Crosslinking sensitizer for fluorine-containing polymer

A cross-linking sensitizer and polymer technology, which is applied in the field of cross-linking sensitizers, can solve the problems of poor product stability, low smoke generation, and high volatility, and achieve low volatility, small smoke generation, and non-toxic Self-aggregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

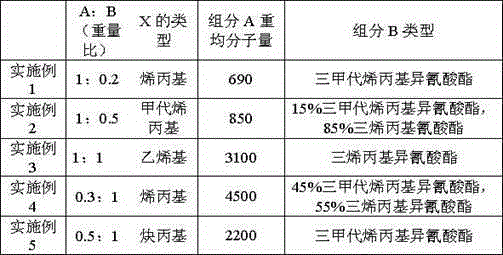

[0018] Examples 1 to 5: A cross-linking sensitizer for fluoropolymers, the cross-linking sensitizer is formed by mixing component A and component B, said component A: component B The mass ratio is 1:0.1~10, and component A conforms to the following general structural formula (1):

[0019] (1)

[0020] Where X is vinyl, allyl, methallyl or propargyl, n=2-15, and the weight average molecular weight of X is 600-5000;

[0021] The component B is at least one of triallyl isocyanate, trimethylallyl isocyanate, triallyl cyanate, and trimethylallyl cyanate.

[0022] The weight average molecular weight of the above component A is 1000-3000.

[0023] Specifically as described in Table 1:

[0024] Table 1

[0025]

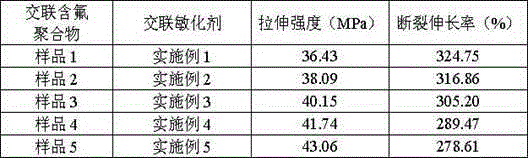

[0026] A crosslinked fluoropolymer using the above crosslinked sensitizer is obtained through the following steps:

[0027] The first step of ingredients: mix the following substances by mass in a high-speed mixer for 10 minutes;

[0028] 100 parts of ethylene-tetrafluoroethylene copolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com