Steel for upper deck of cargo oil tank of tanker

A technology for cargo oil tanks and decks, which is applied in the field of ship plate steel, can solve problems such as threats to the health of operators, failure to consider corrosion, and high construction and inspection costs, so as to reduce maintenance costs, inhibit the formation of corrosion slag, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 (real ship cargo oil tank hanging piece)

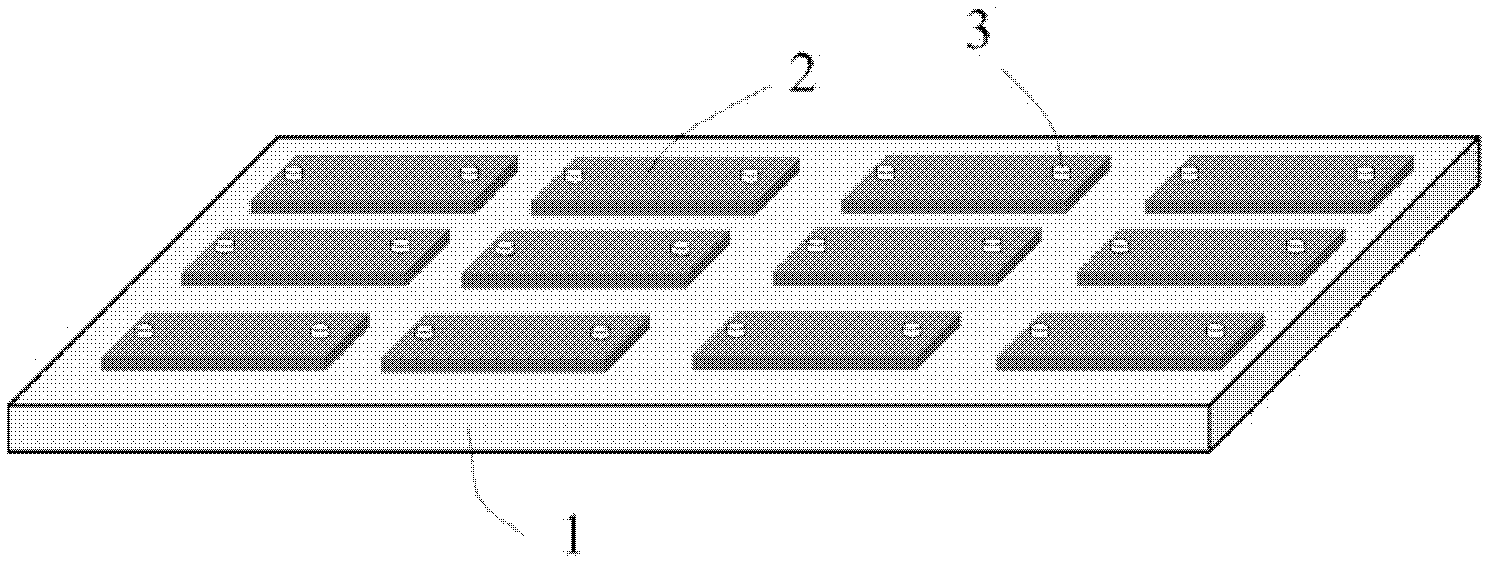

[0039] For the above-mentioned various steels, cut 4 parallel samples of length 100mm×width 50mm×thickness 5mm on the surface, polish each surface of the sample to 600# with sandpaper, and measure the size and weight of the sample after cleaning with alcohol and acetone , Test a 100mm×50mm surface of the sample, in order to prevent the corrosion of other surfaces from affecting the test results, it is sealed with epoxy resin. according to the sample figure 1 The method shown is to install and fix the sample on the upper deck of the cargo oil tank of the real ship, with the test side facing down, and the test period is 2 years.

[0040] After the test, the corrosion rate of the steel was calculated using the weight loss method, and the results are shown in Table 3.

Embodiment 2

[0041] Embodiment 2 (simulation of cargo oil tank environment)

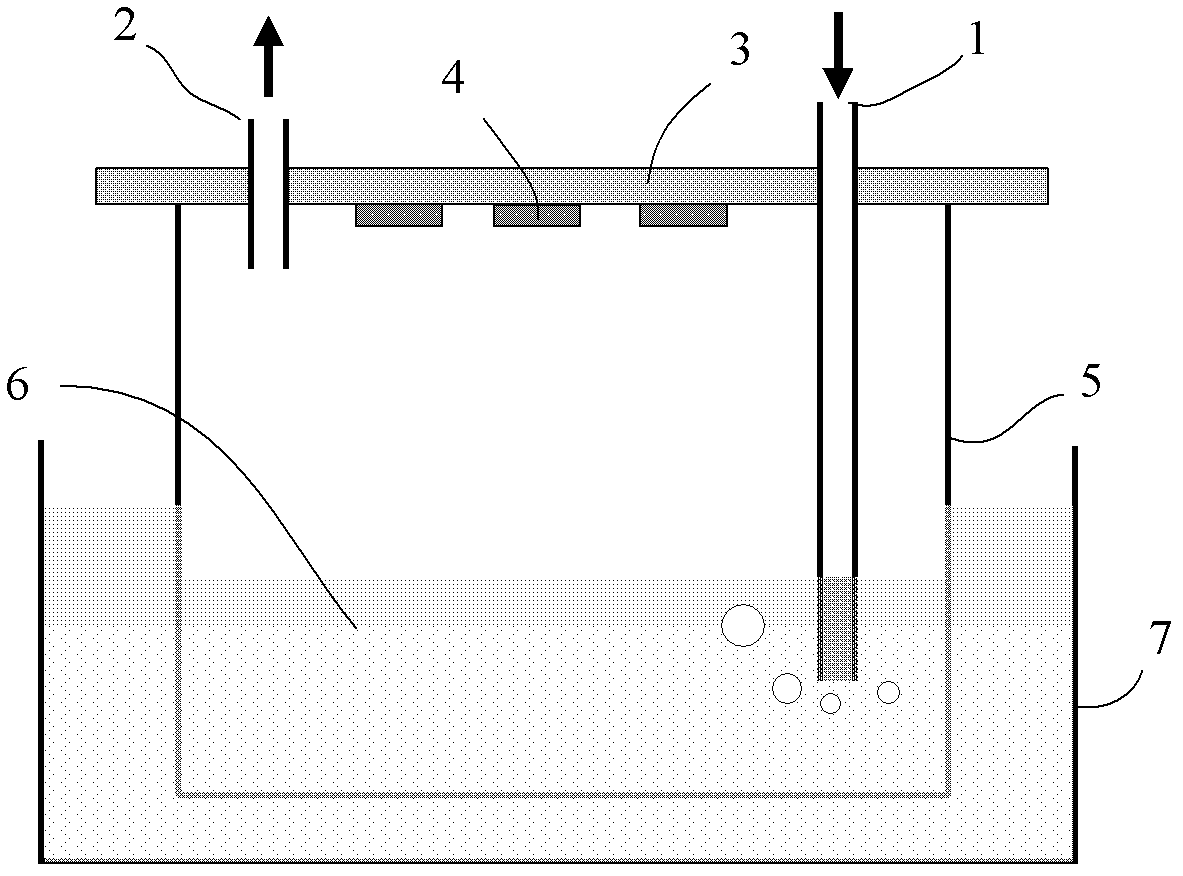

[0042] figure 2 Contains H for analog goods 2 Schematic diagram of the environmental corrosion device for cargo oil tanks. The sample is intercepted from the surface of the above-mentioned various steels, the size is 50mm long x 25mm wide x 5mm thick, and there are 5 parallel samples. Use sandpaper to polish each surface of the sample to 600#, after cleaning with alcohol and acetone, measure the size and weight of the sample, and test a 50mm×25mm surface of the sample, in order to prevent the corrosion of other surfaces from affecting the test results. impact, seal it with epoxy.

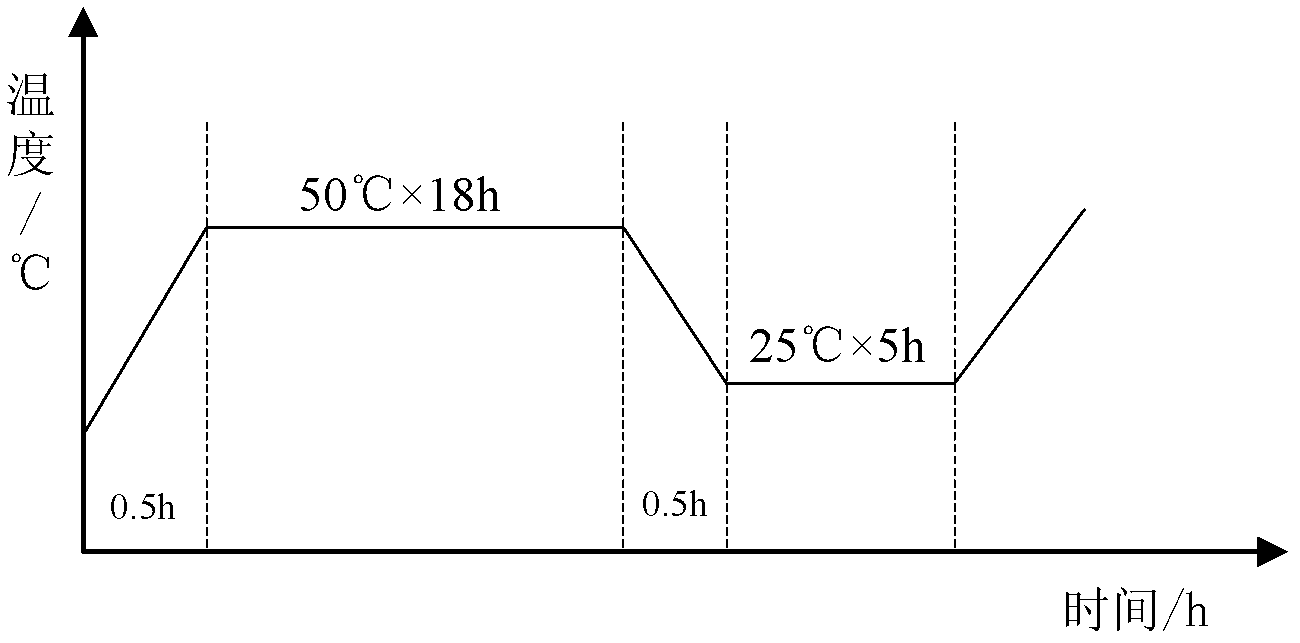

[0043] During the test, first inject a certain amount of 3.5% NaCl aqueous solution into the container, and set the temperature of the solution to a constant temperature of 30°C, fix the sample on the top of the corrosion device, and first pass N 2 Exclude the air in the container, and then pass into an equal amount of the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com