High-uniformity polyester industrial yarn used for safety belt and production method thereof

A technology of uniformity and safety belt, applied in the field of polyester fiber, can solve the problems of uneven strength, uneven fineness, difficulty in silk processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

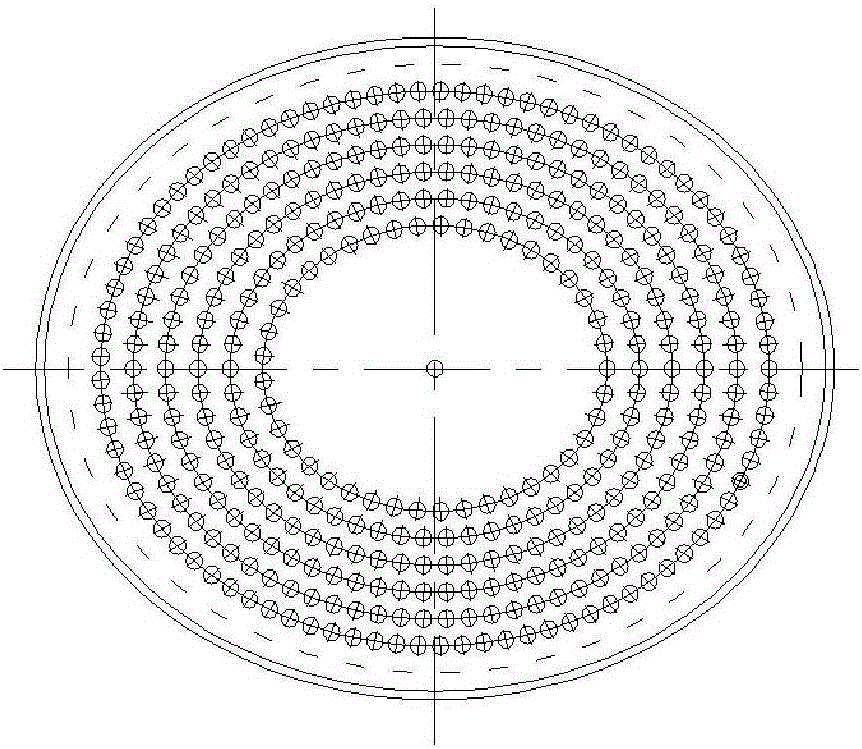

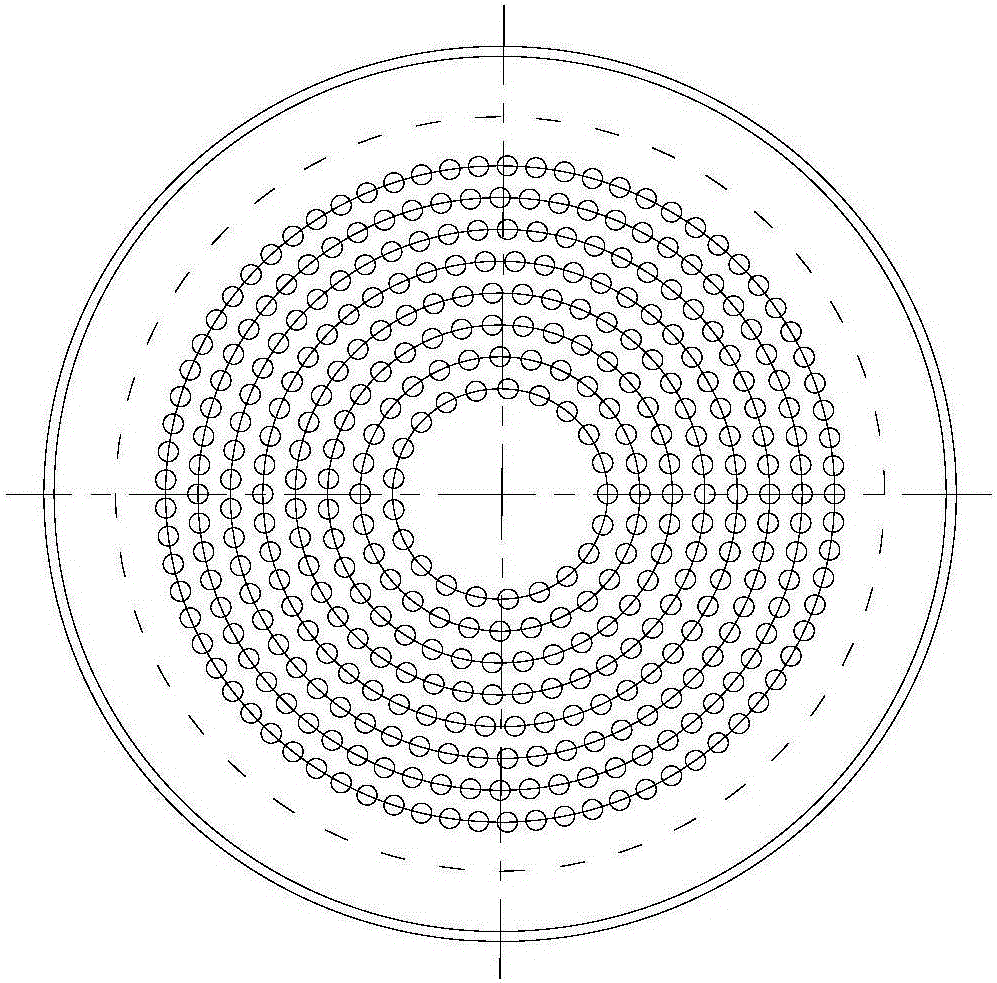

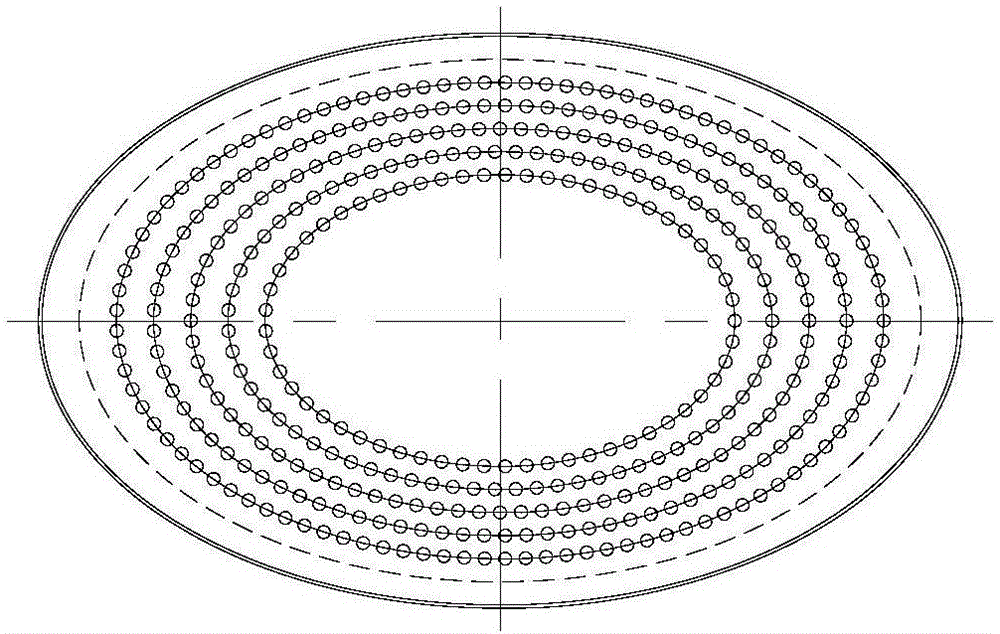

Image

Examples

Embodiment 1

[0052] A preparation method of modified polyester, specifically comprising the following steps:

[0053] (1) Preparation of glycol terephthalate:

[0054] Put terephthalic acid and 2-pentyl-1,3 propanediol with a molar ratio of 1:1.3 into a slurry and add it to the reactor at a concentration of 50 wt%, and the addition amount is 0.3% of the weight of terephthalic acid. Under the catalysis of sulfuric acid, esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurized pressure is normal pressure and the temperature is 180°C. Time is the end point of the esterification reaction to obtain diol terephthalate;

[0055] (2) Preparation of ethylene terephthalate:

[0056] Put terephthalic acid and ethylene glycol into a slurry with a molar ratio of 1:1.2 and put them into the reactor to carry out esterification reaction. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurized pressure is nor...

Embodiment 2

[0064] The preparation process of modified polyester is the same as Example 1, wherein the main technical parameters are referring to Table 1; after adding terephthalic acid glycol ester in step (3), stirring and mixing for 16 minutes, the addition amount is terephthalic acid The catalyst antimony trioxide of 0.011% of the total weight and the add-on are under the effect of the stabilizer triphenyl phosphate of 0.02% of the total weight of terephthalic acid, and start the polycondensation reaction of the low vacuum stage under the condition of negative pressure, the The stage pressure is pumped steadily from normal pressure to absolute pressure 490Pa, the temperature is controlled at 262°C, and the reaction time is 31 minutes; then continue to vacuumize and carry out the polycondensation reaction in the high vacuum stage, so that the reaction pressure drops to an absolute pressure of 90Pa, and the reaction temperature is controlled at 276°C, the reaction time is 51 minutes, and...

Embodiment 3

[0067] The preparation process of modified polyester is the same as Example 1, wherein the main technical parameters are referring to Table 1; after adding terephthalic acid glycol ester in step (3), stirring and mixing for 16 minutes, the addition amount is terephthalic acid 0.03% of the total weight of the catalyst antimony trioxide and the addition of 0.02% of the total weight of terephthalic acid under the action of the stabilizer triphenyl phosphate, under the condition of negative pressure, the polycondensation reaction of the low vacuum stage is started, the The stage pressure is pumped steadily from normal pressure to absolute pressure 498Pa, the temperature is controlled at 263 ° C, and the reaction time is 32 minutes; then continue to vacuumize and carry out the polycondensation reaction in the high vacuum stage, so that the reaction pressure drops to an absolute pressure of 90Pa, and the reaction temperature is controlled at 277°C, the reaction time is 57 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com