Automatic control system and method for offshore production platform

An automatic control system and oil production platform technology, applied in the sequence/logic controller program control, electrical program control, production fluid and other directions, can solve the problems of low production efficiency, high oil production cost, harsh working environment for workers, etc. The effect of reducing the cost of oil production, improving the degree of automatic control and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

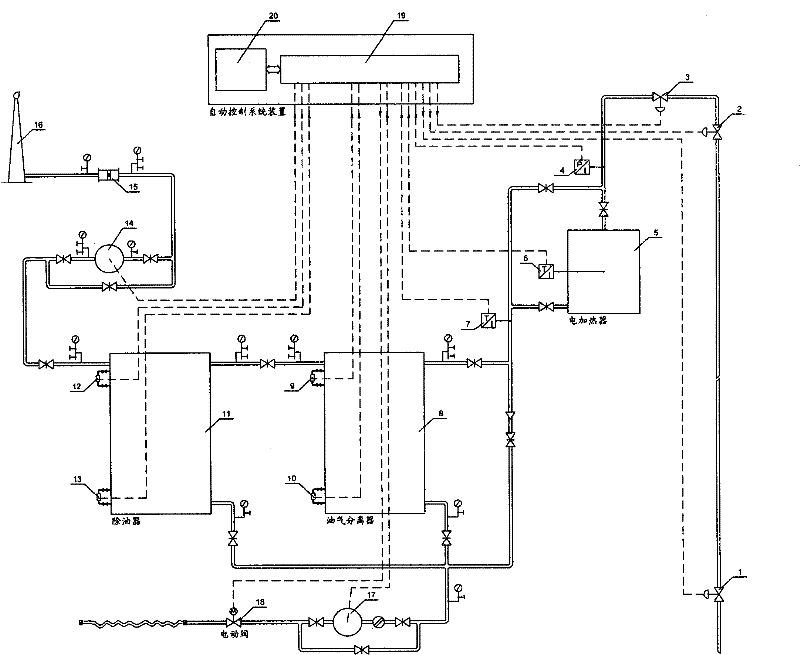

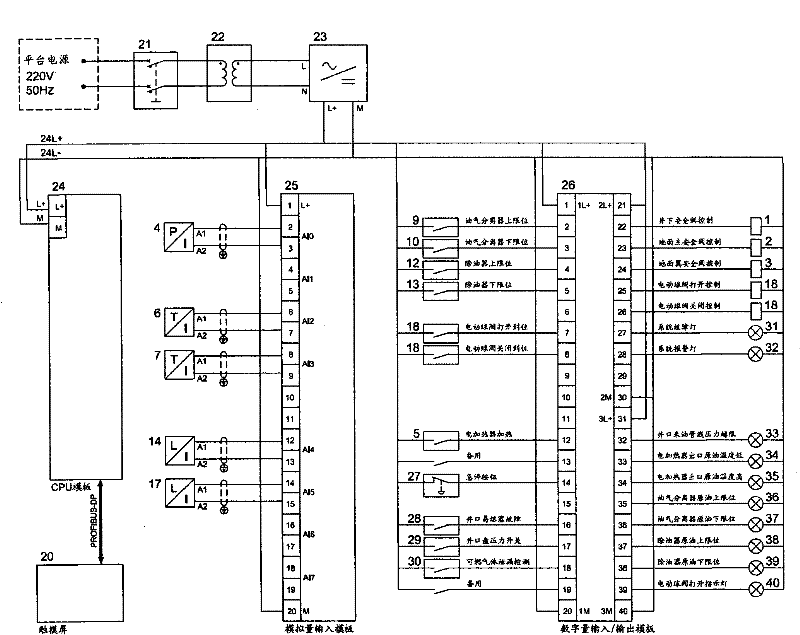

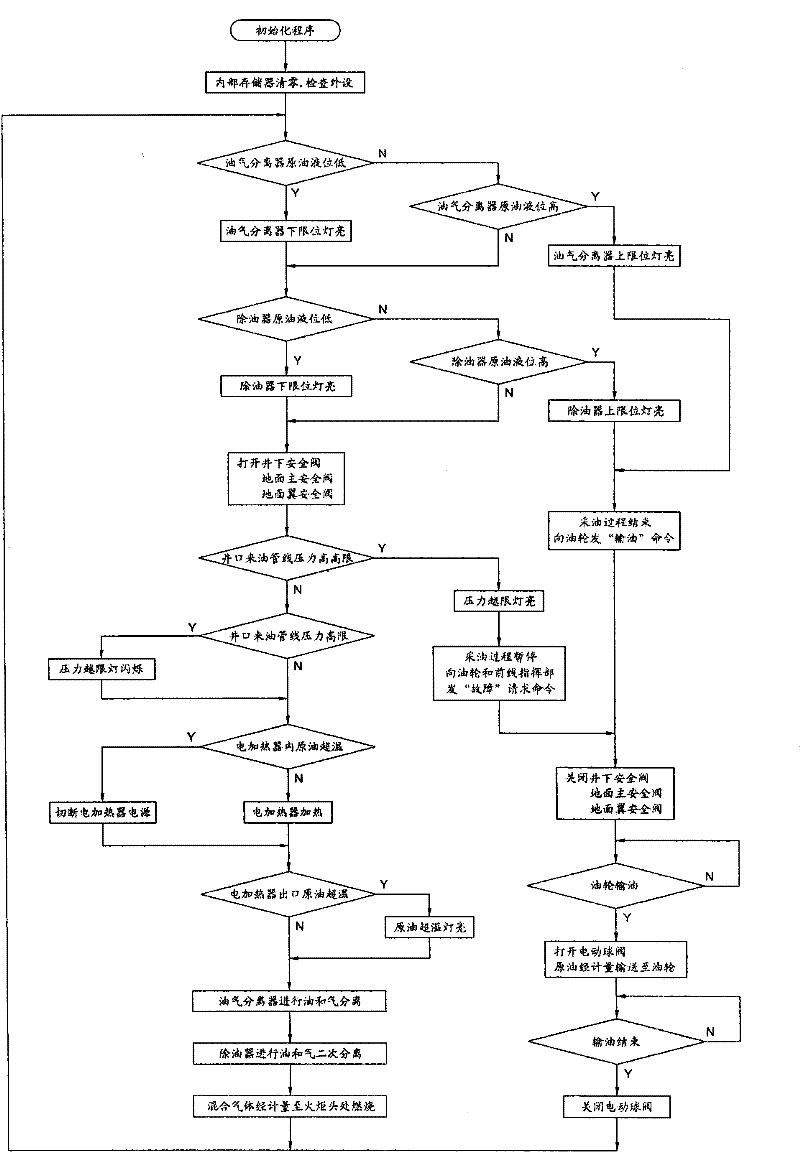

[0024] Such as figure 1 As shown, the downhole safety valve 1, the surface main safety valve 2 and the ground wing safety valve 3 are pneumatic valves, and the opening and closing of these valves are controlled by the PLC controller 19. During the oil production process, these valves are opened, the oil production process is completed, or the oil production process is completed. These valves are automatically closed when there is a suspension for some reason, or when the oil production equipment fails, or a safety accident occurs.

[0025] The pressure of the crude oil in the incoming oil pipeline at the wellhead is detected by the pressure sensor 4, the normal working pressure range is 0.08-0.6 MPa, and the corresponding output of the sensor is 4-20 mA. When the crude oil pressure exceeds 0.6MPa, the PLC controller 19 sends out a high-limit alarm (the pressure over-limit signal light flashes); when the crude oil pressure exceeds 1.0MPa, the PLC controller 19 sends out a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com