Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Adjust molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

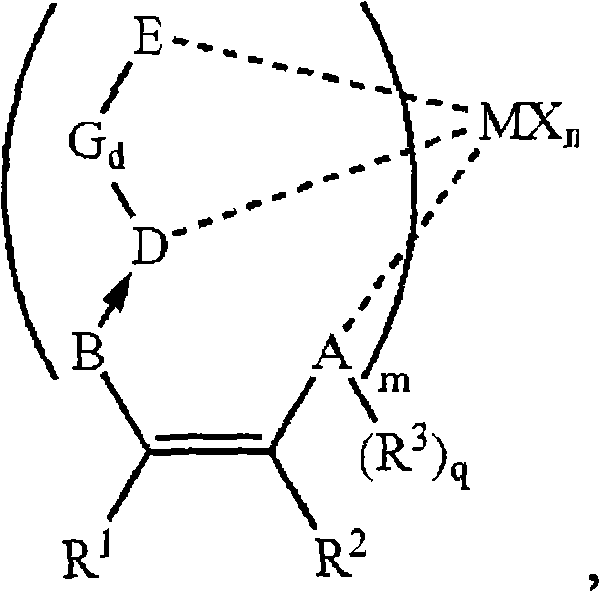

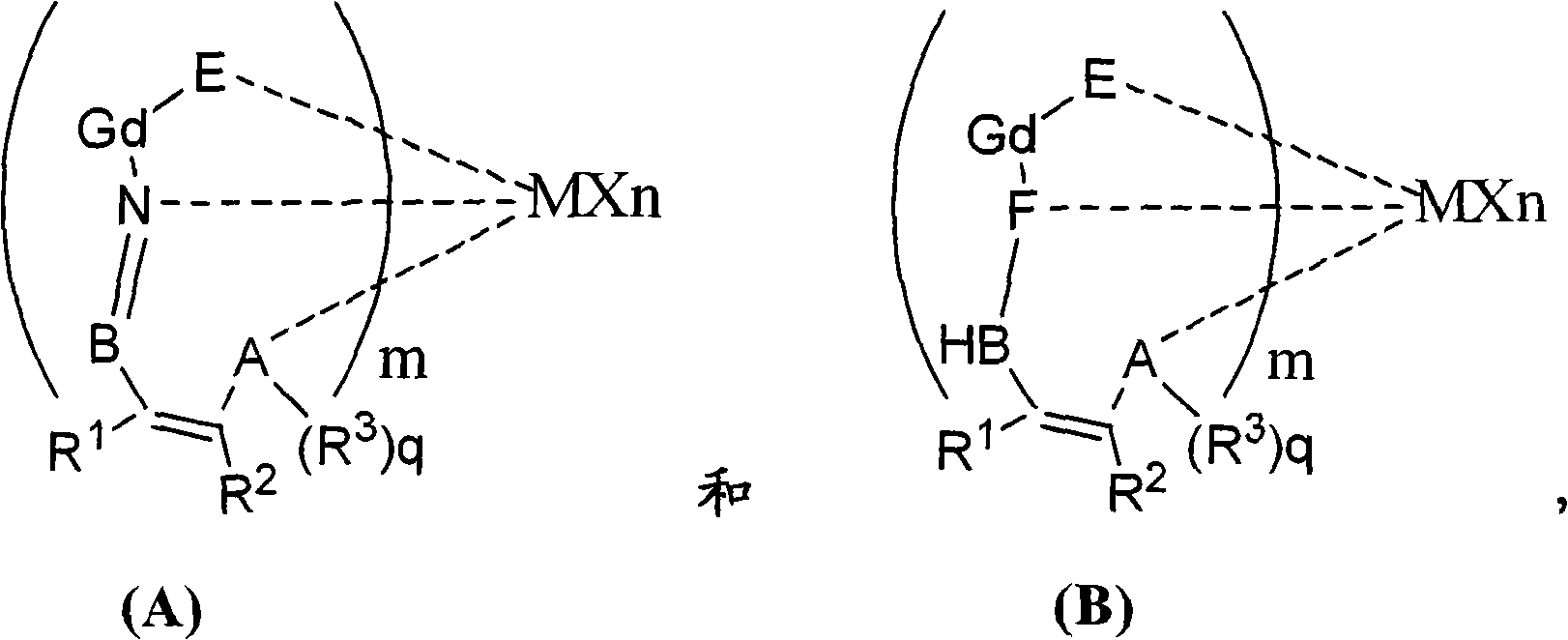

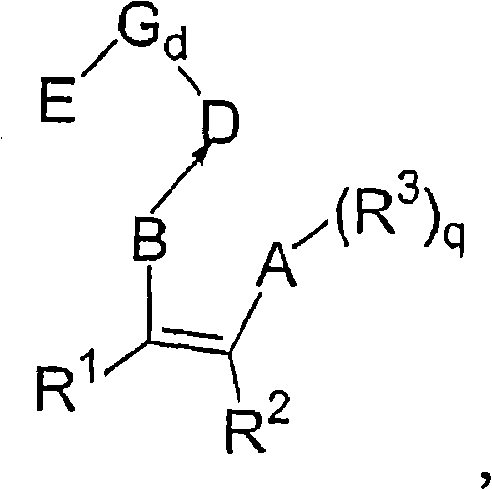

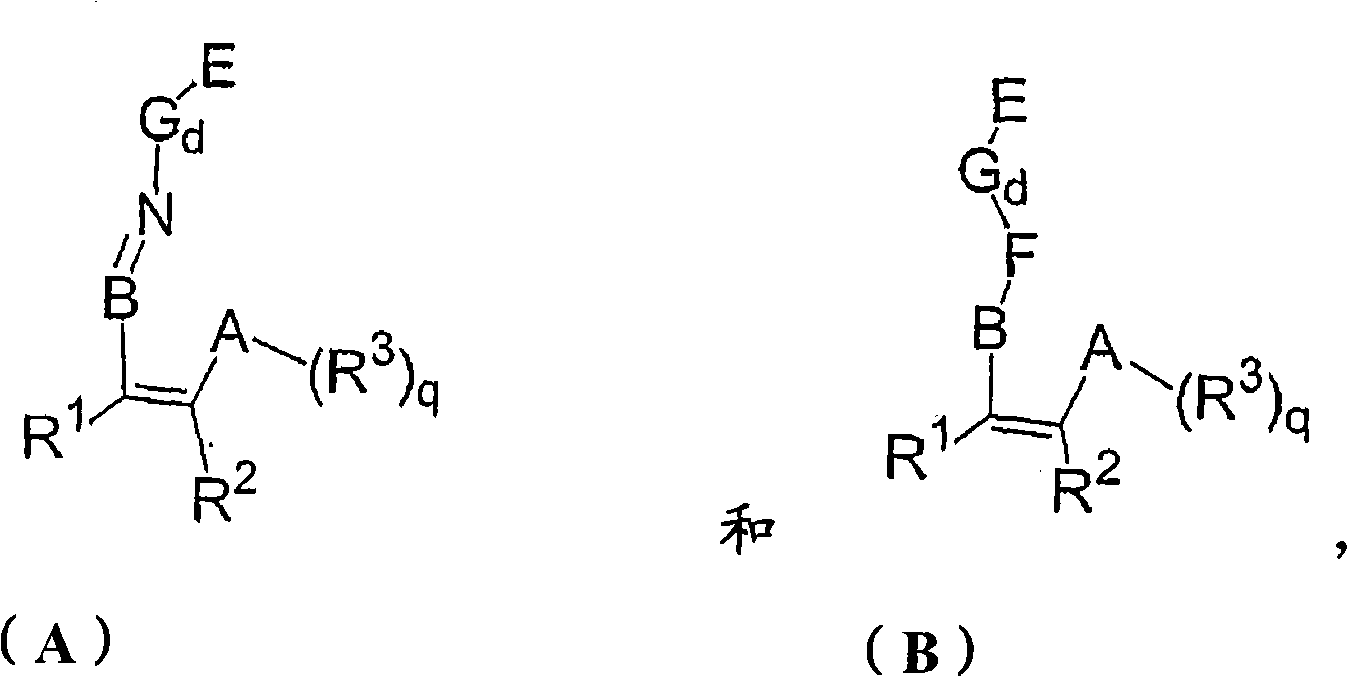

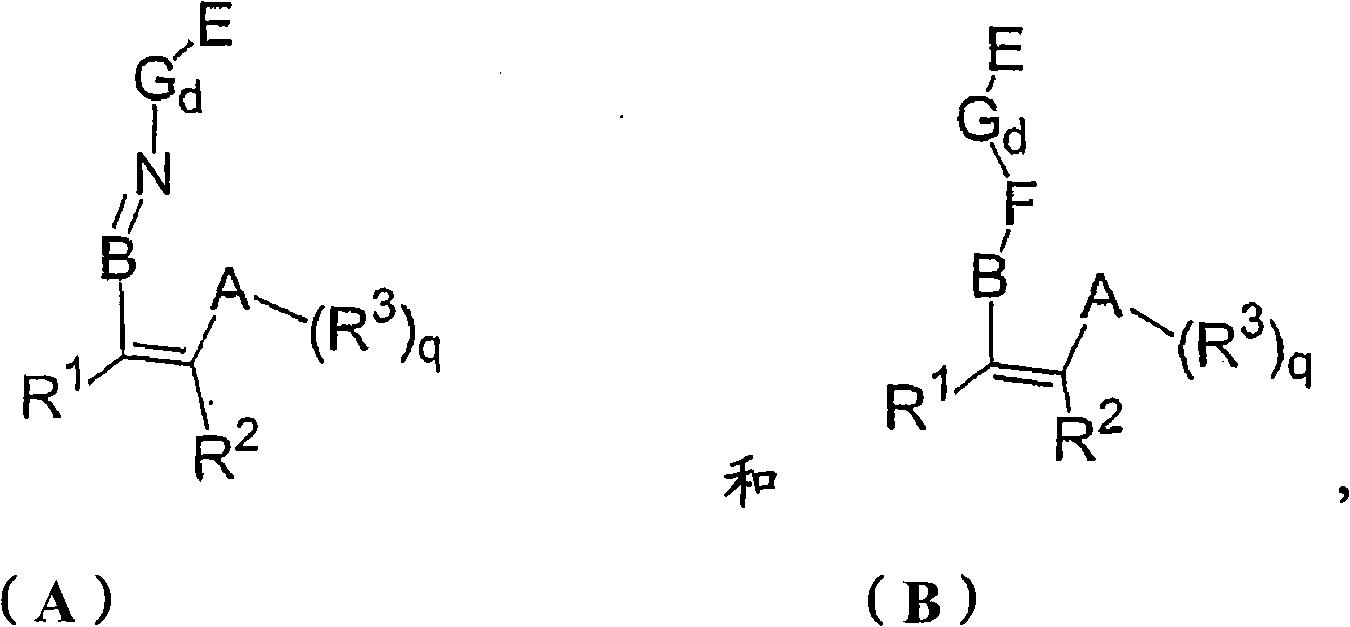

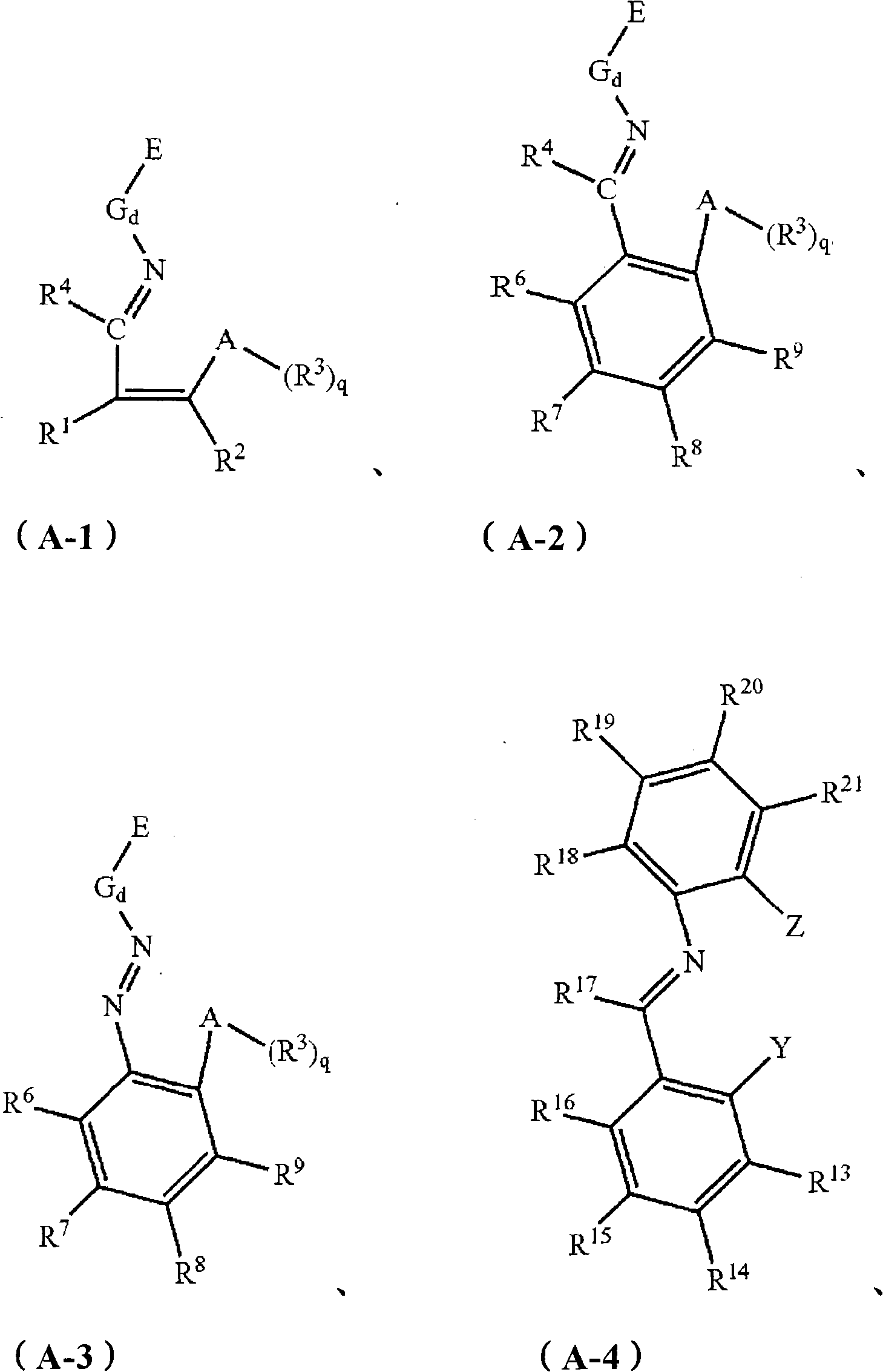

Load type non-metallocene catalyst, preparation method and application thereof

ActiveCN102039191AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOrganic chemistry

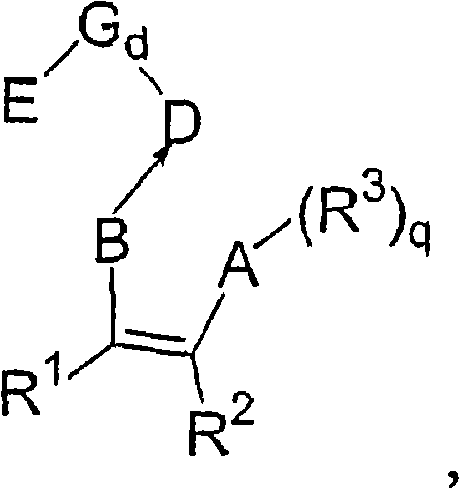

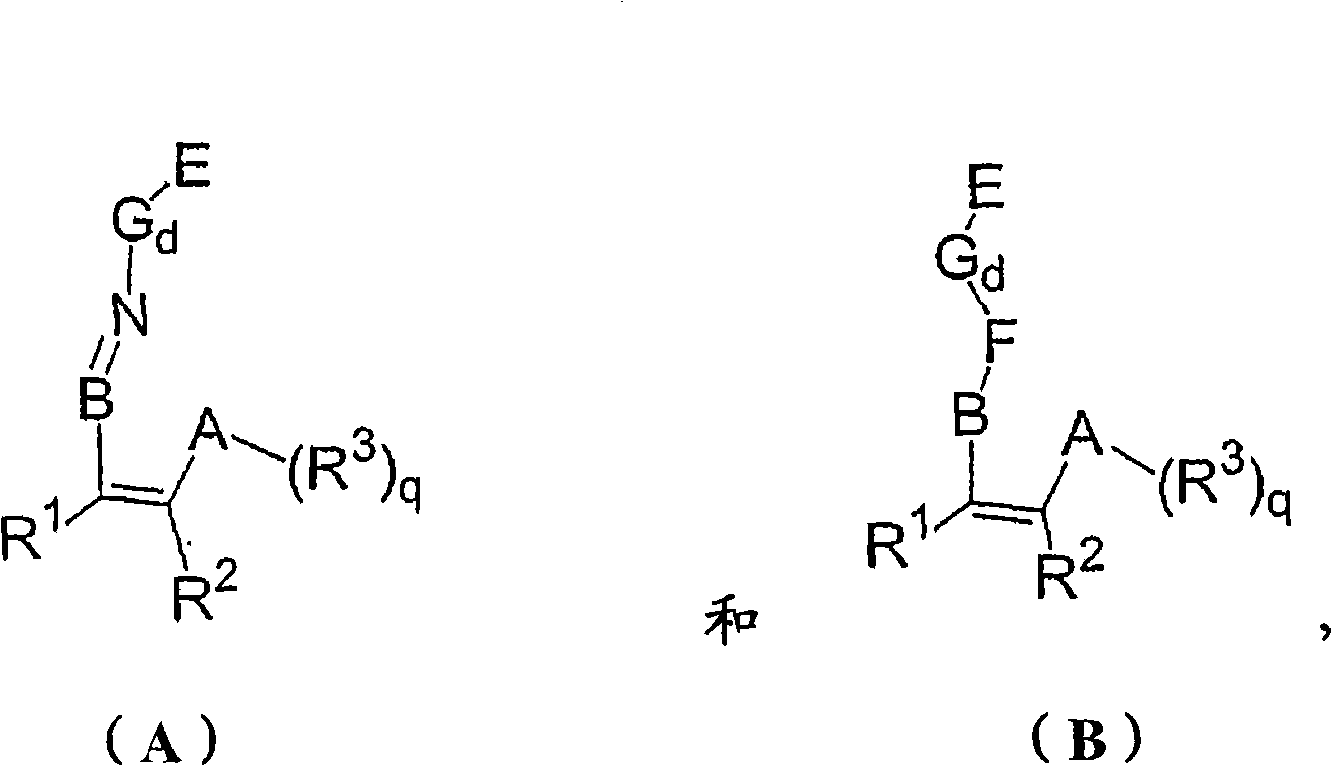

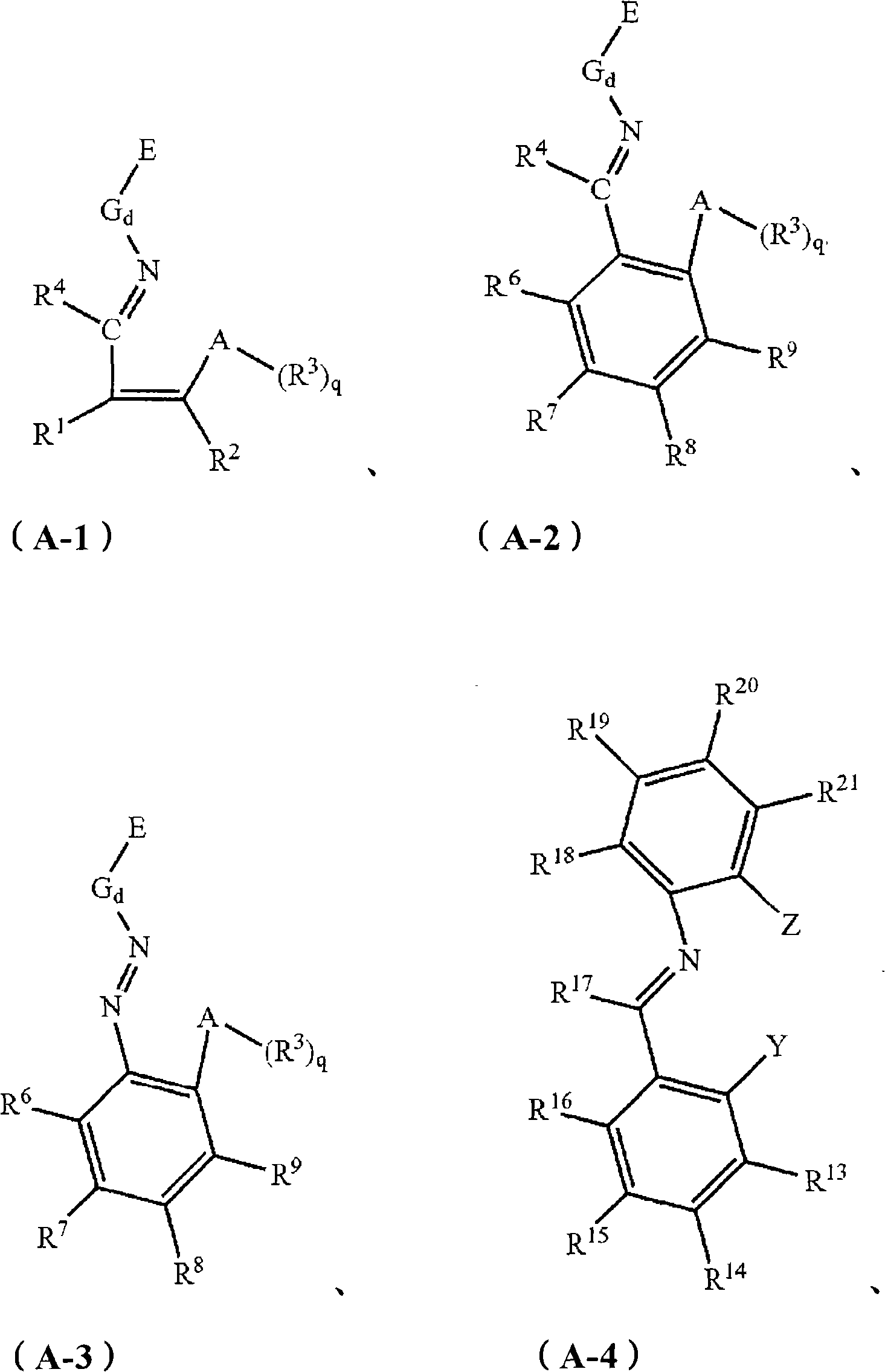

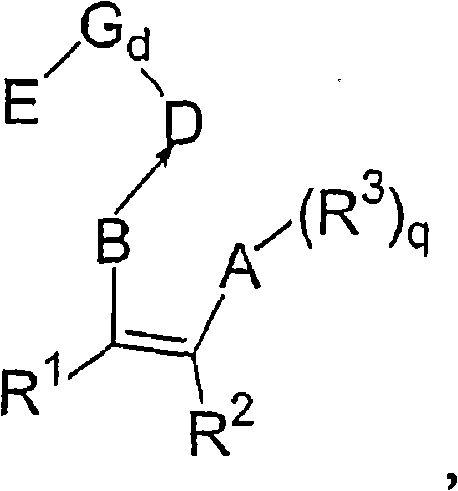

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like, and synergistic reaction which is beneficial to activity development is formed between non-metallocene complexes and chemical conditioning agents inthe catalyst. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

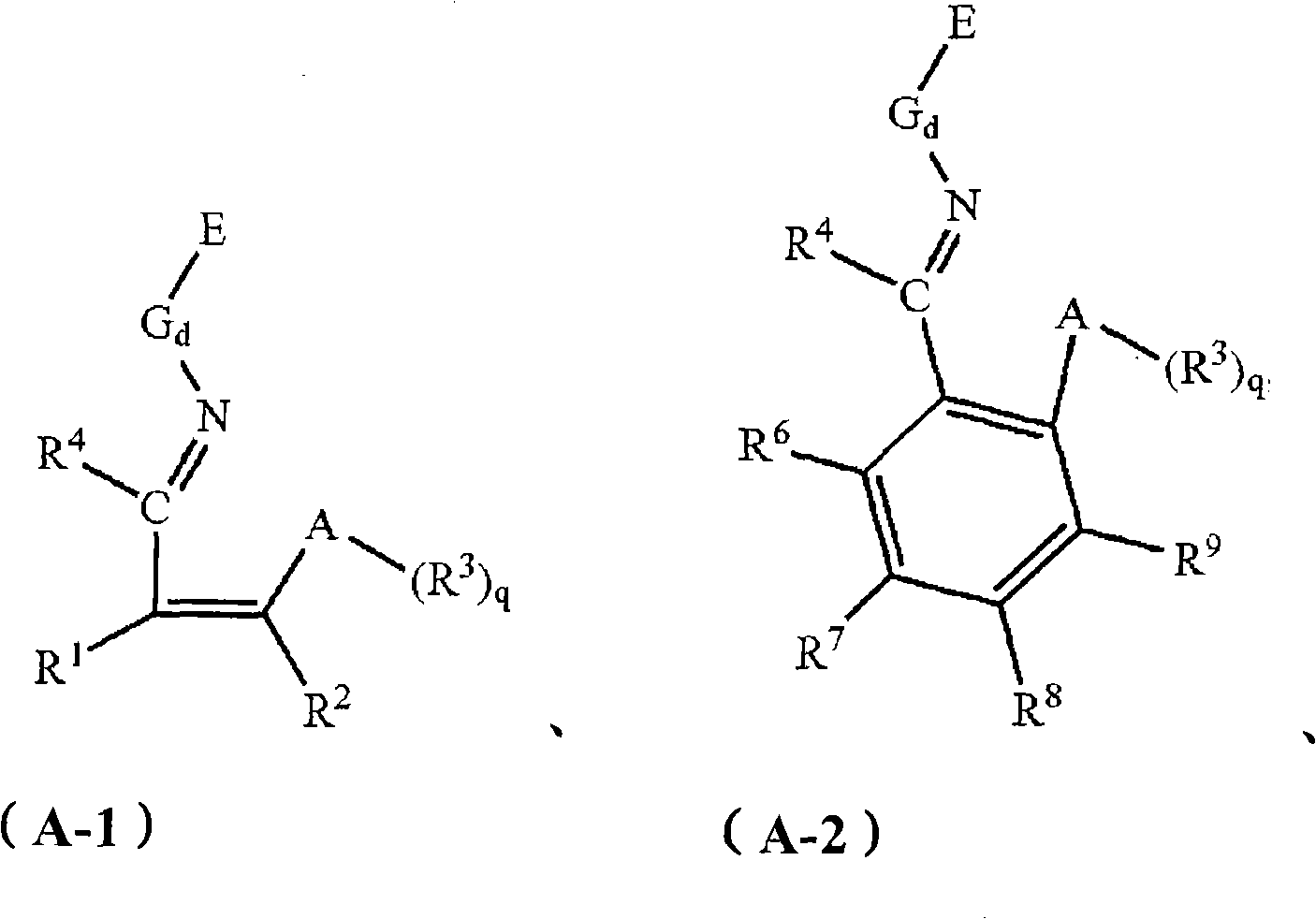

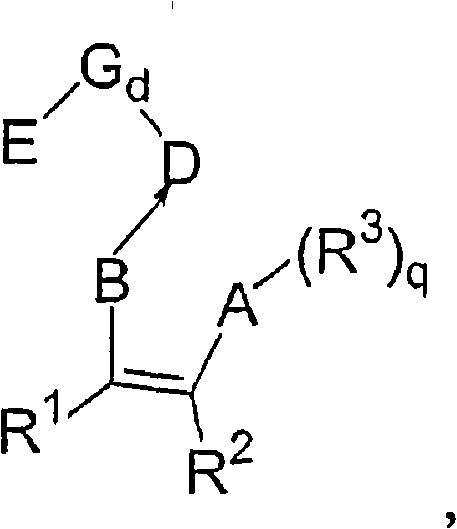

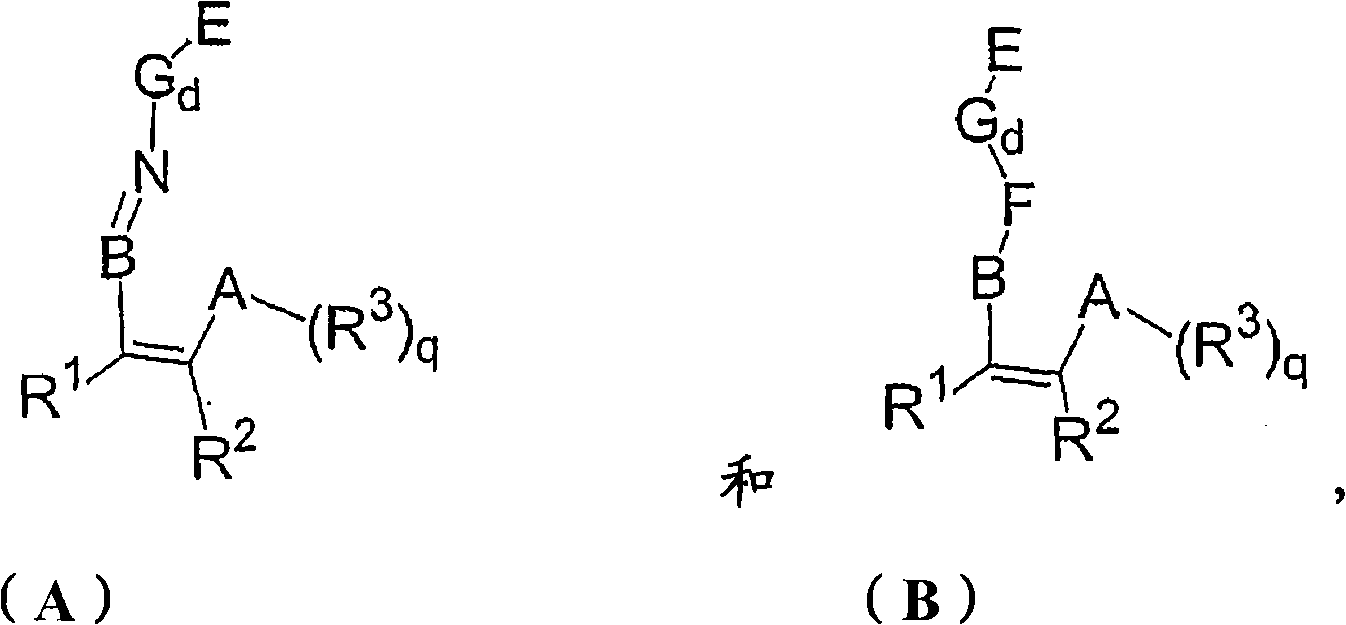

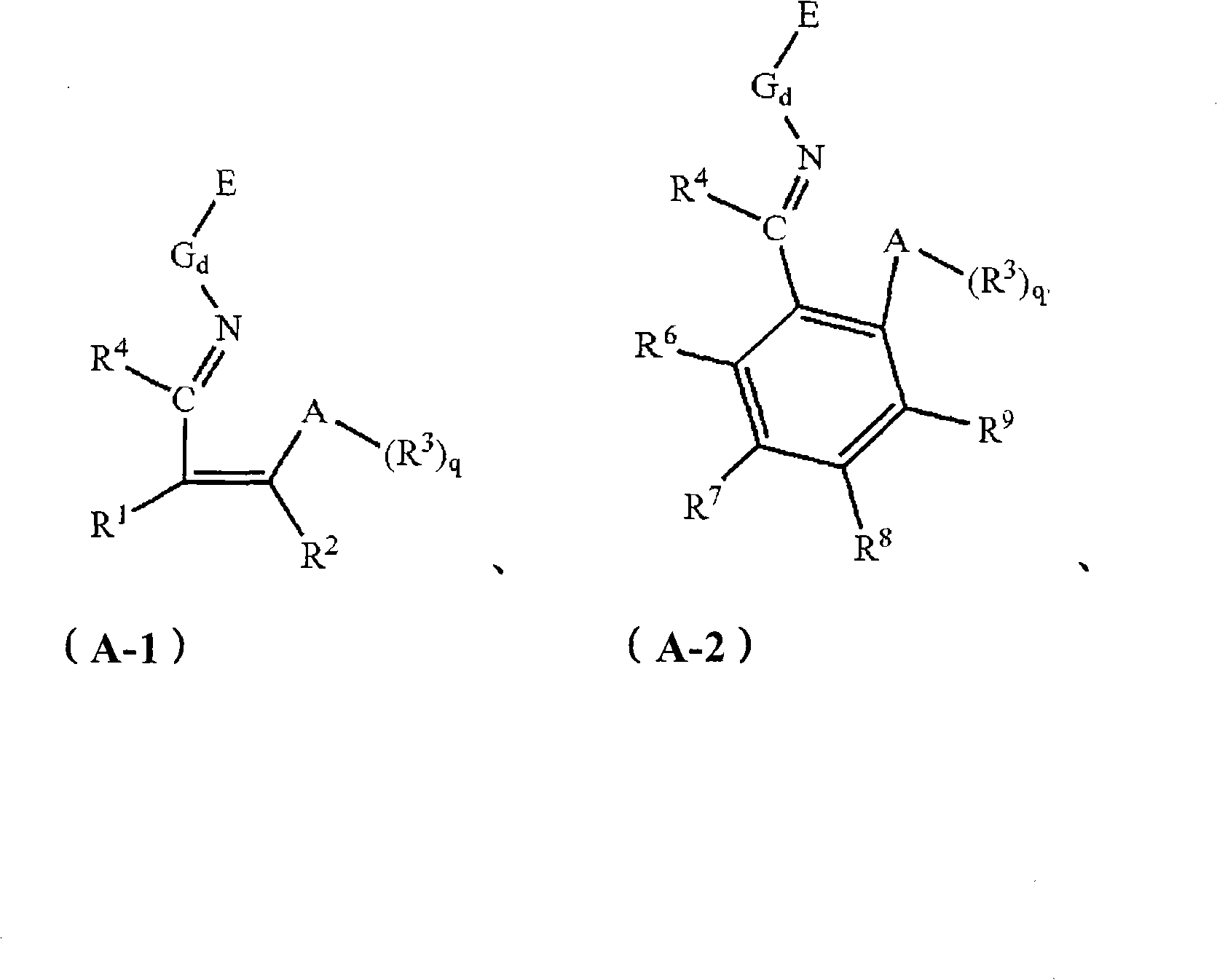

ActiveCN102059153AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059150AThe load is easy to controlAdjust viscosity average molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059152AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059148AThe load is easy to controlAdjust viscosity average molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high boiling silicone oil by using organic silicon high boiling substances

The invention relates to a method for preparing high boiling silicone oil by using organic silicon high boiling substances, comprising hydrolyzation of alcohol and neutralization, wherein the organic silicon high boiling substances are hydrolyzed in the mixed liquid of alcohol and water and refluxed for 1-4 hours; nitrogen purging is carried out on the reactant, and then the reactant is added with hydrogen chloride dissolved in urea, zinc oxide and ammonium bicarbonate and in the system thereof. The invention integrally uses the organic silicon high boiling substances and lowers the chlorine content in silicon oil products, ensures the molecular weight and viscosity to be controllable and mass to be more stable; the usage of the neutralizing agent and latent solvent is reduced greatly, thus reducing the production cost; the process is simple and the industrial production is easy.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

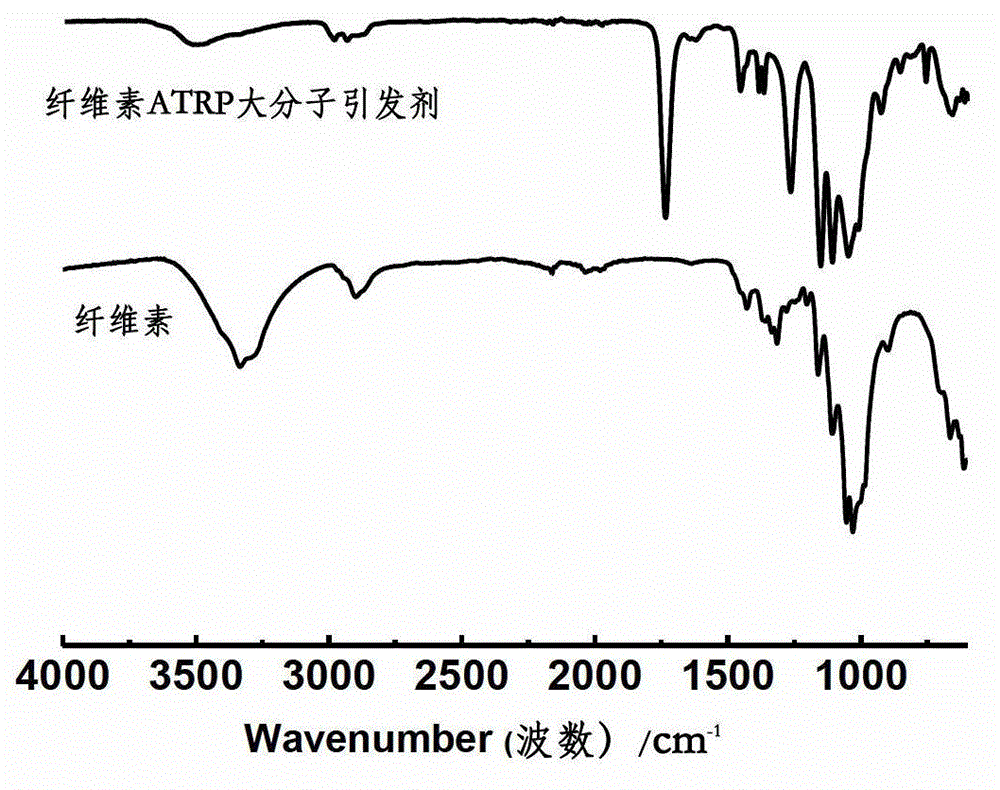

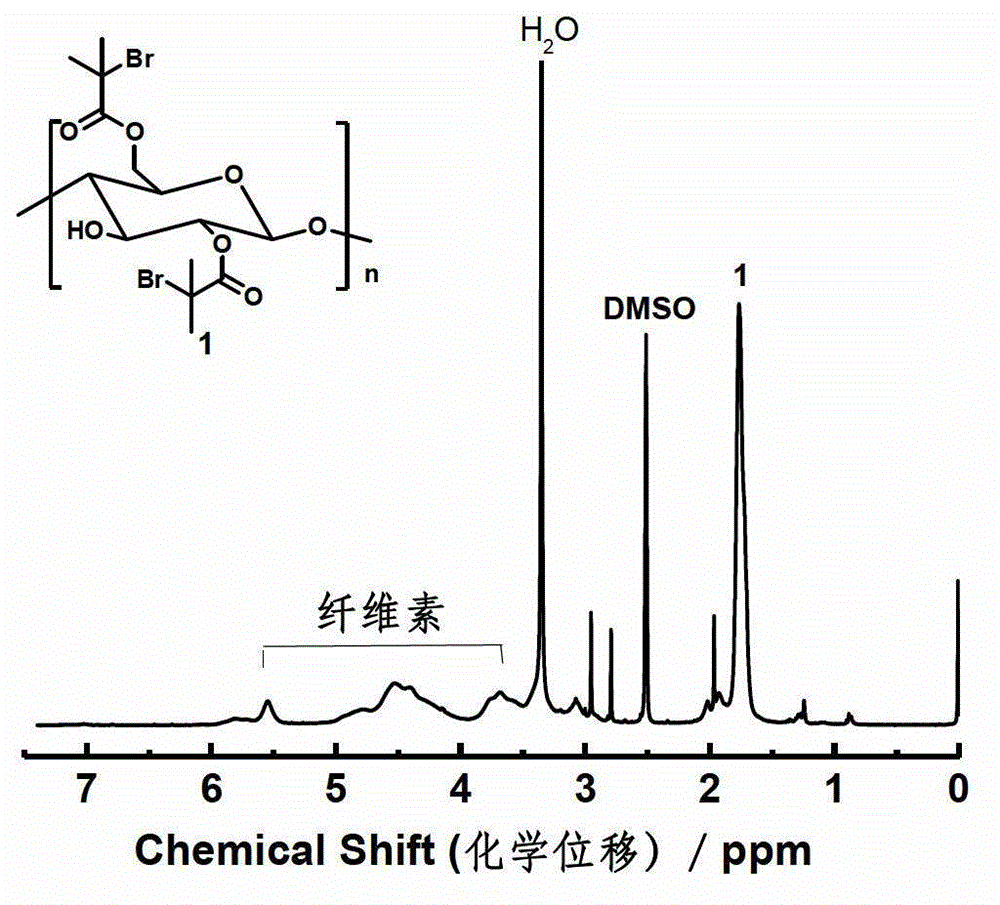

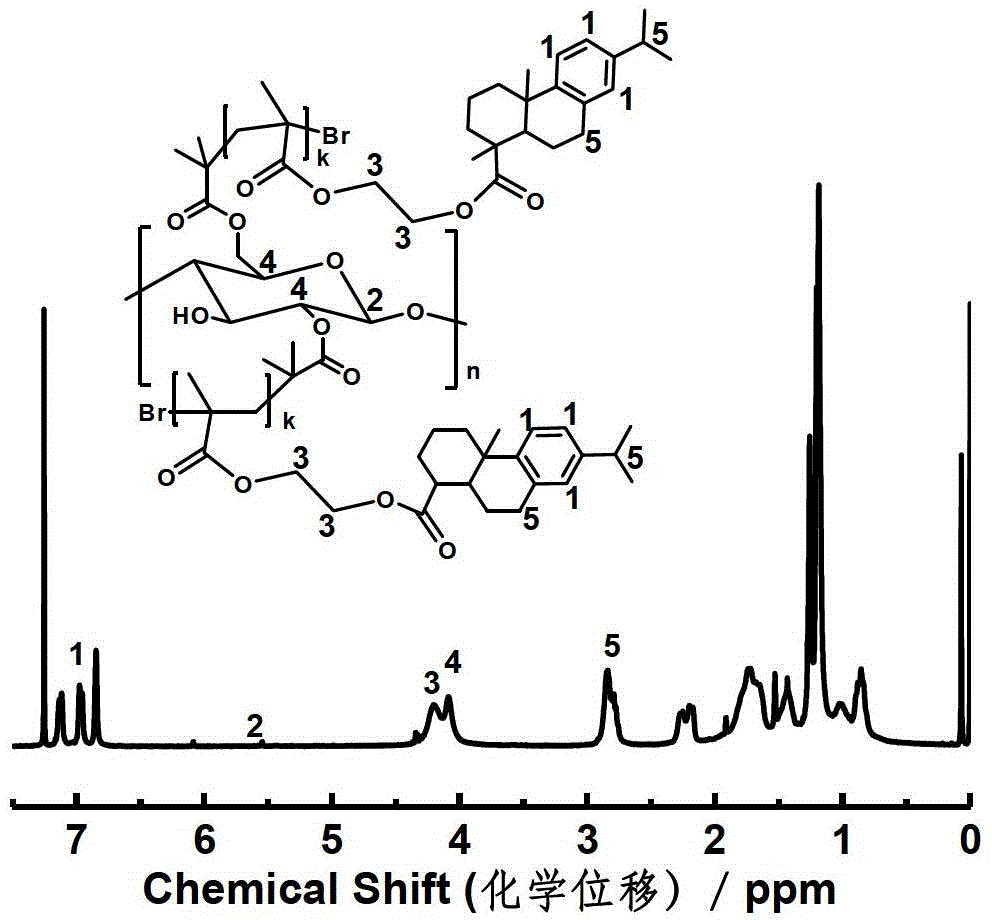

Preparation method of cellulose-g-resin acid grafted copolymer

The invention relates to a preparation method of cellulose-g-resin acid grafted copolymer. The preparation method of the cellulose-g-resin acid grafted copolymer comprises the steps that cellulose atom transfer radical polymerization (ATRP) macroinitiator is synthesized by reaction of cellulose and 2-Bromoisobutyryl bromide in a homogeneous solution system; resin acid monomer, cellulose ATRA macroinitiator, catalytic agents, ligand and rosinyl monomer good solvent are added to a reaction bulb, fully stirred, and dissolved, freezing is carried out for three times, oxygen in the mixed solution is removed in a circulation process of vacuum pumping and nitrogen filling, after the reaction is carried out for 1-24 hours at the temperature of 50-120 DEG C, the polymer is enabled to be deposited in methanol, filtered, and dried, and finally the cellulose-g-resin acid grafted copolymer is obtained. According to the preparation method of the cellulose-g-resin acid grafted copolymer, cellulose-g-resin acid grafted copolymer with different molecular weights and different molecular weight distributions can be obtained. The cellulose-g-resin acid grafted copolymer can be used for improving tenacity of materials by serving as functional additive agents.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

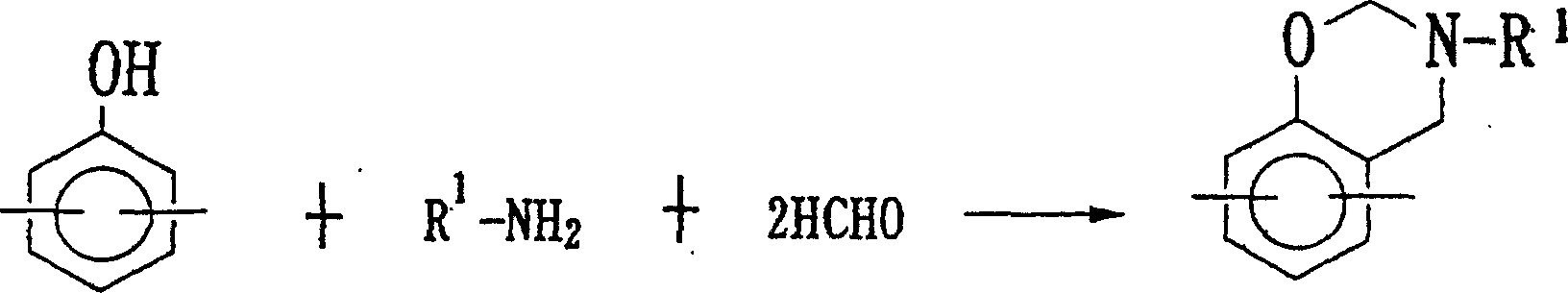

Method for producing benzoxazine resin

The present invention discloses a process for producing a benzoxazine resin which comprises the steps of reacting a phenol compound, an aldehyde compound and a primary amine in the presence of an organic solvent to synthesize a benzoxazine resin and removing generated condensation water and the organic solvent from a system under heating and a reduced pressure, wherein a pressure in the reaction system at the time of removal is set to 260 mmHg or higher.

Owner:HITACHI CHEM CO LTD

Catalyst system and method for polymerizing butadiene

The invention relates to a catalyst system and a method for polymerizing butadiene by using the catalyst system. The catalyst system comprises soluble nickel compounds, organic aluminum compounds and boron triflouride complexes, wherein ligands are mixtures of any two compounds of oxide compounds including alcohols, esters, ketones and ethers. The catalytic system is high in activity, can catalyze the polymerization of 1,3-butadiene in an alkaline solvent at a temperature of between 20 DEG C below zero and 90 DEC G to synthesize cis-rich polybutadiene rubber having little gel but a cis-content of over 97 percent, even up to 99 percent. The system and the method can realize stable production with low energy consumption in a polymerization process, light rubber sticking in a polymeric kettle and pipes and convenient operation.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of hyperbranched polyborosiloxane containing functional group and preparation method thereof

The invention discloses a hyperbranched polyborosiloxane containing functional groups. The hyperbranched polyborosiloxane containing functional groups has the characteristics of hyperbranched topological structure, stable storage performance, controllable viscosity and the like, and has excellent compatibility with existing high polymer materials. The invention also discloses a preparation methodof the hyperbranched polyborosiloxane containing functional groups, and the preparation method has the advantages of wide monomer source, low cost, easy process control and important application valueand academic significance.

Owner:QUANZHOU NORMAL UNIV

Non-ferrous metal mineral flotation agent

The invention relates to a non-ferrous metal mineral flotation agent which comprises a collecting agent, a foaming agent and a regulating agent, wherein the collecting agent is oily sludge comprising kerosene and / or diesel oil and / or transformer oil and / or heavy oil and / or crude oil. The foaming agent is pine wine oil or hexyl alcohol or n-caprylic alcohol or octanol, and the regulating agent is lime and / or water glass. Compared with the prior art, oily sludge produced in the processes of production, transportation and storage of an oil field, an oil refinery and the like is in resource utilization as the collecting agent of the flotation agent, and an agent produced under the coordinating function of the collecting agent, the foaming agent and the regulating agent forms to be the novel flotation agent used for mineral processing production of non-ferrous metal, using amount of various product oil is greatly saved, and agent cost of the flotation agent for flotation and enrichment production of the non-ferrous metal is reduced.

Owner:陕西长大石油化工产品有限公司

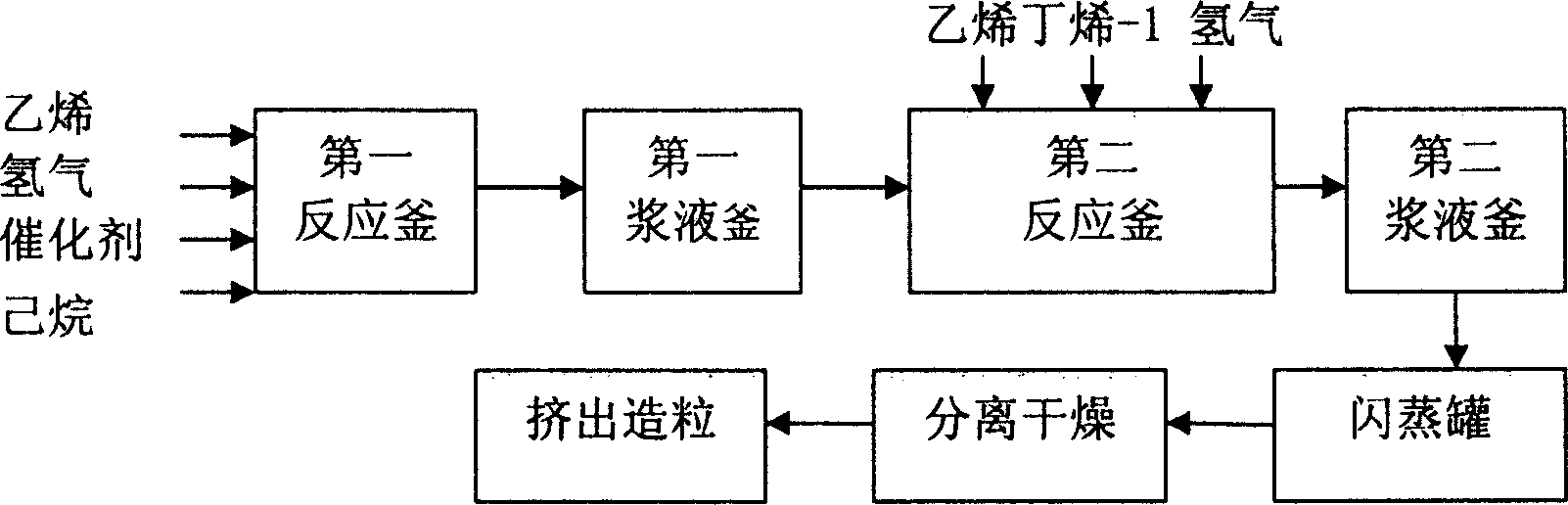

Preparation method of high density polyethylene communication cable insulating material

InactiveCN1903901AGuaranteed StrengthAdjust molecular weightPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The present invention relates to a preparation method of double-peak high-density polyethylene communication cable insulating material. It is characterized by that on the Mitsui chemical high-density polyethylene technological equipment a double-slurry polymerization reactors series-connected reaction process can be adopted. Said invention is an improvement of existent technological process, namely, the catalyst only is added into the first reactor, and in the first reactor the comonomer butylene-1 is not added, the added quantity of hydrogen is controlled, the molecular weight distribution and density of polymer produced by two reactors can be regulated so as to make first reactor polymer be low molecular weight high-density polyethylene, the second reactor polymer be high molecular weight high-density polyethylene so as to obtain polymer-grade polyethylene whose molecular weight is formed into double-peak distribution. After the adjuvant is added into the above-mentioned material and granulated, the communication cable insulating material product can be made up by utilizing large equipment.

Owner:SINOPEC YANGZI PETROCHEM

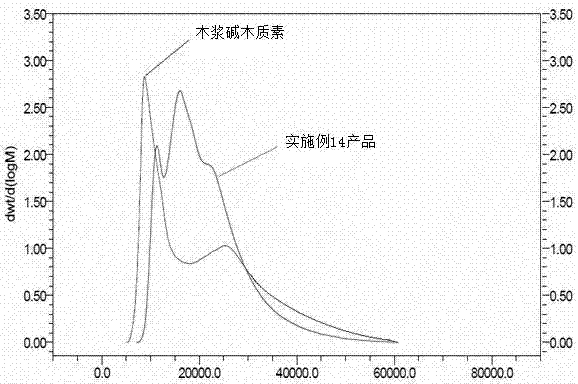

Lignin serial coal water slurry dispersing agent and preparation method thereof

ActiveCN103045317AIncreased average molecular massImprove hydrophilicityLiquid carbonaceous fuelsSulfite saltPolyethylene glycol

The invention relates to lignin serial coal water slurry dispersing agent and a preparation method thereof, and belongs to the technical field of dispersing agent which is prepared by coal water slurry. The dispersing agent comprises the following raw material components in parts by weight: 1,000 parts of alkali lignin, 20 to 50 parts of polyethylene glycol, 2 to 10 parts of carboxylic acid, 1 to 5 parts of concentrated sulfuric acid, 0.1 to 1 part of hydroquinone, 20 to 60 parts of acrylic acid, 60 to 150 parts of vinyl monomer, 200 to 400 parts of sodium sulfite, 300 to 500 parts of acetaldehyde solution, 30 to 50 parts of oxidant and 10 to 20 parts of reducing agent. Compared with the prior art, the lignin serial coal water slurry dispersing agent adopts the alkali lignin as a raw material, so that the cost is reduced, the average molecular mass of the lignin is remarkably improved, the hydrophily is obviously enhanced, and the dispersing effect is prominently improved; and in addition, the dispersing agent has the advantages of low cost, simple preparation technique, more generality of raw materials, wide sources of the raw materials, cheaper price and good modifying effect; and the resource utilization is implemented for wastes, so that the environmental pollution from the wastes is reduced.

Owner:DONGFANG ELECTRIC CORP LTD

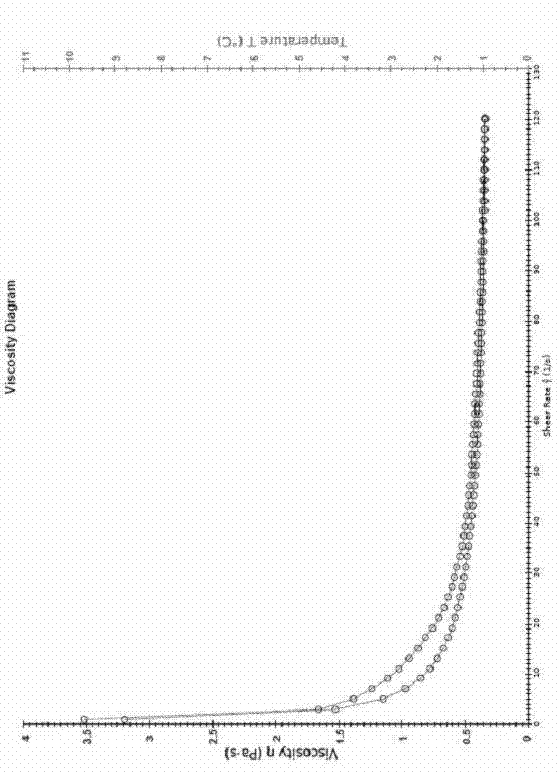

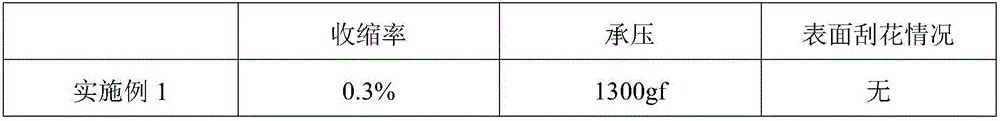

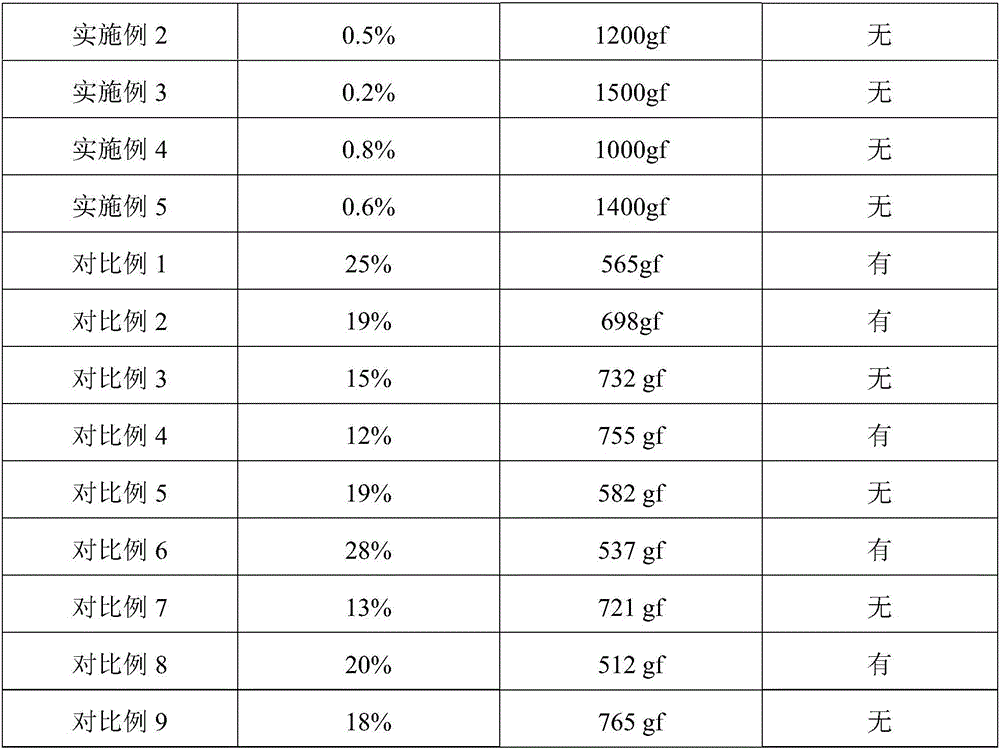

Low-shrinkage UV curing PUA resin, as well as preparation method and application thereof to preparation of hot bending membrane

The invention provides low-shrinkage UV curing PUA resin, as well as a preparation method and application thereof to preparation of a hot bending membrane. The preparation method of the UV curing PUA resin comprises the following steps: performing reaction on diisocyanate, polyalcohol and a chain extender under the existence of a catalyst to obtain polyurethane; and adding acrylic monomers into the obtained reaction system and reacting to obtain the UV curing PUA resin, wherein the molar ratio of the polyalcohol to the diisocyanate is (10-40):1, the polyalcohol is a mixture of polyester polyol and polyether polyol, and the molar ratio of the polyester polyol to the polyether polyol in the mixture is (3-10):1. According to the UV curing PUA resin prepared by the method, the shrinkage rate is below 0.8 percent after the UV curing PUA resin is cured; when the film-forming thickness is 2.5 microns, the UV curing PUA resin can bear the pressure being more than 1000 gf; when 0000# steel wool moves on the UV curing PUA resin back and forth for 10000 times, the surface is not scratched, and high flexibility and wear resistance are achieved.

Owner:江苏旭泽技术有限公司

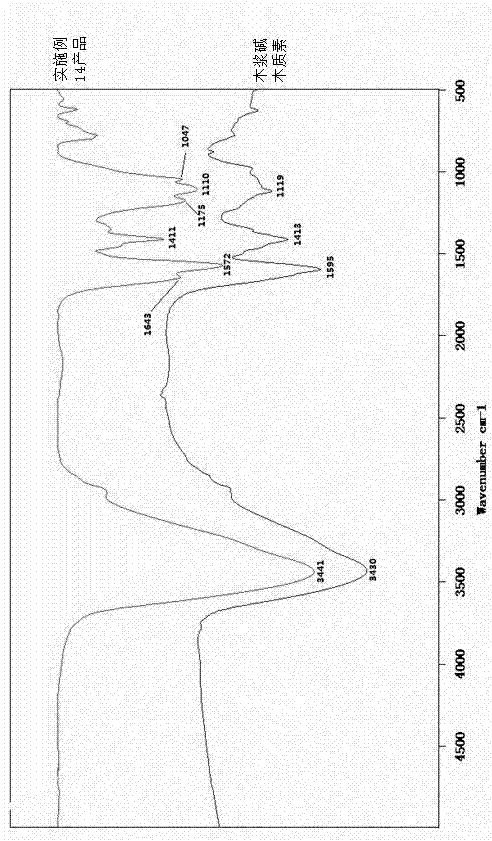

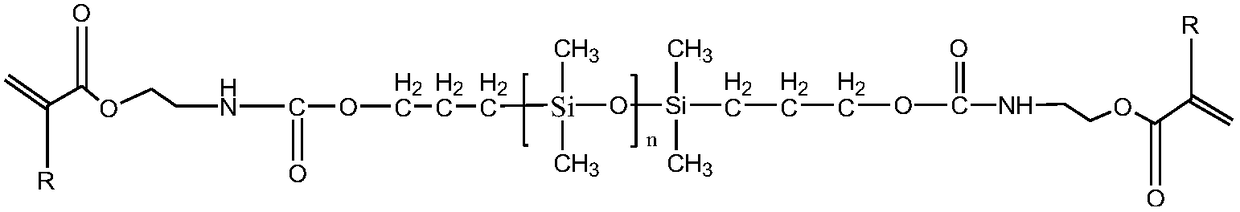

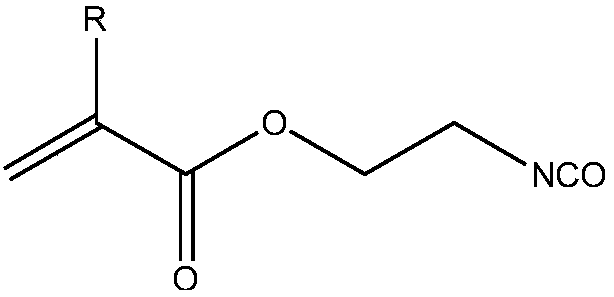

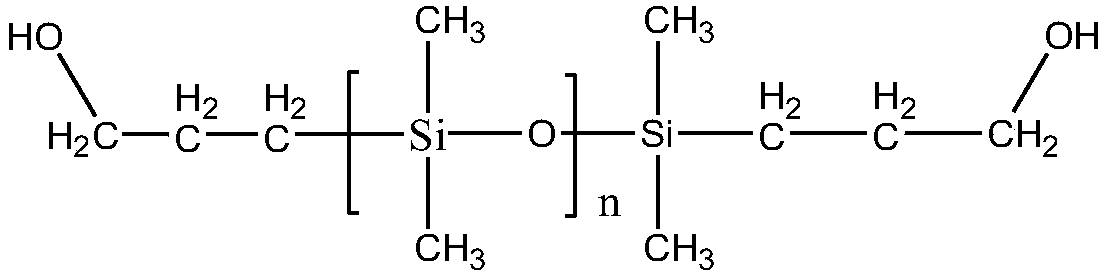

UV light-cured organic silicon polyurethane acrylate monomer and preparation method thereof

The invention relates to a UV light-cured organic silicon polyurethane acrylate monomer and a preparation method thereof. The preparation method comprises the following steps: dissolving a certain amount of hydroxyalkyl dual end-capped polydimethylsiloxane and an AOI-VN monomer into an organic solvent, adding a certain amount of polymerization inhibitor, reacting under action of a catalyst for 4-6hours at a reaction temperature of 40-60 DEG C; after reaction is ended, adsorbing through active carbon, wherein dosage of the active carbon is 2-4% of mass of a mixture system; filtering and removing the solvent to obtain the organic silicon polyurethane acrylate monomer. The monomer prepared by the invention can be directly used as prepolymer, and further can be added into a resin or paint formula as an additive. After being light-cured, the product has performance such as water resistance and high temperature resistance of an organic silicon material.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

Preparation method of butyl rubber

The invention provides a preparation method of a butyl rubber. The preparation method of the butyl rubber is characterized by comprising the steps of introducing an ether compound into a preparation process. According to the preparation method of the butyl rubber provided by the invention, lewis acid is adopted as an initiator, and the ether compound is introduced into a reaction system, so that mass and heat transfer of the reaction system can be effectively changed, the butyl rubber is uniformly dispersed in the system, continuous production of the butyl rubber is ensured, frequent startingand stopping during a production process are avoided, and the product quality stability is good. In addition, according to the preparation method of the butyl rubber provided by the invention, the molecular weight and the molecular weight distribution of the butyl rubber can be effectively adjusted, and the processability of the butyl rubber is improved.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

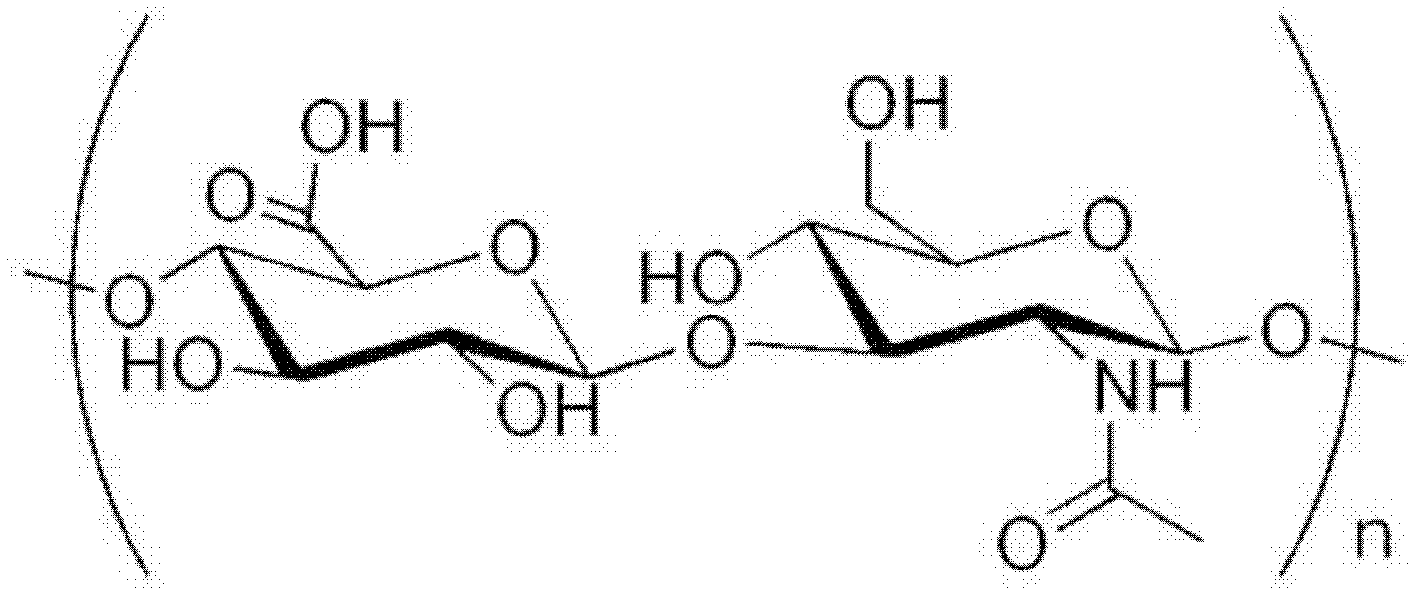

Method for manufacturing low molecular weight hyaluronic acid

ActiveCN102630231AAdjust molecular weightRemove hasOrganic active ingredientsCosmetic preparationsActivated carbonDecomposition

The present invention relates to a method for converting high molecular weight hyaluronic acid produced by Streptococcus ID9102 to a low molecular weight hyaluronic acid. More particularly, the present invention relates to a method for uniformly reducing the molecular weight of hyaluronic acid by reacting high molecular weight hyaluronic acid with activated carbon under certain decomposition conditions while retaining the properties of hyaluronic acid.; Compared with the typical methods which require complicated additional processing conditions such as pH treatment, reaction catalysts, and heating, the method for converting high molecular weight hyaluronic acid to low molecular weight hyaluronic acid according to the present invention provides convenient processing by eliminating the inconvenience of retreatment for removing input materials and even having the effect of removing impurities, to conveniently and economically produce high purity, low molecular weight hyaluronic acid. The method of lowering molecular weight according to the present invention is advantageous in that the molecular weight of low molecular weight hyaluronic acid may be variously adjusted by changing reaction conditions using activated carbon.; The low molecular weight hyaluronic acid according to the present invention may be manufactured to comply with pharmaceutical standards as well as with cosmetic or food standards while retaining the properties of hyaluronic acid.

Owner:IL DONG PHARMA CO LTD

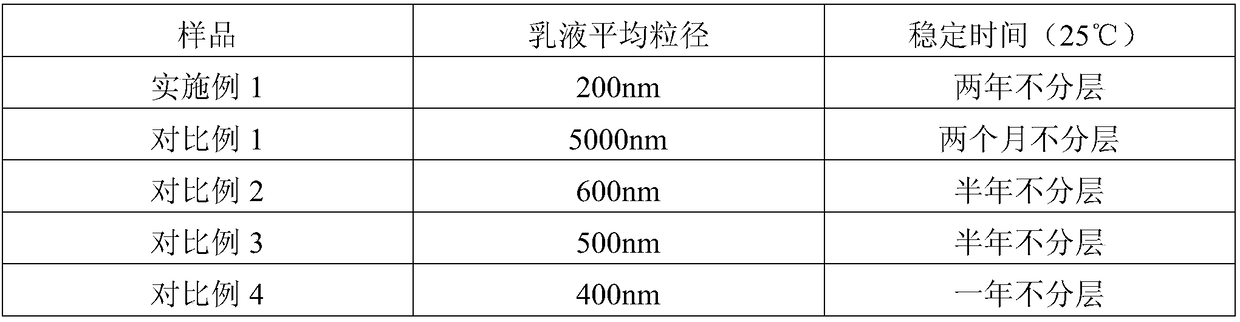

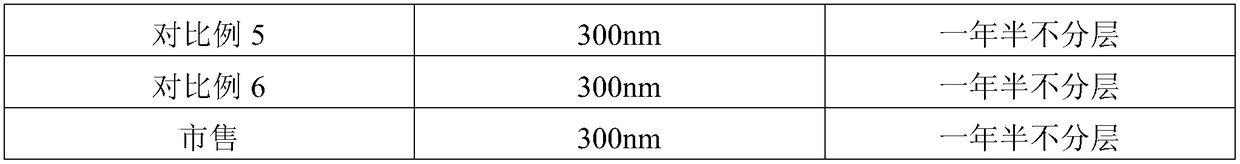

Cationic rosin size emulsifier and preparation method thereof

ActiveCN108396589AAdjust molecular weightAvoid interferenceWater-repelling agents additionAcetic acidEmulsion

The invention provides a cationic rosin size emulsifier and a preparation method thereof. The cationic rosin size emulsifier is prepared from dimethylaminoethyl methacrylate, styrene, chitosan, glacial acetic acid, water, acrylic acid, acrylamide, potassium sodium tartrate and an initiator. The obtained emulsifier has a good stability, can be used to directly emulsify rosin, and has the advantagesof small use amount, good effect and low cost, a rosin size emulsion obtained after emulsification has nanoscale particles and a stable quality, and can be stably stored (at -5 to 50 DEG C) for a long time; and the rosin size emulsion obtained after emulsification is applied to sizing, has the advantages of small use amount of other sizing additives, small use amount of a sizing agent, good effect and low cost, and makes sized paper have certain antibacterial and bactericidal effects and good durability.

Owner:辽宁兴东科技有限公司

Preparation method and application of 4,4'-substituted benzil core-based luminescence and host material

ActiveCN105176520AEasy to synthesizeSingle structureOrganic chemistryOrganic compound preparationImbalance problemsChemistry

The invention belongs to the technical field of organic photoelectric materials, and discloses a preparation method and an application of a 4,4'-substituted benzil core-based luminescence and host material. The luminescent material is prepared through a Buchwald-Hartwig coupling reaction from 4,4'-dibromobenzil as an initial reaction raw material under the protection of nitrogen. The luminescent material adopts 4,4'-substituted benzil as a host structure, and the connection mode of a donor is changed to adjust the molecular weight, the pi conjugacy and eletrophilicity, the charge transfer ability and the photochromism of the material and effectively solve the carrier imbalance problem of unipolar luminescent materials. The material can be used in organic light-emitting diodes to greatly improve the external quantum efficiency of traditional fluorescent organic light-emitting diode devices.

Owner:SOUTH CHINA UNIV OF TECH

Self-flame retardant antibacterial aqueous polyester resin and preparation method thereof

InactiveCN110563936ANot easy to dissociateDurable Flame RetardancyFireproof paintsAntifouling/underwater paintsCarboxylic acidFire retardant

The invention relates to a self-flame retardant antibacterial aqueous polyester resin and a preparation method thereof. The resin comprises the following components in parts by weight: 6.0-12.0 partsof organic anhydride, 3.0-5.0 parts of carboxylic acid Schiff base, 3.0-8.0 parts of polybasic acid, 6.0-20.0 parts of polyhydric alcohols, 1.2-3.5 parts of 2-chloro-5-bromobenzoic acid, 1.5-3.5 partsof dimethylolpropionic acid, 2.0-5.0 parts of xylene, 2.0-5.0 parts of a neutralizing agent and 45.0-65.0 parts of deionized water. The self-flame retardant antibacterial aqueous polyester resin provided by the invention is good in coloring property, low in viscosity, high in hardness, good in fullness, good in brightness, and the like, is free of external flame retardant or antibacterial agent when an aqueous coating is prepared, is long in flame retardant and antibacterial effect lasting and high in efficiency, and can be applied to inner and outer wall coatings, aqueous industrial coatings, aqueous wood product coatings, and the like.

Owner:UNION FOSHAN CHEM +1

Polyacrylic acid or copolymer thereof and preparation method of polyacrylate or copolymer salt thereof

ActiveCN101921359BGood production safetyPromote environmental protectionPolymer scienceSodium Hypophosphite Monohydrate

Owner:湖南葆华环保科技有限公司

Liquid polybutadiene rubber, epoxidized liquid polybutadiene rubber and preparation methods of two

The invention provides liquid polybutadiene rubber, epoxidized liquid polybutadiene rubber and preparation methods of the two and relates to the field of rubber preparation. The preparation method ofthe liquid polybutadiene rubber comprises the following steps: mixing a polymer grade butadiene monomer and an organic solvent, mixing with an initiator and a telomere at the temperature of 30-50 DEGC, carrying out a polymerization reaction at the temperature of 30-50 DEG C for 3-5 hours, and terminating the reaction. According to the method, the liquid polybutadiene rubber can be obtained, and the molecular weight and the structure of the liquid polybutadiene rubber are adjustable. The preparation method of the epoxidized liquid polybutadiene rubber comprises the following steps: mixing theliquid polybutadiene rubber with an organic acid and hydrogen peroxide, and carrying out an epoxidation reaction. The reaction process is simple, the epoxidation process is mild in reaction, and the prepared epoxidized liquid polybutadiene rubber is stable in performance.

Owner:SHANDONG YUHUANG CHEM CO LTD

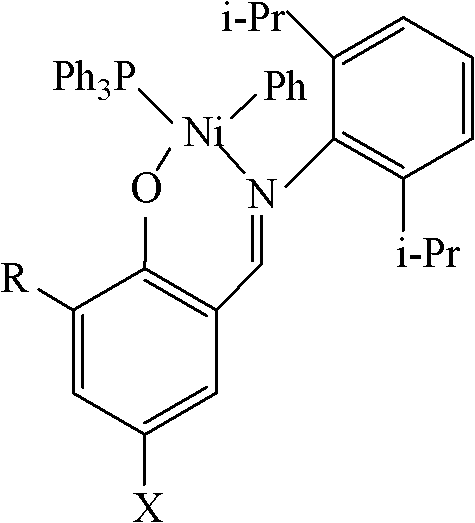

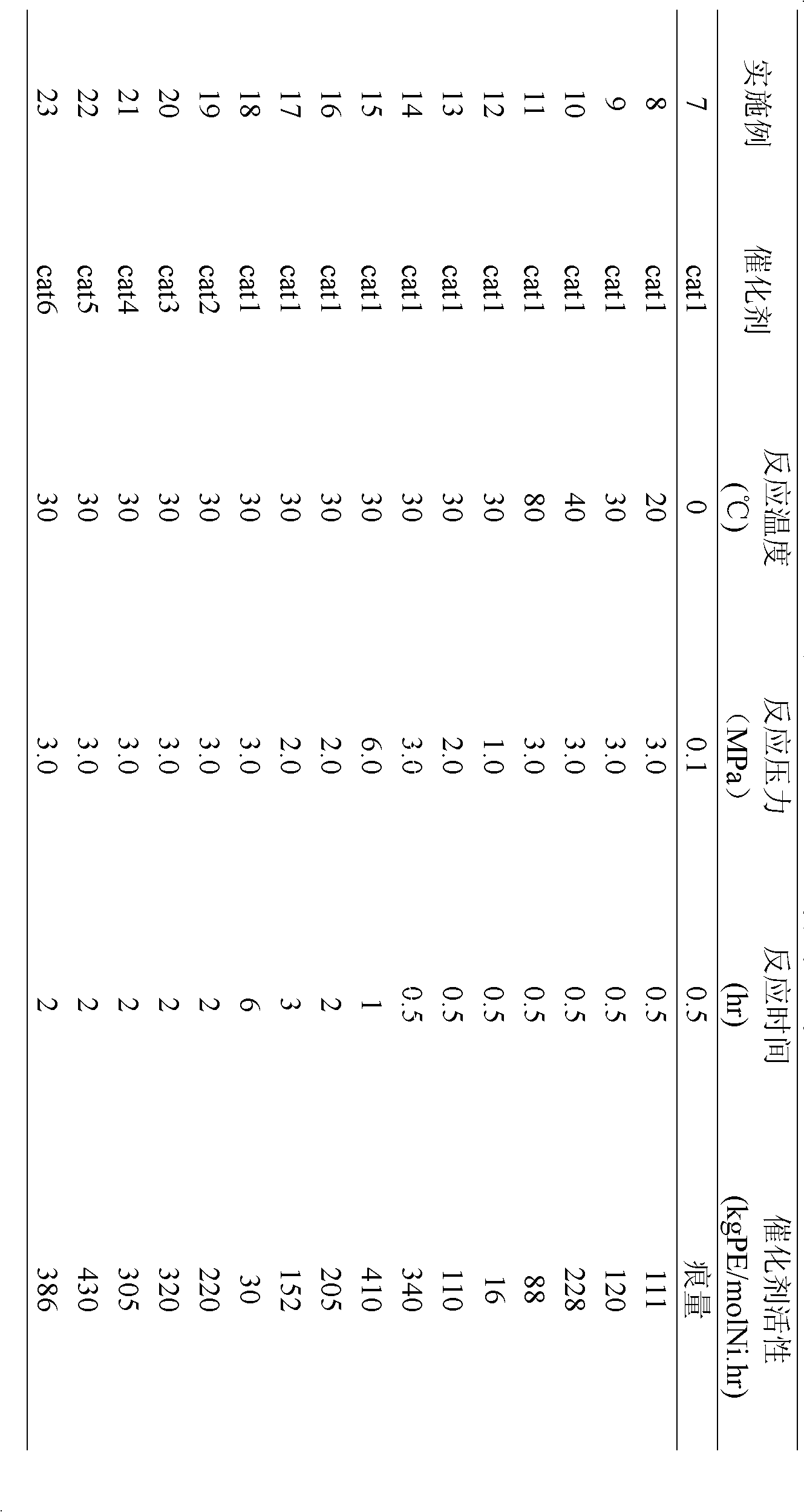

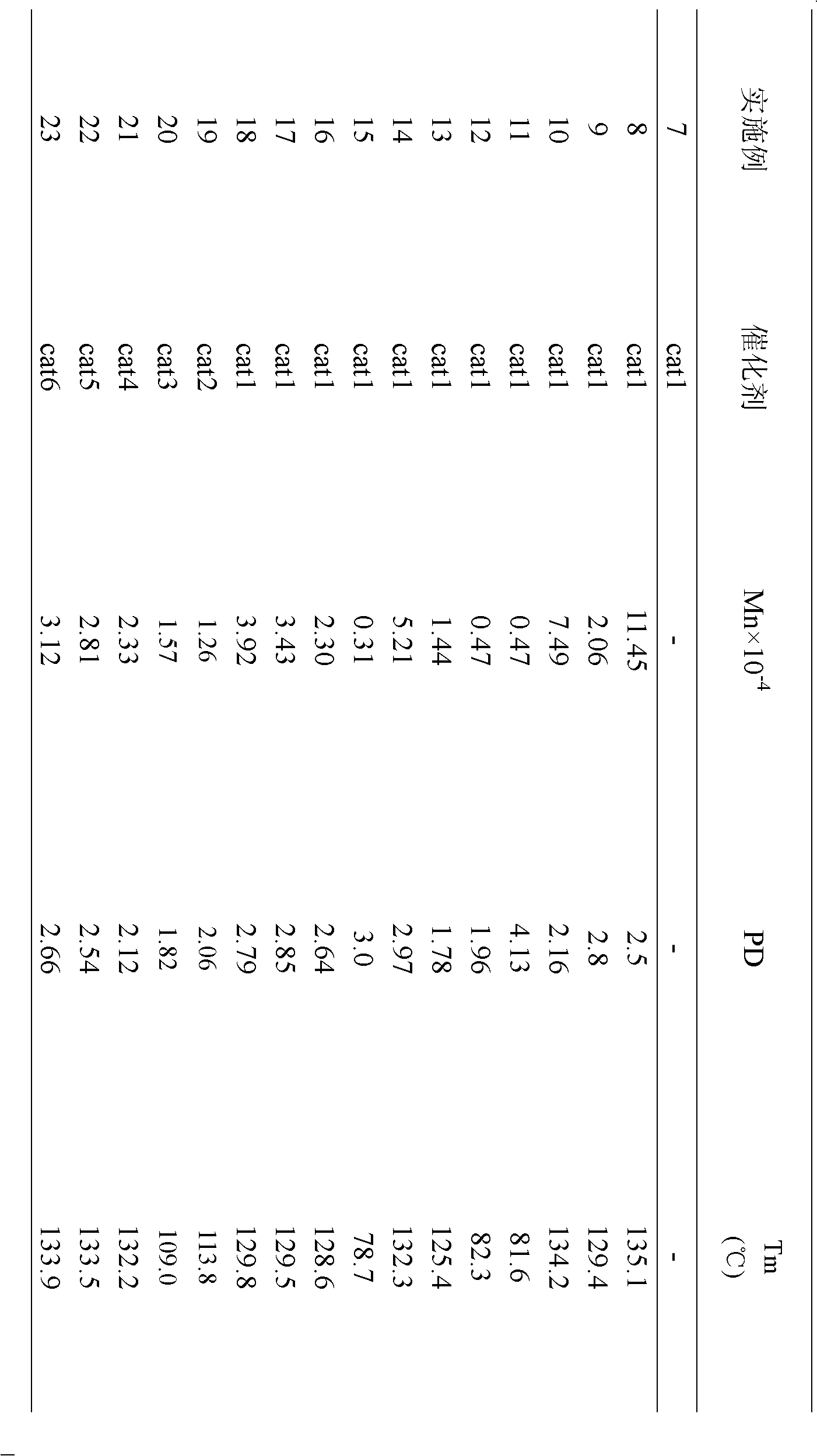

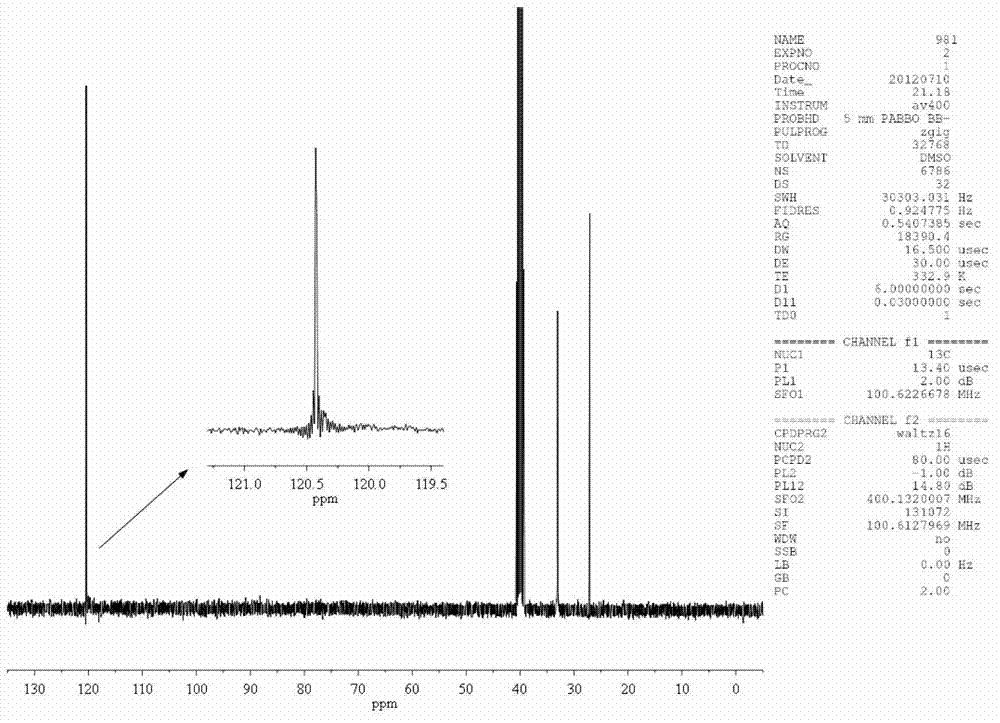

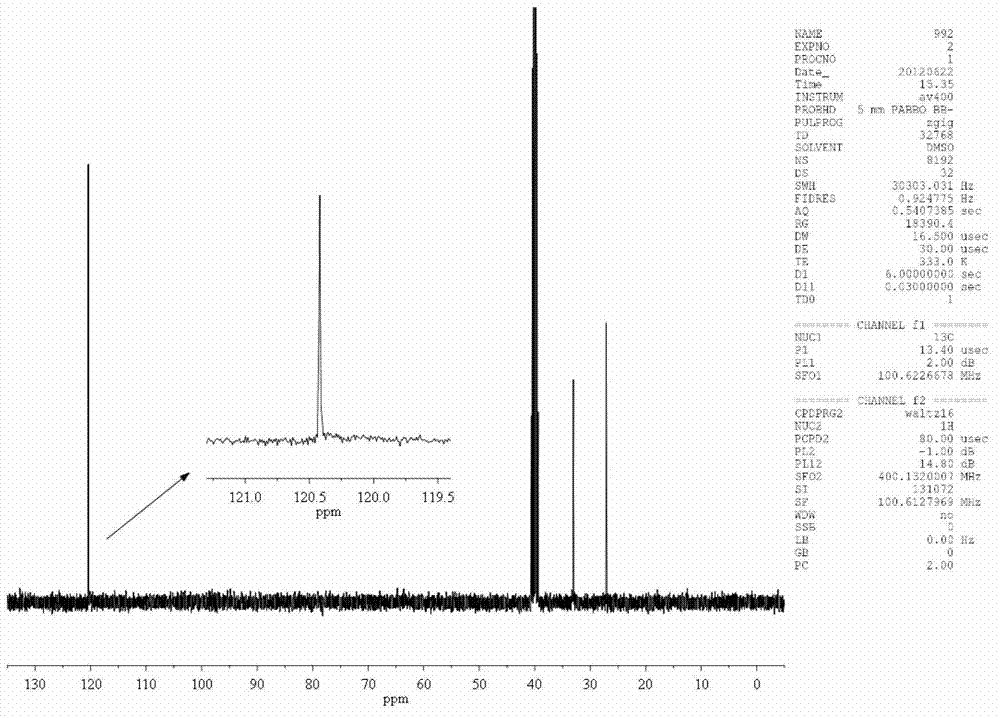

2,6-diisopropyl aniline salicylaldiminato nickel, and preparation and application thereof

The invention relates to a 2,6-diisopropyl aniline salicylaldiminato nickel, and preparation and application thereof. The preparation method comprises the steps of: adding 2,6-diisopropyl aniline into salicylaldehyde with substituent by a molar ratio of 1:1-1.5; reacting under effect of acetate for 60-80 DEG C; dissolving the obtained salicylaldiminato in a solvent and adding NaH by a molar ratio of 1:1-6; reacting at -20-5 DEG C; transferring a clear liquid to an aromatic hydrocarbon or ether solvent of trans-[NiCl(Ph)(PPh3)2] by a molar ratio of 1-3:1; reacting at -20-40 DEG C; pumping out the solvent; and recrystallizing by an organic solvent to obtain the catalyst. The catalyst is used for catalysis of ethene polymerization and adjusts molecular weight, molecular weight distribution and polymer branched structure of an ethene polymer through adjusting polymerization conditions or hydroxy ortho-position substituent of salicylaldiminato.

Owner:PETROCHINA CO LTD

Catalyst system and method for polymerizing butadiene

The invention relates to a catalyst system and a method for polymerizing butadiene by using the catalyst system. The catalyst system comprises soluble nickel compounds, organic aluminum compounds and boron triflouride complexes, wherein ligands are mixtures of any two compounds of oxide compounds including alcohols, esters, ketones and ethers. The catalytic system is high in activity, can catalyzethe polymerization of 1,3-butadiene in an alkaline solvent at a temperature of between 20 DEG C below zero and 90 DEC G to synthesize cis-rich polybutadiene rubber having little gel but a cis-contentof over 97 percent, even up to 99 percent. The system and the method can realize stable production with low energy consumption in a polymerization process, light rubber sticking in a polymeric kettleand pipes and convenient operation.

Owner:CHINA PETROLEUM & CHEM CORP

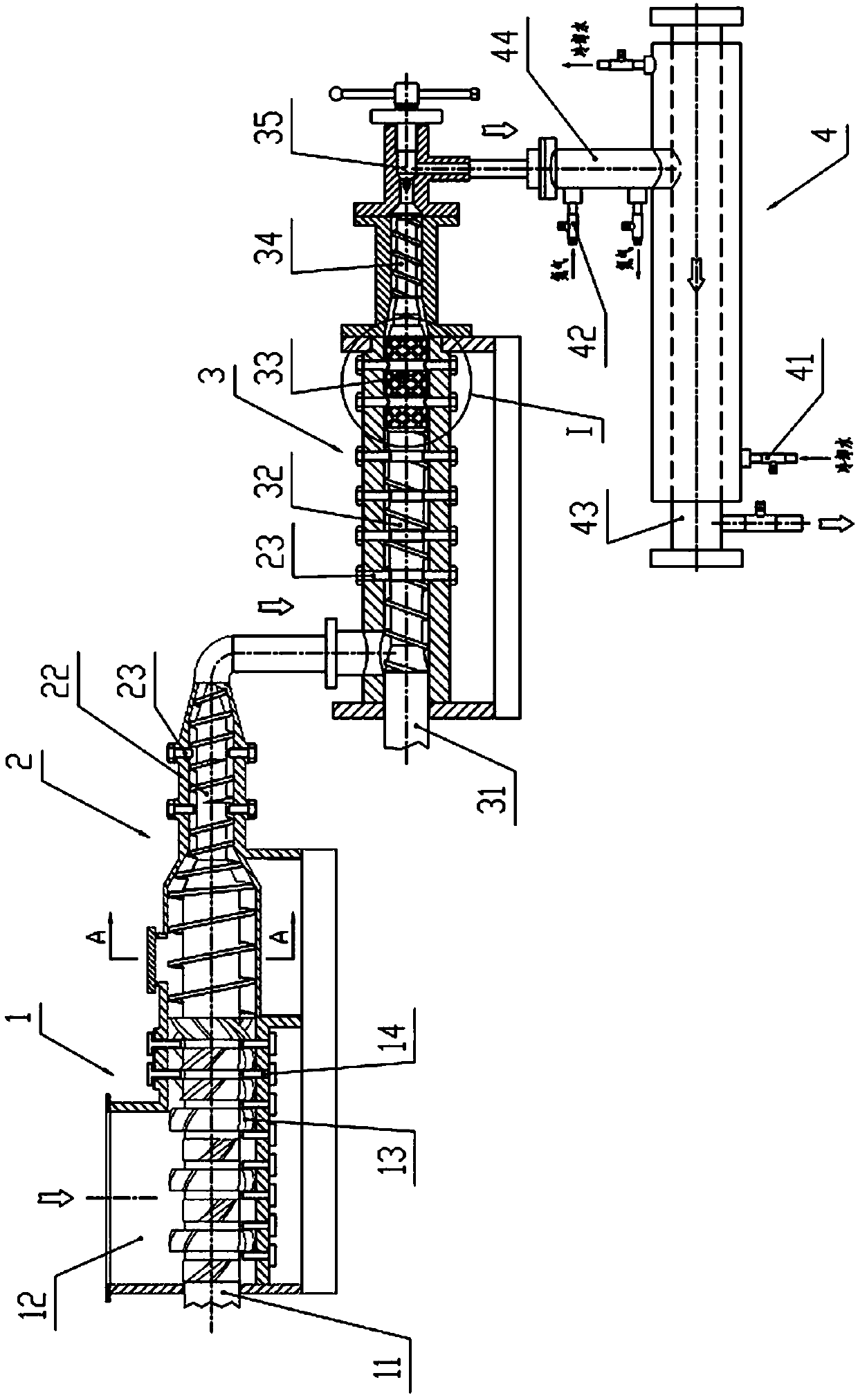

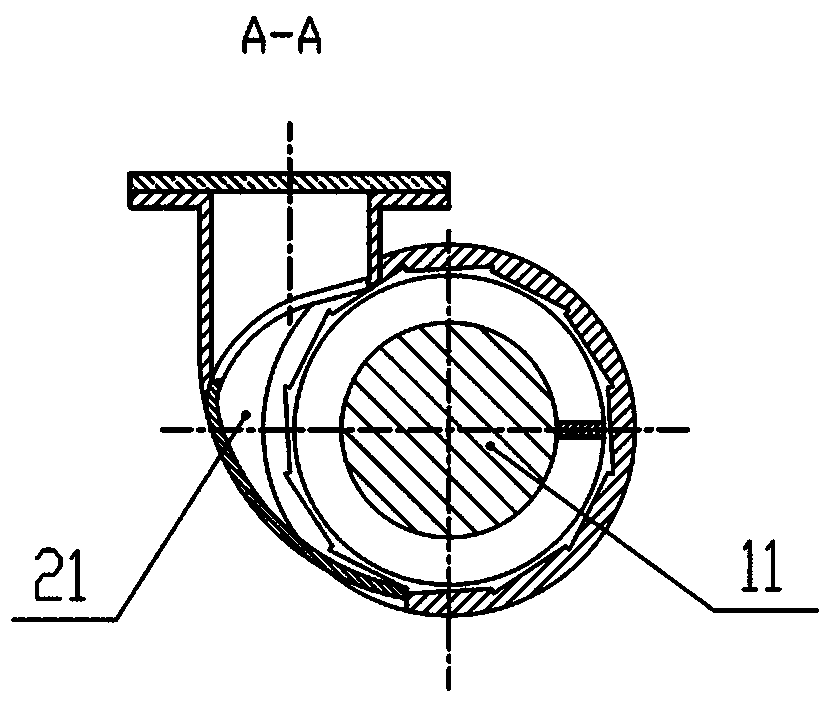

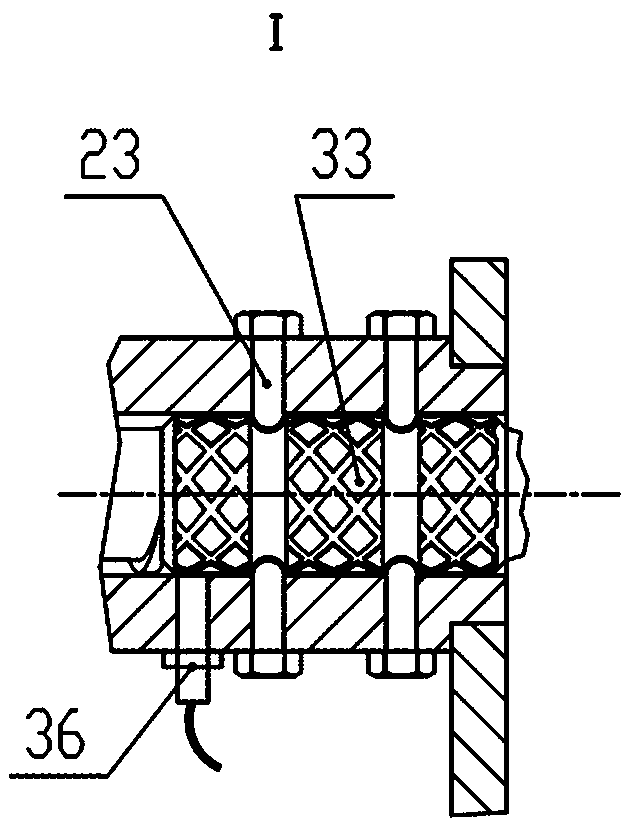

Low molecular liquid rubber preparation device

The invention discloses a low molecular liquid rubber preparation device. The low molecular liquid rubber preparation device comprises a solid-state rubber crushing section, a rubber heating softeningsection, a rubber high-temperature degrading section and a liquid-state rubber cooling section; the solid-state rubber crushing section can crush rubber as small particles; a heating cavity is formedin the side surface of a spiral cylinder of the rubber heating softening section; the rubber is heated and softened in the heating cavity under the effect of an extrusion screw rod; a small-outer-diameter extrusion section is arranged at an outlet end of the rubber heating softening section, so that softened rubber ultralong molecular chains are ruptured to become viscous pasty rubber; the rubberhigh-temperature degrading section comprises a degrading screw rod; a variable shaft diameter extrusion section is arranged at an inlet end of the degrading screw rod; a degrading shaft section is arranged at the middle part of the degrading screw rod; the viscous pasty rubber is extruded on the degrading shaft section to heat to the degrading temperature and to degrade as low molecular liquid rubber; and the liquid-state rubber cooling section is provided with a nitrogen protecting system. All process steps for producing the low molecular liquid rubber are realized by using the extrusion screw rod; and the low molecular liquid rubber preparation device is suitable for continuous industrial production.

Owner:HARBIN BOSHI AUTOMATION

Method for preparing isotactic polyacrylonitrile and application thereof

The invention provides a method for preparing isotactic polyacrylonitrile, which comprises the following steps: (1) proportionally and evenly mixing acrylonitrile and urea; (2) freezing the mixture obtained in the step (1) under low-temperature condition to form a urea-acrylonitrile compound; (3) dispersing the urea-acrylonitrile compound obtained in the step (2) in liquid nitrogen, and carrying out gamma-ray irradiation; and (4) carrying out polymerization reaction on the irradiated substance obtained in the step (3) in a low-temperature environment. The isotactic triad (mm) content in the isotactic polyacrylonitrile prepared by the method is greater than or equal to 98%; and the polymerization yield and the molecular weight of polyacrylonitrile can be regulated by controlling the gamma-ray irradiation time and polymerization reaction time.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of resin for photoresist

InactiveCN109942741AAdjust molecular weightImprove applicabilityPhotosensitive materials for photomechanical apparatusRefluxOrganic solvent

The invention discloses a preparation method of resin for photoresist. The preparation method is characterized in that the resin is prepared by the steps of dissolving one or more monomers with acid active groups and one or more monomers with polar groups into a solvent containing a certain amount of moisture, and carrying out ATRP reaction in the presence of an initiator. The preparation method comprises the following steps: (1) heating the solvent containing a certain amount of moisture to 50-80 DEG C, so as to obtain a preheated organic solvent containing moisture; (2) dissolving the monomers and an initiator into the organic solvent containing the same moisture with the organic solvent in the step (1), so as to obtain a raw material solution; (3) dropwise adding the raw material solution into the preheated organic solvent containing moisture, and carrying out content-temperature reflux reaction at 50-80 DEG C for 10-30 hours; and (4) cooling to the room temperature, precipitating resin with a non-polar solvent, filtering, and drying, so as to obtain the resin for the photoresist, wherein the moisture content in the solvent is 1ppm-1500ppm. According to the preparation method, the molecular weight of the polymer resin is regulated through the regulation of the water content, so that other impurities are not introduced, and the control of the molecular weight is relatively precise.

Owner:NINGBO NATA OPTO ELECTRONICS MATERIAL CO LTD

Preparation method of styrene-acrylic resin with high solid content

The present invention relates to a preparation method of styrene-acrylic resin with high solid content, which belongs to the field of functional polymer. The preparation method comprises the following steps: mixing comonomer, functional monomer and an initiator evenly and drop-wise adding the mixture into a solution at the temperature of 130 DEG C to 140 DEG C, to obtain styrene-acrylic resin after conventional free radical polymerization reaction for six to eight hours. The method provided by the invention is able to introduce a novel compound containing polymerizable double bond and chain transfer hydrosulphonyl into a reaction system, generating a co-polymer with branched structure in situ. Under the condition of the same molecular weight, the viscosity of the branched co-polymer is lower than that of the linear co-polymer; the mass ratio of the novel compound containing polymerizable double bond and chain transfer hydrosulphonyl to alpha methyl styrene linear dipolymer is adjusted; the styrene-acrylic resin with relatively low viscosity and high solid content can be obtained by adjusting the branching degree and molecular weight of the reaction copolymer.

Owner:CHANGZHOU UNIV +1

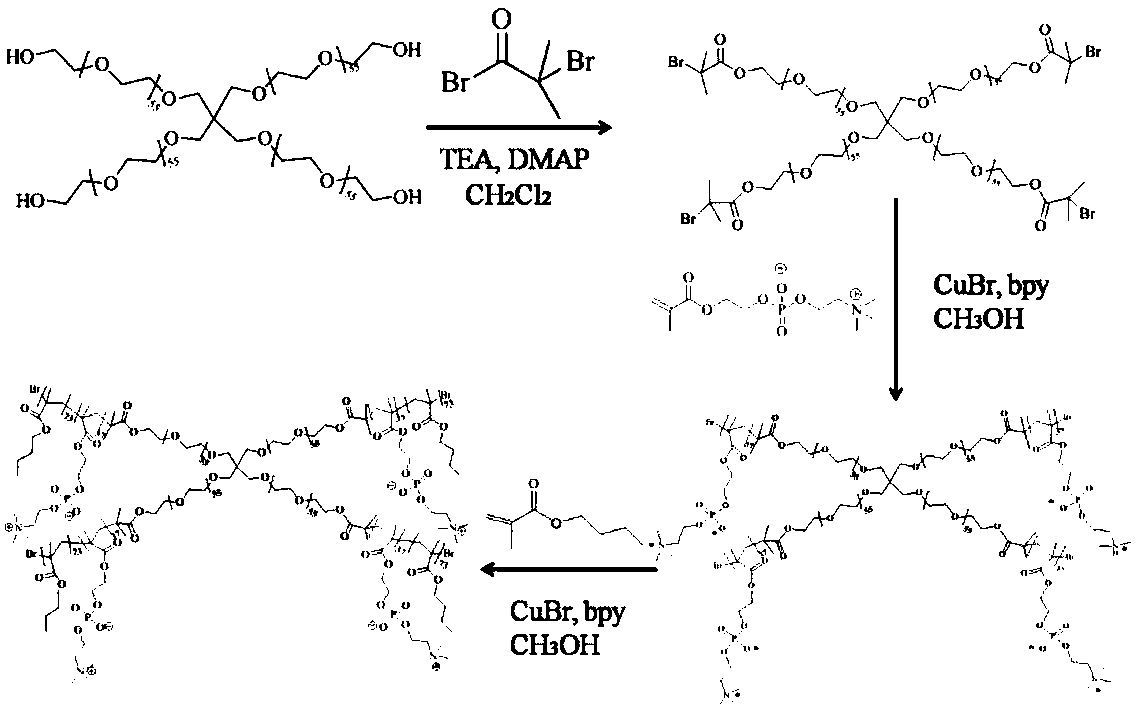

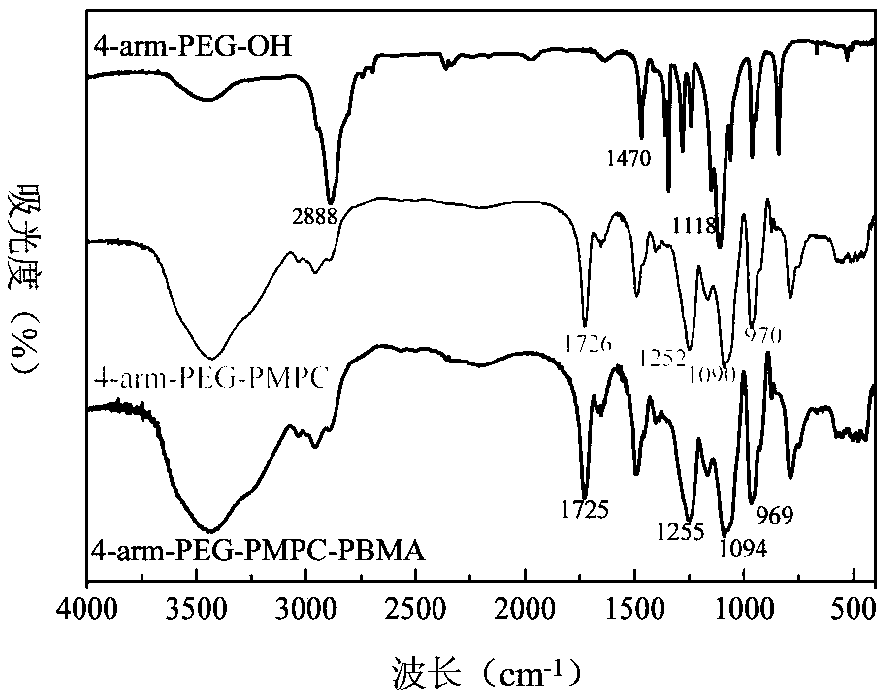

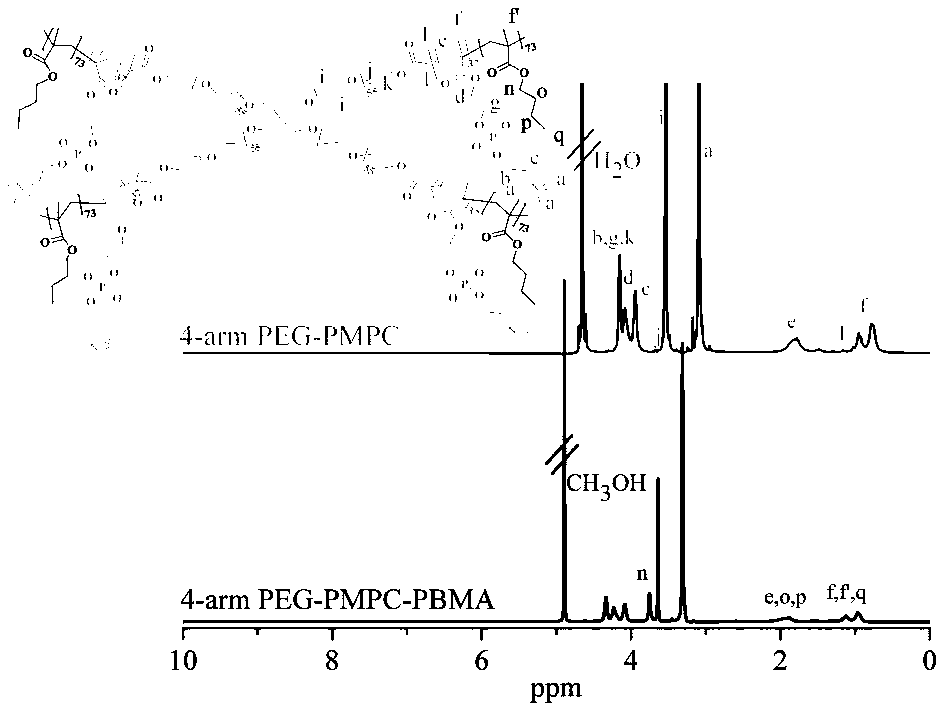

Star polymer drug carrier and preparation method thereof

InactiveCN109666108AStructure Precise ControlAdjust molecular weightPharmaceutical non-active ingredientsEmulsion deliveryPoly(2-methacryloyloxyethyl-phosphorylcholine)Atom-transfer radical-polymerization

The present invention provides a star polymer drug carrier and a preparation method thereof, wherein the carrier is an amphiphilic star polymer material. The preparation method comprises: synthesizinga star multi-arm polyethylene glycol-poly-2-methacryloyloxyethyl phosphorylcholine (PEG-PMPC) compound by using star multi-arm polyethylene glycol as a raw materials through an esterification reaction and atom transfer radical polymerization (ATRP), and introducing a hydrophobic segment polyacrylate compound to form a drug carrier loading a hydrophobic drug, wherein the star multi-arm polyethylene glycol-poly-2-methacryloyloxyethyl phosphorylcholine (PEG-PMPC) compound has good hydrophilicity. According to the present invention, the polymer can be used as the drug carrier, can form drug-loading micelles in water through self-assembly, and is used in tumor treatment.

Owner:TIANJIN UNIV

HDPE pipe and preparation method thereof

InactiveCN111675848ADoes not affect other mechanical strength indicatorsGood flexibilityPolymer sciencePtru catalyst

The invention provides an HDPE pipe and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing and reacting a vanadium-modified SBA-15 molecular sieve withtitanium tetrachloride and butyl titanate to prepare a catalyst; grafting graphene with polyglutamic acid to obtain a filler; then, under the action of a catalyst, carrying out a polymerization reaction on vinyl fluoride, 1-octene, hydrogen, ethylene and the like used as raw materials to obtain a resin matrix; and finally, carrying out melt blending on the resin matrix and filler to obtain the HDPE resin. On the premise that other mechanical strength indexes are not affected, the flexibility of the HDPE resin can be greatly improved, market vacancy is made up, and the HDPE resin has good market prospects.

Owner:长沙三思新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com