylidene fluoride resin

ActiveCN108467451BEasy to operateThe polymerization reaction process is mild and stableWater contaminantsWater/sewage treatment bu osmosis/dialysisReaction temperaturePolyvinylidene difluoride

The invention discloses a preparation method of hydrophilic polyvinylidene fluoride resin, comprising: (1) 200-400 parts of deionized water, 60-90 parts of VDF monomer, 10-50 parts of comonomer, dispersant 0.05 to 1.5 parts, 0.1 to 0.5 parts of chain transfer agent, 0.1 to 1.0 parts of initiator are reacted at a stirring speed of 50 to 80 rpm, the reaction temperature is 20 to 40 ° C, the reaction time is 12 to 24 hours, and the reaction pressure is 2.0 to 4.5 Mpa to obtain a suspension polymerization product; (2) washing the suspension polymerization product obtained in step (1), centrifugal dehydration, and drying to obtain a hydrophilic polyvinylidene fluoride resin product. The process of the invention is simple, suitable for industrialization, and the obtained ultrafiltration membrane has good hydrophilicity, high membrane flux, long service life and good removal effect on metal ions.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +2

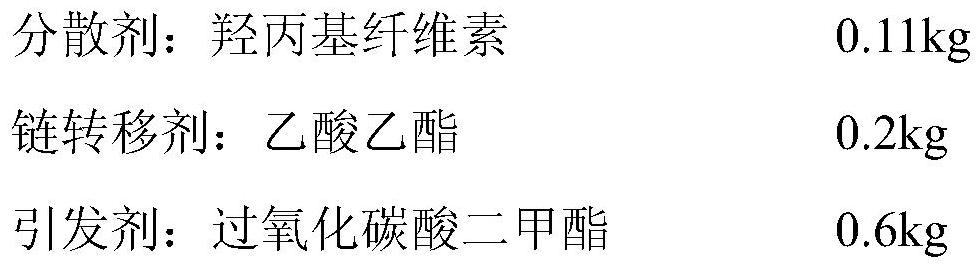

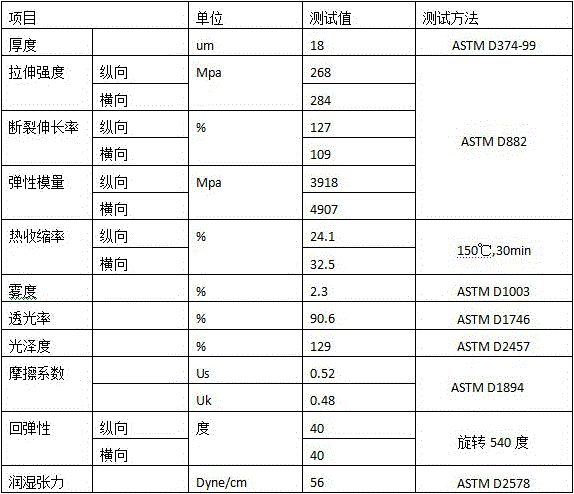

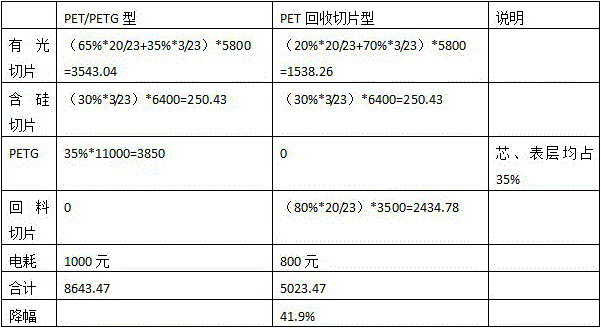

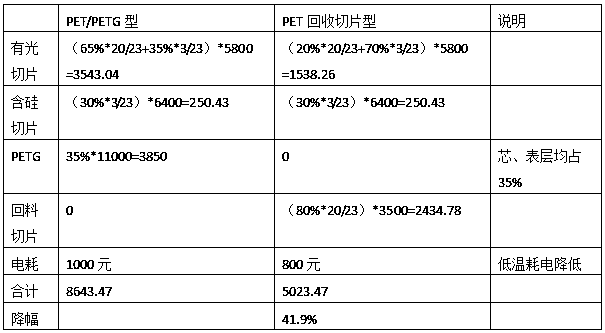

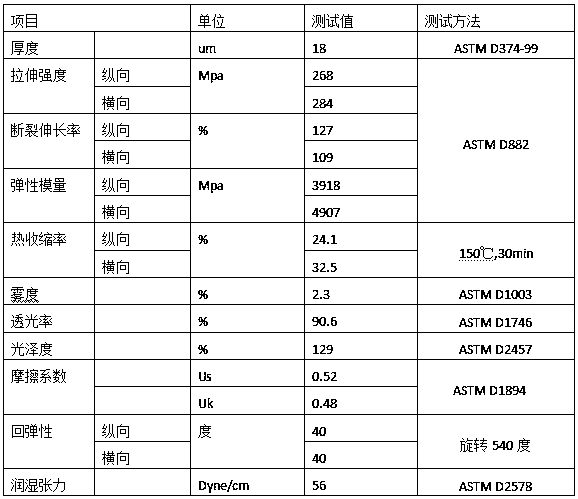

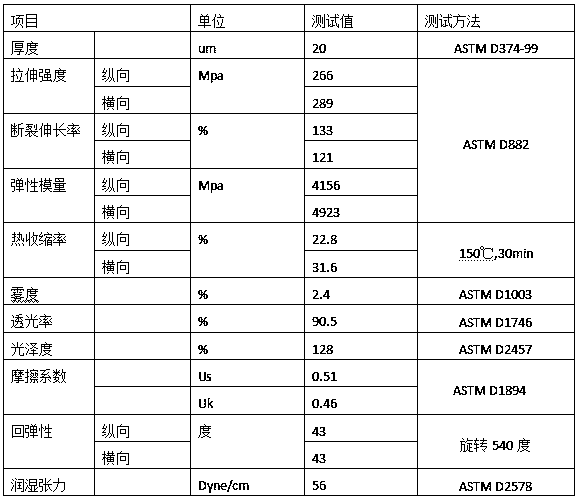

Low-cost eco-friendly polyester film for twist packaging and preparation method of polyester film

ActiveCN105966018ALow intrinsic viscosityImprove flexibilitySynthetic resin layered productsPolyesterSurface layer

The invention discloses a low-cost eco-friendly polyester film for twist packaging and a preparation method of the polyester film. The film comprises an upper and lower surface layers and a core layer. The core layer is composed of 20-30% of bright polyester chips and 70-80% of recovery chips. Each of the upper and lower surface layers is composed of 70% of bright polyester chips and 30% of silicon-contained chips. The core layer adopts PET recovery chips which are low in price and are clean. Meanwhile, longitudinal and transverse stretch technology is used for adjustment. Mainly, the longitudinal stretch ratio is reduced to 2.8-3.2, and the transverse stretch ratio is reduced to 3.5-3.7. A special low-temperature setting process is carried out at 80-120 DEG C to further reduce crystallization tendency of the film, so that the degree of crystallinity of the film can be controlled and the twist ability of the film is improved. A twist film having a resilience angle less than 45 degrees when rotated at 540 degrees, and the cost is reduced by about 40%.

Owner:SHANDONG FENGHUA PLASTIC TECH CO LTD

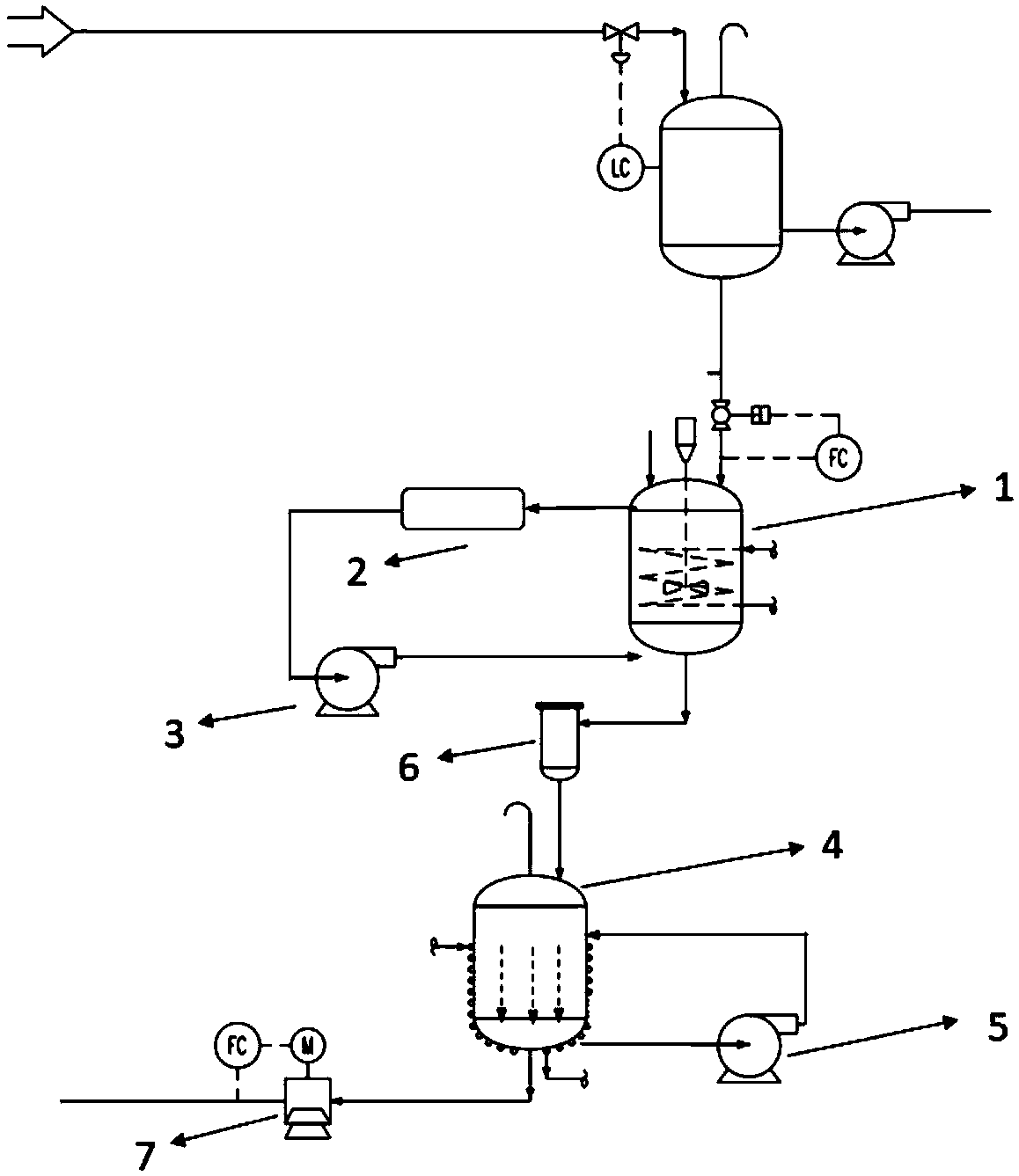

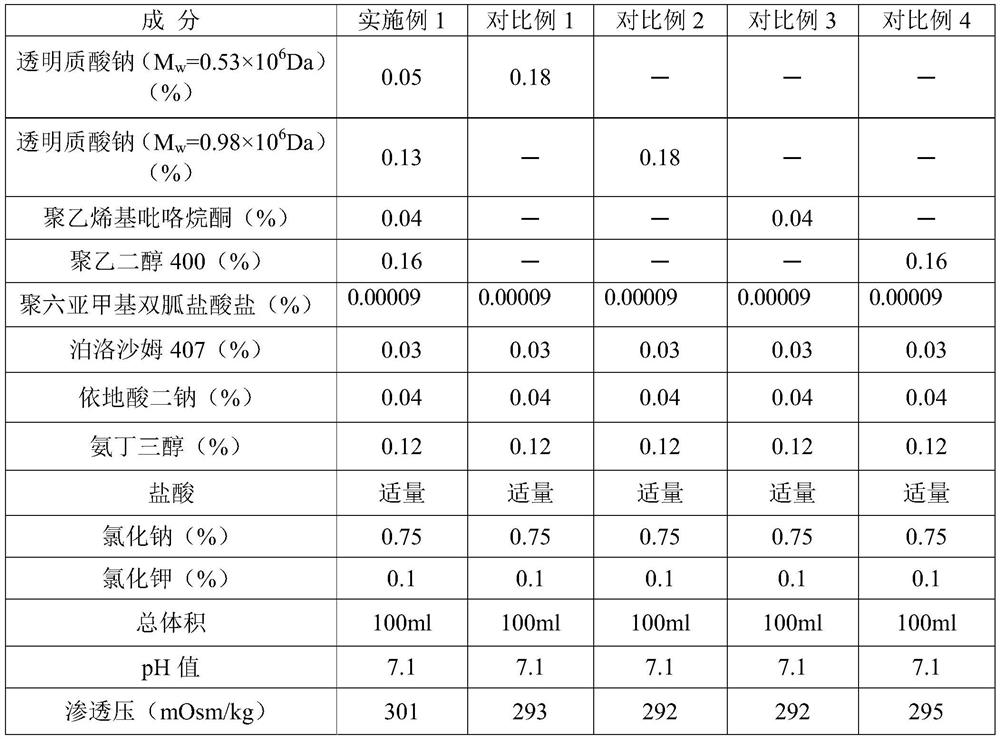

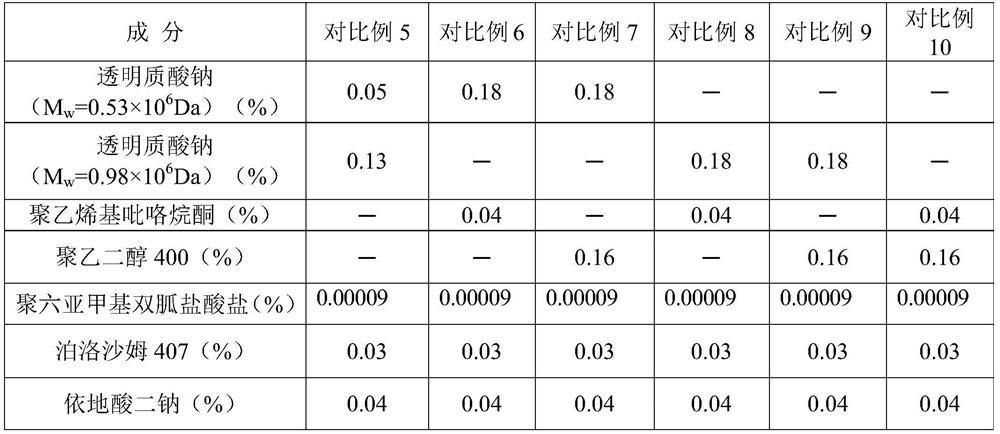

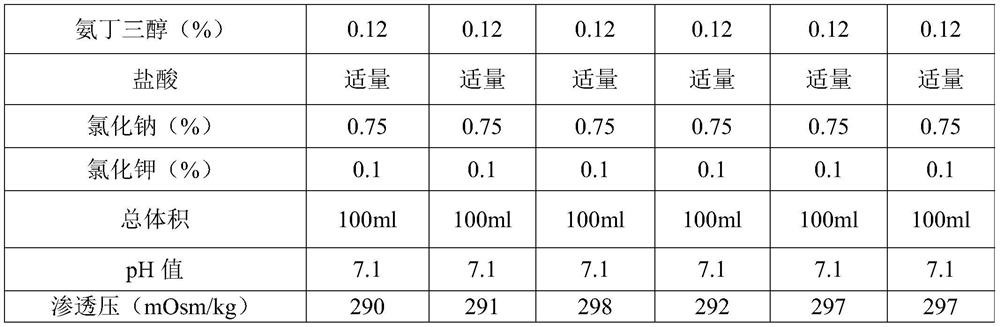

Ophthalmic lubricating liquid composition and application thereof

PendingCN113908171AImprove moisturizingHigh affinityBiocideSenses disorderEye drynessPolyethylene glycol

The invention relates to an ophthalmic lubricating liquid composition and application thereof. The ophthalmic lubricating liquid composition is compounded by selecting sodium hyaluronate with different molecular weights, polyvinylpyrrolidone and polyethylene glycol with a proper weight ratio are supplemented, under the synergistic effect of the components, the moisturizing and tackifying effects are achieved, the prepared lubricating liquid composition has excellent lubrication and moisture retention properties, dry eyes can be effectively inhibited, and the comfort level of wearing glasses is improved. According to the ophthalmic lubricating liquid composition, the biguanide preservative, tromethamine and edetate disodium are compounded to form a preservative system, and under the synergistic effect of the three, effective collision between the preservative and microorganisms is remarkably improved, so that the effect of effectively improving the corrosion resistance of the preservative and microorganisms can be achieved under the condition that the dosage of the biguanide preservative is not increased. Therefore, the lubricating liquid still has efficient corrosion resistance and biocompatibility.

Owner:南京睿远医疗技术有限公司

A kind of flat polyester fiber fdy yarn and preparation method thereof

ActiveCN106835338BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterYarn

The invention relates to a flat polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. The spinning melt comprises a saturated fatty acid metal salt and polyester, wherein a mass ratio of the saturated fatty acid metal salt to polyester is (0.0005-0.002):1; the filtered pressure during spinning is 84-126kg / cm<2>; a die-swell ratio of the spinning melt is 1.22-1.34; and the saturated fatty acid metal salt refers to a fatty acid metal salt with the carbon atom number of 12-22, the melting point of 100-180 DEG C and the dynamic viscosity of less than or equal to 1Pa.s. The saturated fatty acid metal salt is added into the spinning melt, and the filtered pressure and extrudate swelling during spinning can be effectively reduced, so that the product has an excellent shape preserving effect; meanwhile, the saturated fatty acid metal salt can serve as a nucleating agent, so that the fiber curing speed is increased, and the fiber shape preserving effect is improved. In addition, the fiber structure regularity is not greatly damaged by the saturated fatty acid metal salt, and excellent performances of the polyester fibers are maintained.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A kind of low-cost environment-friendly polyester film for kink packaging and preparation method thereof

ActiveCN105966018BLow intrinsic viscosityImprove flexibilitySynthetic resin layered productsPolyesterSurface layer

The invention discloses a low-cost eco-friendly polyester film for twist packaging and a preparation method of the polyester film. The film comprises an upper and lower surface layers and a core layer. The core layer is composed of 20-30% of bright polyester chips and 70-80% of recovery chips. Each of the upper and lower surface layers is composed of 70% of bright polyester chips and 30% of silicon-contained chips. The core layer adopts PET recovery chips which are low in price and are clean. Meanwhile, longitudinal and transverse stretch technology is used for adjustment. Mainly, the longitudinal stretch ratio is reduced to 2.8-3.2, and the transverse stretch ratio is reduced to 3.5-3.7. A special low-temperature setting process is carried out at 80-120 DEG C to further reduce crystallization tendency of the film, so that the degree of crystallinity of the film can be controlled and the twist ability of the film is improved. A twist film having a resilience angle less than 45 degrees when rotated at 540 degrees, and the cost is reduced by about 40%.

Owner:SHANDONG FENGHUA PLASTIC TECH CO LTD

A Polyester Spinning Method for Reducing Extrusion Swelling Ratio

ActiveCN106835335BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterFiber

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Polyethylene terephthalate and its production method

ActiveCN103289064BLow intrinsic viscosityBad apperancePolymer sciencePolyethylene terephthalate glycol

Owner:MITSUI CHEM INC

Polyester spinning method capable of reducing extrusion swelling ratio

ActiveCN106835335AReduce bloatPressure decreases after filtrationFilament forming substance formingArtificial thread manufacturing machinesPolyesterSwelling ratio

The invention relates to a polyester spinning method capable of reducing extrusion swelling ratio. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the extrusion swelling ratio of the spinning melt is 1.20 to 1.32; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s. The polyester spinning method has the advantages that by adding the saturated fatty acid metal salt into the spinning melt, which is equivalent to adding a lubricant, the post-filtering pressure during spinning is reduced, the exit swelling is effectively reduced, and a product has good shape preserving effect; the saturated fatty acid metal salt can be used as a nucleating agent, so that the curing speed of fibers is accelerated, and the shape preserving effect of the fibers is further improved; the saturated fatty acid metal salt has no great damage to the regularity of the polyester fiber structure, and the self excellence property of the polyester fiber is maintained.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A hyperbranched polymer viscosity reducer for high-strength concrete and preparation method thereof

ActiveCN112552517BSpecial branched topological molecular structureLow intrinsic viscosityCompound aPolymer science

The invention relates to a hyperbranched polymer viscosity reducer for high-strength concrete and a preparation method thereof. Step 1: Carrying out a ring-opening reaction between a benzene ring compound having two or more primary amino functional groups and epichlorohydrin to obtain Compound A; Step 2: compound A and solid base ring closure reaction to obtain glycidylamine compound B 1 ; Step 3: Glycidylamine Compound B 1 Carry out ring-opening and ring-closing reactions M times to obtain compound B 1+M , M≥0; Step 4: Glycidylamine compound B 1+M , monomethyl ether and the sodium hydroxide solution whose mass concentration is 50wt% can be reacted to obtain the required hyperbranched polymer viscosity reducer; the present invention relies on the low viscosity, high solubility and larger space volume characteristics of the hyperbranched polymer, Effectively reduce the entanglement between polycarboxylate superplasticizer chains and increase the occupancy of unadsorbed sites on the surface of cement particles, improve the dispersion performance of the superplasticizer and the thickness of the adsorption layer on the surface of the cementitious material particles.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD

Polyester Resin for Compression Forming, Method of Producing the Same and Method of Producing Preforms

InactiveUS20070249856A1Low intrinsic viscosityHigh intrinsic viscosityOrganic chemistryCompression moldingProduction rate

A polyester resin suitably used for forming preforms by compression forming, the polyester resin having an intrinsic viscosity of 0.70 to 1.00 dL / g and, a molecular weight distribution (Mz / Mn) of not smaller than 3.0, and a diethylene glycol content of not larger than 2.3 mol %. The polyester resin is effectively prevented from depositing on conveyer means of the synthetic resin feeding device, the timing of falling the molten resin mass onto the compression forming mold is not deviated and, besides, the resin can be extruded in an increased amount from the extruder without accompanied by an excess increase in the torque of the extruder. Therefore, the preforms can be formed by compression forming maintaining good productivity. Besides, since the resin has a high degree of fluidity, the preforms that are the formed articles are free of wrinkles, shade or forming distortion, featuring good formability.

Owner:TOYO SEIKAN KAISHA LTD

Low-viscosity polyester and its preparation method

The invention relates to a low-viscosity polyester and a preparation method thereof. The low-viscosity polyester with an intrinsic viscosity of 0.300 to 0.500 dL / g is prepared by controlling the adding time of a catalyst in a synthesis process, wherein the catalyst is added when the average polymerization degree of an intermediate product of a polycondensation reaction reaches 8 to 17; wherein thepolycondensation reaction temperature is 260 to 273 DEG C; the catalyst is ethylene glycol antimony; the modulation process of ethylene glycol antimony comprises the following steps: uniformly mixingethylene glycol antimony and ethylene glycol; circularly introducing nitrogen or inert gas with water content less than 200ppm in the mixing process, wherein the content of a cyclic oligomer in the prepared low-viscosity polyester is less than 2 percent by weight. According to the low-viscosity polyester and the preparation method thereof disclosed by the invention, the content of the oligomer inthe product is lowered by controlling the adding time of the catalyst in the synthesis process, the polycondensation reaction temperature and the modulation process of ethylene glycol antimony addedin the synthesis process, and the prepared low-viscosity polyester has high quality and excellent popularization value.

Owner:ZHEJIANG UNIFULL IND FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com