Preparation method of high-nitrogen stainless steel spherical powder

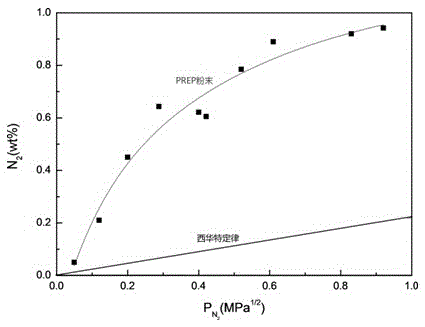

A high-nitrogen stainless steel and spherical powder technology, applied in the field of high-nitrogen stainless steel spherical powder preparation, can solve the problems of poor batch stability of powder, high price of high-purity element powder, low powder fluidity, etc. The effect of improving the yield of fine powder and suppressing the precipitation of nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

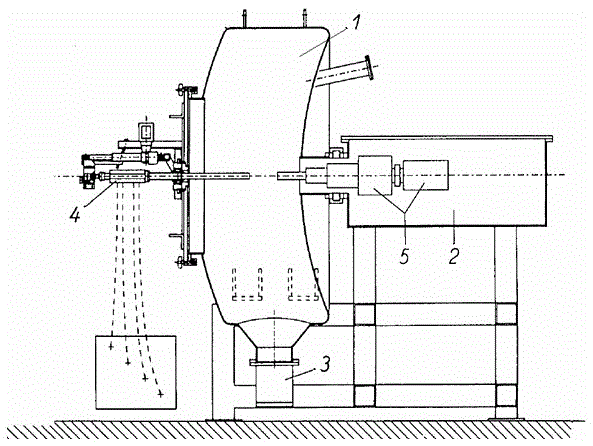

[0026] Embodiment 1: Preparation of high nitrogen austenitic stainless steel spherical powder

[0027] The percentage by weight is: Cr17.5%, Mo2.6%, Ni13.5%, the rest is Fe element, and the austenitic stainless steel melting and casting raw material with a total weight of 100kg is used for smelting and obtaining ingots; secondly, through the forging process, the stainless steel The ingot is made into a forged bar with a microstructure density of 99.6%. After machining on a lathe and a precision CNC lathe, an austenitic stainless steel electrode rod with a diameter of 40mm and a length of 800mm is obtained, and the surface roughness is 1.6μm; The obtained electrode rod is placed in the electrode rod installation chamber 2, and the nitrogen atomization chamber 1 is evacuated until the vacuum degree of the equipment reaches 1×10 -3 Fill high-purity nitrogen at Pa, and the partial pressure of nitrogen in the equipment is 1.5×10 5 Pa; turn on the atomization equipment to prepare...

Embodiment 2

[0029] Example 2: Preparation of high-nitrogen nickel-free austenitic stainless steel spherical powder

[0030] The percentage by weight is: Cr18.5%, Mn13%, Mo3.5%, the rest is Fe element, and the austenitic stainless steel melting and casting raw material with a total weight of 100kg is used to melt and obtain ingots; secondly, through forging process, the stainless steel ingots are cast A forged bar with a microstructure density of 99.8% was made, and after machining on a lathe and a precision CNC lathe, an austenitic stainless steel electrode rod with a diameter of 60 mm and a length of 600 mm was obtained, with a surface roughness of 3.2 μm; the obtained electrode The rod is placed in the stainless steel electrode rod installation chamber 2, and the nitrogen atomization equipment 1 is vacuumed until the vacuum degree of the atomization equipment reaches 5×10 -3 Fill high-purity nitrogen at Pa, and the partial pressure of nitrogen in the atomization equipment is 2.5×10 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com