Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about How to "Maintain good performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

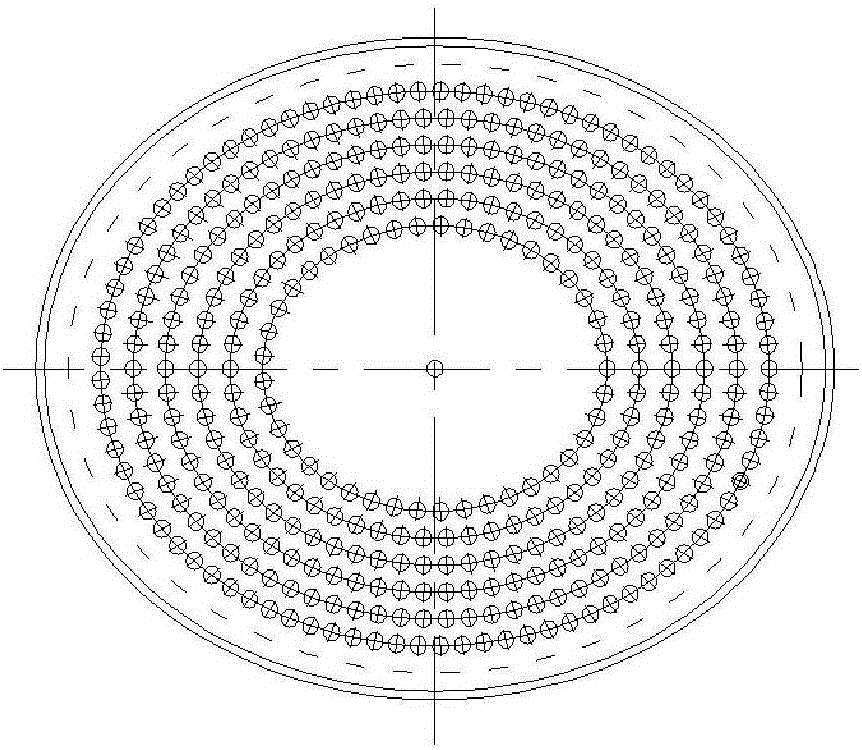

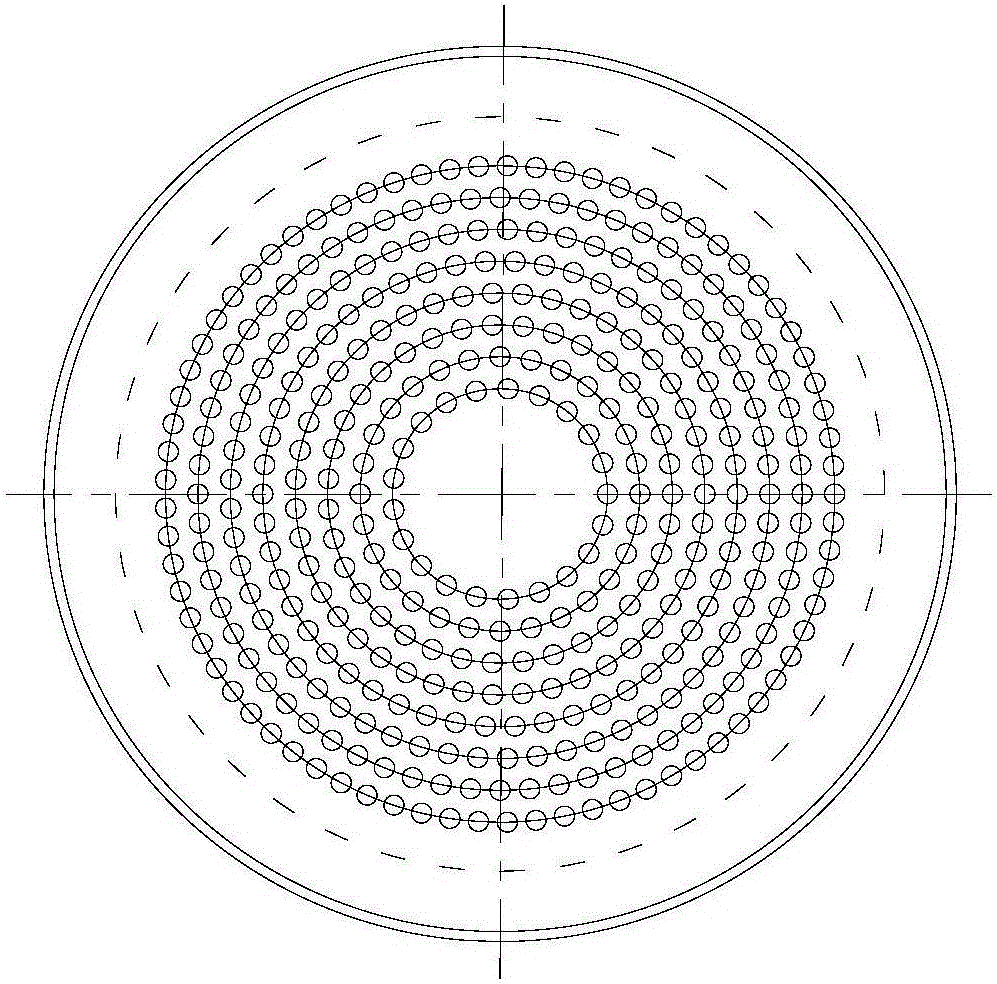

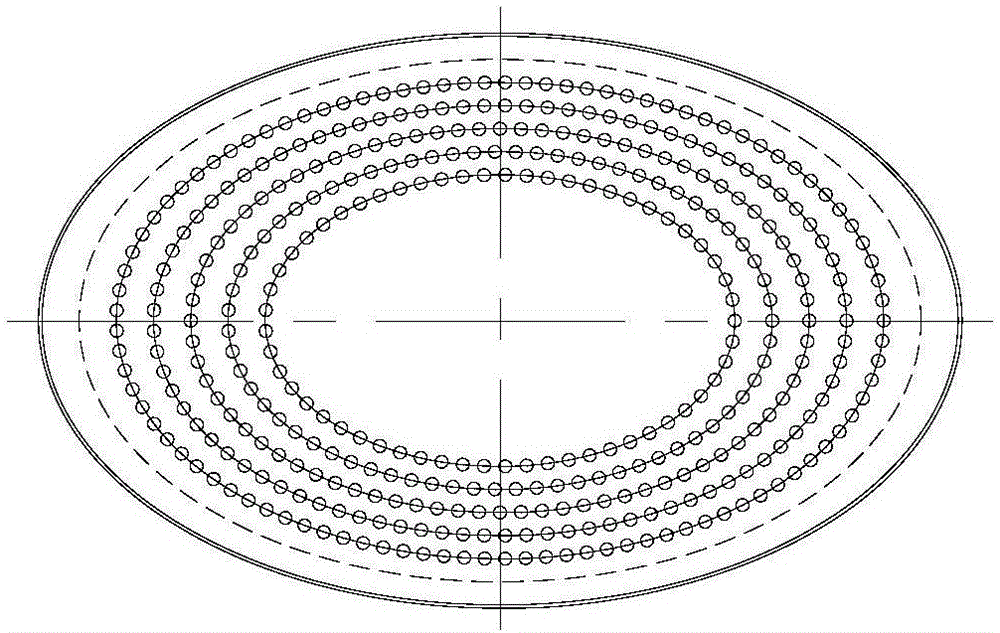

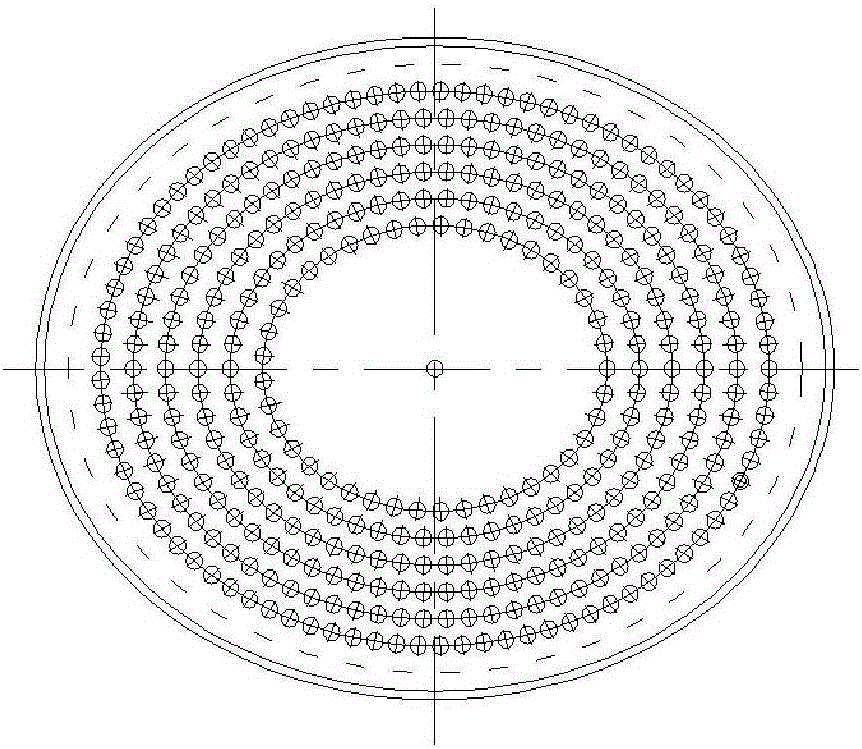

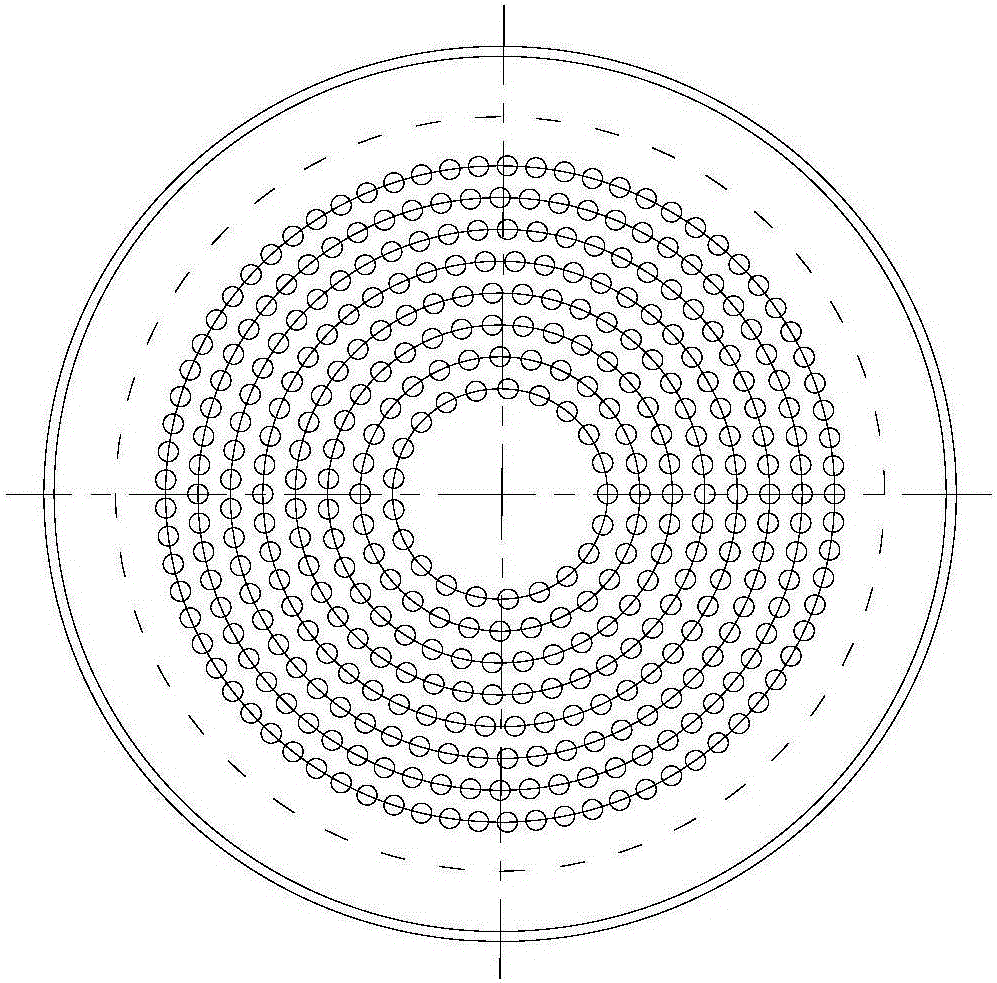

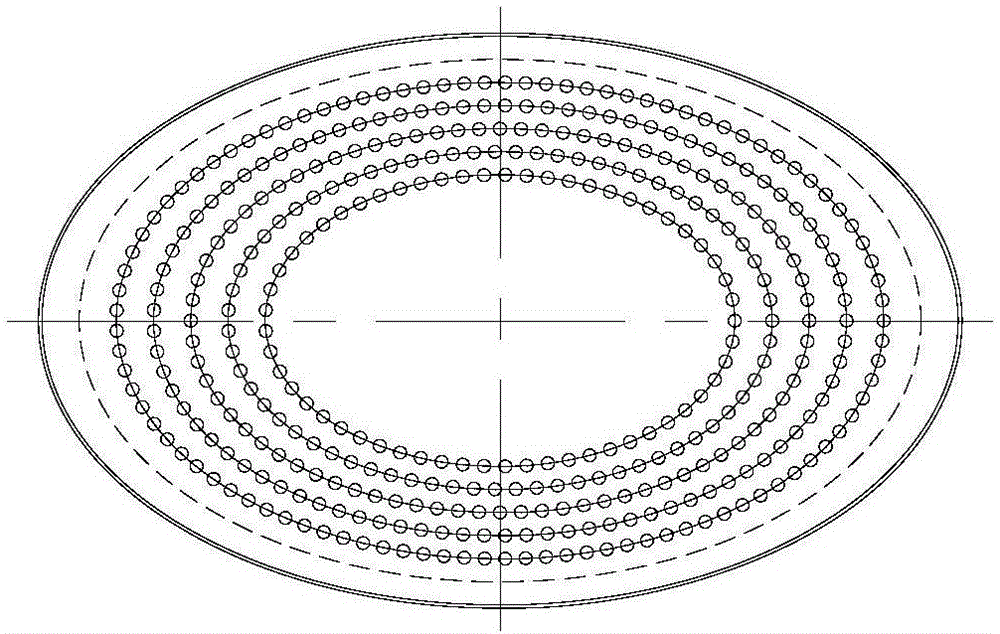

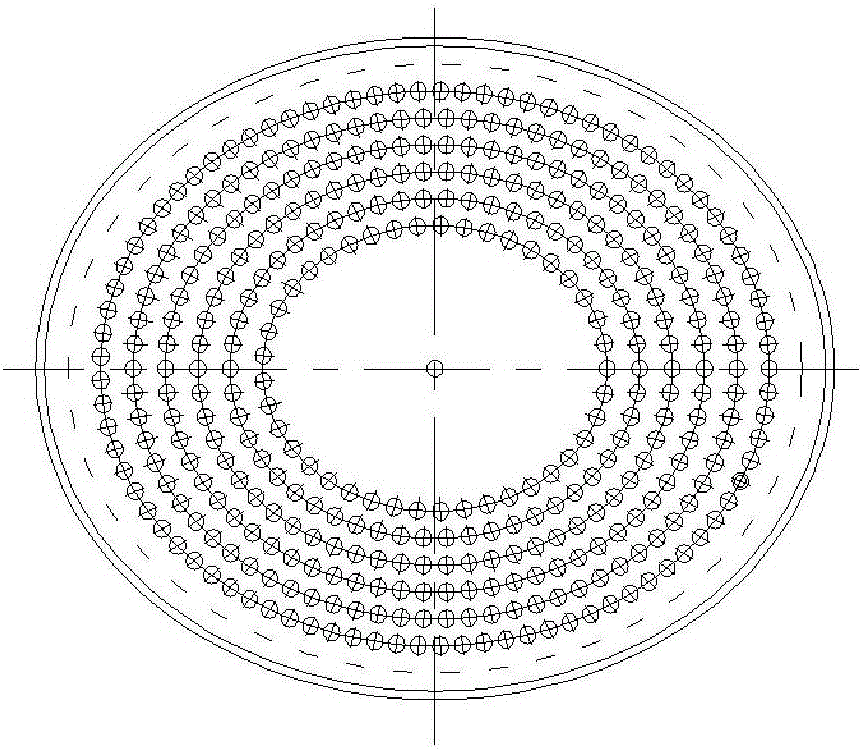

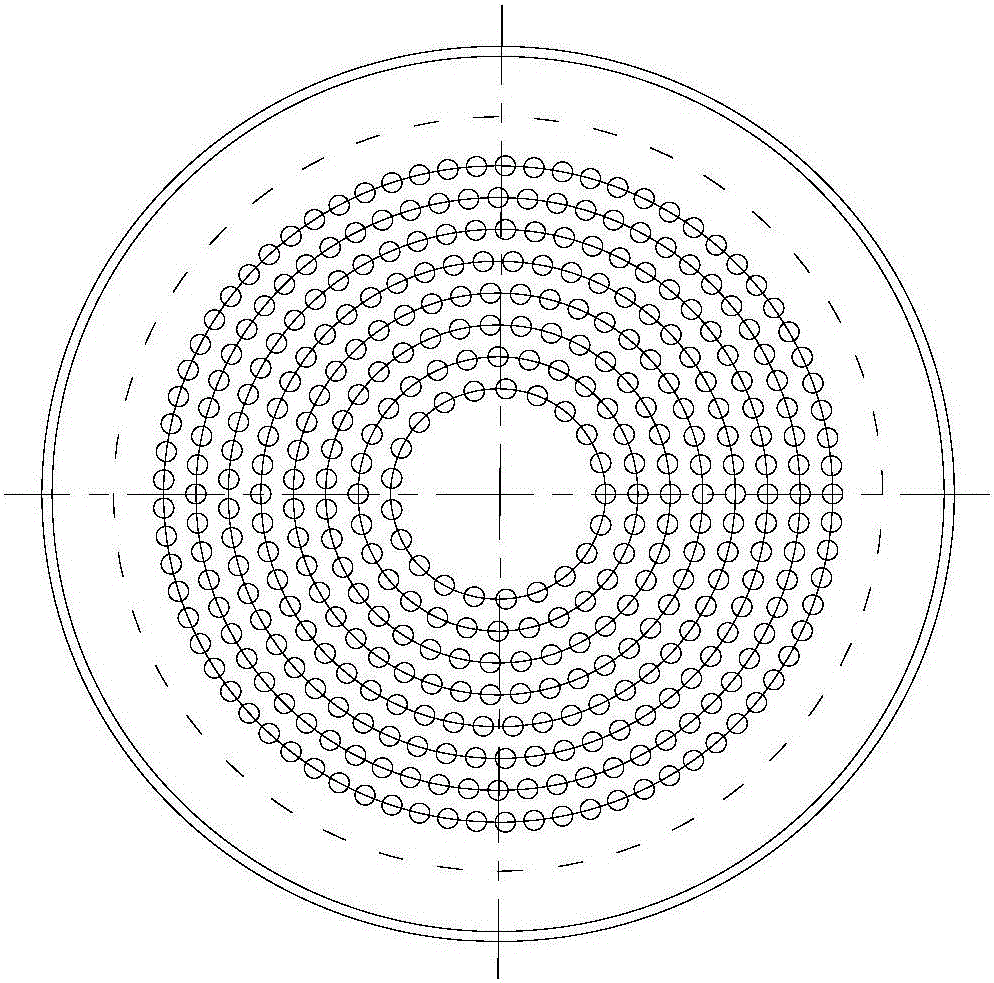

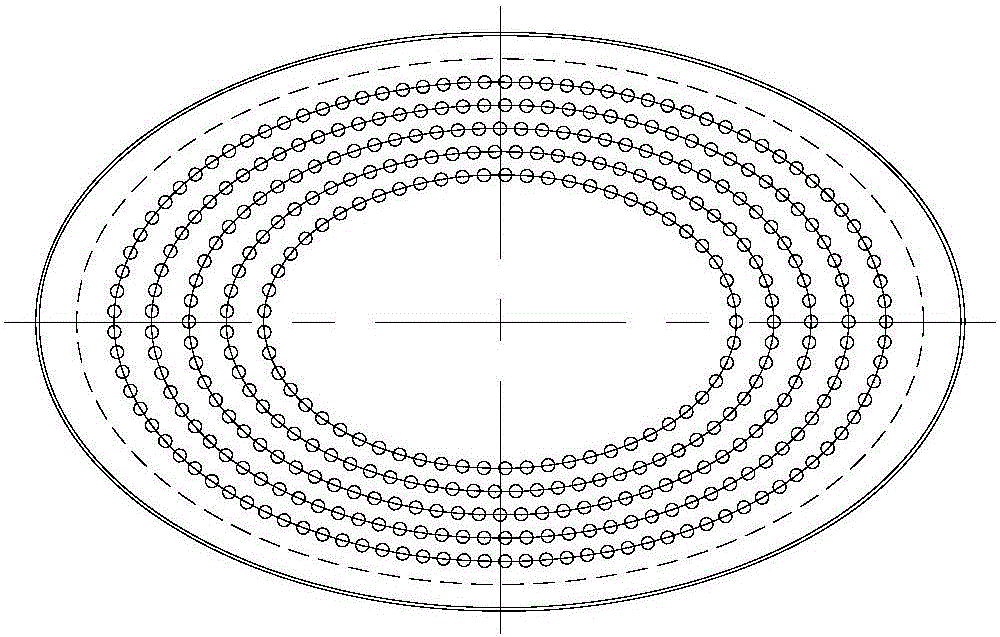

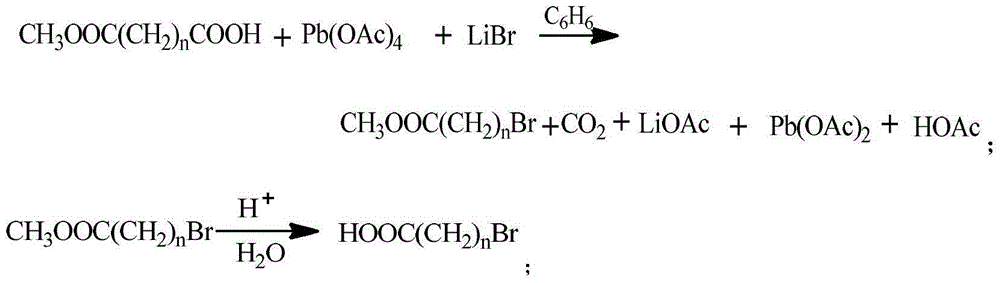

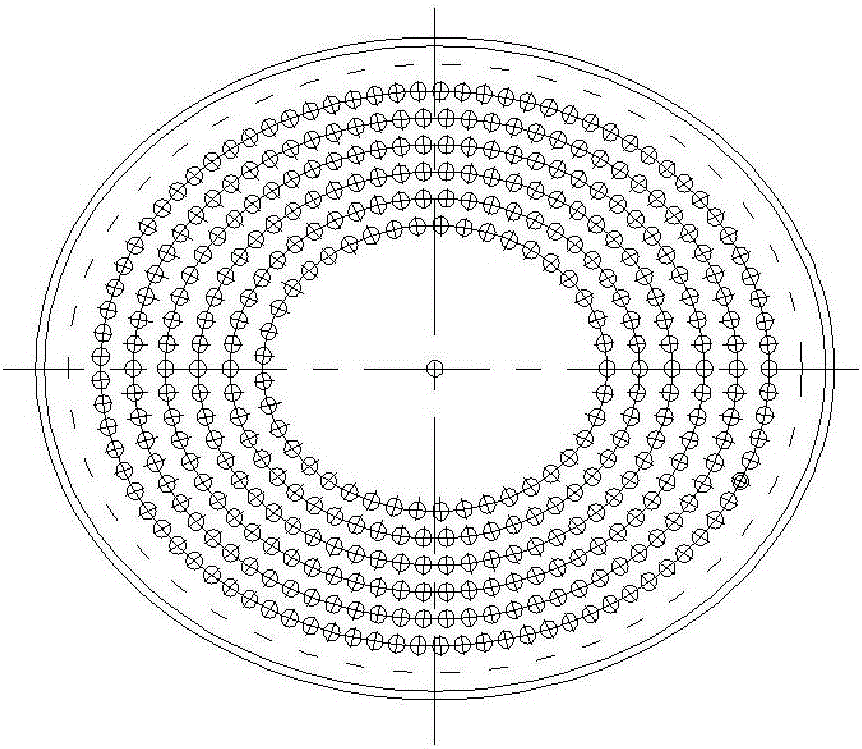

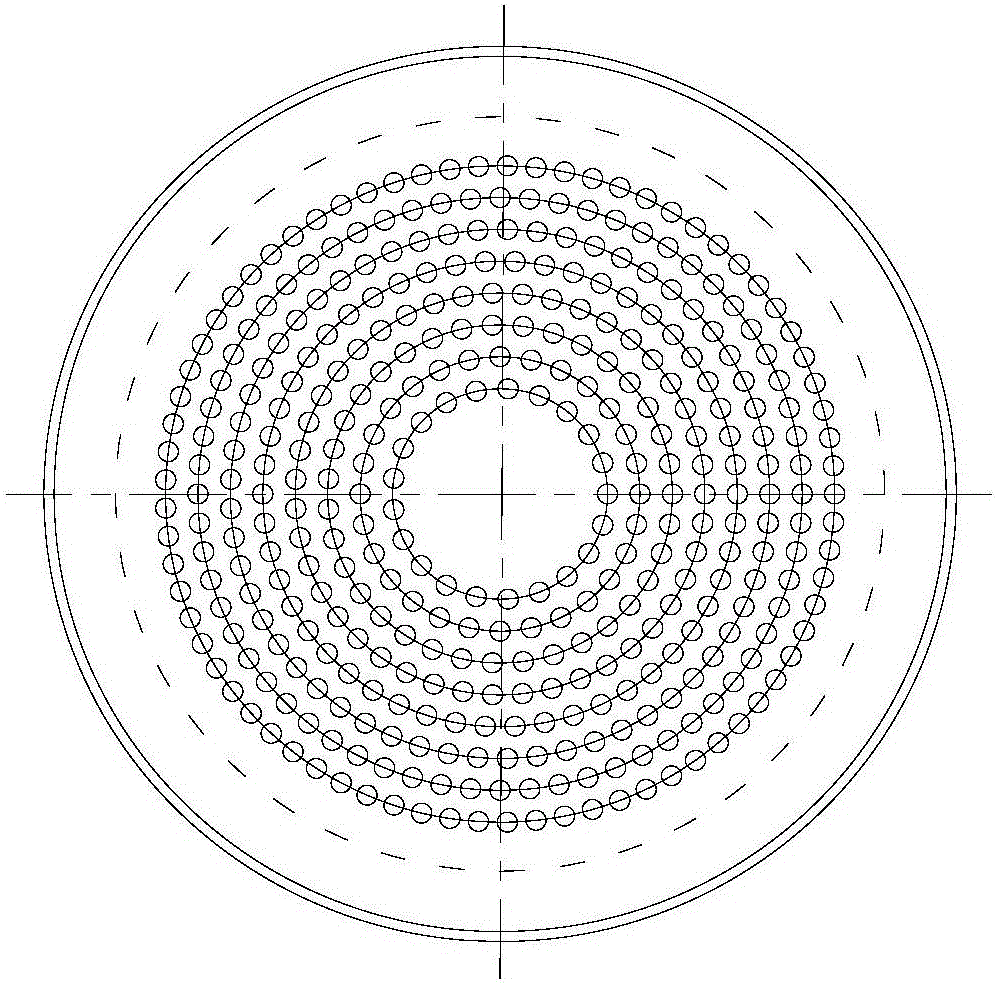

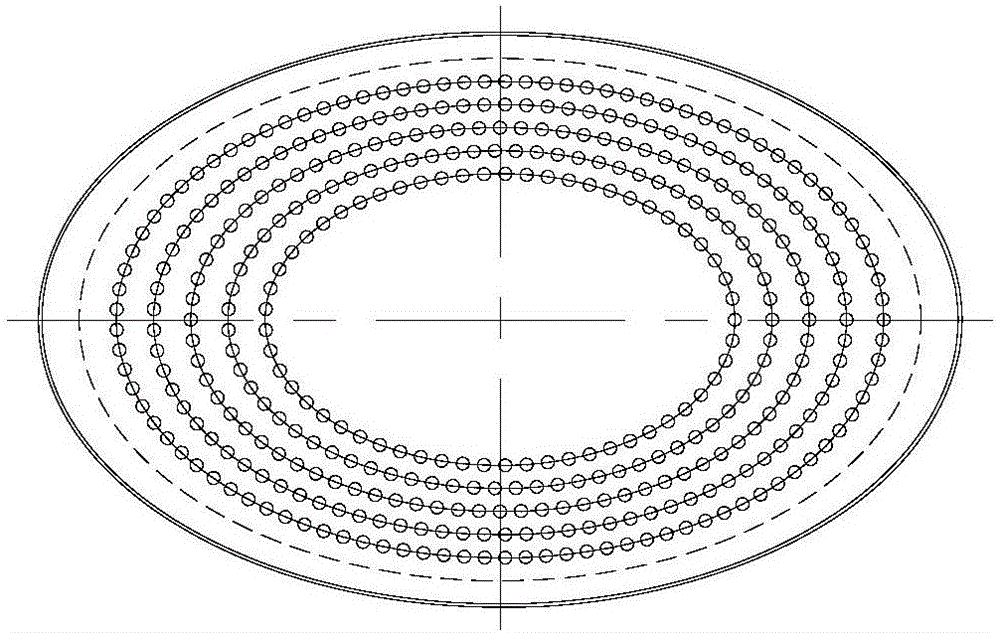

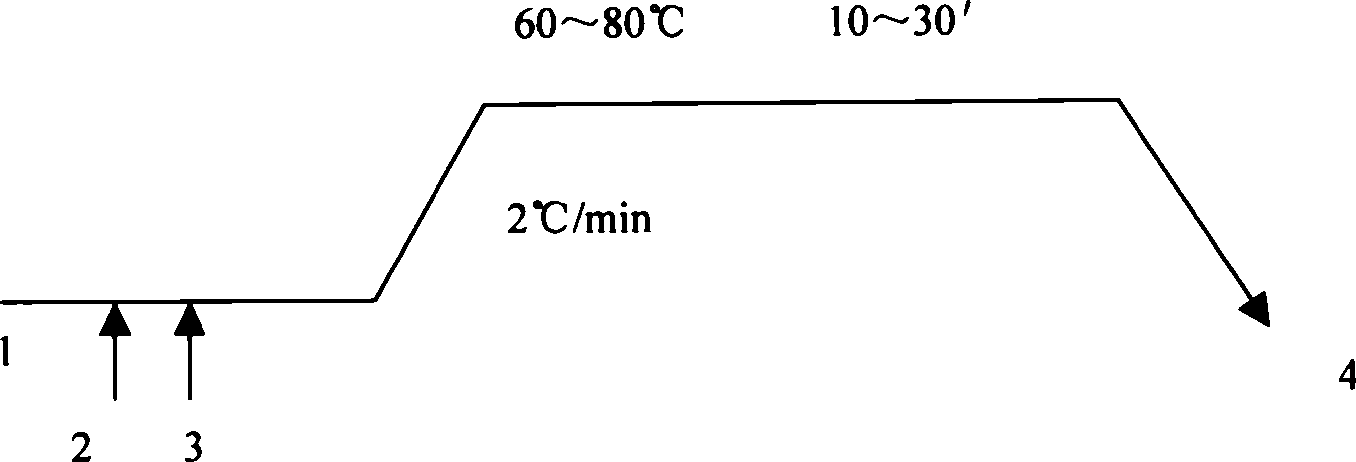

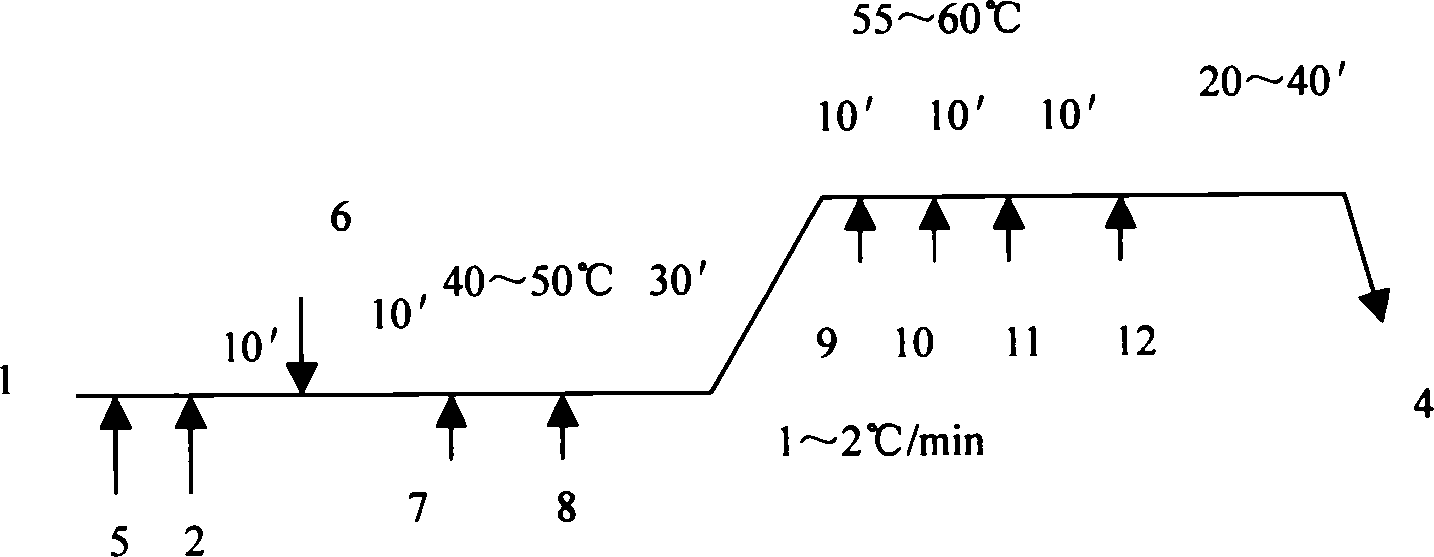

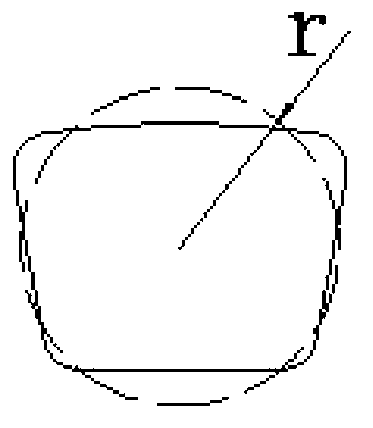

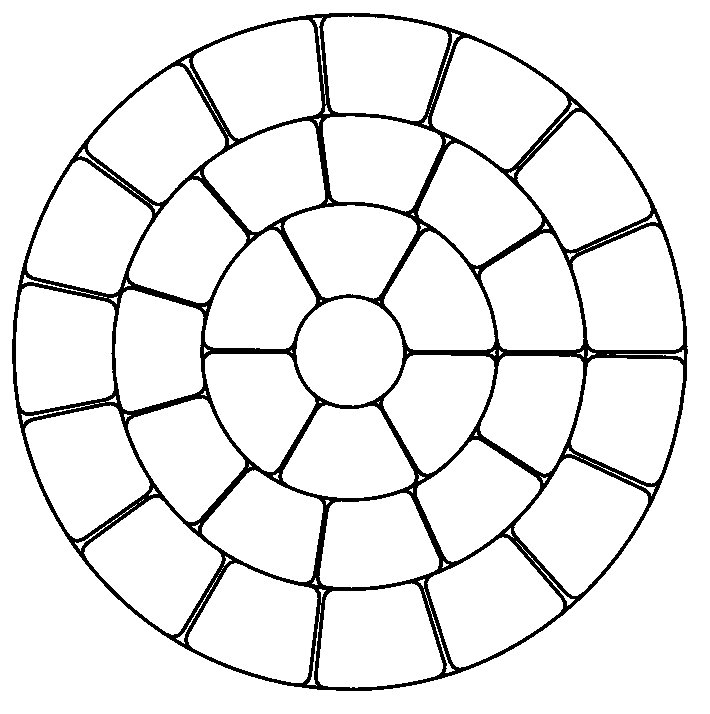

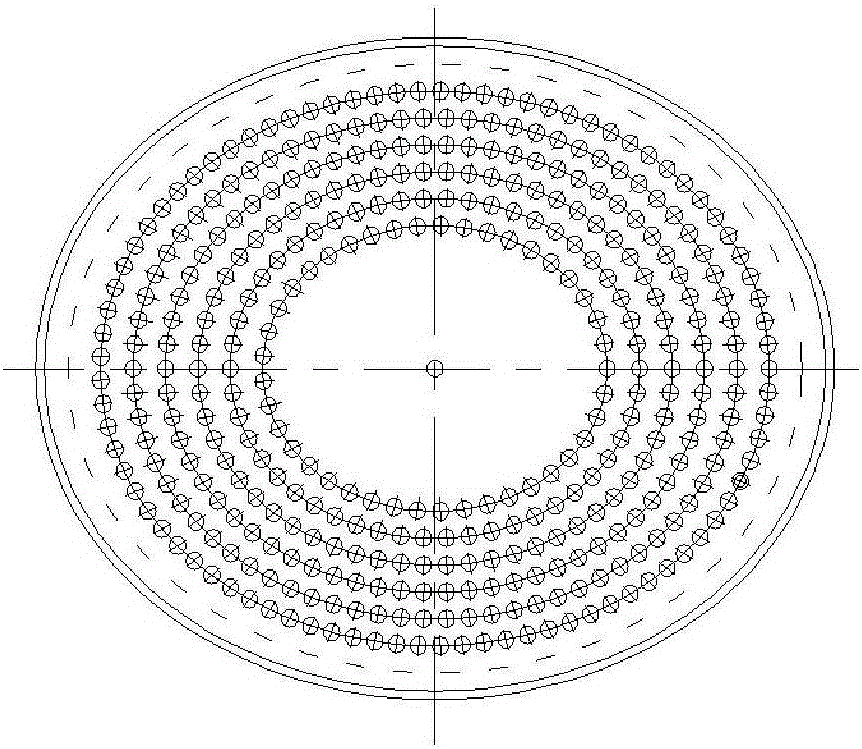

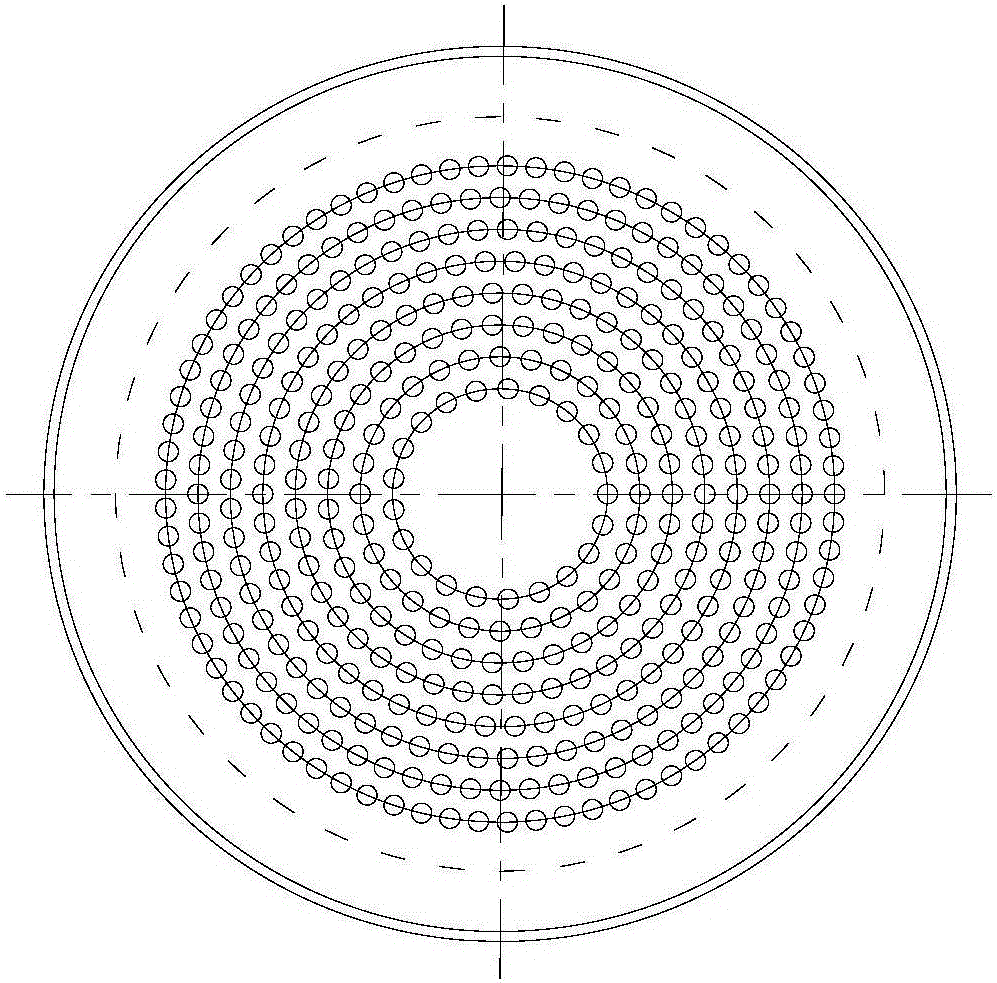

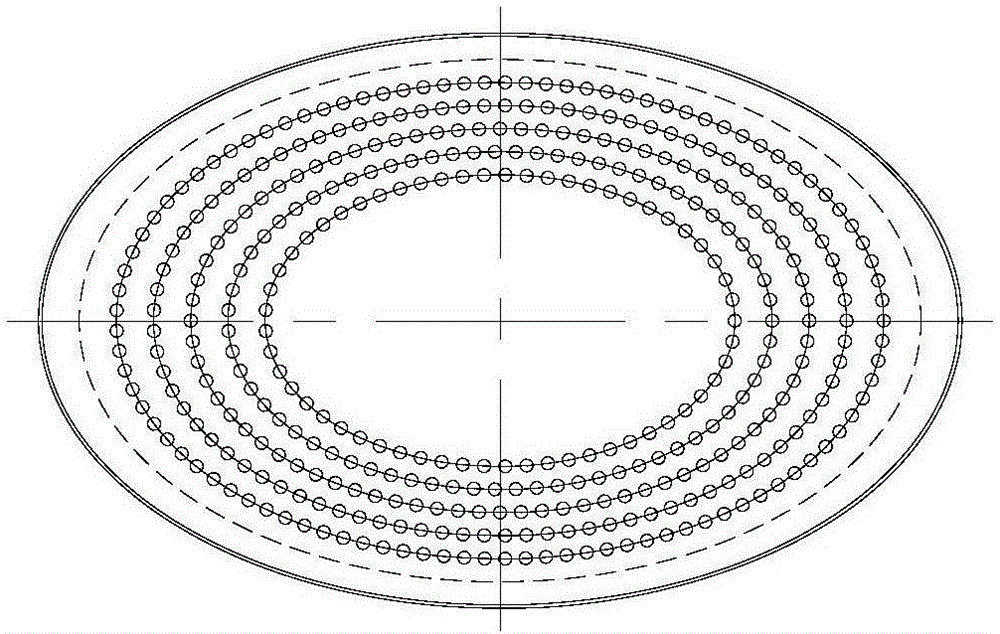

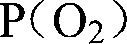

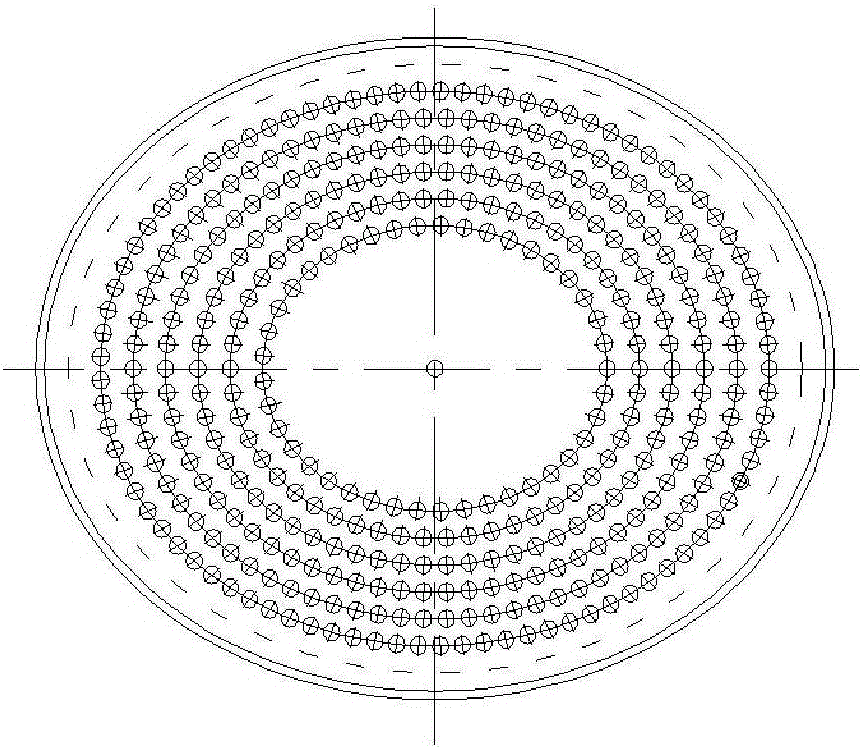

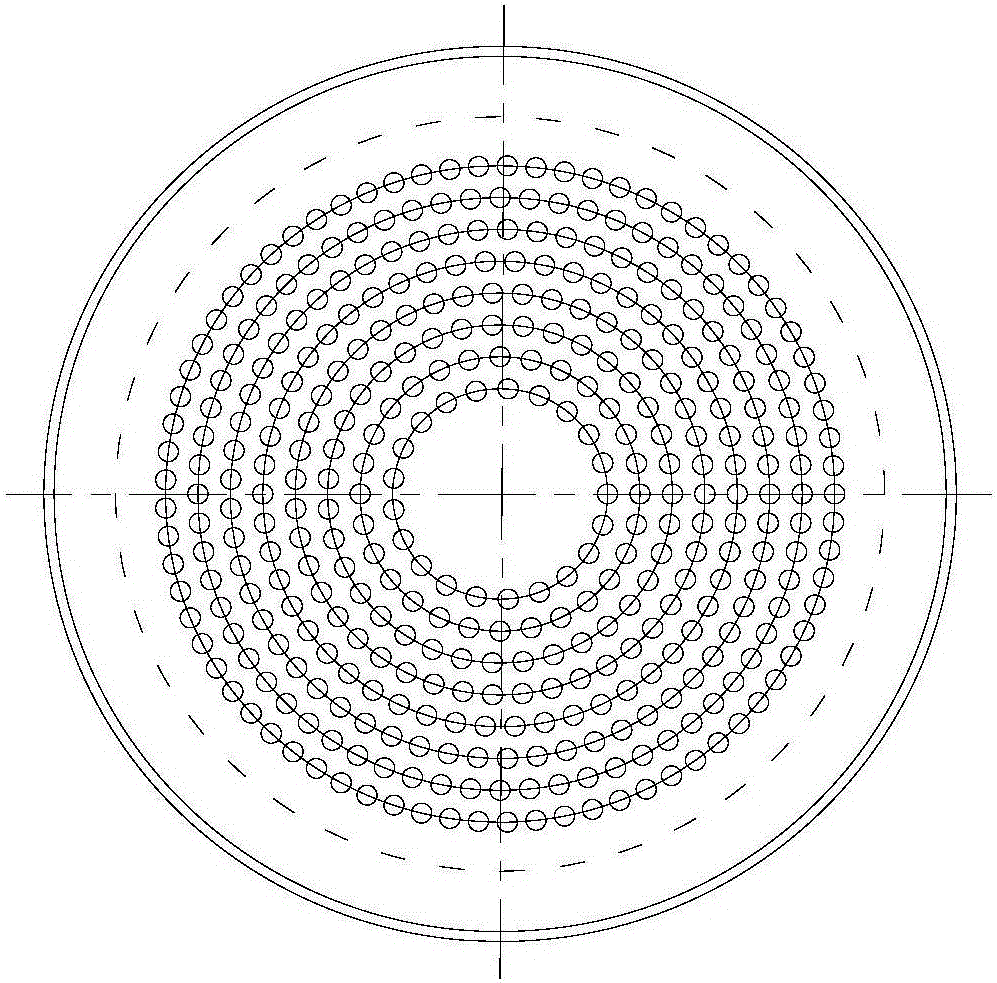

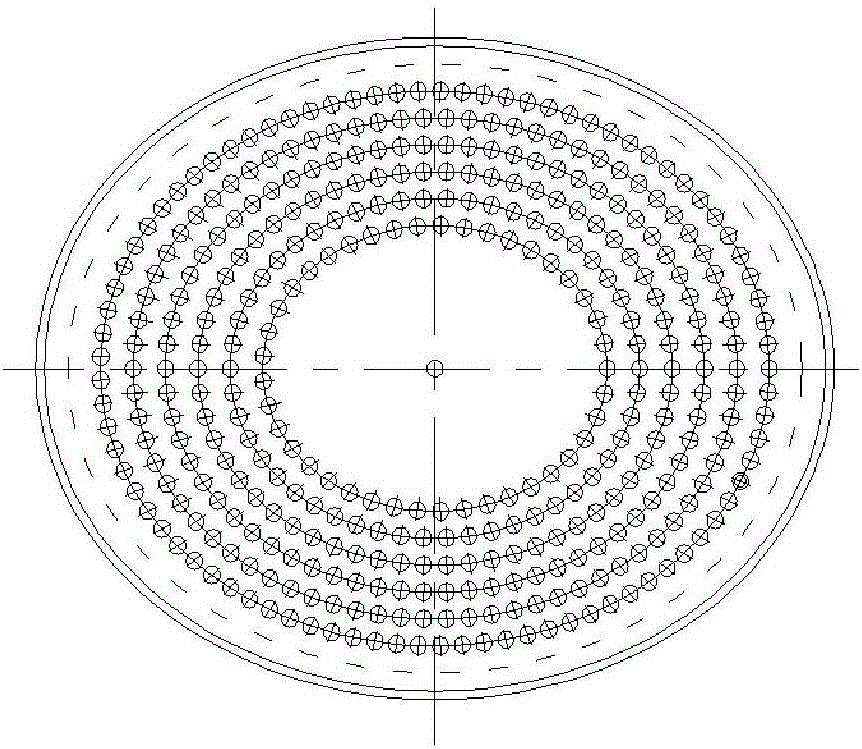

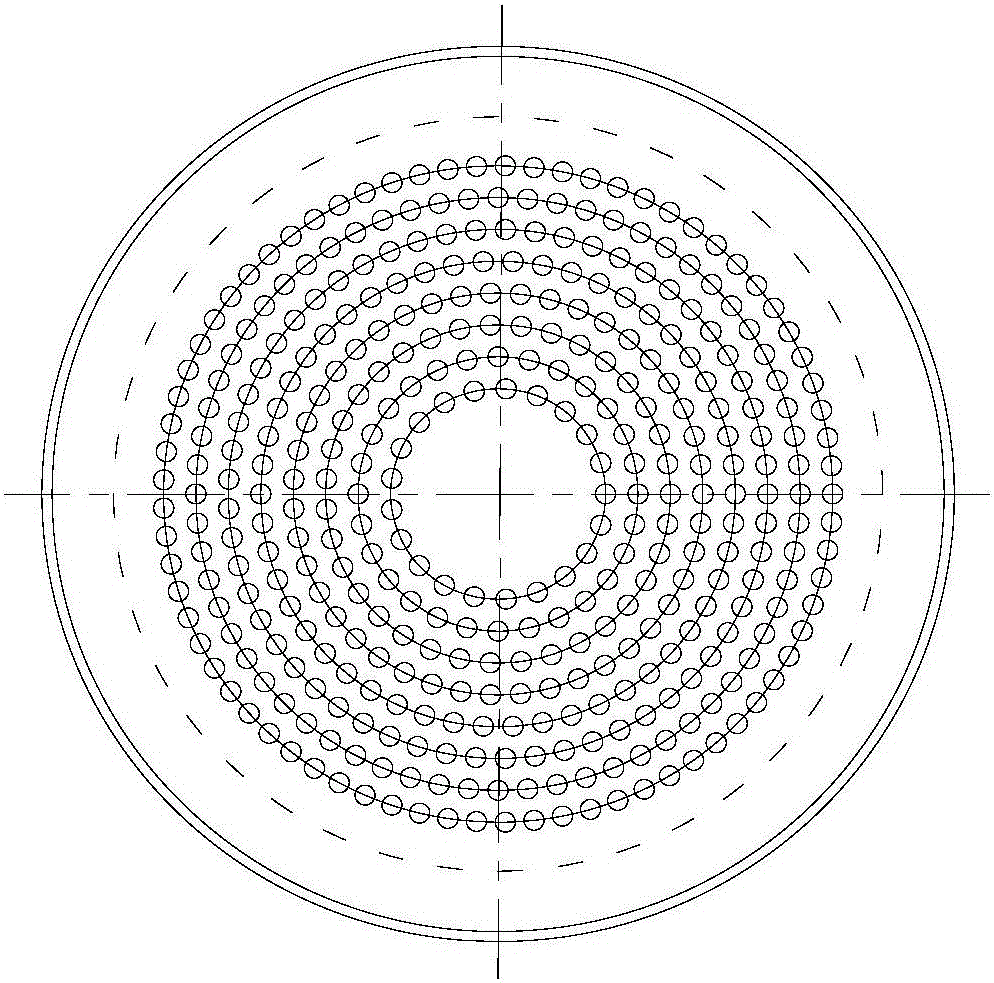

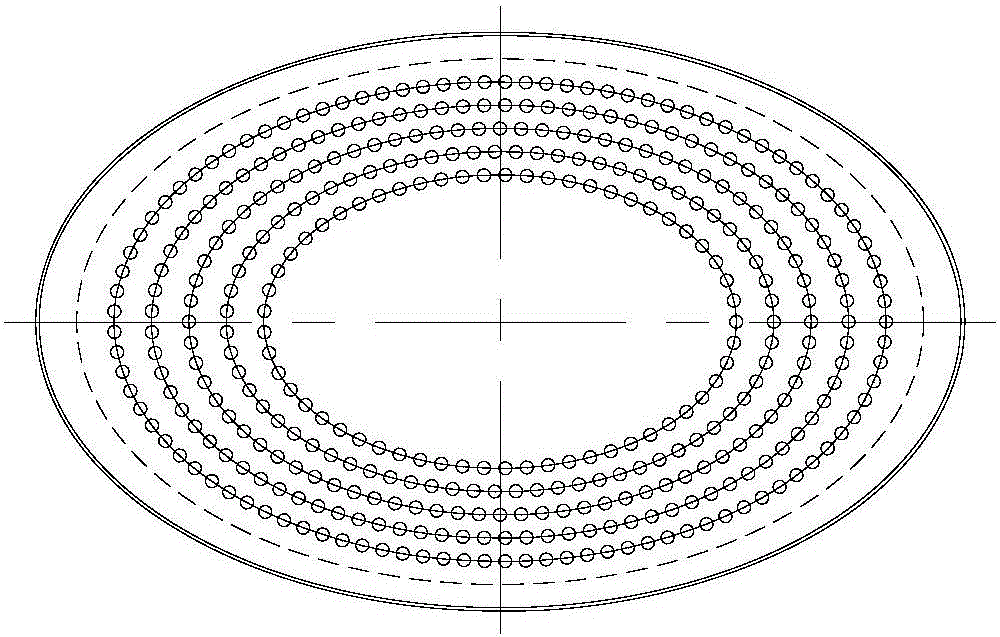

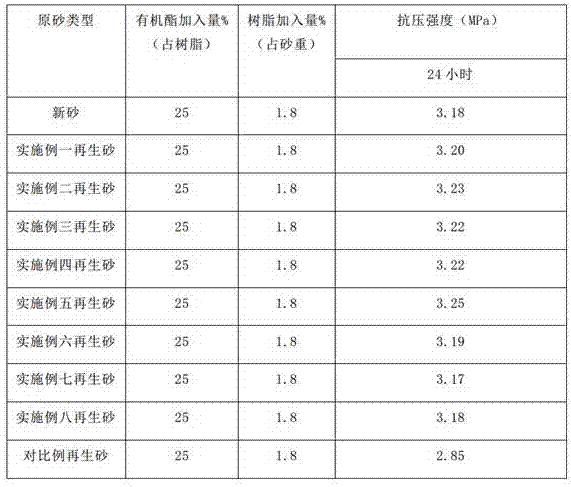

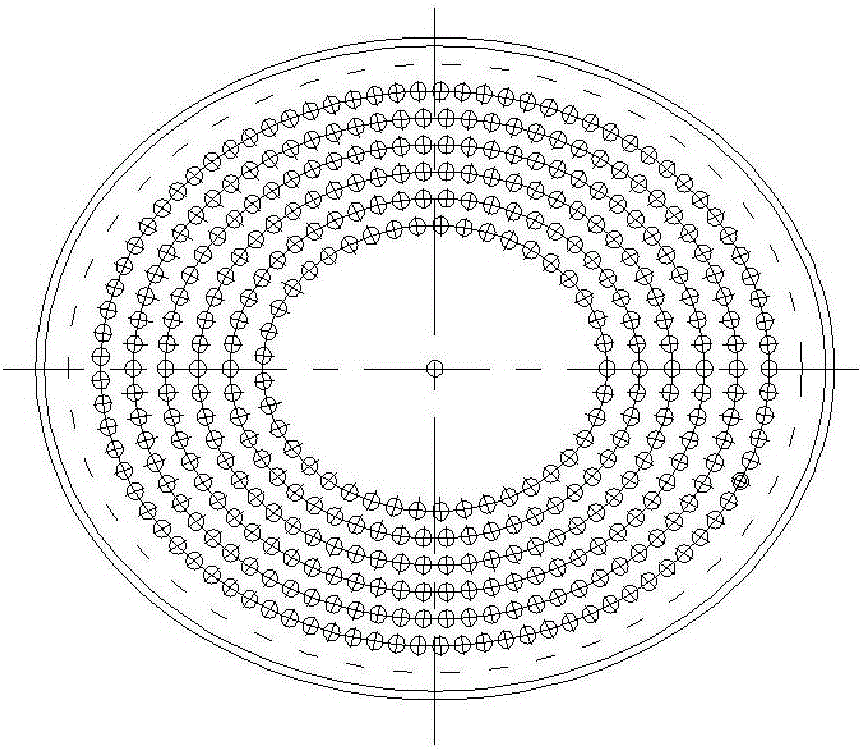

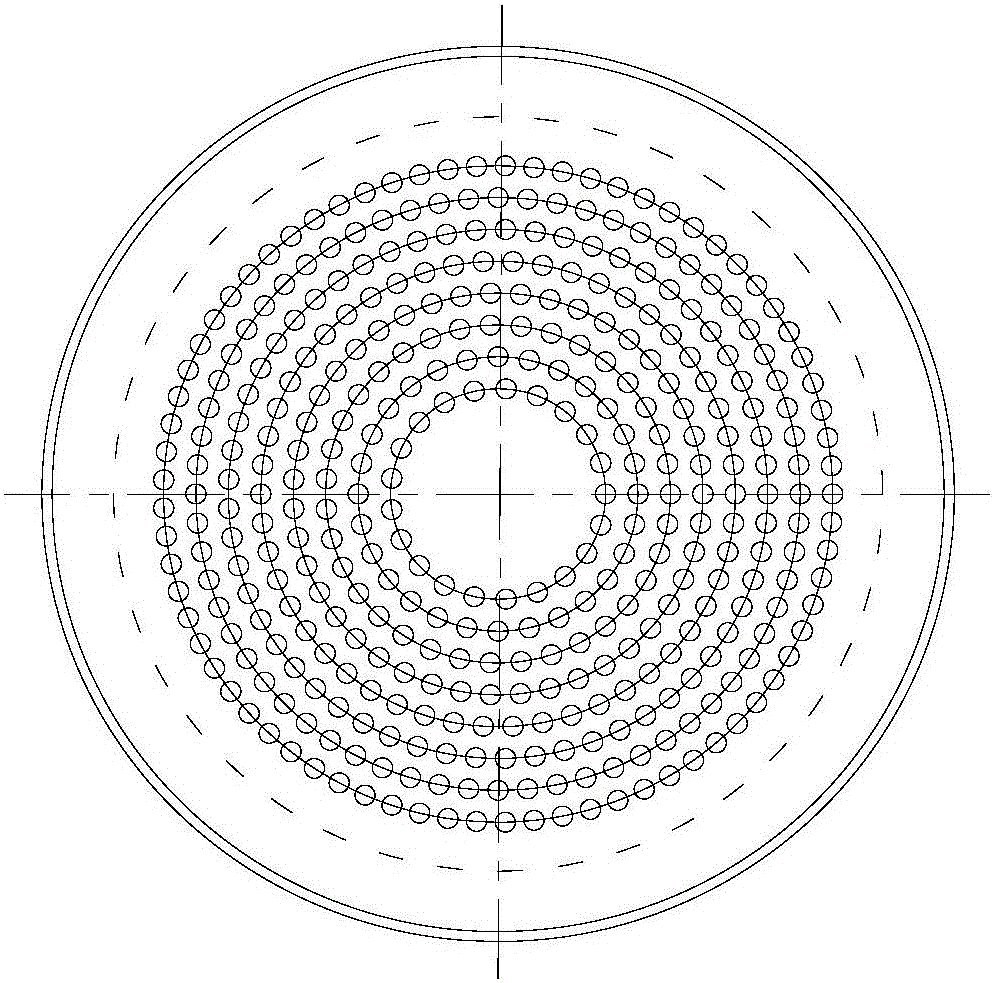

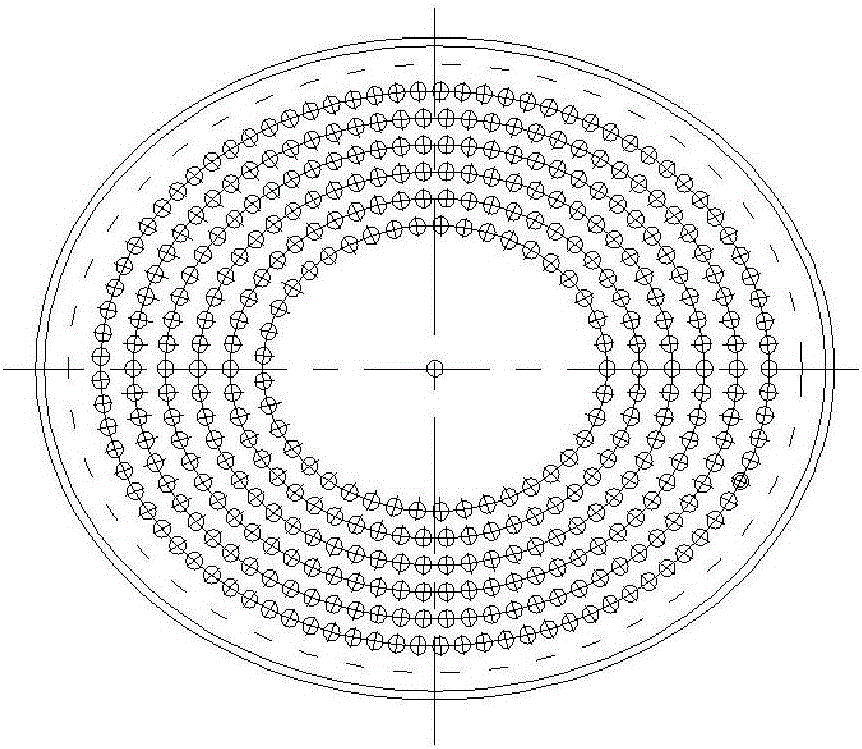

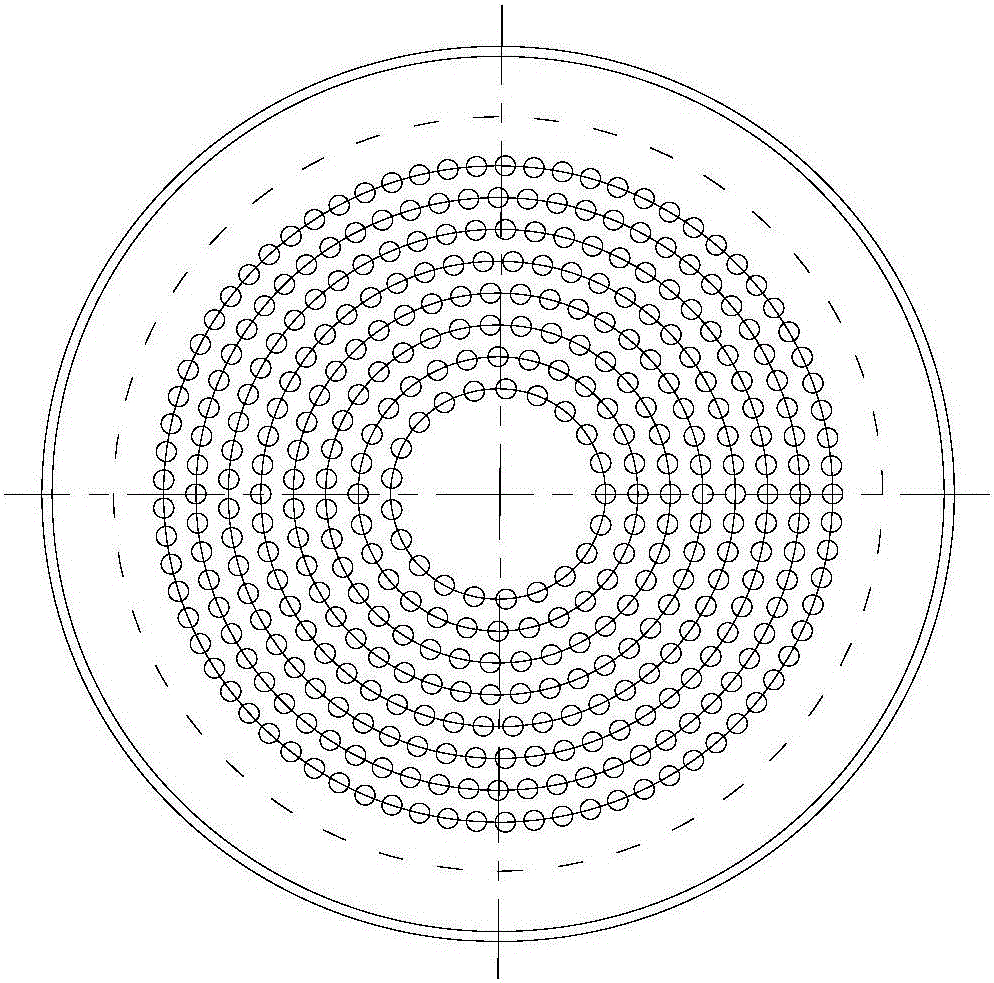

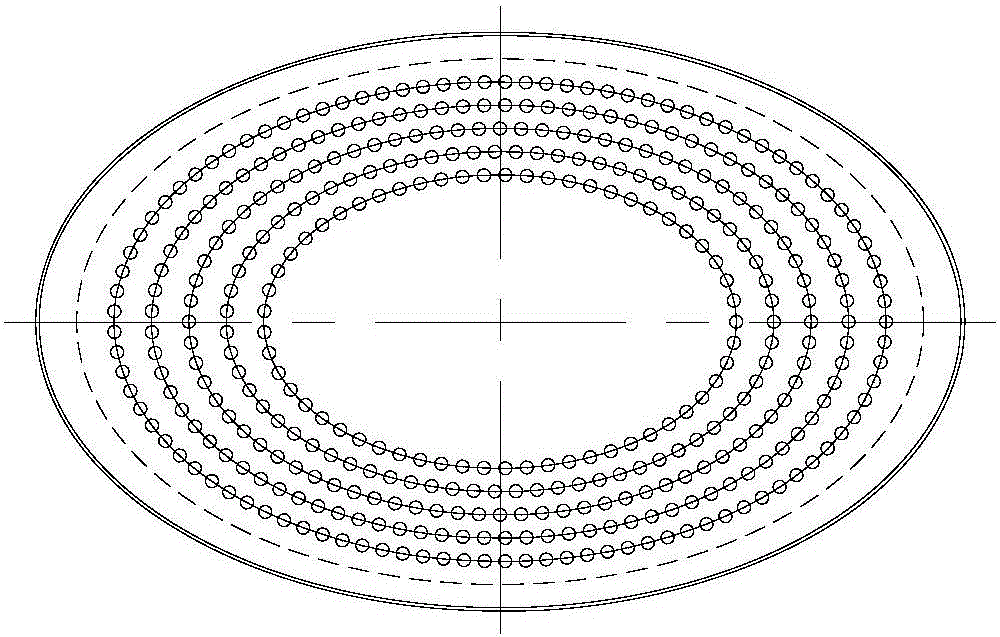

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

High-uniformity polyester industrial yarn used for safety belt and production method thereof

ActiveCN106381557AIncreased free volumeReduce melt viscositySpinnerette packsHollow filament manufactureYarnLow vacuum

The invention relates to a high-uniformity polyester industrial yarn used for a safety belt and a production method thereof. The raw material of the high-uniformity polyester industrial yarn is modified polyester composed of a terephthalic acid chain segment, a glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The production method is characterized in that terephthalic acid and branched chain-containing dihydric alcohol are subjected to an esterification reaction under catalysis of concentrated sulfuric acid to obtain dihydricalcohol terephthalate; then terephthalic acid and glycol are prepared for the esterification reaction to obtain ethylene terephthalate; finally ethylene terephthalate and dihydricalcohol terephthalate are stirred and mixed, under a catalyst and a stabilizing agent, the condensation polymerization reactions under a low vacuum phase and a high vacuum phase are carried out to prepare the modified polyester, and the modified polyester is subjected to metering, extrusion by a porous spinneret, cooling, oiling, stretching, thermoforming and reeling to prepare the high-uniformity polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Separator comprising microcapsules and electrochemical device having the same

ActiveUS20140120402A1Improve performanceImprove thermal stabilityFinal product manufactureLi-accumulatorsPorous coatingElectrochemistry

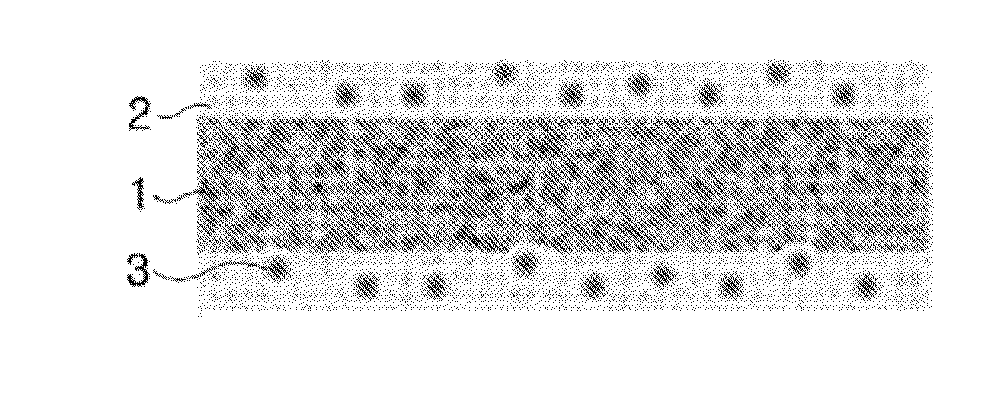

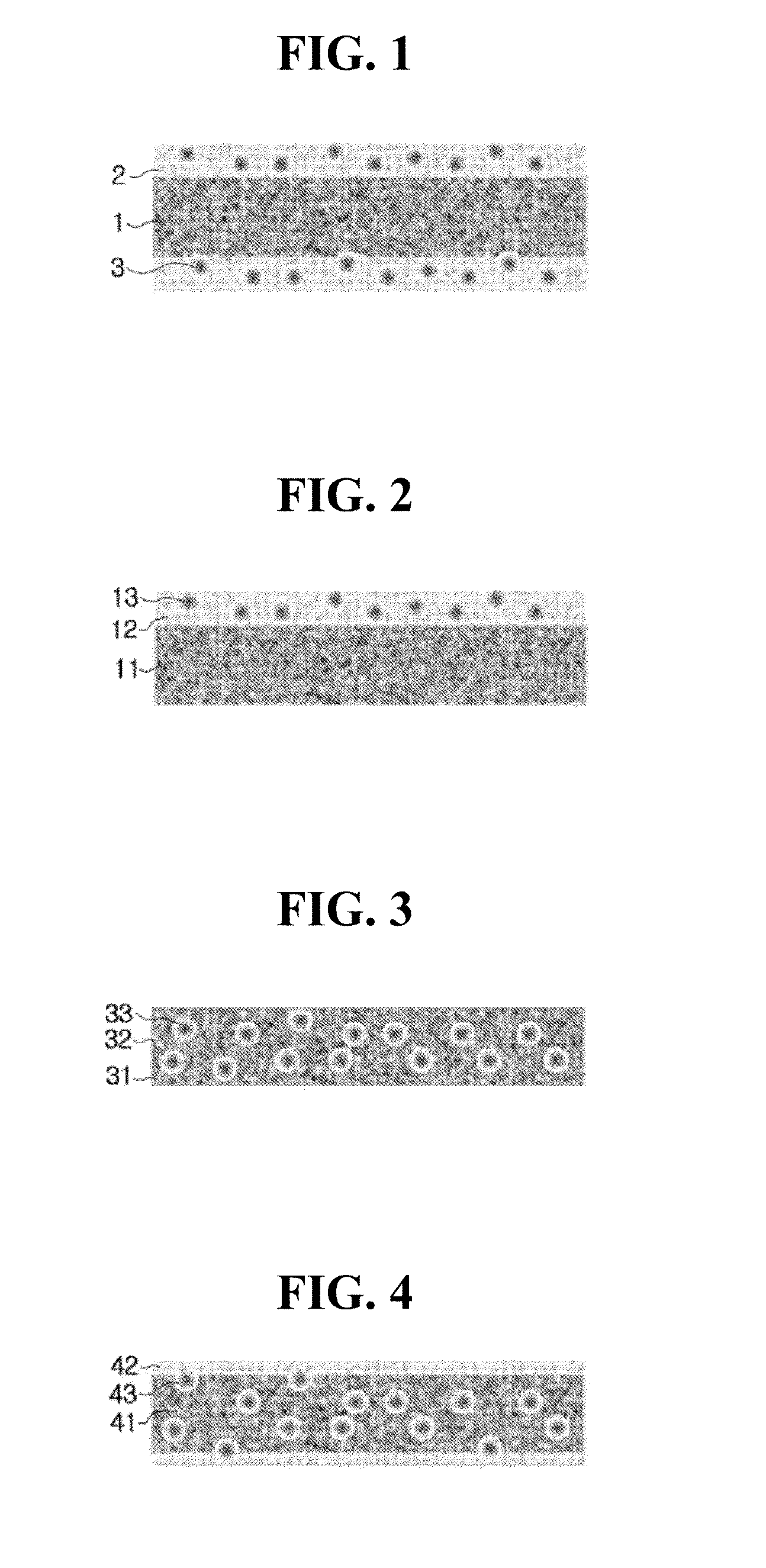

The present invention refers to a separator, comprising a porous substrate having multiple pores; a porous coating layer formed on at least one area selected from at least one surface of the porous substrate and the pores of the porous substrate, and comprising multiple inorganic particles and a binder polymer, the binder polymer being existed on a part or all of the surface of the inorganic particles to connect and immobilize the inorganic particles therebetween; and microcapsules dispersed in at least one area selected from the pores of the porous substrate and pores formed by vacant spaces between the inorganic particles present in the porous coating layer, and containing therein an additive for improving the performances of an electrochemical device, and an electrochemical device having the same.

Owner:TORAY BATTERY SEPARATOR FILM +1

Method for preparing sheet-like microcrystal cellulose and modification processing method

InactiveCN101070352AMaintain physical propertiesMaintain mechanical propertiesAcetic acidDispersed media

This invention relates to preparation method of a flakiness microcrystalline cellulose, as well as its surface reshaping method. The process: in water disperse medium, take reaction with sulfuric acid to gain flakiness microcrystalline cellulose, then surface by acetic acid esterification or SAA absorption modifing, repass wash, filter , dryness, gain the product. The mass ratio of water and cellulose is 3 to 25:1, sulfuric acid volumetric concentration for 30 to 80%, temperature for 10 - to 85 deg, time for 5 to 120 minutes. The mass ratio of acetic ester modifier or SAA and microcrystalline cellulose is 0.1 to 5: 100. The modifier not only keep the favorable physics and mechanical property of cellulose, but also improve dispersibility, greatly advance consistency with high molecular material, broaden the application area.

Owner:LUDONG UNIVERSITY +1

High-uniformity colored polyester industrial yarn and preparation method thereof

ActiveCN106245150AIncreased free volumeReduce melt viscositySpinnerette packsMonocomponent polyetheresters artificial filamentChemistryPolyethylene terephthalate glycol

The invention relates to a high-uniformity colored polyester industrial yarn and a preparation method thereof. The raw material of the high-uniformity colored polyester industrial yarn is modified polyester composed of terephthalic acid chain segments, ethylene glycol chain segments and dihydric alcohol chain segments containing branched chains. The method for preparing the high-uniformity colored polyester industrial yarn comprises the following steps: carrying out an esterification reaction between terephthalic acid and dihydric alcohol containing branched chains under catalysis of concentrated sulfuric acid, thereby obtaining polyethylene terephthalate; matching terephthalic acid and ethylene glycol to carry out an esterification reaction, thereby obtaining ethylene glycol terephthalate; finally, stirring and mixing the two products, carrying out condensation polymerization at low vacuum stage and high vacuum stage in the absence of catalysts and stabilizers, thereby obtaining modified polyester; metering the modified polyester, adding black master batch, performing porous spinneret extrusion, cooling, oiling, stretching, heat setting, winding, thereby obtaining the high-uniformity colored polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

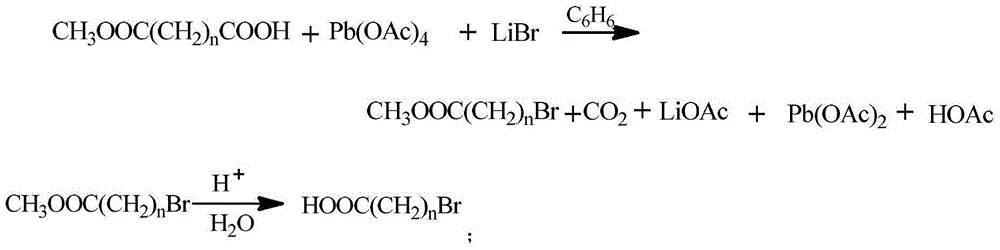

Differential-shrinkage cotton-like composite filament and preparation method thereof

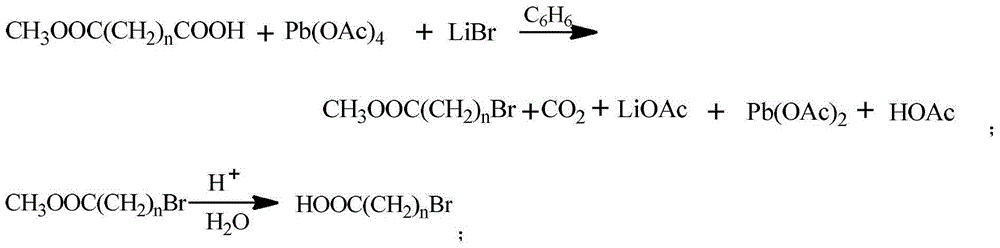

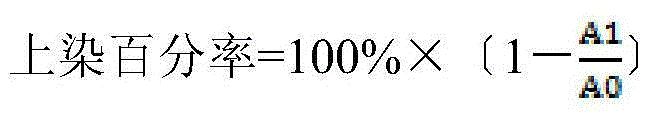

ActiveCN104562340AGood flexibilityGood compatibilityOrganic compound preparationAmino-carboxyl compound preparationPolyesterFatty acid ester

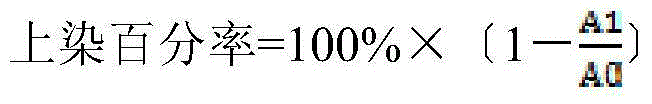

The invention relates to a differential-shrinkage cotton-like composite filament and preparation method thereof; the differential-shrinkage cotton-like composite filament is a composite filament blended by a modified polyester POY filament and a modified polyester FDY filament; the modified polyester consists of polyester and aminoadipic acid glycol ester; the aminoadipic acid glycol ester is dispersed among the molecular chains of the polyester; and the aminoadipic acid glycol ester takes effect of hydrogen bond among the molecular chains of the polyester, so as to stabilize the positions of the aminoadipic acid glycol ester with respect to the molecular chains of the polyester; in condition of the temperature is 90-130 degrees centigrade, the free volume spaces among the molecular chains inside the fiber of the differential-shrinkage cotton-like composite filament are increased by 20-30v / v%. The aliphatic ester increases the free volume of the polyester fiber in order to increase the diffusion degree of the dye, thereby increasing the dyeing performance of the polyester fiber. The differential-shrinkage cotton-like composite filament is applicable to clothes fabric, bedding article, decoration article, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

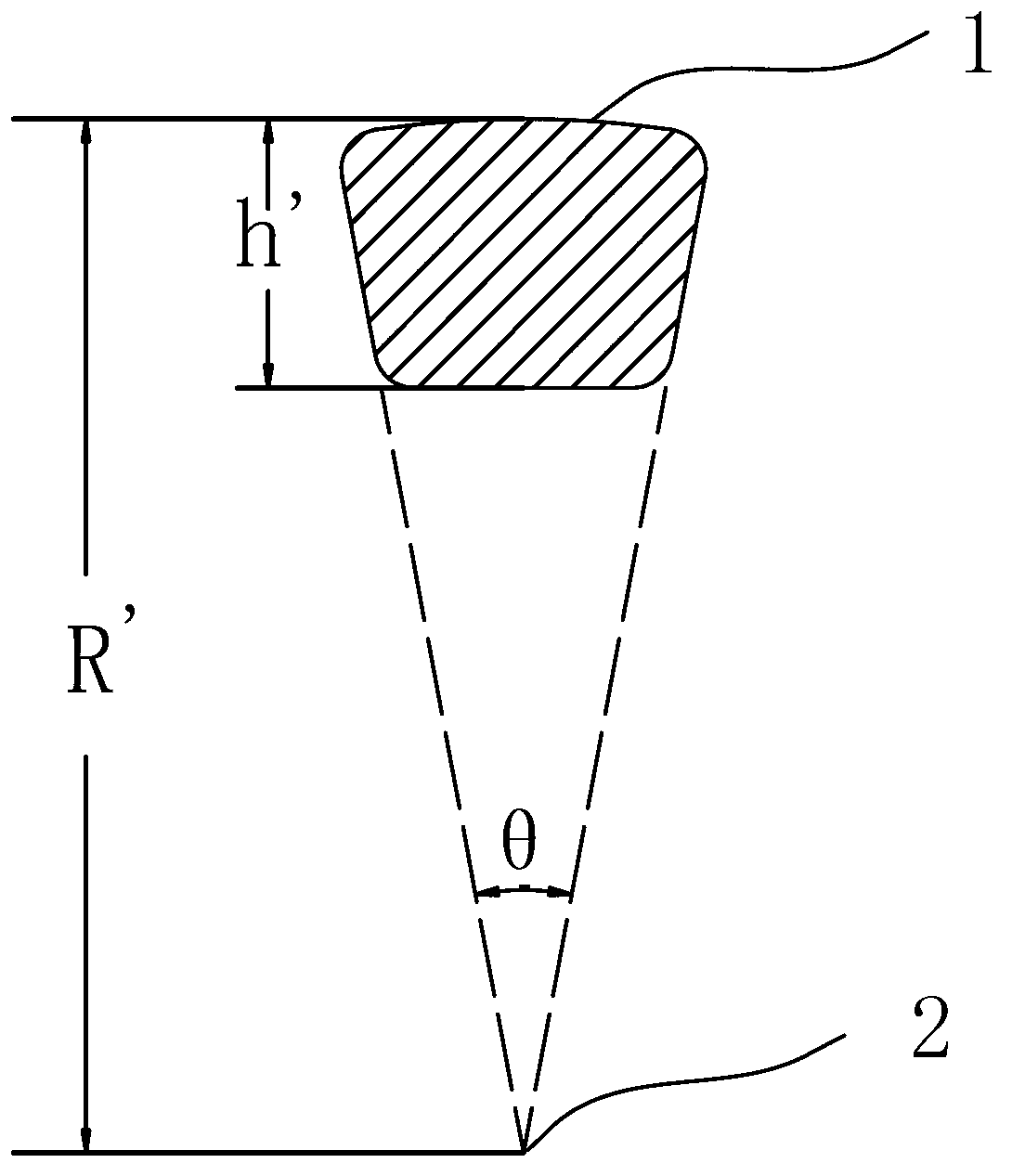

Porous super-bright trilobal profiled polyester fiber and production method thereof

ActiveCN106400166AImprove dyeing effectEasy to processFilament/thread formingMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a porous super-bright trilobal profiled polyester fiber and a production method thereof. Modified polyester is spun by adopting a porous spinneret with the cross section shape of spinneret micro-pores being trilobal in order to produce the porous super-bright trilobal profiled polyester fiber; the spinneret micro-pores are arranged in the porous spinneret in an elliptical manner, the pore center of every spinneret micro-pore is positioned in a concentric ellipse, concentric ellipses are serial ellipses, the long axes of all the ellipses are collinear, and the short axes of all the ellipses are collinear. A preparation method of the modified polyester comprises the following steps: reacting terephthalic acid with ethylene glycol to prepare ethylene terephthalate, adding diol terephthalate prepared from terephthalic acid and branched chain-containing diol, and continuously reacting to obtain the modified polyester. The porous super-bright trilobal profiled polyester fiber produced in the invention has excellent performances, the liner density deviation ratio is not greater than 0.5%, the breaking strength CV value is not greater than 4.0%, the fracture elongation CV value is not greater than 8.0%, and the yarn unevenness CV value is not greater than 2.0%.

Owner:JIANGSU HENGLI CHEM FIBER

Linen-like type differential shrinkage composite filament and preparation method thereof

ActiveCN104480568AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationFiberPolyester

The invention relates to a linen-like type differential shrinkage composite filament and a preparation method thereof. The linen-like type differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the breakage elongation of the linen-like type differential shrinkage composite filament is 40.0+ / -3.0%, the network degree of the linen-like type differential shrinkage composite filament is 95+ / -5 piece / m; the modified polyester consists of polyester and amino fatty acid gylcol ester; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the linen-like type differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The linen-like type differential shrinkage composite filament can be used in the industries such as high-class woof fabrics and clothes.

Owner:JIANGSU HENGLI CHEM FIBER

Hydrophobic and ultraviolet radiation aging-resistant wood-based composite material and preparation method thereof

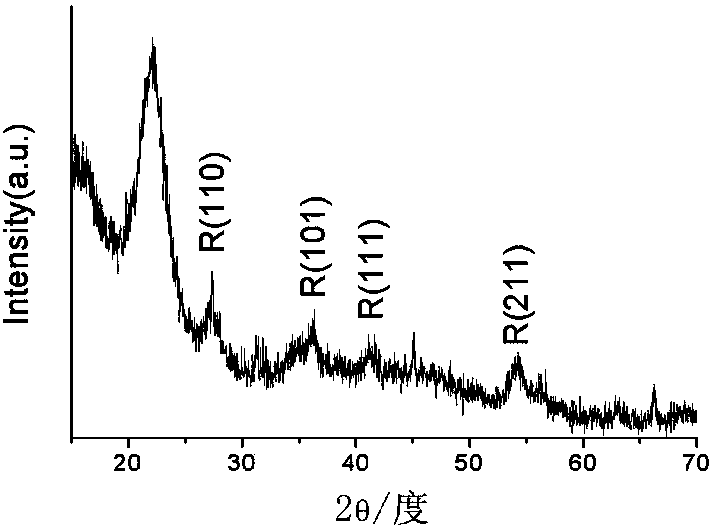

InactiveCN104260169AGood for maintaining good performanceMaintain good performanceWood treatment detailsReed/straw treatmentTitaniumAqueous solubility

The invention discloses a hydrophobic ultraviolet radiation aging-resistant wood-based composite material and a preparation method thereof. The surface layer of the composite material is of a titanium dioxide layer with a micro-nano secondary structure and the crystal structure of the composite material is of a rutile type. The preparation method comprises the processes of precursor solution preparation, multistage dipping and drying: firstly dispersing a water-soluble titanium source in a 5-7mol / L sodium chloride aqueous solution to obtain a solution a, wherein the concentration of the water-soluble titanium source is guaranteed to be 0.001-0.500 mol / L; uniformly adding an alkaline matter into the solution a to obtain a precursor solution, wherein the concentration of the alkaline matter is guaranteed to be 0.001-0.500 mol / L; dipping a wooden base material into the precursor solution, reacting at a room temperature for 1-10 days, cleaning and drying for 1-2 days to obtain a wood-based composite material; dipping the wood-based composite material in 0.8-1.2% of a low-surface energy matter solution, reacting at a room temperature for 0.2-1 day and drying for 1-2 days to obtain the hydrophobic ultraviolet radiation aging-resistant wood-based composite material. According to the preparation method, a titanium dioxide surface layer with a rutile type micro-nano secondary structure can be constructed on the surface of the wooden base material so that the wood-based composite material is excellent in hydrophobicity and ultraviolet radiation aging resistance.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Wool-like differential shrinkage composite filament and preparation method thereof

ActiveCN104480567AGood flexibilityGood compatibilityNew-spun product collectionOrganic compound preparationPolyesterFiber

The invention relates to a wool-like differential shrinkage composite filament and a preparation method thereof. The wool-like differential shrinkage composite filament is a composite filament prepared from modified polyester POY filaments and modified polyester FDY filaments which are subjected to fiber mixing processing; the amino fatty acid gylcol ester is dispersed among the molecular chains of the polyester and has a hydrogen bonding function with the molecular chains of the polyester, so that the relative positions of the amino fatty acid gylcol ester and the molecular chains of the polyester are fixed; under the condition that the temperature is 90-130 DEG C, the free volume space among the molecular chains of fiber of the wool-like differential shrinkage composite filament is increased by 20-30v / v%. Due to adoption of the aliphatic ester, the free volume of the polyester fiber is increased, so that the diffusion degree of dye is increased, and the dyeing property of the polyester fiber is improved. The wool-like differential shrinkage composite filament can be used in the industries such as clothes fabrics, bedding articles and decorative articles.

Owner:JIANGSU HENGLI CHEM FIBER

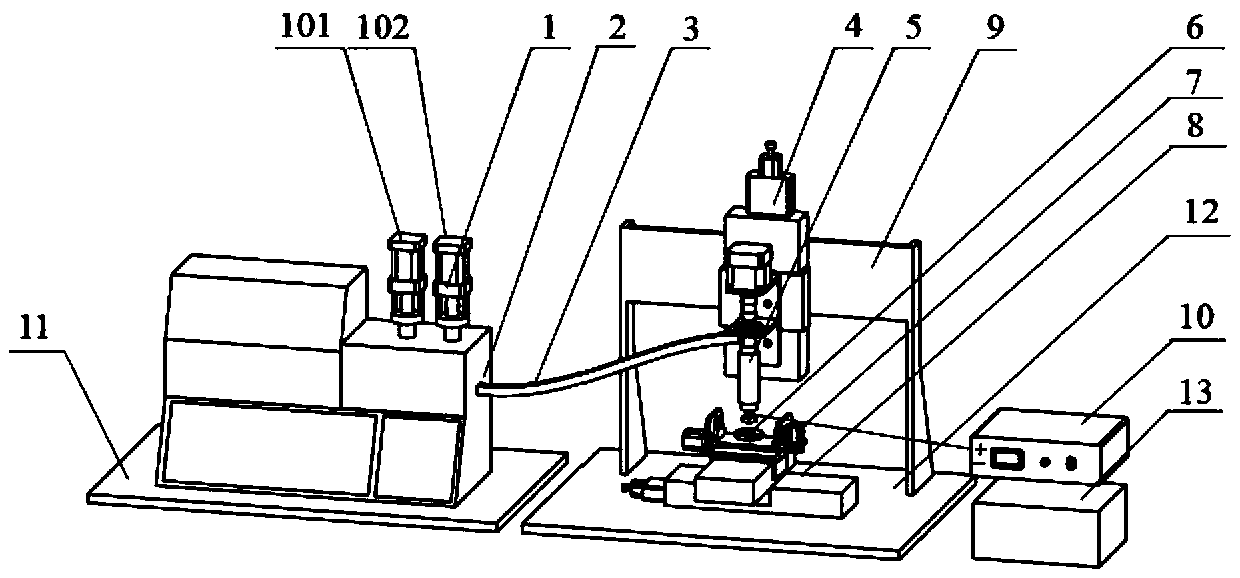

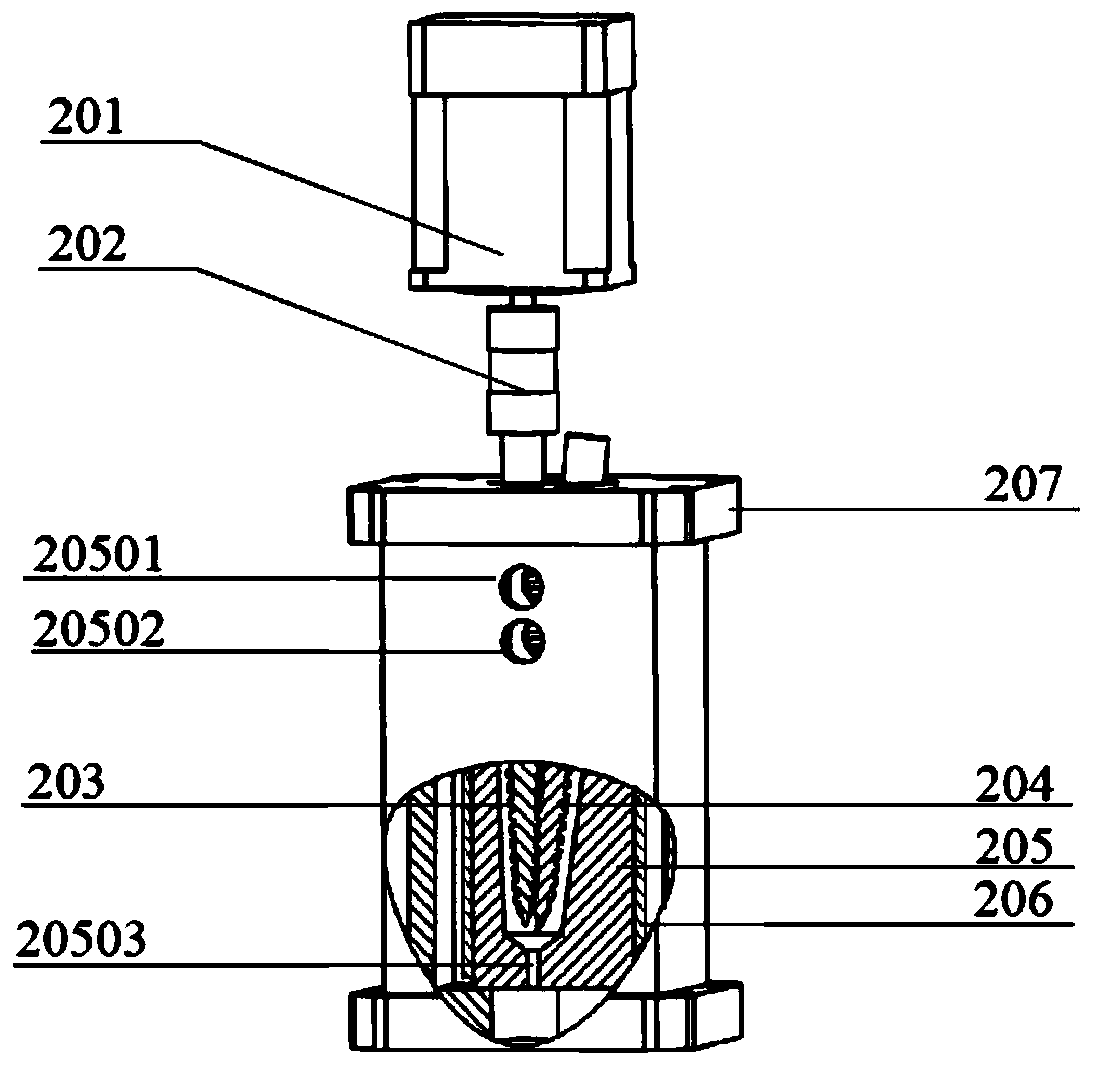

3D printer for integral manufacturing of functionally graded material and forming structure, and working method thereof

PendingCN109732905APrecise Controlled ExtrusionContinuous and stable printingAdditive manufacturing apparatus3D object support structuresImage resolutionEngineering

The invention provides a 3D printer for integral manufacturing of a functionally graded material and a forming structure, and a working method thereof. A feeding module, a mixing module and a printingsprayer are split; and through ingenious arrangement of the components, integral manufacturing of the continuous functionally graded material and the complex three-dimension structure can be achieved. The 3D printer has the characteristics and outstanding advantages of active, efficient and uniform mixing of various materials, high print resolution (due to micro-nano microscale characteristic structure printing), diverse applicable materials, high production efficiency, low cost and simple structure; and particularly, the 3D printer can achieve integral manufacturing of the continuous functionally graded material and the complex three-dimension structure based on material composition and microstructures.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

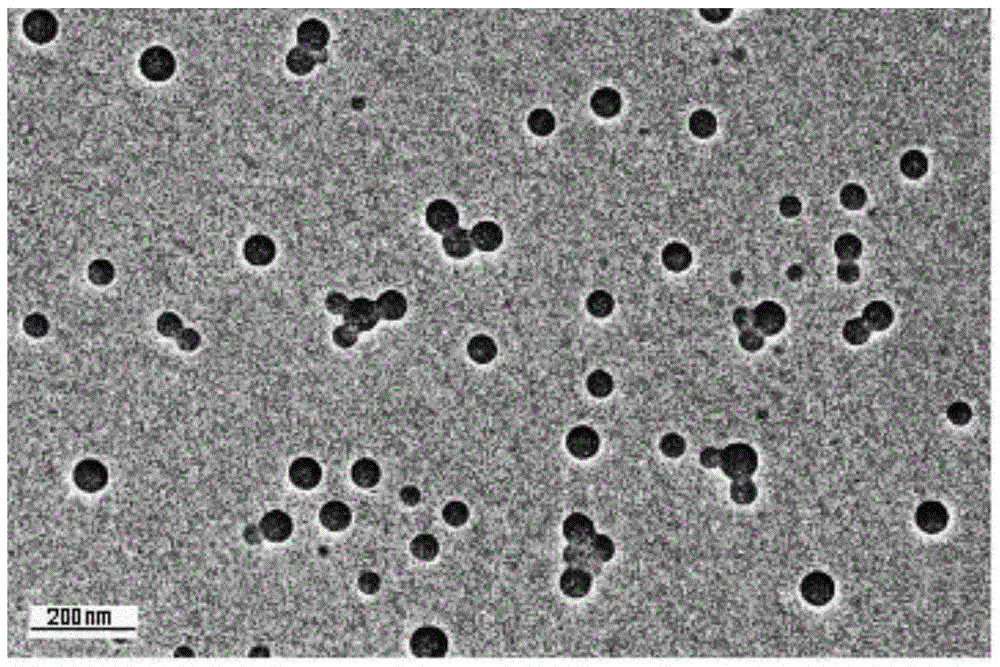

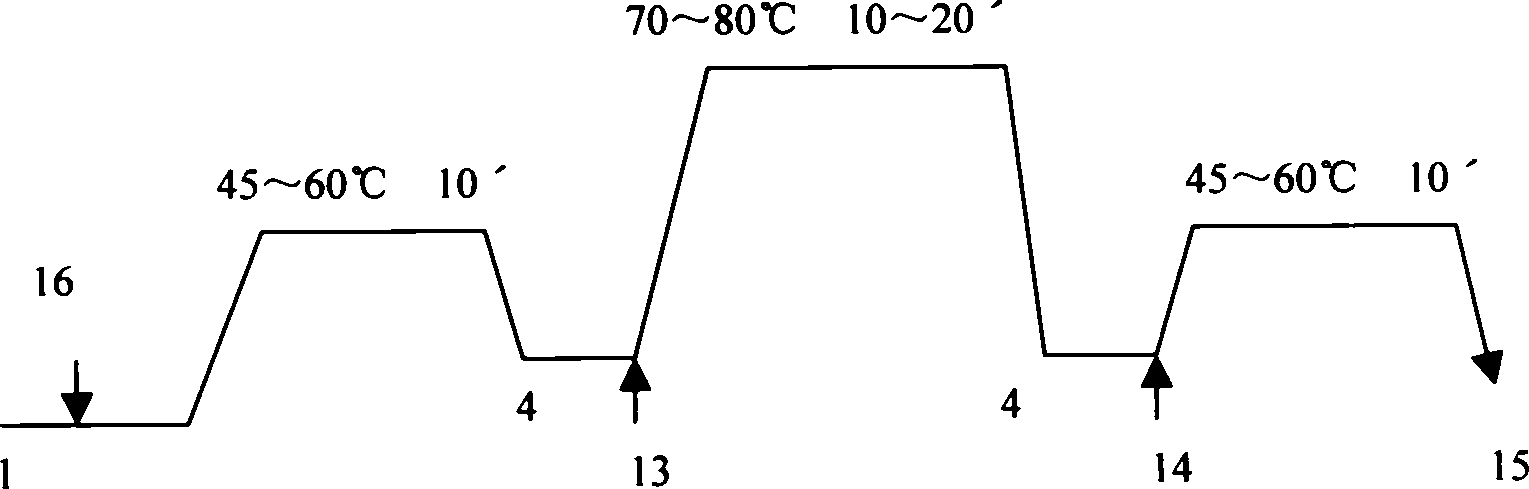

Inorganic/organic composite casing layer nanometer phase-change capsule cool-storage fluid and preparation method thereof

InactiveCN105542051ASmall particle sizeHigh phase change enthalpyHeat-exchange elementsMetal alkoxideIn situ polymerization

The invention belongs to the field of a phase change material technology for cool storage, and discloses an inorganic / organic composite casing layer nanometer phase-change capsule cool-storage fluid and a preparation method thereof. The preparation method comprises the following steps: hydrolysis and condensation are carried out for metal alkoxide, modification is carried out with an organosilicon coupling agent, modified metal oxide sol is obtained; a styrene monomer, an acrylic ester comonomer, a chain transferring agent, an initiator and an alkane core material are mixed for forming an oil phase, the oil phase is added into an emulsifier and deionized water for forming a water phase, homogeneous emulsification is carried out, and miniemulsion is obtained; the miniemulsion is heated to 40-80 DEG C, in situ polymerization is carried out for 10-50 minutes, the modified metal oxide sol is added drop by drop, and after a reaction, a composite casing layer nanometer phase change capsule emulsion is obtained; the emulsion is added into an antifreeze, water is added for dilution, and the product is obtained. Metal oxide and organic polymers are compounded into a casing layer; the product has the advantages of high heat conduction performance, high specific heat capacity and good mechanical stability at the same time, and the product can be used as phase-change cool-storage fluid for cool storage air-conditionings.

Owner:SOUTH CHINA UNIV OF TECH

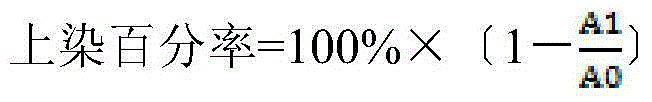

Milk protein fiber blended color spinning yarn and its production method

ActiveCN1884650ABright colorImprove performanceYarnLiquid/gas/vapor textile treatmentYarnMilk protein

The invention discloses a milk protein fiber spinning yarn and manufacturing method, which is characterized by the following: making quality percentage in the mixed color spinning yarn at 5-100 percent milk protein fiber; dyeing milk protein fiber and other fibers respectively; adopting active dye for milk fiber through acid dyeing and alkaline color fixing course; reducing fiber destroying; keeping kinds of superior quality of fiber; satisfying personal pursuit for comfortable costume, health and fashion.

Owner:平湖市华孚金瓶纺织有限公司

Cable aluminum alloy wire stock and preparation method thereof

ActiveCN102994818AMaintain good performanceReduce gapNon-insulated conductorsMetal/alloy conductorsRare-earth elementCopper

The invention relates to the field of non-ferrous metal wire stocks, in particular to a cable aluminum alloy wire stock and a preparation method thereof. The cable aluminum alloy wire stock comprises the following ingredients in percentage by weight: 0.04-0.15% of silicon, 0.5-0.9% of ferrum, 0.1-0.3% of copper, 0.06-0.08% of zinc, 0.05-0.2% of boron, 0.01-0.04% of antimony, 0.05%-0.08% of nickel, 0.05-0.09% of zirconium, 0.05-0.08% of rare earth and the balance of aluminum and inevitable impurities. According to the cable aluminum alloy wire stock, by regulating the content of the rare earth in the wire stock and introducing other doped elements, the conductivity of the cable aluminum alloy wire stock can achieve more than 62% of IACS, the tensile strength can achieve 135MPa, the elongation rate can reach about 30%, especially the creeping resistance property is obviously improved, and the comprehensive electrical property can be obviously improved.

Owner:ANHUI PACIFIC CABLE CO LTD

Differential shrinkage composite filament and preparing method thereof

ActiveCN106381558AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureFiberAlcohol

The invention relates to a differential shrinkage composite filament and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the differential shrinkage composite filament; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. The differential shrinkage composite filament is subjected to plying and doubling by modified polyester POY filament and FDY filament, then is composited through network, and finally reeled. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing dihydric alcohol are subjected to a reaction to obtain terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The filament has excellent fiber performance, the linear density deviation ratio is less than or equal to 2.0%, a breaking tenacity CV value is less than or equal to 4.0%, a breaking elongation CV value is less than or equal to 8.0%, and a crimp contraction variation coefficient CV value is less than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

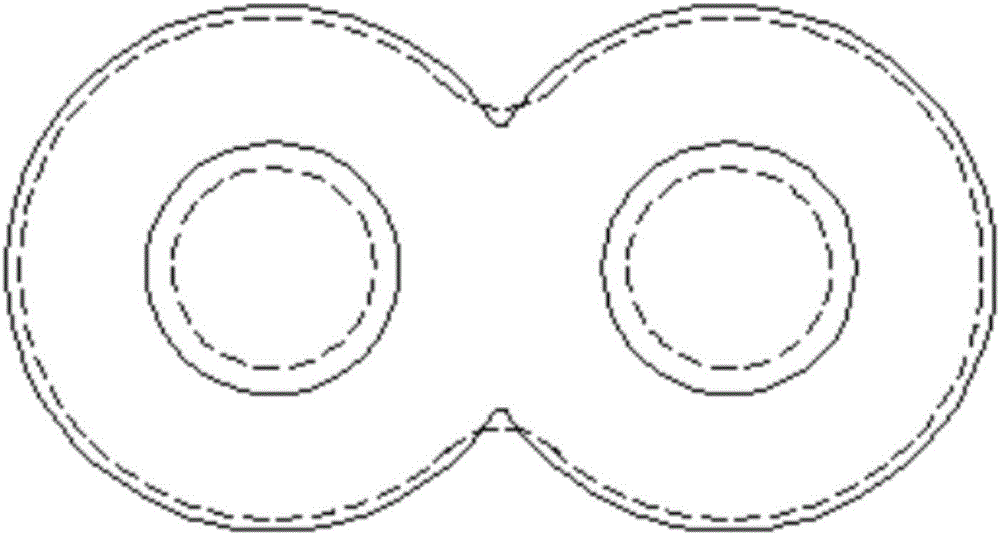

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

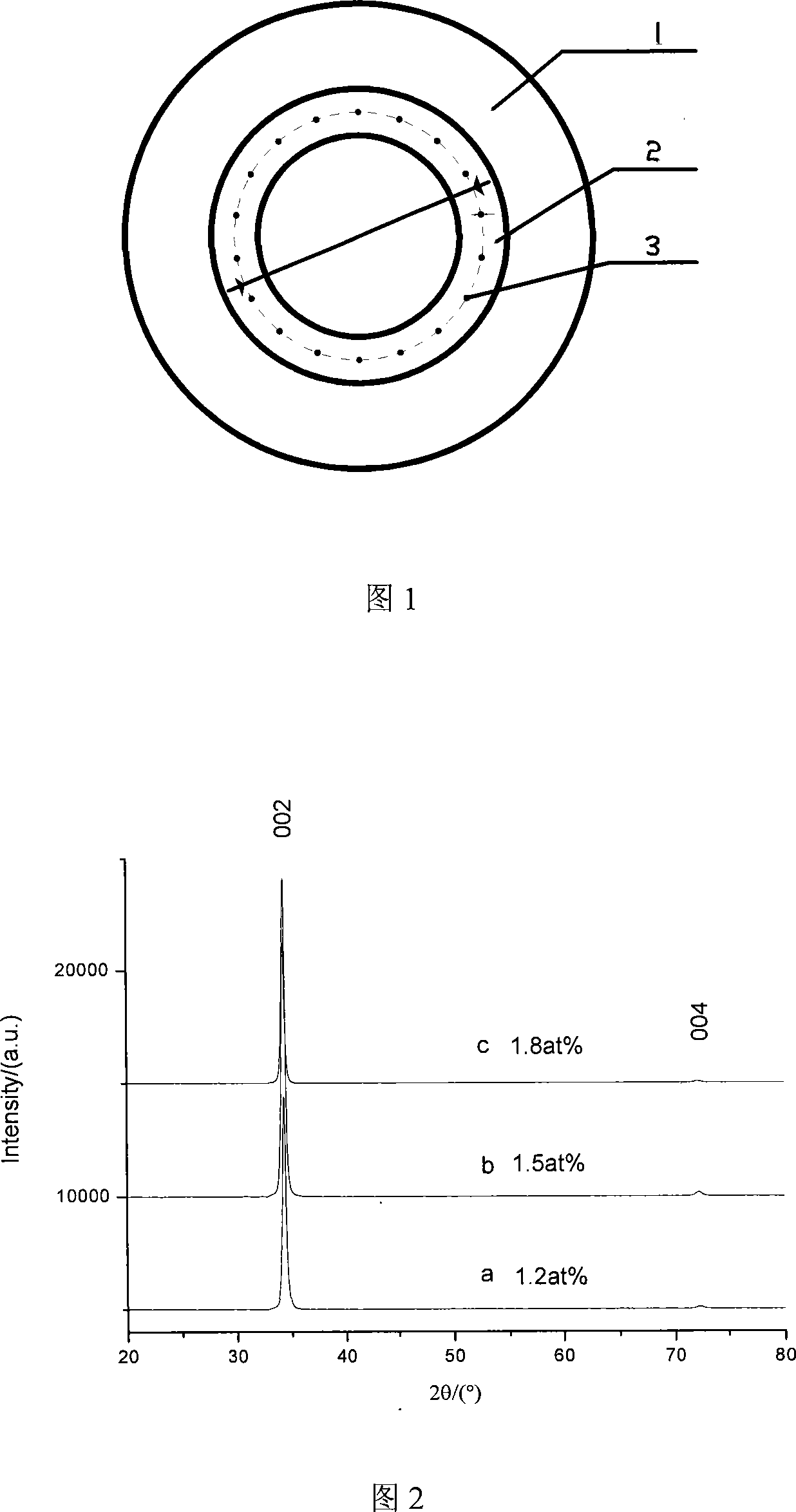

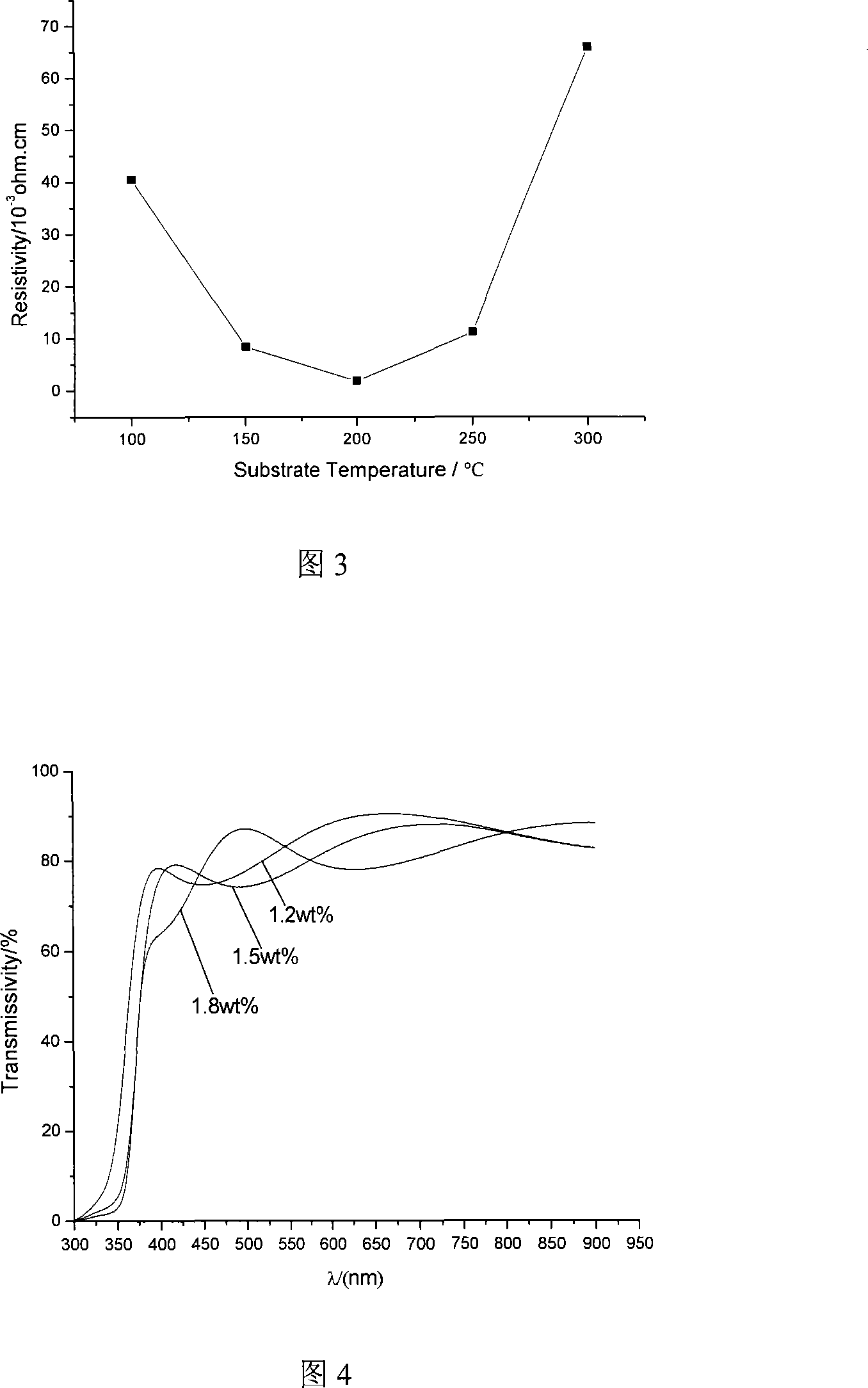

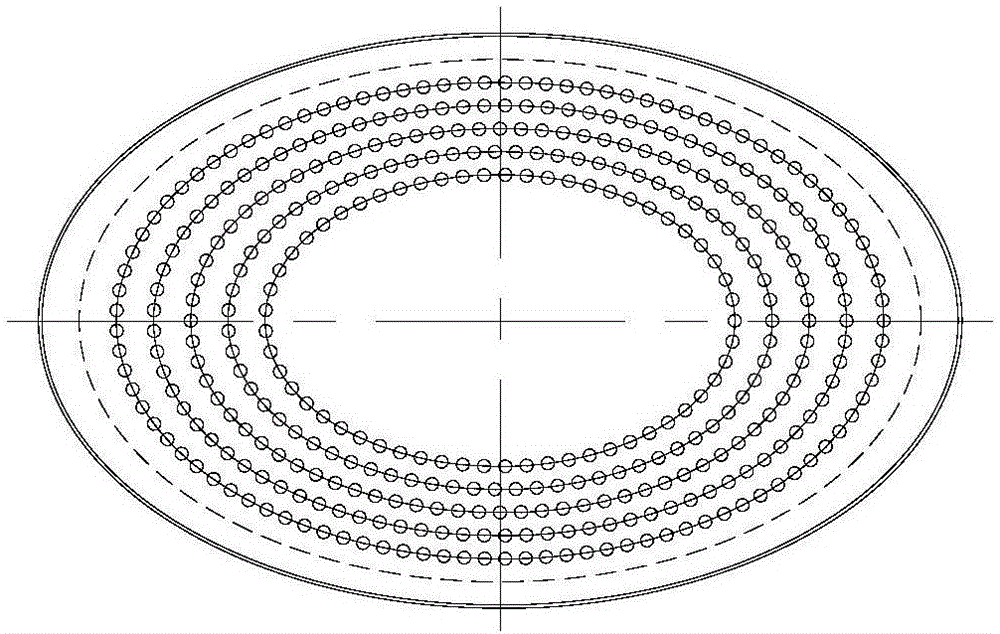

Method for preparing polycrystalline doping molybdenum zinc oxide transparent conductive film

InactiveCN101158028ALow resistivityGood optical clarityVacuum evaporation coatingSputtering coatingOptical transparencyCharge carrier mobility

The invention belongs to the transparent conductive film technical field, in particular to a preparation method of a polycrystalline molybdenum doped zinc oxide transparent conductive film. The steps of the method are that: a zinc inlay molybdenum target is taken as a target and ordinary glass is taken as substrate, the substrate temperature is 100-300 DEG C, through a reactive dc magnetron sputtering method, an Ar ion beam bombards and sputters the target, the sputtering current is 150-300mA, the sputtering voltage is 100-400 V, the work pressure of a reaction chamber is 0.45-2.5 Pa, the percentage of the parcial pressure P (O 2 ) = Po 2 / (Po 2 +P Ar ) of the reactive gas O 2 is 4.0 to 10.0%, the sputtering time is 40-100 minutes, thus forming the molybdenum-doped zinc oxide transparent conductive film with a polycrystalline structure. The film thickness is 100-250 nm. The film prepared by the invention is characterized by low resistivity, high visible light range of optical transparency and high carrier mobility. The invention has industrial production prospect and has good technological stability. The invention is a novel method in the preparation of ZMO transparent conductive oxide films and the guarantee of excellent quality of parts produced by films.

Owner:FUDAN UNIV

Porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and preparation method thereof

ActiveCN106283251AImprove cooling effectImprove fiber propertiesSpinnerette packsMonocomponent copolyesters artificial filamentYarnBreaking strength

The invention relates to porous PTT (polytrimethylene terephthalate)-fiber HOY (high oriented yarn) and a preparation method thereof. According to the preparation method, the porous PTT-fiber HOY is prepared from modified PTT by spinning with a porous spinneret; spinneret orifices in the porous spinneret are arranged in an oval shape, that is, the centers of the spinneret orifices are located on concentric ellipses adopting series ellipses, major axes of all the ellipses are collinear, and minor axes of all the ellipses are collinear. The porous PTT-fiber HOY is prepared from modified PTT through measurement, extrusion, cooling, oiling and winding. A preparation method of modified PTT comprises the steps as follows: terephthalic acid and 1,3-propanediol react, trimethylene terephthalate is prepared, diol terephthalate prepared from terephthalic acid and branched-chain-containing diol through a reaction is added, reaction is continued, and modified PTT is obtained. The prepared HOY has excellent fiber performance, the deviation rate of linear density is lower than or equal to 0.2%, the breaking strength CV value is lower than or equal to 2.5%, and the breaking elongation CV value is lower than or equal to 5.0%.

Owner:JIANGSU HENGLI CHEM FIBER

High-homogeneity car model polyester industrial yarn and preparation method thereof

ActiveCN106245149AIncreased free volumeReduce melt viscositySpinnerette packsMelt spinning methodsYarnCar model

The invention relates to a high-homogeneity car model polyester industrial yarn and a preparation method thereof. The high-homogeneity car model polyester industrial yarn uses modified polyester formed by a terephthalic acid chain segment, an ethylene glycol chain segment and branched chain-containing diol as a raw material. The preparation method of the high-homogeneity car model polyester industrial yarn comprises the following steps: subjecting the terephthalic acid and the branched-chain diol to an esterification reaction under the catalysis of concentrated sulfuric acid to obtain dihydroxy alcohol terephthalic acid; subjecting the terephthalic acid and the ethylene glycol to an esterification reaction to obtain dimethyl terephthalate; finally stirring and mixing the two, subjecting a polycondensation reaction at low vacuum phase and high vacuum stage under the action of a catalyst and a stabilizer to obtain modified polyester, subjecting the modified polyester to metering, porous spinneret extruding, cooling, oiling, stretching, heat setting and winding to obtain the high-homogeneity car model polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

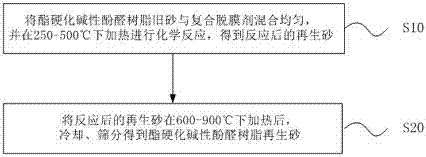

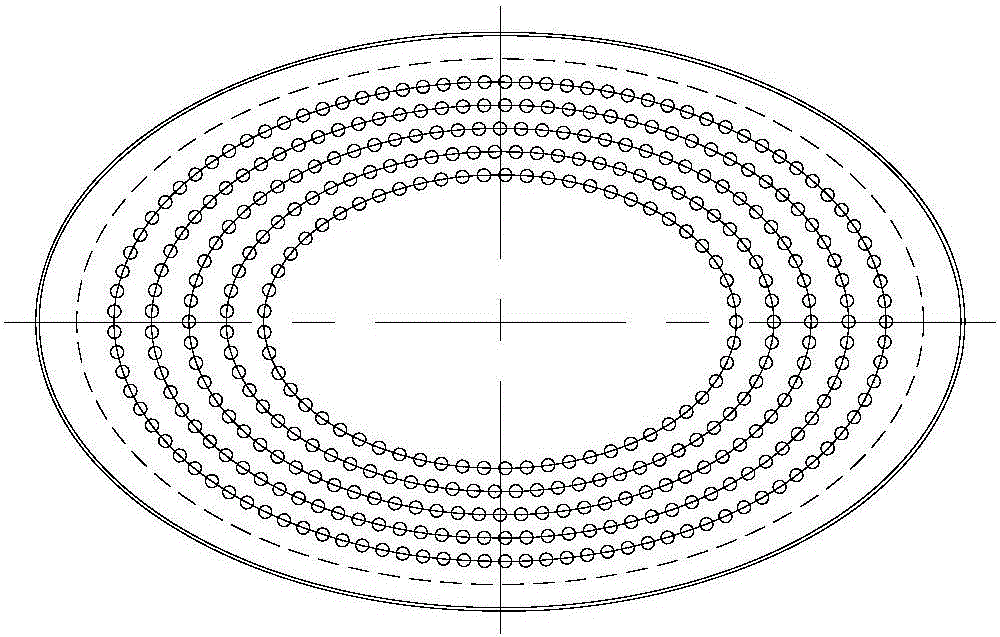

Reclaiming method for ester-hardened alkaline phenolic resin used sand

ActiveCN107321912AGuaranteed performanceImprove performanceMould handling/dressing devicesOrganic acidInorganic salts

The invention provides a reclaiming method for ester-hardened alkaline phenolic resin used sand. The reclaiming method for the ester-hardened alkaline phenolic resin used sand comprises the steps that the ester-hardened alkaline phenolic resin used sand and a compound film-releasing agent are evenly mixed, and then conduct chemical reaction after being heated at 250-500 DEG C, wherein the compound film-releasing agent comprises inorganic acid, organic acid, inorganic salt and water; and reclaimed sand after reaction is heated at 600-900 DEG C and then subjected to cooling and screening, and ester-hardened alkaline phenolic resin reclaimed sand is obtained. According to the reclaiming method for the ester-hardened alkaline phenolic resin used sand, resin films alkaline oxide adhering to the surface of the ester-hardened alkaline phenolic resin used sand can be removed, a sand grain bonding problem and a potassium and sodium remaining problem are avoided, and it is ensured that the obtained ester-hardened alkaline phenolic resin reclaimed sand has the excellent performance which is the same as or similar to the excellent performance of new sand.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Porous soft polyester fiber FDY yarn and preparing method thereof

ActiveCN106381547AImprove dyeing effectEasy to processSpinnerette packsHollow filament manufactureYarnFiber

The invention relates to a porous soft polyester fiber FDY yarn and a preparing method thereof. According to the invention, modified polyester employs a porous spinneret for spinning to prepare the porous soft polyester fiber FDY yarn; an arrangement mode of the spinneret holes on the porous spinneret is in an elliptical shape, the aperture center of the spinneret holes is positioned on concentric ellipses, the concentric ellipses are a series of ellipses, the long shafts of all ellipses are collinear, and the short shafts are collinear. the porous soft polyester fiber FDY yarn is prepared by metering modified polyester slices, extruding, cooling, oiling, stretching, thermoforming and reeling the material. A preparation method of the modified polyester comprises the following steps: terephthalic acid and glycol are subjected to a reaction to prepare ethylene glycol terephthalate, terephthalic acid and branched chain-containing hexanediol are subjected to a reaction to obtain the terephthalic acid glycol ester, and continuous reacting is carried out on the material to obtain the product. The yarn has excellent fiber performance, the linear density deviation ratio is less than or equal to 0.5%, the breaking tenacity CV value is less than or equal to 4.0%, breaking elongation CV value is less than or equal to 8.0%, and a yarn unevenness CV value is less than or equal to 2.0.

Owner:JIANGSU HENGLI CHEM FIBER

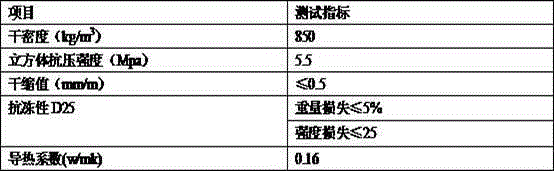

Lightweight wall special-purpose cell concrete, and production method thereof

InactiveCN105272352AReduce shrinkage cracksMaintain good performanceSolid waste managementCeramicwareFiberPolyvinyl alcohol

The invention discloses a lightweight wall special-purpose cell concrete, and a production method thereof. The production method comprises following steps: (1) rapid hardening sulphoaluminate cement, ordinary Portland cement, and dry discharge fly ash are delivered into a double helix conical mixer so as to obtain a composite cementing agent via premixing; (2) water, cold-water-soluble polyvinyl alcohol powder, polypropylene reinforcing fiber, calcium stearate water repellent, a silane coupling agent, expanded perlite, and polyphenyl foam particle are delivered into an agitator; (3) the composite cementing agent obtained via step (1) is delivered into the agitator, and micropore foam prepared from a micropore foaming agent via compressed air is sprayed into the agitator, an uniform slurry is obtained via mixing stirring, and slurry volume weight is controlled to be 1000 to 1200kg / m3; (4) the uniform slurry is pumped into lightweight wall products or cast-in-situ wall forming moulds; and (5) finished products are obtained via curing, hardening, moulding, and demoulding. The lightweight wall special-purpose cell concrete can be used for producing various lightweight wall products and cast-in-situ lightweight concrete walls, and is an ideal material used for producing energy-saving lightweight walls and products.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +2

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

High-performance PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy prepared by waste electrical PC/ABS material and preparation method and application thereof

The invention discloses a high-performance PC (Polycarbonate) / ABS (Polyacrylonitrile) alloy prepared by waste electrical PC / ABS material and a preparation method and an application of high-performance PC (Polycarbonate) / ABS (Polyacrylonitrile) alloy. The PC / ABS alloy comprises the following material components by weight: 95-97 parts of waste electrical PC / ABS crushed materials, 0.2-0.4 part of B-215 long-acting heat stabilizer, 2-4 parts of SBS (sodiumbisulfite) flexibilizer, 1-2 parts of EMA flexibilizer and 0.3-0.5 part of anti-ultraviolet agent. The PC / ABS alloy provided by the invention has the characteristics of high performance, high flame retardance, high impact resistance, high coldness resistance, high stability and static electricity resistance and the like, can be used for manufacturing an intelligent electric meter housing, a meter housing, a fax machine housing or a copier housing and the like.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Polycarbonate/glass fiber alloy used for cold resistant housing of intelligent water meter and preparation method thereof

ActiveCN102311625AImprove performanceSave energyTime integral measurementGlass fiberULTRAMARINE BLUE

The invention discloses polycarbonate / glass fiber alloy used for the cold resistant housing of an intelligent water meter and a preparation method thereof. The polycarbonate / glass fiber alloy comprises, by weight, 30 to 50 parts of PC, 30 to 50 parts of an PC recycled material, 0.3 to 0.5 part of a fireproof agent FR2025, 0.5 part to 2 parts of titanium dioxide, 9.5 to 11.5 part of glass fiber, 2 to 5 parts of EMA, 0.1 to 0.5 part of an anti-oxidant1010, 0.1 to 0.5 part of an anti-oxidant 168, 0.3 to 0.5 part of an ultraviolet resistant agent UV-531, 0.03 to 0.08 part of diffusion powder EBS, 0.04 to 0.08 part of ultramarine blue powder, 0.02 to 0.04 part of iron oxide red powder 0.005 to 0.01 part of high temperature resistant florescent yellow powder and 2 to 5 parts of a cold resisting agent 2602. The alloy has the characteristics of high performance, high cold resistance, high fire retardancy, high impact, high stability, resistance to static electricity and the like, and can be used for preparing the housing of intelligent water meters used in chilly regions and for preparing terminal rows.

Owner:江苏百凌电器有限公司

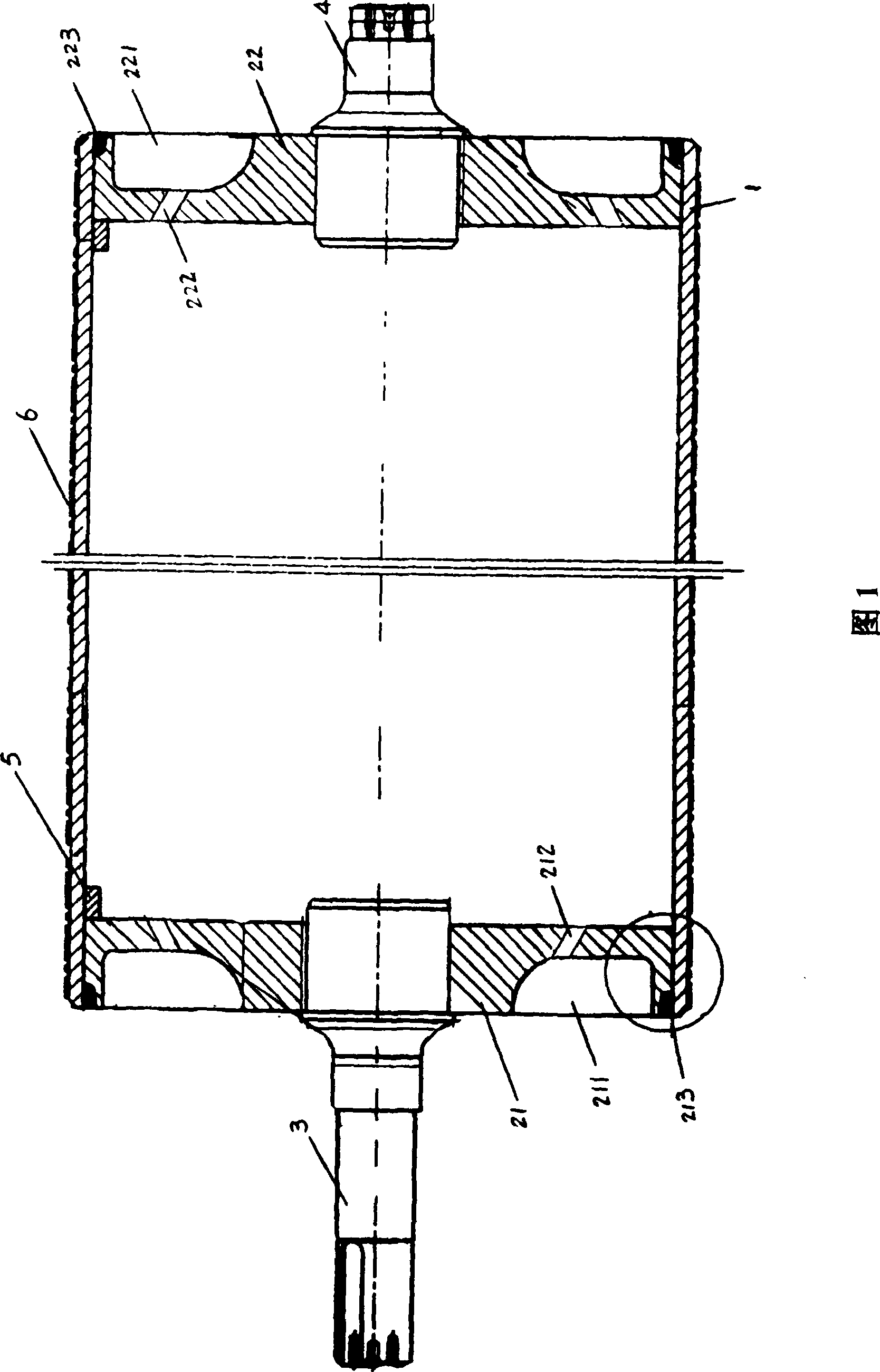

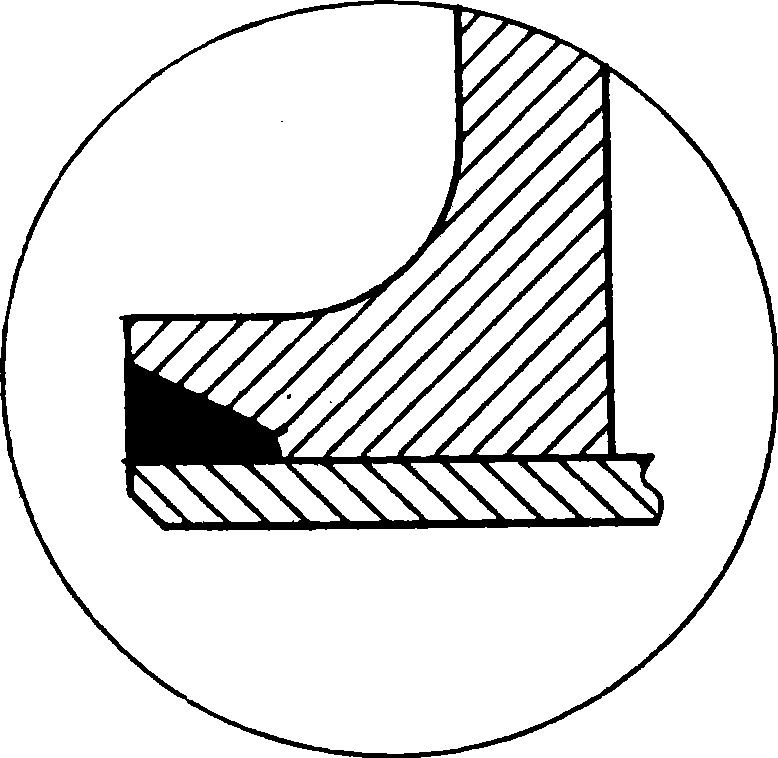

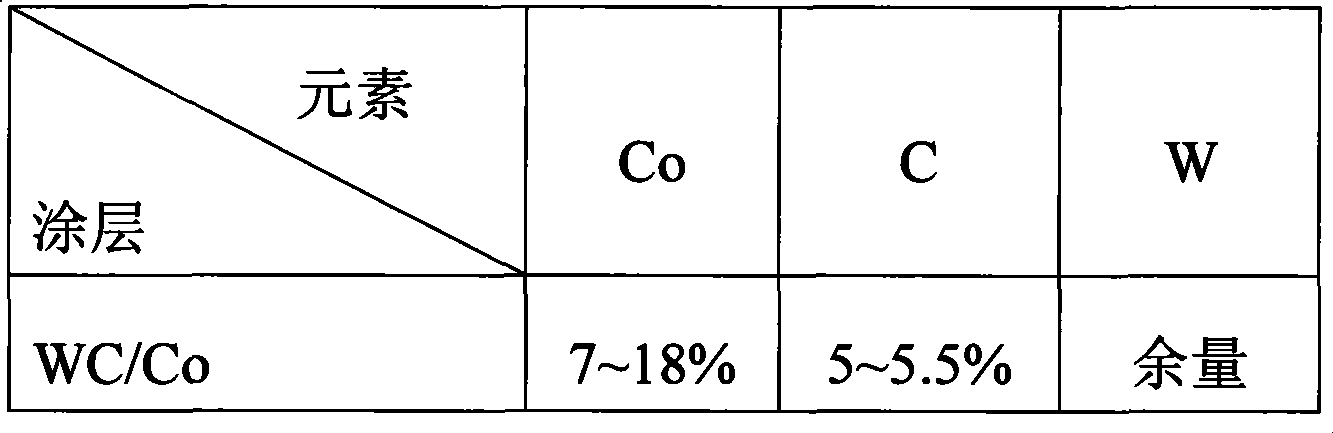

Intermediate-frequency quenching hard-surface strain roller and manufacture method thereof

ActiveCN101362152AReduce oxidationLow oxide contentMolten spray coatingFurnace typesProduction lineIntermediate frequency

The invention relates to a tension roller used in a cold rolling production line, in particular to a tension roller with a mid-frequency quenching hard surface, and a manufacturing method thereof. The tension roller comprises a roller and round side covers which are fixedly and closely covered at the openings of the two ends of the roller, and the circle centers of the two side covers are in coupling connection with a left axle head and a right axle head respectively. The tension roller is characterized in that: the outer surface of the roller is covered with a spaying layer, the outsides of the two side covers are provided with concave grooves in a surrounding way, the concave groove is internally provided with a through hole communicated with the interior of the roller; the spaying layer adopts the functional metal ceramic coating which is composed of compound metal ceramics of WC / Co metal ceramics and metal or alloy. The tension roller mainly solves the technical problems that the existing product roller surface is sprayed with hard chromium plating on the outer surface and is easy to be pressed into concave pits or protuberances by sundries such as ferric oxide, etc. When in use, drawing stamps or stains are formed on the surface of the finished product, the band steel, thus influencing the surface quality of the band steel, and the tension roller is beneficial to radiating the interior of the roller when in use.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Method for inhibiting expansion of lithium ion polymer battery

InactiveCN102044704AImprove thermal stabilityPrevent bulging deformationCell electrodesFinal product manufacturePorosityPolyolefin

The invention relates to a method for inhibiting expansion of a lithium ion polymer battery. The method comprises the following steps: (1) respectively rolling positive and negative plates in thermal state at the temperature of 50-150 DEG C, wherein a diaphragm is a polyolefin micropore one with thickness of 9-40mm and porosity of 25-50%; (2) winding the positive and negative plates and the diaphragm into a battery cell conventionally, and packaging the battery cell in an aluminium-plastic packaging film; (3) preparing non-water electrolyte containing lithium salt and a film-forming additive through uniform mixing, wherein the lithium salt contained in the non-water electrolyte is one of or a mixture of any two of LiPF6, LiBF4, LiBOB, LiN(CF3SO2)2 or LiN(C2F5SO2)2 and has concentration of 0.4-1.2mol / L; and the film-forming additive in the non-water electrolyte is vinylene carbonate (VC), propylene sulphite (PS) or any mixture of the VC and the PS and accounts for 0.5-4% by weight of the solvent; and (4) injecting the non-water electrolyte into the aluminium-plastic packaging film, and sealing the packaging film. The invention has the beneficial effect of effectively preventing the battery from bulging deformation under high temperature.

Owner:TIANJIN LISHEN BATTERY

Cutting seedling method for grape

The invention discloses a cutting seedling method for grape. The method comprises the following steps: (1) selecting an annual plant which is 0.8-1.0 centimeter in width for serving as a cutting; (2) storing at a low temperature; (3) soaking the lower end of the cutting into clear water for 20-25 hours, and soaking in a growth regulating agent for 5-8 hours; (4) inserting the cutting on which calluses occur into a hole, and irrigating for 4-5 times; (5) after cottage, spraying a bactericide, erecting a rod after a new seedling grows to 25 centimeters, pulling a rope, tying the new seedling and pinching. The cutting seedling method for the grape disclosed by the invention is simple in steps, convenient to operate and low in cost, has the characteristics of short cultivation period, quick growth of nursery stocks and high survival rate while excellent performance of grape stock plants are effectively ensured, and has important practice and popularization significances.

Owner:卞佳林

High-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn and preparation method thereof

ActiveCN106283250AIncreased free volumeReduce melt viscositySpinnerette packsMonocomponent copolyesters artificial filamentYarnAlcohol

The invention relates to high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn and a preparation method thereof. The high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn is prepared from modified polyester formed by terephthalic acid chain segments, glycol chain segments and branch-containing dihydric alcohol chain segments. The preparation method of the high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn includes the steps that terephthalic acid and branch-containing dihydric alcohol are subjected to an esterification reaction under catalysis of concentrated sulfuric acid to obtain terephthalic acid dihydric alcohol ester; then terephthalic acid and glycol are matched for an esterification reaction, and terephthalic acid gylcol ester is obtained; finally, terephthalic acid dihydric alcohol ester and terephthalic acid gylcol ester are stirred and mixed, polycondensation at a low-vacuum stage and a high-vacuum stage is carried out under the effects of a catalyst and a stabilizer, modified polyester is prepared and subjected to metering, porous spinneret plate extrusion, cooling, oiling, stretching, heat setting and winding, and the high-uniformity, high-strength and ultralow-shrinkage type polyester industrial yarn is prepared.

Owner:JIANGSU HENGLI CHEM FIBER

Grafted modified ultra-high molecular weight superfine polyethylene and solid phase grafting method thereof

The invention provides a method for adopting solid phase grafting for preparing grafted polyethylene from ultra-high molecular weight superfine polyethylene and grafted polyethylene prepared through the same. The effective grafting rate of a grafting monomer is larger than 0.5%, a basic polymer is polyethylene, the polyethylene is powder and spherical or spherical-like granulates, and the average grain diameter is 10-100 micrometers; the standard deviation is 2-15 micrometers, and the bulk density is 0.1-0.3 g / mL; the viscosity average molecular weight (Mv) of the polyethylene is larger than 1*10<6>. The method is simple in technology, low in cost and easy to implement, and promotes industrial production. The thermal property, mechanical property, polarity and the like of the grafted polyethylene are obviously improved, and the original good performance of the polyethylene is kept.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com