Film method for recycling CO in high-pressure exhaust from production of acetic acid by carbonylation

A technology of carbonylation and tail gas, which is applied in the field of CO purification, can solve the problems of inability to directly use membrane separation technology, membrane damage, and high requirements for membrane feed gas, and achieve the effects of small-scale equipment, convenient operation, and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

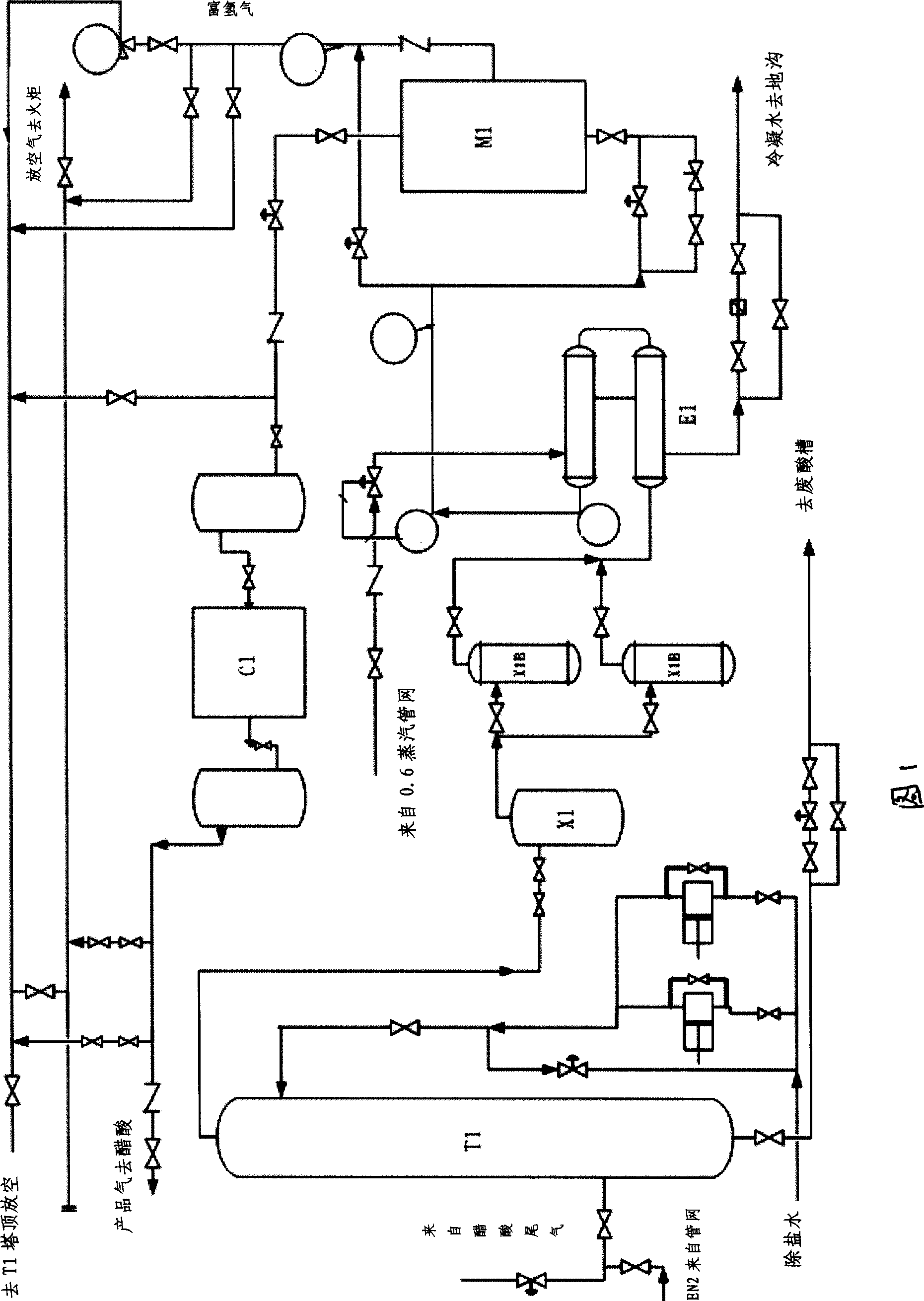

Image

Examples

Embodiment 1

[0040]

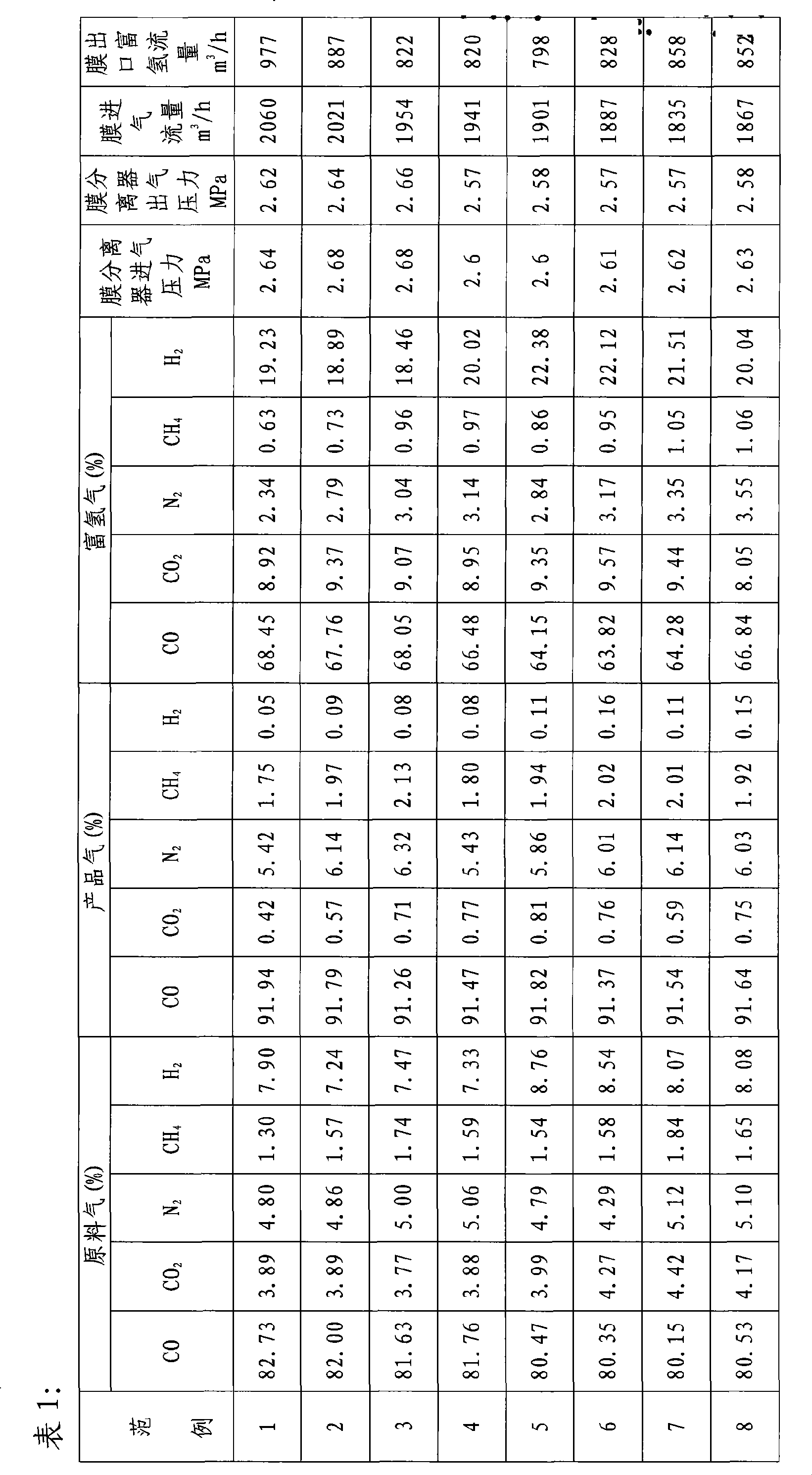

[0041] It can be seen from the above examples that the membrane separation device can achieve the design purpose after it is actually put into operation, and the CO content of the product gas reaches more than 91%, which meets the process requirements and realizes the continuous recovery and utilization of the high-pressure tail gas of acetic acid.

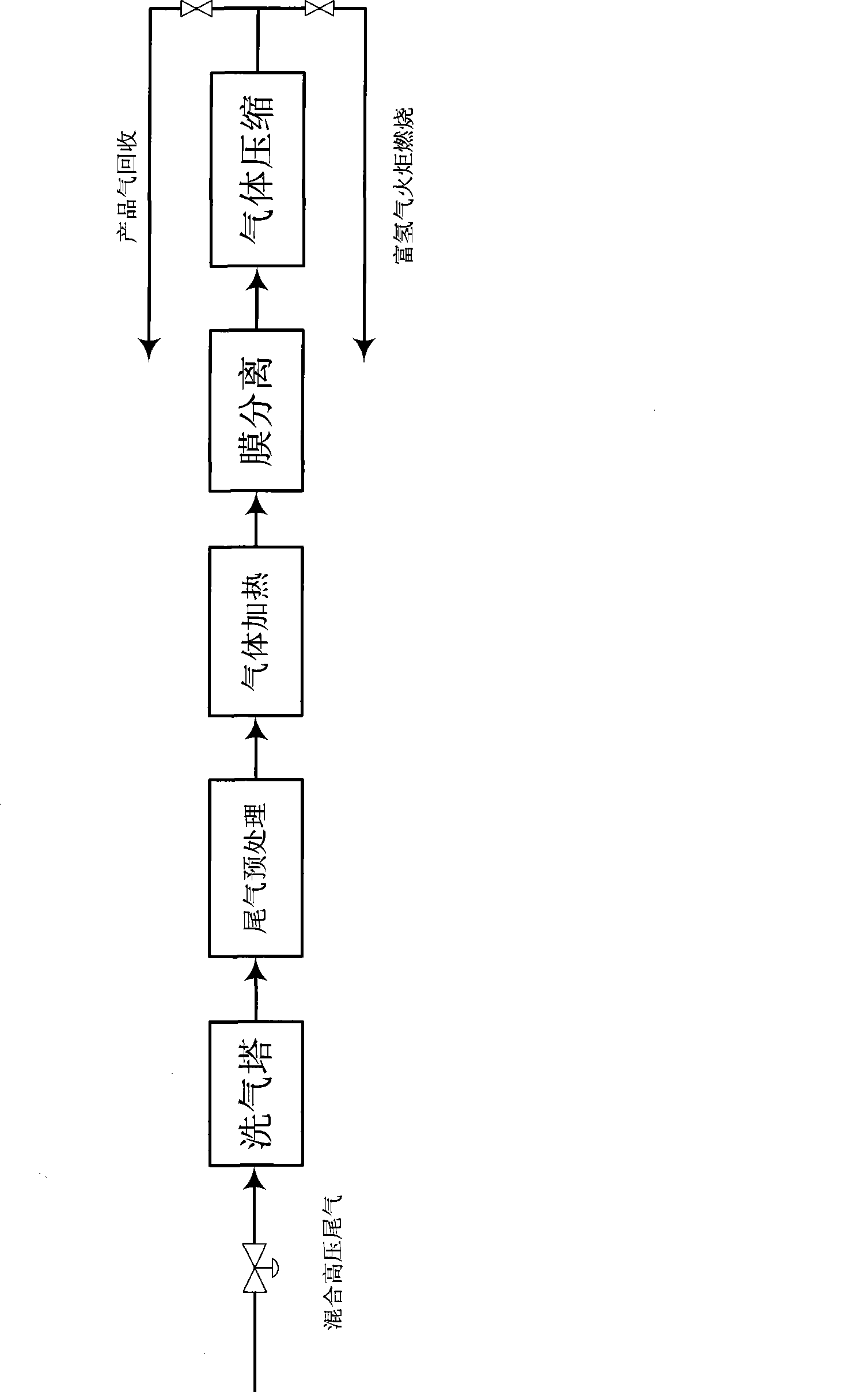

[0042] Through the pretreatment system composed of scrubber, mist eliminator and combined filter, the "harmful" components in the exhaust gas are removed to prevent the influence on the stable operation of the membrane; in practical applications, 2 sets of Prison membranes are selected The effective separation of tail gas has been realized, the processing gas volume and product gas composition have met the working requirements, and the optimized combination has been realized; it can be seen from the example 2 Can not effectively remove, so the present invention adjusts the gas volume that product gas enters acetic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com