Cable aluminum alloy wire stock and preparation method thereof

A technology of aluminum alloy and aluminum alloy monofilament, which is applied in the direction of cable/conductor manufacturing, metal/alloy conductor, circuit, etc. It can solve the problems of elongation, flexibility and creep resistance that cannot meet the requirements, low safety and stability, etc. , to achieve the effect of easy removal of impurities, simplified operation steps and cost saving of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0110] Preparation of aluminum alloy wire for cables:

[0111] (1) Melting: According to the formula in Table 1, first melt aluminum and aluminum-iron alloy at 720-730°C according to the proportion, then heat up to 780-790°C and add copper, zinc, antimony, Nickel, zirconium; after fully mixing, add light rare earth-aluminum master alloy according to the proportion at 760-770°C; after fully mixing, add europium-aluminum master alloy according to the proportion at 730-740°C; Add scandium-aluminum master alloy and boron-aluminum master alloy according to the proportion at 790°C; when adding the master alloy, it should be fed at different positions of the aluminum liquid as much as possible, so that the composition of the master alloy can be more quickly and evenly in the aluminum liquid Disperse in medium; after fully mixing, pour refining agent at 775-785°C for refining, the components of the refining agent are: 60wt% sodium nitrate, 10wt% graphite powder, and 30wt% cryolite. T...

Embodiment 8

[0122] Preparation of rare earth aluminum alloy stranded conductor:

[0123] 1) Cold wire drawing: the aluminum alloy wire rod obtained in Example 1 is subjected to a cold wire drawing process to obtain a rare earth aluminum alloy monofilament wire;

[0124] 2) Stranding: the cross-sectional area of the conductor is 70mm obtained by stranding through the concentric layer stranding process 2 Rare earth aluminum alloy stranded conductor;

[0125] 3) Annealing: Pack and anneal the rare earth aluminum alloy stranded conductor obtained in step 2; There are three middle and lower temperature zones, the temperature of the upper temperature zone is 340-350°C, the temperature of the middle temperature zone is 350-360°C, the temperature range of the lower temperature zone is 360-370°C, and the annealing time is 6h.

[0126] After the annealing process, the monofilaments in the obtained aluminum alloy stranded conductor are more closely combined, and there is no obvious gap between t...

Embodiment 9

[0128] Preparation of Rare Earth Aluminum Alloy Shaped Stranded Conductor:

[0129] 1) Cold wire drawing: the aluminum alloy wire obtained in Example 1 is subjected to a cold wire drawing process to obtain a rare earth aluminum alloy monofilament wire.

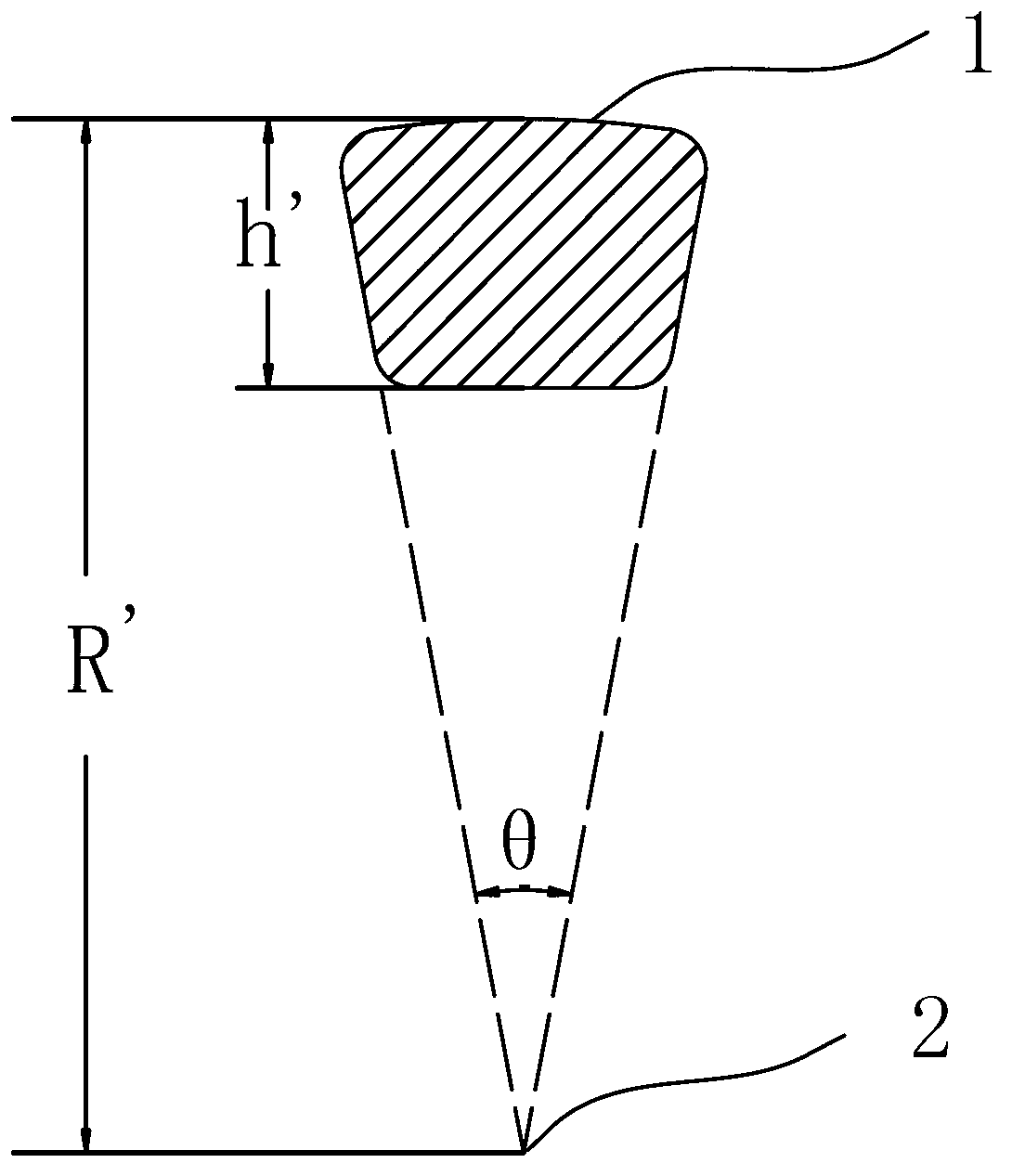

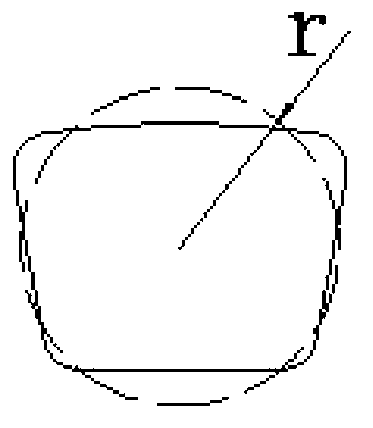

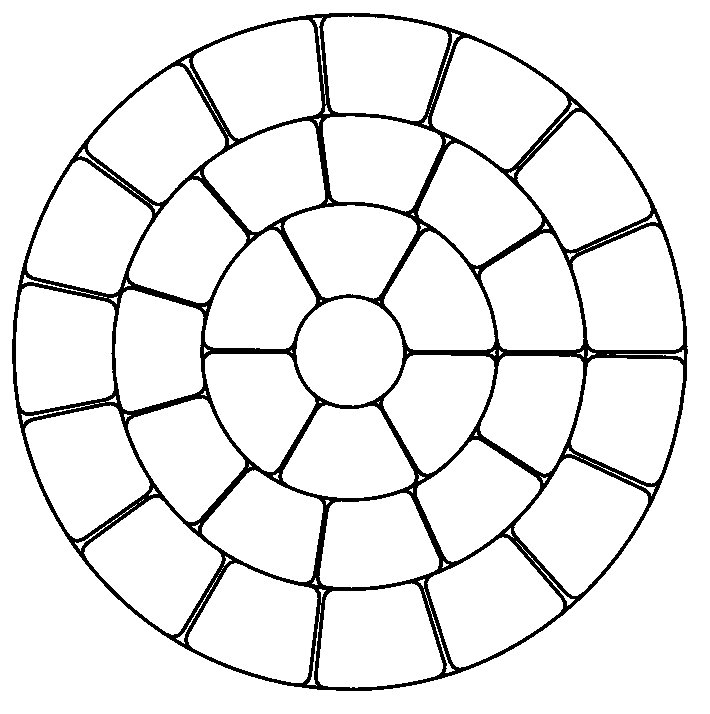

[0130] 2) The first layer of stranding: such as image 3 As shown, the stranding center of the special-shaped aluminum alloy stranded conductor is a circular monofilament with a radius of 1.39 mm. The first layer is formed by twisting six special-shaped aluminum alloy monofilament wires. The thickness of this layer is 2.61mm and the outer radius is 4mm. The height is equivalent to the thickness of the layer, the arc radius R' is 4.08mm, and it is obtained by extrusion deformation of a circular monofilament with a diameter r of 3.15mm; the structure of the monofilament refers to figure 1 and figure 2 ;

[0131] 3) The second layer of stranding: such as image 3 As shown, the second layer is formed by twisting 11 special-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com