High-bright-black, scratch-resistant and thin-walled polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the thin-walled polypropylene composite material and its preparation, in the field of high gloss black and scratch resistance, can solve the problems of easy to appear scratches, intolerance to scratches, low hardness, etc. It has the effect of long-term effect, low production cost and high melting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific examples. Unless otherwise specified, each component in the examples is by weight.

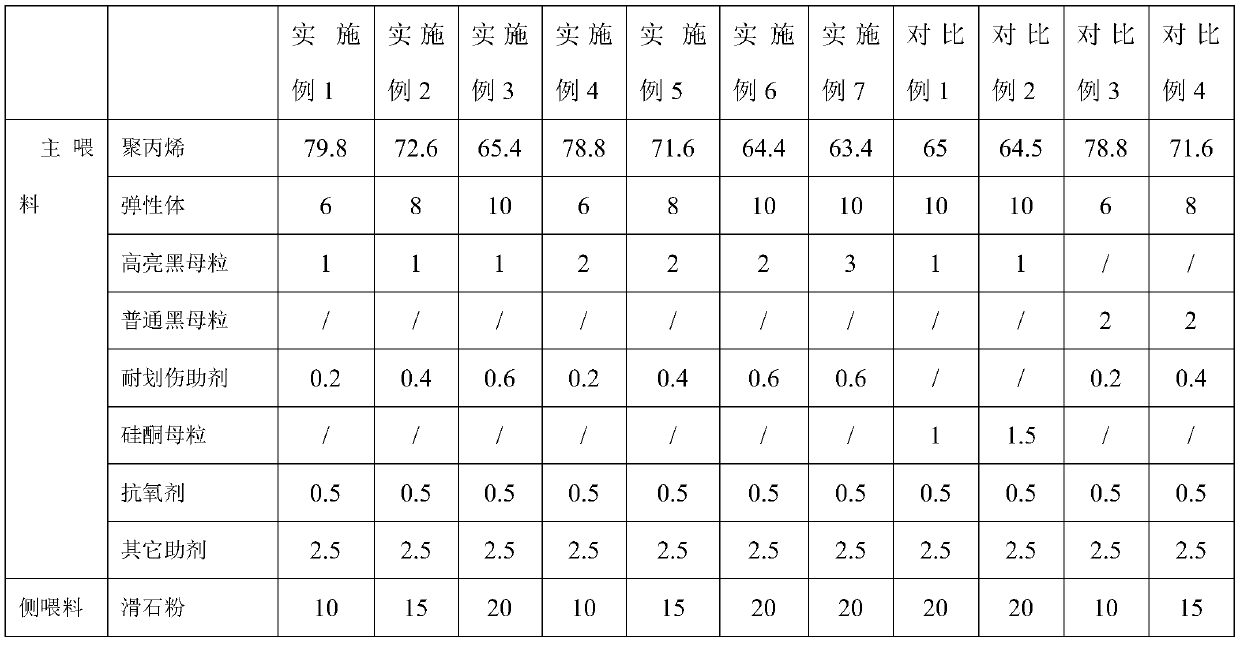

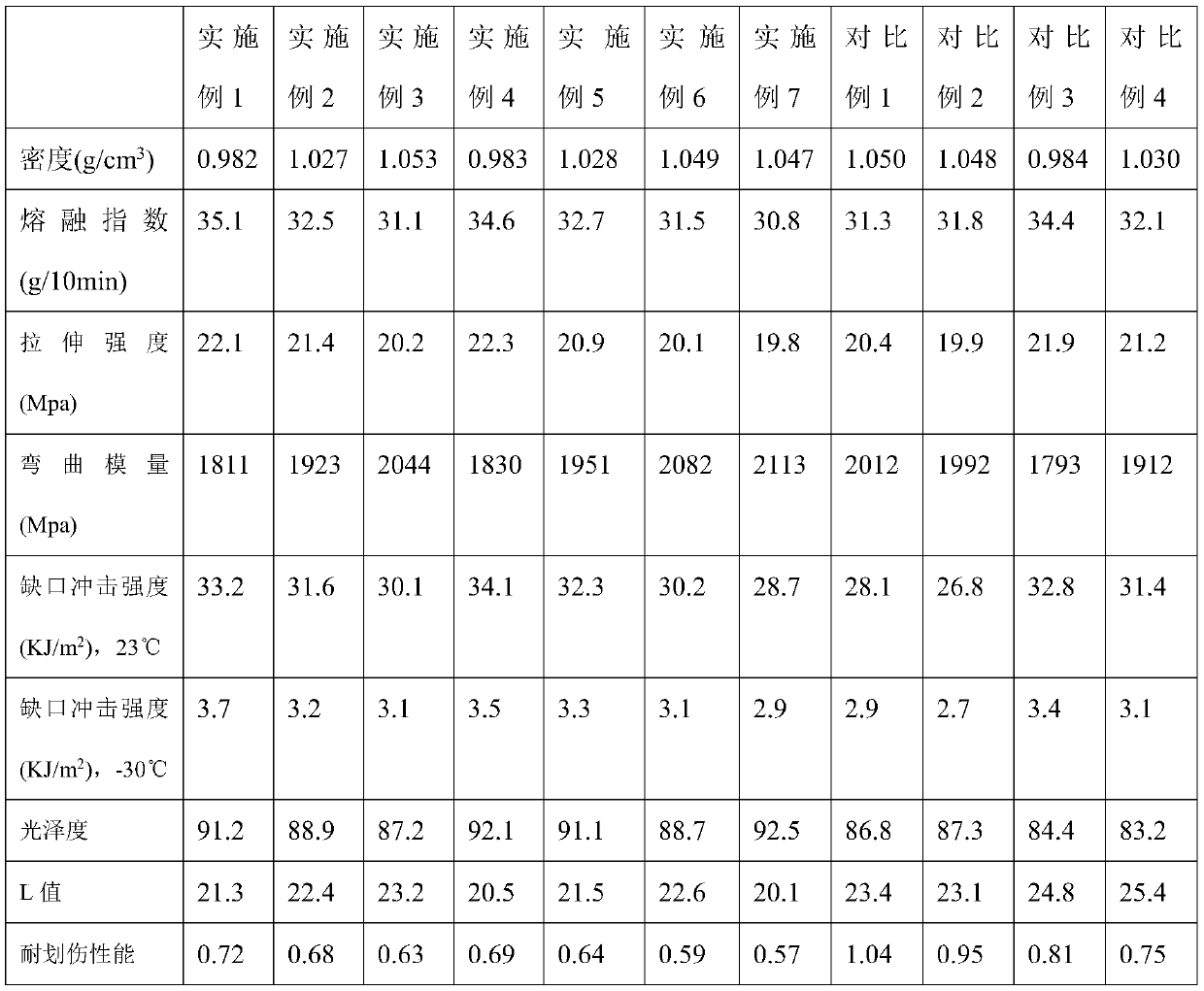

[0031] The contents of each component contained in the examples of the present invention and the comparative examples are shown in Table 1.

[0032] Table 1

[0033] Each main component content (mass percentage composition) in embodiment and comparative example

[0034]

[0035] The polypropylene described in the examples and comparative examples in the above Table 1 is a copolymerized polypropylene, which is compounded with PP511 and BX3920 at a ratio of 1:1. The brand PP511 is produced by Zhongsha Tianjin Company, and the melt flow rate is 30g respectively. / 10min, the brand BX3920 is produced by SK Company in South Korea, and the melt flow rate is 100g / 10min. Described talcum powder is the talcum powder of about 5000 meshes, commercially available. Described elastomer is the thermoplastic POE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com