Method for preparing polyimide fibers

A polyimide fiber and polyamic acid spinning technology, which is applied in fiber treatment, fiber chemical characteristics, wet spinning, etc., can solve the problem of affecting the storage and performance of polyamic acid fiber and the low performance of polyimide fiber , unfavorable continuous production and other issues, to achieve the effect of high imidization degree and high orientation degree, simple synthesis method, and conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

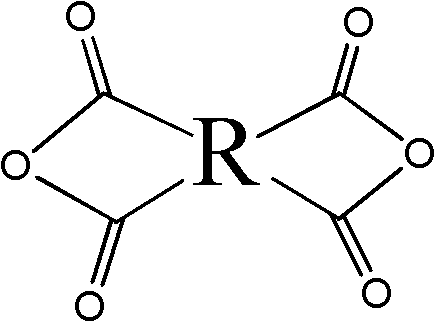

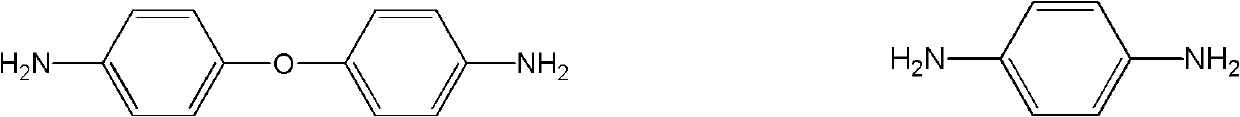

[0031] Synthesis of polyamic acid solution: according to the molar ratio of PMDA: ODA = 1.05: 1, the ODA monomer is first placed in a three-necked flask, and a metered amount of solvent dimethylformamide (DMF) is added, and stirred under nitrogen protection. ODA was completely dissolved, then PMDA was added in batches and stirred to make the solid content 10%, and then stirred at 50° C. for 5 hours to obtain a viscous polyamic acid solution.

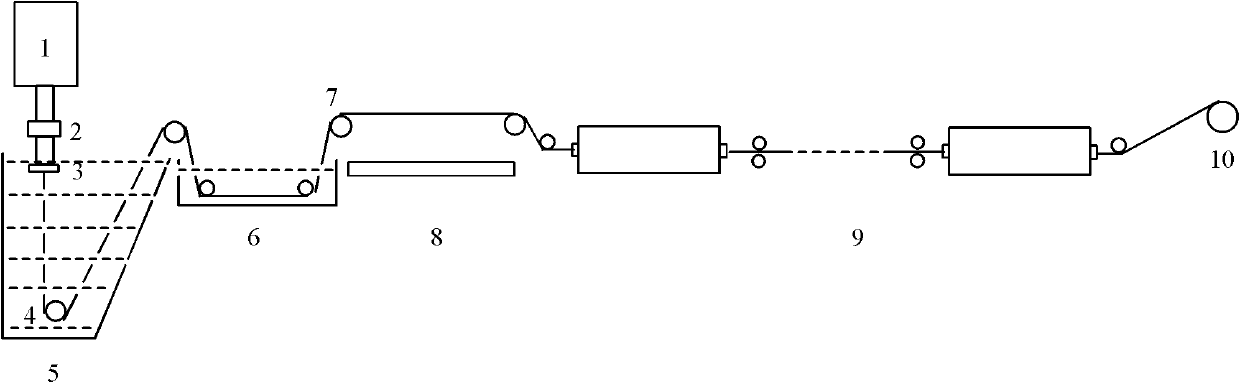

[0032] Preparation of polyimide fiber: filter the polyamic acid solution and move it into the storage tank (1), vacuum degassing, and then spinning by wet process. The polyamic acid solution is pumped out by the metering pump (2) and sprayed out through the spinneret (3), and the obtained polyamic acid fiber is drawn by the godet roller (4) and enters the coagulation bath (5) for solidification, and then passes through the godet roller After traction, it enters the cleaning bath (6) for washing. Both the coagulation bath and the cleaning...

Embodiment 2

[0034] Synthesis of polyamic acid solution: according to the molar ratio of PMDA:ODA=0.95:1, the ODA monomer is first placed in a three-necked flask, and the metered solvent dimethylacetamide (DMAc) is added, stirred under nitrogen protection to make ODA was completely dissolved, then PMDA was added in batches and stirred to make the solid content 20%, and stirred at 0°C for 2 hours to obtain a viscous polyamic acid solution.

[0035] Preparation of polyimide fiber: filter the polyamic acid solution and move it into the storage tank (1), vacuum degassing, and then spinning by wet process. The polyamic acid solution is pumped out by the metering pump (2) and sprayed out through the spinneret (3), and the obtained polyimide fiber is drawn by the godet roller (4) and enters the coagulation bath (5) for solidification, and the coagulation bath consists of The mixed solution of water and ethanol is dried by the hot plate (8), and then enters into four furnace sections composed of t...

Embodiment 3

[0037] Synthesis of polyamic acid solution: according to the molar ratio of PMDA: ODA = 1.05: 1, the ODA monomer is placed in a three-necked flask first, and the metered solvent dimethylacetamide (DMAc) is added, and stirred under nitrogen protection. ODA was completely dissolved, then PMDA was added in batches and stirred to make the solid content 25%, stirred at 0°C for 2 hours, and then stirred at 40°C for 10 hours to obtain a viscous polyamic acid solution.

[0038]Preparation of polyimide fiber: filter the polyamic acid solution and move it into the storage tank (1), vacuum degassing, and then spinning by wet process. The polyamic acid solution is pumped out by the metering pump (2) and sprayed out through the spinneret (3), and the obtained polyimide fiber is drawn by the godet roller (4) and enters the coagulation bath (5) for solidification, and then passes through the wire guide After being pulled by the roller, it enters the cleaning bath (6) for washing. The coagula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com