Low-cost eco-friendly polyester film for twist packaging and preparation method of polyester film

An environmentally-friendly polyester film technology, applied in the field of polyester film, can solve the problems of high cost and non-environmental protection of twisted packaging films, and achieve the effects of reducing production costs, improving kink resistance, and maintaining hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

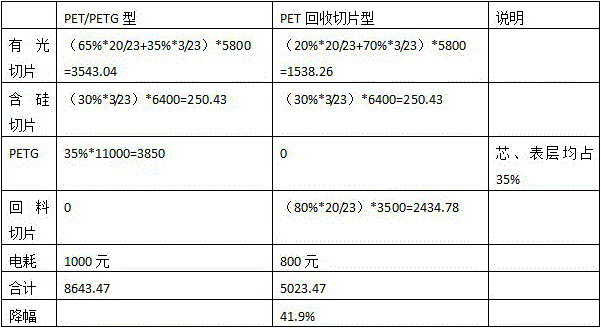

[0032] Embodiment 1. A low-cost, environment-friendly polyester film for twisted packaging with a thickness of 23 microns is prepared by three-layer co-extruded biaxially stretched production equipment at a production speed of 200 m / min. It consists of upper and lower surface layers and a core layer.

[0033] The thickness of the core layer is 20um, 20% bright polyester chips, 80% recycled polyester chips, the thickness of both surface layers is 1.5um, 70% bright polyester chips, 30% silicon-containing polyester chips ( Silica concentration 3000ppm, particle size 3.9um).

[0034] The production process of this example mainly includes the following steps:

[0035] A. Preparation of the core layer: Fluidize the proportioned core layer polyester slices through a fluidized bed at a temperature of 170°C for 15-20 minutes into a drying tower, and dry them at a temperature of 160°C for 4-5 hours in the drying tower to obtain Dry raw materials; the dry raw materials are heated into a...

Embodiment 2

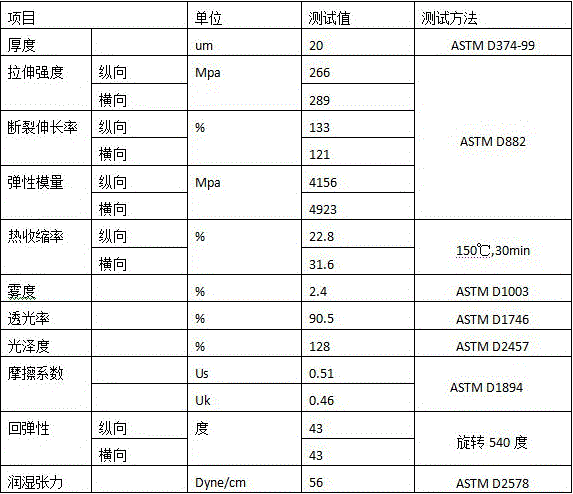

[0049] Embodiment 2, a low-cost environmentally friendly polyester film for twisted packaging with a thickness of 20 microns is prepared by three-layer co-extruded biaxially stretched production equipment, and the production speed is 230m / min. It consists of upper and lower surface layers and a core layer.

[0050] The thickness of the core layer is 17um, 25% bright polyester chips, 75% recycled chips; the thickness of the two surface layers is 1.5um, 70% bright polyester chips, 30% silicon-containing polyester chips (dioxide Silicon concentration 3000ppm, particle size 3.9um).

[0051] The production process of this example mainly includes the following steps:

[0052] A. Preparation of the core layer: Fluidize the well-proportioned core layer raw materials through a fluidized bed at a temperature of 170°C for 15-20 minutes into a drying tower, and dry them in a drying tower at a temperature of 160°C for 4-5 hours to obtain dried raw materials The dry raw material is heated ...

Embodiment 3

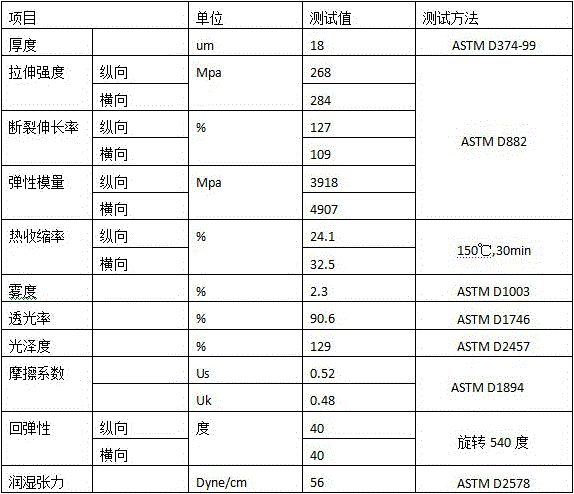

[0066] Example 3: A low-cost, environment-friendly polyester film for twisted packaging with a thickness of 18 microns is prepared using three-layer co-extruded biaxially stretched production equipment at a production speed of 250 m / min. It consists of upper and lower surface layers and a core layer.

[0067] The thickness of the core layer is 15um, 30% bright slices, 70% recycled slices; the thickness of the two surface layers is 1.5um, 70% bright polyester slices, 30% silicon-containing polyester slices (silicon dioxide concentration 3000ppm, particle size 3.9um).

[0068] The production process of this example mainly includes the following steps:

[0069] A. Preparation of the core layer: Fluidize the well-proportioned core layer raw materials through a fluidized bed at a temperature of 170°C for 15-20 minutes into a drying tower, and dry them in a drying tower at a temperature of 160°C for 4-5 hours to obtain dried raw materials The dry raw material is heated into a molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com