High melting index and low density polyethylene for ultrafine fiber leather

A low-density polyethylene and high-melt finger technology, which is applied in the direction of conjugated synthetic polymer artificial filaments, can solve the problems of wide molecular weight distribution of polyethylene, increased melt elasticity, and non-Newtonian enhancement of PE macromolecules. Achieve the effect of narrow molecular weight distribution, good economic benefits and high technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

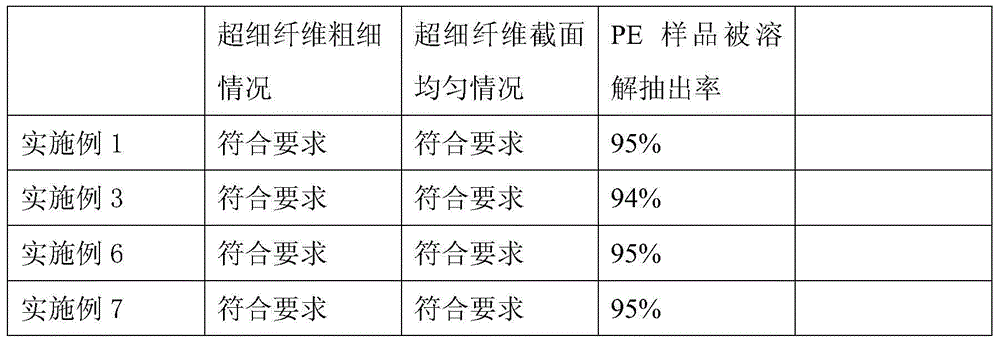

Examples

Embodiment 1

[0023] 1) After the ethylene gas is compressed by the reciprocating piston compressor, it is divided into two streams of main stream and side stream gas with a pressure of 230-240Mpa. The main feed gas, regulator and first initiator enter the first tubular reactor. The steam jacket is gradually heated to 175±10°C, and then the polymerization reaction is carried out in the reaction section, the polymerization temperature is controlled at 300-320°C, the pressure is 230-240Mpa, and the reaction time is 7-8 seconds; in the first tubular reactor , the first peroxidation is tert-butyl neodecanoate, the content is 1ppm, the second peroxide is 2-ethylhexanoic acid tert-butyl peroxide, the content is 4ppm, and the regulator-propionaldehyde content is 225ppm;

[0024] 2) The high-temperature reactant reaches a basic balance after being reacted, and after being cooled, it goes out of the first reaction zone and is combined with the side stream feed gas, the second initiator (compressed ai...

Embodiment 2

[0027] Concrete steps are with embodiment 1.

[0028] Among them: the pressure of the main and side stream feed gas is 235-245Mpa; in the first tubular reactor, the content of the first peroxide is 1.1ppm, the content of the second peroxide is 4.4ppm, and the content of the regulator propionaldehyde is 225ppm ; In the second reactor, the regulator propionaldehyde content is 150ppm, and the compressed air content is 17ppm; the temperature of the first reactor is controlled at 300-320°C, and the temperature of the second reactor is controlled at 300-320°C.

Embodiment 3

[0030] Concrete steps are with embodiment 1.

[0031] Among them: the main and side stream feed gas pressure is 230-240Mpa; in the first tubular reactor, the first peroxide content is 0.95ppm, the second peroxide content is 3.8ppm; the regulator propionaldehyde content is 230ppm , In the second reactor, the compressed air content is 16ppm, and the propionaldehyde content of the regulator is 160ppm; the temperature of the first reactor is controlled at 300-320°C, and the temperature of the second reactor is controlled at 300-320°C.

PUM

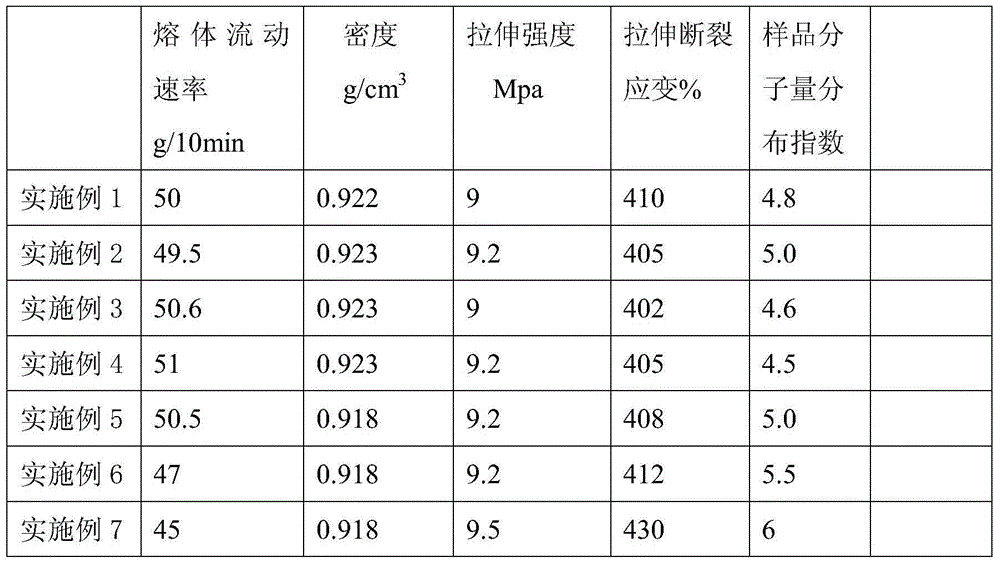

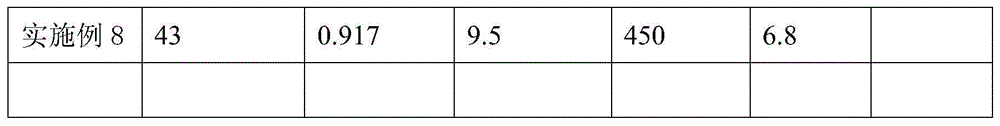

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com