Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

817 results about "Cyanate compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compounds that contain the group −O−C≡N, are known as a cyanates, or cyanate esters. Aryl cyanates such are phenyl cyanate, C6H5OCN, can be formed by a reaction of phenol with cyanogen chloride, ClCN, in the presence of a base.

Precursor source mixtures

A precursor source mixture useful for CVD or ALD of a film comprising: at least one precursor composed of an element selected from the group consisting of Li, Na, K, Rb, Cs, Fr, Be, Mg, Ti, Zr, Hf, Sc, Y, La, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Os, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Hg, B, Al, Ga, In, Tl, Si, Ge, Sn, Pb, As, P, Sb and Bi, to which is bound at least one ligand selected from the group consisting of hydride, alkyl, alkenyl, cycloalkenyl, aryl, alkyne, carbonyl, amido, imido, hydrazido, phosphido, nitrosyl, nitryl, nitrate, nitrile, halide, azide, alkoxy, siloxy, silyl, and halogenated, sulfonated or silyated derivatives thereof, which is dissolved, emulsified or suspended in an inert liquid selected from the group consisting of aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, ethers, aldehydes, ketones, acids, phenols, esters, amines, alkylnitrile, halogenated hydrocarbons, silyated hydrocarbons, thioethers, amines, cyanates, isocyanates, thiocyanates, silicone oils, nitroalkyl, alkylnitrate, and mixtures thereof. The precursor source mixture may be a solution, emulsion or suspension and may consist of a mixture of solid, liquid and gas phases which are distributed throughout the mixture.

Owner:GLOBALFOUNDRIES INC

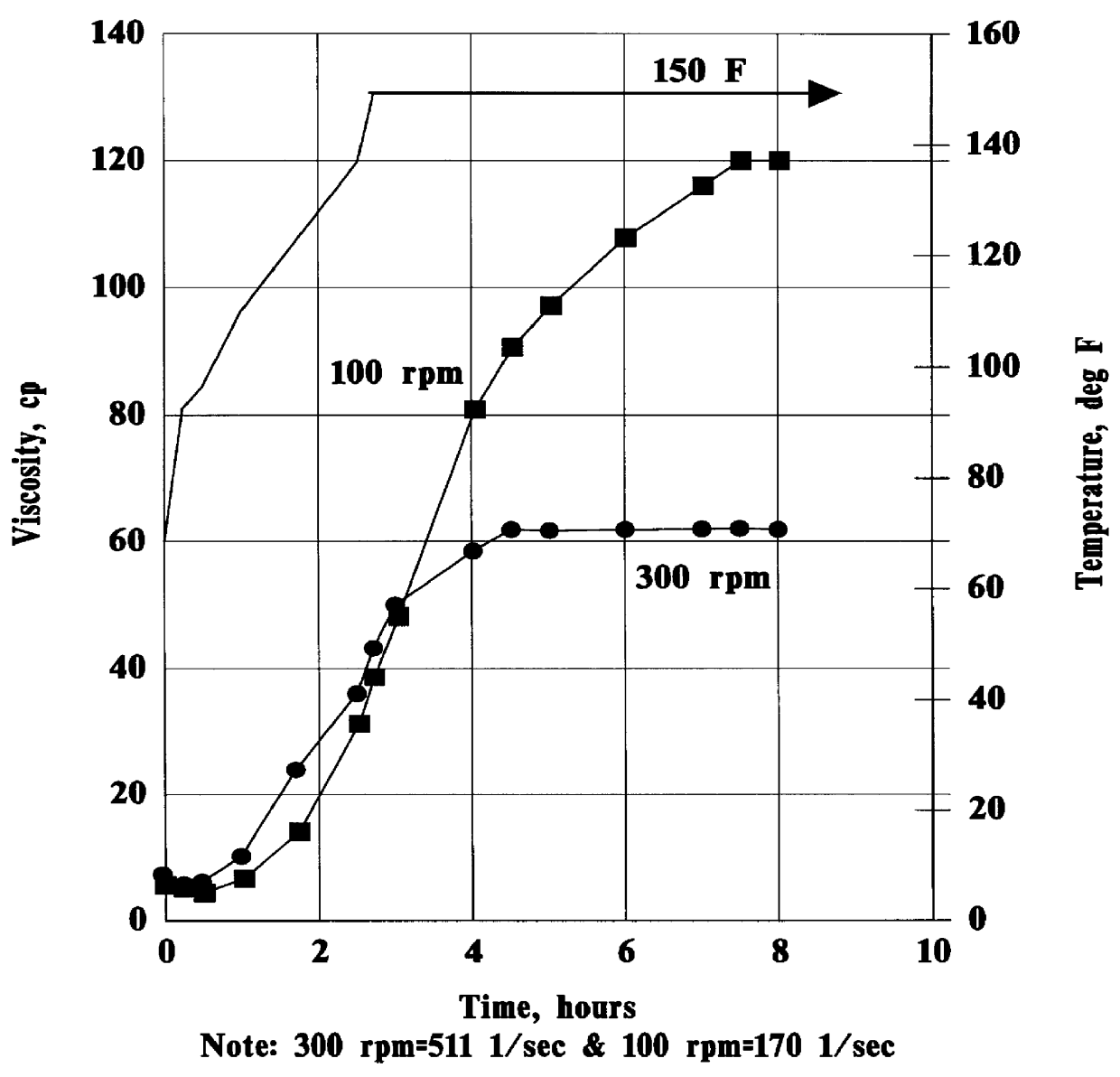

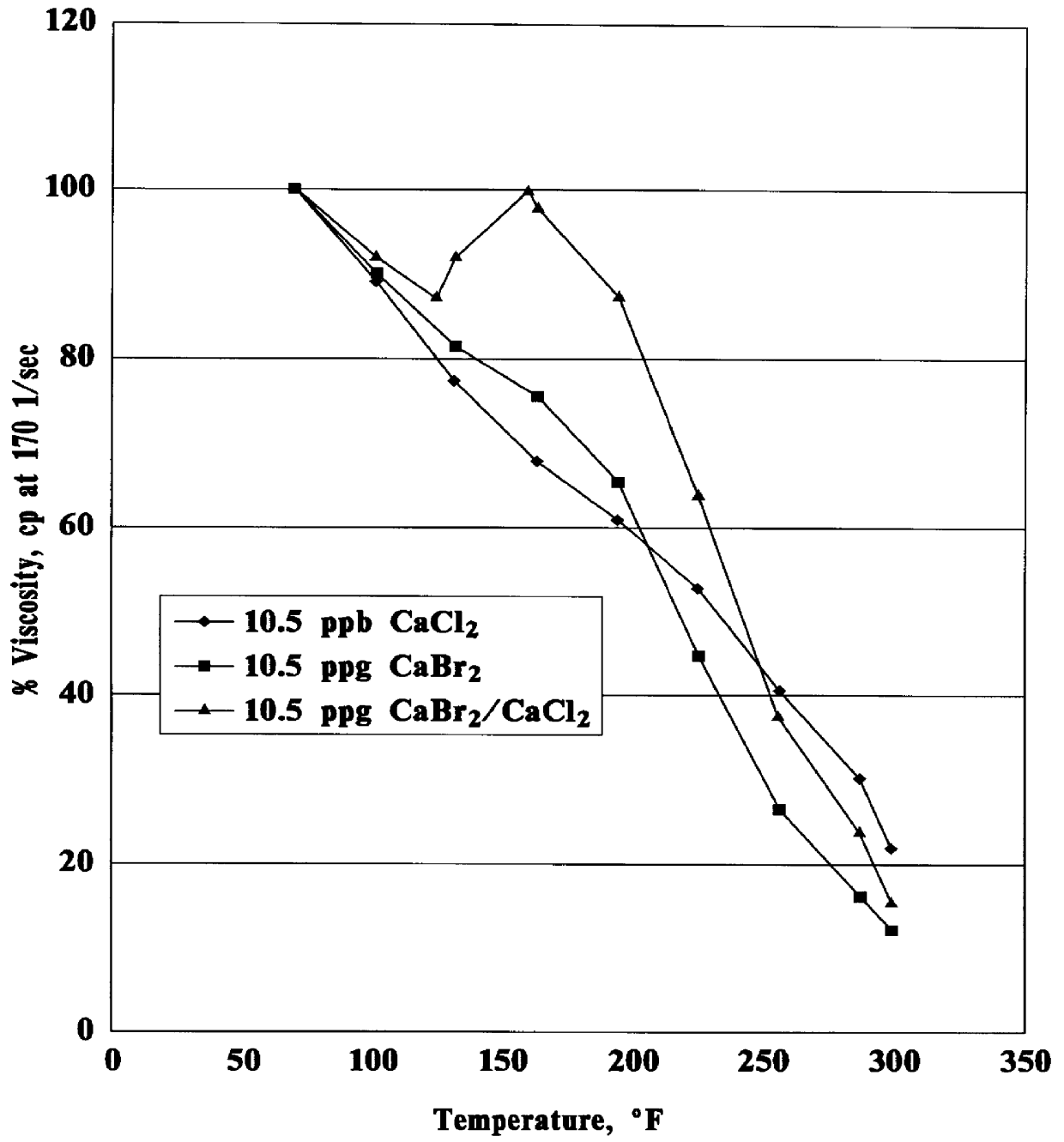

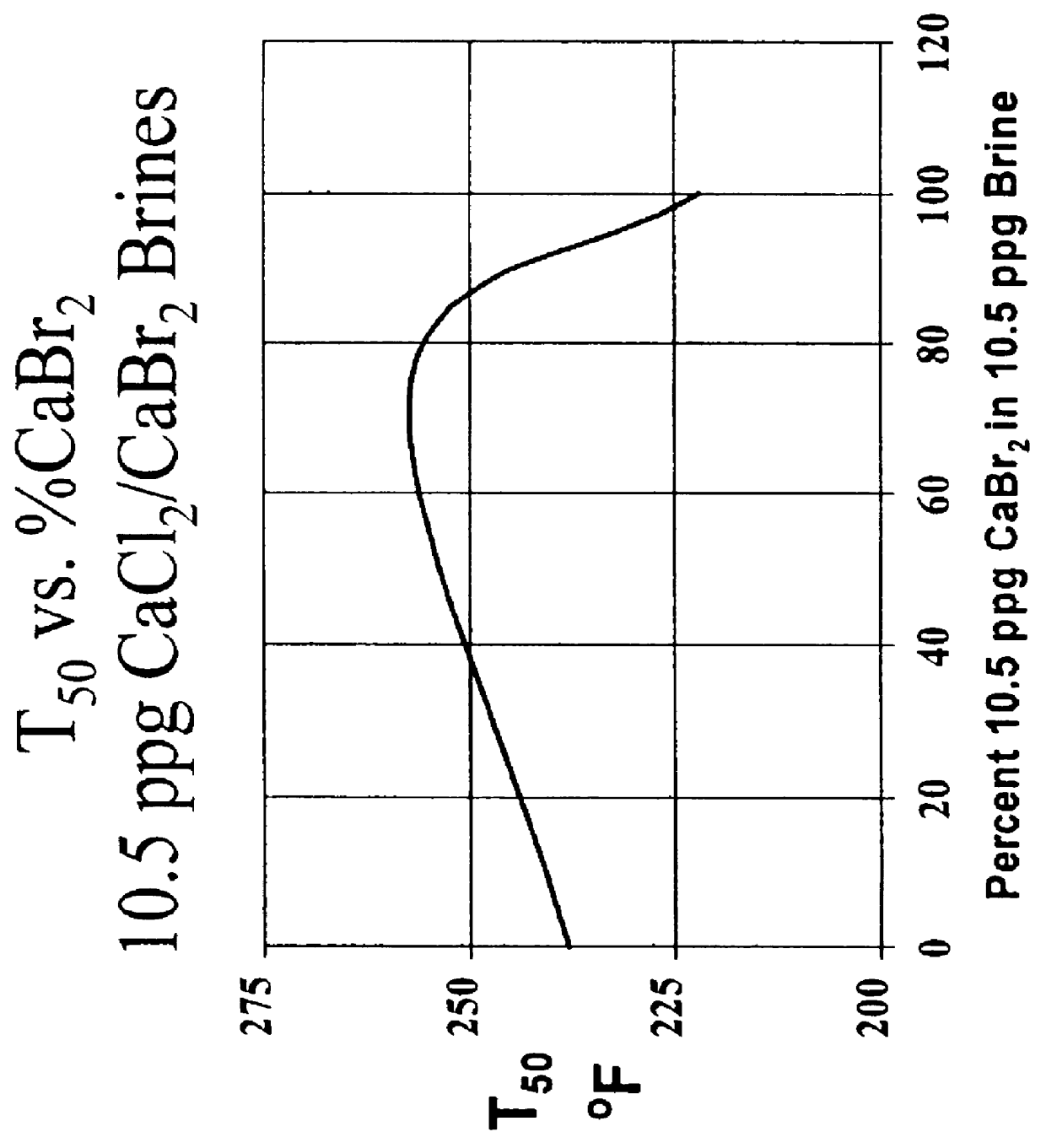

High density, viscosified, aqueous compositions having superior stability under stress conditions

Owner:BJ SERVICES CO

Reverse osmosis composite membranes for boron removal

InactiveUS20110049055A1Semi-permeable membranesGeneral water supply conservationSulfonyl halidePolyamide

Improved methods for reducing boron concentration in seawater or brackish water, while simultaneously maintaining or improving the salt rejection of membrane and flow performance of polyamide reverse osmosis (RO) membranes include contacting the water with a composite membrane comprising moieties derived from an aromatic sulfonyl halide, a heteroaromatic sulfonyl halide, a sulfinyl halide; a sulfenyl halide; a sulfuryl halide; a phosphoryl halide; a phosphonyl halide; a phosphinyl halide; a thiophosphoryl halide; a thiophosphonyl halide, an isocyanate, a urea, a cyanate, an aromatic carbonyl halide, an epoxide or a mixture thereof.

Owner:GENERAL ELECTRIC CO

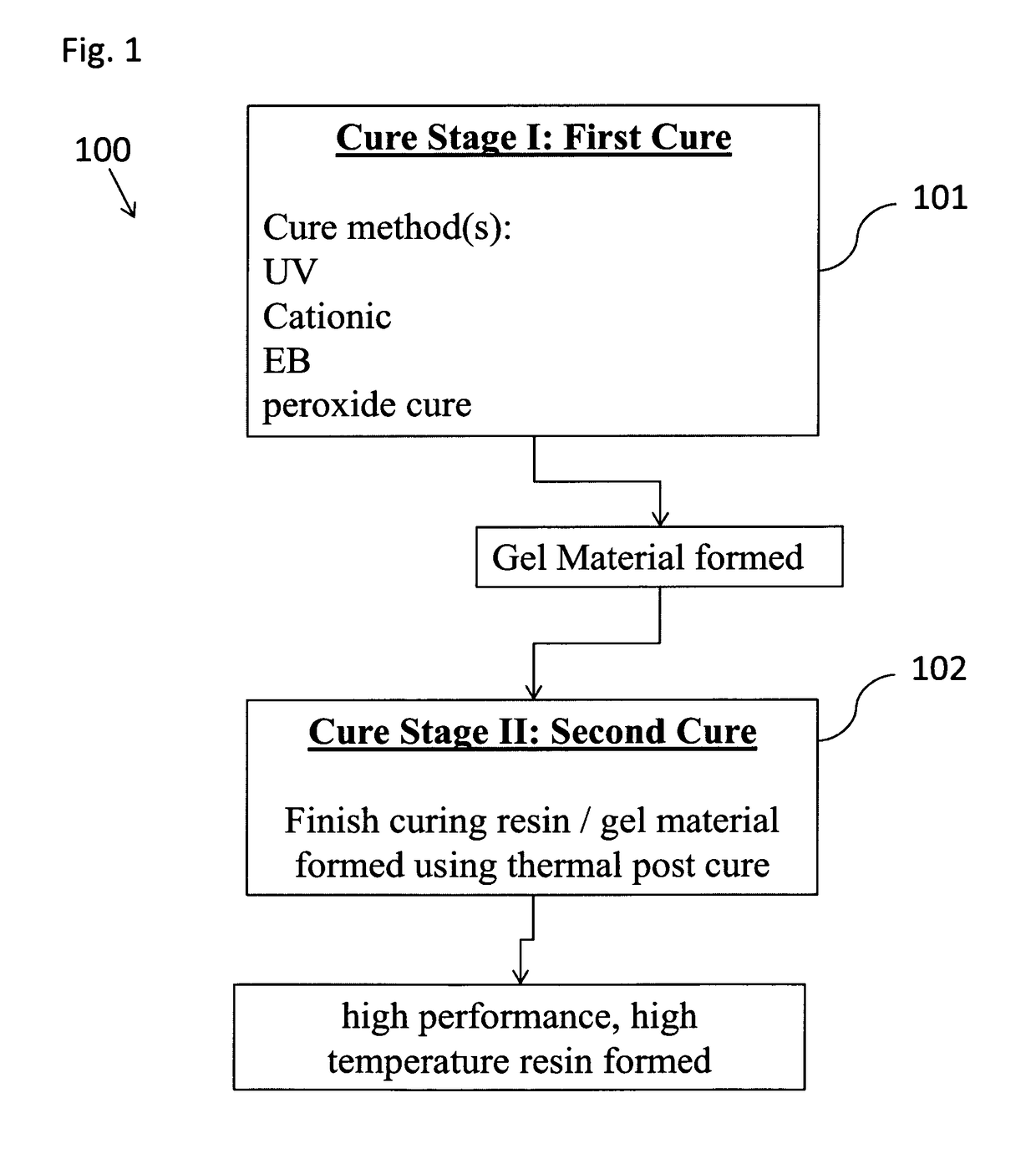

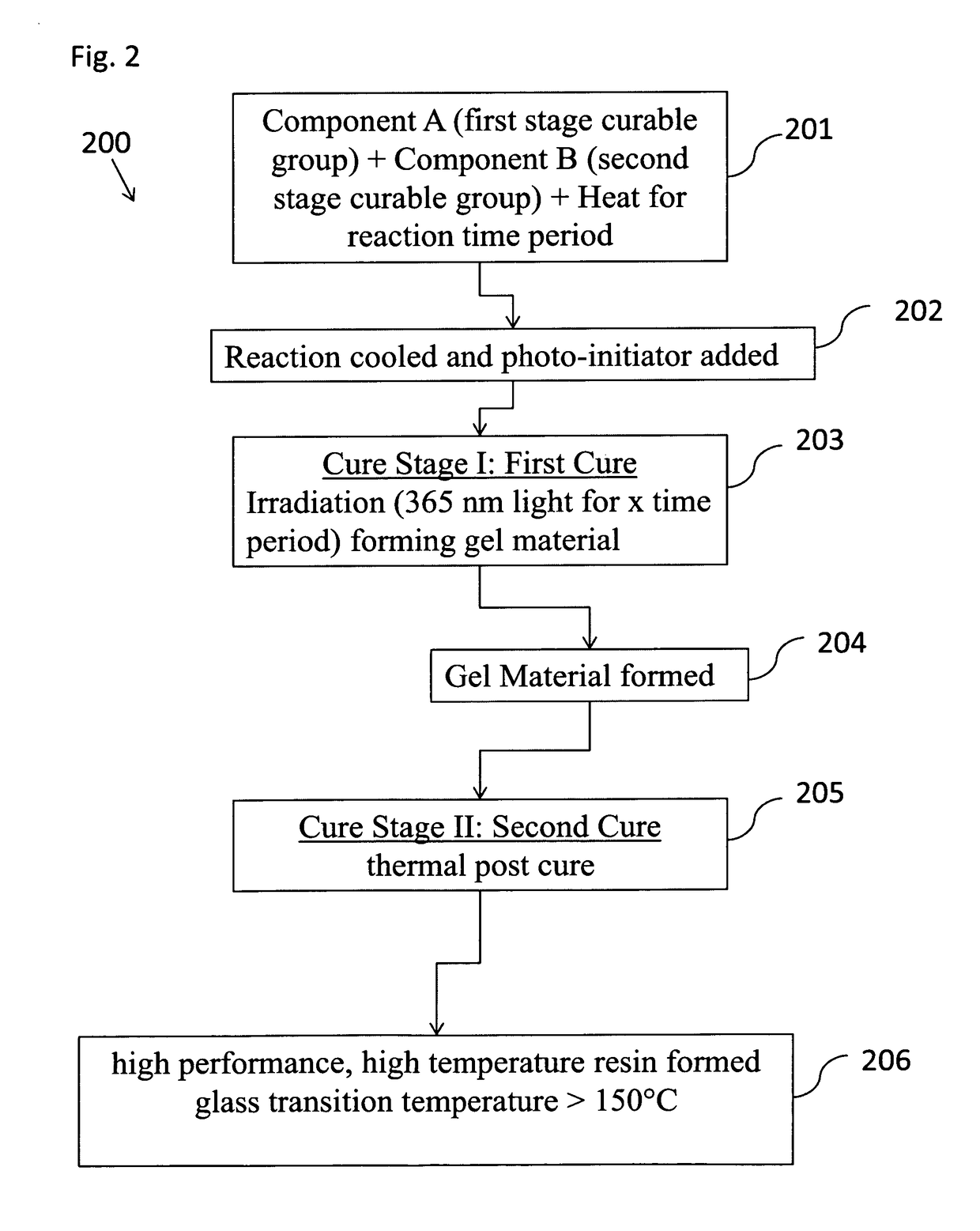

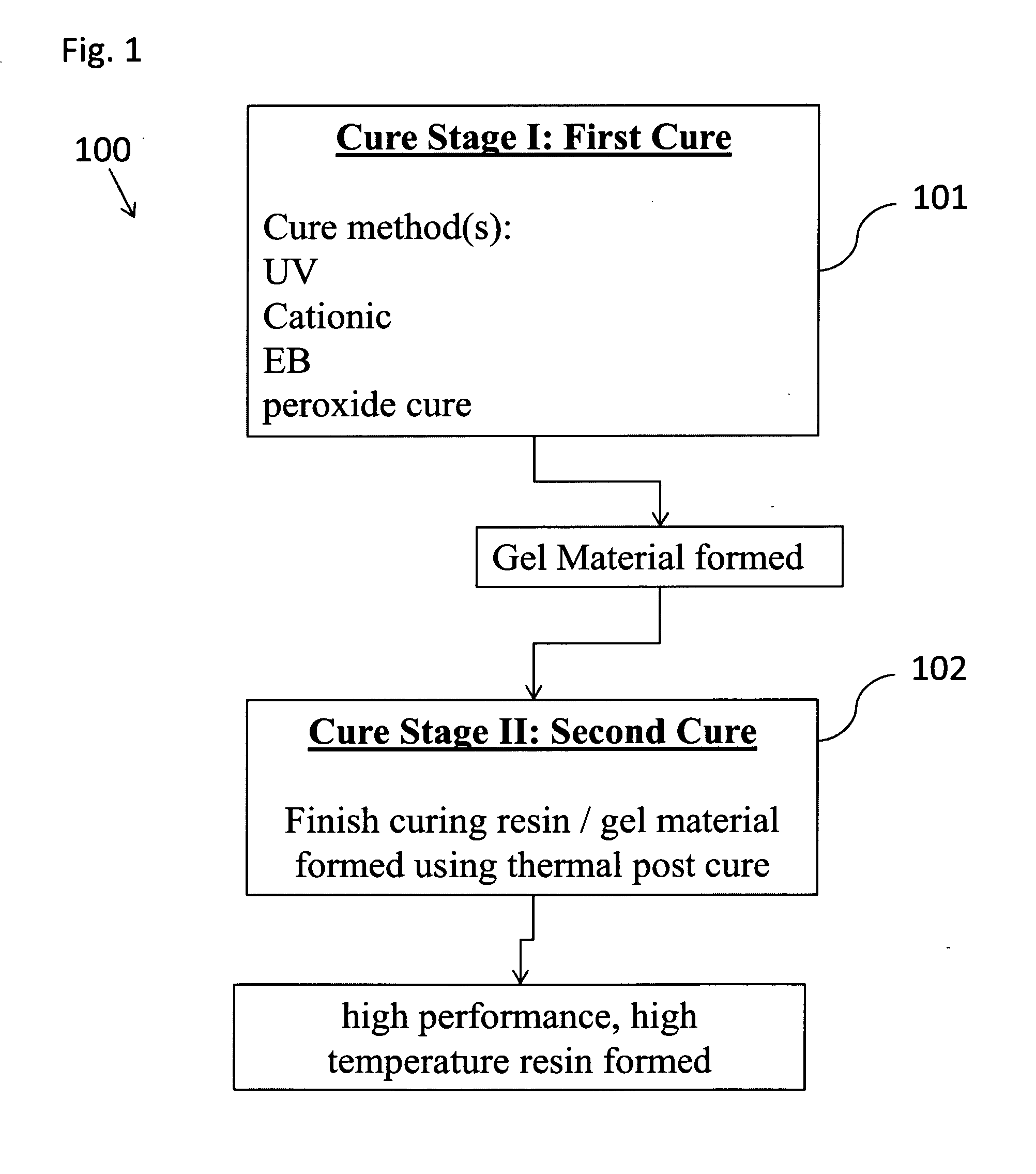

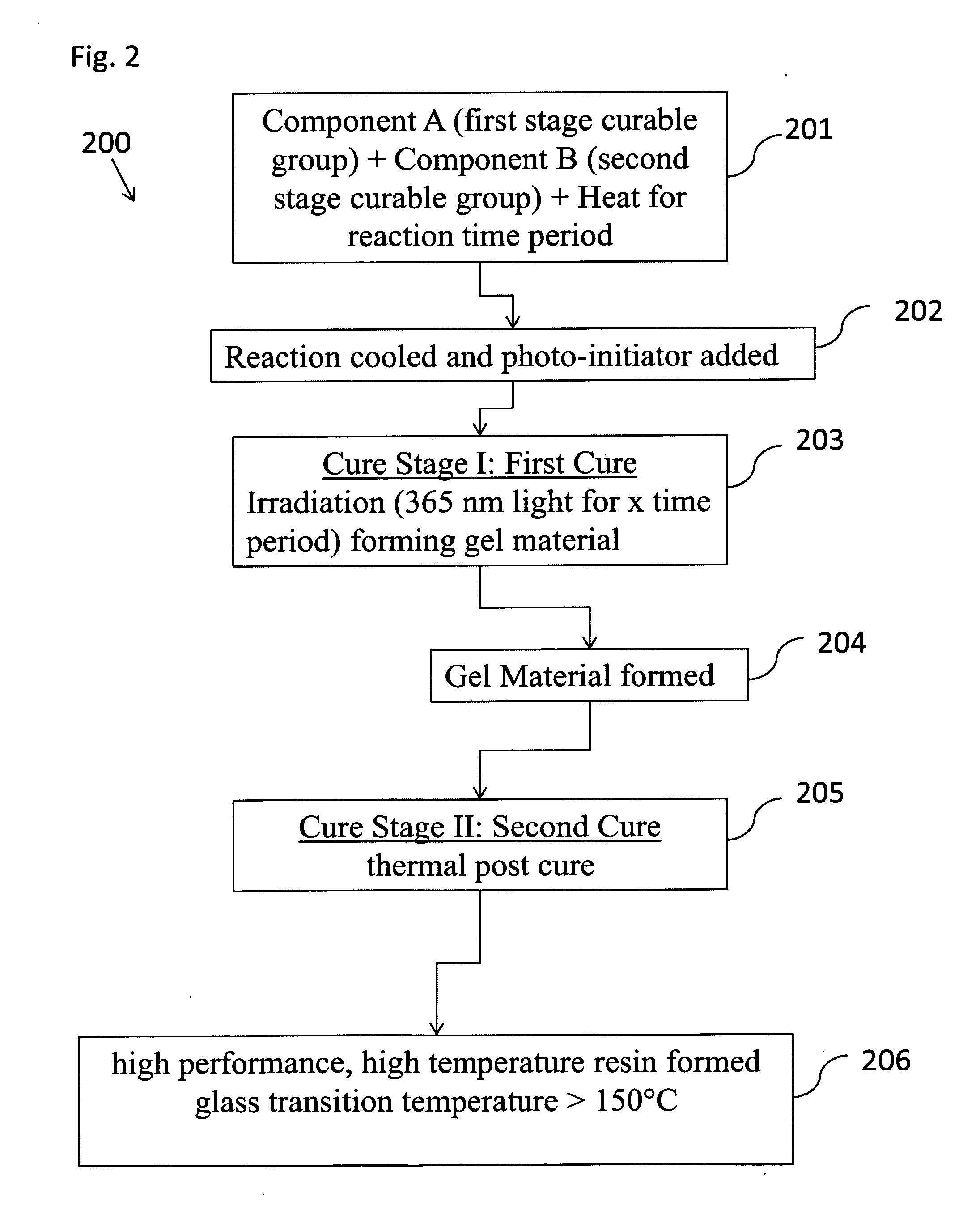

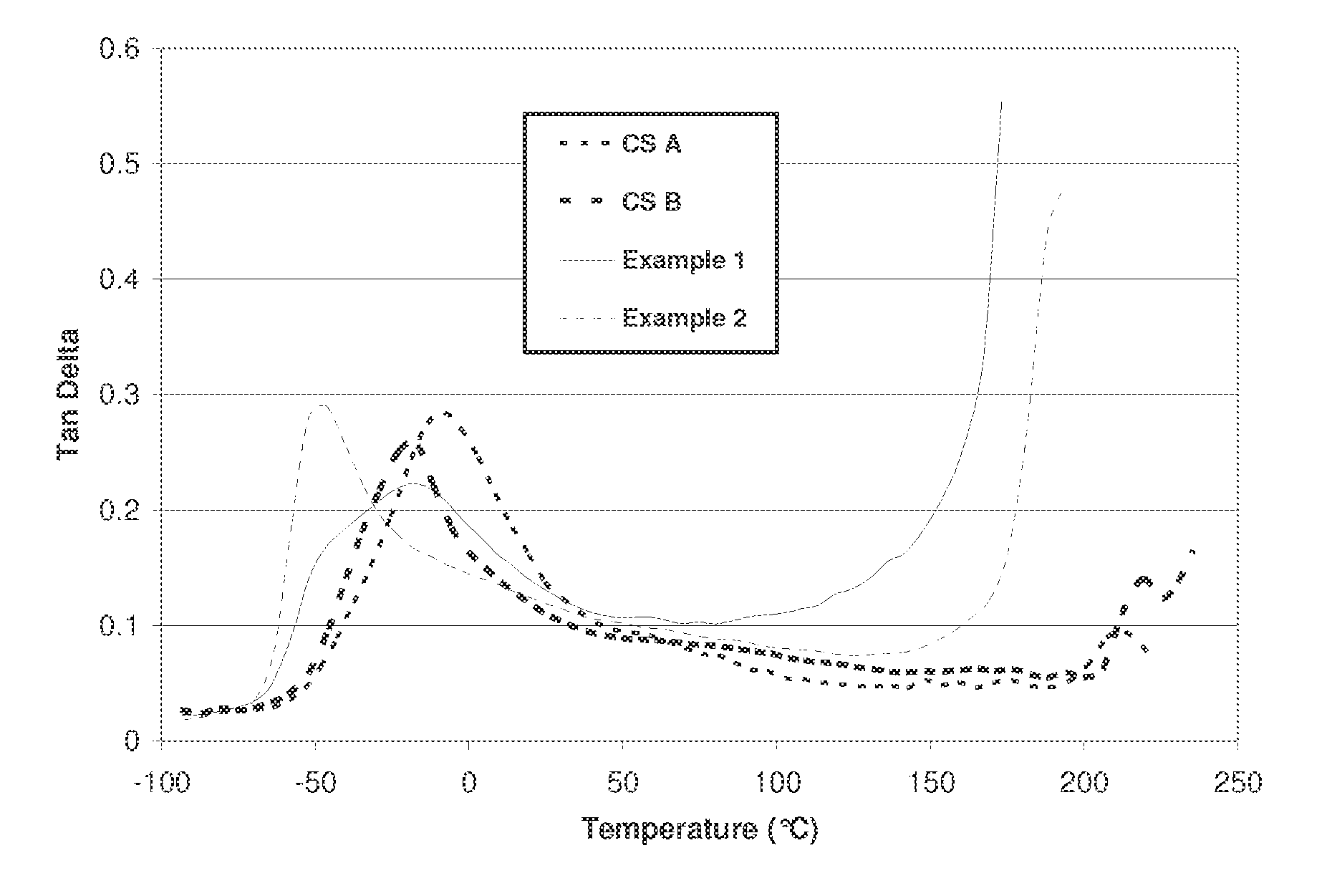

High temperature three dimensional printing compositions

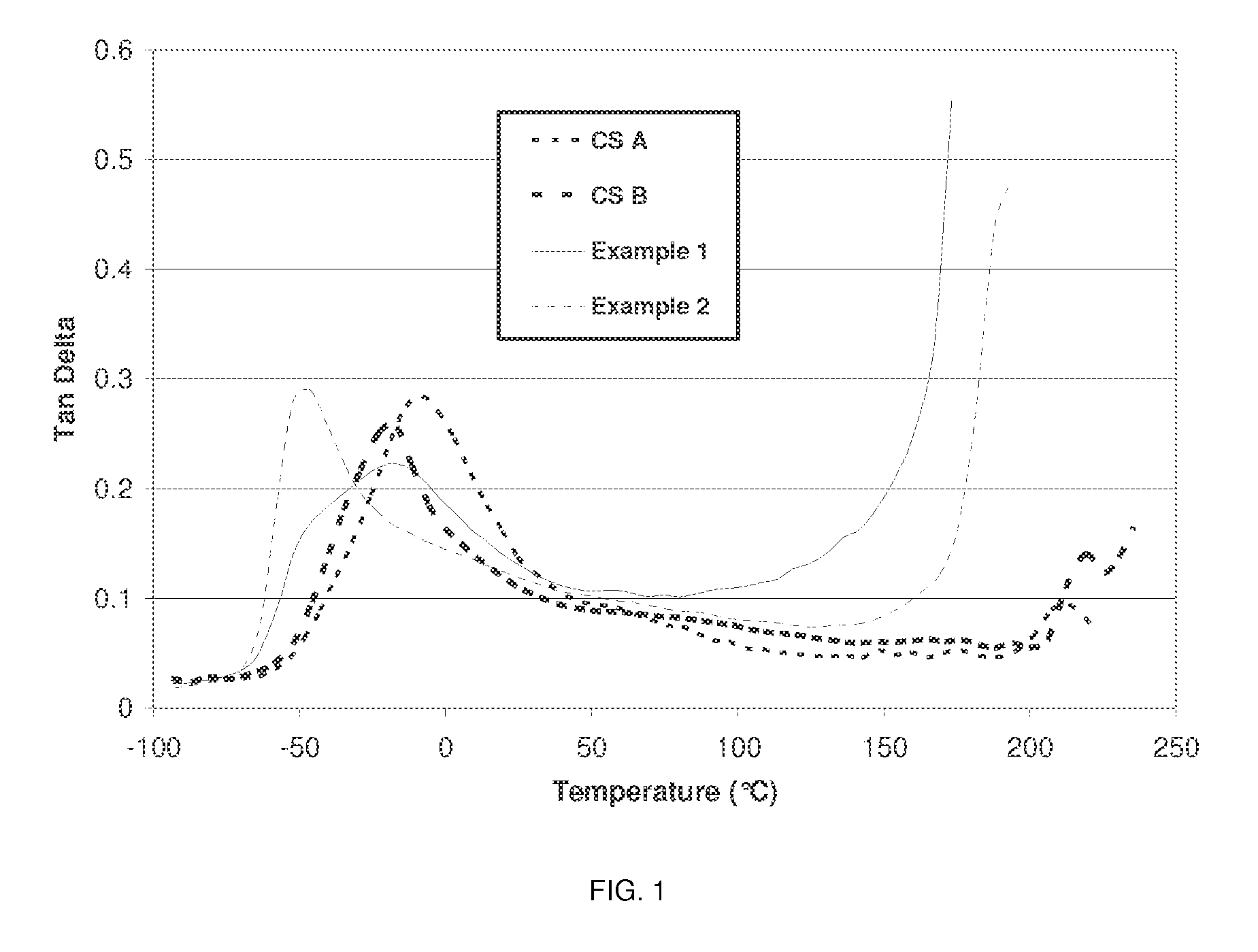

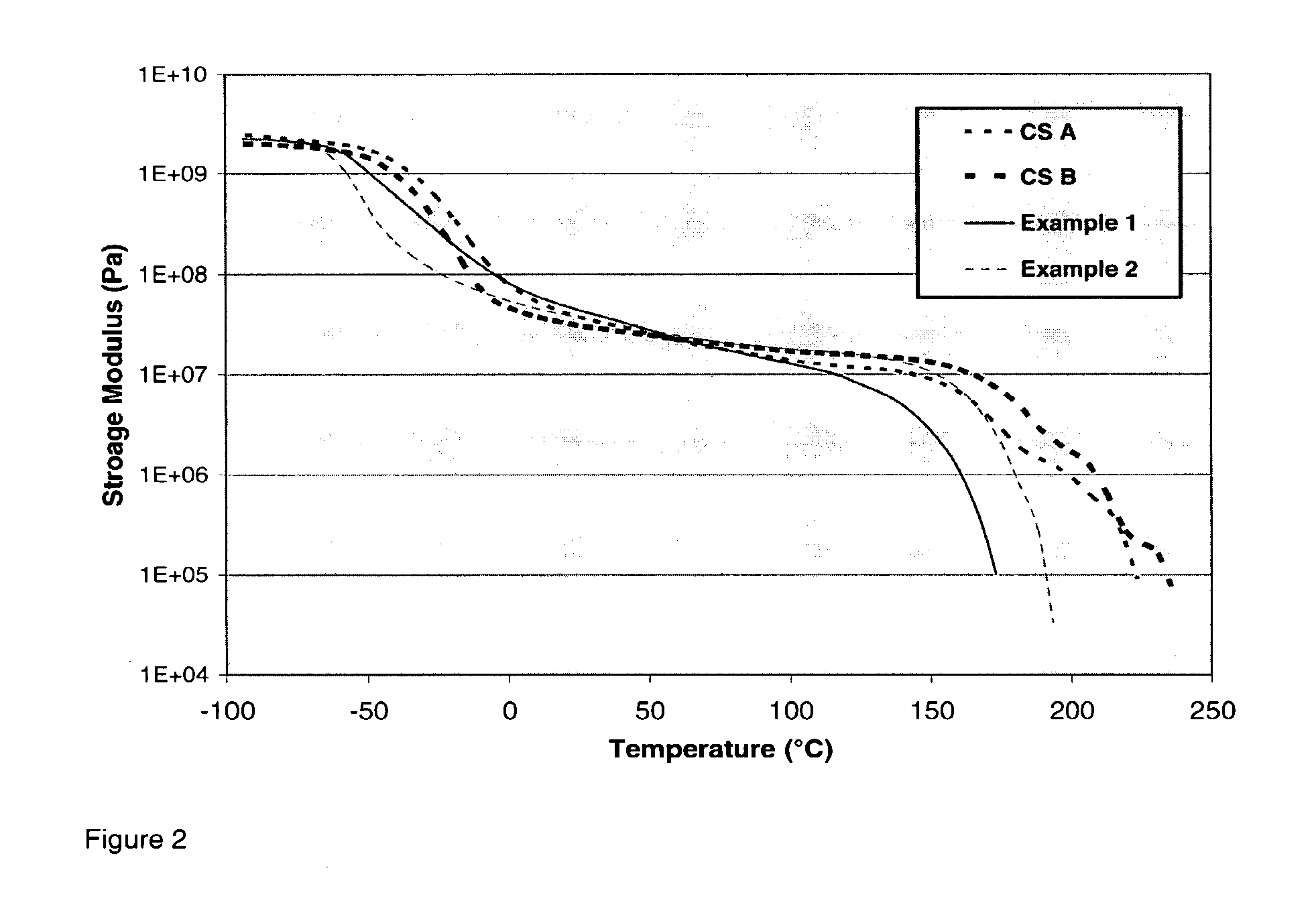

ActiveUS9708440B2Improve performanceHigh-temperature resinAdditive manufacturing apparatusMetal catalystRoom temperature

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150 C.

Owner:NOVOSET

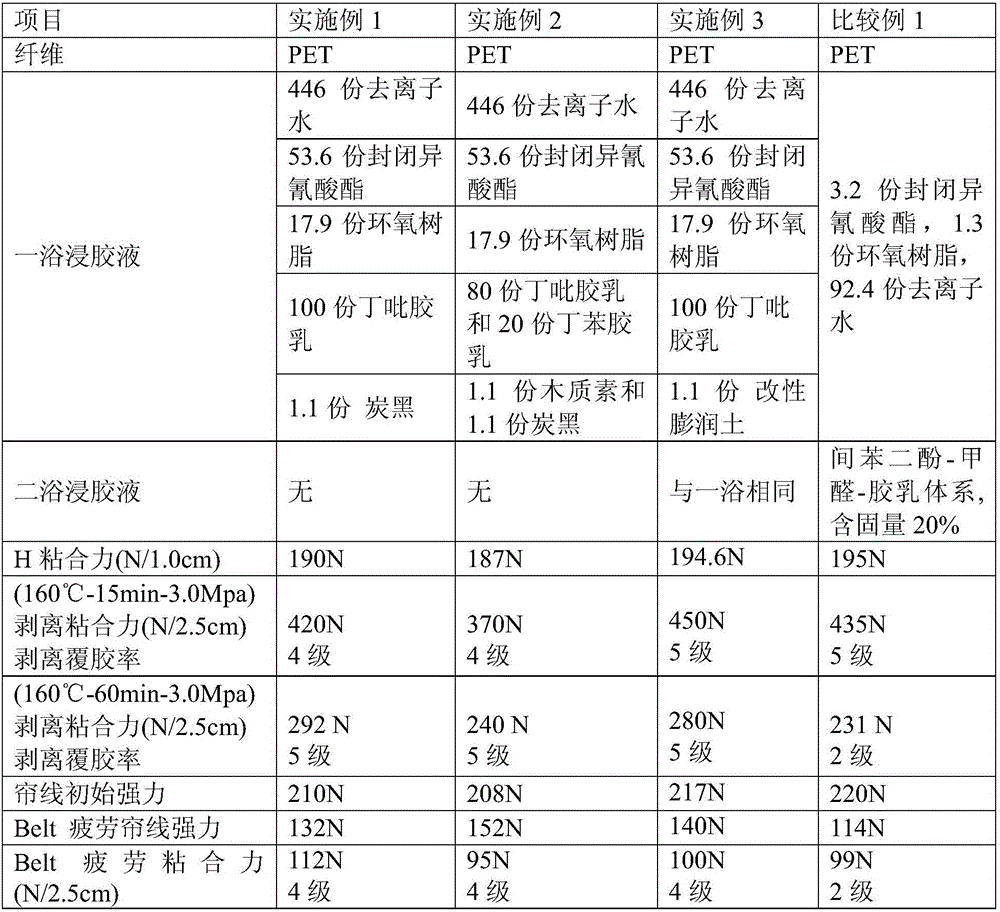

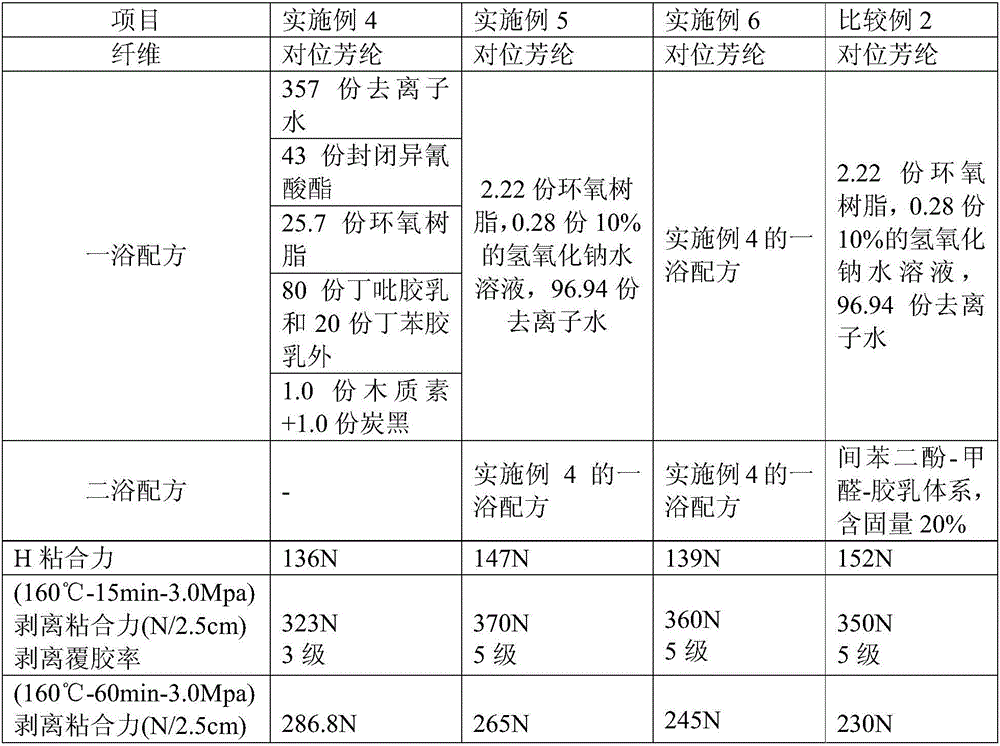

Environment-friendly fiber framework material dip solution and dipping process

The invention relates to an environment-friendly fiber framework material dip solution and a dipping process. The dip solution comprises, by weight parts, 3.3-190 parts of blocked isocyanate compound by dry weight, 6.6-140 parts of epoxy compound by dry weight, 80-100 parts of rubber latex by dry weight, 0.5-20 parts of rubber modifier by dry weight, and the balance water. The content of the dip solution is 5-25%, and a one-bath or double-bath dipping process is adopted to perform coating on a fiber framework material. The dip solution does not contain harmful substances such as resorcinol and formaldehyde and does not cause pollution to the environment, the dipping process is simple in steps and easy to operate, an organic fiber after dipping treatment is low in rigidity and facilitates postprocessing, and the dip solution has a good effect of being bonded to rubber and has a better dipping effect than conventional RFL.

Owner:JIANGSU TAIJI IND NEW MATERIALS CO LTD

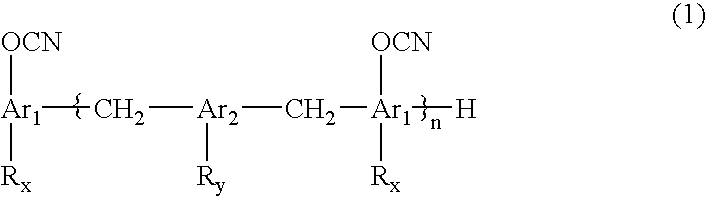

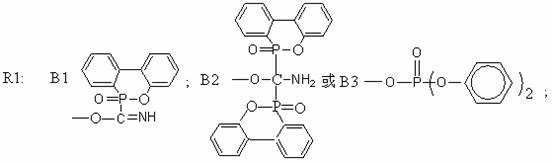

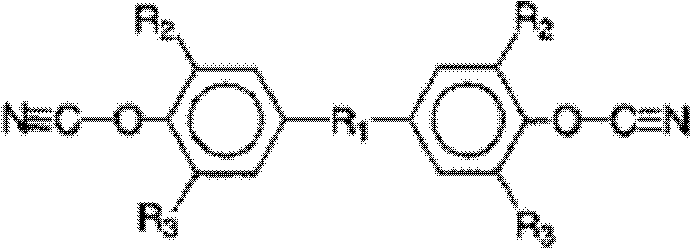

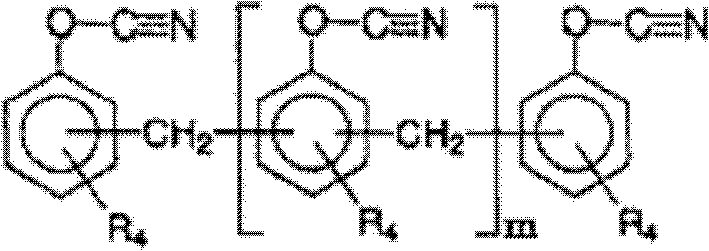

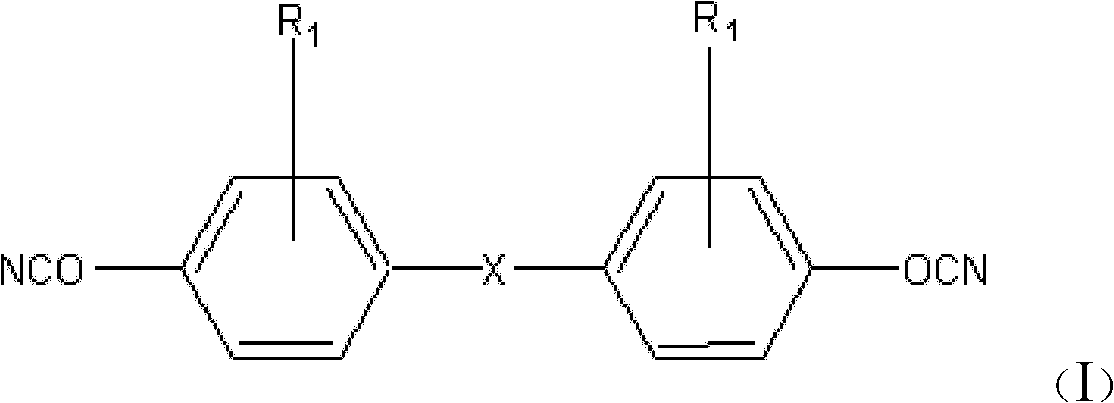

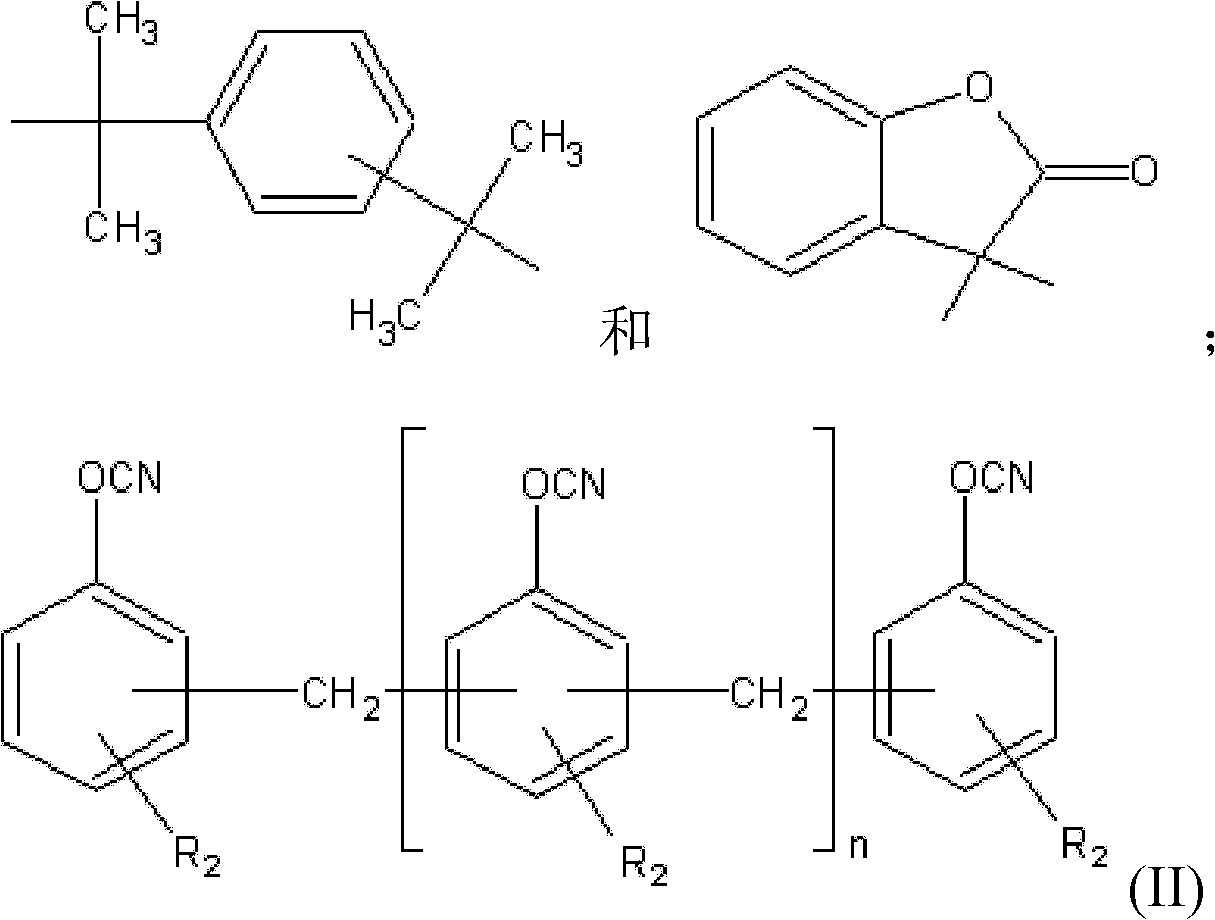

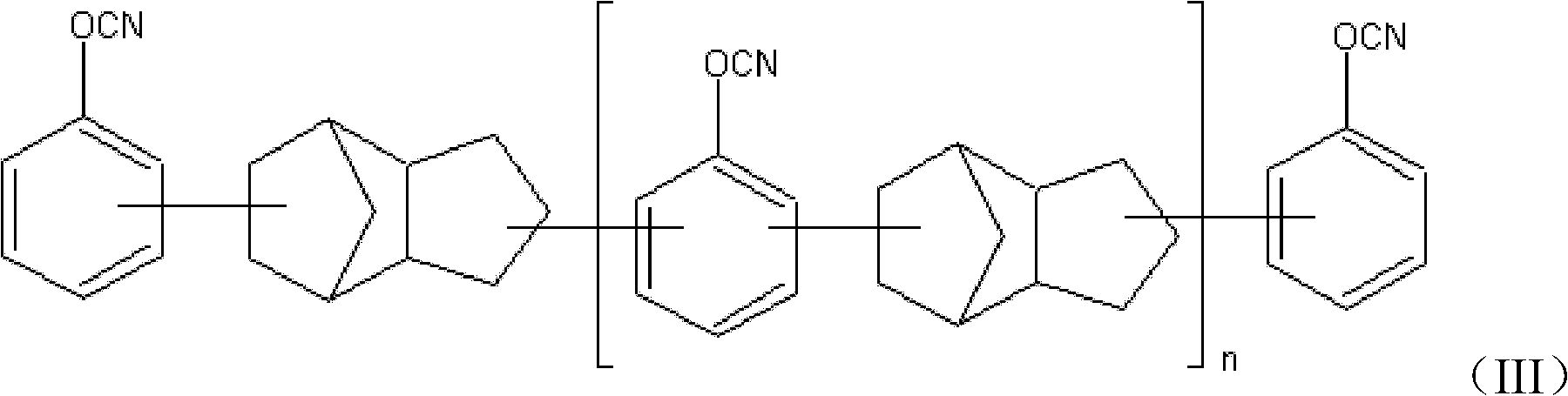

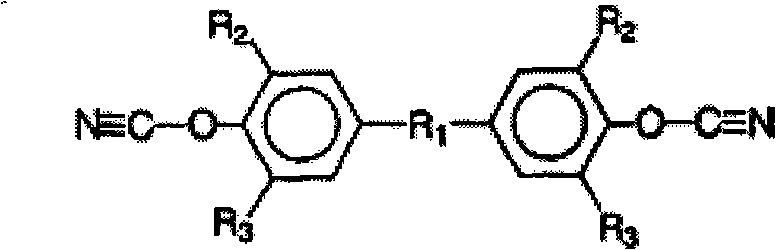

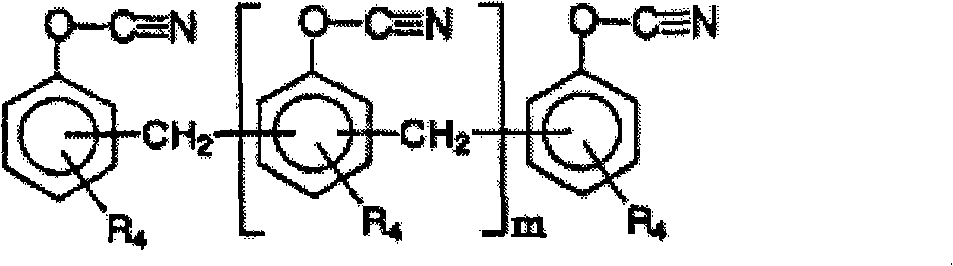

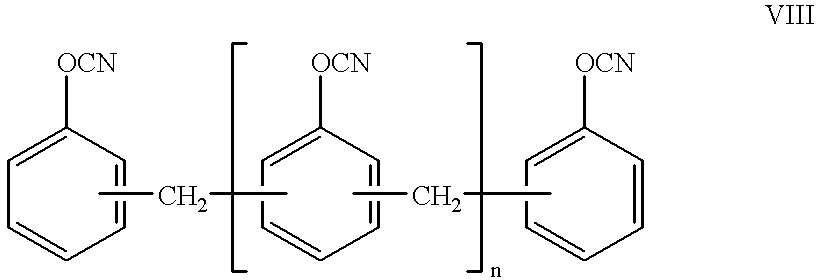

Novel cyanate ester compound, flame-retardant resin composition, and cured product thereof

ActiveUS20060084787A1Improve flame retardant performanceLow dielectric constantFireproof paintsIsocyanic acid derivatives preparationArylHydrogen

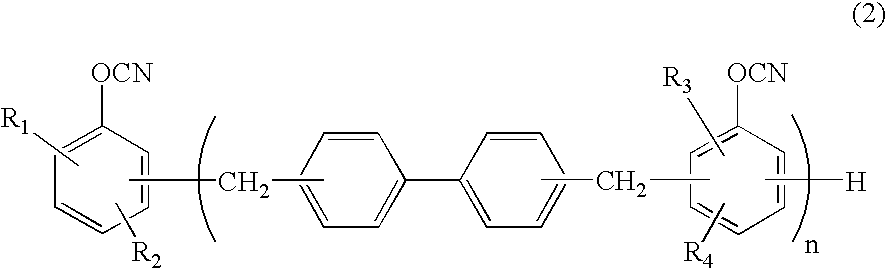

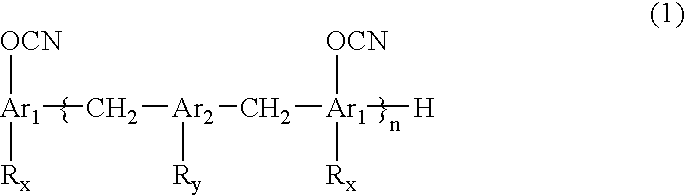

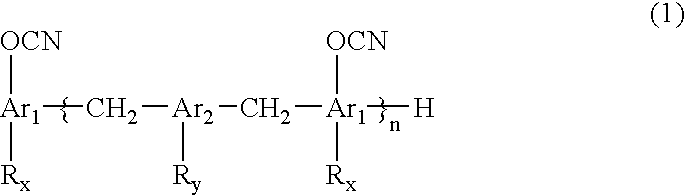

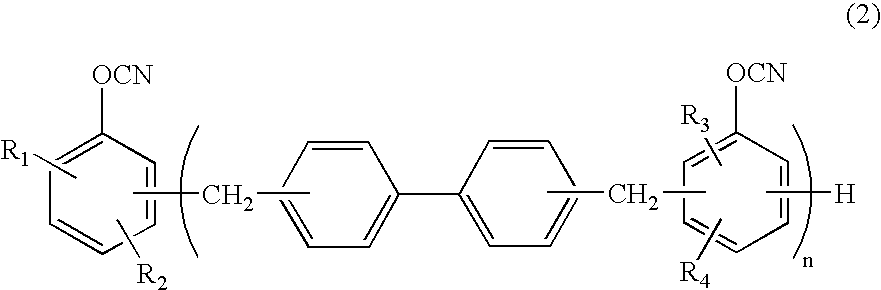

A cyanate ester compound represented by the formula (1), wherein Ar2 represents a phenylene group, a naphthylene group or a biphenylene group, Ar1 represents a naphthylene group or a biphenylene group when Ar2 is a phenylene group, or Ar1 represents a phenylene group, a naphthylene group or a biphenylene group when Ar2 is a naphthylene group or a biphenylene group, Rx represents all substituents of Ar1, each Rx is the same or different and represents hydrogen, an alkyl group or an aryl group, Ry represents all substituents of Ar2, each Ry is the same or different and represents hydrogen, an alkyl group or an aryl group, and n is an integer of 1 to 50.

Owner:MITSUBISHI GAS CHEM CO INC

Novel cyanate ester compound, flame-retardant resin composition, and cured product thereof

InactiveUS20050182203A1Improve flame retardant performanceLow dielectric constantFireproof paintsInsulating substrate metal adhesion improvementArylHydrogen

A cyanate ester compound represented by the formula (1), wherein Ar2 represents a phenylene group, a naphthylene group or a biphenylene group, Ar1 represents a naphthylene group or a biphenylene group when Ar2 is a phenylene group, or Ar1 represents a phenylene group, a naphthylene group or a biphenylene group when Ar2 is a naphthylene group or a biphenylene group, Rx represents all substituents of Ar1 each Rx is the same or different and represents hydrogen, an alkyl group or an aryl group, Ry represents all substituents of Ar2, each Ry is the same or different and represents hydrogen, an alkyl group or an aryl group, and n is an integer of 1 to 50.

Owner:MITSUBISHI GAS CHEM CO INC

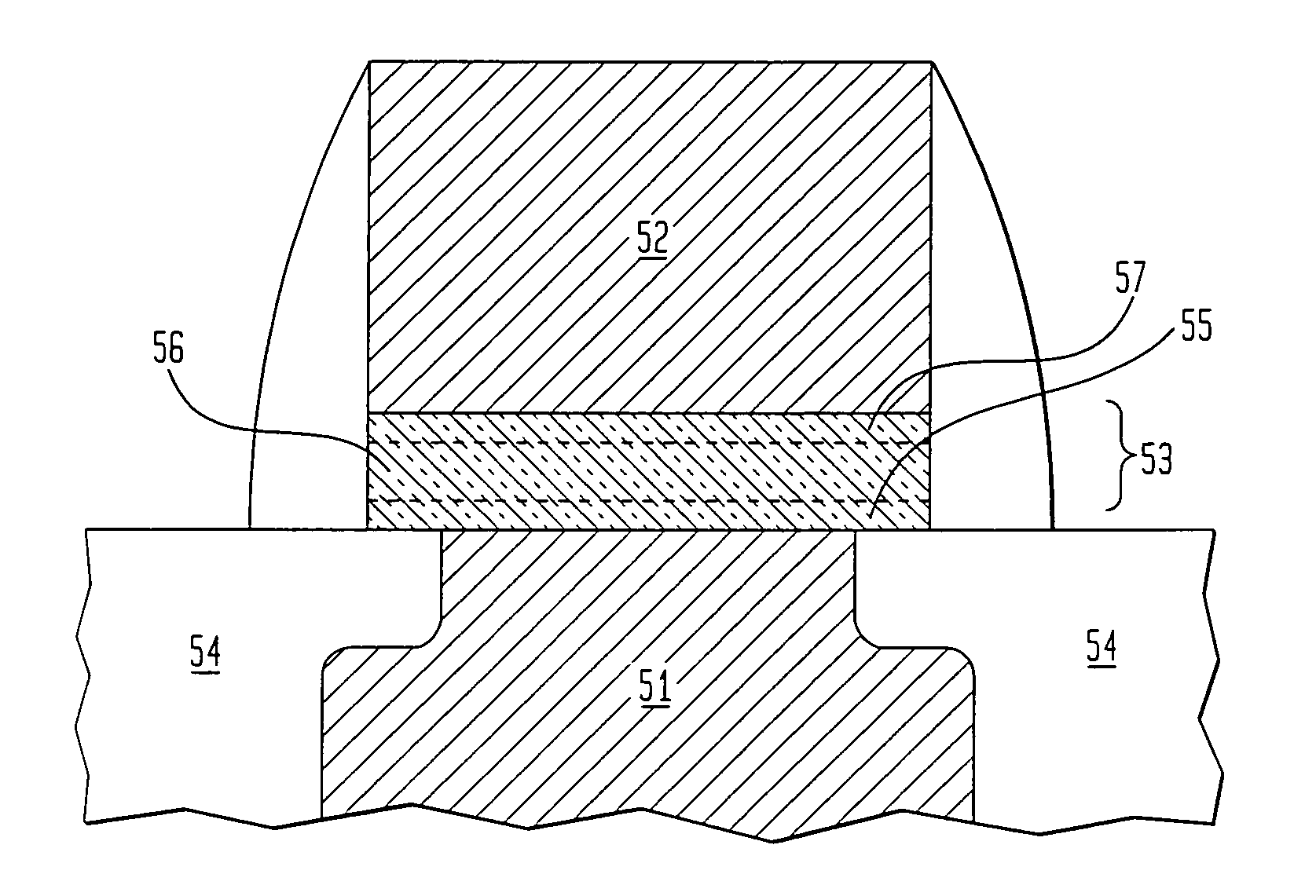

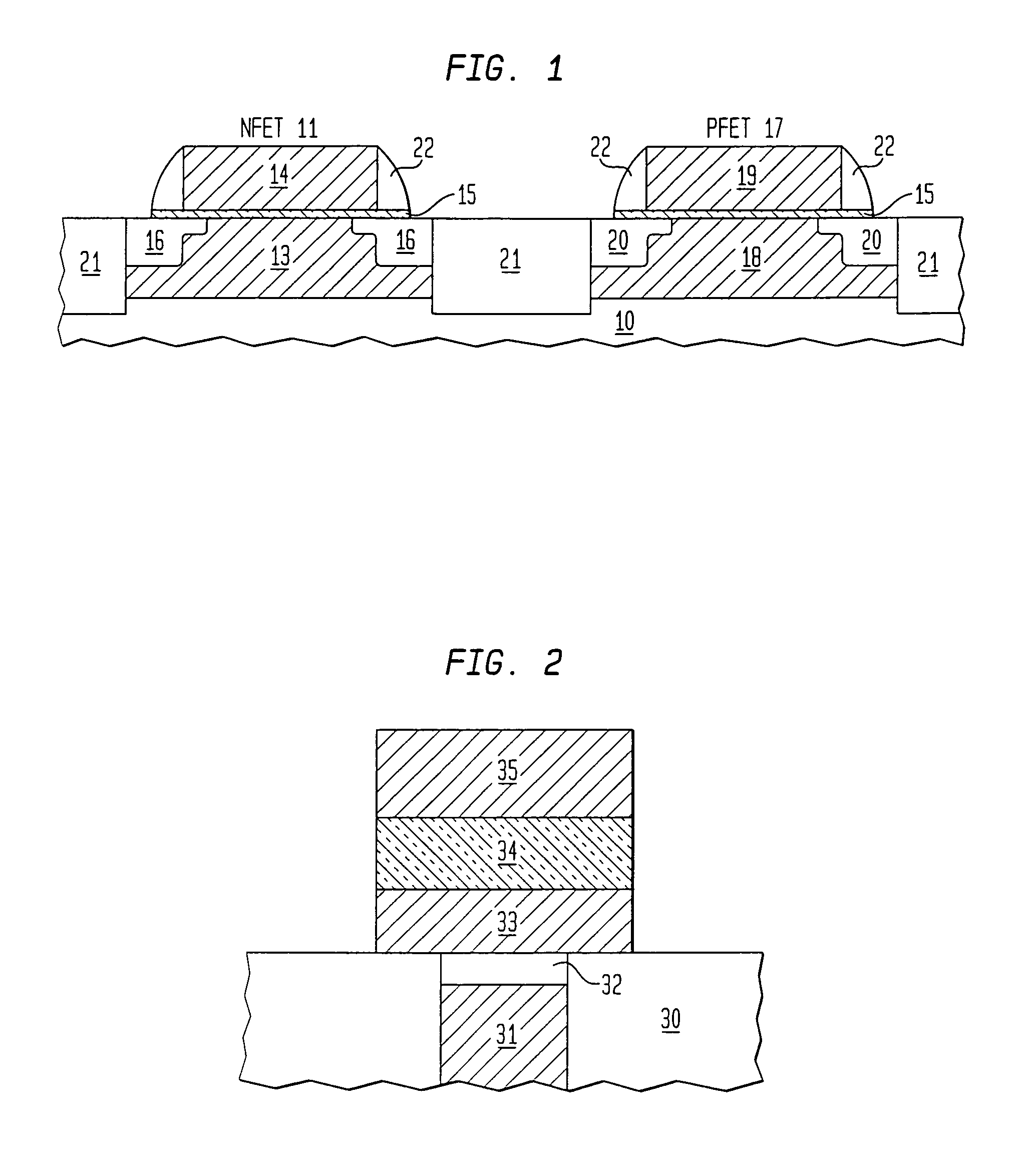

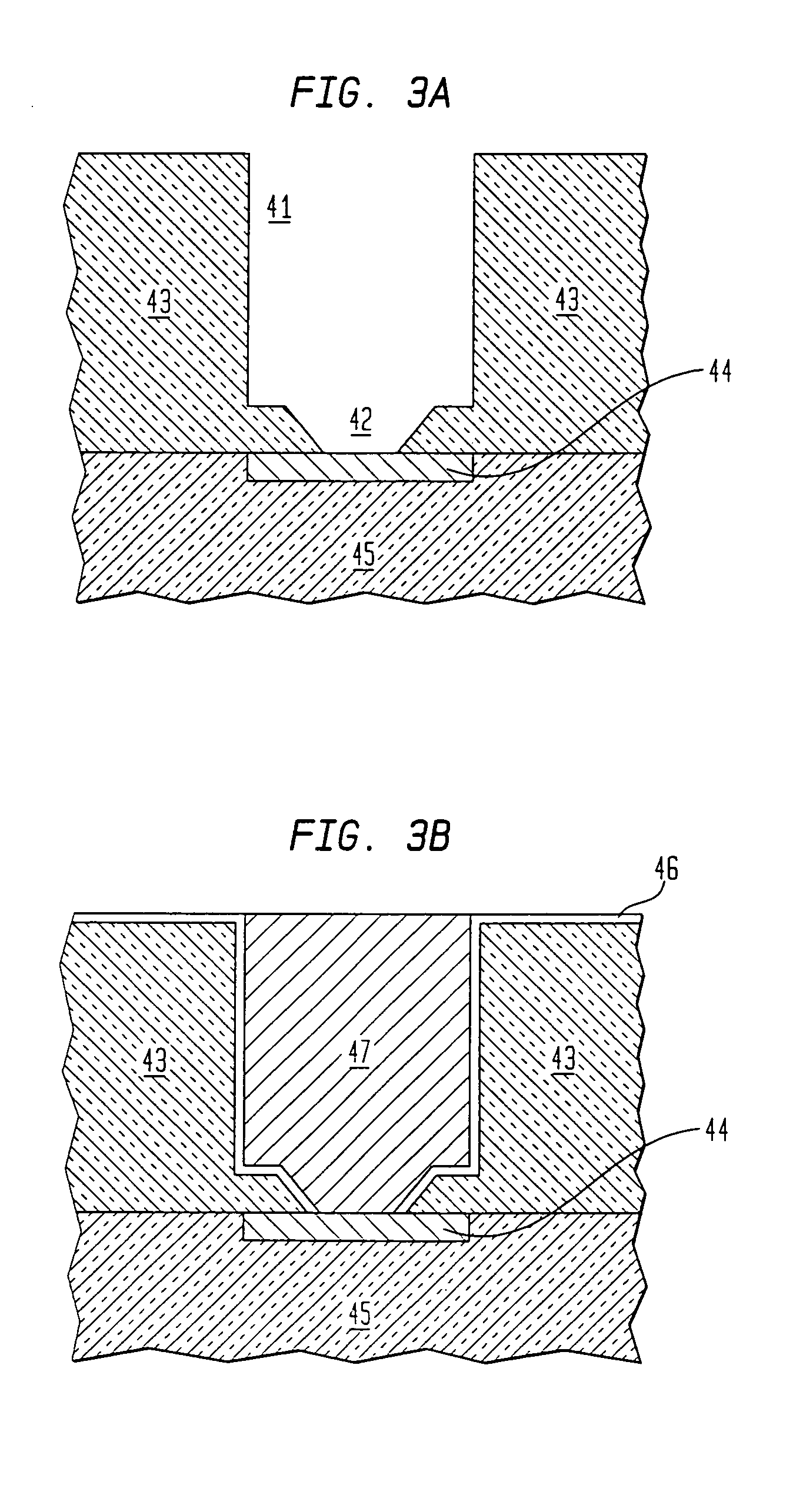

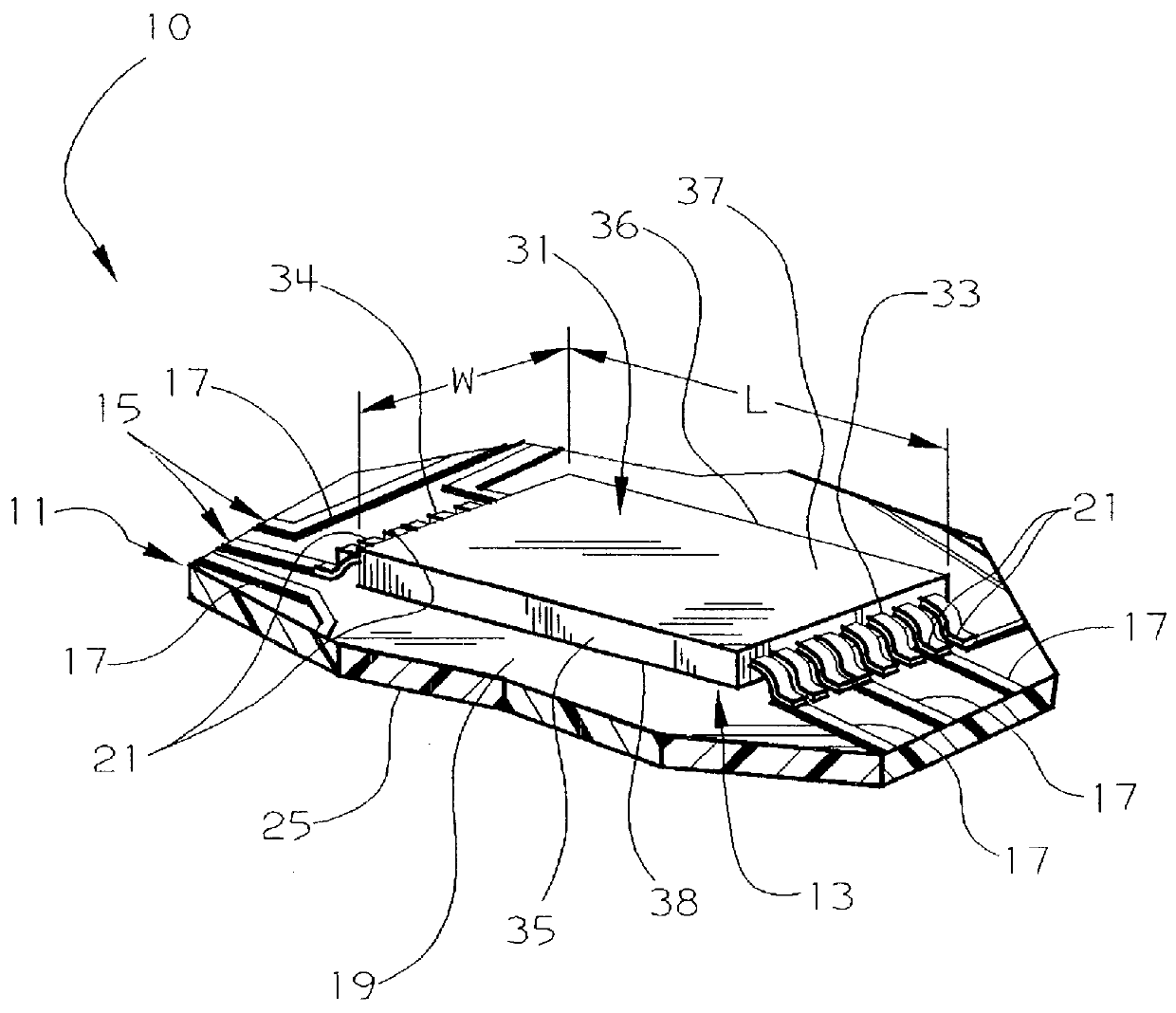

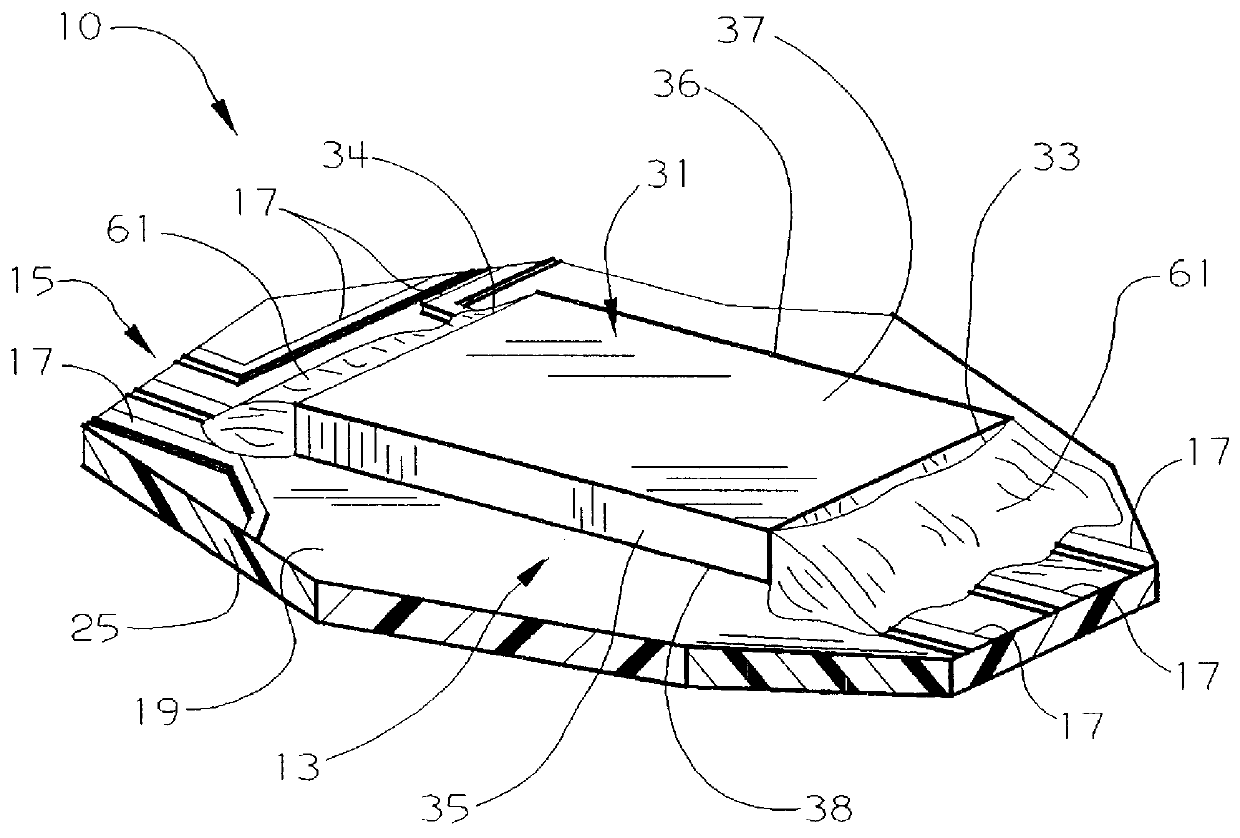

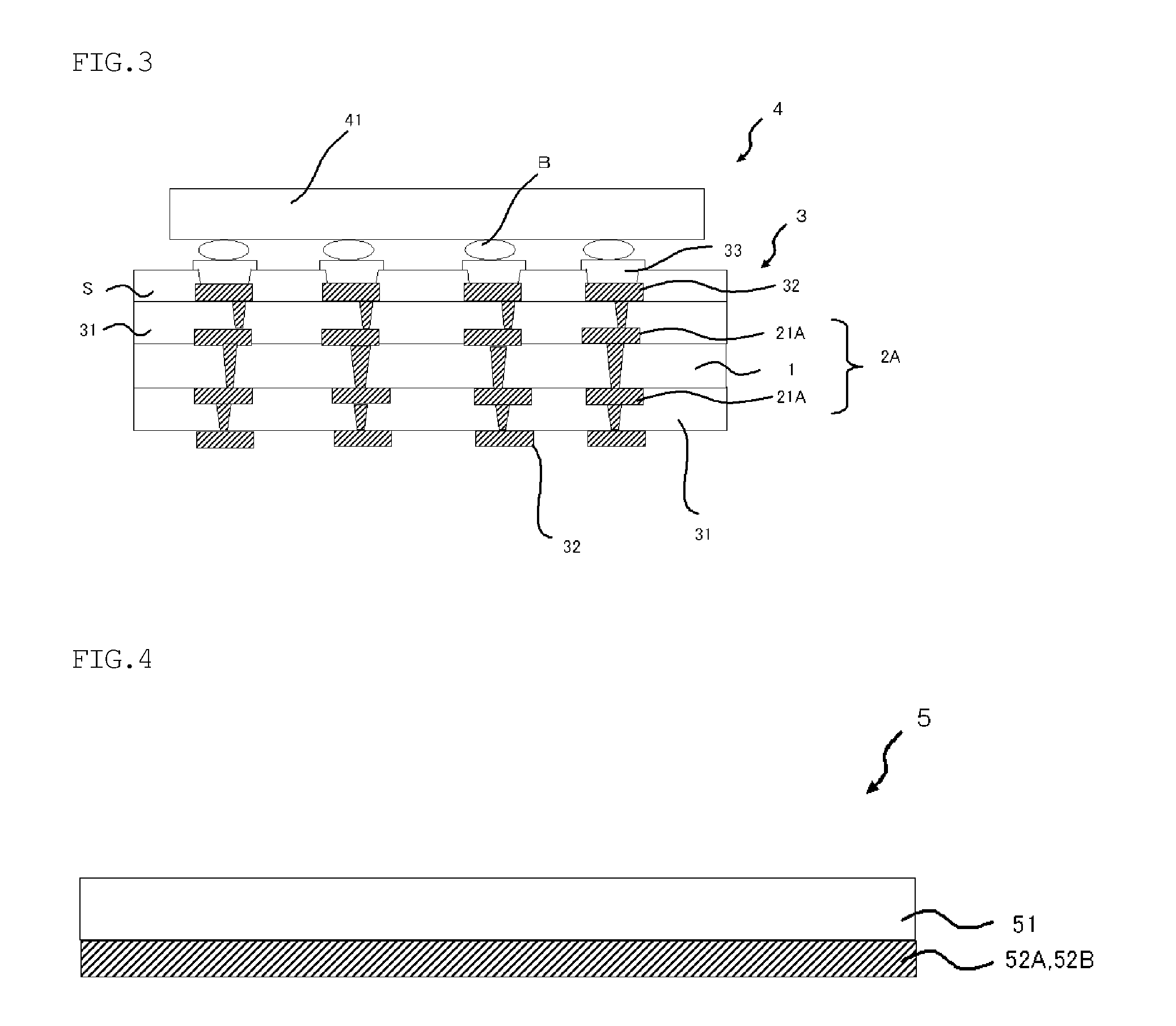

Encapsulating a solder joint with a photo cured epoxy resin or cyanate

InactiveUS6129955AImprove protectionReduce stressPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorEngineering

An electronic package assembly where a low profile integrated circuit chip package is soldered to an organic (e.g., epoxy resin) substrate, e.g., a printed circuit board or card, the projecting conductive leads of the integrated circuit chip package and the solder which substantially covers these leads (and respective conductors on the substrate) having been substantially covered with ultraviolet photocured encapsulant material (e.g., an epoxy resin or a cyanate with a photoinitiator and silica) to provide reinforcement for the solder-lead connections. The encapsulant material is dispensed about the solder and lead joints following solder reflow and solidification so as to substantially surround the solder and any portions of the leads not covered with solder.

Owner:ULTRATECH INT INC

High temperature three dimensional printing compositions

ActiveUS20160369040A1High modulusHigh elongationAdditive manufacturing apparatusPolymer scienceMetal catalyst

A thermosetting resin composition has particular applications in three dimensional (3-D) printing. The thermosetting resin composition exhibits high performance and is characterized by a high temperature two stage cure resin composition. The thermosetting resin composition comprises cyanate esters and other high temperature resins, photo curable monomers, photo initiator, metal catalyst or ionic liquid catalyst. The thermosetting resin composition cures at room temperature to form 3-D objects and upon further post cure these objects exhibit high temperature properties enabling use at temperatures exceeding 150C.

Owner:NOVOSET

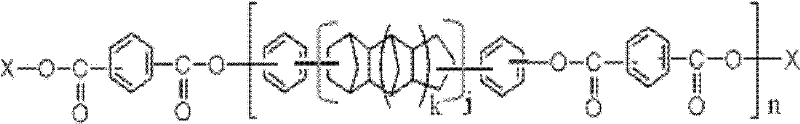

High-frequency thermosetting resin composition, prepreg and laminated sheet

ActiveCN102181143ADoes not affect heat resistanceDoes not affect dielectric propertiesMetal layered productsDielectric lossCopper foil

The invention discloses a high-frequency thermosetting resin composition. The high-frequency thermosetting resin composition comprises the following components in part by weight: 10 to 60 parts of halogen-free epoxy resin, 15 to 70 parts of polyphenyl ether resin, and 5 to 60 parts of composite cyanate resin; an accelerator is 0.01 to 2 parts; and the composite cyanate resin comprises thiocyanate resin. The composition can realize halogen-free flame resistance, and does not influence the heat resistance and dielectric performance of a product; and a laminated sheet prepared from the composition has high peel strength and heat resistance of a copper foil and a low dielectric constant and low dielectric loss under the high-frequency condition.

Owner:SHENGYI TECH SUZHOU

Epoxy resin composition and high-frequency circuit board manufactured thereby

InactiveCN102504201AExcellent dielectric propertiesLow dielectric propertiesCircuit susbtrate materialsSolid componentCopper foil

The invention relates to an epoxy resin composition and a high-frequency circuit board manufactured thereby. The epoxy resin composition comprises the following solid components: (A) cyanate compound or prepolymer thereof, wherein the molecule of the cyanate compound contains at least two cyanato groups; (B) active ester; and (C) epoxy resin containing a naphthol structure; calculated in solid component in parts by weight, the total amount of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, and the component (B), i.e. active ester, is 10-70 parts by weight, and the amount of the component (C), i.e. epoxy resin containing naphthol structure, is 30-90 parts by weight, wherein the weight ratio of the component (A), i.e. the cyanate compound containing at least two cyanato groups in the molecule thereof or the prepolymer thereof, to the component (B), i.e. active ester, is (0.2-5):1. The high-frequency circuit board manufactured by using the epoxy resin composition of the invention comprises a plurality of layers of prepregs which are overlapped mutually, and copper foils which are compressed on the two sides respectively; and each of the plurality of layers of prepregs comprises a base material and the epoxy resin composition which is adhered to the base material through impregnation and drying.

Owner:GUANGDONG SHENGYI SCI TECH

Halogen-free Tg resin composite and presoaked material and laminated board made by adopting same

ActiveCN102134375AExcellent dielectric propertiesLow dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsVitrificationPhosphonium

The invention relates to a halogen-free Tg resin composite and a presoaked material and a laminated board made by adopting the composite. Counted by part by weight of organic solid matters, the halogen-free high-Tg resin composite contains the following components according to part by weight: (A) 10 to 50 parts by weight of cyanate resin; (B) 10 to 50 parts by weight of at least one compound withdihydro-benzoxazine ring; (C) 10 to 50 parts by weight of at least one kind of bismaleimides resin; (D) 10 to 50 parts by weight of at least one kind of poly-epoxy compound; and (E) 5 to 30 parts by weight of at least one kind phosphonium flame retardant. The halogen-free high-Tg resin composite has the performances of low water absorption, low CTE (coefficient of thermal expansion), high Tg, good dielectric property and the like, and the presoaked material and laminated board made by adopting the composite has the characteristics of high vitrification transition temperature, low CTE, low dielectric constant, low water absorption, high thermal resistance and the like, thus being application to multi-layer circuit boards.

Owner:GUANGDONG SHENGYI SCI TECH

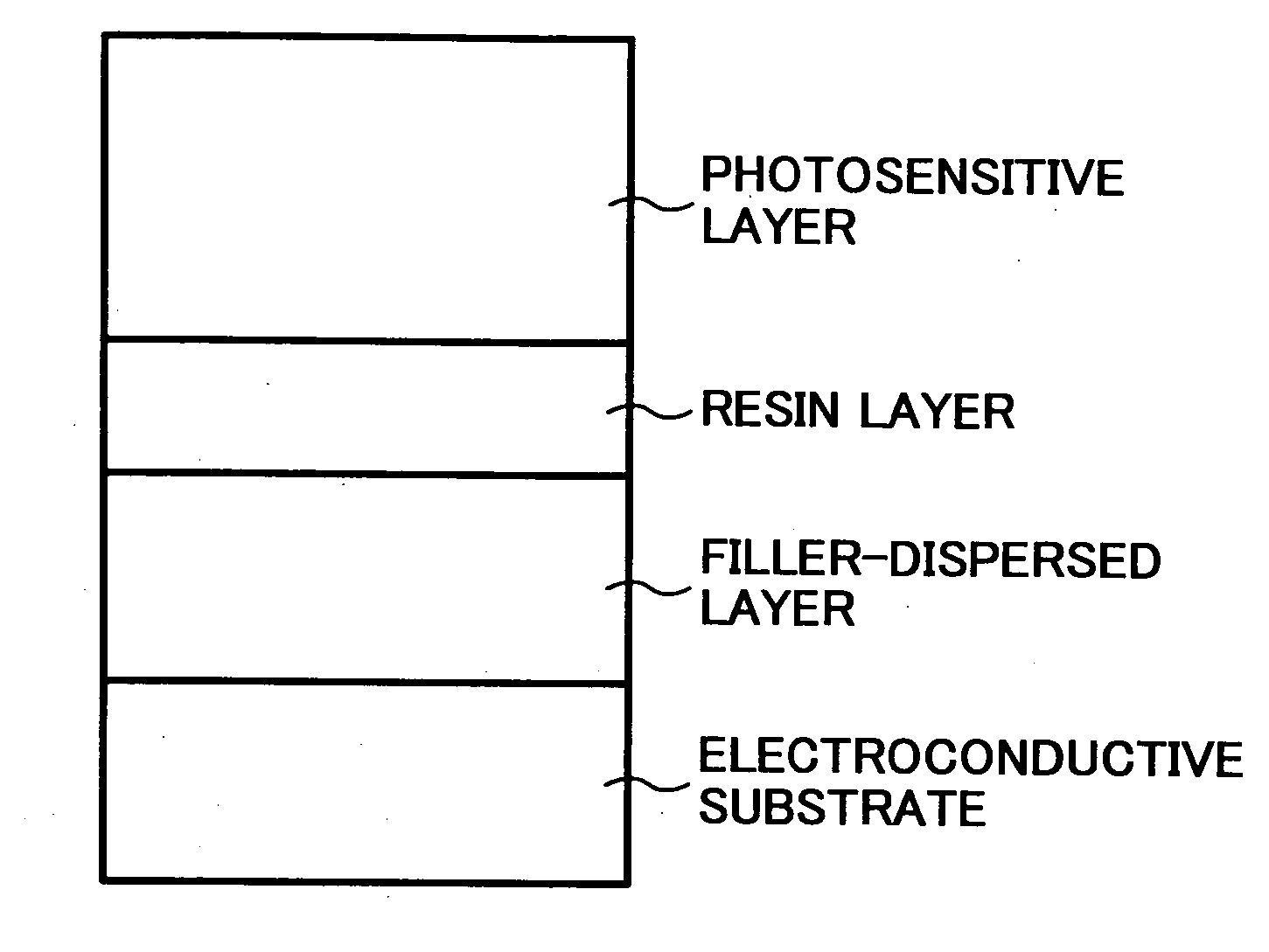

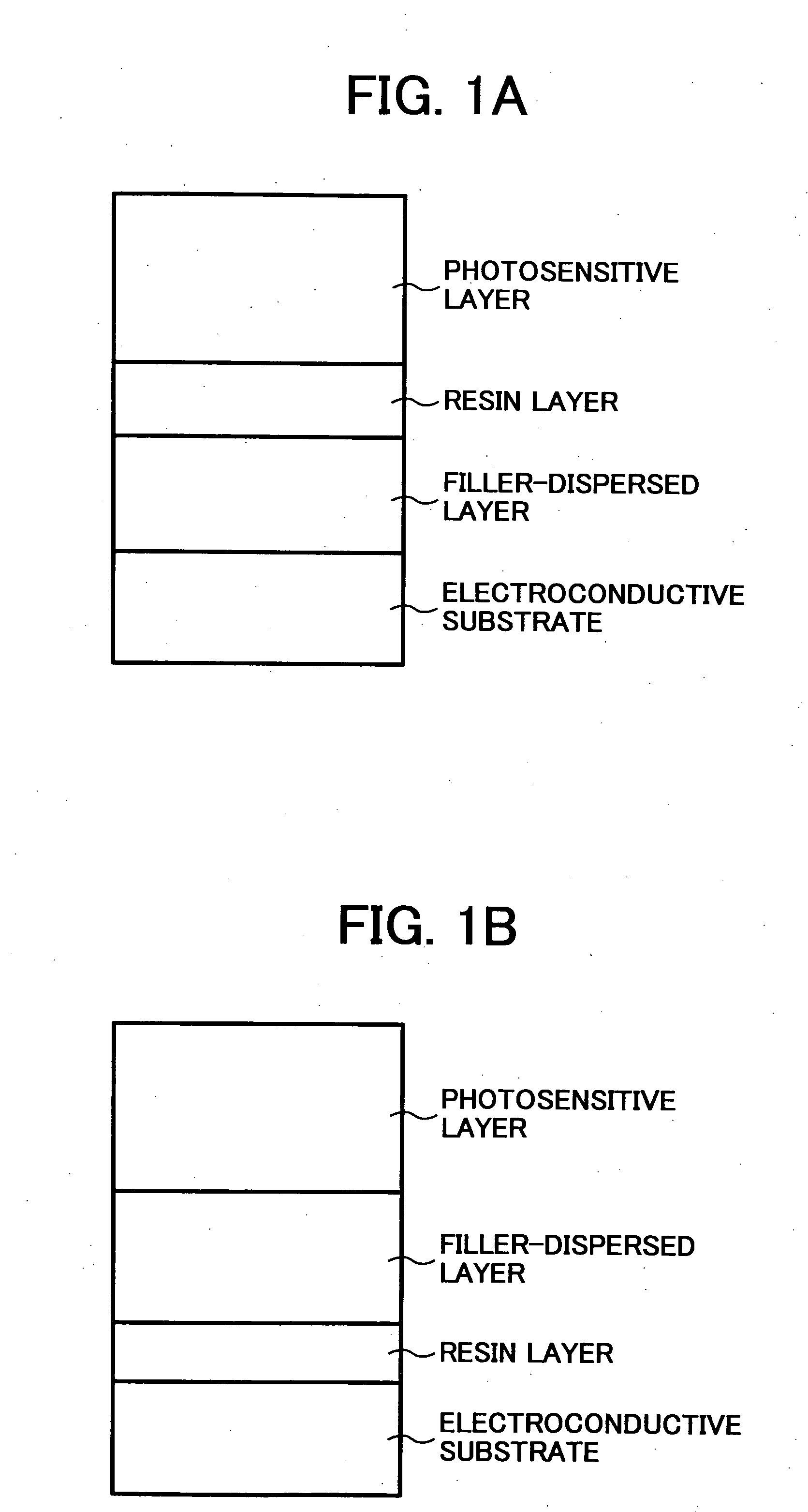

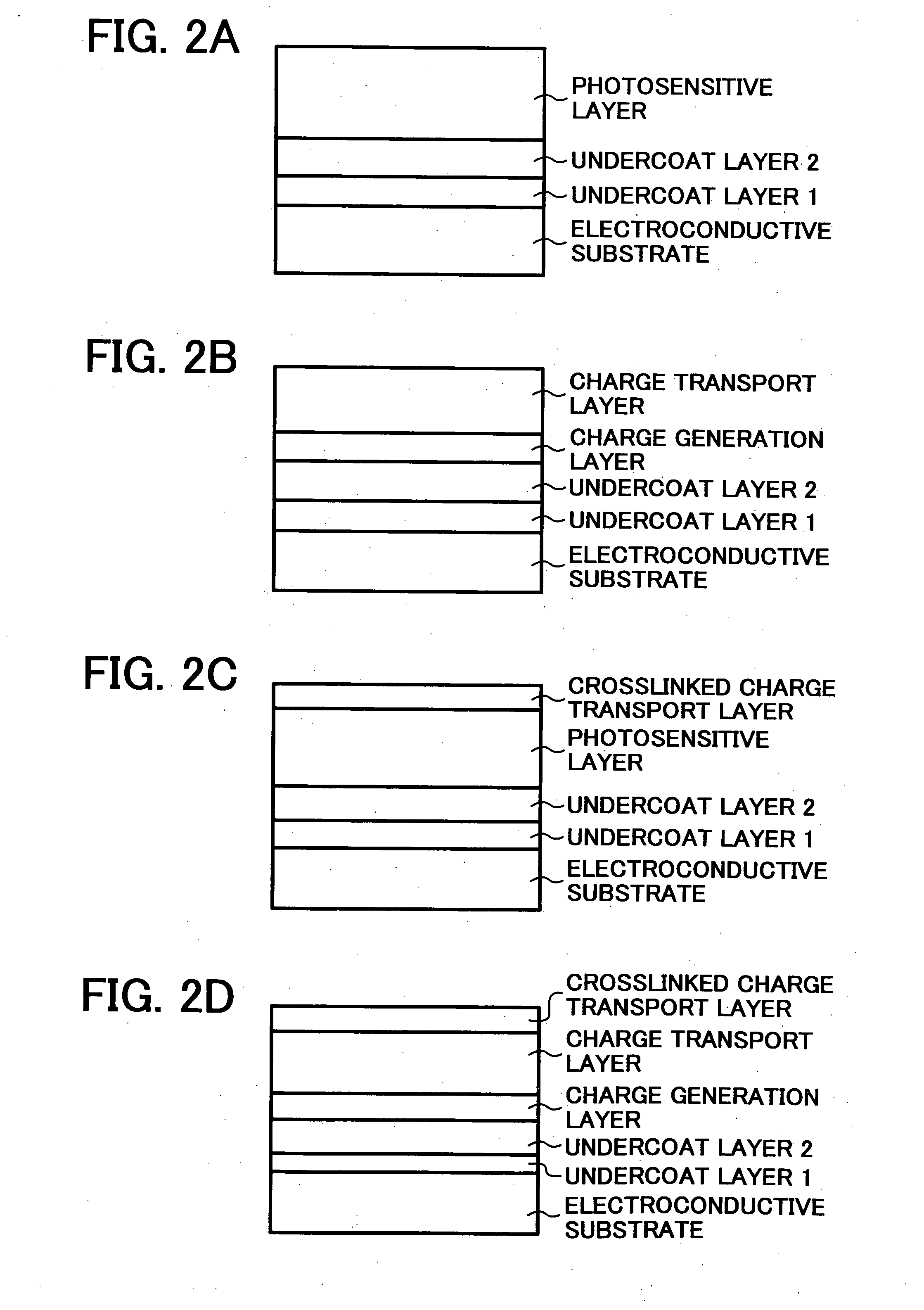

Electrophotographic photoreceptor, and image forming apparatus and process cartridge therefor using the electrophotographic photoreceptor

InactiveUS20060177749A1Highly durableHighly stableElectrographic process apparatusCorona dischargeImaging equipmentMetal

An electrophotographic photoreceptor, including: an electroconductive substrate; a first undercoat layer including no metal oxide, located overlying the electroconductive substrate; a second undercoat layer including a metal oxide and a binder resin, located overlying the first undercoat layer; and a photosensitive layer located overlying the second undercoat layer, wherein the metal oxide included in the second undercoat layer has a specific resistivity not less than 107 Ω·cm and a block isocyanate compound.

Owner:RICOH KK

Epoxy resin composition and high frequency circuit board made of same

InactiveCN101967264AHigh glass transition temperatureExcellent dielectric propertiesCircuit susbtrate materialsMetal layered productsSolid componentCopper foil

The invention relates to an epoxy resin composition and a high frequency circuit board made of the same. The epoxy resin composition comprises the following solid components in part by weight: 10 to 70 parts of component (A) and component (B) and 30 to 90 parts of component (C), wherein the component (A) is a cyanate compound or prepolymer thereof, of which the molecules comprise at least two cyanatos; the component (B) is active ester; the component (C) is epoxy resin of which the molecular structure comprises at least one biphenyl structure; and the weight ratio of the component (A) to the component (B) is 0.2-5. The high-frequency circuit board made of the epoxy resin composition comprises a plurality of layers of semi-solidification sheets which are superimposed and copper foils which are covered on the two sides of the board respectively, wherein the plurality of layers of semi-solidification sheets comprise base materials and the epoxy resin composition which is subjected to soaking and drying and attached to the base materials.

Owner:GUANGDONG SHENGYI SCI TECH

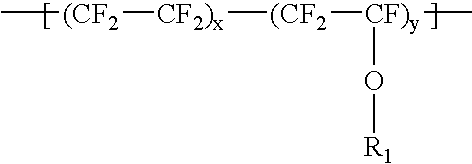

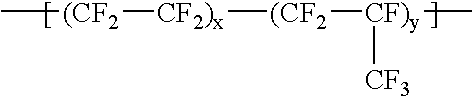

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

InactiveUS20060286365A1Synthetic resin layered productsLiquid/solution decomposition chemical coatingPolyesterPolyamide

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

Compositions useful in electronic circuitry type applications, patternable using amplified light, and methods and compositions relating thereto

A light-activatable polymer composition and polymer composite includes a polymer binder selected from epoxy resins, silica filled epoxy, bismaleimide resins, bismaleimide triazines, fluoropolymers, polyesters, polyphenylene oxide / polyphenylene ether resins, polybutadiene / polyisoprene crosslinkable resins (and copolymers), liquid crystal polymers, polyamides, cyanate esters, or combinations thereof, the polymer binder being present in an amount from 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 96, or 97 weight-percent of the total weight of the polymer composition; a spinel crystal filler present in an amount from 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 20, 25, 30, 35, 40, 45, 50, 55 and 60 weight-percent of the total weight of the polymer composition, and methods for making same are provided.

Owner:EI DU PONT DE NEMOURS & CO

Cyanate resin, polyepoxide and metal complex curing agent

A curable mixture comprising at least one cyanate resin, at least one epoxide compound with more than one epoxy group per molecule, and a metal formula selected from the group consisting of MLxBy, M[SR]xBy, M[SR]x(N)y, M(PHal)m and M(PHal)m(N)n wherein M is a cation of a complexing metal, SR is an organic or inorganic acid residue, L is a chelating ligand, B is a Lewis base, PHal is an ion of a pseudohalide, N is a nitrogen base, x is an integer from 1 to 8, y is an integer from 1 to 5, z is an integer from 7 to 8, m is an integer from 2 to 3 and n is an integer from 1 to 2.

Owner:BAKELITE

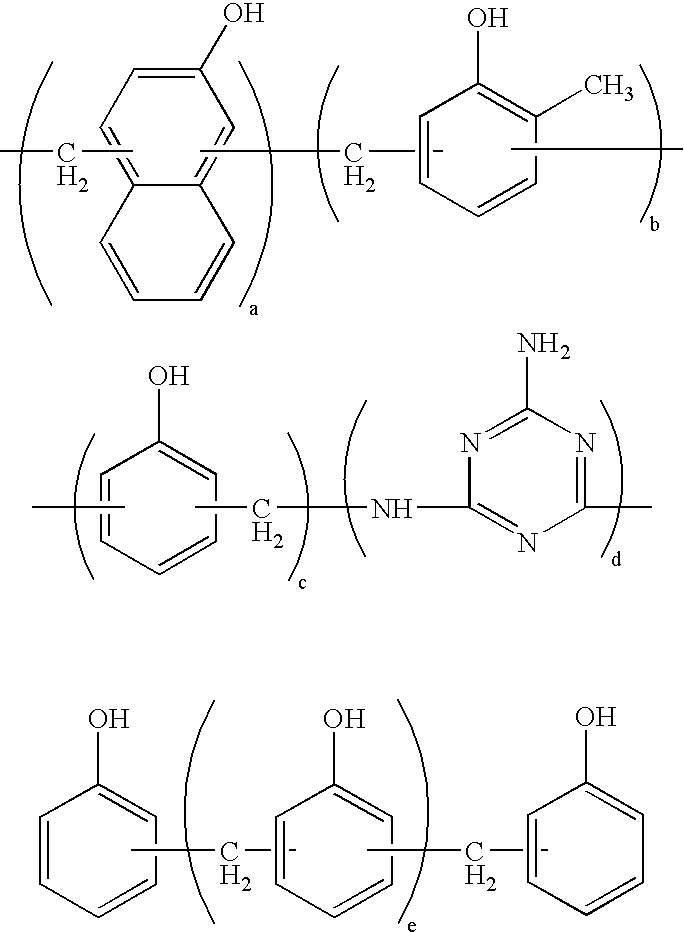

Thermosetting resin composition, multilayer body using same, and circuit board

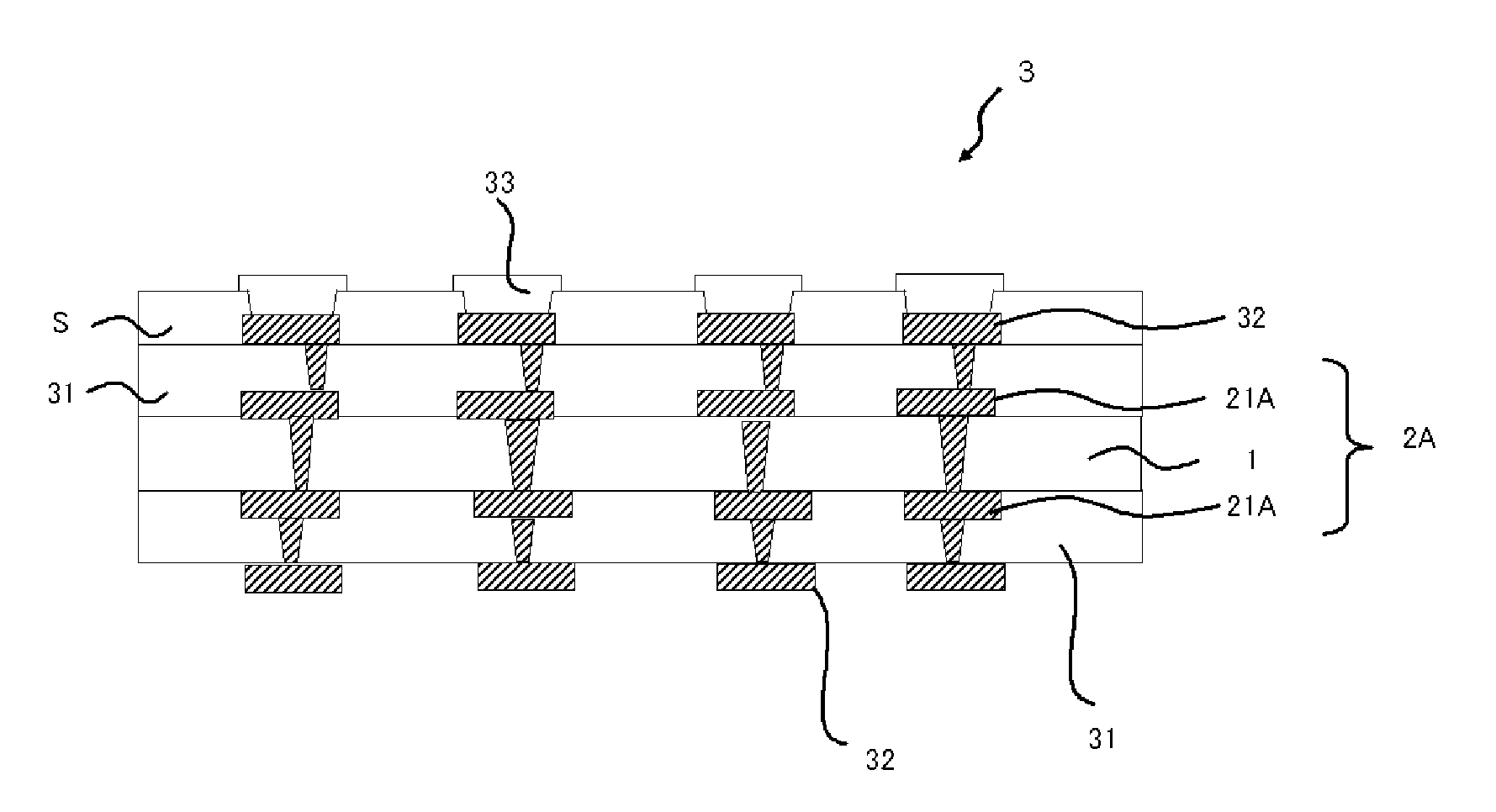

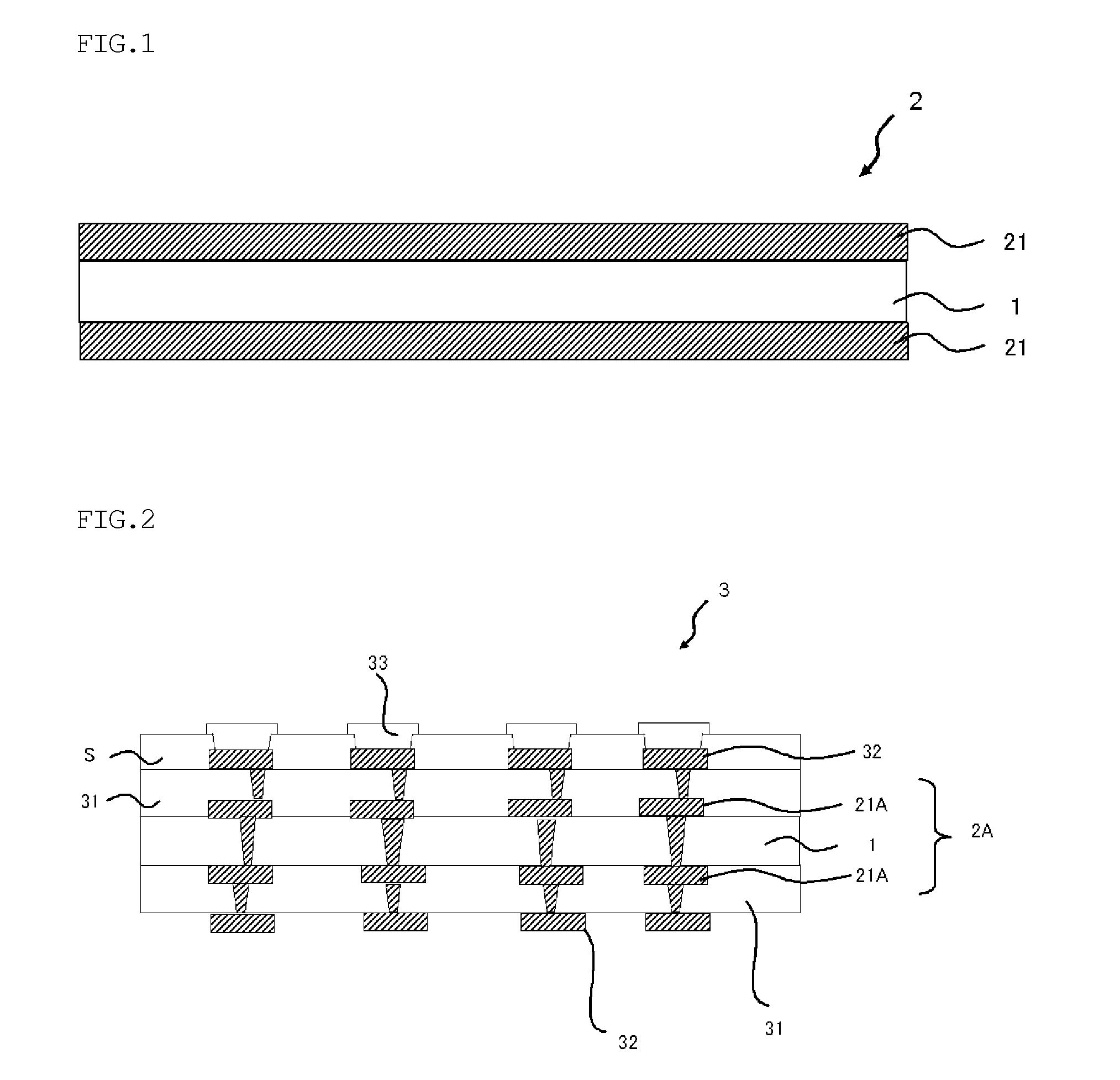

InactiveUS20060205891A1Improve heat resistanceExcellent dielectric characteristicFilm/foil adhesivesGroup 5/15 element organic compoundsPHENOL LIQUIDCyanate compound

The present invention relates to thermosetting resin compositions which are suitably used for manufacturing circuit boards, such as flexible printed circuit boards (FPCs) and build-up circuit boards, and to multilayer bodies and circuit boards manufactured using such thermosetting resin compositions. A thermosetting resin composition contains a polyimide resin component (A), a phenol resin component (B), and an epoxy resin component (C). The mixing ratio by weight (A) / [(B)+(C)] is in a range of 0.4 to 2.0, the mixing ratio by weight being the ratio of the weight of the component (A) to the total weight of the component (B) and the component (C). By using such a thermosetting resin composition, it is possible to manufacture multilayer bodies and circuit boards which are excellent in dielectric characteristics, adhesiveness, processability, heat resistance, flowability, etc. A thermosetting resin composition contains a polyimide resin (A), a phosphazene compound (D), and a cyanate ester compound (E). The phosphazene compound (D) includes a phenolic hydroxyl group-containing phenoxyphosphazene compound (D-1) and / or a crosslinked phenoxyphosphazene compound (D-2) prepared by crosslinking the phenoxyphosphazene compound (D-1), the crosslinked phenoxyphosphazene compound (D-2) having at least one phenolic hydroxyl group. By using such a thermosetting resin composition, it is possible to manufacture multilayer bodies and circuit boards which are excellent in dielectric characteristics, processability, heat resistance, and flame retardance.

Owner:KANEKA CORP

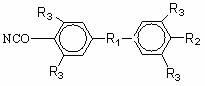

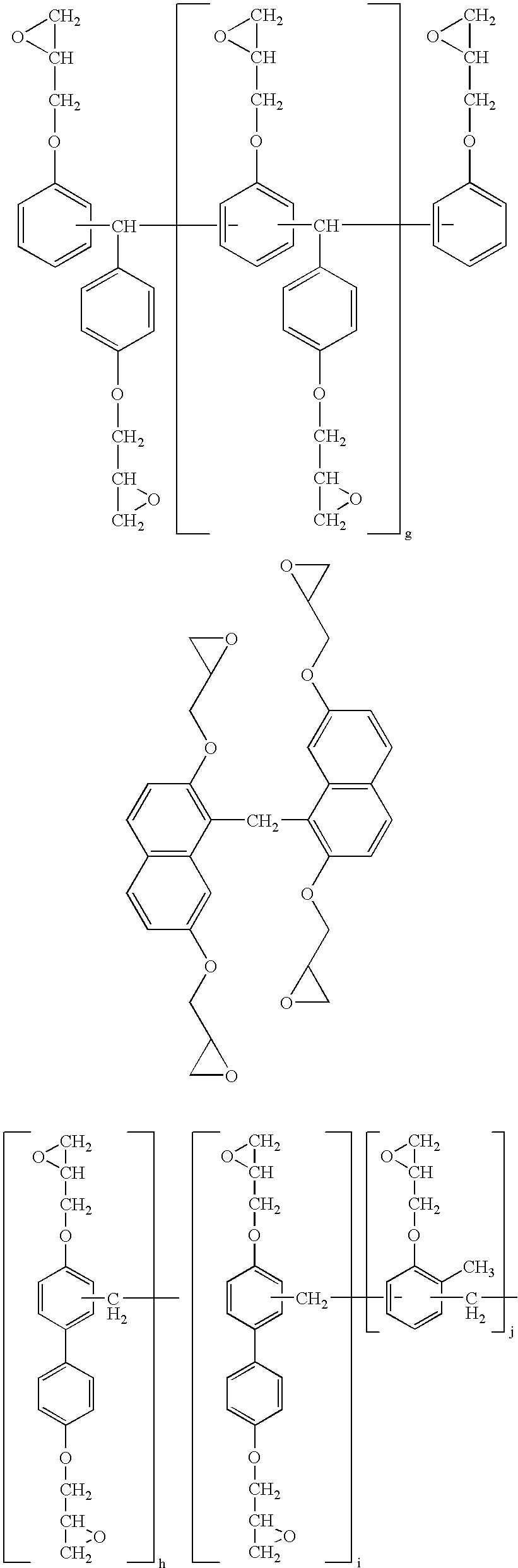

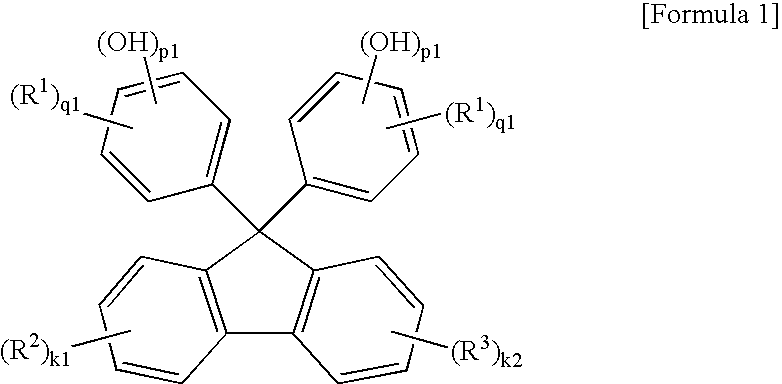

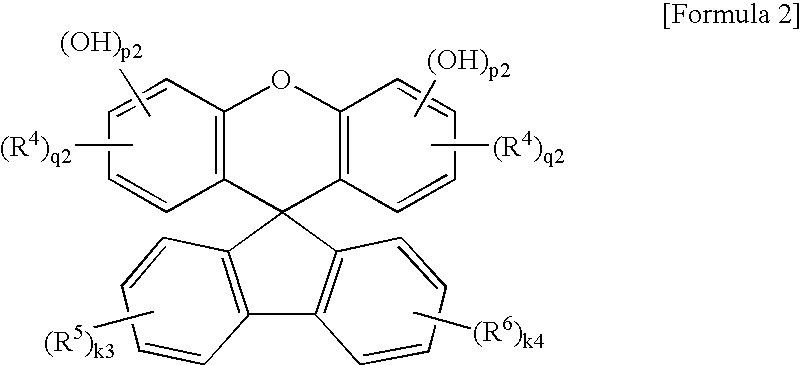

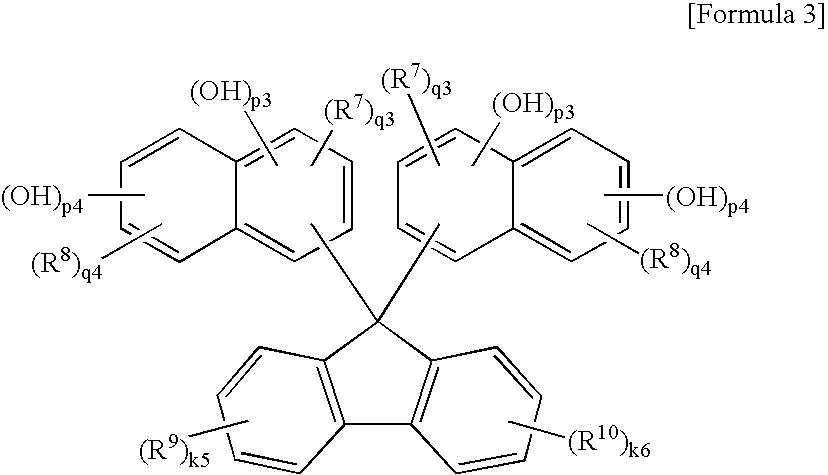

Resine Composition For Printed Circuit Board and Composite Substrate And Copper Laminates Using The Same

InactiveUS20090004488A1Desirable formabilityDesirable processibilityPrinted circuitsThin material handlingComposite substrateCyanate compound

Disclosed is a resin composition for a PCB, the composition including: (a) a polyphenylene ether resin modified via a redistribution reaction of polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene or 9,10-dihydro-9-oxa-10-(dihydroxyaryl)-10-phosphaphenanthrene 10-oxide; (b) a polymer binder; and (c) cyanate ester or a prepolymer of the cyanate ester, wherein, when the polyphenylene ether resin is modified via a redistribution reaction of the polyphenylene ether in the presence of 9,9-bis(hydroxyaryl)fluorene, the composition further includes (d) a flame retardant. Also, a composite substrate and a copper laminate using the same are disclosed.

Owner:DOOSAN CORP

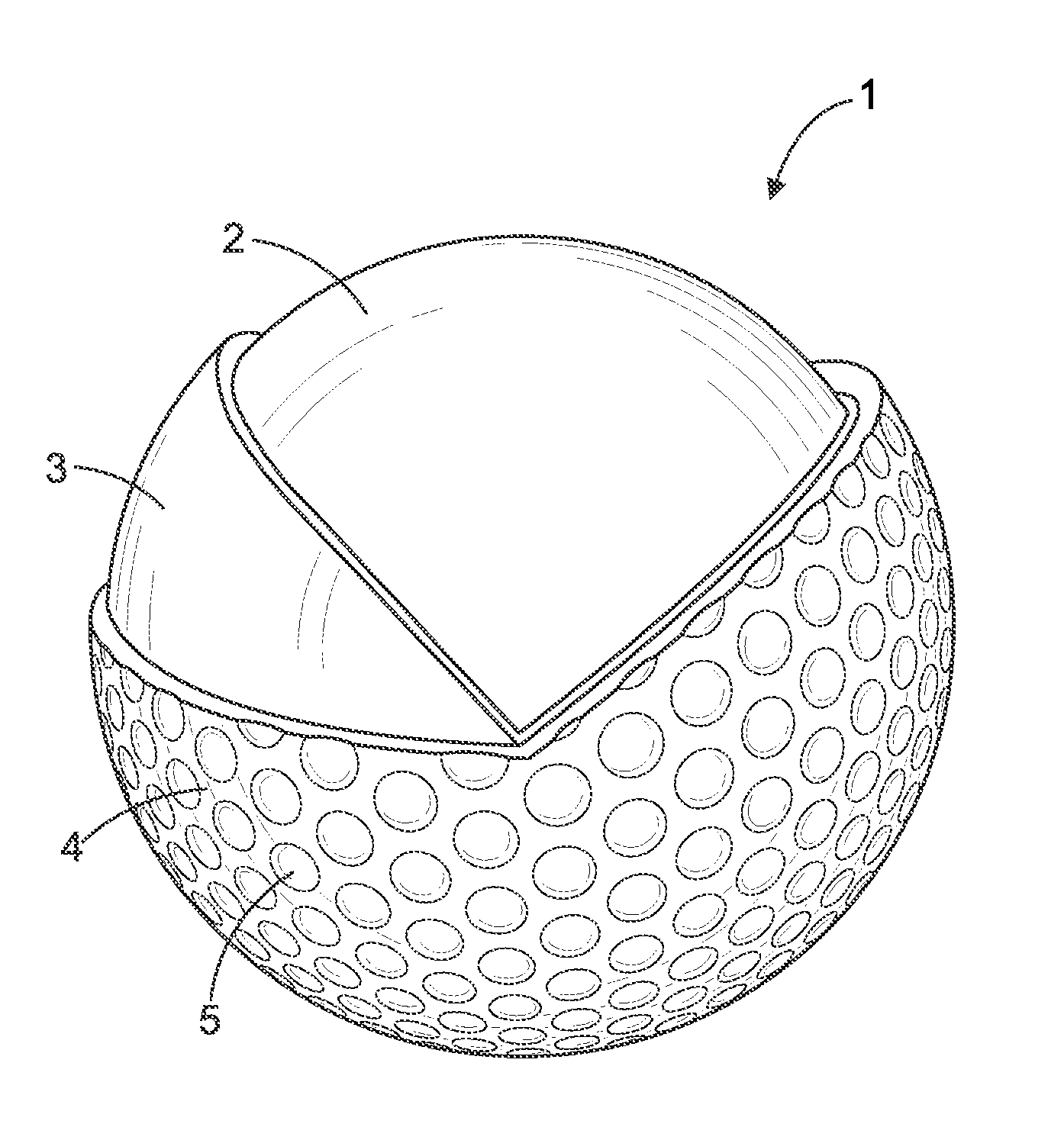

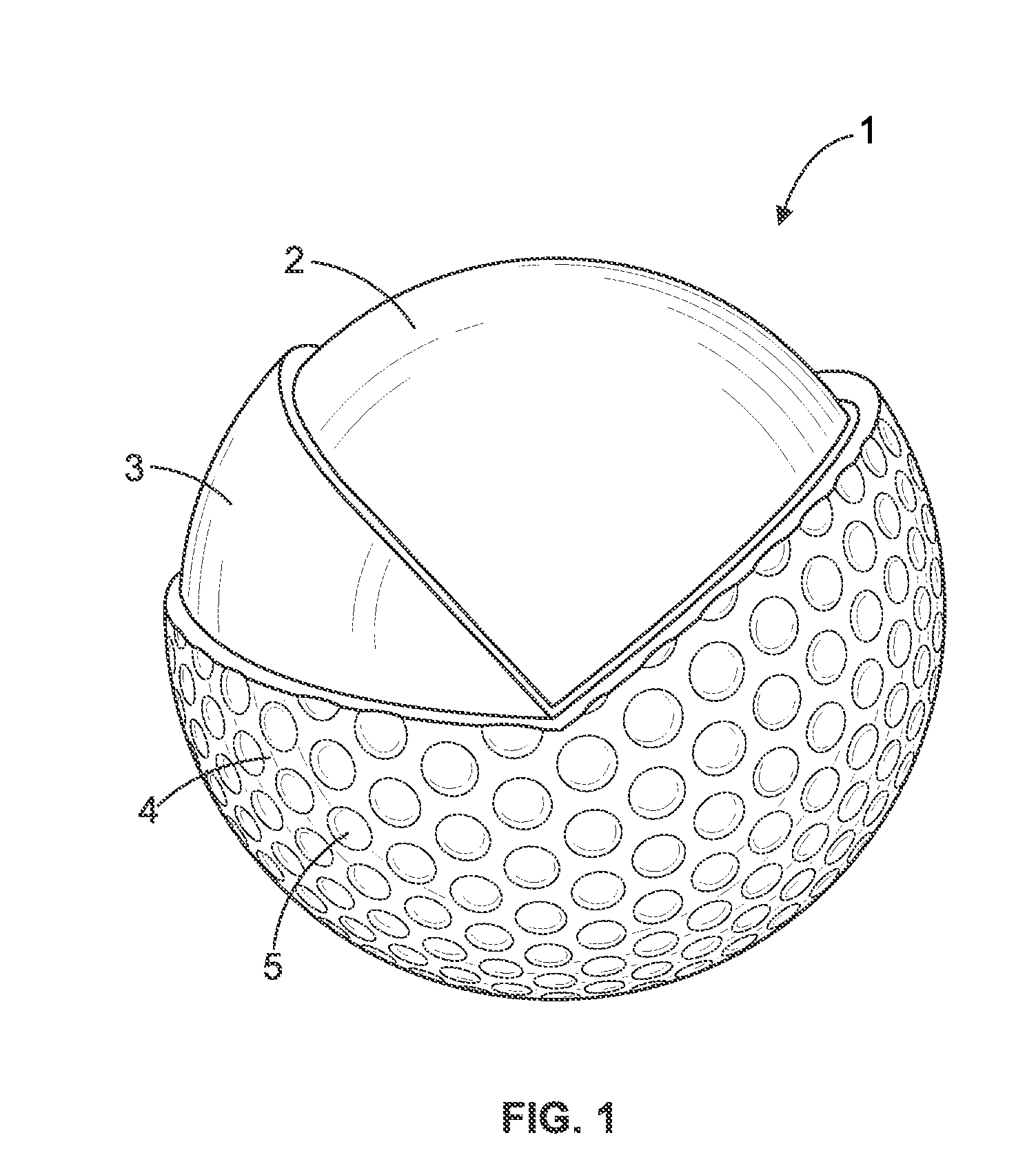

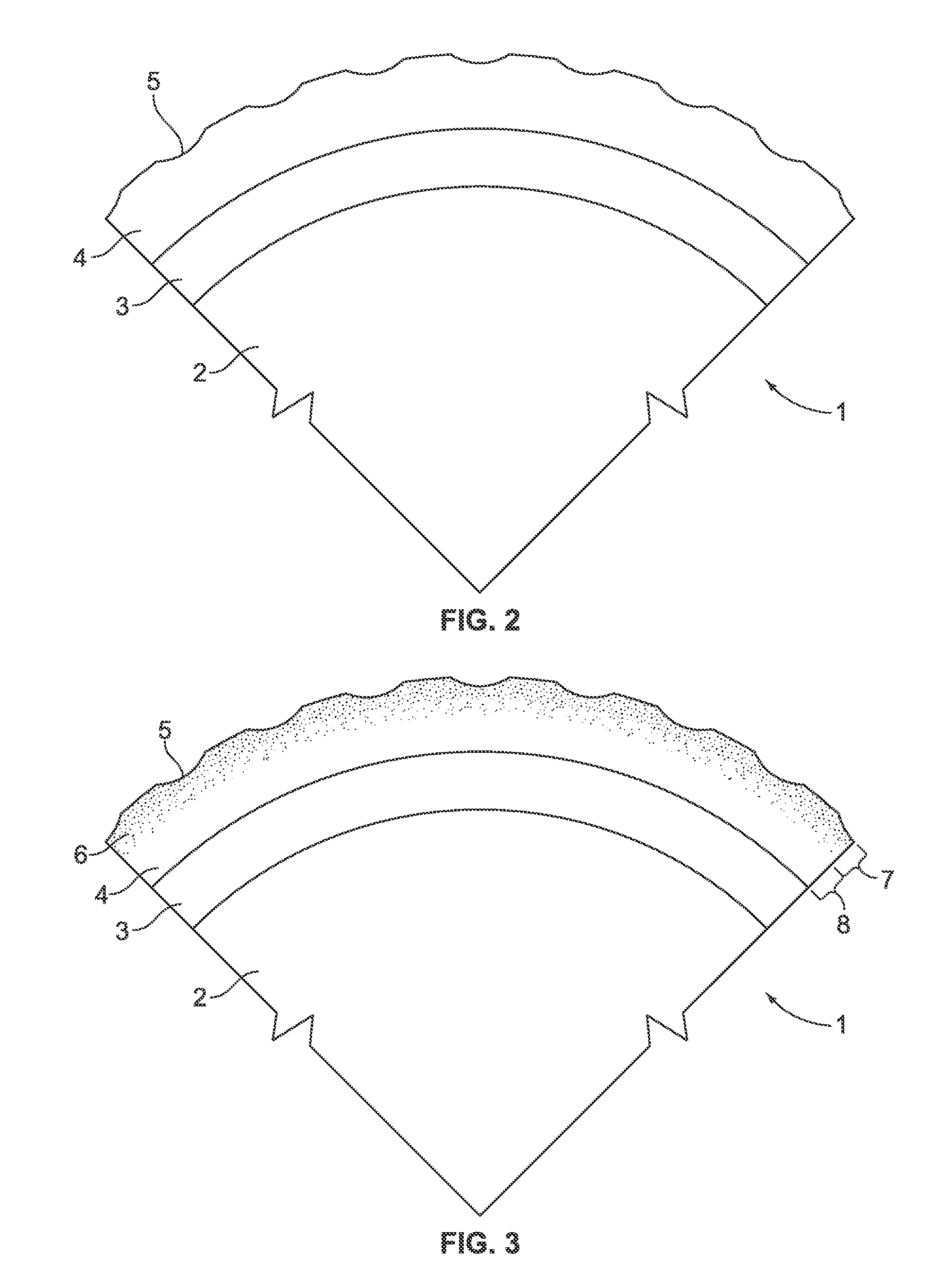

Golf ball and method of manufacturing a golf ball

A golf ball and a method of manufacturing a golf ball is disclosed. In one embodiment, a method of manufacturing a golf ball includes molding a cover made of thermoplastic resin over at least one intermediate layer of a golf ball; permeating an isocyanate solution comprising an isocyanate compound and a co-reactant compound into an outer portion of the cover; and permeating a catalyst into the outer portion of the cover. The catalyst catalyzes a reaction between the isocyanate compound and the co-reactant compound to form a reaction product. The co-reactant compound can be a second isocyanate compound, the catalyst can be a quaternary ammonium salt, and the reaction product can be isocyanurate. The reaction product modifies at least one physical property of the outer portion such that the physical property of the outer portion is different than the physical property of the inner portion. The modified physical property can be microindentation hardness, where the microindentation hardness of the outer portion is greater than the microindentation hardness of an inner portion of the cover.

Owner:NIKE INC

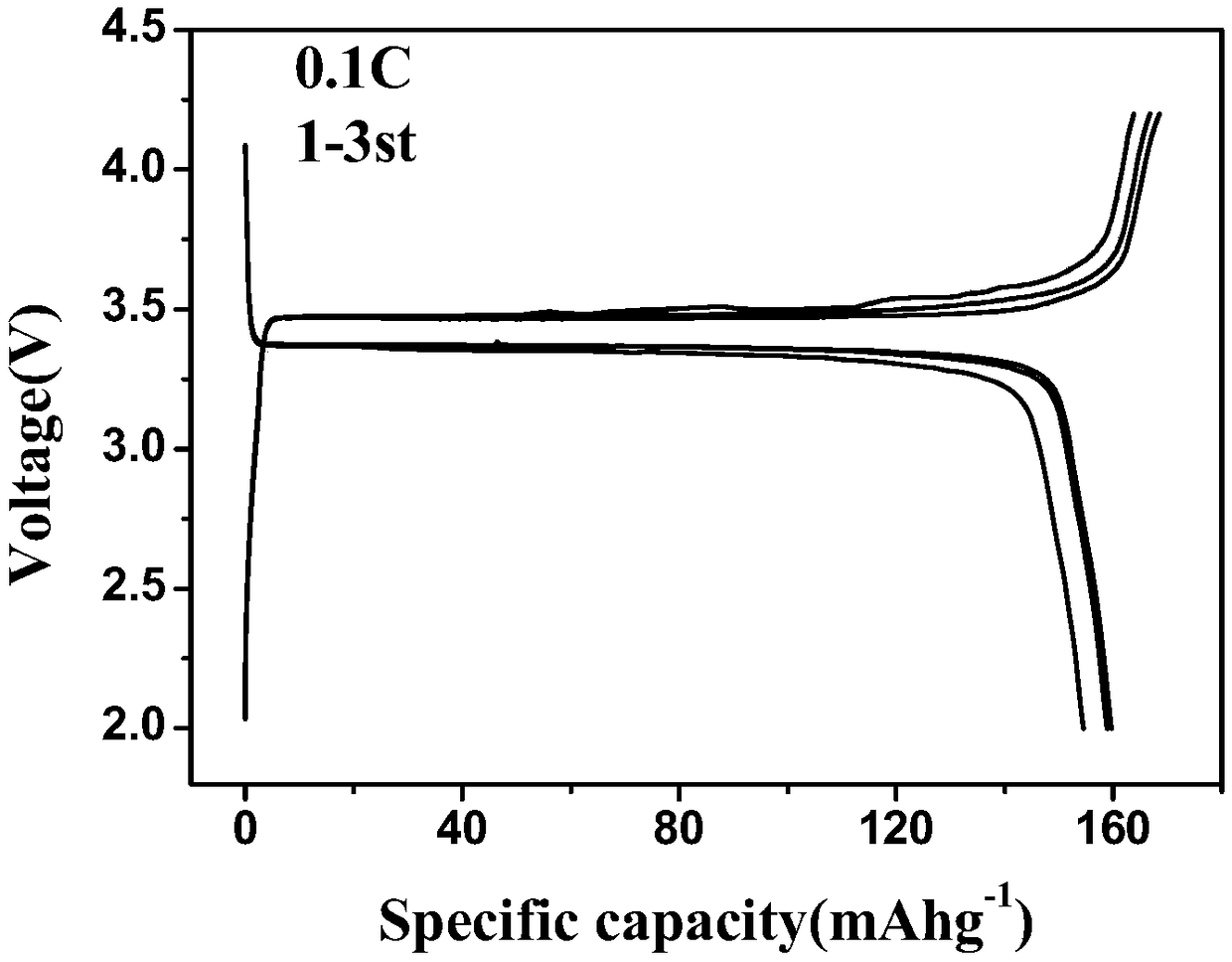

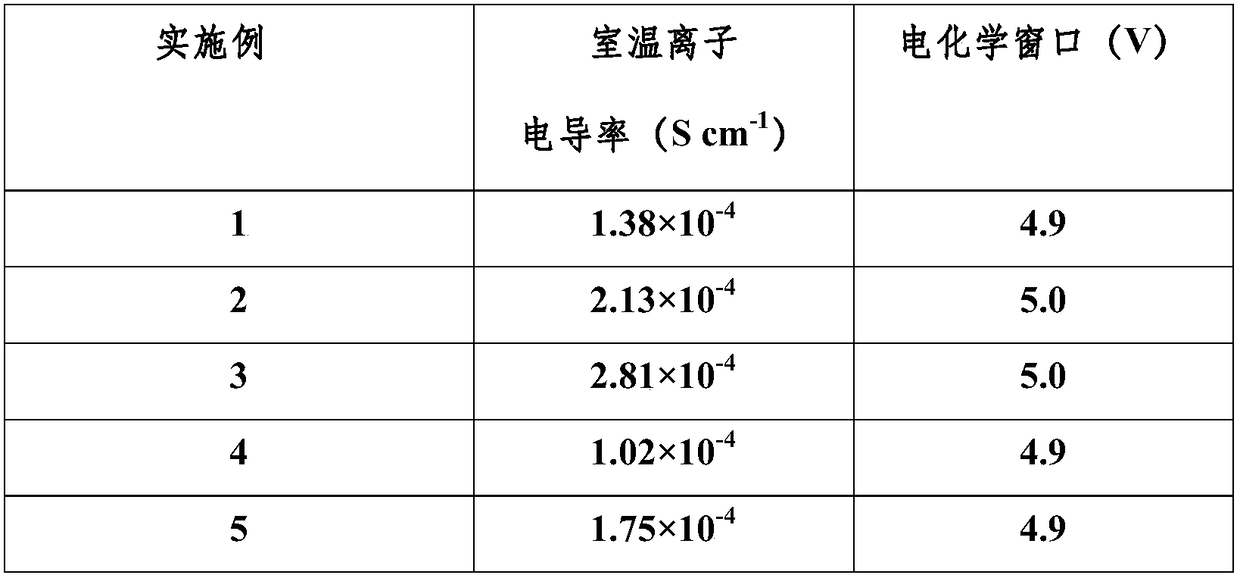

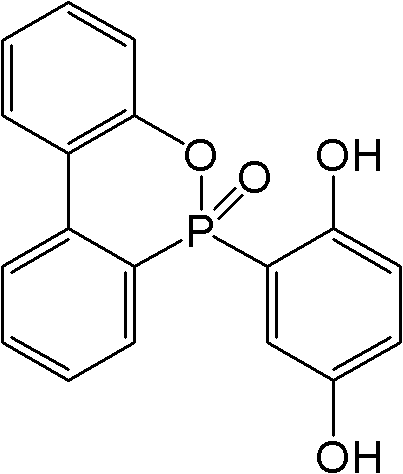

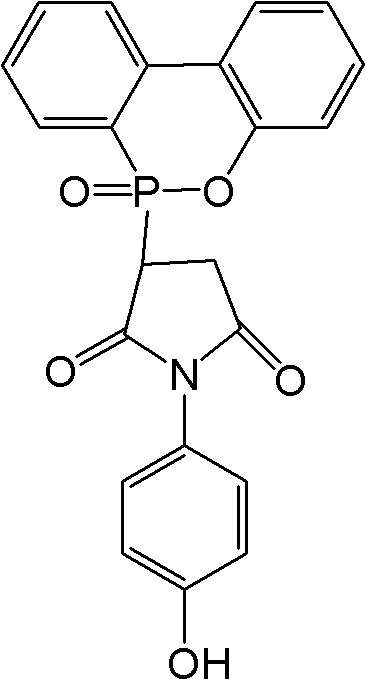

Preparation and application of organic-inorganic composite solid-state electrolyte

ActiveCN108878959AImprove mechanical propertiesImprove thermal stabilitySolid electrolytesSecondary cellsSolid state electrolytePtru catalyst

The invention relates to preparation and application of an organic-inorganic composite solid-state electrolyte, and relates to the technical field of a lithium ion battery electrolyte. The organic-inorganic composite solid-state electrolyte is prepared by selecting an isocyanate compound having rigid characteristic, a flexible chain segment compound capable of complexing and dissociating with lithium ions, inorganic nanoparticles, a conductive lithium salt and an organic solvent and adding a tin catalyst for crosslinking and curing. With the isocyanate compound, the mechanical property and thethermal stability of the composite solid-state electrolyte can be improved; by the flexible chain segment compound and the inorganic nanoparticles, the ion conductivity, the ion transfer number and the wide electrochemical window of the composite solid-state electrolyte can be improved, the charge-discharge performance of the lithium ion battery is improved, and the interface contact of the solid-state lithium ion battery is improved; and the organic-inorganic composite solid-state electrolyte has the advantages of excellent interface stability, wide electrochemical window, wide working temperature range, high ion conductivity and versatile shapes and is applicable to a lithium ion polymer battery.

Owner:BEIJING UNIV OF TECH

Thermosetting resin composition, prepreg prepared from composition, and laminated board prepared from composition and used for printed circuit board

ActiveCN102585480AEasy to processLow dielectric constantSynthetic resin layered productsMetal layered productsDielectric loss factorMetal foil

The invention relates to a thermosetting resin composition, a prepreg prepared from the composition, and a laminated board prepared from the composition and used for a printed circuit board. The thermosetting resin composition comprises phosphorus-containing low molecular weight polyphenyl ether resin, epoxy resin, cyanate resin and an accelerator. The prepreg prepared from the resin composition comprises a base material and the thermosetting resin composition which is impregnated and dried and attached to the base material. The laminated board prepared from the resin composition and used for the printed circuit board comprises a plurality of superposed prepregs and metal foils laminated on one side or two sides of the superposed prepregs, wherein each prepreg comprises the base material and the thermosetting resin composition which is impregnated and dried and attached to the base material. The thermosetting resin composition has low dielectric constant and dielectric loss factor and high heat resistance, glass transition temperature, flame retardance and the like; and the laminated board prepared from the composition and used for the printed circuit board has high metal foil peeling strength, heat resistance and dielectric property and is suitable for a high-frequency high-speed electronic circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

Prepolymers and polymers for elastomers

InactiveUS20100266799A1Isocyanic acid derivatives preparationOrganic compound preparationPolyesterPolyol

A prepolymer or elastomer is the reaction product of reactants (a) at least one polyester polyol or fatty acid derived polyol which is the reaction product of at least one initiator and a mixture of fatty acids or derivatives of fatty acids comprising at least about 45 weight percent monounsaturated fatty acids or derivatives thereof, (b) optionally, at least one polyol which is different from the polyol of (a); and (c) at least one isocyanate compound (herein after isocyanate) having an average of at least about 1.8 isocyanate groups per molecule. A process comprises admixing reactants (a) at least one polyol composition comprising the fatty acid derived polyol which is the reaction product of at least one initiator and a mixture of fatty acids or derivatives of fatty acids comprising at least about any of 45 weight percent monounsaturated fatty acids or derivatives thereof; and (b) at least one isocyanate having an average functionality of at least about 1.8 under reaction conditions to form a reaction product which is an elastomer or prepolymer is formed therefrom. An article, coating or thermoplastic polyurethane comprises the elastomer is formed from the prepolymer of or using the process of the invention.

Owner:DOW GLOBAL TECH LLC

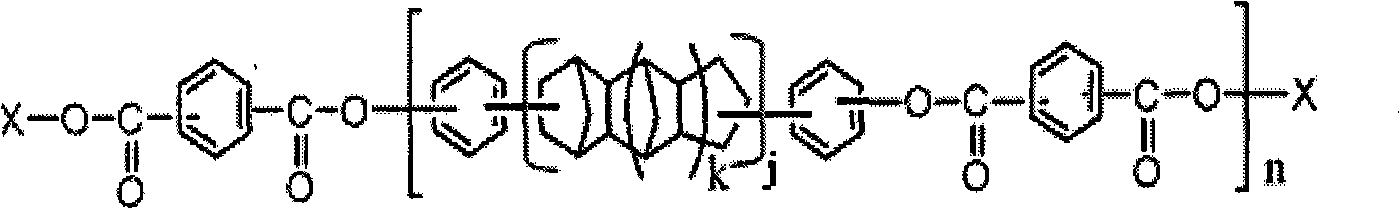

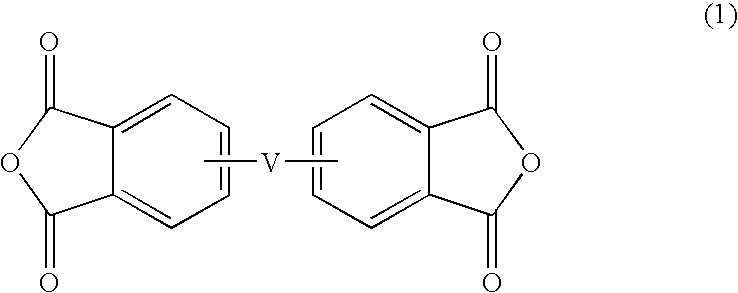

Epoxy resin composition, prepreg, laminate board, multilayer printed wiring board, semiconductor device, insulating resin sheet, and process for manufacturing multilayer printed wiring board

InactiveUS20100227170A1Reduction factorPreventing defect in appearanceSynthetic resin layered productsPrinted circuit aspectsHydrogenEthyl group

Disclosed is an epoxy resin composition essentially containing (A) an epoxy resin having a structure represented by the general formula (1), (B) a curing agent, (C) an inorganic filler and (D) a cyanate resin and / or a prepolymer thereof, wherein Ar represents a fused aromatic hydrocarbon group; r is an integer of 1 or more; X is a hydrogen or an epoxy group (glycidyl ether group); R1 represents one selected from the group consisting of a hydrogen, a methyl group, an ethyl group, a propyl group, a butyl group, a phenyl group and a benzyl group; n is an integer of 1 or more; p and q are an integer of 1 or more; and p's and q's in respective repeating units may be the same as or different from one another.

Owner:SUMITOMO BAKELITE CO LTD

Production of low-free TDI polyurethane curing agent, curing agent therefrom and its products

A low-free radical TDI polyurethane curing agent, its production and product are disclosed. The process is carried out by putting tolylene-diisoester cyanate, solvent S and catalyst A into reactor, adding into antioxidant and long-chain alcohol, agitating in reactor, heating, keeping temperature, inspecting NCO value, adding into phase-transferring solvent X while reaching NCO value to 20-40%, adding into catalyst B till reaching NCO value to 10-15, adding into inhibitor to stop reaction, adding into solvent S, decreasing pressure, distilling and removing phase-transferring solvent X. It's cheap and convenient.

Owner:BEIJING ZHANCHEN CHEM +2

Fibre-reinforced polyurethane modified polyisocyanurate composite material and preparation method thereof

The invention discloses a fiber reinforced polyurethane modified polyisocyanurate composite material and a preparation method thereof. It is characterized in that it is composed of a fiber mat and a polyisocyanate-containing polyurethane composition poured on the fiber mat, foamed and cured. Among the components of the polyurethane composition, The weight of the polyurethane composite material includes 75%-96% of combined polyalcohol and 1%-3% of foaming agent. The invention adopts polyol as the main raw material and water as the foaming agent, so that the composite material has good fluidity while having excellent characteristics, and can be demolded quickly; the molecular hydroxyl number is between 2 and 4, Polyols with a hydroxyl value between 300 and 700 can reduce the viscosity of the composite material and improve fluidity. The use of small molecular polyols can reduce the viscosity of the composite material, improve fluidity, and increase the initial strength of the product, which can be quickly released from the mold. .

Owner:SHANGHAI HAOHAI CHEM +1

Polyurethane shape memory macromolecule material and synthetic technique thereof

A polyurethane shape memory polymer material and its synthesis are disclosed. The process is carried out by vacuum dewatering, pre-polymerization reacting 2,4-toluene diiso-cyanate with DMF under N2 protection, dripping into polyhydric alcohol to obtain pre-polymer, chain-extending reacting DMPA with 1,4-BDO, neutralization reacting TEA with DMPA carboxyl, and adding water 300-1000 ml to obtain final product. The final solution concentration is 15-25 mol%. It has excellent waterproof, gas-permeation performances and moisture-penetrability.

Owner:XI'AN POLYTECHNIC UNIVERSITY

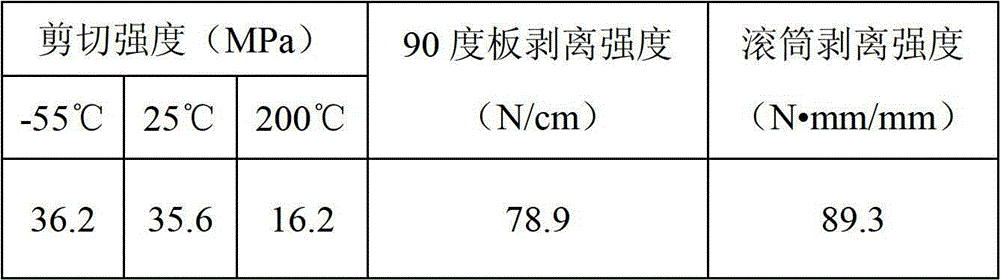

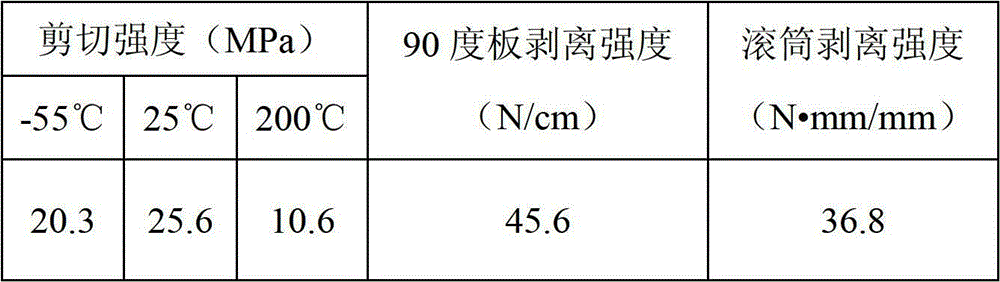

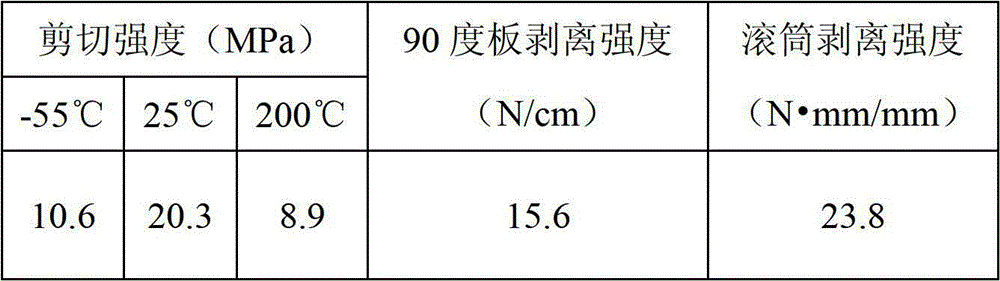

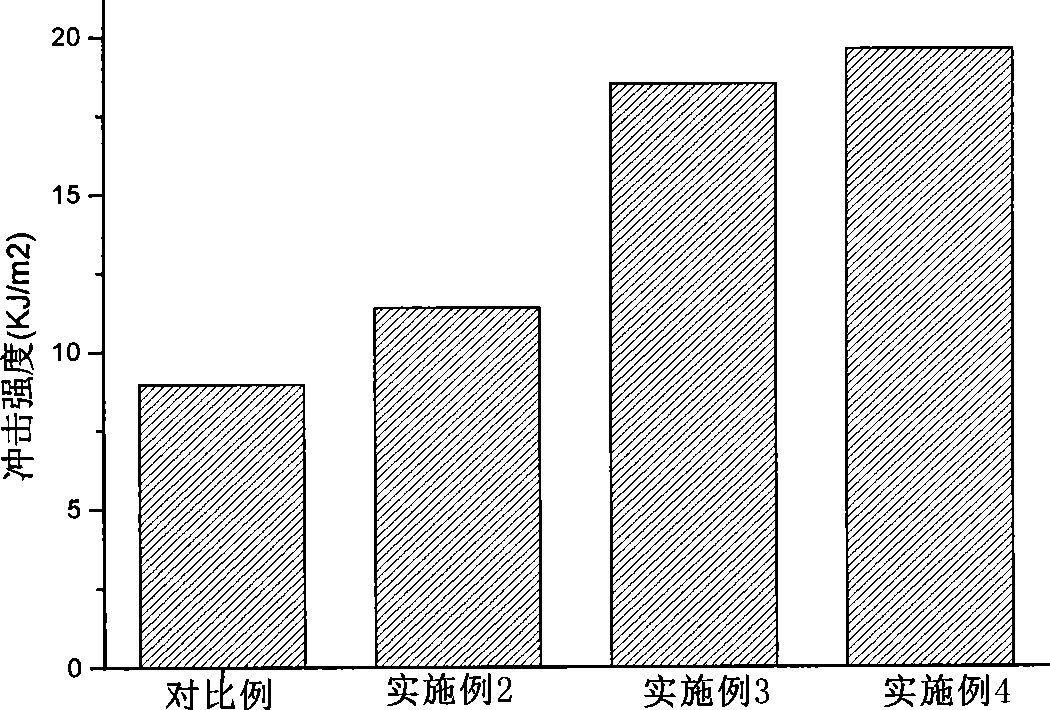

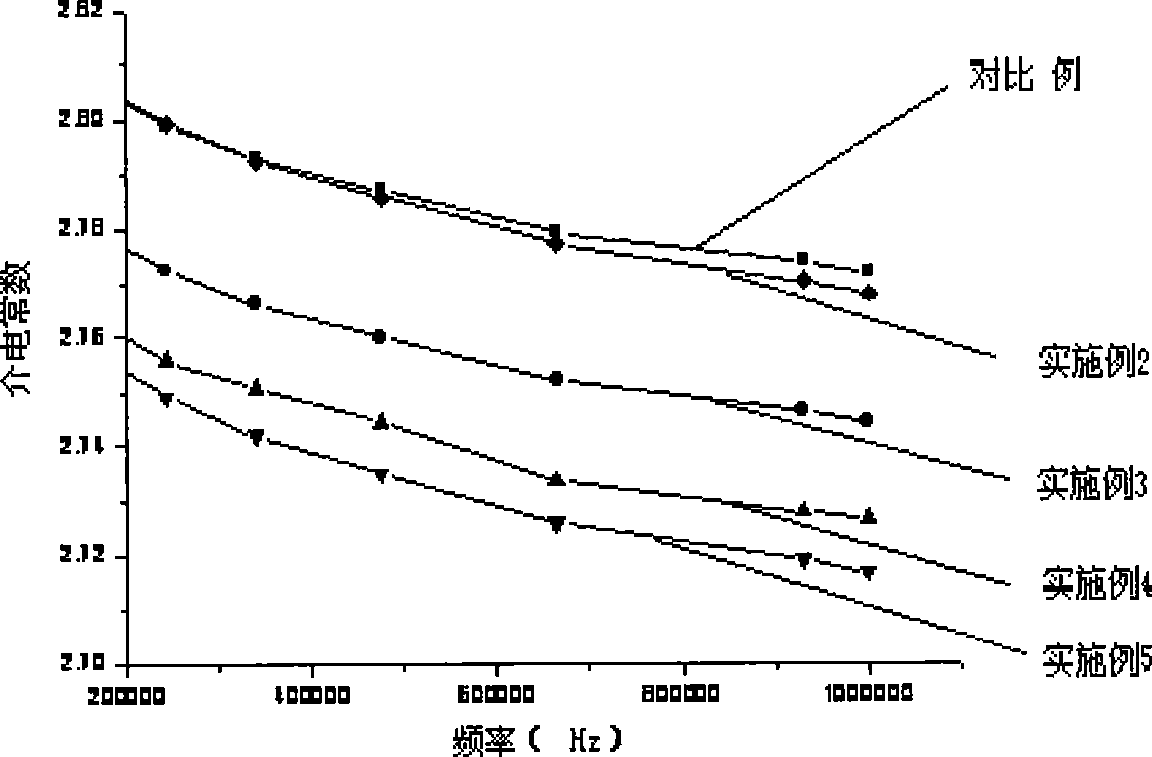

Modified cyanate adhesive film and preparation method thereof

ActiveCN102876247AGood mechanical propertiesEasy to operateNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention relates to a modified cyanate adhesive film and a preparation method thereof, belonging to the field of modified cyanate adhesive films and preparation methods thereof. The invention aims at solving the technical problems that the surface of the cyanate adhesive film prepared by using the existing cyanate adhesive film preparation method is apt to be crystallized during placing at room temperature, the mechanical performance is low and the curing temperature is high. The modified cyanate adhesive film is prepared by using the following components in parts by weight: 60-100 parts of cyanate resin, 5-40 parts of epoxy resin, 1-50 parts of toughened resin, 1-10 parts of activated thinner and 1-5 parts of accelerator. The preparation method comprises the following steps of: 1) weighing raw materials; 2) preparing matrix resin; 3) preparing adhesive; and 4) preparing the modified cyanate adhesive film. The modified cyanate adhesive film and the preparation method thereof are used in the fields of aerospace and electronic information.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Polymeric additives to improve print quality and permanence attributes in ink-jet inks

One-part and two-part fixatives are provided in conjunction with underprinting or overcoating at least one ink printed on a print medium. The one-part fixative of the present invention comprises a polymer in a vehicle. The polymer is selected from the group consisting of vinyl-based polymers, condensation polymers, and copolymers thereof and the polymer has a glass transition temperature within a range of -50° C. to +100° C., a melting temperature within a range of 30° C. to 150° C., and a molecular weight (weight average basis) within a range of 3,000 to 100,000. The fixative is contained in a separate cartridge from the ink-jet ink print cartridge(s). The two-part fixative of the present invention comprises (1) a reactive monomer or oligomer in a vehicle, the reactive monomer or oligomer selected from the group consisting of iso-cyanates and epoxy-terminated oligomers, and (2) at least one second component selected from the group consisting of polyols, polyvinyl alcohols, and base catalysts. The reactive monomer or oligomer is contained in a separate cartridge from the ink-jet ink print cartridge(s), while the second component(s) is contained in at least one ink-jet ink print cartridge. The reactive monomer or oligomer reacts with the second component(s) on the print medium to form a polymer, which has a glass transition temperature within a range of -20° C. to +50° C. and a melting temperature within a range of 30° C. to 100° C. Enhancement of waterfastness, smearfastness, smudgefastness, and lightfastness is provided by use of the fixative solution of the present invention.

Owner:HEWLETT PACKARD DEV CO LP

Modified ethylene rhodanate resin and preparation thereof

The invention relates to a modified cyanate resin and a preparation method thereof. Distilled water and Gamma-Methlacryloyl oxyl propyl trimethoxy silane are evenly mixed according to a mole ratio of 1.4:1 to 1.2:1; high concentration HCI is added to the solution until the PH value thereof is 1 to 2; after 10 to 15 minutes, the solution is heated up to 50 DEG C to 60 DEG C and reacts continuously for 4 hours to 6 hours; a hyperbranched polysiloxane with double bond as terminal group is obtained through vacuum drying. By weight, 1 portion to 25 portions of the hyperbranched polysiloxane and 100 portions of cyanate are evenly mixed at the temperature of 80 DEG C to 150 DEG C to obtain the modified cyanate resin. The resin has high tenacity, quick curing, more prominent thermal stability, more excellent electrical property and damp-heat resistance. The preparation method adopted is characterized by wide applicability and simple operation process.

Owner:SUZHOU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com