Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451 results about "Oil tanker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil tanker, also known as a petroleum tanker, is a ship designed for the bulk transport of oil or its products. There are two basic types of oil tankers: crude tankers and product tankers. Crude tankers move large quantities of unrefined crude oil from its point of extraction to refineries. For example, moving crude oil from oil wells in a producing country to refineries in another country.

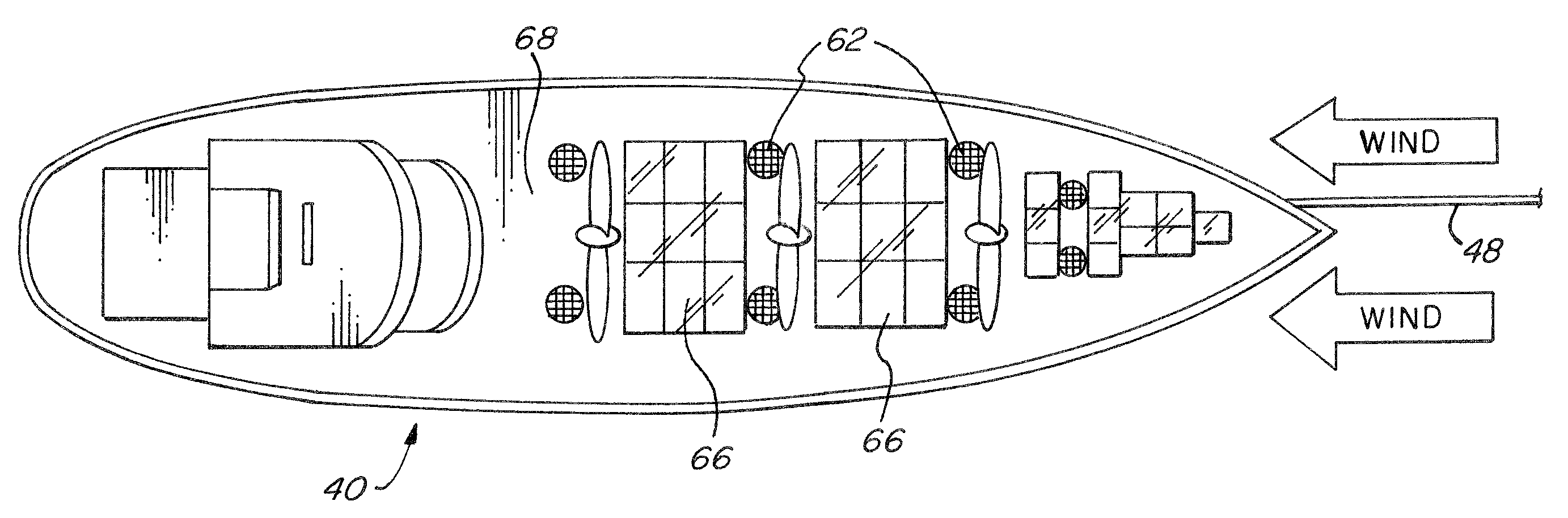

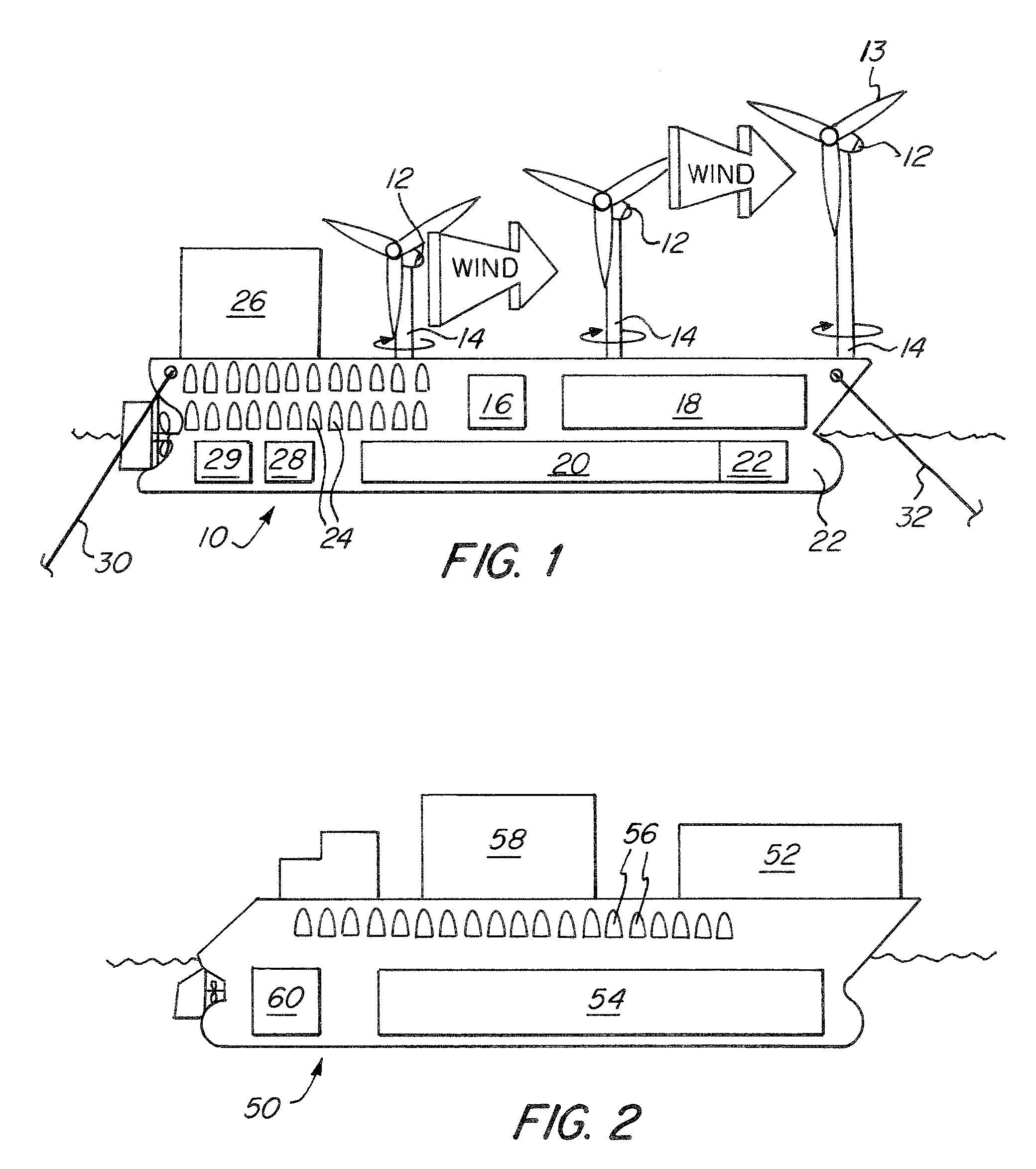

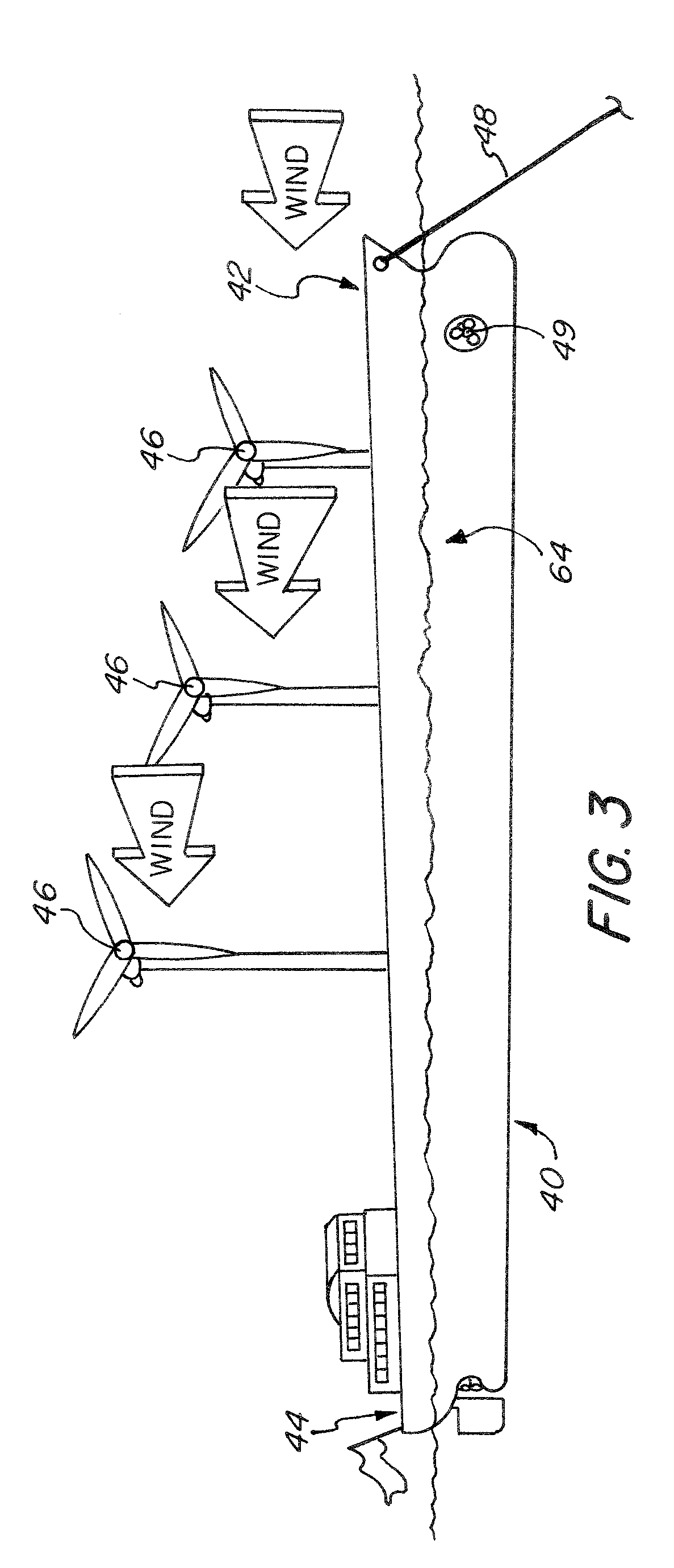

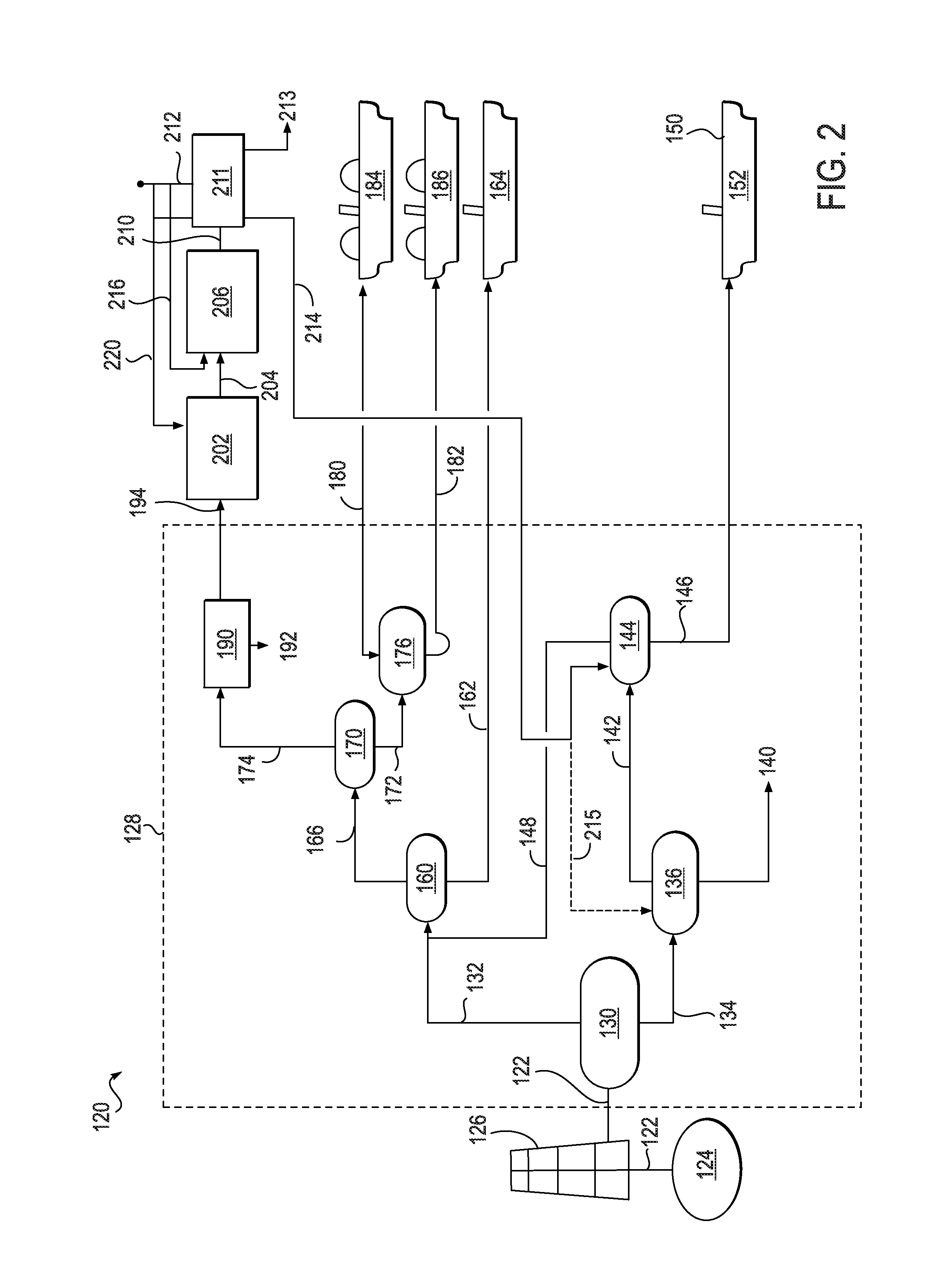

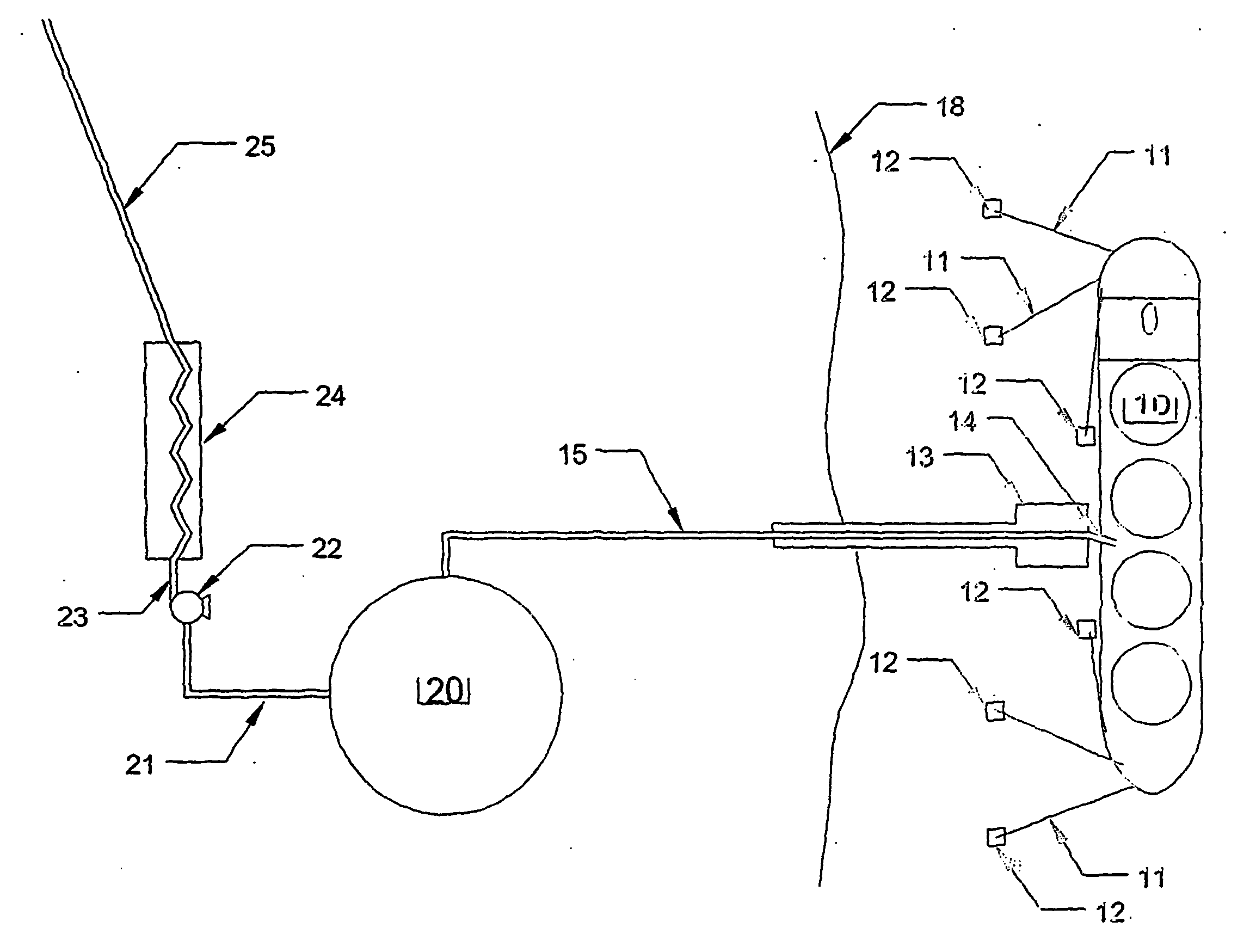

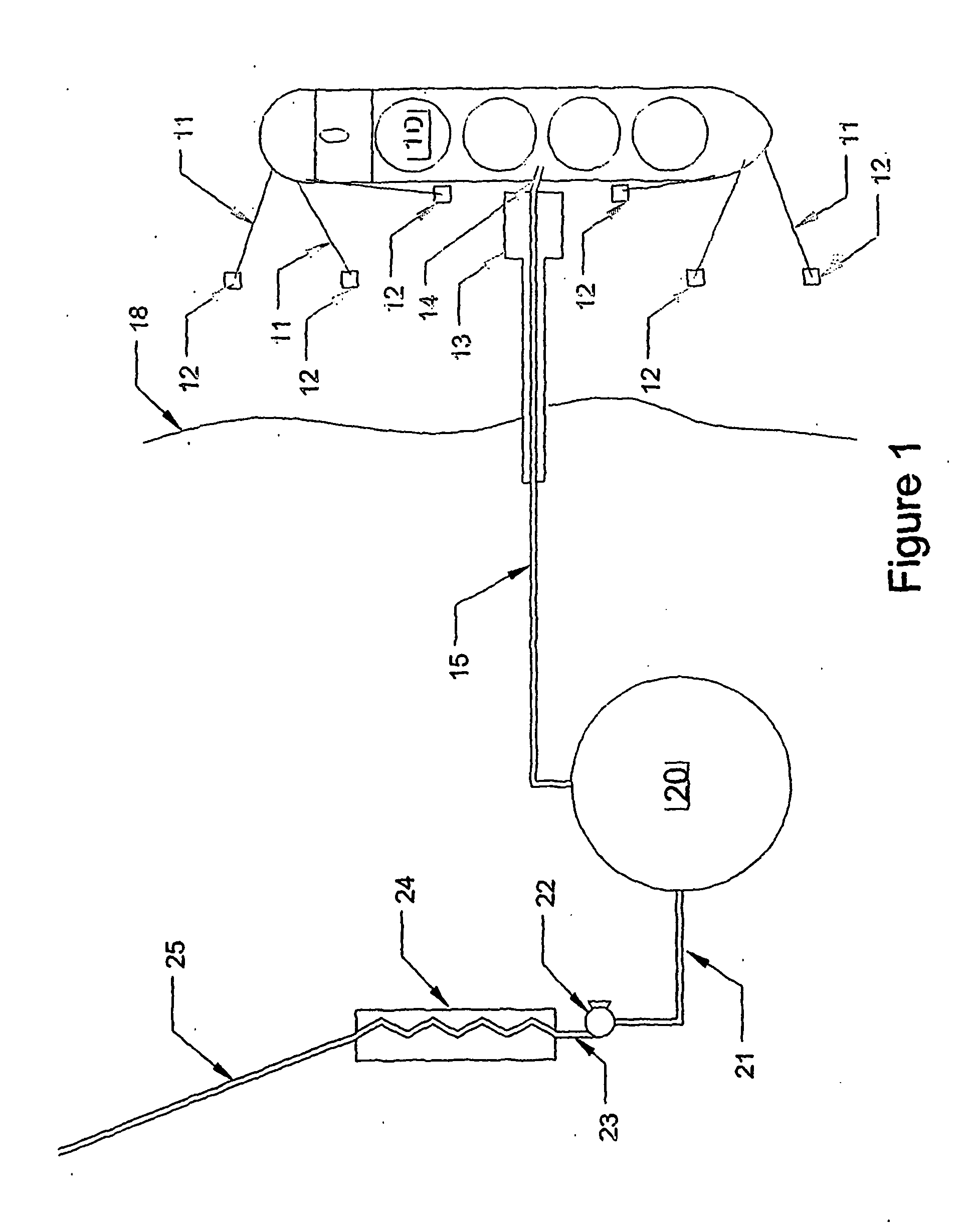

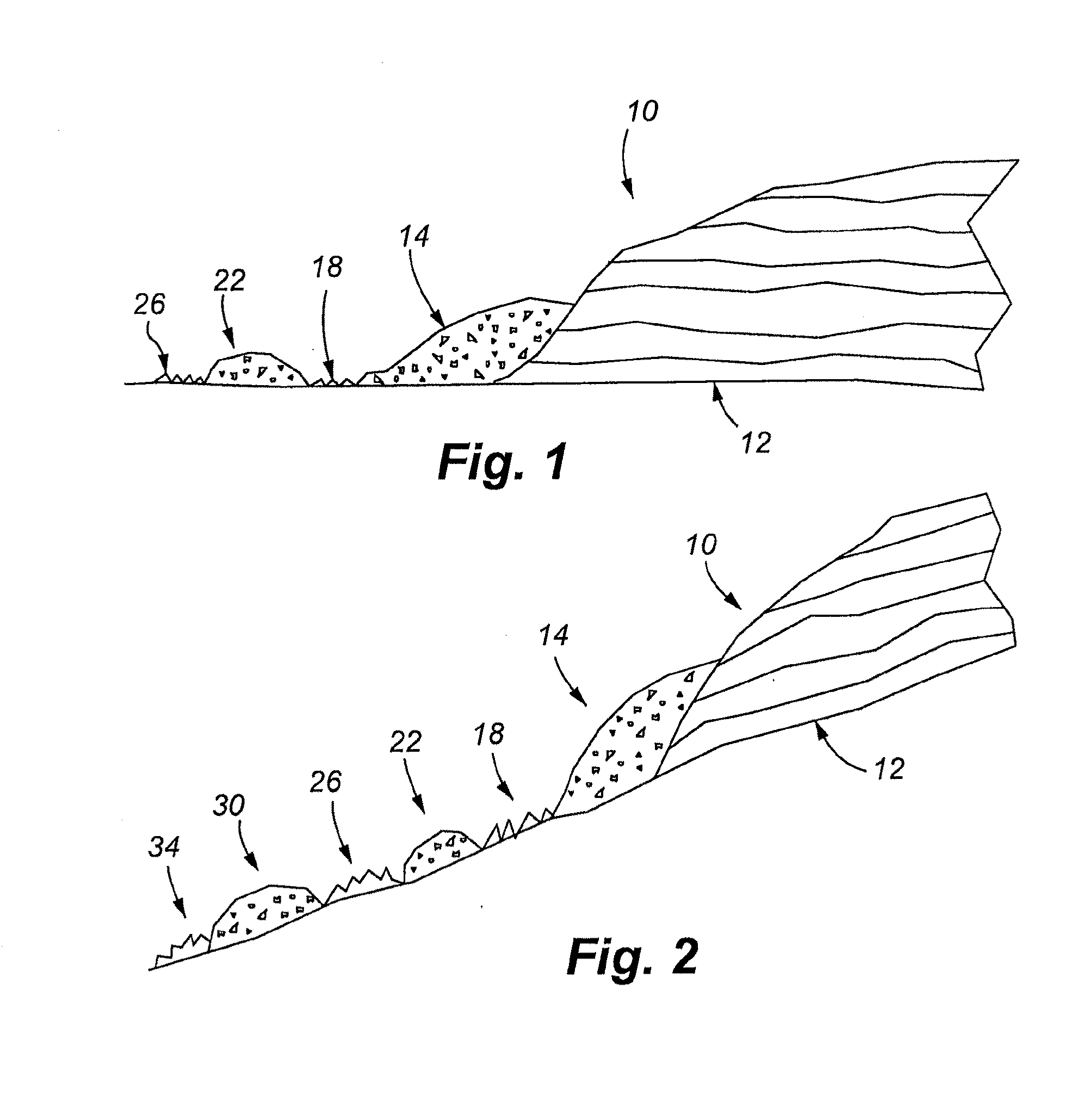

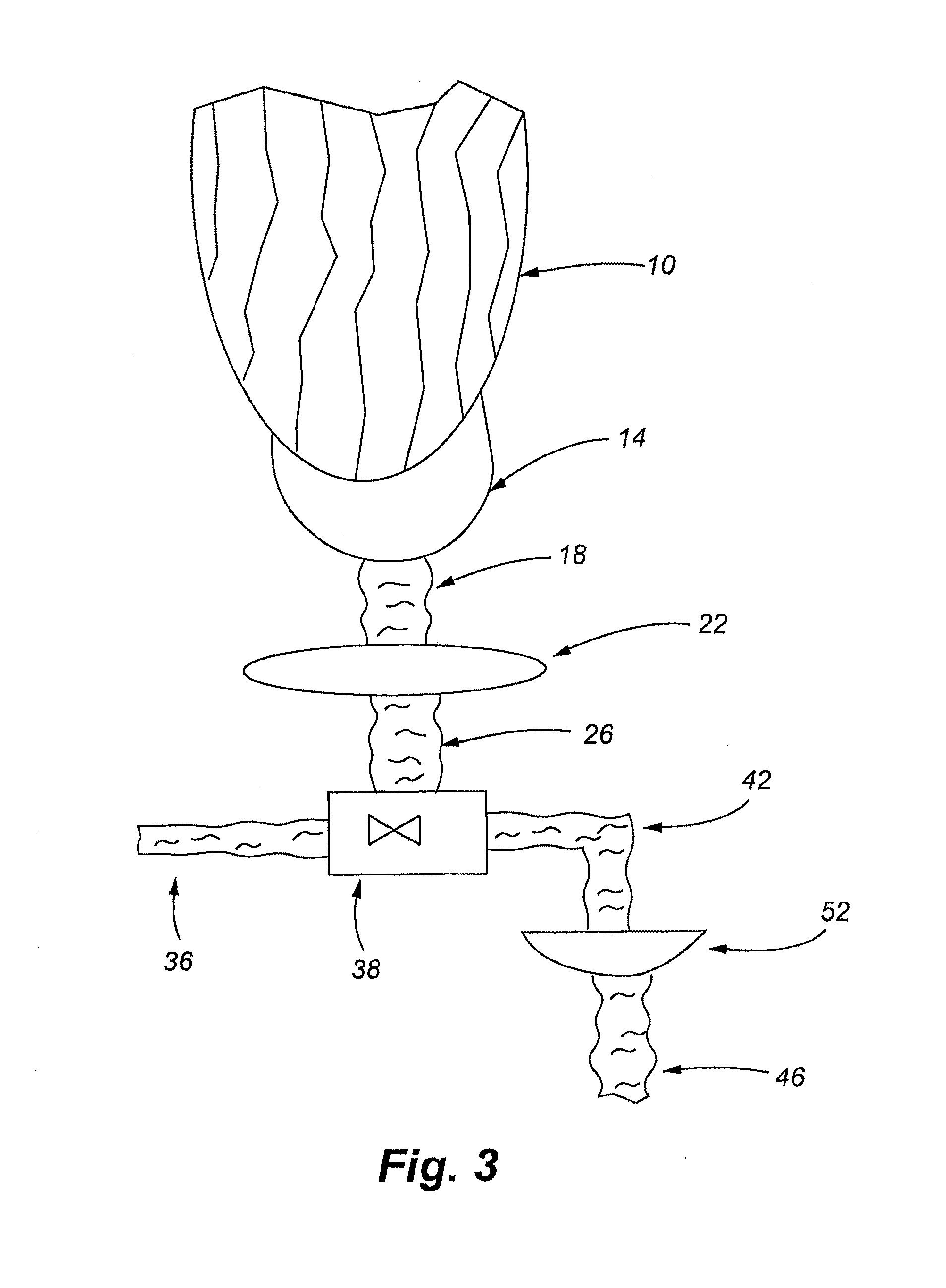

Wind Power System

A system for capturing and converting and / or storing wind energy includes a vessel adapted to receive at least one wind machine for capturing wind and a device for converting wind energy to storable energy. A method of adapting a vessel, such as a surplus cargo ship or an oil tanker, for use as a offshore power generating system comprises equipping a vessel with devices for capturing a renewable energy source, positioning the vessel at sea to capture the renewable energy source, converting the renewable energy to a storable energy source, and storing the converted energy, and repositioning the vessel to capture further renewable energy or transport the stored, converted energy.

Owner:POLESTAR LTD LLC

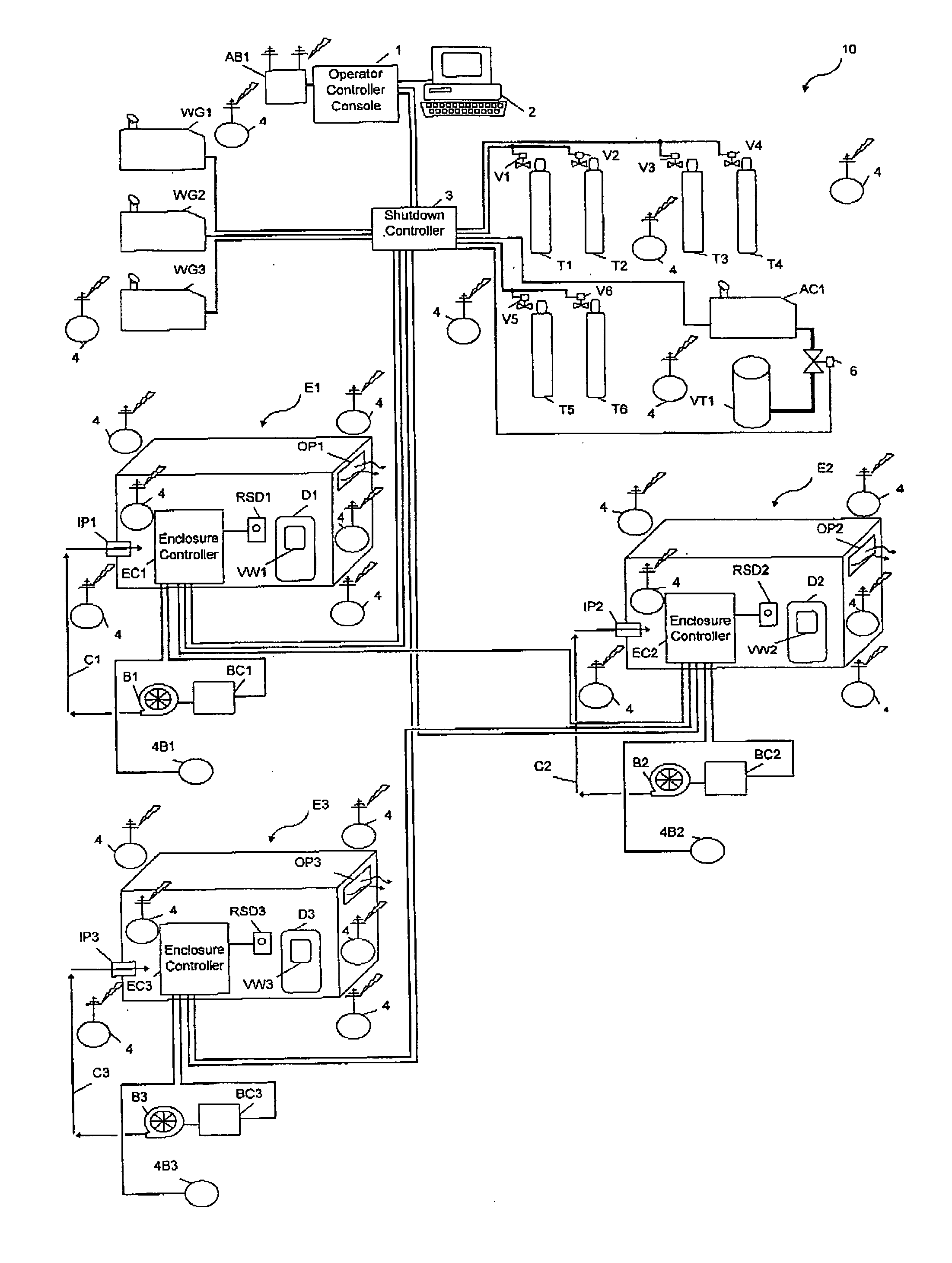

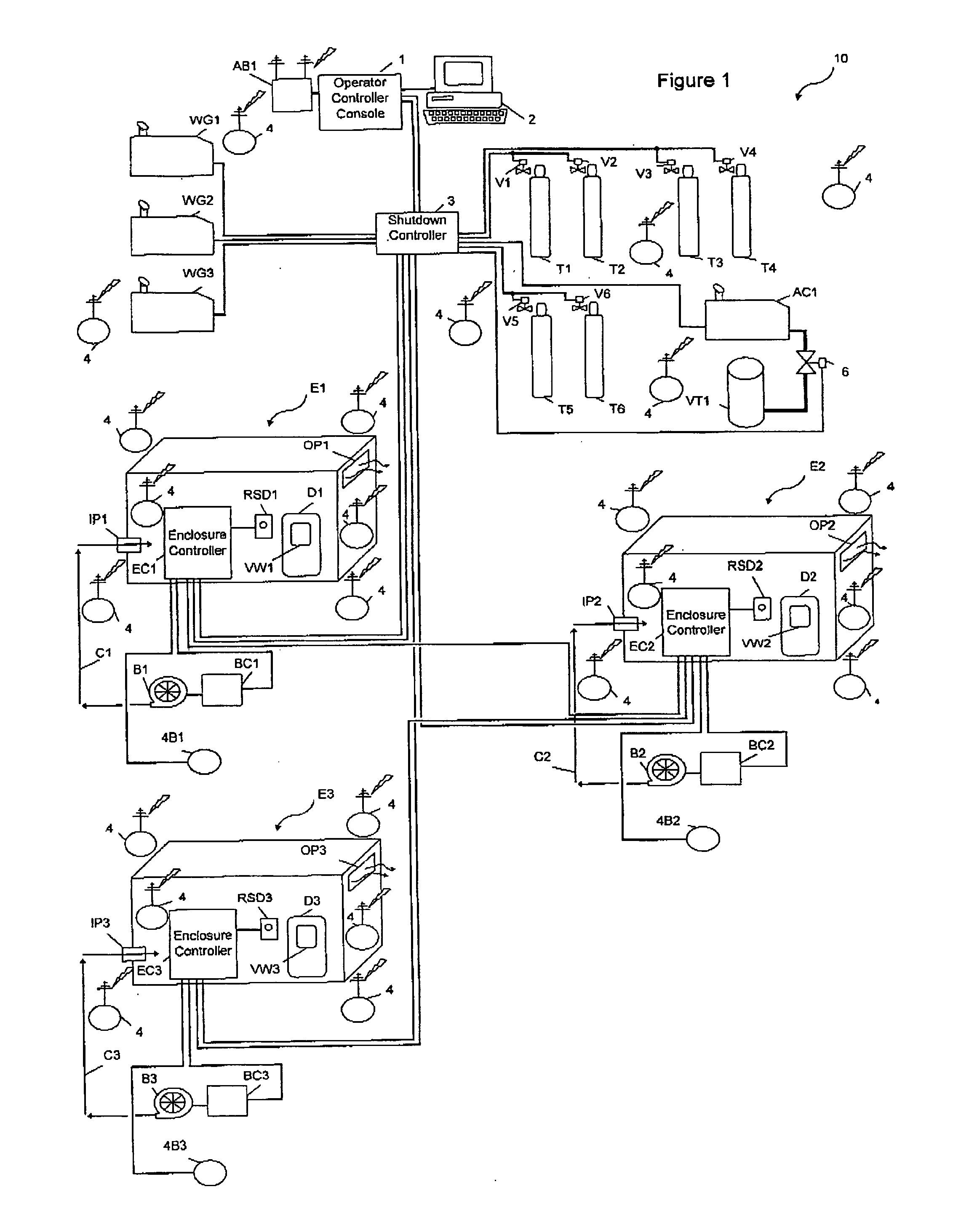

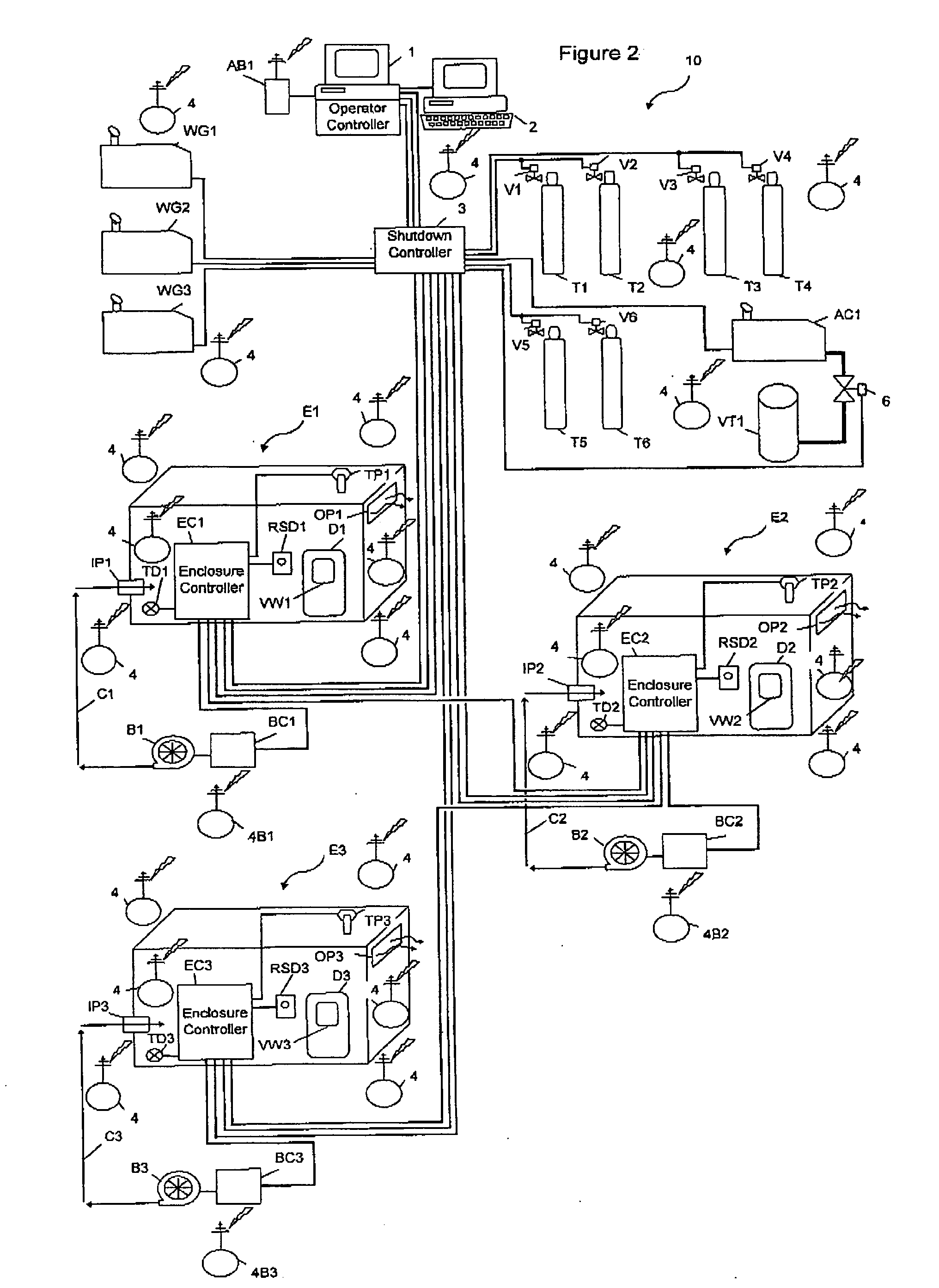

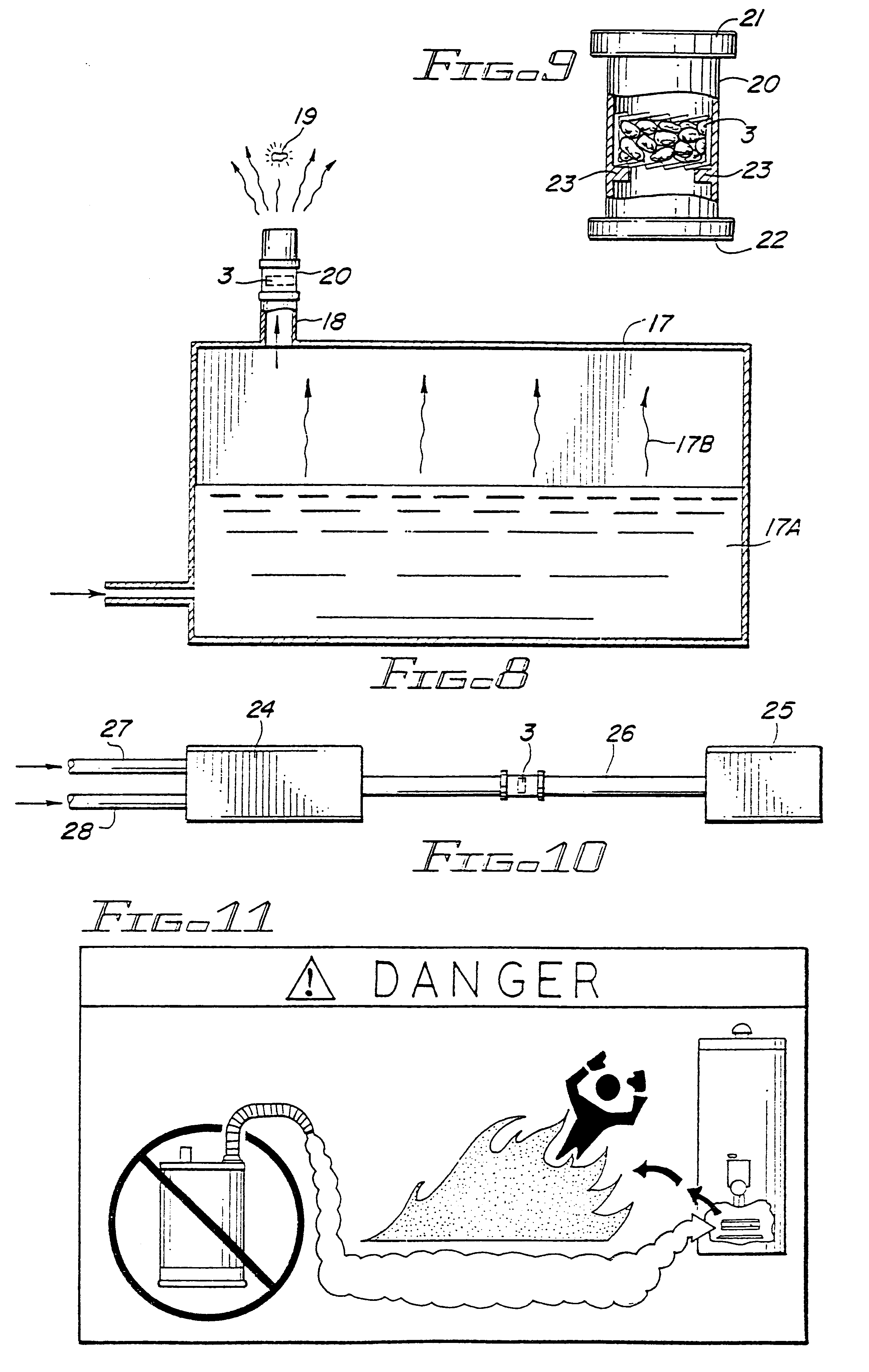

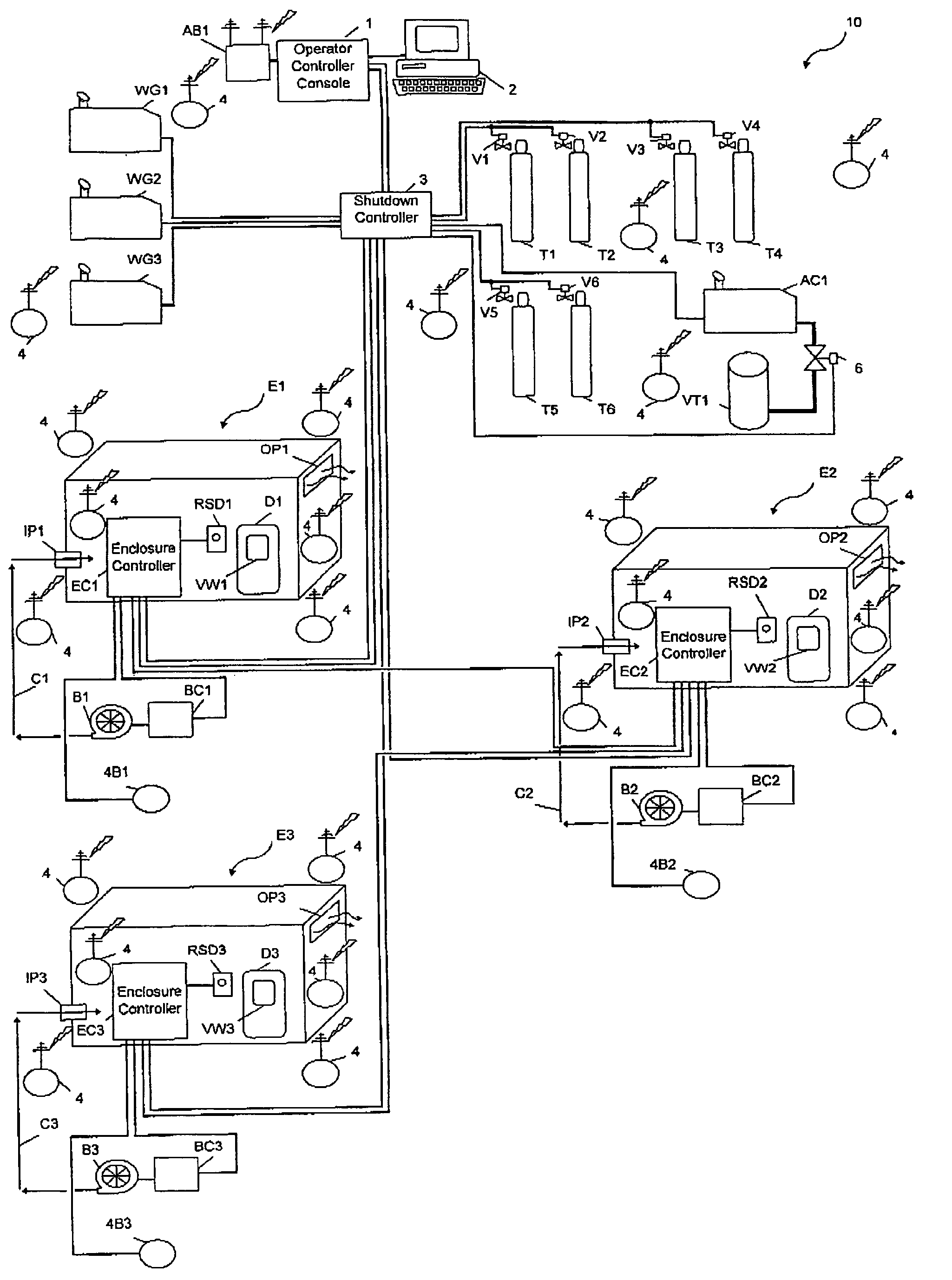

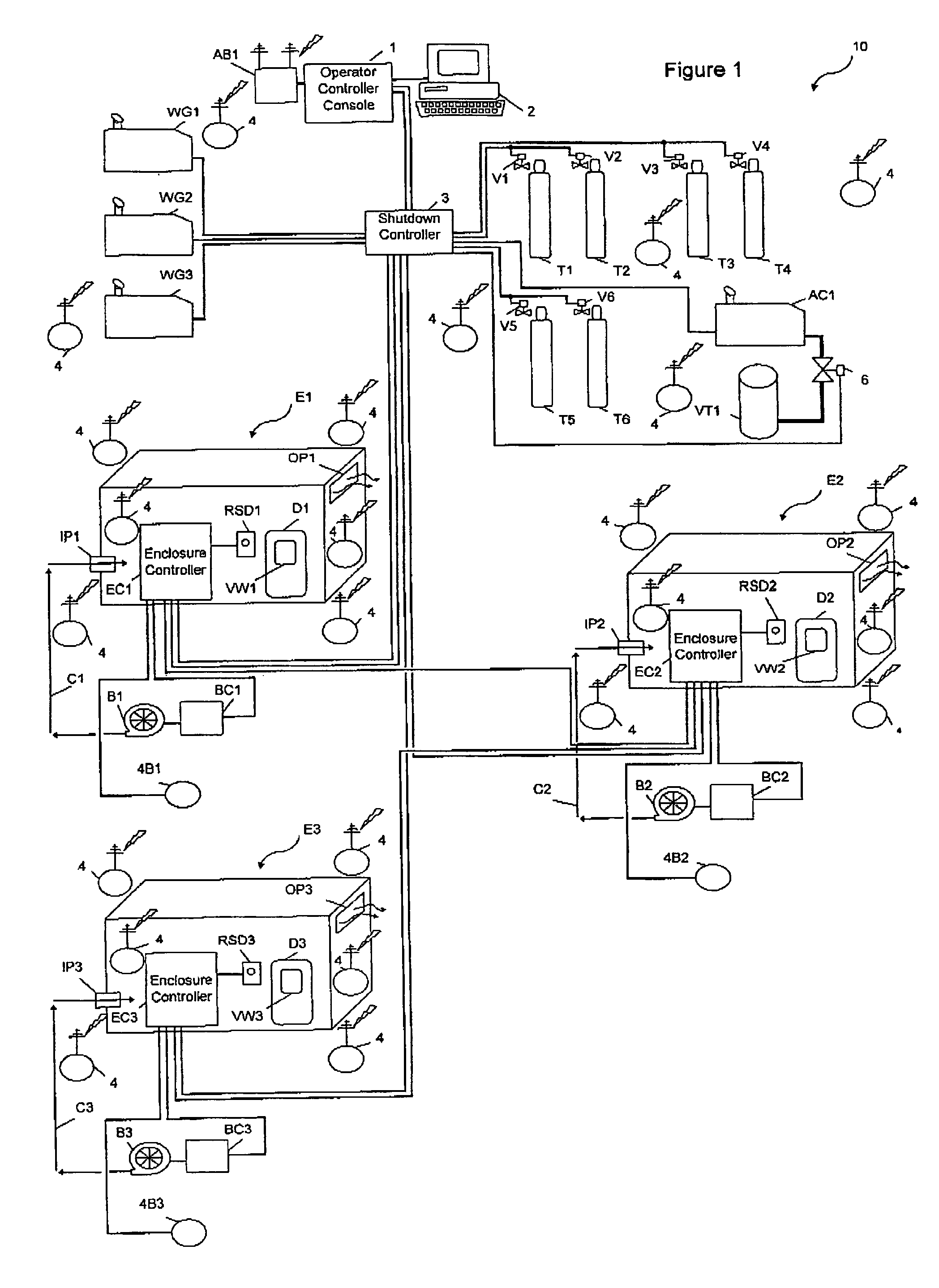

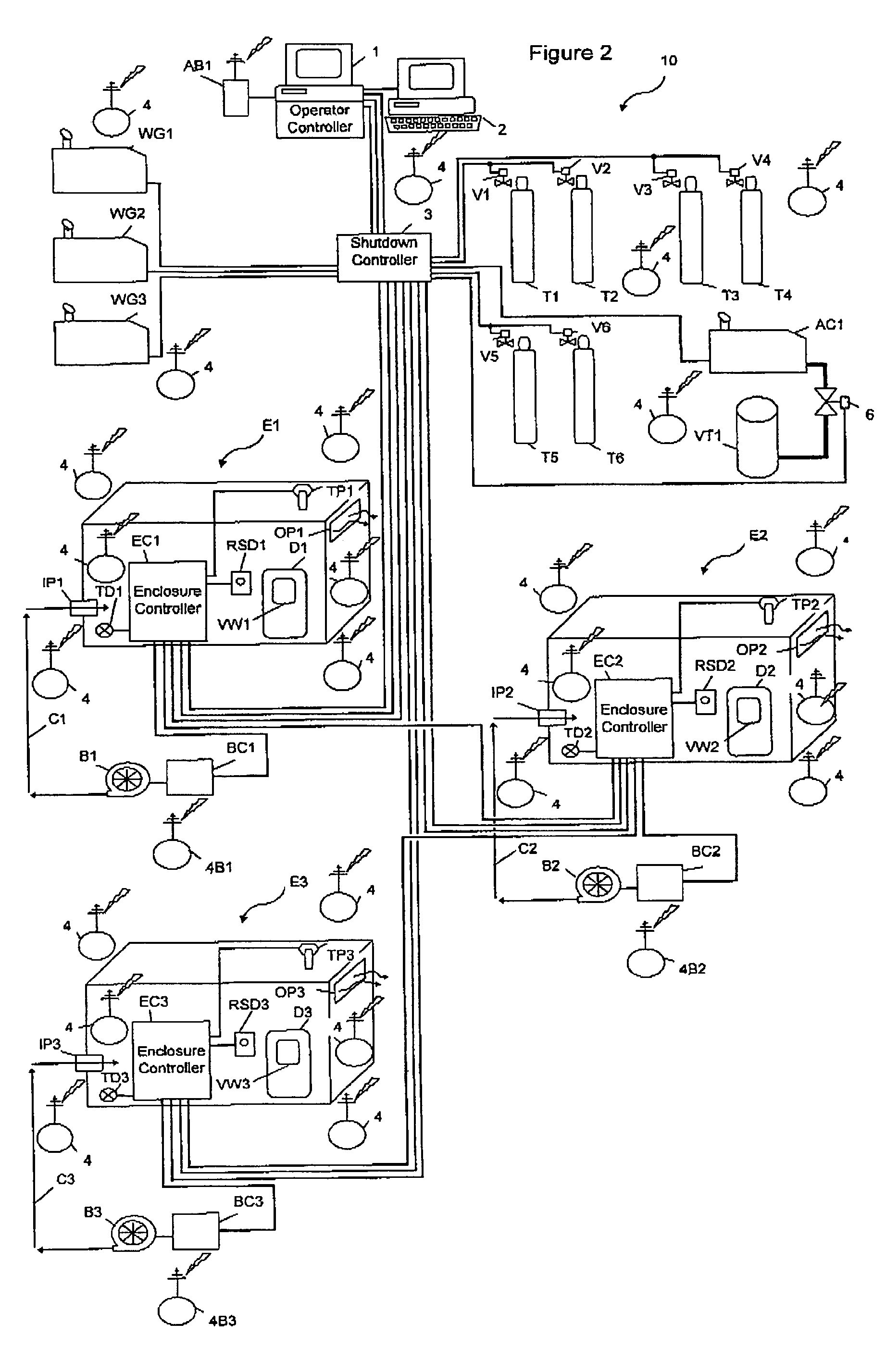

Enclosure system allowing for hot work within the vicinity of flammable and combustible material

InactiveUS20070052543A1Welding/cutting auxillary devicesElectric testing/monitoringCompound (substance)Hot work

An enclosure constructed around an area at which hot work is to be performed at a facility containing flammable or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like. Facilities include petroleum drilling and production platforms, oil tankers, petroleum and chemical plants, and petroleum tank farms. Gas detection monitoring apparatuses are used with the enclosure which will automatically simultaneously shutdown one or more enclosures.

Owner:ALFORD SAFETY SERVICES

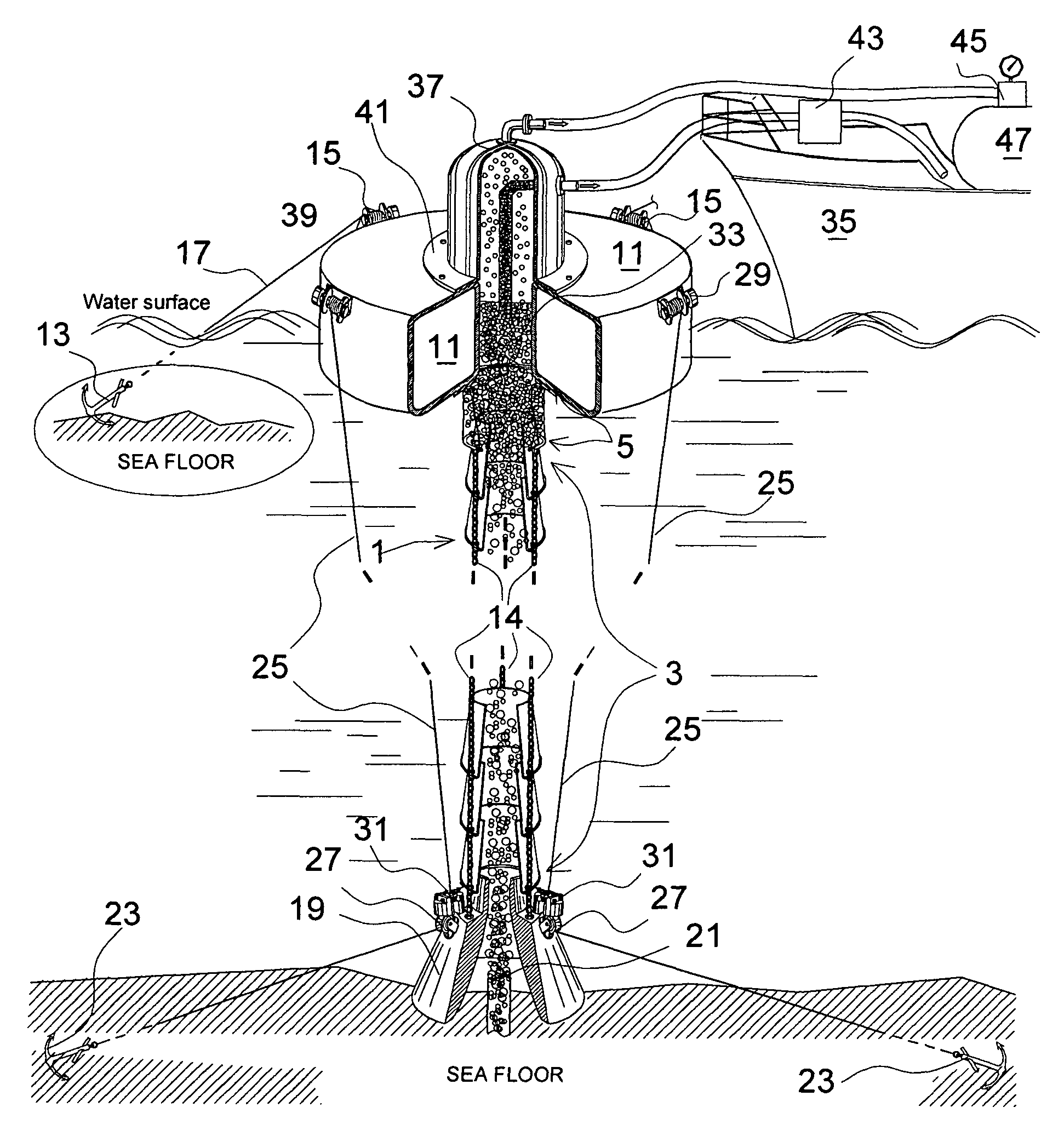

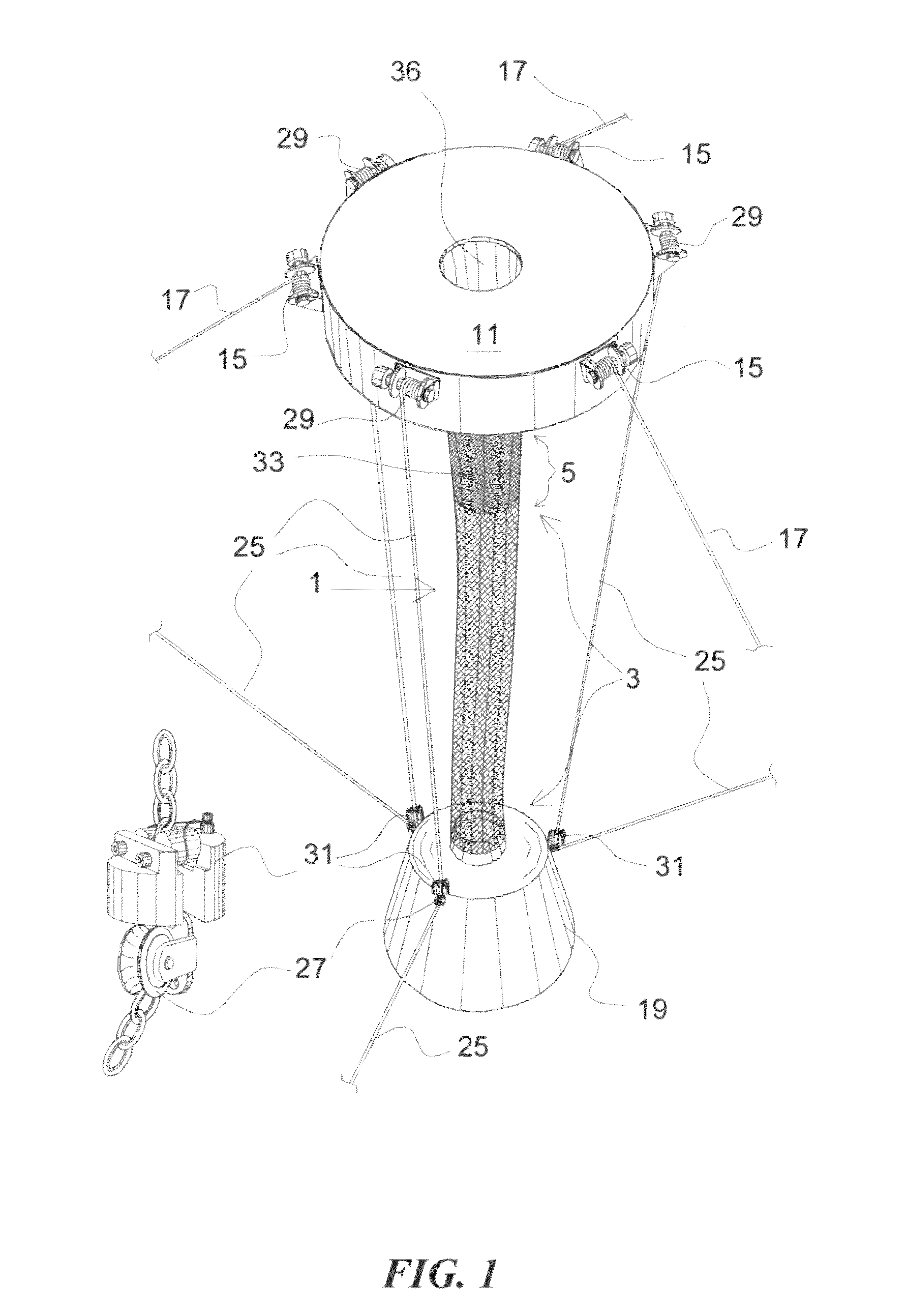

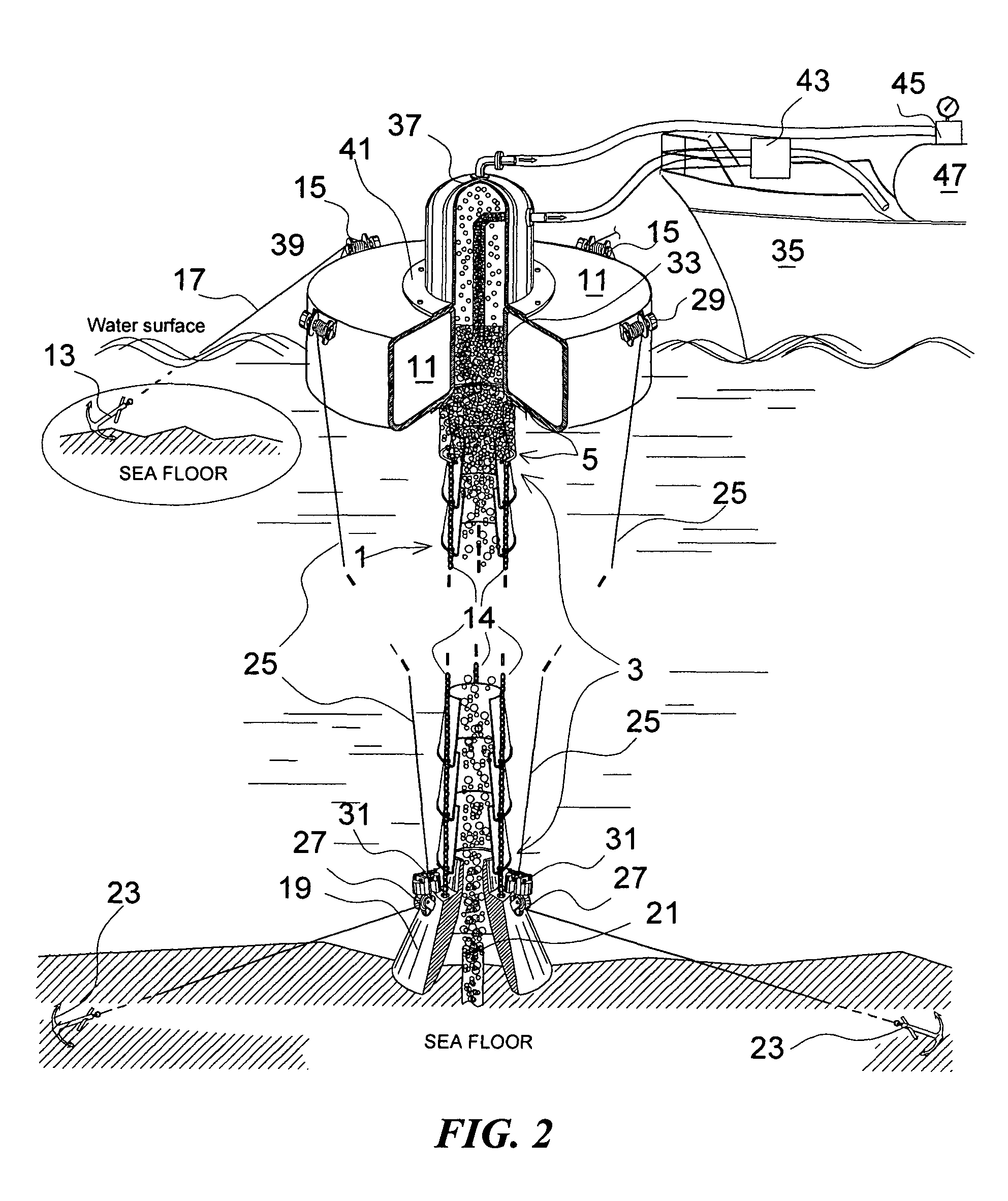

Marine oil leak recovery and marine petroleum mining method

A vertical flexible oil flow director hose is used to recover, to guide, and to filter the spilled oil from its source beneath the sea floor to the surface of water and to accumulate the floating oil therein for being ready to be pumped into an oil tanker. The said hose extends in the sea all the way from the sea floor to the surface of water by connecting its lower end to a circular sinking weight block and its upper end to a hollow doughnut-shaped floating device. The said hose includes two main portions abutting each other, the lower portion is for guiding and displacing water out through the gaps or meshes. The upper portion is for continued guiding and accumulating the oil in its upper section. A gas-tight dome cap having an opening at its bottom may be used to cap the upper opening of the oil accumulator well in the floating object, for holding the gas as necessary. A gas-compressor and gas tank or tanks will be equipped on the oil tanker ready to take and to store the gas.

Owner:CHE HUE NGUYEN

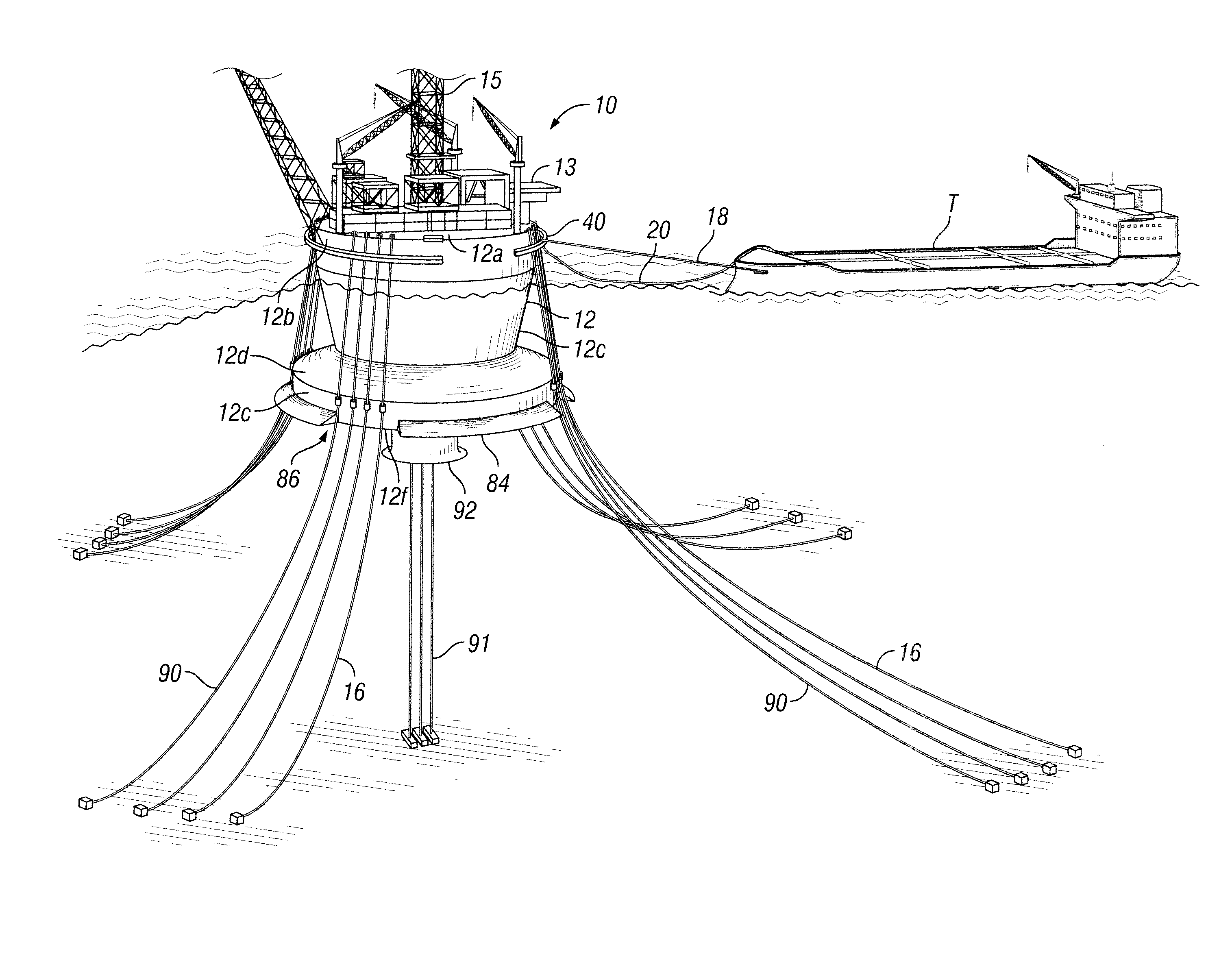

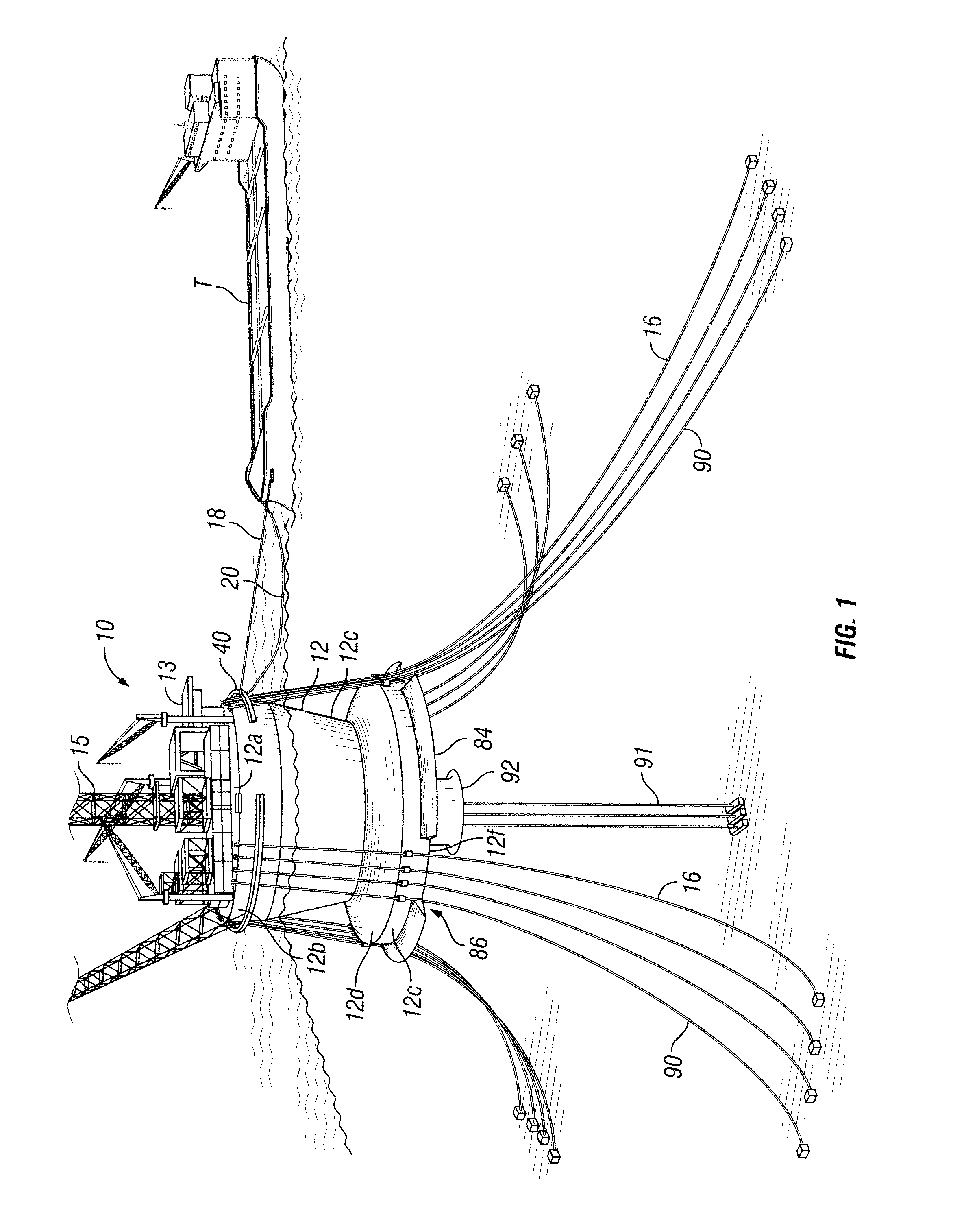

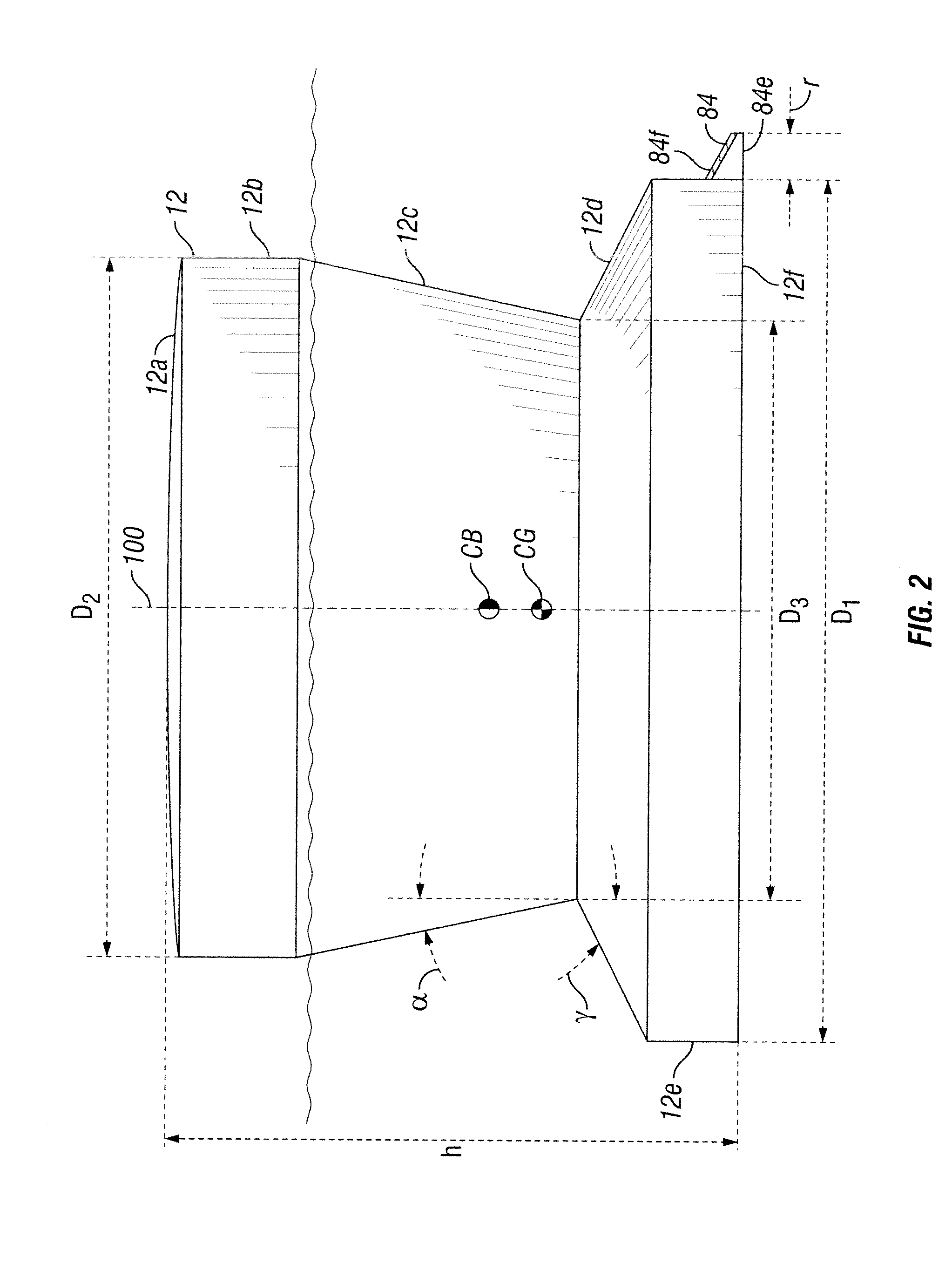

Offshore buoyant drilling, production, storage and offloading structure

An offshore structure having a vertically symmetric hull, an upper vertical wall, an upper inwardly-tapered wall disposed below the upper vertical wall, a lower outwardly-tapered wall disposed below the upper sloped wall, and a lower vertical wall disposed below the lower sloped wall. The upper and lower sloped walls produce significant heave damping in response to heavy wave action. A heavy slurry of hematite and water ballast is added to the lower and outermost portions of the hull to lower the center of gravity below the center of buoyancy. The offshore structure provides one or more movable hawser connections that allow a tanker vessel to moor directly to the offshore structure during offloading rather than mooring to a separate buoy at some distance from the offshore storage structure. The movable hawser connection includes an arcuate rail with a movable trolley that provides a hawser connection point that allows vessel weathervaning.

Owner:JURONG SHIPYARD

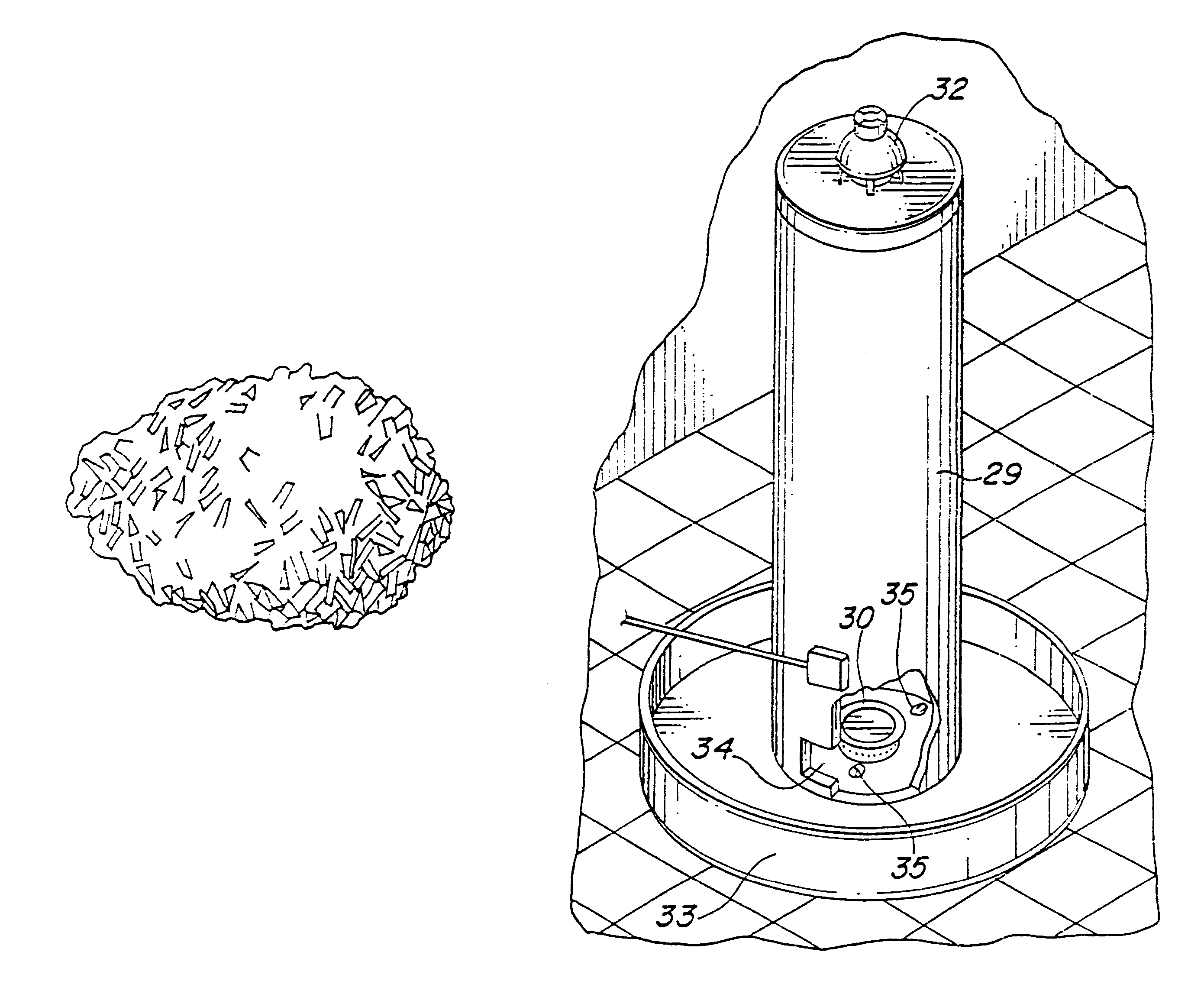

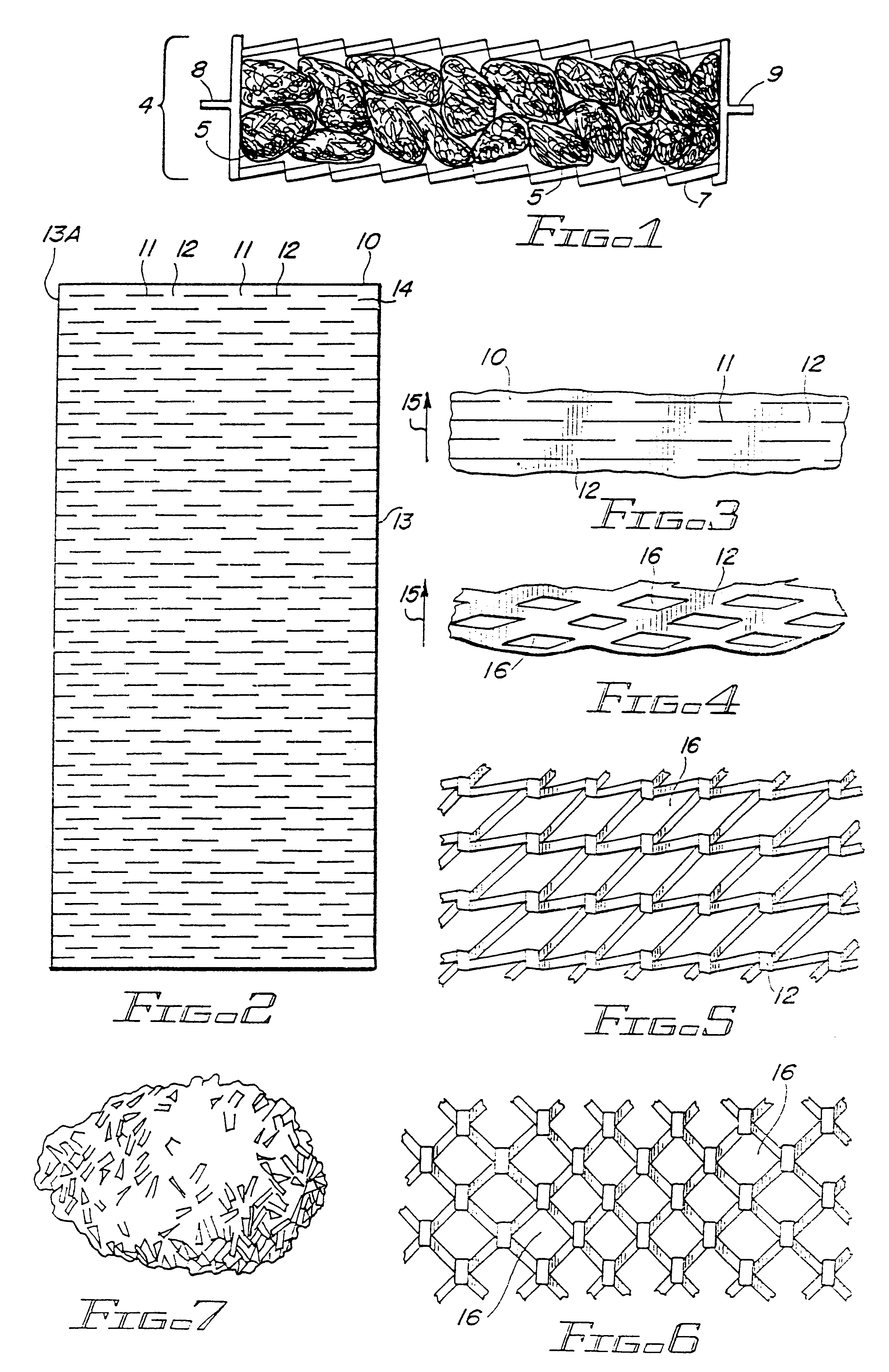

Flame arrester

InactiveUS6216791B1Improve abilitiesEasy to assemblePaper/cardboard articlesMachines/enginesCombustion systemFlame arrester

A highly efficient flame arrester adapted for use in preventing an external flame from backflashing upstream in a pipe, or a conduit, or a stream carrying a flammable substance. The flame arrester comprises a contained layer of nested ellipsoids formed from expanded metal sheets made from magnesium alloy foil. The arrester is useful in fuel tanks, combustion systems, sea-going tankers, hot water, or space heaters, and the like.

Owner:ALHAMAD SHAIKH GHALEB MOHAMMAD YASSIN

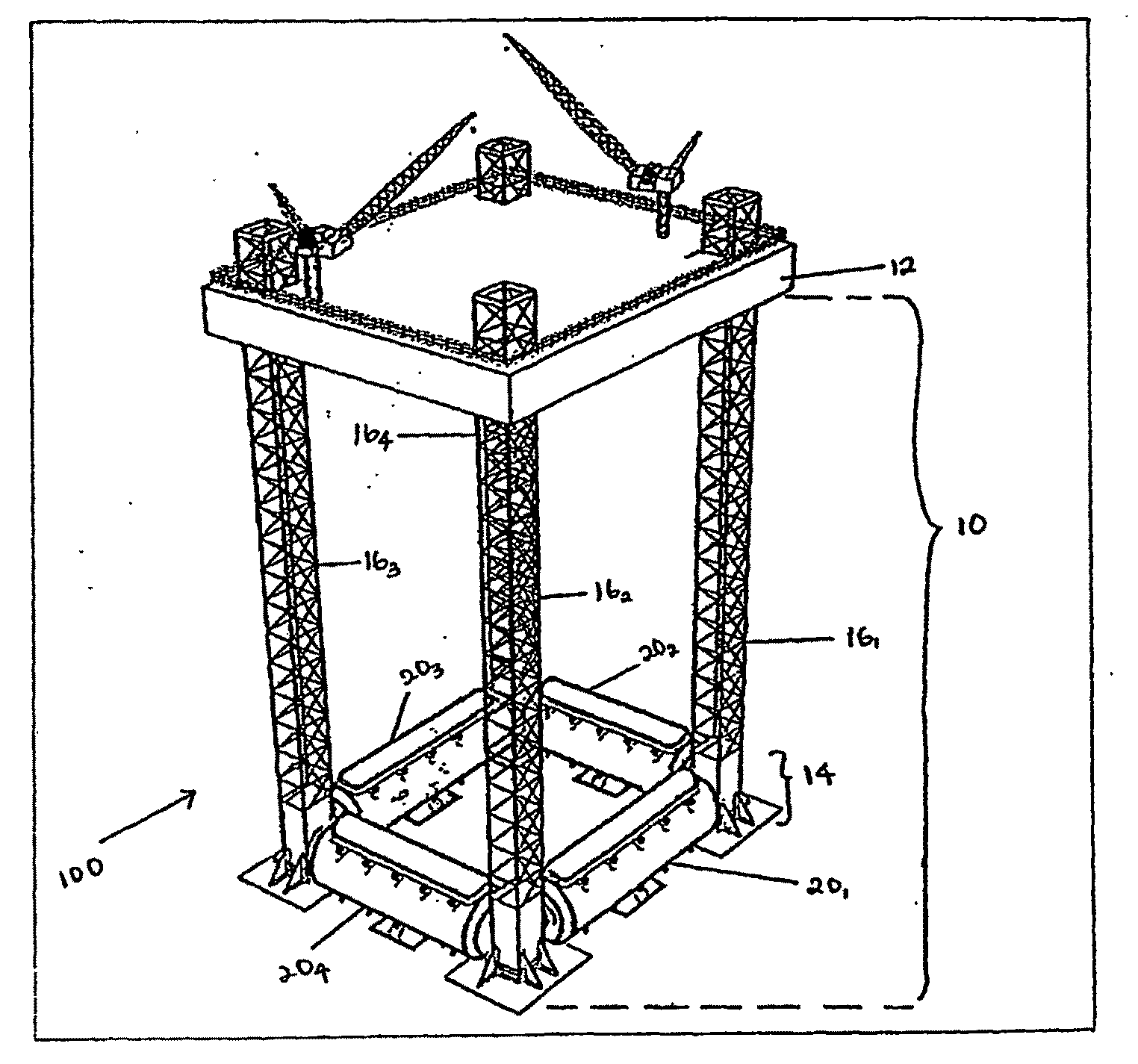

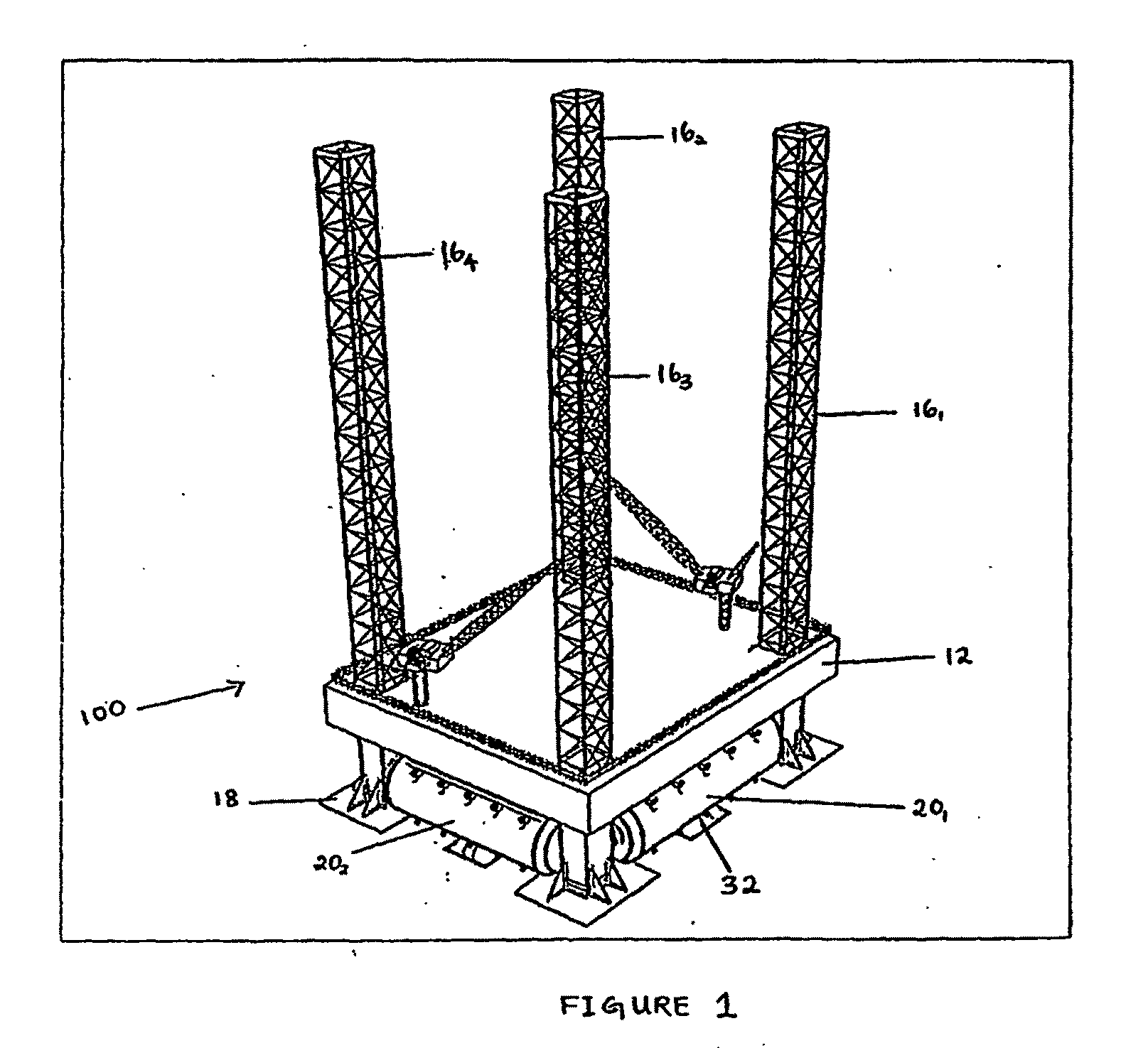

Offshore oil production platform

The present invention relates to an offshore oil production platform. The platform includes a deck (12) and a sub-structure (10) comprising plurality of ballast chambers (20) and at least one of connecting leg (16) connected from the ballast chambers (20) to the deck (12). The ballast chambers (20) include at least one oil storage compartment (22), at least one ballast compartment (24) and at least one air pressure compartment (26). The oil and gas storage compartment (22) is for storing processed oil and gas. During installation of the platform, the ballast chambers (20) are ballasted with sea water (46) which allows lowering of the connecting legs (16) towards the sea bed (34). After the ballast chambers (20) reach the sea bed (34), locking means is actuated to a locked position to prevent movement of the sub-structure (10) of the platform. The deck (12) is moved up to a predetermined height from sea level by jacking means. After the oil is extracted, it is then processed and separated to processed oil and gas. The processed oil and gas are then stored in the oil and gas storage compartment (22). The oil and gas are then transferred to a buoy and then loaded to tanker vessels by connecting conduits. During the de-installation of the oil production platform, the ballast chambers (20) are de-ballasted whereby the sea water (46) in the ballast compartment (24) is flushed out. Thus, the sub-structure (10) of the platform moves upwards to reach the deck (12). When the base (14) touches the deck (12), the locking means is actuated thereby locking the sub-structure (10) together with the deck (12). Finally, the oil production platform is towed to its new destination for further extraction of oil.

Owner:NADARAJAH NAGENDRAN C +1

Submerged pipeline manifold for offloading mooring buoy and method of installation

In certain offshore locations, for example off the West Coast of Africa, FPSO facilities provide an offloading facility to receive and load produced crude oil onto shuttle tankers. In such arrangements FPSO facilities use spread moored tankers with flowlines suspended in the water column to an offloading buoy or buoys which are located 1,000 to 1,500 meters away from the FPSO. Typically steel pipe flowlines as used with intermediate floatation to provide a suitable configuration that will avoid detrimental loads being imposed resulting from relative motions of the FPSO and the offloading buoy. According to the invention, a Suspended Pipe Line End Manifold (SPLEM) is connected to the end of the flowline assembly for support during towout. The SPLEM is positioned near the buoy and then connected at the sea surface to the bottom of the buoy by flexible leads such as anchor chains. The SPLEM is then flooded by selectively flooding compartments to cause it to sink to an operational position below the buoy. Next, additional submarine hoses or flexible pipe are connected to complete the flowline to the buoy.

Owner:FMC TECH INC

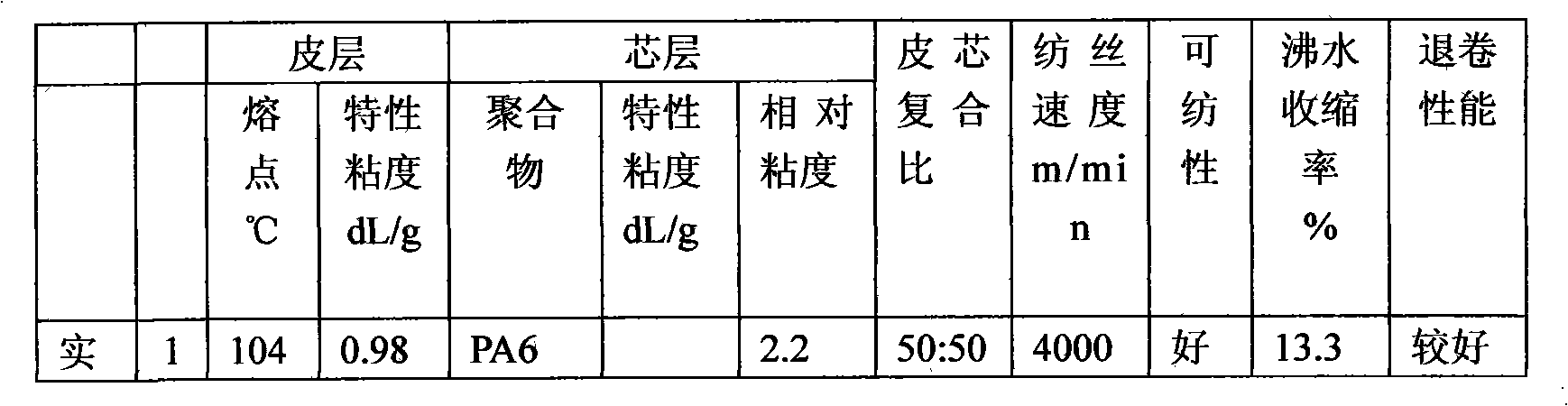

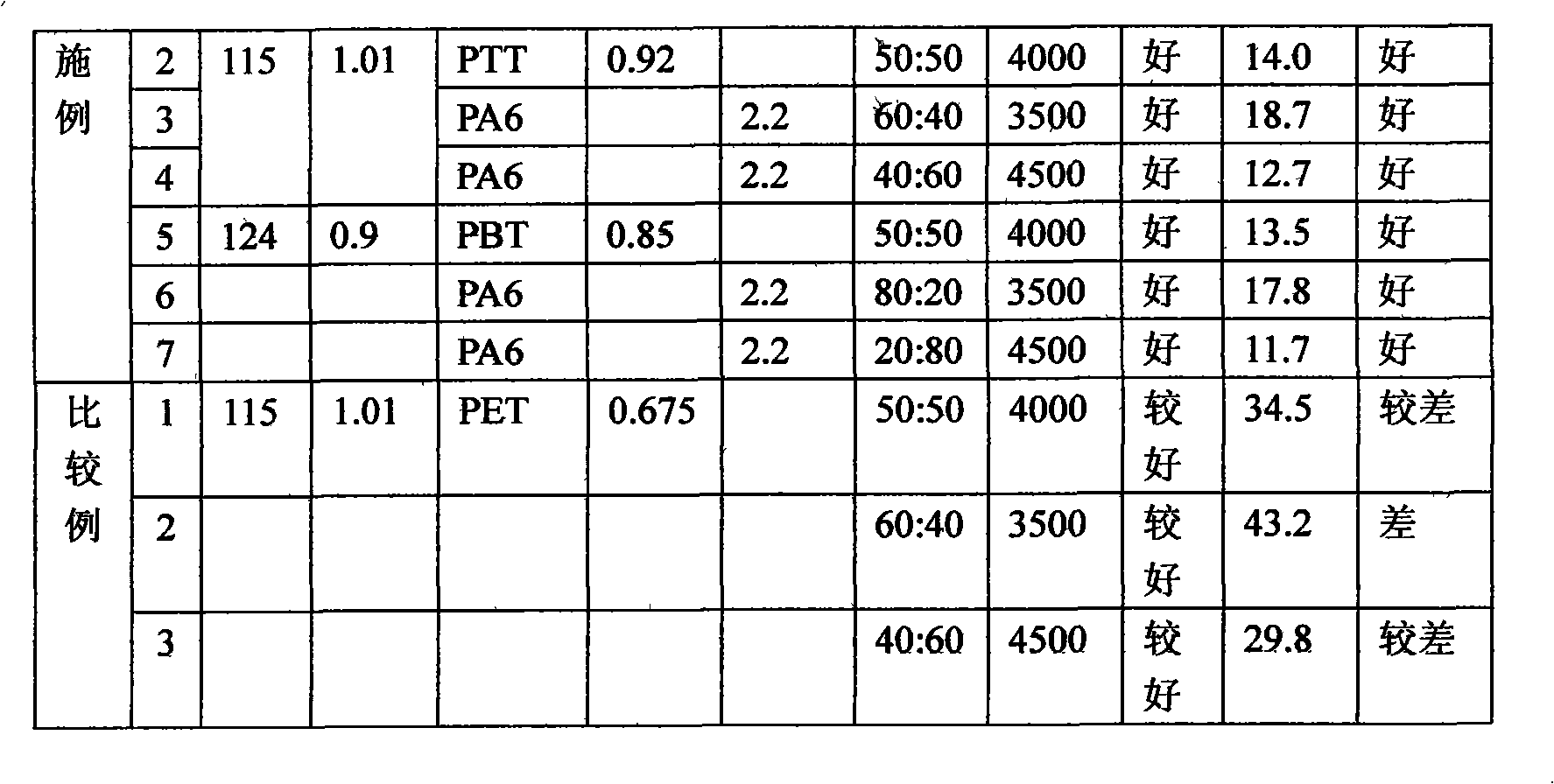

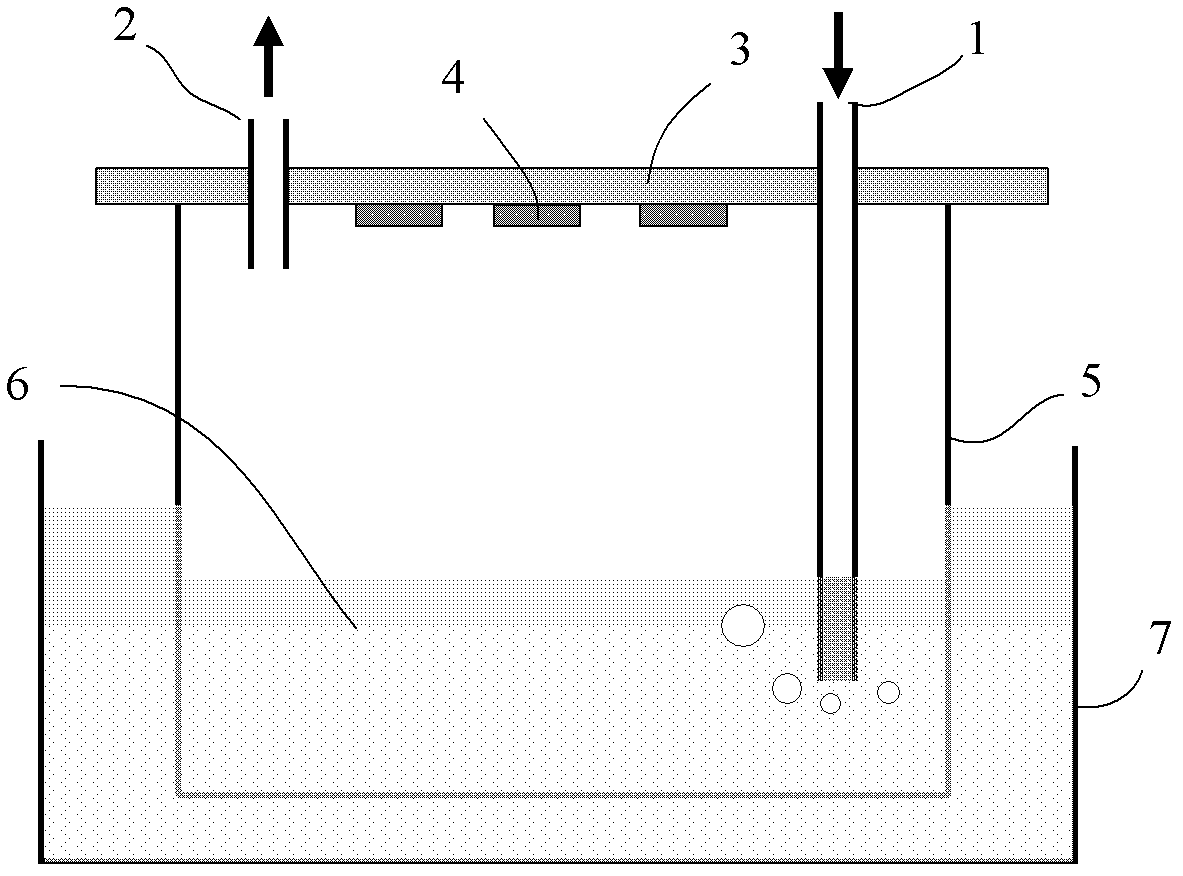

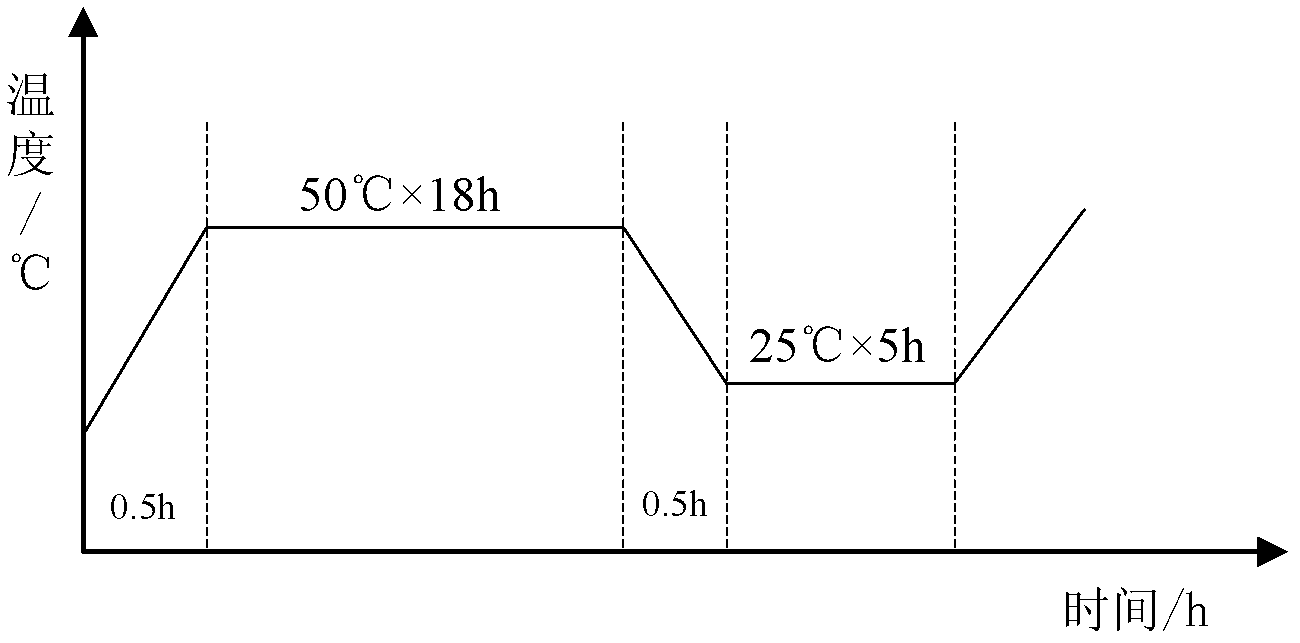

Method for preparing sheath core composite long fiber with low melting point

InactiveCN101619506AHigh boiling water shrinkageProcessing conditions are not easy to controlSpinning head liquid feederFilament/thread formingFiberState of art

The invention discloses a method for preparing a sheath core composite long fiber with a low melting point, which comprises the following steps: (1) drying components of a sheath layer and a core layer; (2) preparing a sheath core composite long fiber with a low melting point; respectively melting and extruding the two components by a screw rod extruder, after fusant is metered by a metering pump, leading the fusant to flow into an assembly of a composite spinning machine to carry out the composite spinning of the two components and ejecting a fiber from a fiber ejecting plate; cooling the fiber by blowing, oiling the fiber by an oil tanker, controlling the tension of the fiber by a fiber guide disk and coiling the fiber to obtain the sheath core composite long fiber with the low melting point. Aiming at the defects in the prior art, the invention provides a method for preparing the sheath core composite long fiber with a low melting point, which has low sheath layer melting point, low and stable fiber boiling water shrinking rate and favorable dyeing performance.

Owner:ZHEJIANG SCI-TECH UNIV

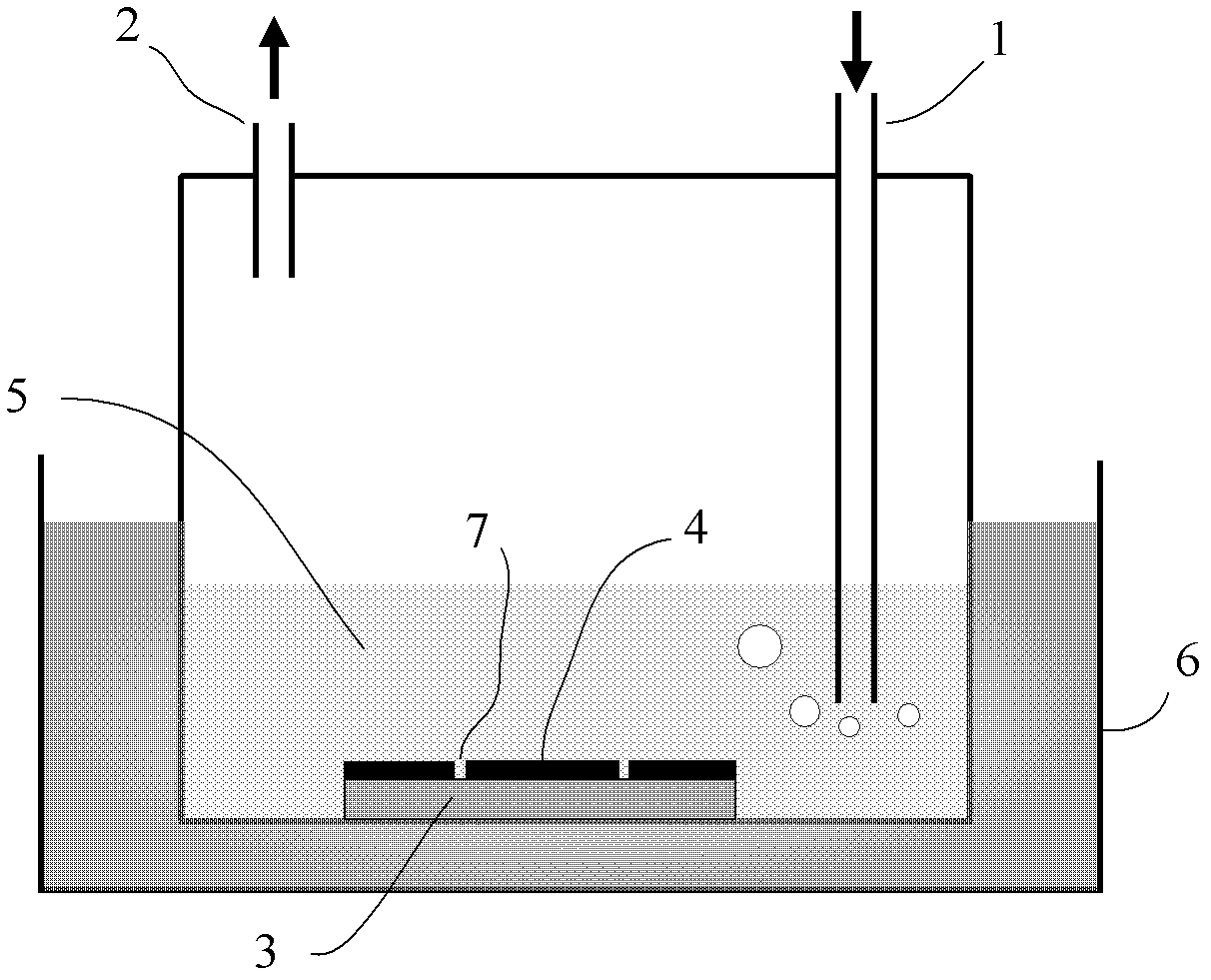

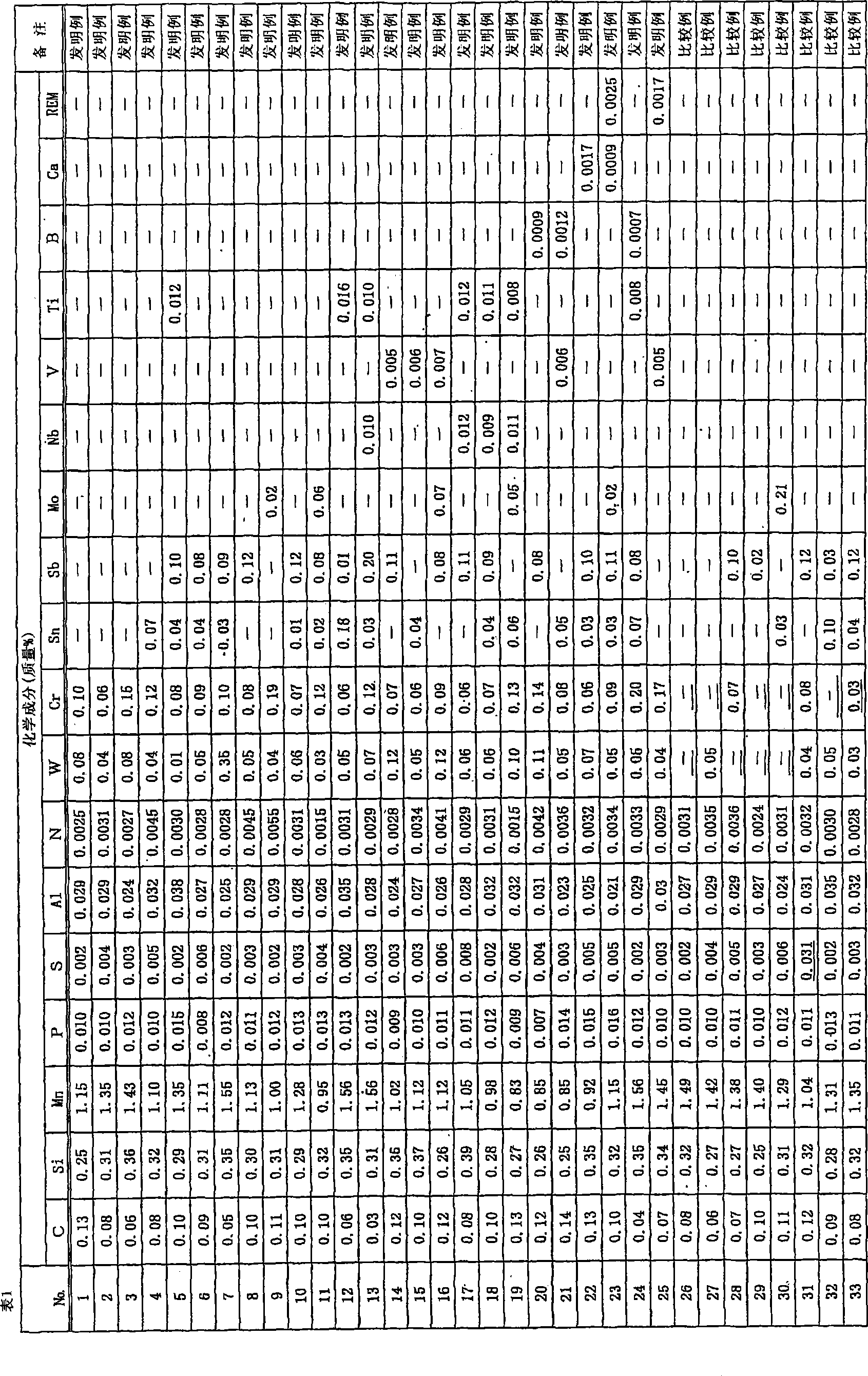

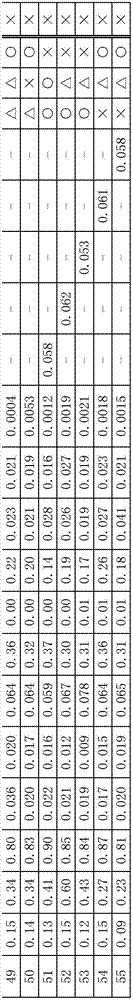

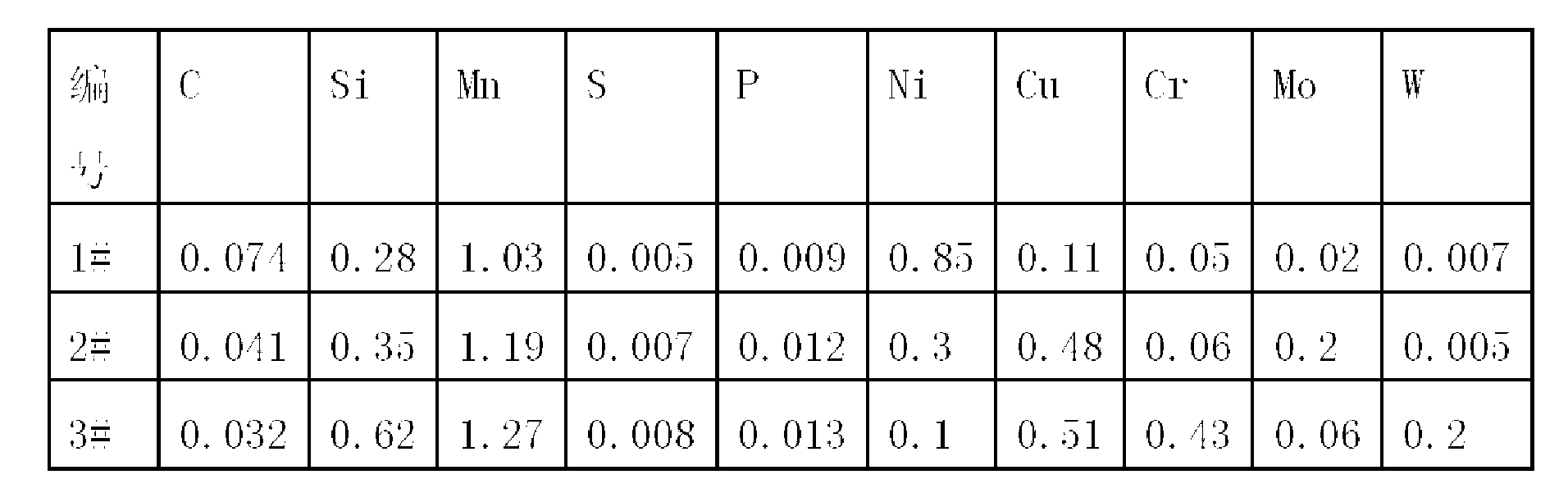

Steel for upper deck of cargo oil tank of tanker

The invention provides steel for the upper deck of a cargo oil tank of a tanker, which belongs to the technical field of ship plate steel. The steel comprises the following chemical components expressed in mass percentage: C 0.01 to 0.3%, Si 0.02 to 2.0%, Mn 0.05 to 2.0%, S <= 0.01%, P<= 0.05%, Ni 0.05 to 2.0%, Cu 0.05 to 2.0%, Cr 0.005 to 1.0%, Zr 0.005 to 0.2% and Hf 0.005 to 0.2%, with the balance being Fe. As needed, the steel also comprises one or more selected from the group consisting of 0.0005 to 0.2% of Ca, 0.0005 to 0.2% of Mg, 0.0005 to 0.2% of Sr and 0.0005 to 0.2% of Ba, and / or one or more selected from the group consisting of 0.0005 to 0.3% of Sn, 0.0005 to 0.3% of Sb and 0.0005 to 0.3% of Te, and / or one or more selected from the group consisting of 0. 0005 to 0.3% of W, 0.0005 to 0.3% of Mo, 0.0005 to 0.3% of Co and 0.0005 to 0.3% of REM. The steel has the advantages of excellent general corrosion resistance, greatly reduced maintenance cost and effectively improved reliability of the upper deck of the cargo oil tank in a service process.

Owner:CENT IRON & STEEL RES INST

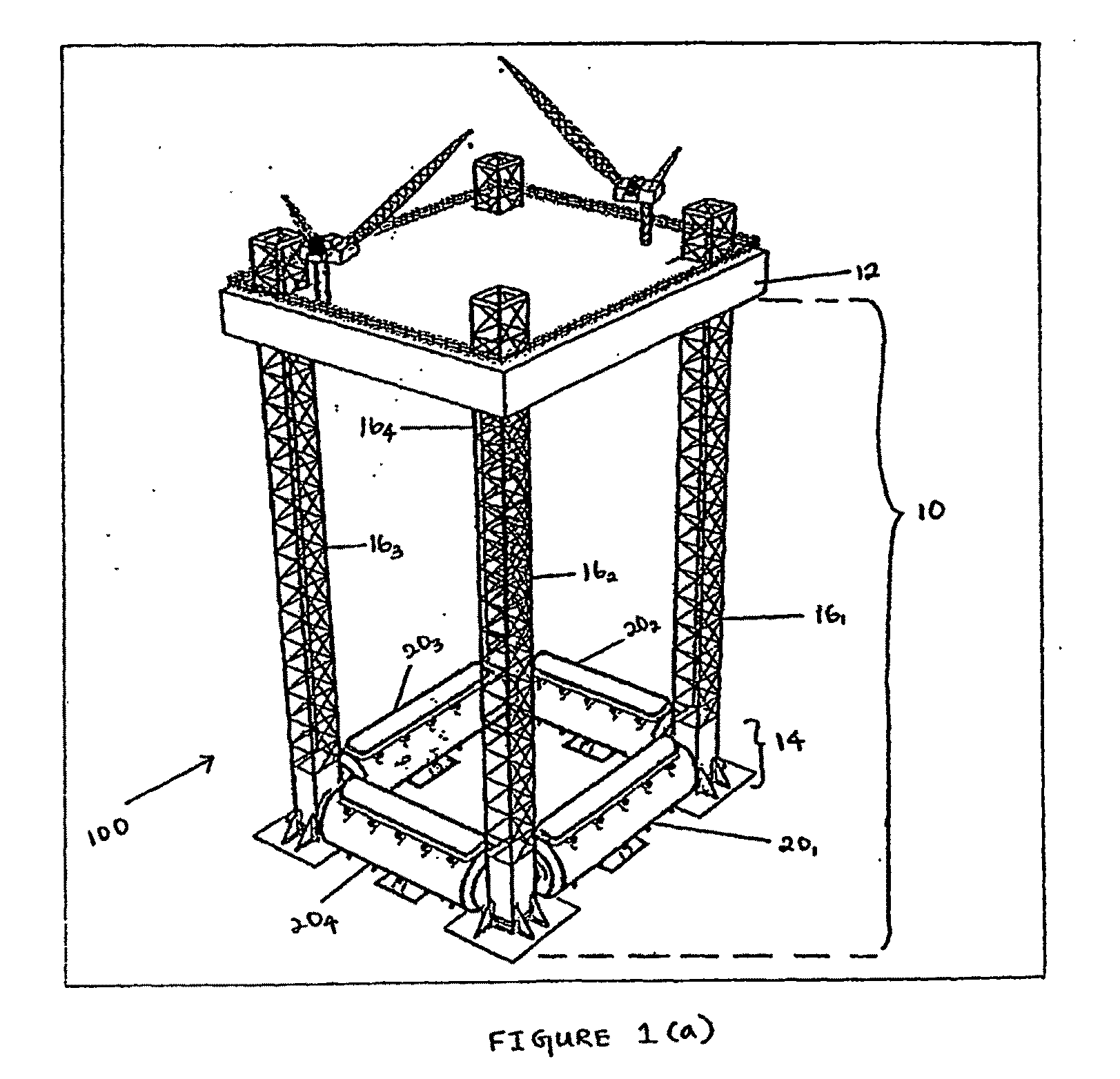

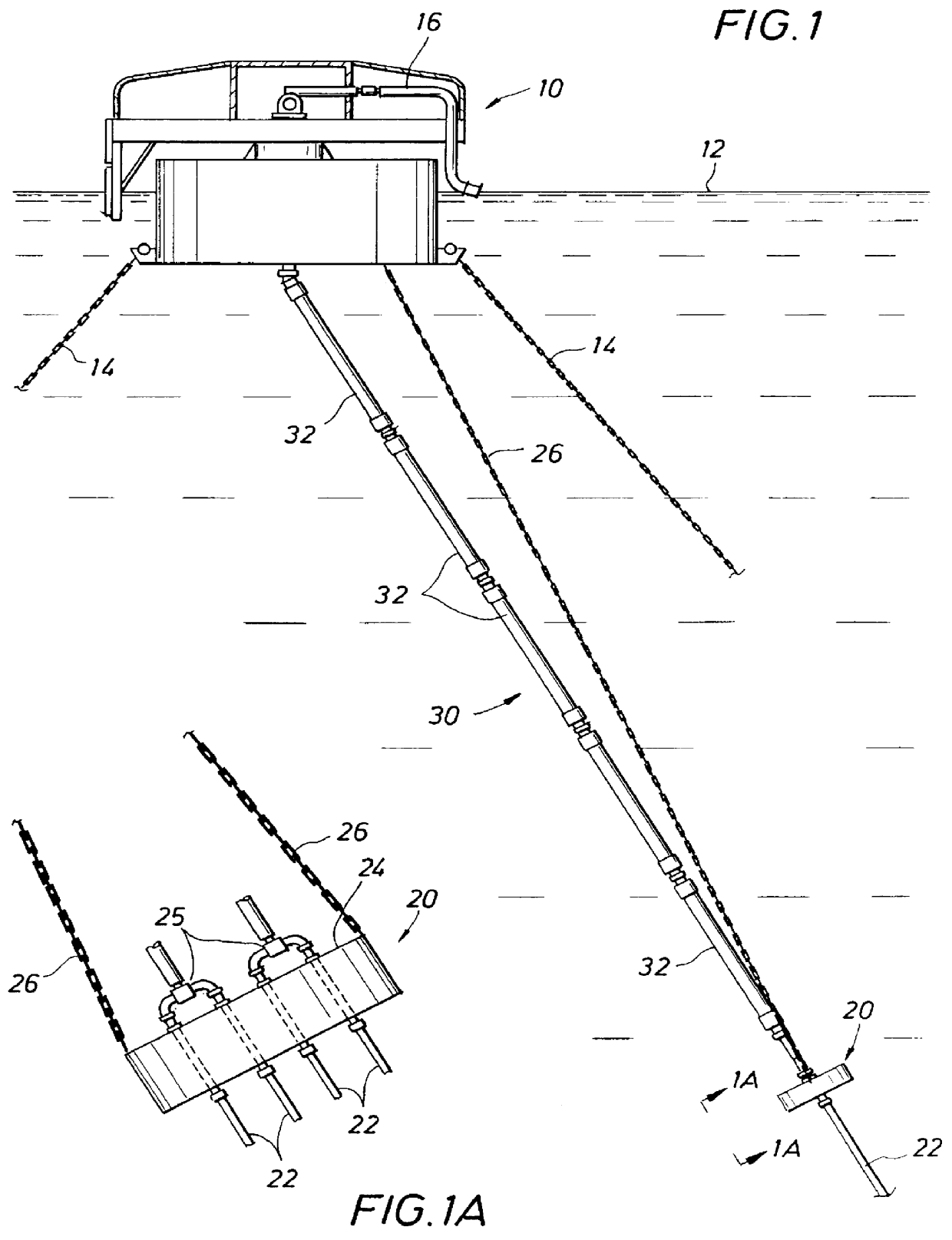

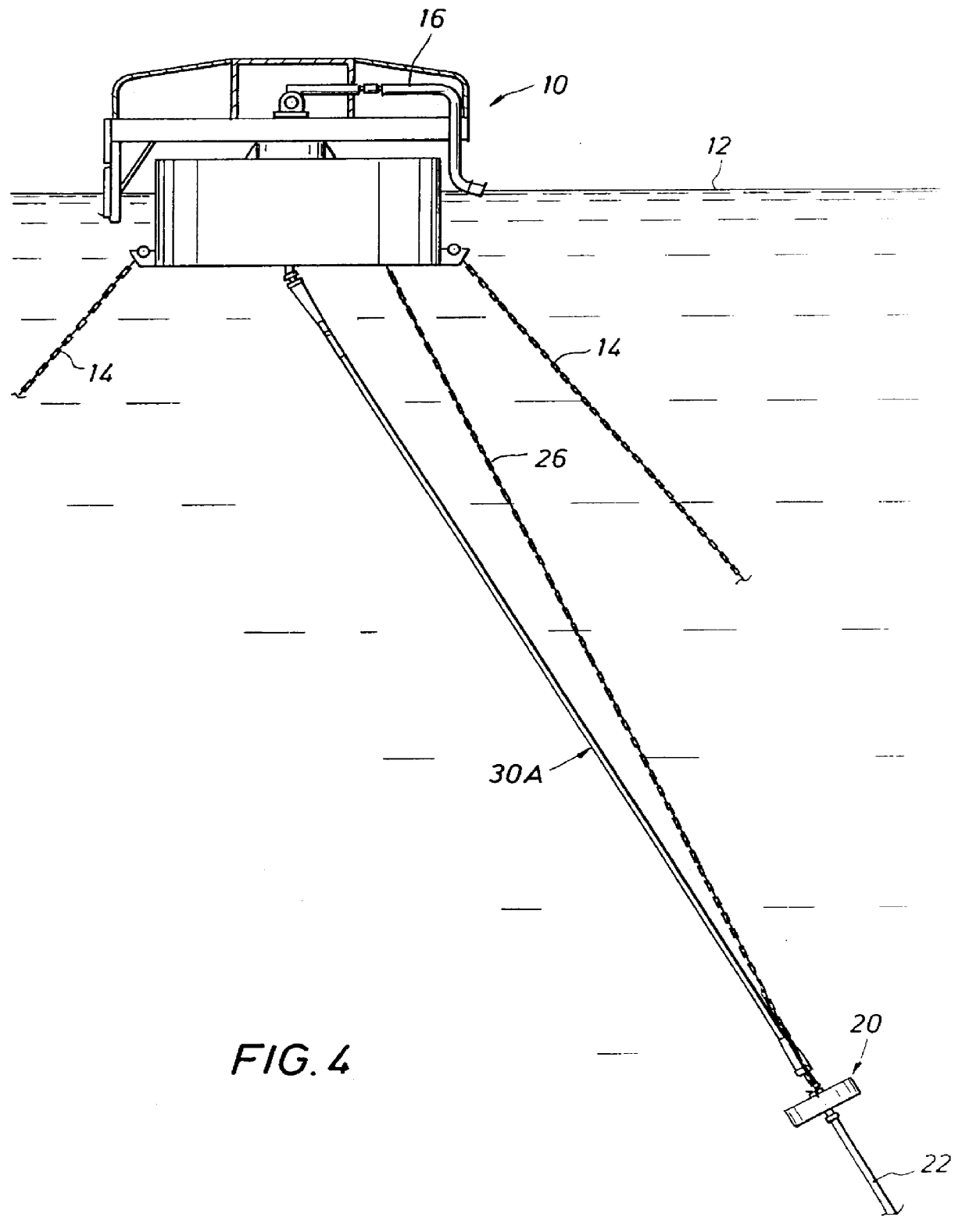

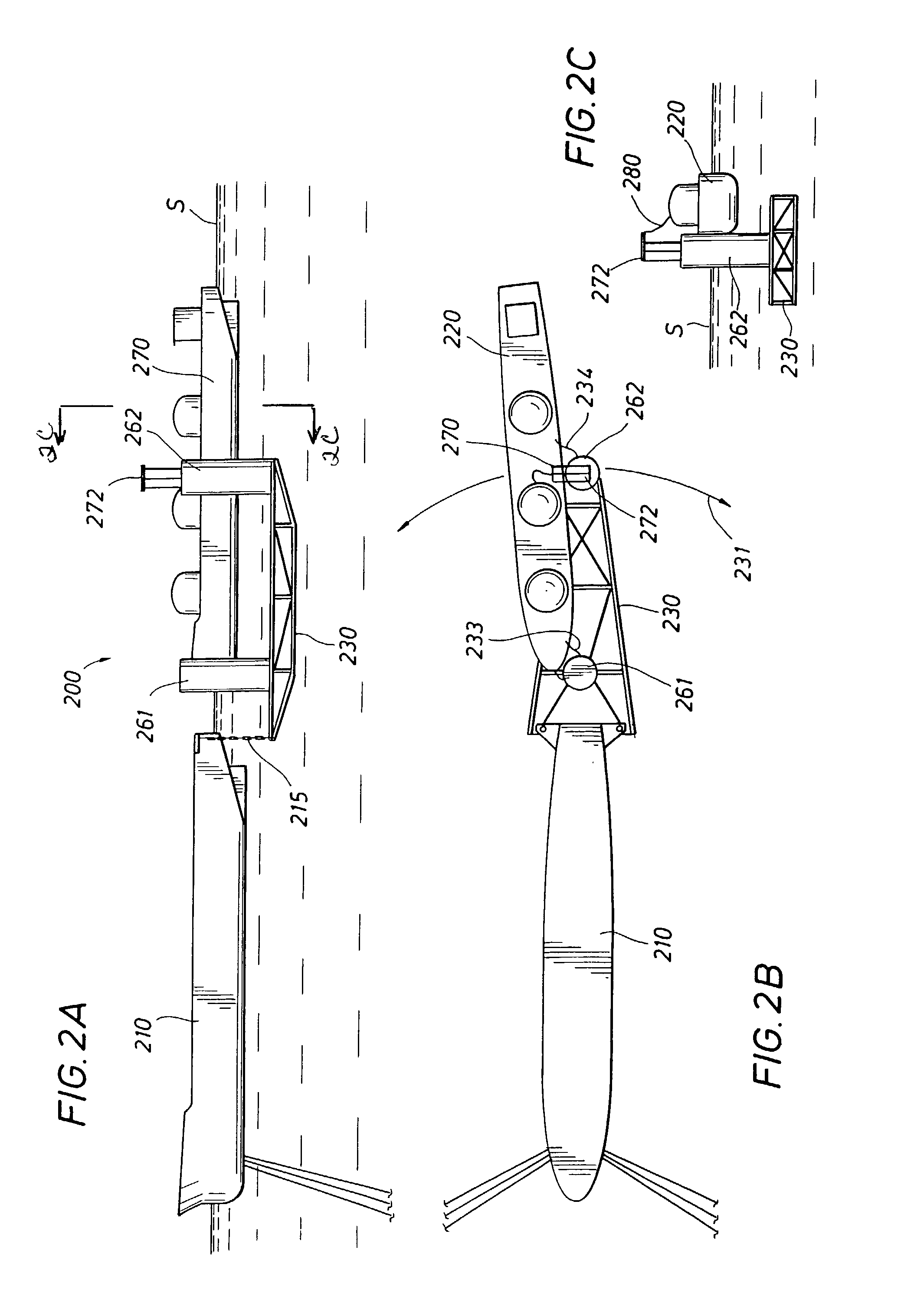

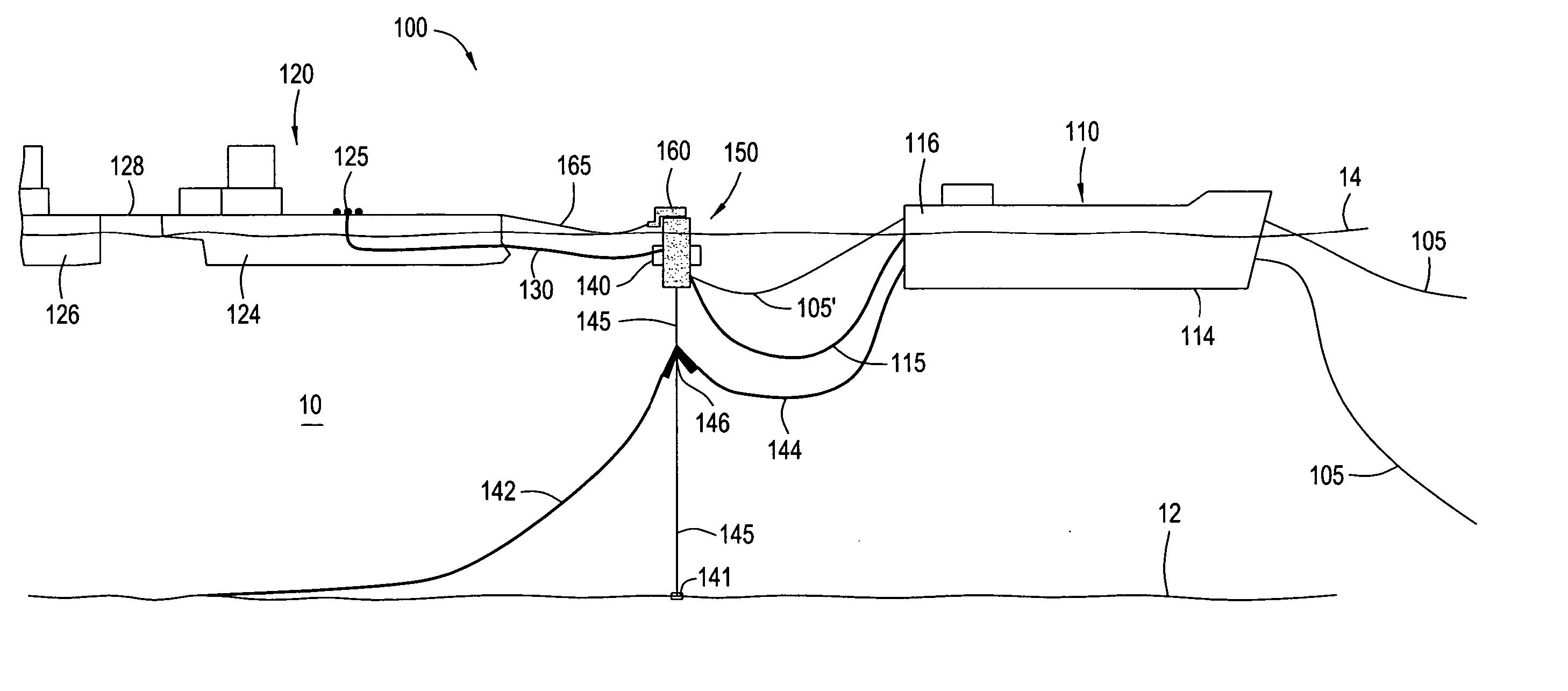

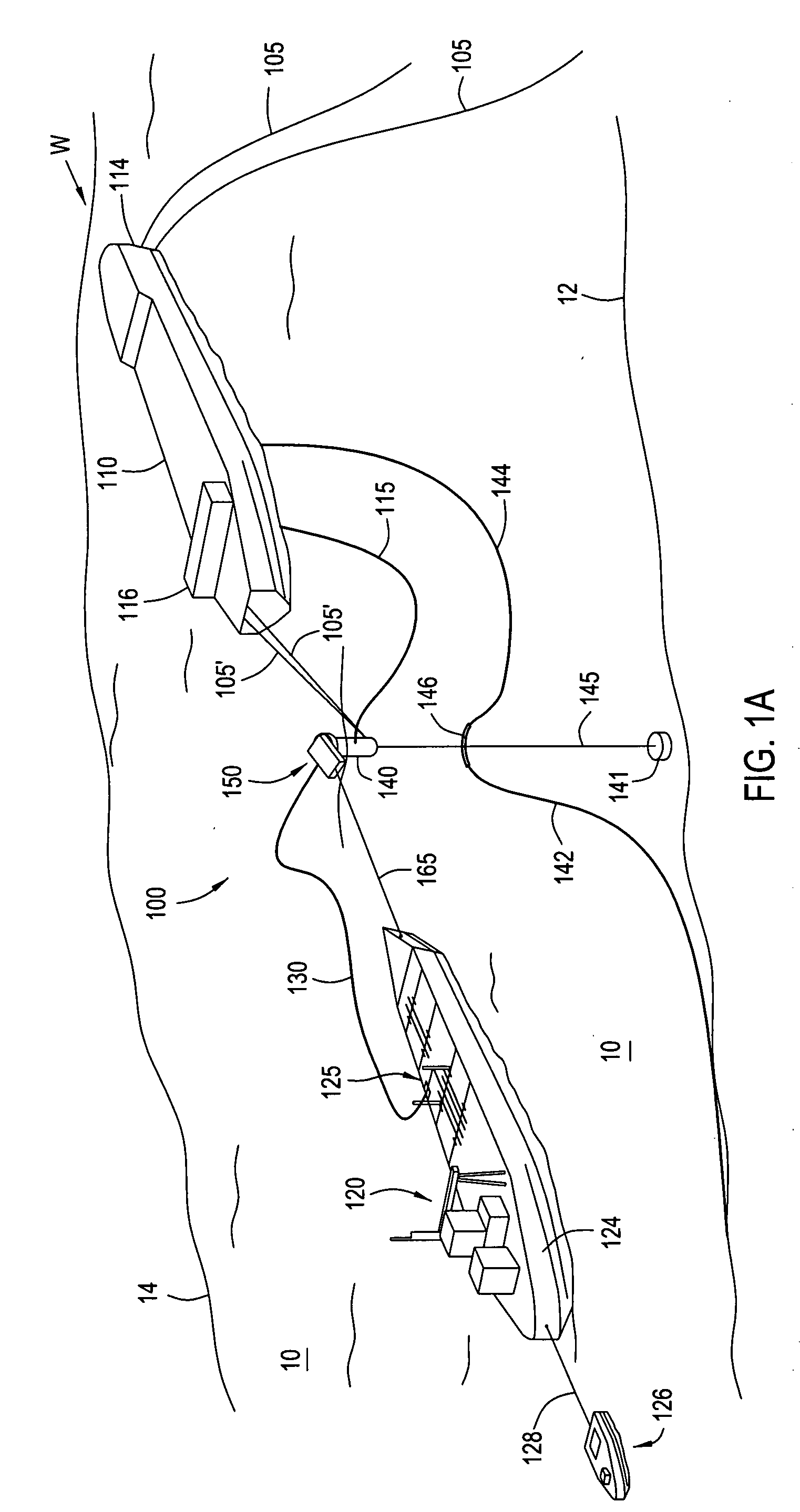

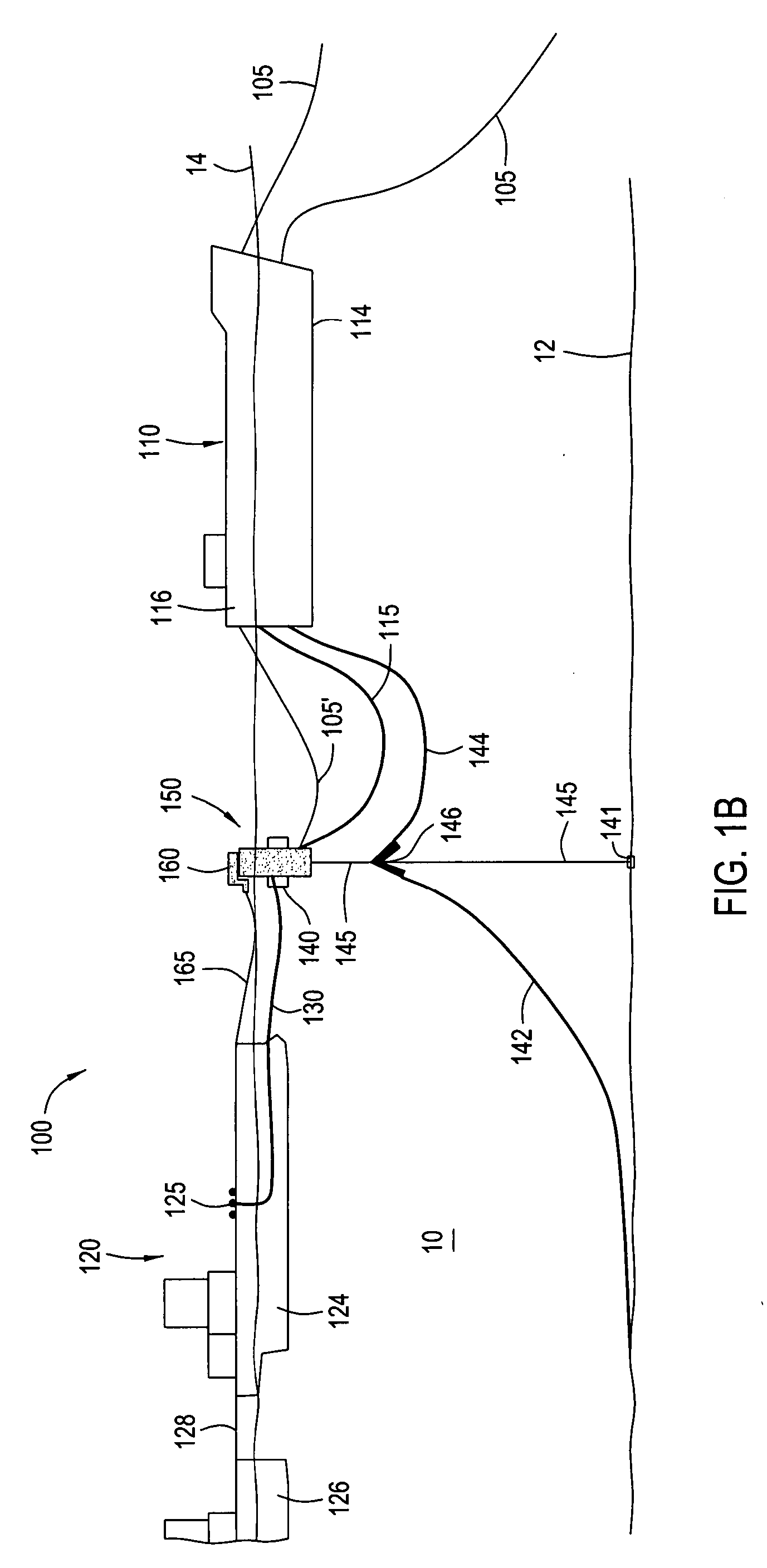

Offloading arrangements for speard moored FPSOs

InactiveUS20030061980A1Avoid contactRapid disconnectionCargo handling apparatusPassenger handling apparatusMooring systemFishery

A mooring arrangement between a floating storage body spread moored in deep water and a shuttle tanker, the arrangement including a single point buoyant member that is adapted for mooring a shuttle tanker in offloading position relative to a floating production, storage and offloading vessel (FPSO) with a link between the floating storage body and the single point buoyant member. One embodiment (100) of the invention employs a submerged yoke (30), having one end (31) rotatably coupled to a FPSO (10) and a second end (32), supported by a buoy. A mooring hawser (28) extends from the buoy to the shuttle tanker and product hoses connect the shuttle tanker with the FPSO and extend along the submerged yoke. In another embodiment, the mooring buoy is stationed by a hold-back mooring system (303-304) and the FPSO or the tanker or both is provided with traction devices (308) to move the tanker into loading position with respect to the FPSO. Other embodiments of the invention establish mooring of a shuttle tanker so that it can weathervane 360 degrees during offloading activity. In another embodiment, the mooring buoy (600) is provided with a dynamic positioning system (614) for controlling shuttle tanker positioning with respect to conditions of the environment or for moving the tanker to a desired position during loading.

Owner:SOFEC

Oil-containing sludge pyrolysis and its resource treatment method

InactiveCN102874997ARealize resourcesEasy to separateSludge treatment by pyrolysisByproduct vaporizationActivated sludgeSorbent

The invention relates to an oil-containing sludge pyrolysis and its resource treatment method, and belongs to the field of environmental protection and energy saving technologies. The oil-containing sludge pyrolysis and its resource treatment method comprises the following steps of: adding a gangue powder and Fe3O4 into an oil-containing sludge; respectively carrying out mixing, granulation, preheated drying (using a pyrolysis gas as a heat source) and pyrolysis on the mixture; cooling the pyrolysis gas discharged out from a pre-drier by the use of circulating water such that steam and hydrocarbons in the pyrolysis gas are condensed respectively in the forms of oil-containing sewage and liquid hydrocarbon; allowing the oil-containing sewage to enter a sewage treatment plant so as to reach the standard, recovering and utilizing liquid hydrocarbon, and activating sludge to prepare a magnetic carbonaceous adsorbent. According to the invention, resource of the oil-containing sludge can be completely realized, and the carbonaceous adsorbent with large pore volume and specific surface area can be prepared. The invention is especially suitable for pyrolysis treatment of oil-containing sludge (such as oil tank bottom mud, oil-field oil extraction sludge, tank car or oil tanker bottom mud and the like) with high oil content.

Owner:CHINA PETROLEUM & CHEM CORP +1

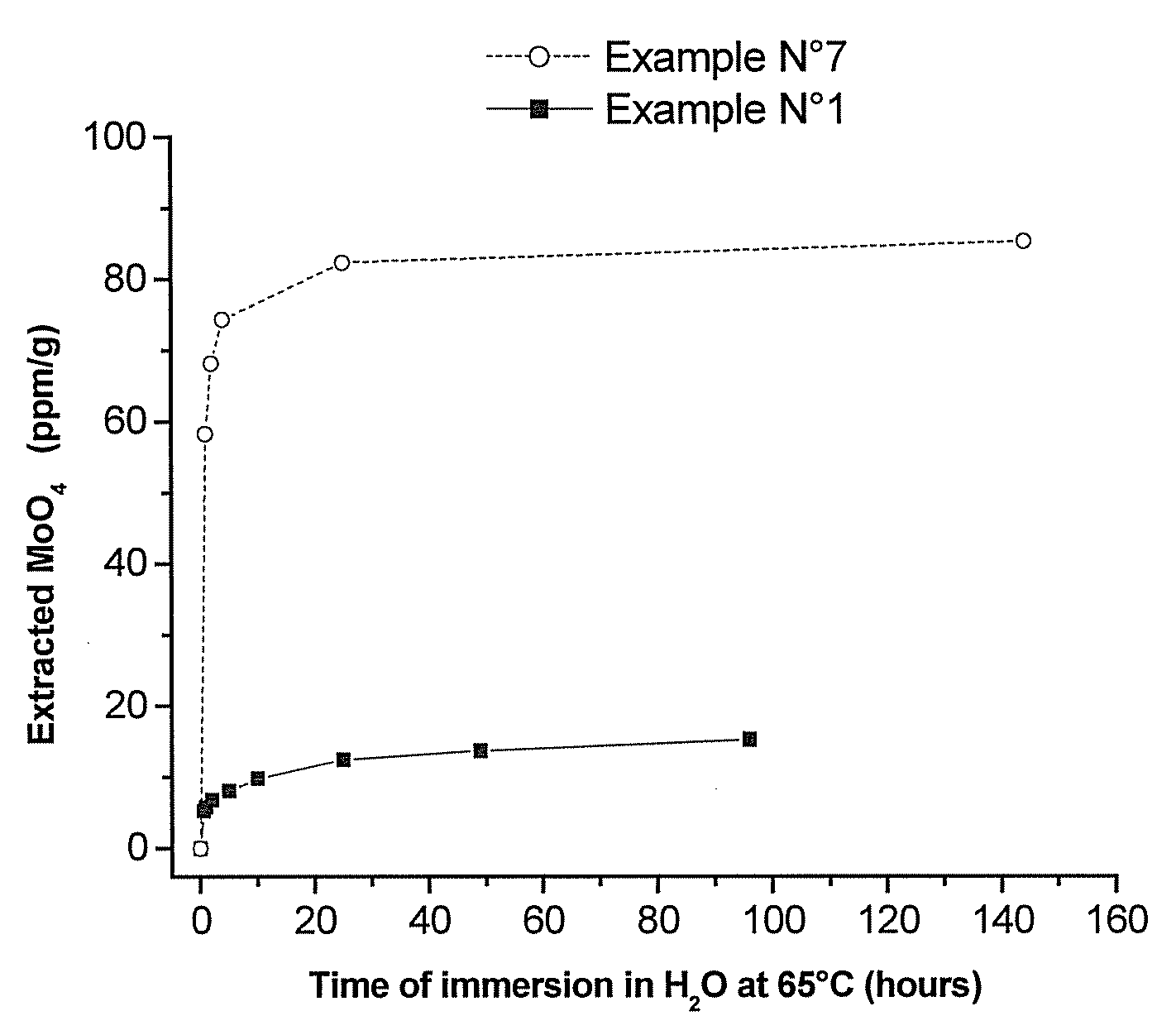

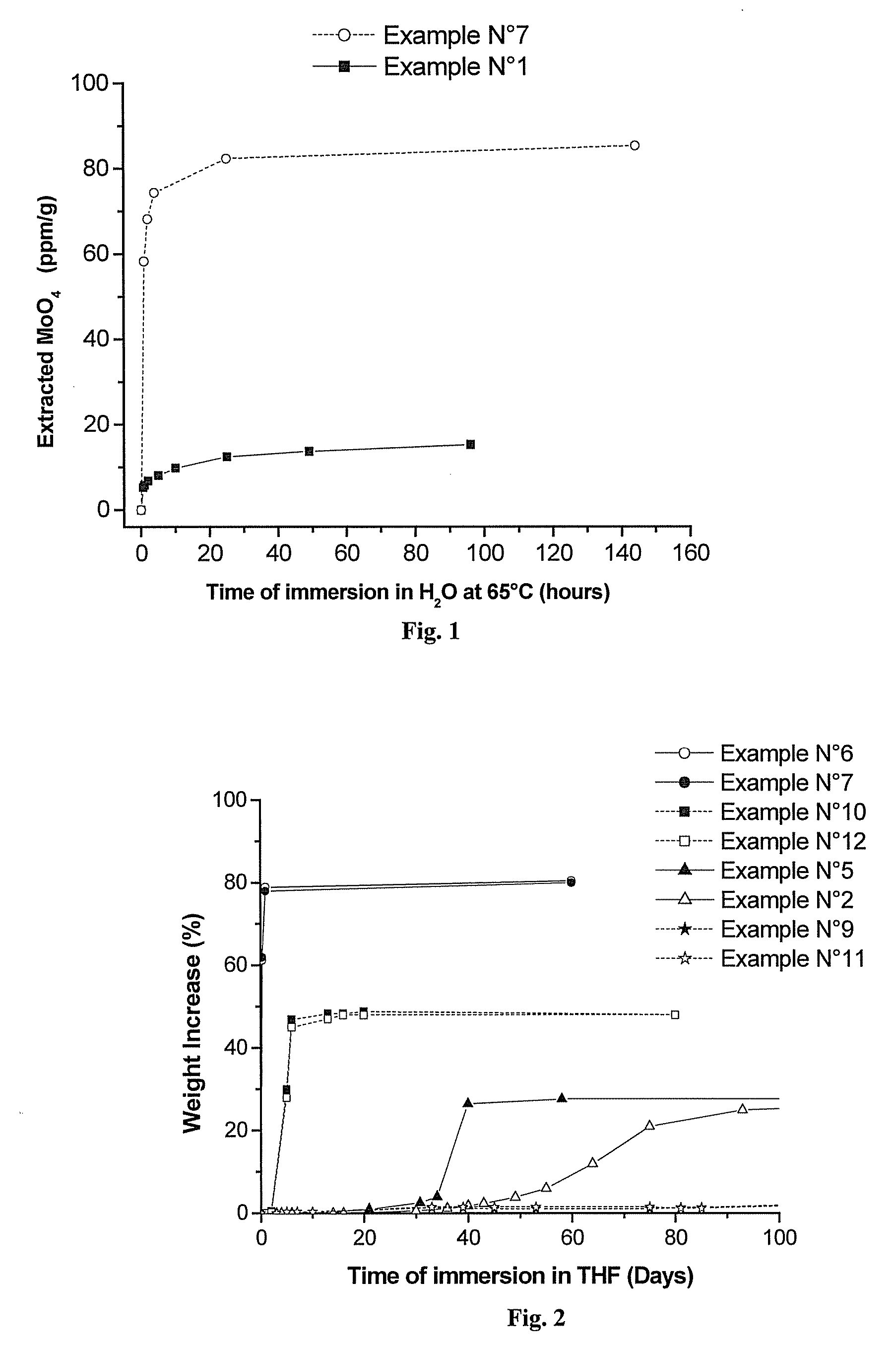

Polymeric Compositions With Modified Siloxane Networks, Corresponding Production And Uses Thereof

InactiveUS20080017070A1Good chemical resistanceHigh hardnessGroup 4/14 element organic compoundsCoatingsEpoxyPolymer science

The present invention describes a composition of thermosetting resins, in particular epoxy resins, combined with modified polysiloxane networks to form a continuos interpenetrated network characterized by the presence of metals such as boron, molybdenum and tungsten, linked to Si via an oxygen atom. These compositions, can be used to make adhesives, composites and coatings that exhibit excellent hardness, chemical resistance, fast curing, damp tolerance and are self priming with slow release of a corrosion inhibitor or of functional additives. The material of the present invention can be used in particular as a coating, in the marine field, for yachts and for large metal vessels, such as oil tankers and more in particular for cargo or ballast tanks and on hulls. It can be used for the maintenance and protection of trains, automotive vehicles and in electric applications such as for the production of dielectric shields and in those fields where high performance is needed.

Owner:PREZZI LUCA

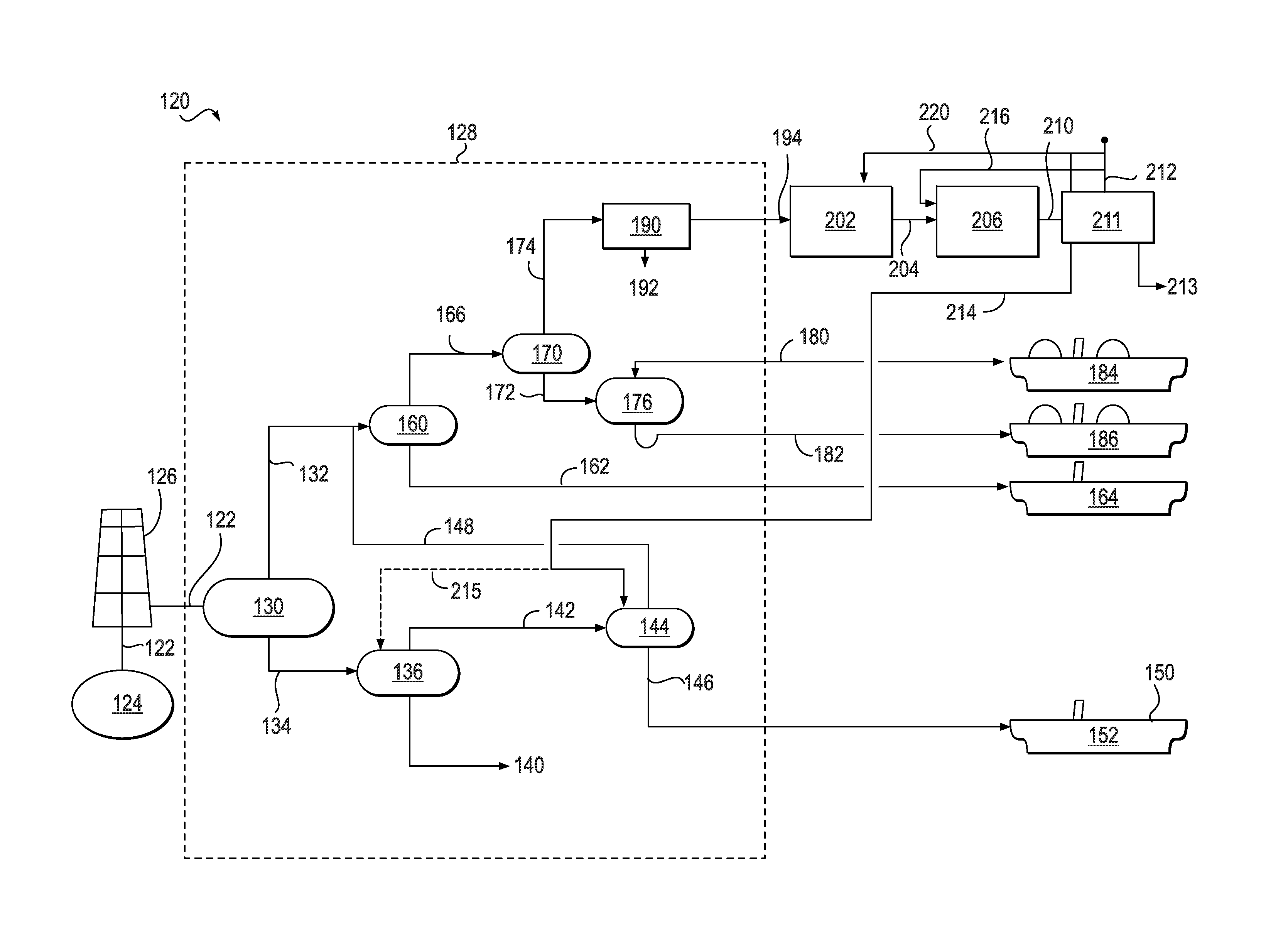

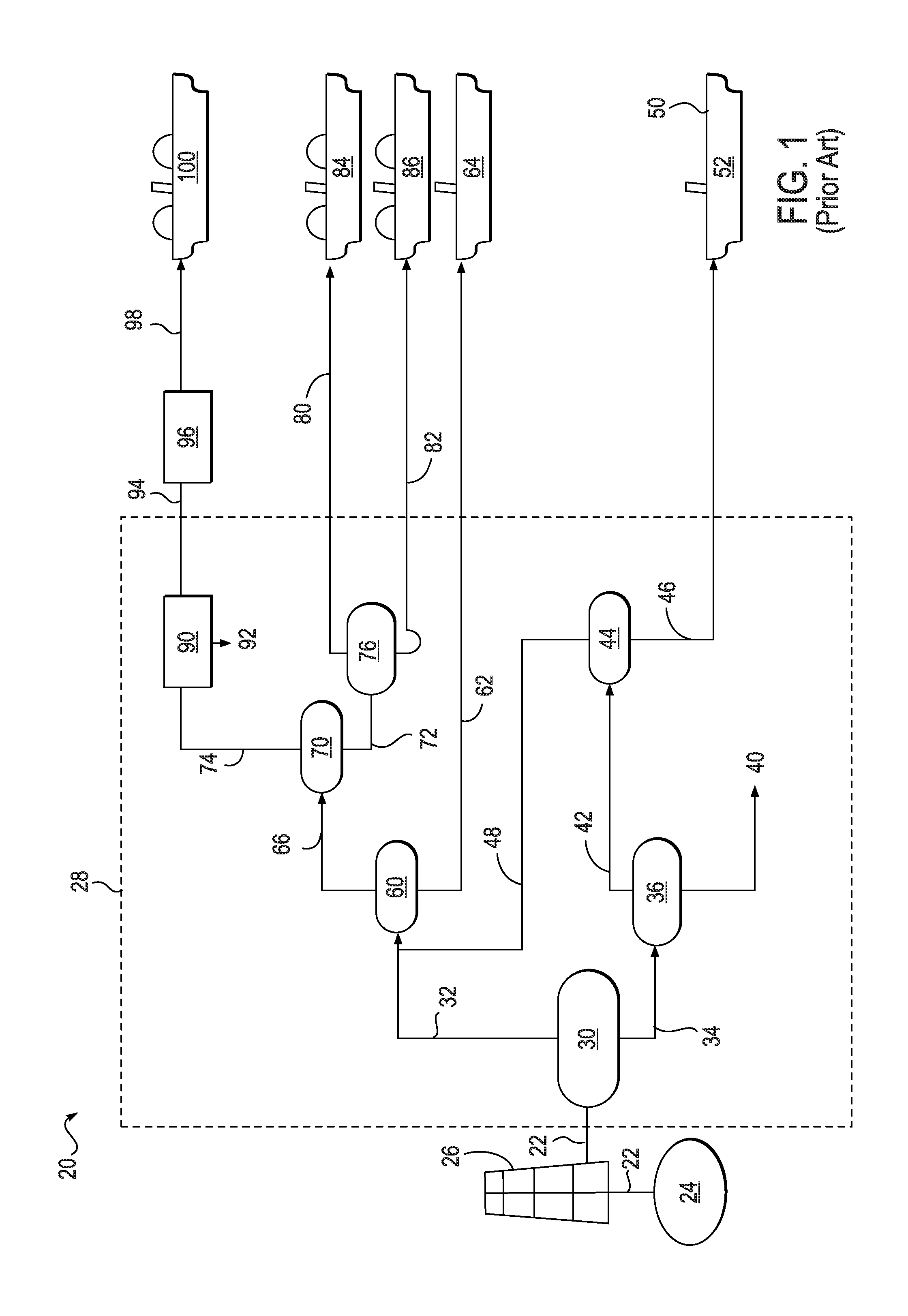

Process and system for blending synthetic and natural crude oils derived from offshore produced fluids

ActiveUS20110240288A1Refining to change hydrocarbon structural skeletonLiquid hydrocarbon mixture recoveryPtru catalystLiquefied petroleum gas

A process and system are described for the processing of gas associated with crude oil production, i.e. associated gas. A separation complex is used to separate produced fluids produced from a hydrocarbon reservoir into crude oil, liquefied petroleum gas, water, and natural gas. At least a portion of the natural gas is converted into synthesis gas in a synthesis gas generator. A combination of a synthesis gas conversion catalysts and hydroconversion catalysts are used in a synthesis gas reactor to convert the synthesis gas into a liquid effluent stream containing liquefied petroleum gas and a synthetic crude oil. The liquefied petroleum gas and synthetic crude oil from the synthesis gas reactor is sent to the separation complex. Liquefied petroleum gas is separated both from the synthetic crude oil and a natural crude oil obtained from the produced fluids. The system and process permits synthetic crude oil to be blended with the natural crude oil producing a blended stabilized crude oil having 2 wt % or more of the synthetic crude oil and with a pour point of 60° C. or less. Use of a common facility for separation operations on the natural crude oil and synthetic crude oil thus reduces capital costs and allows converted associated gases to be shipped with the natural crude oil on a conventional crude oil tanker.

Owner:CHEVROU USA INC

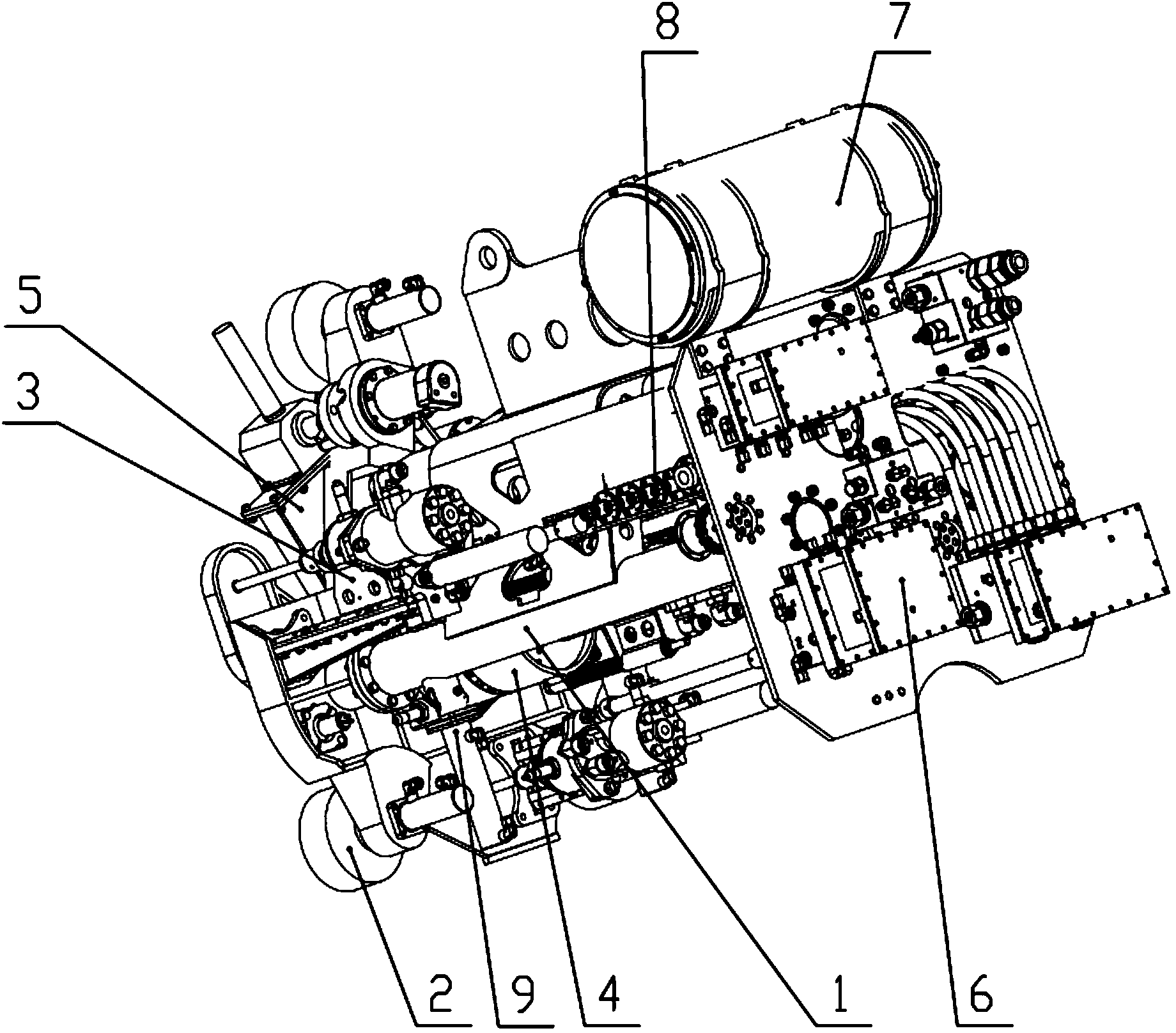

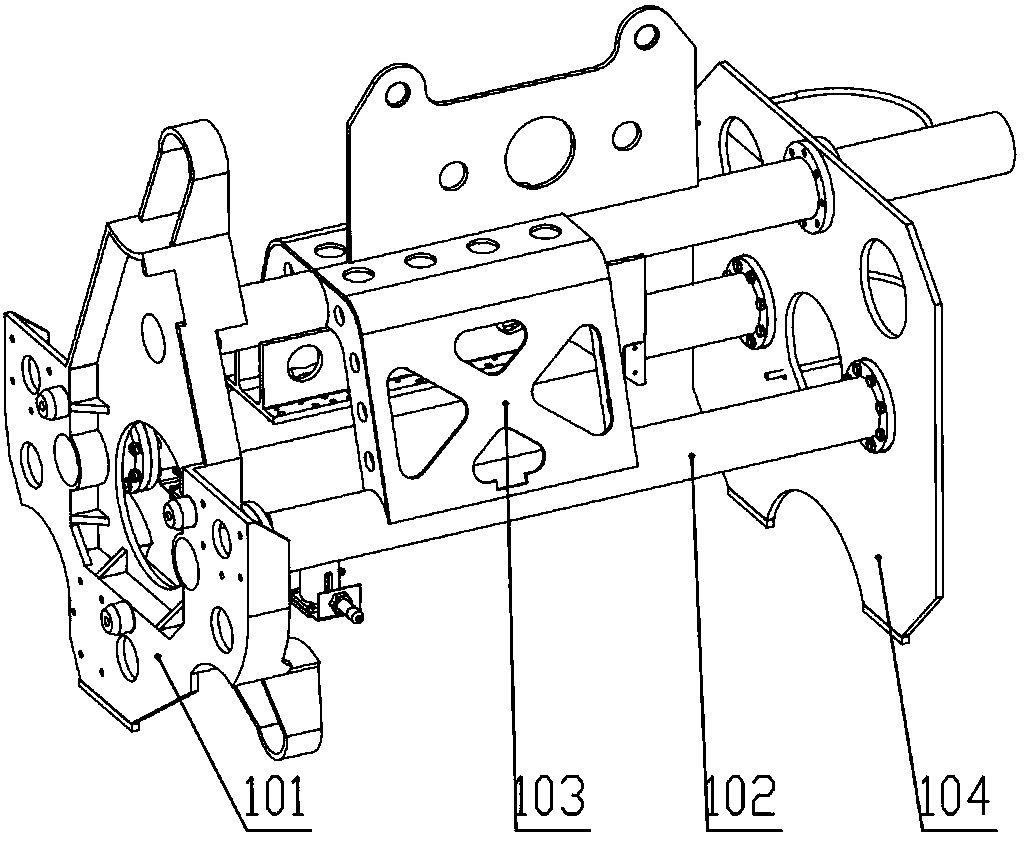

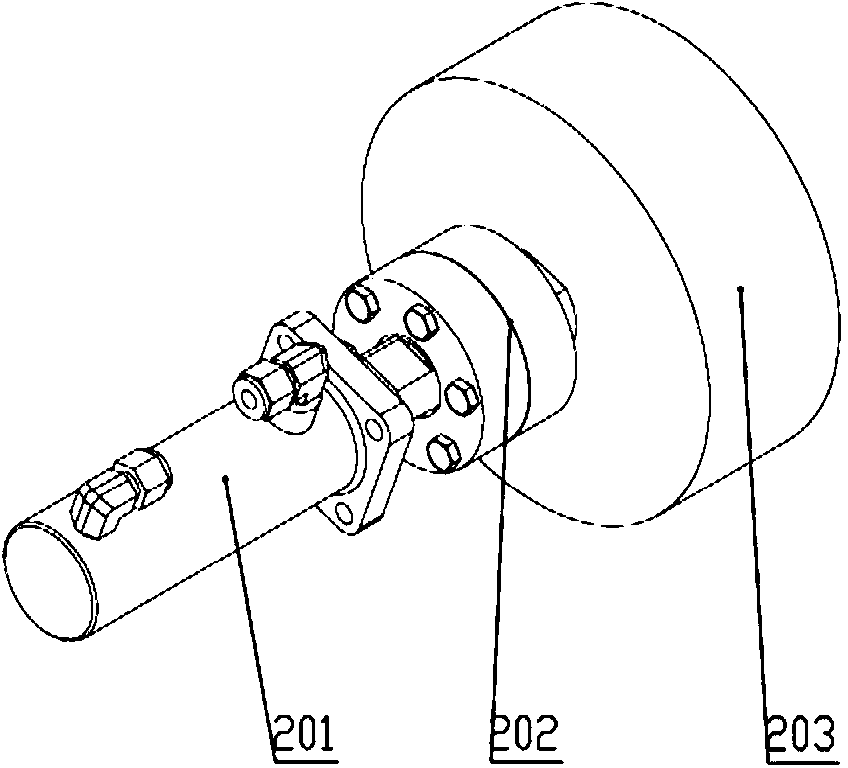

Miniature salvage drilling device and method coordinated with ROV (Remote Operated Vehicle) for marine oil tanker

ActiveCN104354843AReduce operational riskSimple homeworkVessel salvagingBoring/drilling componentsSeawaterOil tanker

The invention belongs to the technical field of marine ships, and discloses miniature salvage drilling device and method coordinated with ROV for a marine oil tanker. The device comprises a main frame, a pre-positioning device, an accurate positioning device, a hollow drilling rig, an oil pumping valve, a hydraulic control valve unit, an electronic control cabin and an assorted sensor, wherein the oil pumping valve is connected with the main frame through a clamping mechanism of the oil pumping valve; the pre-positioning device is arranged on the periphery of a front base plate of the main frame; the accurate positioning device is arranged on the front base plate of the main frame; the hollow drilling rig is arranged in the center of the main frame; the hydraulic control valve unit, the electronic control cabin and the assorted sensor are arranged at the rear part of the main frame. The miniature salvage drilling device disclosed by the invention is small in volume and light in weight, can be conveniently loaded by the ROV to carry out operations under seawater without the complicated hoisting operation, and can further be attached to a ship wreck in any random posture, so that the device is very suitable for the situation that the posture of the ship wreck is undefined in the seabed.

Owner:SHANGHAI JIAO TONG UNIV

Discharge of liquified natural gas at offshore mooring facilities

InactiveUS20070128957A1Efficiently and inexpensively heatsCargo handling apparatusPassenger handling apparatusProcess engineeringShore

A method and arrangement for transferring liquified natural gas from a seagoing tanker to an on-shore facility including boosting the pressure of the liquefied natural gas to above the critical pressure and passing the liquefied natural gas through a heat exchanger immersed into the sea thereby heating the gas to near ambient temperature.

Owner:KORSGAARD JENS

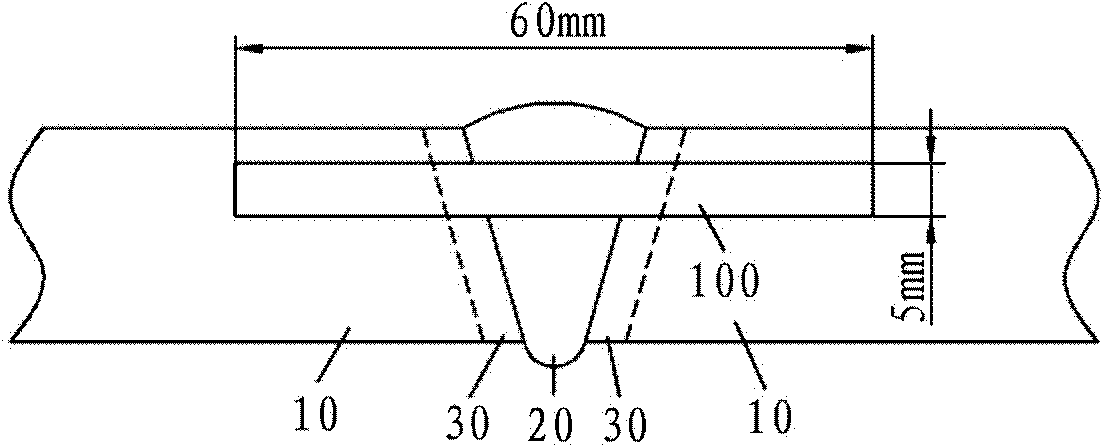

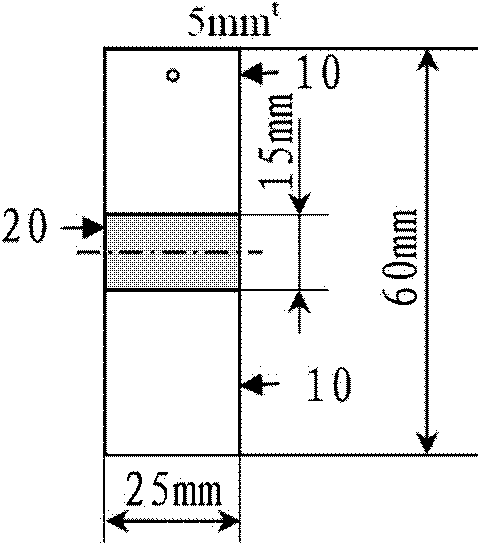

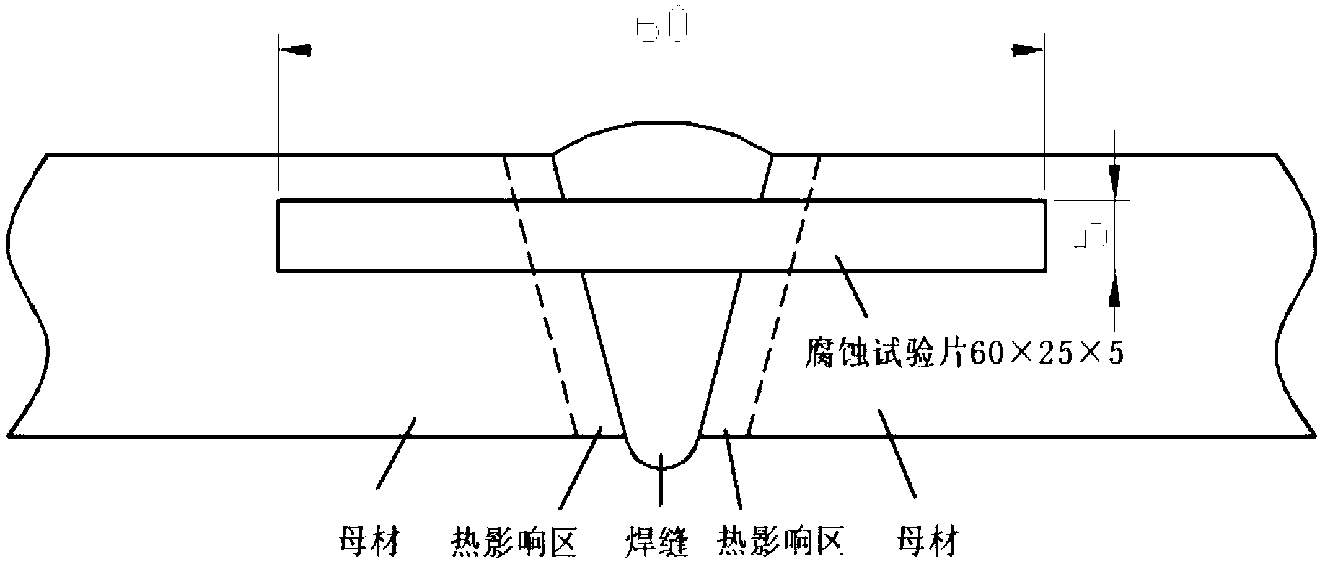

Gas shield welding wire for oil cargo tank of oil tanker

The invention discloses a gas shield welding wire for an oil cargo tank of an oil tanker, which comprises the following components in percent by mass: 0.01-0.15 percent of C, 0.1-1 percent of Si, 1-2 percent of Mn, not more than 0.015 percent of P, not more than 0.012 percent of S, 0.1-1 percent of Ni, 0.1-1 percent of Cu, more than 0 and not more than 0.1 percent of Cr, 0.01-0.25 percent of Ti, more than 0 and not more than 0.1 percent of Al and the balance of iron and other unavoidable impurities. The gas shield welding wire for the oil cargo tank of the oil tanker has excellent uniform corrosion resistance and corrosive pitting resistance even in a crude oil corroding environment; and a weld joint has better mechanical property.

Owner:CENT IRON & STEEL RES INST

Combined Riser, Offloading and Mooring System

ActiveUS20080096448A1Save on installation costsReduce installation costsCargo handling apparatusPassenger handling apparatusMooring systemLine tubing

A combined riser, offloading and mooring system is provided for the offloading of hydrocarbons from a floating production vessel (FPV), onto a tanker. The system preferably includes an offloading buoy tethered to the mudline by at least one mooring line. The offloading buoy and the mooring line can be part of an offloading buoy system for supporting a production riser and fluid jumper lines. Additionally, the offloading buoy system can support an offloading jumper line from the FPV to a fluid connector on the offloading buoy system through which hydrocarbon fluid is loaded via an offloading hose onto a tanker. The combined riser, offloading and mooring system also preferably includes at least one set of FPV mooring lines for securing the floating production vessel to the offloading buoy system. The system further preferably includes a hawser line for connecting the tanker to the offloading buoy system. In this manner, the number of mooring lines for the floating production vessel may be reduced.

Owner:EXXONMOBIL UPSTREAM RES CO

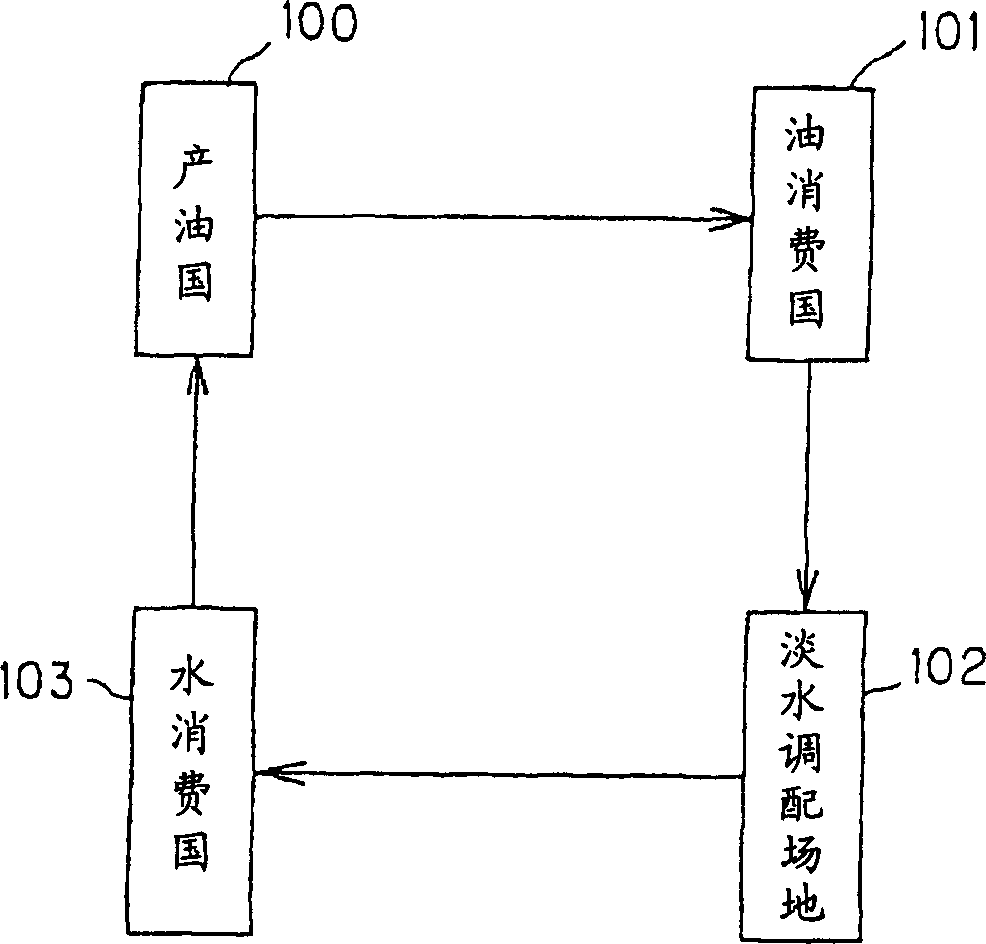

Methods and systems for producing, trading, and transporting water

InactiveUS20140014188A1Reduce riskQuality improvementData processing applicationsWaterborne vesselsTransport systemSalt water

Methods and systems for producing, trading, transporting, conveying, and storing non-salt water are disclosed. More specifically, methods and systems for producing, trading, transporting, and storing large quantities of water having specific characteristics are provided. Various transport systems are disclosed, including devices and methods for utilizing standard shipping containers on ships, oil tankers, barges, boats, trains, trucks, planes, and other modes of transportation. More particularly, this invention relates to delivering drinkable water to the water-poor regions of the globe using large bags or membranes in shipping containers, empty cargo holds, or empty oil tankers' cargo holds.

Owner:WATERS OF PATAGONIA

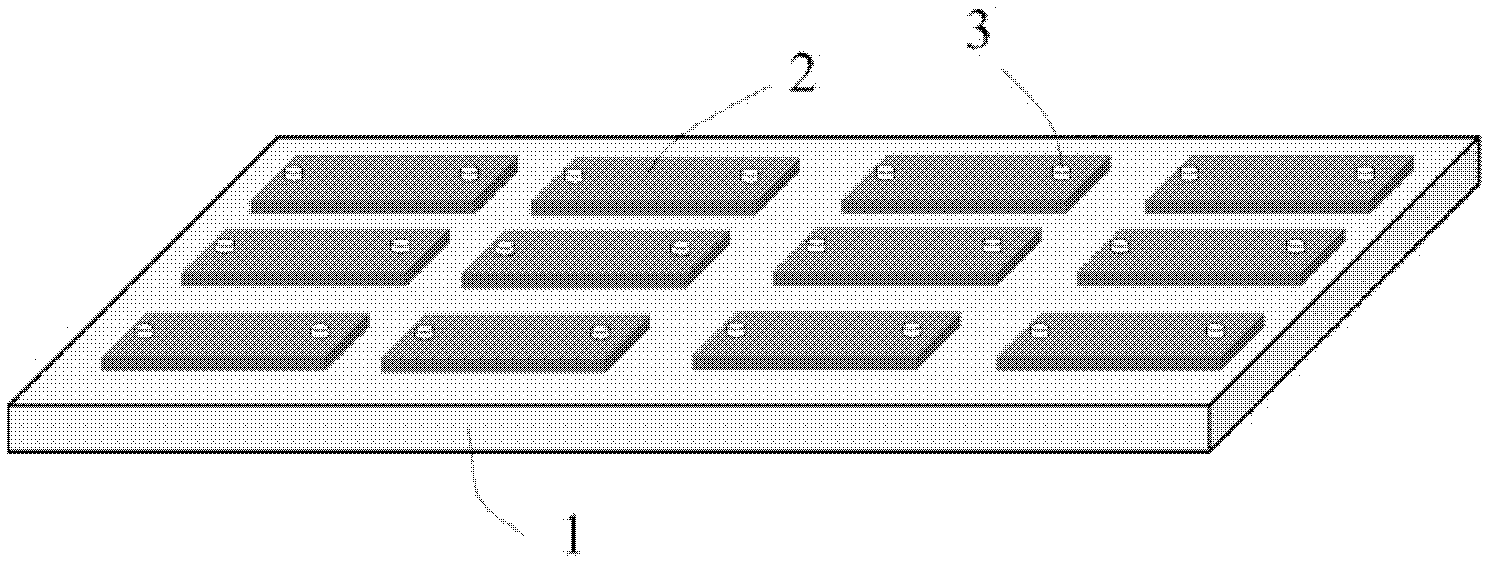

Method for preparing colored light-extinction polyester filament

InactiveCN102251308AImprove spinnabilityEasy to processFilament forming substance formingFilament/thread formingPolyesterPolymer science

The invention relates to a method for preparing a colored light-extinction polyester filament. The method comprises the following steps of: firstly smashing a polyester chip after being subjected to pre-crystallization into powder and mixing the power with pigment and a light-extinction agent to obtain a mixture, and then drying the mixture and adding a dispersing agent after solid phase polymerization, and melting and extruding to obtain a polyester master batch; and mutually mixing the melted and extruded polyester master batch with a melt of a polyester parent body, then spinning and shaping to obtain a tow, and air blast cooling and shaping to obtain the polyester filament after oiling through an oil tanker, drawing and winding. According to the invention, solid phase polymerization on polyester is carried out in the preparation process of the master batch so that the excessive degradation of the polyester is avoided, the viscosity of the polyester is increased, the subsequent spinning operation is easy and the product quality of filament is improved; ethers, polyhydric alcohol or ester compounds serving as dispersing agents are added in the master batch preparation process so that the pigment and the light-extinction agent are easily dispersed without condensing, the filament spinnability is greatly improved and the sequence processability of the filament is improved; and the manufacturing cost is greatly saved.

Owner:TAICANG ZHENHUI CHEM FIBER

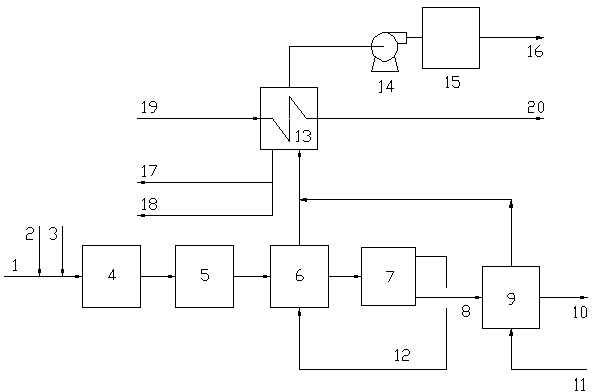

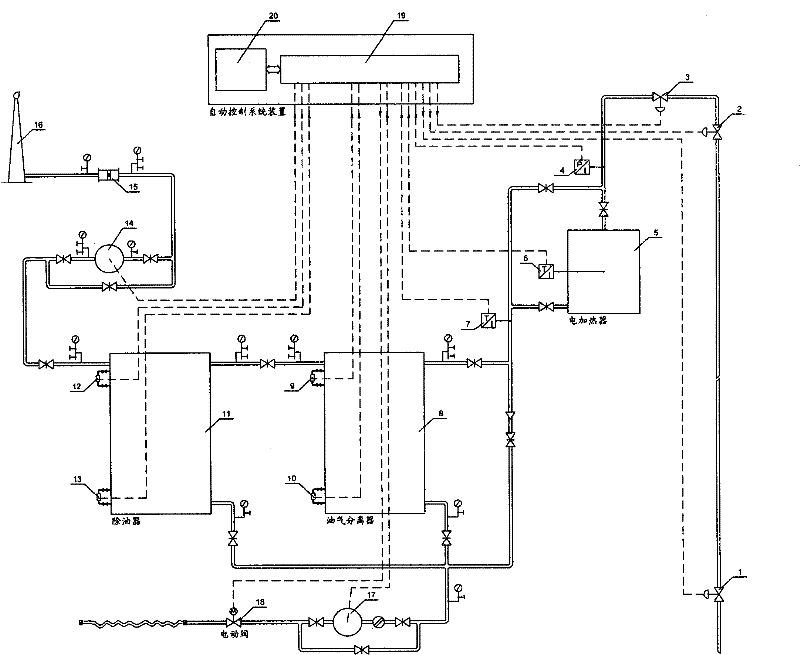

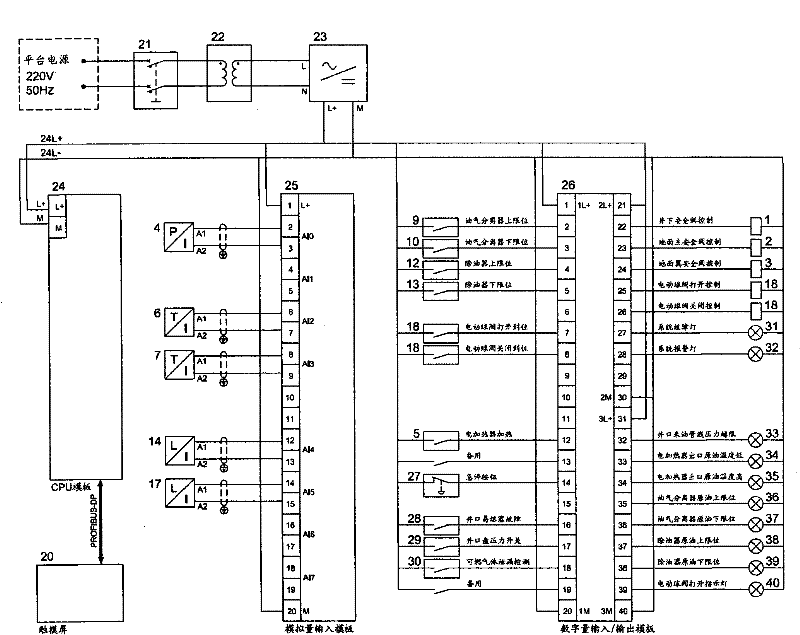

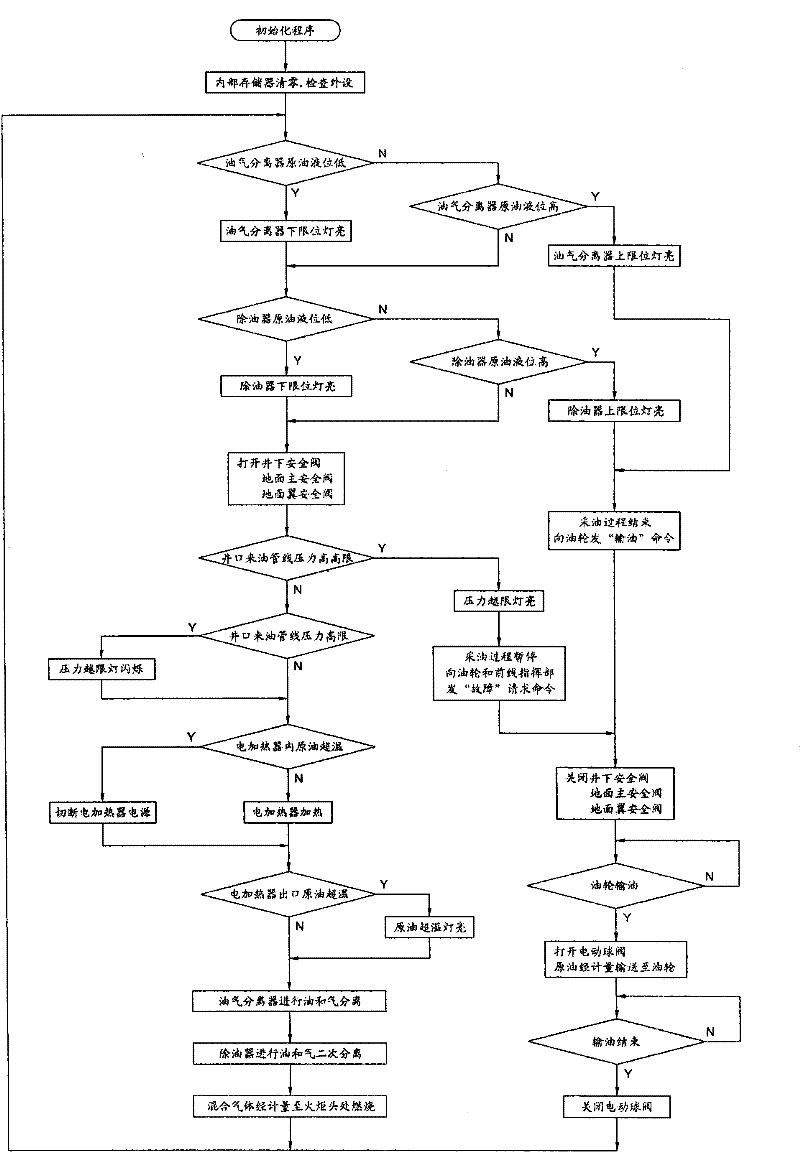

Automatic control system and method for offshore production platform

InactiveCN102337868AMeet unattended requirementsImprove working environmentFluid removalWell/borehole valve arrangementsAutomatic controlAutomated control system

The invention discloses an automatic control system and method for an offshore production platform. The system consists of an automatic control device, a crude oil treatment system and an oil transmission system, wherein the automatic control device consists of a PLC (programmable logical controller), a touch screen and peripheral test equipment; the crude oil treatment system comprises main devices such as an electrical heater, an oil-gas separator, an oil eliminator and the like; and the oil transmission system comprises an oil tanker, an oil transmission pipeline and an electric valve. The PLC and the touch screen which are positioned in the automatic control device are used for monitoring the process parameters of the production process through programming, treating the crude oil according to the crude oil treatment process flow and automatically controlling the oil tanker to collect the crude oil of the platform at fixed point; the PLC has perfect alarming, failure self-diagnosis and protection functions; and the touch screen can display the procedure parameters of the crude oil treatment in real time, perform manual intervention on the crude oil treatment procedure as well as automatically pop up the failure message screen in case of alarm and failure events. The data exchange can be realized between the PLC and the touch screen through a field bus.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

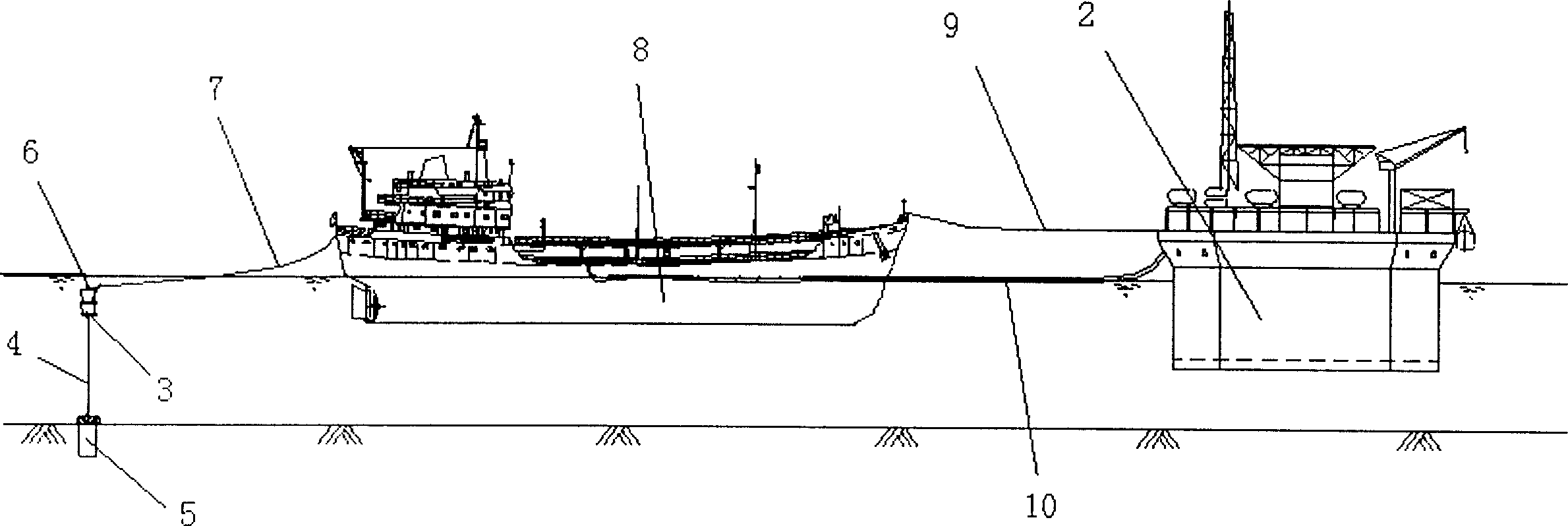

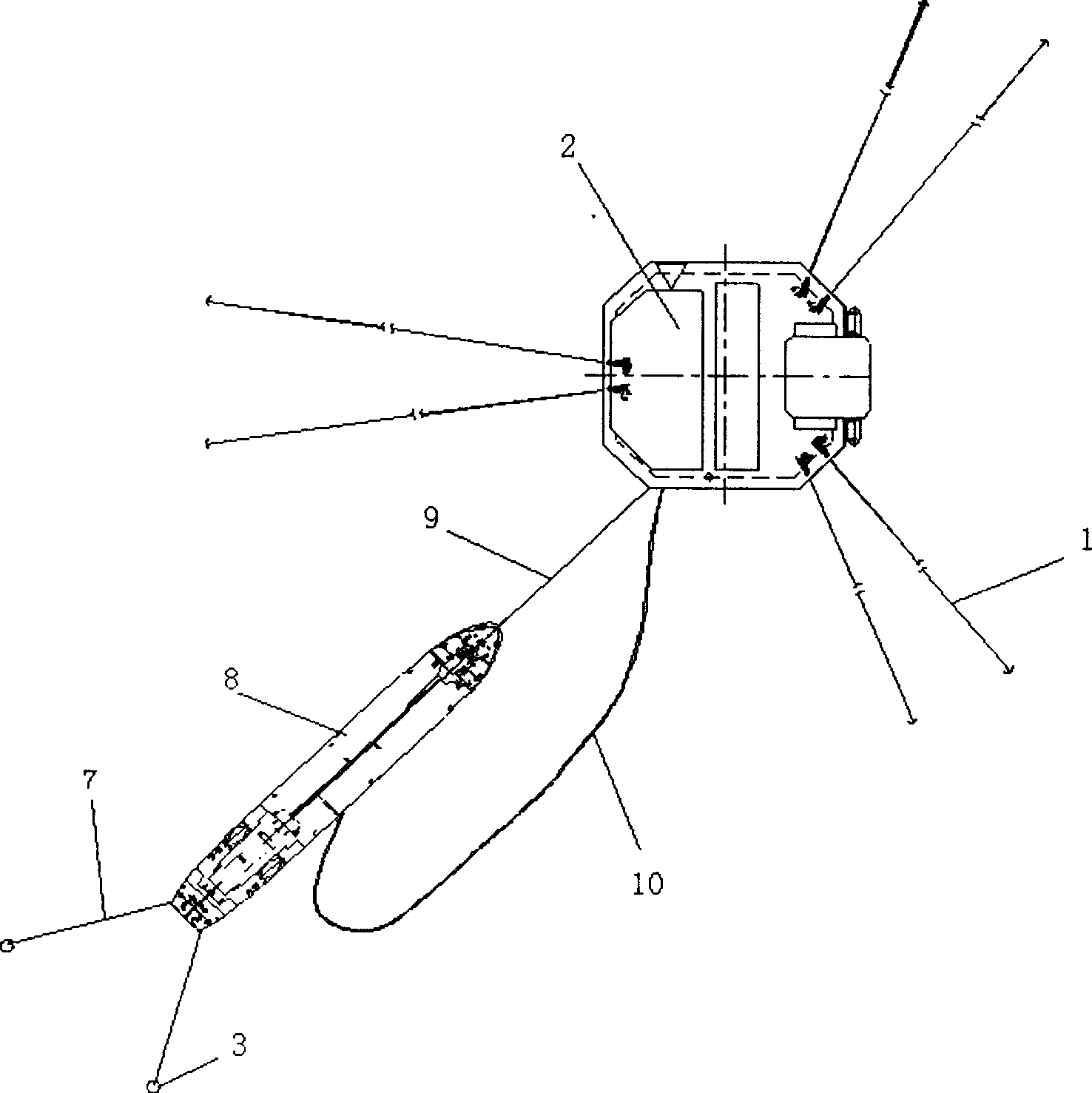

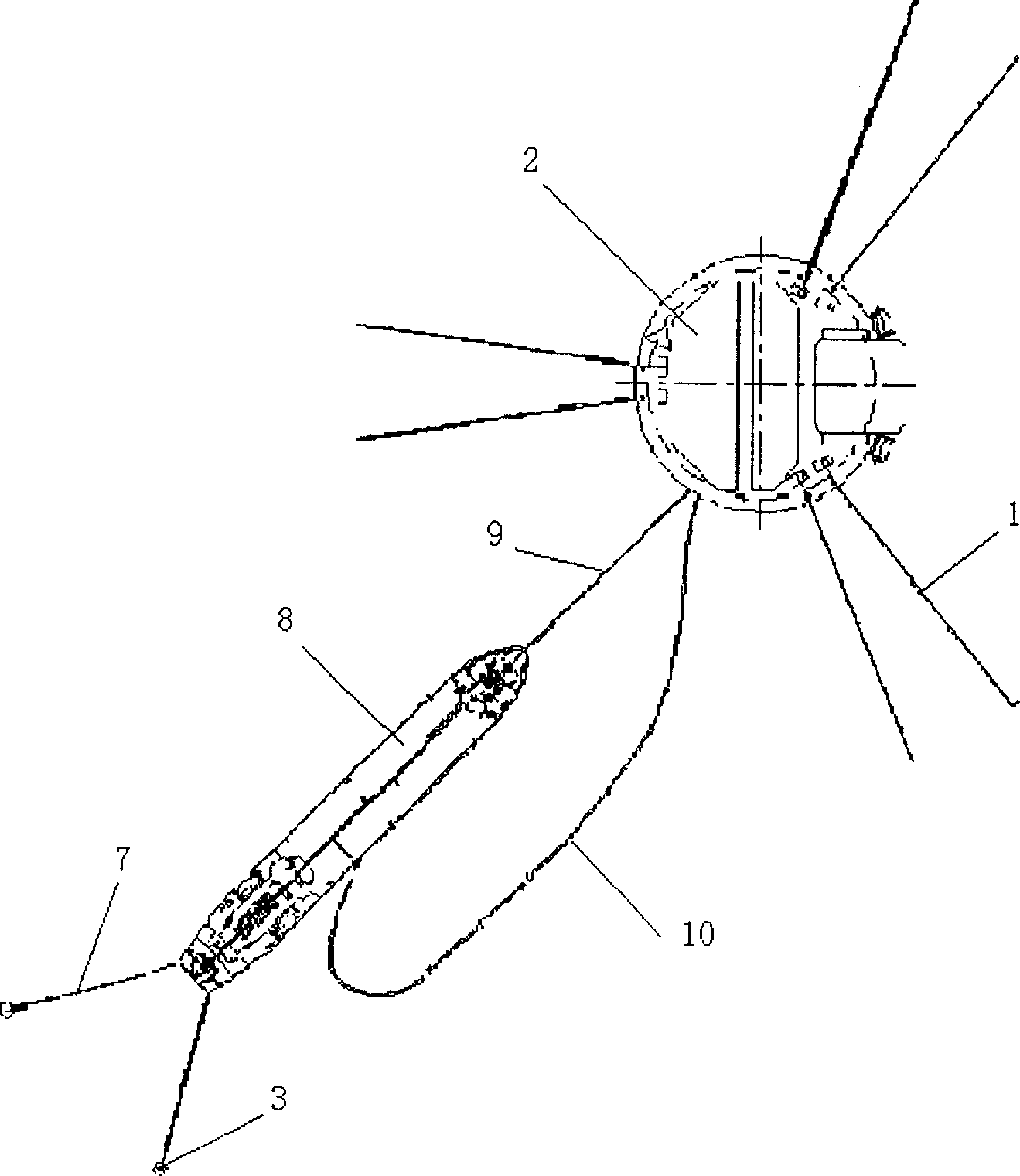

Flexible connection berthing method and apparatus for transferring oil on sea

InactiveCN1817736AEfficient developmentSolve the problem of unable to moor oil transportationAnchoring arrangementsOcean bottomFloating platform

A flexible connecting and anchoring method and its apparatus for delivering petroleum between oil tanker and floating petroleum recovering and storing platform are disclosed. At least one set of flexible connection apparatus anchored to seabed is arranged on sea surface. The cable at the stern of an oil tanker is tied to the float bowl of said flexible connection apparatus and the cable at its bow is tied with the cable of said floating platform. A flexible petroleum delivering pipe is connected between oil tanker and floating platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

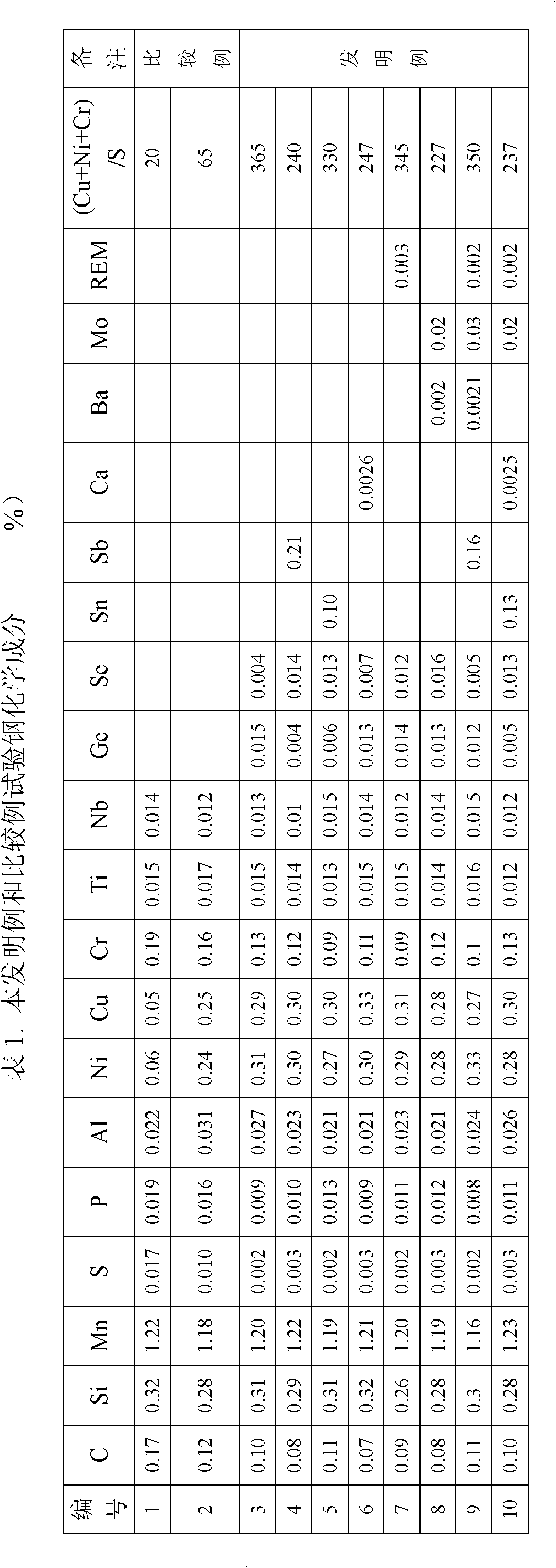

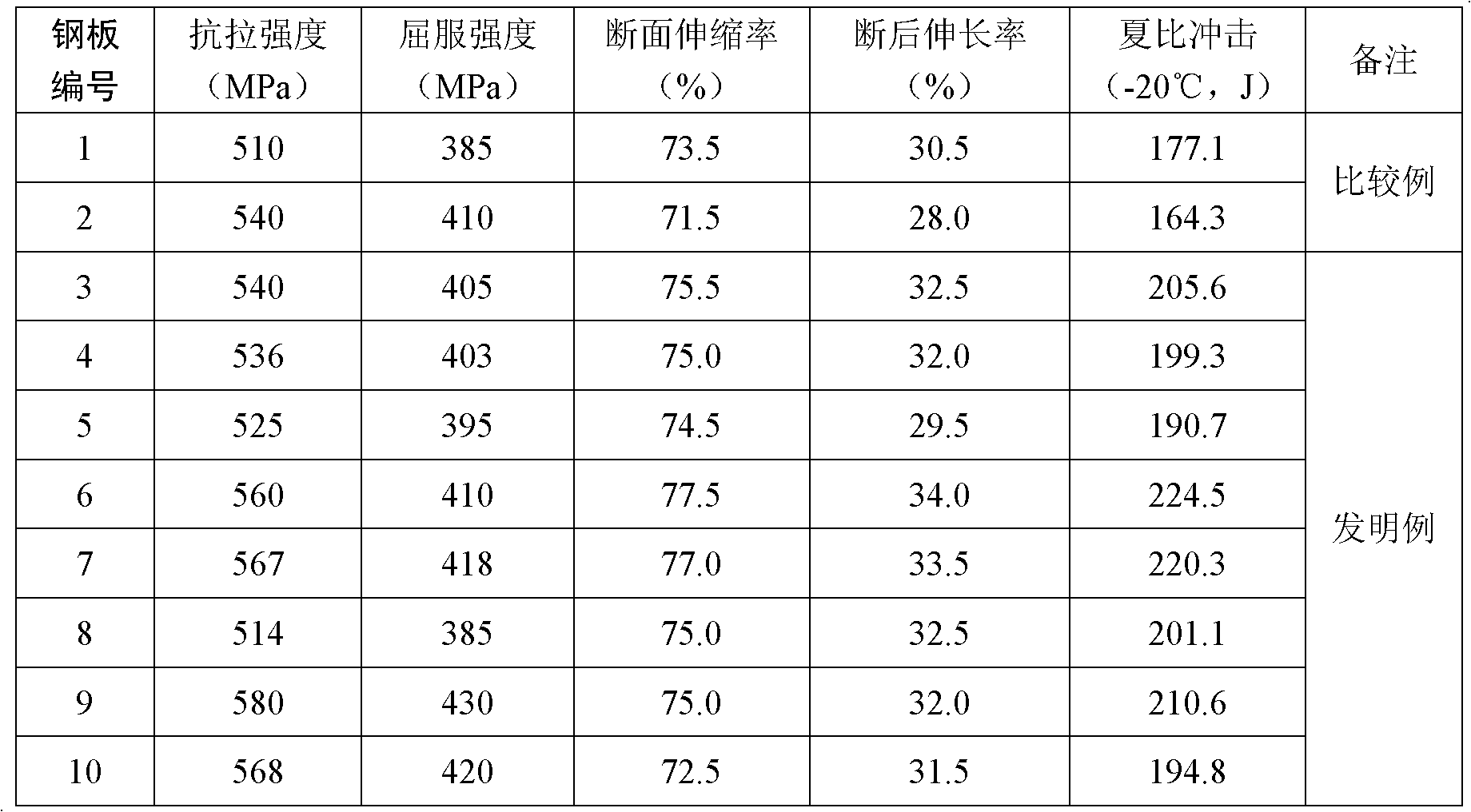

Steel for lower plate of cargo oil tank of tanker

InactiveCN102492897AImprove localized corrosion resistanceLower pH valueHigh concentrationProlongation

The invention provides steel for the lower plate of a cargo oil tankof a tanker, which belongs to the technical field of ship plate steel. The steel comprises, by mass, 0.01 to 0.3% of C, 0.02 to 2% of Si, 0.1 to 2.0% of Mn, no more than 0.01% of S, no more than 0. 02% of P, 0.05 to 2.0% of Ni, 0.05 to 2.0% of Cu, 0.005 to 1.0% of Cr, 0.0005 to 0.3% of Se, 0.0005 to 0.3% of Ge, with the balance being Fe; preferably, (Cu + Ni + Cr) / S is 200 to 480. The steel can also comprise one or more selected from the group consisting of 0.0005 to 0.3% of Sn, 0.0005 to 0.3% of Sb and 0.0005 to 0.3% of Te, and / or one or more selected from the group consisting of 0. 0005 to 0.3% of W, 0.0005 to 0.3% of Mo, 0.0005 to 0.3% of Co and 0.0005 to 0.3% of REM, and / or one or more selected from the group consisting of 0.0001 to 0.2% of Ca, 0.0001 to 0.2% of Mg, 0.0001 to 0.2% of Sr and 0.0001 to 0.2% of Ba. The steel has the advantages of excellent local corrosion resistance under the conditions of a high concentration of Cl<-> and a high acidity and effective prolongation of the service life of a steel plate when the steel plate is coated by a protective layer or is exposed.

Owner:CENT IRON & STEEL RES INST

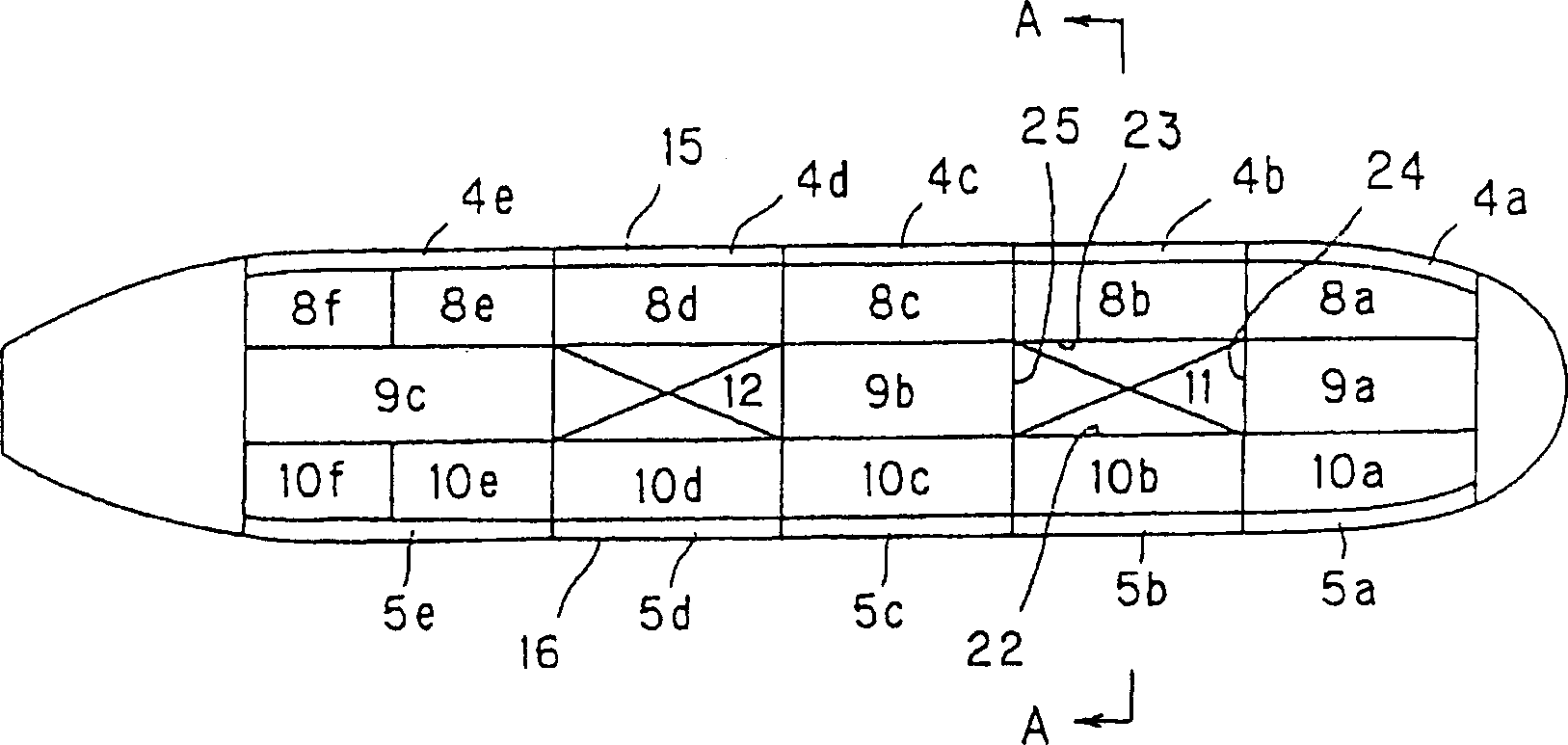

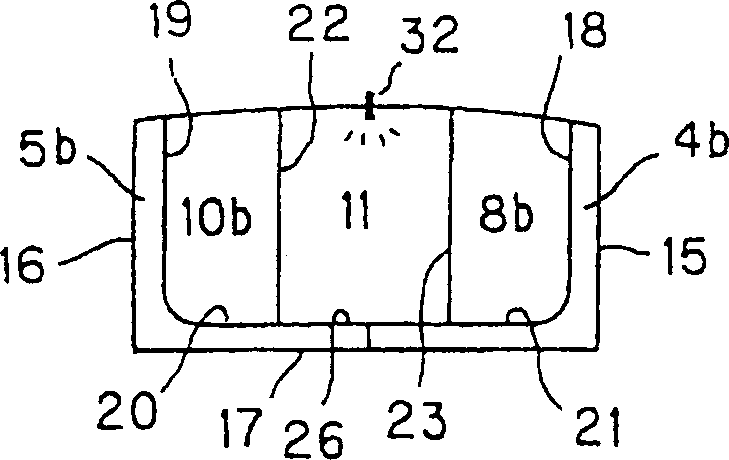

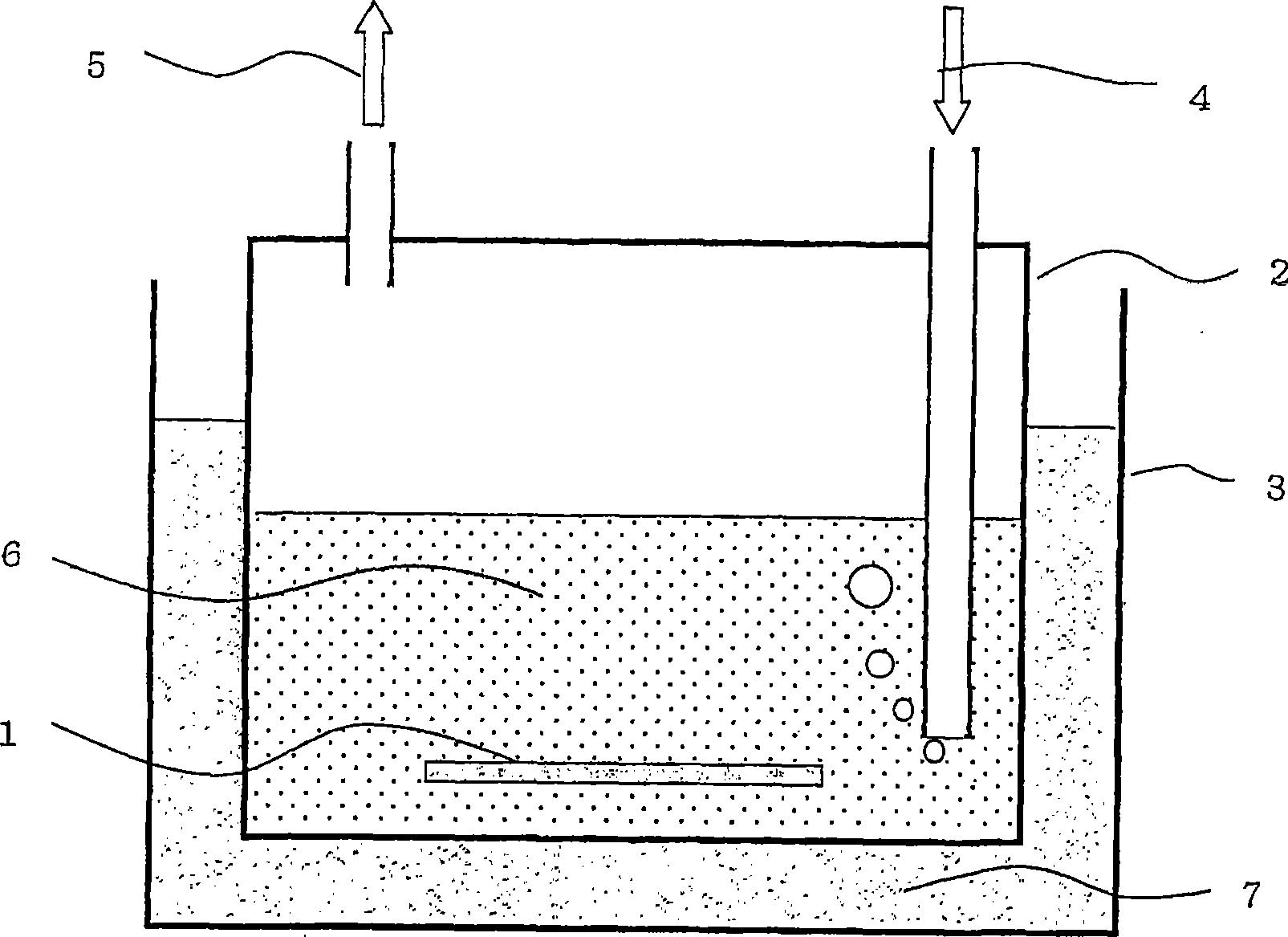

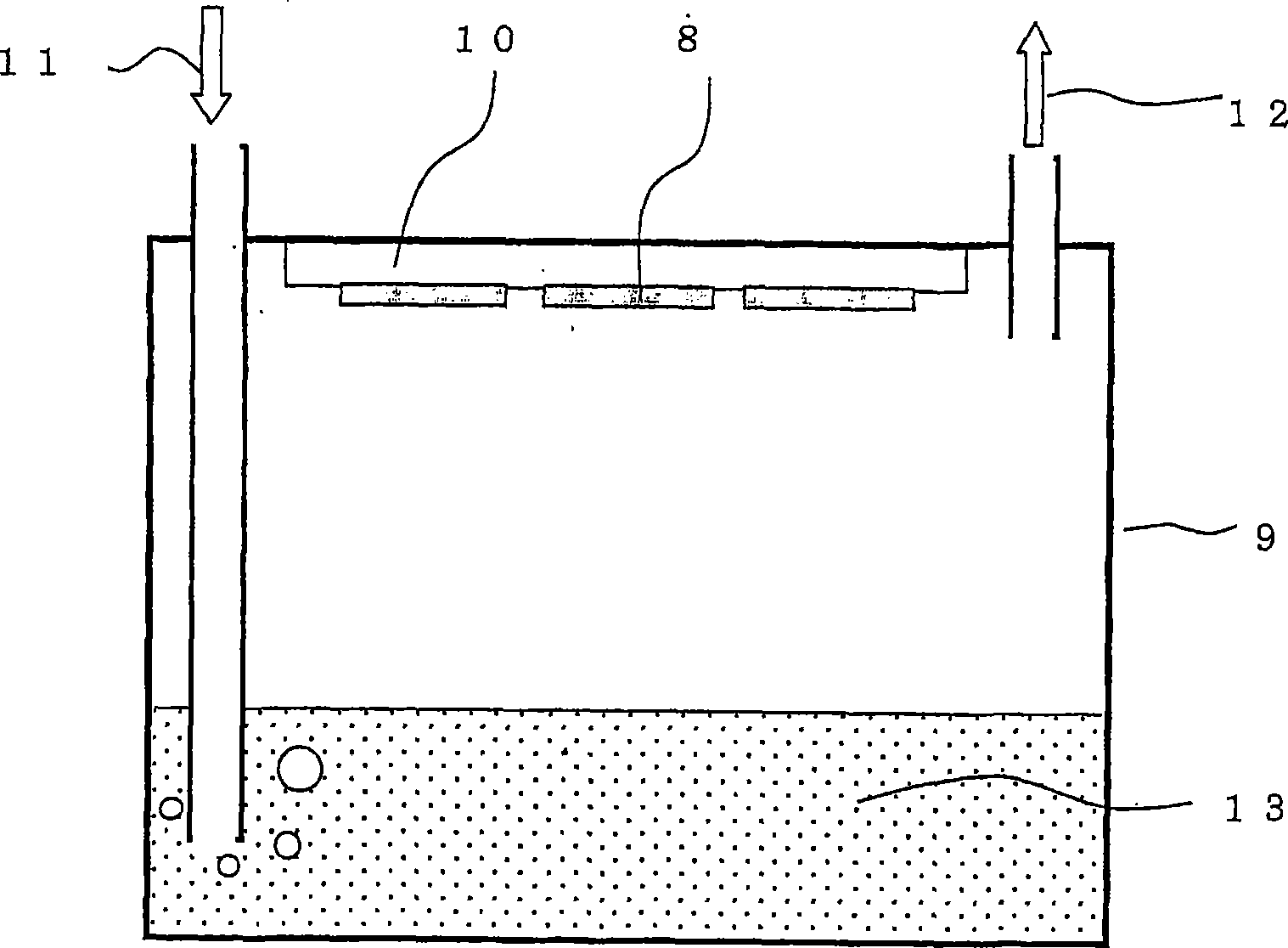

Ship structure for transporting oil and fresh water

InactiveCN1406812ANo empty sailingHull interior subdivisionSelf-bailing equipments/scuppersFresh waterBallast tank

The invention provides a hull construction of a oil tank for transporting oil and fresh water by using all ballast tanks formed in a double hull space as fresh water tanks 4a-4e and 5a-5e, and two combining tanks 11, 12 are provided at a central portion of a hull for combining a sea water ballast tank and a fresh water cargo tank. In this manner, non-wasteful sailing of an oil tanker can be realized by utilizing the tanker for transporting oil cargoes on a forward route and fresh water on a backward route.

Owner:约瑟夫·W·L·哈

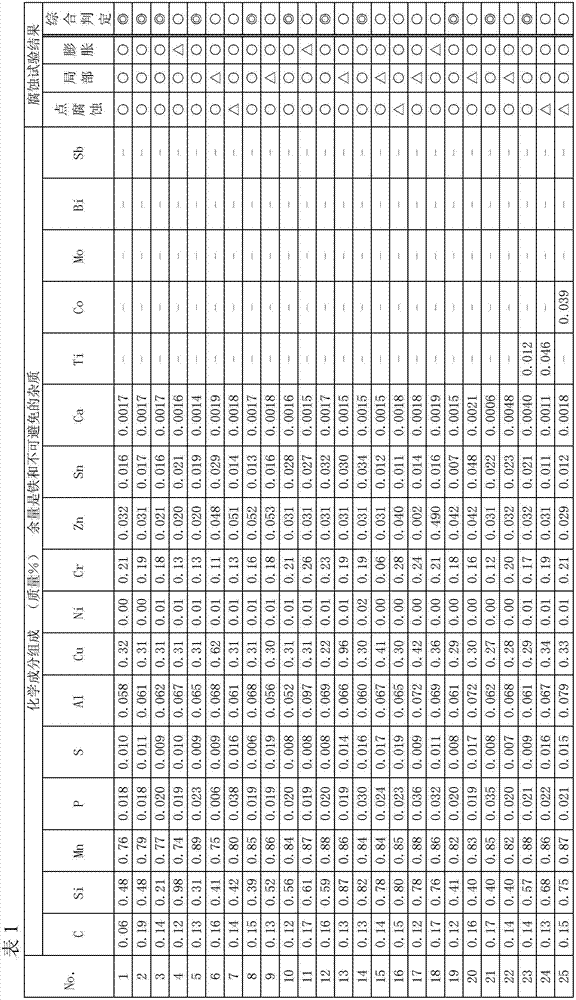

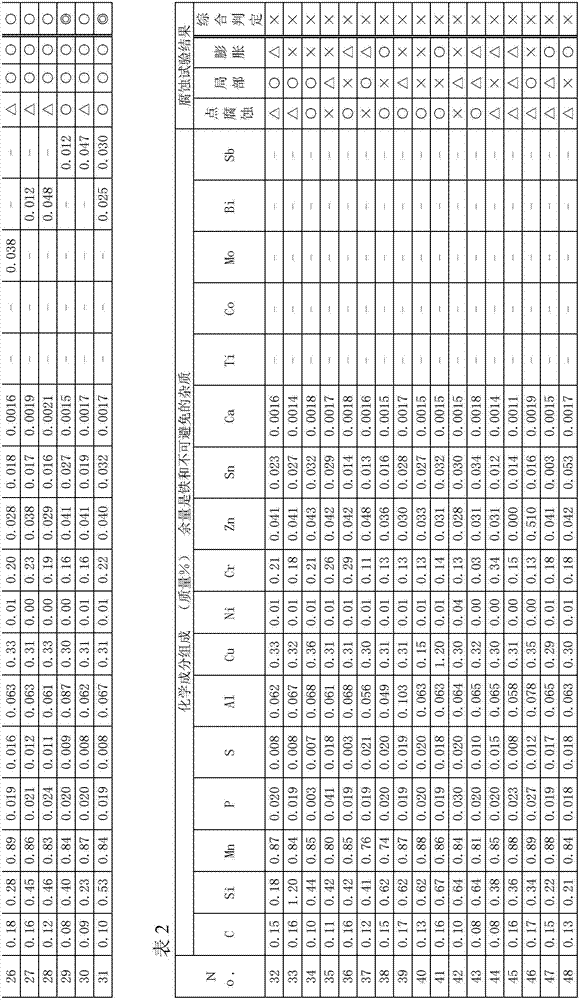

Corroson-resistant steel material for crude oil storage tank, and crude oil storage tank

Disclosed is a steel material which, when used in an oil tank for an oil tanker, a tank for transporting a crude oil, a tank for storage of a crude oil or the like, can reduce a local corrosion on a bottom plate or a general corrosion on a top board or a side board. The steel material for a crude oil storage tank has the following chemical composition: C: 0.001-0.16 mass%, Si: 0.01-1.5 mass%; Mn: 0.1-2.5 mass%; P: 0.025 mass% or less; S: 0.01 mass% or less; Al: 0.005-0.1 mass%; N: 0.001-0.008 mass%; W: 0.001-0.5 mass%; and Cr: not less than 0.06 mass% and less than 0.20 mass%; with the remainder being Fe and unavoidable impurities.

Owner:JFE STEEL CORP

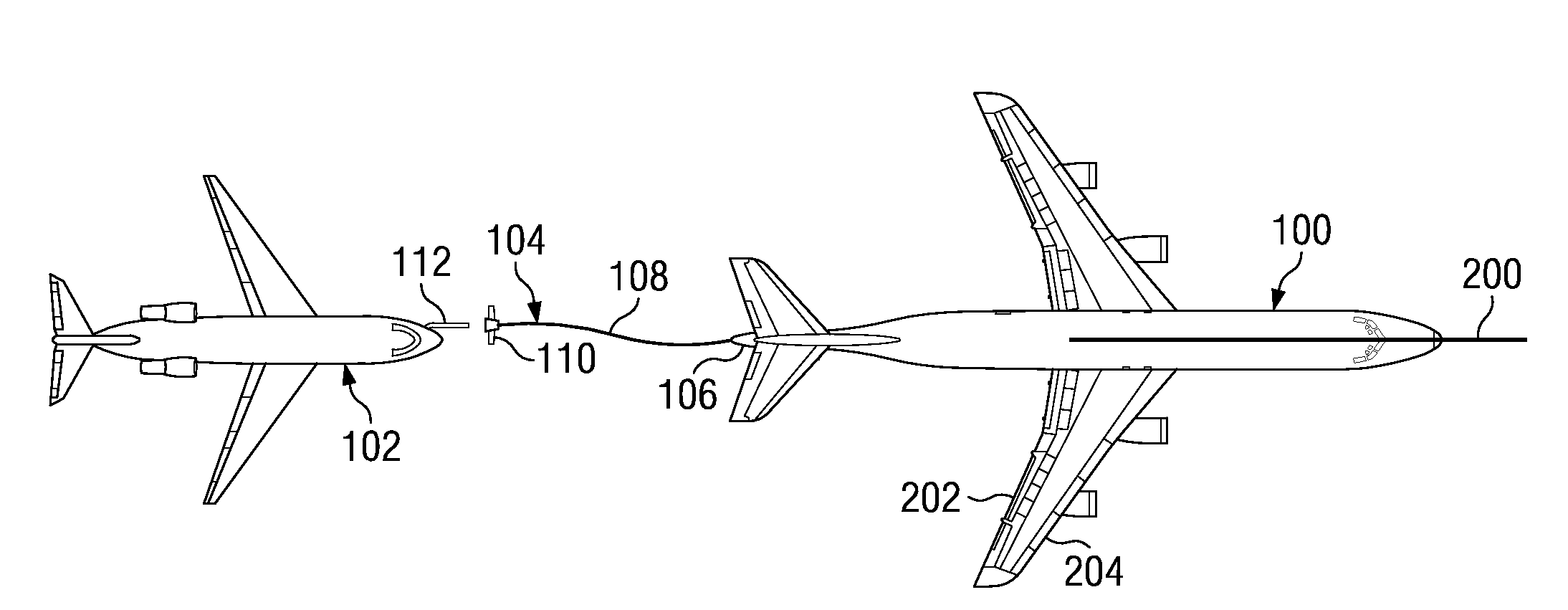

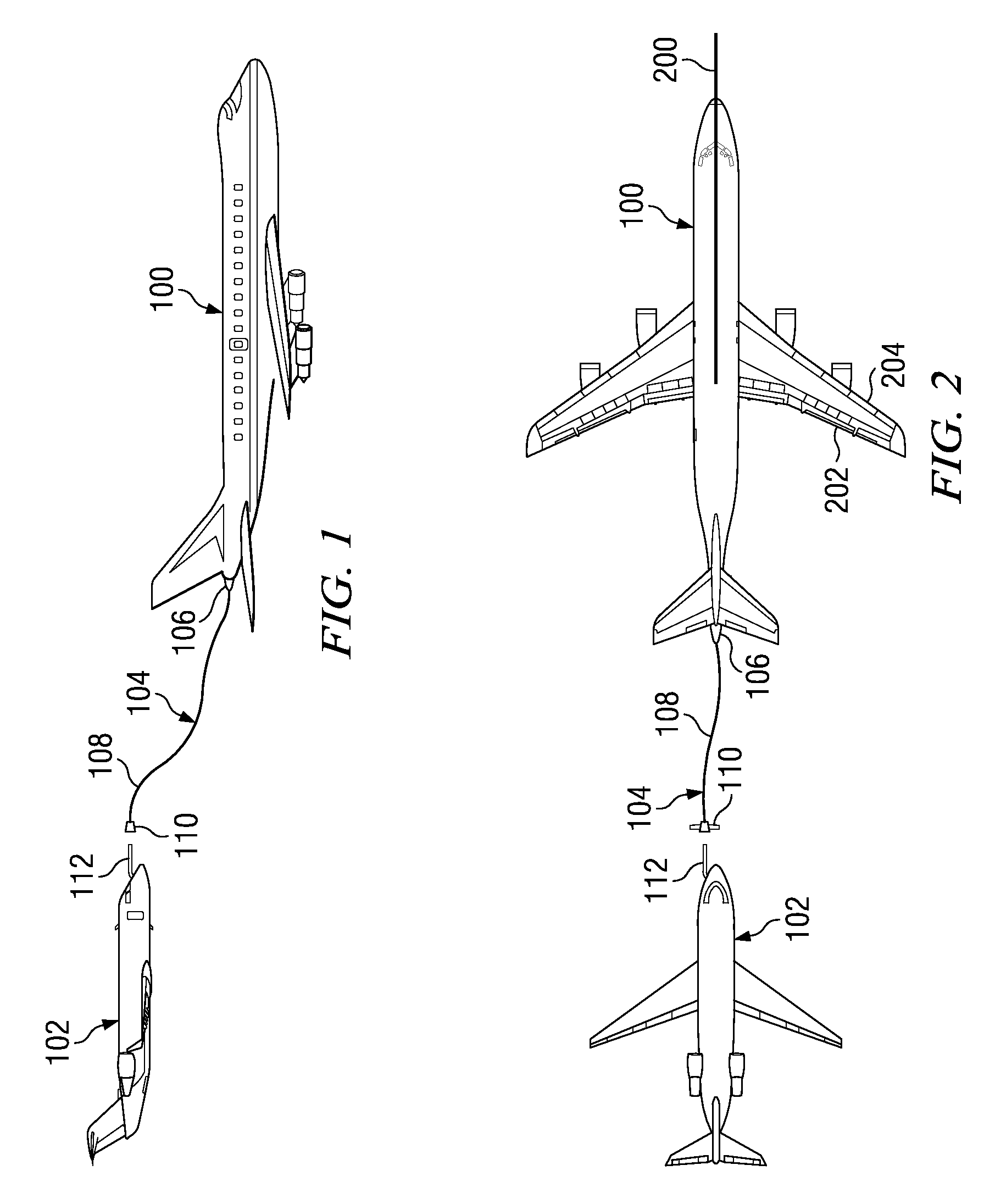

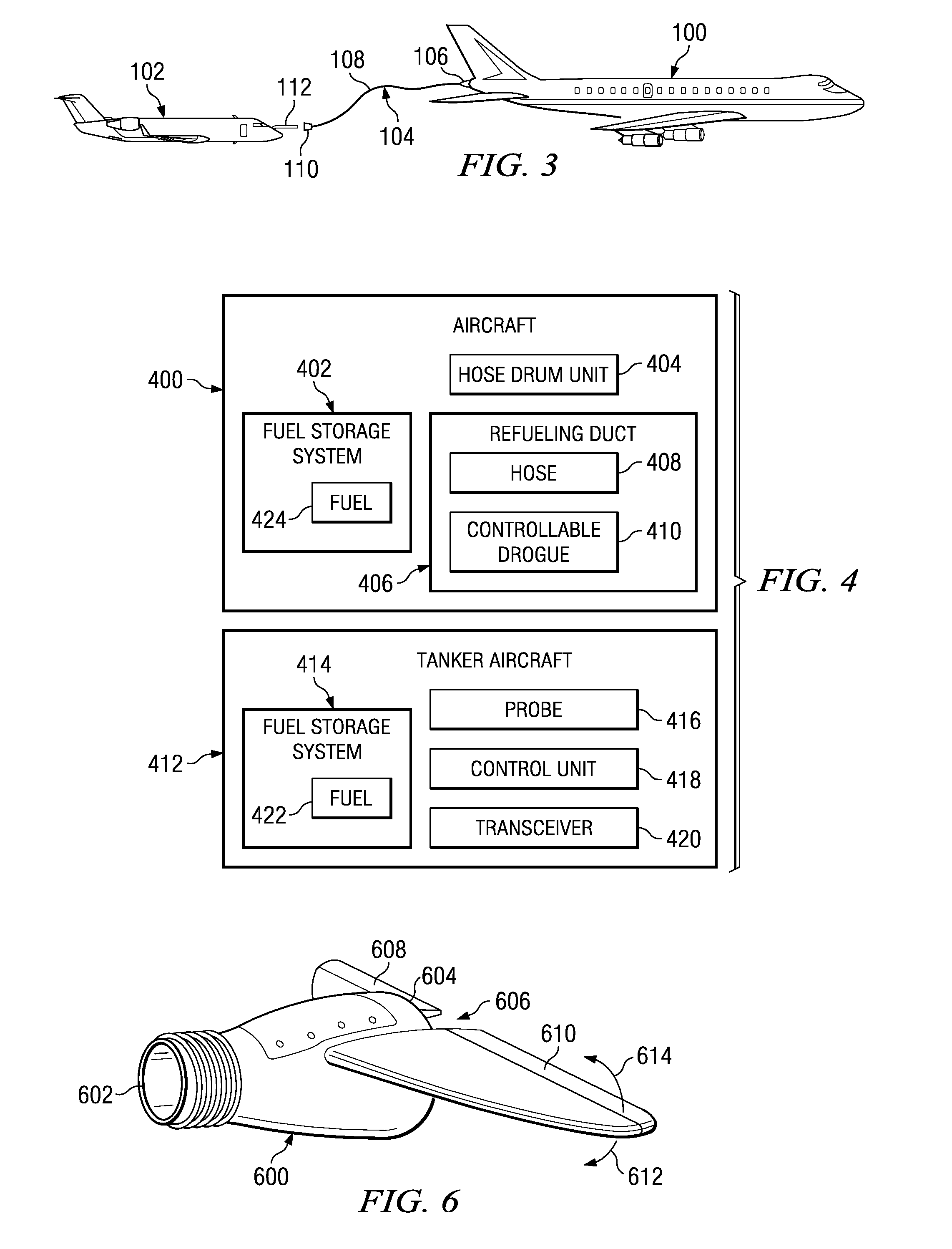

Method and apparatus for aerial fuel transfer

A method and apparatus for transferring fuel onto or off of an aircraft. A refueling transfer duct is deployed from an aft station of the aircraft being serviced while the aircraft is flying, wherein the transfer apparatus comprises a hose with a controllable drogue attached to its free end. The refueling duct is positioned through control signals sent by a tanker aircraft to the controllable drogue to form a favorably positioned refueling duct capable of a finite final docking maneuver. The positioned refueling duct is connected to the tanker aircraft positioned behind the aircraft to form a connection. The fuel is transferred through the connection to a fuel tank or fuel storage system located within the aircraft.

Owner:THE BOEING CO

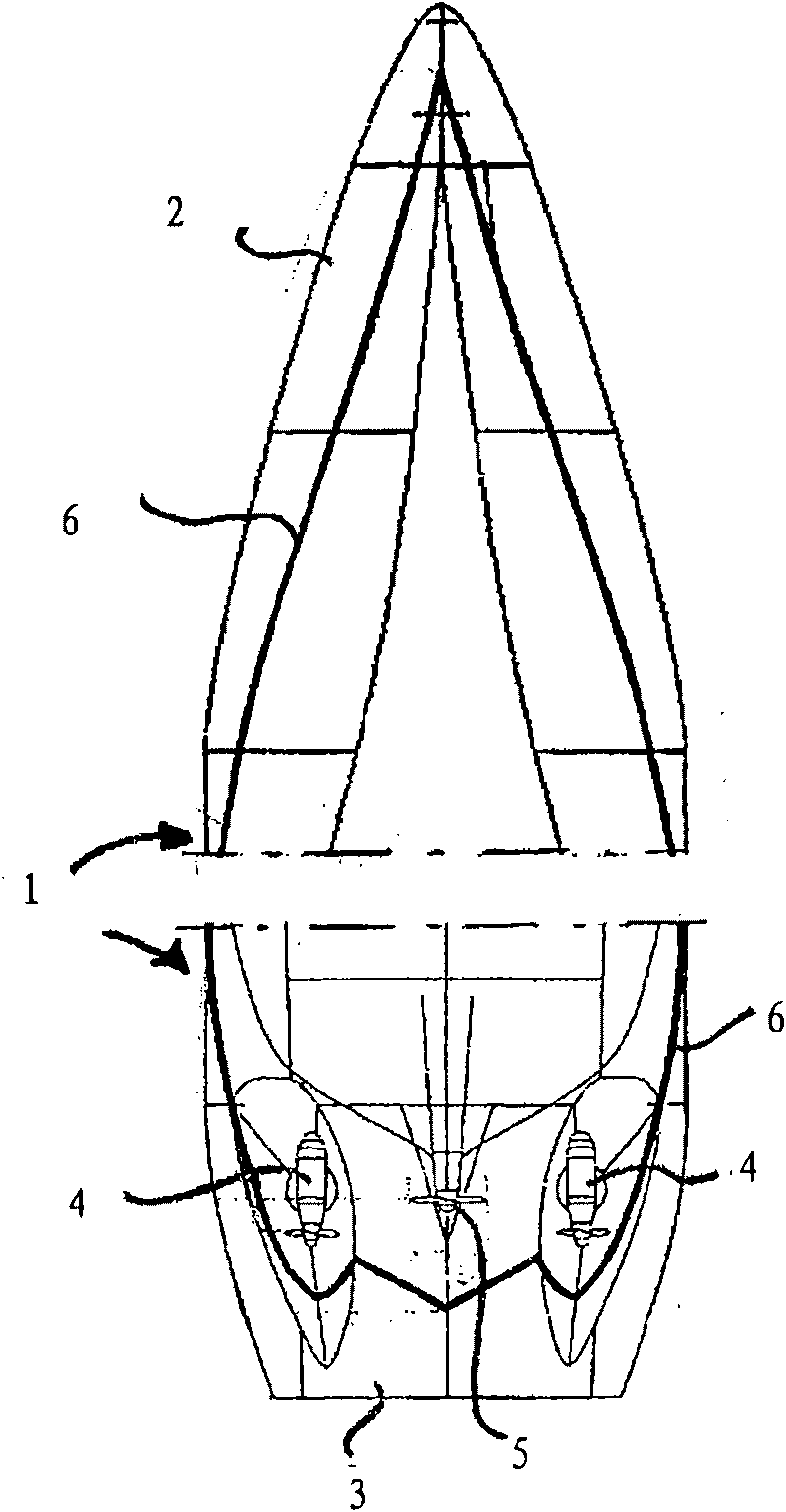

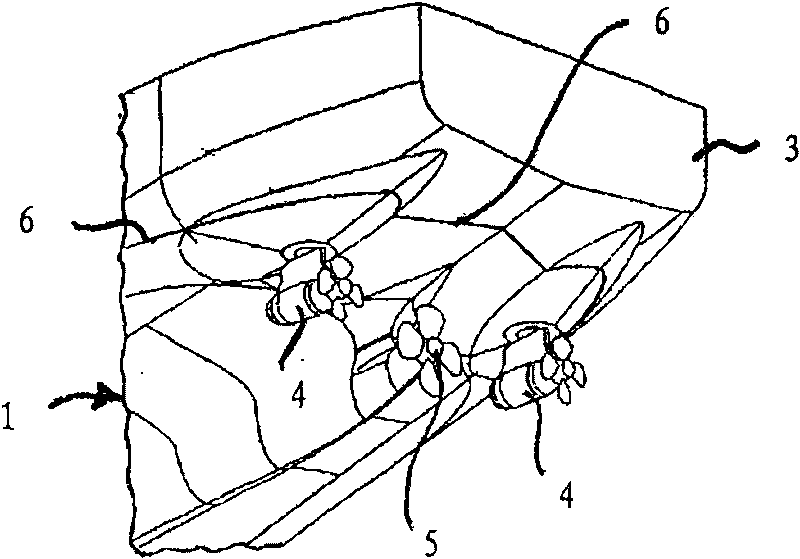

Method for improving the ice-breaking properties of a water craft and a water craft constructed according to the method

ActiveCN101730644AEasy to operateDoes not affect the designIce breakersPropulsive elementsPropellerWatercraft

A method of providing a watercraft, especially an icebreaker or a cargo ship, tanker or similar transport vessel, with improved ice penetration characteristics and a watercraft manufactured according to the method, which watercraft has a hull (1) with a first end (2) and a second end (3) and which is equipped at said second end with a propulsion arrangement, which provides the main propulsive thrust of the watercraft, while the watercraft moves with either end ahead, and the steering of the watercraft, whereby said second end (3) of the watercraft is shaped and designed so that it, as such, has efficient ice penetration characteristics. Said propulsion arrangement is chosen so as to include at least three propulsion devices, at least the majority of which are rudder propeller devices (4) and which are arranged at least at two different distances from said second end (3) of the watercraft so that when the watercraft moves in ice or ice build-ups said second end (3) ahead, the propeller with one or more propulsion devices located near said second end (3) of the watercraft is arranged to break ice and the propeller with one or more propulsion devices located farther away from said second end (3) of the watercraft is arranged to remove disintegrated ice or ice chunks away from the ice build-up.

Owner:AKER ARCTIC TECH

Steel material with excellent corrosion resistance for tank upper deck of crude oil tanker or for hold of bulk carrier

The invention provides a steel material for a tank upper deck of a crude oil tanker or for a hold of a bulk carrier and the steel material presents excellent corrosion resistance even if exposed an inclement corrosion environment having sulfur-containing materials such as sulfur, sulfoxides and sulfide. Compared with conventional steel materials, the steel material provided by the invention has the sme or higher welding property and heat processing property. The steel material for the tank upper deck of the crude oil tanker is characterized in that the content of C is 0.01-0.30%, Si is 0.20-1.0%, Mn is 0.50-1.60%, P is 0.005-0.040%, S is 0.005-0.020%, Al is 0.050-0.100%, Cu is 0.20-0.10%, Ni is below 0.03%(containing 0%), Cr is 0.05-0.30%, Zn is 0.001-0.05%, Sn is 0.005-0.050% and Ca is 0.0005-0.0050%, and the balance Fe with inevitable impurities.

Owner:KOBE STEEL LTD

Flux-cored wire for cargo oil tank of oil tanker

InactiveCN102699566AImprove acid resistance of weldsInhibit pitting corrosion developmentWelding/cutting media/materialsSoldering mediaEngineeringMechanics

The invention relates to a flux-cored wire for a cargo oil tank of an oil tanker and belongs to the technical field of flux-cored wires. The flux-cored wire can be full of titanium type powder, titanium calcium type powder or alkaline powder. Deposited metal of the flux-cored wire contains the following components in percentage by mass: 0.01-0.2 percent of C, 0.1-1.5 percent of Si, 0.5-2.5 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.012 percent of S, 0.01-2.5 percent of Ni, 0.01-1 percent of Cu, 0.01-0.5 percent of Ti, more than or equal to 0 but less than to equal to 1 percent of Cr, more than or equal to 0 but less than or equal to 1 percent of Mo, more than or equal to 0 but less than to equal to 1 percent of W, more than or equal to 0 but less than to equal to 0.1 percent of B, more than or equal to 0 but less than to equal to 0.1 percent of Re and more than or equal to 0 but less than to equal to 0.1 percent of Al, and the balance Fe and other inevitable impurities. According to the demands, the deposited metal of the flux-cored wire can also contain at least one of the following components in percentage by mass: more than 0 but less than or equal to 0.3 percent of Sb, more than 0 but less than or equal to 0.3 percent of Sn, more than 0 but less than or equal to 0.3 percent of As, more than 0 but less than or equal to 0.3 percent of Se and more than 0 but less than or equal to 0.3 percent of Pb. The flux-cored wire has the advantage that after welding, the wire has good uniform corrosion resistance and pitting corrosion resistance without antiseptic treatment, so that the overall corrosion resistance of the oil tanker is improved.

Owner:CENT IRON & STEEL RES INST

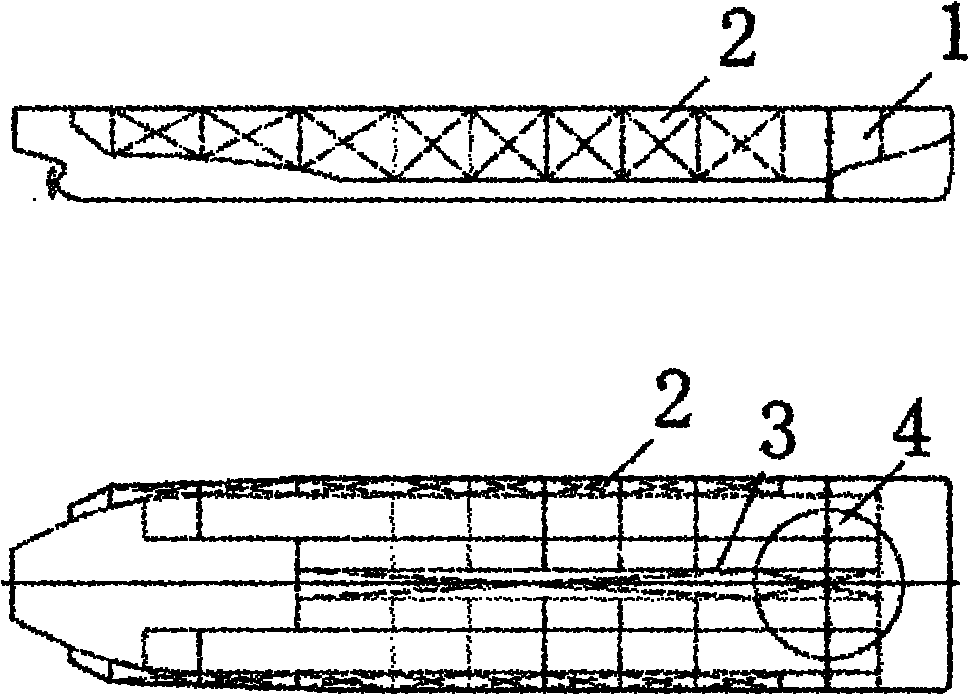

Modification method of large-scale crane ship

InactiveCN101913412AIncrease the areaSatisfy the requirements of floating state controlHull decksSpecial purpose vesselsWork performanceHoneycomb like

The invention discloses a method in the technical field of shipping hoisting, in particular to a modification method of a large-scale crane ship based on a large-scale oil tanker with longer parallel middle body. The floating force is increased through assembling a modified ship bow and box-shaped floating bodies at the two sides of a ship body, and the modification of the large-scale crane ship is realized through replacing a main deck by a beamless flat deck, arranging a crane and reinforcing the interior of the ship body. The invention meets the requirement on controlling the floating state during the working of the large-scale crane ship, improves the total longitudinal strength of the shipping through the arrangement of a modified deck and a centerline bulkhead, and meets the requirement on local intensity through the design of a barrel-shaped honeycomb structure. Rapid dispensation of ballast water during working is realized through the optimized design of a ballast tank and the arrangement of a ballast water pump; the work performance and the control performance are improved through configuring an auxiliary machine, an anchoring machine, a winch and a bow thruster so as to realize that the large-scale oil tanker is modified into the large-scale crane ship on the basis of little modification, therefore, the time and the cost are saved; and the method has larger economic effect and finds a new way for developing old ships.

Owner:SHANGHAI JIAO TONG UNIV +1

Enclosure system allowing for hot work within the vicinity of flammable and combustible material

InactiveUS7193501B1Welding/cutting auxillary devicesElectric testing/monitoringThermodynamicsHot work

An enclosure constructed around an area at which hot work is to be performed at a facility containing flammable or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like. Facilities include petroleum drilling and production platforms, oil tankers, petroleum and chemical plants, and petroleum tank farms. Gas detection monitoring apparatuses are used with the enclosure which will automatically simultaneously shutdown one or more enclosures.

Owner:ALFORD SAFETY SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com