Preparation method of hydrophilic polyvinylidene fluoride resin

A technology of polyvinylidene fluoride resin and hydrophilicity, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as shedding of nanoparticles and failure to remove heavy metal ions, and achieve low intrinsic viscosity, High rejection rate, mild polymerization reaction process and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

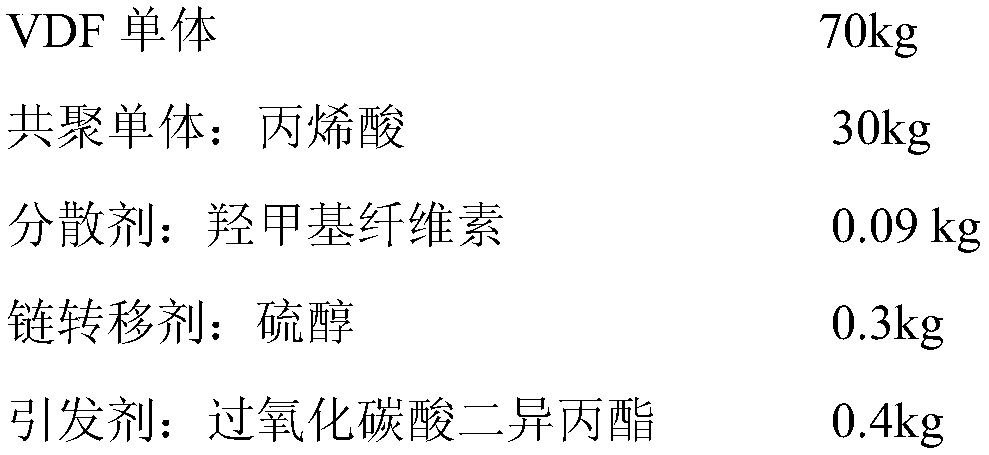

[0029] A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0030]

[0031] The preparation method is as follows:

[0032] (1) Suspension polymerization

[0033] After adding 240kg of deionized water to the polymerization kettle, replace it with high-purity nitrogen gas. After the replacement is qualified, add 70kg of VDF monomer, 30kg of acrylic acid, 0.09kg of hydroxymethyl cellulose, 0.3kg of mercaptan, 0.4kg of diisopropyl peroxycarbonate and 10kg of deionized water was reacted at a stirring speed of 55rpm, the reaction temperature was 35°C, the reaction time was 12h, and the reaction pressure was 2.7Mpa to obtain a suspension polymerization product;

[0034] (2) Post-processing of suspension polymerization products

[0035] The suspension polymerization product obtained in step (1) was first washed 3 times with 20°C deionized water (washing speed 30rpm), then washed 3 times with 60°C deionized water, and then centrifuged for ...

Embodiment 2

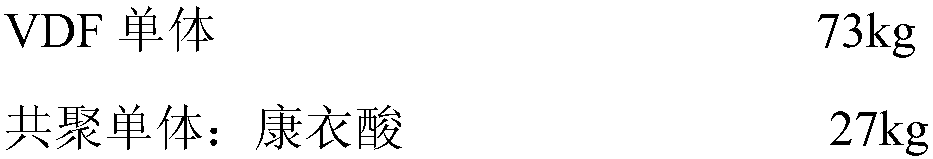

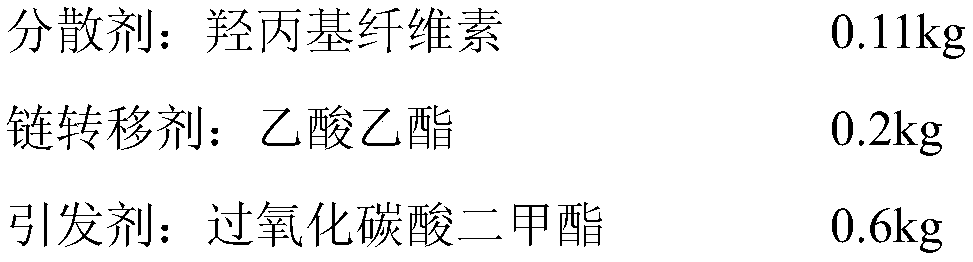

[0037] A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0038]

[0039]

[0040] A kind of preparation method of hydrophilic polyvinylidene fluoride resin, concrete steps are as follows:

[0041] (1) Suspension polymerization

[0042] Add 270kg of deionized water to the polymerization kettle and replace it with high-purity nitrogen gas. After the replacement is qualified, add 73kg of VDF monomer, 27kg of conynic acid, 0.11kg of hydroxypropyl cellulose, 0.2kg of ethyl acetate, and 0.6kg of dimethyl peroxycarbonate. Ester and 10kg of deionized water were reacted at a stirring speed of 60rpm, the reaction temperature was 28°C, the reaction time was 15h, and the reaction pressure was 3.0Mpa to obtain a suspension polymerization product;

[0043] (2) Post-processing of suspension polymerization products

[0044] Wash the suspension polymerization product obtained in step (1) with 25°C deionized water for 3 times (washing speed 3...

Embodiment 3

[0046]A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0047]

[0048] A kind of preparation method of hydrophilic polyvinylidene fluoride resin, concrete steps are as follows:

[0049] (1) Suspension polymerization

[0050] Add 290kg deionized water to the polymerization kettle and replace it with high-purity nitrogen gas. After the replacement is qualified, add 77kg VDF monomer, 13kg conynic acid, 10kg acrylic acid, 0.4kg hydroxypropyl cellulose, 0.4kg hydroxymethyl cellulose, 0.2kg ethyl acetate, 0.44kg dipropyl peroxycarbonate and 10kg deionized water were reacted at a stirring speed of 65rpm, the reaction temperature was 26°C, the reaction time was 18h and the reaction pressure was 3.5Mpa to obtain a suspension polymerization product;

[0051] (2) Post-processing of suspension polymerization products

[0052] The suspension polymerization product obtained in step (1) was first washed 3 times with 30°C deionized water (was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com