Grafted modified ultra-high molecular weight superfine polyethylene and solid phase grafting method thereof

An ultra-high molecular weight, grafted polyethylene technology, applied in the field of grafted polymer and its preparation, can solve the problems of difficulty in realizing large-scale low-cost production, complex reaction process, increase production cost, etc., and achieve easy industrial production and process. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the above-mentioned powder can adopt the method disclosed in the invention patent application titled "ultra-high molecular weight ultra-fine polyethylene powder and its preparation method" submitted by the applicant on the same day of the application, and the full text of which is incorporated in this application as a reference .

[0045] Specifically, the above-mentioned powder is prepared by the following method: a preparation method of ultra-high molecular weight and ultra-fine particle diameter polyethylene powder, which includes the following steps:

[0046] Under the action of a catalyst, ethylene undergoes a polymerization reaction; wherein, the temperature of the polymerization reaction is -20 to 100°C; in ethylene, the content of carbon monoxide is less than 5ppm, the content of carbon dioxide is less than 15ppm, and the content of conjugated dienes is less than 10ppm;

[0047] The catalyst is prepared by a method comprising the following ste...

preparation example 1

[0106] Preparation Example 1 The preparation of ultra-high molecular weight ultra-fine particle diameter polyethylene powder

[0107] In the reactor fully replaced by high-purity nitrogen, add 4.94g of anhydrous magnesium chloride, 18.9g of isooctyl alcohol, and 30ml of decane in sequence, raise the temperature to 130°C under stirring, and maintain it for 2 hours, then add 2.65g of tetrabutyl titanate The ester and 2.05g of diisobutyl phthalate were reacted at 130°C for 1 hour, and finally cooled to room temperature to form a homogeneous transparent solution, namely mixture I.

[0108] Add 200ml of titanium tetrachloride to the reaction kettle, stir and preheat to 0°C, add the mixture I dropwise to the titanium tetrachloride in about 2 hours. After the dropwise addition was completed, the temperature was raised to 110° C. within 2 hours. 1.23 g of internal electron donor diisobutyl phthalate was added. After reacting at this temperature for 2 hours, remove the reaction liqui...

Embodiment 1

[0113] Preparation of PE-g-MAH: In the reactor fully replaced by high-purity nitrogen, add 40g of polyethylene particles with an average particle diameter of 85 microns prepared in Preparation Example 1 (the standard deviation is 8.21 microns, and the viscosity-average molecular weight is 1.3× 10 6 , molecular weight distribution is 9.2), add 2.0g benzoyl peroxide, add 2.8g maleic anhydride (MAH), add 4mL tetrahydrofuran and 5mL xylene; then turn on the mechanical stirring, stir rapidly for 3 hours; finally put the reactor into In an oil bath at 100°C, react for 2 hours to obtain the crude grafted product.

[0114]Refining of PE-g-MAH: Weigh about 4g of crude graft, add 200mL xylene into a 500mL distillation flask, heat and dissolve, reflux for 4h, add acetone (about 200mL) after cooling, shake well, let it settle and filter , and then washed once with acetone, put the filtrate in a 50°C oven to dry for 12 hours, and cool to obtain a refined graft.

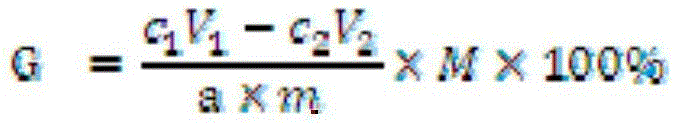

[0115] Infrared characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com