Heating roller heating method and heating roller

A heating method, heating roller technology, applied in chemical instruments and methods, paper/cardboard containers, containers, etc., to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

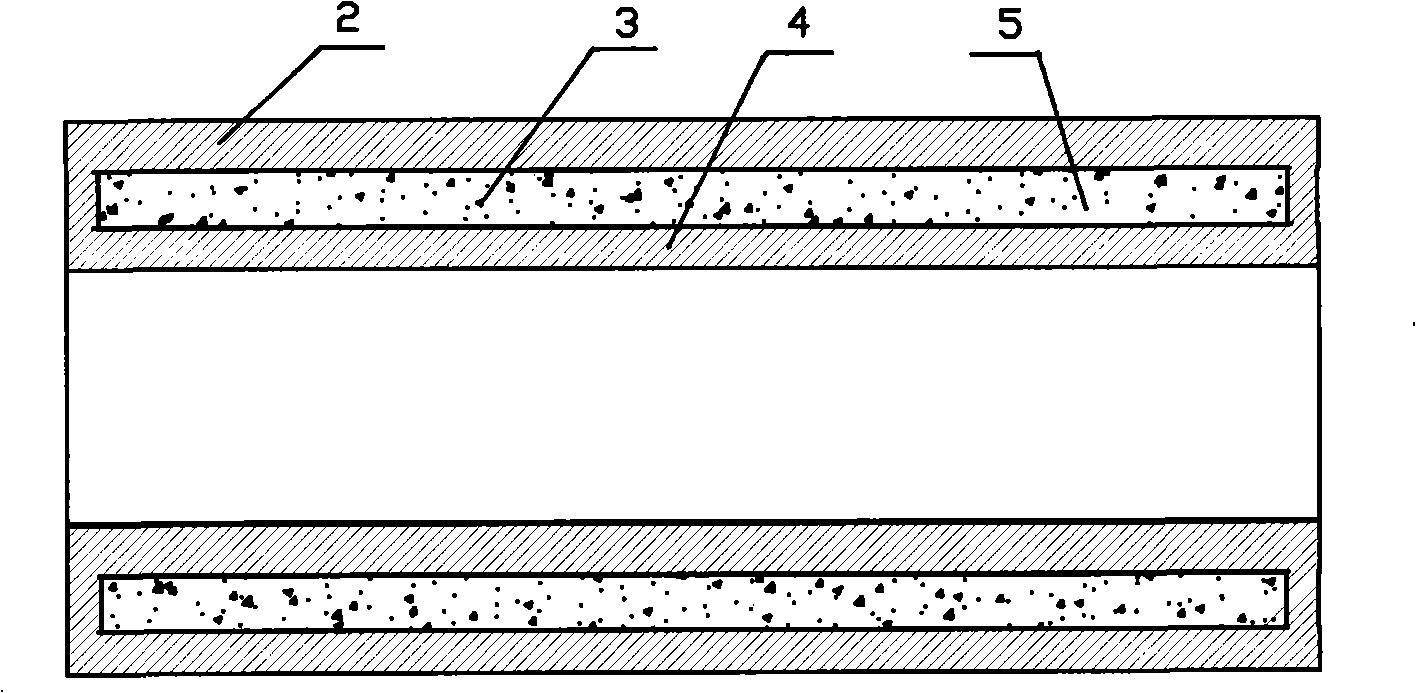

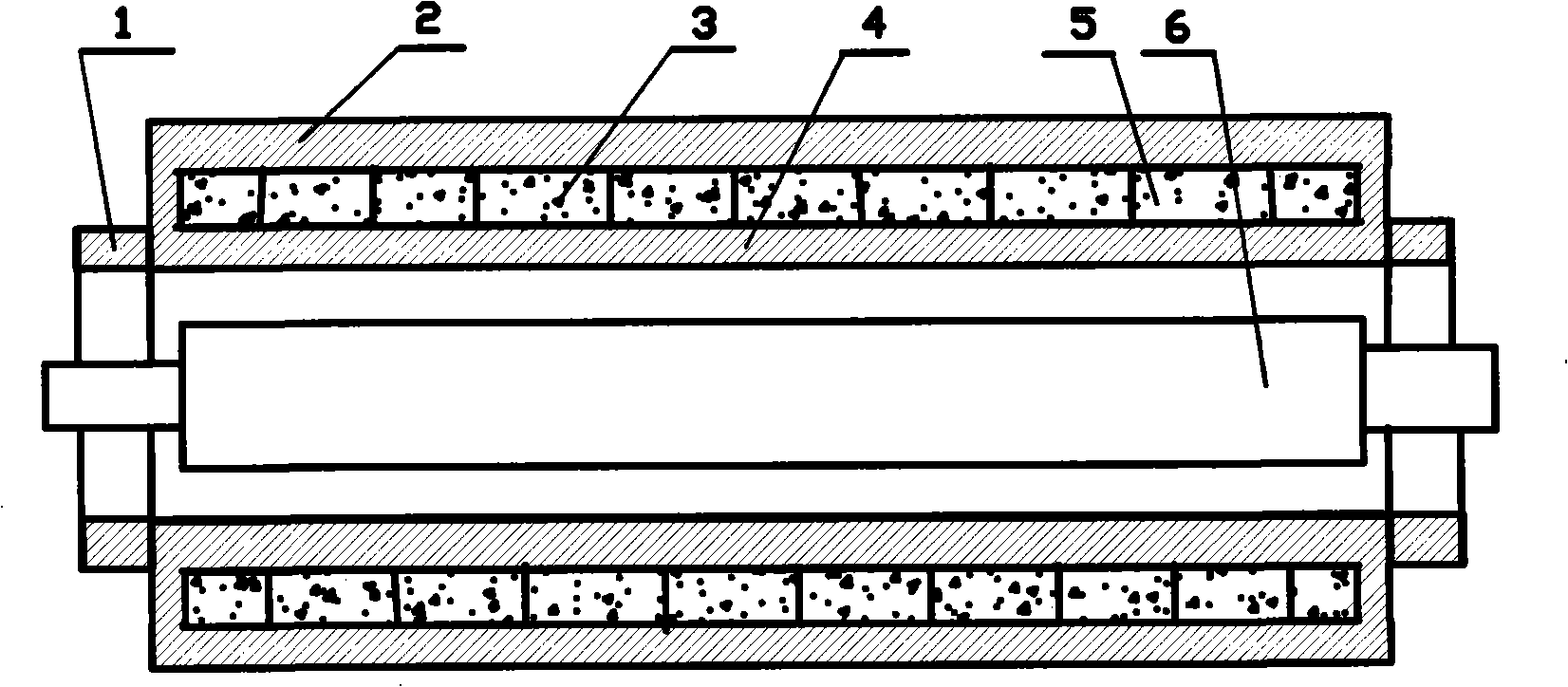

[0035] attached figure 2 and image 3 As an embodiment of the present invention, it is an electrically heated rubber heating roller, which at least includes a heating roller outer layer 2 and a heating roller inner layer 4, and is provided with heating roller supports and transmissions for supporting the heating roller at both ends of the heating roller. The shaft 1 is provided with an electric heating tube 6 for heating the heating roller inside the heating roller; there is a heating roller interlayer 5 between the heating roller outer layer 2 and the heating roller inner layer 4, thereby forming a sandwich structure. The heating roller interlayer 5 is a closed independent cavity, and the heat-conducting liquid medium in the interlayer of the independent cavity makes the temperature of the outer surface of the heating roller uniform in a self-circulating flow state. The heating roller interlayer 5 is in the form of a continuous full cylinder. The heating roller interlayer ...

Embodiment 2

[0038] attached Figure 4 and Figure 5As another embodiment of the present invention, it is a heating roller of a printing machine heated by oil or steam. The heating roller at least includes a heating roller outer layer 2 and a heating roller inner layer 4. The heating roller support of the roller, the transmission shaft 1, the inner layer 4 of the heating roller is filled with heating oil or steam 7, and there is a heating roller interlayer 5 between the outer layer 2 of the heating roller and the inner layer 4 of the heating roller, thus forming a kind of interlayer structure. The heat-conducting liquid medium 3 is filled in the heating roller interlayer 5, and the heat-conducting liquid medium 3 is potassium-sodium molten metal, pure water, ethanol, and the outer layer 2 of the heating roller passes through the potassium-sodium molten metal and pure water in the heating roller interlayer 5. , Ethanol substances, heated by heat conduction. The heating roller interlayer ...

Embodiment 3

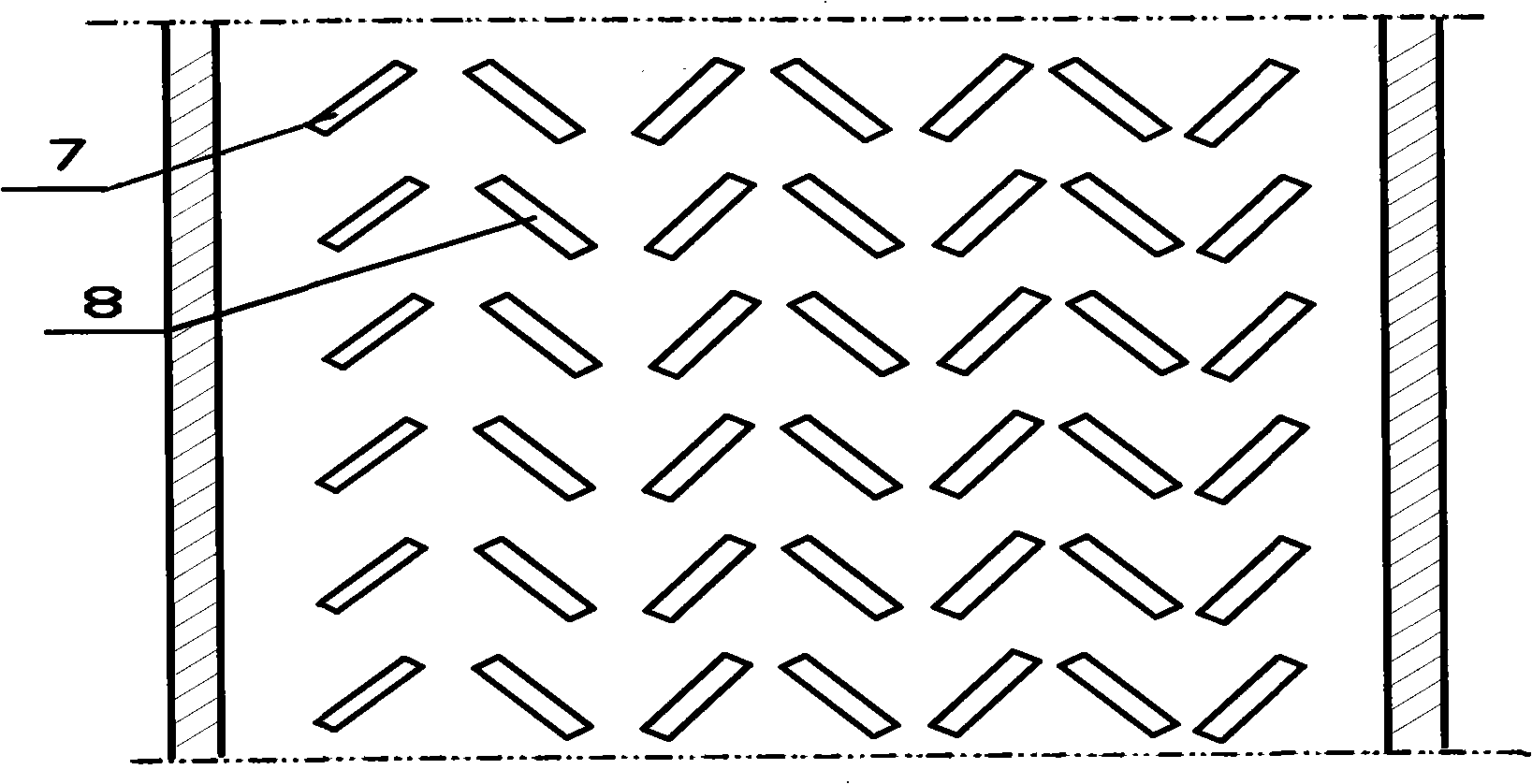

[0041] attached Figure 6 and Figure 7 Another embodiment of the present invention is a plastic film heating roller, which is an electromagnetically heated single-arm heating roller. The heating roller at least includes an outer layer 2 of a heating roller and an inner layer 4 of a heating roller. The heating roller support and transmission shaft 1 supporting the heating roller are provided with an electromagnetic heating device 11 for heating the heating roller inside the heating roller, and there is a heating roller interlayer 5 between the heating roller outer layer 2 and the heating roller inner layer 4, A sandwich structure is thus formed. The heat-conducting liquid medium 3 is filled in the heating roller interlayer 5. The heat-conducting liquid medium 3 is Sanjie HD synthetic heat-conducting oil produced by Changzhou Hongyuan Sanjie Chemical Co., Ltd. Heat conduction oil is heated by heat conduction. The heating roller interlayer 5 is a non-continuous annular cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com