Steel material with excellent corrosion resistance for tank upper deck of crude oil tanker or for hold of bulk carrier

A corrosion-resistant, bulk carrier technology, applied in the field of steel for cabins, can solve problems such as difficulty in ensuring corrosion resistance, and achieve excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064]Hereinafter, the present invention is described in more detail by enumerating the examples. The present invention is certainly not limited by the following examples. Of course, it can also be suitably modified and implemented in the scope of meeting the purpose of the foregoing and the following, and these are all included in the technology of the present invention. In the range.

[0065] [Preparation of test material]

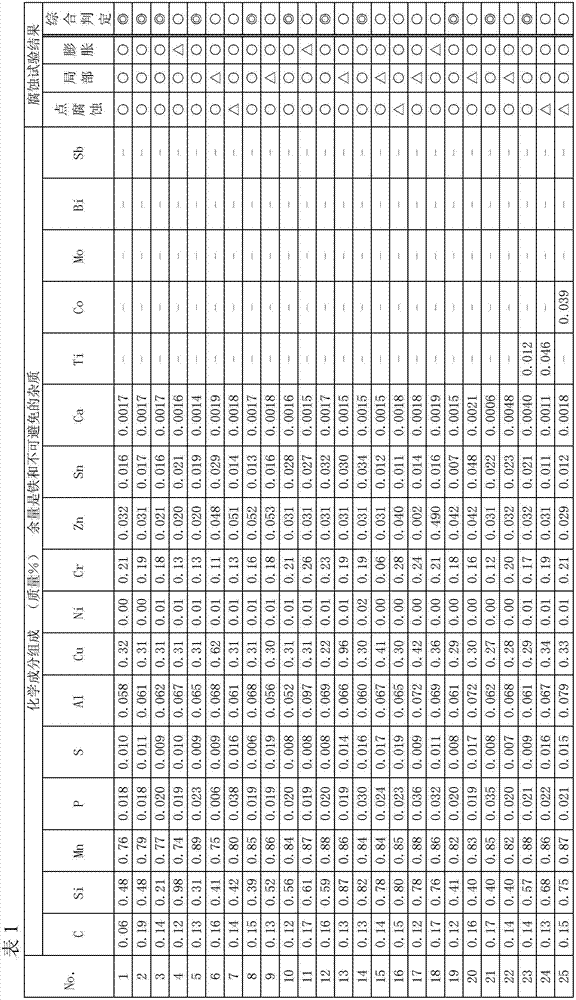

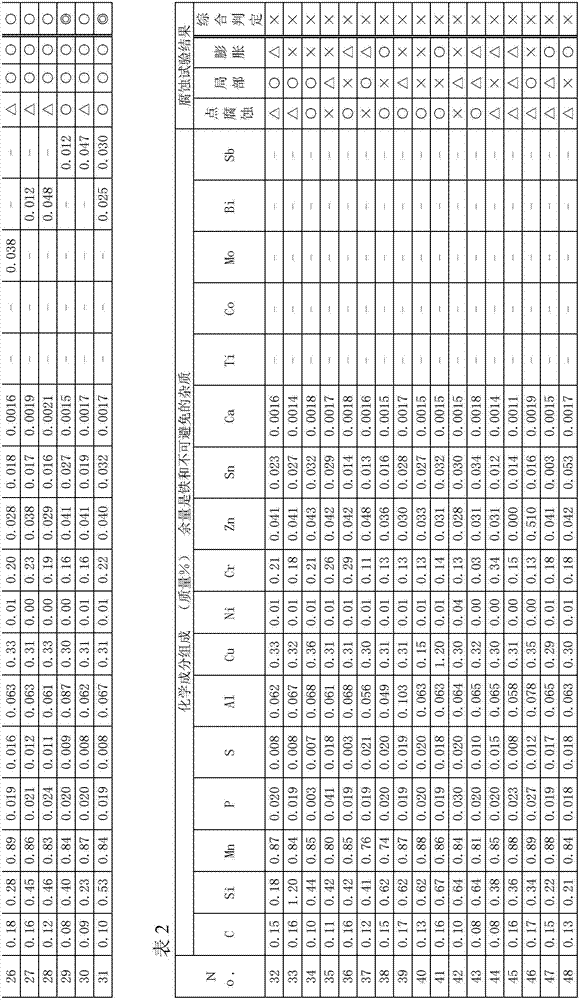

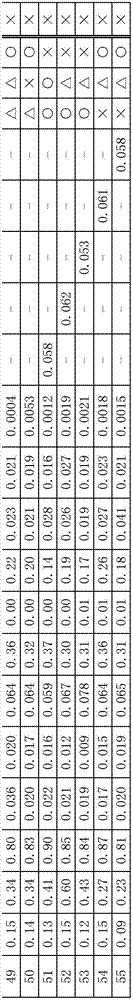

[0066] Steel materials satisfying the composition shown in Tables 1 and 2 (the balance is iron and unavoidable impurities) were smelted in an electric furnace, hot-rolled and heat-treated as needed to obtain steel raw materials with a plate thickness of 10 mm. Then, a test piece (TP) having a size of 30×30×5 (mm) was cut out from the steel raw material. Next, the entire surface of TP was ground to SiC #600 with a wet rotary grinder, washed with water and acetone, dried, and used for the following test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com