Crushing device for sewage presser

A technology of crushing device and press, applied in grain processing and other directions, can solve the problems of operation and maintenance, insufficient cutting and crushing, difficult to achieve crushing effect, etc., and achieve the effect of unattended operation.

Inactive Publication Date: 2013-09-11

扬州清溢环保科技有限公司 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the crushing device of the existing waste press machine is prone to the problem of insufficient cutting and crushing during the working process. For some hard objects, it is difficult to achieve the ideal crushing effect, and the reverse direction cannot be realized when there is an operation failure Operation and alarm require manual operation and maintenance, which is very inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

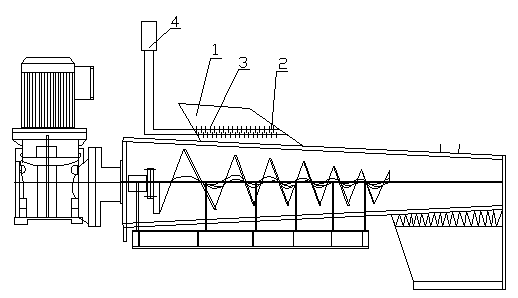

[0008] A crushing device for a dirt press. The crushing device is arranged below the feed inlet 1. The crushing device includes a crushing grid and an intelligent control box 4, including two rows of parallel rotating shafts 2, two A plurality of cutting blades 3 and spacers are arranged on each rotating shaft 2 at intervals, and the cutting blade 3 and the inner ring of the spacers are hexagonal.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a crushing device for a sewage presser. The crushing device is arranged below a feeding hole; the crushing device comprises a crushing grid and an intelligent control box comprising two rows of parallel rotating shafts, wherein multiple cutting blades and gaskets are arranged on the two rotating shafts at intervals; and the cutting blades and inner rings of the gaskets are hexagonal. The blade assembly is coupled to rotate under the drive of double shafts, a strong extrusion force is generated, hard solids such as sticks, bamboo chips, mineral water bottles, shoes, small stones, iron nails and short steel bars can be completely crushed through the sharp blades, and downstream equipment is powerfully protected; and due to the reverse operating function, automatic alarm, automatic adjustment and automatic switch functions, the crushing grid is provided with a control box, and an independent and complete system can be automatically formed. When solid blockage occurs, the control box transmits a signal to the crushing grid, so that the blades automatically and reversely rotate, the barriers exit and enter the control box to be crushed, the whole process is intelligently controlled, and the unattended operation requirement is completely met.

Description

Technical field [0001] The invention relates to a dirt crushing device, in particular to a crushing device of a dirt press. Background technique [0002] At present, the crushing device of the existing dirt press is prone to insufficient cutting and crushing during the working process. For some hard objects, it is difficult to achieve the ideal crushing effect, and the reverse direction cannot be achieved when there is a malfunction. Operation and alarm require manual operation and maintenance, which is very inconvenient. Summary of the invention [0003] In order to solve the above problems, the present invention provides a pulverizing device of a dirt press with simple structure, thorough pulverization and high degree of automation. [0004] The technical solution of the present invention is: the crushing device is arranged below the feed inlet, the crushing device includes a crushing grid and an intelligent control box, including two rows of parallel rotating shafts, and the two...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B02C18/14B02C18/18

Inventor 谈家彬夏四清吴静吴军王凤云黄伟航石延松王春兵戴家将潘伟

Owner 扬州清溢环保科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com