Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

751results about "Filament-forming treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

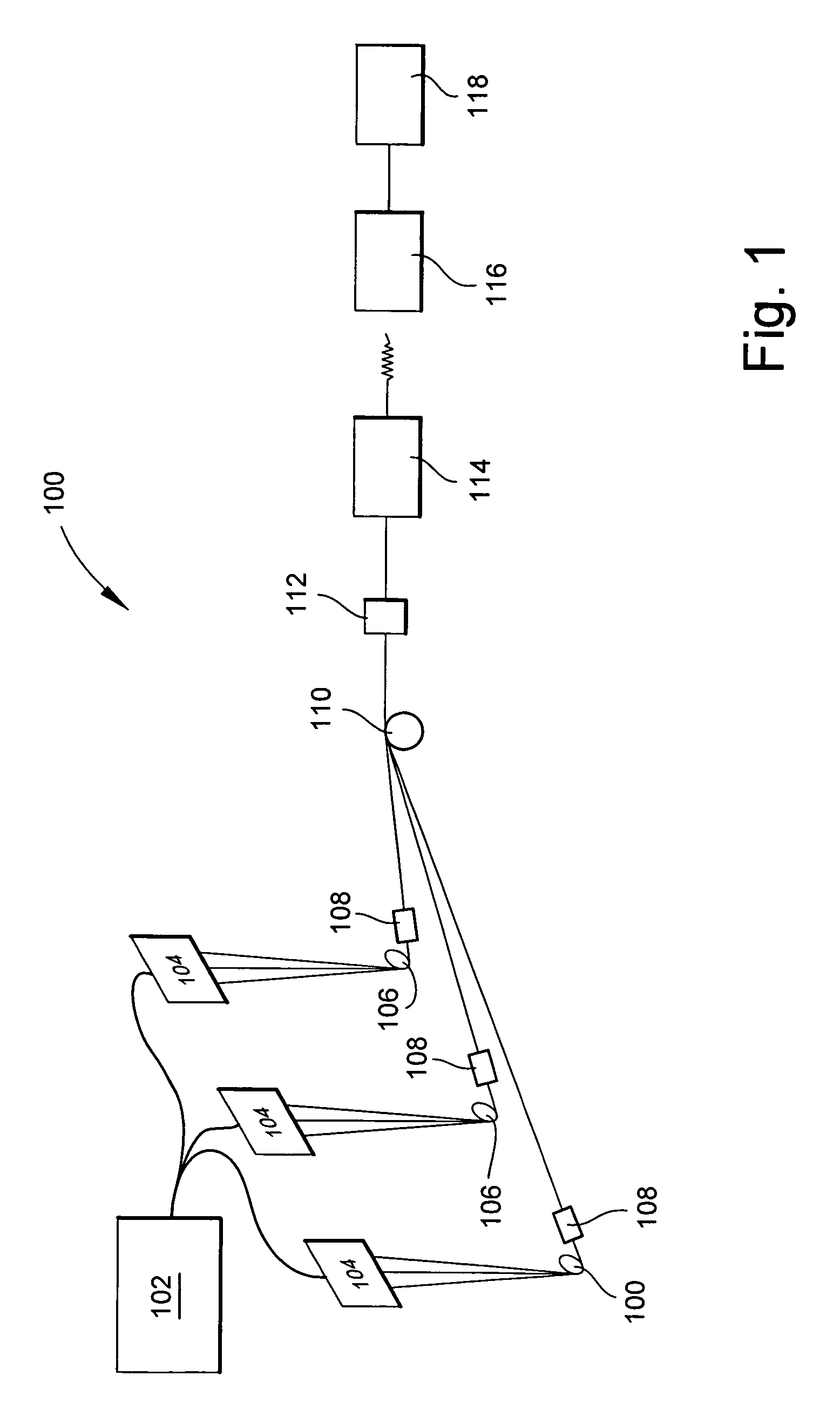

Process for preparing a simulated in situ polyethylene blend

A process comprising:(i) providing a first polyethylene, prepared independently, having a melt index in the range of about 5 to about 3000 grams per 10 minutes and a density in the range of about 0.900 to about 0.975 gram per cubic centimeter and a second polyethylene, prepared independently, having a flow index in the range of about 0.01 to about 30 grams per 10 minutes and a density in the range of about 0.860 to about 0.940 gram per cubic centimeter, the weight ratio of the first polyethylene to the second polyethylene being in the range of about 75:25 to about 25:75;(ii) blending the first polyethylene with the second polyethylene;(iii) melting the blend; and, prior to extrusion or pelletizing,(iv) passing the molten blend through one or more active screens, in the case of two or more active screens, positioned in series, each active screen having a micron retention size in the range of about 2 to about 70, at a mass flux of about 5 to about 100 pounds per hour per square inch.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

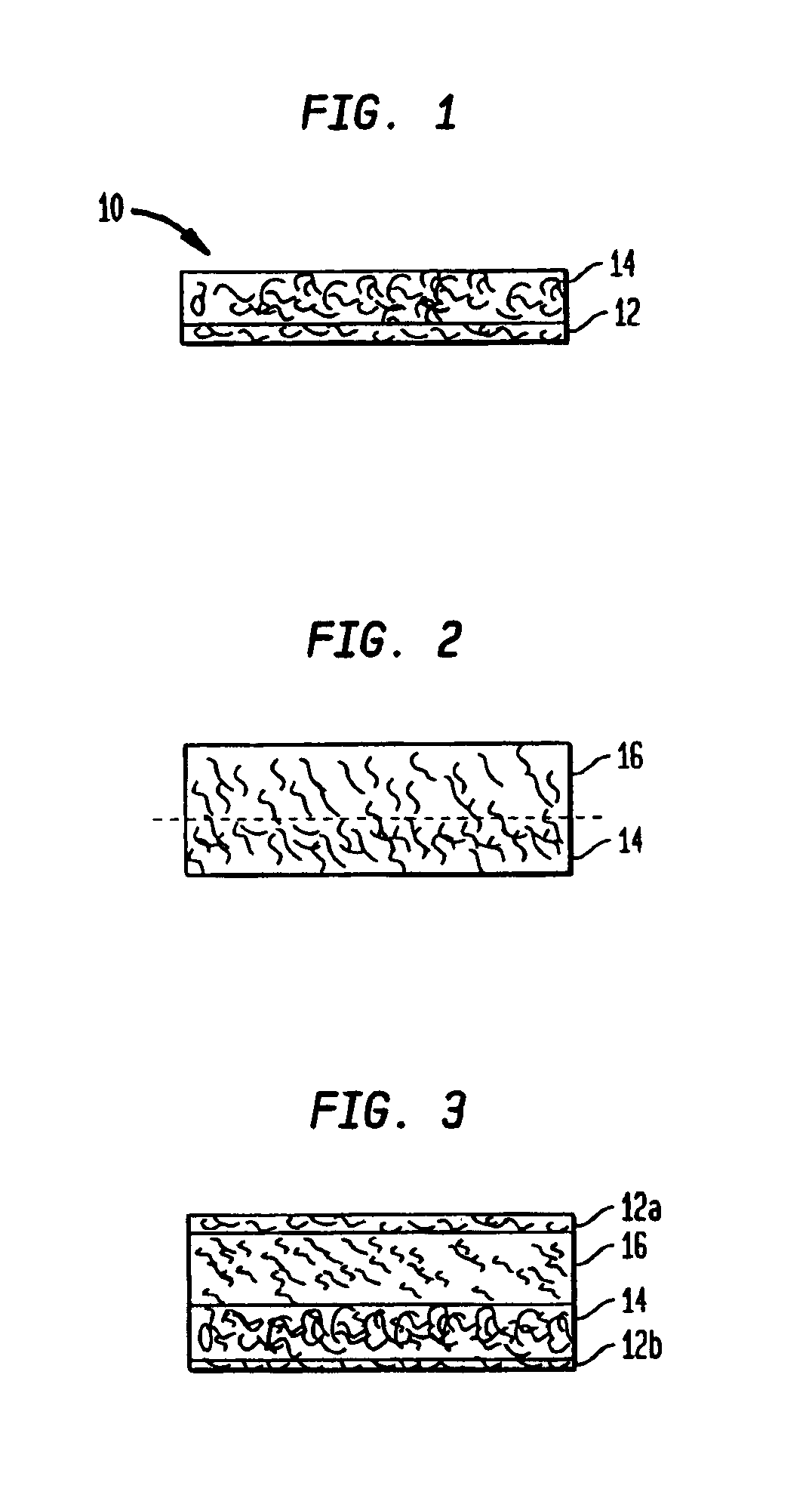

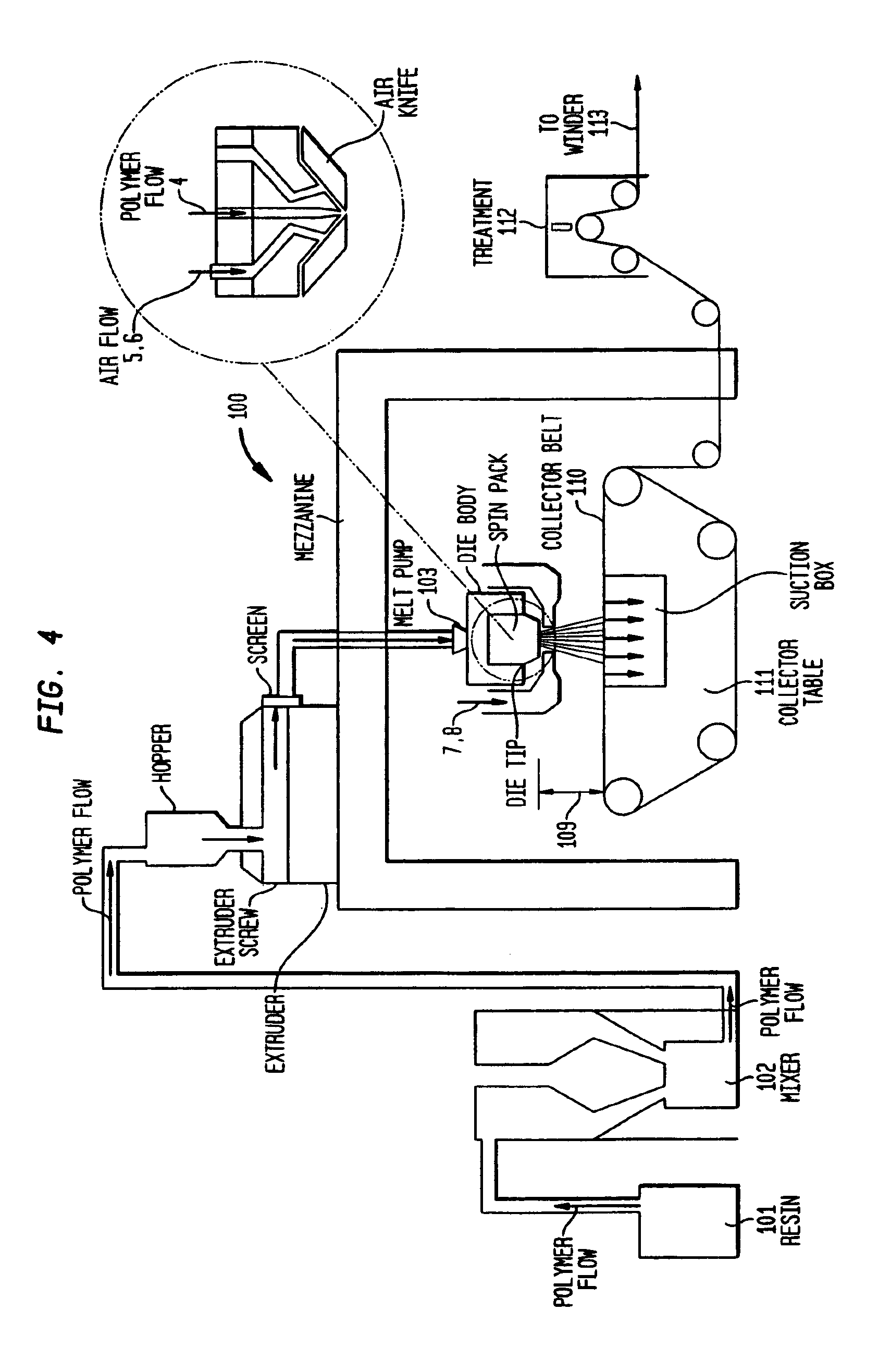

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

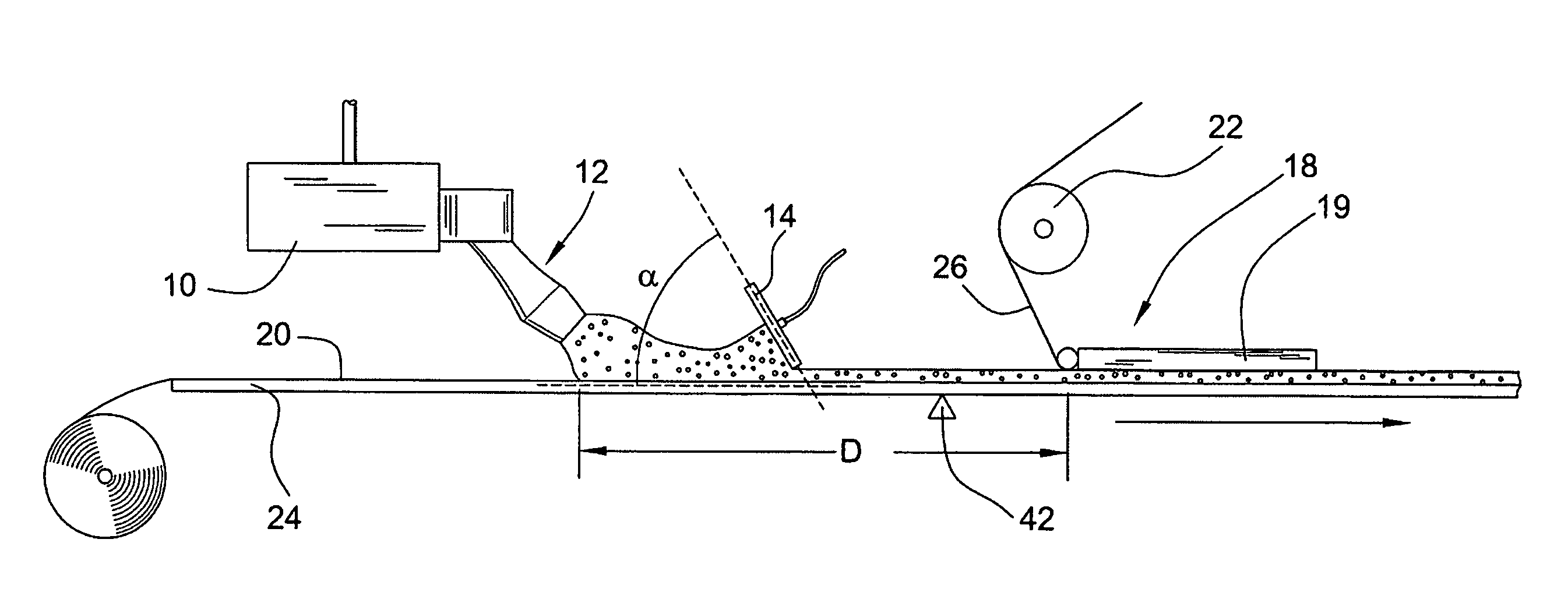

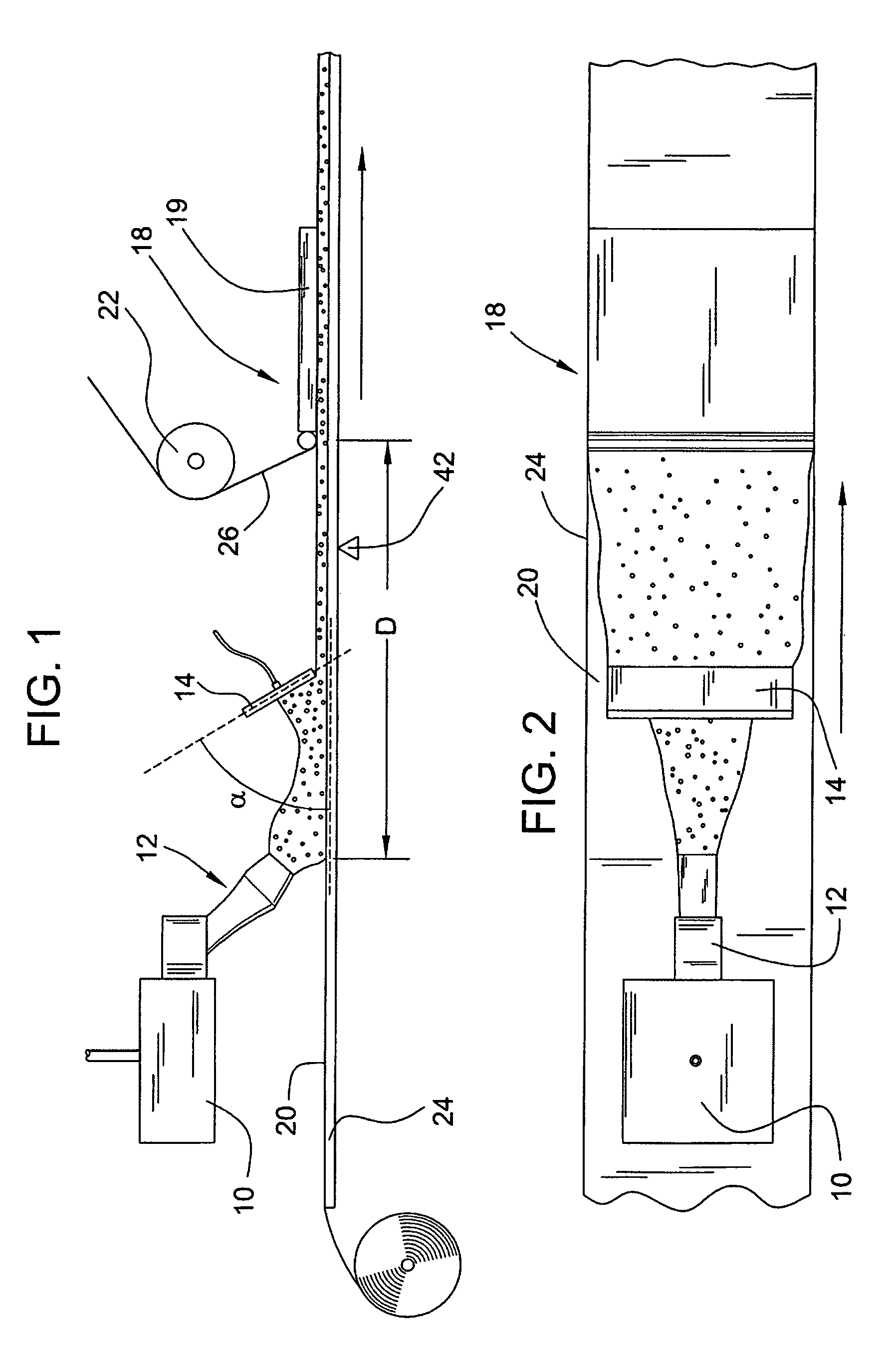

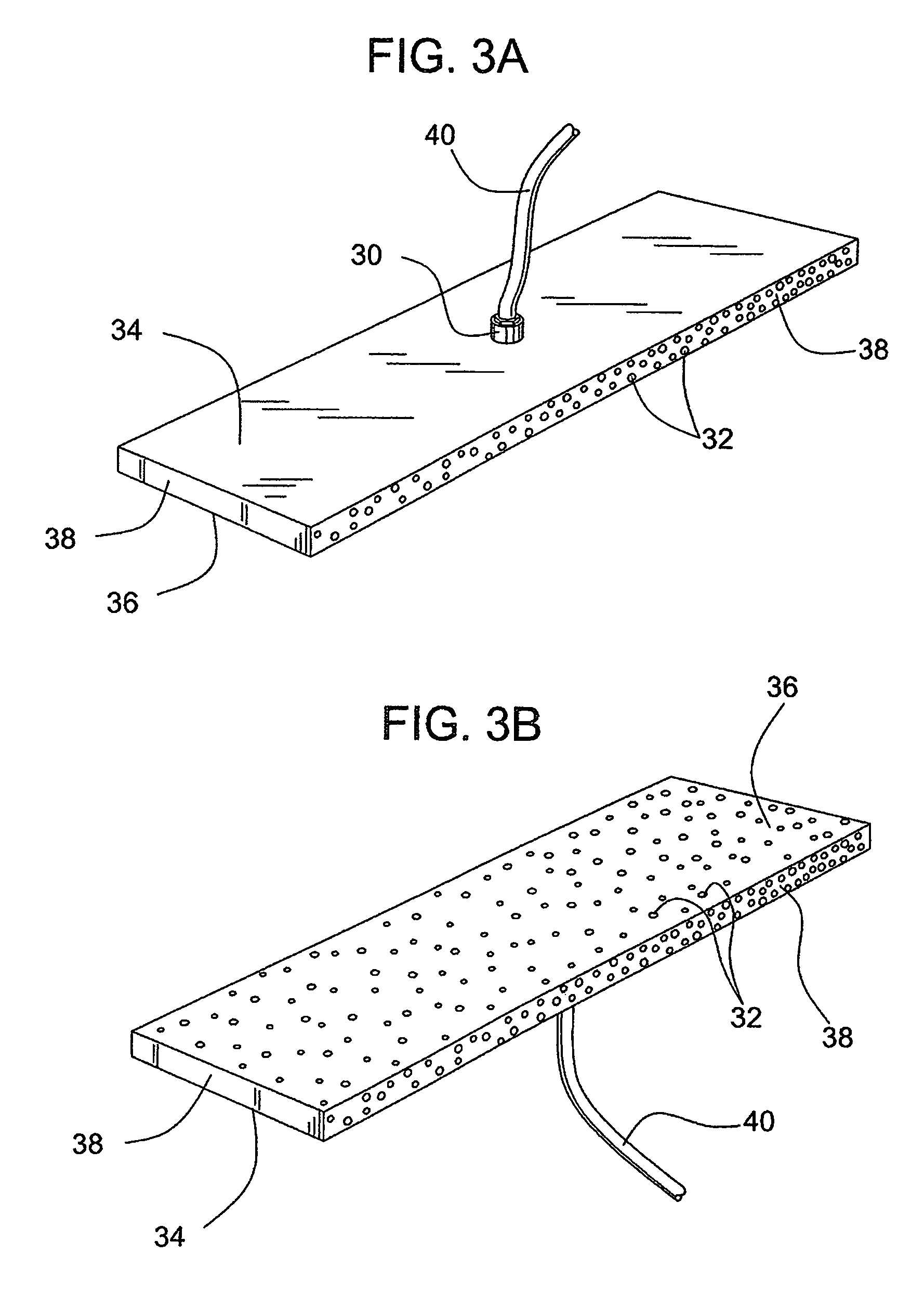

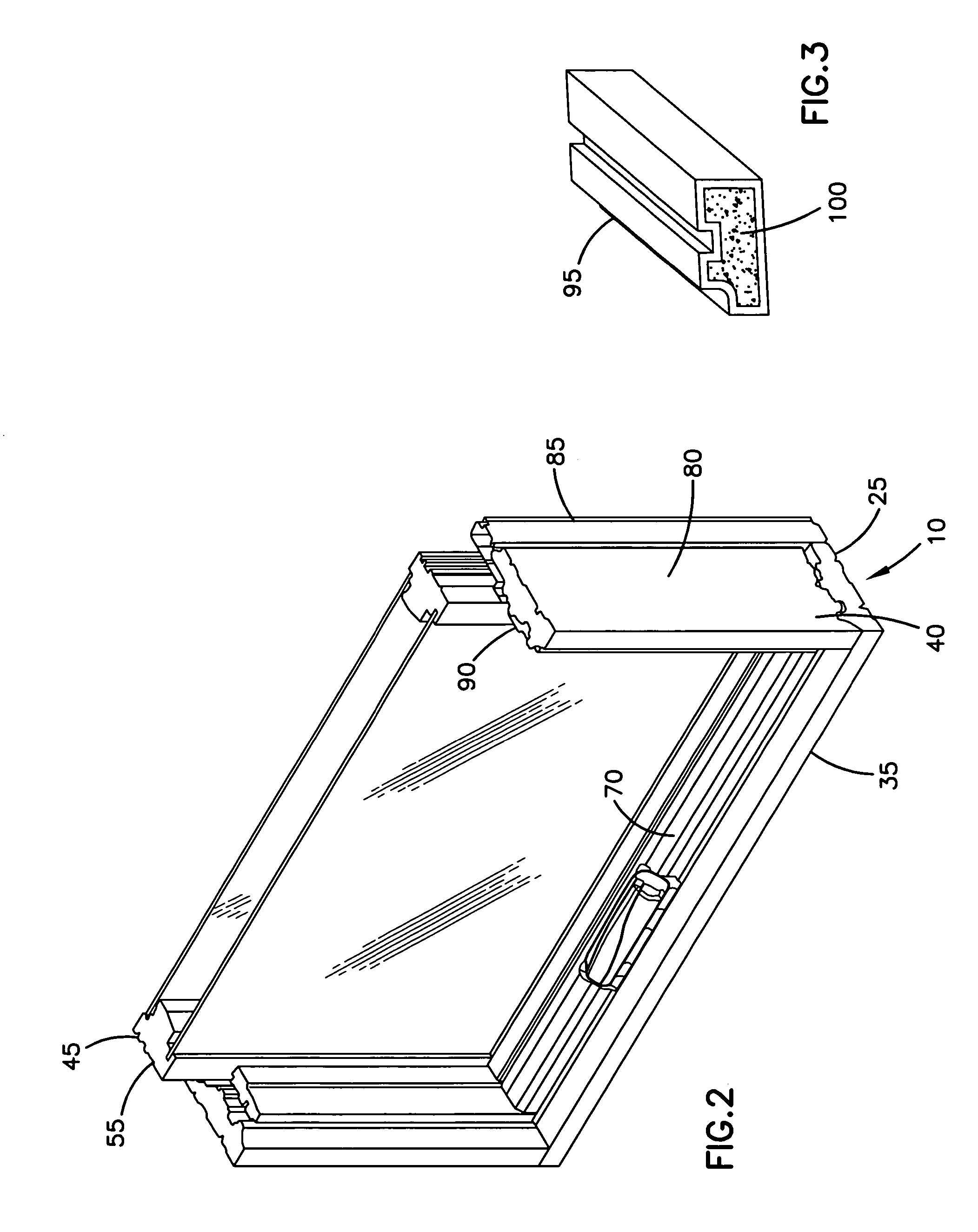

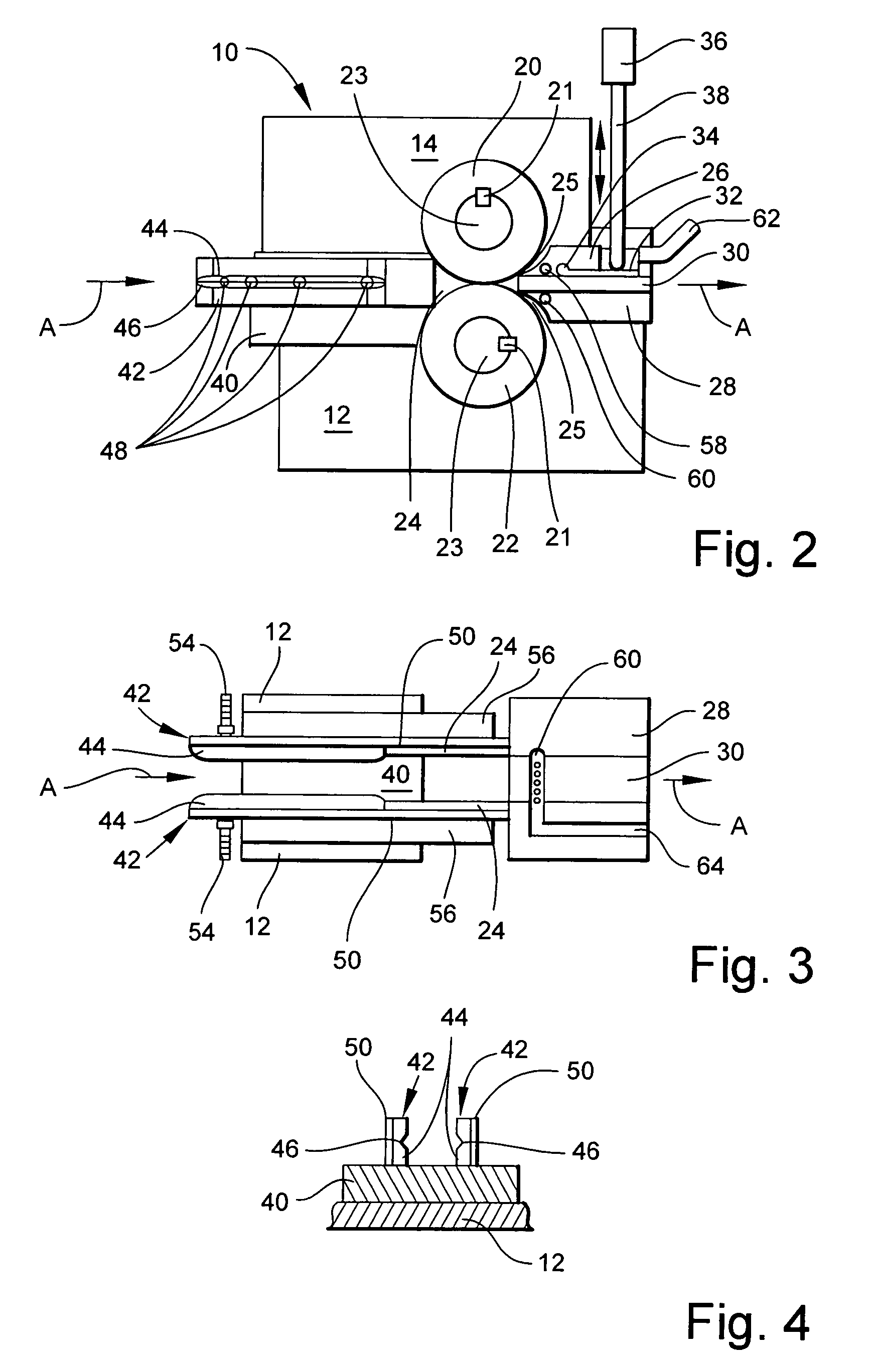

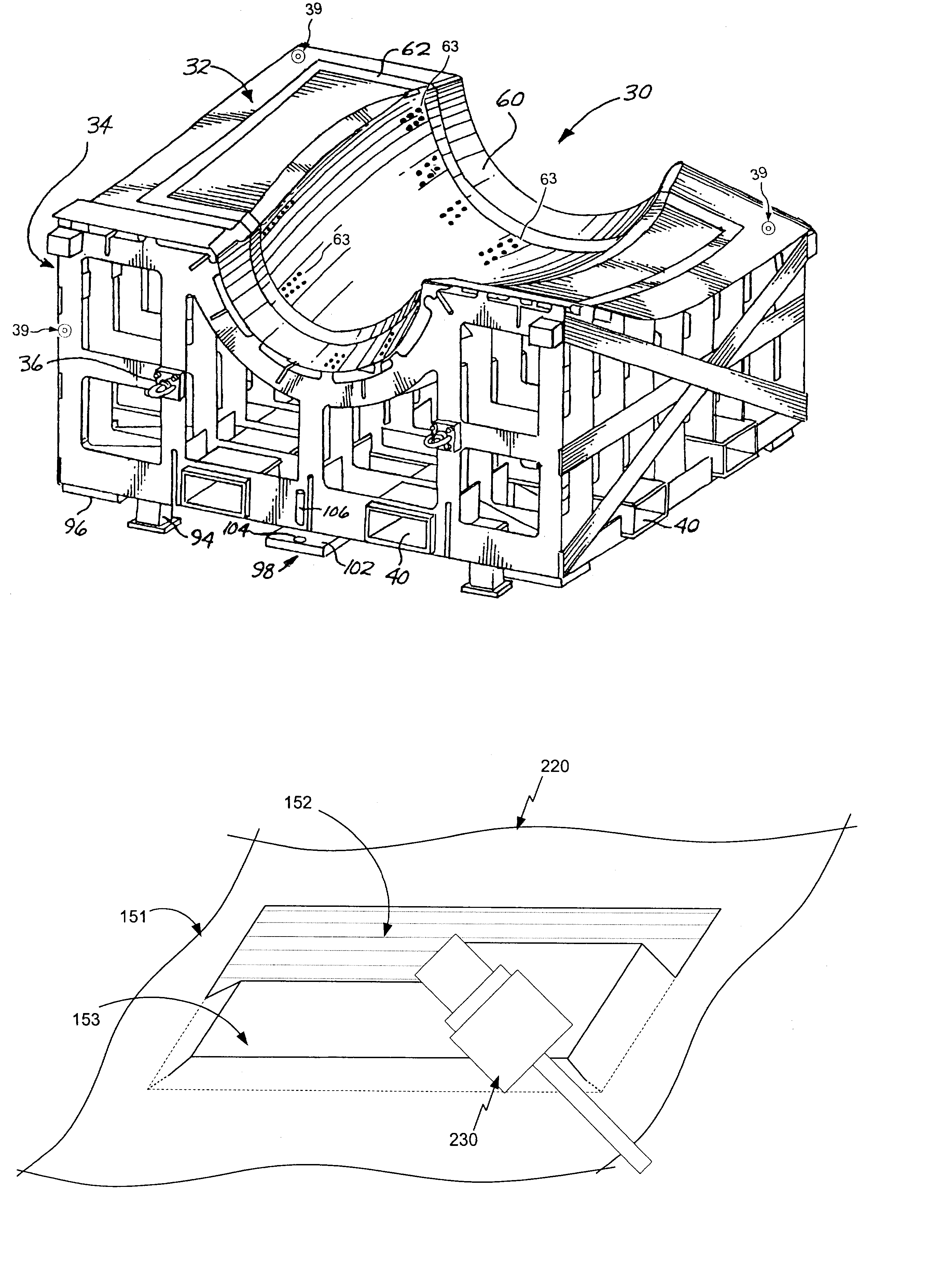

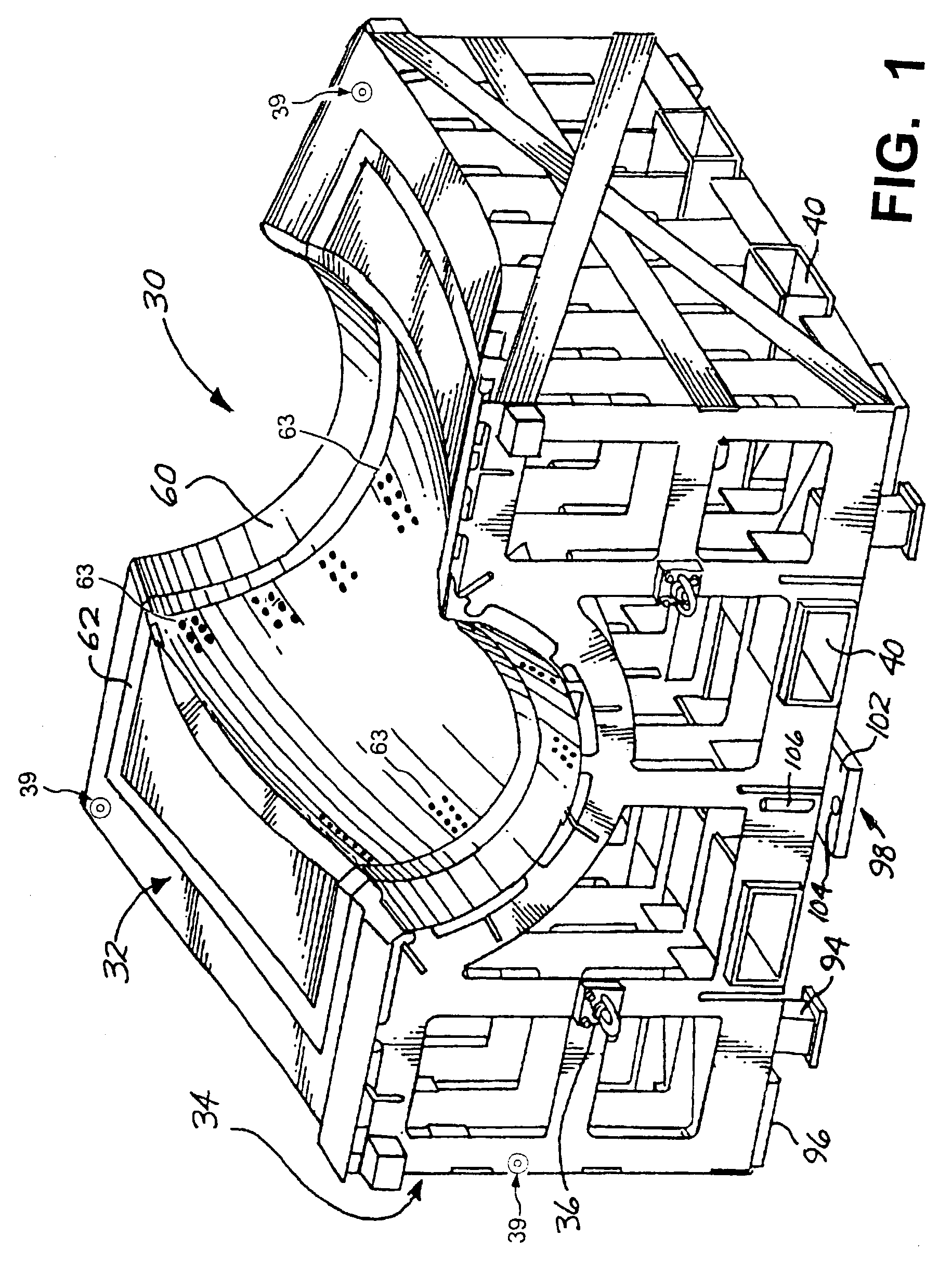

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

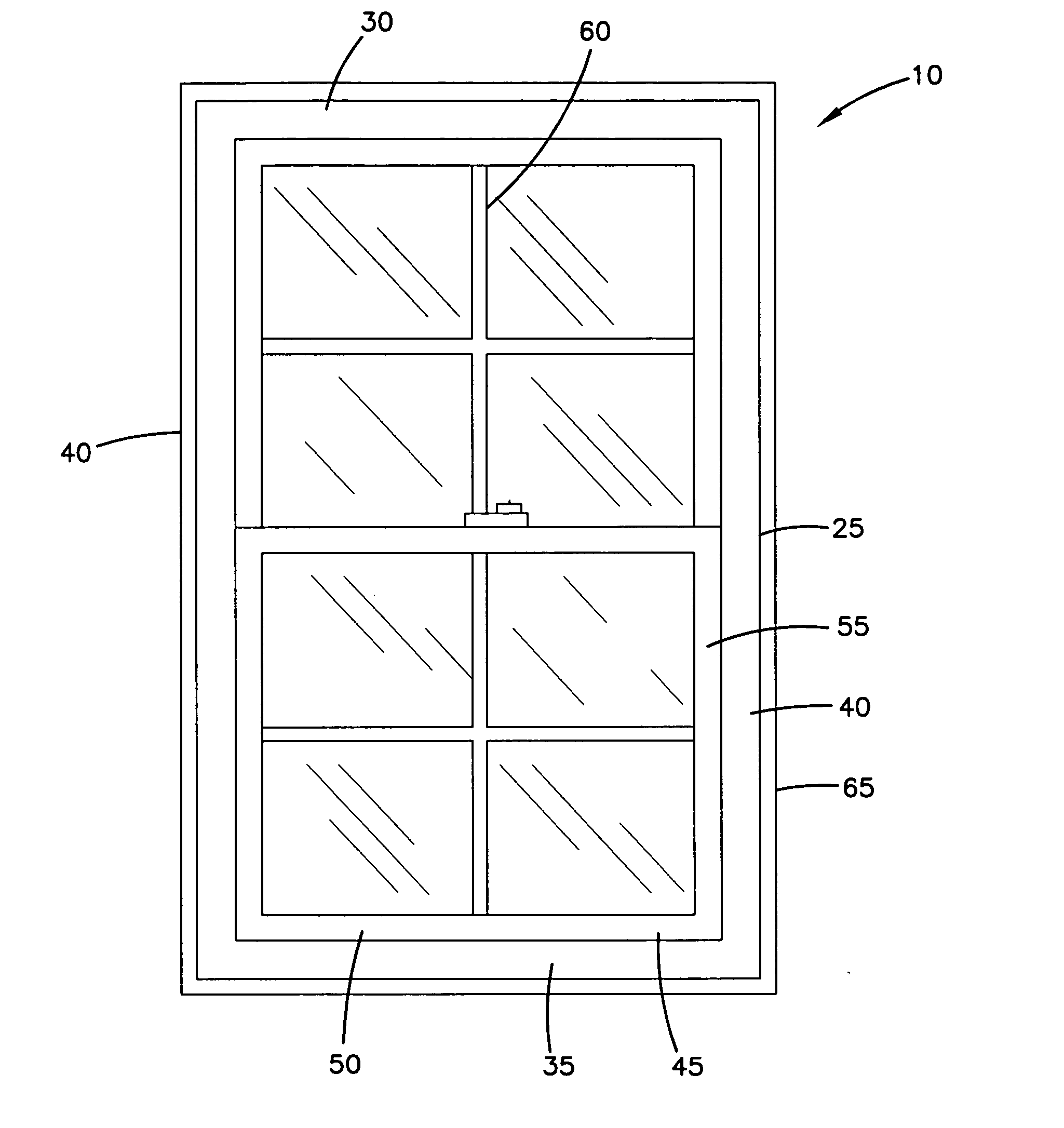

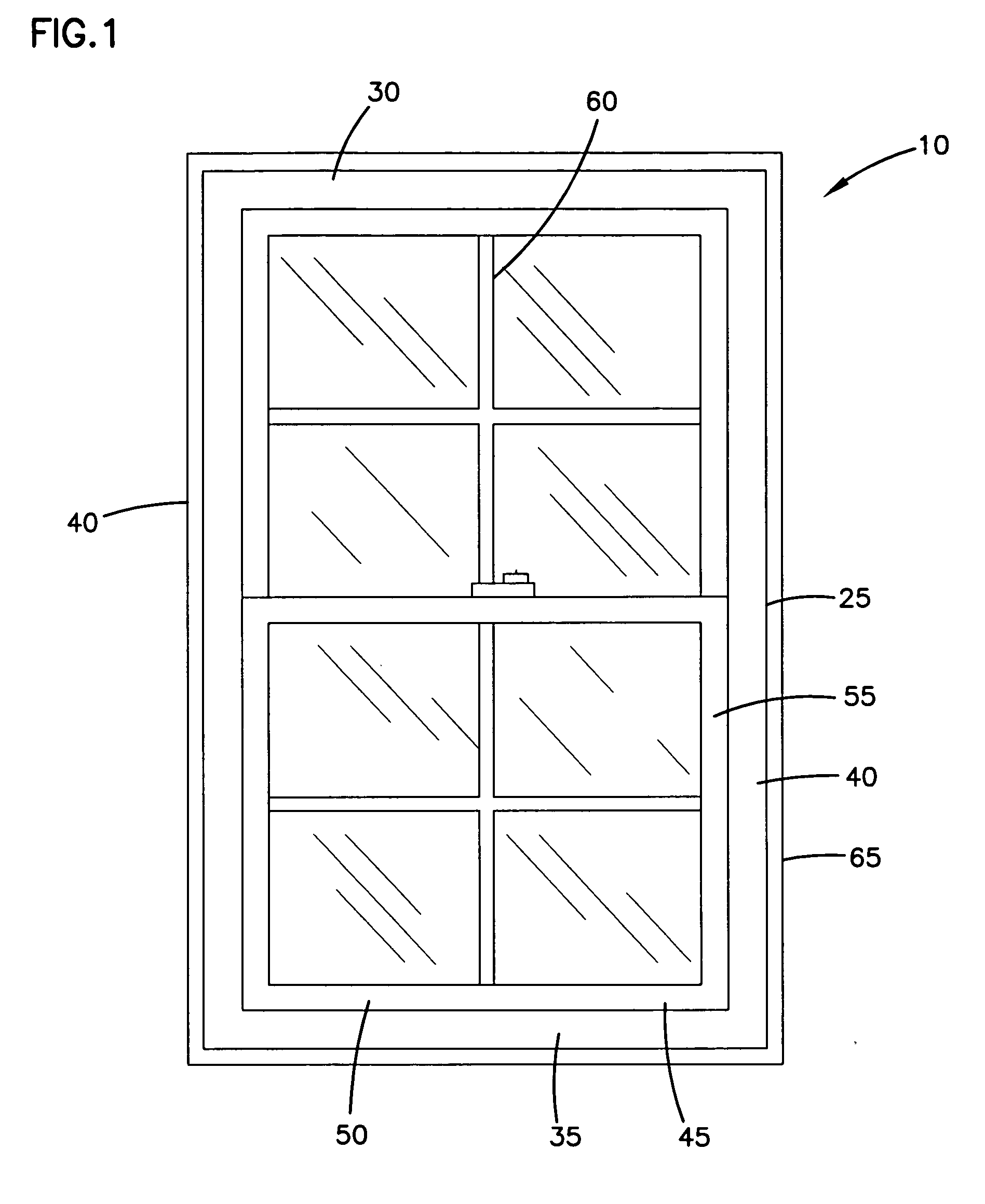

Biopolymer structures and components

InactiveUS20050019545A1Keep shapeIncrease valueVehicle arrangementsAlcoholic beverage preparationBiopolymerEngineering

Structures can be formed from a composition, which can be referred to as a biopolymer, that includes fermentation solids and thermoactive material. Methods of making biopolymer products include for example extruding, injection molding, or compounding fermentation solid and thermoactive material. Structures formed from biopolymer can include lumber replacements, window components, door components, siding assemblies, and other structures.

Owner:POET RES INC

Polymeric composites having enhanced reversible thermal properties and methods of forming thereof

Polymeric composites and methods of manufacturing polymeric composites are described. In one embodiment, a set of microcapsules containing a phase change material are mixed with a dispersing polymeric material to form a first blend. The dispersing polymeric material has a latent heat of at least 40 J / g and a transition temperature in the range of 0° C. to 50° C. The first blend is processed to form a polymeric composite. The polymeric composite can be formed in a variety of shapes, such as pellets, fibers, flakes, sheets, films, rods, and so forth. The polymeric composite can be used as is or incorporated in various articles where a thermal regulating property is desired.

Owner:OUTLAST TECH LLC

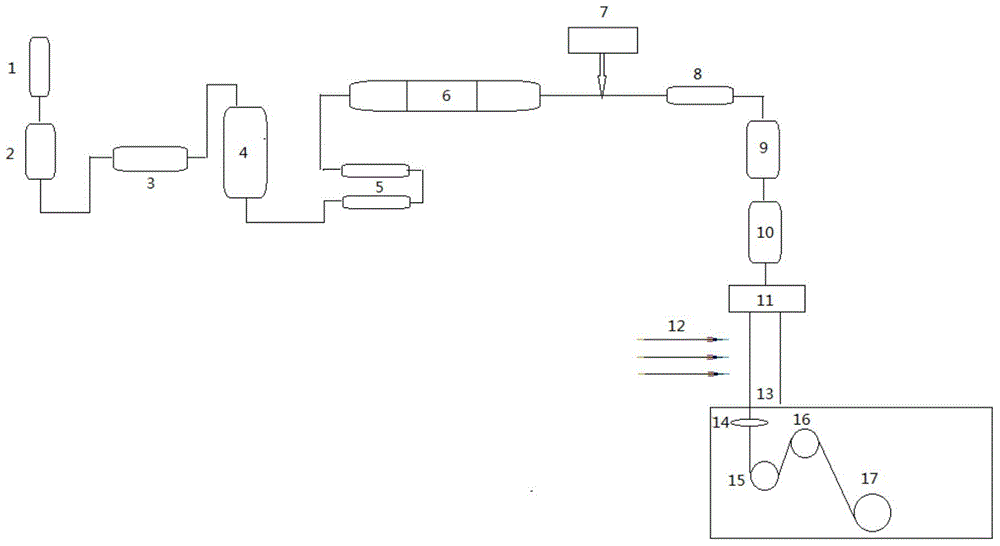

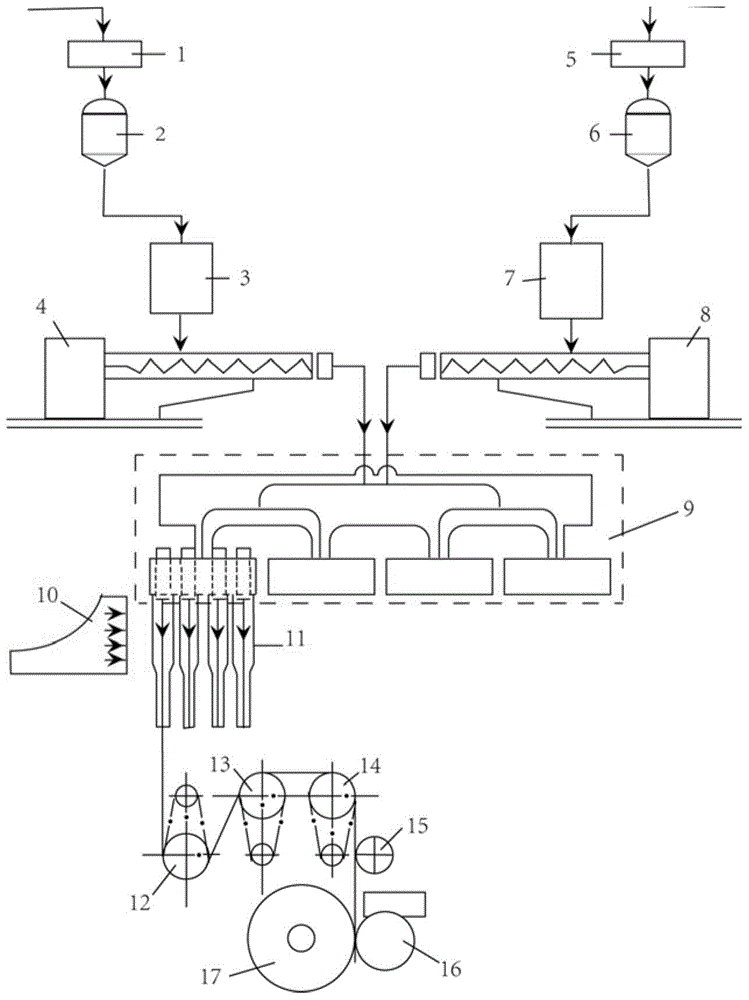

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

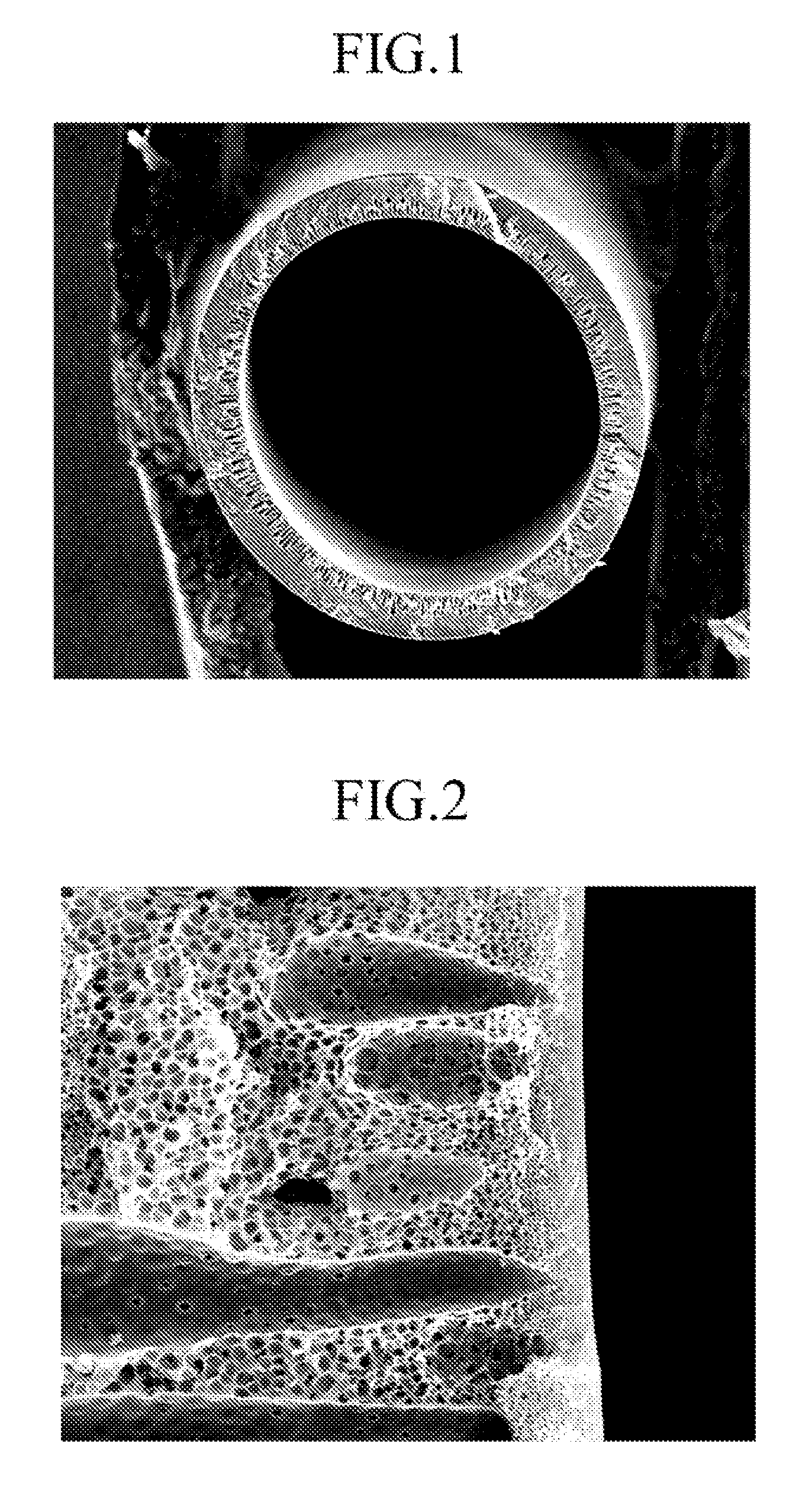

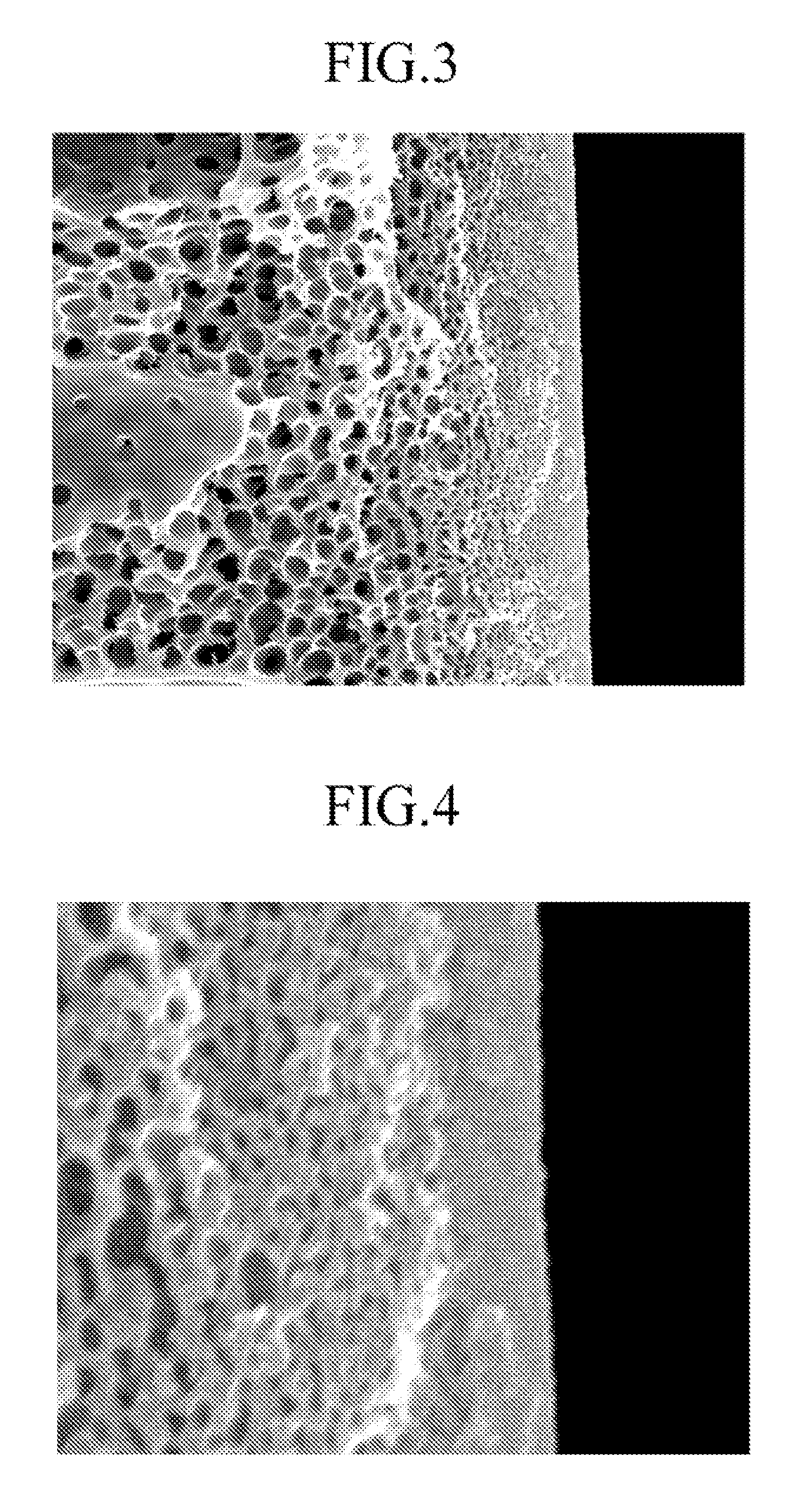

Hollow fiber, dope composition for forming hollow fiber, and method of making hollow fiber using the same

InactiveUS20090297850A1Improve permeabilityHigh selectivitySuture equipmentsCosmetic preparationsHollow fibreFiber

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

Process of making cellulose acetate tow

ActiveUS7585441B2Artificial filament physical treatmentArtificial filaments from cellulose derivativesFiberPlasticizer

In the manufacture of a fiber tow, particularly cellulose acetate tow, the tow is plasticized prior to entry into the crimper. The preferred plasticizer is water.

Owner:DEUT BANK AG NEW YORK BRANCH AS COLLATERAL AGENT +1

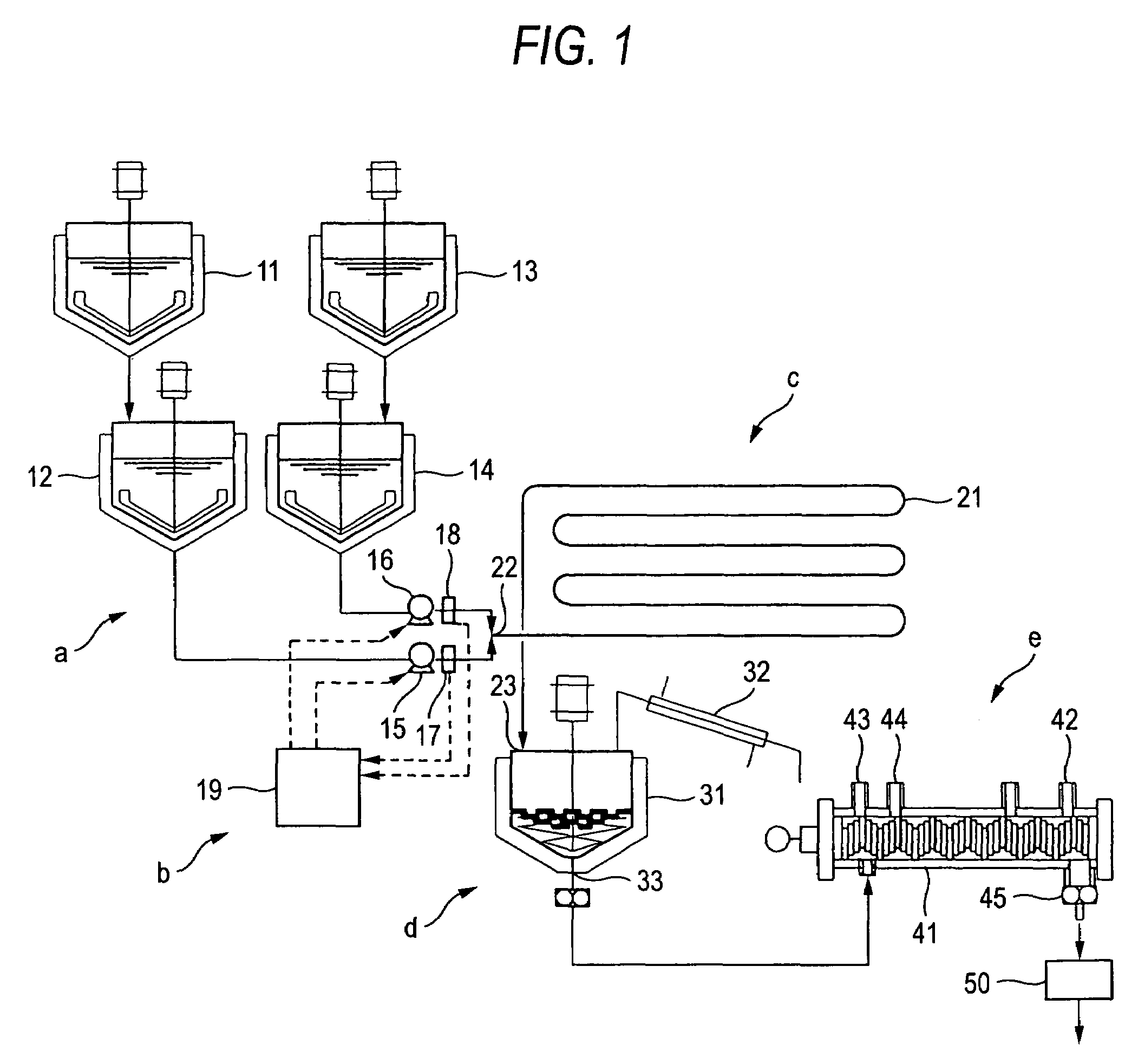

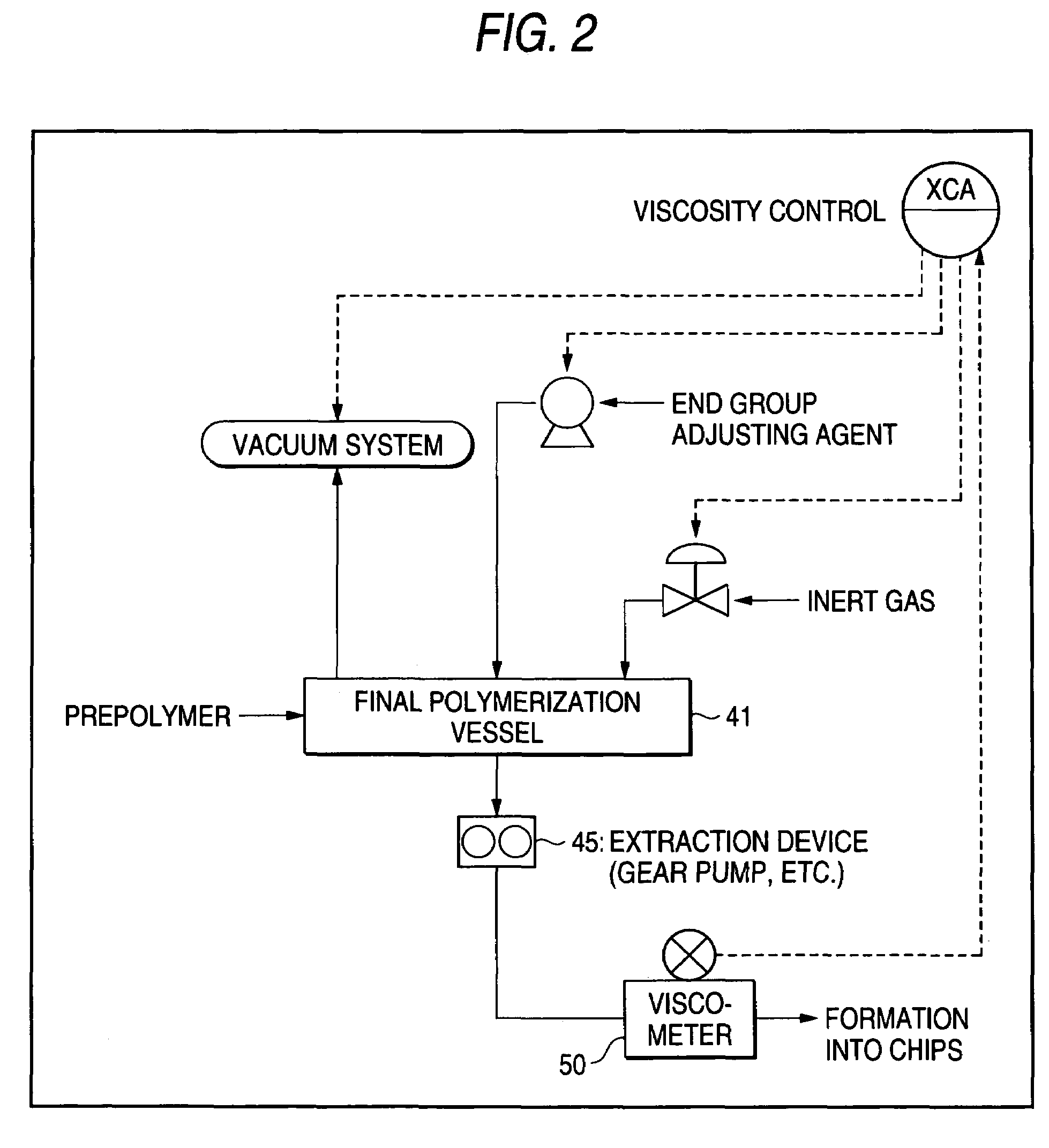

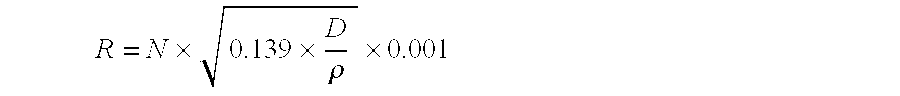

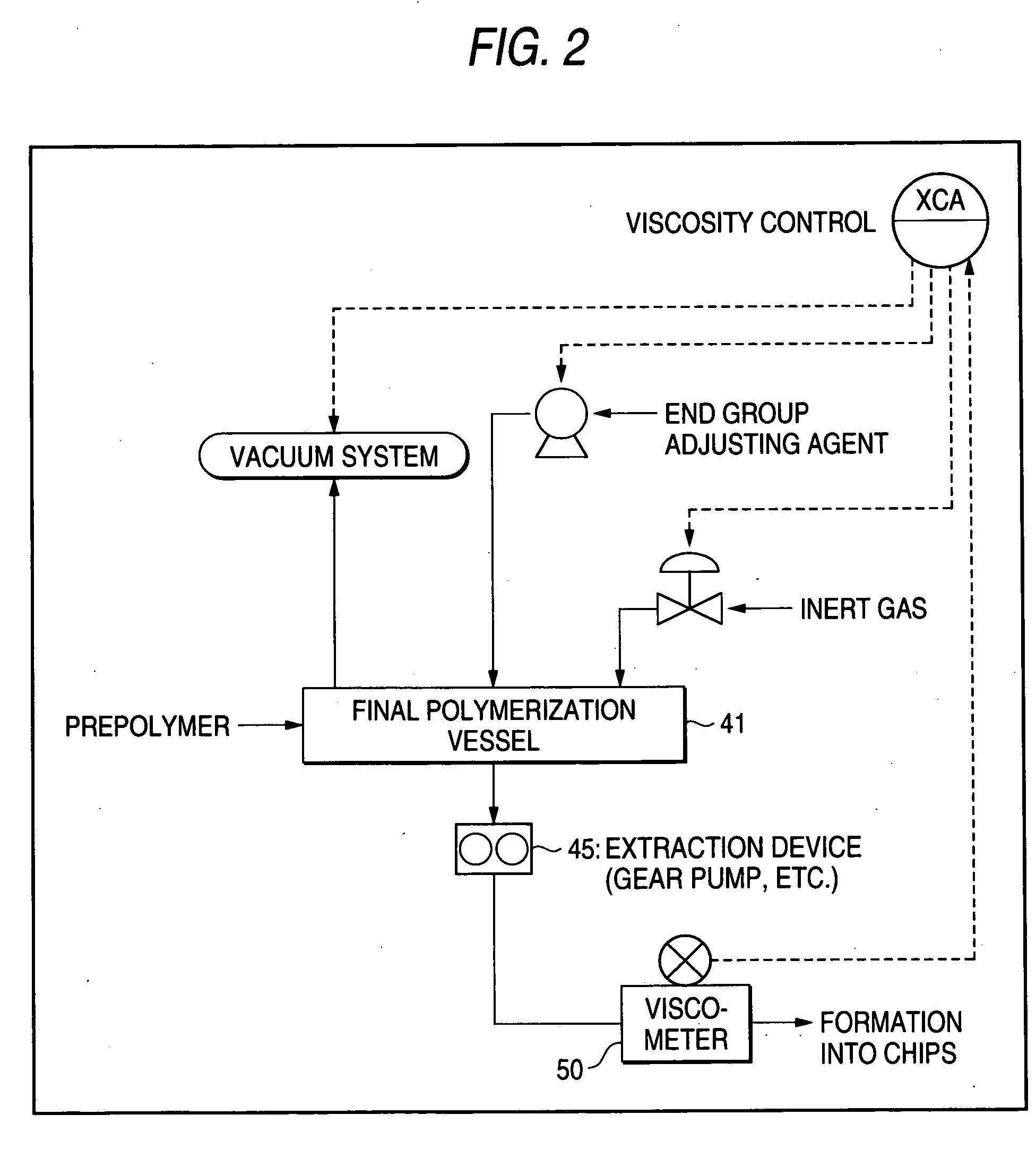

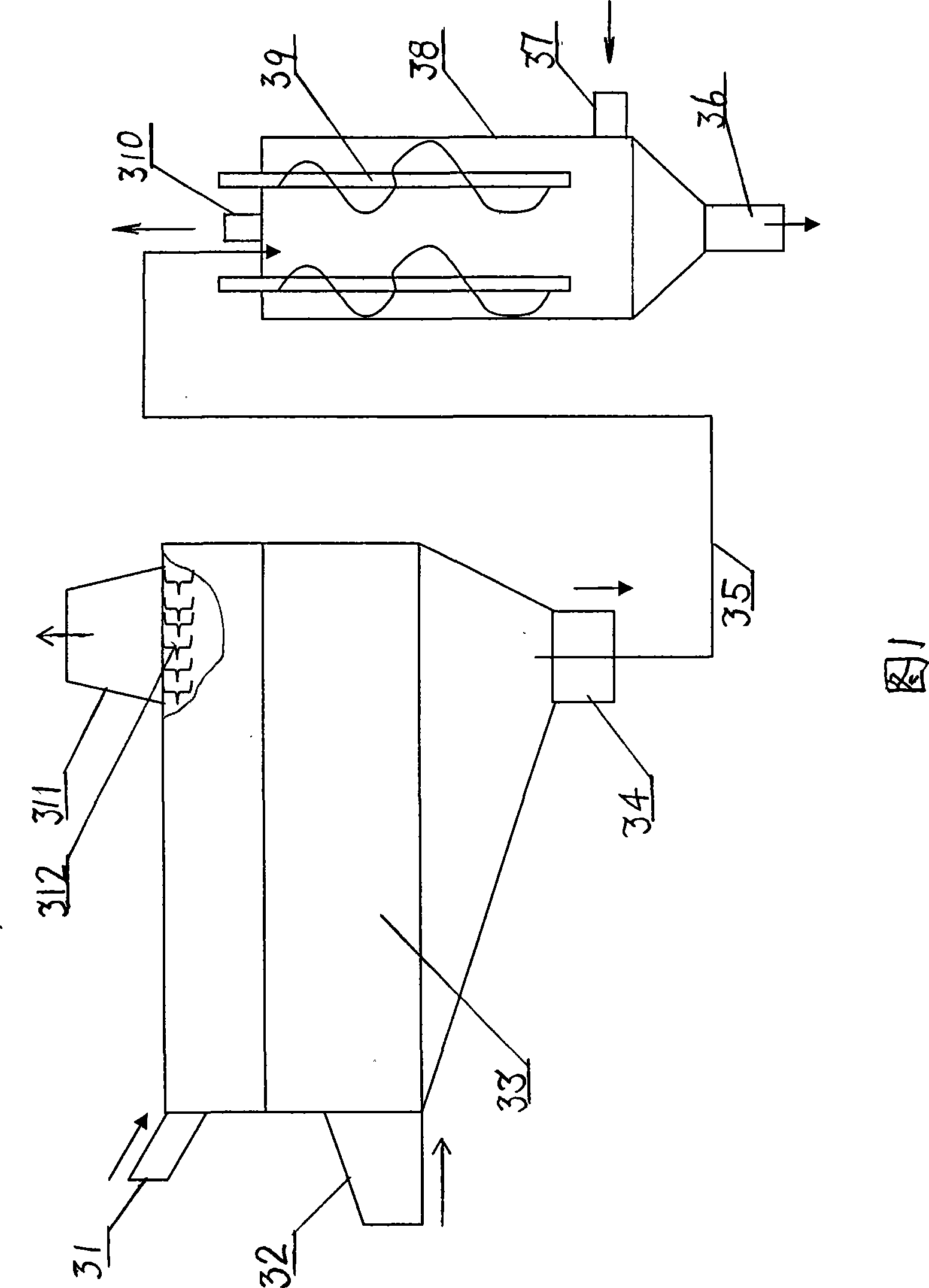

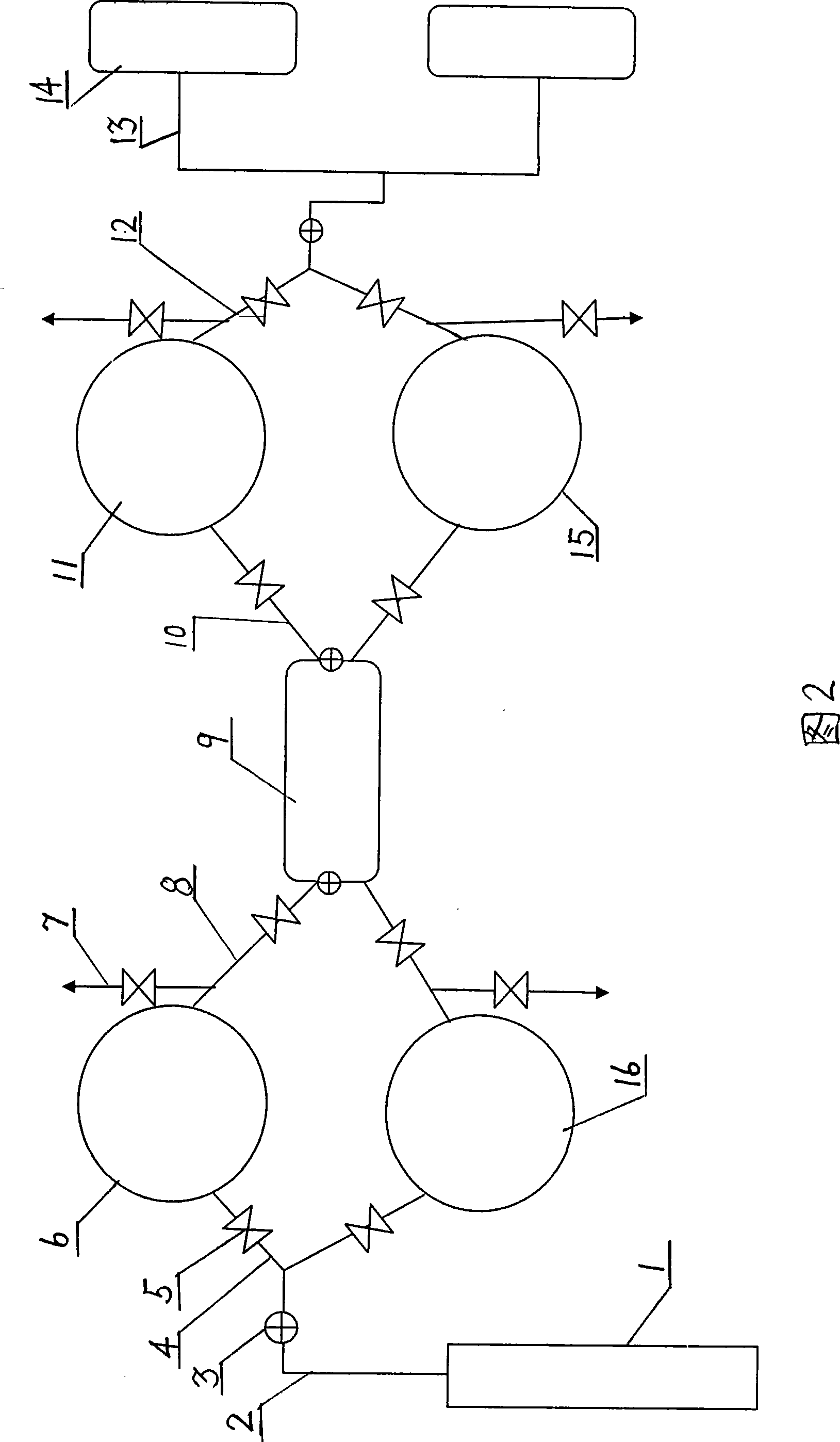

Method for continuous production of polyamide

InactiveUS7381788B2Quality improvementThe degree of polymerization is controllableCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsPolyamideCarboxylic acid

Provided is a continuous production method of a polyamide with stabilized polymerization degree and good quality, particularly an aromatic-containing polyamide. A continuous production method of a polyamide, comprising (a) a raw material preparation step of individually melting a diamine and a dicarboxylic acid, or producing a salt of amine and carboxylic acid in water, (b) a raw material introduction step of continuously introducing the prepared raw materials into a tubular reaction apparatus, (c) an amidation step of passing the introduced raw materials through the tubular reaction apparatus, thereby effecting amidation to obtain a reaction mixture containing an amidated product and a condensed water, (d) an initial polymerization step of introducing the reaction mixture into a continuous reaction apparatus capable of separation and removal of water, and elevating the polymerization degree while separating and removing water at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide prepolymer, and (e) a final polymerization step of introducing the polyamide prepolymer into a continuous reaction apparatus capable of separation and removal of water, and further elevating the polymerization degree at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide adjusted to a desired relative viscosity [RV].

Owner:TOYOBO CO LTD

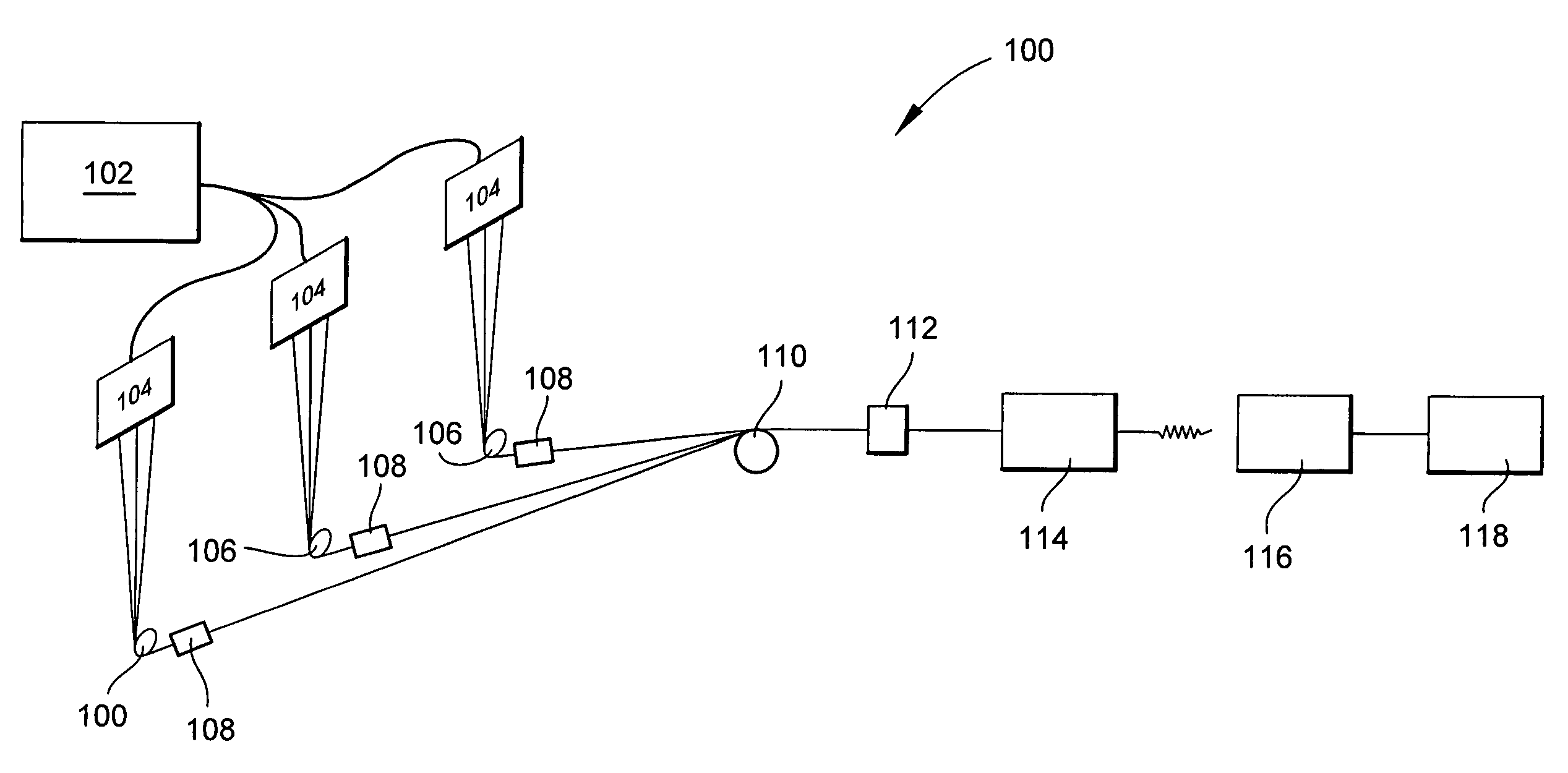

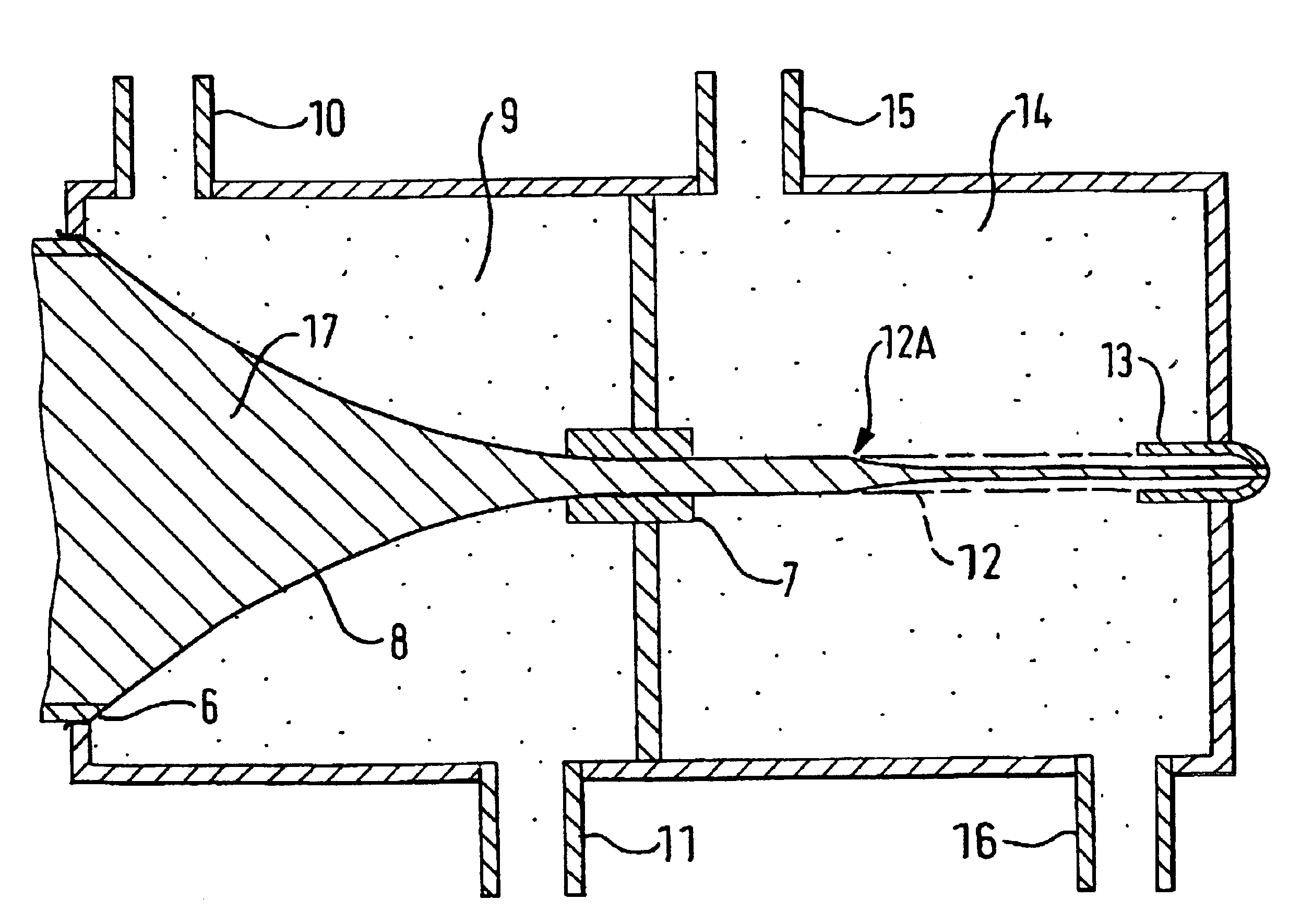

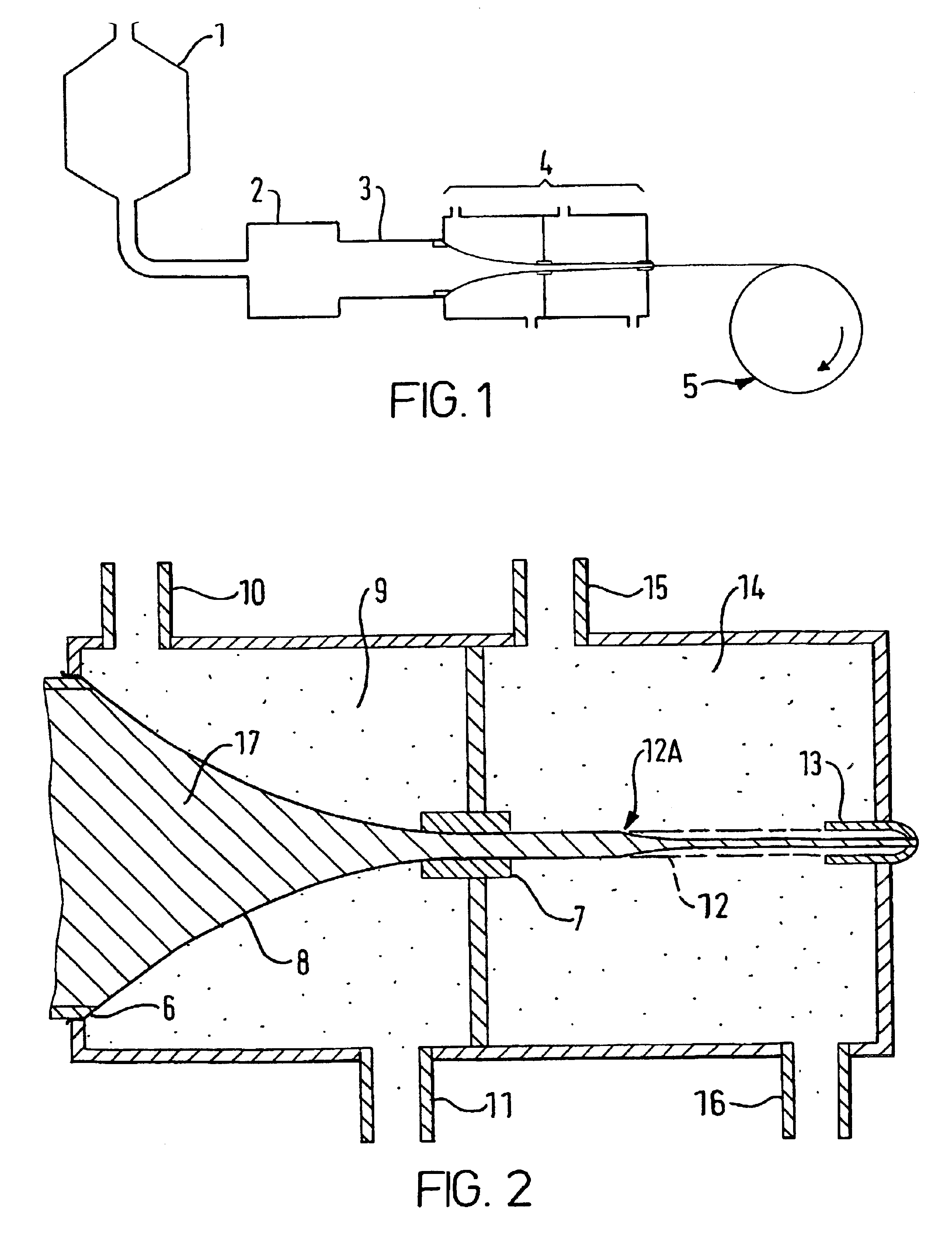

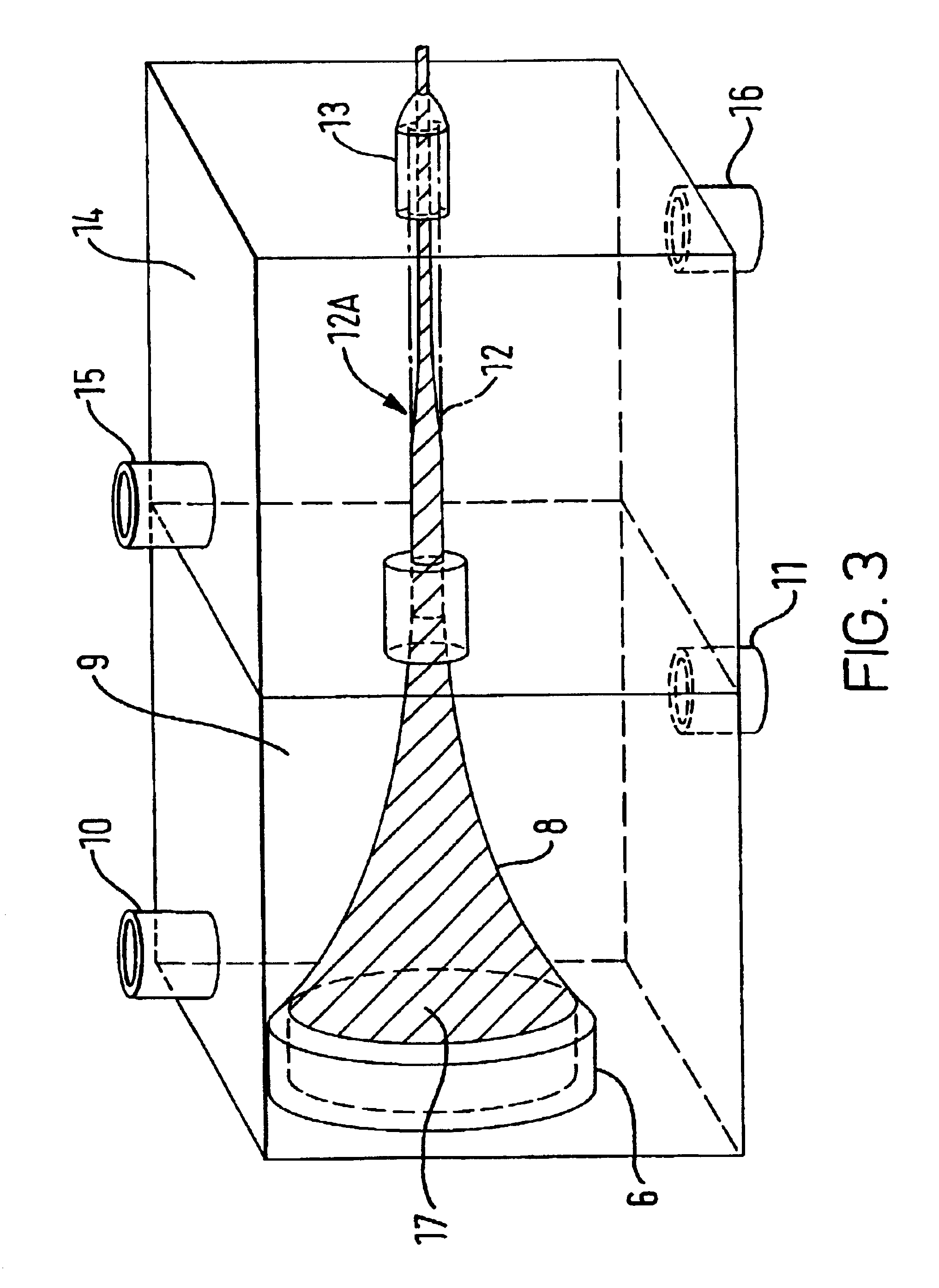

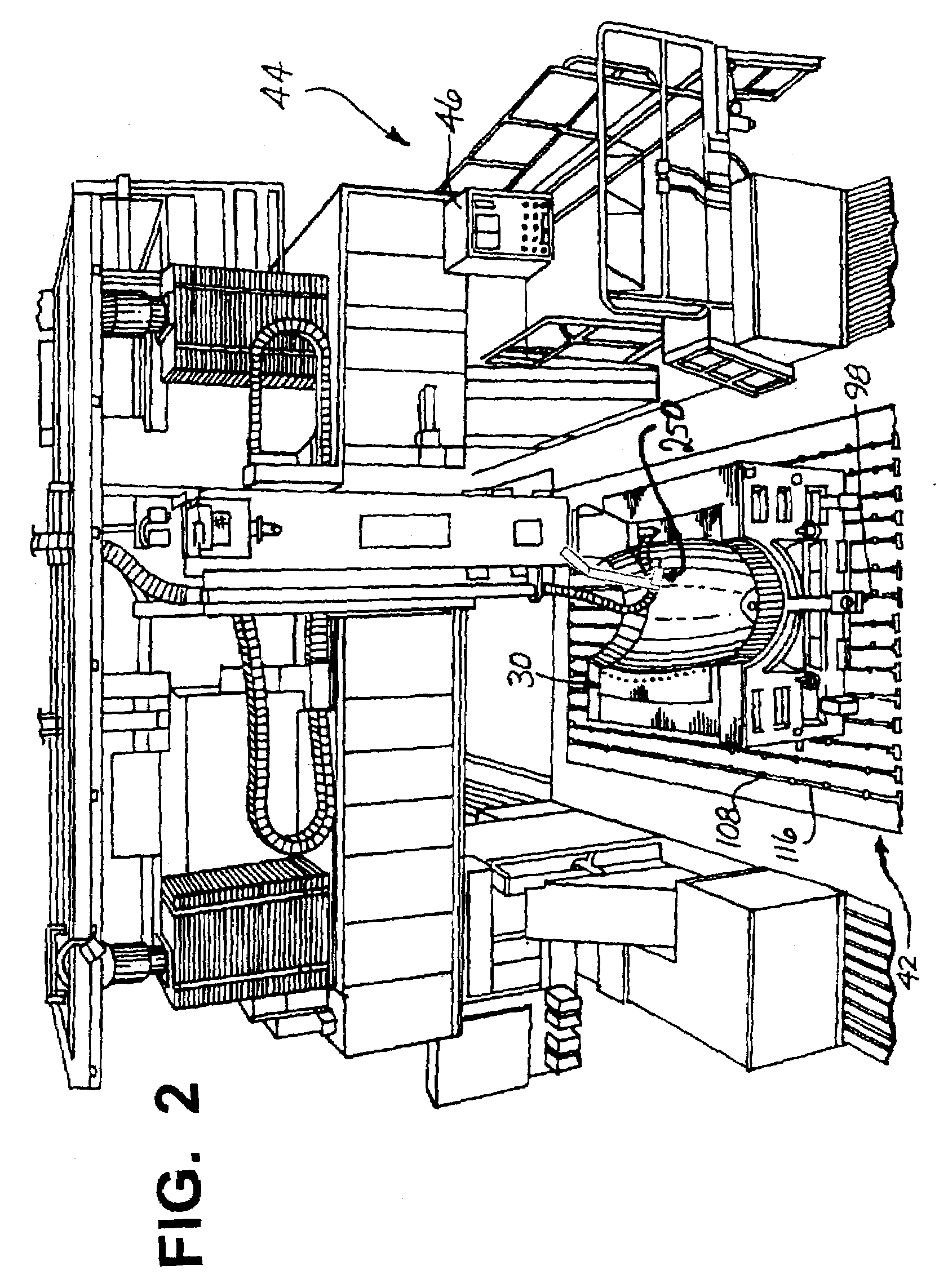

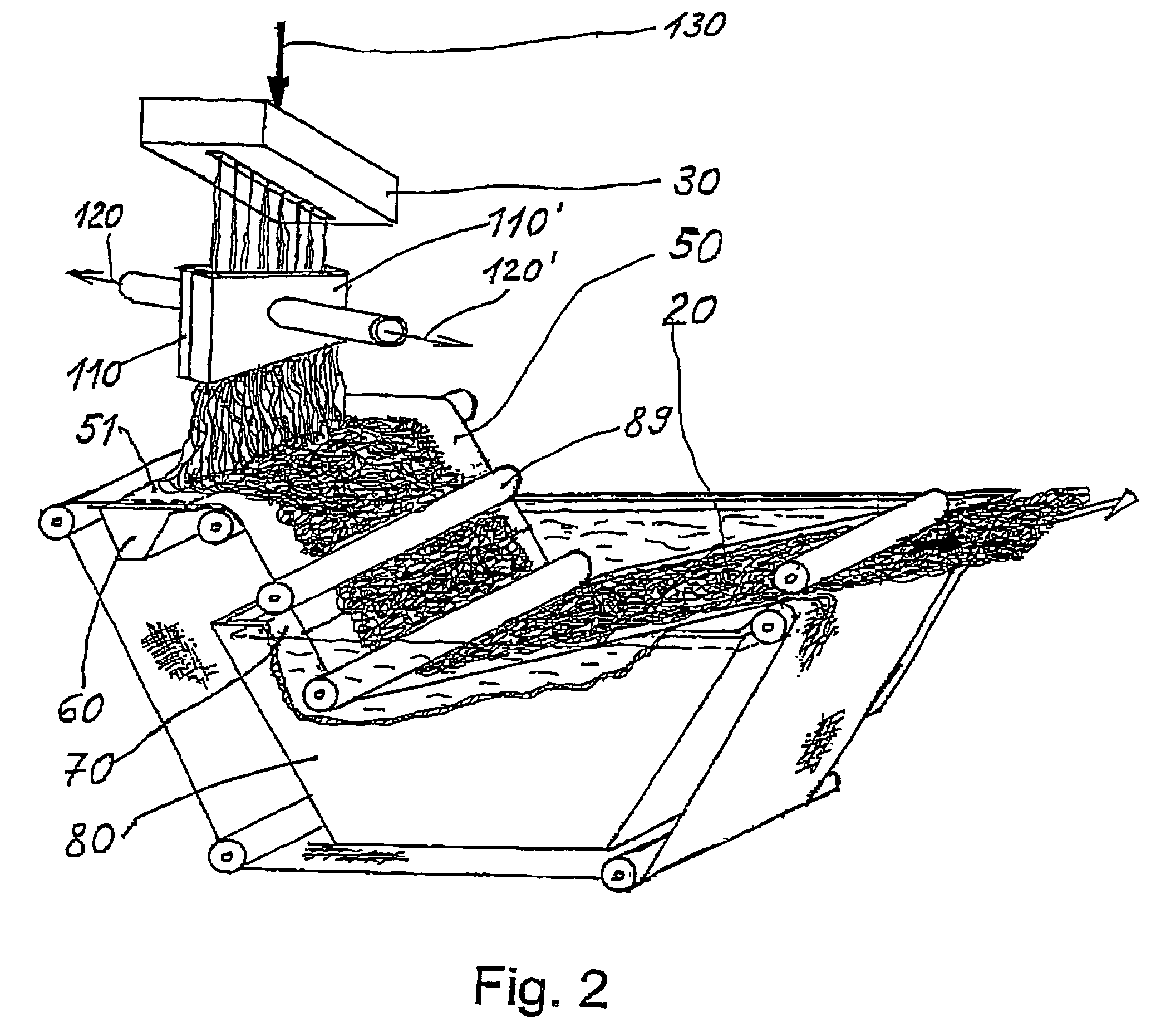

Apparatus and method for forming materials

InactiveUS6858168B1Improves molecular orientationReduce pressure requirementsSpinnerette packsConfectioneryHydrogenSolid mass

An apparatus and method for forming liquid spinning solution into a solid formed product whereby the solution is passed through at least one tubular passage (17) having walls formed at least partly of semipermeable and / or porous material. The semipermeable and / or porous material allows parameters, such as the concentration of hydrogen ions, water, salts and low molecular weight, of the liquid spinning solution to be altered as the spinning solution passes through the tubular passage(s).

Owner:SPINOX LTD

Production method of fine-denier porous POY black yarn

InactiveCN102443859AImprove spinnabilityReduced stabilitySpinnerette packsMelt spinning methodsProduction rateYarn

The invention discloses a production method of a fine-denier porous POY black yarn. The method comprises the following steps of: drying semi-dull slices, drying black masterbatch, adding the slices and the black masterbatch material into a screw extruder, fusing the added materials in the screw extruder, respectively processing the fused materials in a metering pump and a spinning beam, spinning on a pack, cooling the materials by lateral blowing, applying oil on strands, processing the strands in draw-off godets GR1 and GR2, winding and shaping, and inspecting products. The method is characterized in that the step of drying the black masterbatch comprises the following sub-steps of: based on a continuous drying mode, firstly, adding the black masterbatch into a crystallization and drying tank, introducing heated dry air from the lower part of the crystallization and drying tank, and blowing out the heated dry air from the top of the crystallization and drying tank so as to dry the black masterbatch, wherein the drying time is 2 hours, the dried black masterbatch falls into an intermediate material storage bin for storage under the crystallization and drying tank, and the black masterbatch is further injected by a masterbatch injector under the intermediate material storage bin. The production method of the fine-denier porous POY black yarn has high masterbatch spinnability and better cooling effect, and can improve the oil application uniformity of spinning cakes and the productivity.

Owner:桐乡市中洲化纤有限责任公司

Triple purpose lay-up tool

The present invention provides a method and apparatus for use in manufacturing a composite part includes molding a composite part on a lay-up tool, machining a sacrificial portion of a first surface for securing a first hardware device with the composite part while the part is on the lay-up tool and cutting the part forming a peripheral edge while the part is on the lay-up tool. The method can further include positioning the first hardware device in contact with a machined interface of the composite part and machining the part including drilling a plurality of positioning holes through the hardware device and the part while the part is on the lay-up tool. The machining can include machining the sacrificial portion creating a machined interface and positioning the hardware device on the machined interface.

Owner:THE BOEING CO

Method for preparing colorized fire-retardant delustering hollow polyester filament

ActiveCN101597816AWith colorFlame retardantFlame-proof filament manufactureHollow filament manufactureFiberState of art

The invention relates to a method for preparing a polyester filament, in particular to a method for preparing a colorized fire-retardant delustering hollow polyester filament. The method mainly solves the technical problem of the prior art that color master batches and a delustering agent added into a fire-retardant slice can influence the viscosity of a fused mass during the spinning and the friction to a device in the processing process so that colorized, fire-retardant and delustering finished polyester fiber and the like cannot be prepared. The preparation method comprises the following steps: adding a copolymerization fire retardant in the process of preparing a polyester slice to form the fire-retardant slice; performing pre-crystallization on and drying the fire-retardant slice, the color master batches and delustering master batches, and evaporating the water content; mixing the fire-retardant slice with the color master batches and the delustering master batches, passing the mixture into a double screw extruder to perform heating melting, performing filter mixing and measuring allocation on the fused mass, and spinning the fused mass into tows; and performing cooling molding on the tows through lateral blow, and obtaining a finished product after oil tanker oiling, drafting, networking and winding.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

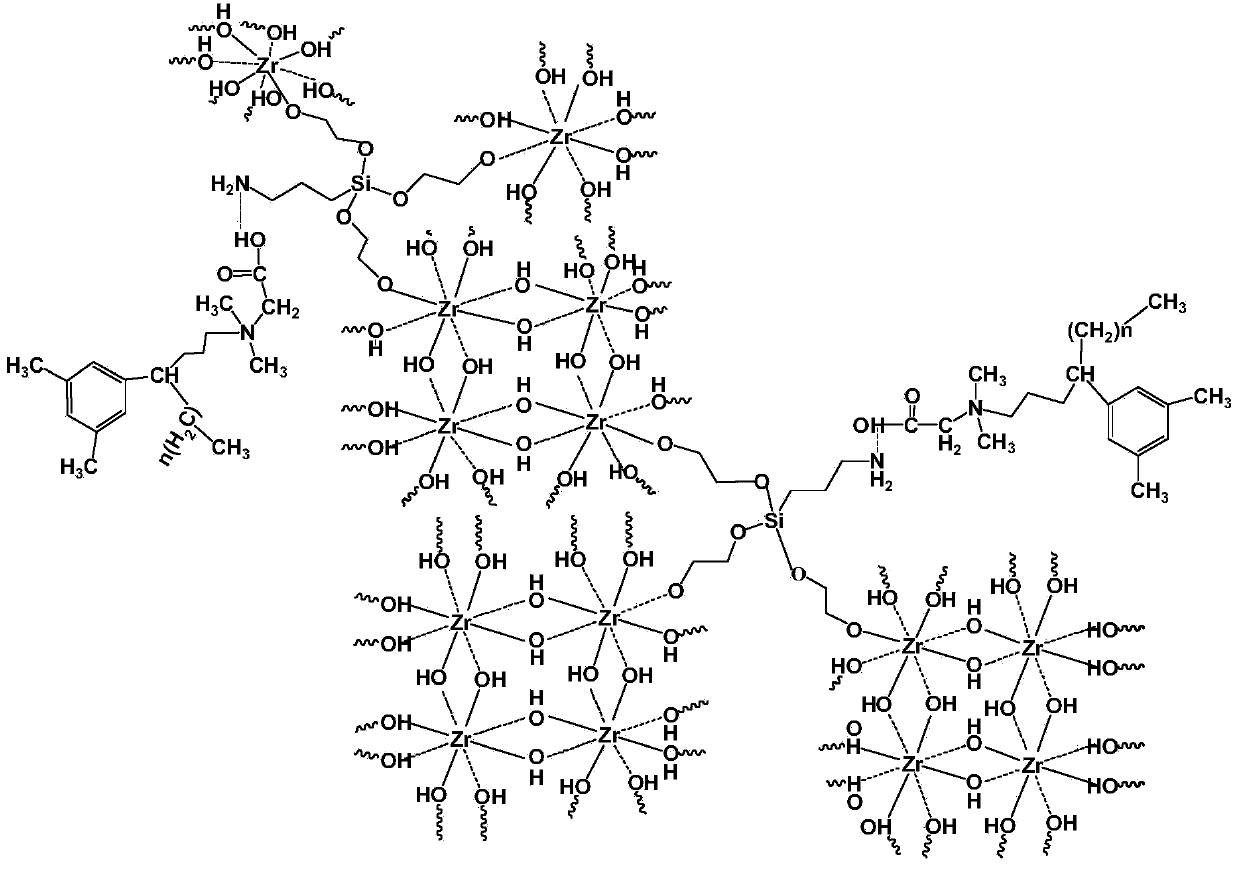

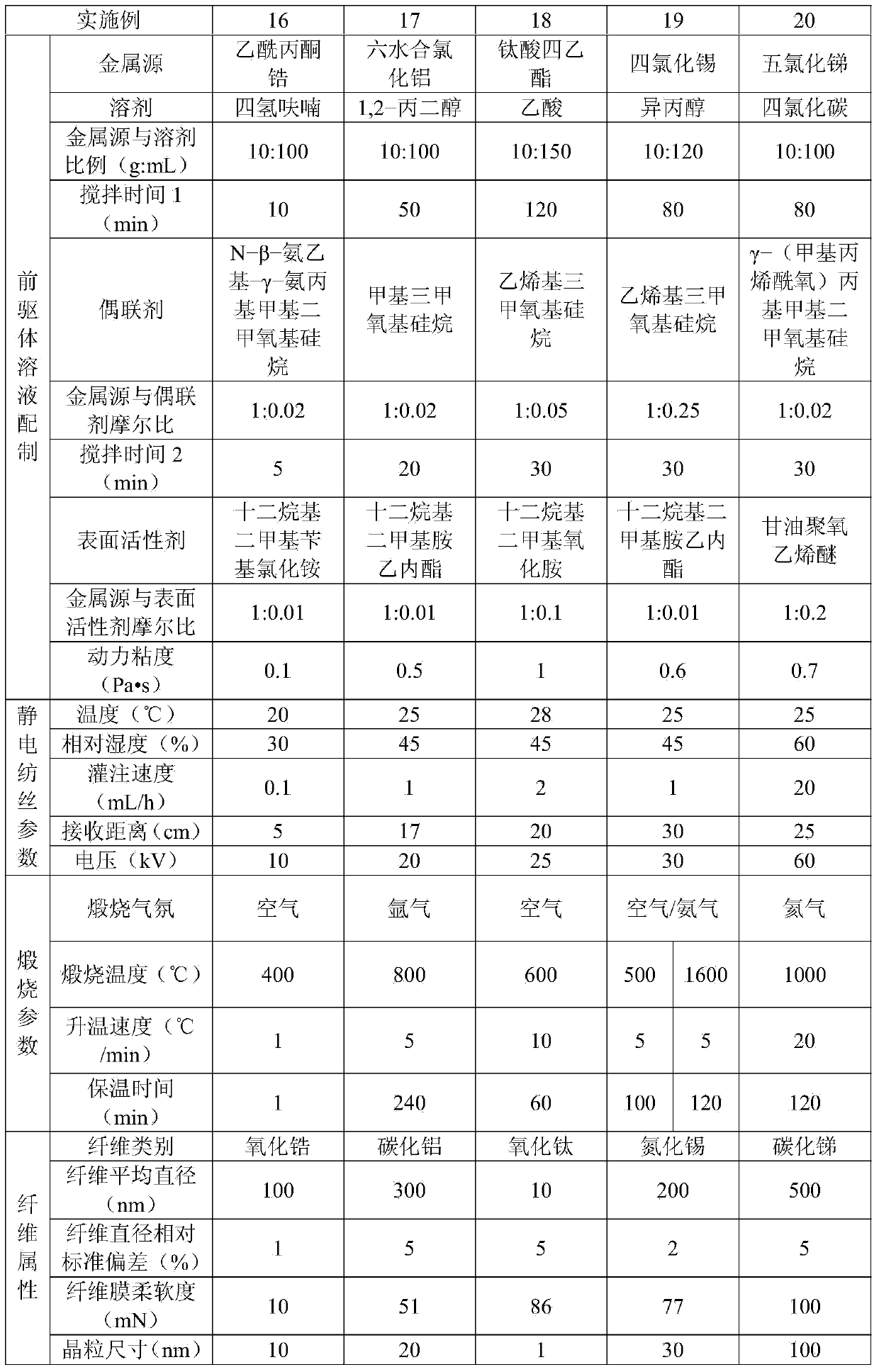

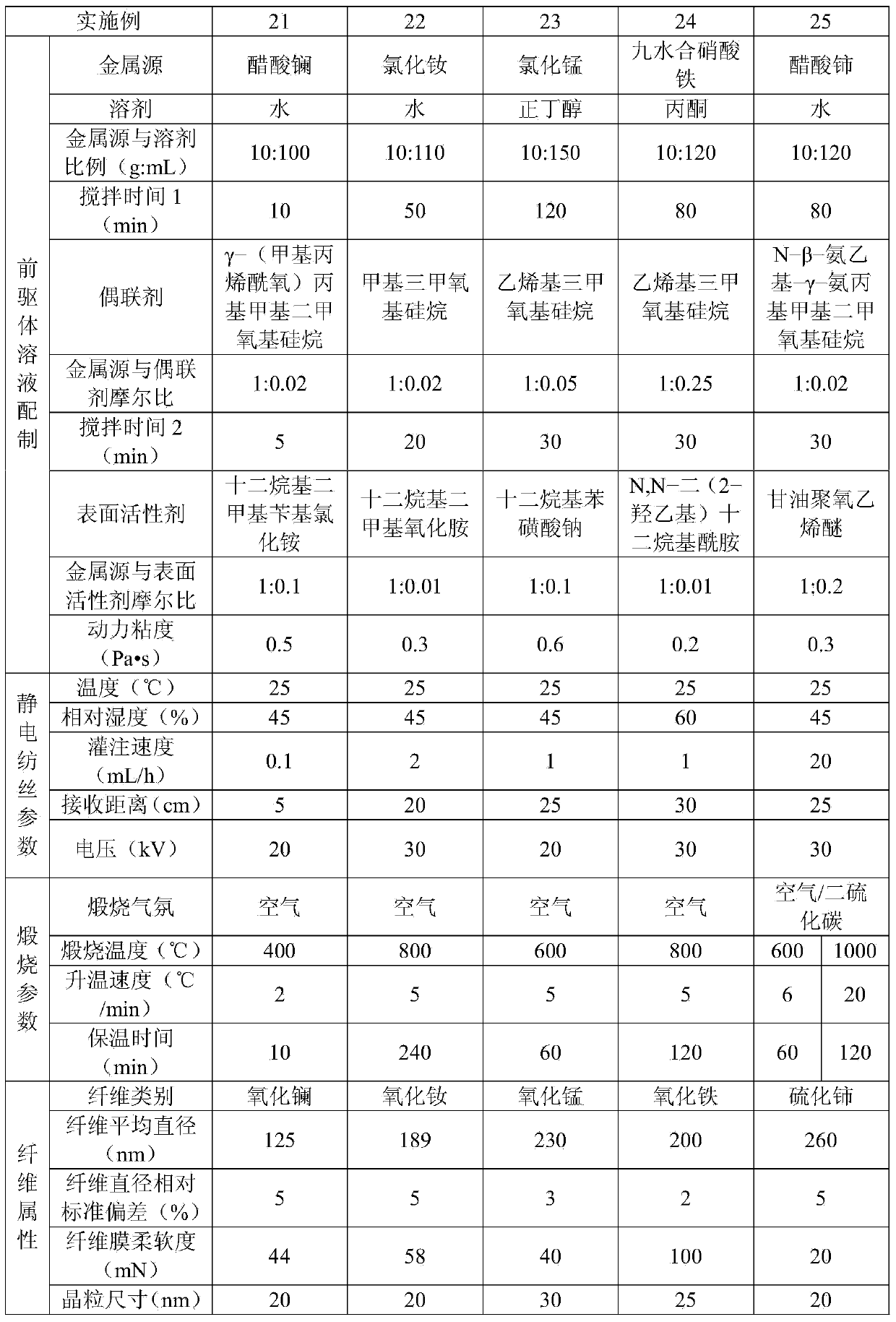

Flexible inorganic fiber material and preparation method thereof

ActiveCN104178822AHigh content of inorganic componentsHigh yieldInorganic material artificial filamentsFilament-forming treatmentFiberThermal insulation

The invention relates to a flexible inorganic fiber material and a preparation method thereof. The preparation method of the flexible inorganic fiber material comprises the steps as follows: firstly, at least one metal source is dissolved in a solvent, a coupling agent and a surfactant are added sequentially and uniformly mixed to prepare a homogeneous and stable precursor solution which contains interpenetrating molecular chains adopting a three-dimensional network structure, and then a precursor fiber material is prepared by the precursor solution through a spinning forming process; and the precursor fiber material is calcined in an appropriate atmosphere to obtain the flexible inorganic fiber material. According to the invention, various inorganic fiber materials can be prepared through different spinning processes, the preparation process is simple and high in yield, and the prepared inorganic fiber material has good flexibility and has broad application prospect in the fields of catalysis, energy, electronics, filtration, thermal insulation and the like.

Owner:嘉兴富瑞邦新材料科技有限公司

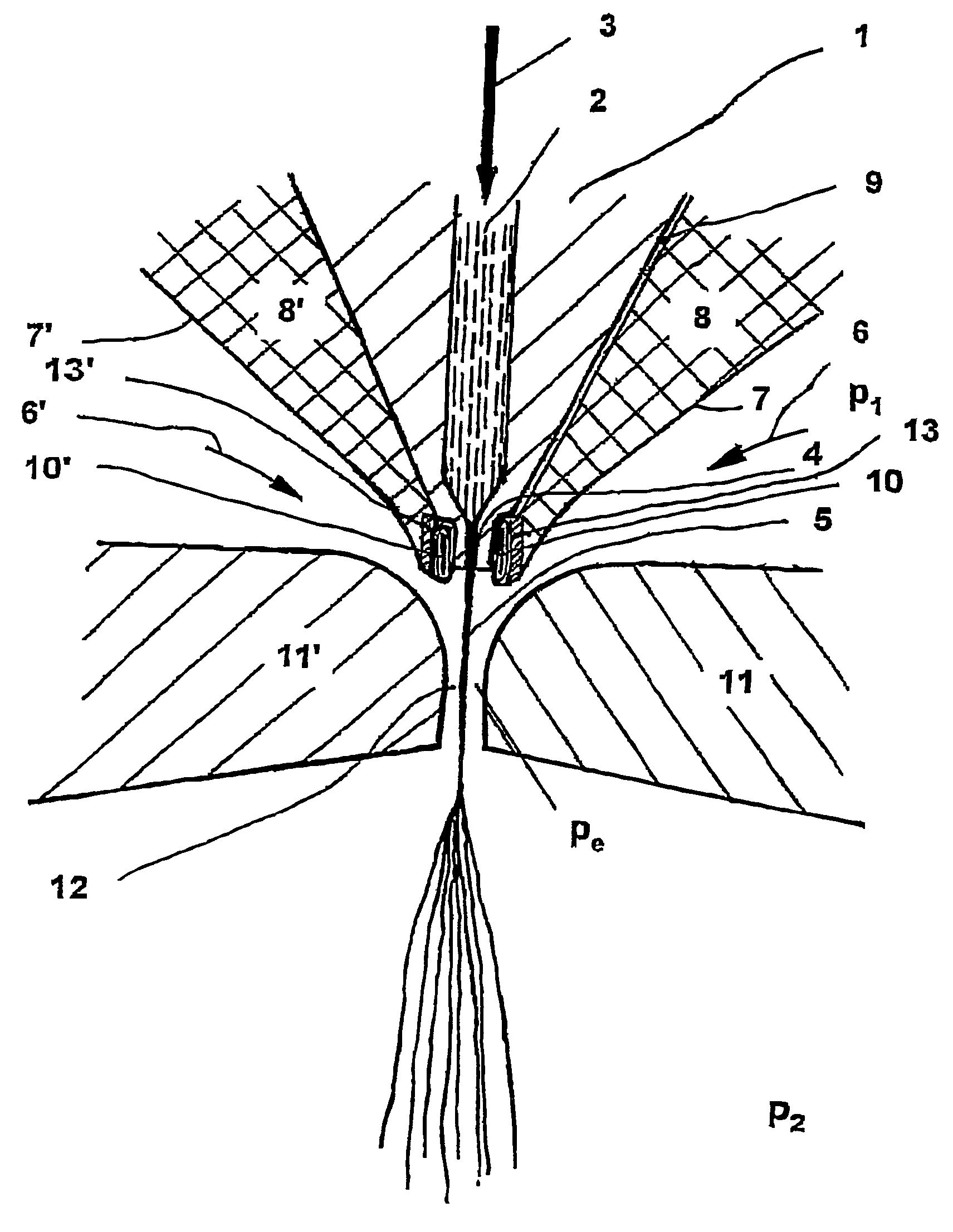

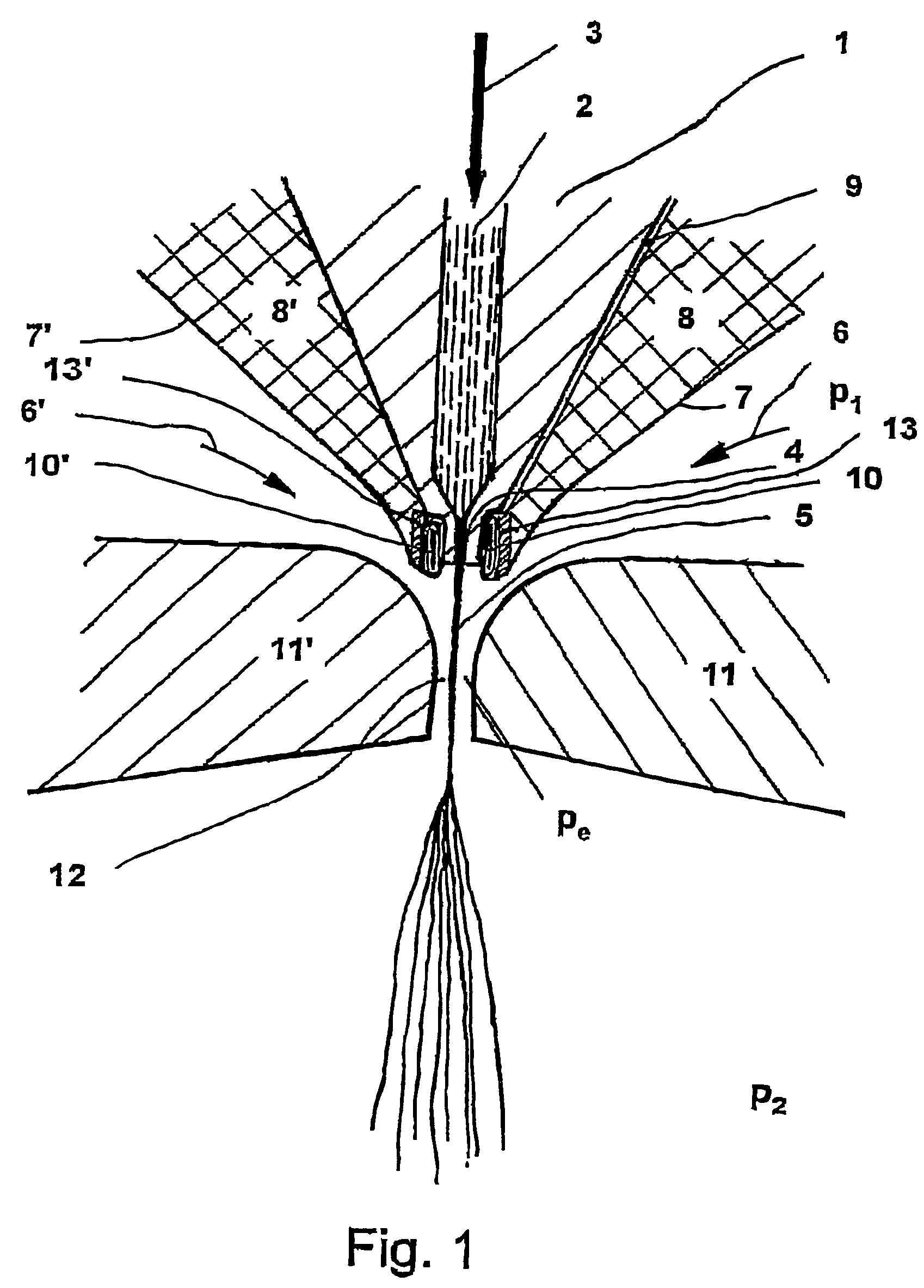

Method and device for producing substantially endless fine threads

InactiveUS7922943B2Reduced strengthMore energySpinnerette packsMonocomponent cellulose artificial filamentYarnPolymer solution

The invention relates to a method and a device for producing substantially endless fine threads from polymer solutions, especially spinning material for lyocell, wherein the spinning material is spun from at least one spinning hole or a spinning slot. The spun thread or film is drawn by high-speed accelerated gas flows using a Laval nozzle whose narrowest cross-section is located beneath the point where the spinning material exists. The threads are arranged on a strip in the form of a non-woven or are taken up in the form of a yarn and are subsequently separated in spinning baths by means of solvents.

Owner:GERKING LUDER

Elastic nonwoven fabric, process for producing the same, and textile product comprising the elastic nonwoven fabric

InactiveUS20100190405A1Increase elasticityPleasant textureAbsorbent padsMelt spinning methodsPolymer scienceCrystallization temperature

(1) An elastic nonwoven fabric and a fiber product using the elastic nonwoven fabric, the elastic nonwoven fabric containing a crystalline resin composition containing low crystalline polypropylene and high crystalline polypropylene, the low crystalline polypropylene satisfying items (a) and (b) below, and a crystallization temperature (Tc) of the crystalline resin composition measured with a differential scanning calorimeter (DSC) being from 20 to 100° C.:(a) a melting point (Tm-D) being from 0 to 120° C., which is defined as a peak top of a peak observed on the most high temperature side of a melt endothermic curve obtained by maintaining at −10° C. for 5 minutes and increasing in temperature at 10° C. per minute in a nitrogen atmosphere with a differential scanning calorimeter (DSC); and(b) a stereoregularity index ([mm]) being from 50 to 90% by mol;(2) an elastic nonwoven fabric and a fiber product using the elastic nonwoven fabric, the elastic nonwoven fabric being produced by using a crystalline resin composition containing low crystalline polypropylene satisfying items (c) to (h) below, and a releasing agent: (c) [mmmm]=20 to 60% by mol; (d) [rrrr] / (1−[mmmm])≦0.1; (e) [rmrm]>2.5% by mol; (f) [mm]×[rr] / [mr]2≦2.0; (g) mass average molecular weight (Mw)=10,000 to 200,000; and (h) molecular weight distribution (Mw / Mn)<4; and(3) an elastic nonwoven fabric and a fiber product using the elastic nonwoven fabric, the elastic nonwoven fabric containing core / shell type composite fibers containing low crystalline polypropylene satisfying the items (c) to (h) have excellent elastic recovery property and pleasant texture without stickiness.

Owner:IDEMITSU KOSAN CO LTD

Method of improving surface cohesion performance of relative molecular weight polyethylene

InactiveCN1693544AGood adhesionImprove surface adhesionFilament-forming treatmentStretch-spinning methodsPolymer scienceUltimate tensile strength

The invention discloses a method for improving surface bonding performance of ultrahigh molecular polyethylene filter (UHMWPE), including the steps as follows: (1) dissolving polar polymer in a routine extractant of ultrahigh weight-average relative molecular weight polyethylene jelly glue filter with a relative molecular weight of 1,000,000-5,000,000 to make a composite extractant, where the polar polymer accounts for 0.1wt%-10wt% (weight percent); (2) extracting the said jelly glue fiber at 0.4-5 atmospheres at 0-80 deg.C in the composite extractant for 0.1-20 min, and then by the postprocessing procedures, such as stretching, making an ultrahigh relative molecular weight polyethylene fiber with the surface bonding performance has been improved to a higher extent. The advantages of the invention are that it maximumly holds original fiber strength and the surface bonding performance of UHMWPE has a relatively outstanding improved effect.

Owner:DONGHUA UNIV

Method and apparatus for extruding a ceramic material

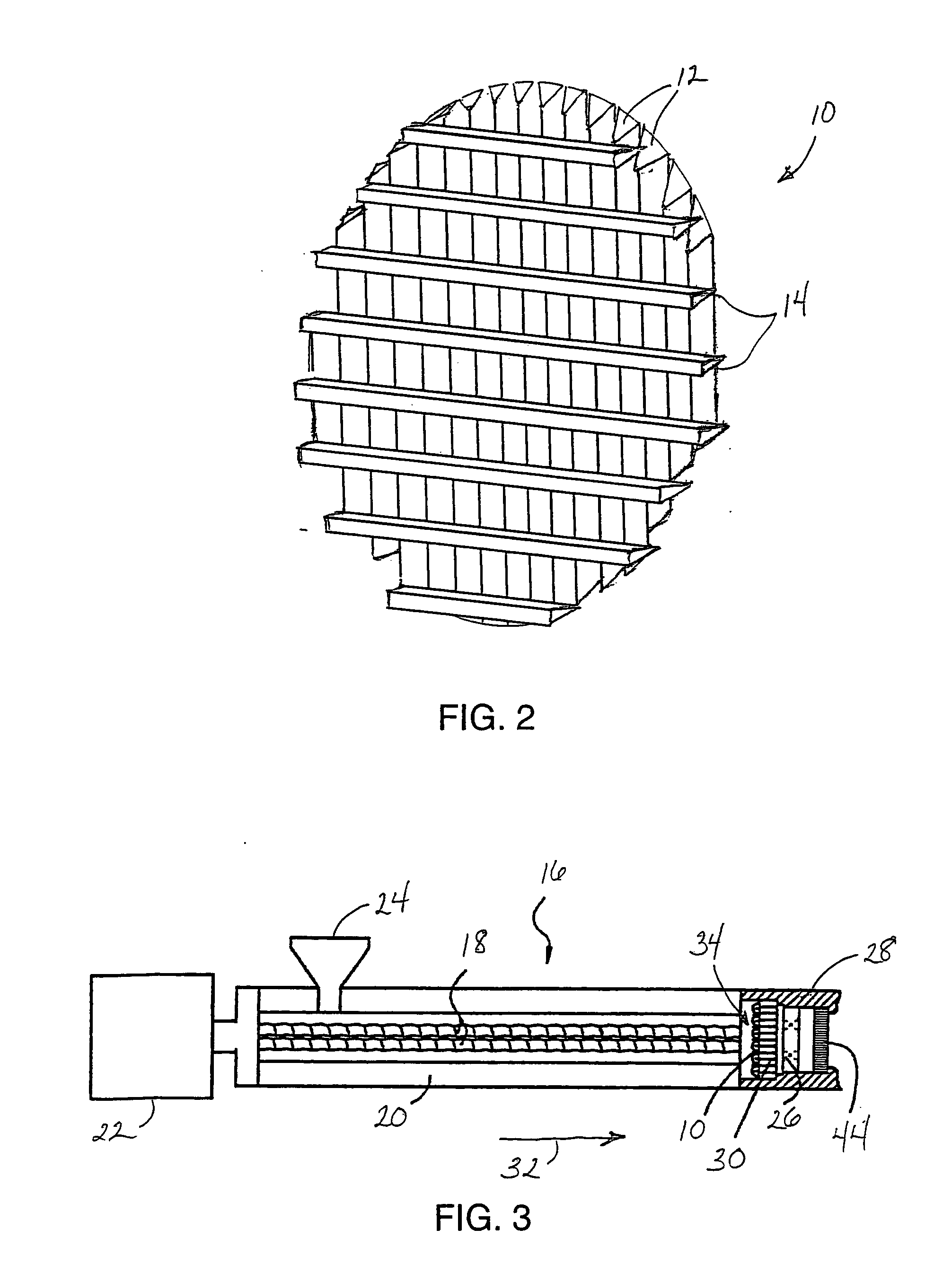

A method is provided for manufacturing a thin-walled honeycomb ceramic substrate by extruding a plasticized ceramic batch material through a filter screen having wedge shaped filter wires to remove foreign particulate and agglomerated batch material. The filter wires are supported by a set of support wires attached substantially perpendicular to the filter wires. The support wires are may also be advantageously wedge shaped. The filter screen of the present invention may have a wear resistant layer at the surface of the screen, typically a boride or a nitride. The wear resistant coating may also be a nickel-based coating.

Owner:CORNING INC

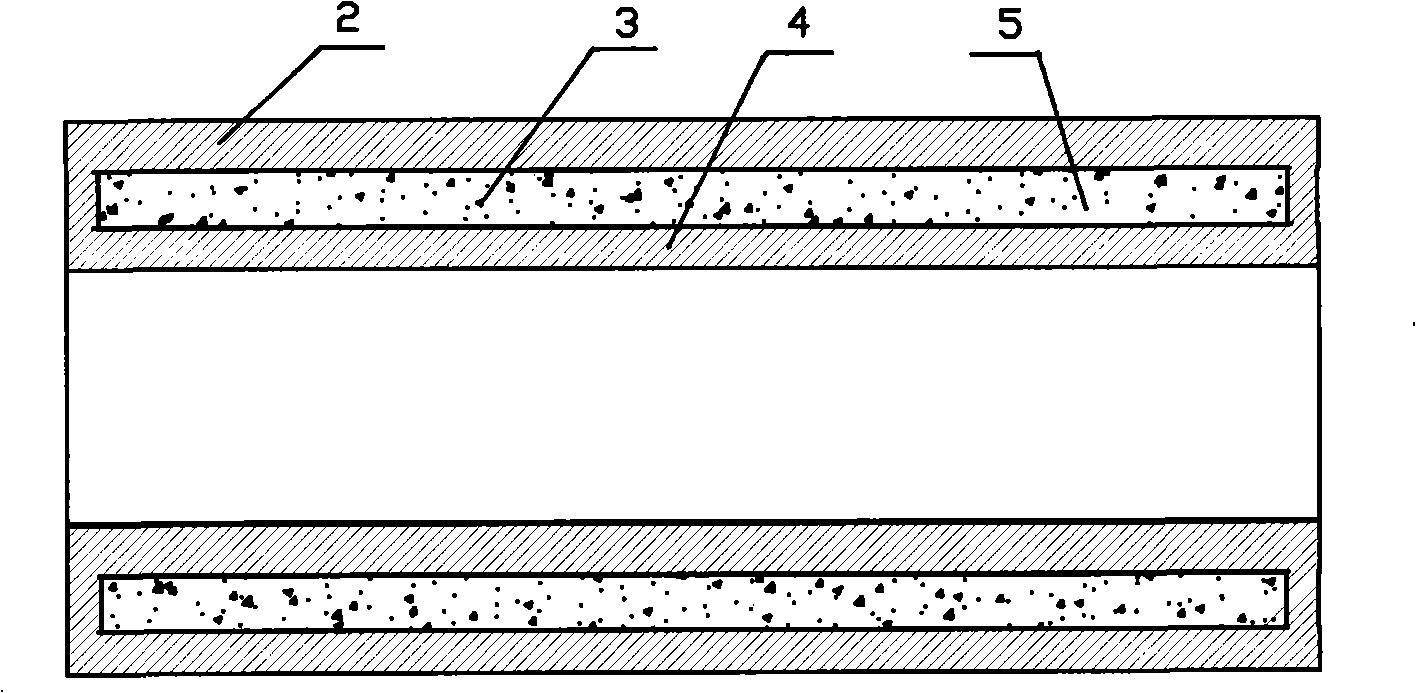

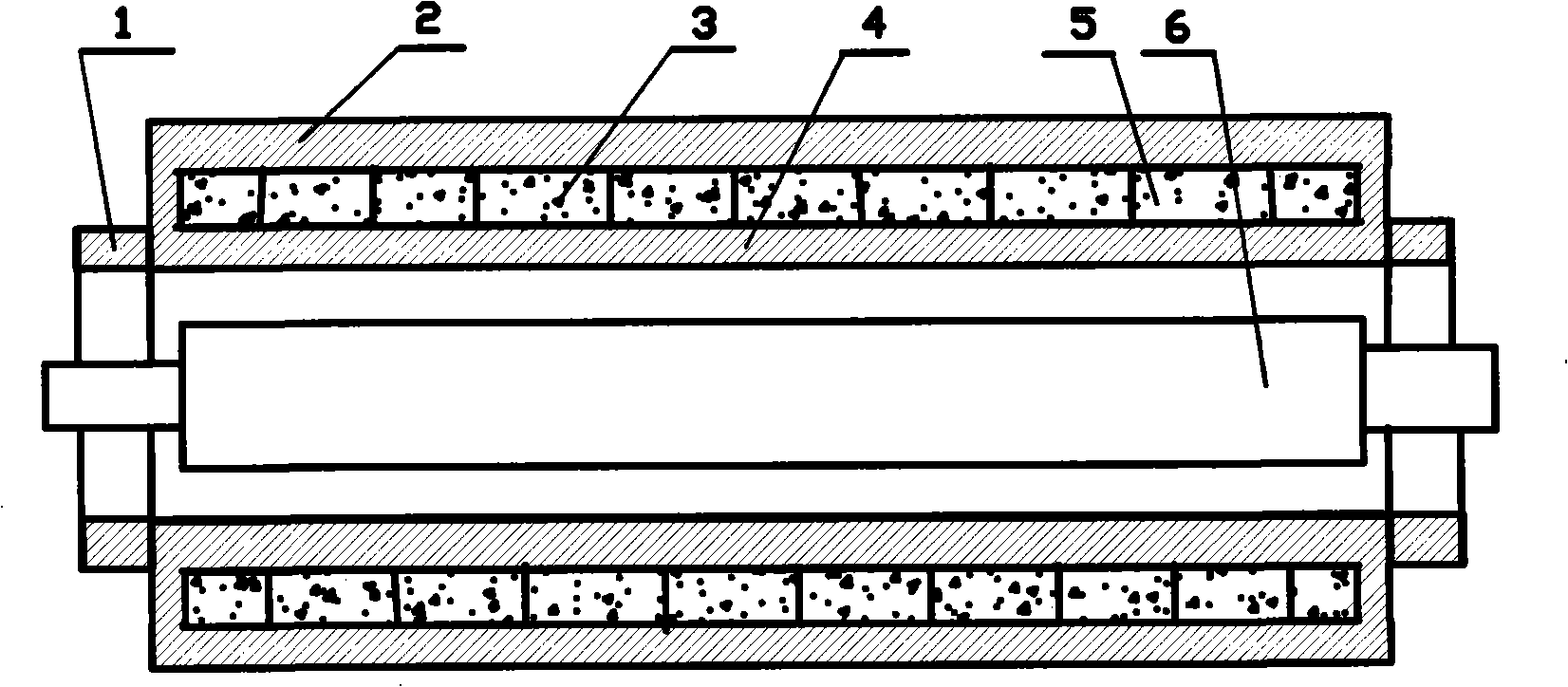

Heating roller heating method and heating roller

InactiveCN101254638AImprove uniformityUniform temperatureTransfer printingBox making operationsLiquid mediumHeat conducting

The invention discloses a heating roller heating method and a heating roller. The heating roller is heated in an oil, steam, electric or electromagnetic heating manner, and is characterized in that the heating roller has an interlayer structure, a thermally-conductive liquid medium is filled in the interlayer of the heating roller for homogenizing the temperature of the heating roller; and the outer surface of the heating roller is heated in a heat conduction manner through the thermally-conductive liquid medium in the interlayer of the heating roller. The heating roller structure comprises a heating roller with the interface structure, and the thermally-conductive liquid medium in the interface of the heating roller for homogenizing the temperature of the heating roller. The thermally-conductive liquid medium can be heat conducting oil, molten metal such as potassium and sodium, pure water, ethanol-like substance, etc.

Owner:株洲科力通用设备有限公司

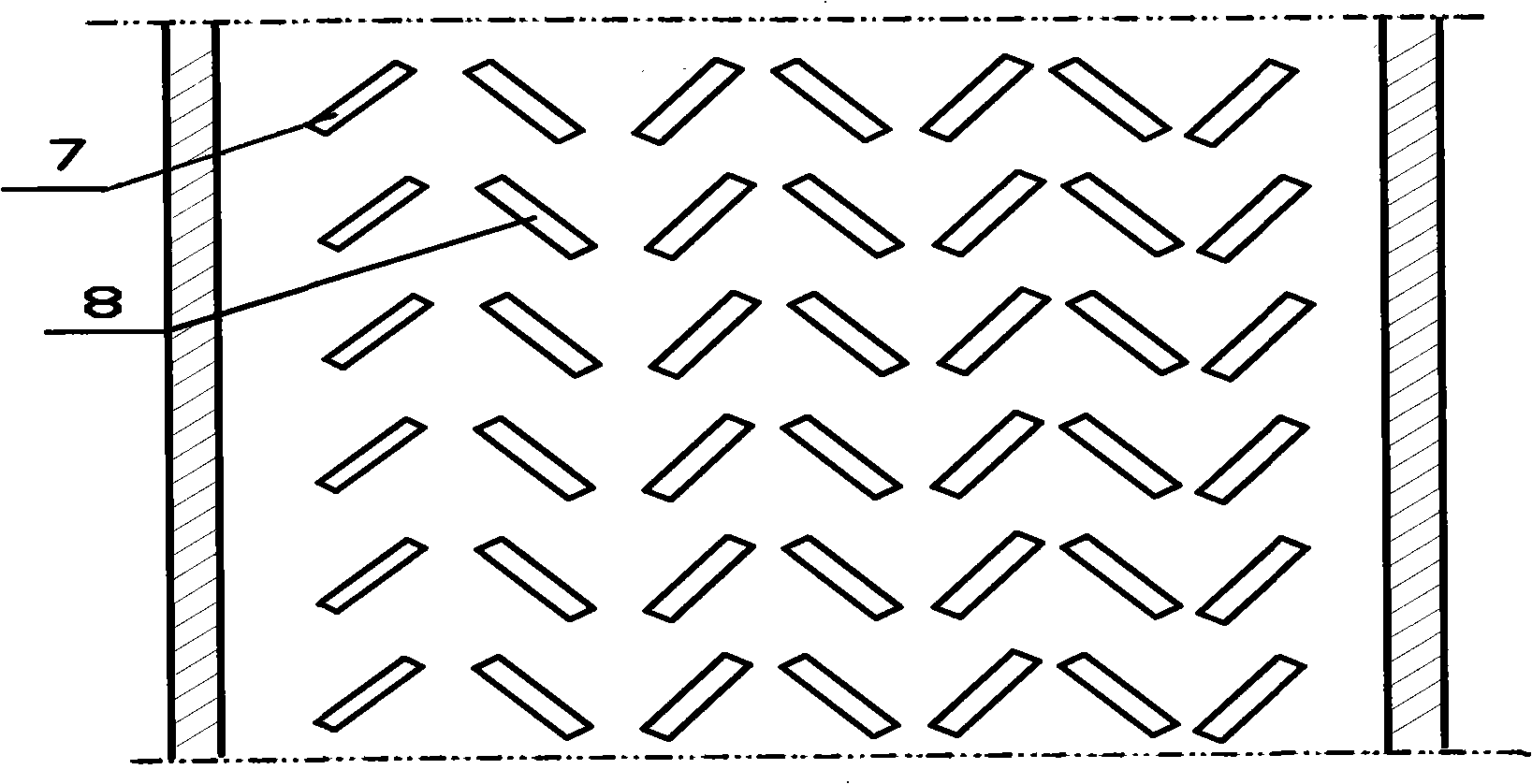

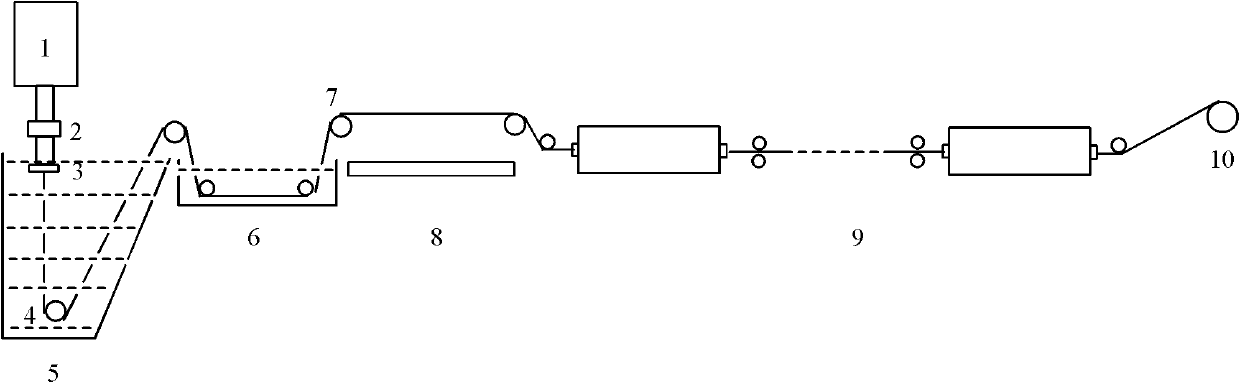

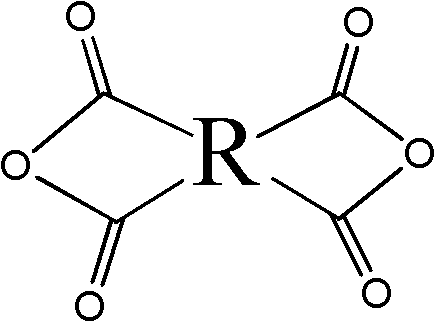

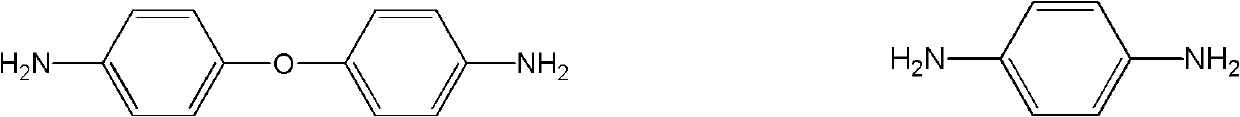

Method for preparing polyimide fibers

ActiveCN102168317AGood effectImprove performanceArtificial filament washing/dryingArtificial filament heat treatmentFiberPolyamide

The invention discloses a method for preparing polyimide fibers, and belongs to the technical field of the polyimide fibers. The method is characterized in that: polyamide acidic solution is subjected to spinning by adopting a wet spinning or dry wet spinning process, and fibers are subjected to processes of coagulating and drying or processes of washing, drying, heat treatment cyclizing and stretching continuously and are rolled finally to form the polyimide fibers. The method comprises the following specific steps of: reacting diamine with dianhydride in solvent under the protection of nitrogen to obtain polyamide acidic spinning solution; filtering the spinning solution, pouring the filtered spinning solution into a storage tank for defoaming, spinning according to the wet spinning or dry wet spinning process, pumping the spinning solution by a metering pump, and spraying from a spinneret plate; dragging by a silk guide roller, coagulating in coagulating bath, drying directly by a hot roller or a hot plate or drying by the hot roller or the hot plate after washing, and performing heat cyclizing and stretching by three sections or more than three sections of furnace sections; and finally, rolling silk. In the method, the integral process is continuous, smooth, compact and short in time, high imidization degree and degree of orientation are realized, and the high-performance fibers are obtained.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Preparation method for super fine denier polyester filaments

InactiveCN102965745AHigh strengthLow elongationFilament/thread formingArtificial filament heat treatmentFiberPolyester

The invention relates to the technical field of preparation methods for polyester filaments, particularly to a preparation method for super fine denier polyester filaments. The preparation method adopts super bright PET chips as raw materials to implement the production through the steps of pre-crystallization, drying, extrusion, filtering, distribution of spinning box bodies, filament splitting by a metering pump, filament spraying, lateral air blowing, winding and packing of finished products. According to the preparation method adopted by the invention, finally finished fibers have the performances of high strength, low elongation, low heat shrinkage and the like; the breaking strength of the fibers is larger than 7.0 cN / dtex; the breaking elongation of the fibers is less than 14%; the boiling water shrinkage of the fibers is less than 1.8%; and the dry heat shrinkage is less than 4.5%. And at the same time, the preparation method has the characteristics of short production flow, high spinning speed, fewer broken filaments, fewer broken ends, low production cost and the like, and is not only used for top grade sewing threads, embroidery threads and fishing nets, but also heavily applied in various vehicle airbags, base camp tent fabrics and various industries adopting high strength fibers as auxiliary materials or reinforcing materials.

Owner:NANTONG HUALUN CHEM FIBER

Method for producing fine denier nylon FDY filament with aromatic function

InactiveCN101736433AHas aroma functionSimple production processFilament/thread formingFilament-forming treatmentMasterbatchFiber

The invention relates to a method for producing a fine denier nylon FDY filament with aromatic function. The technical problem to be solved is to produce a filament that the filament number is between 0.5 and 1.0dtex, and the aroma retention time is long. In the production method, the weight ratio of three raw materials, namely nylon chips to fine denier nylon masterbatch to aromatic microcapsules is 1:5-20 percent: 0.5-10 percent. The process comprises the following steps of: 1) keeping steady pressure in a spinning component; 2) adopting 40-100-mesh metal sand for filtration; 3) adopting a spinneret plate, wherein the aperture of the spinneret plate is between 0.1 and 0.3mm, and the slenderness ratio is 2-4; 4) arranging an annealing device (1) behind the spinning component, and forming a windless region (2) with the height of between 20 and 40cm between the annealing device (1) and cross air blow (3); 5) ensuring that the position of a beam concentration point is 600 to 1,000mm away from the spinneret plate; and 6) ensuring that the spinning winding speed is between 3,000 and 5,000m / min.

Owner:HANGZHOU NORMAL UNIVERSITY

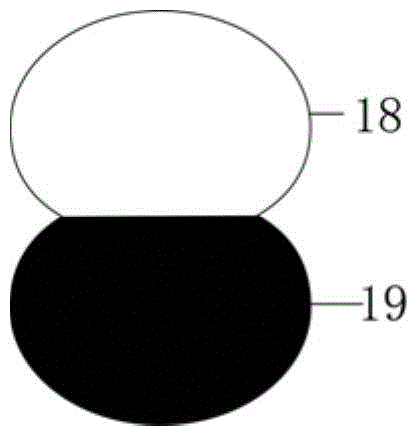

Polyester elastomer/PET composite elastic fiber and preparation method thereof

ActiveCN104831417AIncrease elasticityImprove performanceMelt spinning methodsConjugated synthetic polymer artificial filaments1,4-ButanediolElastomer

The invention discloses a polyester elastomer / PET composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of firstly carrying out reduced-pressure direct esterification on terephthalic acid, 1,4-butanediol and double-ended hydroxyl polyether in a certain proportion in the presence of catalysts, carrying out melt polycondensation to obtain a polyester elastomer, and carrying out a spin-draw-winding one-step process on the prepared polyester elastomer and PET, so as to obtain the polyester elastomer / PET composite elastic fiber, wherein the breaking strength of the polyester elastomer / PET composite elastic fiber is 2.8cN / dtex-3.56cN / dtex, the elongation at break is 16.9%-30.4%, the curling degree is 60%-75%, the curling elasticity rate is 97%-99%, the capillary water absorption height is 9.7cm / 30min-14.1cm / 30min. Compared with normal composite elastic fibers, the polyester elastomer / PET composite elastic fiber has relatively excellent elasticity and relatively soft hand feeling, and the fabric capillary suction effect of the polyester elastomer / PET composite elastic fiber is even higher than those of cotton fabrics; the preparation method is short in production process, high in spinning speed and low in cost, and the prepared composite elastic fiber can be directly used in subsequent weaving without being processed into interlaced yarns.

Owner:SICHUAN UNIV +1

Powerful three-dimensional crimp memory fibers and production method thereof

InactiveCN103590139AAccurate measurementEasy to curlMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberMetallurgy

The invention relates to a powerful three-dimensional crimp memory fiber and a production method thereof. Raw materials employed include Poly(1,4-cyclohexylene dimethylene terephthalate) (PCT for short) and poly(trimethylene terephthalate) (PTT for short); and the raw materials are melted, mixed and subjected to blend spinning. According to the invention, a blend melt which is formed by melting and blending the polymers and even and stable in dispersion is subjected to spinning, drafting and the like, so that three-dimensional short fibers with very excellent crimp and memory properties can be obtained. On one hand, the PCT has very good crimp and compression reversion properties, and more easily form lots of dense crimps under the synergistic effect of the high elasticity performance of the PTT, and the PTT has extremely good memory performance and is capable of locking the crimps formed; and as a result, the powerful three-dimensional crimp memory fibers are capable of always keeping the oringinal crimp state.

Owner:YANGZHOU GUANGTAI CHEM FIBER

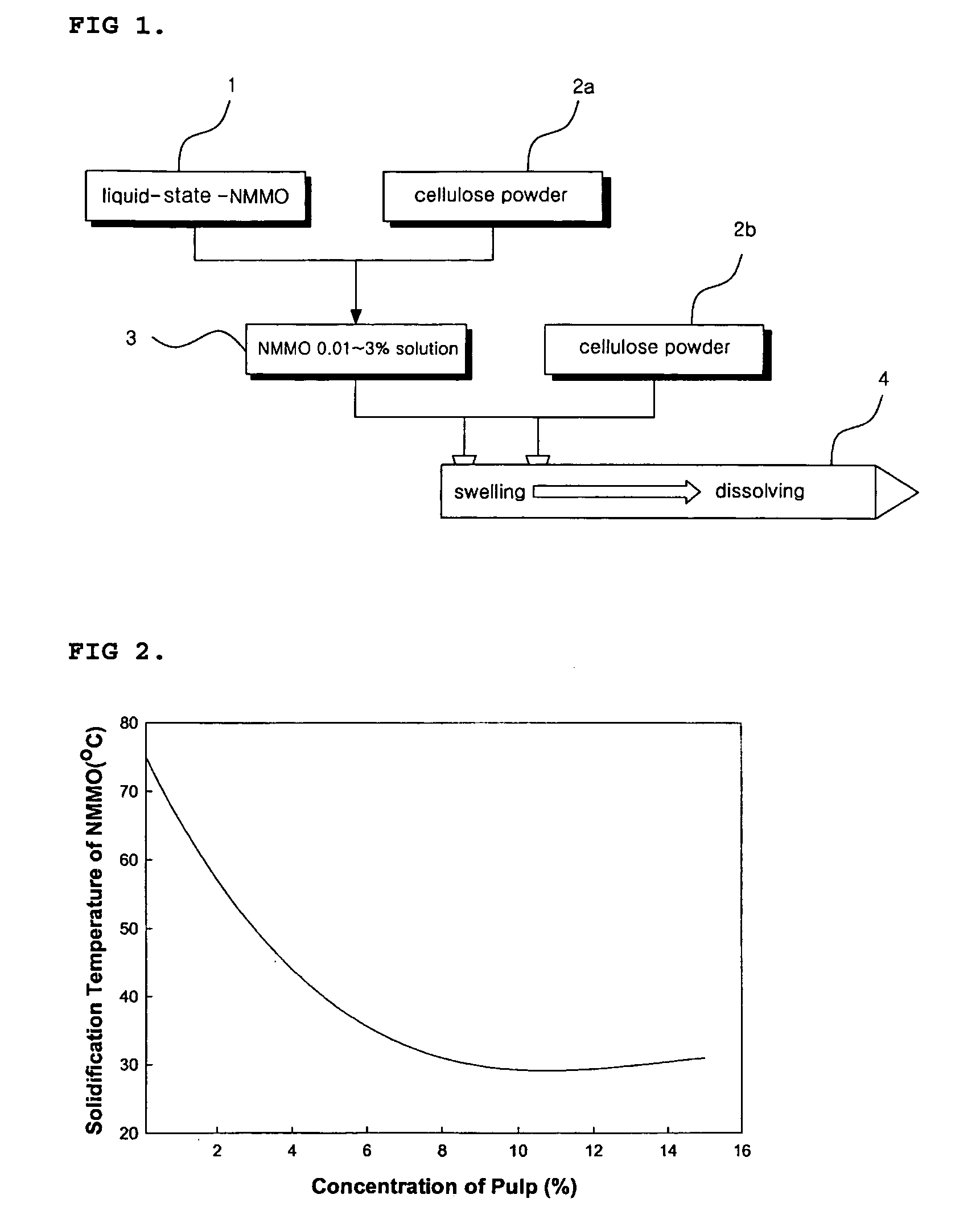

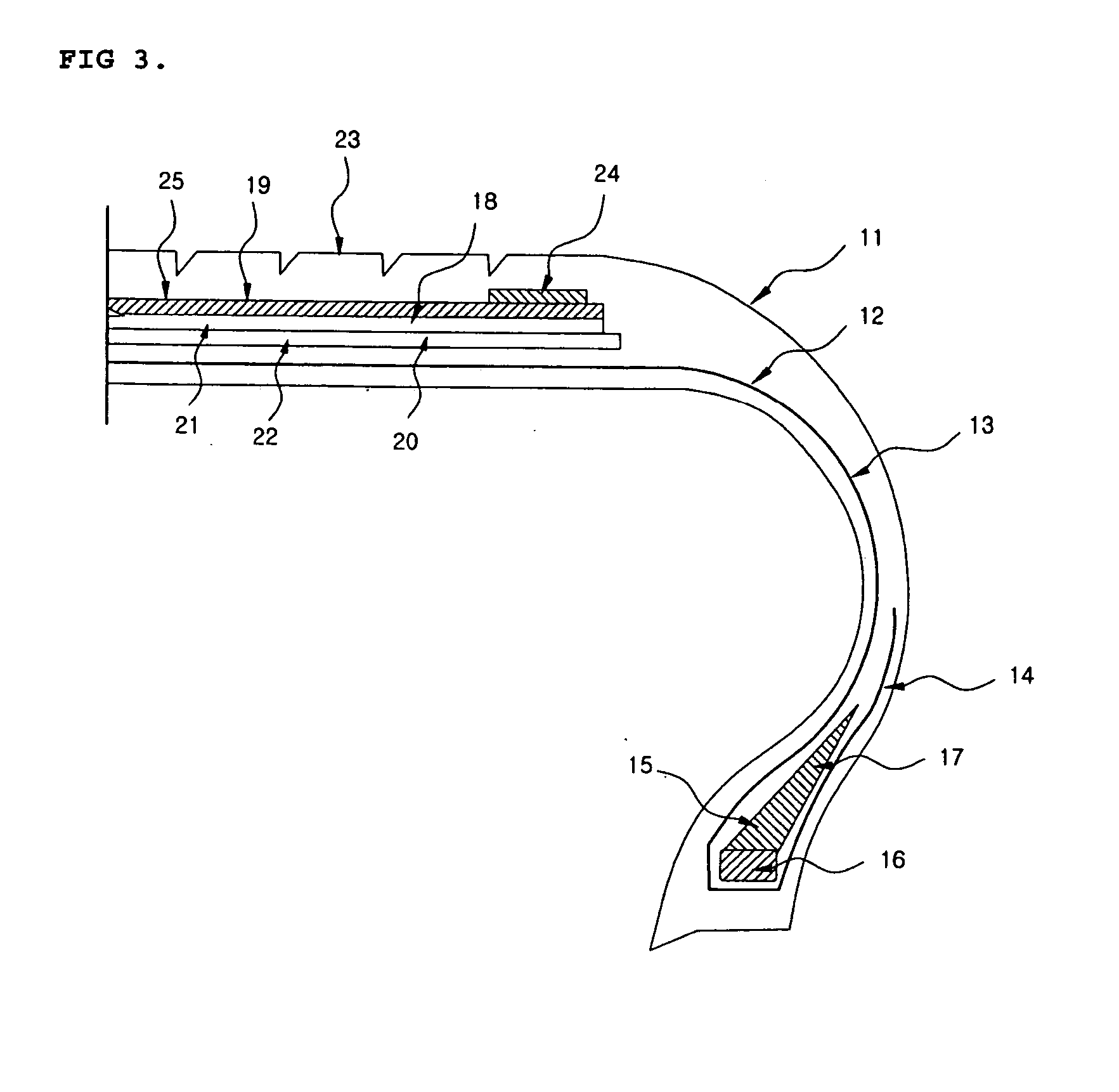

Cellulose dip cord produced from highly homogeneous cellulose solution and tire using the same

ActiveUS20050066646A1Smoothly swollenGood physical propertiesMonocomponent cellulose artificial filamentCellulosic plastic layered productsYarnPolymer science

The present invention relates to a method for producing tire using high strength lyocell dip cord, and more particularity, to a lyocell dip cord and tire produced by a method comprising the steps of: (A) dissolving 0.01 to 3 wt % of cellulose powder in portions in concentrated liquid N-methylmorpholine N-oxide (NMMO) to prepare cellulose-containing NMMO solution; (B) feeding the NMMO solution and cellulose powder into an extruder having a screw to be subjected to dispersing, mixing, shearing, kneading, melting and measuring ability in the extruder to prepare a swollen and homogenized cellulose solution; (C) spinning the cellulose solution through a spinning nozzle, passing the spinning solution through an air gap to a coagulation bath and coagulating the spinning solution to obtain a multifilament; (D) subject the multifilament to water-wash, drying and oil-treatment, followed by winding; and (E) twisting the wound yarn with a twisting machine to prepare a greige cord, weaving the greige cord and dipping the woven cord in a dipping solution. According to the present invention, by lowering of solidification temperature of NMMO by dissolving a small amount of pulp in concentrated liquid NMMO, it is possible to prepare a homogeneous cellulose solution at a low temperature. Also, the lyocell dip cord prepared according to the present invention has excellent adhesion to rubber, tenacity and modulus. And, the tire in which the lyocell dip cord according to the present invention is applied to the carcass ply has excellent dimensional stability and handling stability.

Owner:HYOSUNG ADVANCED MATERIALS CORP

Method for continuous production of polyamide

InactiveUS20060122360A1Quality improvementExcellent oxygen barrier propertiesCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsPolyamideCarboxylic acid

Provided is a continuous production method of a polyamide with stabilized polymerization degree and good quality, particularly an aromatic-containing polyamide. A continuous production method of a polyamide, comprising (a) a raw material preparation step of individually melting a diamine and a dicarboxylic acid, or producing a salt of amine and carboxylic acid in water, (b) a raw material introduction step of continuously introducing the prepared raw materials into a tubular reaction apparatus, (c) an amidation step of passing the introduced raw materials through the tubular reaction apparatus, thereby effecting amidation to obtain a reaction mixture containing an amidated product and a condensed water, (d) an initial polymerization step of introducing the reaction mixture into a continuous reaction apparatus capable of separation and removal of water, and elevating the polymerization degree while separating and removing water at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide prepolymer, and (e) a final polymerization step of introducing the polyamide prepolymer into a continuous reaction apparatus capable of separation and removal of water, and further elevating the polymerization degree at a temperature higher than the melting point of the finally obtained polyamide to obtain a polyamide adjusted to a desired relative viscosity [RV].

Owner:TOYO TOYOBO CO LTD

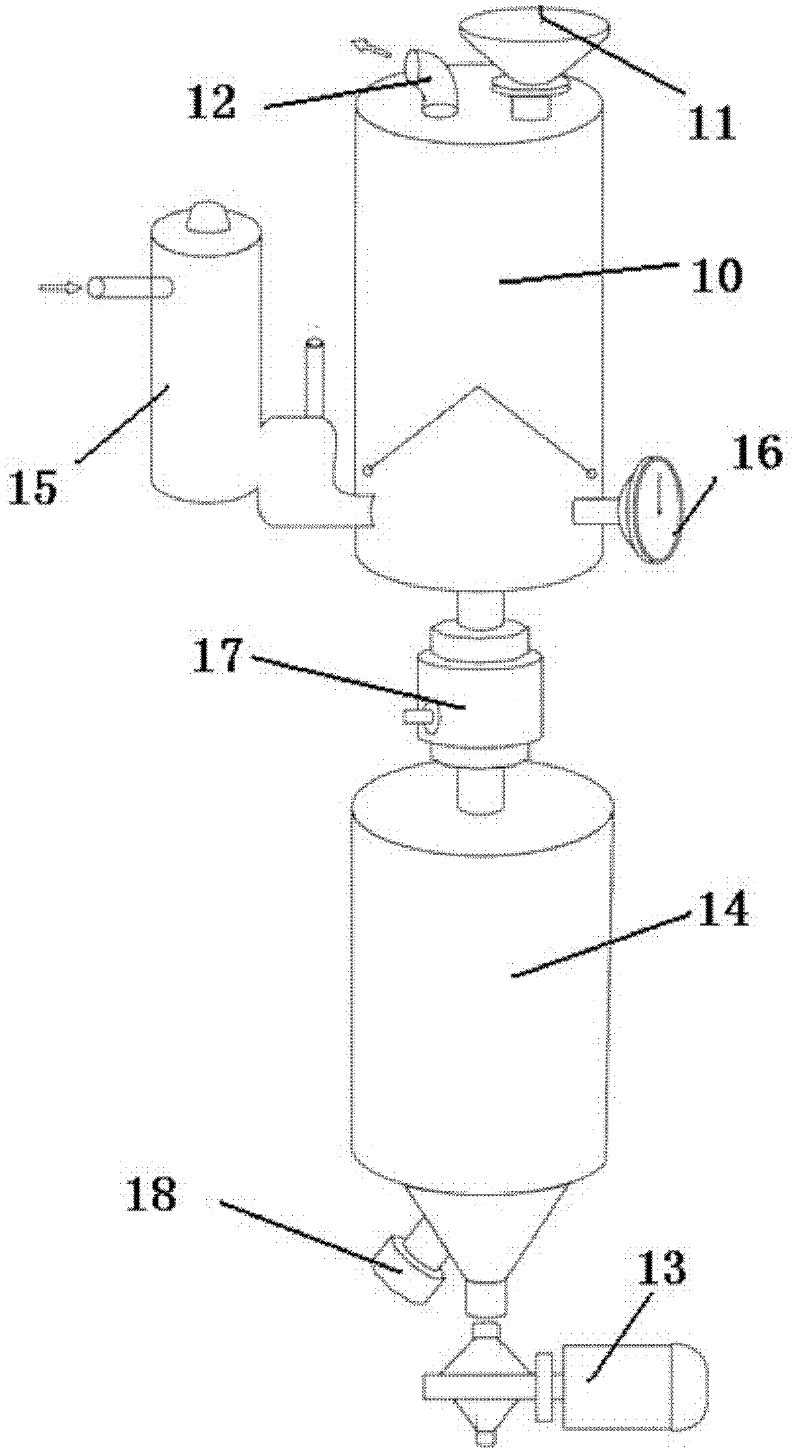

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

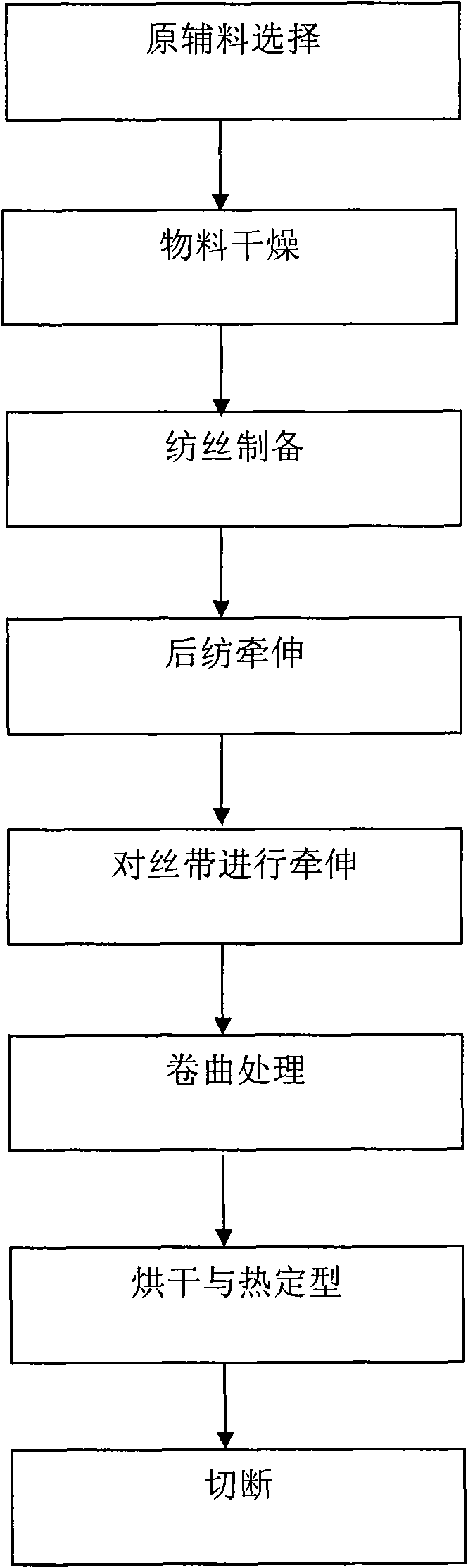

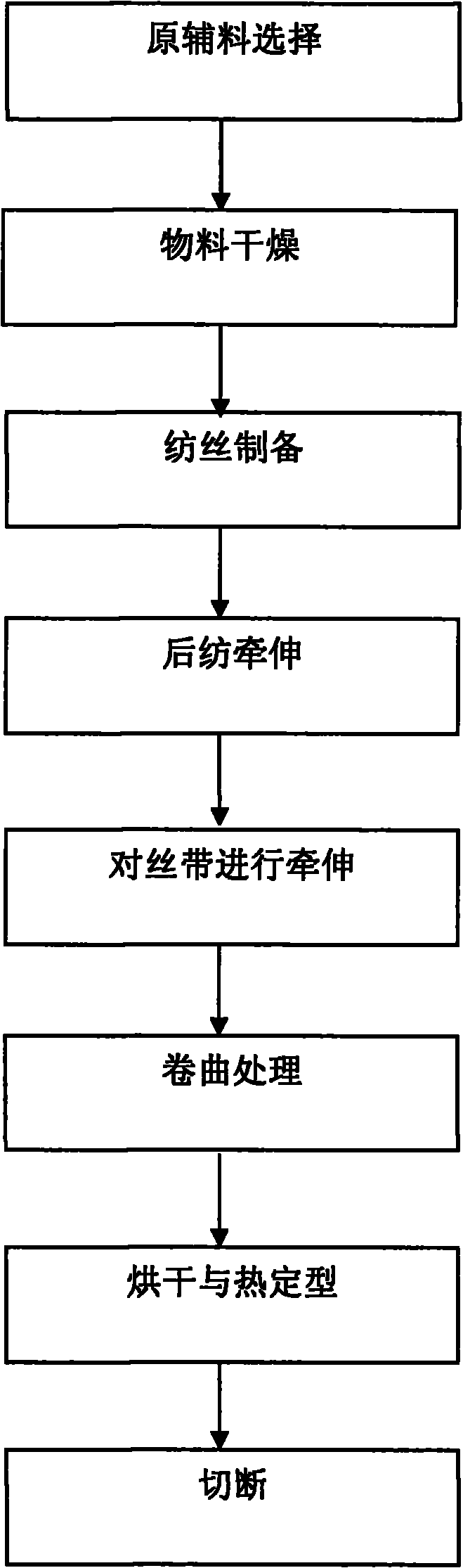

Preparation method of regenerative colored polyester fiber

InactiveCN101994163AIncrease elasticityImprove insulation performanceFilament manufactureHeating/cooling textile fabricsPolyesterHeat resistance

The invention discloses a preparation method of regenerative colored polyester fiber, comprising the following steps of: selecting supplementary materials; drying the materials; carrying out spinning preparation and post-spinning extension; evenly extending by two traction rollers under a heating state; rolling the extended raw tows; drying and thermally forming the raw tows; and finally, cutting the dried tows according to customer demands to obtain the regenerative colored polyester fiber with needed lengths. Because the produced regenerative colored fiber is directly spun in the natural color, the traditional color difference is greatly reduced. The obtained product has even color, is colorfast and has high strength, good thermal stability, good elasticity, good wear resistance, low water absorption moisture regain, good acid and base resistance, bio-incising resistance, and the like.

Owner:扬州天富龙集团股份有限公司

Industrial brush bristles and brush comprising same

ActiveCN101675839AImprove acid resistanceExtended service lifeBristleFilament-forming treatmentBristleEngineering

The invention relates to industrial brush bristles and a brush comprising the brush bristles. The brush bristles comprise the following components: matrix resin, anti-hydrolysis agent and / or acid absorption agent and antioxidant agent. The invention is applicable to industry, particularly in burnishing, polishing, cleaning and other treatments after cutting marble and / or metal, and the like.

Owner:DUPONT XINGDA FILAMENTS +1

Easy-to-dye terylene BCF and method for preparing same

InactiveCN101338455AImprove spinnabilitySolve the two major problems of dyeing at room temperatureFibre mixingLap-winding devicesFiberYarn

The invention relates to a chromophil terylene BCF and a preparation method thereof, which belong to the technical field of the terylene. The chromophil terylene BCF is characterized in that the terylene BCY is in a tri-leaflet shape which is also called as Y-shaped microcellular structure. The preparation method is characterized in that (1) the slice of raw terylene materials is pre-crystallized and dried by a dryer; (2) the slice of the raw terylene materials are melted by an extruder; (3) multifilament yarn which is in the tri-leaflet shape which is also called as the Y-shaped microcellular structure is sprayed by a tri-leaflet spinneret plate; (4) a tow is cooled to be formed into initial raw silk; (5) oil solution is applied to spinning; (6) the spinning is extended; (7) the spinning undergoes the process of bulking in a deformation box; (8) the spinning is cooled and curled; (9) the spinning undergoes the process of link making; (10) the spinning is rolled into a drum. The chromophil terylene BCF solves two problems that the current BCF has poor spinnability and is difficult to be dyed under normal temperature, provides newly-invented BCF fiber for manufacturing the suede of a blanket and creates conditions for manufacturing the blanket that has good spreadability, beautiful appearance and low manufacturing cost.

Owner:上海繁太实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com