Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

355 results about "Heat torch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat torch is a tool or device that is used to heat up a substance quickly, whether it is air, metal, plastic, or other materials. Heat torches typically provide a way to quickly heat a concentrated area of material for uses such as molding, metallurgy, hardening, and solidification.

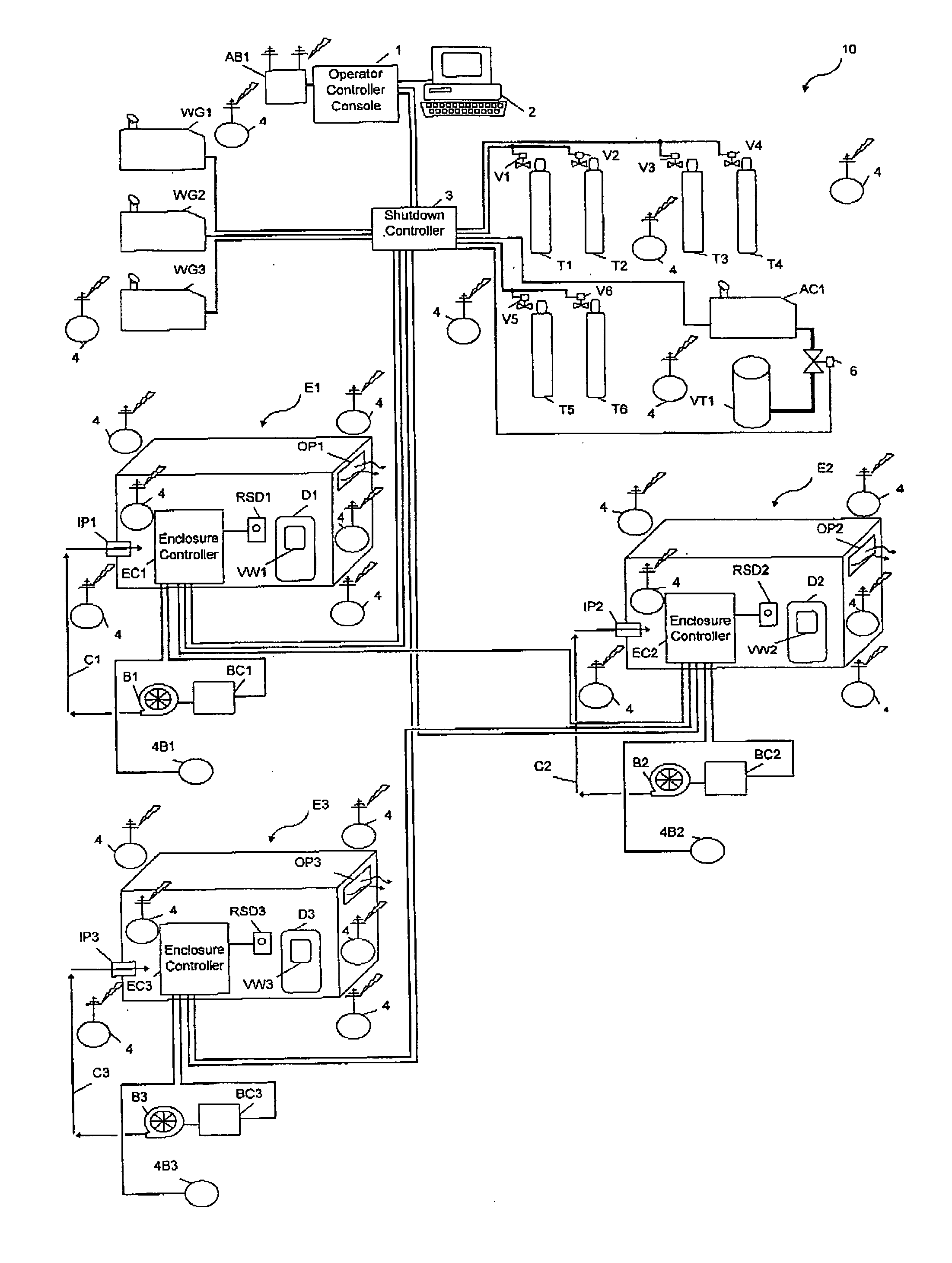

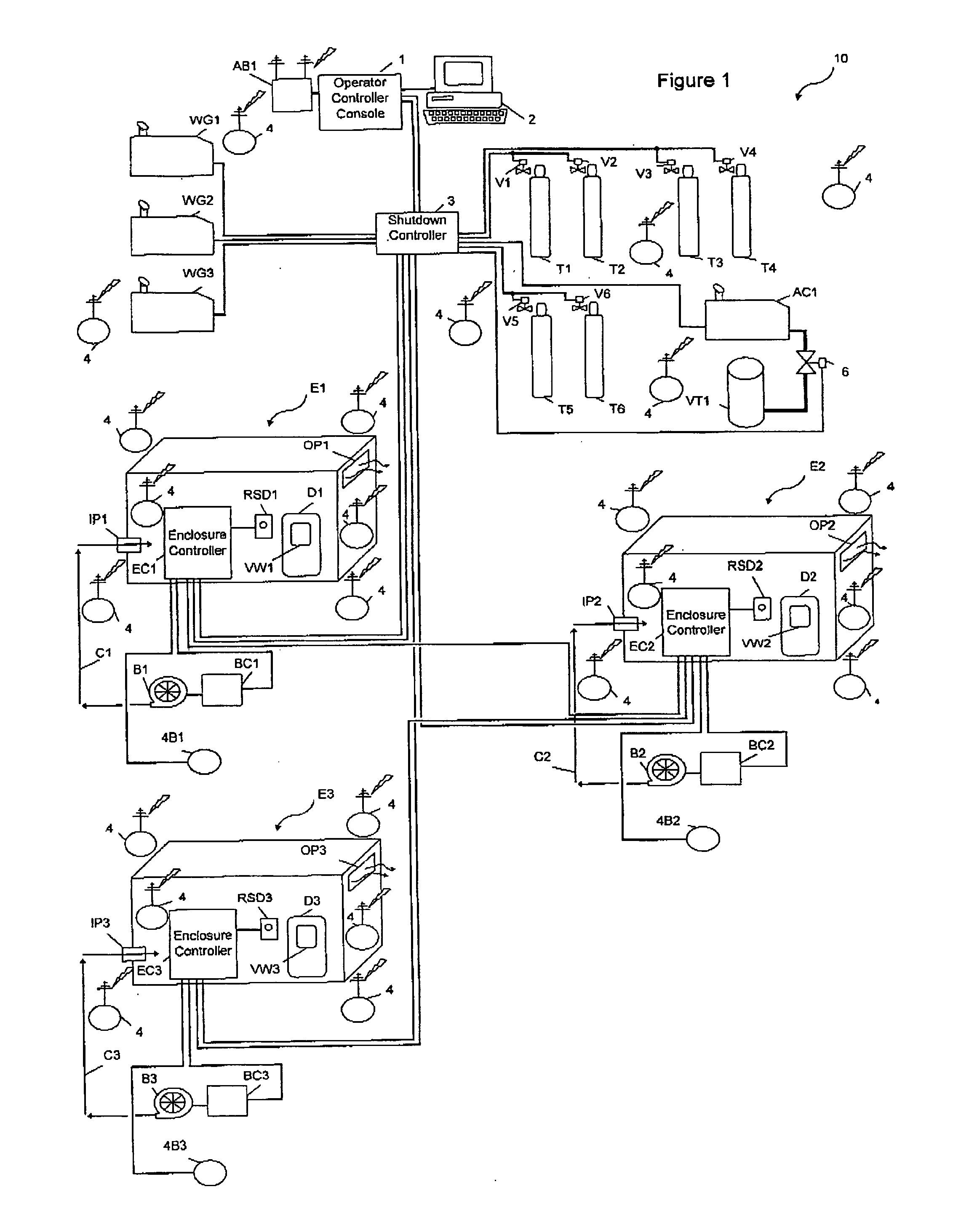

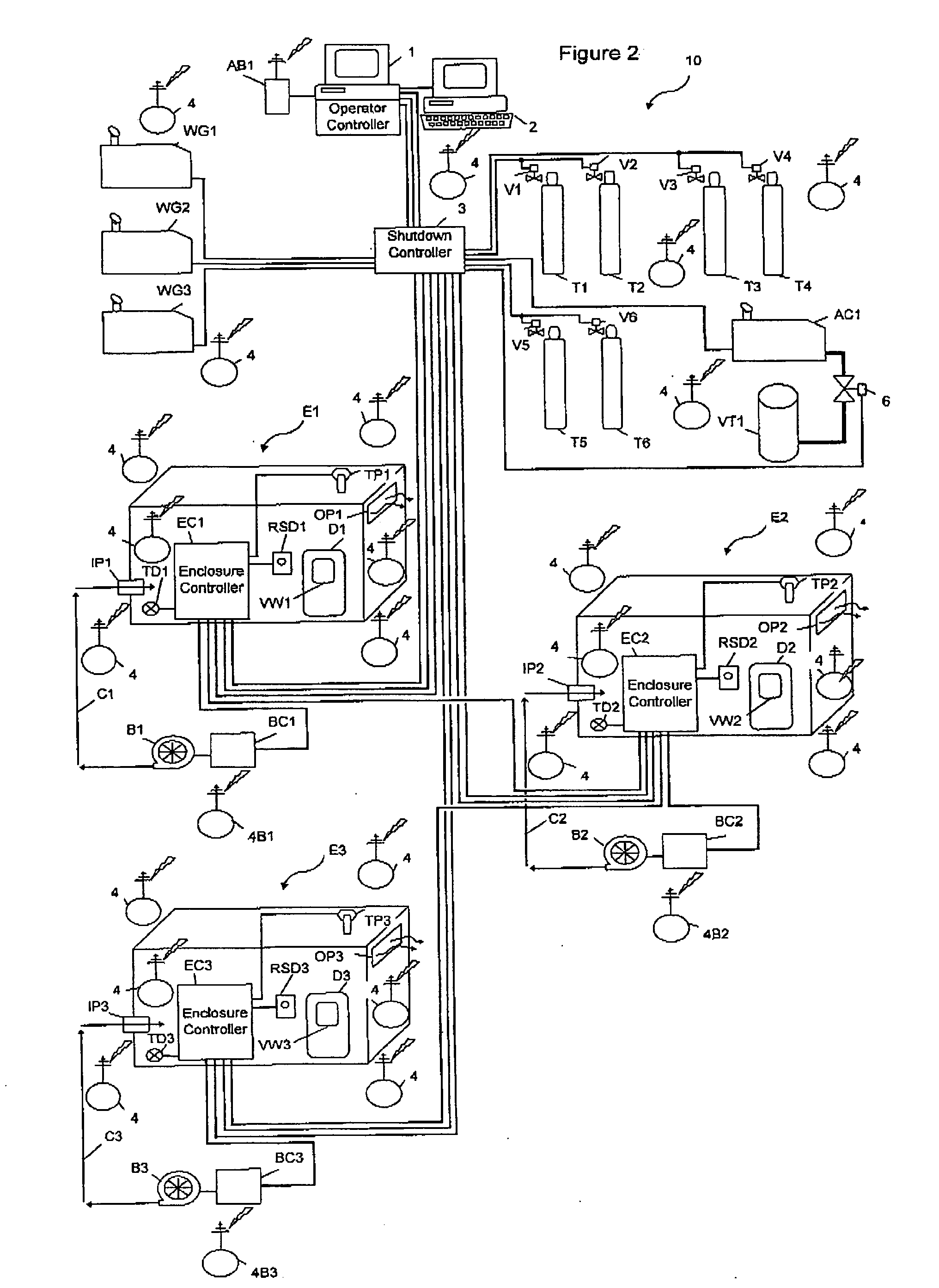

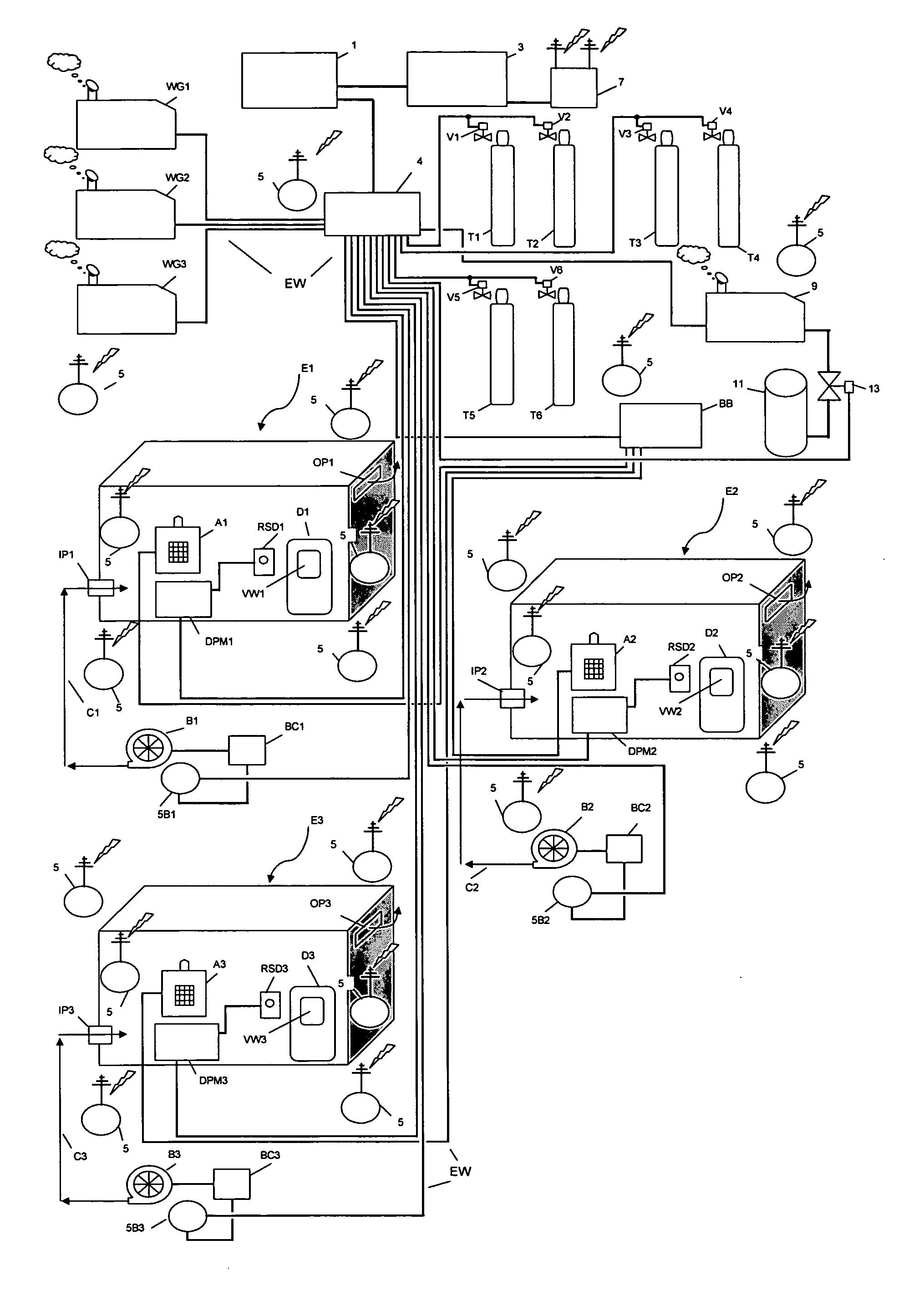

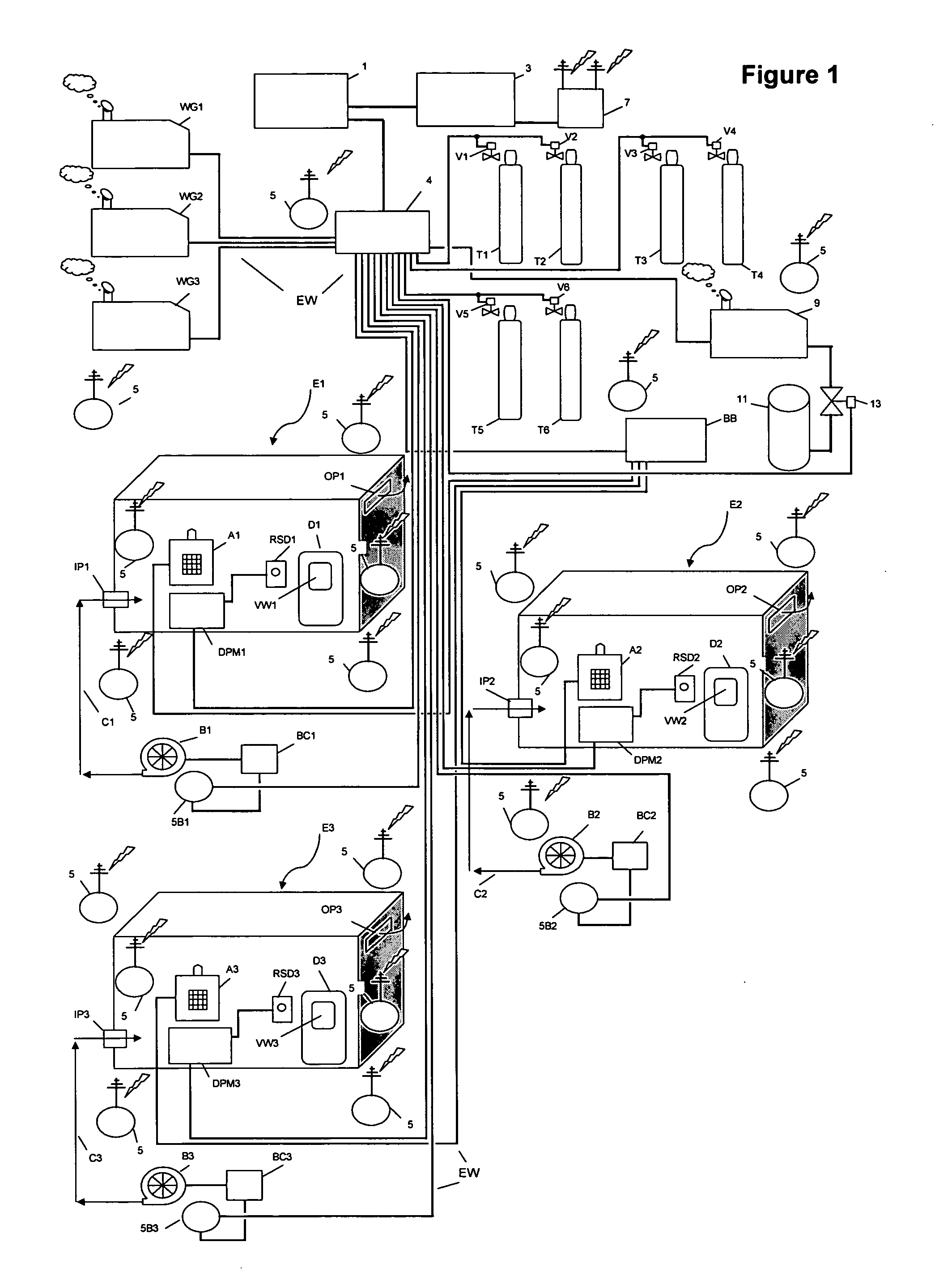

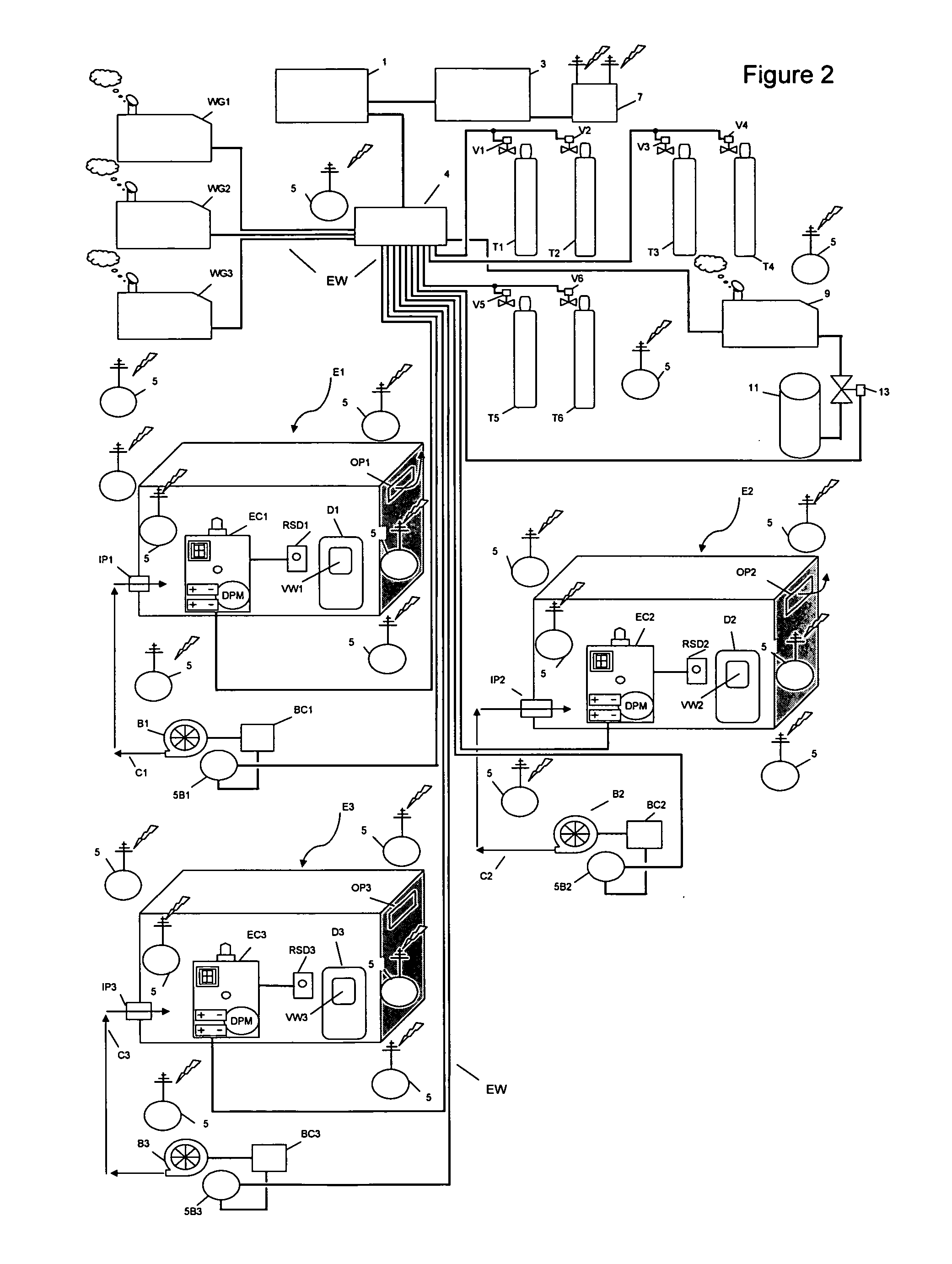

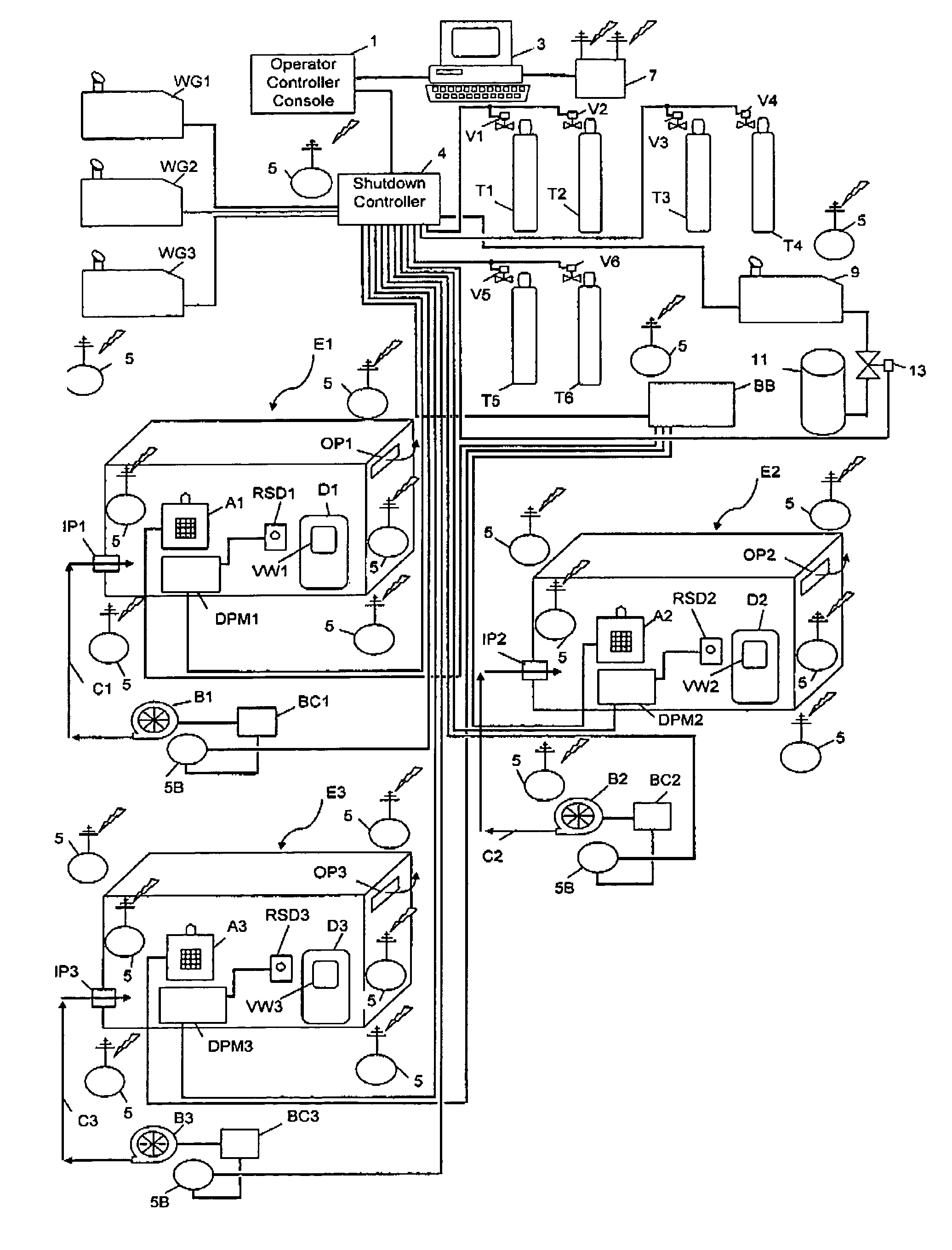

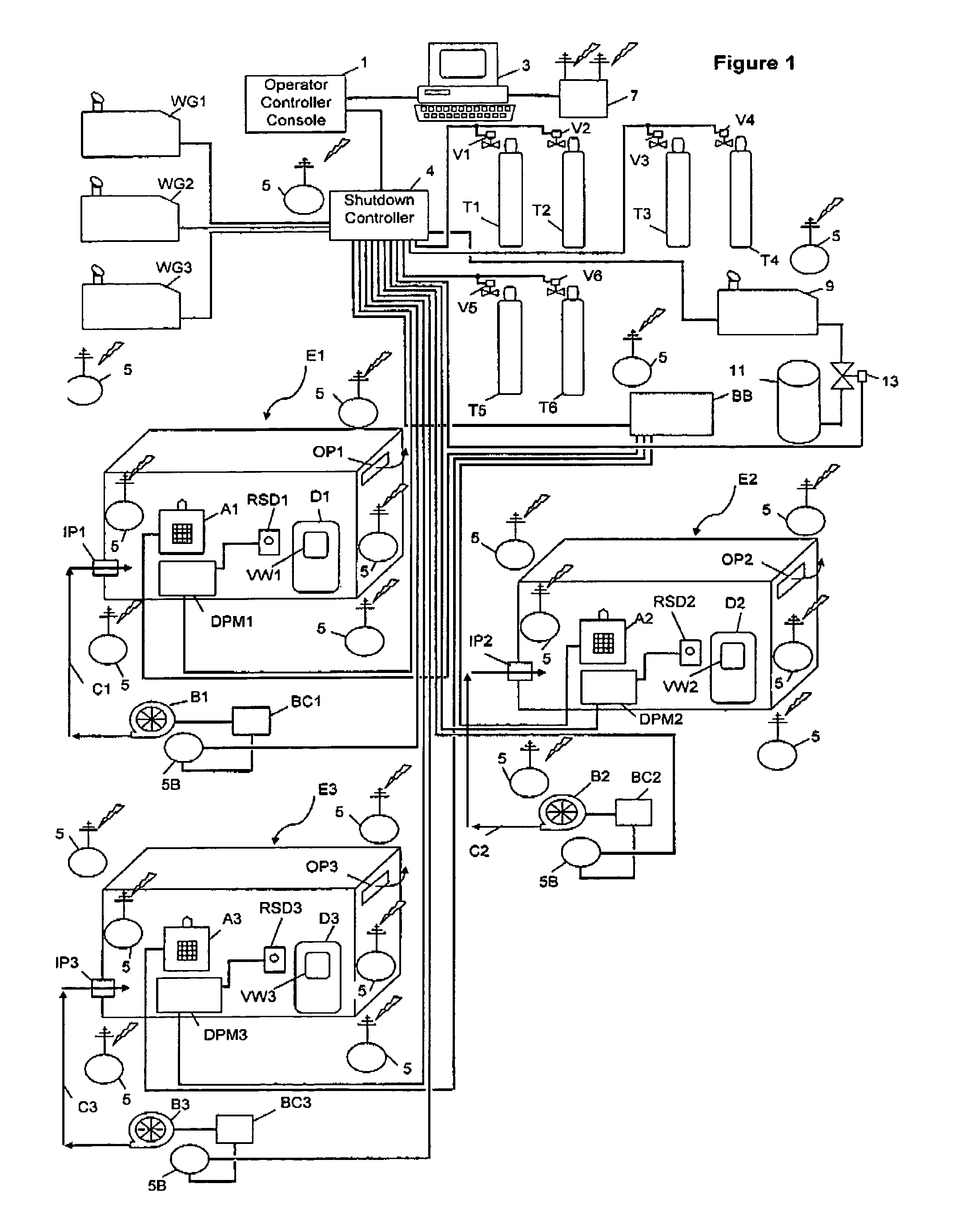

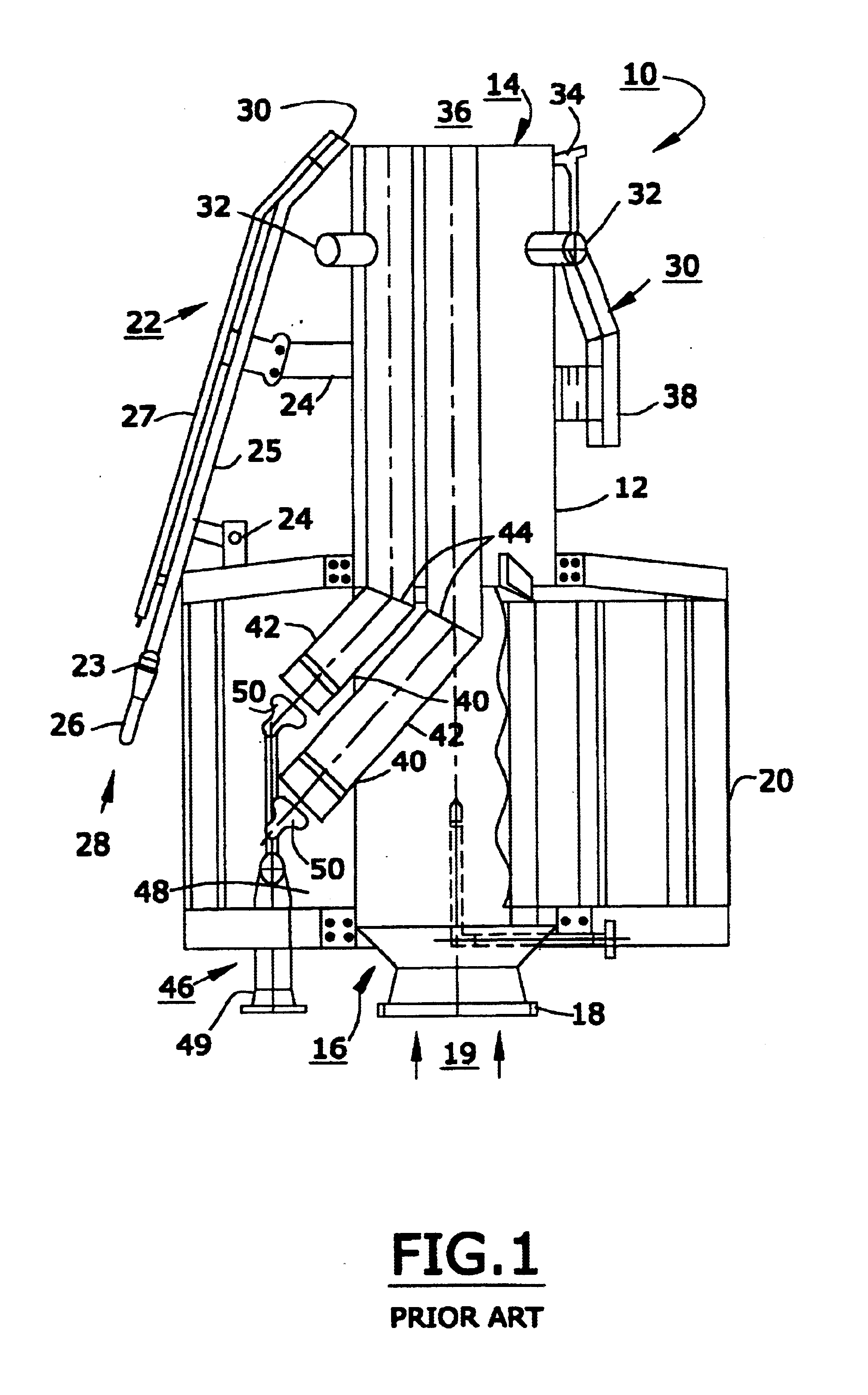

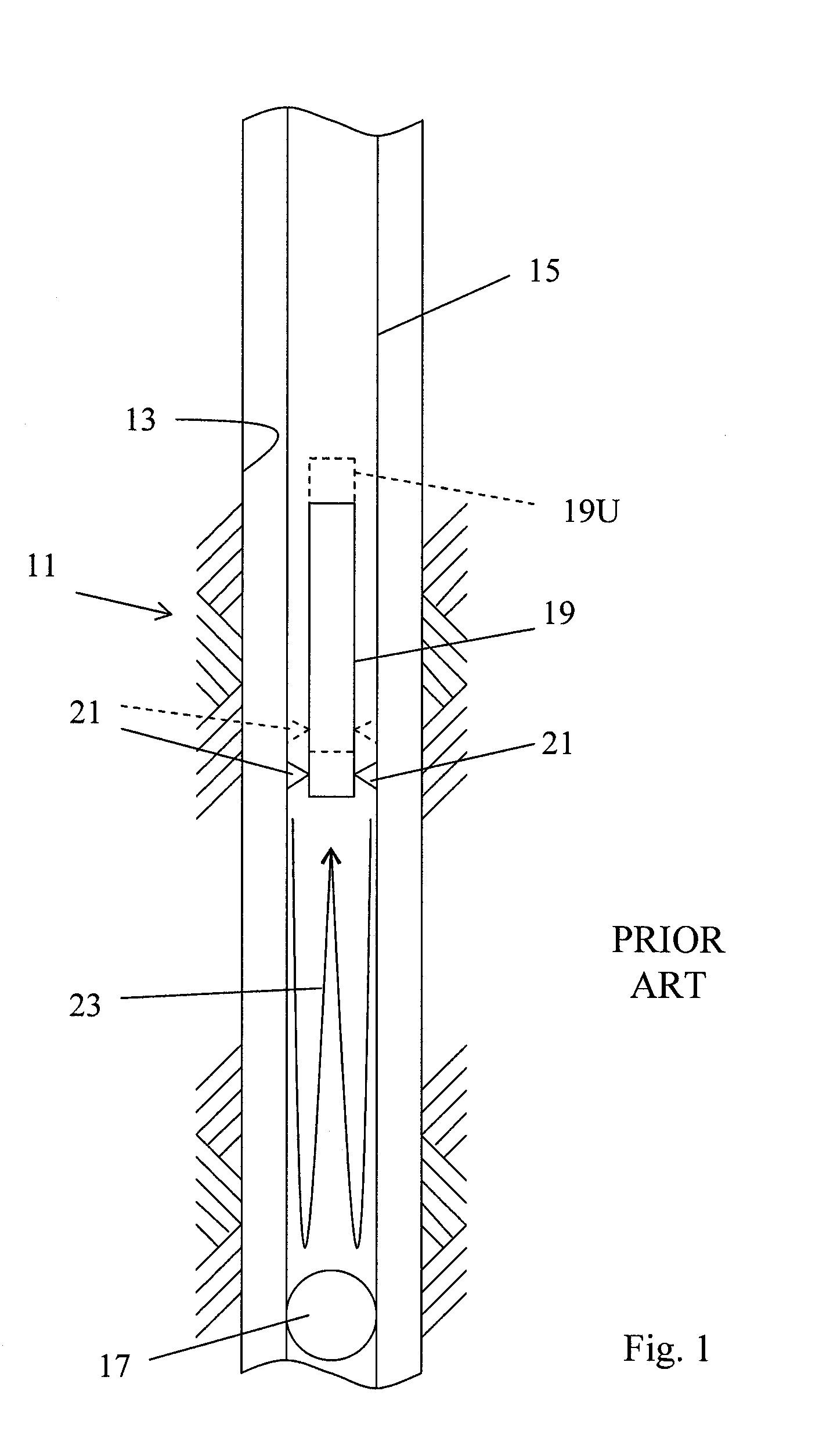

Enclosure system allowing for hot work within the vicinity of flammable and combustible material

InactiveUS20070052543A1Welding/cutting auxillary devicesElectric testing/monitoringCompound (substance)Hot work

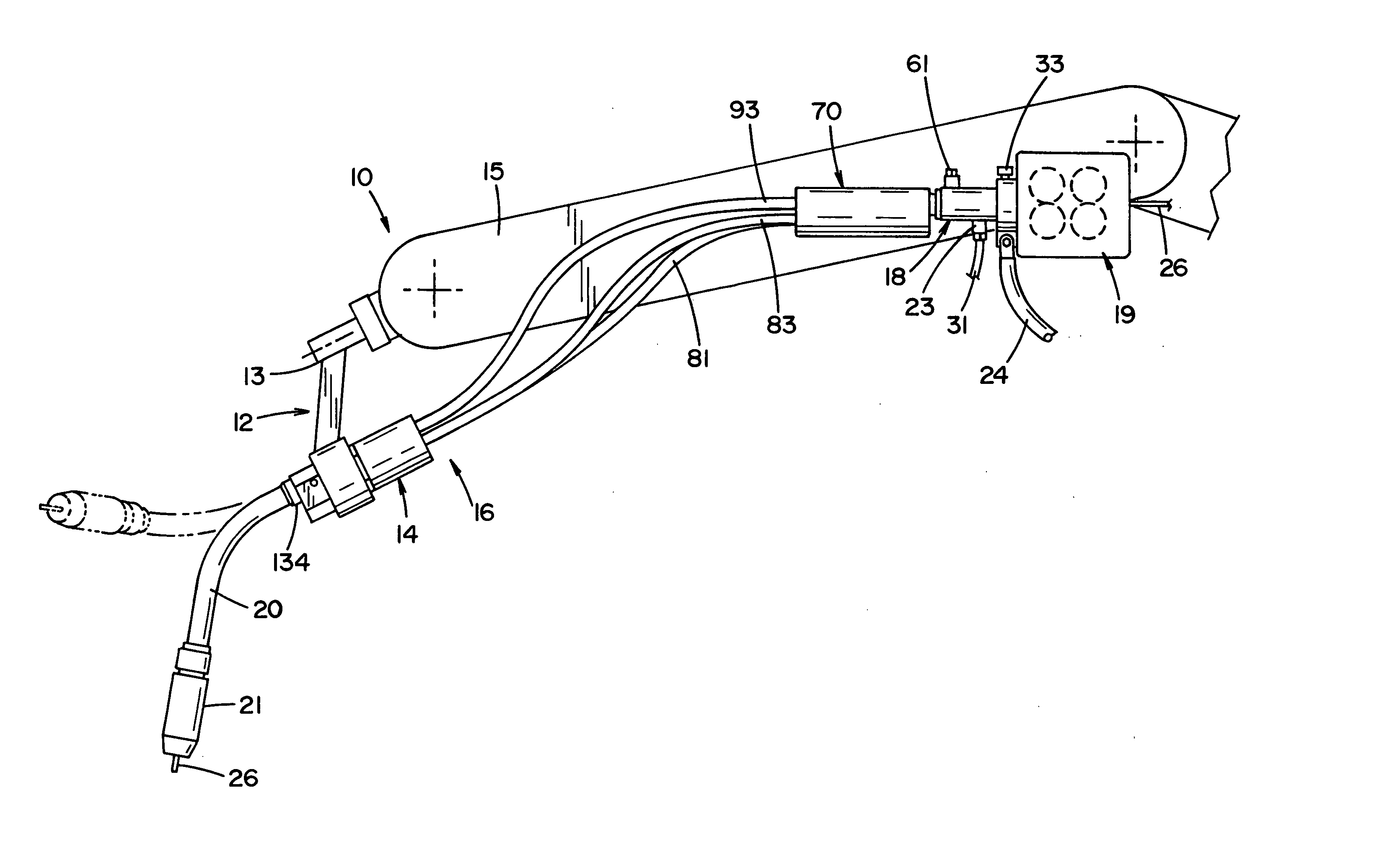

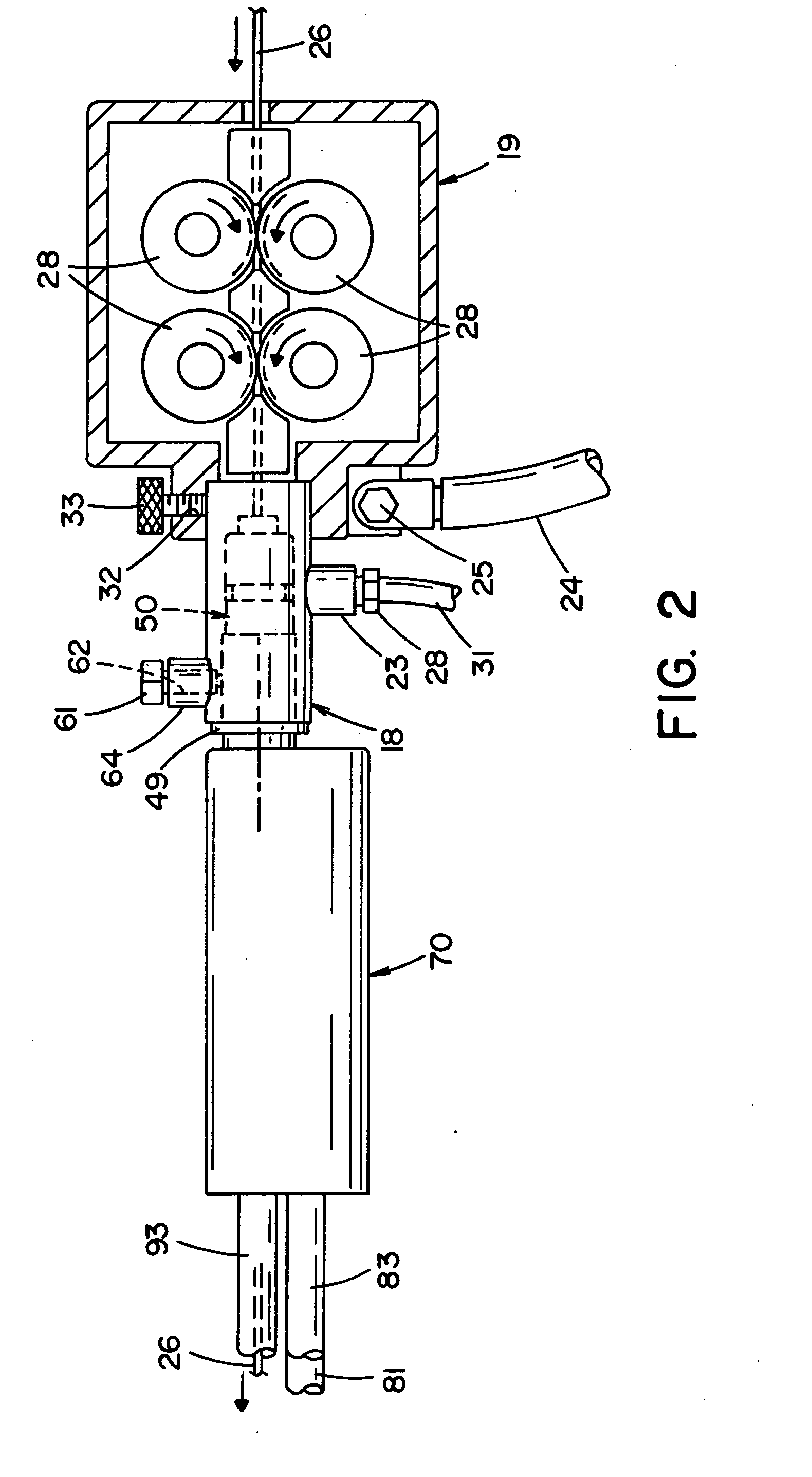

An enclosure constructed around an area at which hot work is to be performed at a facility containing flammable or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like. Facilities include petroleum drilling and production platforms, oil tankers, petroleum and chemical plants, and petroleum tank farms. Gas detection monitoring apparatuses are used with the enclosure which will automatically simultaneously shutdown one or more enclosures.

Owner:ALFORD SAFETY SERVICES

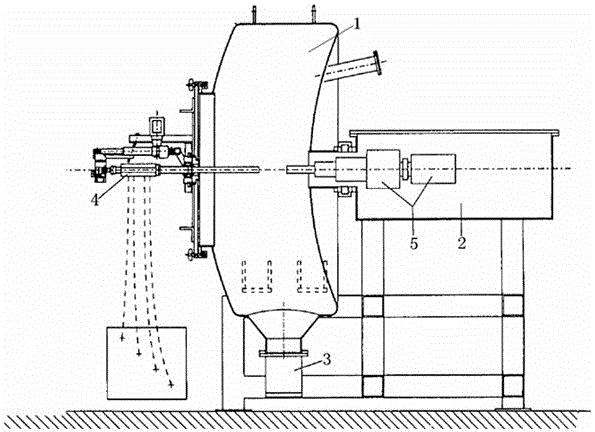

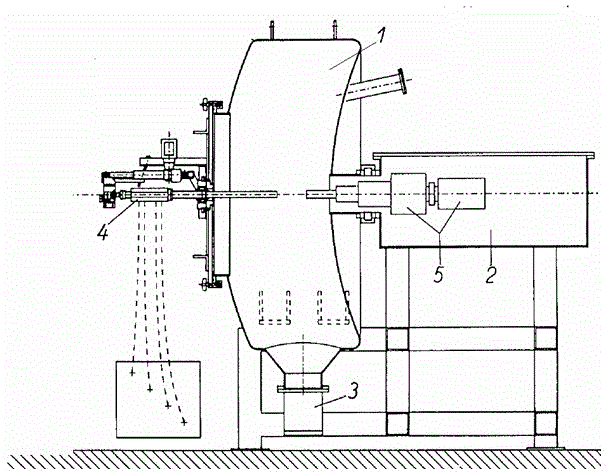

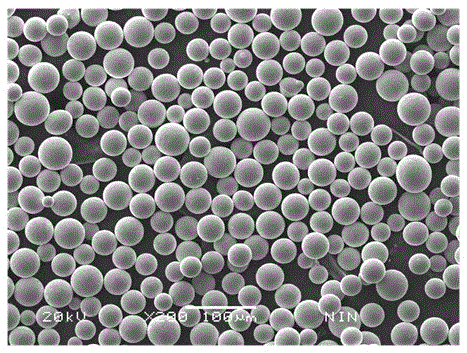

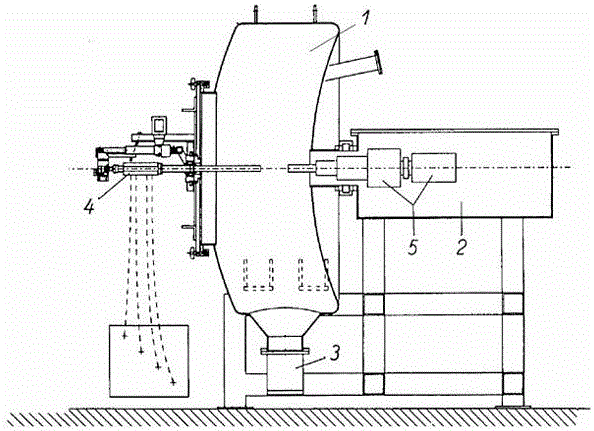

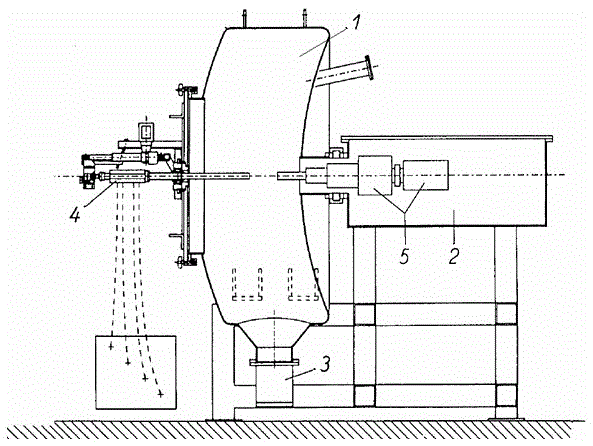

Method for preparing Inconel 625 alloy spherical powder

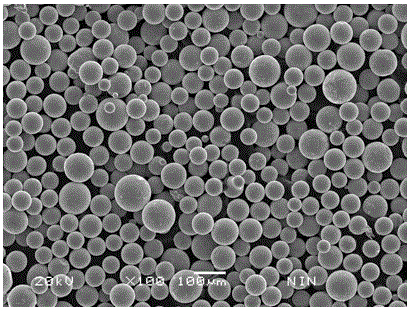

InactiveCN105689730AFast pure meltingReduce the introductionTransportation and packagingMetal-working apparatusPlasma torchPressure range

A method for preparing Inconel 625 alloy spherical powder comprises following steps: according to the AMS 5666G standard, two-time vacuum smelting of alloy ingredient compositions and a master ingot is carried out; through forging and mechanical machining, the master ingot is made into an alloy electrode bar; atomizing equipment is subject to pre-vacuum-pumping treatment, mixed inert shielding gas is led into the atomizing equipment, and the pressure ranges from 0.1*105 Pa to 3*105 Pa; the electrode bar is fed into an atomizing chamber through a feeding system, a plasma torch is used for heating the end face of the electrode bar, metal liquid drops are prepared through the centrifugal effect of a rotating electrode, and the metal liquid drops are instantly solidified into the spherical metal powder; and a powder collecting device containing an electrostatic separation component carries out inclusion removing treatment and pure powder collection on the metal spherical powder. The method has the beneficial effects of being high in production efficiency, high in batch stability, high in fine powder yield and the like and can easily prepare the Inconel 625 alloy spherical powder with the high purification, the good sphericility degree and the high liquidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

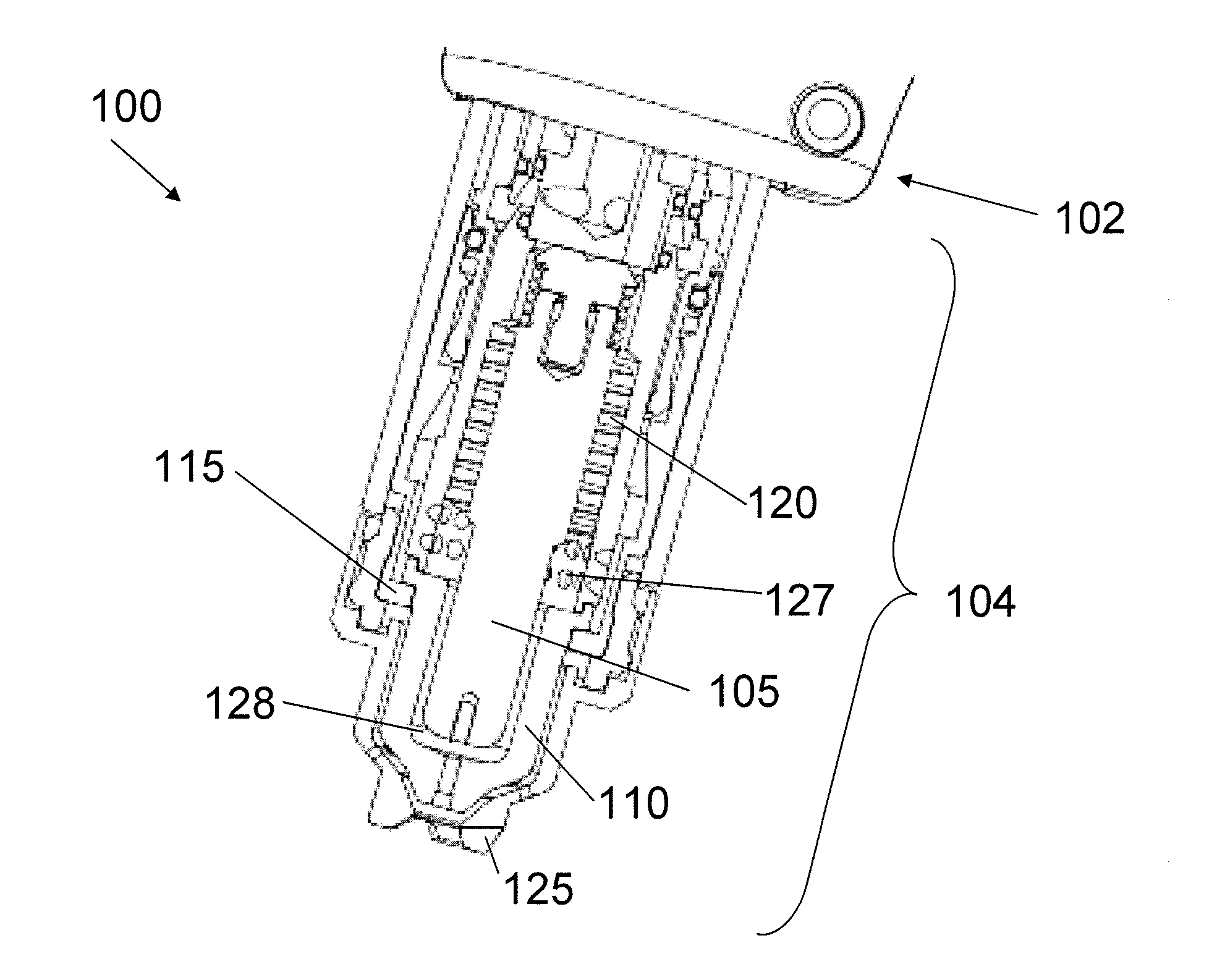

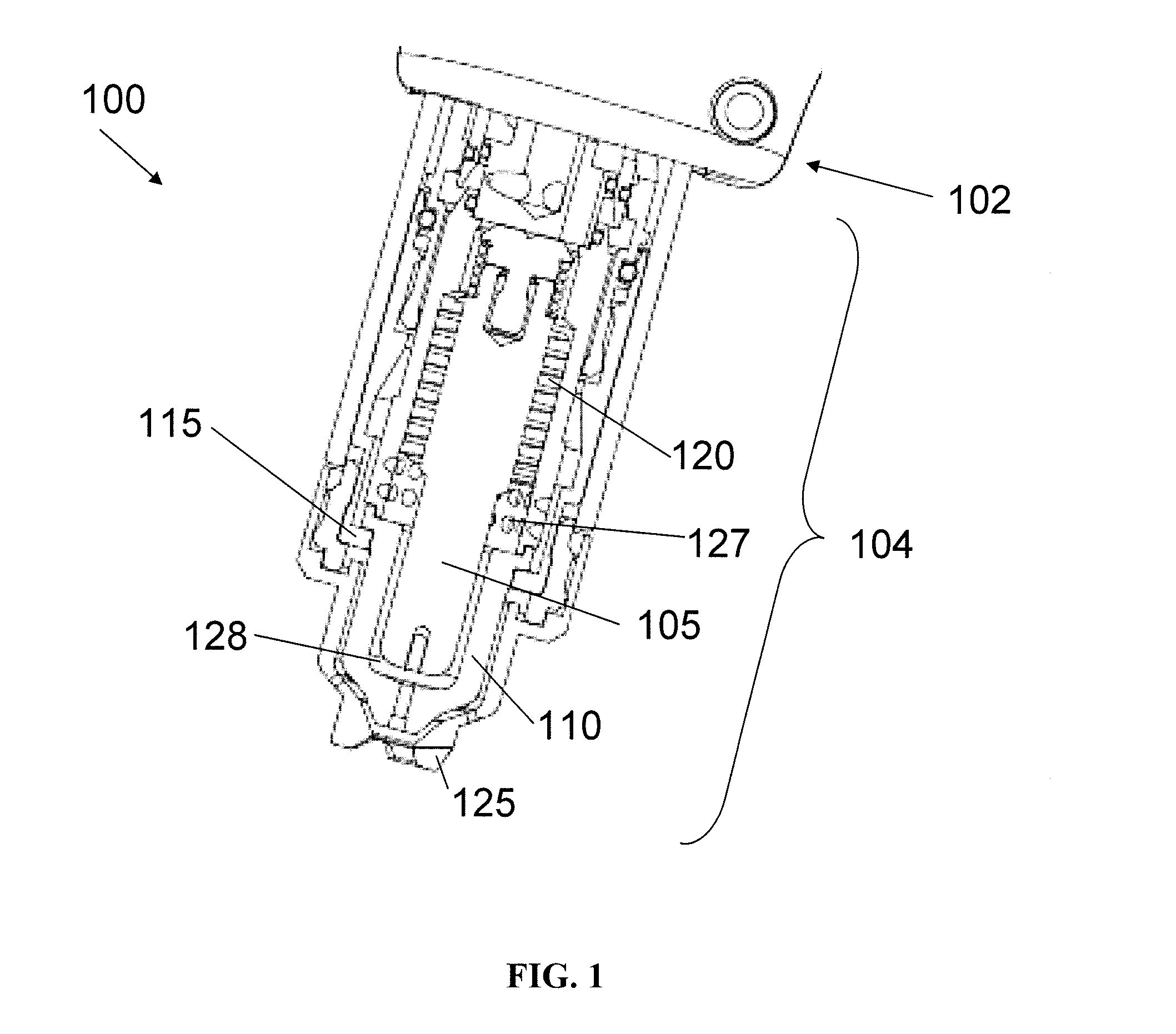

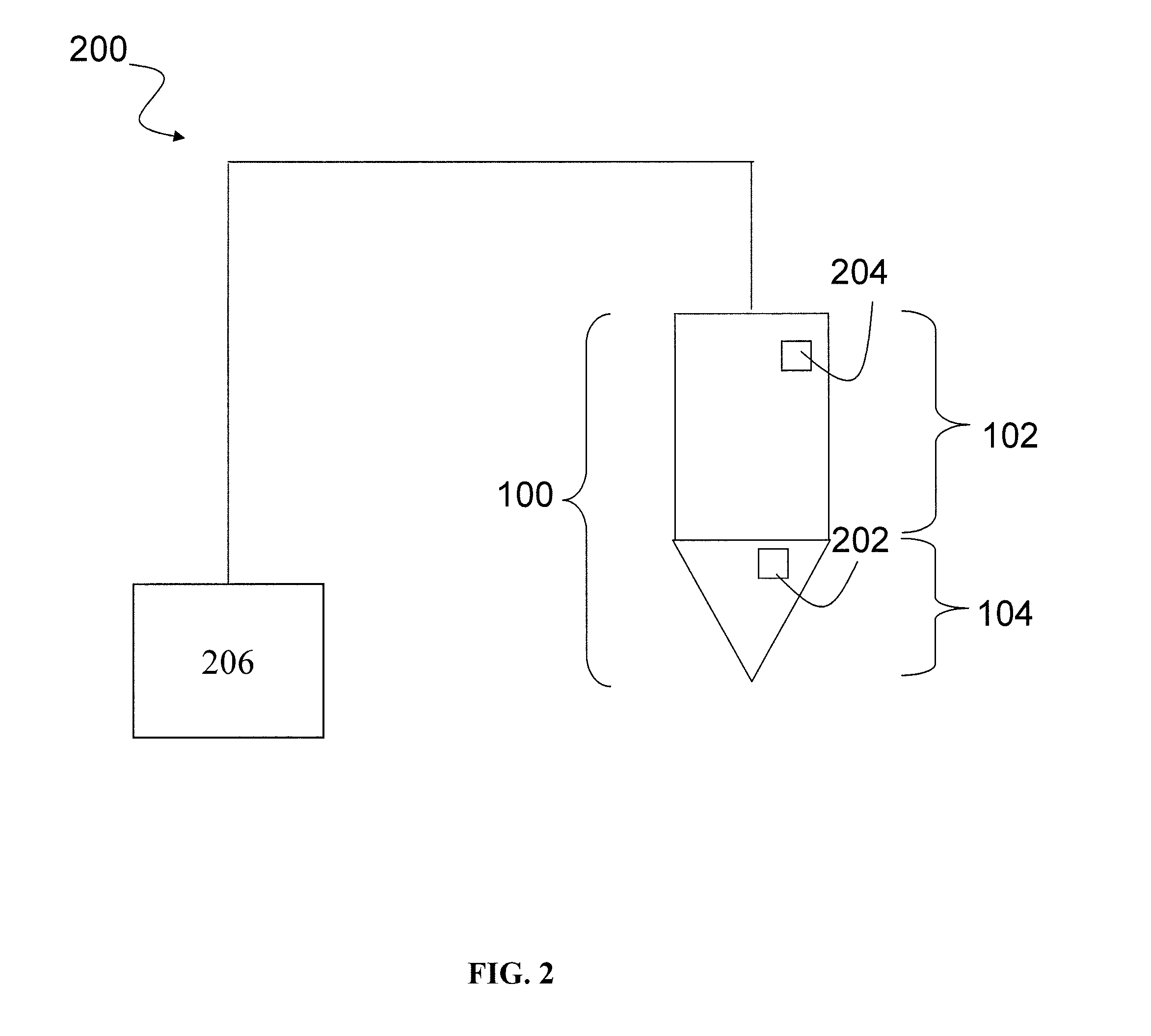

Optimization and Control of Material Processing Using a Thermal Processing Torch

InactiveUS20130263420A1Improve cut qualityProlong consumable lifeMeasurement/indication equipmentsPlasma welding apparatusProcess systemsEngineering

A method is provided for configuring two thermal processing systems. The method includes providing a first consumable for use in a first thermal processing torch and a second consumable for use in a second thermal processing torch. The first and second consumables have substantially identical physical characteristics. The first and second torches are mounted in a first thermal process system and a second thermal processing system, respectively. The method also includes sensing, by the first thermal processing system, first data stored in a first signal device associated with the first consumable and sensing, by the second thermal processing system, second data stored in a second signal device associated with the second consumable.

Owner:HYPERTHERM INC

Method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder

The invention provides a method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder. The preparation method comprises the following steps: preparing materials of alloy components according to ASTM F1295 standards and carrying out two times of vacuum melting on a mother alloy ingot; preparing the mother alloy ingot into an alloy electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing mixed inert protective gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The method provided by the invention has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the Ti-6Al-7Nb medical titanium alloy spherical powder with high sphericity degree, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

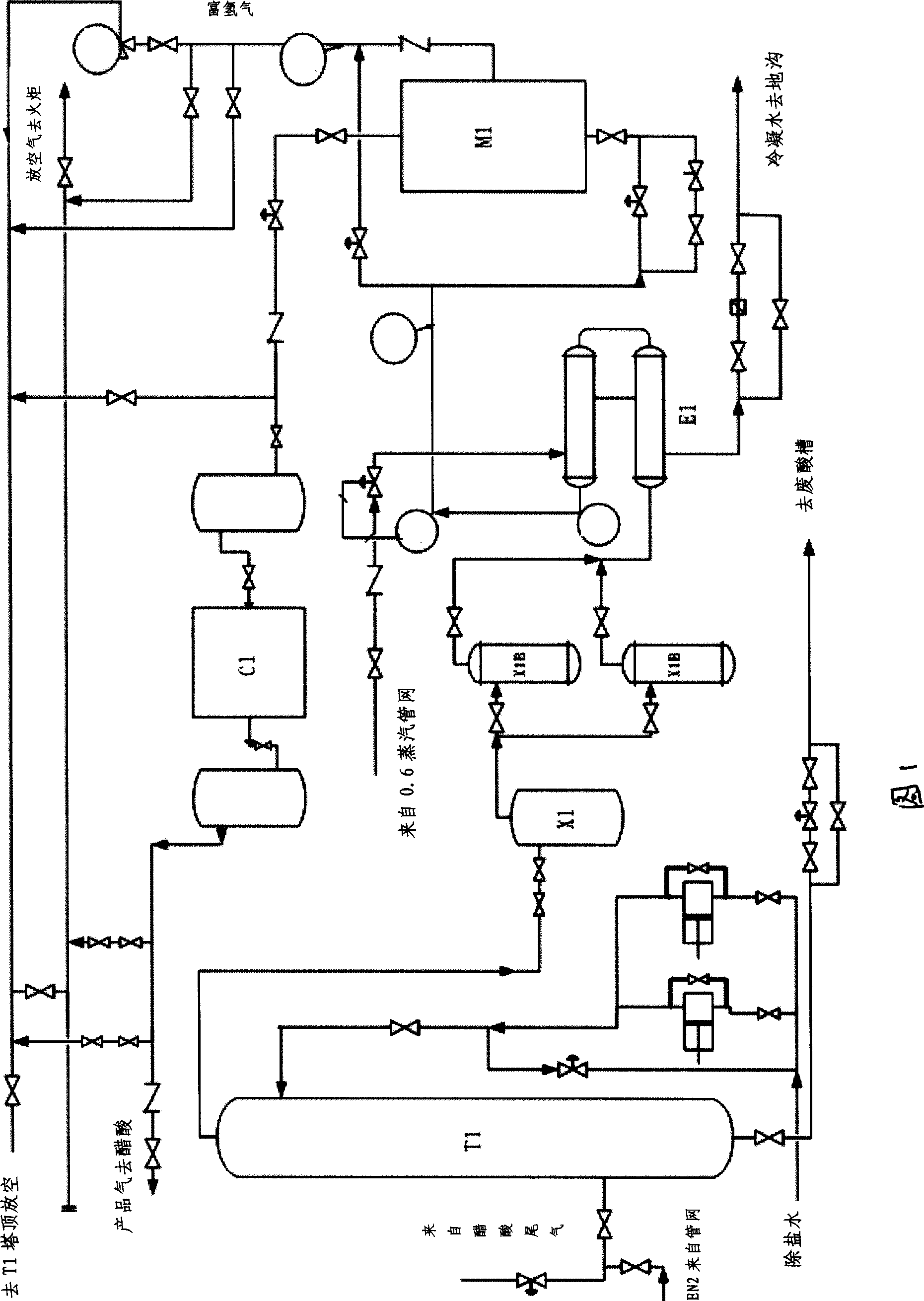

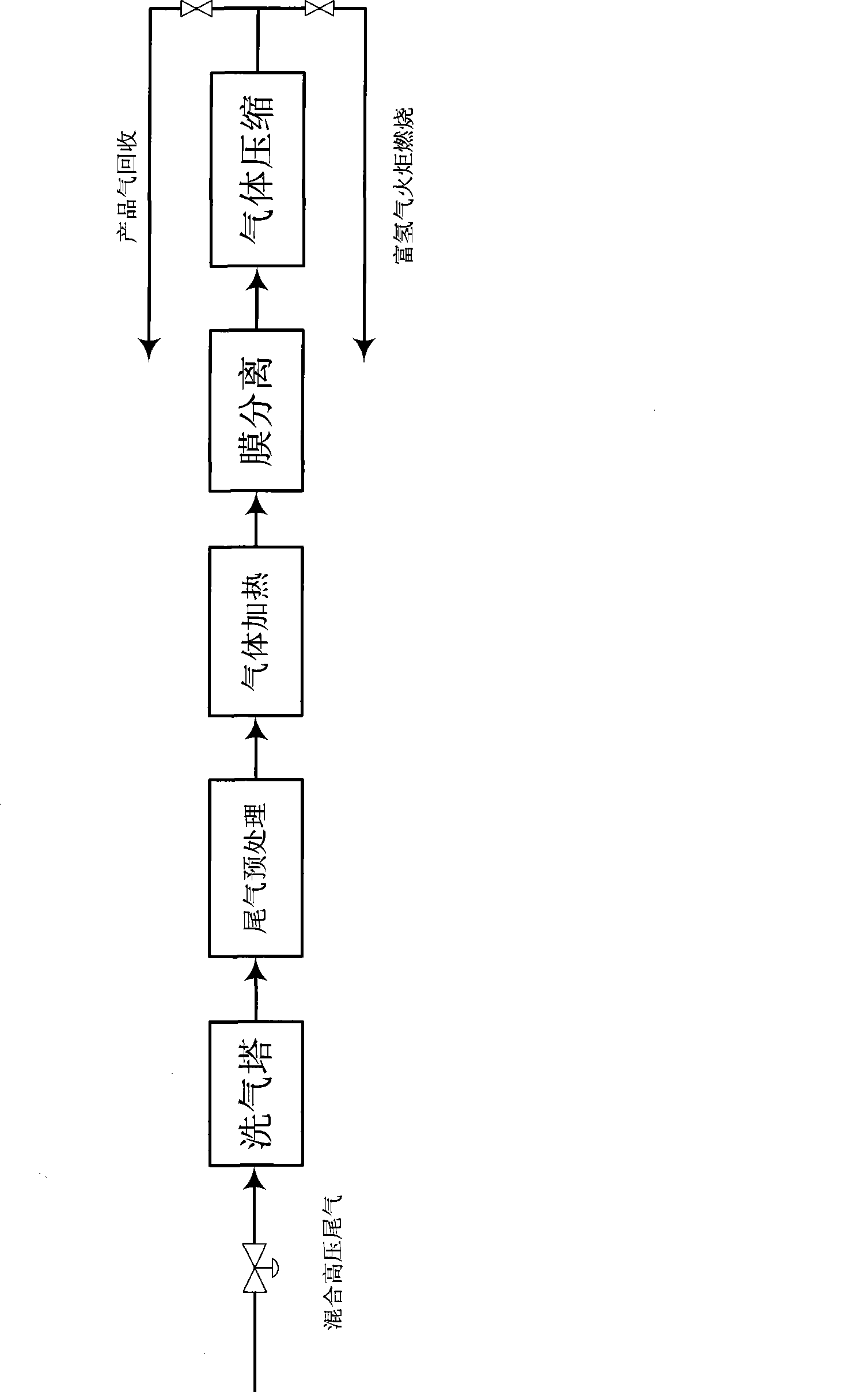

Film method for recycling CO in high-pressure exhaust from production of acetic acid by carbonylation

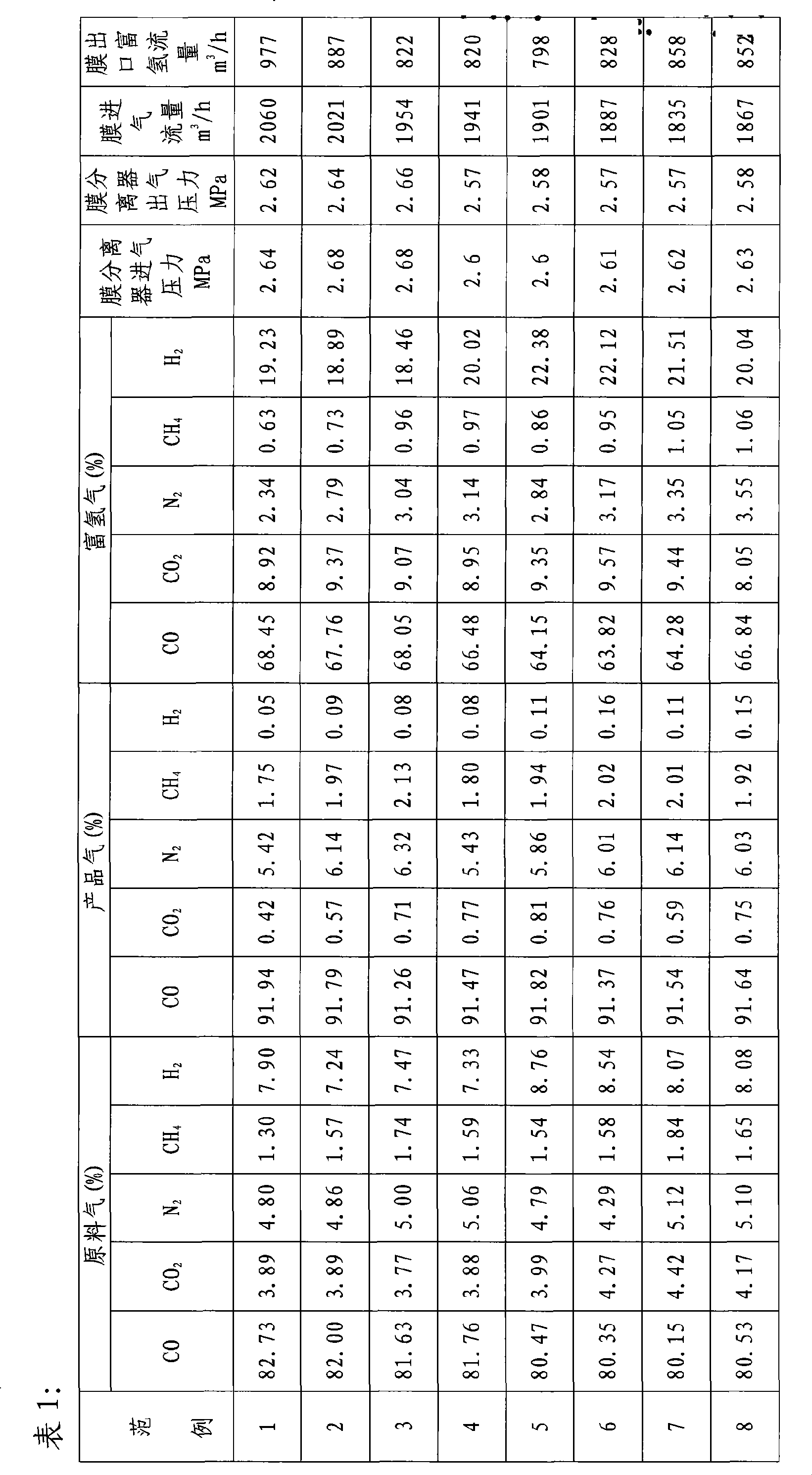

ActiveCN101439256AMeet the need for protectionImprove operational reliabilityOrganic compound preparationDispersed particle separationAcetic acidMaterial balance

The invention discloses a method for recovering CO from a high-pressure acetic acid tail gas produced by carbonylation through a membrane process and a device thereof. The tail gas is treated by three steps, that is, pretreatment, membrane separation and gas compression: the tail gas that passes a gas washing tower, a demister and a combined filter enters a Prisen membrane separator through a heater, the tail gas after the membrane separation enters a compressor, a product gas is recovered and reused, and hydrogen rich gas flows to a torch for burning. In the method, two Prisen membrane systems help control the amount of the feed gas entering a membrane, the product gas and the hydrogen rich gas to reach N2 material balance, ensure the CO recovery rate and achieve the purpose of the long and stable operation of a membrane separation device; and the content of the CO in the final product gas is not less than 91%.

Owner:JIANGSU SOPO CHEM

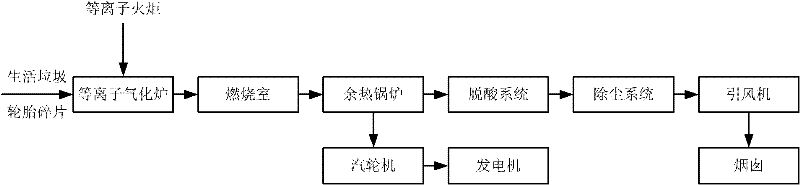

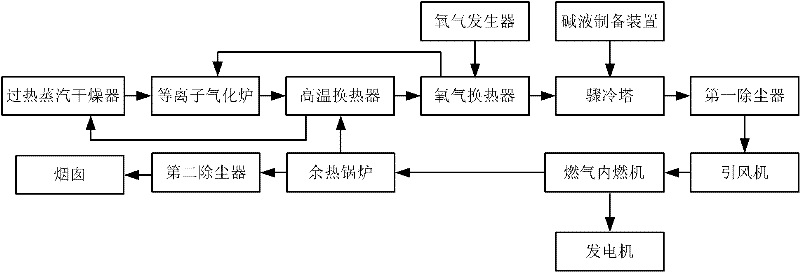

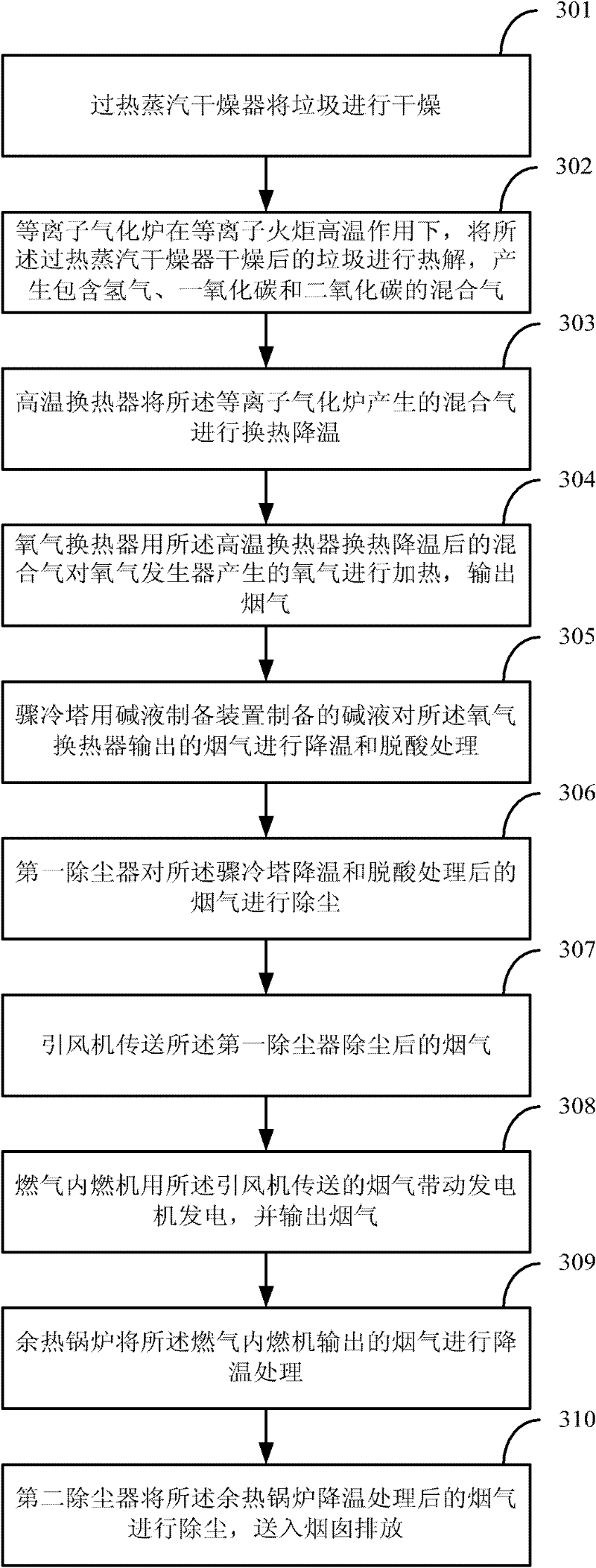

Plasma waste treatment system and method

InactiveCN102284467AIncrease profitImprove thermal efficiencySolid waste disposalRecuperatorInternal combustion engine

The invention discloses a plasma garbage treatment system and method, comprising: a superheated steam drier to dry garbage; a plasma gasification furnace pyrolyzing the dried garbage under the high temperature of a plasma torch to generate hydrogen, carbon monoxide and carbon dioxide Mixed gas; the high temperature heat exchanger performs heat exchange and cooling of the mixed gas; the oxygen heat exchanger uses the mixed gas after heat exchange and cooling to heat the combustion-supporting oxygen to output flue gas; the quench tower uses lye to cool the oxygen output from the oxygen heat exchanger The flue gas is cooled and deacidified; the first dust collector removes dust from the flue gas treated by the quenching tower; the induced draft fan transmits the flue gas after the first dust collector removes dust; the gas internal combustion engine uses the flue gas transmitted by the induced fan to drive the generator Generate electricity and output flue gas; the waste heat boiler cools the flue gas output by the gas-fired internal combustion engine; the second dust collector removes dust from the flue gas cooled by the waste heat boiler, and sends it to the chimney for emission. By adopting the invention, the waste heat utilization rate and thermal efficiency of waste treatment can be improved.

Owner:BEIJING ENERGY INVESTMENT HLDG

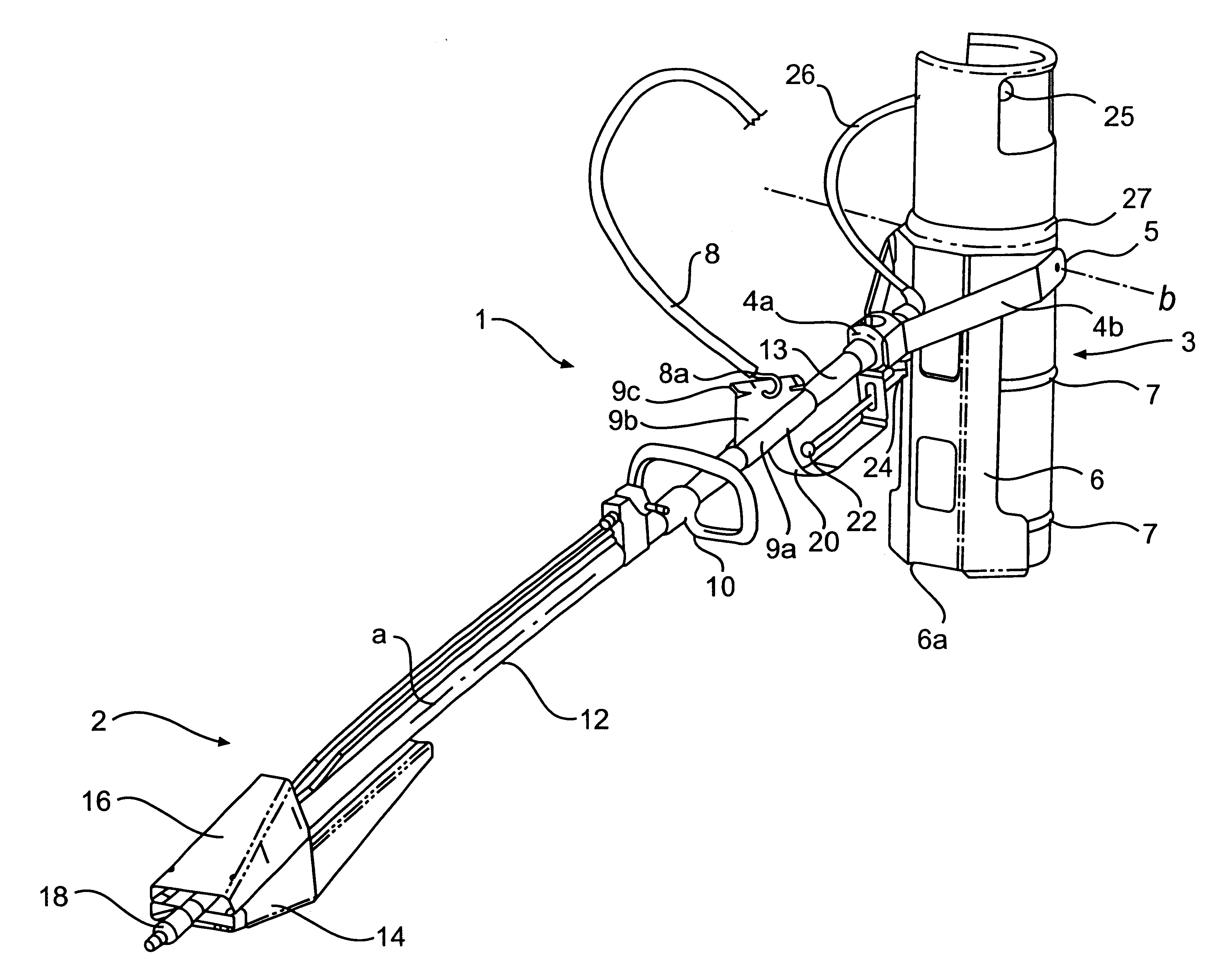

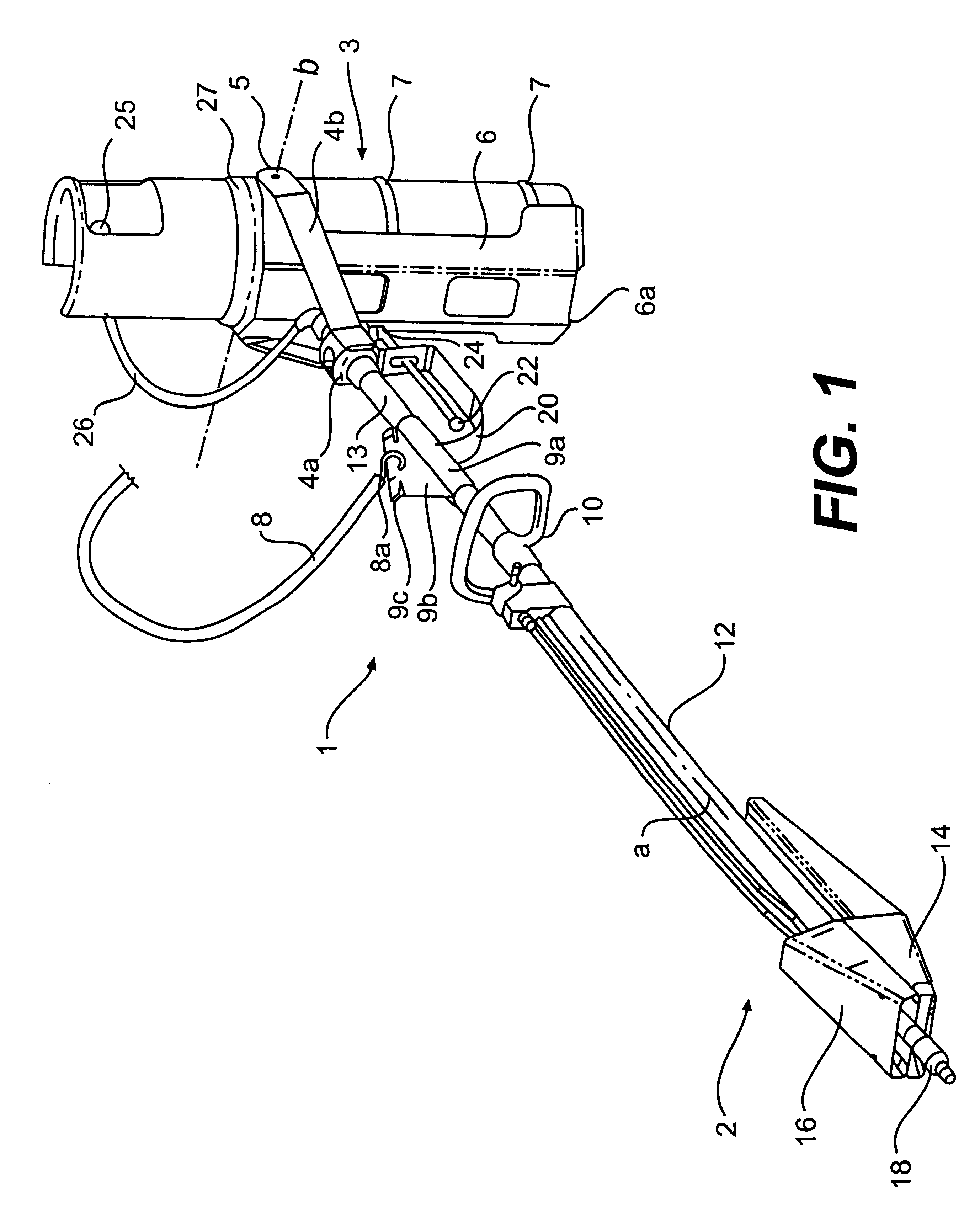

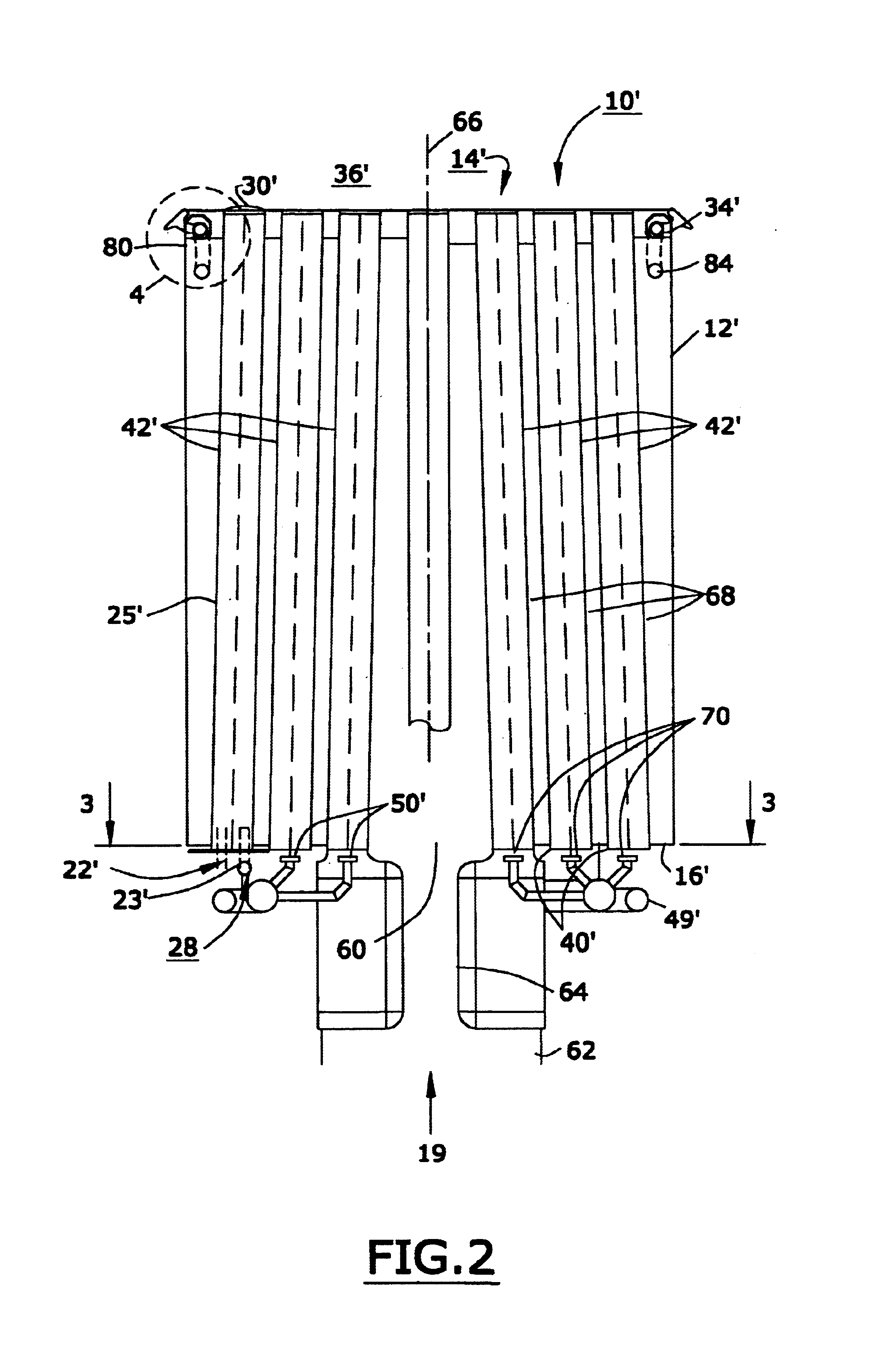

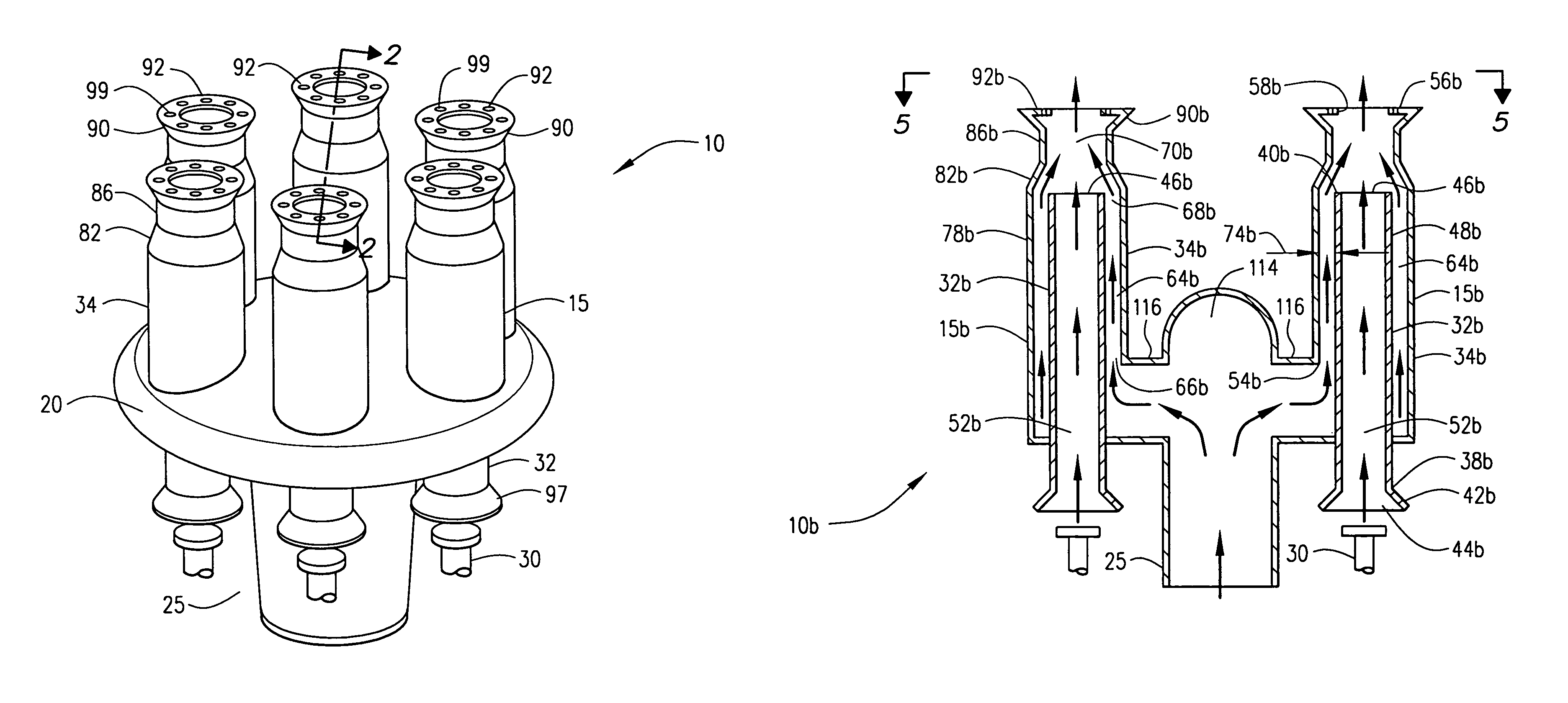

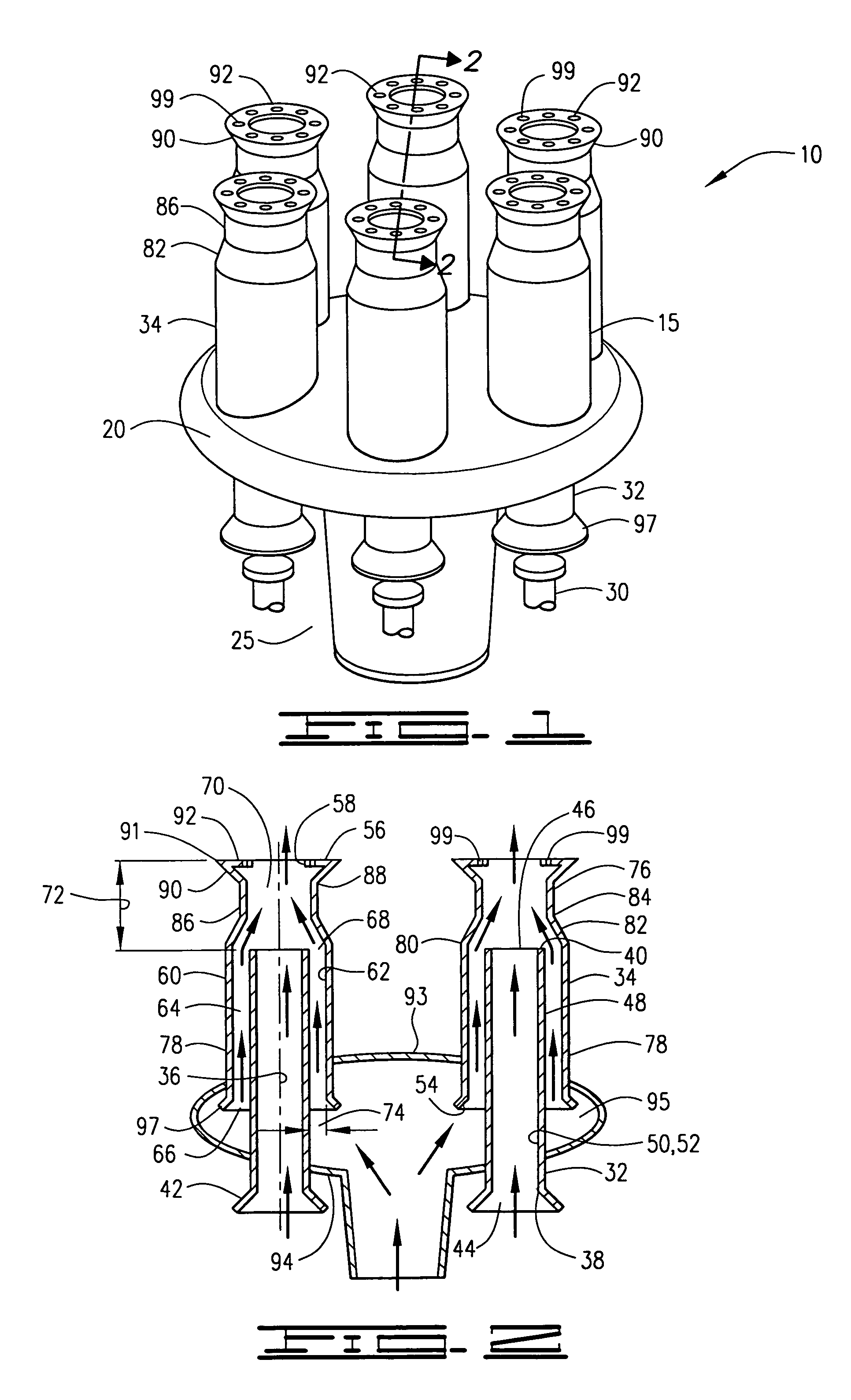

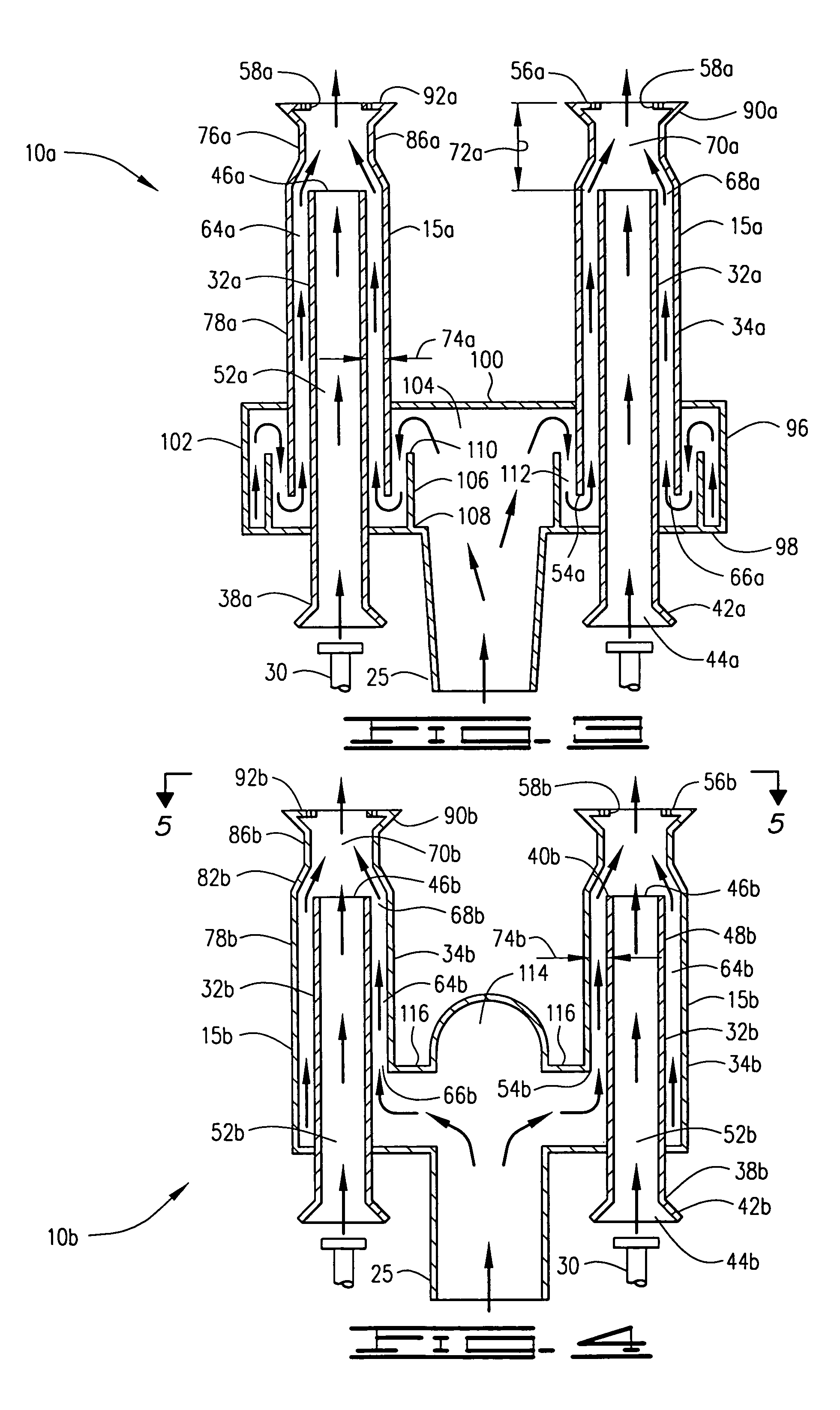

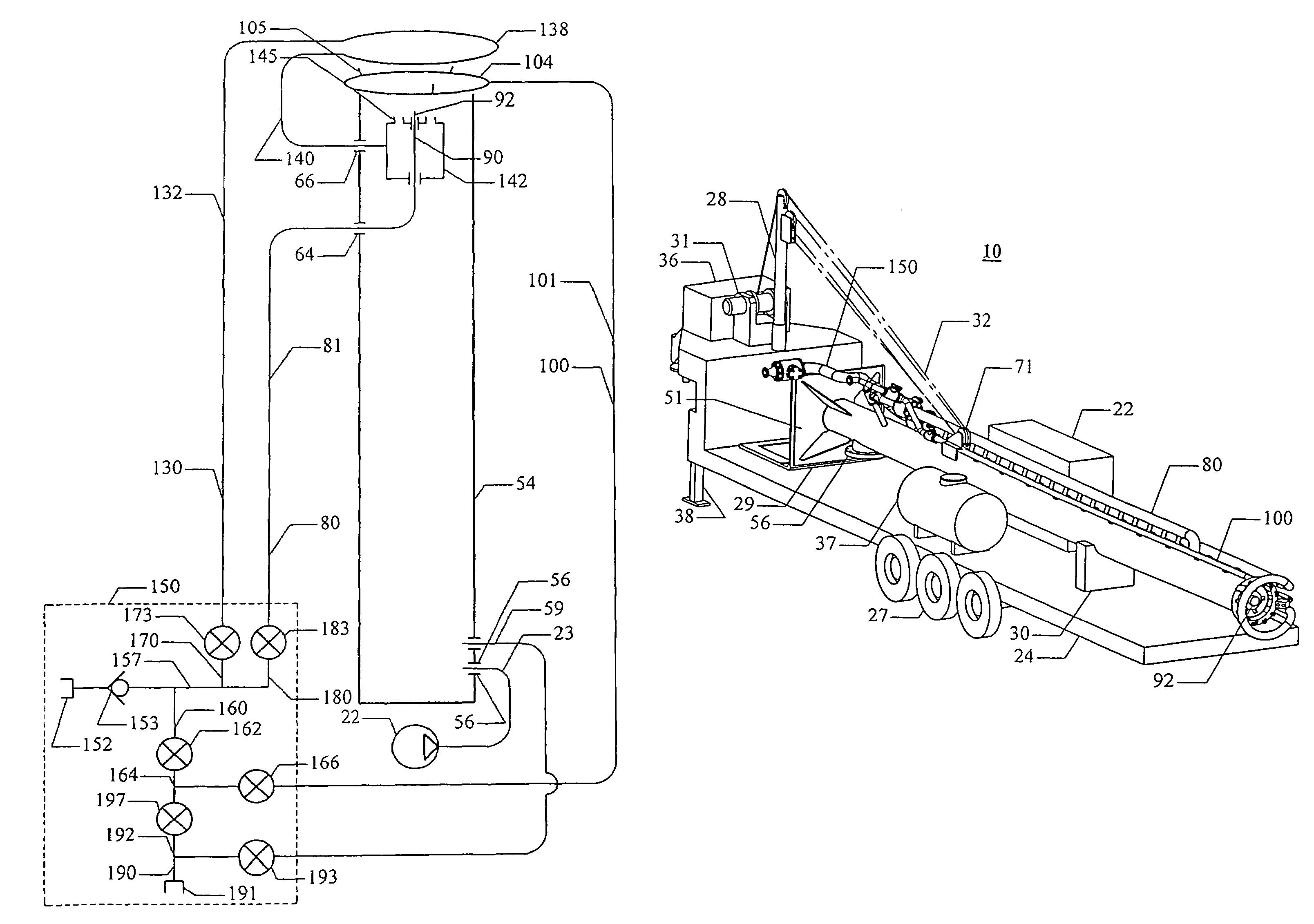

Enclosure system for hot work within the vicinity of flammable or combustible material

One or more enclosures constructed about one or more objects at which hot work is to be performed at a facility containing flammable and / or combustible material. Hot work includes such things as welding, torch cutting, grinding and the like that produces heat, spark, slag or flame. The one or more enclosures are capable of being simultaneously and independently controlled and monitored by a single control and monitoring system.

Owner:ALFORD SAFETY SYST +1

Preparation method of spherical 304 stainless steel powder

The invention discloses a preparation method of spherical 304 stainless steel powder. Materials are mixed according to components of 304 stainless steel, a 304 stainless steel alloy bar is prepared with forging and machining preparation methods and then is machined into a 304 stainless steel electrode bar, the electrode bar is loaded into a reaction chamber, the reaction chamber is subjected to vacuum pumping, pre-vacuum-pumping treatment is performed on atomizing equipment, the reaction chamber is filled with inert gas in a certain ratio, and the oxygen content of the atmosphere is smaller than 0.1wt%; the electrode bar is sent into an atomizing chamber through a feeding system, the end surface of the electrode bar is heated by a plasma torch, the end melts uniformly, metal droplets are prepared under the centrifugal effect of a rotating electrode and then are instantaneously solidified into spherical metal powder, and finally, the powder is packaged through multi-layer vacuum heat sealing. The 304 stainless steel powder prepared with the method is not oxidized easily at the high temperature and is high in sphericity degree, free of hollow powder and satellite powder and controllable in particle size distribution.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

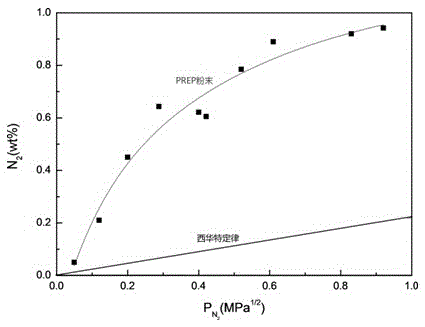

Preparation method of high-nitrogen stainless steel spherical powder

InactiveCN105618776AEnhance nitrogen increase rateIncrease powder nitrogen contentStainless steel electrodeMetal impurities

The invention provides a preparation method of high-nitrogen stainless steel spherical powder. The preparation method comprises the following steps: preparing materials according to stainless steel components and carrying out a melting process of a mother alloy ingot; preparing the mother alloy ingot into a common stainless steel electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing high-purity nitrogen gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; ionizing the nitrogen gas in an electric arc region into nitrogen ions, high-energy nitrogen molecules and un-ionized nitrogen neutral atoms so as to improve the nitrogen content of stainless steel; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The preparation method of the high-nitrogen stainless steel spherical powder has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the stainless steel spherical powder with high nitrogen content, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

Enclosure system for hot work within the vicinity of flammable or combustible material

Owner:ALFORD SAFETY SYST +1

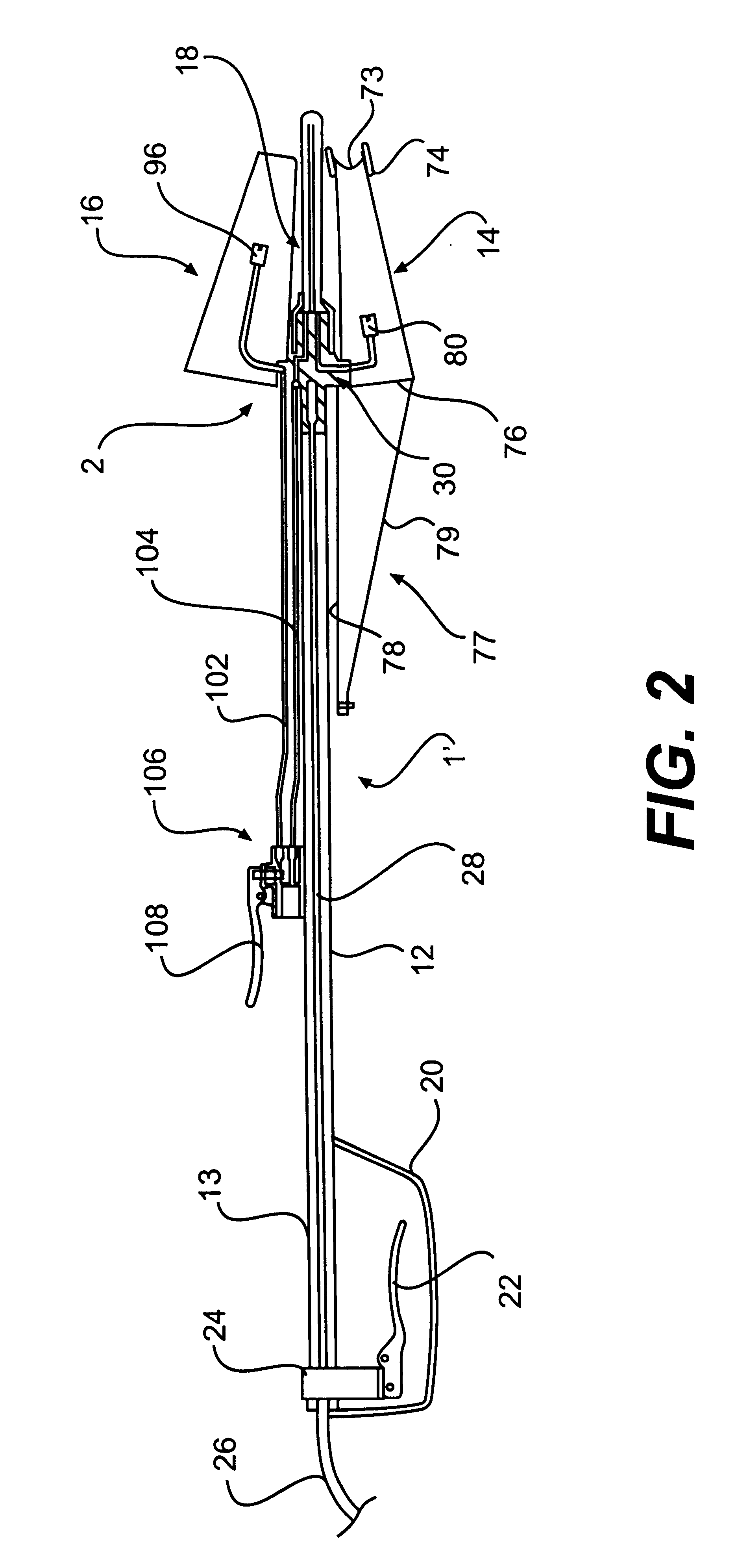

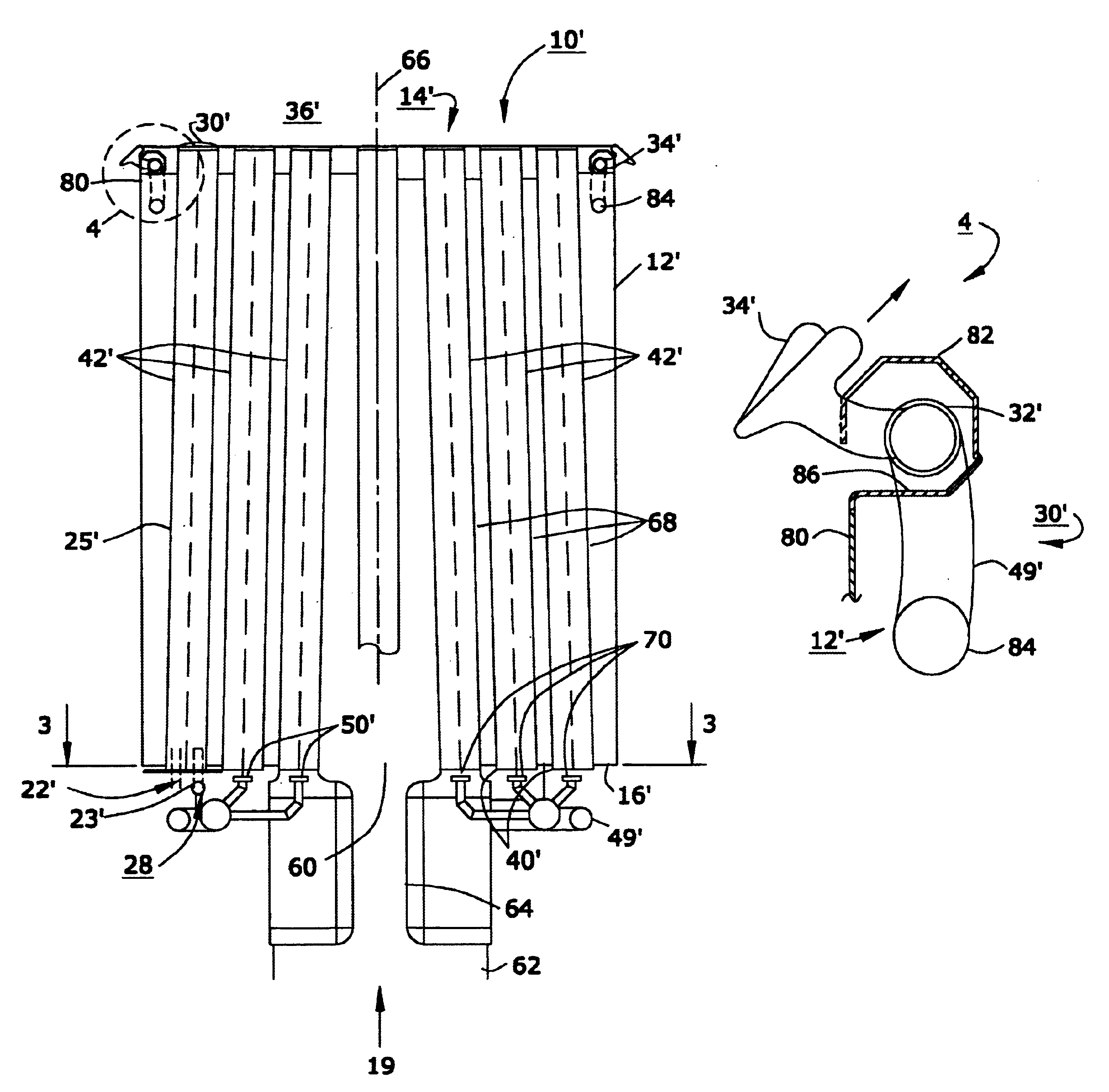

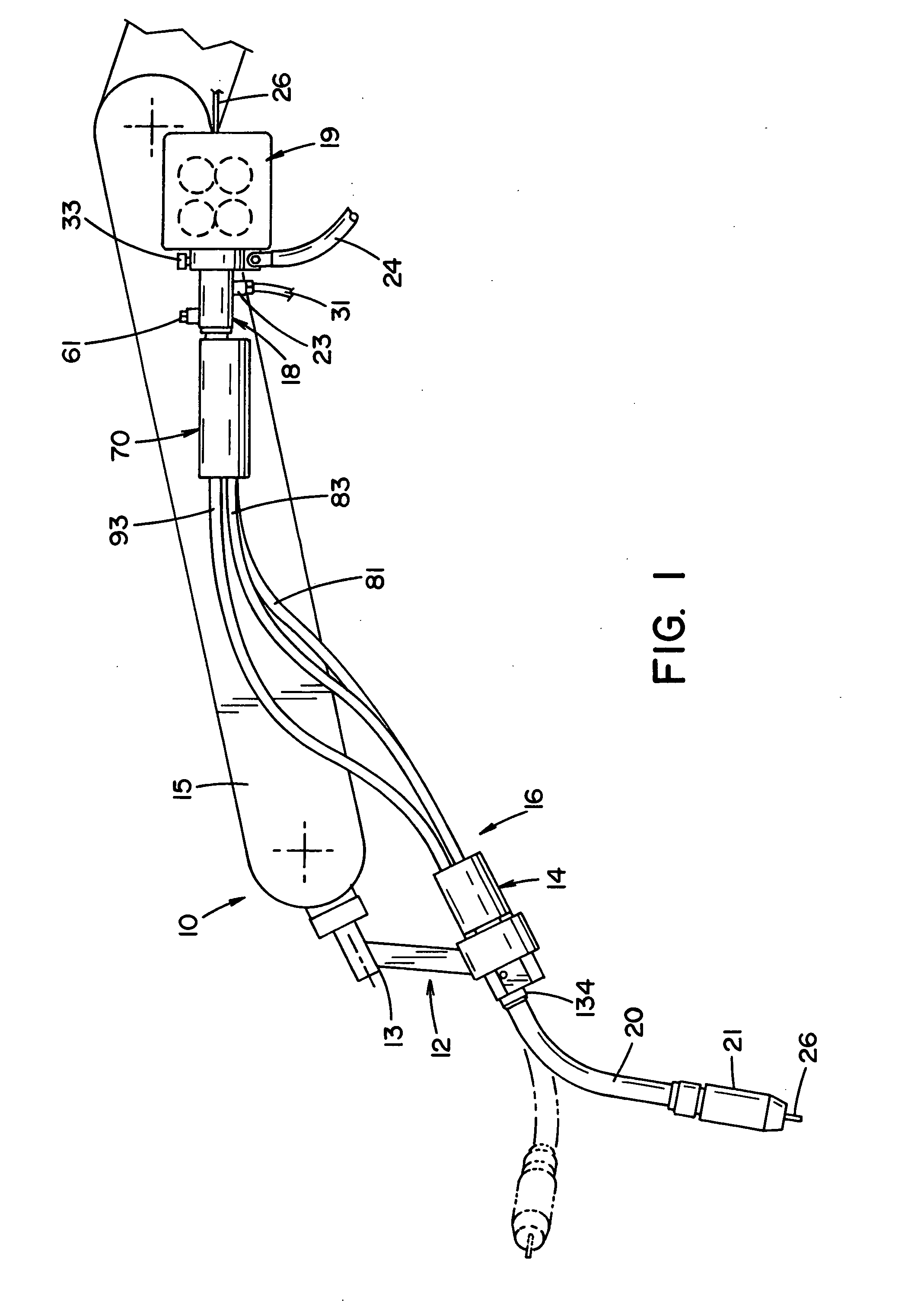

Torches and burners for flame cultivation and flaming

The invention relates to an LPG combusting burner device for flaming and flame cultivation purposes and an improved hand-held torch that may incorporate such burner device. The burner device includes a primary burner (14) having at least one fuel delivery nozzle or jet (80) arranged within an open combustion chamber (71) defined within a burner skirt (70) such as to direct a stream of fuel towards a flame delivery opening of the skirt (70), and a vaporiser (18) located in heat exchanging proximity to the primary burner (14) and having a pressurization chamber with an inlet for liquid LPG fuel and an outlet for gaseous LPG fuel, the inlet being arranged to be in fluid communication with a source of pressurized LPG and the other being in communication with the nozzle of the primary burner. A metering duct (37) is located in close vicinity or within the vaporiser (18) and arranged to discretely limit the amount of liquid fuel entering the vaporisation chamber via its inlet, and a first pressure reduction duct (52) is provided in the flow path of gaseous fuel between the vaporisation chamber outlet and the nozzle of the primary burner (14) the first pressure reduction duct (52) arranged to impart a discrete pressure drop to gaseous fuel flowing therethrough between the vaporisation chamber (50) and the nozzle of the primary burner (14), the discrete pressure drop being such as to generate a low velocity combustion flame in the primary burner (14) during normal burner operation.

Owner:D J BATCHEN

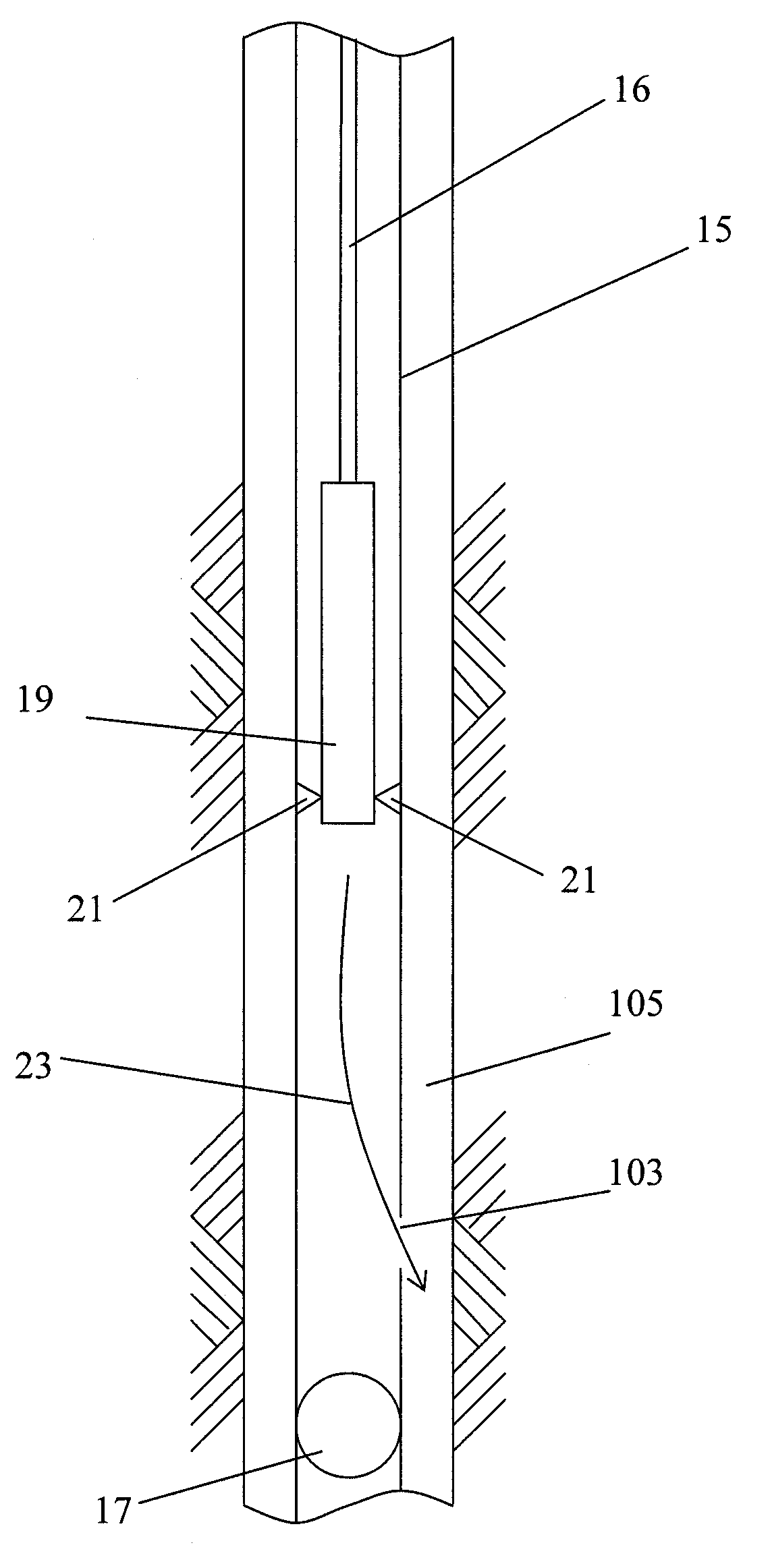

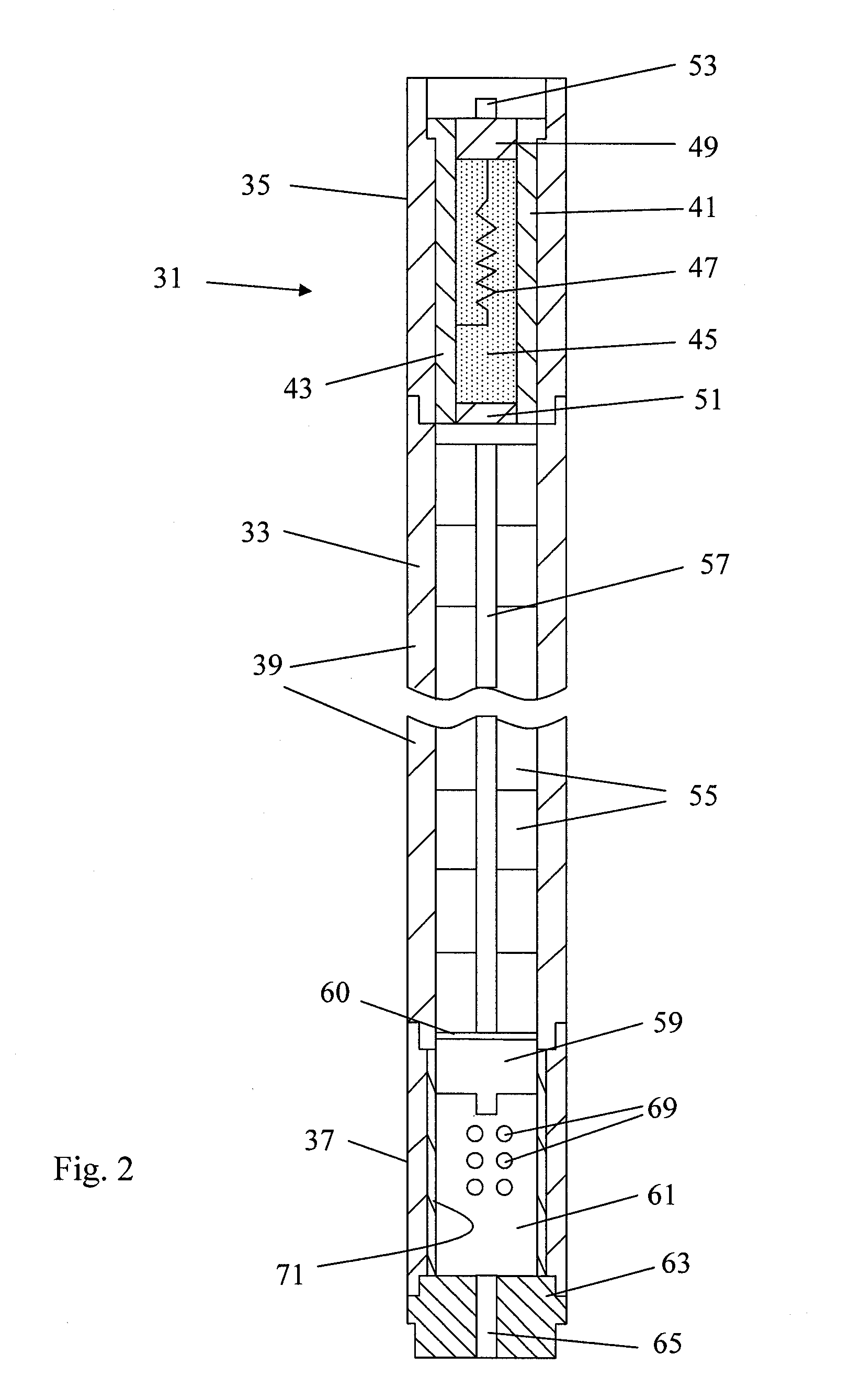

Gas-assisted flare burner

InactiveUS6840760B1Prolong lifeReduce sensitivityIncinerator apparatusNon-combustible gases/liquids supplyGas passingCombustible gas

An improved flare burner for burning combustible gases in petroleum and petrochemical installations. A cylindrical shell has a closed bottom and an open top. A central opening in the bottom is connectable to a source of the gas to be burned. A plurality of linear steam / gas tubes is disposed within the shell, each tube extending to the open end of the shell and also extending through the shell bottom. A lower steam distribution sub-assembly below the shell bottom includes individual steam jets adjacent the ends of the tubes for educting air to the upper end of the tube. A pilot gas sub-assembly for igniting the flare gas is disposed within the shell. Gas to be burned is passed into the interior of the shell through the bottom opening and moves to the open end. Steam injected into the steam / air tubes educts air, and air and steam exit the tubes and mix with the gas to create a combustible mixture. The pilot light assembly provides an open flame which ignites the mixture. The upper end of the shell is reinforced by a rolled collar. An upper steam distribution subassembly within the collar includes a manifold and jets extending beyond the collar to provide additional air and steam for combustion and prevent fires from overflowing the burner and becoming attached to the outside surface of the shell.

Owner:KELLER MICHAEL R +2

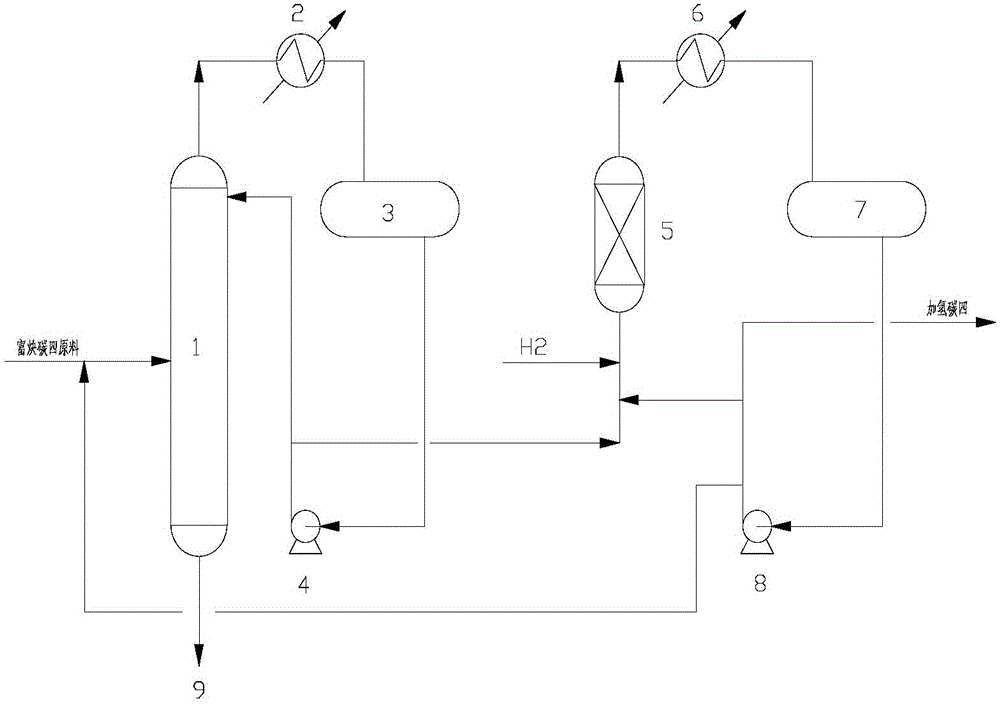

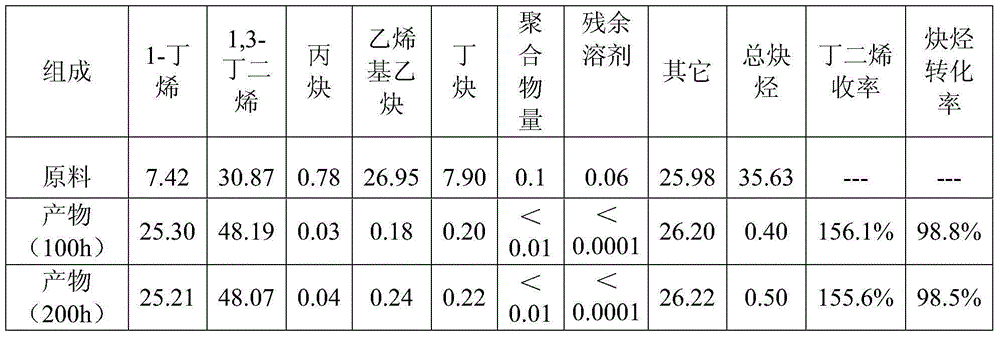

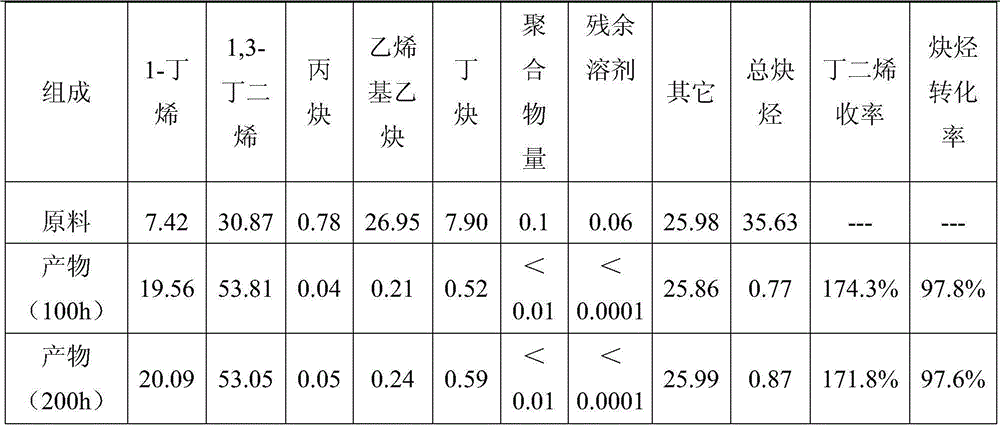

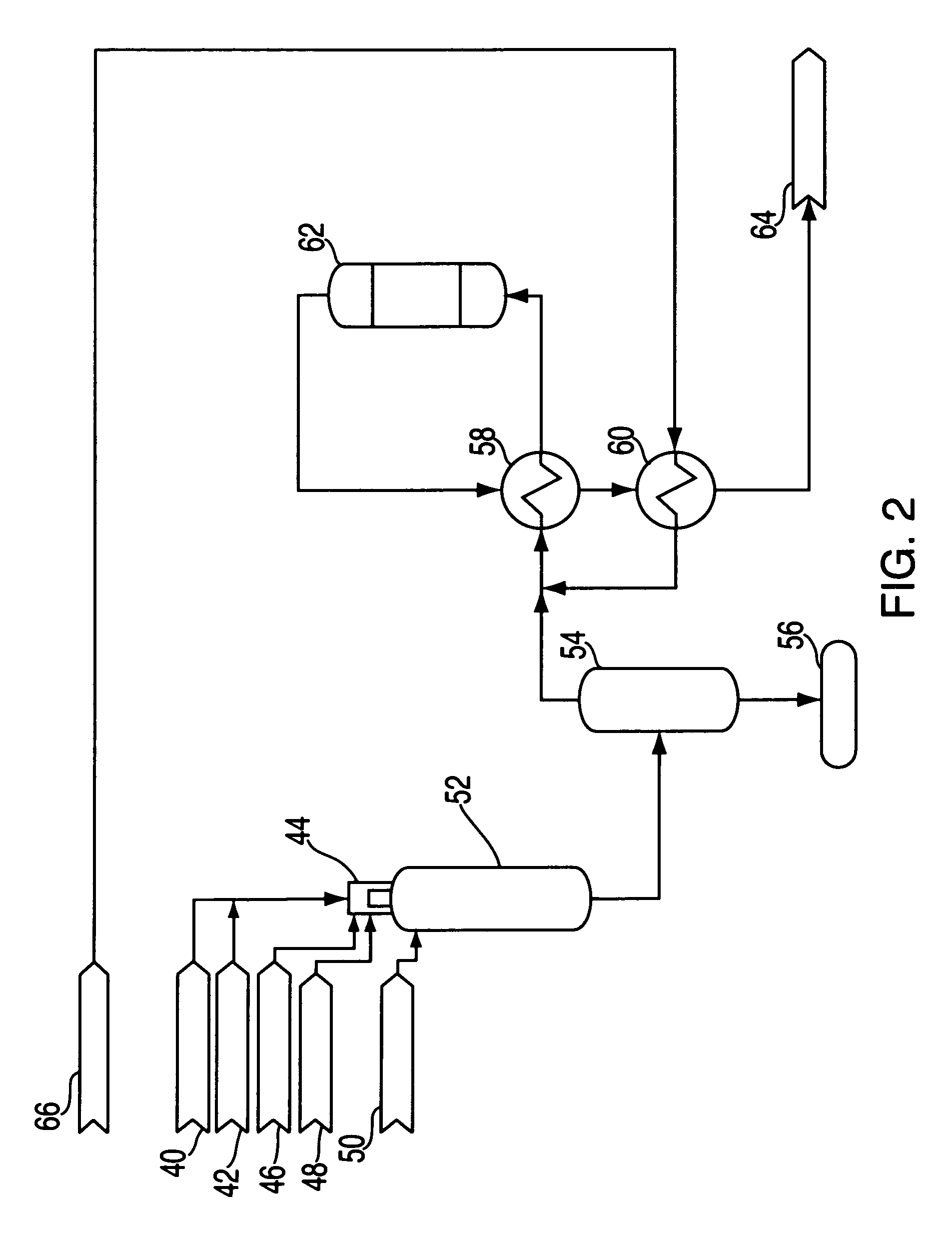

Alkyne-rich C4 selective hydrogenation technology

ActiveCN105566032AIncrease contentReduce contentDistillation purification/separationHydrocarbonsFuel tankAlkyne

The invention relates to a hydrogenation technology and concretely relates to an alkyne-rich C4 selective hydrogenation technology. The technology comprises that an alkyne-containing C4 material from an extracting device or a storage tank enters a rectifying tower, impurities and C4 in the alkyne-containing C4 material are separated, the C4 is collected at the tower top, is condensed through a condenser and is fed into a return tank, the impurities are collected at the tower bottom and are fed into a fuel tank, the C4 is pressurized through a hydrogenation raw material pump, one part of the C4 is used as a return liquid and is returned to the rectifying tower, the other part of the C4 and H2 are mixed and are fed into a hydrogenation reactor, the hydrogenated material is cooled through a cooler and is fed into a gas separation tank, noncondensable gas is fed to a torch, the liquid is divided into three parts through a circulating pump, the first part is returned to a feeding inlet of the rectifying tower, a second part is returned to an inlet of the hydrogenation reactor and the third part as a hydrogenation product is discharged from the device. The technology solves the problems of easy catalyst inactivation and polymerization of dialkene and alkyne in the reaction, improves butadiene and butylene recovery rates of the extracting device and effectively prolongs a service life of the hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP

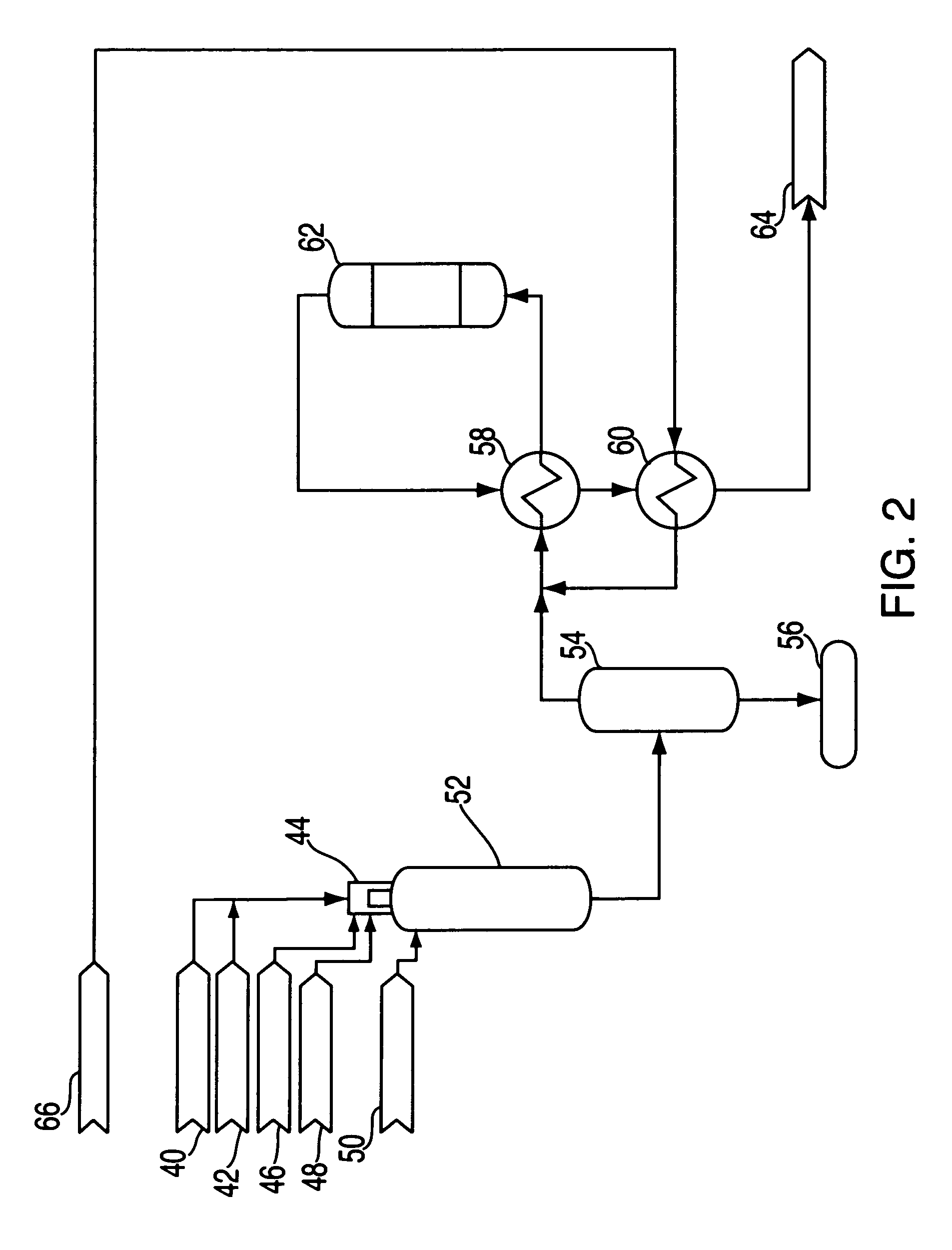

Self-regulating bio-gas treatment system

A self-regenerating bio-gas treatment system that uses the bio-gas instead of atmospheric are as media transport between adsorber and desorber tanks. Each tank includes at least four horizontally stacked and evenly spaced apart, perforated trays each capable being filled with fluidized carbon which migrates downward in the adsorber tank to remove contaminants from the bio-gas. With the bio-gas function as its media transport, the carbon media continuously moves downward over the perforated trays and eventually collected in the bottom of the adsorber tank. The spent carbon is then delivered to the desorber tank. The desorber tank is filled with an inert gas produced by an inert gas generator which causes the carbon media to be regenerated. The inert gas strips the carbon media of contaminates and is then delivered to a ground flare. The carbon media is returned to the adsorber tank and re-used to treat bio-gas. A plurality of heat exchangers, blowers, valves and interconnecting conduits keep the bio-gas, the inert gas, and the carbon media continuously flowing through the system thereby enabling the system to be used at different sizes of landfills or treatment plants.

Owner:SNAP ENERGY SYST

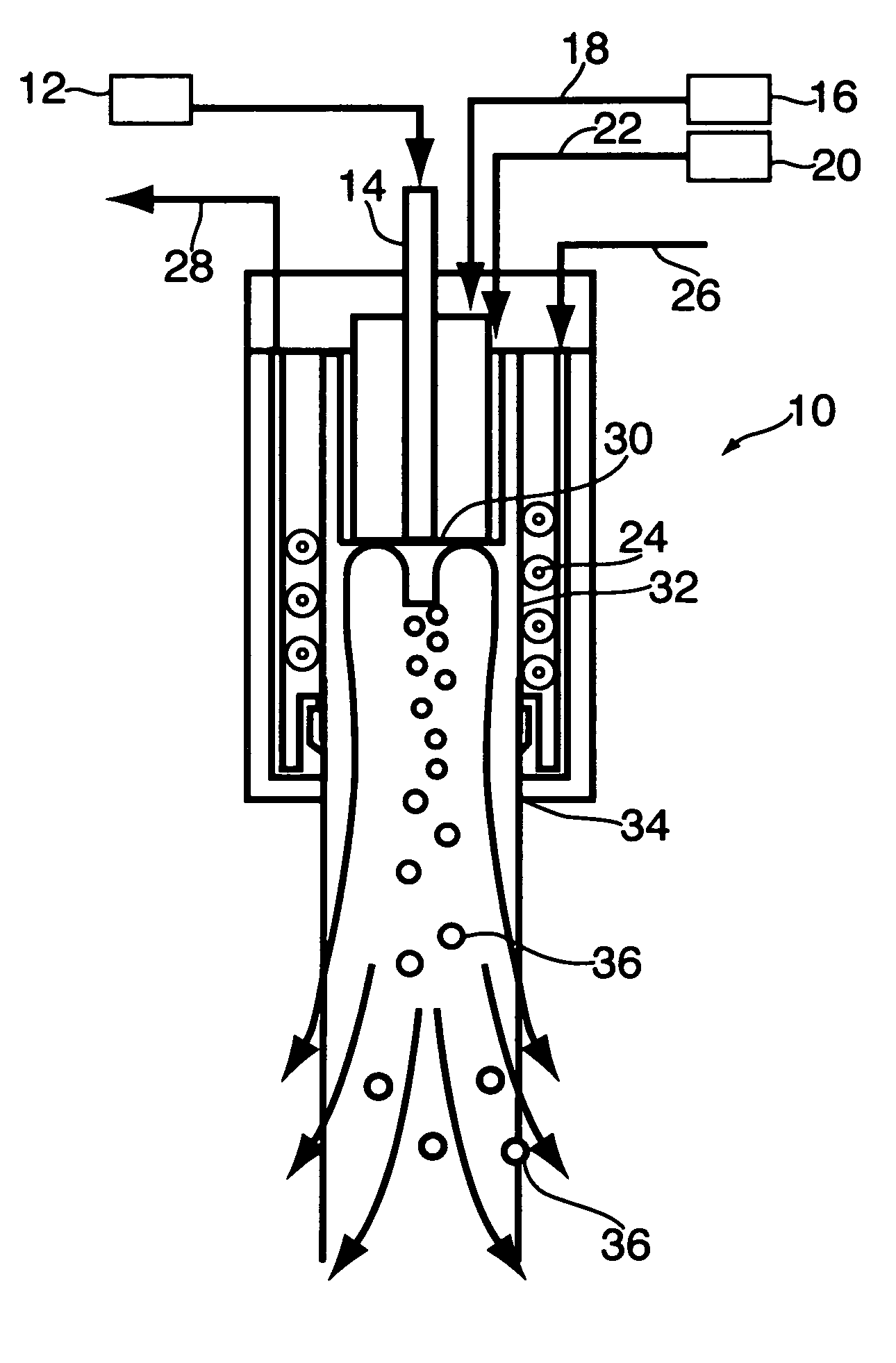

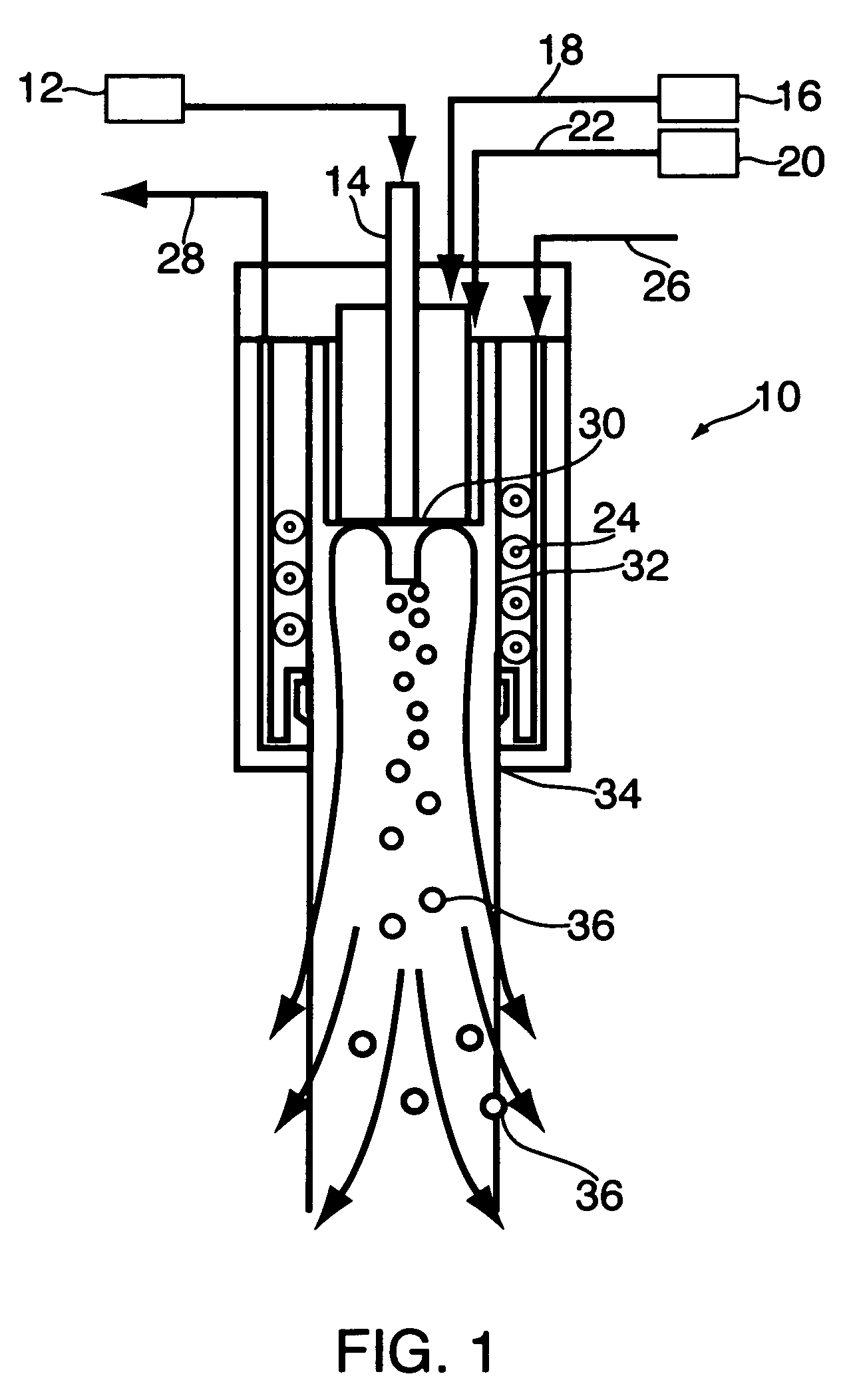

Method producing metal nanopowders by decompositon of metal carbonyl using an induction plasma torch

InactiveUS7967891B2Increase flexibilityImprove toleranceMaterial nanotechnologyTransportation and packagingMetallurgyInduction plasma technology

Owner:TEKNA PLASMA SYST INC

Flare apparatus

ActiveUS7967600B2Incinerator apparatusNon-combustible gases/liquids supplyCombustible gasProduct gas

A flare apparatus for burning combustible gases. A flare tip unit comprises an inner member and an outer member defining an annulus therebetween. The annulus defines an annular gas passage through which combustible gas passes. Air moved by a motive force, preferably steam, passes through the inner member and a steam / air mixture exits an outlet of the inner member. The combustible gas and an air / steam mixture mixes in a premix zone between the inner member outlet and the exit opening of the outer member. The combustible gas / air / steam mixture is ignited for burning in the atmosphere above the exit opening. The flare apparatus may include a plurality of flare tip units.

Owner:JOHN ZINK CO LLC

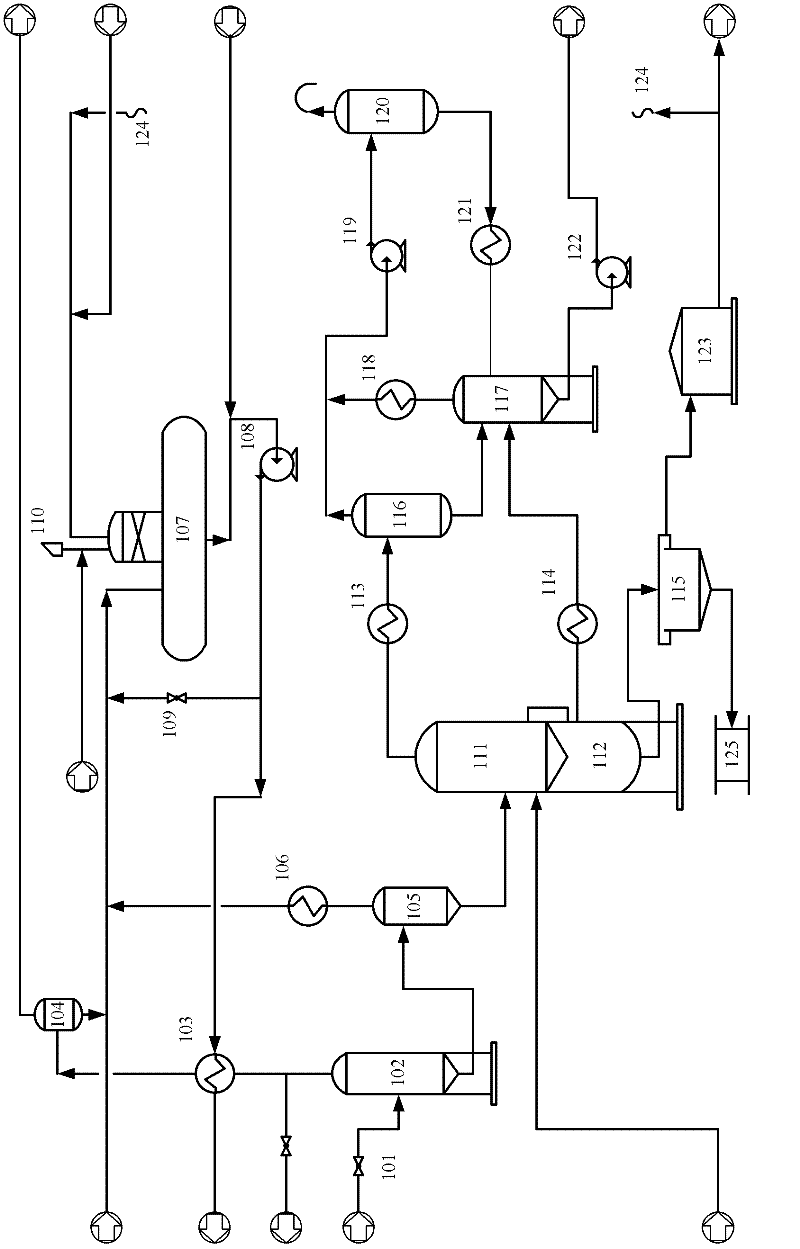

Process and system for treating gasified grey water

InactiveCN102557315AReduce energy consumptionStrong emergency response capabilityMultistage water/sewage treatmentMechanical energyEnvironmental engineering

The invention discloses a process and system for treating gasified grey water. According to the process, a power quantity exchange process is provided so as to recover pressure energies contained in high-temperature high-pressure gasified black water, and the pressure energies are converted into mechanical energies so as to carry out external action; after treated grey water is subjected to the combined pressurization of a power quantity exchanger and a centrifugal pump driven by a motor, the grey water is heated by high-pressure flash steam, and then, is conveyed to a gasification section for use; the pressure of the gasified high-pressure black water is reduced to 1.0 MPa after the gasified high-pressure black water passes through the power quantity exchanger, the gasified high-pressure black water is conveyed to be subjected to high-pressure flash treatment, and then, the flash process is not changed; and in order to facilitate the pressure regulation of a high-pressure flash tank and avoid overpressure, a regulation valve is arranged in front of a control valve which leads a high-flash separator to a conversion section, and the high-flash separator is led to a total torch, and the occurrence of environmental incidents, such as torch extinguishment or direct emission and the like, is avoided. According to the process and system for treating the gasified grey water, the process is combined with the system, and the problems of energy source waste, environment pollution, cumbersomeness in operation, and the like, in the prior art can be effectively solved through the improvement on the prior art and the scientific and rational energy utilization.

Owner:XI AN JIAOTONG UNIV

Unburned flare gas sample system

InactiveUS20100319468A1Reduce and prevent precipitationAccurate temperatureComponent separationWithdrawing sample devicesLine tubingManual insertion

A sample system withdraws a sample of unburned flare gas from a feed line and delivers a liquid free sample to a high pressure gas chromatograph for analysis. In one embodiment, the sample system may be fitted with an automatic insertion system. In other embodiments, the sample system may be static or have manual insertion. The sample system includes a liquid separator to separate liquids from the sample. In one embodiment, the sample system is housed in an insulated and heated cabinet to prevent condensation of liquids as the sample moves through the sample system.

Owner:WELKER ENG

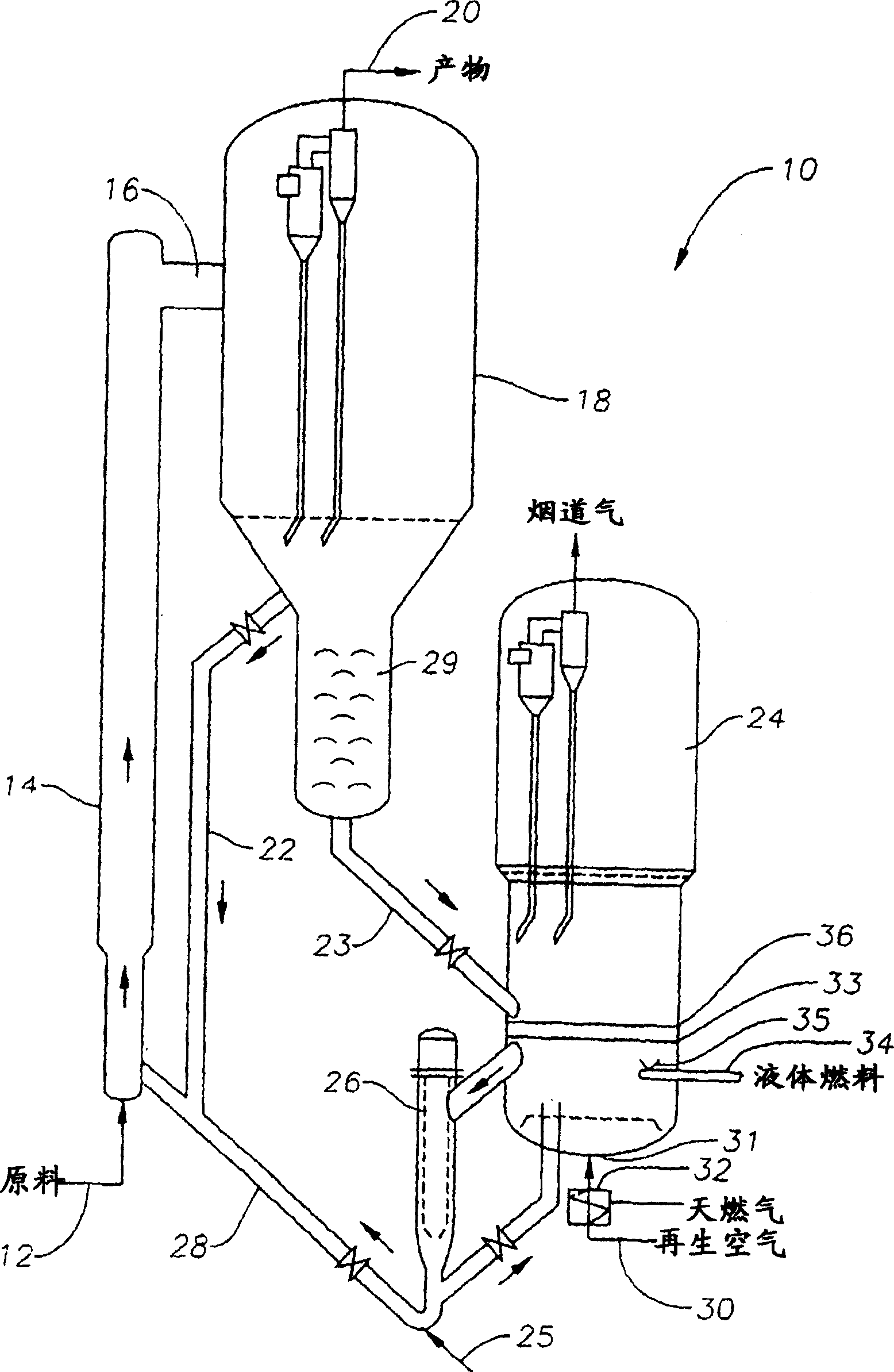

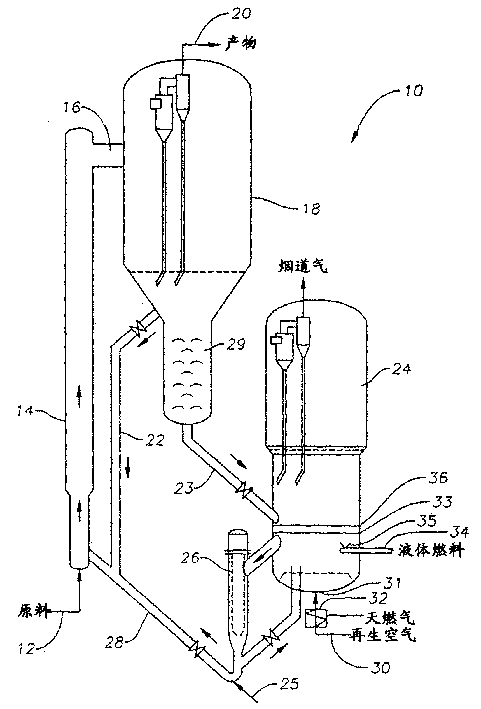

Method for adding heat to a reactor system used to convert oxygenates to olefins

The present invention provides a method for adding heat to a reactor system used to convert oxygenates to olefin, in which supplemental heat is added with a heating fuel, e.g., a torch oil, having low autoignition temperature, low sulfur, and low nitrogen content.

Owner:EXXONMOBIL CHEM PAT INC

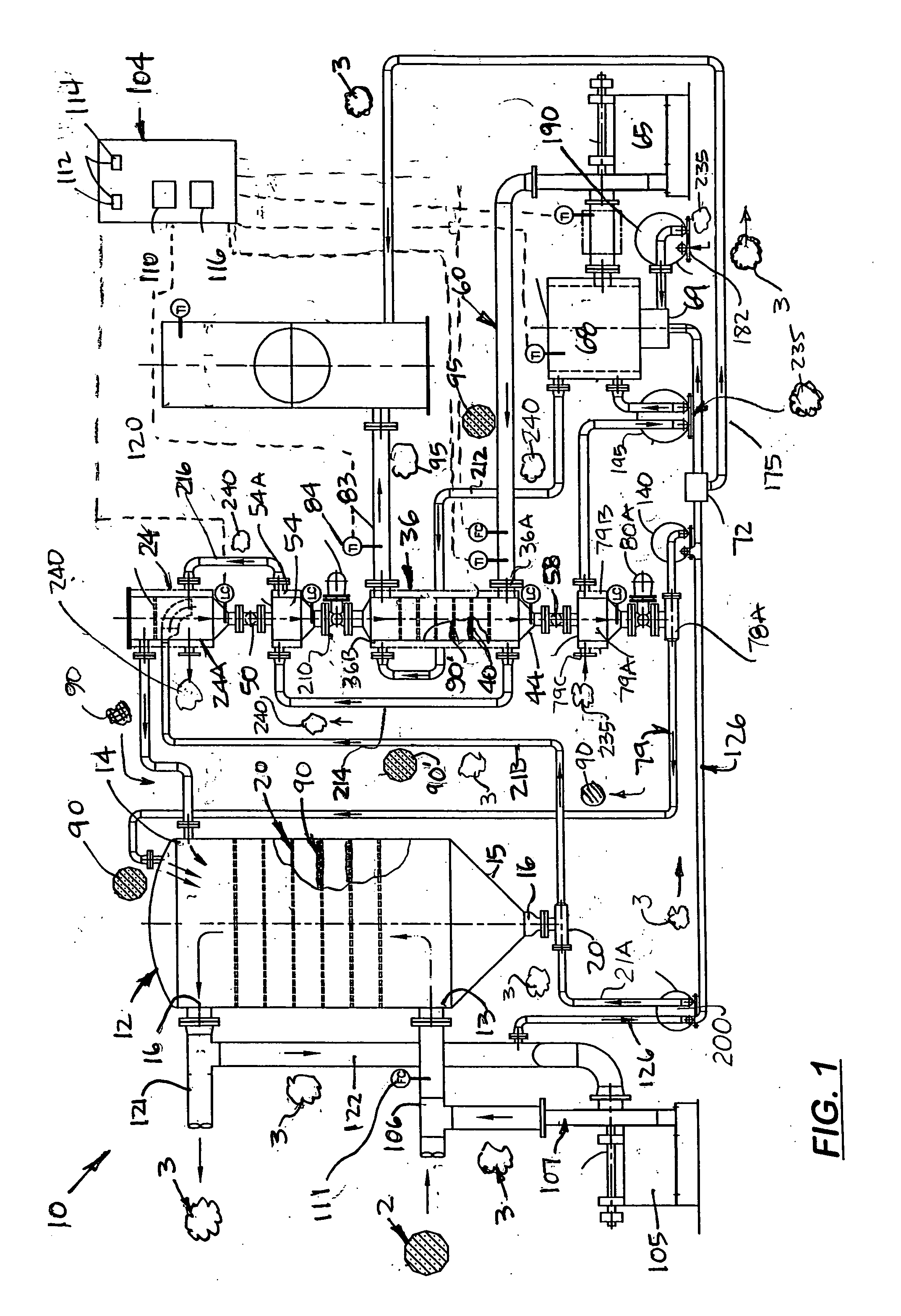

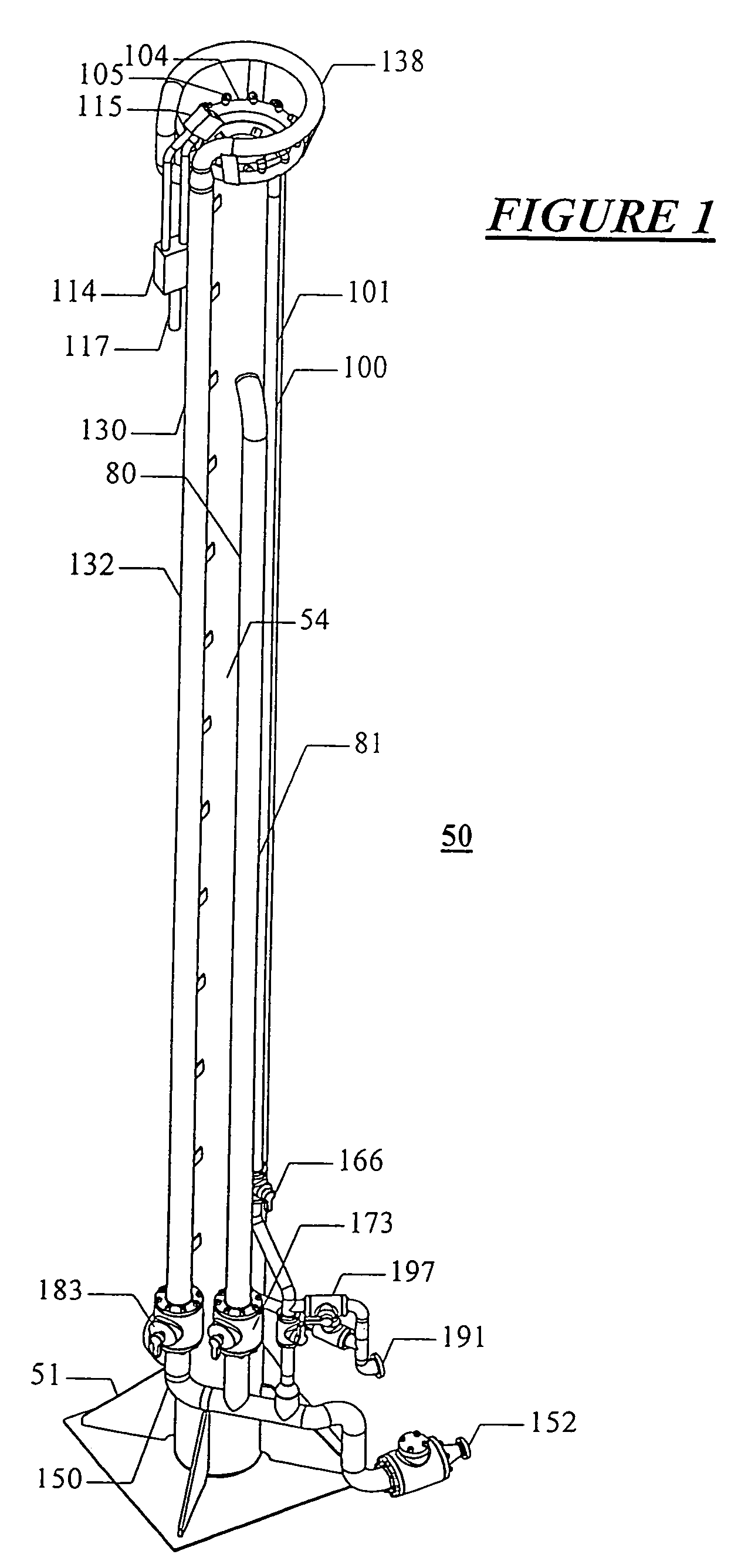

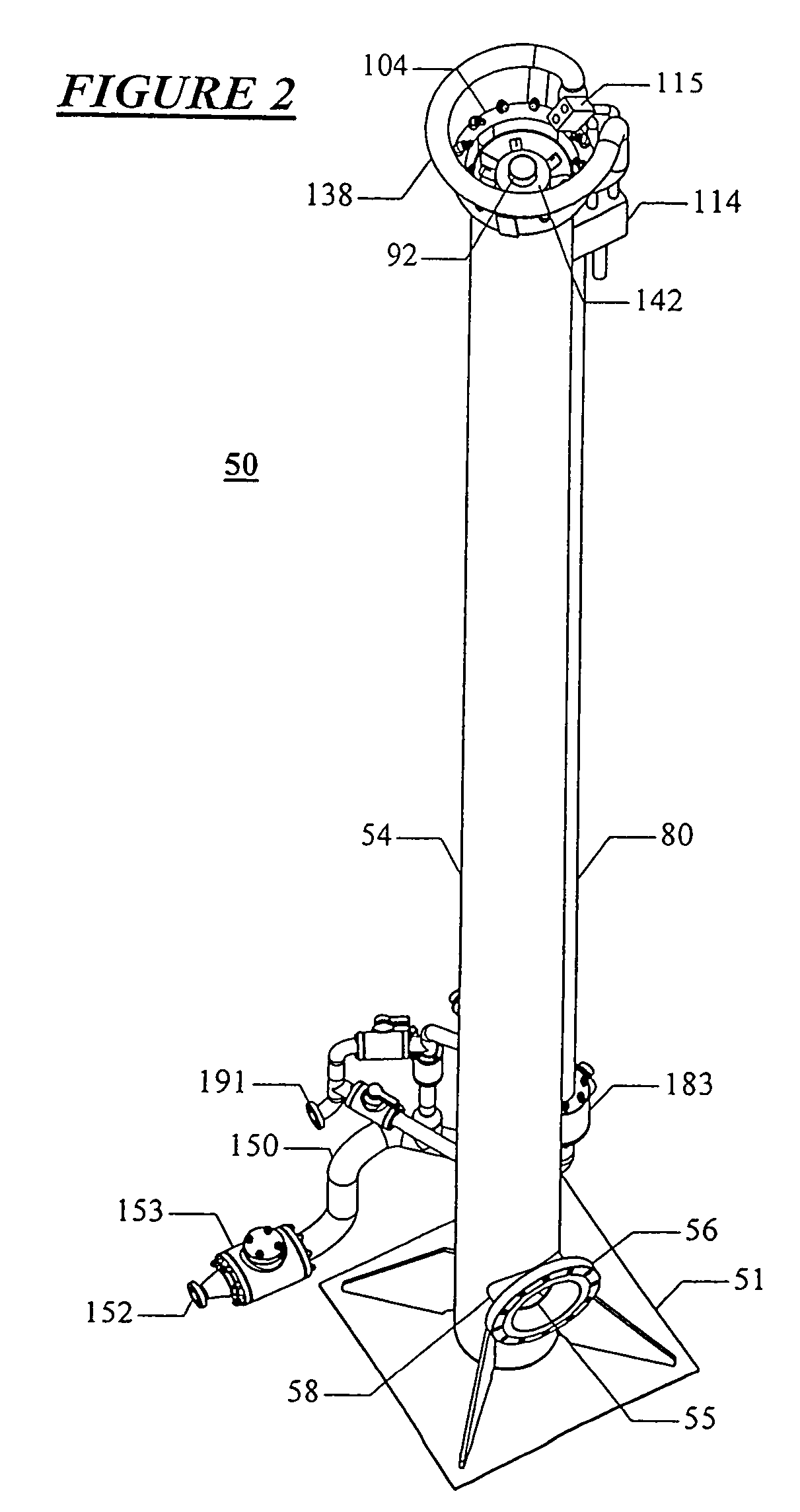

Trailer mounted smokeless dual-phase burner system

The smokeless liquid two-phase burner system of the present invention relates to a method and apparatus for burning a wide variety of flammable liquids using an integrated burner system. The system has both a primary injection path and an alternate injection path for the fuel to be burned, as well as a main air pump or blower. The present invention also provides a method and apparatus for selectably injecting a secondary stream of a gas or vapor or volatile liquid into a flare system for the purpose of enhancing combustion. The apparatus is self-contained and self erecting on a transportable trailer.

Owner:EXPRO AMERICAS

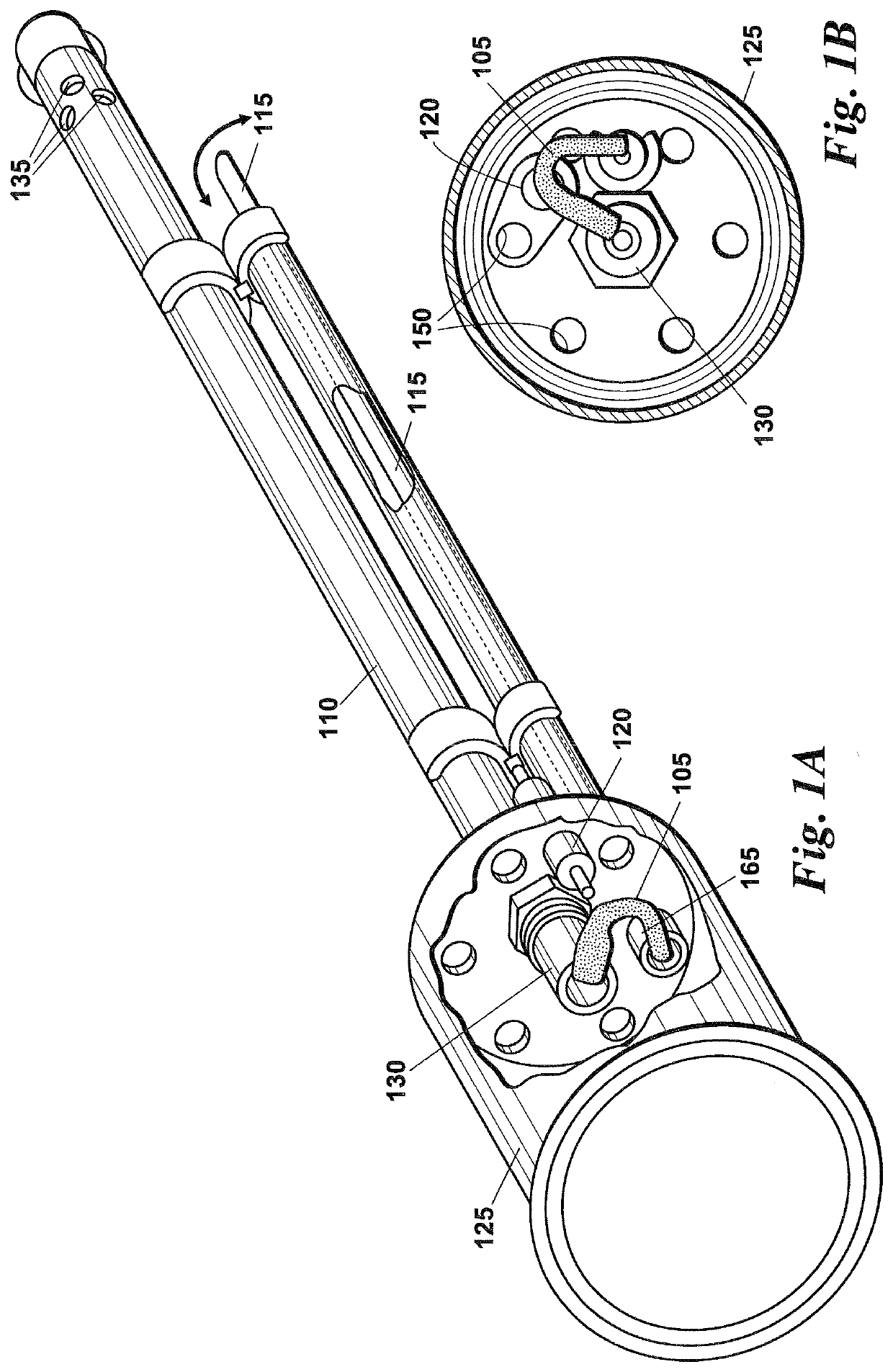

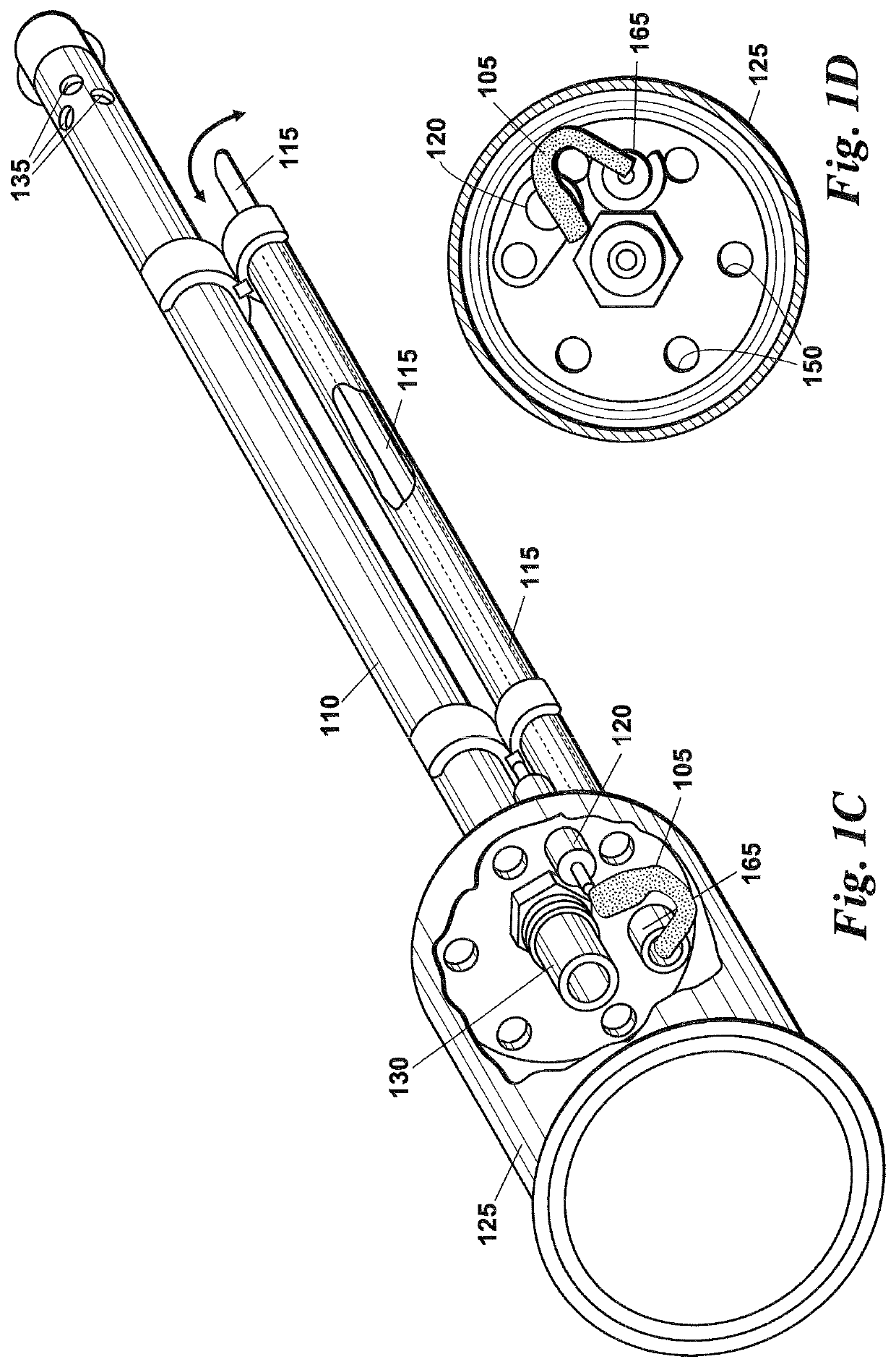

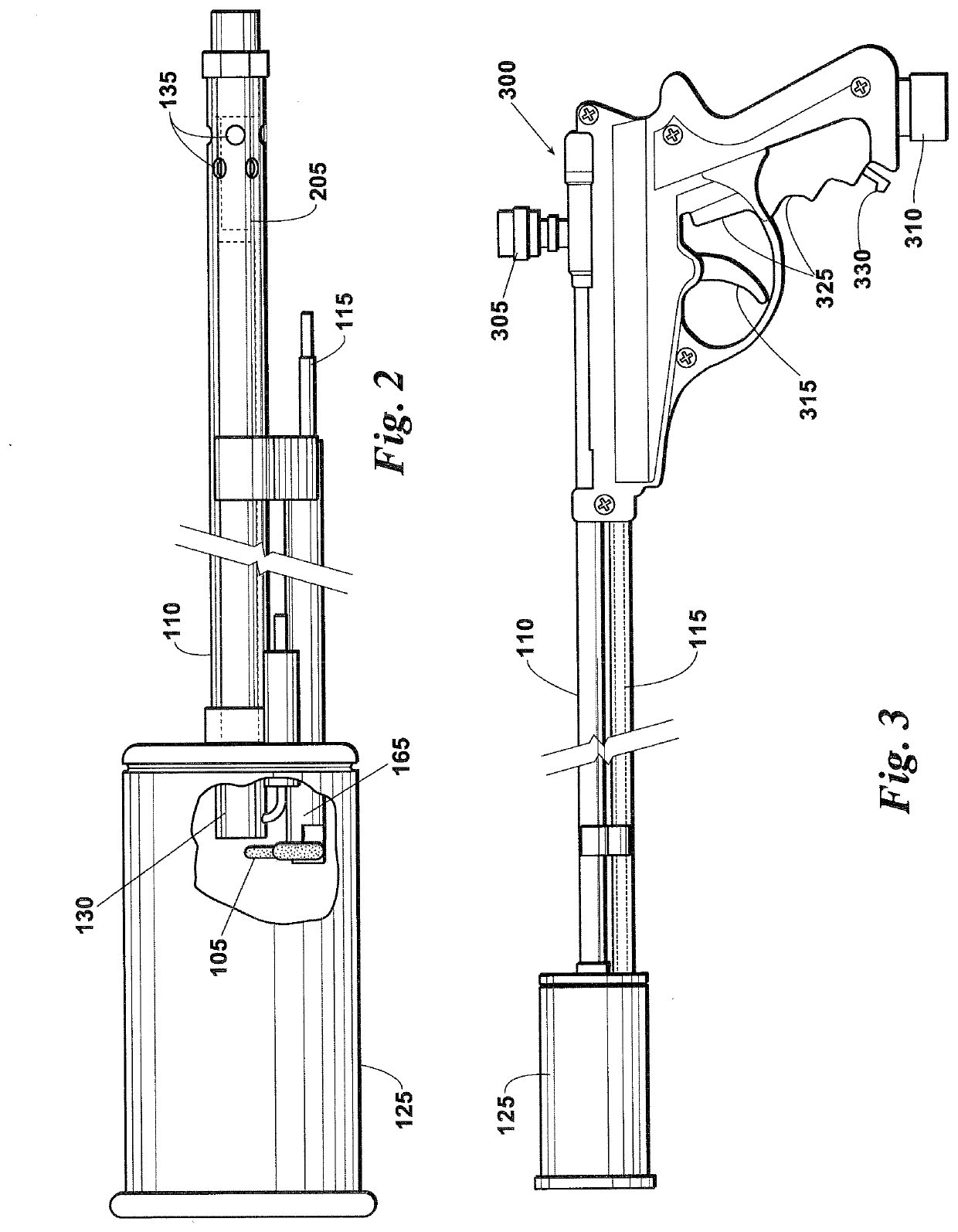

Perforating Torch Apparatus and Method

In cutting a downhole pipe in proximity to a closure in the pipe, the pipe is first perforated. A perforating torch is positioned with a pipe in proximity to the closure. The perforating torch produces cutting fluids in a first radial direction and produces an opening in the pipe, which cutting fluids produce a reaction force opposite to the first radial direction. This reaction force drives the perforating torch into contact with the pipe, anchoring it against any pressure wave produced by the cutting fluids and reflected off of the closure. Once the pipe is opened, a cutting torch is operated to sever the pipe. Any pressure wave generated by the cutting torch is vented through the opening.

Owner:ROBERTSON MICHAEL C

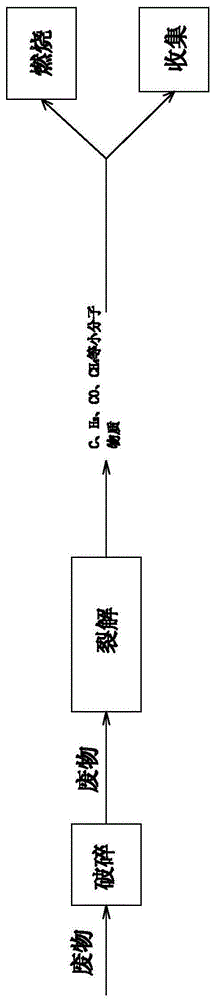

Method for treating waste by adopting microwave plasma

InactiveCN104645915AWon't happenCause secondary pollutionGas treatmentWaste processingLiquid wasteHazardous substance

The invention discloses a method for treating waste by adopting a microwave plasma torch. The method comprises the following steps: pretreatment of waste, namely preparing solid waste, liquid waste and gaseous waste, and crushing the solid waste by virtue of a crushing device; and pyrolysis, namely generating a plasma torch by carrying out ionization on gas by utilizing a microwave plasma generation device, and carrying out the pyrolysis on the pre-treated waste by virtue of the plasma torch, wherein organic matters in the waste are pyrolyzed into micromolecular substances such as C, H2, CO, and CH4, and inorganic matters in the waste are molten at the high temperature to form a matter in a glass state. According to the method, the waste is pyrolyzed by virtue of the plasma torch generated by the microwave plasma generation device, the waste is pyrolyzed into the micromolecular substances, such as carbon oxide, carbon powder, methane, and hydrogen, and the matter in the glass state, no harmful matter is generated in the treatment process, the secondary pollution for the environment is avoided, the treatment procedure is simple, and the efficiency is relatively high.

Owner:GUANGDONG NEW UVI PRINTING EQUIP & TECH CO LTD

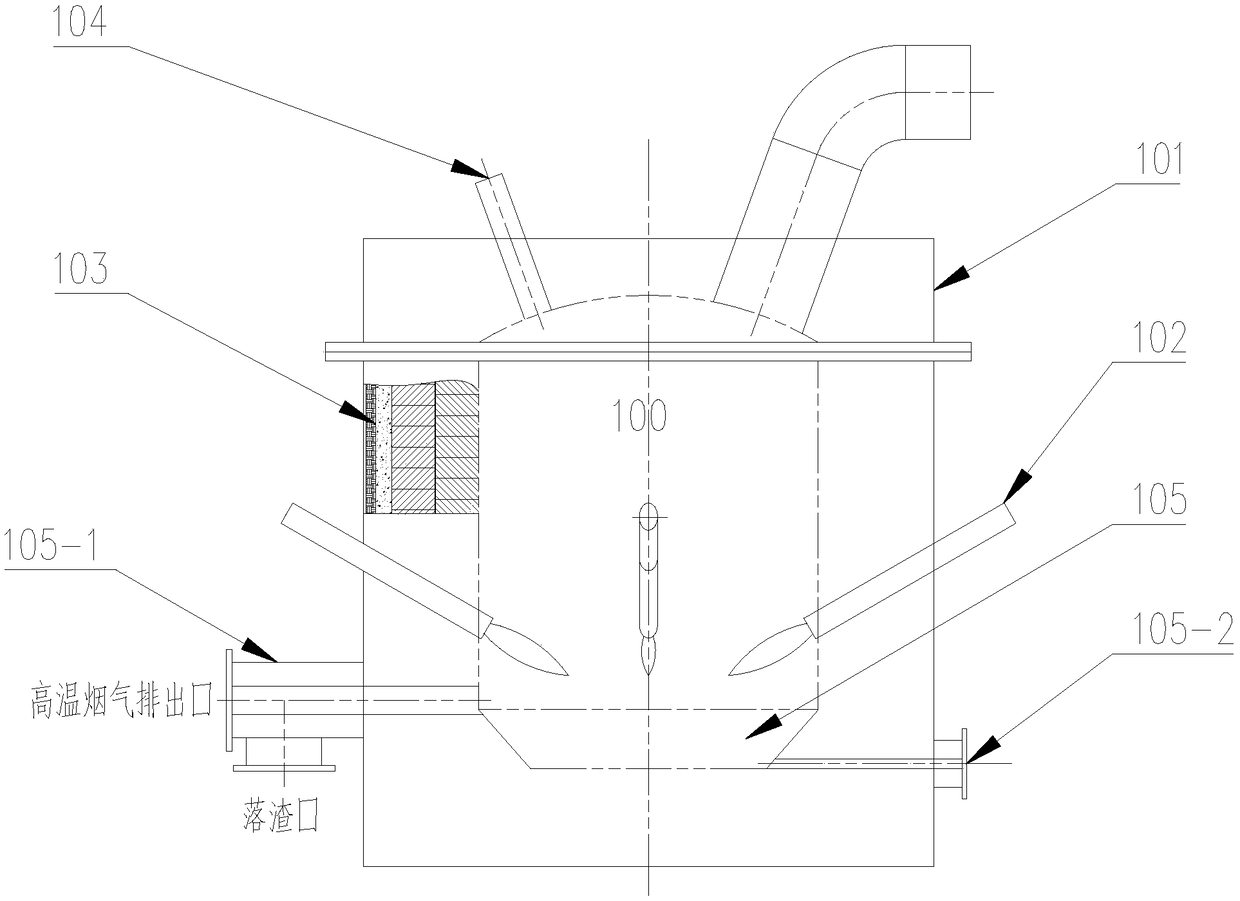

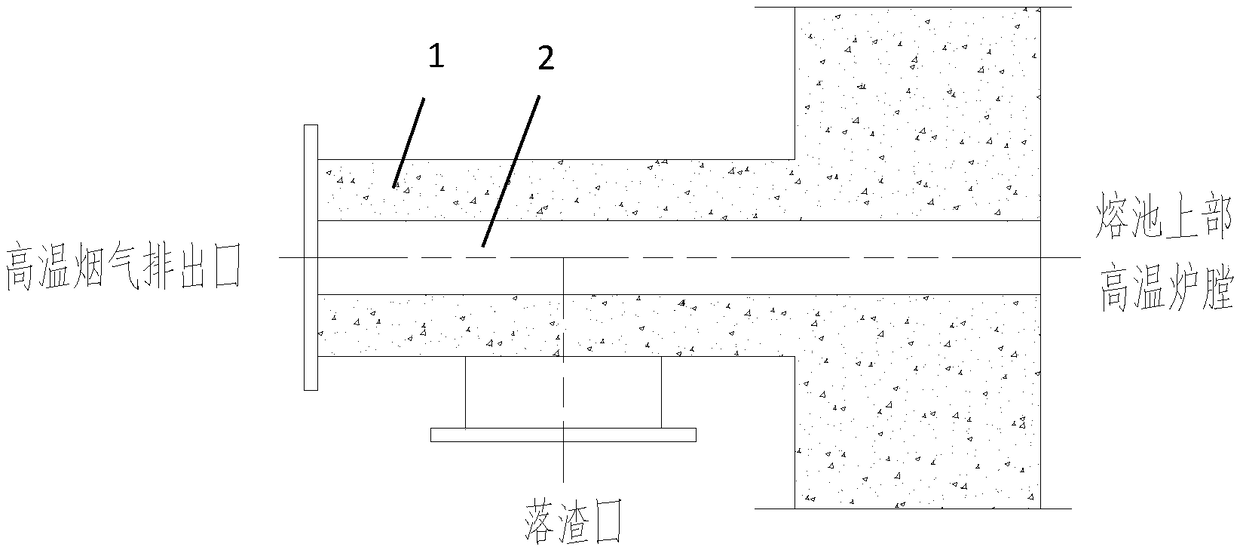

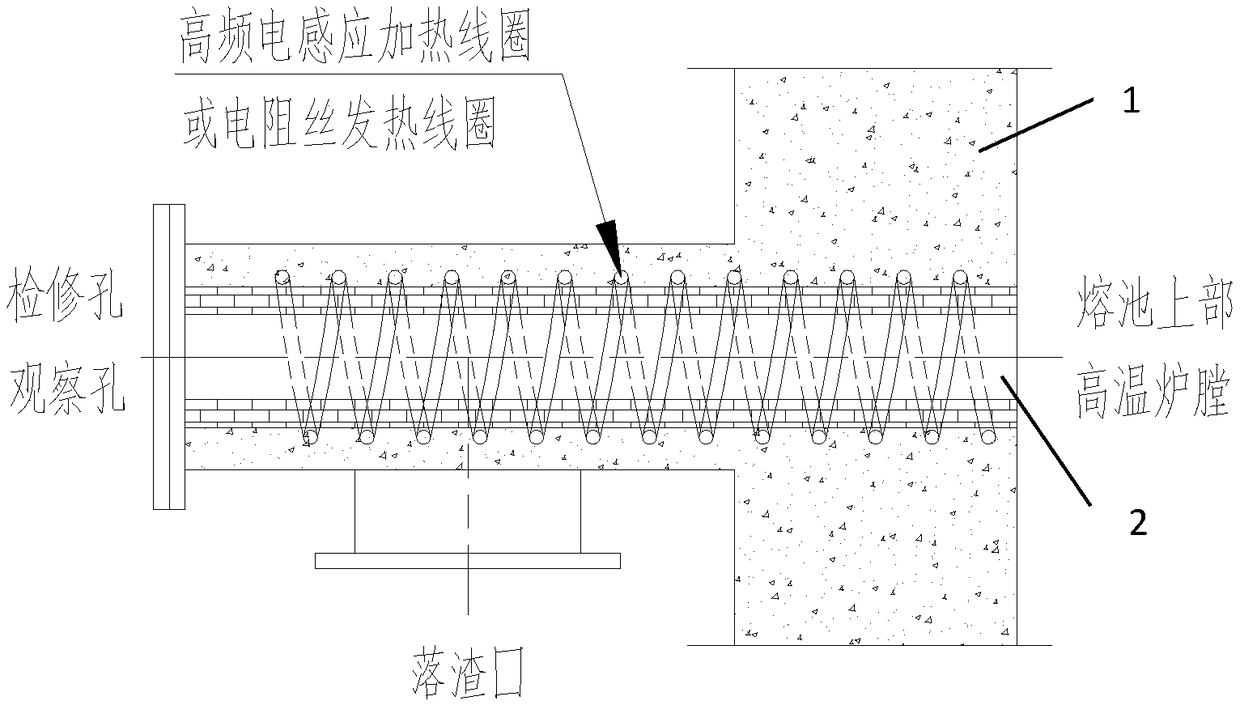

Plasma melting furnace with continuous overflow slag discharge function and application thereof

PendingCN109469910AImprove thermal efficiencyHigh degree of automationIncinerator apparatusSlagThermal efficiency

A plasma melting furnace with a continuous overflow slag discharge function is proposed, the melting furnace comprises a furnace body, a plasma torch heating system and a bath. A material inlet is arranged on the top of the furnace body, a furnace chamber is coaxially produced in the furnace body, the bath includes a bath body, a continuous overflow slag discharge port and an intermittent clean discharge port, the plasma torch heating system comprises a plasma torch generator and a generator protective heat insulating sleeve which tightly sleeves the outside of the plasma torch generator, andthe plasma torch generator is uniformly arranged along the circumferential direction of the furnace body. At least one plasma torch generator is arranged at a place above the continuous overflow slagdischarge port or at the two sides of the continuous overflow slag discharge port. The melting furnace realizes efficient and rapid melting and continuous overflow slag discharge of a low-calorific-value hazardous waste plasma melting furnace, and finally achieves the purposes of high processing capacity, high thermal efficiency, low labor consumption, high automation degree, low operation risk and low equipment investment of the low-calorific-value hazardous waste plasma melting equipment.

Owner:AEROSPACE ENVIRONMENTAL ENG

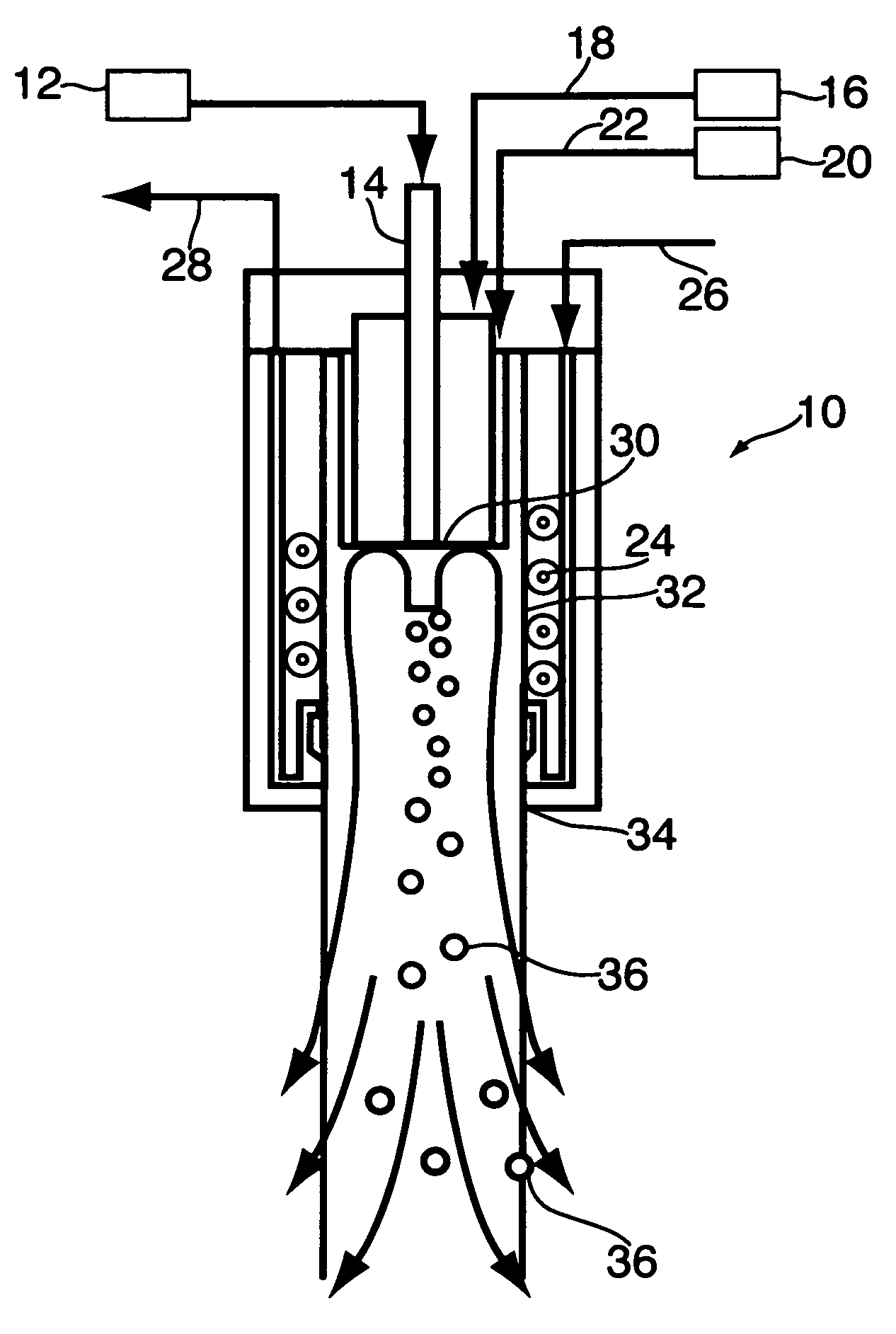

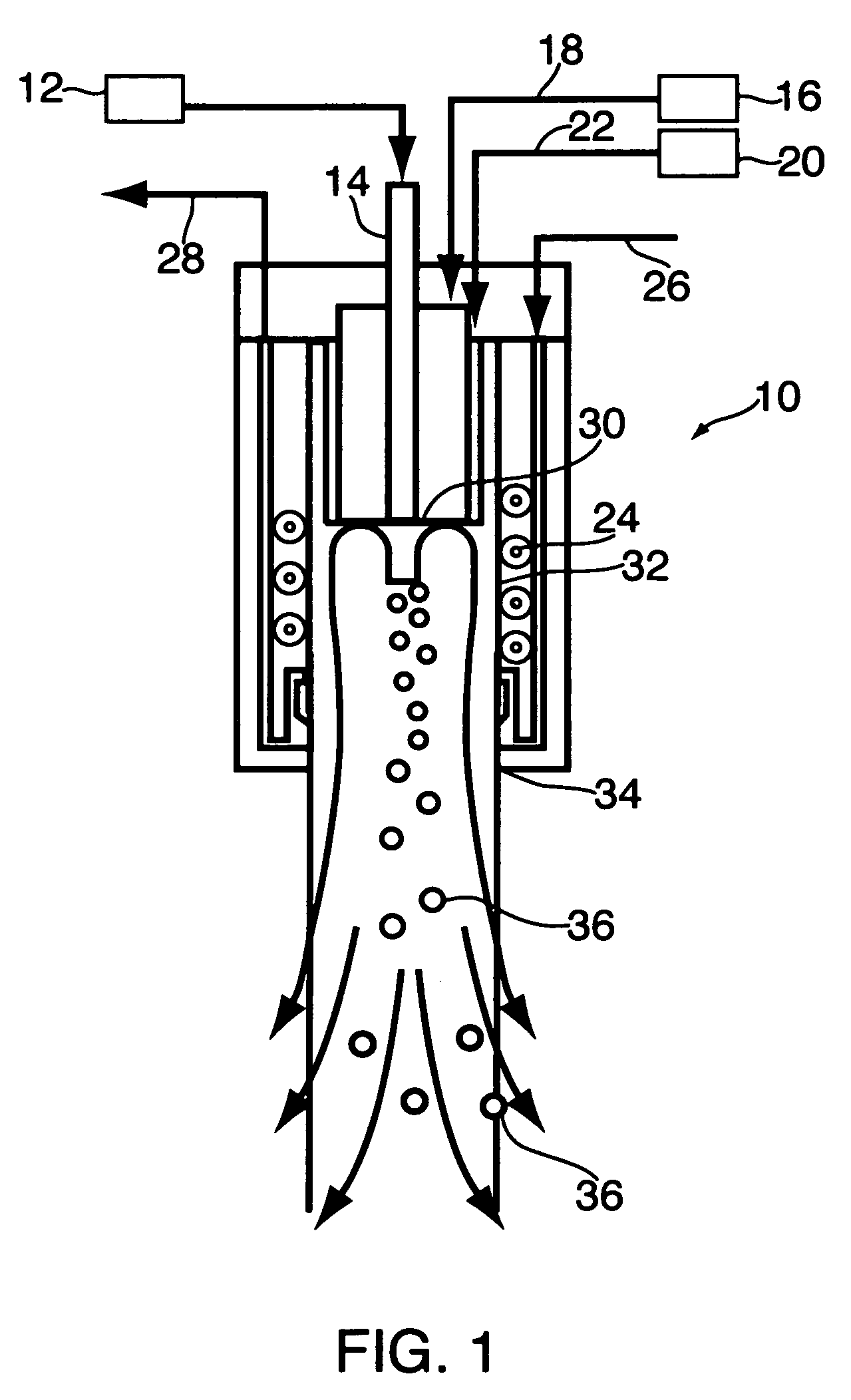

Method producing metal nanopowders by decompositon of metal carbonyl using an induction plasma torch

InactiveUS20070277648A1Less variation in qualityIncrease flexibilityMaterial nanotechnologyTransportation and packagingInduction plasma technologyTorch

A process for synthesizing metal nanopowders by introducing metal carbonyl into an induction plasma torch. By taking advantage of the much lower dissolution temperature of carbonyl as opposed to the high melting temperature of conventional metal powder feeds less torch power is required. Moreover, in contrast to current powder production techniques utilizing electrode based plasma torches, the induction plasma torch does not introduce contaminants into the nanopowder.

Owner:TEKNA PLASMA SYST INC

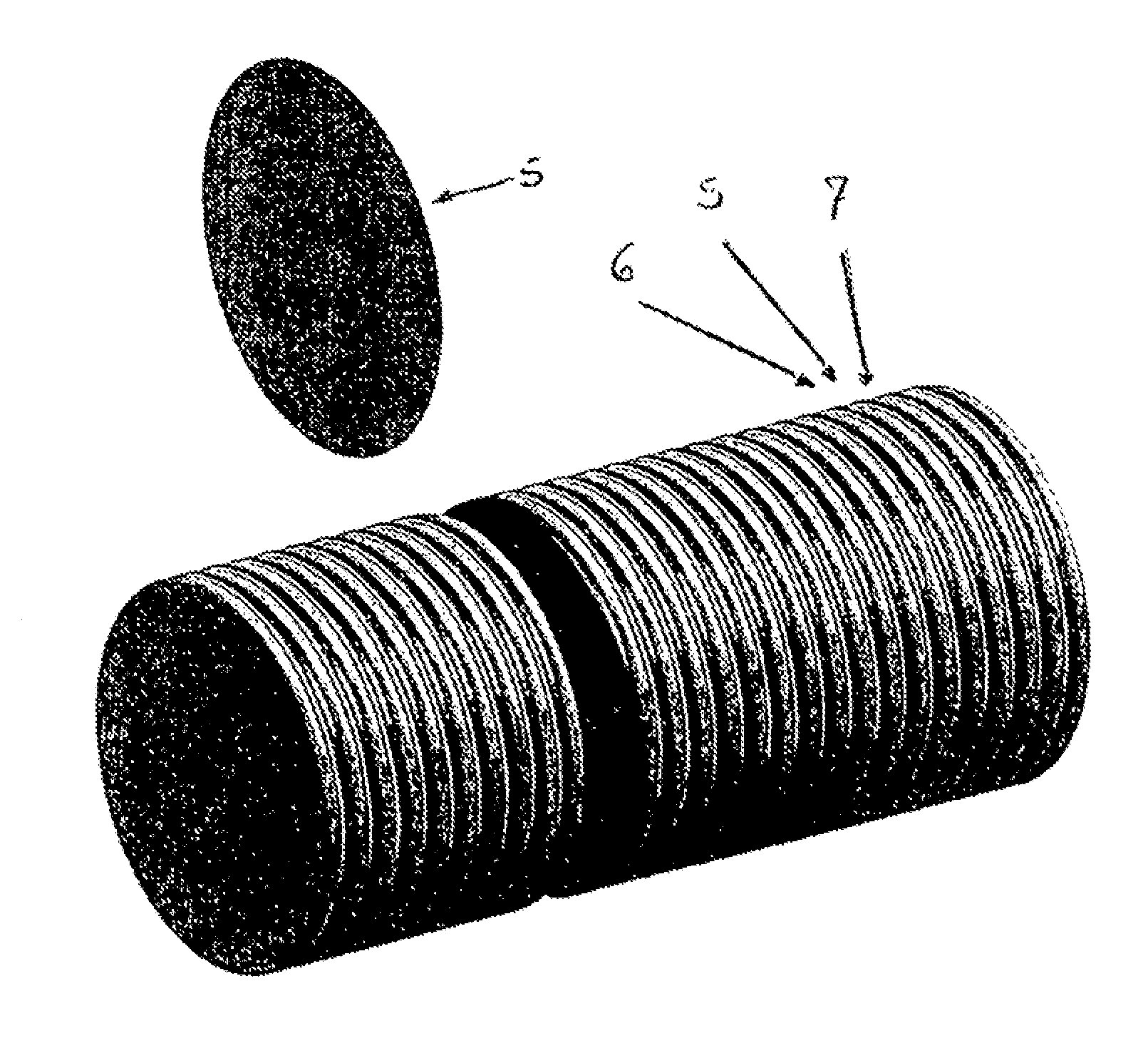

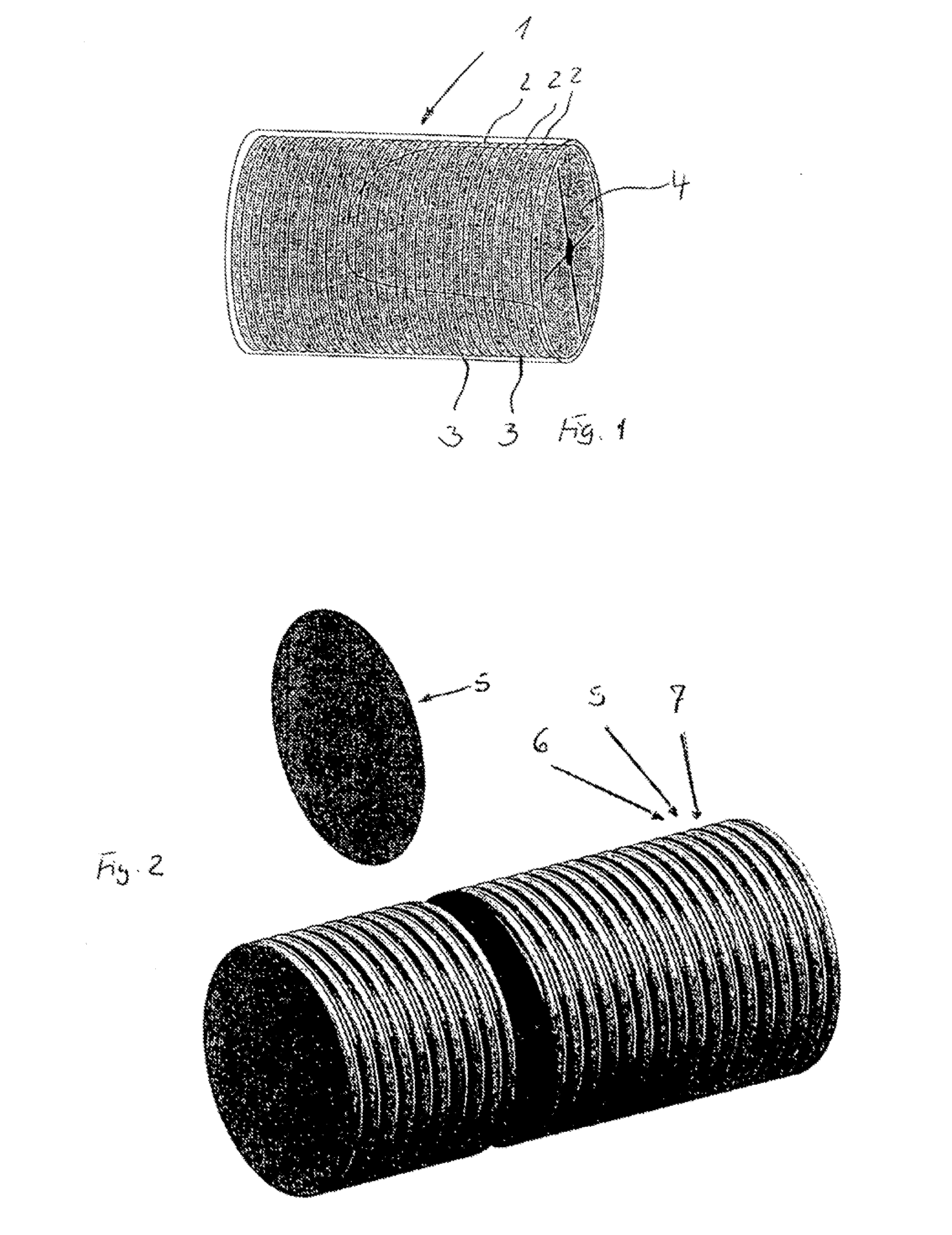

Active body

InactiveUS20120160121A1Easily storeSave in massAmmunition projectilesFirework flares/torchesAnti adhesiveFlare

An active body (1) includes flares (2, 6, 7) arranged adjacent, above, or behind each other, wherein at least one hydrophobic separating layer (3, 5) is integrated between the flares, or flare disks (2, 6, 7), thereby preventing the flares (2, 6, 7) from attaching or sticking. In one embodiment, the hydrophobic separating layer (3) is applied to at least one side of the flares (2), preferably as a powder preferably consisting of microspheres, or the like. In another embodiment, a separating disk is disposed between the flares (6, 7) as the separating layer (5), which in addition is anti-cohesive and anti-adhesive.

Owner:RHEINMETALL WAFFE MUNITION GMBH

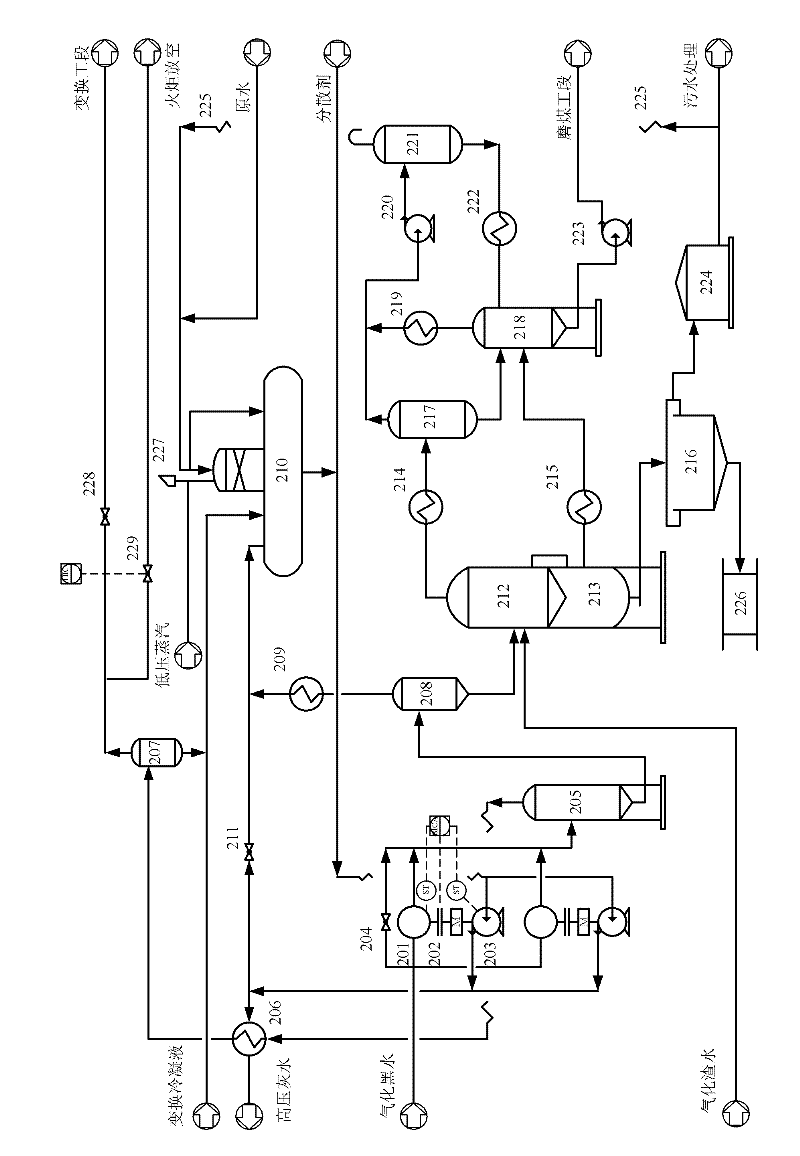

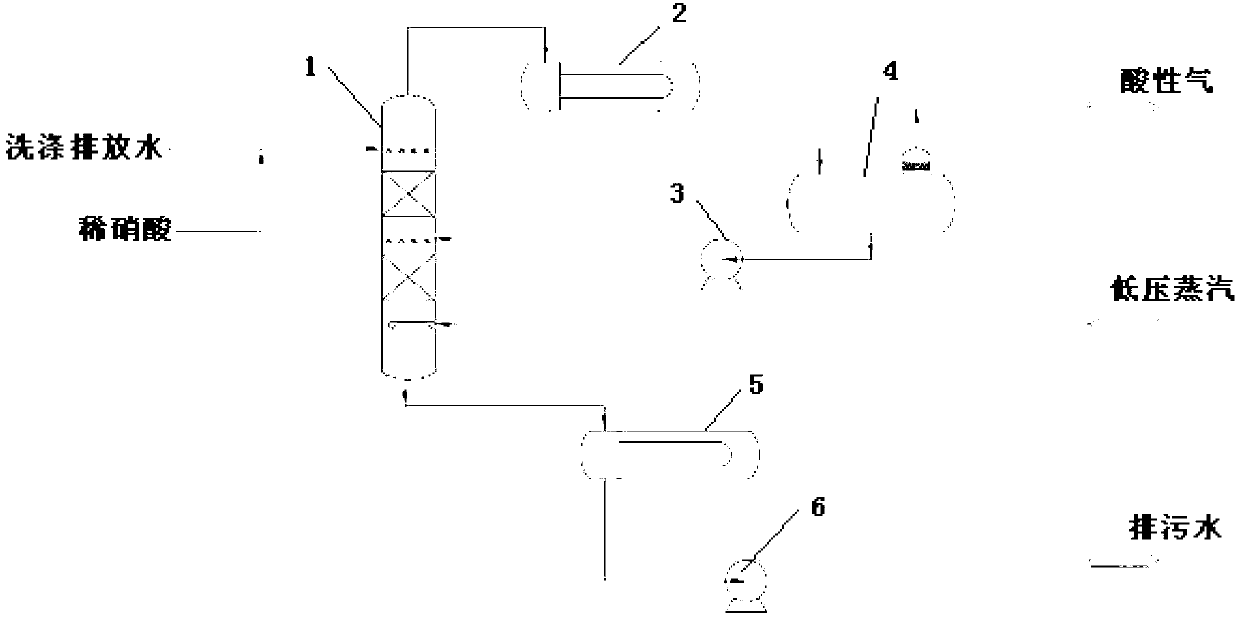

Method for stripping gas washing water

ActiveCN103101988AAvoid introducingStress corrosion mitigationWater/sewage treatment by heatingCounter flowGas phase

The invention discloses a method for stripping gas washing water, which solves the problems caused by the existing method for stripping the gas washing water, such that equipment and pipes are easy to corrode, and the production and investment of the equipment are high. The technical scheme comprises the following steps of: neutralizing the gas washing water, and then putting in a stripping tower to contact the low-pressure steal counter flow; stripping the gases, such as H2S, CO2 and NH3, dissolved in the washing and discharging water to gas-phases; cooling the gases coming from the top of the stripping tower to 80-100 DEG C via a stripping gas cooler; separating the gas from liquid via an acidic gas separating tank; returning the separated liquid to the stripping tower via a return pump of the stripping tower; conveying the acidic gas to a torch; cooling the wastewater produced by stripping to 40-50 DEG C via a wastewater cooler; and conveying the wastewater to a wastewater processing device after a drainage pump is pressurized. The method for stripping the gas washing water disclosed by the invention has simple processes, can effectively resolve the corrosion of the stripping tower, relative equipment and pipes, can prolong the service life of the equipment, and can reduce the investment cost of the equipment.

Owner:WUHUAN ENG

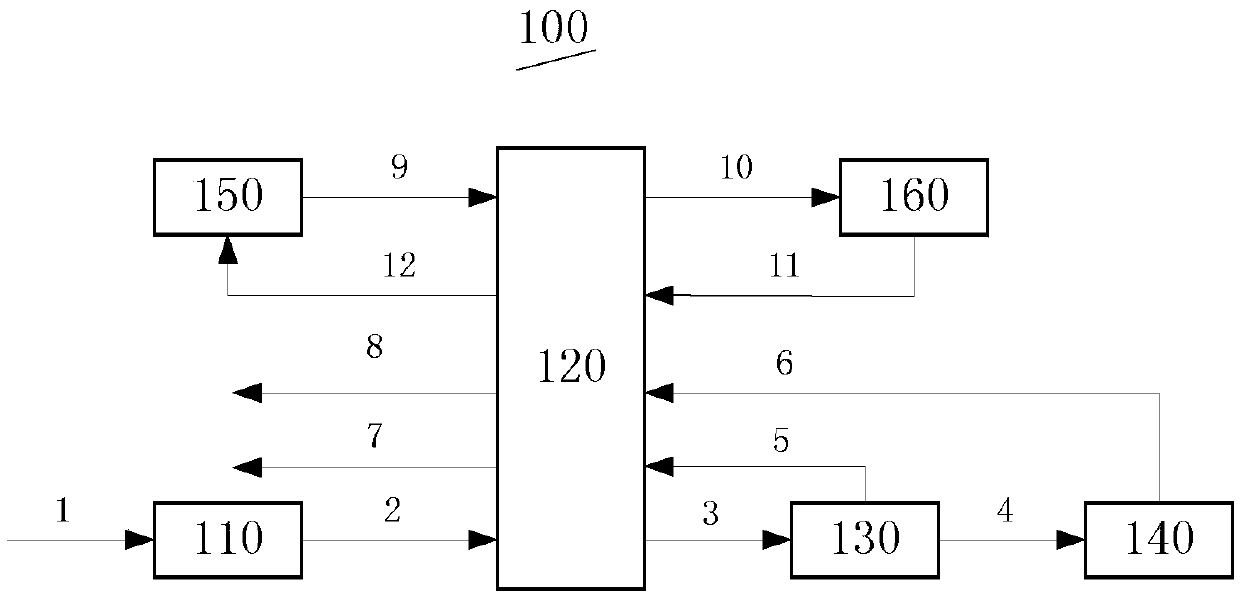

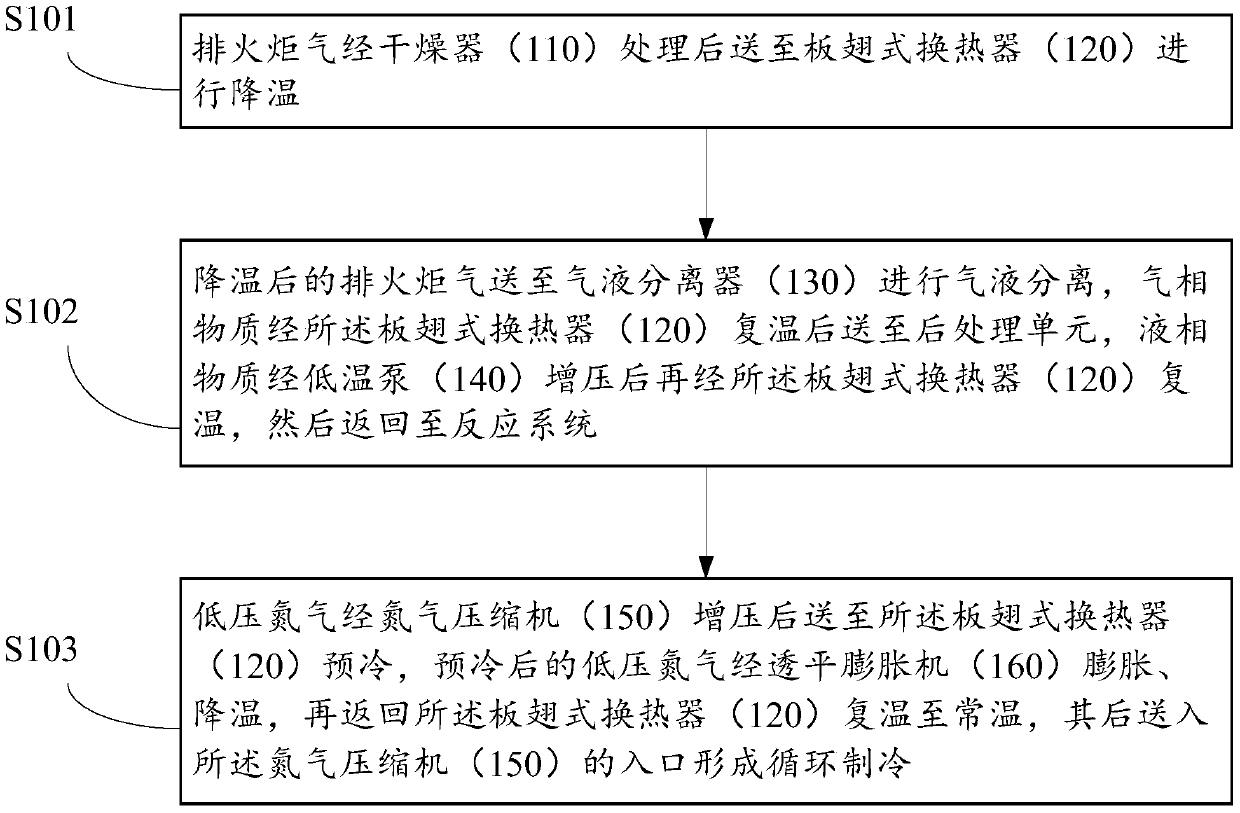

Cryogenic separation recycling system and method for exhausted polyolefin flare gas

The invention provides a cryogenic separation recycling system for exhausted polyolefin flare gas. The system comprises a dryer (110) communicated to a plate-fin heat exchanger (120), a gas-liquid separator (130), a cryopump (140), a nitrogen compressor (150) and a turbo expander (160); the exhausted flare gas is processed through the dryer (110), the dried exhausted flare gas is delivered to the plate-fin heat exchanger (120) to be cooled and then delivered to the gas-liquid separator (130) for gas-liquid separation, a gas phase is reheated by the plate-fin heat exchanger (120) and then delivered to a postprocessing unit, and a liquid phase is pressurized by the cryopump (140) and then reheated by plate-fin heat exchanger (120) to return to a reaction system; low-pressure nitrogen is pressurized by the nitrogen compressor (150) and then delivered to the plate-fin heat exchanger (120) to be precooled, the precooled nitrogen is expanded and cooled by the turbo expander (160) and then returns to the plate-fin heat exchanger (120) to be reheated to the normal temperature, and the reheated nitrogen is delivered to an inlet of the nitrogen compressor (150) to form circulating refrigerating. Hydrocarbon substances in the exhausted flare gas can be maximumly recycled, so that the downstream can conveniently utilize the exhausted flare gas.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Gas powered torch

ActiveUS20200132298A1Started quickly and easilyReliable ignitionElectric spark ignitersGaseous fuel burnerLiquid propaneDirect combustion

Various embodiments utilize a novel approach to igniting the natural gas flame that is emitted from the end of the torch. According to one embodiment a rotary diverter within the ignition bell of the GrillGun is used to shunt a portion of the higher velocity gas flow to an area in the bell where the ignition spark is out of the direct burning gas stream. According to another embodiment the ignition bell has a plate that largely covers its open end that reduces the length of the flame that is emitted and focuses it. Still another embodiment has a check valve that operates to stop the flow of gas to the gas conduit when the GrillGun is dropped or tipped over or liquid propane is otherwise presented into the check valve by any other means.

Owner:HEALEY ROBERT W

Torch hex end structure

InactiveUS20070102410A1Apparent advantageCompletely disassembling the gunArc welding apparatusEngineeringTorch

A welding gun assembly for directing a welding wire toward a workpiece, having a torch at a forward portion of the gun; a welding wire feeder at a rearward portion of the gun; a first housing positioned adjacent the torch; and a second housing positioned adjacent the wire feeder. The second housing has a hexagonally shaped opening for receiving a conduit having a hexagonal portion. The conduit is positioned in one of six positions in the housing. The first housing has a hexagonal shape for being mounted to a hexagonal opening of a remote arm. A block having a hexagonal shape is received within a hexagonal opening of the housing. A hexagonal conduit is received within the block and secured in one of six positions.

Owner:LINCOLN GLOBAL INC

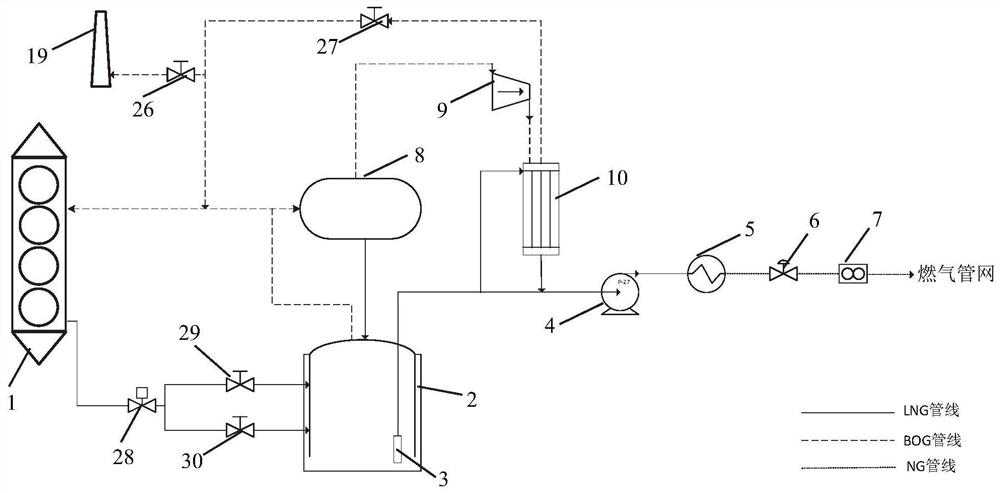

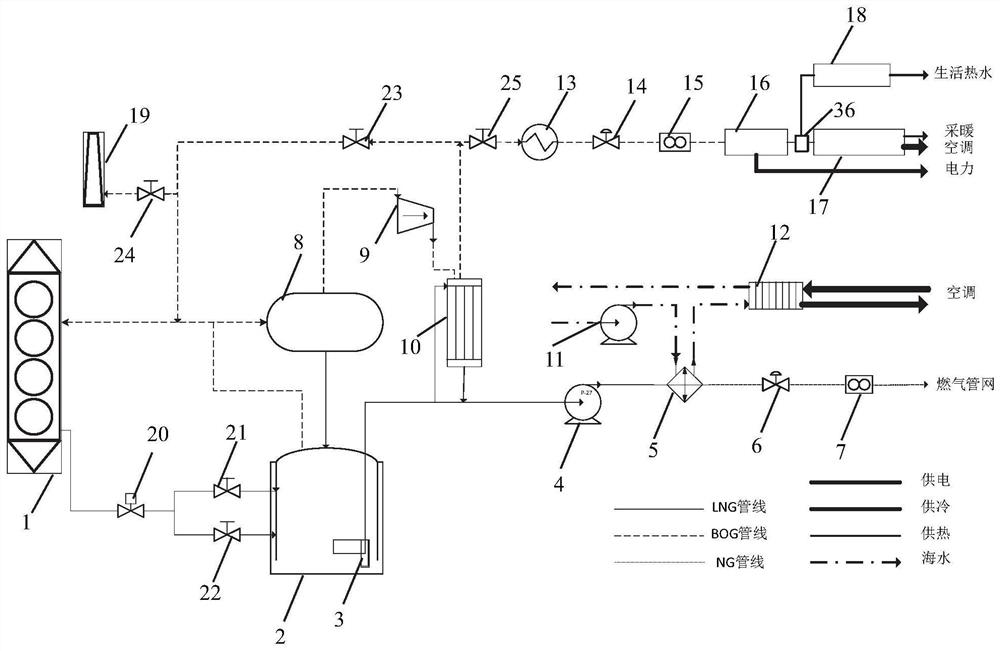

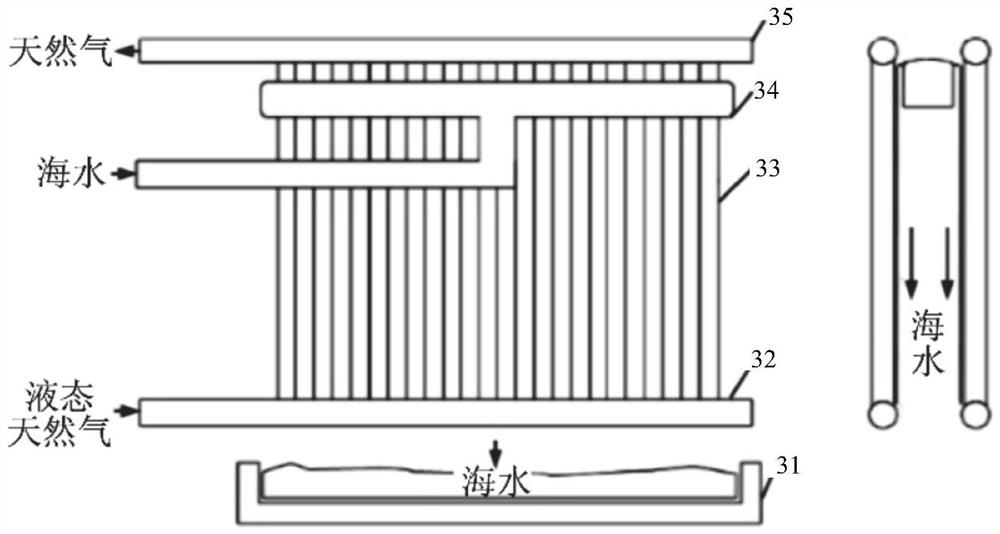

BOG comprehensive utilization system for LNG receiving station

PendingCN112963732ARealize the technical effect of energy saving and emission reductionRealize cascade utilizationGas handling/storage effectsPipeline systemsLithium bromideEnergy recovery

The invention relates to a BOG comprehensive utilization system for an LNG receiving station. The BOG comprehensive utilization system for the LNG receiving station comprises an LNG transport ship, an LNG storage tank, an immersed pump, a high-pressure pump, a vaporizer, a pressure regulator A, a metering device A, a buffering tank, a BOG compressor, a recondenser, a sea water pump, a heat exchanger A, a heat exchanger B, a power generation device, a lithium bromide unit, a waste heat boiler, a torch and a plurality of valves. The BOG comprehensive utilization system for the LNG receiving station has the following beneficial effects: a gas internal-combustion engine is used for combusting BOG for power generation, and BOG originally discharged through combustion is reused, so that the technical effects of energy conservation and emission reduction are realized; a heat exchange pipeline is arranged, and a free cold source is provided for an air conditioner through seawater; while the need of a vaporization process is met, gradient utilization of energy is realized through cold energy recovery, and energy conservation and emission reduction are achieved; and different energy consumption requirements of the LNG receiving station can be met, waste can be turned into wealth, energy loss and waste are reduced, the energy utilization rate is increased, the gradient utilization of energy is realized, and a good good economic value is achieved.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com