Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "High melt index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-melting-point polyester hot melt adhesive with better fluidity

The invention discloses a synthesis method of a high-melting-point polyester hot melt adhesive with better fluidity. The synthesis method comprises the following steps of: (1) carrying out esterification reaction on p-phthalic acid, m-phthalic acid, fatty dicarboxylic acid, ethylene glycol and C3-C6 diol under the action of titanate serving as a catalyst; and (2) adding a stabilizer and a surfactant to the products obtained in the step (1), and carrying out reduced-pressure condensation polymerization reaction to obtain a product, namely the high-melting-point polyester hot melt adhesive with better fluidity. The obtained polyester hot melt adhesive has good adhesion performance, better fluidity when used at high temperature, and excellent wet leveling property.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

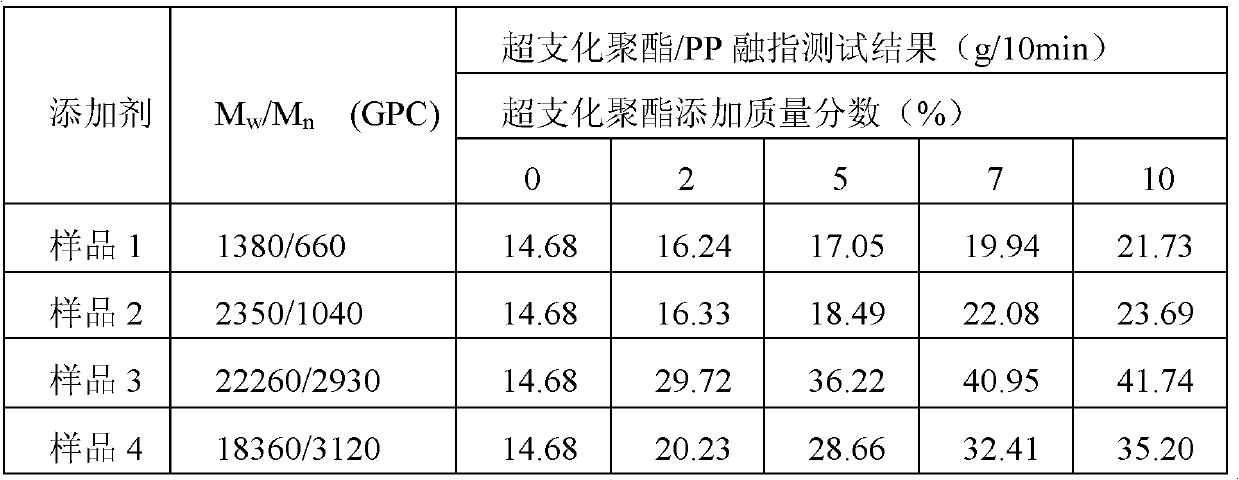

Application of fatty acid modified hyperbranched polyester to plastic processing

InactiveCN105315441AImprove appearance performanceHigh yield strengthPolymer scienceHyperbranched polyester

The invention discloses application of fatty acid modified hyperbranched polyester to plastic processing, belonging to the technical field of plastic processing aids. The application of fatty acid modified hyperbranched polyester comprises the steps of adding 0.5-3% of fatty acid modified hyperbranched polyester into plastics, uniformly mixing, extruding for granulating, and drying to obtain a modified plastic product. Plastics including polypropylene and the like are modified through mixing the plastics including polypropylene and the like and hyperbranched polyester at a high speed, and then, granulating by extruding through a double-screw extruder; the hyperbranched polyester is added into plastic matrixes, so that the processing temperature of the plastics can be remarkably lowered, the apparent property of the plastics is improved, and relatively high melting flowability is realized through relatively low additive amount; the decomposition temperature of the fatty acid modified hyperbranched polyester is relatively high and can be up to 290 DEG C; and the melt index of the modified plastics is remarkably increased, and meanwhile the dispersing performance of a filling system is improved.

Owner:WEIHAI CY DENDRIMER TECH

Stretched PVA (polyvinyl alcohol) film and preparation method for same

InactiveCN102604294AWiden the melting point distanceImprove water resistanceSynthetic resin layered productsPolymer scienceSwelling ratio

A stretched PVA (polyvinyl alcohol) film and a preparation method for the same belong to the field of high polymer packaging materials, and aim to solve the problems of high energy consumption, low production efficiency, complicated process and special equipment production during processing with water serving as solvent in the prior art. The stretched PVA film is of a monolayer structure or three-layer structure, wherein the monolayer structure refers to B, and the three-layer structure sequentially refers to A / B / A or B / A / B. The method includes the steps of melting plasticization, extrusion granulation, and uniaxial stretching or biaxial stretching so that the stretched PVA film is obtained. The stretching melting range of the stretched PVA film is from 160 DEG C to 240 DEG C. The stretched PVA film meets national standard of biological degradability, and the degradation ratio is larger than or equal to 70%. The stretched PVA film is high in water resistance, and the swelling ratio of the stretched PVA film soaking in water at the temperature of 23 DEG C for 48 hours is smaller than or equal to 120%.

Owner:朱春英

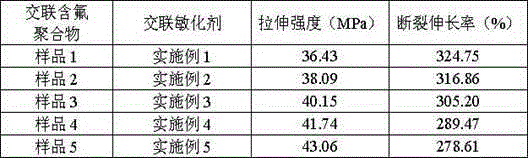

Adjustable performance irradiation crosslinking ethylene-tetrafluoroethene copolymer insulation material

InactiveCN105061876AAdjustable performanceLow smoke productionPlastic/resin/waxes insulatorsCross-linkPolymer science

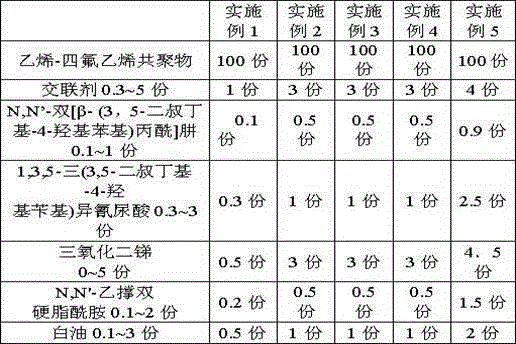

The invention relates to an adjustable performance irradiation crosslinking ethylene-tetrafluoroethene copolymer insulation material, which comprises the following components by mass part: an ethane-tetrafluoroethene copolymer, a cross-linking agent, N,N-'-dis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hydrazine, 1,3,5-tri(3,5-di-tert-butyl-4-hydroxyphenyl)isocyanuric acid, antimonony oxide, N, N'-ethylene bis-stearamide, and white oil, the cross-linking agent is made by mixing a component A and a component B, the mass ratio of the component A: the component B is 1: 0.1-10; the component B is at least one of triene propyl isocyanate, TMAIC, triallyl cyanate ester and TMAIC. The fluorine-containing polymer has the advantages of difficult self-polymerization, low volatileness, increased product stability, difficult volatileness, difficult self-polymerization, little smoke amount during the processing process, white sample color, non discolouring after irradiation and good product stability.

Owner:中广核三角洲(江苏)塑化有限公司

Spherical magnesium halide adduct, a catalyst component and a catalyst for olefin polymerization prepared therefrom

ActiveUS20120184694A1Promote resultsParticles in good shapeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorBromine

A magnesium halide adduct represented by the formula (I): MgX2.mROH.nE.pH2O, in which X is chlorine, bromine, a C1-C12 alkoxy, a C3-C10 cycloalkoxy or a C6-C10 aryloxy, with the proviso that at least one X is chlorine or bromine; R is a C1-C12 alkyl, a C3-C10 cycloalkyl or a C6-C10 aryl; E is an o-alkoxybenzoate compound represented by the formula (II): in which R1 and R2 groups are independently a C1-C12 linear or branched alkyl, a C3-C10 cycloalkyl, a C6-C10 aryl, a C7-C10 alkaryl or an C7-C10 aralkyl, the R1 and R2 groups are identical to or different from the R group; m is in a range of from 1.0 to 5.0; n is in a range of from 0.001 to 0.5; and p is in a range of from 0 to 0.8, is disclosed. A catalyst component useful in olefin polymerization, which comprises a reaction product of (1) the magnesium halide adduct, (2) a titanium compound, and optionally (3) an electron donor compound, is also disclosed.

Owner:CHINA PETROCHEMICAL CORP +1

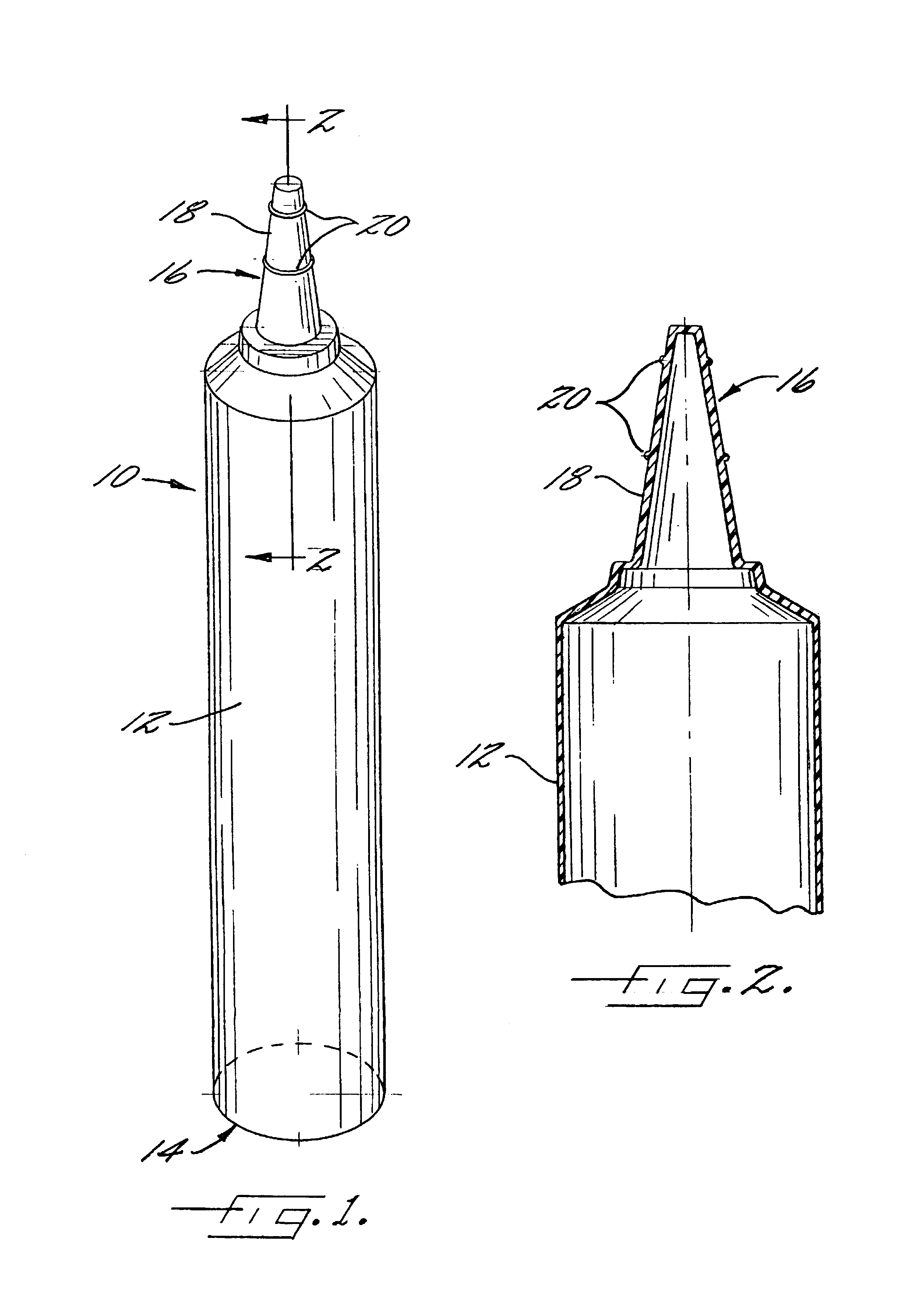

Composition for molding thin-walled parts, and injection-molded squeeze tube made thereof

InactiveUS6838523B2High melt indexHigh tear strengthEnvelopes/bags making machineryLayered productsLow-density polyethyleneVitrification

Compositions for injection-molding of long, thin-walled, one-piece squeeze tubes include low-density polyethylene having a density less than about 0.925 g / cc and a melt index of at least about 50 g / 10 minutes, and polypropylene having a high melt index greater than about 800 g / 10 minutes, wherein the high melt index is attained by peroxide degradation of the polypropylene during melt processing. The compositions can also include a polymer that is miscible and compatible with low-density polyethylene and polypropylene for enhancing flow of the molding composition in the mold, the polymer having a glass transition temperature Tg of about −20 to −40° C., and / or metallocene resin having a density less than about 0.915 g / cc.

Owner:SONOCO DEV INC

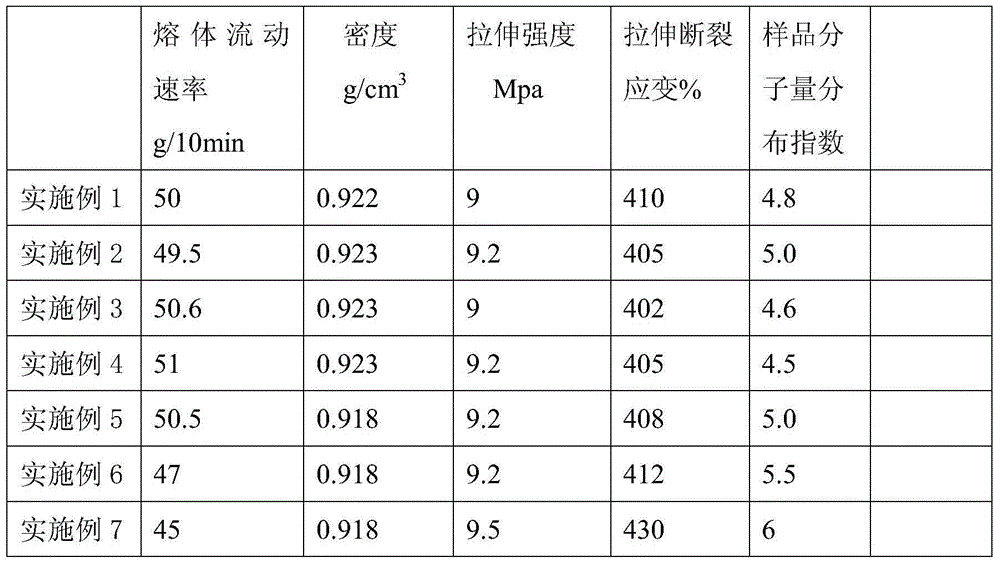

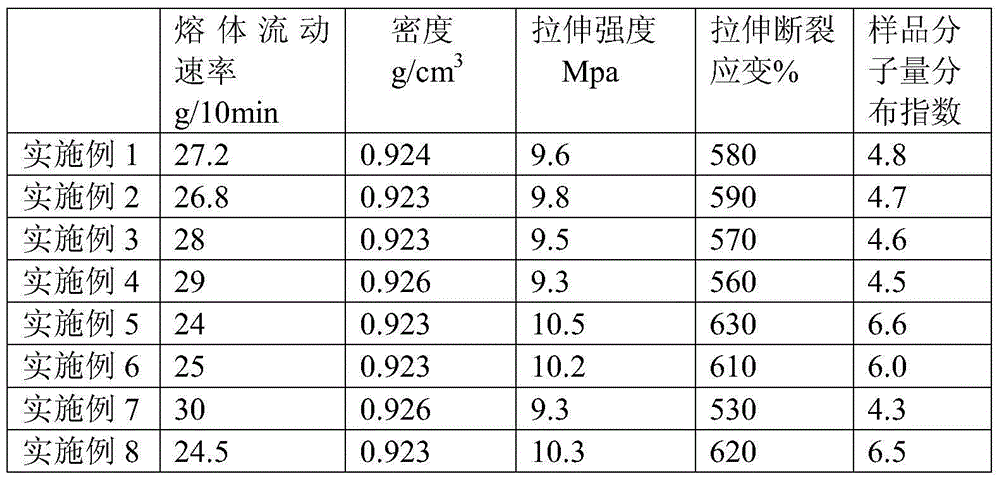

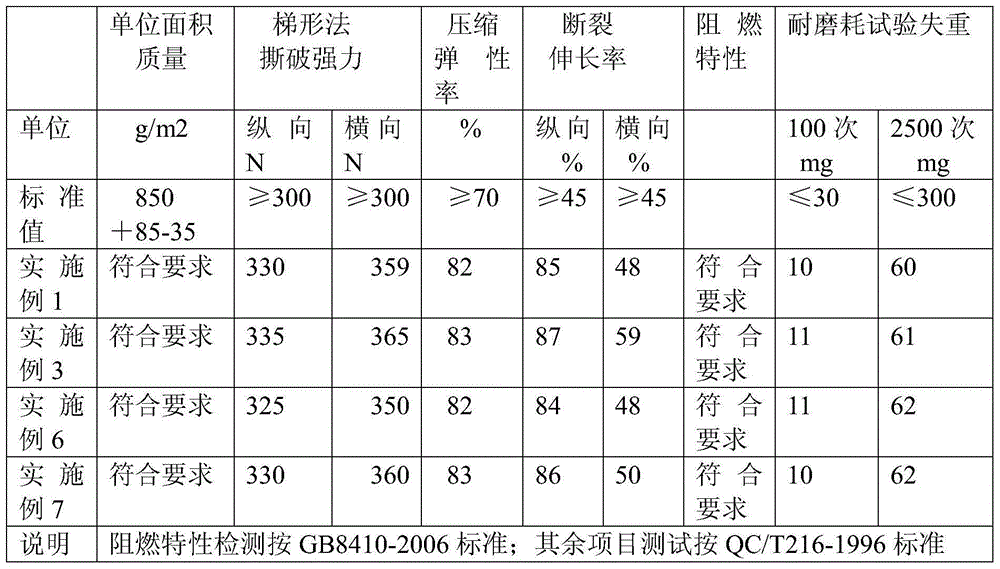

High melting index and low density polyethylene for ultrafine fiber leather

ActiveCN104371048ANarrow molecular weight distributionHigh melt indexConjugated synthetic polymer artificial filamentsLow-density polyethylenePolymer science

The invention belongs to the technical field of ultrafine fiber synthesized leather, and specifically relates to a high melting index and low density polyethylene for ultrafine fiber leather. The high melting point of the polyethylene is 190 DEG C, 2.16 kg, under 42-60 g / min, the density of the polyethylene is 0.915-0.924 g / cm3, and the molecular weight distribution index is 3 to 10. During the melting and spinning process, the high flowing performance of the polyethylene resin can be utilized to convert part of the polyethylene resin into ultrafine flows so as to produce normal mixed fibers, which can be extracted out by a specific solvent from common fibers; at the same time, the other part of the polyethylene resin is converted into ultrafine fibers to produce ultrafine fiber synthesized leather. The polyethylene is produced by a tubular type E-process high pressure polymerization technology apparatus through a special technological method, the technical content is high, and the polyethylene has a good economic profit.

Owner:CHINA PETROLEUM & CHEM CORP +1

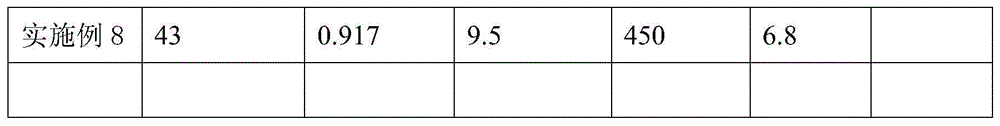

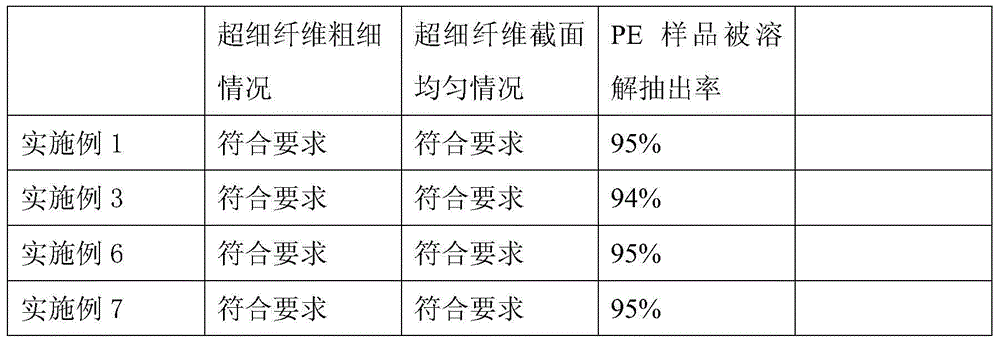

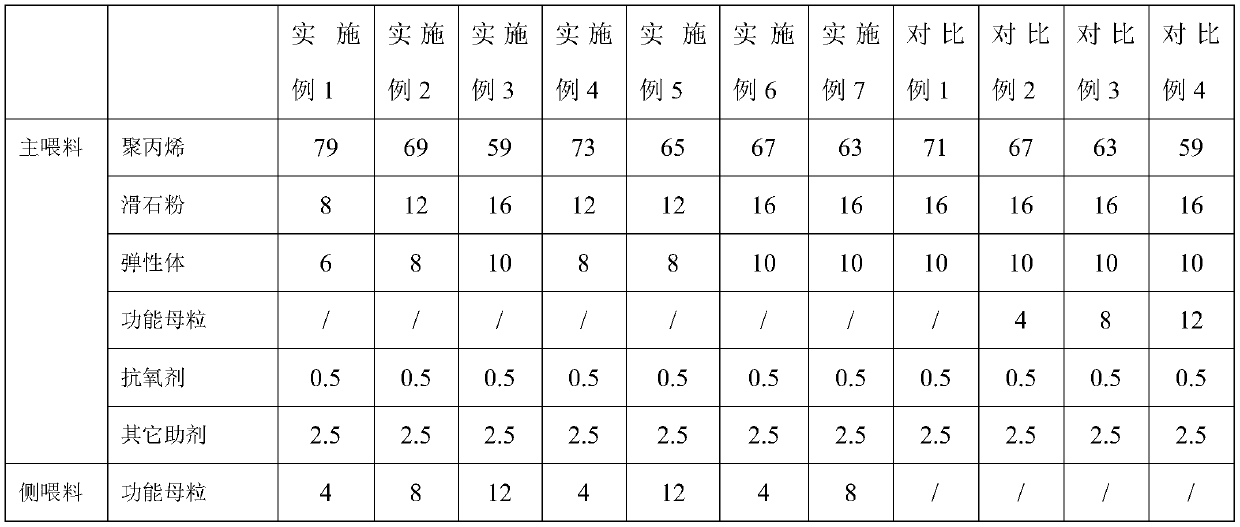

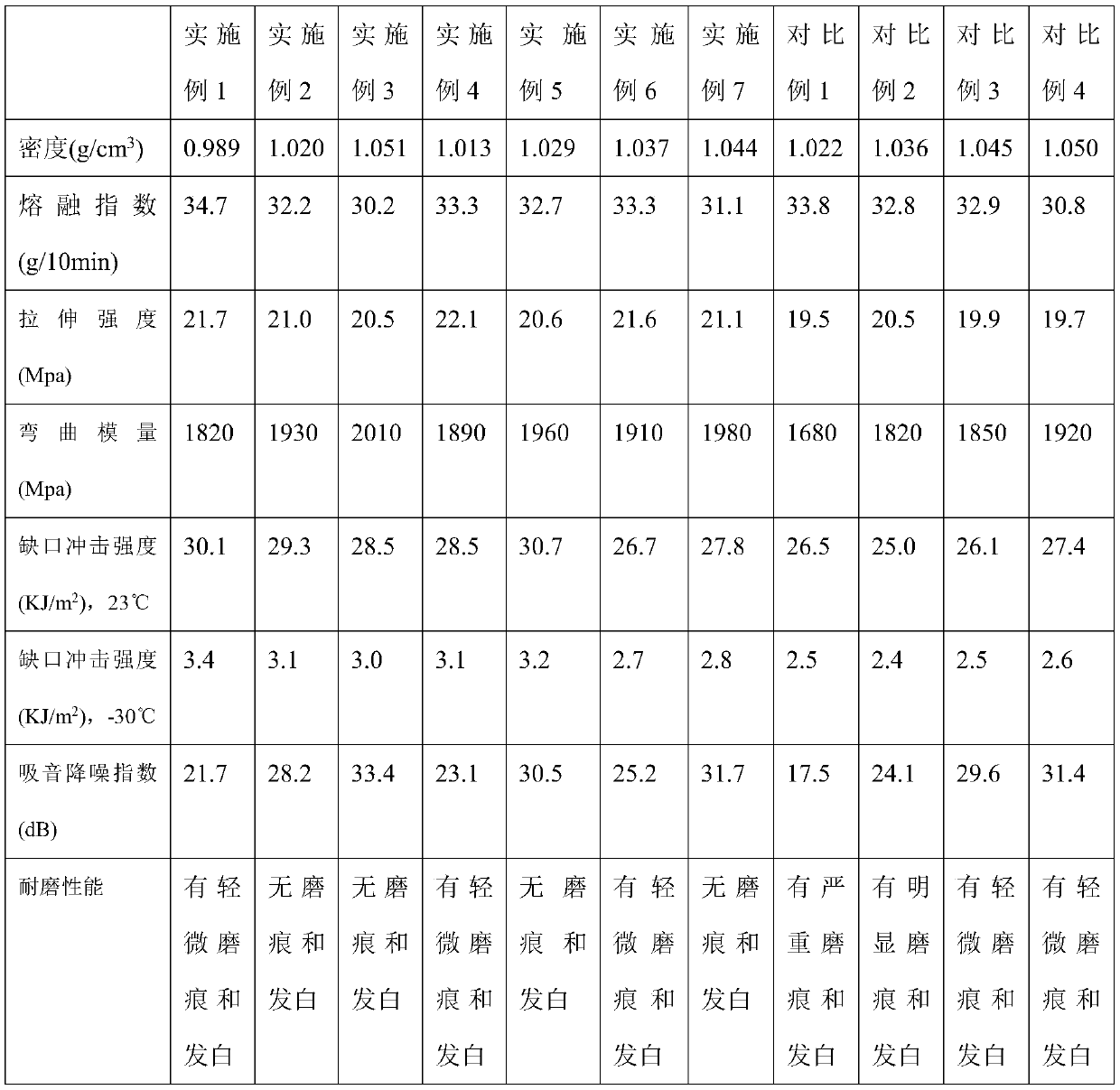

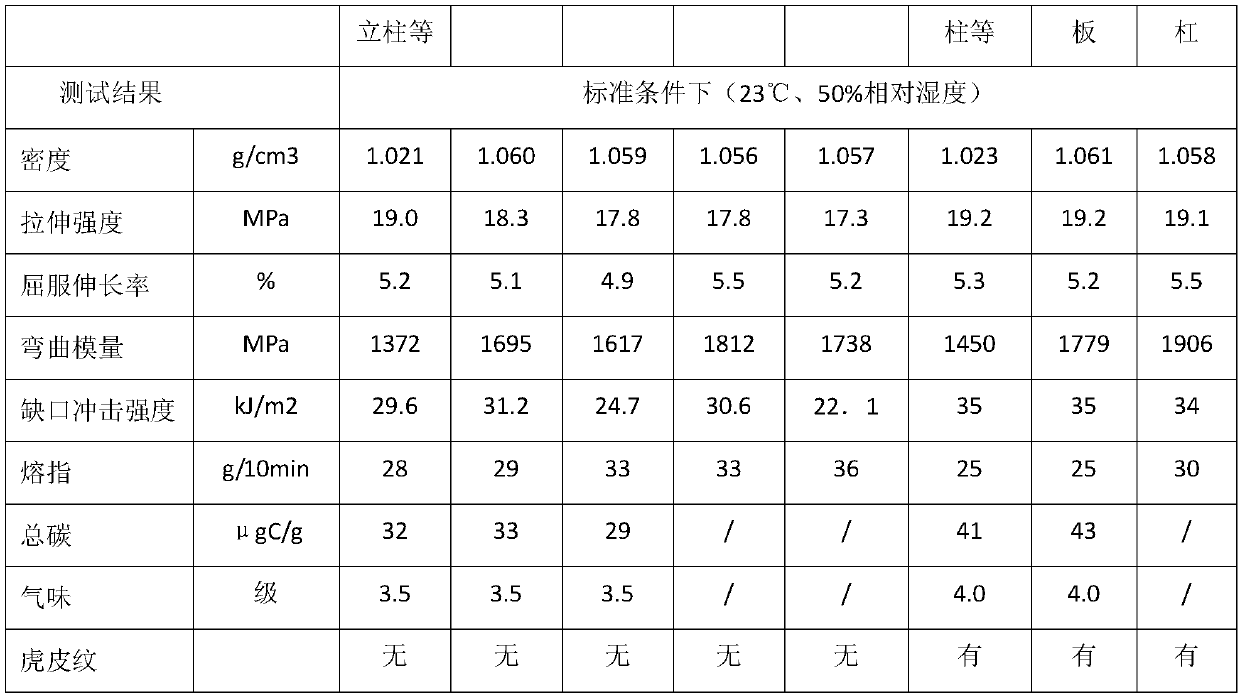

Wear-resistant, noise-reducing and thin-walled polypropylene composite material and preparation method thereof

The invention discloses a wear-resistant, noise-reducing and thin-walled polypropylene composite material and a preparation method thereof. The wear-resistant, noise-reducing and thin-walled polypropylene composite material comprises the following raw materials in parts by weight: 59-79 parts of polypropylene; 8 to 16 parts of talcum powder; 6-10 parts of an elastomer; 4 to 12 parts of a functional master batch; 0-1 part of an antioxidant and 0-3 parts of other auxiliary agents; the ultrahigh molecular weight polyethylene in the functional master batch has unique self-lubricating, wear-resisting and impact-resisting properties, so that the wear-resisting, impact-resisting and other mechanical properties of the thin-walled polypropylene composite material are remarkably improved by adding the ultrahigh molecular weight polyethylene; the functional master batch takes high-fluidity polypropylene as a carrier; when the polymer system is extruded from a twin-screw extruder or an injection molding machine, nano silicate can be well and uniformly dispersed into a composite material system, a unique chain layer structure of the nano silicate plays a role in dissipating sound transmission,and meanwhile, the nano silicate and ultra-high molecular weight polyethylene in the functional master batch generate a synergistic effect to ensure that the prepared composite material has excellentsound absorption and noise reduction functions.

Owner:ZHEJIANG PRET NEW MATERIALS

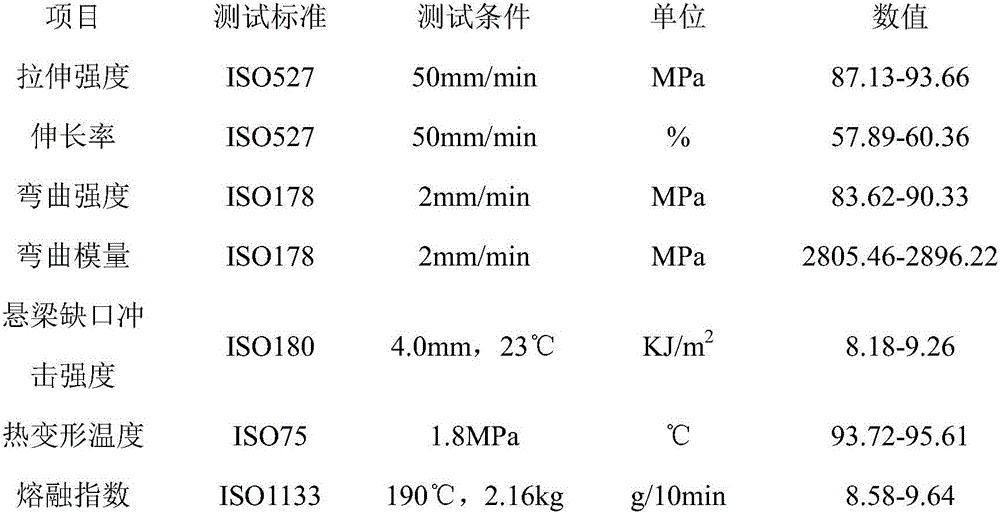

Graphene printing material

InactiveCN106589864AHigh tensile strengthHigh heat distortion temperatureAdditive manufacturing apparatusHeat deflection temperaturePolymer science

The invention discloses a graphene printing material and belongs to the technical field of 3D printing materials. The graphene printing material comprises, by weight, 5.5-7.6 parts of graphene, 24.6-30.4 parts of waste plastic, 34.2-38.2 parts of polylactic acid, 11.6-22.7 parts of potassium tripolyphosphate, 18.3-24.5 parts of adipate, 9.2-17.3 parts of a special synthetic agent, and 5.2-9.5 parts of a starch synthetic agent. The graphene printing material has high tensile strength, high bending strength and high notch impact strength and is high in thermal deformation temperature and melt index. A product produced through 3D printing technology is high in quality, has high anti-impact property and is high in strength. The material has wide market prospect.

Owner:GUANGXI ZHUMENG SANTI TECH CO LTD

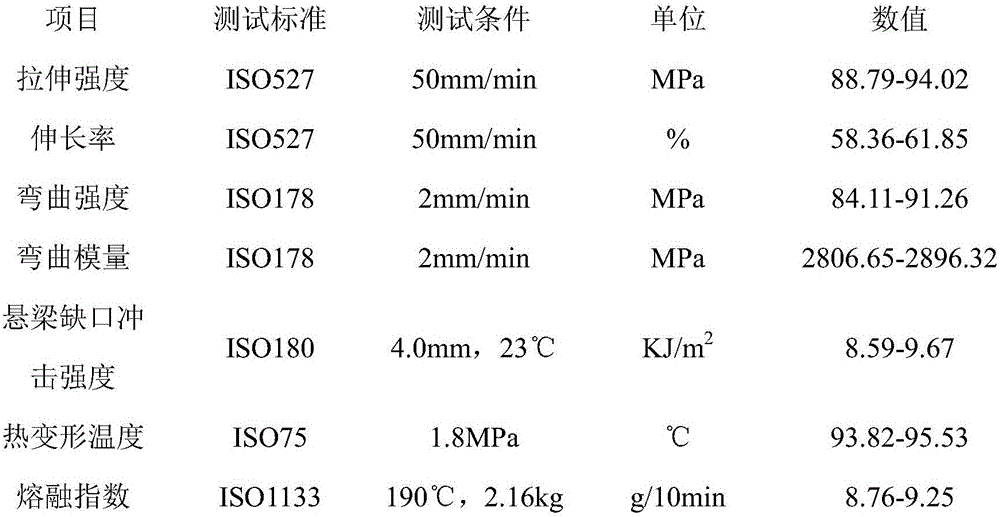

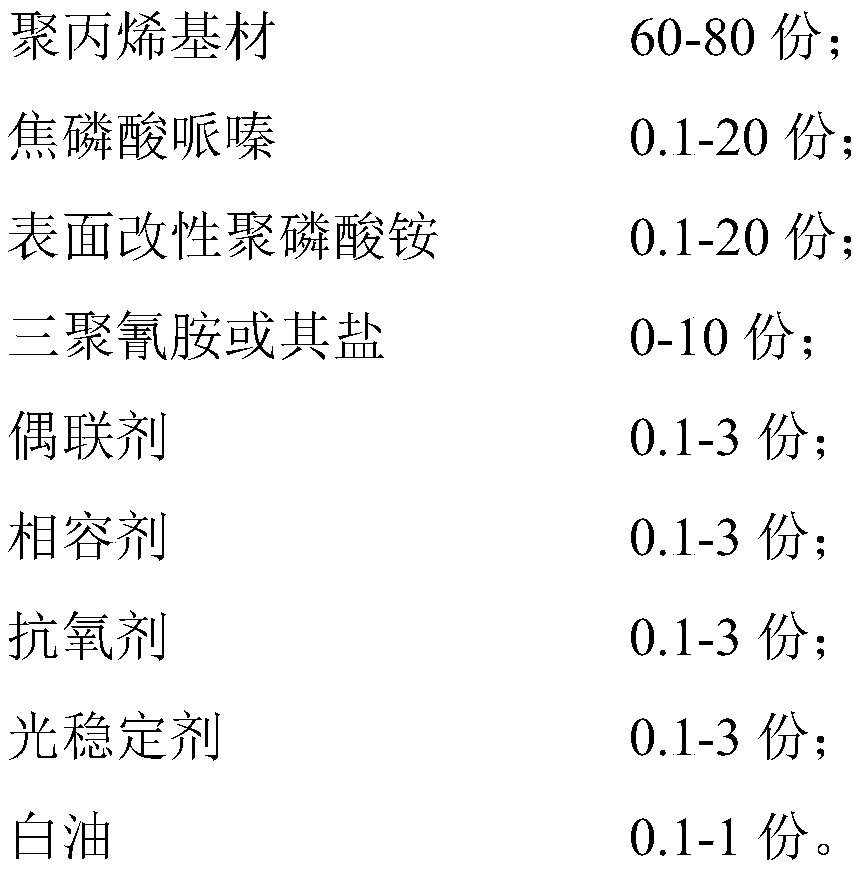

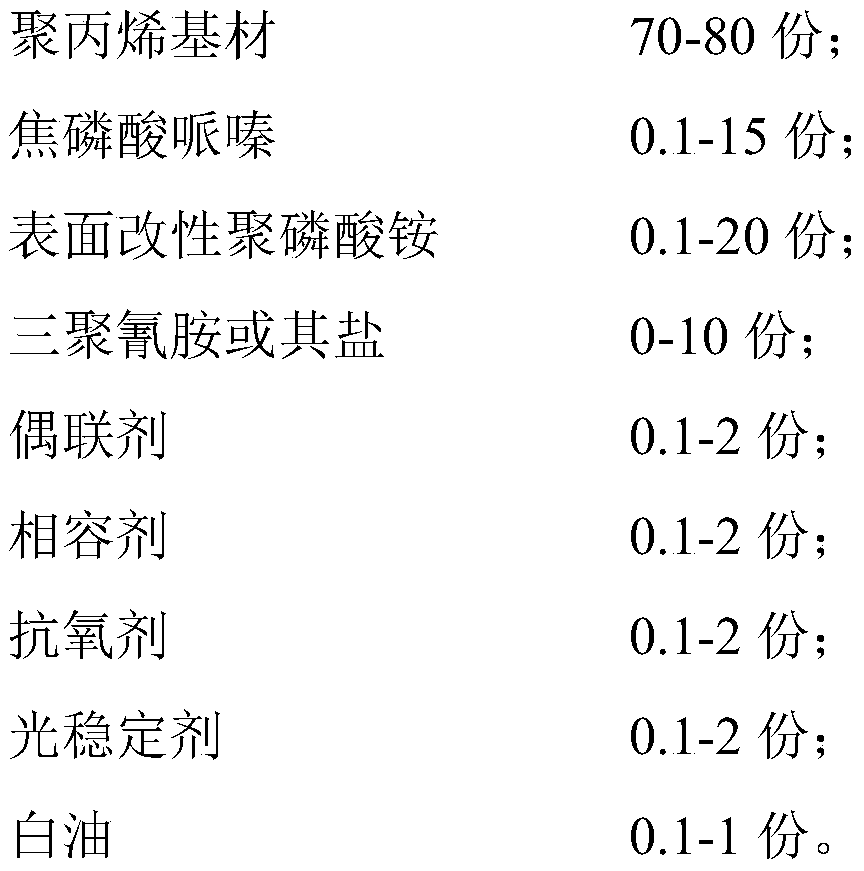

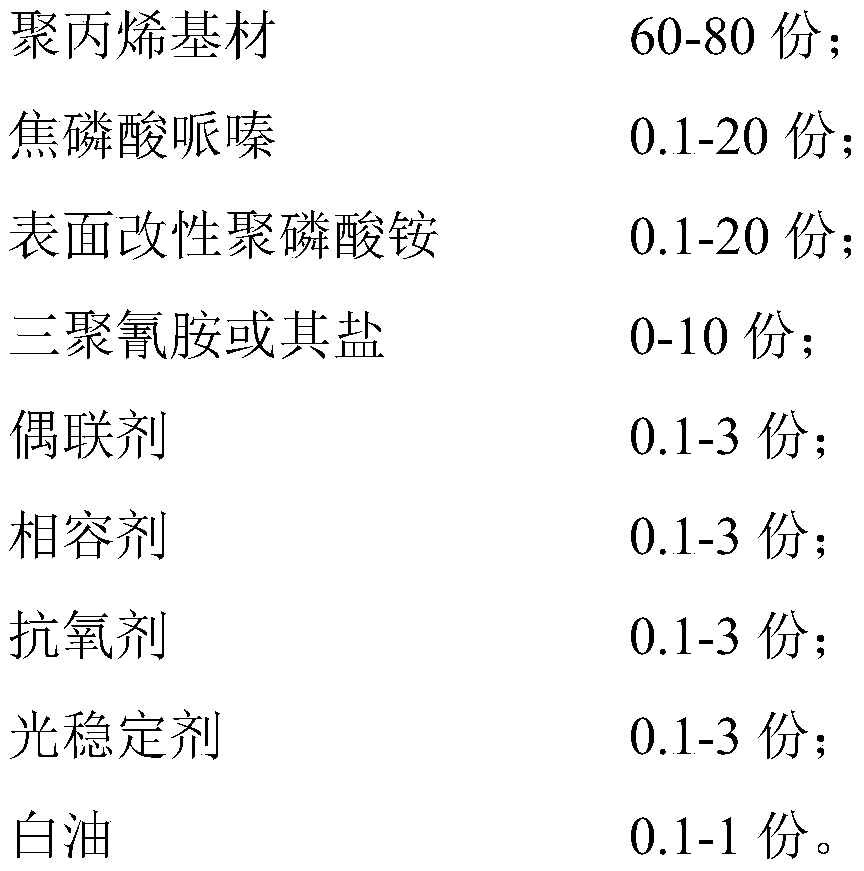

High-melt-index halogen-free flame-retardant polypropylene material and preparation method thereof

The invention relates to a high-melt-index halogen-free flame-retardant polypropylene material and a preparation method thereof. The high-melt-index halogen-free flame-retardant polypropylene materialcomprises the following components in parts by weight: 60 to 80 parts of polypropylene base material, 0.1 to 20 parts of pyrophosphoric acid piperazine, 0.1 to 20 parts of surface modified ammonium polyphosphate, 0 to 10 parts of melamine or salt thereof, 0.1 to 3 parts of coupling agent, 0.1 to 3 parts of compatilizer, 0.1 to 3 parts of antioxygen, 0.1 to 3 parts of light stabilizer, and 0.1 to1 part of white oil. The preparation method comprises the steps of weighing the raw materials in parts by weight, premixing the dried polypropylene base material and the dried white oil in a dual-motion mixer for 5 to 8 minutes, and uniformly mixing; adding the pyrophosphoric acid piperazine, the surface modified ammonium polyphosphate, the melamine or the salt thereof, the coupling agent, the campatilizer, the antioxygen and the light stabilizer according to the parts by weight, and continuously mixing for 5 to 8 minutes so as to obtain a uniform mixture; and putting in a charging hole of a double-screw extruder, mixing and extruding the materials through a screw rod, and extruding from a die head. Compared with the prior art, the halogen-free polypropylene material provided by the invention can effectively solve the problems such as high pollution of a traditional triazine carbon-forming agent system, poor compatibility of a flame retardant and a matrix, and low flame retardant efficiency.

Owner:SHANGHAI RES INST OF CHEM IND

Preparation method of polypropylene material with high appearance performance, high performance and low emission for automobile interior and exterior decoration

The invention discloses a polypropylene material with high appearance performance, high performance and low emission for automobile interior and exterior decoration and a preparation method of the polypropylene material. The polypropylene material is prepared from components in percentage by weight as follows in a composition formula: 30.8%-89.4% of a PP matrix, 0-25% of a flexibilizer, 10%-30% oftalcum powder, 0-10% of PP L-Modu, 0.6%-2.2% of an antioxidant and 0-2% of a scraping assistant. The polypropylene material has the following beneficial effects: 1, the problems of appearance such astiger skin and the like frequently occurring to parts such as a dashboard are solved by the characteristics of high liquidity and low crystallization temperature of PP L-Modu; 2, by adding PP L-Modu,the injection temperature is reduced, and properties such as emission and the like can be improved; 3, PP L-Modu can effectively improve liquidity of the material and reduce the crystallization temperature of the material, processing windows of the material are increased, and the production requirements of bumpers and other small parts for thin walls can be met.

Owner:ZHEJIANG PRET NEW MATERIALS

Preparation method and application of hyperbranched polyester

The invention belongs to the technical field of high polymer materials and discloses a preparation method and application of hyperbranched polyester for improving the flowability of polypropylene. The preparation method of hyperbranched polyester comprises the following steps: adding a dicarboxylic acid and trihydric alcohol into a flask; after carrying out air replacement 2-3 times under the protection of protective gas, adding an organic tin metal catalyst; heating to a set reaction temperature; under the condition that the protective gas keeps flowing moderately, carrying out reaction, and separating out water produced in reaction; and at the end of the reaction, cooling the obtained product to room temperature, thereby obtaining a reaction product. Hyperbranched polyester prepared by using the method disclosed by the invention is used as an additive. The synthesis method of hyperbranched polyester, provided by the invention, is simple in process and low in cost and the prepared hyperbranched polyester can significantly improve the melt index of polypropylene.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

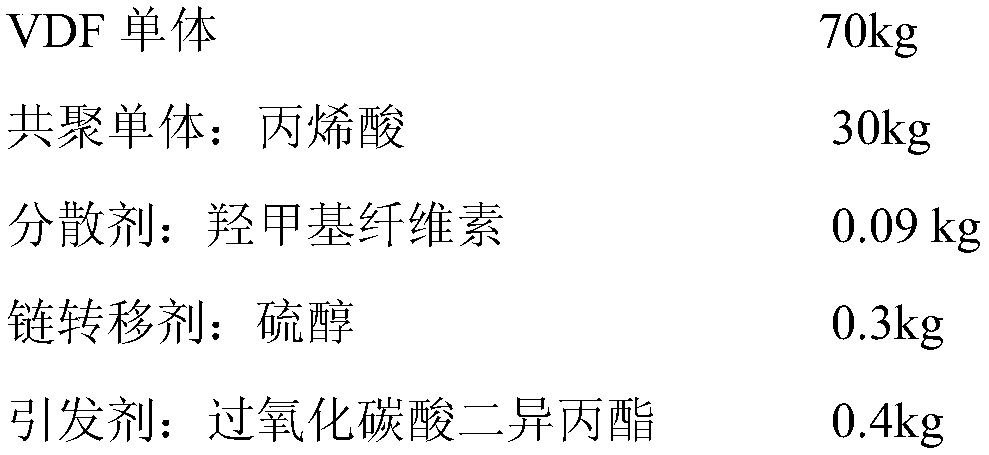

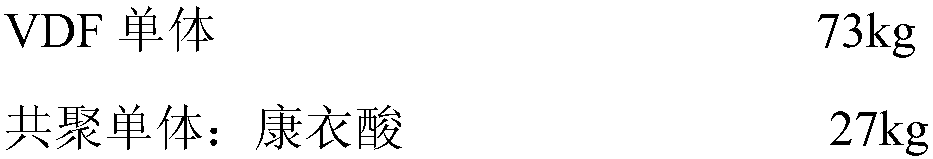

Preparation method of hydrophilic polyvinylidene fluoride resin

ActiveCN108467451AEasy to operateThe polymerization reaction process is mild and stableWater contaminantsWater/sewage treatment bu osmosis/dialysisFiltration membraneReaction temperature

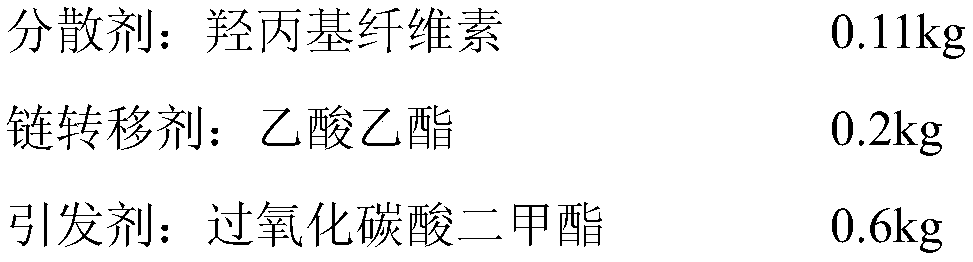

The invention discloses a preparation method of hydrophilic polyvinylidene fluoride resin. The preparation method comprises the steps that 1, 200-400 parts of deionized water, 60-90 parts of VDF monomers, 10-50 parts of comonomers, 0.05-1.5 parts of dispersing agents, 0.1-0.5 part of chain transfer agents and 0.1-1.0 part of initiator react with one another at the stirring rotating speed of 50-80rpm, and a suspension polymerization product is obtained, wherein the reaction temperature ranges from 20 DEG C to 40 DEG C, the reaction time is 12-24 hours, and the reaction pressure is 2.0-4.5 Mpa;2, the suspension polymerization product obtained in the first step is washed, centrifugally dehydrated and dried to obtain the hydrophilic polyvinylidene fluoride resin product. The method is simplein process and suitable for industrialization. An ultra-filtration membrane prepared from the obtained product has relatively good hydrophilicity, relatively high membrane flux, long service life andgood metal ion removal effects.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +2

Polyester hot melt adhesive for making films and preparation method thereof

ActiveCN102102003AAvoid generatingReduced cyclization rateFilm/foil adhesivesPolymer scienceReaction temperature

The invention discloses a method for preparing a polyester hot melt adhesive for making films, which comprises the following steps of: (1) adding terephthalic acid, butanediol and a titanium catalyst into an esterification kettle for primary esterification, wherein the reaction temperature is 170-195DEG C; (2) adding adipic acid, maleic acid, isophthalic acid, propylene glycol, neopentyl glycol and a p-toluenesulfonic acid catalyst into the kettle for secondary esterification, wherein the reaction temperature is 180-205DEG C; and (3) adding a stabilizing agent, and performing polycondensation under reduced pressure to obtain the polyester hot melt adhesive product which is quick in crystallization and easily forms a film.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Conductive thermoplastic powder, preparation and uses thereof

ActiveCN101402812AObvious advantagesObvious positive effectPowdery paintsElectrically-conductive paintsThermoplasticElectrically conductive

The invention discloses a conductive thermoplastic powder which comprises the following components counted in weight portions: 20 to 25 portions of conductive master batch, 10 to 15 portions of grafting sticky master batch and 47 to 74 portions of accessory ingredient. In the invention, specific conductive carbon black and polyethylene powder are uniformly mixed by a high mixer and are pelletized by a double screw extruder for standby; the prepared grain material and other compounds are pelletized by the double screw extruder and ground into powder; and the prepared conductive thermoplastic powder improves the MFR of a composite, has better flatting performance, can reduce the processing energy consumption and has an excellent adhesive attraction under the situation of ensuring high sticking intensity. The conductive thermoplastic powder can be used for coating the surface of metal pipes, combines the advantages of plastic with metal pipe organically, can be applied to the underground environment of coal ores, prolongs the service life of the pipes and simultaneously does not reduce the intensity of the pipes and reduces the investment on the coal ore enterprises.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

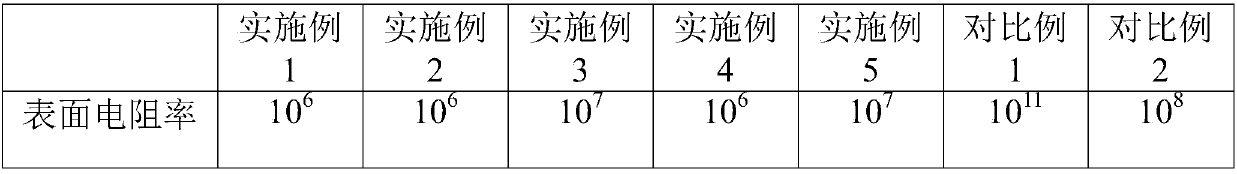

Conductive foamed polypropylene material and preparation method thereof

The invention discloses a conductive foamed polypropylene material and a preparation method thereof. The conductive foamed polypropylene material is prepared from a conductive foamed polypropylene prefabricated material and a foaming agent, the adding amount of the foaming agent accounts for 2-5% of the weight of the conductive foamed polypropylene material, and the conductive foamed polypropyleneprefabricated material is prepared from the following components in parts by weight: 54 to 86.8 parts of polypropylene, 8 to 15 parts of conductive carbon black, 0 to 10 parts of a toughening agent,5 to 20 parts of a filler, 0.1 to 0.5 part of an antioxidant and 0.1 to 0.5 part of a processing aid. According to the invention, a micro-foaming process is applied to a conductive modified polypropylene material, conductive carbon black is added to form a cross-linked network structure, and based on the formation of foam holes in the material, the conductive carbon black dispersed in a base material is gathered in the base body intensively in volume, so that the effective and compact conductive path is formed in the material so as to reduce the use amount of the conductive additive of the material, effectively and significantly reduce the surface resistance of the material, improve the conductive effect of the material and reduce the cost of the material; and the preparation process is simple, and the prepared polypropylene material is excellent in performance.

Owner:HEFEI GENIUS NEW MATERIALS

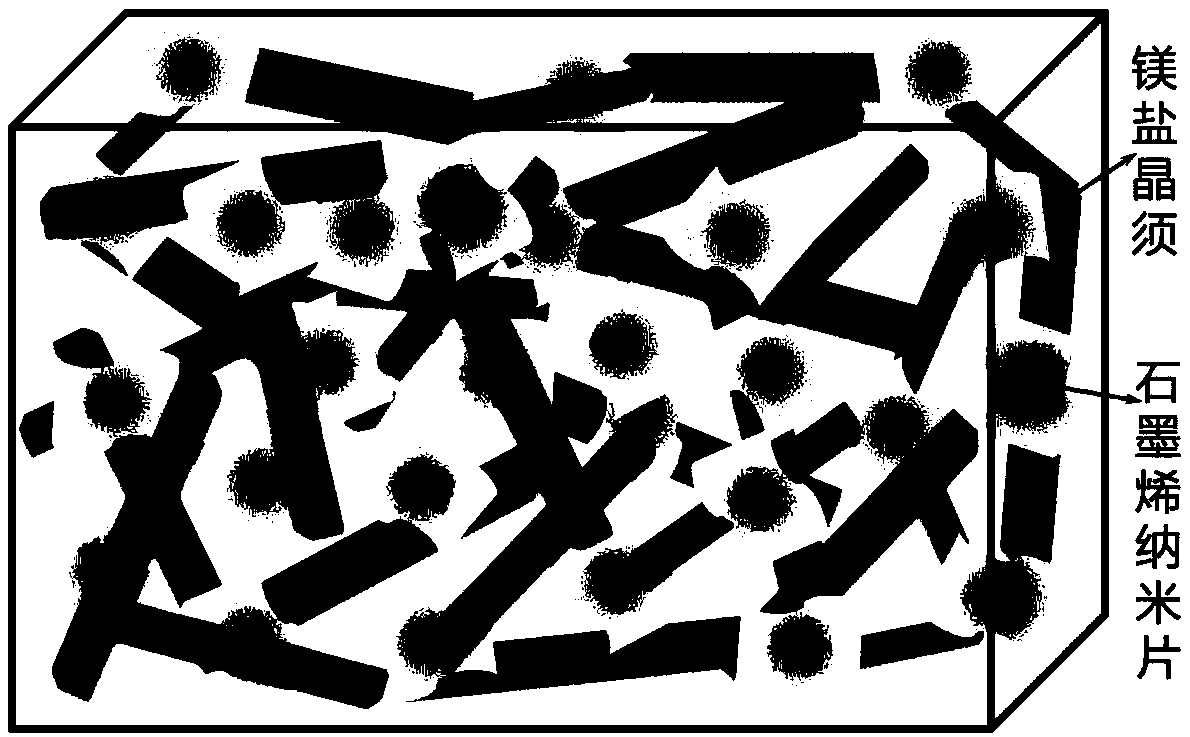

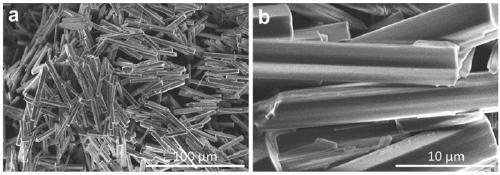

Polymer composite material containing micro-nano hybrid structure filler, and preparation method thereof

InactiveCN111303511AHigh crystallinityLarge specific surface areaPolycrystalline material growthFrom normal temperature solutionsMagnesium saltNano hybrid

The invention discloses a polymer composite material containing a micro-nano hybrid structure filler, and a preparation method thereof, wherein the composite material is composed of graphene nanosheets, magnesium salt whiskers and a polymer matrix. According to the invention, a stable, perfect and efficient heat-conducting network chain is constructed in a polymer matrix by adopting an organic-inorganic hybrid composed of multi-scale and multi-dimensional graphene nanosheets and magnesium salt whiskers, so that the heat-conducting property of the composite material is greatly improved under the condition of low filler addition amount while good melt processability is ensured; the hybrid structure filler also has good reinforcing and toughening effects on the composite material, and significantly improves the comprehensive mechanical properties of the composite material; and the method is simple in production process, easy to implement, rich in raw material source, safe, environment-friendly and low in production cost.

Owner:ENN GRAPHENE TECH CO LTD

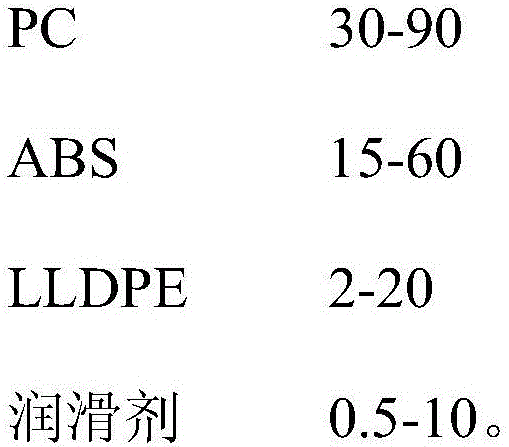

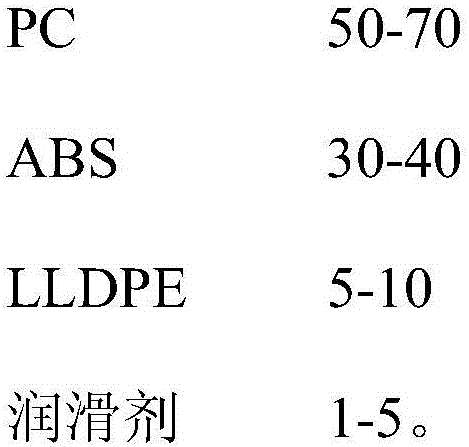

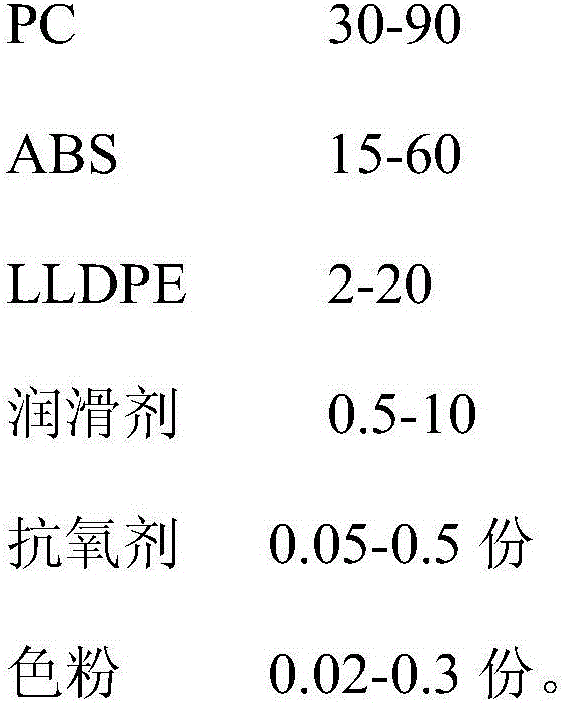

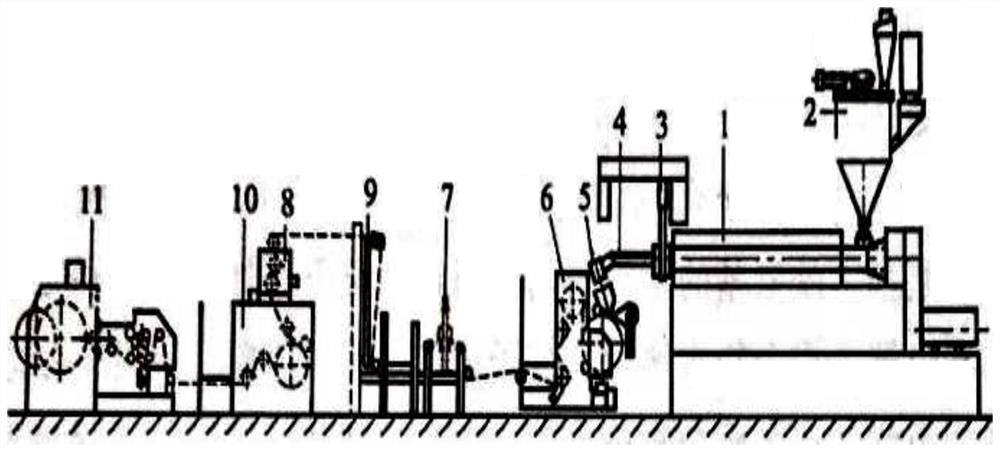

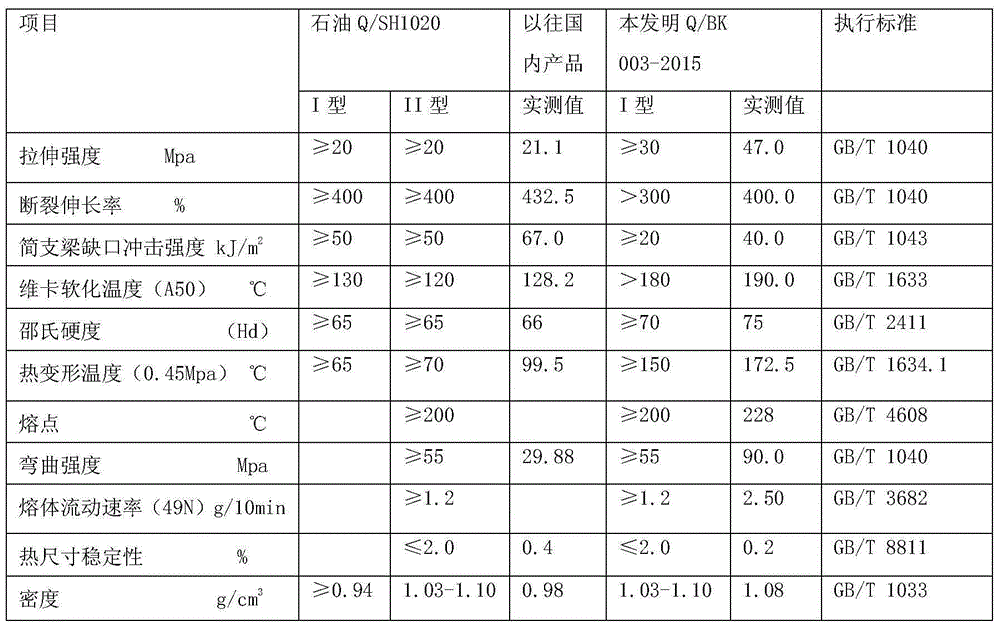

PC-ABS alloy for thin-wall product and preparation method of alloy

Provided is a PC-ABS alloy for a thin-wall product and a preparation method of the thin wall product PC-ABS alloy. The PC-ABS alloy comprises, by weight, 30-90 parts of PC, 15-60 parts of ABS, 2-20 parts of LLDPE and 0.5-10 parts of lubricant. Through adding the flow modifier compounding linear low density LLDPE and lubricant in the PC-ABS material, the method hugely increases the melting point of the PC-ABS alloy, thus making the die stamping of the injection molding process of thin-wall product smooth, making the product fusion connection strength high and not prone to break.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

Metallocene linear low-density polyethylene reinforced wrapping film manufacturing process

InactiveCN111805950AReduce thicknessImprove puncture resistanceSynthetic resin layered productsFlat articlesWaxLow-density polyethylene

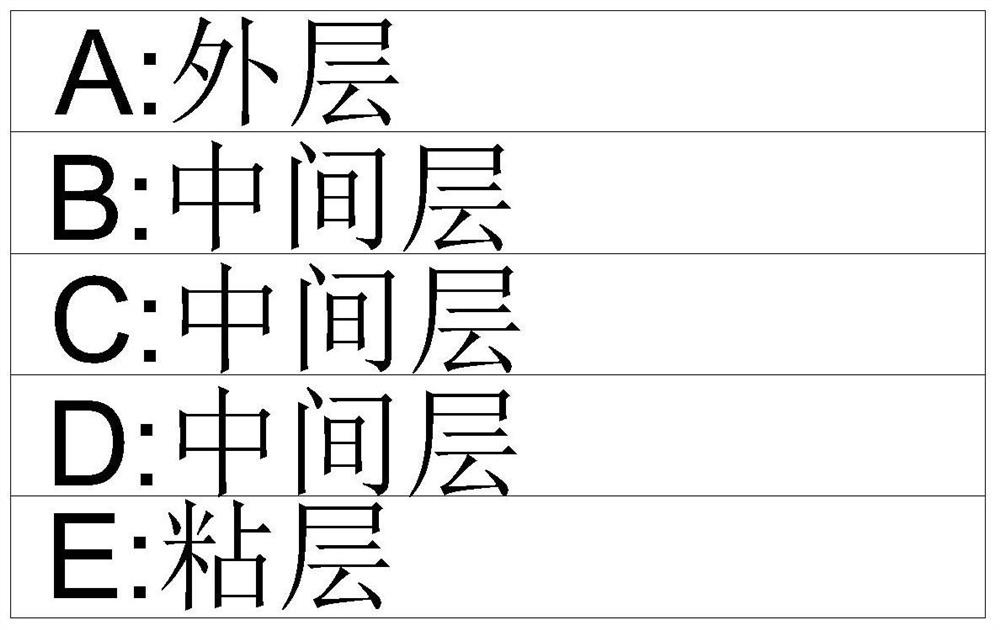

The invention relates to the technical field of wrapping films, and discloses a metallocene linear low-density polyethylene reinforced wrapping film manufacturing process. The process is characterizedin that mLLDPE-a and mLLDPE-b in a wrapping film structure are two metallocene linear low-density polyethylene with different melt indexes respectively, are used for improving the strength, and are used for adjusting melt index of blended material according to different equipment characteristics; an mLLDPE-c is metallocene linear low density polyethylene with a high viscosity mark and is used forimproving the viscosity of a finished product film, polyethylene is thermoplastic resin prepared by polymerizing ethylene and also comprises a copolymer of ethylene and a small amount of alpha-olefinin industry, and the polyethylene is odorless, nontoxic and wax-like in hand feeling, has excellent low-temperature resistance (the lowest use temperature can reach minus 100 DEG C to minus 70 DEG C)and good chemical stability, can resist erosion of most acids and alkalis (does not resist acids with oxidizing properties), is insolubility in common solvents at normal temperature, and has low water absorption and excellent electrical insulation, and the layer A is the mLLDPE-a + mLLDPE-b + LLDPE; the B layer is mLLDPE-a + mLLDPE-b + LLDPE, the C layer is mLLDPE-a + mLLDPE-b + LLDPE, the D layer is mLLDPE-a + mLLDPE-b + LLDPE, and the E layer is mLLDPE-c.

Owner:上海瑞泽丰标准技术服务有限公司

High-softening-point ultra-high-molecular-weight polyethylene alloy material and preparation method thereof

The invention relates to a high-softening-point ultra-high-molecular-weight polyethylene alloy material and a preparation method thereof, and is used for mainly solving the problems that a conventional polyamide (PA) / (ultra) high-molecular-weight polyethylene (UHMWPE) plastic alloy material is low in vicat softening point, is not resistant to high temperature and slow in rebound velocity. The alloy material comprises the following components by the weight percentage: 40-80% of ultra-high-molecular-weight polyethylene resin, 30-60% of nylon resin, 2-15% of an inorganic nanomaterial, 0-10% of a compatibilizer, 0.5% of a chain extender, and 6-12% of an ultra-high-molecular-weight polyethylene maleic anhydride graft material. The high-softening-point ultra-high-molecular-weight polyethylene alloy material improves the vicat softening point and the rebound velocity, is resistant to high temperature, can meet the requirements of high temperature, high pressure and strong friction, reduces the product producing cost and is beneficial for extrusion molding.

Owner:QIQIHAR NORTH KUN SYNTHETIC POLYMER MATERIALS

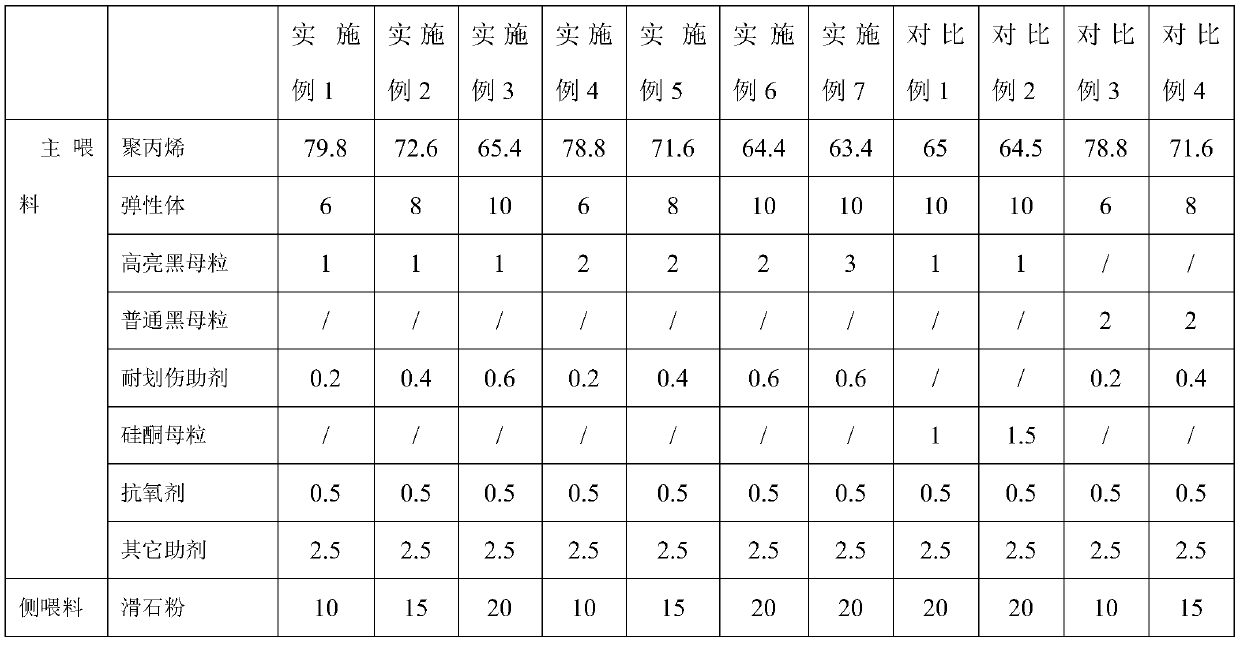

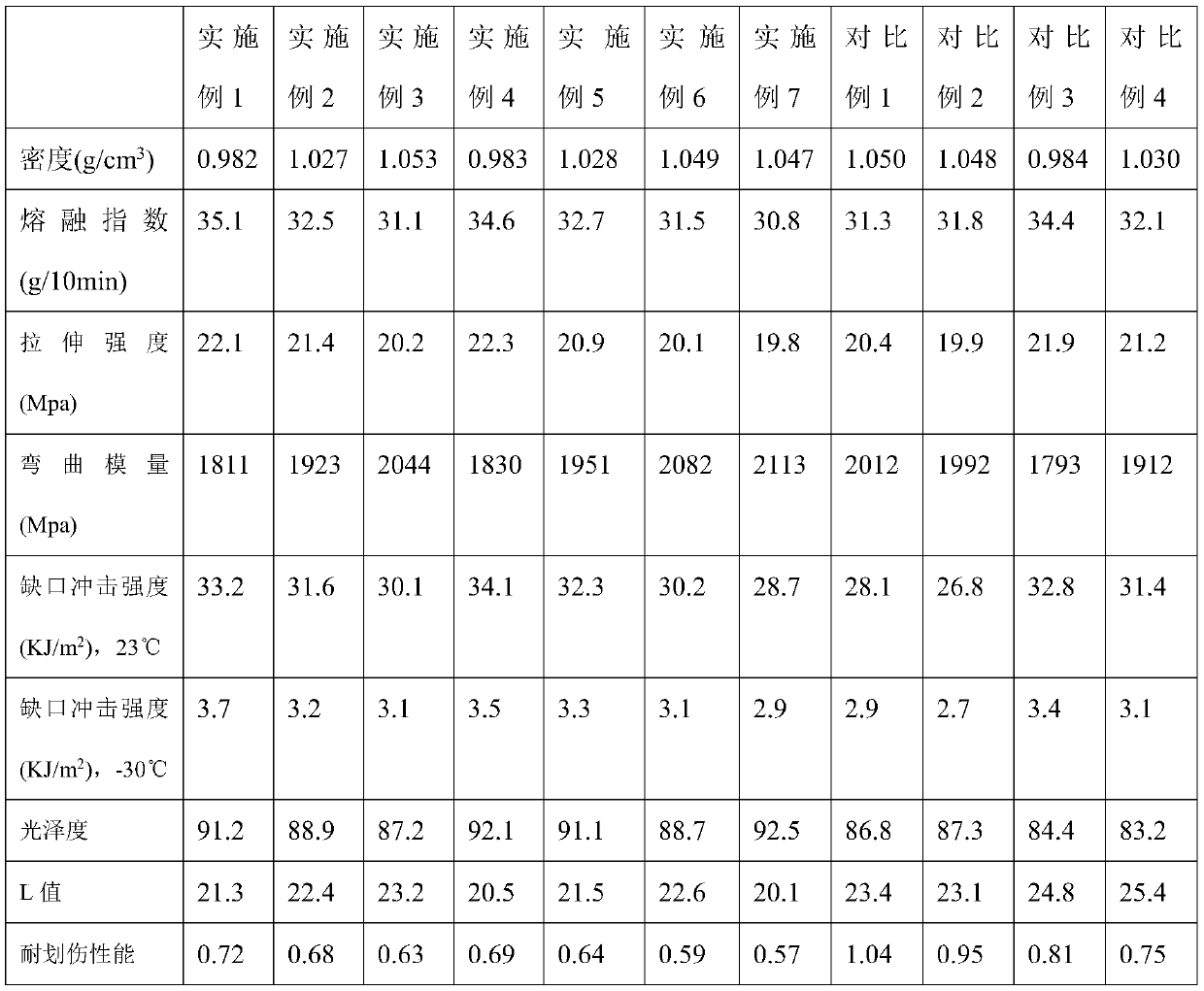

High-bright-black, scratch-resistant and thin-walled polypropylene composite material and preparation method thereof

The invention discloses a high-bright-black, scratch-resistant and thin-walled polypropylene composite material and a preparation method thereof. The high-bright-black, scratch-resistant and thin-walled polypropylene composite material comprises the following raw materials in parts by weight: 63.4-79.8 parts of polypropylene, 10-20 parts of talcum powder, 6-10 parts of an elastomer, 1-3 parts of high-bright-black masterbatches, 0.2-0.6 part of a scratch-resistant auxiliary agent, 0-1 part of an antioxidant and 0-3 parts of auxiliary agents. According to the invention, ultrafine-particle-size carbon black in the high-bright-black masterbatches has an extremely strong coloring effect, and a hyperdispersant has a strong dispersion effect, so the polypropylene composite material achieves stable, uniform and high-bright-black aesthetic effects; meanwhile, through introduction of an organic silicon polymer with a special structure, the polypropylene composite material has good scratch resistance; under the condition of adding a small amount of the organic silicon polymer, compared with a traditional silicone scratch-resistant auxiliary agent, the organic silicon polymer has long-acting property and durability, can significantly improve the scratch resistance of the surface of the polypropylene material and reduce the surface friction coefficient of the polypropylene material, and canplay a synergistic role with polyethylene wax in the high-bright-black masterbatches to improve the scratch resistance of the polypropylene composite material.

Owner:ZHEJIANG PRET NEW MATERIALS +3

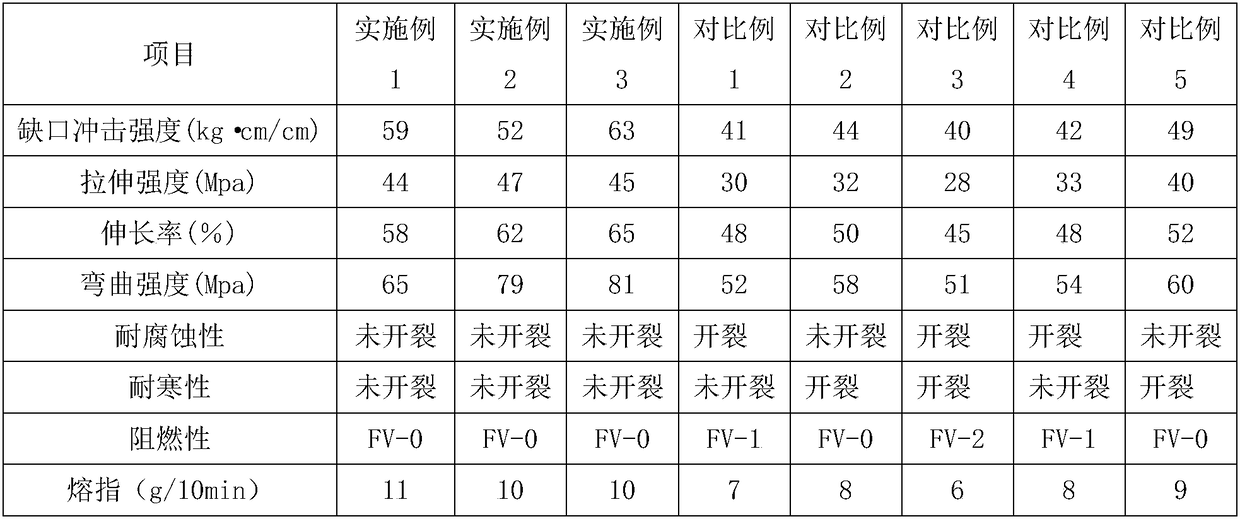

Special material for new-energy battery shell and preparation method thereof

InactiveCN109233094AImprove flame retardant performanceImprove mechanical propertiesNew energyPolypropylene

The invention discloses a special material for a new-energy battery shell and a preparation method thereof. The special material for the new-energy battery shell comprises the following raw materialsin parts by weight: 100-135 parts of polypropylene, 5-12 parts of niobium pentoxide, 6-15 parts of sodium tetrachloropalladate, 8-14 parts of modified chabazite powder, 8-12 parts of modified lignin and 2-6 parts of xylitol. The special material for the new-energy battery shell has excellent flame retardance, good mechanical properties, corrosion resistance and cold resistance, a high melt index and good fluidity and is easy to process.

Owner:FOSHAN LINGXIN INFORMATION TECH CO LTD

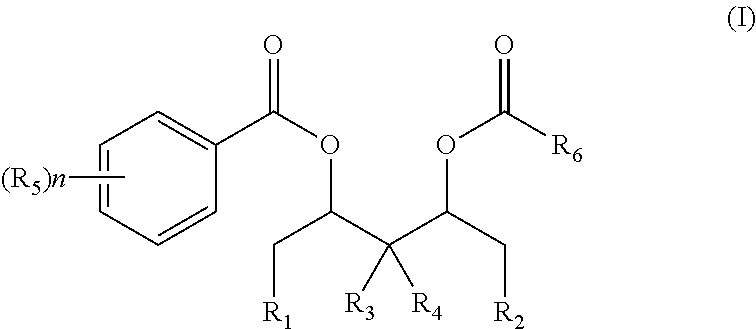

Catalyst component for olefin polymerization, catalyst, and use thereof

The present disclosure provides a solid catalyst component for olefin polymerization, comprising magnesium, titanium, a halogen, and an electron donor, wherein the electron donor is at least one selected from the group consisting of diol diester compounds as shown in Formula (I). The catalyst according to the present disclosure has significantly improved polymerization activity, hydrogen response, and stereoselectivity. According to the present disclosure, when the catalyst system containing a diol diester compound as shown in Formula (I) of the present disclosure is used in olefin polymerization, the catalyst shows good comprehensive performance, including high catalytic activity. In particular, in the presence of highly concentrated hydrogen, the catalyst has an improved hydrogen response and / or isotacticity of the polymers obtained can be significantly improved. The catalyst of the present disclosure is beneficial for obtaining polymers with a high melt index and high isotacticity, and for development of polymers of different grades.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing PNT (para nitro toluene) copolyester hot melt adhesive used for film manufacturing

InactiveCN104479118AHigh melt indexFast crystallizationNon-macromolecular adhesive additivesPolymer sciencePressure reduction

The invention discloses a method for preparing PNT (para nitro toluene) copolyester hot melt adhesive used for film manufacturing. The method comprises the following steps: (1) terephthalic acid, isophthalic acid, neopentyl glycol and 1,3 propylene glycol have an esterification reaction under the action of titanium catalysts; (2) stabilizers and anti-oxydants are added to products of the step (1), so a pressure-reduction condensation polymerization reaction is conducted, and the PNT copolyester hot melt adhesive which is used for film manufacturing and is high in crystallization speed and short in opening time can be obtained.

Owner:ANHUI ZHUCHENG INFORMATION TECH

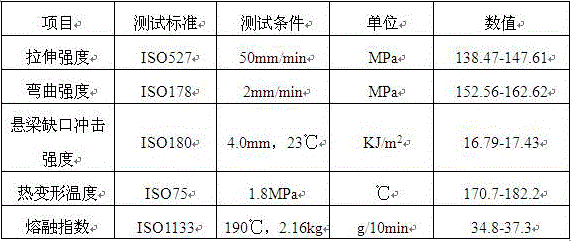

High-impact glass fiber composite for 3D printing

InactiveCN106634000AHigh heat distortion temperatureHigh melt indexAdditive manufacturing apparatusFlexural strengthStearic acid

The invention discloses a high-impact glass fiber composite for 3D printing and belongs to the technical field of preparation of materials for 3D printing. The high-impact glass fiber composite for 3D printing is prepared from the following raw materials in parts by weight: 85-123 parts of glass fibers, 24-33 parts of waste plastic, 11-15 parts of acetylglutamine, 4-7 parts of metaldehyde, 7-11 parts of polyurethane, 8-10 parts of alkyd resin, 6-12 parts of zinc acrylate resin, 5-9 parts of high chlorinated polyethylene resin, 9-16 parts of stearic acid, 4-7 parts of polyacrylamide, 12-20 parts of a specific synthetic agent and 8-12 parts of a flame retardant. The high-impact glass fiber composite for 3D printing has the characteristics of high tensile strength, bending strength and notch impact strength, high heat deformation temperature, high melt index and the like, and a product printed with a 3D printing technology has high quality, high impact resistance and high strength, and has broad market prospect.

Owner:蒙宇

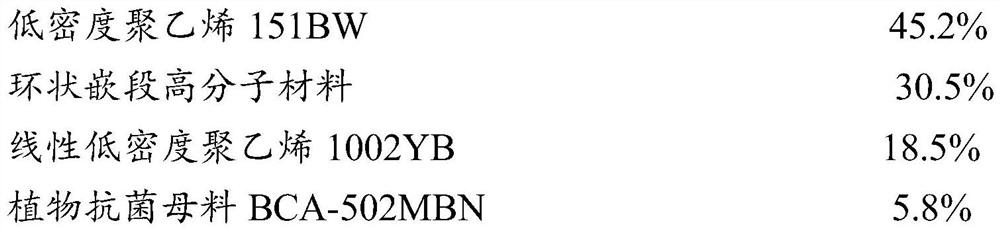

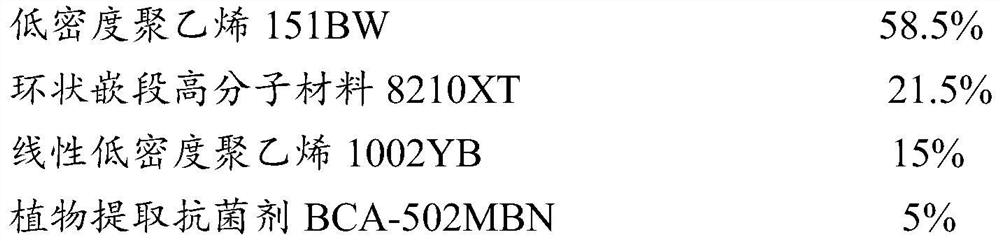

Preparation method of polyethylene special material for vehicle decorative non-woven fabric back glue

The invention belongs to the technical field of polymer synthesis and specifically relates to a preparation method of a polyethylene special material for vehicle decorative non-woven fabric back glue. On a tubular E-method high pressure polymerization process device, appropriate initiator and molecular weight regulator are selected, and ethylene feed mainstream and sidestream are added in appropriate proportion, and appropriate polymerization pressure and polymerization temperature are selected. Then, vehicle decorative non-woven fabric back glue special polyethylene with high melt index (22-32g / 10min under conditions of 190 DEG C and 2.16 kg) and medium-low density (0.920-0.934g / cm<3>) is developed and prepared. The method is simple and is easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

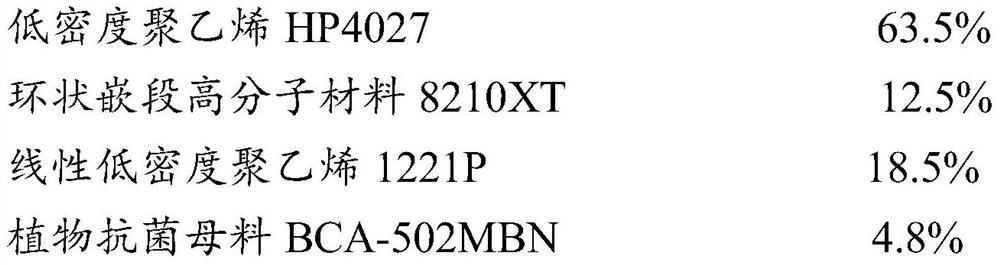

Polyethylene composite film and preparation method thereof

ActiveCN114347611AImprove tearabilityAvoid curlClimate change adaptationSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of high polymer materials, and particularly relates to a polyethylene composite film and a preparation method thereof. The invention provides a polyethylene composite film. The polyethylene composite film comprises an outer layer, a middle layer and an inner layer which are sequentially bonded, the preparation raw materials of the outer layer comprise first low-density polyethylene and high-density polyethylene; the middle layer is prepared from the following raw materials: second low-density polyethylene, an annular block high polymer material, a plant antibacterial master batch and linear low-density polyethylene; the inner layer is prepared from the following raw materials: first low-density polyethylene, metallocene low-density polyethylene and plant antibacterial master batch. The polyethylene composite film provided by the invention has relatively good linear easy-to-tear property and antibacterial property.

Owner:江门市华龙膜材股份有限公司

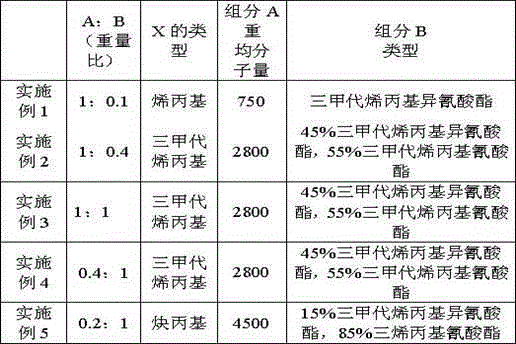

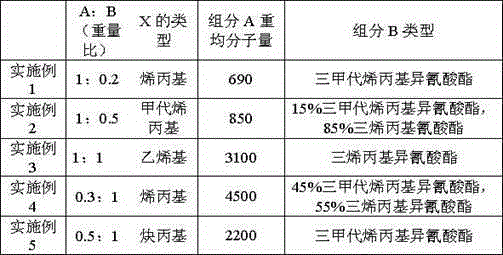

Crosslinking sensitizer for fluorine-containing polymer

The invention discloses a crosslinking sensitizer for a fluorine-containing polymer. The crosslinking sensitizer is characterized by being formed by mixing a component A and a component B according to the mass ratio of 1 to 0.1-10; the component A conforms to the structural formula (1) (please see the formula in the specifications), wherein X represents vinyl or allyl or methylallyl or propargyl, n ranges from 2 to 15, and the weight-average molecular weight of X ranges from 600 to 5000; the component B is at least one of triallyl isocyanate, trimethyl allyl isocyanate, triallyl cyanate and trimethyl allyl cyanate. At a machining temperature, the fluorine-containing polymer is not prone to self-polymerization, low in volatility and not prone to volatilization or self-polymerization, and product stability can be improved; it is found in the machining process that a sample of the crosslinking sensitizer is small in smoke amount, white and luster in color, free of after-radiation color changes and quite high in product stability in the use process.

Owner:中广核三角洲(江苏)塑化有限公司

Graphene 3D printing material with high melt index

InactiveCN106566217AImprove melt indexHigh tensile strengthAdditive manufacturing apparatusPolymer scienceFlexural strength

The invention discloses a graphene 3D printing material with a high melt index and belongs to the technical field of preparation of materials for 3D printing. The graphene 3D printing material with the high melt index contains the following raw materials in parts by weight: 5.4-7.7 parts of graphene, 25-31 parts of waste plastics, 35-40 parts of polylactic acid, 12-23 parts of sodium hexapolyphosphate, 18-24 parts of propylene glycol methyl ether acetate, 9-18 parts of specific synthesizer and 5-9 parts of starch synthesizer. The graphene 3D printing material disclosed by the invention has the characteristics of high tensile strength, flexural strength and notch impact strength, high thermal deformation temperature and melt index, and the like; and products printed through a 3D printing technology are high in quality, high in impact resistance and high in strength, thereby having a broad market prospect.

Owner:GUANGXI ZHUMENG SANTI TECH CO LTD

Electric-conducting flame-retarding thermoplastic powder, preparation method and applications thereof

InactiveCN103254487AGuarantee the appearance qualityHigh melt indexFireproof paintsPowdery paintsPolyolefinHigh intensity

The invention relates to electric-conducting flame-retarding thermoplastic powder, a preparation method and applications of the electric-conducting flame-retarding thermoplastic powder. The electric-conducting flame-retarding thermoplastic powder consists of the following components in percentage by weight: 20-25% of an electric-conducting master batch, 10-15% of a grafted adhesive master batch, 20-30% of a halogen-free flame-retarding master batch and 30-50% of a polyolefin mixture and accessory ingredients. According to the invention, the electric-conducting flame-retarding thermoplastic powder is formed through granulating and grinding the electric-conducting master batch, the flame-retarding master batch, the adhesive master batch and other compositions as well as accessory ingredients of the other compositions through a dual-screw extruder, has a favorable leveling property and a good adhesive force to steel tubes besides the anti-static and flame-retarding characteristics required by the use of an underground coal mine. The electric-conducting flame-retarding thermoplastic powder, the preparation method and applications of the electric-conducting flame-retarding thermoplastic powder, provided by the invention, can be used for coating inner surfaces and outer surfaces of steel tubes, combine the advantages of no rustiness of plastic and high intensity of metal tubular products, and prolong the service life of steel tubes on the basis of meeting the anti-static and flame-retarding characteristics and the like of pipelines used in the coal mine.

Owner:SHANXI ANDELU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com