Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

467results about How to "Increased free volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

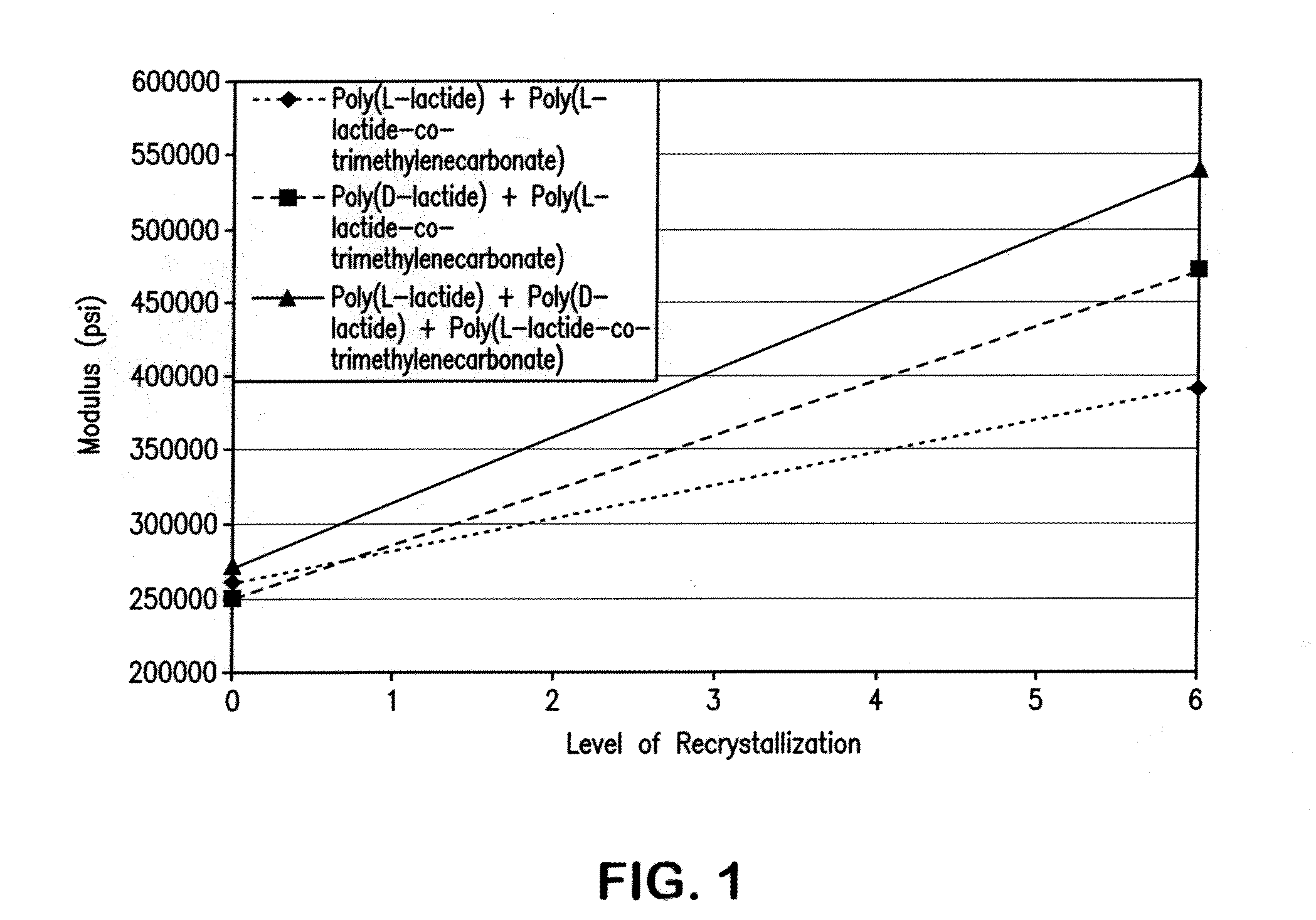

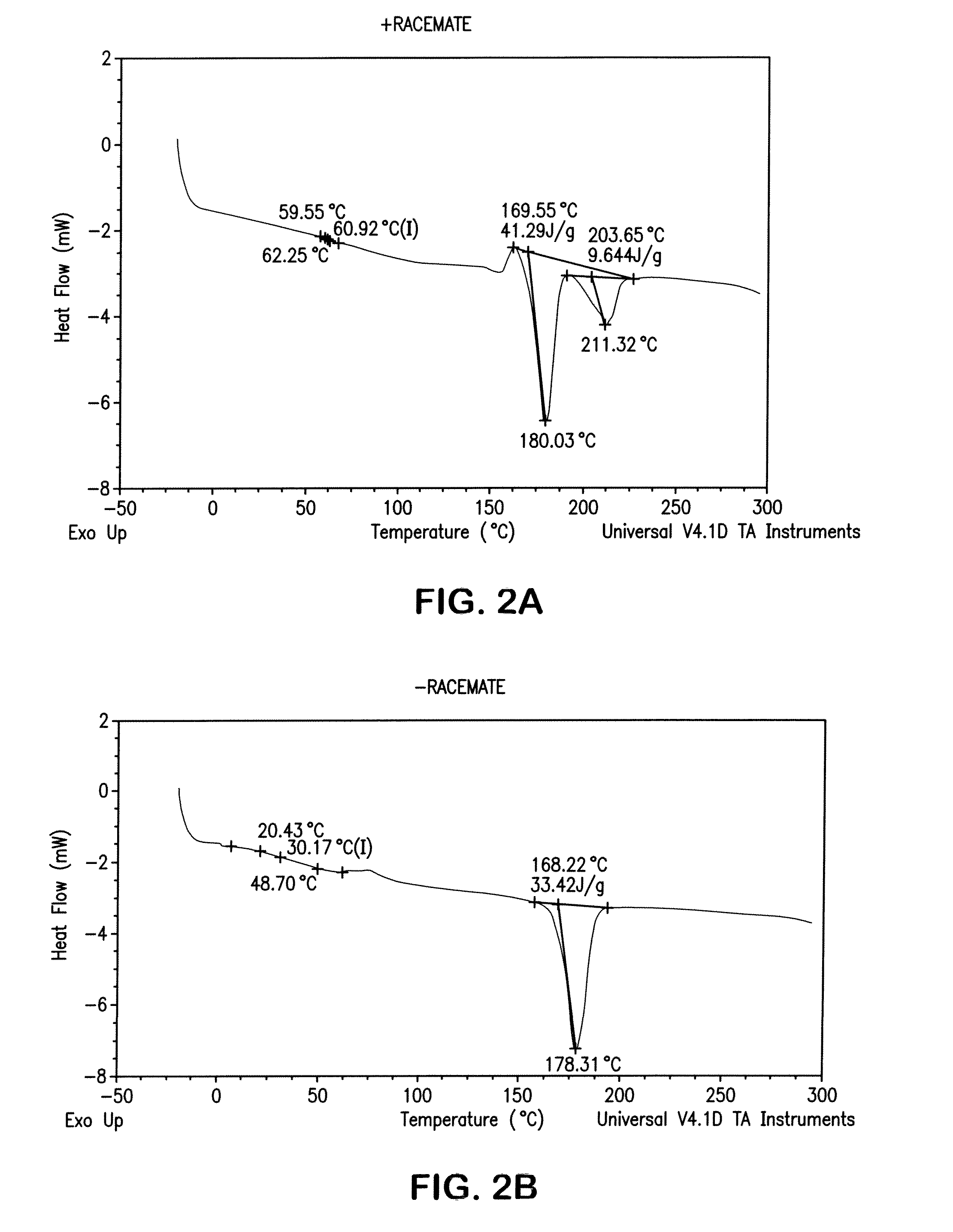

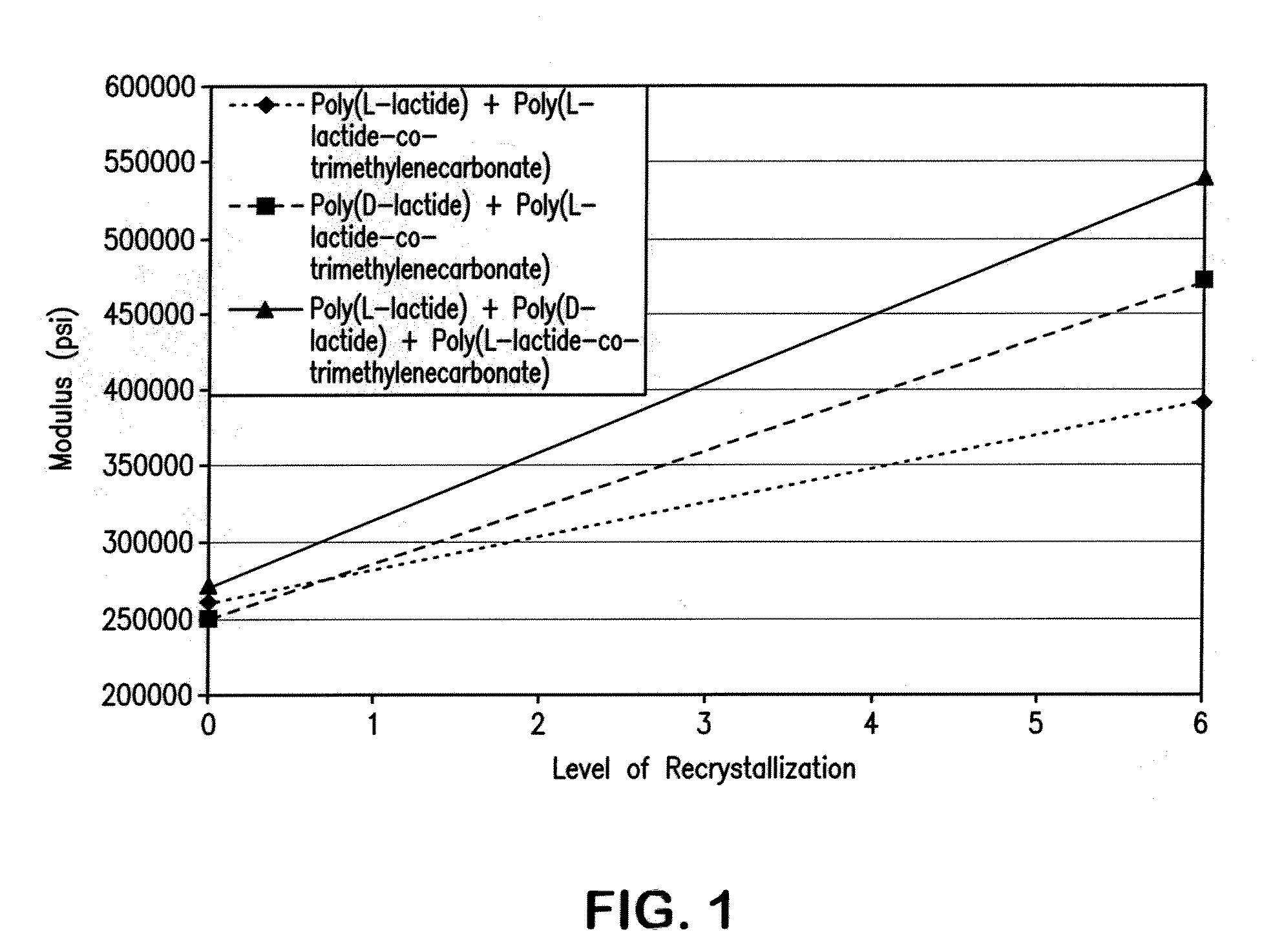

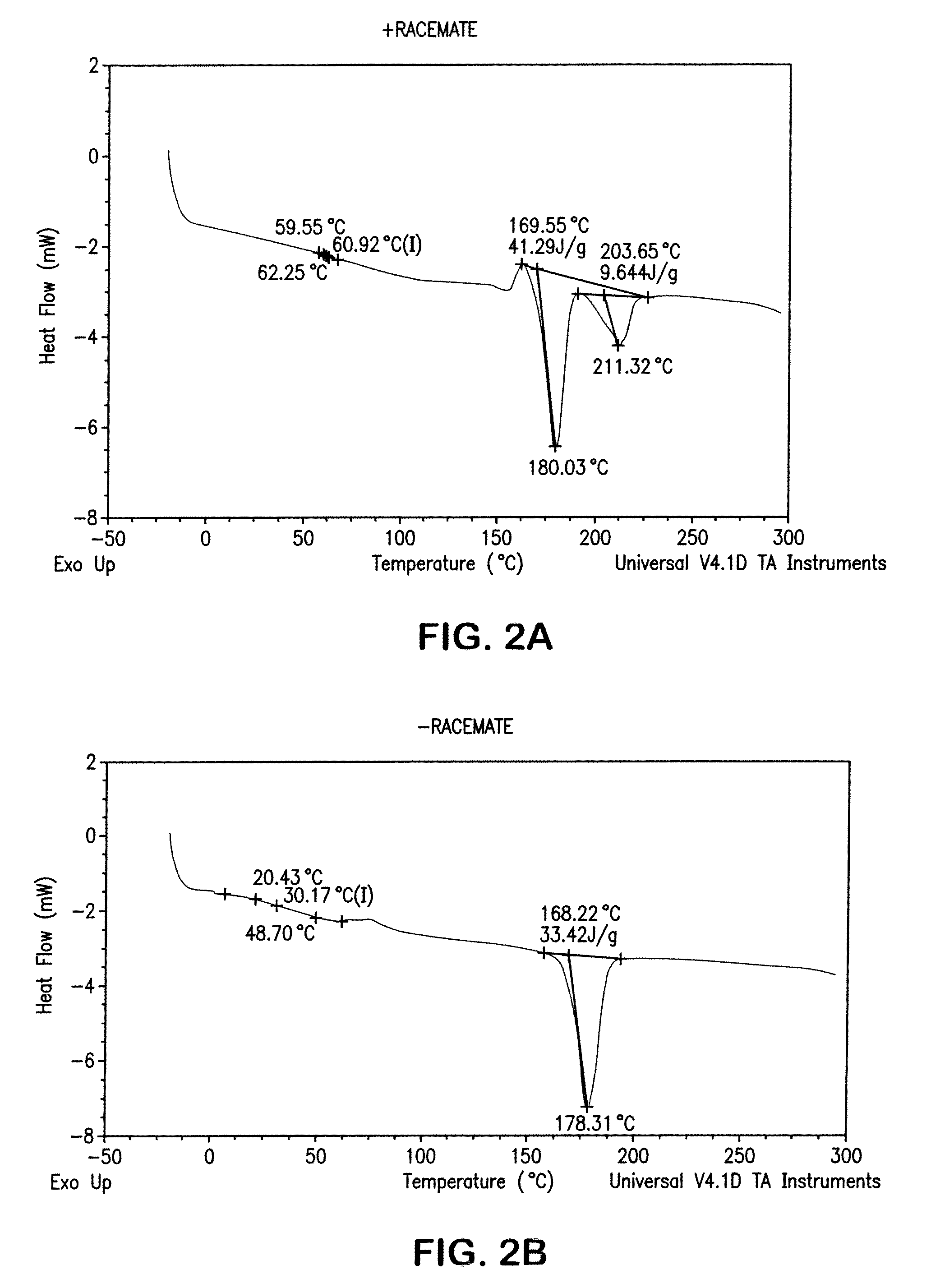

Bioabsorbable polymeric composition for a medical device

ActiveUS20080118546A1Less inflammatoryLower potential for traumaStentsSurgeryMedical deviceCopolymer

Owner:ORBUSNEICH MEDICAL PTE LTD

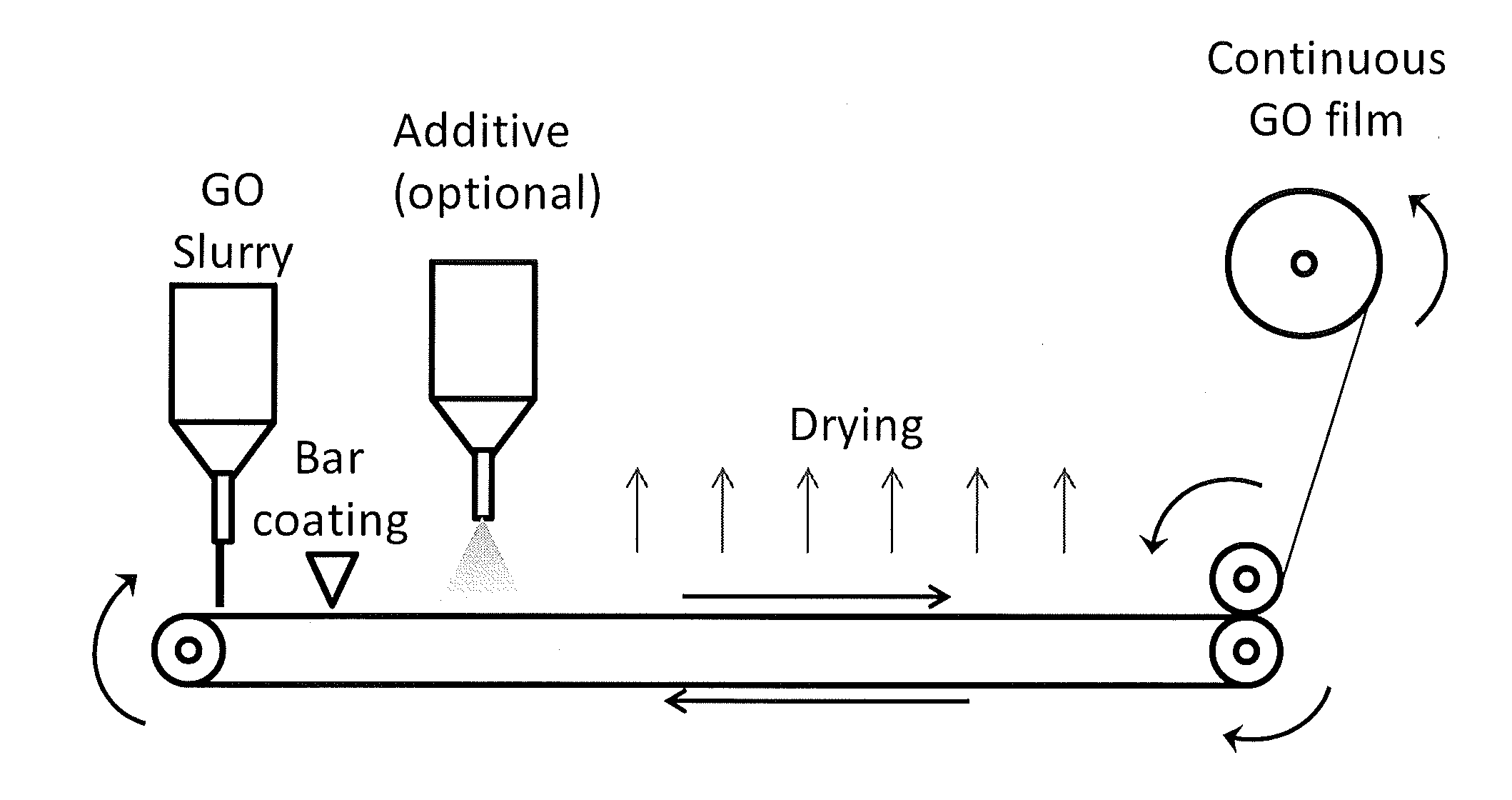

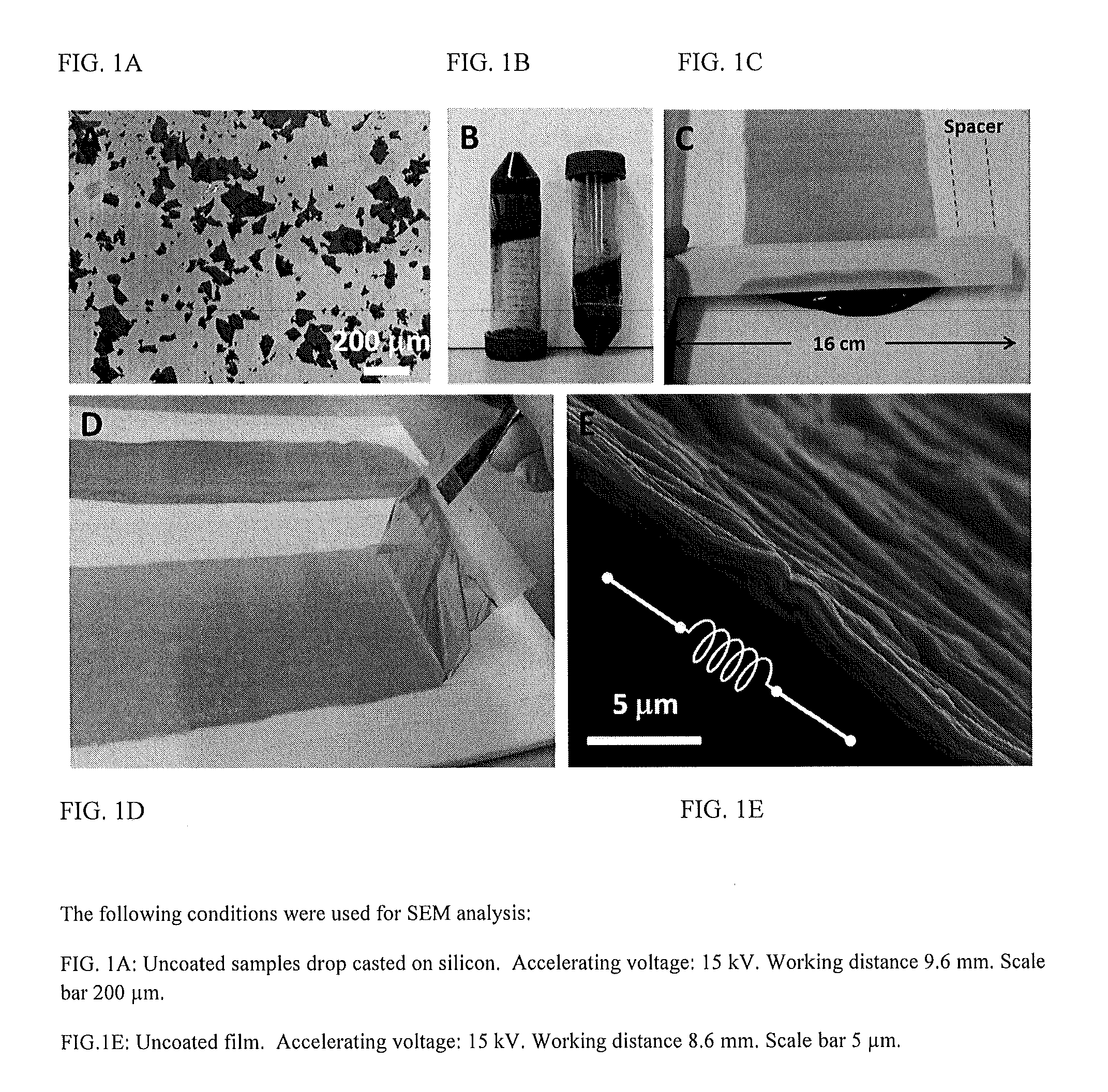

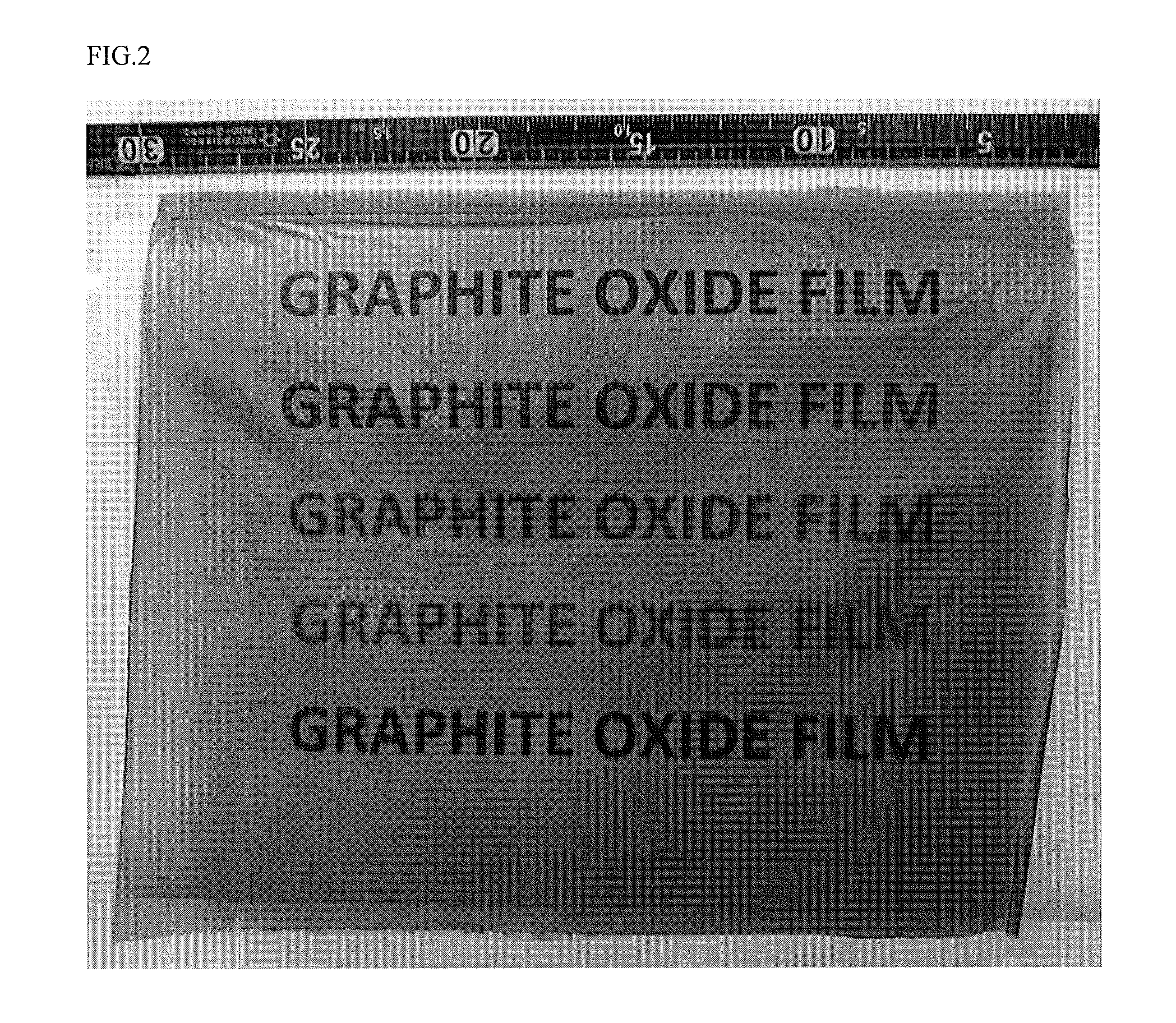

Method for preparing graphene oxide films and fibers

ActiveUS20150111449A1Improve conductivityHigh densityCarbon compoundsFilament/thread formingFiberSolid content

We report a method of preparation of highly elastic graphene oxide films, and their transformation into graphene oxide fibers and electrically conductive graphene fibers by spinning. Methods typically include: 1) oxidation of graphite to graphene oxide, 2) preparation of graphene oxide slurry with high solid contents and residues of sulfuric acid impurities. 3) preparation of large area films by bar-coating or dropcasting the graphene oxide dispersion and drying at low temperature. 4) spinning the graphene oxide film into a fiber, and 5) thermal or chemical reduction of the graphene oxide fiber into an electrically conductive graphene fiber. The resulting films and fiber have excellent mechanical properties, improved morphology as compared with current graphene oxide fibers, high electrical conductivity upon thermal reduction, and improved field emission properties.

Owner:PENN STATE RES FOUND +1

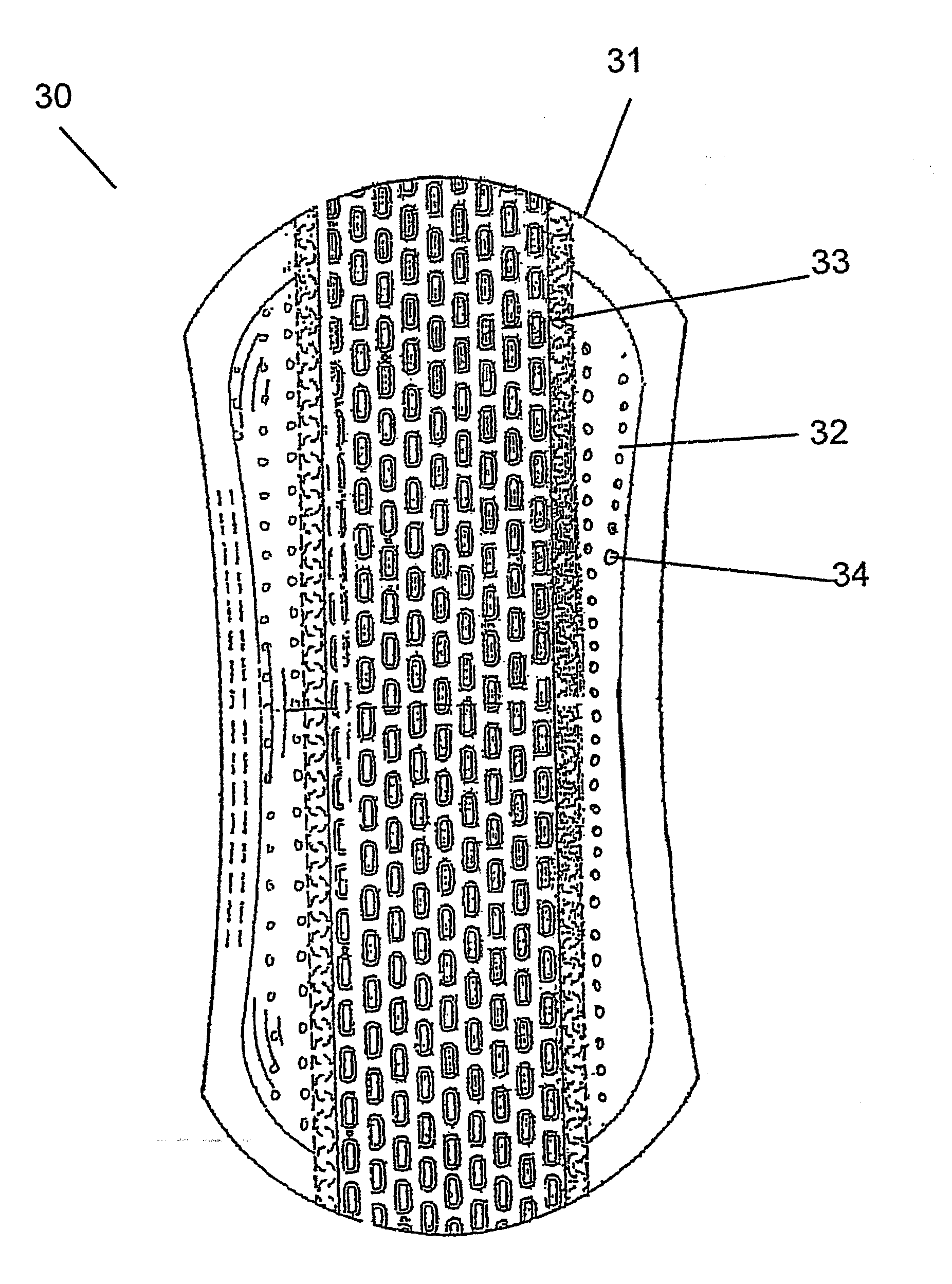

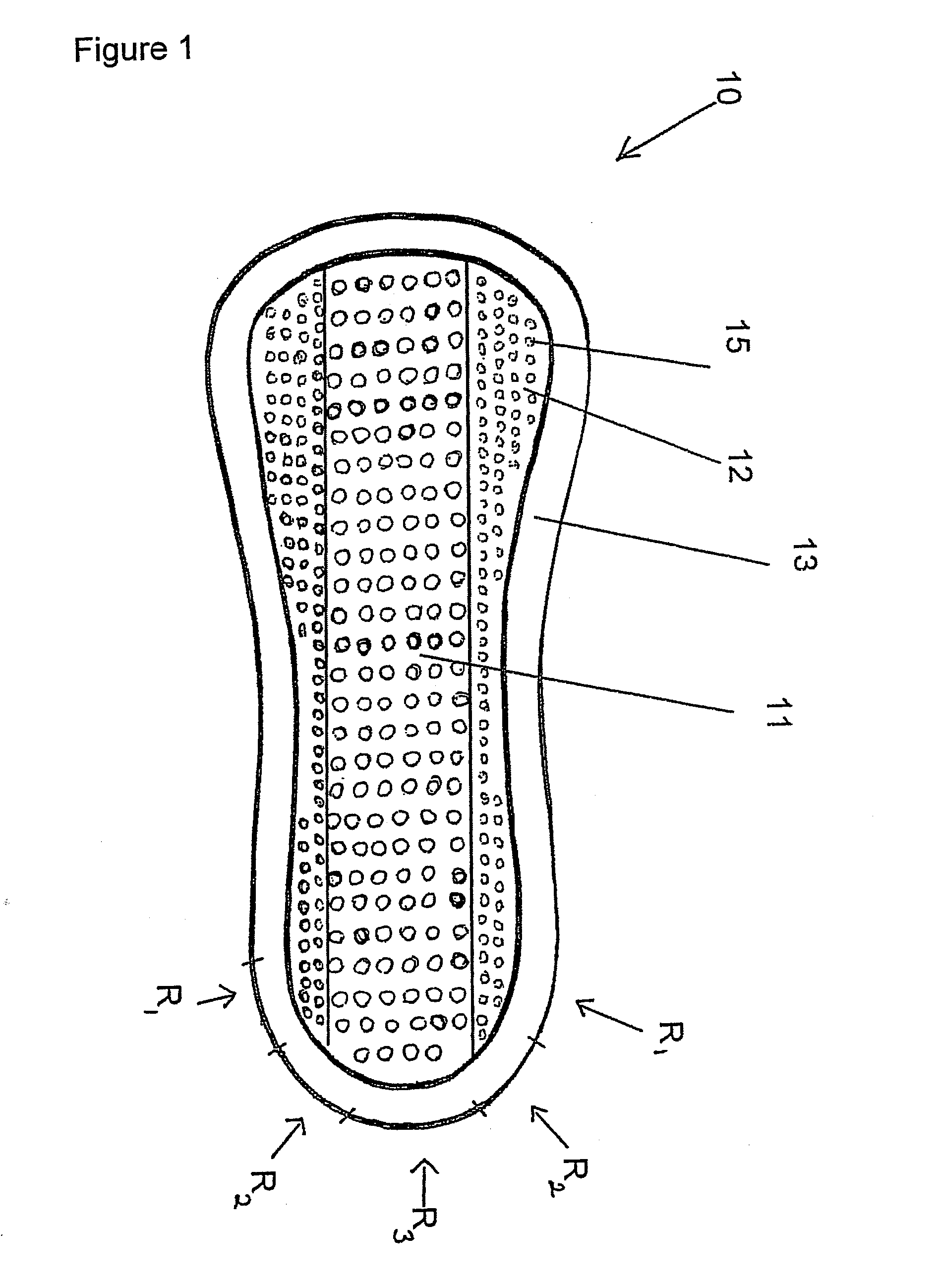

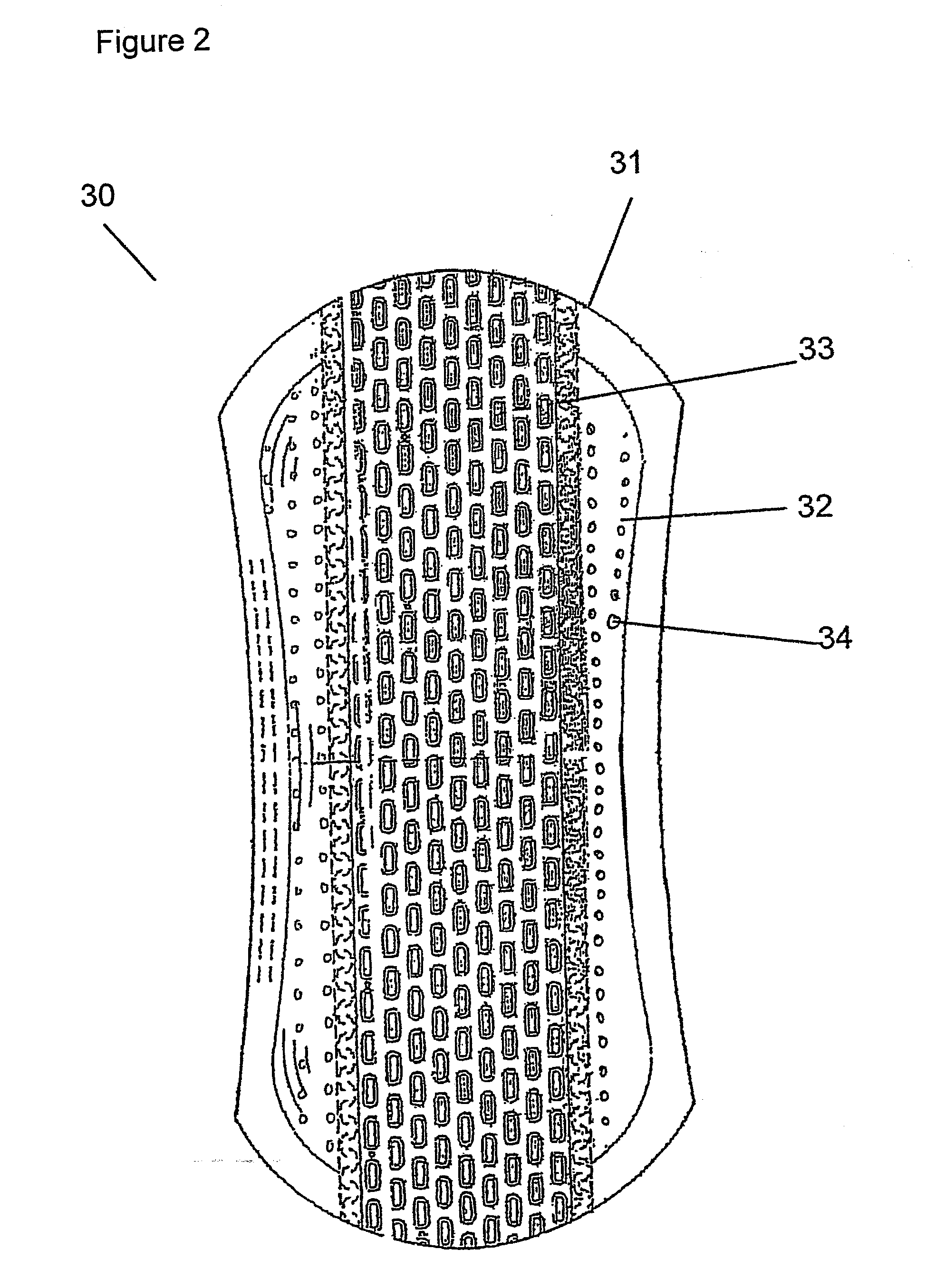

Absorbent product

InactiveUS20110106036A1Increased free volumeDistanceSanitary towelsBaby linensMechanical engineeringMoisture

The invention refers to an absorbent product including a liquid permeable apertured top sheet facing the wearer during use, and a liquid-impermeable back sheet facing away from the wearer during use, whereby longitudinally extending textile-like edges are positioned on both longitudinal sides of the top sheet whereby the textile-like edges comprise apertures. Hereby, the textile-like edges will amongst others have the capacity to transport moisture that is formed at the interface between the textile-like edges and the wearer skin. Further, the apertures will allow a certain acquisition, i.e., liquid can be transported to the absorbent structure of the product.

Owner:SCA HYGIENE PROD AB

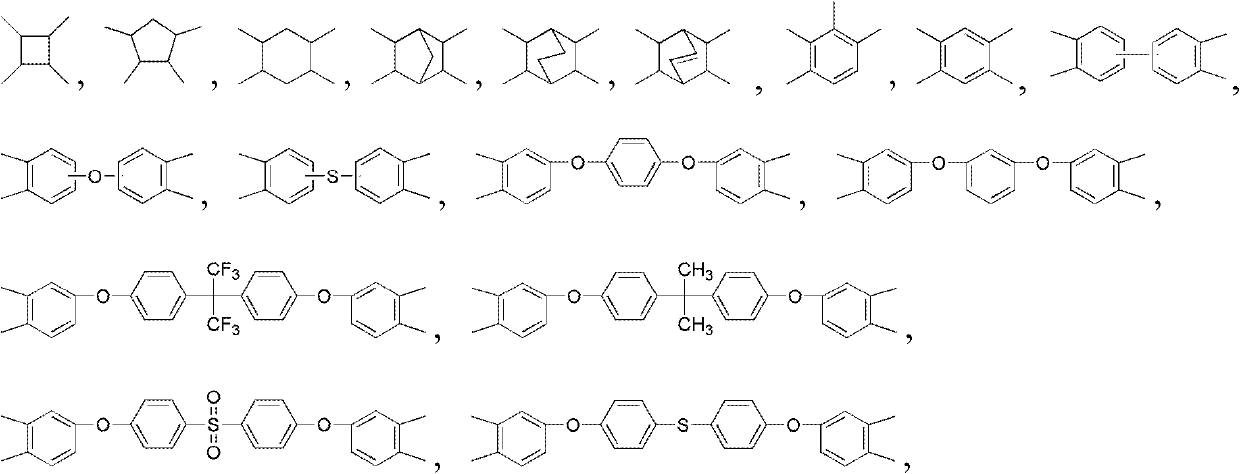

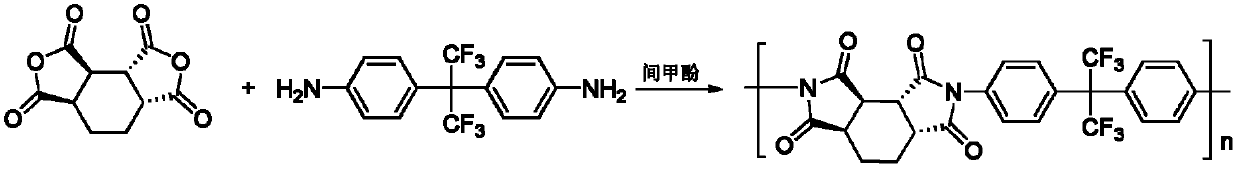

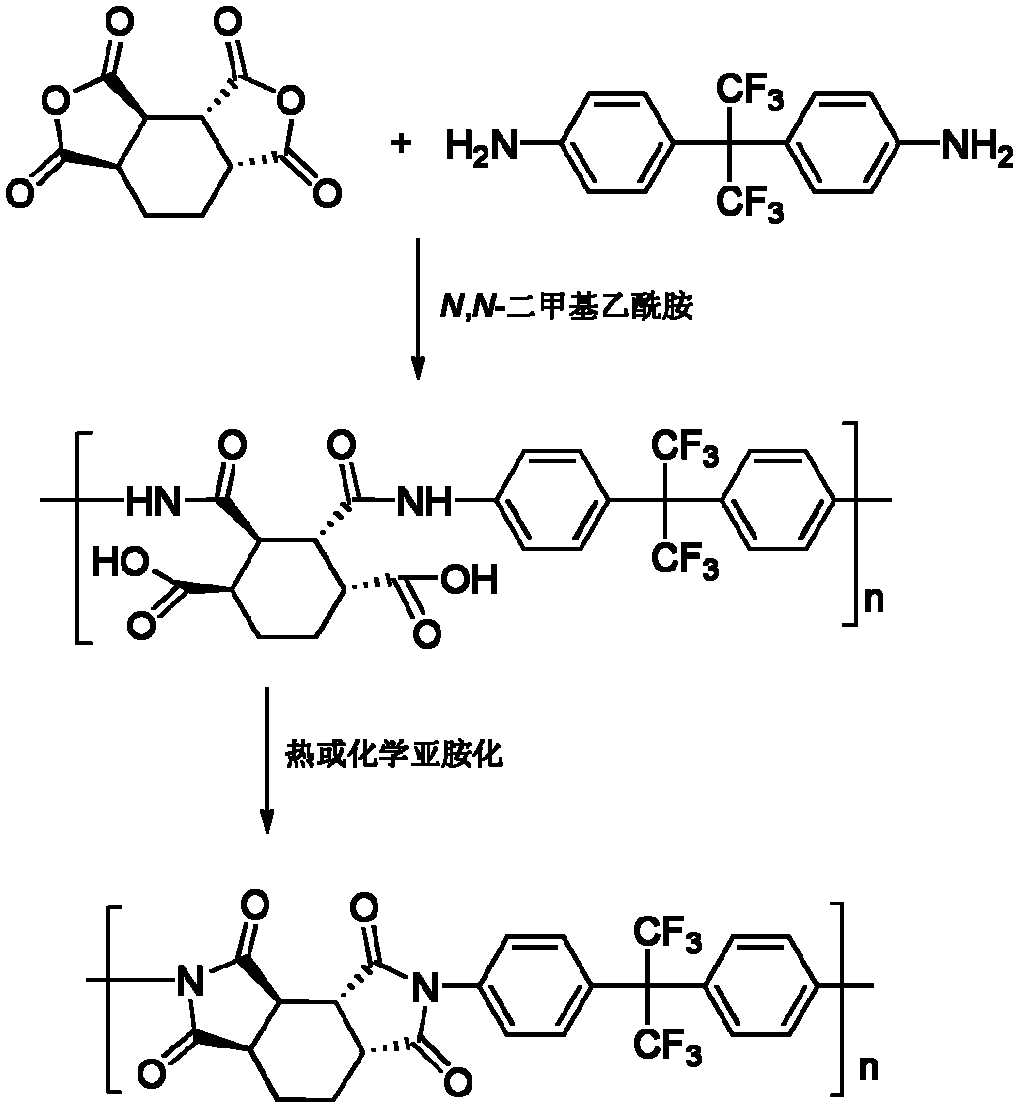

Colorless and transparent polyimide resin material and preparation method thereof

ActiveCN102382303AHigh transparencyHigh glass transition temperatureCharge-transfer complexUltraviolet lights

The invention discloses a colorless and transparent polyimide resin material. 1,2,3,4-cyclohexanetetracarboxylic dianhydride is chosen as dianhydride monomer or comonomer to carry out polycondensation reaction with primary diamine, so that the polyimide resin material is prepared. Because the 1,2,3,4-cyclohexanetetracarboxylic dianhydride comonomer has a distorted molecular structure, a large free volume exists between polymer molecular chains, and thereby the formation of charge transfer complex (CTC) in and between polyimide molecules is inhibited; and meanwhile, because of the introductionof a lipid structure, the electron-stimulated transition mode in the polyimide molecular chains is changed, the absorption of the aromatic polyimide in the visible light region is remarkably weakened, and thereby the transparency of the polymer is greatly increased. The ultraviolet light transmission cutoff wavelength of a produced polyimide film is 280nm to 380nm, the light transmissivity at 450nm is 86 to 94 percent, moreover, the glass-transition temperature is 250 DEG C to 400 DEG C, and the polyimide resin material has a good application prospect in the fields of flexible substrate materials for solar cells, flexible transparent conducting film substrate materials, liquid crystal display materials and the like.

Owner:WUHAN YIMAIDE NEW MATERIALS TECH CO LTD

Cleaning Method

InactiveUS20130276242A1Easy to cleanLower Level RequirementsOrganic detergent compounding agentsWashing processesWash waterCleaning methods

The invention provides a method for the cleaning of a soiled substrate, the method comprising treating the substrate with a solid particulate cleaning material and wash water, the treatment being carried out in an apparatus comprising a drum comprising perforated side walls and having a capacity of between 5 and 50 litres for each kg of fabric in the washload, wherein said solid particulate cleaning material comprises a multiplicity of polymeric particles at a particle to fabric addition level of 0.1:1-10:1 by mass, each particle being substantially cylindrical or spherical in shape and having an average density in the range of 0.5-2.5 g / cm3 and an average volume in the range of 5-275 mm3, and wherein said drum comprising perforated side walls is rotated at a speed which generates G forces in the range of from 0.05 to 900 G. The polymeric particles may comprise foamed or unfoamed polymeric materials which may comprise either linear or crosslinked polymers. Preferably, at least one detergent is employed in the cleaning process. The invention provides optimum cleaning performance as a result of improved mechanical interaction between substrate and cleaning media and is preferably used for the cleaning of textile fabrics. The method allows for significant reductions in the consumption of detergents, water and energy when compared with the conventional wet cleaning of textile fabrics, and also facilitates reduced washing-related textile fabric damage. The invention also envisages a cleaning composition comprising a solid particulate cleaning composition and at least one additional cleaning agent. In particular embodiments of the invention, the solid particulate cleaning material is separated and recovered and then re-used in subsequent cleaning processes. Typically, the solid particulate cleaning material is itself cleaned intermittently in order to maintain its efficacy.

Owner:XEROS LTD

Bioabsorbable Polymeric Composition for a Medical Device

ActiveUS20090281249A1Less inflammatoryLower potential for traumaStentsSurgeryMedical deviceCopolymer

Owner:ORBUSNEICH MEDICAL PTE LTD

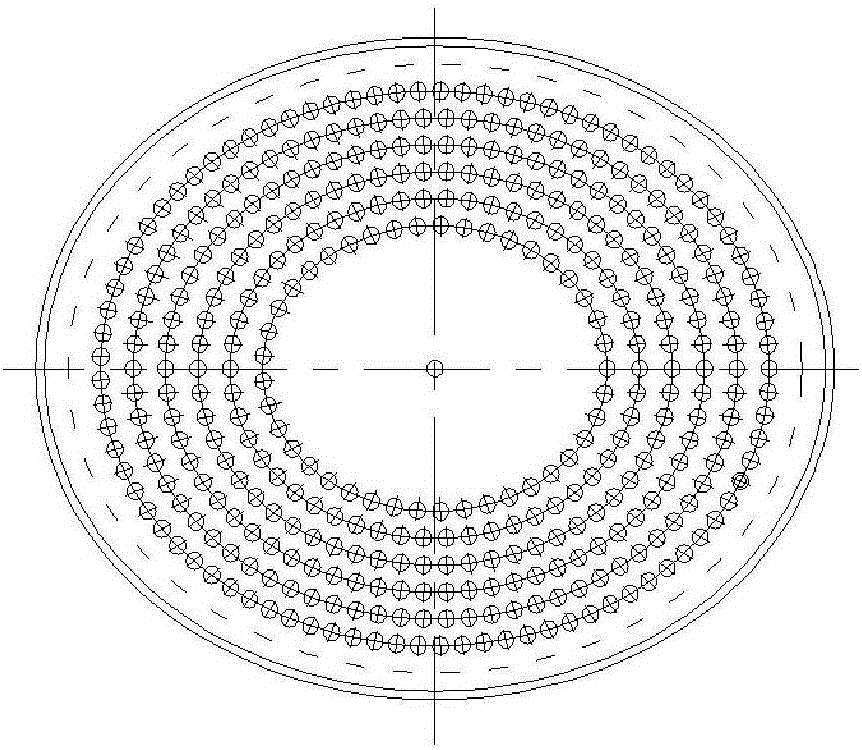

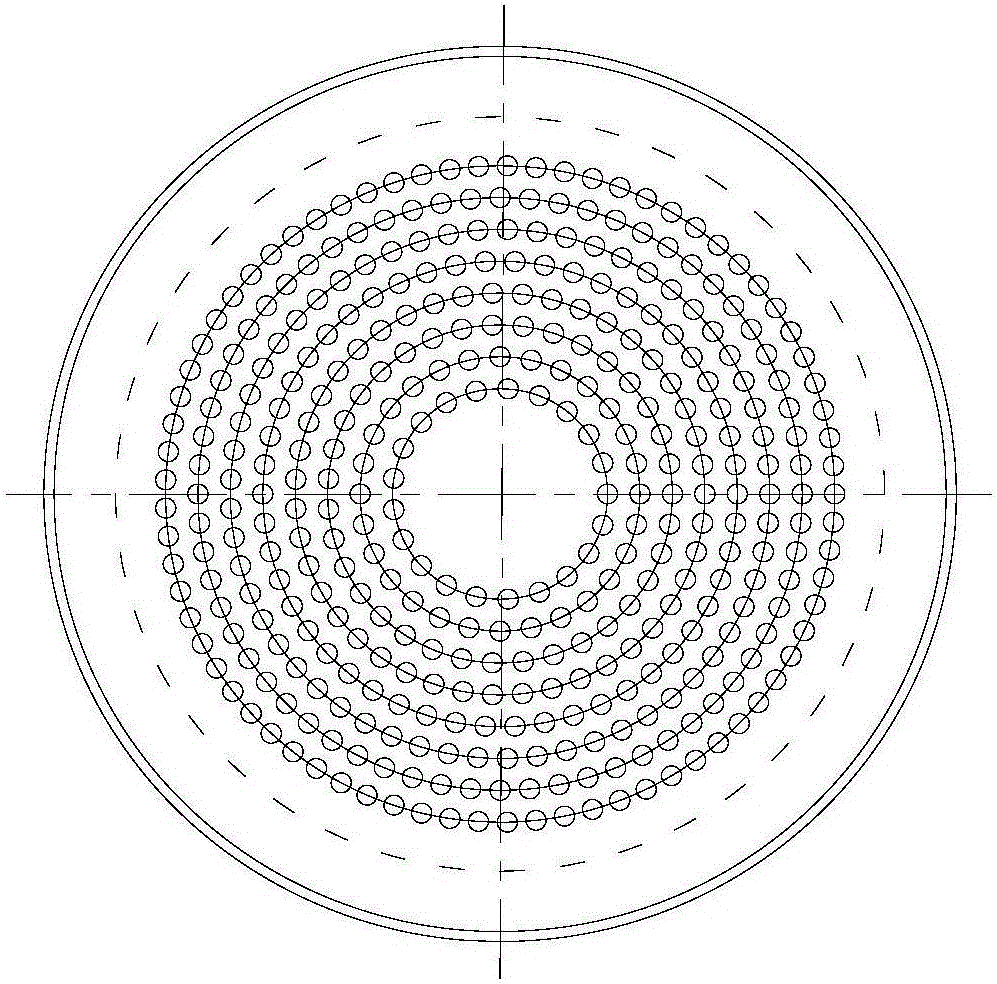

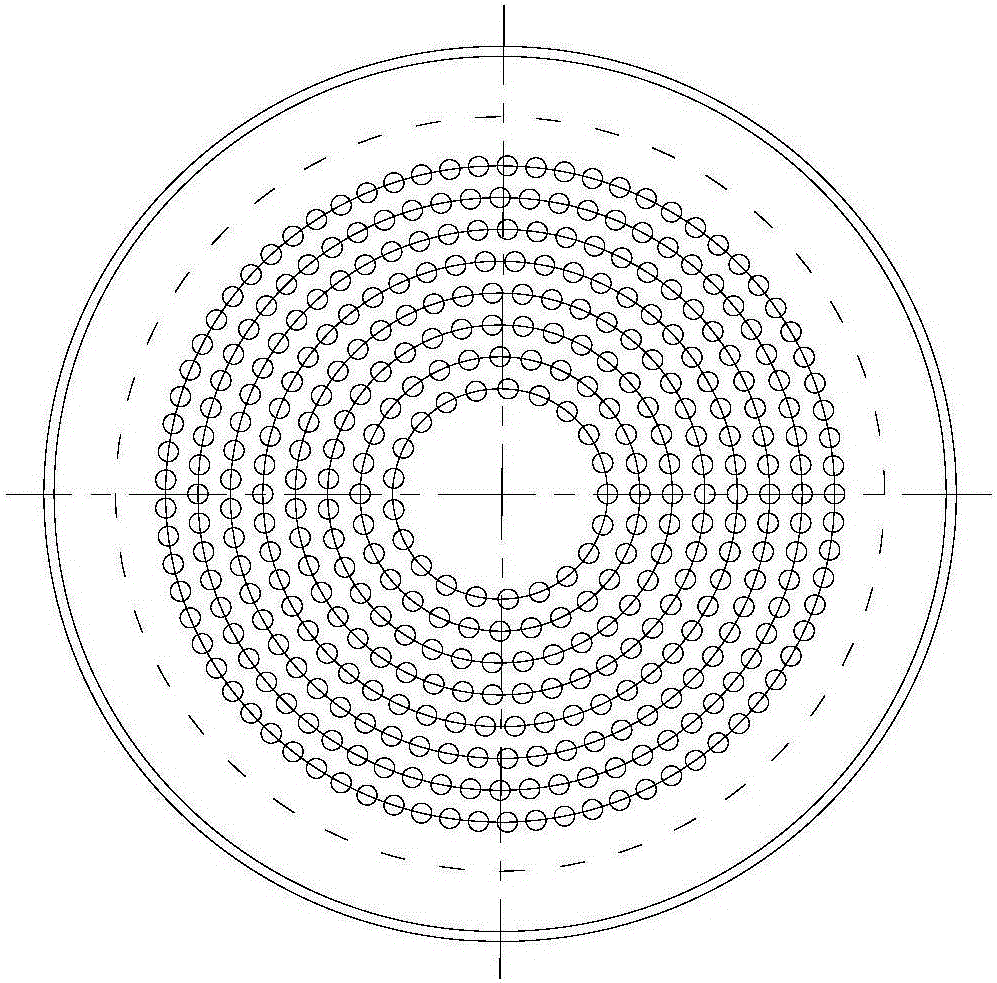

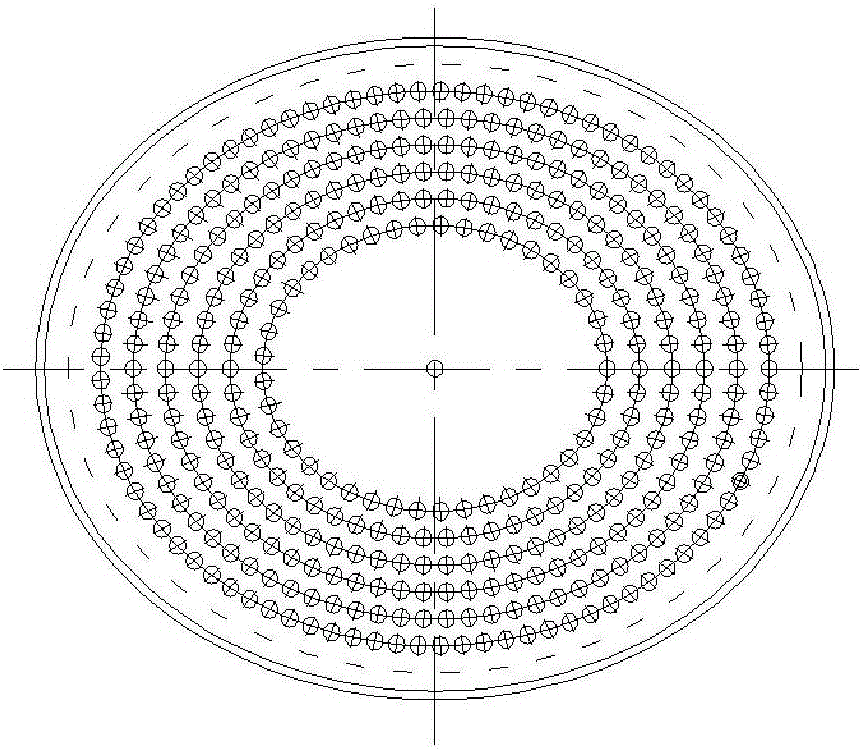

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

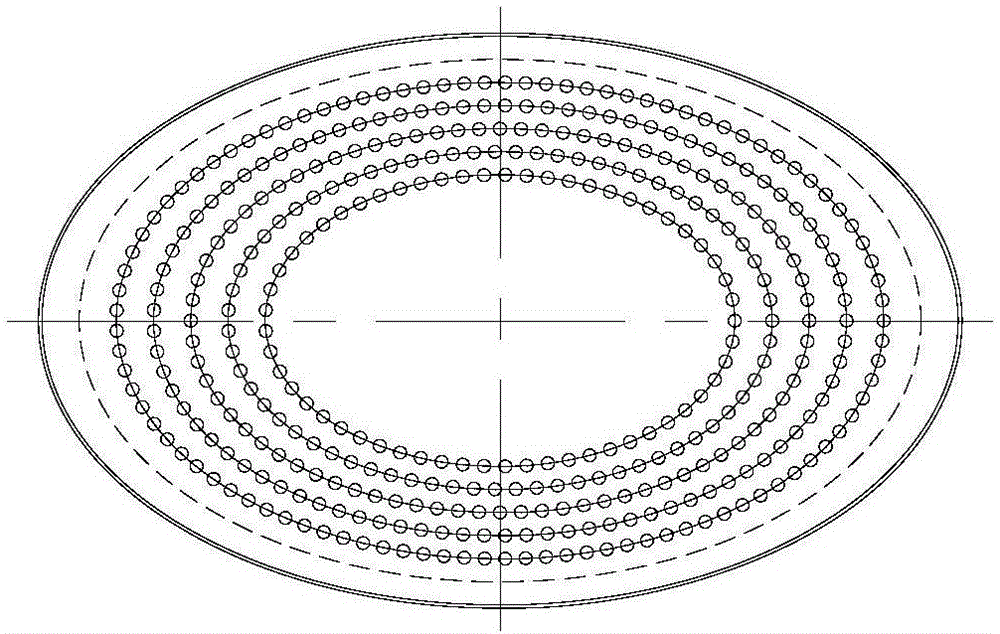

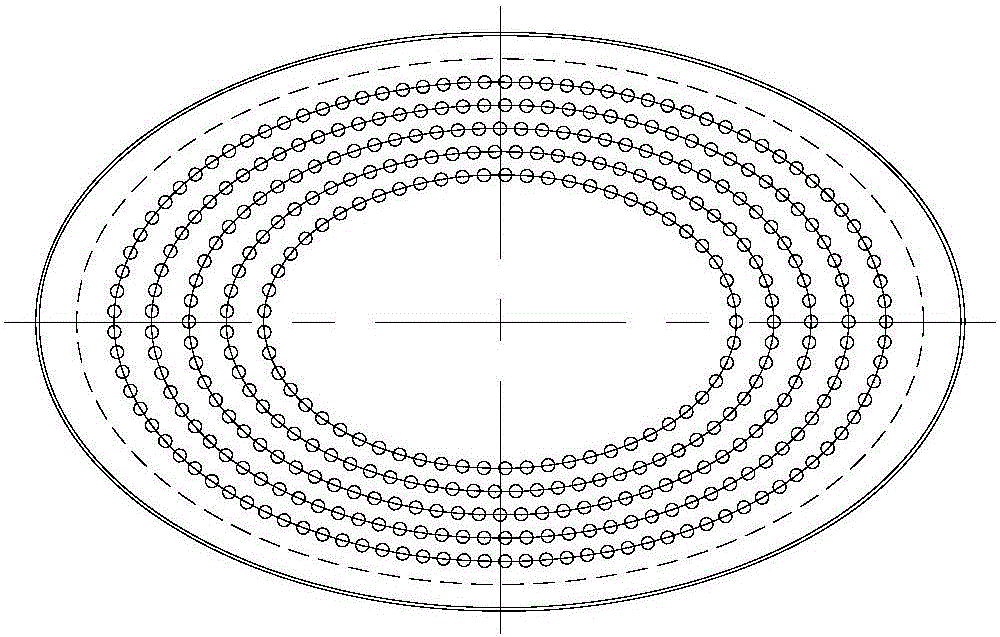

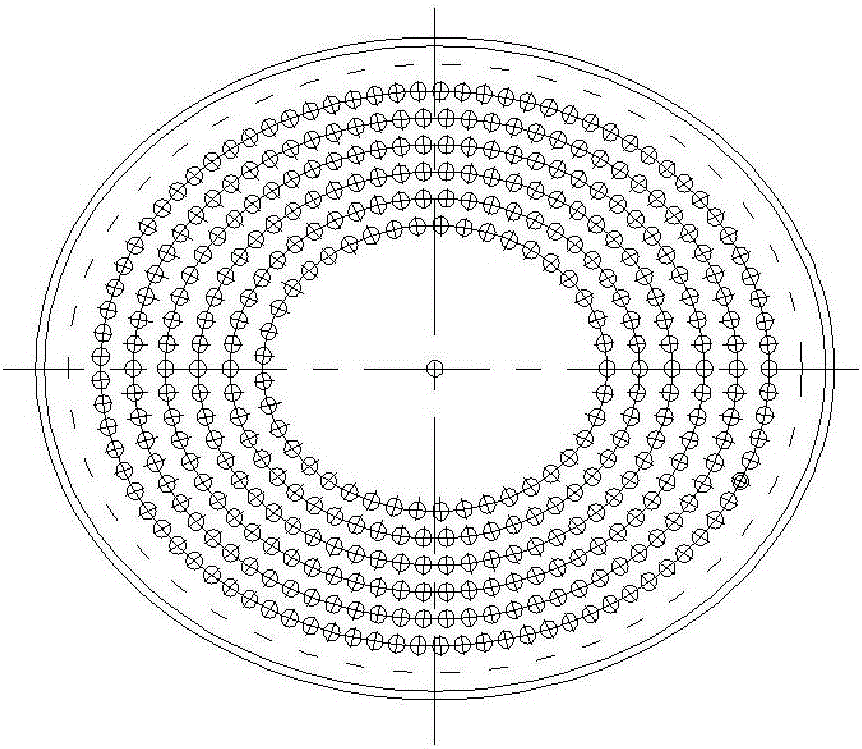

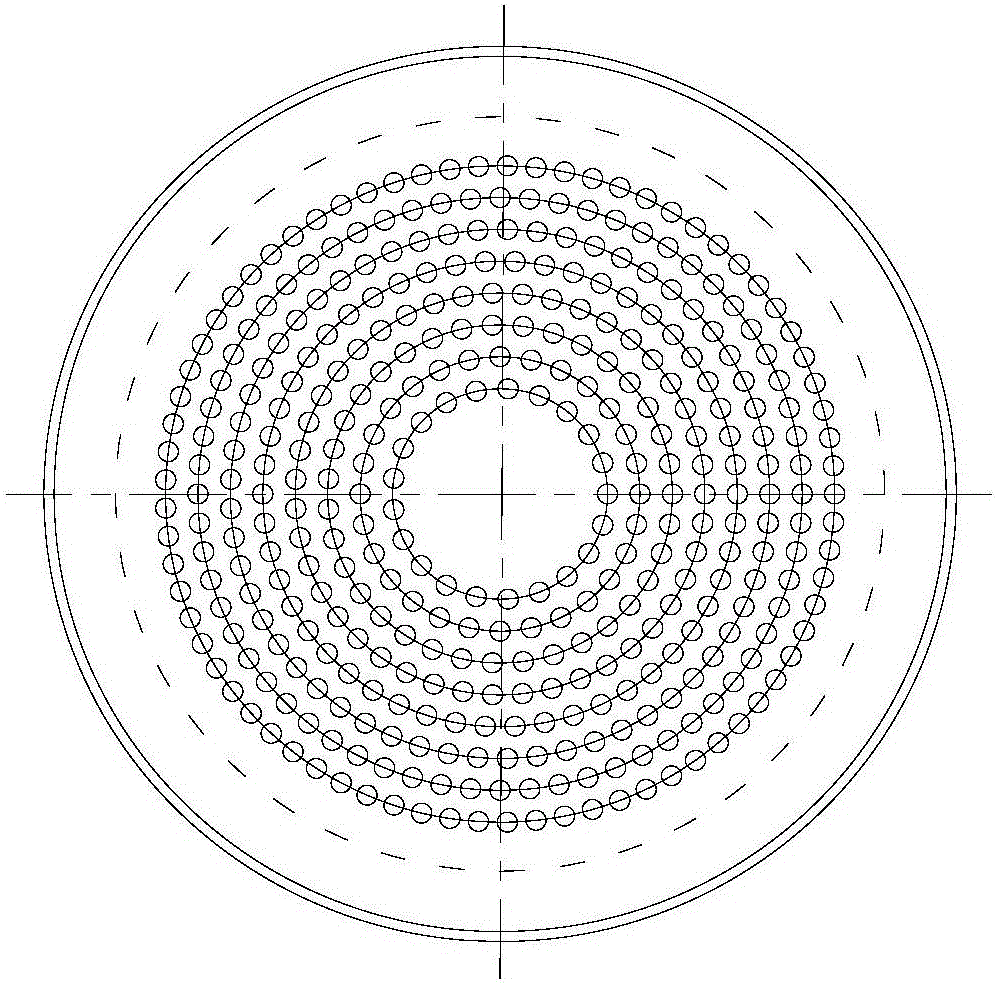

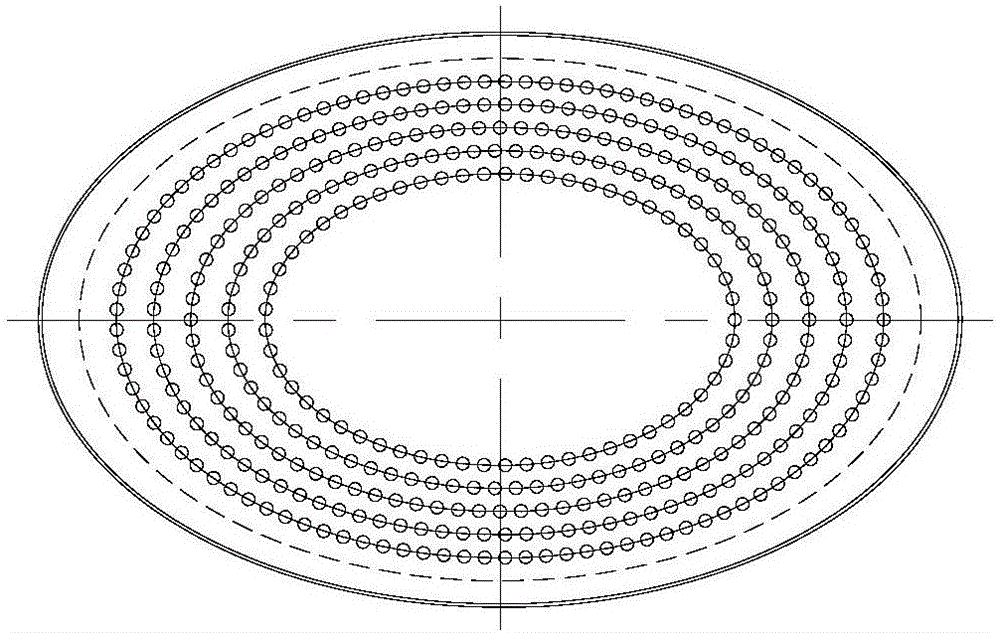

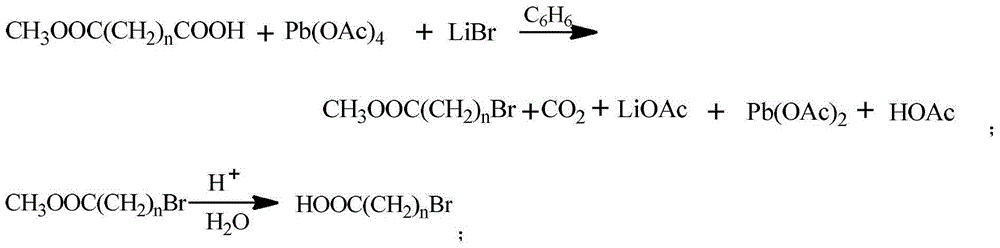

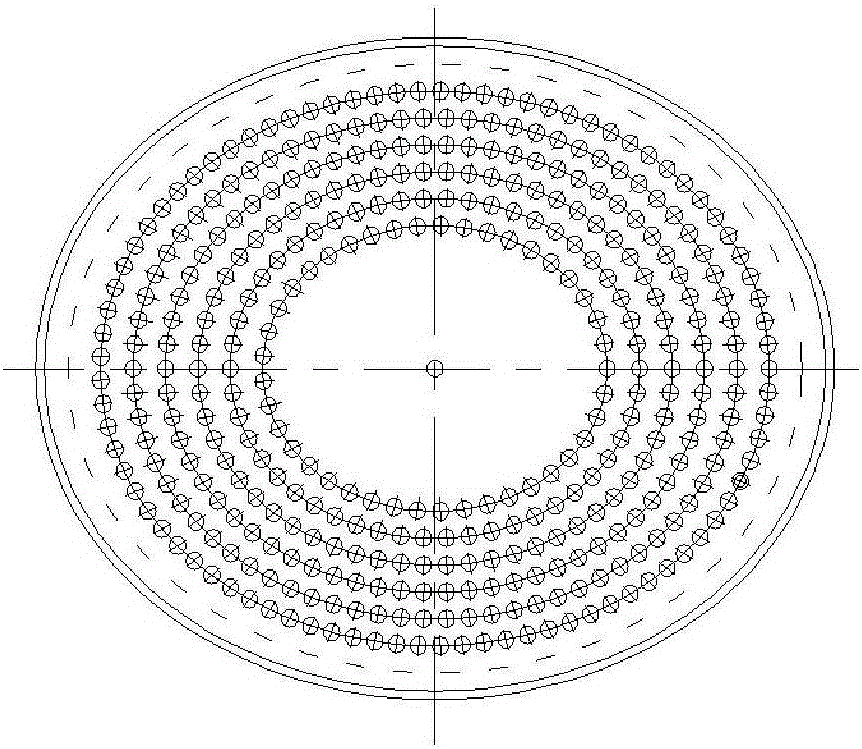

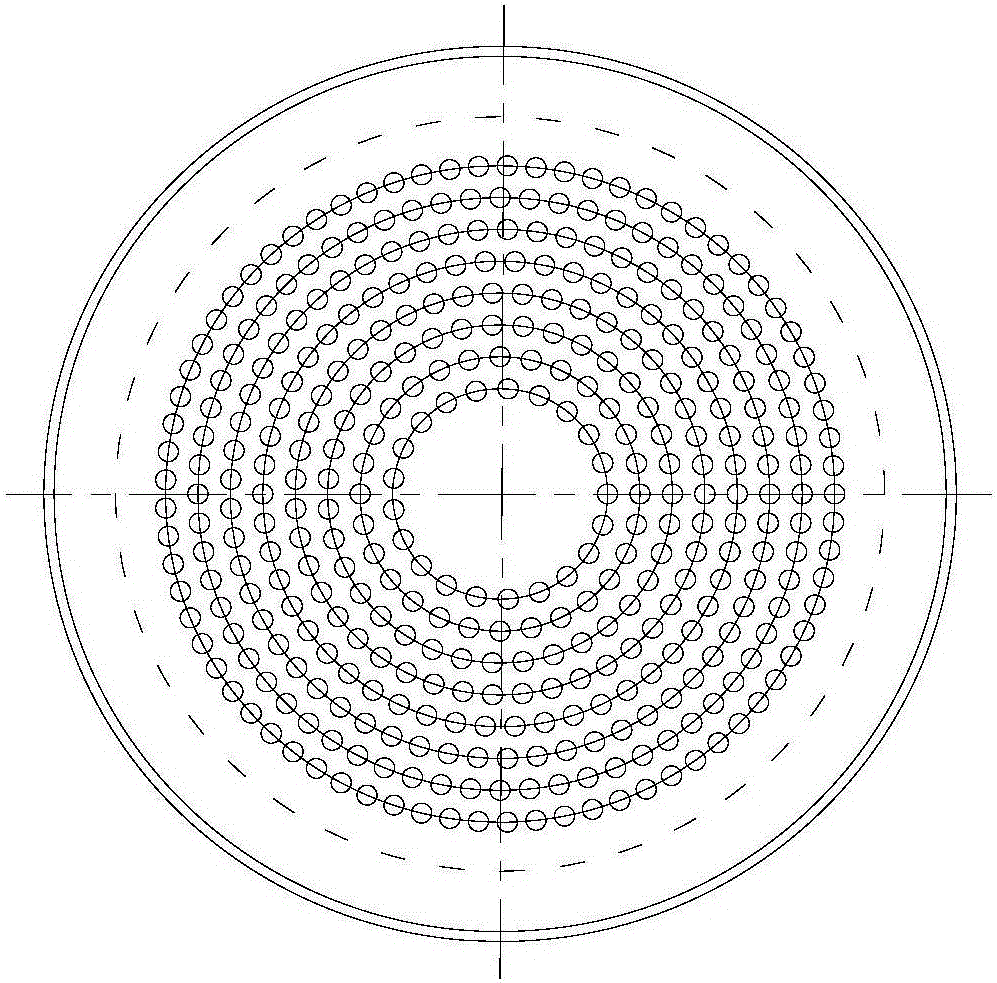

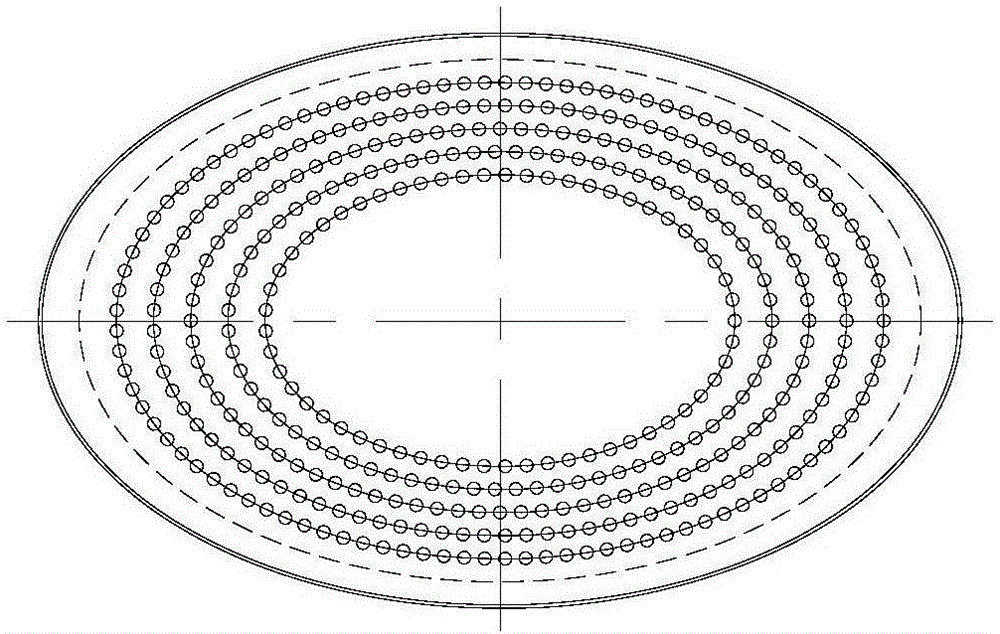

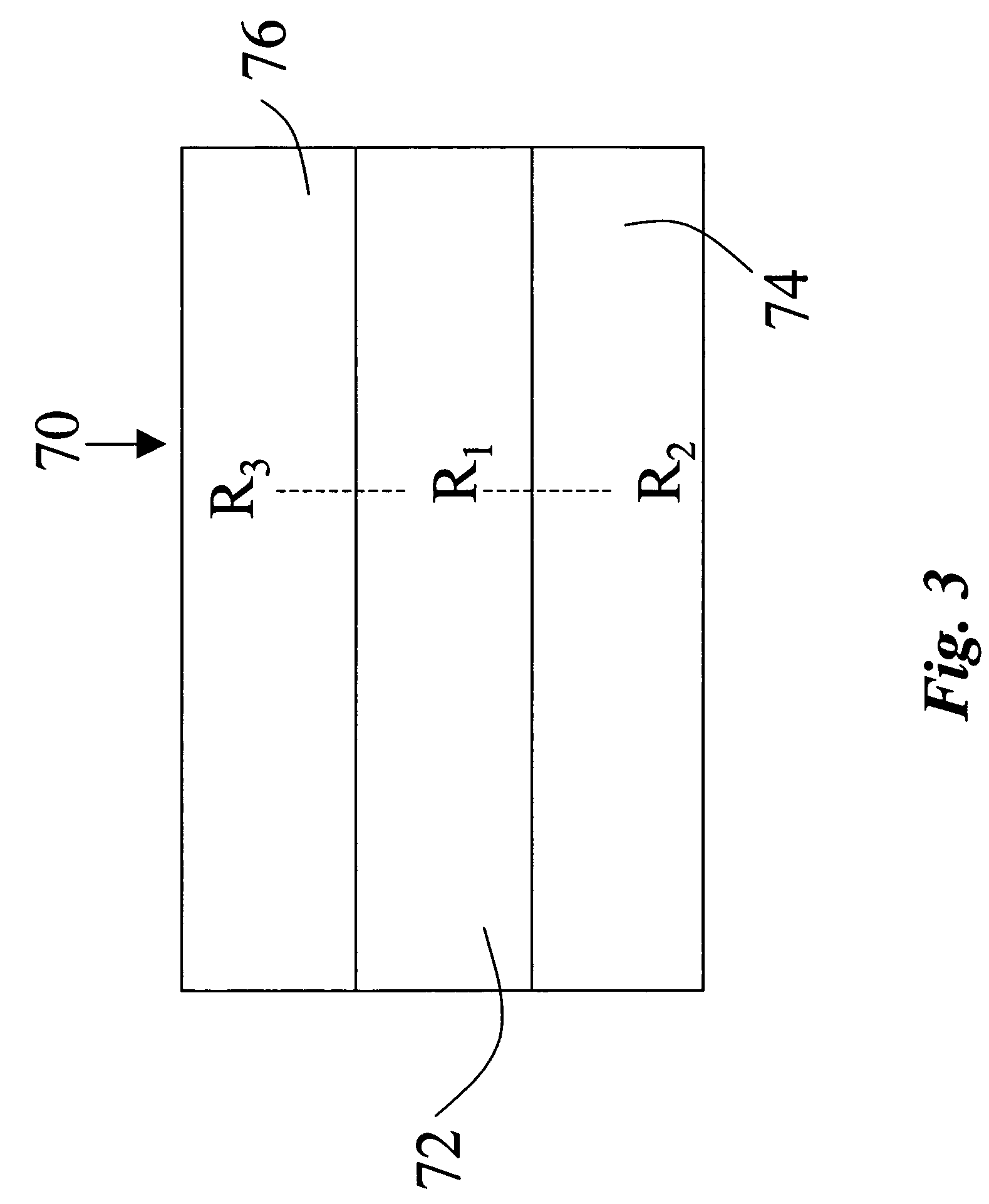

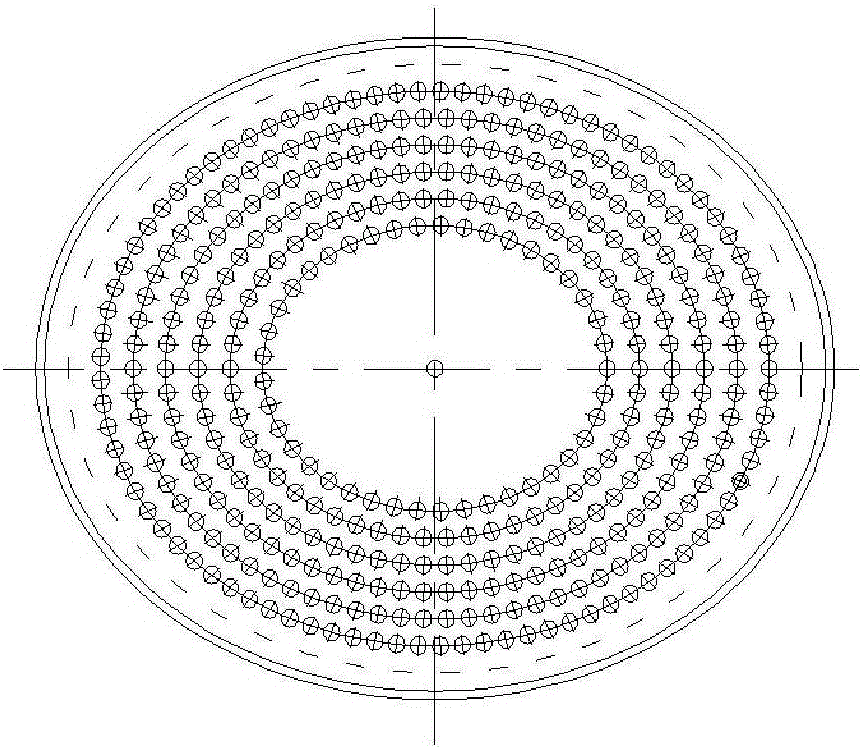

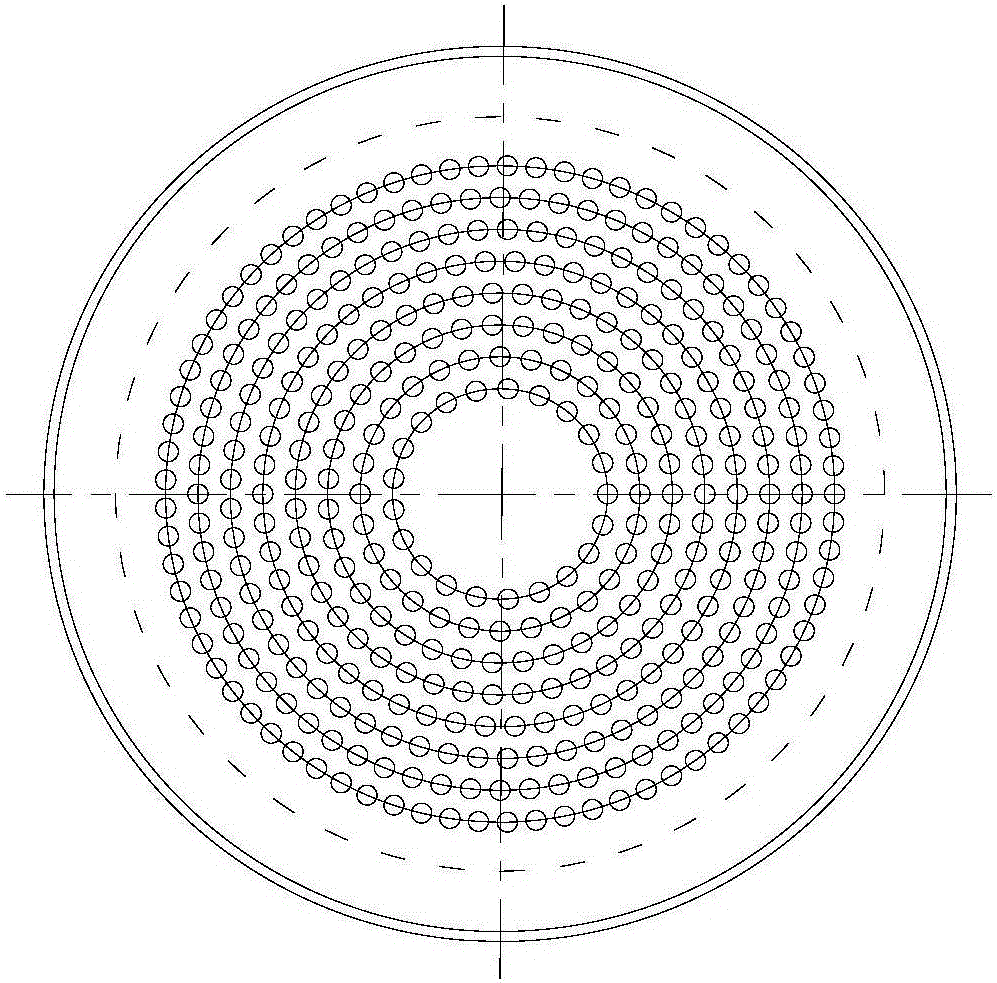

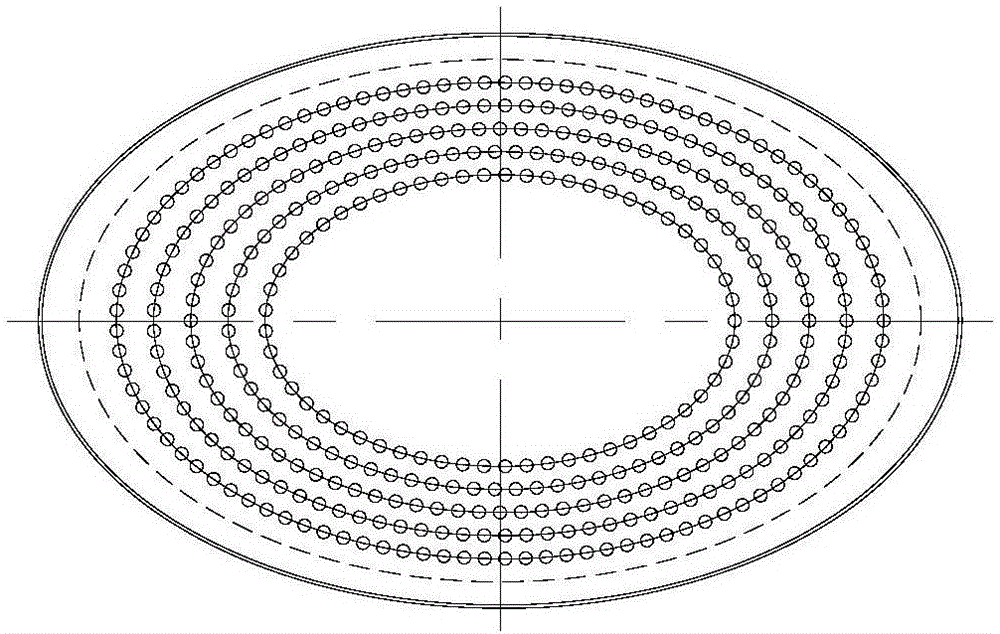

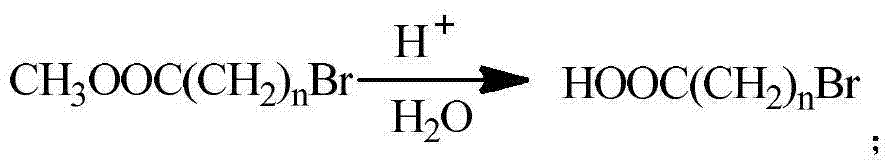

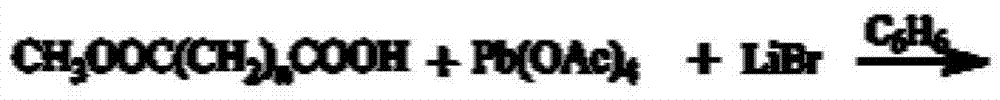

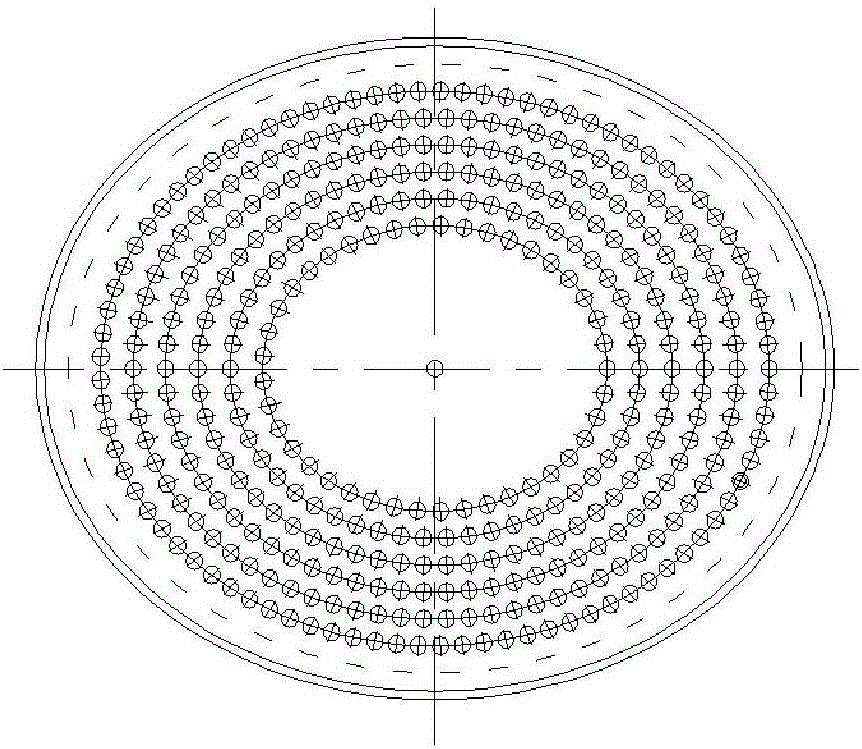

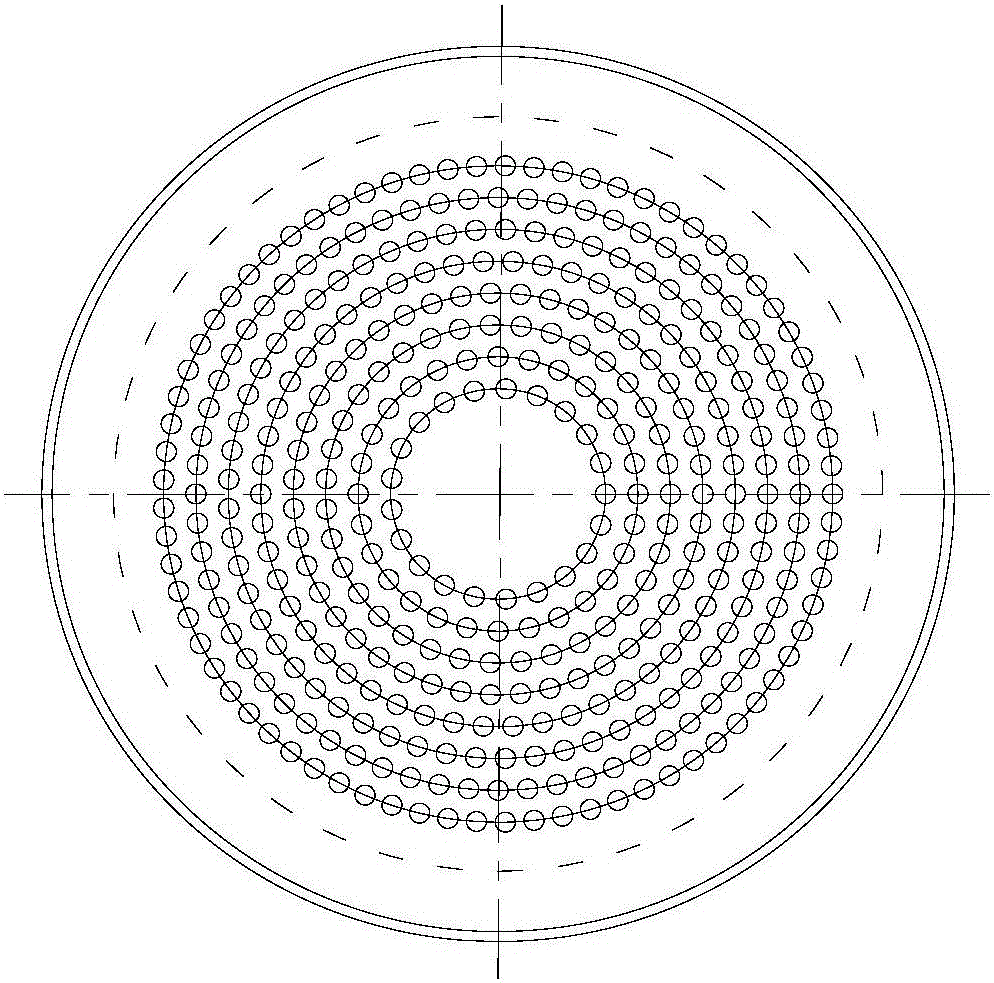

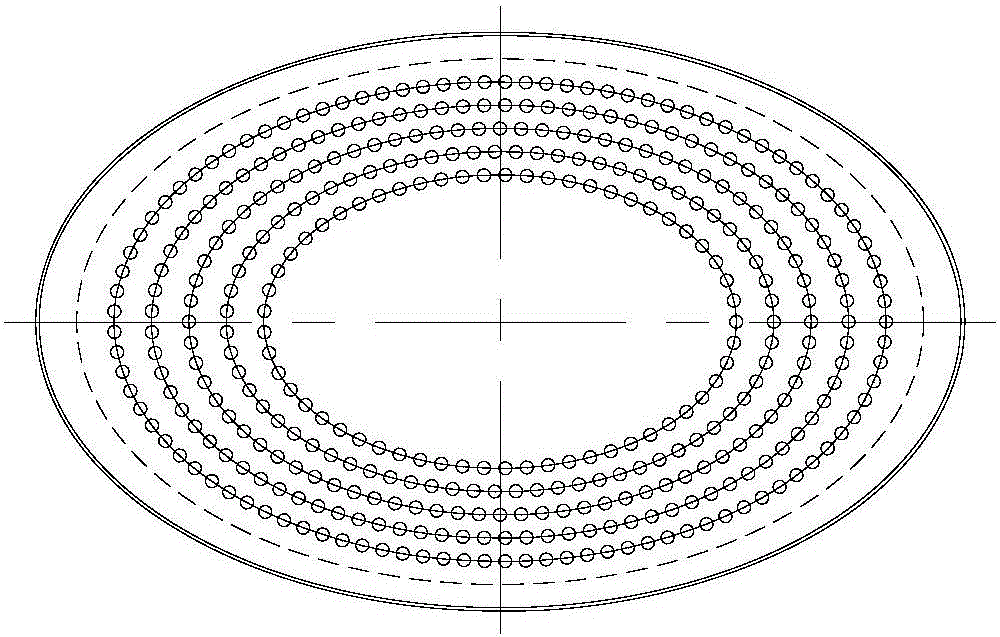

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

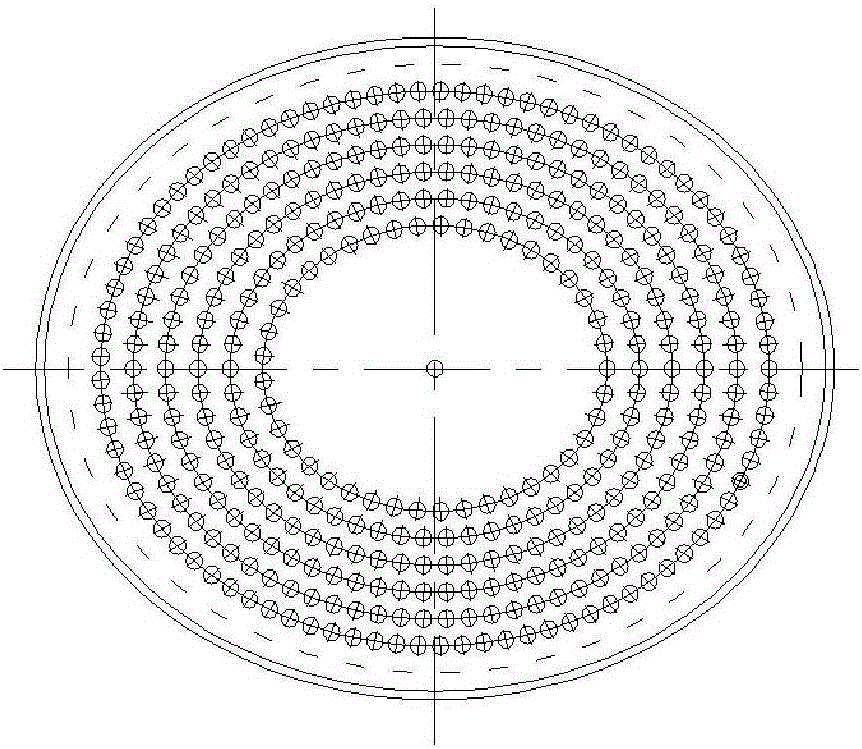

High-uniformity polyester industrial yarn used for safety belt and production method thereof

ActiveCN106381557AIncreased free volumeReduce melt viscositySpinnerette packsHollow filament manufactureYarnLow vacuum

The invention relates to a high-uniformity polyester industrial yarn used for a safety belt and a production method thereof. The raw material of the high-uniformity polyester industrial yarn is modified polyester composed of a terephthalic acid chain segment, a glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The production method is characterized in that terephthalic acid and branched chain-containing dihydric alcohol are subjected to an esterification reaction under catalysis of concentrated sulfuric acid to obtain dihydricalcohol terephthalate; then terephthalic acid and glycol are prepared for the esterification reaction to obtain ethylene terephthalate; finally ethylene terephthalate and dihydricalcohol terephthalate are stirred and mixed, under a catalyst and a stabilizing agent, the condensation polymerization reactions under a low vacuum phase and a high vacuum phase are carried out to prepare the modified polyester, and the modified polyester is subjected to metering, extrusion by a porous spinneret, cooling, oiling, stretching, thermoforming and reeling to prepare the high-uniformity polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Photocromic Primer Composition Having High Impact Resistance and Transparent Material Coated With the Same

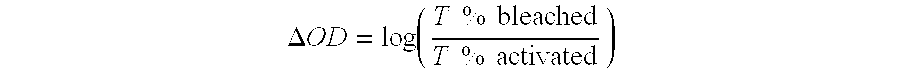

ActiveUS20070275234A1High optical densityMore stabilitySpiro-condensed pyran compound compositionsSynthetic resin layered productsEpoxyPhotochromism

Disclosed are a primer composition having photochromic property and impact resistance for coating transparent materials and a photochromic transparent material having a primer layer formed by coating and curing the primer composition. The primer composition for coating transparent materials comprises: a) 5-90 parts by weight of a polyurethane containing Brønsted salt; b) 5-50 parts by weight of a polyepoxy resin; and c) 140 parts by weight of a photochromic dye, based on 100 parts by weight of the total primer composition. The photochromic transparent material having a primer layer formed by coating and curing the primer composition shows excellent photochromic property and impact resistance.

Owner:LG CHEM LTD

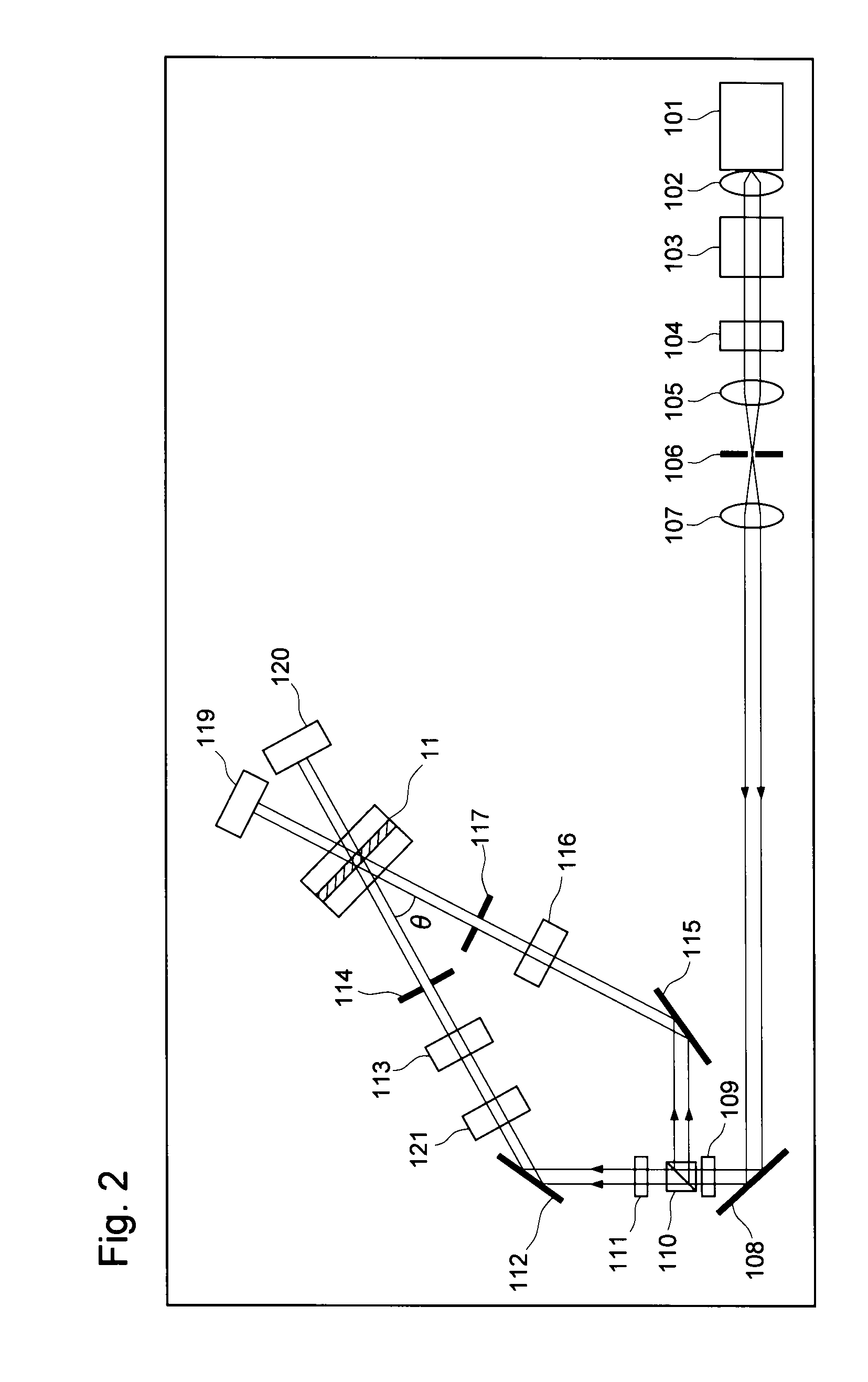

Hologram recording material and hologram recording medium

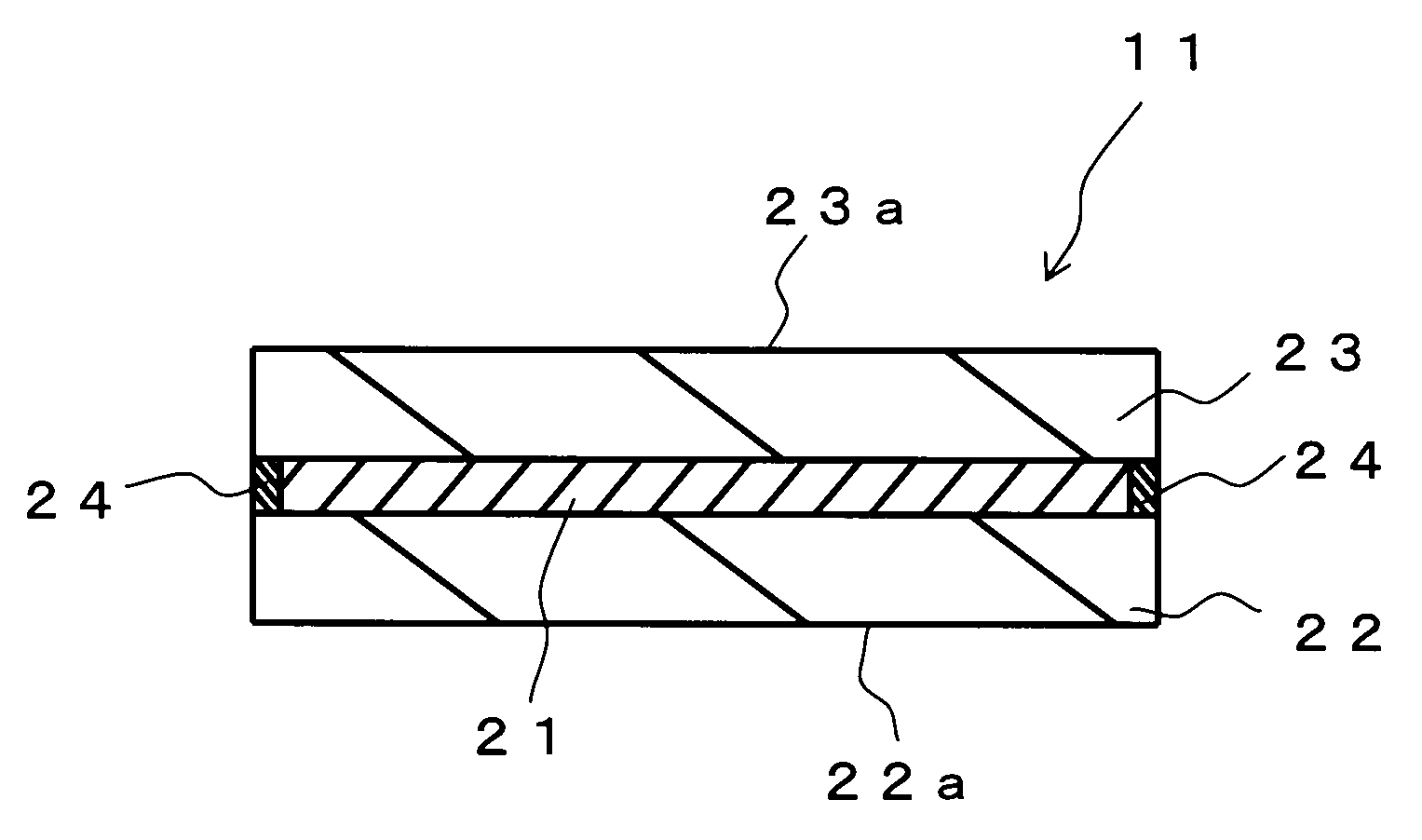

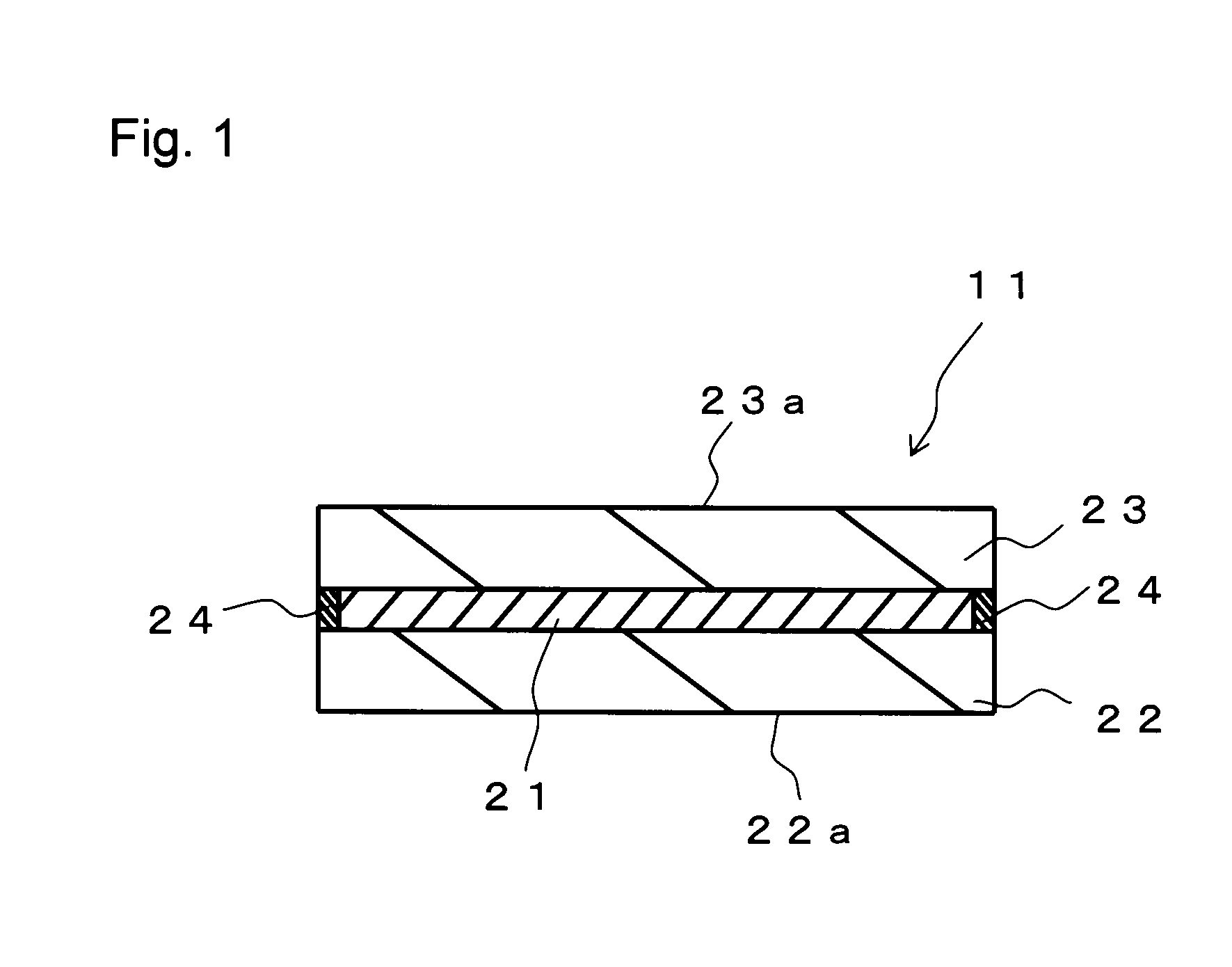

InactiveUS20100086859A1Increased free volumePrevent shrinkagePhotomechanical apparatusRecord information storageVolume hologramMeth-

The present invention provides a hologram recording material and a hologram recording medium, which are suitable for volume hologram record and can attain high refractive index change, flexibility, high sensitivity, low scattering, environment resistance, that is, storage stability, durability, low dimensional change (low shrinkage) and high multiplicity in holographic memory recording using not only a green laser but also a blue laser. A hologram recording material comprising: a radical photopolymerizable compound; and a matrix which is a dispersion medium for the radical photopolymerizable compound, wherein the radical photopolymerizable compound comprises a (meth)acrylamide derivative represented by the following general formula (I): CH2═CR1—CONR2—CH2—O—R3 (I) wherein R1 represents H or a CH3 group, R2 represents H or an organic group, and R3 represents an organic group having 3 or more carbon atoms in total. A hologram recording medium 11 which has a hologram recording layer 21.

Owner:TDK CORPARATION

Composite differential shrinkage yarn and preparation method thereof

The invention relates to a composite differential shrinkage yarn and a preparation method thereof. The composite differential shrinkage yarn is formed by compositing of a POY (polyester pre-oriented yarn) body and an FDY (fully drawn yarn) body, both the POY body and the FDY body are made of modified polyester by means of spinning, the modified polyester is formed by polyester and amino fatty acid gylcol ester, the amino fatty acid gylcol ester is scattered among molecular chains of the polyester, and a hydrogen-bond interaction among the amino fatty acid gylcol ester and the molecular chains of the polyester enables opposite positions of the amino fatty acid gylcol ester and the molecular chains of the polyester to be fixed; in the condition with temperature ranging from 90 DEG C to 130 DEG C, free volume spaces among molecular chains inside a fiber of the composite differential shrinkage yarn are enlarged by 20-30v / v%. The composite differential shrinkage yarn has the advantages that the free volume of polyester fibers is increased by the aid of fatty acid ester, so that diffusing degree of dye is improved, dyeing property of the polyester fibers is improved, and the composite differential shrinkage yarn is applicable to fashion fabric, decorative fabric and the like formed by means of spinning, knitting and warp knitting.

Owner:JIANGSU HENGLI CHEM FIBER

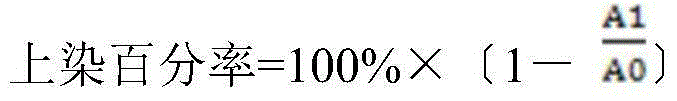

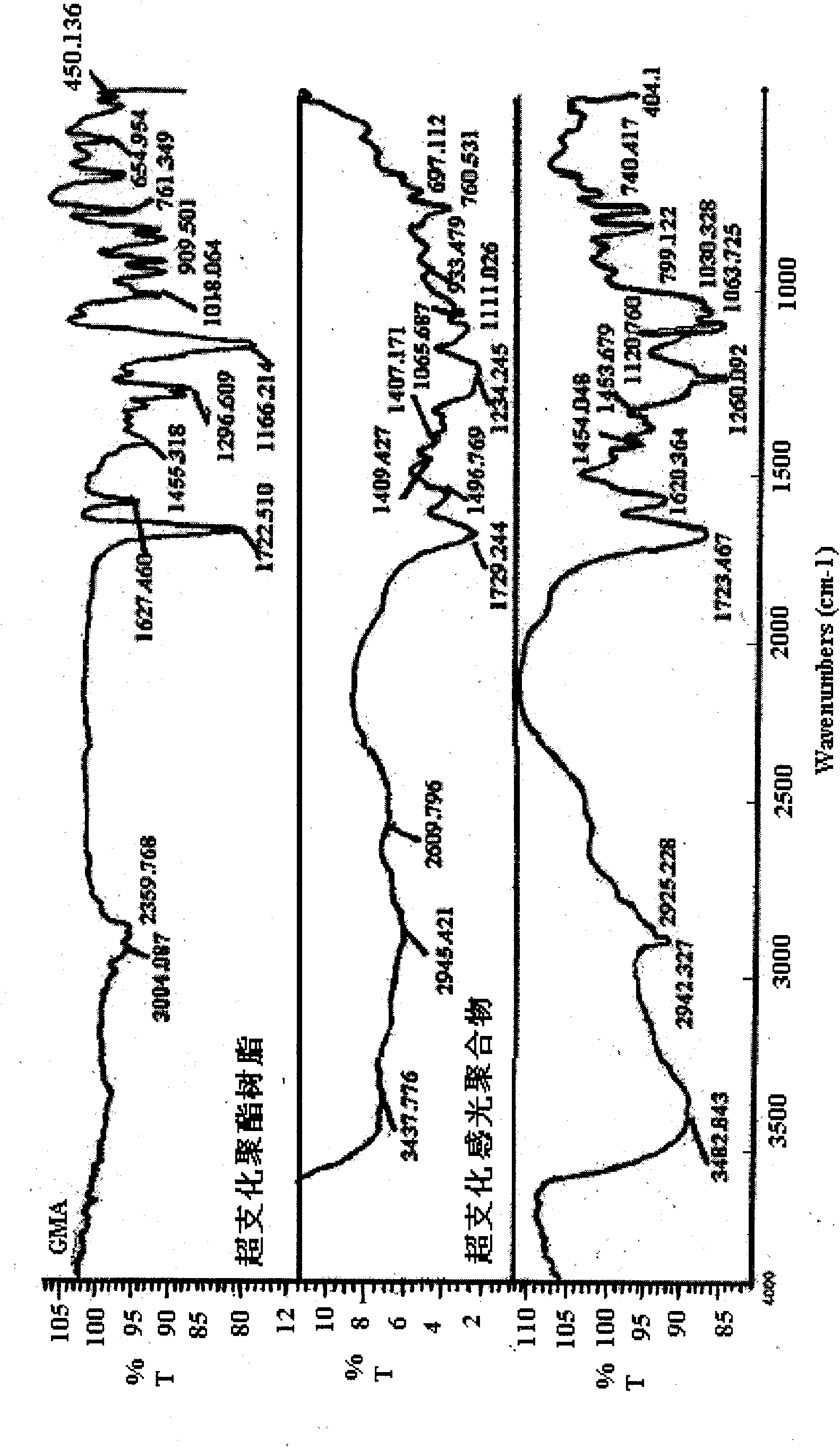

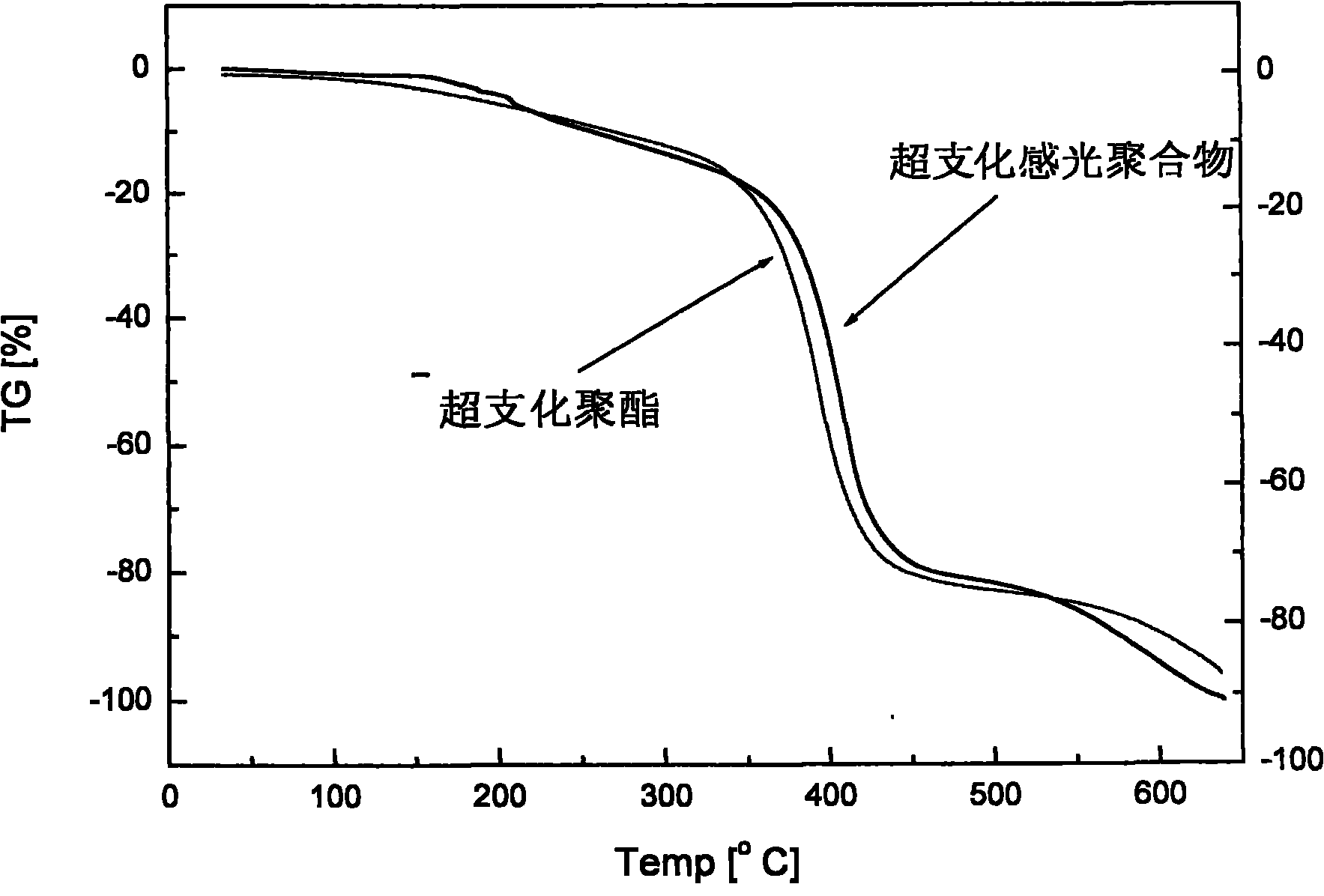

Hyperbranched polyester lithium ion battery gel electrolyte and preparation method thereof

InactiveCN101814628AImprove ionic conductivityModerate mechanical strengthFinal product manufactureElectrolyte accumulators manufactureInternal resistanceOxygen

The invention relates to a hyperbranched polyester lithium ion battery gel electrolyte and a preparation method thereof. The gel electrolyte is formed by mixed liquor prepared from 5-30 percent by mass of hyperbranched photopolymer resin, 5-25 percent by mass of cross-linking agent, 1-10 percent by mass of initiator, 20-50 percent by mass of plasticizer, 20-50 percent by mass of lithium salt and the like by using a radiation crosslinking method or a heating crosslinking method and the like. In the invention, the hyperbranched structure of a hyperbranched polyester can effectively prevent chain segments from being crystallized, whereas the molecular conformation similar to a spheric shape can increase the free volume of the polyester; bigger space and fewer -COO- and ether bond structures among branch points of the hyperbranched polyester have very strong interreaction with oxygen in the carbonic ester plasticizer, and therefore, a large amount of liquid electrolyte can be contained, and the gel electrolyte has very high dissolving capacity on salts, which is beneficial to ionic migration and the increase of electrical conductivity so that a lithium ion battery prepared from the hyperbranched polyester lithium ion battery gel electrolyte has long service life, small internal resistance, better specific energy, simple preparation process and no pollution.

Owner:ZHANJIANG NORMAL UNIV

High-uniformity colored polyester industrial yarn and preparation method thereof

ActiveCN106245150AIncreased free volumeReduce melt viscositySpinnerette packsMonocomponent polyetheresters artificial filamentChemistryPolyethylene terephthalate glycol

The invention relates to a high-uniformity colored polyester industrial yarn and a preparation method thereof. The raw material of the high-uniformity colored polyester industrial yarn is modified polyester composed of terephthalic acid chain segments, ethylene glycol chain segments and dihydric alcohol chain segments containing branched chains. The method for preparing the high-uniformity colored polyester industrial yarn comprises the following steps: carrying out an esterification reaction between terephthalic acid and dihydric alcohol containing branched chains under catalysis of concentrated sulfuric acid, thereby obtaining polyethylene terephthalate; matching terephthalic acid and ethylene glycol to carry out an esterification reaction, thereby obtaining ethylene glycol terephthalate; finally, stirring and mixing the two products, carrying out condensation polymerization at low vacuum stage and high vacuum stage in the absence of catalysts and stabilizers, thereby obtaining modified polyester; metering the modified polyester, adding black master batch, performing porous spinneret extrusion, cooling, oiling, stretching, heat setting, winding, thereby obtaining the high-uniformity colored polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Organosol including amphipathic copolymeric binder having crystalline material, and use of the organosol to make dry tones for electrographic applications

InactiveUS7005225B2Reduce polydispersityExceptional uniformityDevelopersElectrographic processes using charge patternCrystalline materialsCopolymer

The present invention relates to amphipathic copolymeric binder particles that incorporate polymerizable crystallizable compounds chemically incorporated into a dispersible (D) portion and / or solvatable (S) portion of the copolymer. The invention also pertains to dry particulate electrophotographic toners incorporating an amphipathic copolymer comprising one or more polymerizable crystallizable compounds. Methods of making these dry electrophotographic toner particles, and methods of electrophotographically forming an image on a substrate using these toners, are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

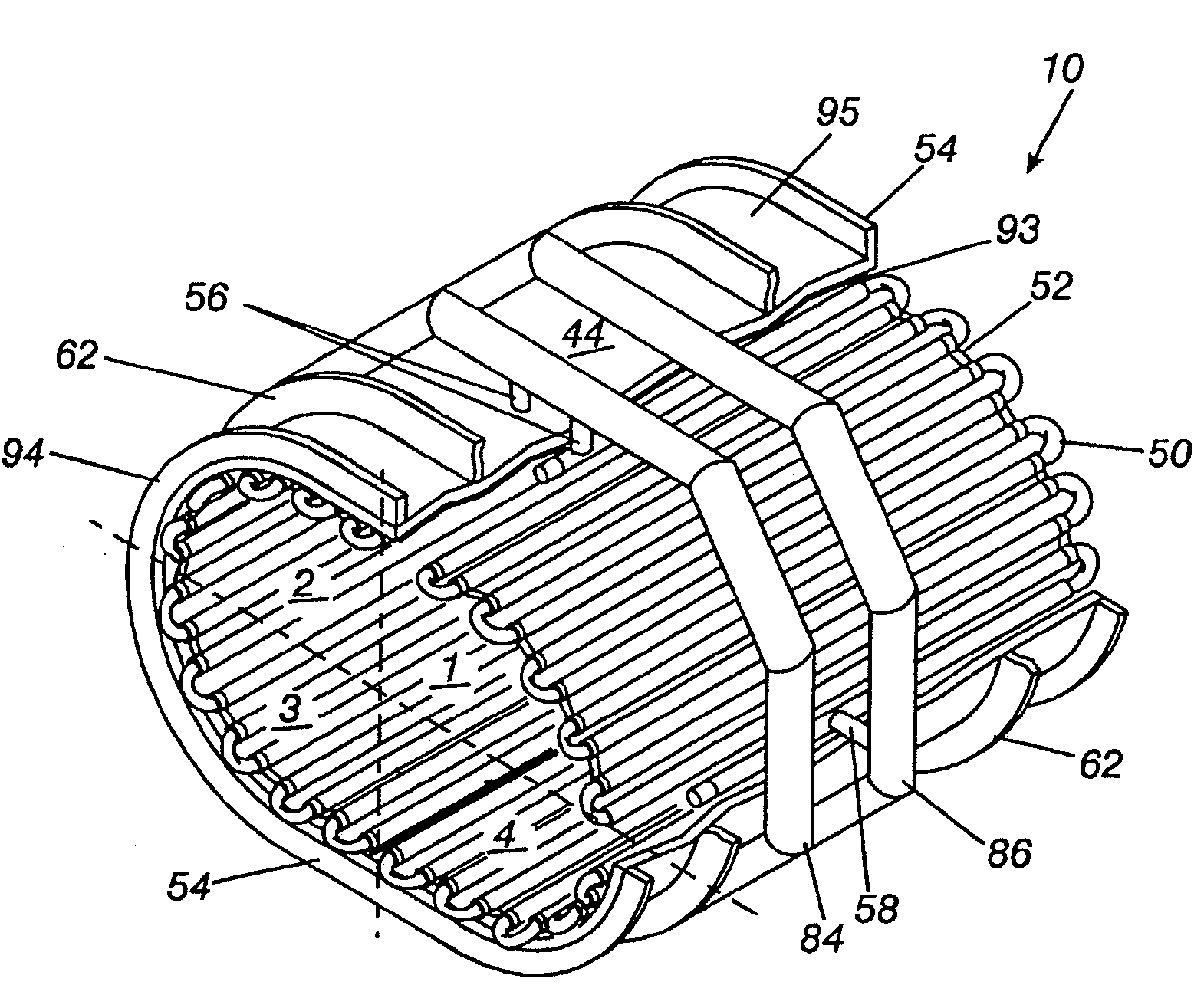

Adjustable heat exchange apparatus and method of use

InactiveUS20080296006A1Low densityLimited operating lifeEnvelopes/bags making machineryBoiler water tubesBiomedical engineering

Owner:AMERIFAB INC

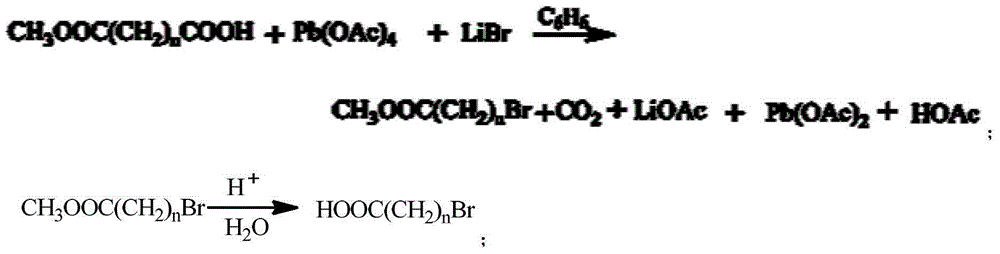

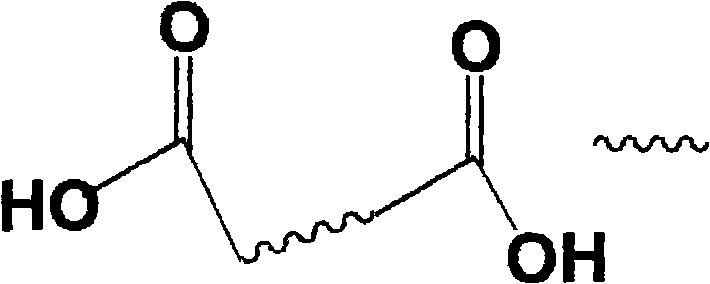

Differential-shrinkage cotton-like composite filament and preparation method thereof

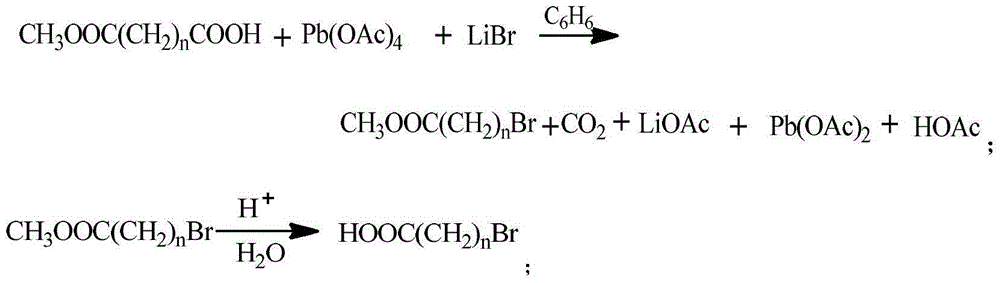

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

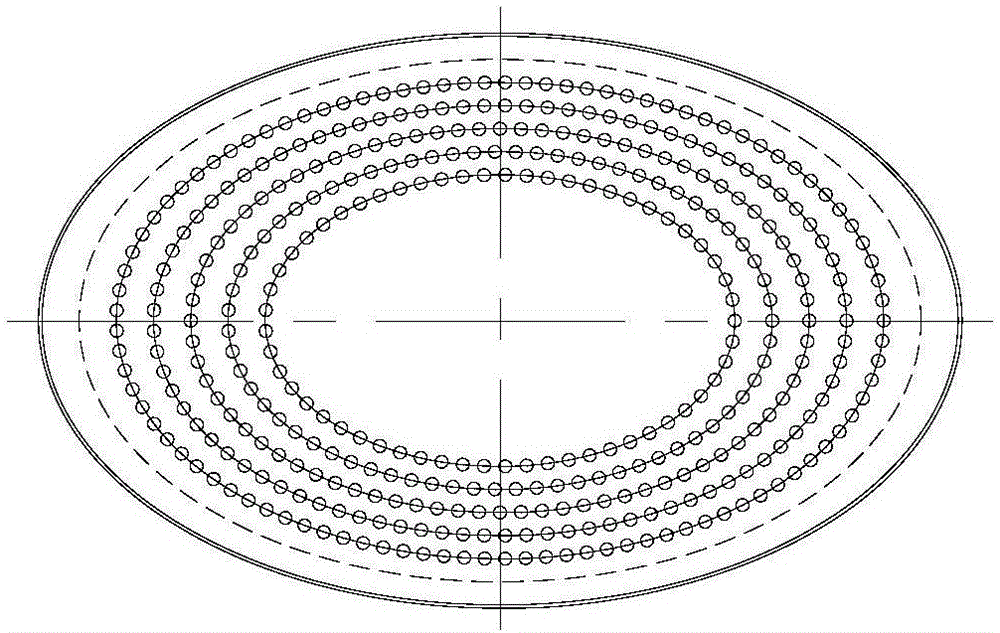

Porous super-bright trilobal profiled polyester fiber and production method thereof

ActiveCN106400166AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of polyvinyl chitosan mixed film

InactiveCN101007243AHigh mechanical strengthGood chemical stabilitySemi-permeable membranesAcetic acidMethyl carbonate

The invention involves a preparation method used for separating the polyvinyl alcohol / chitosan mixing film of methanol / dimethyl carbonate, the preparation process is as follows: 1) dissolving the polyvinyl alcohol with the deionized water as solvent in 80 ~ 100 degree C and gaining uniform casting film solution which polyvinyl alcohol concentration is 5wt%; 2) dissolving the chitosan with the glacial acetic acid and deionized water as solvent in 20-40DEG C and gaining uniform casting film solution which chitosan concentration is 1wt%; 3) according certain radio mixing the ratio of PVA and chitosan solution uniformly and debubbling; 4) making film on the glass plate with casting method; 5) thermal treating the film 2~4 hours in 120 ~ 150 degree C. Compared with traditional separation methods, the method has some characteristics such as high one-time separation degree, simple precess, low energy consumption and pollution-free.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

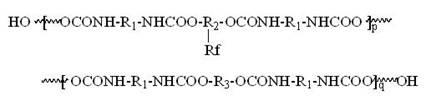

Polyester type polyurethane material with side chain containing fluorine and preparation method thereof

The invention provides a polyurethane material with a side chain containing fluorine, which is formed by copolymerizing a flexible chain section formed by common commercial polyester dibasic alcohol and a rigid chain section formed by diisocyanate and a chain extender, and is characterized in that the chain extender is dihydric alcohol with a side chain containing a perfluor alkyl group or mixture formed by the dihydric alcohol with the side chain containing the perfluor alkyl group and other low-molecule dihydric alcohol or diamine. The invention further provides a preparation method of the polyurethane material with the side chain containing the fluorine. Due to the fact that the chain extender is connected onto a polyurethane main chain (hard section) in a side chain mode, the movement of a fluorocarbon side chain is hardly limited by the polyurethane main chain while the fluorocarbon side chain can remarkably change a phase structure of the polyurethane (separation degree of a soft section and the hard section), and the novel polyurethane material is provided with good surface performance and body performance.

Owner:SICHUAN UNIV

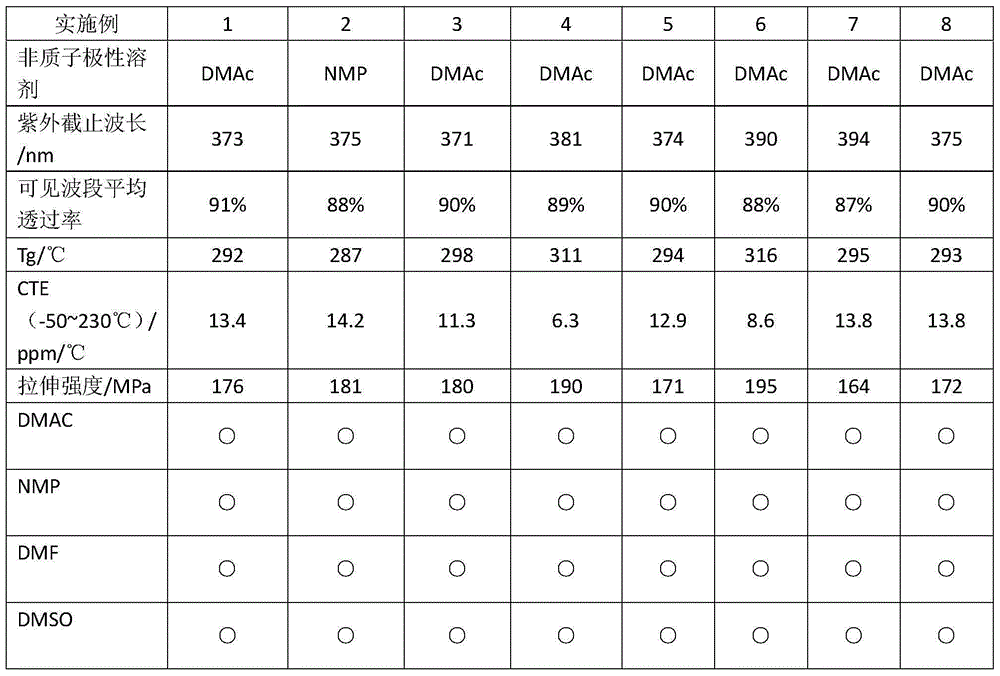

Preparation method of soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film

InactiveCN105017534AReduce the potential energy of the condensation reactionExcellent mechanicsPolymer scienceThermal expansion

The invention discloses a preparation method of a soluble, colorless, transparent and low-thermal-expansion-coefficient polyamide imide film. According to the prepared film, fluorine-containing diamine monomers serve as diamine monomers, trimellitic anhydride acid chloride serves as anhydride monomers, and the polyamide imide film is further prepared through a trimethylchlorosilane activation mechanism under a simple and moderate synthesis condition. The prepared polyamide imide film has high dimensional stability (the CTE is 5-15 ppm / DEG C or so) and good temperature resistance (Tg is 300 DEG C or so), the transmittance of visible light wavebands is 90% or so, the prepared polyamide imide film can be dissolved in an aprotic polar solvent and is convenient to machine and process, and the comprehensive performance of the prepared polyamide imide film meets the material performance requirement of a part of devices in the microelectronics and optoelectronics field.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

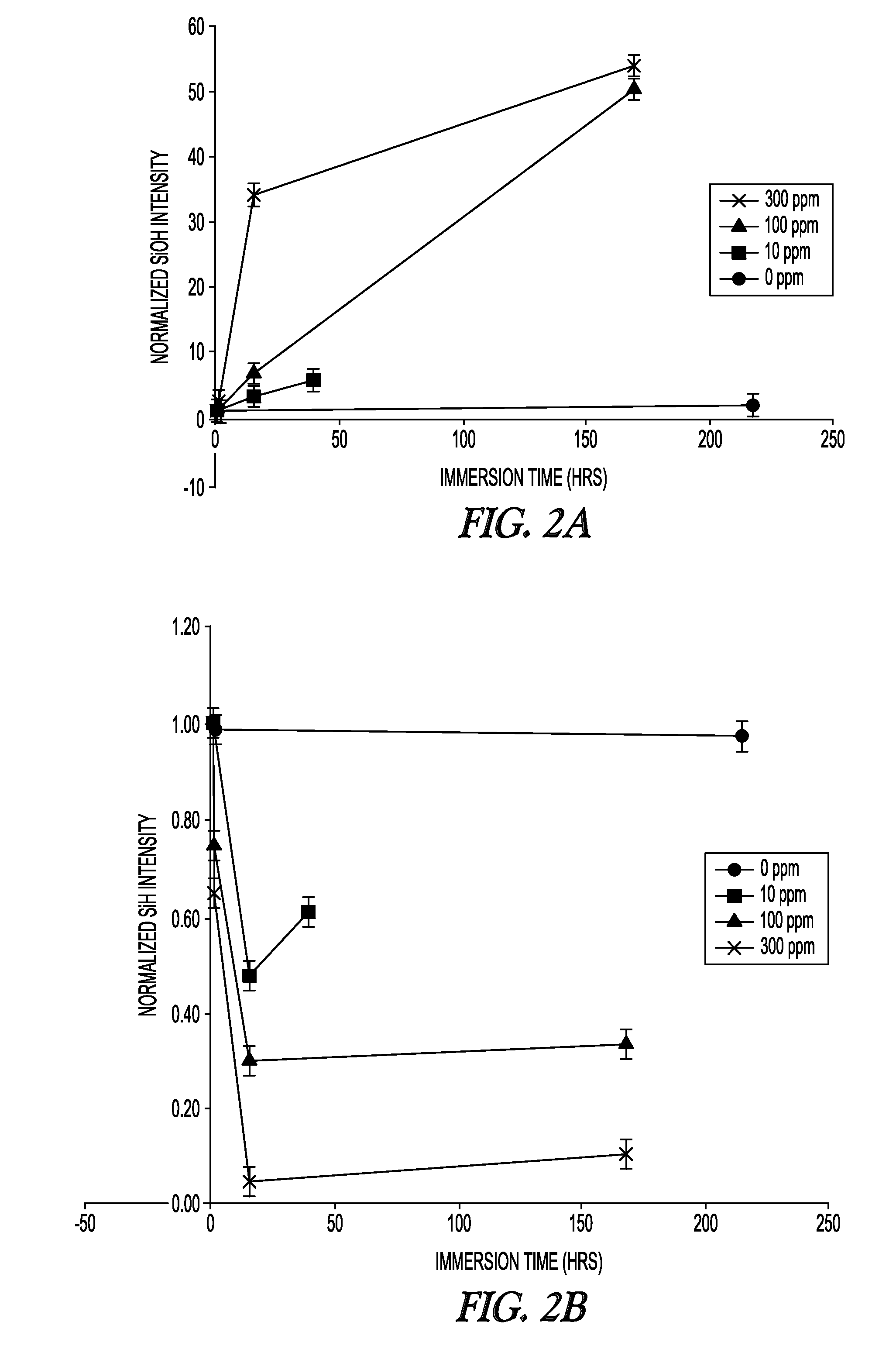

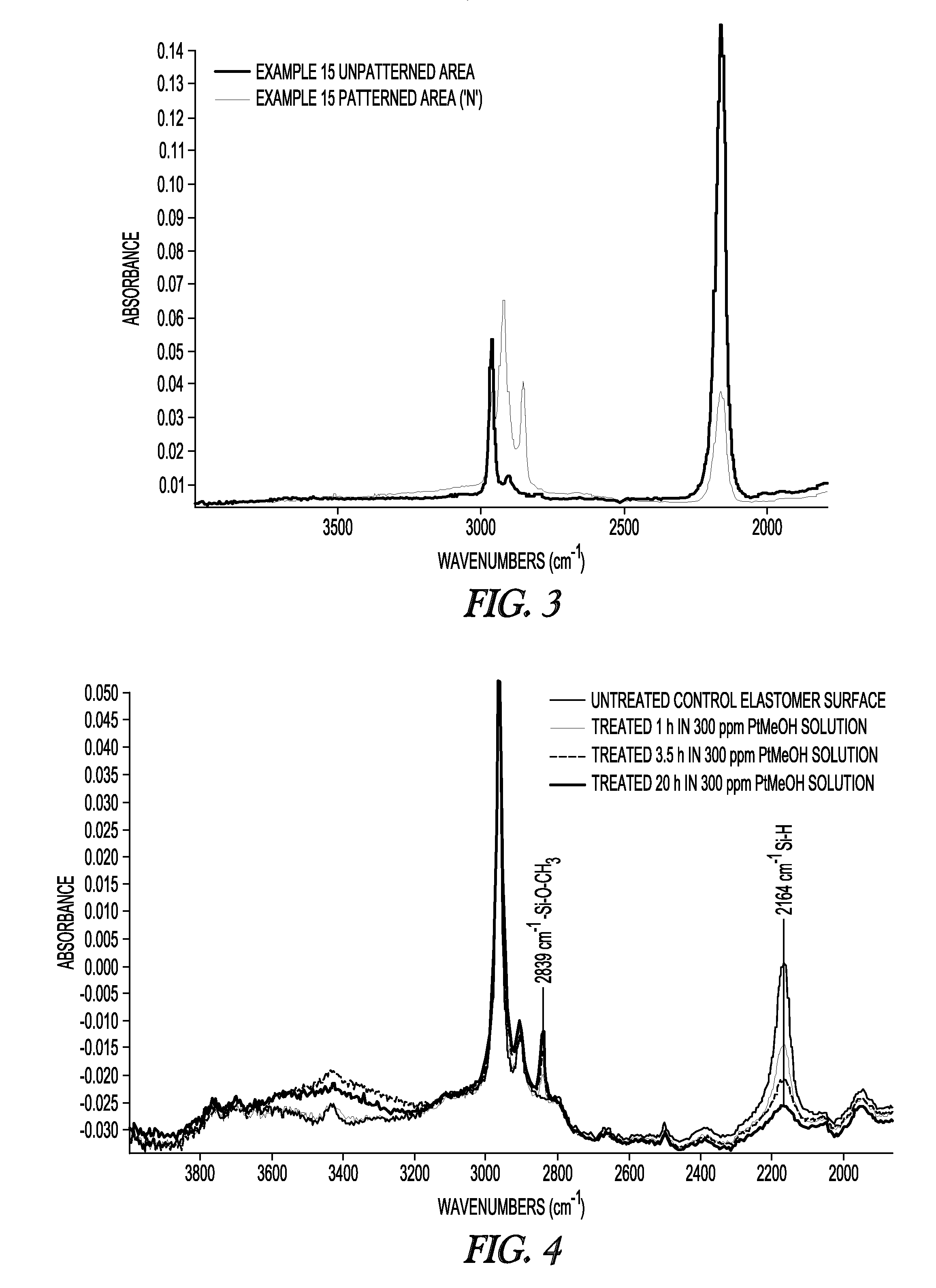

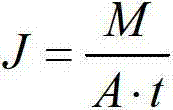

Organopolysiloxane compositions and surface modification of cured silicone elastomers

InactiveUS20140322519A1Improve hydrophilicityAmenable to patterningSemi-permeable membranesMembranesPolymer sciencePtru catalyst

The present invention relates to a method of treating a surface comprising a silicone elastomer having a plurality of Si—H groups by contacting at least one region of the surface with a solution comprising a surface treatment compound, to give a treated surface with Si—OH, Si—OR, or Si—C groups. The present invention relates to a hydrosilylation-curable silicone composition. In some examples, the hydrosilylation-curable silicone composition includes an organohydrogen-polysiloxane having an average of at least forty silicon-bonded hydrogen atoms per molecule, a cross-linking agent having an average of at least two aliphatic unsaturated carbon-carbon bonds per molecule, and a hydrosilylation catalyst, wherein the mole ratio of silicon-bonded hydrogen atoms in the composition to aliphatic unsaturated carbon-carbon bonds in the composition is at least 20:1. The invention also relates to membranes, methods of making membranes, gas permeable supports for membranes, and methods of gas separation using membranes.

Owner:DOW CORNING CORP

Preparation method of polyurethane pervaporation phenol/water separating membrane compounded by inorganic particles

InactiveCN103084077AHigh temperature resistantHigh temperature resistanceDistillationFiberDiphenylmethane

The invention discloses a preparation method of a polyurethane pervaporation phenol / water separating membrane compounded by inorganic particles, and belongs to the field of pervaporation membrane separation. The polyurethane membrane basic material is obtained by polymerizing and mixing monomer hydroxyl-terminated polybutadiene, toluene diisocynate, 4,4'-diamine diphenylmethane solution, cyclodextrin and silica or carbon fiber powder. The preparation method comprises the following steps: reacting hydroxyl-terminated polybutadiene with toluene diisocynate to obtain blocked prepolymer, then adding 4,4'-diamine diphenylmethane solution and cyclodextrin as chain extenders to perform the chain extension, and adding inorganic modified particle silica or carbon fiber powder (using N,N-dimethylacetamide as solvent) to obtain prepolymer solution of polyurethane; casting the solution on a polyfluortetraethylene plate to form a membrane, solidifying for 1-1.5 hours at room temperature, and moving the membrane to an oven at 80 DEG C to thermally treat to obtain the polyurethane membrane compounded by inorganic particles. The preparation method disclosed by the invention is simple in process, and the prepared membrane has good heat and chemical stability and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Organosol liquid toner including amphipathic copolymeric binder having crosslinkable functionality

InactiveUS7052816B2Reduce polydispersityExceptional uniformityDevelopersAdditive ingredientOrganic chemistry

Liquid toner compositions having utility in electrographic applications. Organosol liquid toner compositions comprise binder particles dispersed in a nonaqueous liquid carrier, wherein the particles are derived from ingredients comprising one or more crosslinkable amphipathic copolymer(s). The organosol is easily combined with additional ingredients, such as one or more visual enhancement additives and other desired ingredients, and subjected to mixing processes to form a liquid toner composition. Methods of making and electrographically printing liquid toners derived from these organosols are also described.

Owner:S PRINTING SOLUTION CO LTD

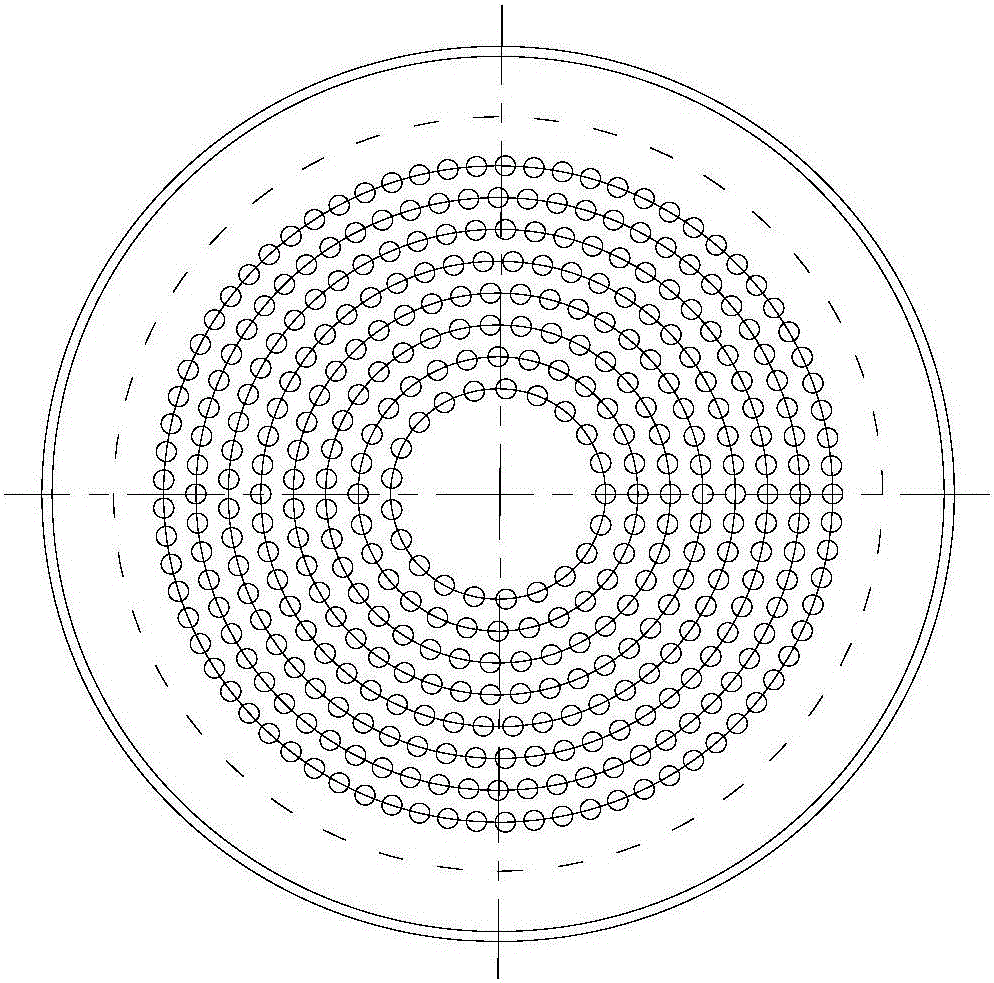

Porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and preparation method thereof

ActiveCN106283251AImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

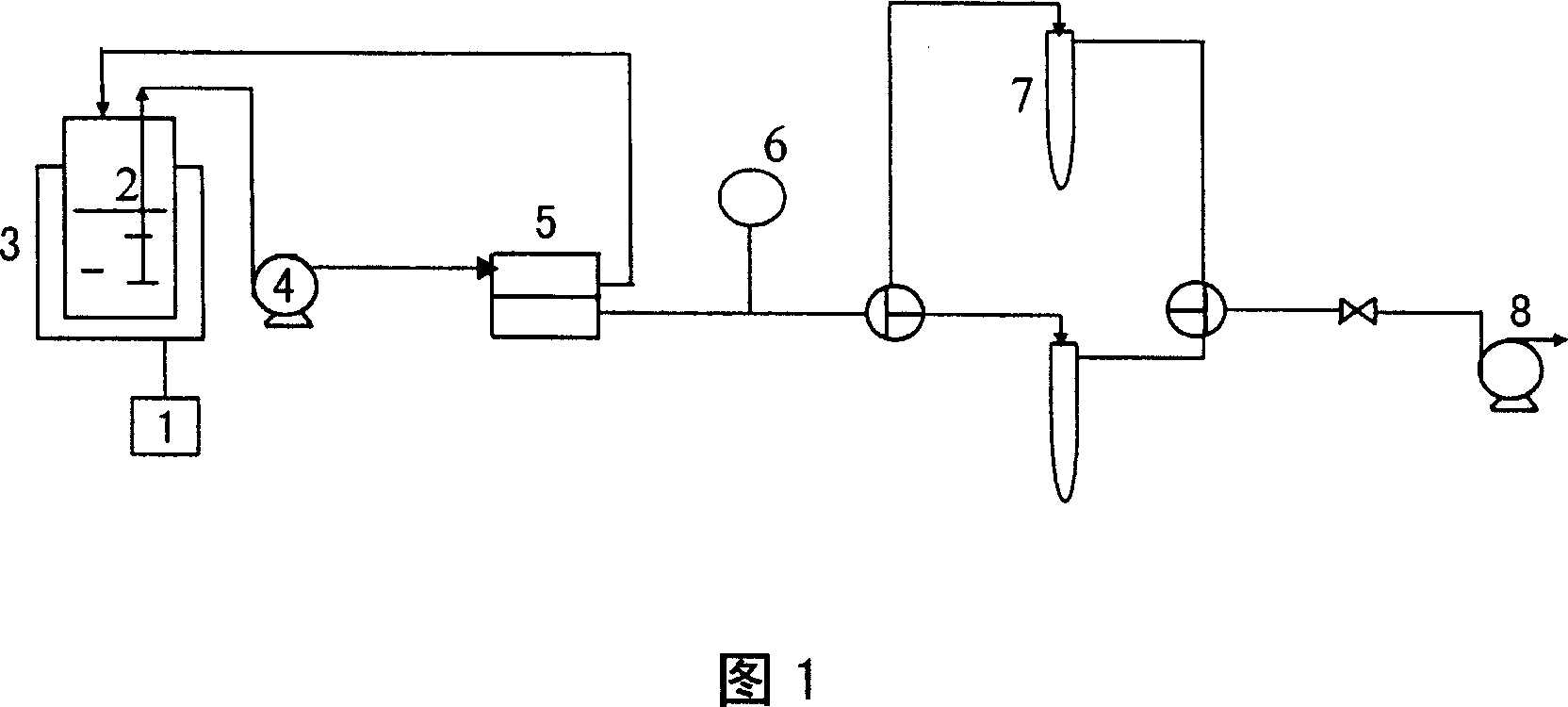

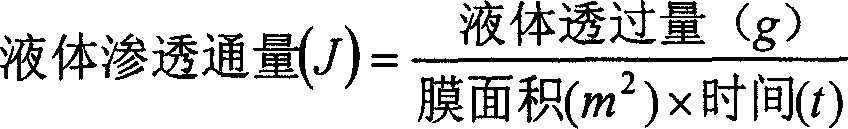

High-flux hyperbranched polysiloxane pervaporation membrane and preparation method thereof

The invention relates to a high-flux hyperbranched polysiloxane pervaporation membrane and a preparation method thereof, and belongs to the technical field of membrane separation. The preparation method for the membrane comprises the following process steps: mixing and reacting hyperbranched polysiloxane, hydroxyl terminated polysiloxane, a catalyst and a solvent to obtain a casting solution, coating the casting solution on a polymer porous basement membrane, and drying to obtain the high-flux hyperbranched polysiloxane pervaporation membrane. The hyperbranched polysiloxane pervaporation membrane prepared by the method has the characteristics of high permeation flux and high swelling resistance; and moreover, the preparation method is simple, convenient to operate, high in production repeatability and high in membrane structure controllability, and the high-flux hyperbranched polysiloxane pervaporation membrane is suitable for removing low-concentration alcohols from water, particularly suitable for separating low molecular alcohols from fermentation liquor.

Owner:WUXI UNMIXED CLEANSE EQUIP

High-modulus and low-shrinkage type activated polyester industry yarn and preparation method thereof

ActiveCN104499081AIncreased free volumeIncrease polarityNew-spun product collectionMelt spinning methodsPolyesterFiber

The invention relates to a high-modulus and low-shrinkage type activated polyester industry yarn and a preparation method thereof. The high-modulus and low-shrinkage type activated polyester industry yarn is prepared from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fibers is increased by 10-15v / v% when the high-modulus and low-shrinkage type activated polyester industry yarn is at 70-80 DEG C, a part of activating agent molecules are dispersed into fiber gaps, more -OHs and -NHs with strong activity are introduced, and the reactivity of the polyester fiber is improved; and the high-modulus and low-shrinkage type activated polyester industry yarn can be applied to light trucks, canvas conveyer belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

High-homogeneity car model polyester industrial yarn and preparation method thereof

ActiveCN106245149AIncreased free volumeReduce melt viscositySpinnerette packsMelt spinning methodsYarnCar model

The invention relates to a high-homogeneity car model polyester industrial yarn and a preparation method thereof. The high-homogeneity car model polyester industrial yarn uses modified polyester formed by a terephthalic acid chain segment, an ethylene glycol chain segment and branched chain-containing diol as a raw material. The preparation method of the high-homogeneity car model polyester industrial yarn comprises the following steps: subjecting the terephthalic acid and the branched-chain diol to an esterification reaction under the catalysis of concentrated sulfuric acid to obtain dihydroxy alcohol terephthalic acid; subjecting the terephthalic acid and the ethylene glycol to an esterification reaction to obtain dimethyl terephthalate; finally stirring and mixing the two, subjecting a polycondensation reaction at low vacuum phase and high vacuum stage under the action of a catalyst and a stabilizer to obtain modified polyester, subjecting the modified polyester to metering, porous spinneret extruding, cooling, oiling, stretching, heat setting and winding to obtain the high-homogeneity car model polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com